Multi-hook-face titanium alloy part forming device and method

A forming device, titanium alloy technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of uneven force at the R angle, increased part forming, and material flow influence, so as to avoid uneven thickness, The effect of improved process plasticity and uniform material thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 A kind of forming device of multi-curved titanium alloy parts

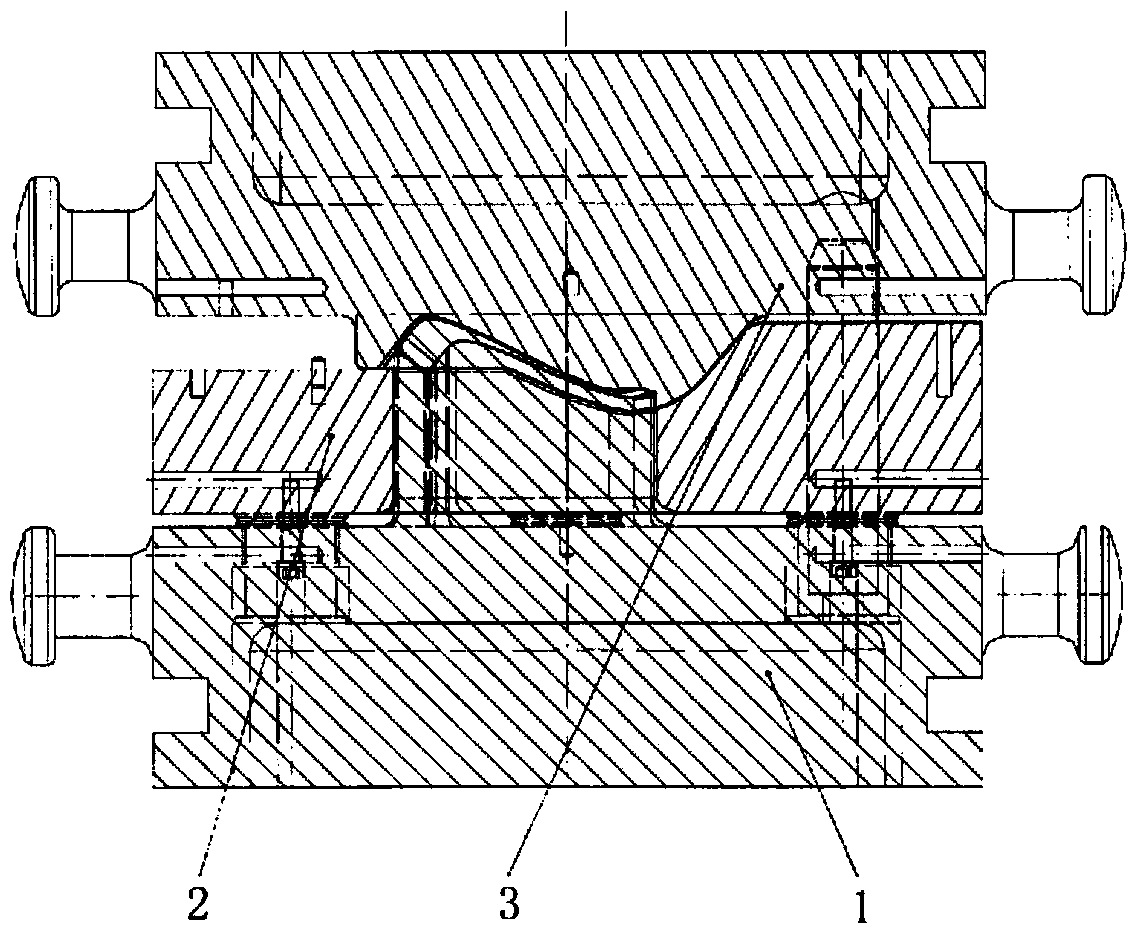

[0021] like image 3 and Figure 4 As shown, the multi-curved titanium alloy part forming device includes a male mold (1), a blank holder (2), a female mold (3) and a push rod (4).

[0022] The blank holder (2) is flexibly connected with the die (3) through the push rod (4) moving up and down.

Embodiment 2

[0023] Embodiment 2 A kind of multi-curved surface titanium alloy part forming method

