Patents

Literature

88results about How to "Will not cause scrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

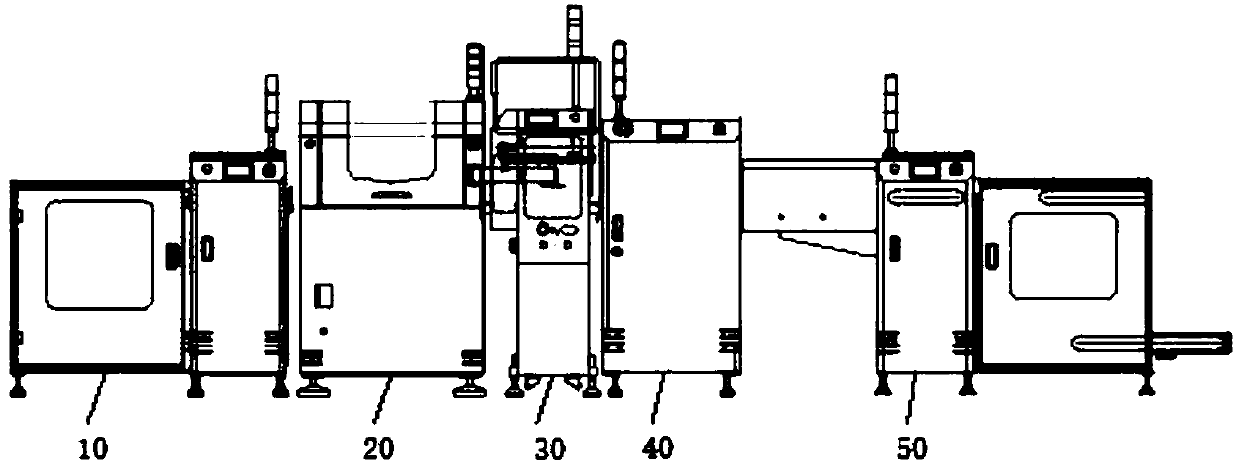

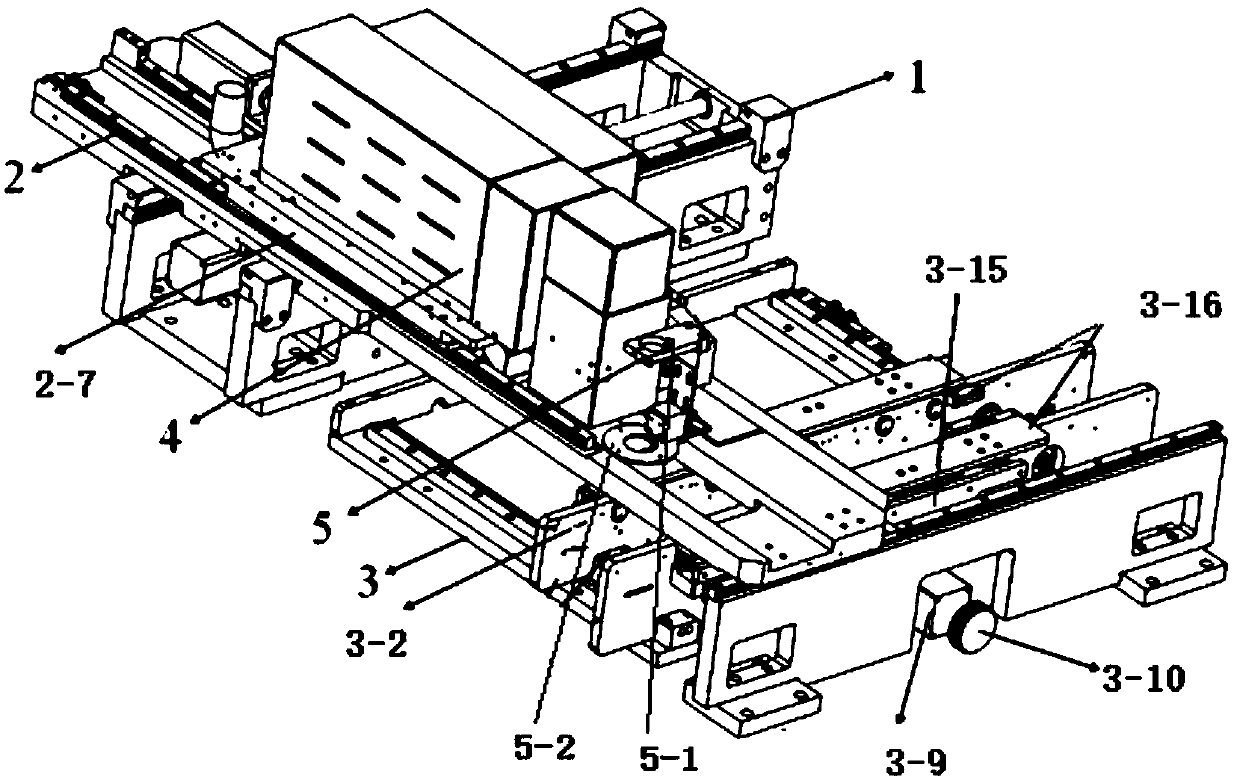

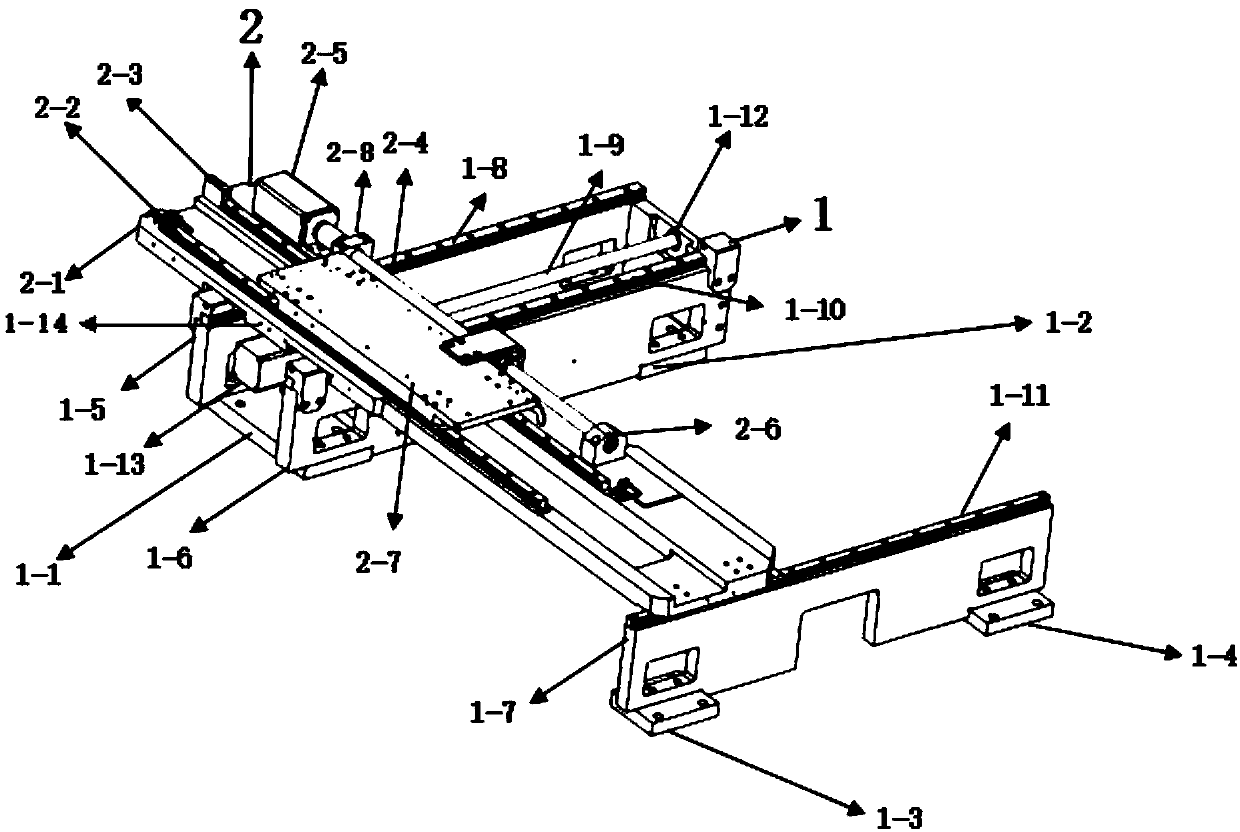

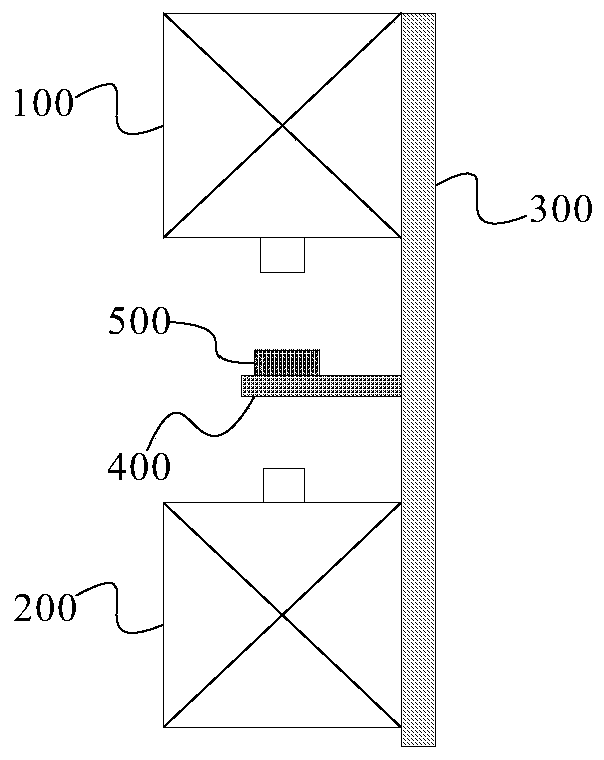

Full-automatic PCB laser coding machine with sorting function, method and system

ActiveCN107598382AEasy to integrateWill not cause scrapPrinted circuit manufactureLaser beam welding apparatusEngineeringCcd camera

The invention provides a full-automatic PCB laser coding machine with a sorting function. The full-automatic PCB laser coding machine comprises a module mechanism, a track conveying mechanism, a lasercoding optical mechanism, a CCD visual positioning, code scanning and detecting mechanism, a PCB sensor and a control mechanism. The module mechanism can move in the horizontal direction, and movement of the module mechanism enables the laser coding optical mechanism and a CCD camera to synchronously move, enables the laser coding optical mechanism to move to the position above a PCB coding position, and enables the CCD camera to move to a PCB mark position or a position above the PCB coding position. The control mechanism responds to generate a warning signal when code reading results fed back by the camera are unqualified. According to the full-automatic PCB laser coding machine with the sorting function, a method and a system, the CCD visual positioning, code scanning and detecting mechanism automatically positions the coding position, after coding through the laser coding optical mechanism is completed, the CCD visual positioning, code scanning and detecting mechanism conducts code scanning and detecting, and the situation that the entire batch of products are scrapped due to the fact that PCB products coded badly are put in storage is avoided.

