Patents

Literature

521results about How to "Easy chip removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microemulsion metal cutting fluid

ActiveCN104164283AMeet cutting processing requirementsHigh thermodynamic stabilityLubricant compositionEmulsionNonferrous metal

The invention discloses a microemulsion metal cutting fluid which contains 1-20 wt% of fatty oil, 1-40 wt% of emulsifier, 5-40 wt% of co-emulsion, 5-30 wt% of wear and rust inhibitor, 1-20 wt% of penetrant, 5-30 wt% of pH regulator, 0.5-5 wt% of defoaming agent and 0.1-5 wt% anticorrosive bactericide. The microemulsion metal cutting fluid has excellent lubricating, antiwear, antirust, cleaning and cooling properties, and can be widely used in precise cutting work of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

Drilling fluid with synthesized substrate

A synthetic basic well-drilling liquid is proportionally prepared from the basic liquid composed of basic liquid and aqueous solution of CaCl2, primary emulsifier, secondary emulsifier, wetting agent, flowing regulator, filter loss reducer and organic earth through mixing. Its advantages are no pollution and high effect to protect oil-bearing stratum.

Owner:CNOOC TIANJIN BRANCH +3

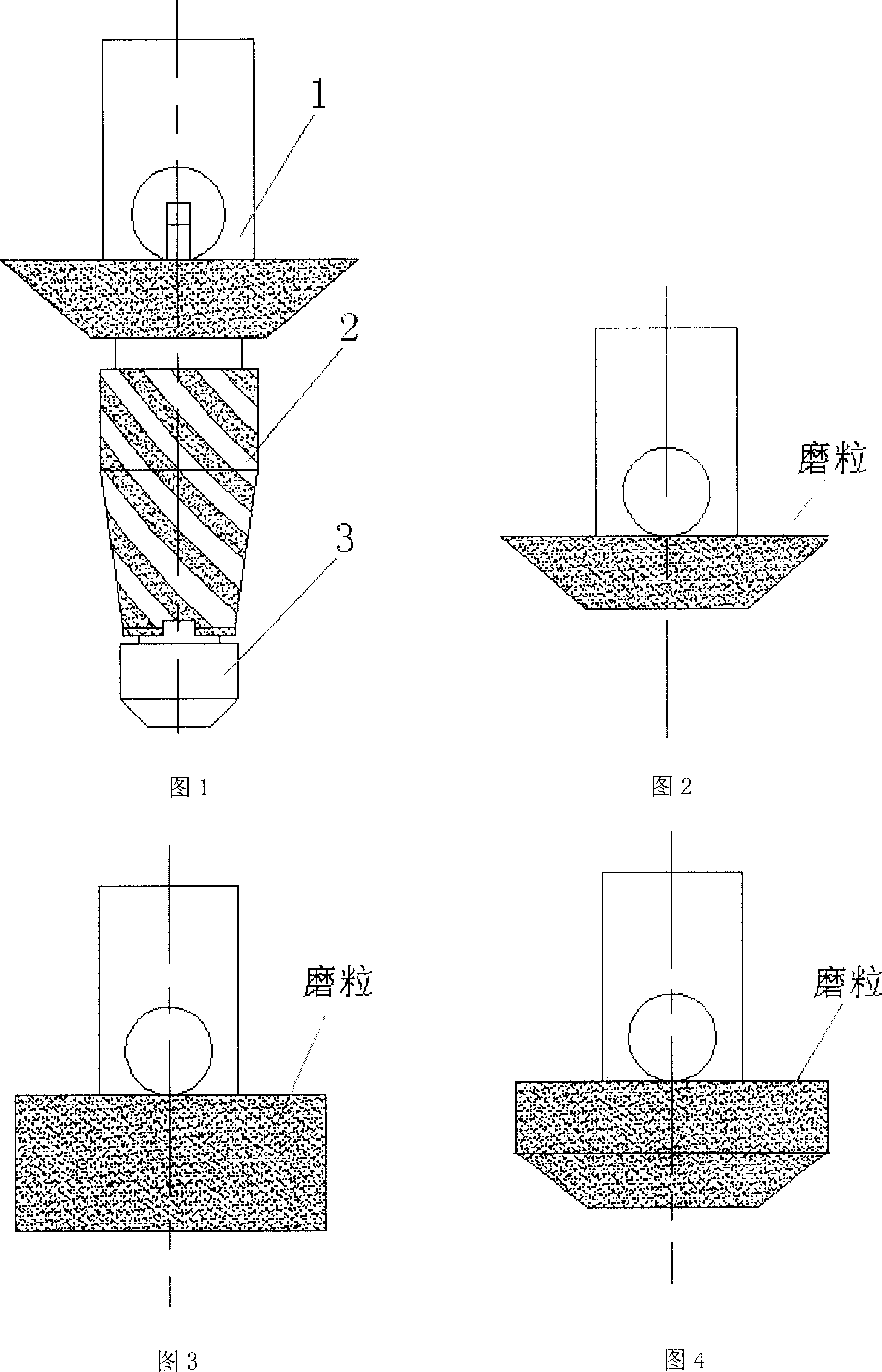

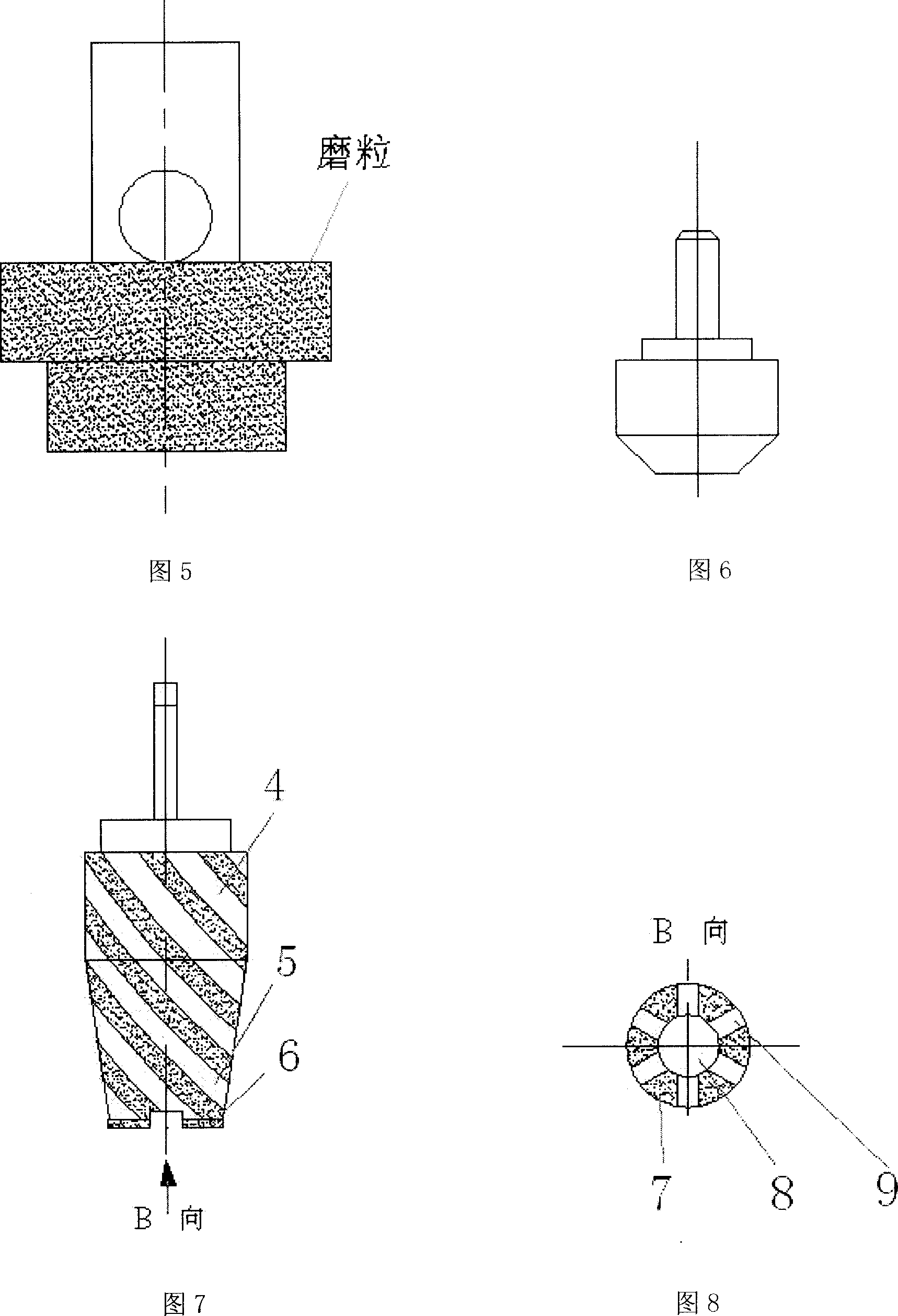

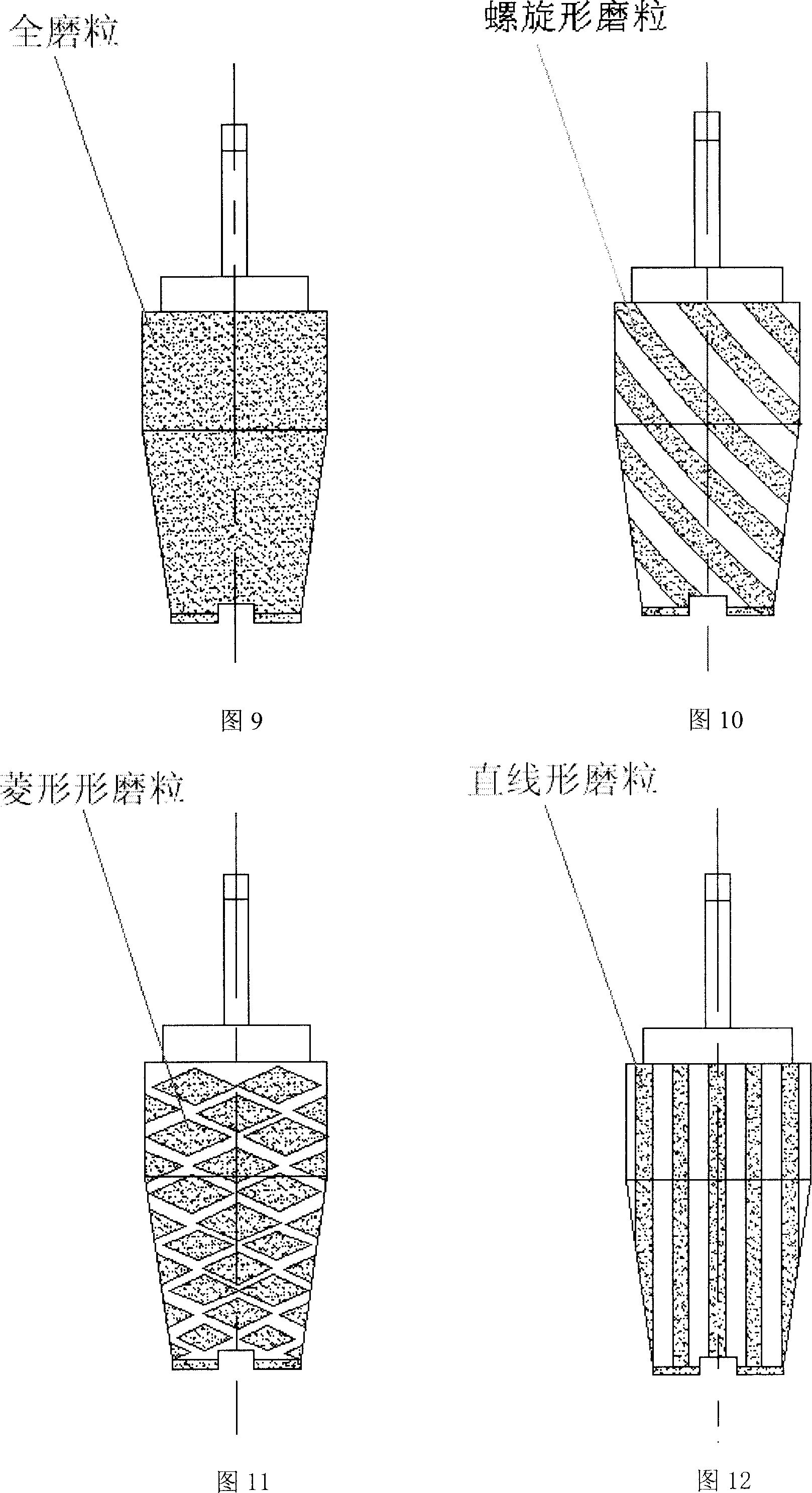

Drilling/grinding integrated combined tool

InactiveCN1935430AImprove processing qualityExtend your lifeTransportation and packagingAbrasion apparatusStructural engineeringConoid

The present invention relates to an integral combined cutting-tool with hole-drilling and hole-grinding functions. Said cutting-tool is formed from three portions of counter-boring hole-grinding and hole-sinking section, hole-expanding and hole-grinding section and guide head. Said invention also provides the concrete structure of the above-mentioned every portion and its production method.

Owner:DALIAN UNIV OF TECH

Water-soluble discharging medium compound for electrospark wire-electrode cutting

The invention discloses a water-solubility discharging dielectric combination for electrospark wire electrode cutting, comprising the following components: 20 to 46 percent weight of polyalkyl glycol and / or polyatomic alcohol, 2 to 8 percent weight of alkylol amine, 26 to 40 percent weight of water-solubility anti-rust agent, 2 to 4 percent weight of non-ionic surface active agent, 3 to 6 percent weight of anionic surface active agent, 1 to 2 percent weight of thickening agent solution, 0.2 to 1.0 percent weight of anti-foam agent, 0.01 to 0.04 percent weight of copper alloy corrosion inhibitor, 0.2 to 0.5 percent weight of mildew inhibitor, 0.5 to 1.0 percent weight of water quality stabilizing agent and equilibrium amount of distilled water; moreover, all components are simply mixed to obtain the combination. The combination can be used for a long time with zero emission or little emission; meanwhile, the invention does not cause pollution, toxin and harm to work environment and the nature and is nonirritating to human body.

Owner:BEIJING DONGXING LUBRICANT CO LTD

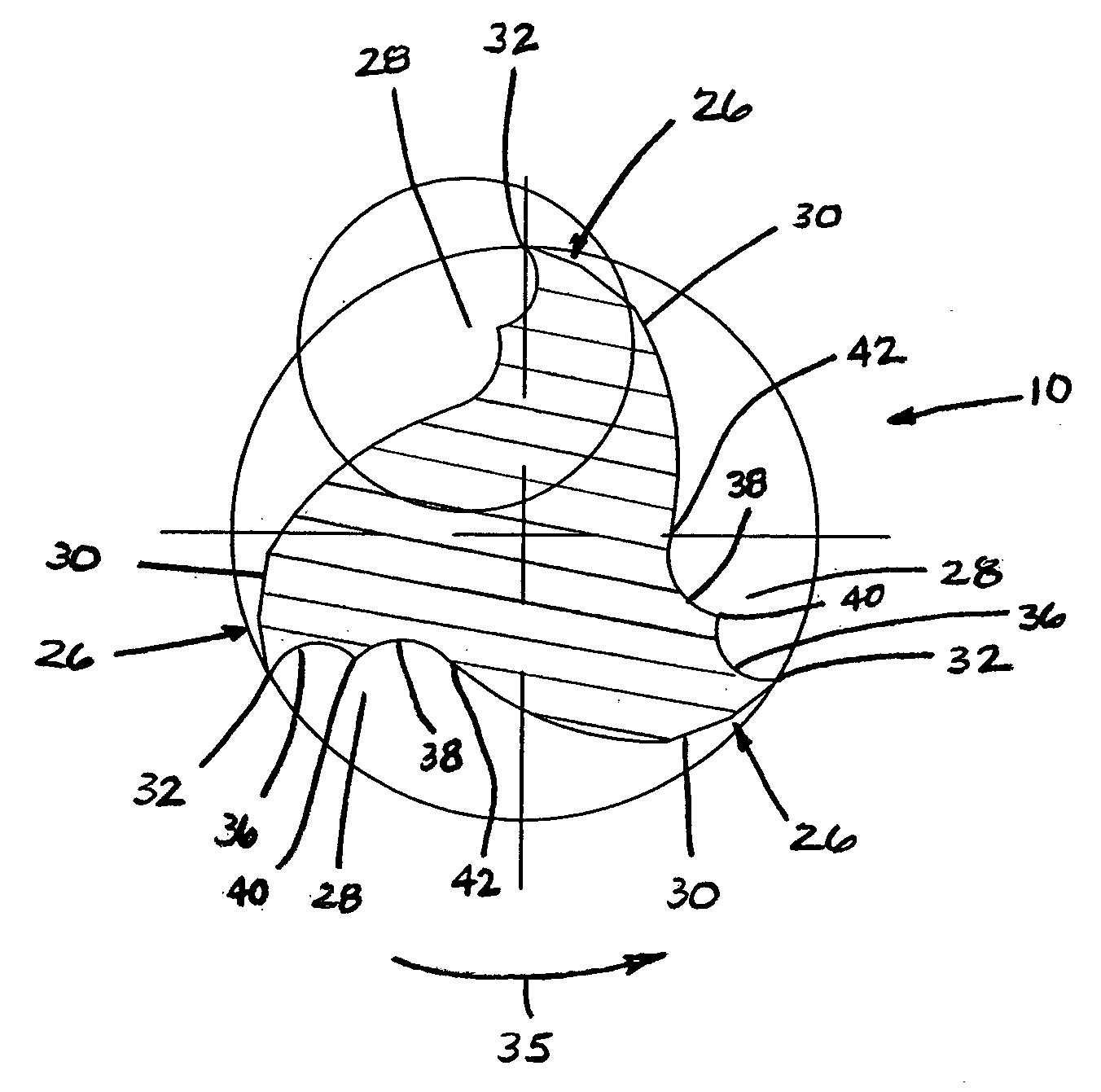

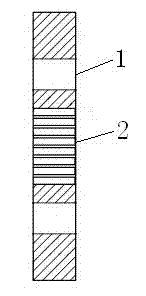

Helical flute end mill with multi-section cutting edge

ActiveUS20060045637A1Desirable performanceEasy chip removalMilling cuttersShaping cuttersFluteEngineering

An end mill is provided that includes a shank section and a fluted section. One or more helical teeth are disposed along an outer surface of the fluted section. Each helical tooth has a cutting surface and a relief wall that intersect to form an angle defining a helical cutting edge. The cutting surface of each helical tooth includes a first section, a second section, and a take-off peak disposed between the first section and second section. The cutting edge of each helical tooth includes a first portion having a first constant angle, and a second portion having a second constant angle unequal to the first constant angle, and an arcuate transition section connecting the first portion and second portion. Some embodiments of the present invention include more portions than the aforesaid first and second portions.

Owner:BERKSHIRE PRECISION TOOL

Helical flute end mill with multi-section cutting surface

A rotary cutting end mill is provided. The end mill includes a shank section and a fluted section. The fluted section has a first end integrally attached to the shank section, a second end, and an outer surface. One or more helical teeth are disposed along the outer surface of the fluted section. Each helical tooth has a cutting surface and a relief wall that intersect to form an angle defining a helical cutting edge. The helical cutting edge defines an outer circumferential cutting path. The cutting surface includes first, second, and third sections, and first and second take-off peaks. The first take-off peak is disposed between the first section and second section. The second take-off peak is disposed between the second section and the third section.