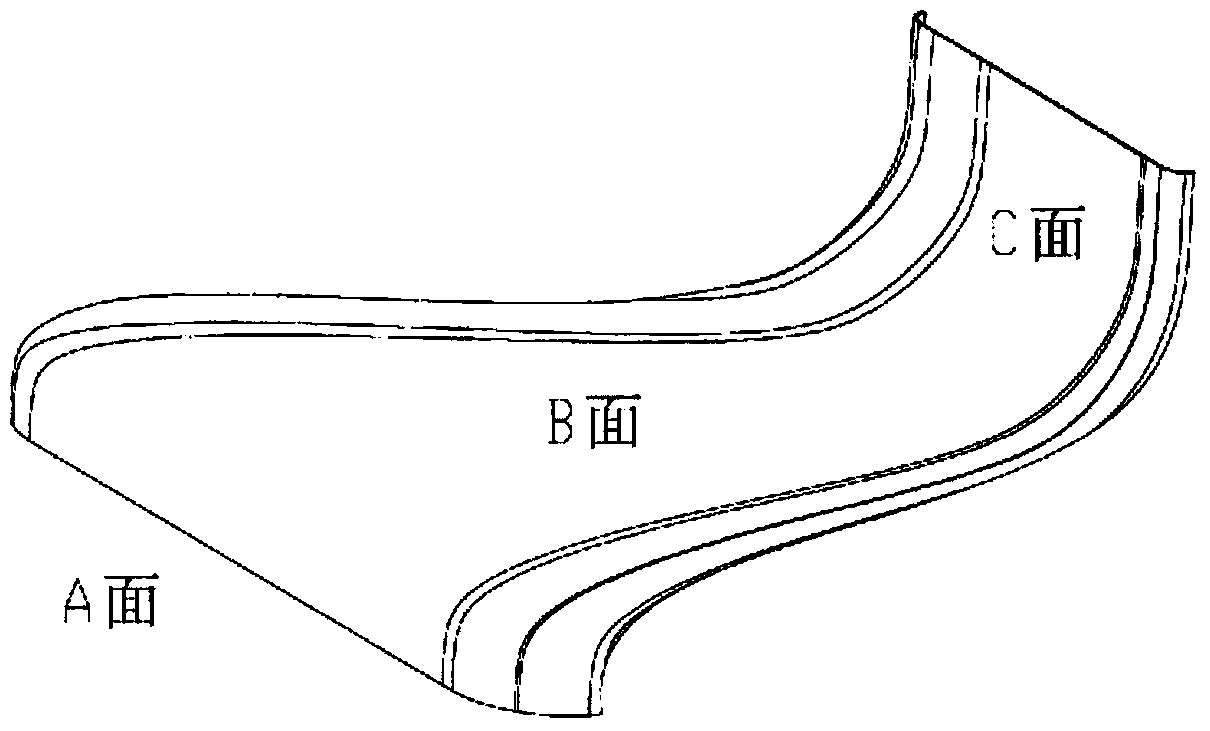

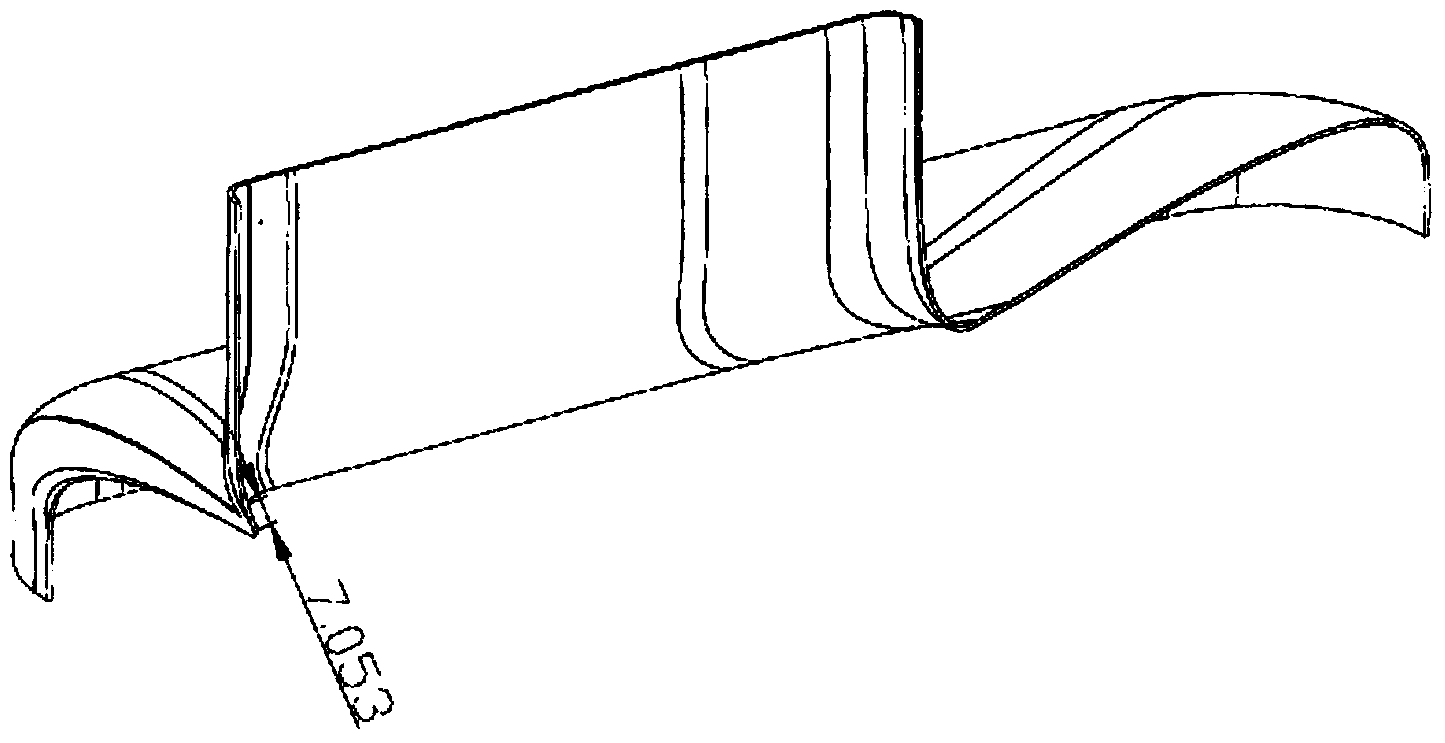

[0024] like figure 1 and figure 2 As shown, the part is a multi-curved, large-bend titanium alloy part, the material grade is TCI, the material thickness is δ0.8, and there are many profiles and complex shapes. The height of the flange of the part is about 20mm, the angle between the A surface and the B surface is 83°, and the angle between the B surface and the C surface is about 70°. There is two-way bending, and the overall bending angle is relatively large.

[0025] Present embodiment is described with processing above-mentioned parts, adopts the device described in embodiment 1, and method is as follows:

[0026] 1) Blanking: According to the male mold, rough the wool into the expanded shape of multi-curved titanium alloy parts;

[0027] 2) Deburring: Grinding the burrs on the edge of the unfolded wool;

[0028] 3) Cleaning: mark and degrease the wool in an organic solvent, and cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com