Numerical control milling method for micro threaded holes of titanium alloy

A CNC milling and titanium alloy technology, applied in the direction of metal processing equipment, tangent device, manufacturing tools, etc., can solve the problems of process control, limited tap sharpening angle, low tap strength, etc., to ensure processing accuracy and processing efficiency, Protects the sharpness of the blade and improves quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

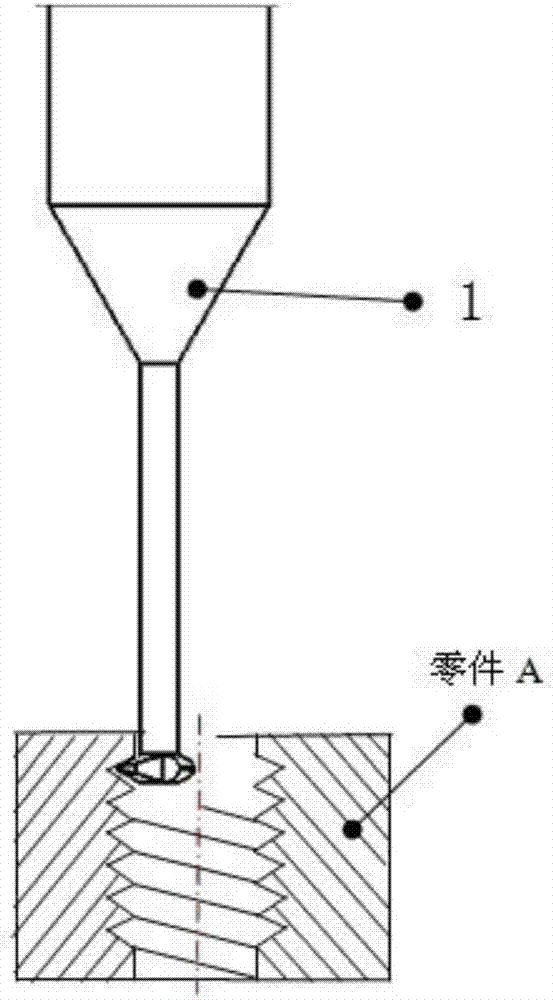

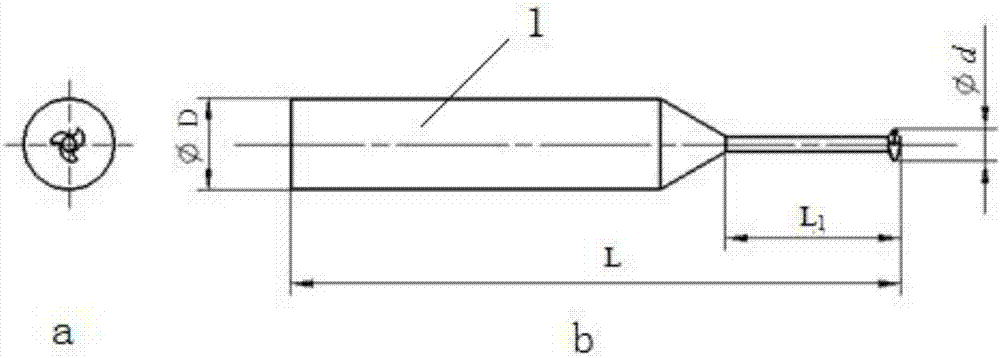

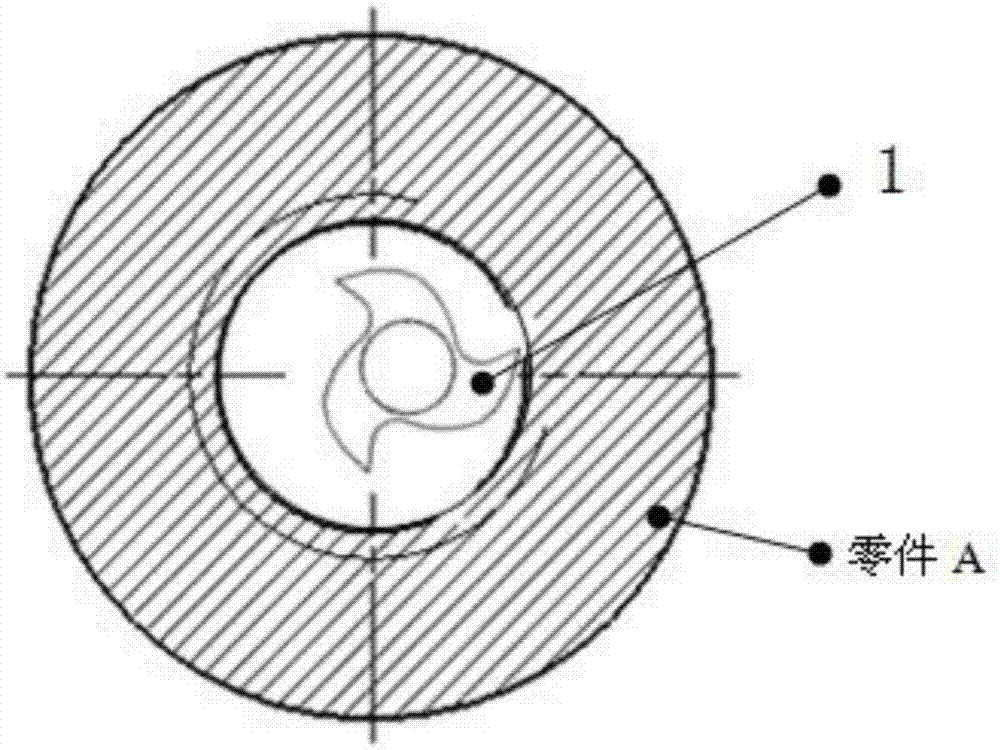

[0027] A kind of numerical control milling method of titanium alloy fine threaded hole (referring to figure 1 ), using the process sequence of drilling, reaming, and thread milling, which is suitable for the actual processing of small batches and high-precision titanium alloy parts.

[0028] The programming of processing method of the present invention is:

[0029] ⑴. Clamp the titanium alloy part A to the workbench of the CNC equipment, find out the machining benchmark of the part, and determine the machining zero point. The numerical control equipment is a high-precision three-axis numerical control machining center, the spindle speed can reach 8000rpm, the spindle has high-speed stability, and the runout is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com