Owner:DAUPHIN PRECISION TOOL

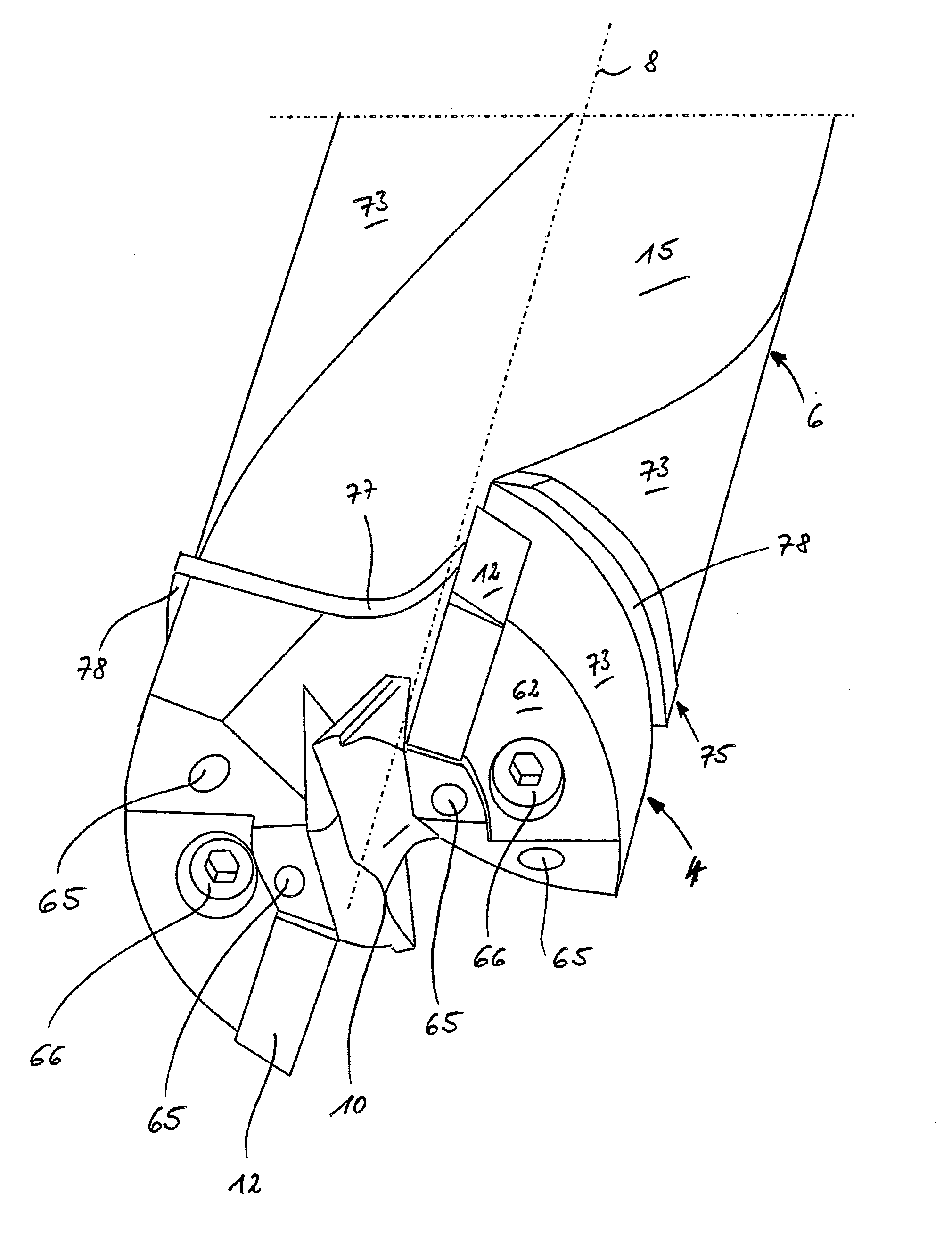

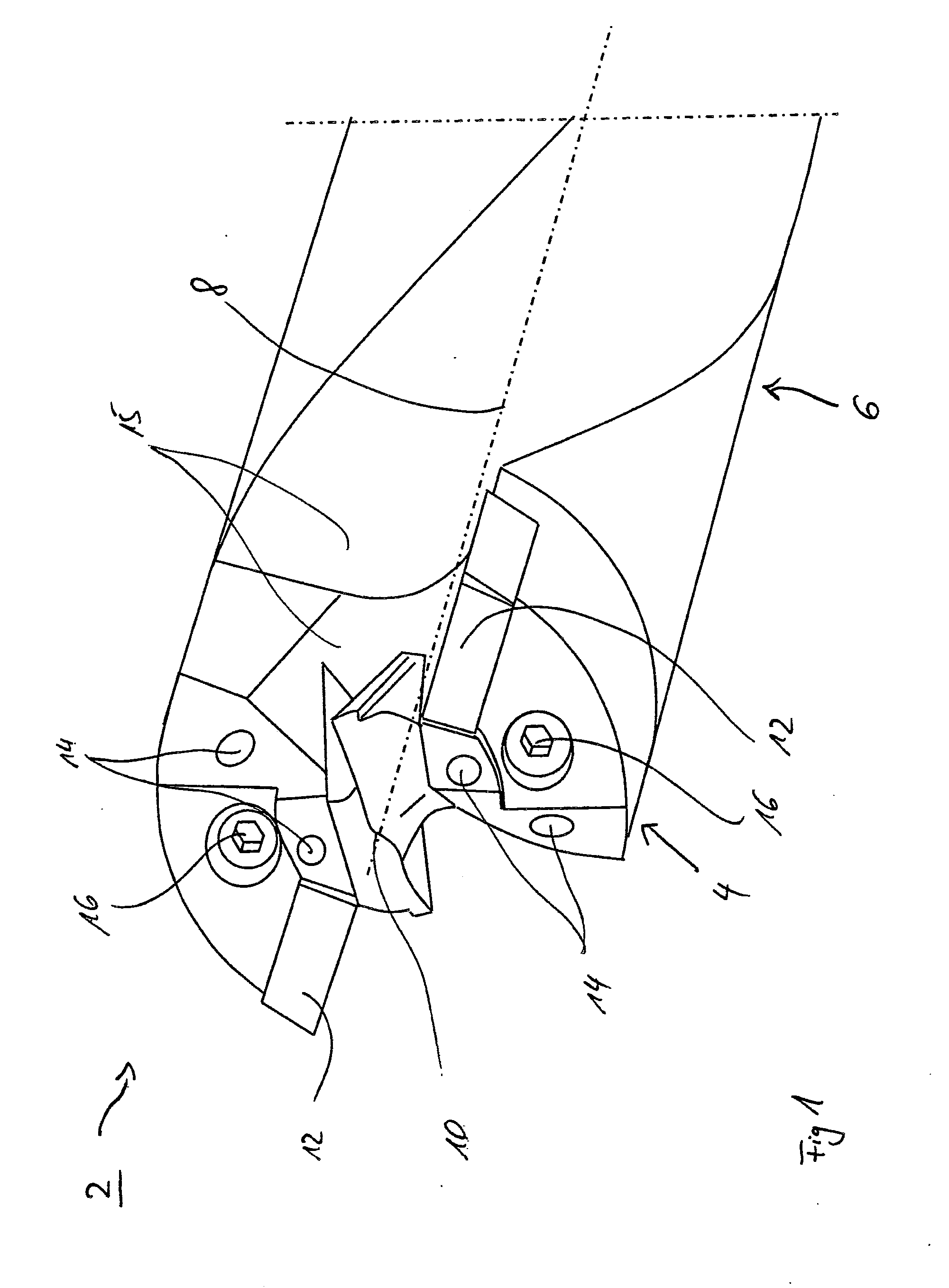

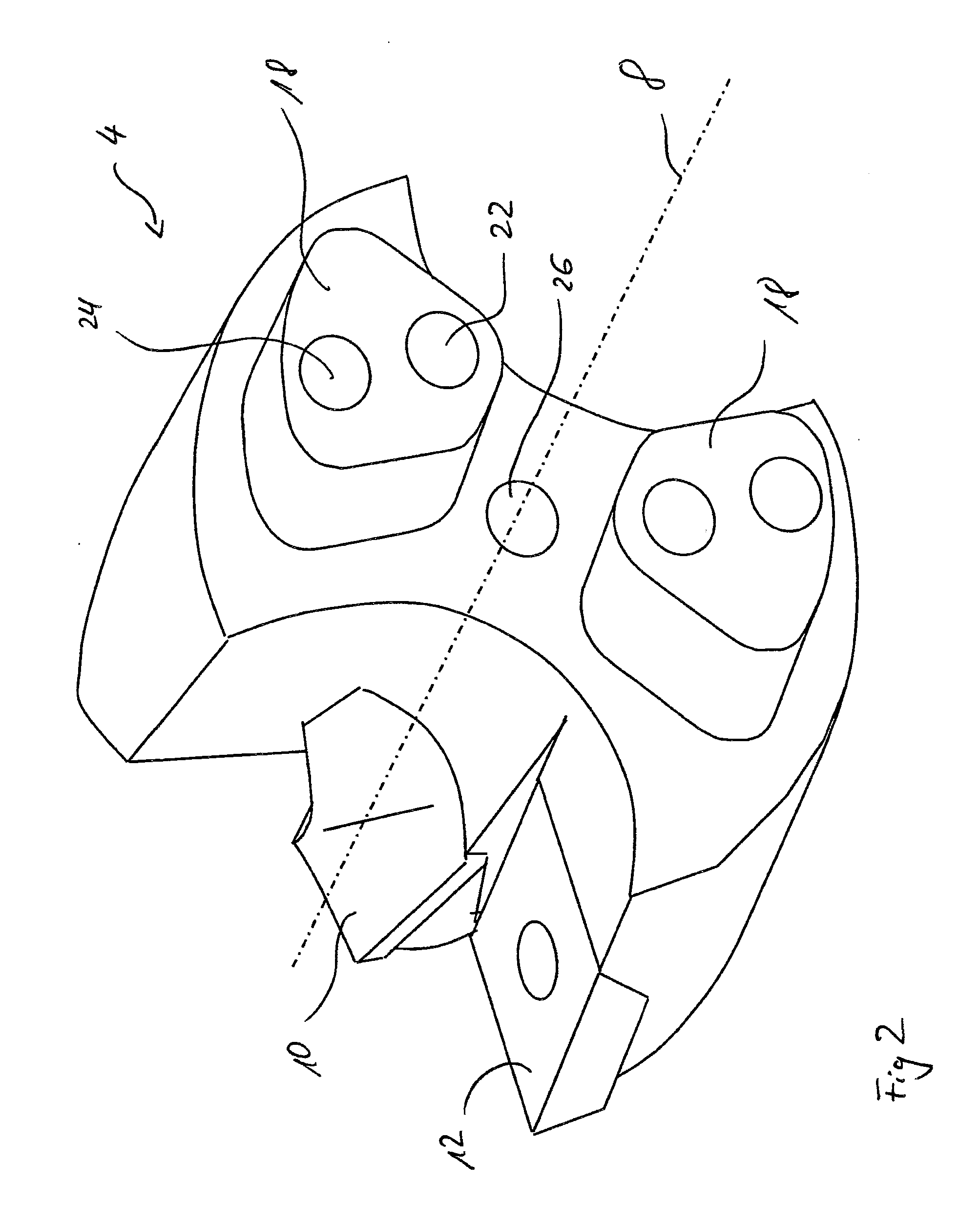

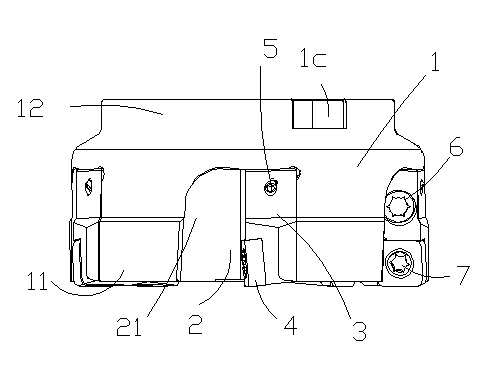

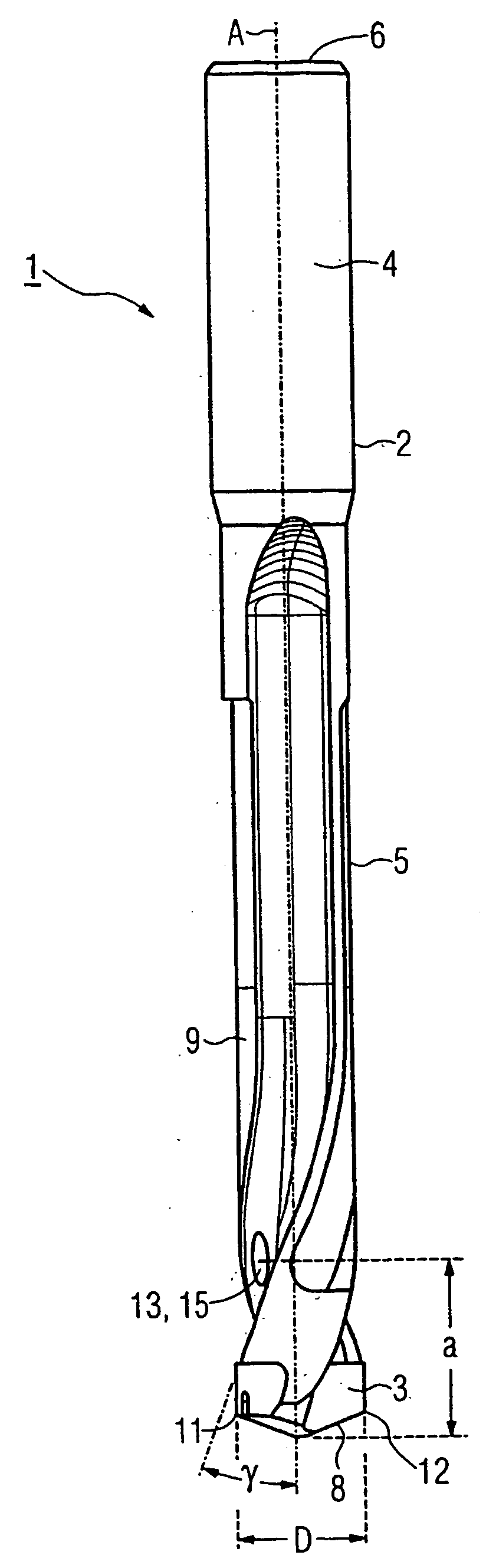

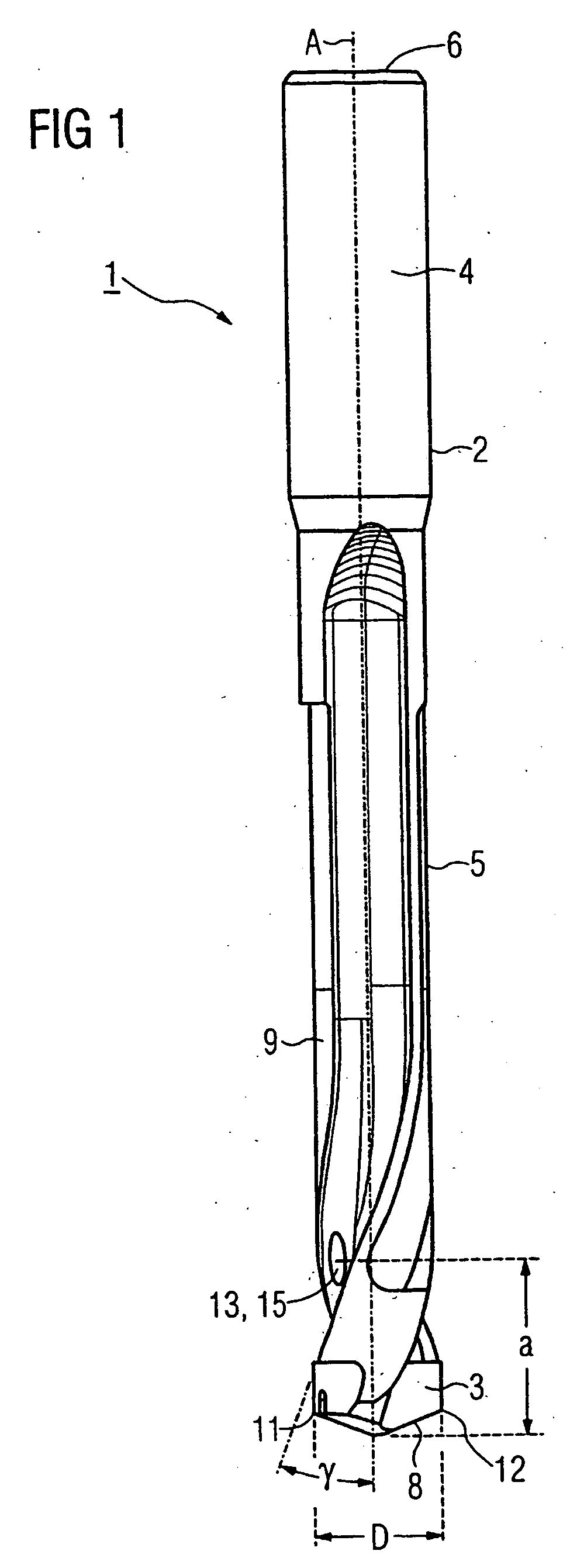

Lathe Tool, In Particular Boring Tool

ActiveUS20110097168A1Better mountingEasy chip removalThread cutting toolsWood turning toolsReliable transmissionCoupling

A boring tool has a receiving part implemented as a borer body and a front part implemented as a borer head, which extend along a central axis and can be removably fastened to one another via driver connection. The driver connection has at least two coupling pairs which are separate from one another and are disposed eccentrically relative to the central axis. Each coupling pair is formed by interlocking coupling elements, namely a receiving pocket and a driver pin. The coupling elements have an asymmetrical cross-sectional area and widen with increasing distance to the central axis. Through this design, a reliable transmission of high torques is achieved with lower strains of the borer body in the area of the driver connection. Simultaneously, an automatic centering of the two tool parts to one another is performed.

Owner:KENNAMETAL INC

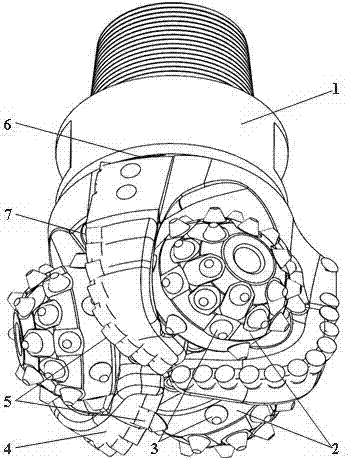

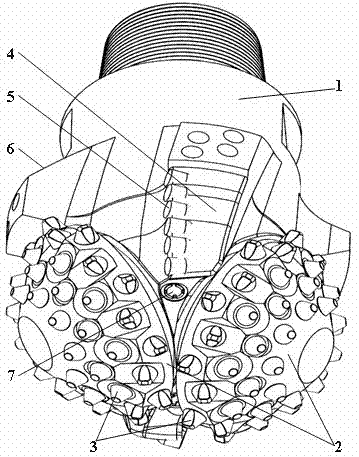

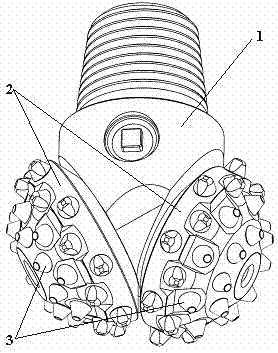

Compound bit formed by PDC (polycrystalline diamond compact) bits and rotary cutting bit

InactiveCN102392605AExtended service lifeIncrease cutting forceConstructionsHigh ratePolycrystalline diamond

The invention discloses a compound bit formed by PDC (polycrystalline diamond compact) bits and a rotary cutting bit. The compound bit comprises a main body (1), rotary cutting bit cones (2), rotary cutting bit cutting teeth (3), PDC blades (4), PDC cutting teeth (5), oil storage sacs (6) and nozzles (7), wherein the main body (1) comprises a cone journal, centralizing blocks, high-pressure slurry channels and a connection screw thread. The compound bit is characterized in that a compound bit cutting unit comprises the rotary cutting bit and a PDC bit cutting unit. The compound bit has the following beneficial effects: the PDC bits complete drilling the central part of the borehole in the drilling process; the linear velocity of the periphery of the borehole is high in the drilling process and the rotary cutting bit and the PDC bit cutting unit complete drilling the periphery of the borehole; and the rotary cutting bit in the compound bit shocks, crushes and cuts the rocks by way of rotary cutting, has high central rock breaking efficiency, high rate of penetration and better dynamic performance, is uniform in wear, simultaneously improves the bit bearing structure, ensures to prolong the service life of the bit while improving the rock breaking efficiency, improves the cutting capability of the compound bit and ensures good gauge protection effect.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

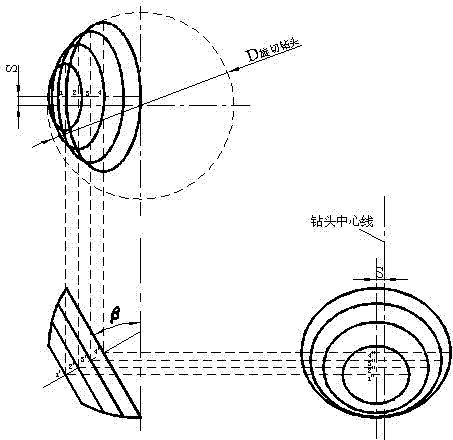

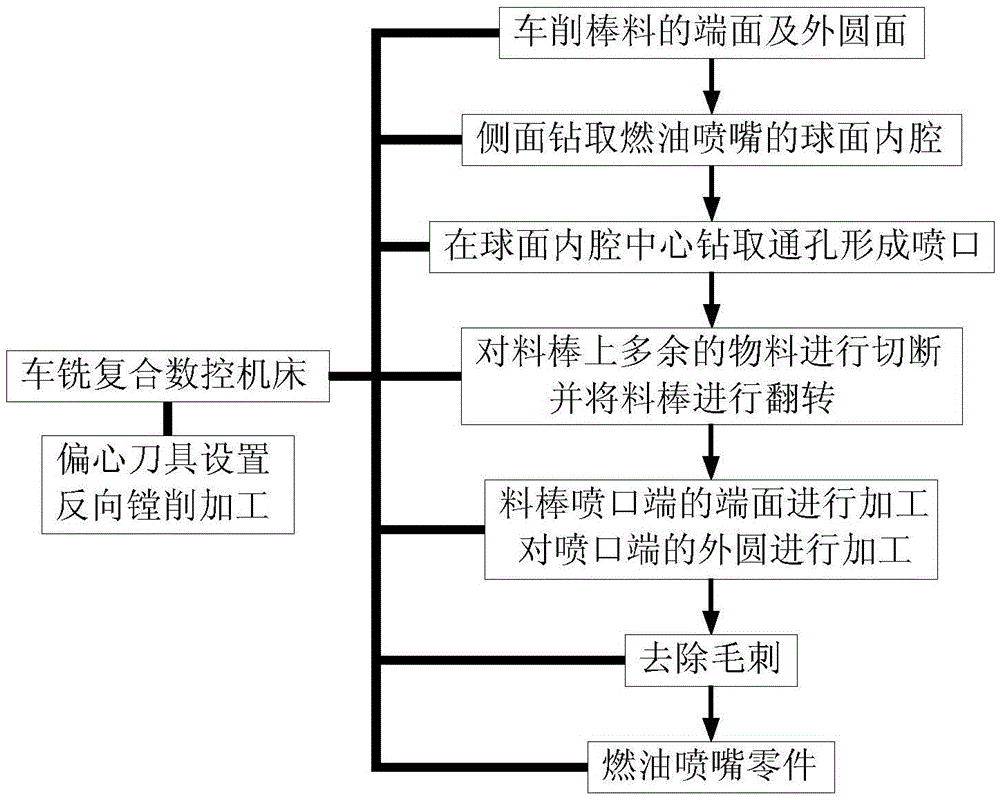

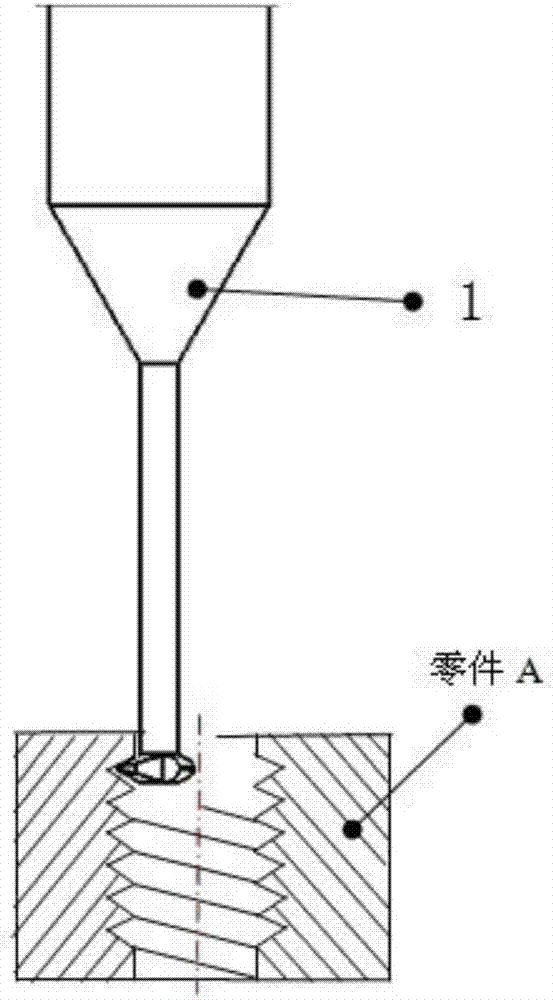

Machining control method for aero-engine fuel nozzle part

ActiveCN105458626AReduce manufacturing costImprove rigidityAircraft componentsTest performanceAviation

The invention discloses a machining control method for an aero-engine fuel nozzle part. A turn-mill combination numerical control machine tool is adopted for carrying out one-time clamping on a bar, and machining in all procedures is carried out; the bar is clamped, the end face and the outer circle face of the bar are turned, a spherical inner cavity of a fuel nozzle is drilled in the side face of the bar, and a through hole is drilled in the center of the spherical inner cavity to form a nozzle; the outer circle face of the machined bar is clamped, residual materials on the bar are cut off, and the bar is turned over; the outer circle face of the turned-over bar is clamped, the end face of the nozzle end of the bar is machined, and the outer circle of the nozzle end is machined; and burrs are removed, and the fuel nozzle part is obtained. The rigidity of a tool is increased through the eccentric structure of the tool, and the cost of the tool is reduced. The reverse boring technology is adopted, chip discharging is facilitated, pulling and scratching caused by scrap iron to an oil spray hole are reduced, and it is guaranteed that the flow test performance parameters of the nozzle are qualified. The machining control method is suitable for machining control over nozzle parts of various aero-engines and auxiliary power device engines.