Owner:苏州市长峰激光技术有限公司

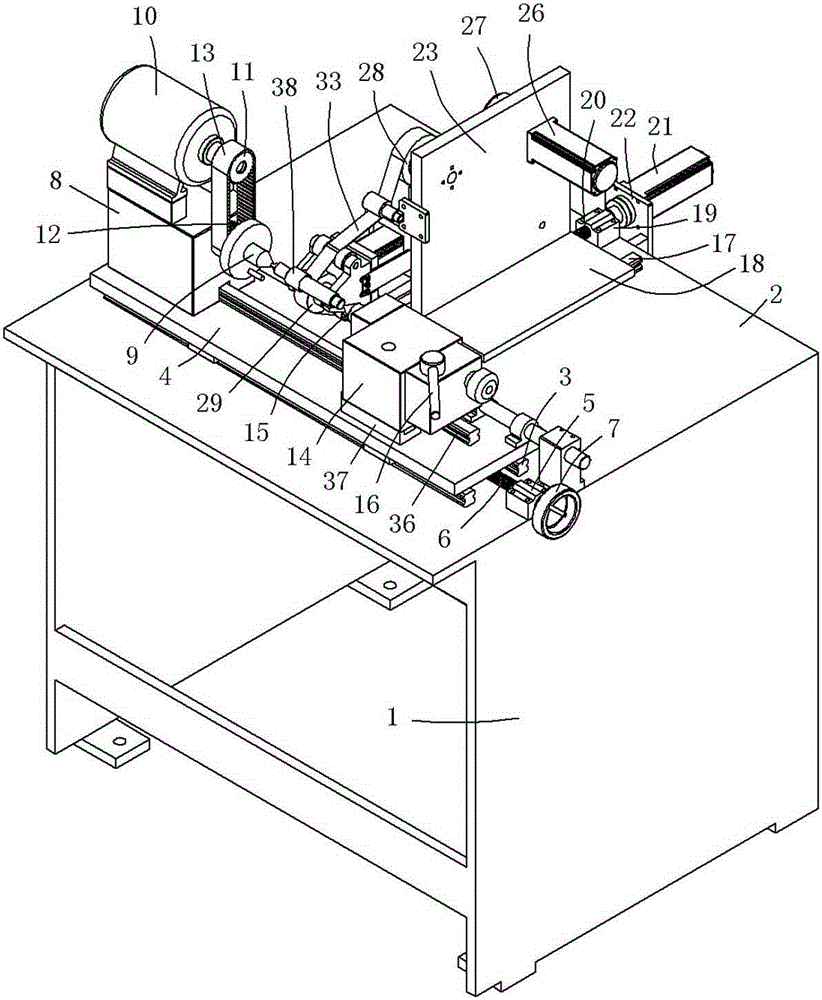

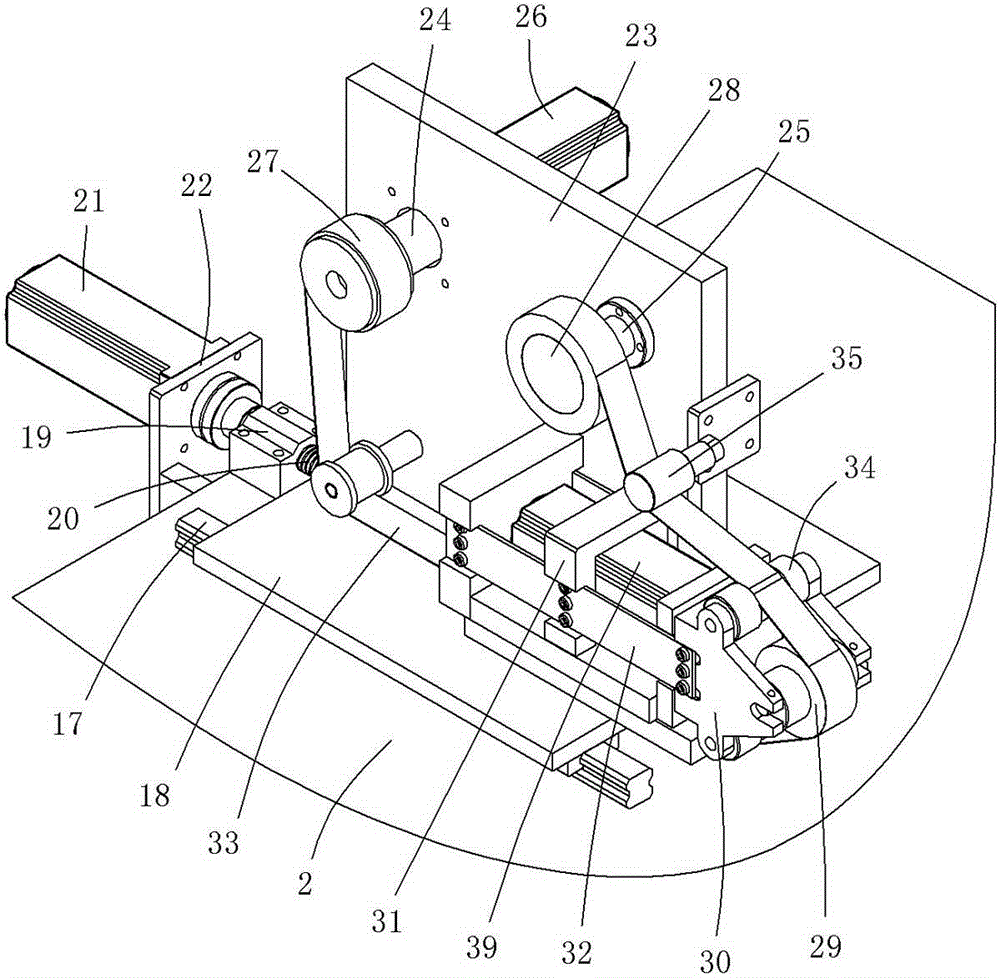

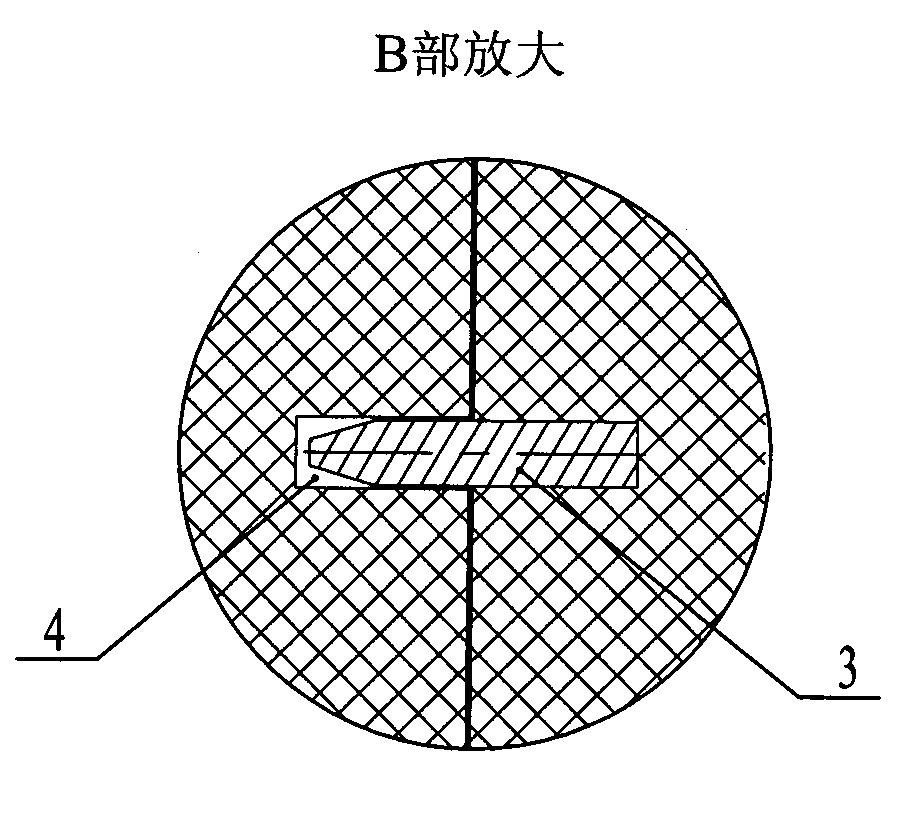

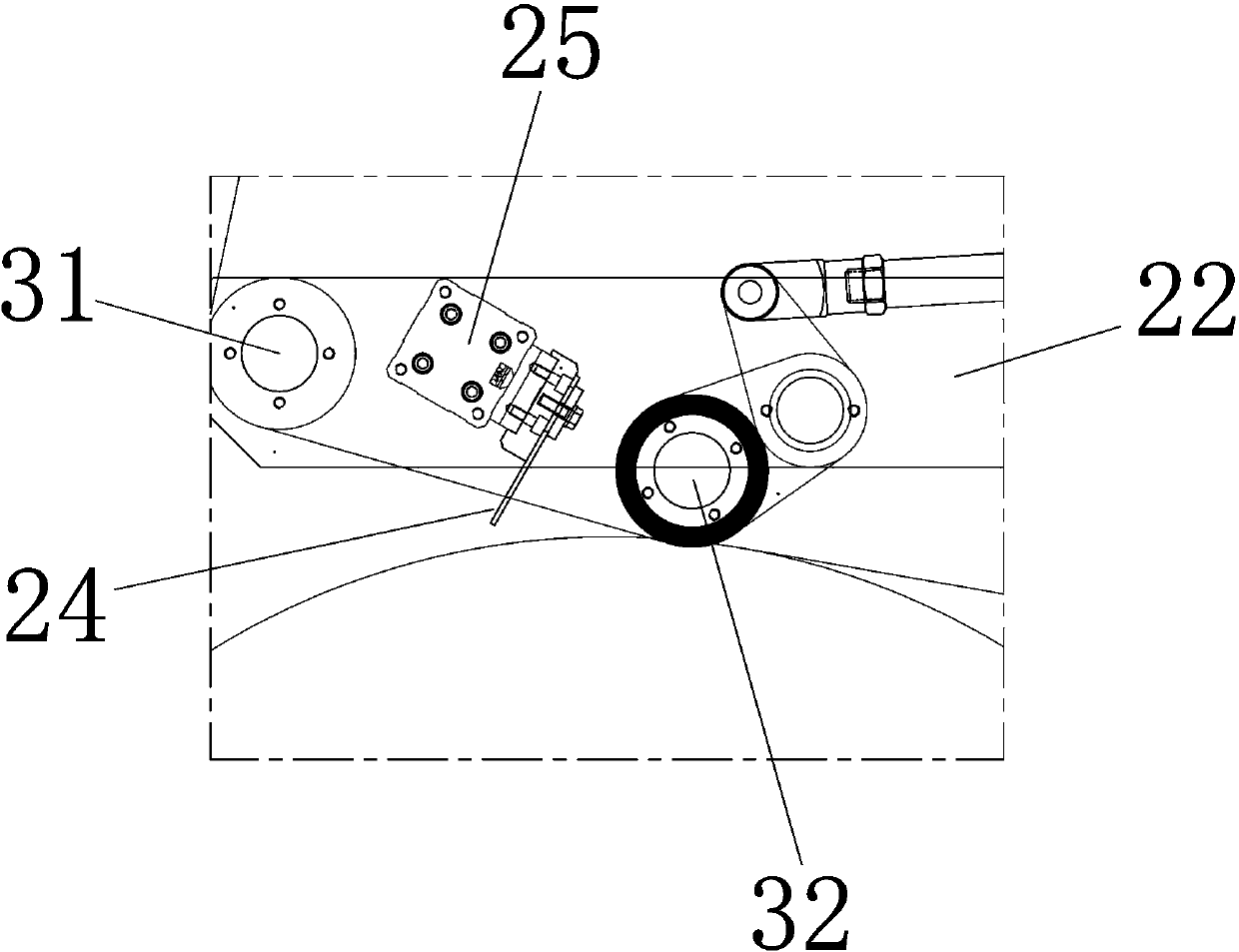

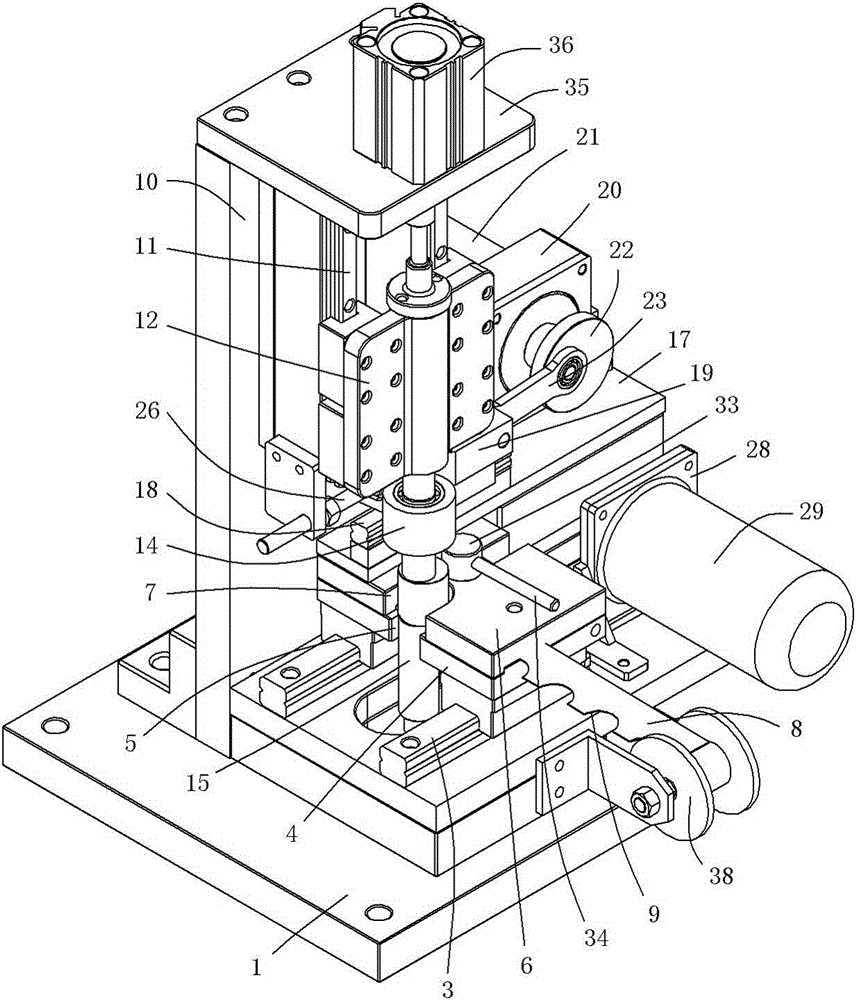

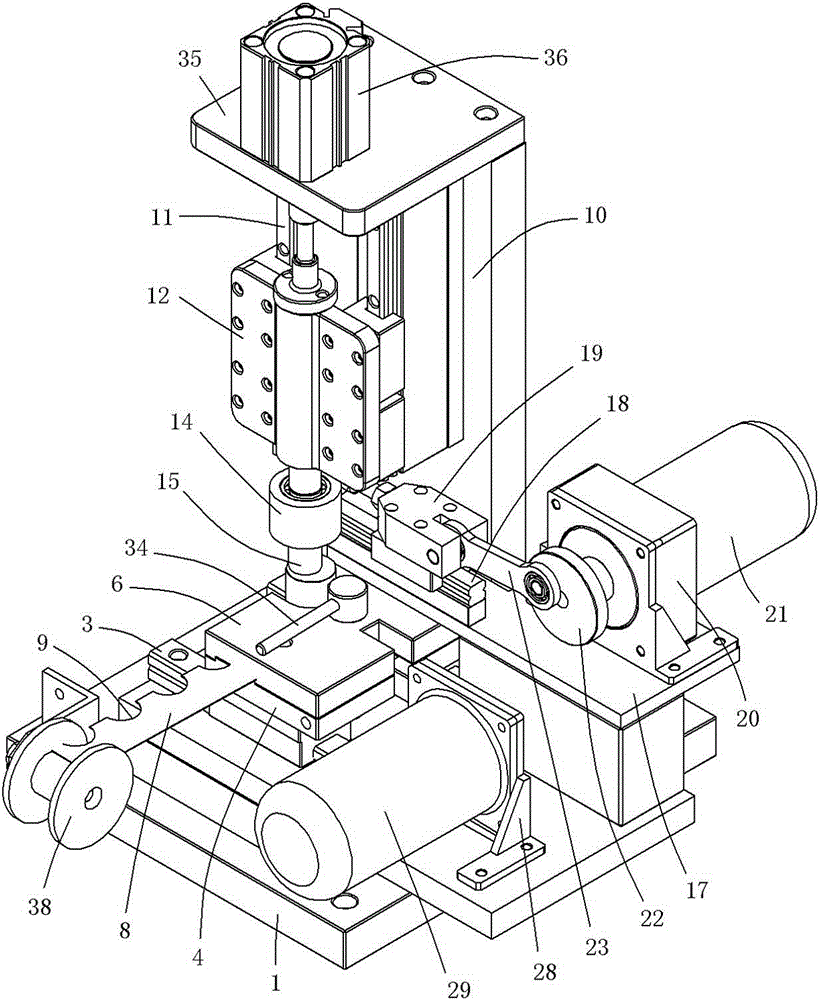

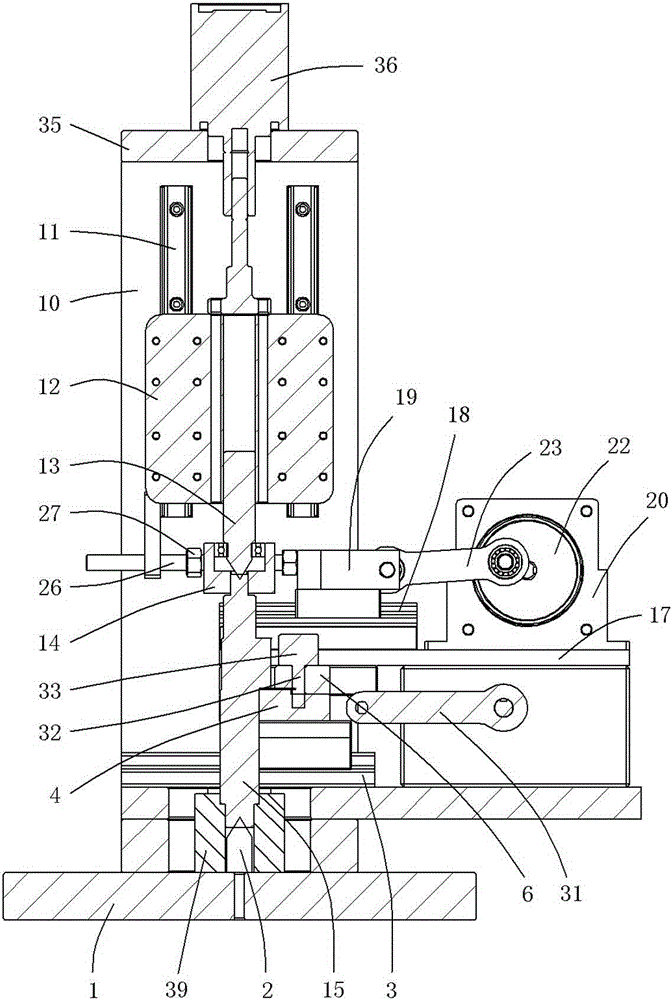

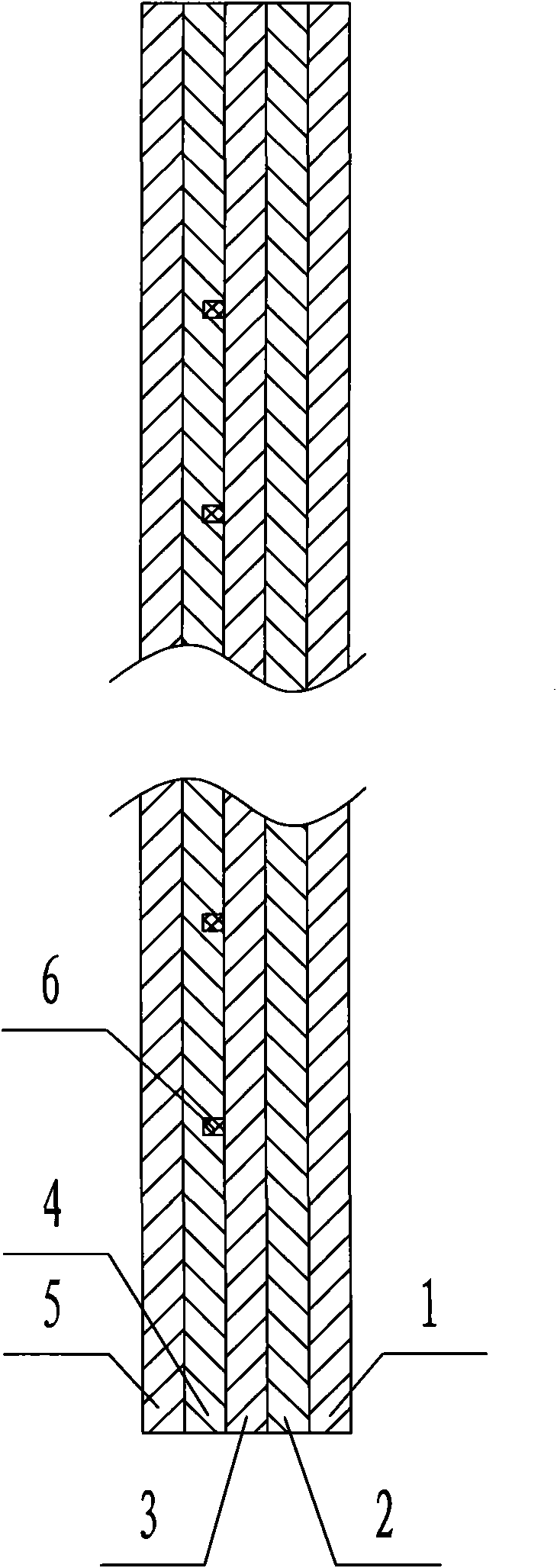

External cylindrical superfinishing machine

The invention provides an external cylindrical superfinishing machine. The machine comprises a frame, a workbench and an abrasive belt, wherein a transverse guide rail, a transverse sliding table, a transverse motion driving mechanism, a longitudinal guide rail, a longitudinal sliding table and a longitudinal motion driving mechanism; a headstock, a headstock center and a rotary driving mechanism are arranged on one side of the transverse sliding table; a tailstock, a sleeve, a tailstock center and a center adjustment mechanism are arranged on the other side of the transverse sliding table; an abrasive belt rack, an abrasive belt driving shaft, an abrasive belt driven shaft, an abrasive belt motor, a rolling abrasive belt wheel, a releasing abrasive belt wheel, a polishing wheel, a polishing wheel rack and a polishing motor are arranged on the transverse sliding table; one end of the abrasive belt winds the releasing belt wheel, and the other end of the abrasive belt moves around the polishing wheel and is fixedly arranged on the releasing abrasive belt wheel. The external cylindrical superfinishing machine has the beneficial effects of simple and compact structure, convenience in operation, integral operation stability and reliability and high processing accuracy, and cannot cause scrap of axial parts.

