High-pressure plunger pump connecting rod processing process device

A high-pressure plunger pump and processing device technology, applied in the field of mechanical parts processing, can solve the inability to guarantee the coaxiality and dimensional accuracy requirements of the inner hole of the copper sleeve and the outer end surface of the small head, and the insufficient processing accuracy of the connecting rod, which affects the entire pump. Assembly quality and other issues, to achieve the effect of convenient chip removal, avoid uneven thickness, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

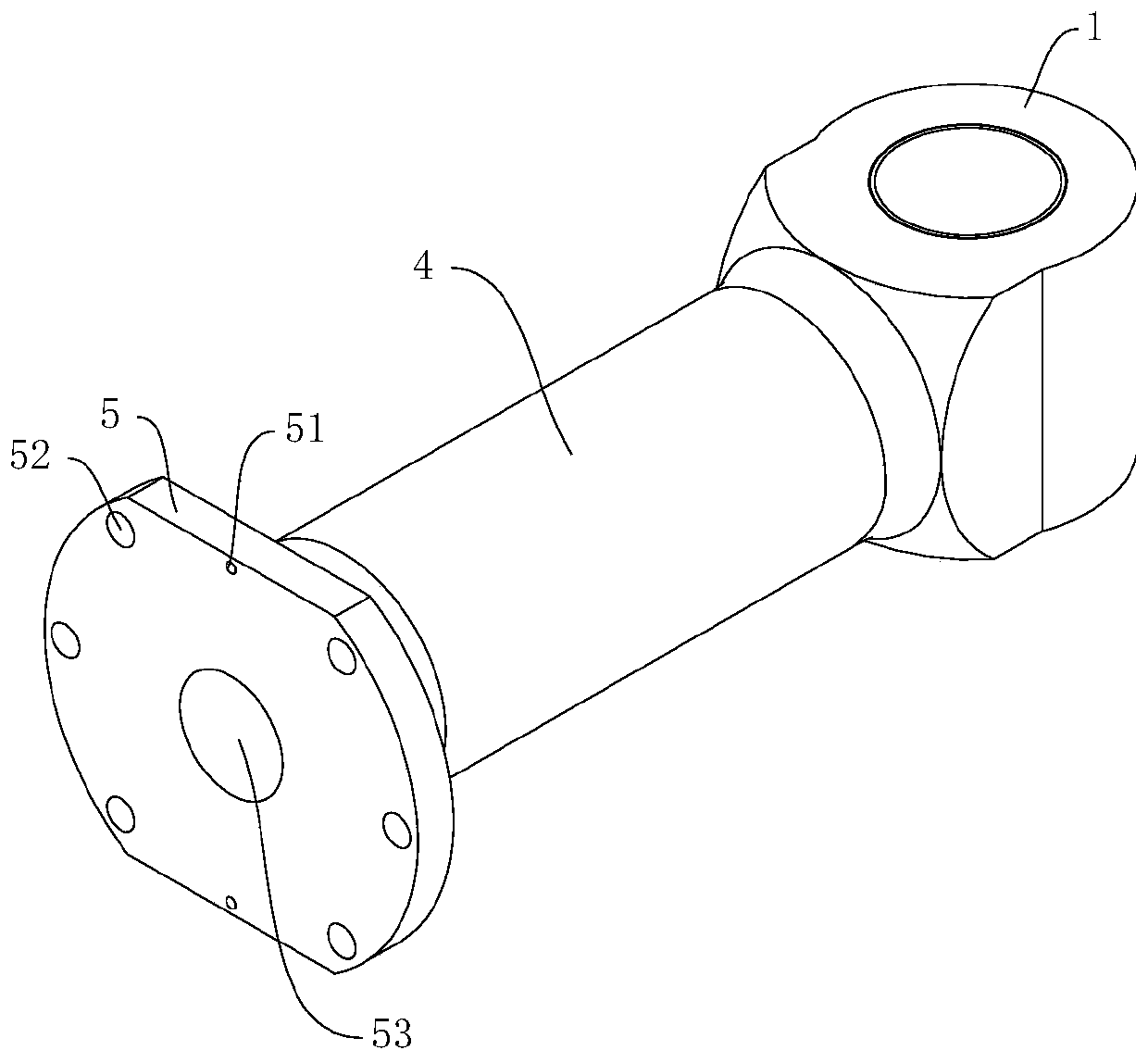

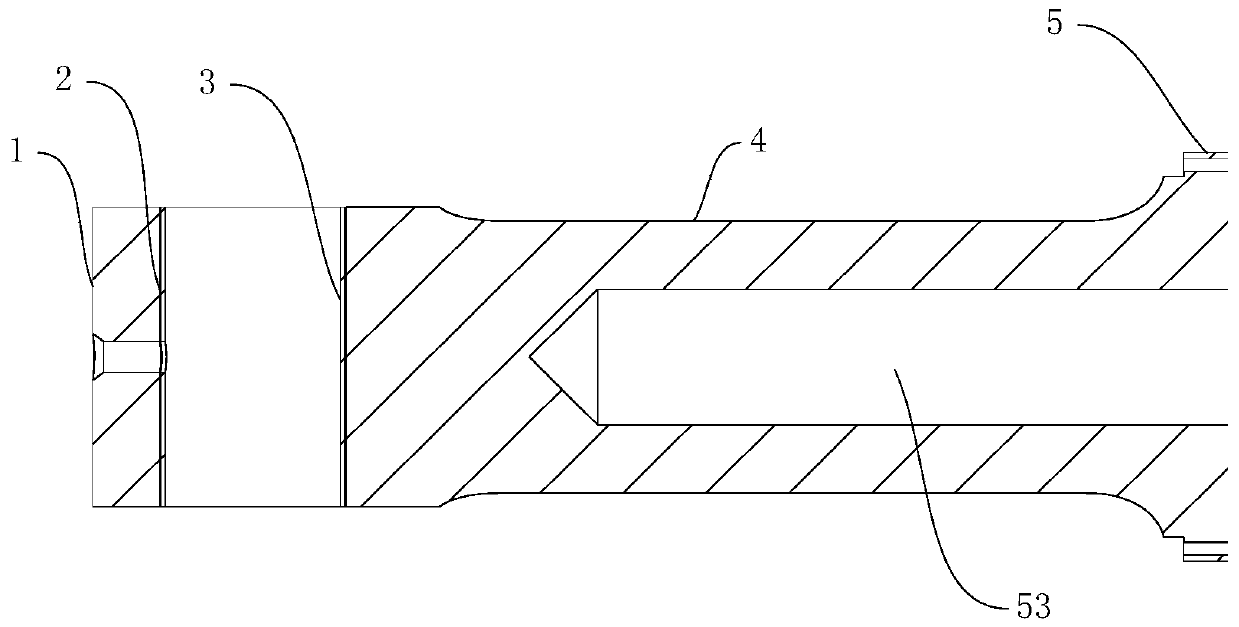

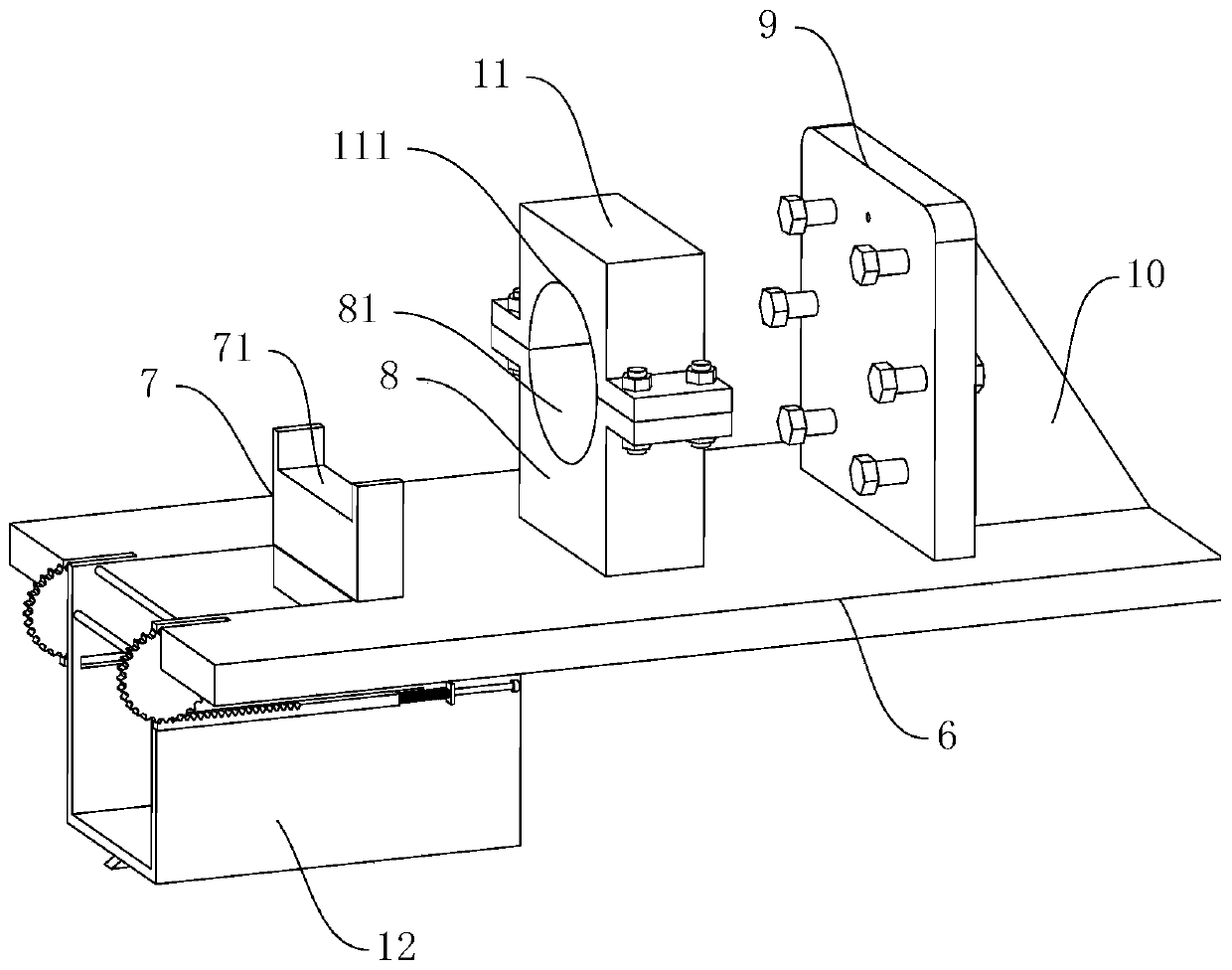

[0044] Embodiment, a kind of high-pressure plunger pump connecting rod processing technology, such as figure 1 , figure 2 As shown, the connecting rod includes a connecting rod big end 5 and a connecting rod small end 1 respectively located at both ends, a large and small connecting body 4 is arranged between the connecting rod big end 5 and the connecting rod small end 1, and six connecting rod big ends 5 are arranged. Bolt holes 52 and two positioning pin holes 51, the big head 5 of the connecting rod is provided with a weight-reducing hole 53 extending into the connecting rod, the small head 1 of the connecting rod is provided with a copper sleeve installation hole 2, and the copper sleeve installation hole 2 is inserted Connected with the copper sleeve 3, the processing technology of the high-pressure plunger pump connecting rod includes the following steps:

[0045] S1: After the blank arrives at the factory, the incoming material grade and incoming inspection are carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com