Owner:CHINA HANGFA SOUTH IND CO LTD

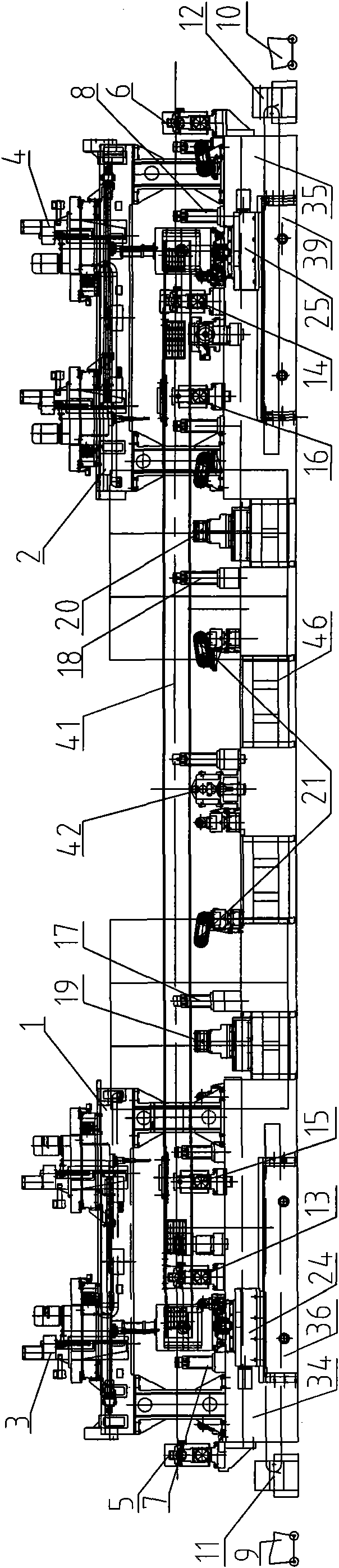

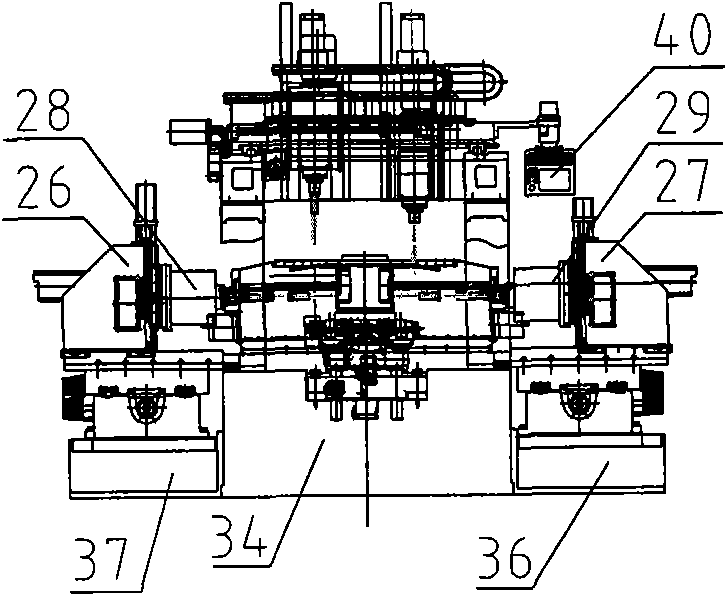

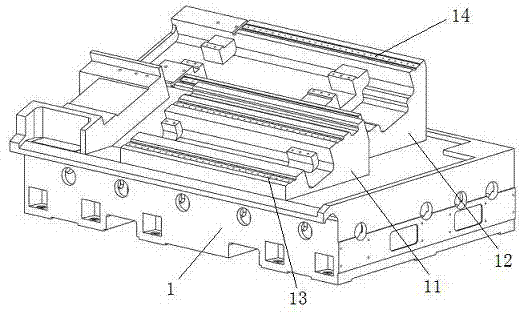

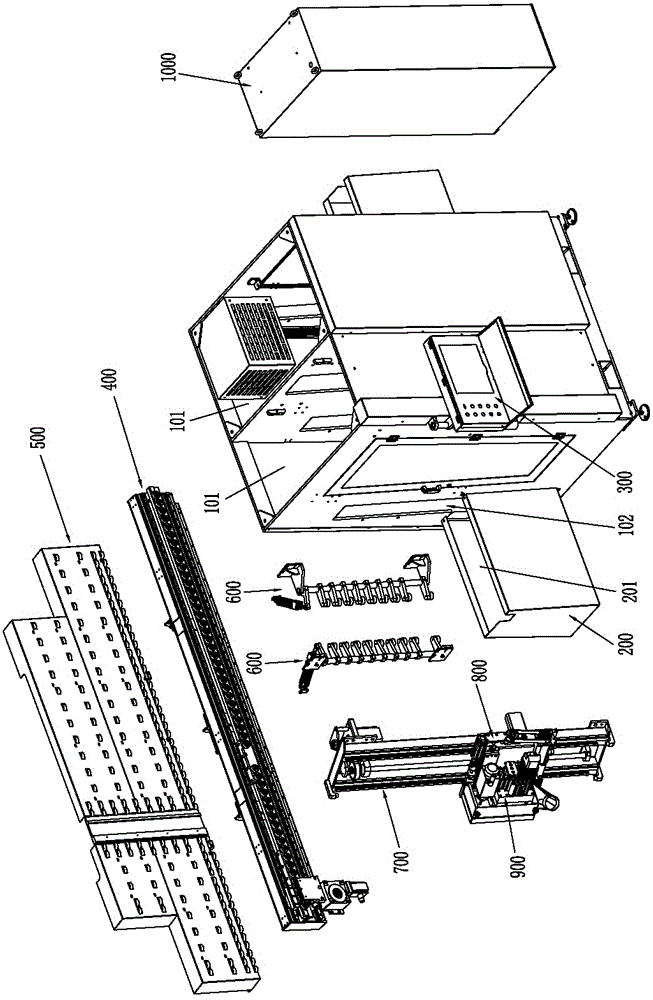

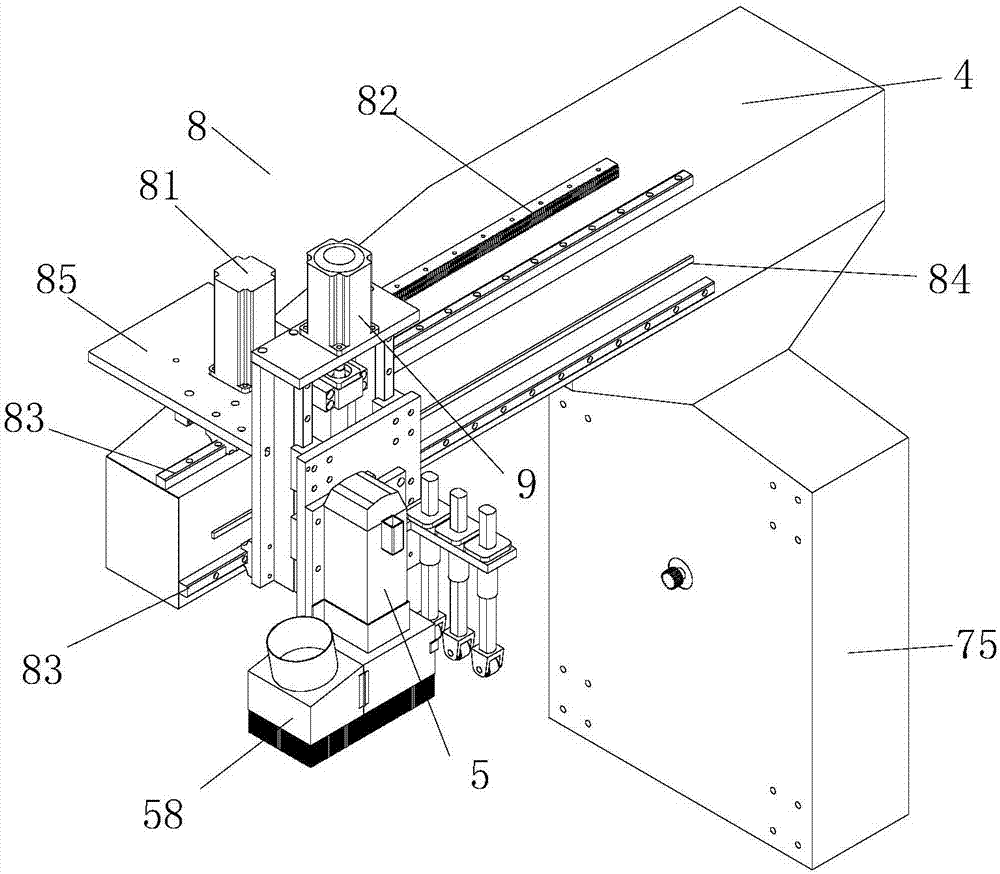

Numerical control center sill combined drilling machine

InactiveCN101934390ASmooth transmissionAccurate locationTransportation and packagingPositioning apparatusEngineeringMachine tool

The invention discloses a numerical control center sill combined drilling machine, which comprises a gantry main body, a lathe bed, side bases, conveying sticks, a fixture, a chip cleaner and a chip collecting box. The technical key points are that: two longitudinal ends of the lathe bed are fully symmetrically arranged; two longitudinal sides of the two-end gantry main body are provided with the side bases; each of the side bases is provided with a three-dimensional numerical control sliding table which is provided with a single spindle box; a longitudinal center line of the two-end gantry main body is uniformly provided with at least two conveying sticks; and each of the conveying sticks is at least provided with a connecting motor. The numerical control center sill combined drilling machine has the advantages of simple mechanical structure, rational configuration of processing elements and power and mechanisms, convenient production operation and maintenance, coordinate variable control scheme, improvement of equipment production flexibility, creation of favorable conditions for future production of various products, improvement of the pollution on field working environment due to hydraulic systems and cooling systems, aerosol cooling and chip cleaning, improvement of the pollution on the working environment, multipoint positioning and clamping, and guarantee of the reliability and the stability of machining precision.

Owner:SHENYANG XINGYE MACHINE TOOL

Anti-impact diamond layer, diamond composite sheet and preparation method for diamond composite sheet

The invention discloses an anti-impact diamond layer, an anti-impact diamond composite sheet and a preparation method for the diamond composite sheet. Coarse granular diamond is used as a main raw material, graphite is used as a filling agent, and iron-based powder is used as an accelerant; the diamond layer comprises the following components in part by weight: 70 to 80 parts of diamond, 10 to 20 parts of graphite powder, and 3 to 12 parts of accelerant; and the accelerant consists of the following materials in part by weight: 45 to 60 parts of iron, 15 to 20 parts of nickel, 5 to 15 parts of cobalt, 5 to 20 parts of manganese, and 3 to 10 parts of silicon. The method comprises the following steps of: mixing the raw materials in the ratio uniformly, pre-pressing the mixture and a hard alloy matrix into a composite sheet, filling into a pyrophyllite block to form a structural block, putting the structural block into a 6-surface diamond presser, sintering and electrolyzing at a high temperature under high pressure, and thus obtaining the diamond composite sheet. The diamond composite sheet has the characteristics of big pores and a mesh connection structure, and is quite suitable for drilling medium hard and hard strata due to excellent sharpness and impact toughness.

Owner:河南亚龙金刚石制品股份有限公司

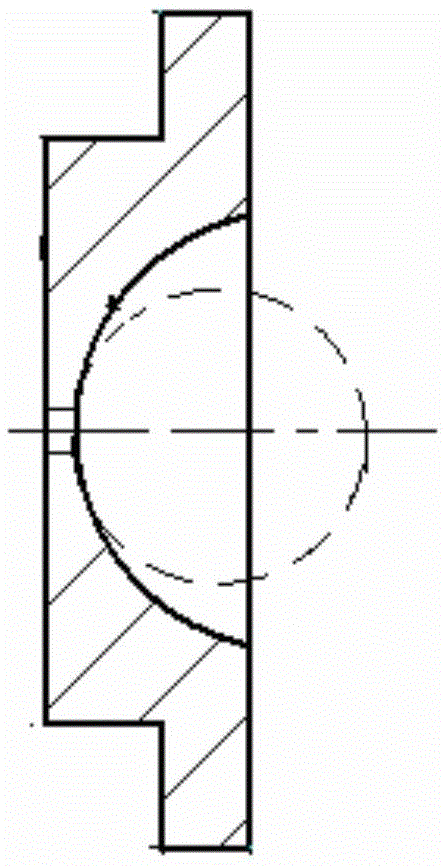

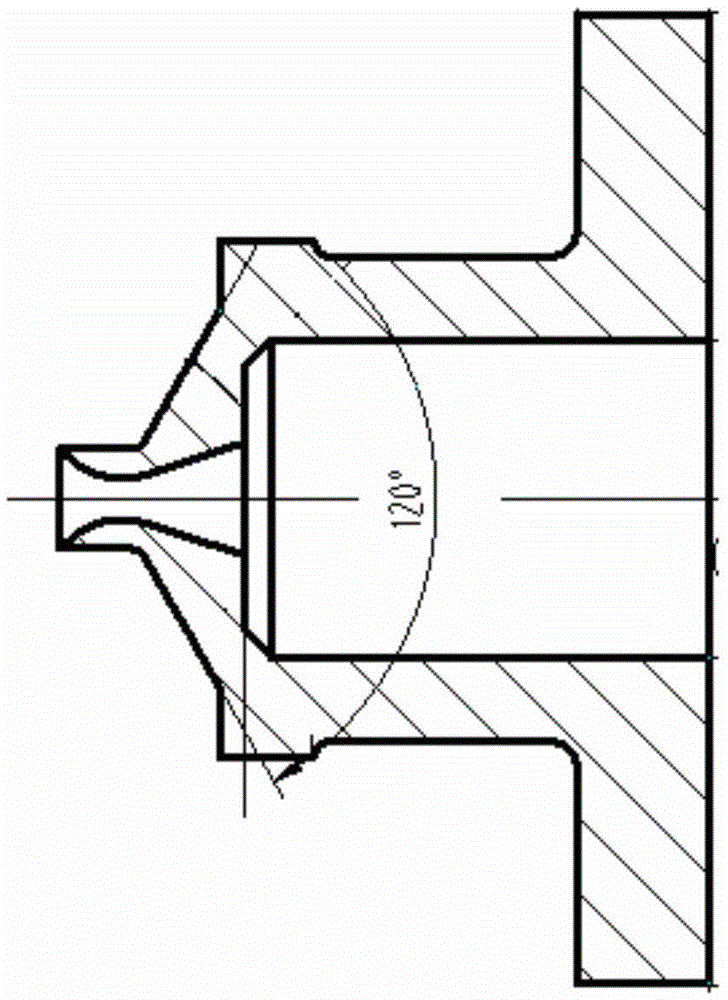

Perforating process of composite carbon fiber material product

ActiveCN1986145ASolve the hole layering problemGuarantee the quality of hole makingAutomatic control devicesTransportation and packagingAlloyCutting force

The perforating process of composite carbon fiber material product includes the following main steps: sorting hard alloy drilling bit with helix angle of 20 deg, vertex angle not smaller than 120 deg and chisel width of 0.06-0.1 D; drilling the guide hole based on the cutting force formula F=CFdxffYFvZFN; reaming at medium speed; and statically withdrawing the reamer. The improved perforating process has no delamination of the composite material, high production efficiency and high product quality.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

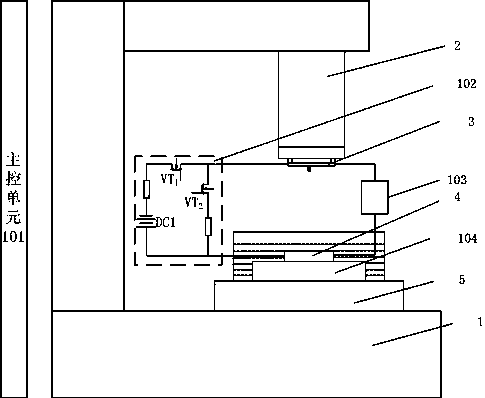

Ultrasonic-modulation electrostatic-induction-drive fine electric spark machining device

InactiveCN103418865ARealize fine feedRealize micro electric discharge machiningElectrical-based machining electrodesElectric circuitsMetal sheetUltrasonic vibration

The invention provides an ultrasonic-modulation electrostatic-induction-drive fine electric spark machining device, which comprises a main control unit, a machine tool body and a power supply. A workbench and a Z-axis lifting feeding mechanism are arranged on the machine tool body. A metal sheet is arranged on the Z-axis lifting feeding mechanism. An ultrasonic vibration and detection device is arranged on the workbench. A workpiece fixture is arranged on the ultrasonic vibration and detection device. The metal sheet, the workpiece fixture and the power supply are serially connected. The ultrasonic vibration and detection device and the power supply are respectively connected with the main control unit. The ultrasonic-modulation electrostatic-induction-drive fine electric spark machining device provided by the invention has the beneficial effects that voltage is respectively applied to the metal sheet and the workpiece fixture through the power supply, the metal sheet and a workpiece on the workpiece fixture are enabled to have attraction force due to charges of different polarities, the metal sheet is bent and deformed under the effect of the attraction force, the metal sheet is enabled to move towards the workpiece on the workpiece fixture to realize fine feeding, the chip removal can be improved through the ultrasonic vibration and detection device and the realization of high-precision fine electric spark machining is facilitated.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