Owner:宁波华表机械制造有限公司

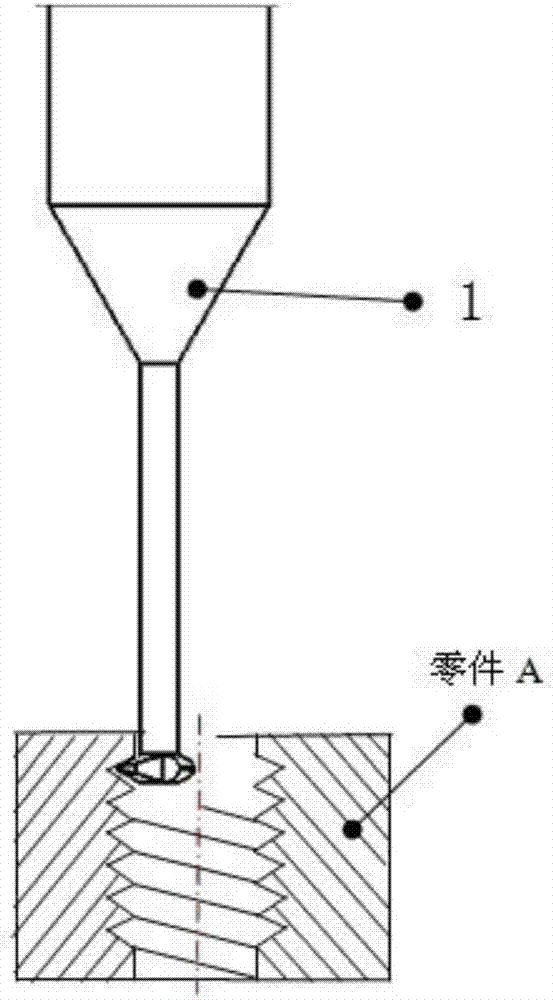

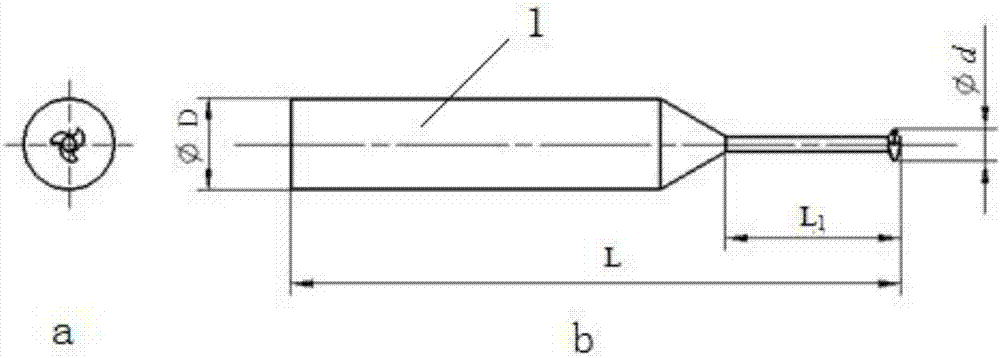

Numerical control milling method for micro threaded holes of titanium alloy

InactiveCN107127406AImprove shape and position accuracyImprove processing efficiencyThread cutting machinesNumerical controlDiameter ratio

The invention relates to a numerical control milling method for micro threaded holes of titanium alloy. The method comprises the specific machining operation steps of replacing a traditional manual tapping method for the titanium alloy with numerical control machining to improve the quality and efficiency of threads, selecting a threaded tool made of hard alloy to ensure high efficiency and batch production of part machining, and selecting a reasonable technical machining method to ensure specification consistency of the threads, circumferential stress uniformity during threaded milling and prevent the tool from being broken. The numerical control milling method is suitable for the micro threaded holes, with the machining range smaller than M3 and the length-diameter ratio higher than 2.5, of the titanium alloy, and the bottleneck problem of tapping of the micro threaded holes, with the large-length-diameter ratio, of the titanium alloy is solved successfully. Meanwhile, drilling and tapping are completed jointly, efficiency is improved by 6-8 times, the grade of precision of the threads of the holes and specification consistency of the threaded holes are improved, and the machining requirement for high precision of titanium alloy parts can be met.

