Manufacturing method for hot stamping die cooling pipeline

A technology for hot stamping dies and cooling pipes is applied in the field of manufacturing cooling pipes inside hot stamping dies, and can solve the problems of melt-through of embedded metal pipes, easy water leakage, uneven cooling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the invention will be further described below in conjunction with the accompanying drawings.

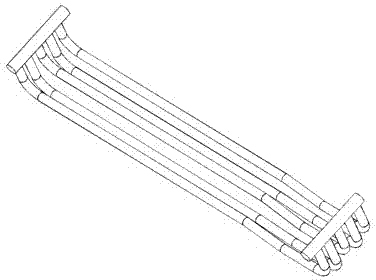

[0014] According to hot stamping parts, designs such as figure 1 The hot stamping die cooling system shown, the cooling system is completely conformal. figure 1 The cooling pipe shown is made of silicon-based ceramic material, and after the support core (1) and the main core (2) are manufactured, they are bonded into a whole with a silicon-based adhesive.

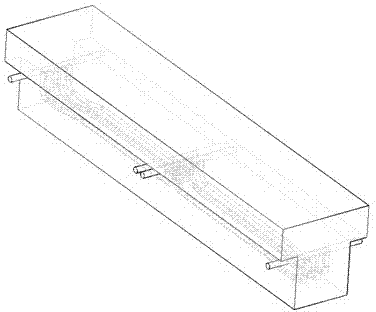

[0015] According to the shape of the part, design the corresponding sand mold shape of the mold, and leave a fixing hole for the ceramic core cooling pipe. Fix the ceramic core cooling pipe in the sand mold before casting, such as figure 2 As shown, the low-temperature pouring method is adopted in the bottom injection casting method. The starting temperature of molten steel is controlled at 10-30°C above the melting point of molten steel, and the temperature at the end of casting is 5°C highe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com