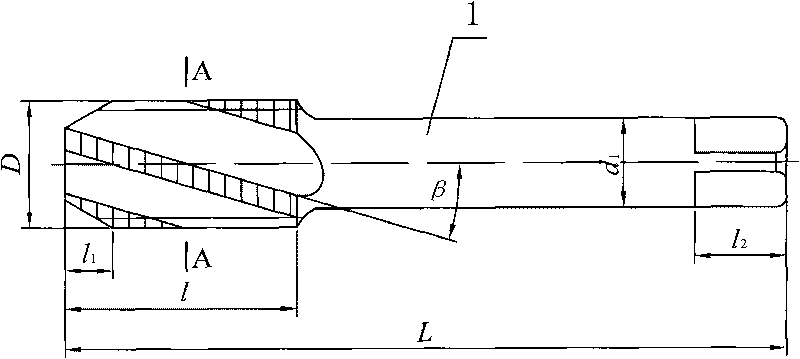

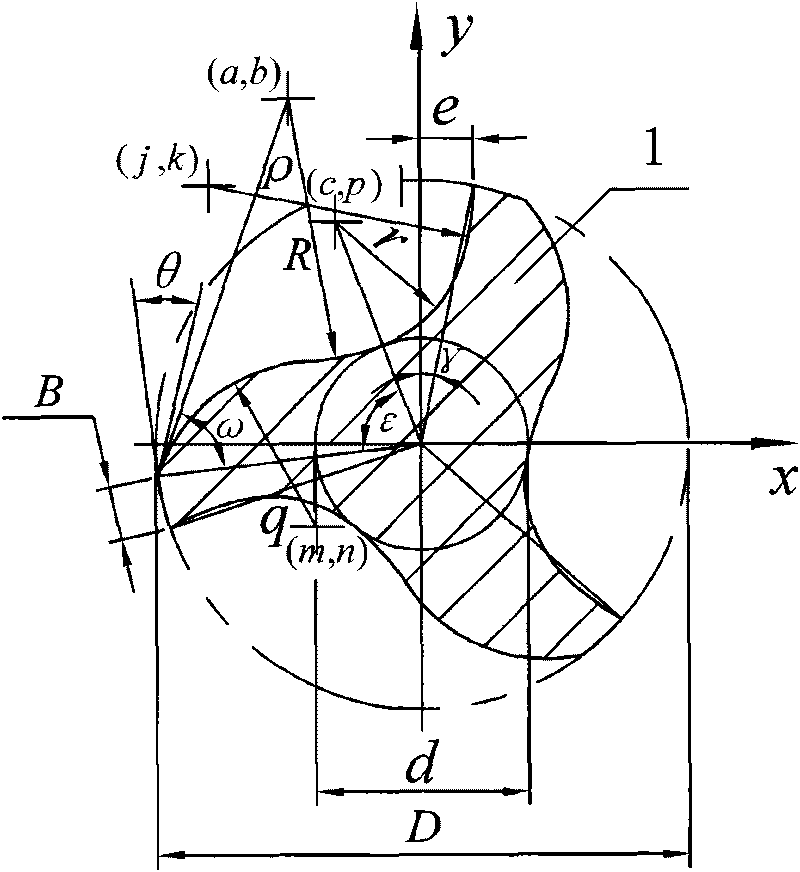

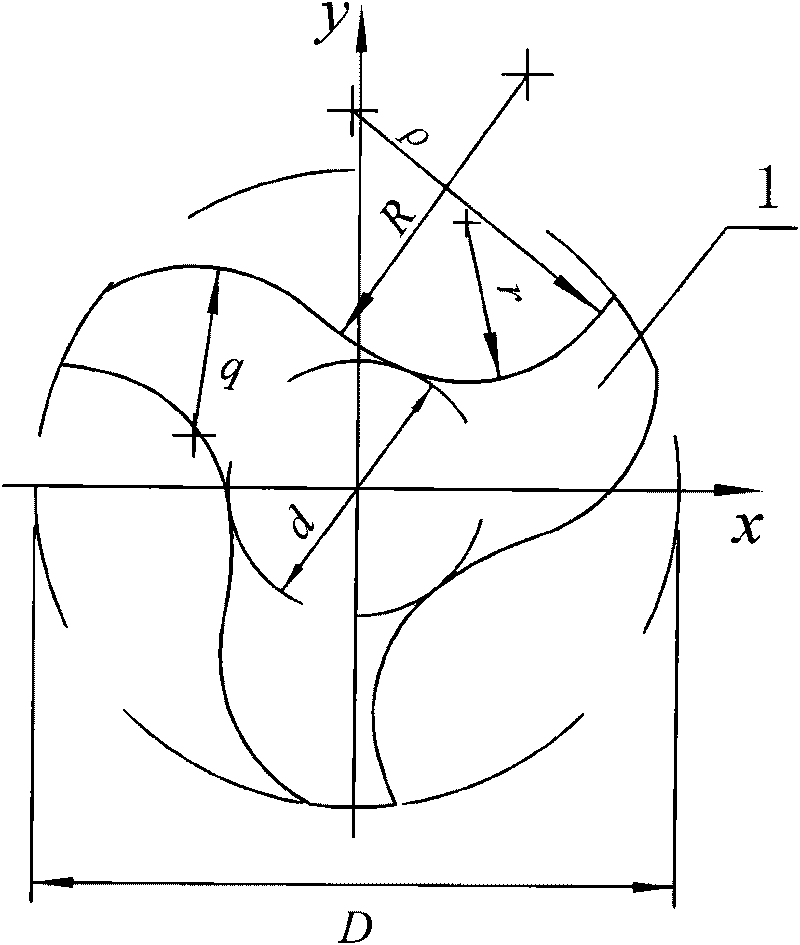

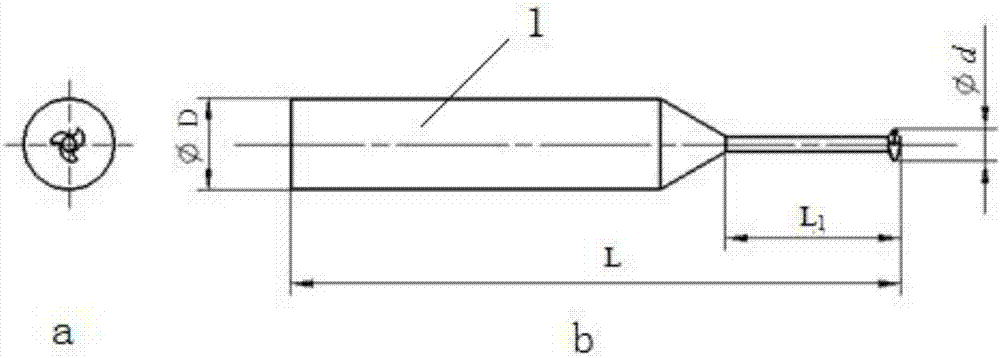

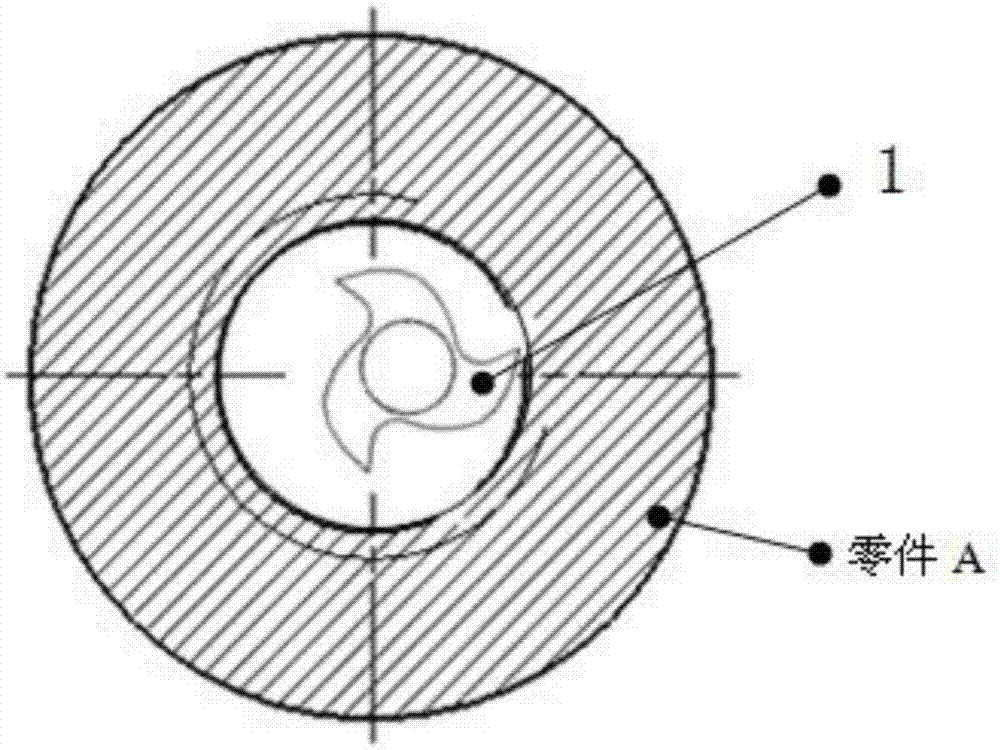

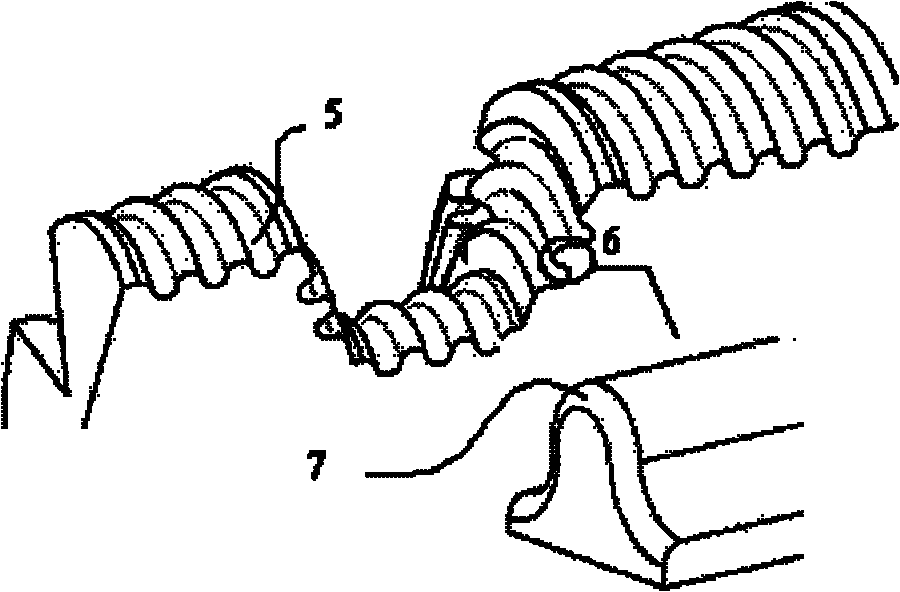

Spiral fluted tap and method for processing same

The invention discloses a spiral fluted tap and a method for processing the same. The spiral fluted tap comprises a tap body provided with a plurality of uniformly distributed spiral flutes on a front cut part, wherein the spiral flute is an S-shaped smooth curved groove formed by sequentially connecting four sections of tangential circular arcs end to end; and the four sections of tangential circular arcs are a cutting circular arc, a chip curling circular arc, a chip accommodating circular arc and a blade back circular arc respectively. The method for processing the spiral fluted tap comprises the following steps of: (1) preparing before processing; (2) processing the spiral flute by a special tool: fitting a blade shape of a cutter by a computer, and then manufacturing the cutter according to the fitted cutter blade shape so as to process the spiral flute; and (3) carrying out subsequent treatment by using a machining process so as to obtain a finished product of the tap body. The spiral fluted tap processed by the method has simple structure and can be molded in one step. Moreover, the processing method is suitable for different processing materials, particularly for processing fluted taps made of light alloys, such as an aluminum alloy and the like.

Owner:XIAN TECHNOLOGICAL UNIV

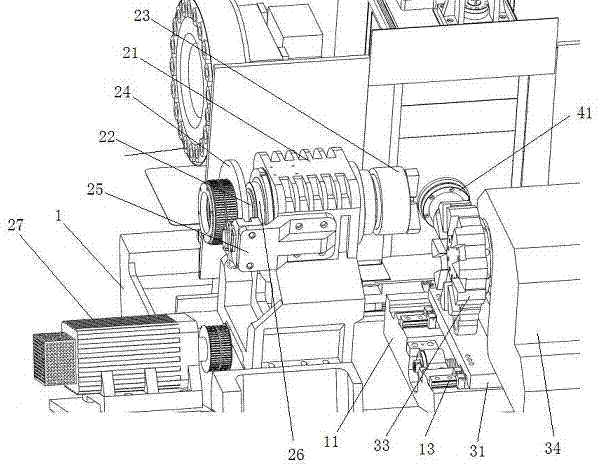

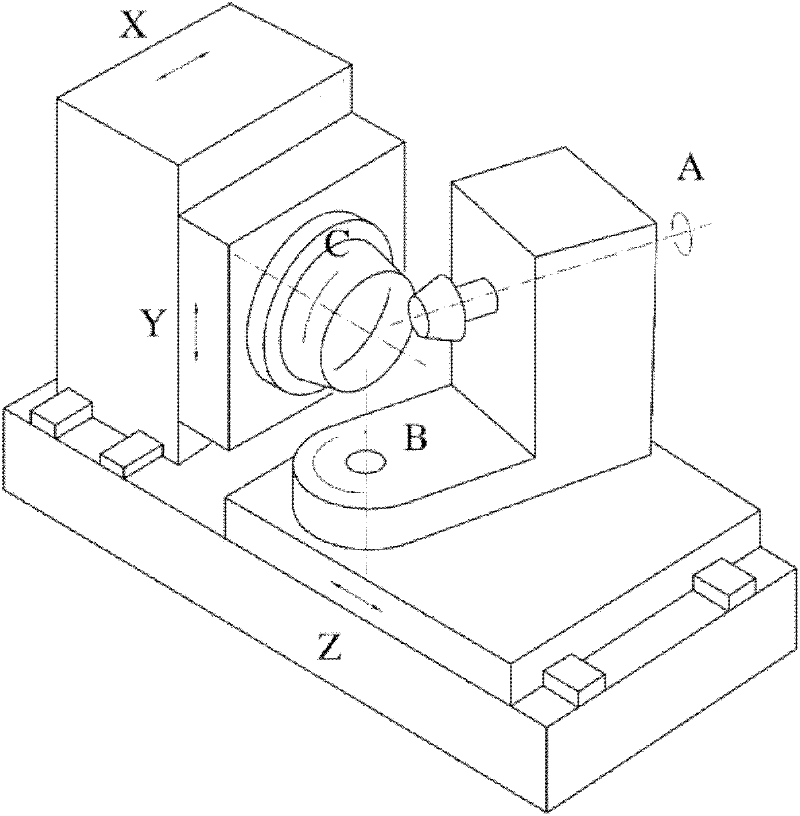

Seven-axis turn-milling machining center

InactiveCN103692220AReasonable layoutCompact structureOther manufacturing equipments/toolsLarge fixed membersEngineeringMachining

The invention discloses a seven-axis turn-milling machining center. The machining center comprises a base, a lathe body arranged on the base, a work-piece clamping unit, a turning unit and a milling unit. An X-axis guide rail A and an X-axis guide rail B which are parallel are arranged on the lathe body. The work-piece clamping unit comprises a spindle box connected with one end of the lathe body and a spindle connected with the spindle box, a work-piece clamp is arranged at one end of the spindle, which faces towards the lathe body, and the end of the spindle, which face towards the lathe body, performs transmission with the motor. A saddle A of the turning unit and a saddle B of the milling unit are connected with the X-axis guide rail A and the X-axis guide rail B through a transmission unit A and a transmission unit B respectively, and a turning tool of the turning unit and a milling electric spindle of the milling unit face towards the work-piece clamp respectively. According to the seven-axis turn-milling machining center, the arrangement is reasonable, the structure is compact, four-axis linkage can be performed during turning or milling, and work-piece machining is flexible and convenient.

Owner:江苏建亚精密机械有限公司

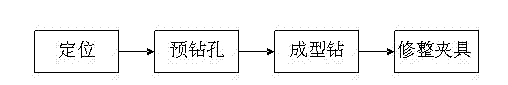

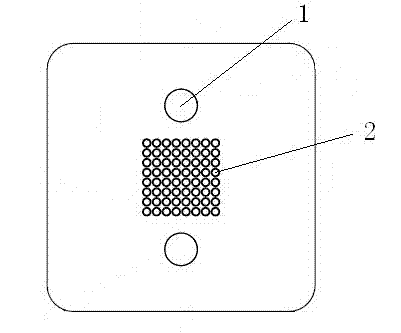

Processing technology of intensive type tinier hole

InactiveCN102773520AGood chip removal performanceImprove accuracy and positionTransportation and packagingBoring/drilling machinesRoughcastDrill bit

The invention discloses a processing technology of an intensive type tinier hole. The processing technology comprises the following steps of: (1), positioning: positioning to-be-processed working parts on which the intensive type tinier holes need to be processed on an operation platform by adopting a tool clamping apparatus; (2) pre-drilling: carrying out pre-drilling on the to-be-processed working parts by adopting a first solid borer to form the intensive type tinier roughcast holes; (3) molding drilling: repairing a position degree and pore size on the intensive type tinier roughcast holes by adopting a second solid borer so as to achieving the design size; and (4) finishing a fixture: removing a borehole trace on the tool fixture. Through the manner, the processing technology provided by the invention has the advantages that the position degree and precision of the hole are improved, meanwhile, the surface quality of the hole wall is improved, and the service life is prolonged.

Owner:KUSN QIAORUI METAL PRODS

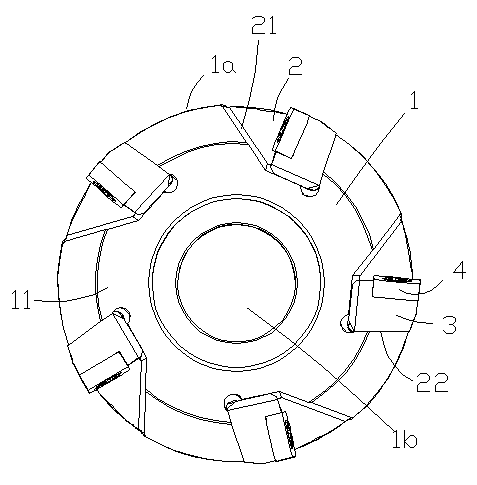

Milling cutter device with function of adjusting height of blade

InactiveCN103008748AHeight adjustableThe combination is firmMilling cuttersDrive shaftMilling cutter

The invention provides a milling cutter device with a function of adjusting the height of a blade. The milling cutter device comprises a cutter plate body, wherein the center of the cutter plate body is provided with a driving shaft hole; at least one cutter placing groove is upward inscribed in the circumference of the cutter plate body and the cutter placing groove extends to the front side face of the plate body; the cutter placing groove is internally provided with a tool holder; a chip removal inclined plane is arranged at a part of the cutter placing groove, corresponding to the tool holder; the tool holder is fixedly provided with the blade; one part of the blade stretches out of the circumference; and the tool holder is provided with an equal-height adjusting screw for adjusting the height of the blade. The milling cutter device with the function of adjusting the height of the blade disclosed by the invention has the advantages that the height of each blade can be effectively adjusted, the chip removal is convenient, a machining effect is good, and the combination of the blade and the cutter plate is firm.

Owner:NINGBO CHUANJINGYU MECHANICAL TECH DEV

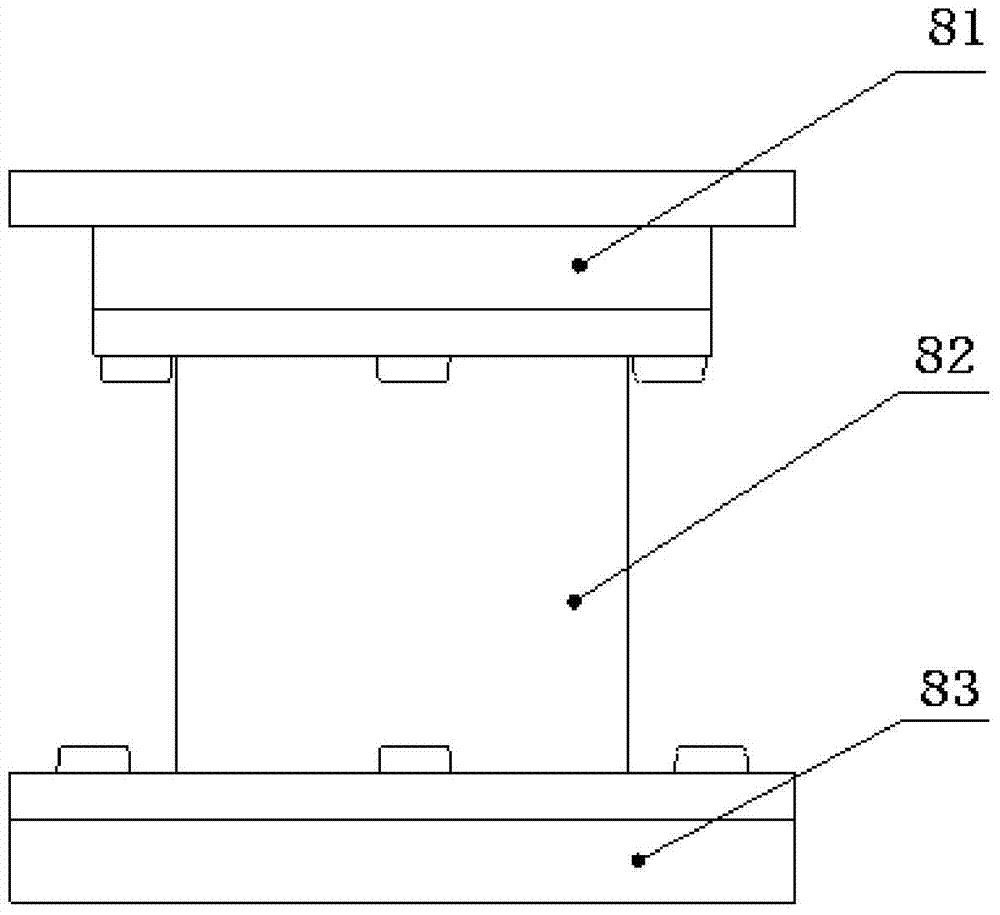

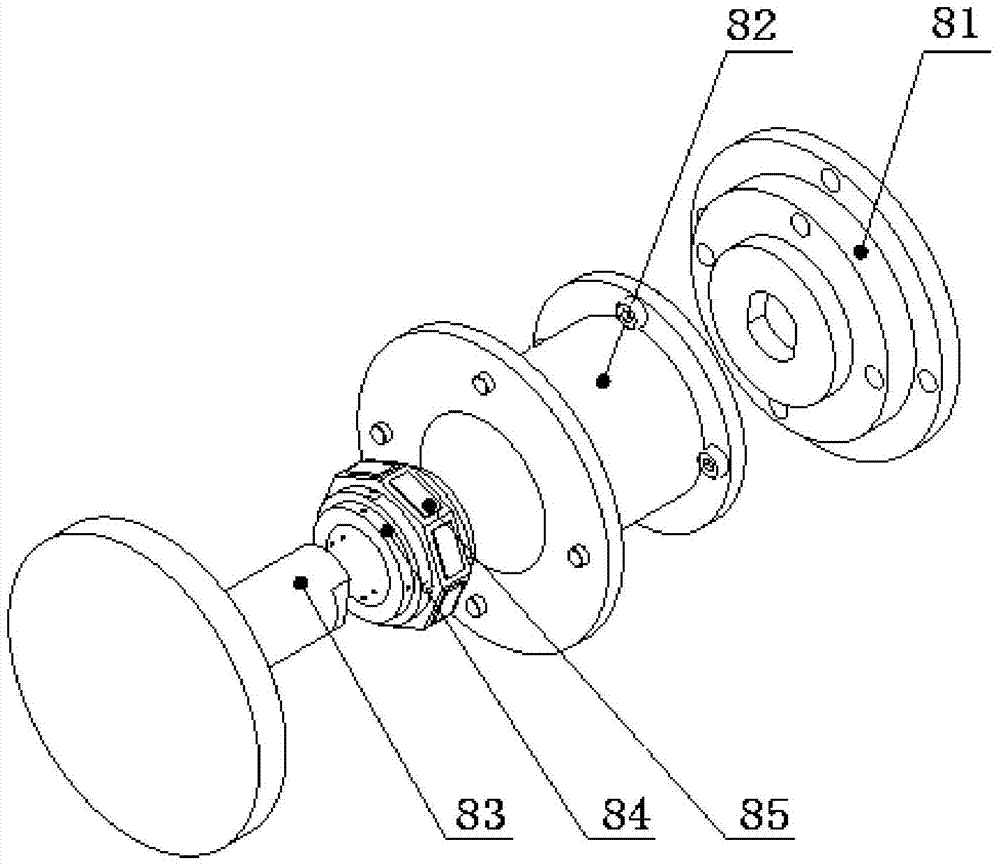

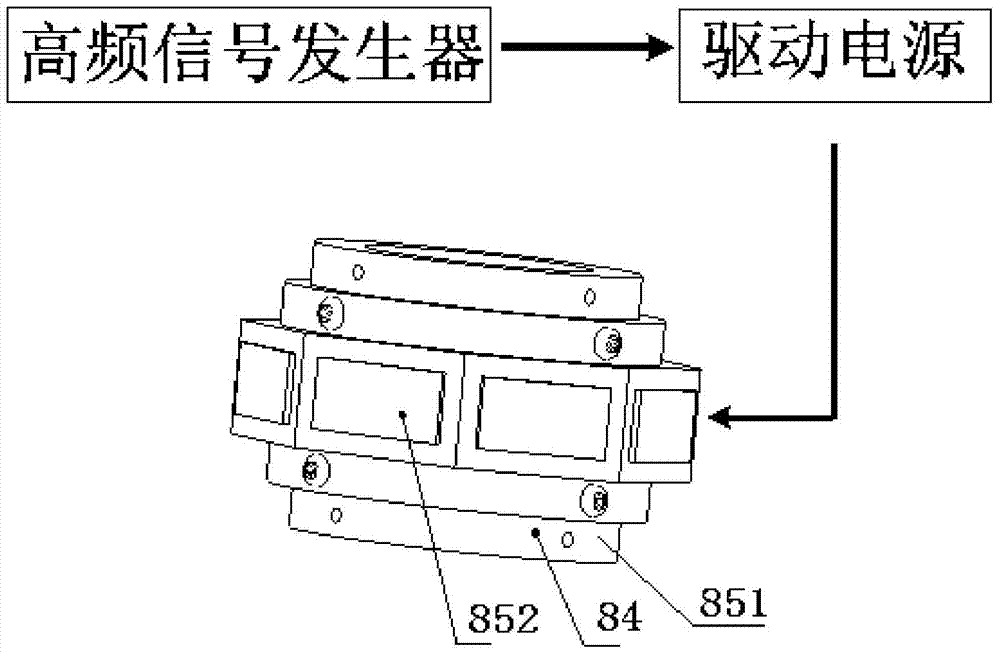

Workpiece loading device and machining device for machining tiny deep holes

InactiveCN103586504AControllable torsional vibrationReduce frictionBoring/drilling machinesEngineeringActuator

A workpiece loading device for machining tiny deep holes comprises a base, an upper cover and a protection shell, wherein the upper cover is used for bearing a workpiece to be drilled, and the protection shell is connected with the base and the upper cover. The base, the upper cover and the protection shell are coaxially arranged. A torsional vibration generating mechanism is arranged inside the protection shell and comprises a torsional actuator for generating torsional vibration and an exciting device for providing an exciting signal for the torsional vibration actuator. The torsional actuator generates the torsional vibration through intelligent materials. The machining device for machining the tiny holes comprises a drilling machine, a main shaft, a drill bit clamp, a drill bit, an intelligent material for driving the drill bit to be torsionally vibrated and a workpiece loading device, wherein the drill bit clamp is fixedly connected with the main shaft, and the drill bit and the workpiece loading device are reversely and torsionally vibrated. The workpiece loading device and the machining device have the advantages that the tiny hole machining efficiency and the machining precision can be improved.

Owner:ZHEJIANG UNIV

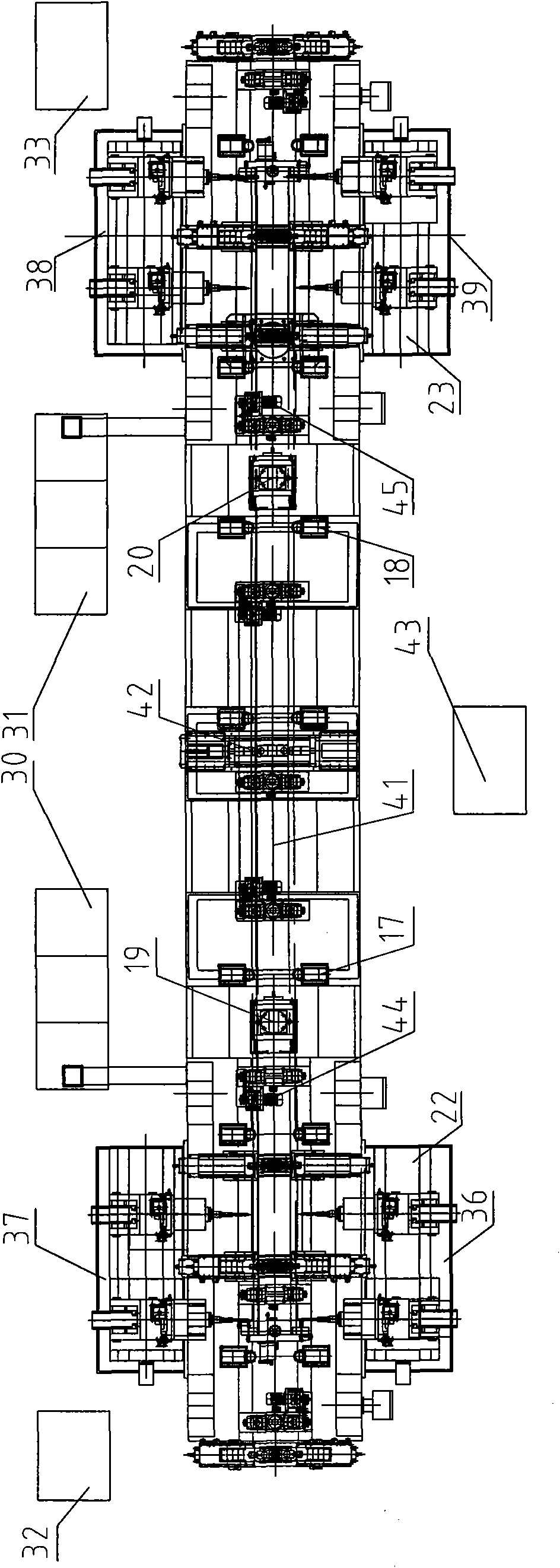

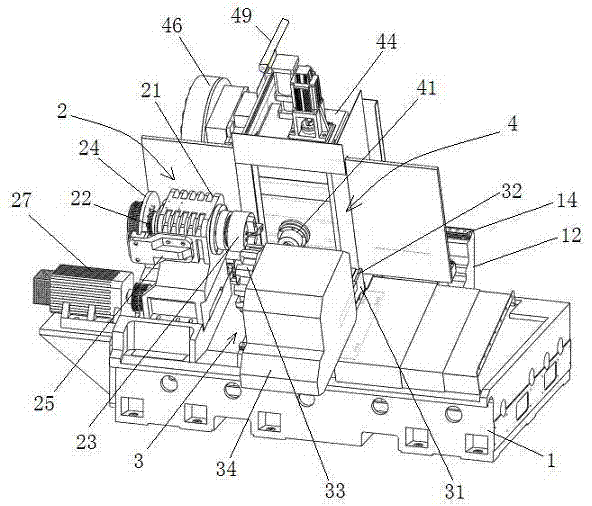

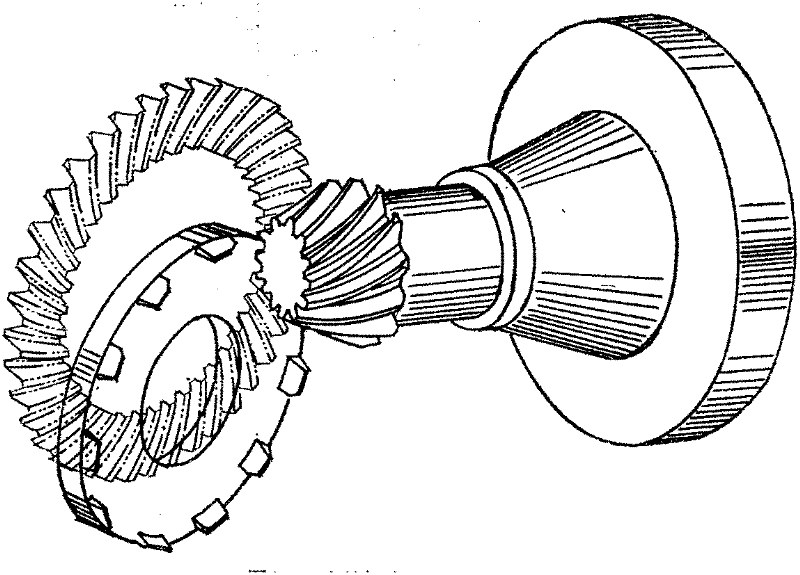

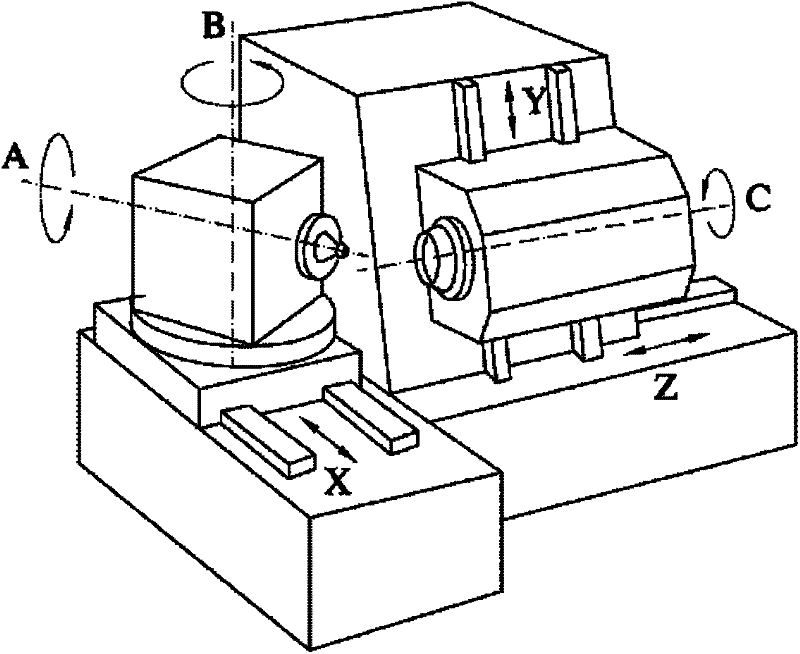

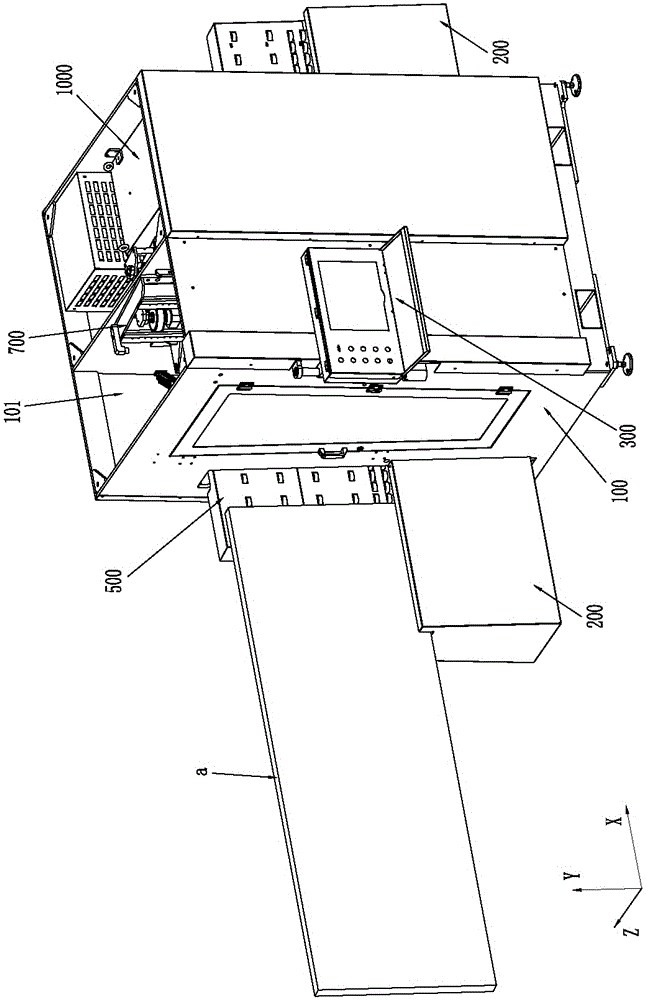

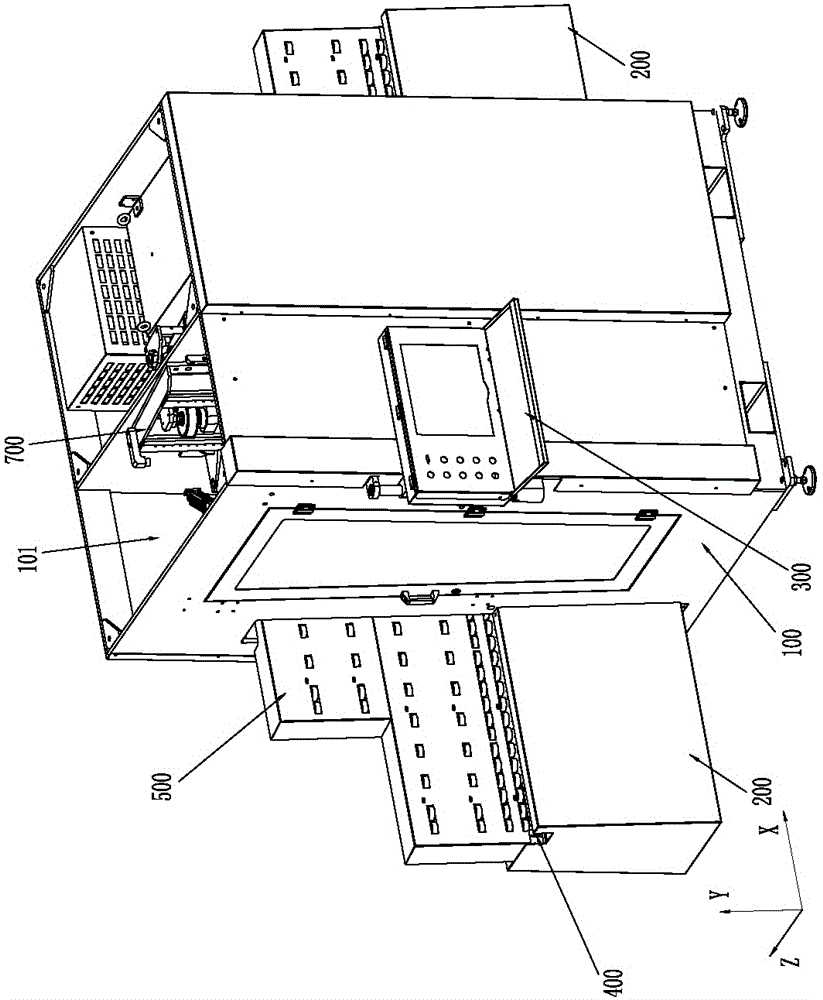

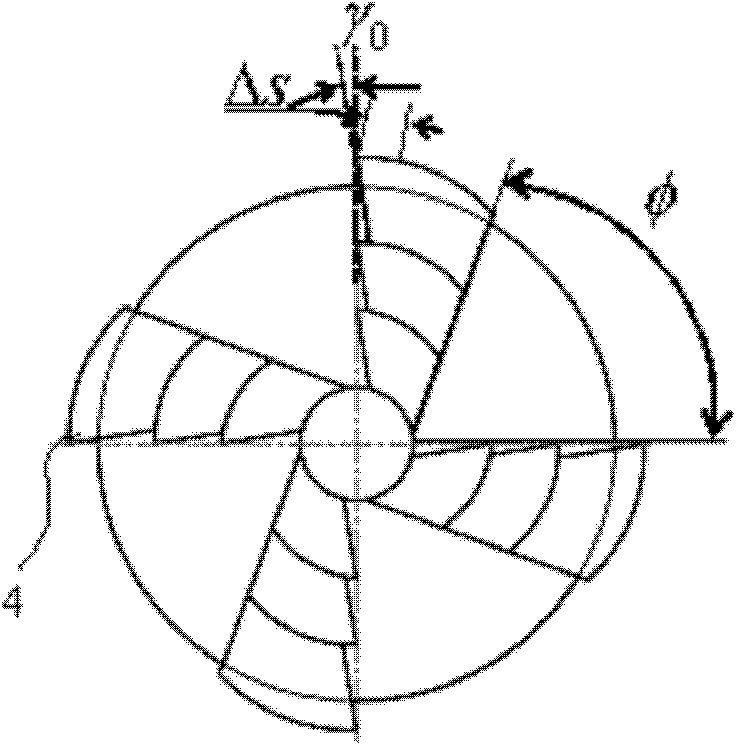

Machine tool and method for machining spiral bevel gear

The invention relates to numerical-control mechanical processing equipment and methods, in particular to a machine tool and a method for machining a spiral bevel gear. The machine tool is provided with a conveyer belt for automatically loading / unloading and a manipulator for loading / unloading the gear, thus, the full automation for machining the gear is realized. The machine tool has a simple structure and a small floor space, can be used for wet-cutting the spiral bevel gear, and can also be used for dry-cutting the spiral bevel gear; the machine tool can be used as a teeth-milling machine of the spiral bevel gear, and can also be used as a teeth-grinding machine of the spiral bevel gear; and the machine tool not only can carry out precision detection on machined gears, but also is provided with an automatic loading / unloading device.

Owner:CHANGSHA HALIANG KAISHUAI PRECISION MASCH CO LTD

Numerical control milling method for micro threaded holes of titanium alloy

InactiveCN107127406AImprove shape and position accuracyImprove processing efficiencyThread cutting machinesNumerical controlDiameter ratio

The invention relates to a numerical control milling method for micro threaded holes of titanium alloy. The method comprises the specific machining operation steps of replacing a traditional manual tapping method for the titanium alloy with numerical control machining to improve the quality and efficiency of threads, selecting a threaded tool made of hard alloy to ensure high efficiency and batch production of part machining, and selecting a reasonable technical machining method to ensure specification consistency of the threads, circumferential stress uniformity during threaded milling and prevent the tool from being broken. The numerical control milling method is suitable for the micro threaded holes, with the machining range smaller than M3 and the length-diameter ratio higher than 2.5, of the titanium alloy, and the bottleneck problem of tapping of the micro threaded holes, with the large-length-diameter ratio, of the titanium alloy is solved successfully. Meanwhile, drilling and tapping are completed jointly, efficiency is improved by 6-8 times, the grade of precision of the threads of the holes and specification consistency of the threaded holes are improved, and the machining requirement for high precision of titanium alloy parts can be met.

Owner:中国船舶重工集团公司第七〇七研究所

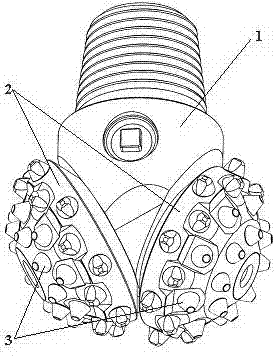

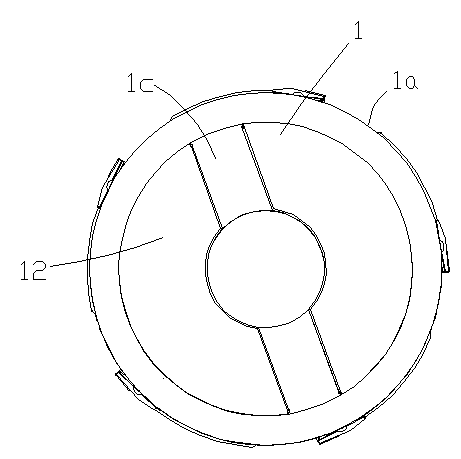

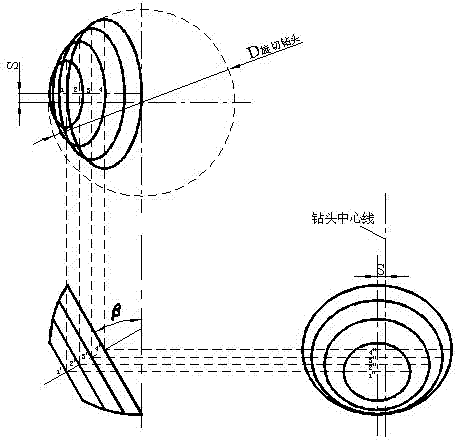

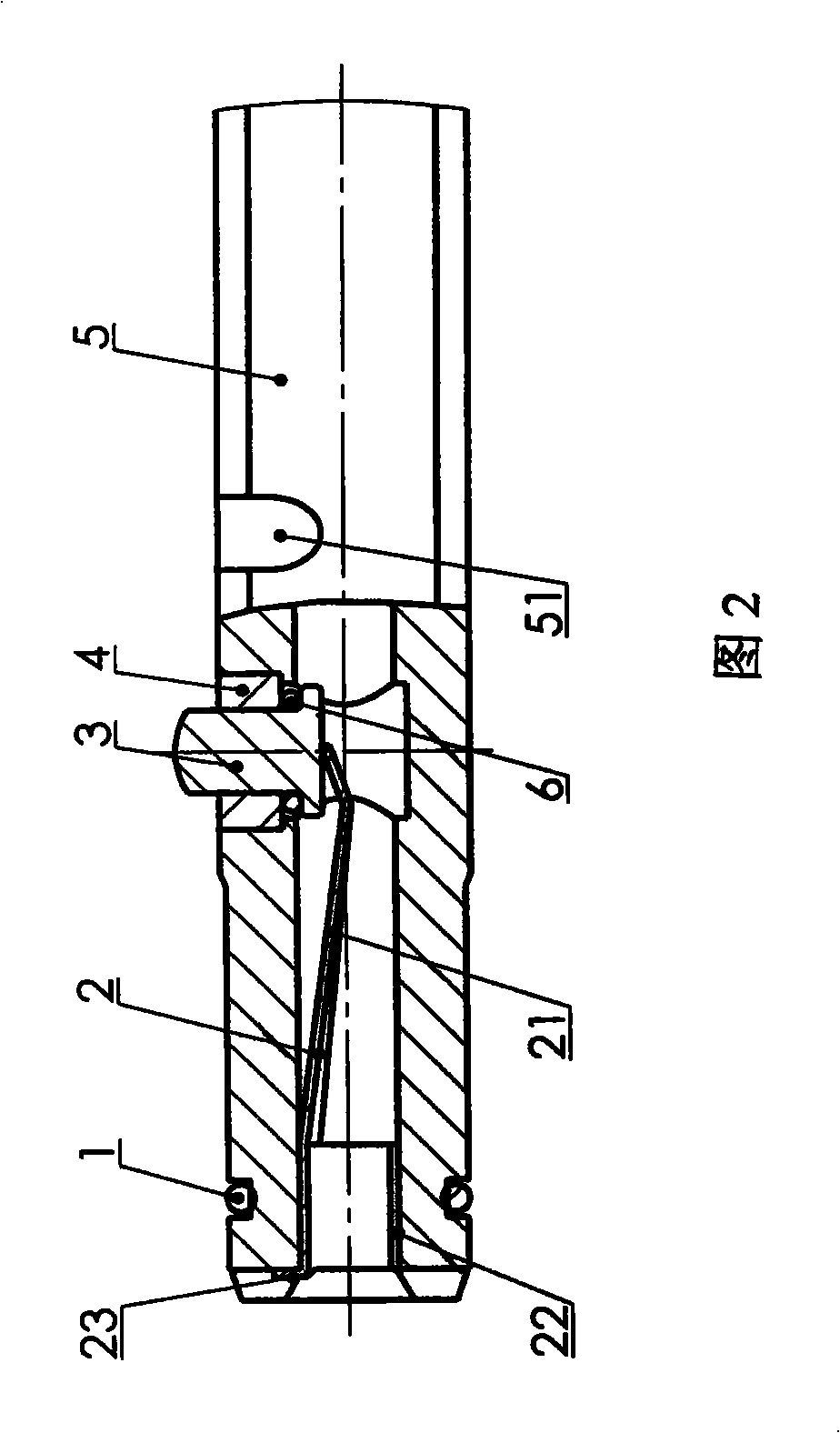

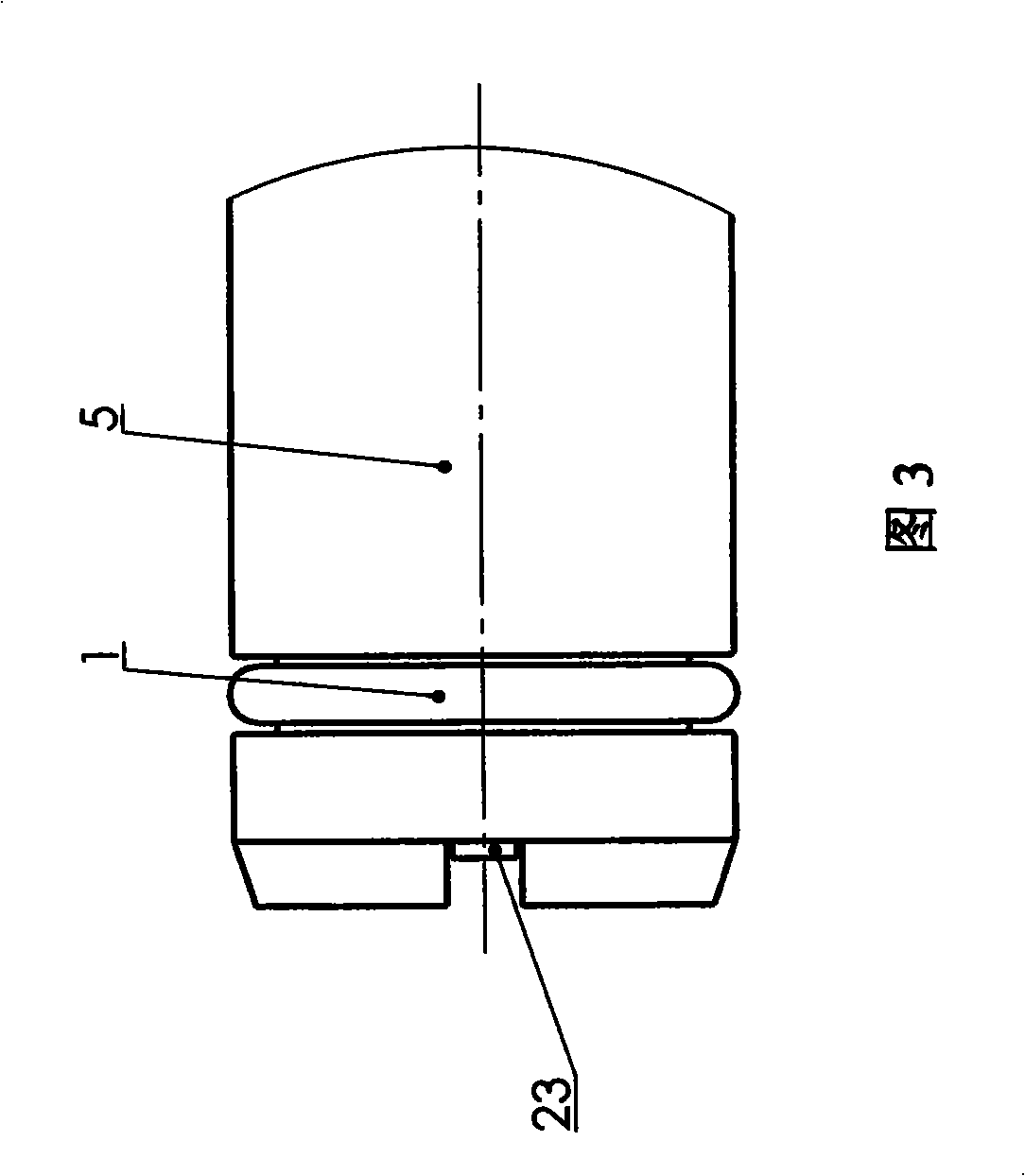

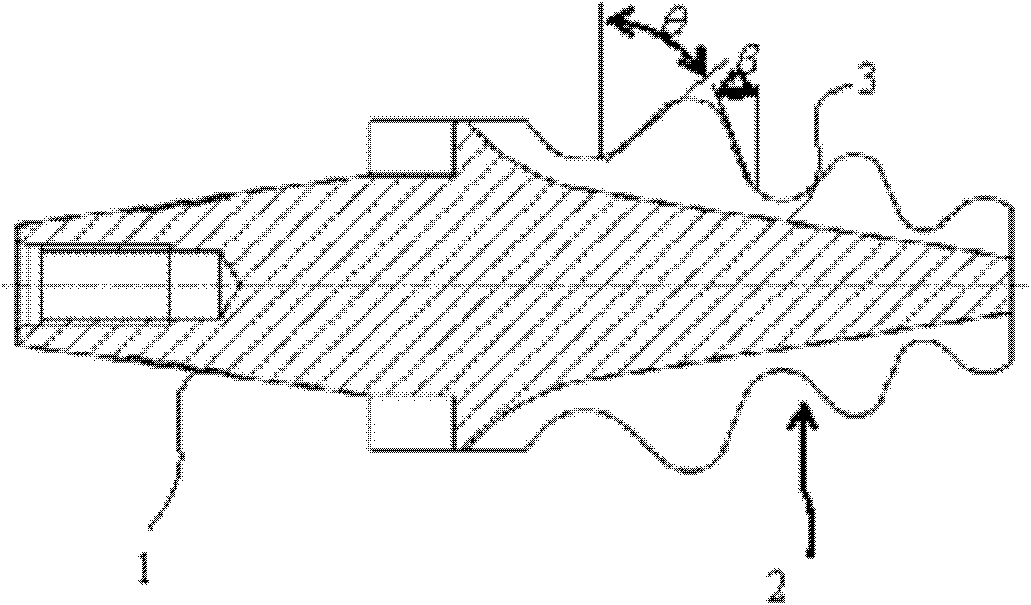

Compound bit formed by rotary cutting bit and PDC (polycrystalline diamond compact) blades

ActiveCN102392603AImprove rock breaking efficiencyHigh rock breaking performance at the centerDrill bitsConstructionsHigh ratePolycrystalline diamond

The invention discloses a compound bit formed by a rotary cutting bit and PDC (polycrystalline diamond compact) blades. The compound bit comprises a main body (1), rotary cutting bit cones (2), rotary cutting bit cutting teeth (3), PDC blades (4), PDC cutting teeth (5), oil storage sacs (6) and nozzles (7), wherein the main body (1) comprises a cone journal, centralizing blocks, high-pressure slurry channels and a connection screw thread. The compound bit is characterized in that a compound bit cutting unit comprises the rotary cutting bit and a PDC bit cutting unit. The compound bit has the following beneficial effects: the rotary cutting bit completes drilling the central part of the borehole in the drilling process; the rotary cutting bit in the compound bit shocks, crushes and cuts the rocks by way of rotary cutting, has high central rock breaking efficiency, high rate of penetration and better dynamic performance, is uniform in wear, simultaneously improves the bit bearing structure and ensures to prolong the service life of the bit while improving the rock breaking efficiency; and the linear velocity of the periphery of the borehole is high in the drilling process and the rotary cutting bit and the PDC bit cutting unit complete drilling the periphery of the borehole, thus improving the cutting capability of the compound bit and ensuring good gauge protection effect.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

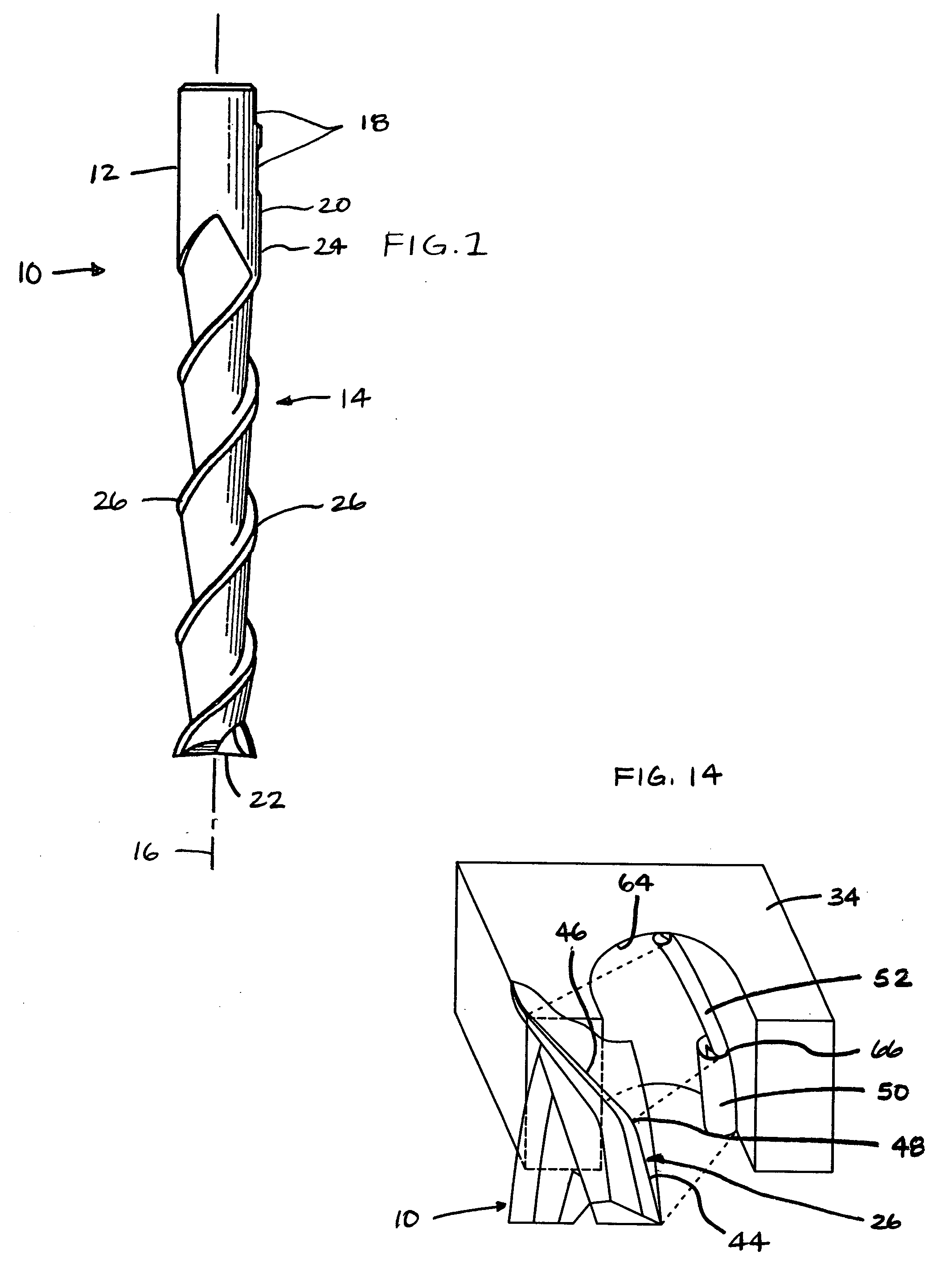

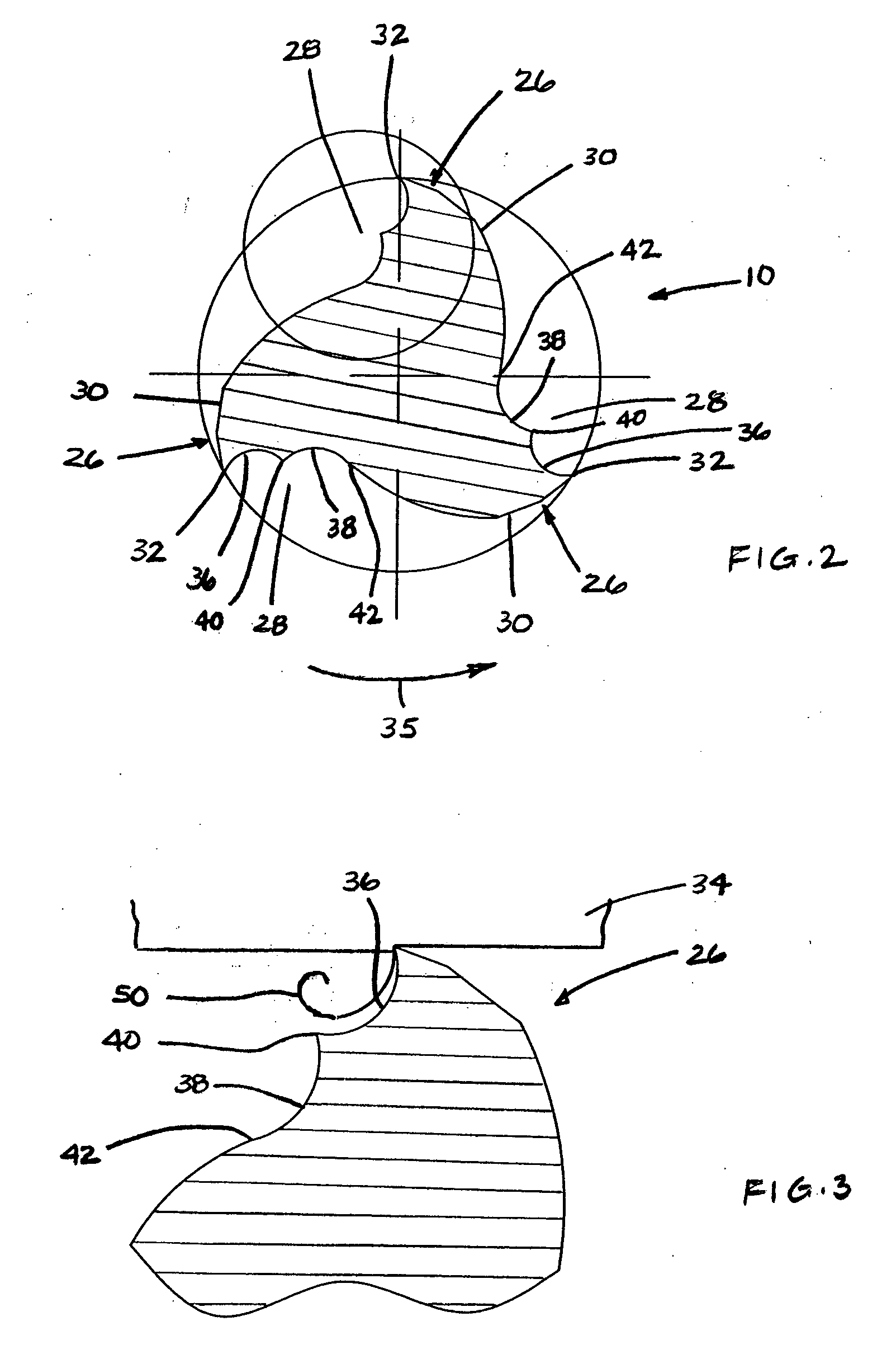

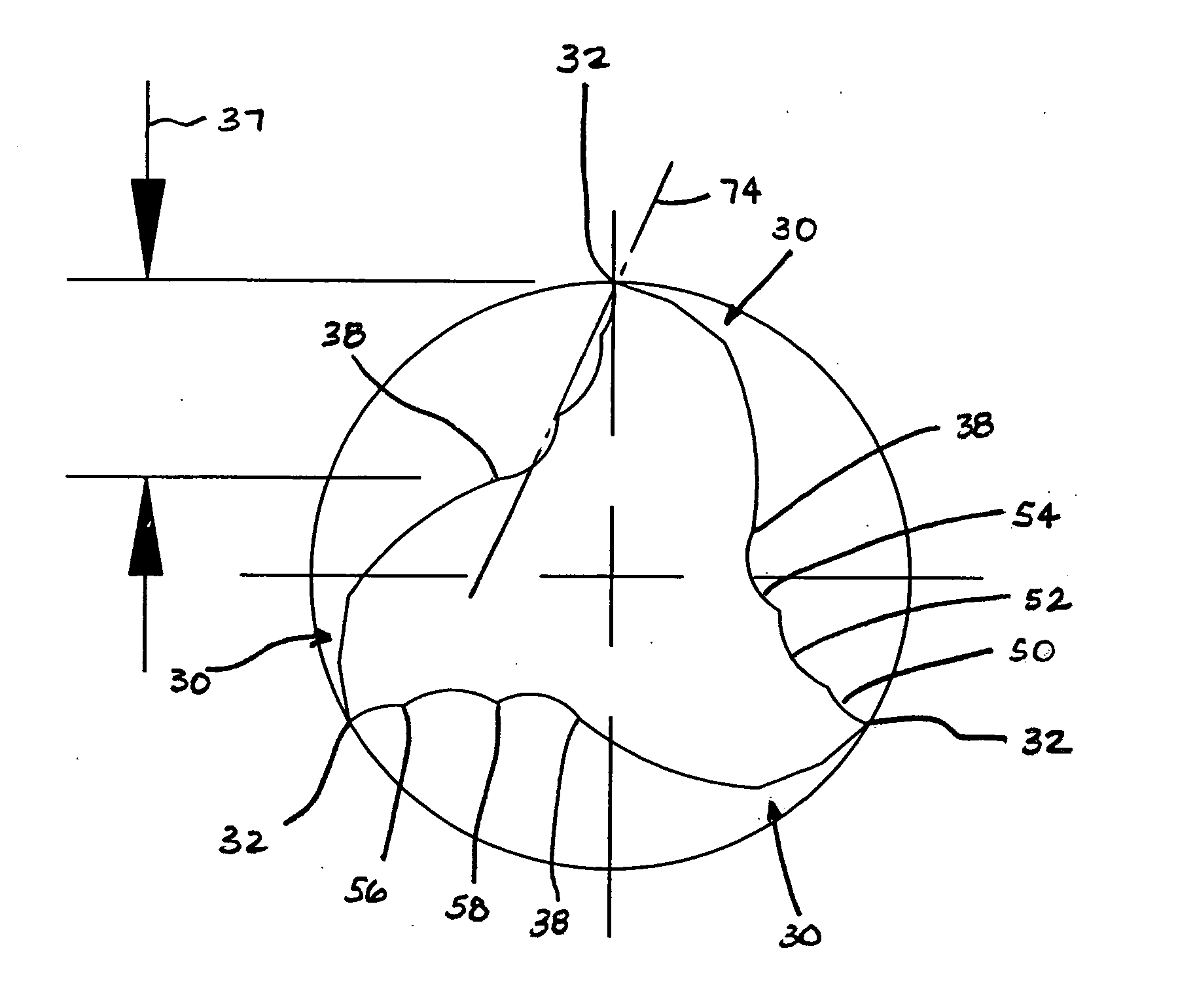

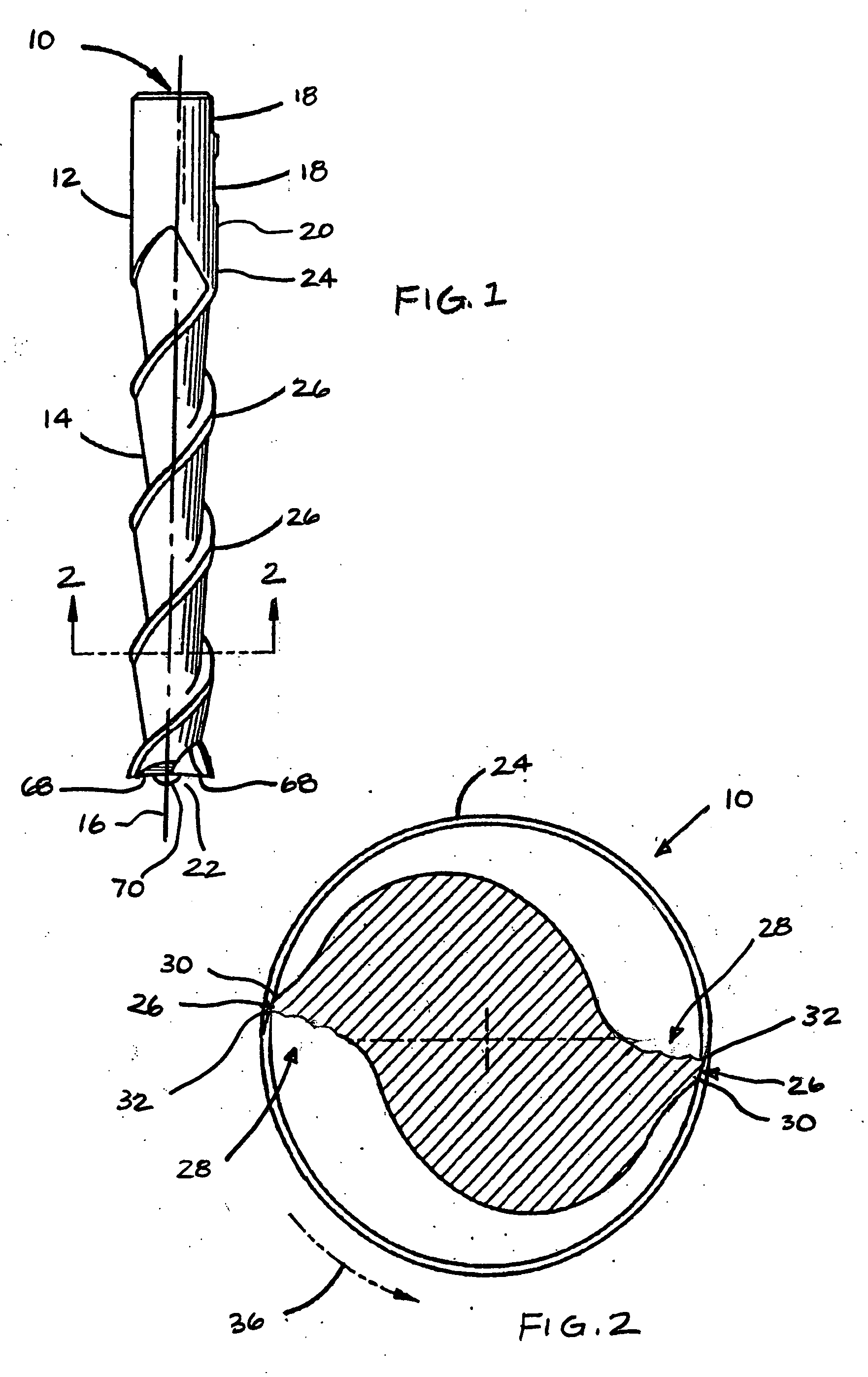

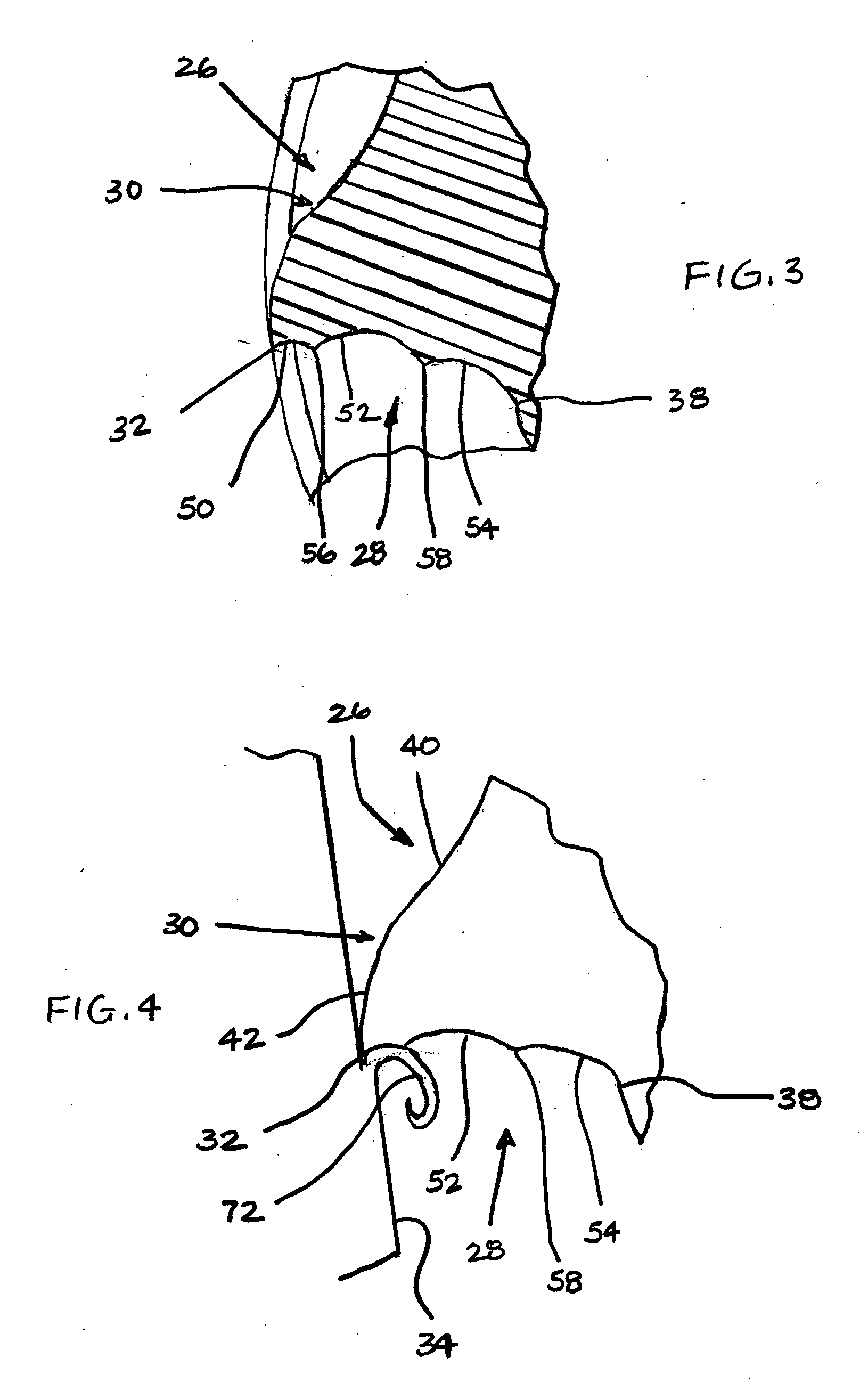

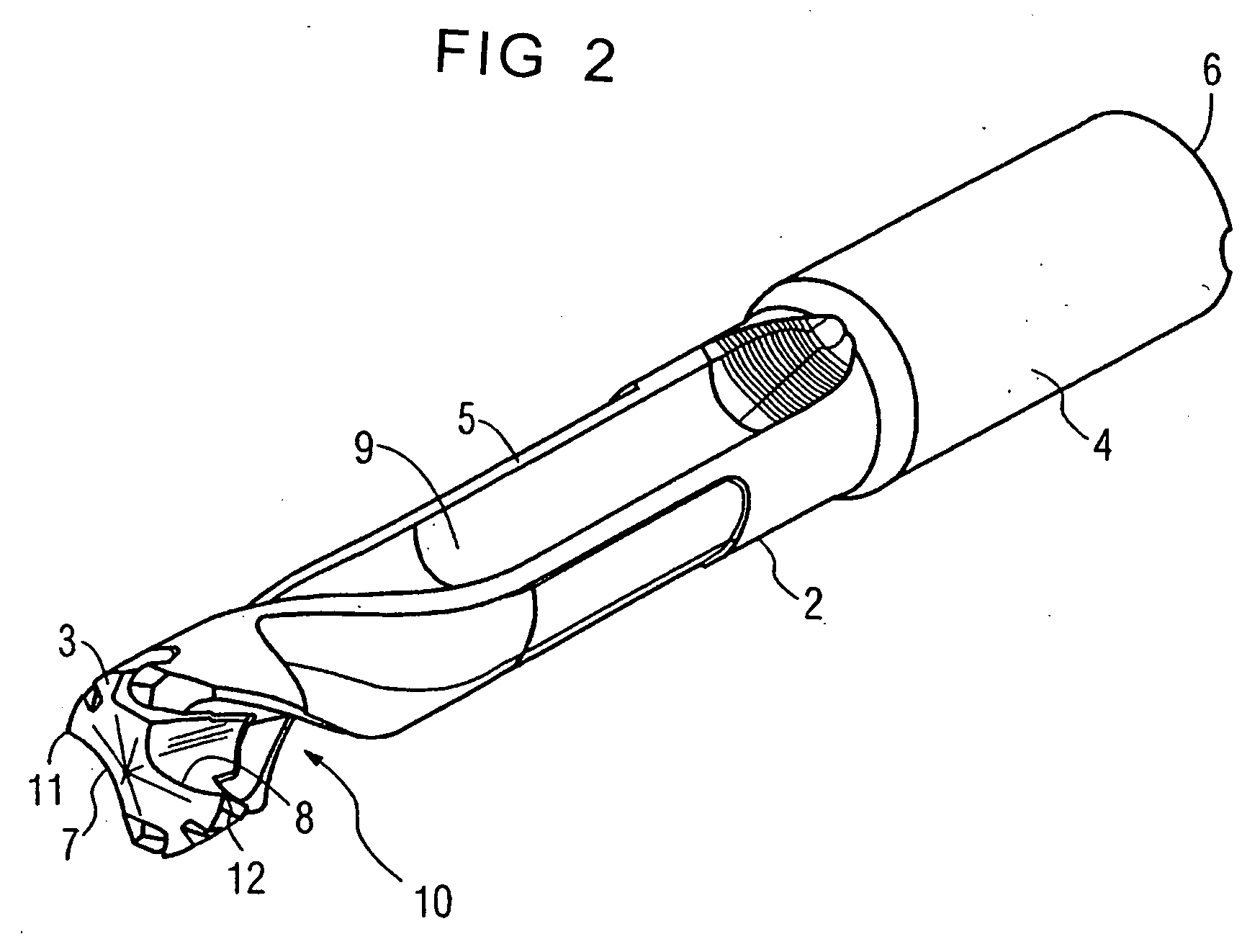

Drill bit

ActiveUS20060204345A1Easy chip removalImprove mechanical propertiesWood turning toolsTransportation and packagingFluteTrademark

A drill bit having a shank portion and a cutting portion, which cutting portion generally has at least two cutting edges, each with an at least partially spiraled or helical flute extending therefrom to the shaft portion. The drill bit has coolant channels that extend from the shaft portion and run substantially straight. The coolant channels have outlet openings that are arranged in the flutes and oriented toward the cutting edges. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KENNAMETAL INC

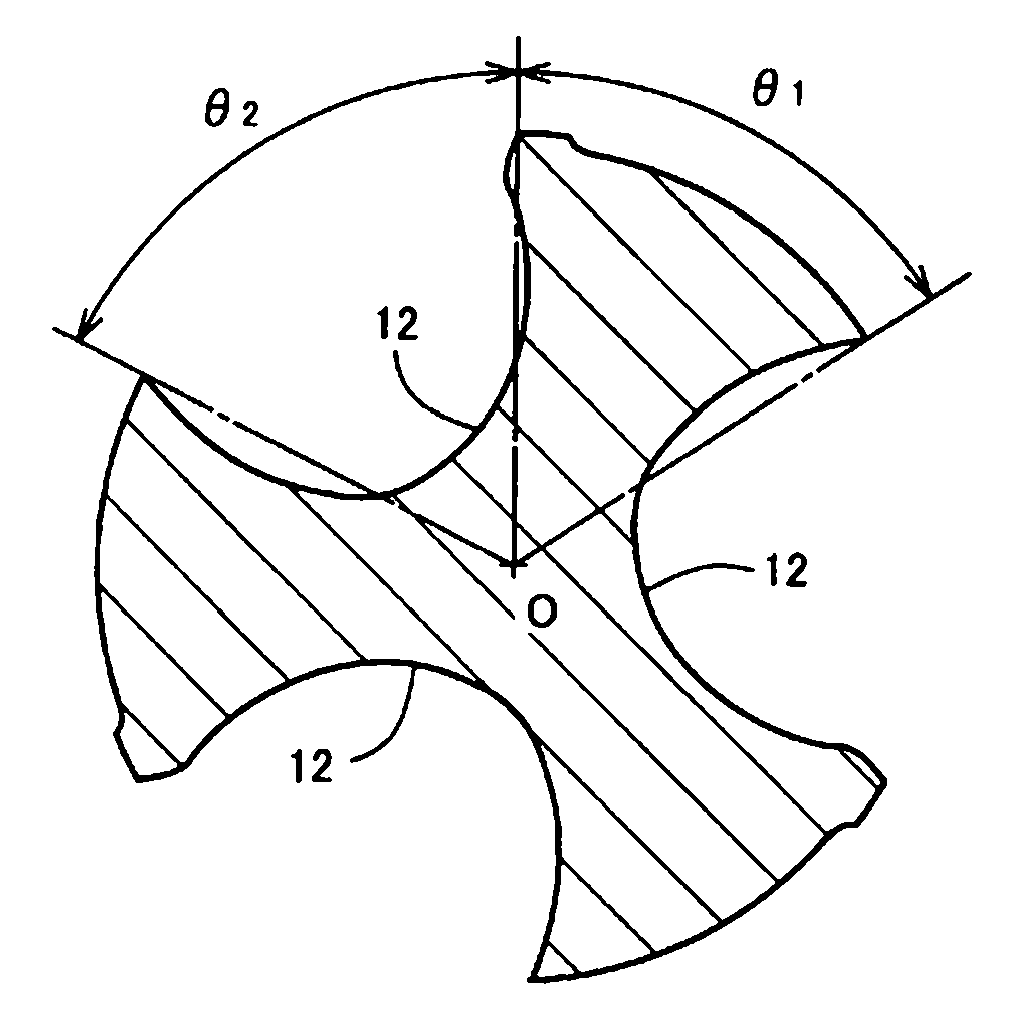

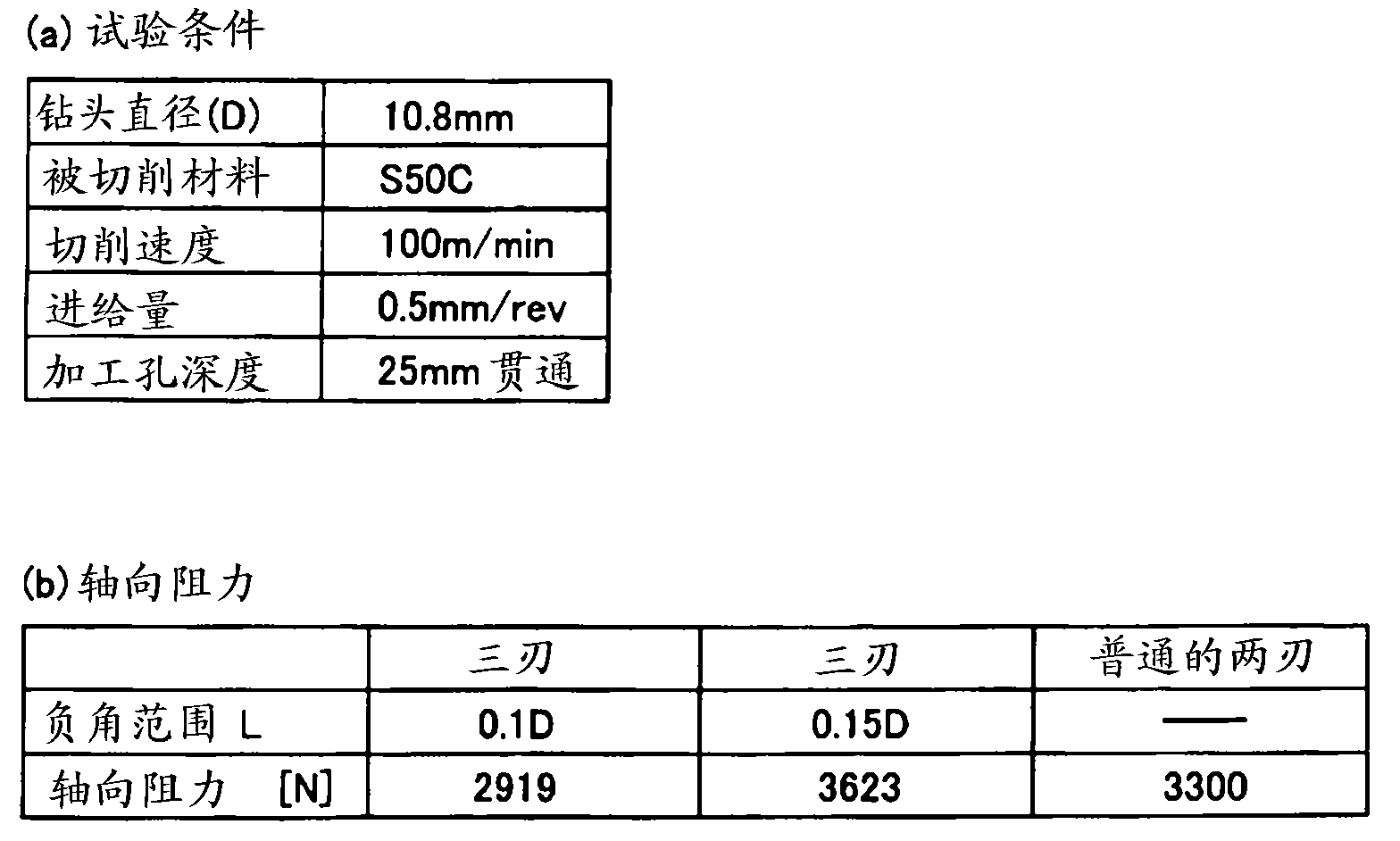

Drill

InactiveCN102170989AEasy to curlImprove discharge effectTransportation and packagingWorkpiecesEdge strengthEngineering

Owner:OSG

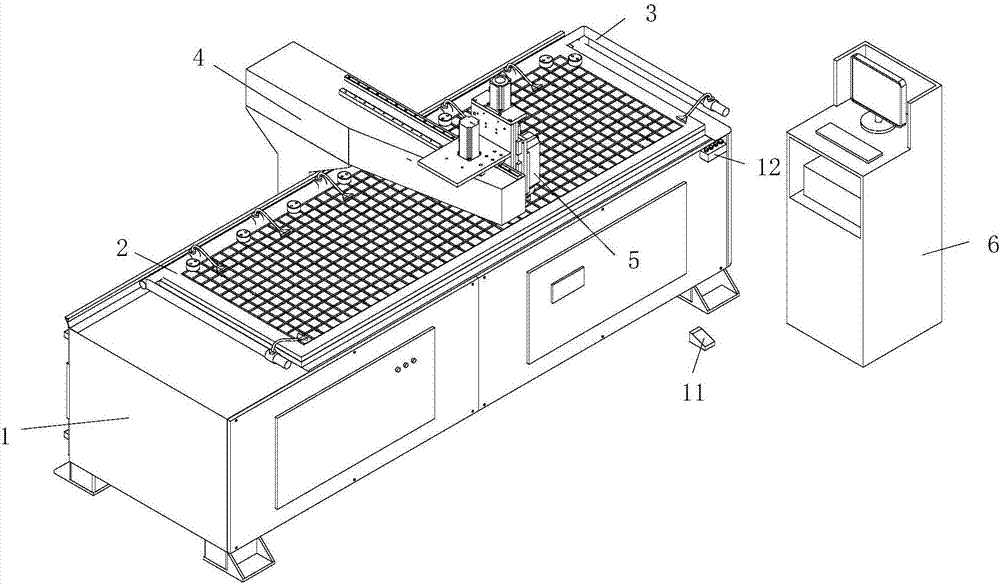

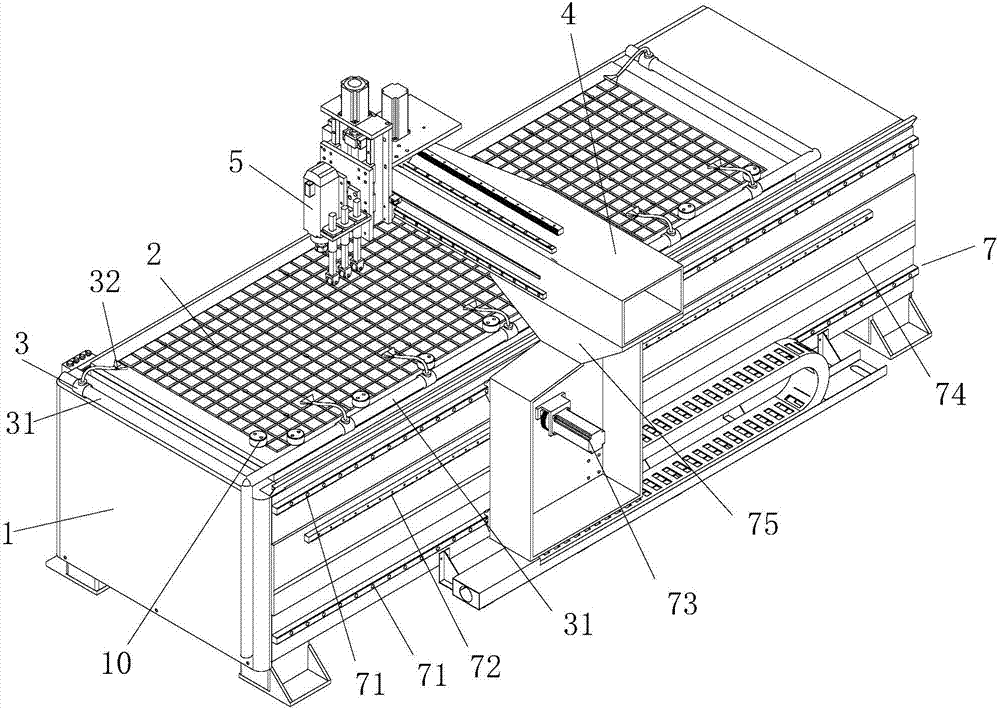

Vertical plate feeding numerical control drill with routing

ActiveCN104626291AHigh precisionMeet the requirements of appearance design processingMulti-purpose machinesNumerical controlEngineering

The invention discloses a vertical plate feeding numerical control drill with routing. The vertical plate feeding numerical control drill comprises a rack part, an X-axis part, a Y-axis part, a Z-axis part, a drill box part, an electric box part and an operation panel part, wherein the X-axis part comprises an X-axis transverse beam, a linear guide rail group, a mounting base plate, a gear, a rack, a clamp cylinder, a clamp fixing end, a clamp moving end and a first servo motor; the Y-axis part comprises a transverse beam, a Y-axis linear sliding rail, a second servo motor, a Y-axis lead screw and a Y-axis mounting plate; the Z-axis part comprises a Z-axis mounting plate, a first Z-axis slide block, a routing electric spindle, a Z-axis lead screw, a third servo motor and a fourth servo motor; and the drill box part is horizontally arranged on the Z-axis mounting plate and comprises a vertical drill, a left-right side drill, a top-bottom side drill and a grooving saw. Multifunctional full-numerical control machining is realized on a machine, the efficiency and machining precision are improved, the cost is saved, the drill is particularly suitable for machining individualized products, and the vertical plate feeding mode contributes to chip removal and dust collection.

Owner:NANXING MACHINERY CO LTD

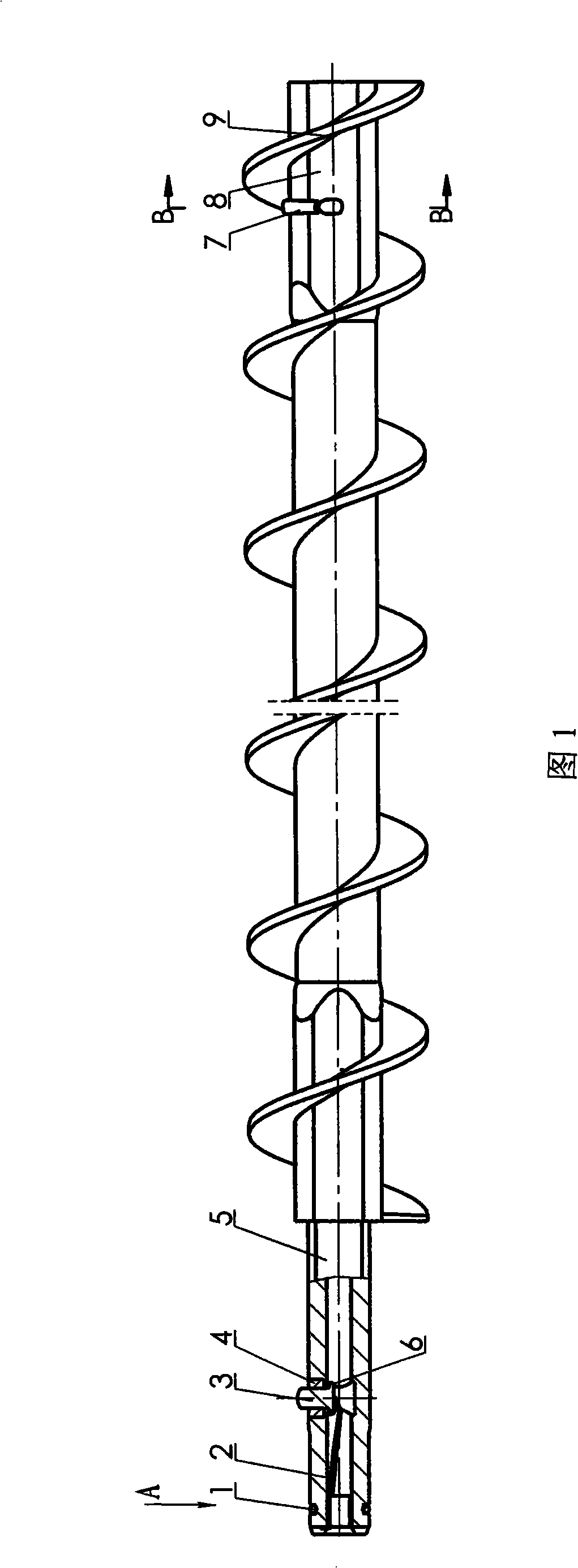

High-efficiency helical water-through jackrod

InactiveCN101294481AImprove water flow capacityImprove ventilationDrilling rodsDrilling casingsWorking environmentGas passing

The invention discloses an efficient water spiral drill pipe which comprises a plurality of drill pipe units. Each drill pipe unit comprises a drill pipe core, a spiral body, a tetragonal rod, a retaining ring, a lateral pin and a spring body which supports the lateral pin for splicing-positioning and connecting two adjacent drill pipe units into one body. The spring body of each drill pipe unit is provide with a cylindrical connector which is nested and clamped in a water and gas vent at the end of the tetragonal rod of the drill pipe unit, a bending knob which is connected with the connector into one body and is clamped in the end groove of the tetragonal rod, and a flat spring which is connected with the connector into one body and is inclined in the water and gas vent of the tetragonal rod; and the tail of the flat spring bends upwards for supporting the bottom end of the lateral pin on the tetragonal rod. The drill pipe has little possibility of blockage, solves the problem that drill pipe is difficult for water and gas passing through, and effectively reduces the occurrence of hole collapse, drill pipe sticking and drill pipe losing, and improves the working environment by reducing coal dust. The drill pipe has the advantages of wide application, high drilling efficiency and reduced drilling cost.

Owner:HEBEI JIKAI IND GRP +1

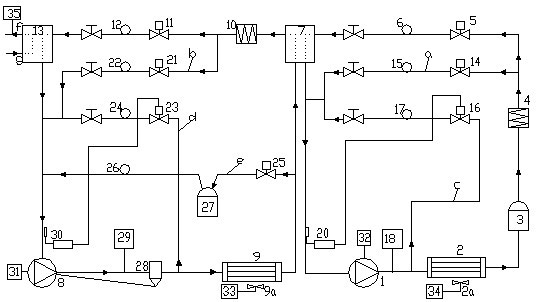

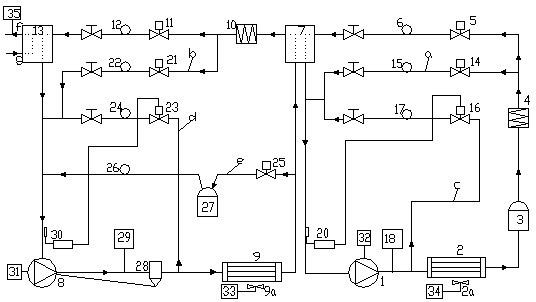

Low temperature cold air two-stage refrigeration system and cold air jet machine thereof

ActiveCN102003823AReduce jet velocityLower gas temperatureCompression machines with cascade operationFluid circulation arrangementEngineeringCold blast

The invention discloses a low temperature cold air two-stage refrigeration system and a cold air jet machine thereof. A two-stage refrigeration structure is used, and the gas temperature at a cold air jet outlet can be effectively decreased to -60 DEG C minimum; an air cooler is used, thereby having high jet speed, being beneficial to breaking and removing chips, and having low cooling temperature suitable for high speed and high accuracy machining; and simultaneously, the two-stage refrigeration structures is respectively with a refrigeration bypass used for cooling a medium at the inlet of a compressor; therefore, along with the prolonged life cycle, the temperature of the compressor can not rise without limit, thereby keeping a long-time proper operating state. Through the regulation of the flow rate of the medium of the refrigeration bypass, the temperature of the cold air is capable of being regulated indirectly; the structure is simple, the operation is convenient, and the use cost is decreased.

Owner:重庆高洁绿色机械设备智能制造研究院有限公司

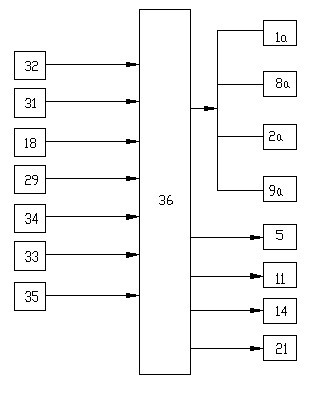

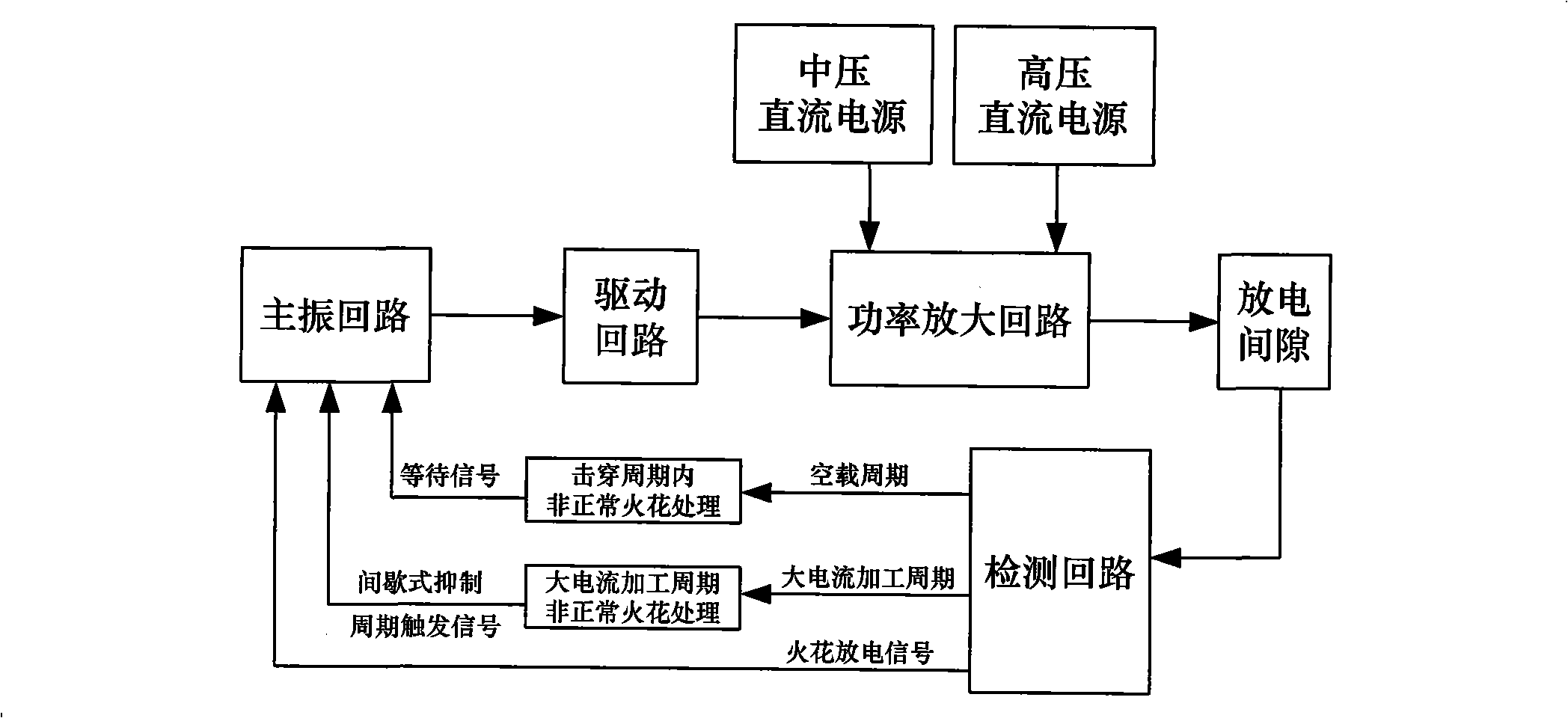

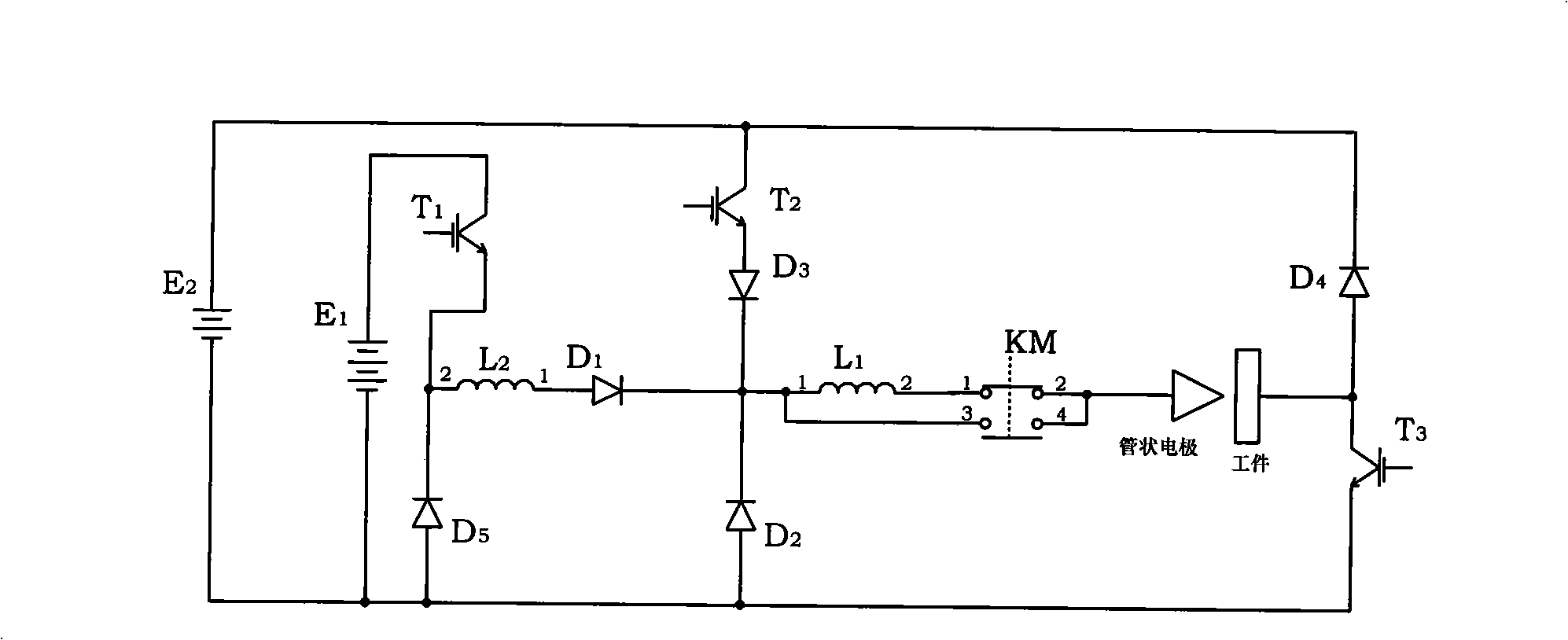

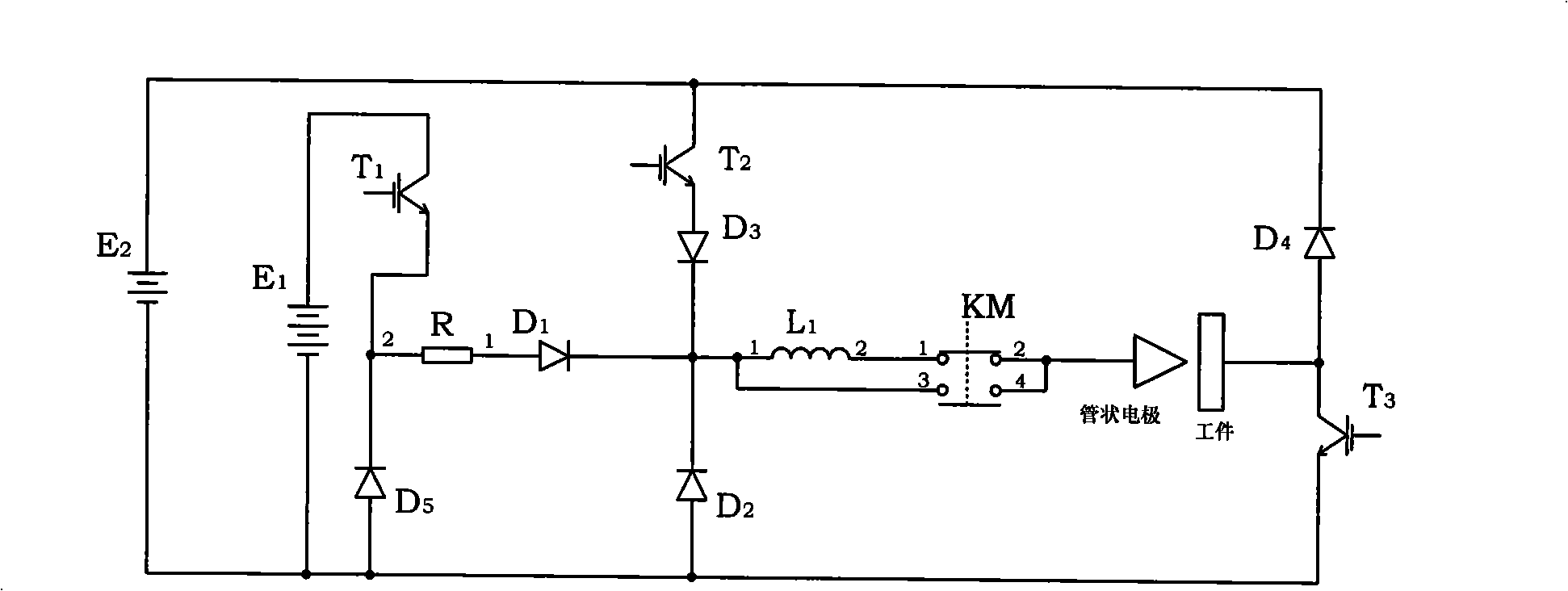

Impulsing power source for spark pinhole processing

InactiveCN101318241AReduce lossAvoid lossElectric circuitsNumerical controlHigh-voltage direct current

The invention discloses electric spark microhole processing pulse power supply suitable for the numerical control electrical discharge wire-cutting, which comprises a main vibration circuit, a driving circuit, a detection circuit, a non-normal spark treatment module in breakdown cycle, a non-normal spark treatment module in heavy current processing cycle, the high voltage direct current power supply, the medium voltage direct current and a power amplification circuit; wherein, the non-normal spark treatment module in breakdown cycle and the non-normal spark treatment module in heavy current processing cycle are arranged between the main vibration circuit and the detection circuit which is used in the real time online detection of gap discharge state; the signals of the no-loaded cycle in breakdown are adopted as the waiting signals of the main vibration circuit, and the signals of the heavy current processing cycle are adopted as trigger signals of the intermittent inhibitive cycle of the main vibration circuit; the switching of the multifunctional processing circuit and the working modes of two power supplies on the same wire-cutting machine can be realized by controlling the on and off time of a first power switch tube (T1).

Owner:HARBIN INST OF TECH +1

Groove broaching machining equipment for custom-made furniture boards

InactiveCN107511896AReduce volumeConvenient loading operation stationWood mortising machinesBark-zones/chip/dust/waste removalEngineeringCantilever

The invention provides a custom-made furniture sheet drawing groove processing equipment, which is characterized in that it includes a frame with a processing platform, a vacuum adsorption platform for vacuum adsorption and fixing the sheet, and a device for removing waste on the vacuum adsorption platform by jetting air. The chip blowing mechanism, the grooving head for grooving, the cantilever beam for hanging the grooving head and the control device; The signal connection of the axis movement mechanism; the slotting machine head is connected with the cantilever beam through the Y-axis movement mechanism and the Z-axis movement mechanism, and the control device is respectively connected with the signals of the Y-axis movement mechanism and the Z-axis movement mechanism; the vacuum adsorption platform, the chip blowing mechanism and the puller The slot machine heads are respectively connected with the control device for signals. The device of the invention can improve processing efficiency and fine workmanship precision, has reliable structure, is convenient to use and has good versatility.

Owner:佛山维尚家具制造有限公司

Compound milling cutter for machining fir tree type blade root wheel groove

InactiveCN101804478AHelps reduce chip breakingHelps reduce chip removalMilling cuttersMilling cutterEngineering

The invention related to a compound milling cutter for machining a fir tree type blade root wheel groove, which belongs to the technical field of machinery manufacture. The compound milling cutter comprises a shank part and a cutting part, wherein the tail end of the shank part is fixed with the cutting part, and a spiral groove and a cutting edge are arranged on the cutting part; the spiral groove is spirally arranged on the cutting edge, and a spiral angle is greater than 5 DEG but less than 10 DEG. In the invention, a V-shaped rough milling cutter, a deepen milling cutter and a semi-finish cutter in an original process are combined through optimum design of the cutting edge, rough machining and semi-finish machining of a supercritical steam turbine of 1000MW are completed, tooling and cutter changing time is reduced, and the cutting speed and the feed rate are increased so that the productivity is improved, and the production cost is reduced.

Owner:SHANGHAI JIAO TONG UNIV

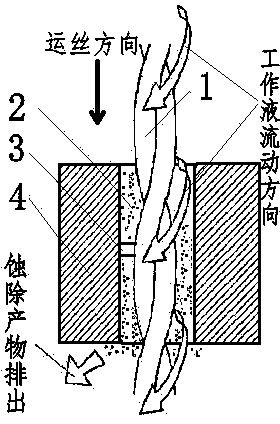

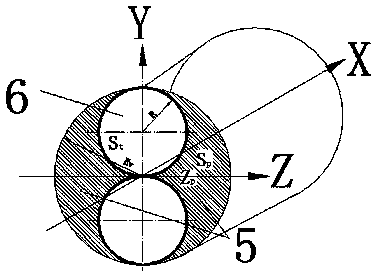

Efficient long-service-life stranded electrode wire for EDM wire

ActiveCN103990877AImprove cutting efficiencyHigh-speed reciprocating wire EDM and low cutting efficiencyElectrical-based machining electrodesCooling effectElectrical and Electronics engineering

An efficient long-service-life stranded electrode wire for an EDM wire is characterized by being formed by stranding at least two electrode wire bodies. Concave cavity grooves and convex discharging joint points are formed on the surfaces of the stranded electrode wire bodies. The concave cavity grooves are not only containing spaces for a working solution but also discharging spaces for inter-electrode corrosion removal products. In addition, feeding of the working solution and the discharging of the corrosion removal products are respectively performed in a spiral mode, and then the inter-electrode cooling effect and the deionization ability are improved. The discharging joint points can form regular discharging, and a discharging pulse interval can be indirectly prolonged. As the surfaces of the electrode wire bodies are provided with the concave parts which serve as the chip containing spaces, the working solution can be fed into inter-electrode in a promoted mode; meanwhile the discharging of the inter-electrode corrosion removal products is accelerated, so that the inter-electrode discharging conditions are improved; due to the regular convex points on the surfaces of the stranded electrode wire bodies, the discharging rule is easier to control. Accordingly, machining efficiency can be enhanced, and surface quality can be improved. Besides, the volume of the chip containing spaces of the stranded electrode wire bodies can be controlled according to the diameter of the electrode wire bodies and the pitch of the stranded wire bodies.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com