Owner:中国船舶重工集团公司第七〇七研究所

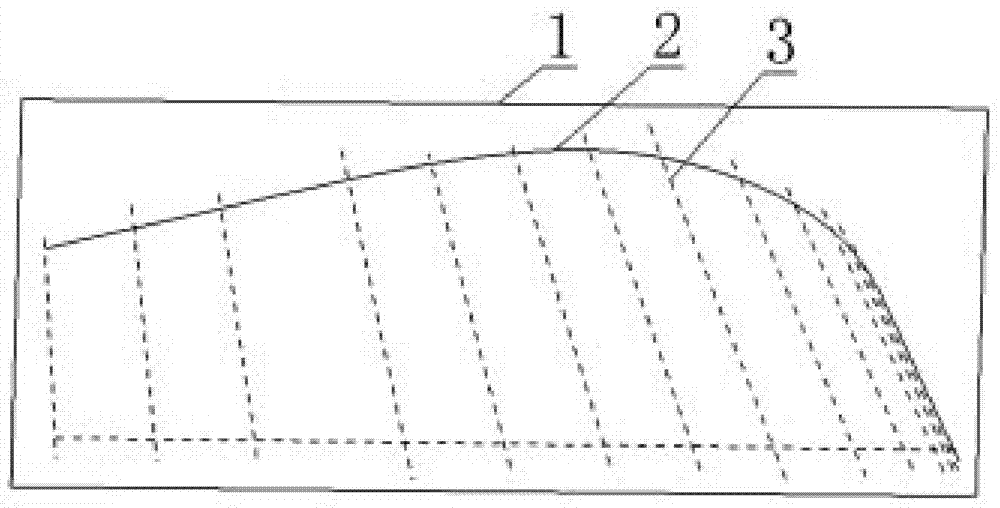

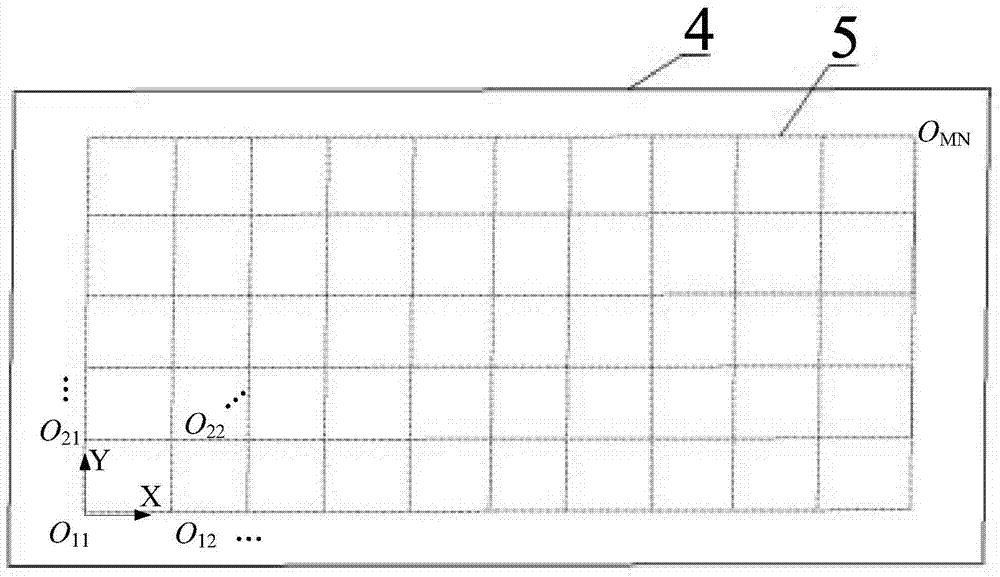

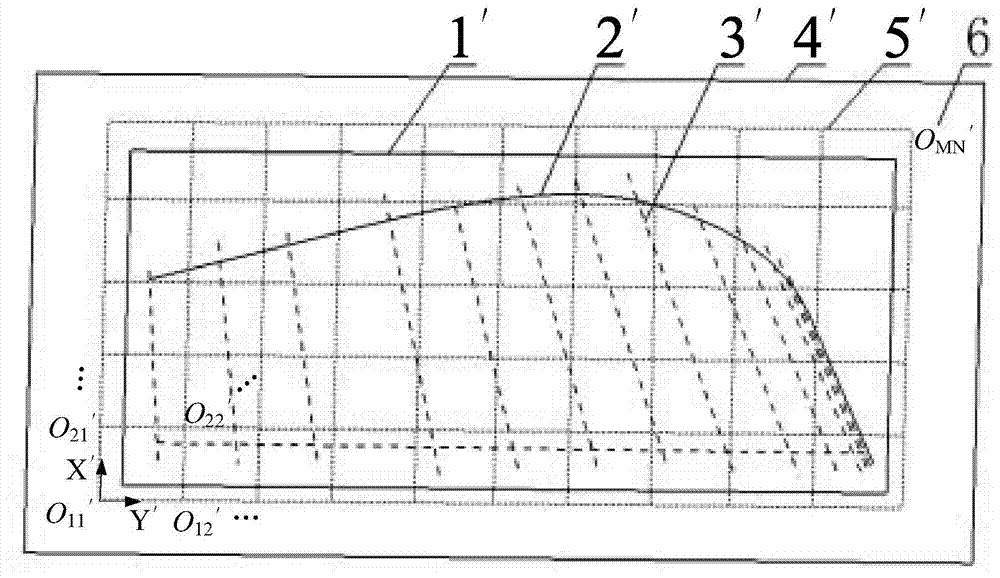

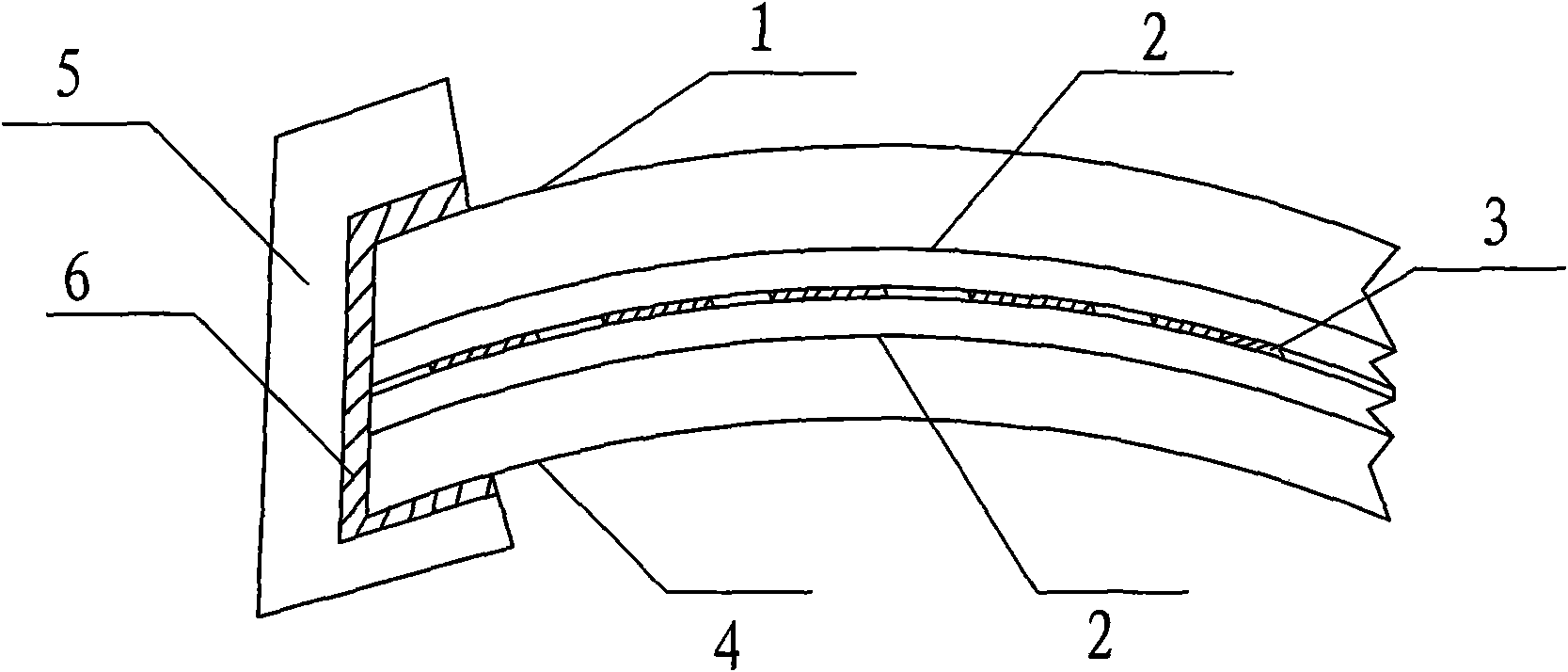

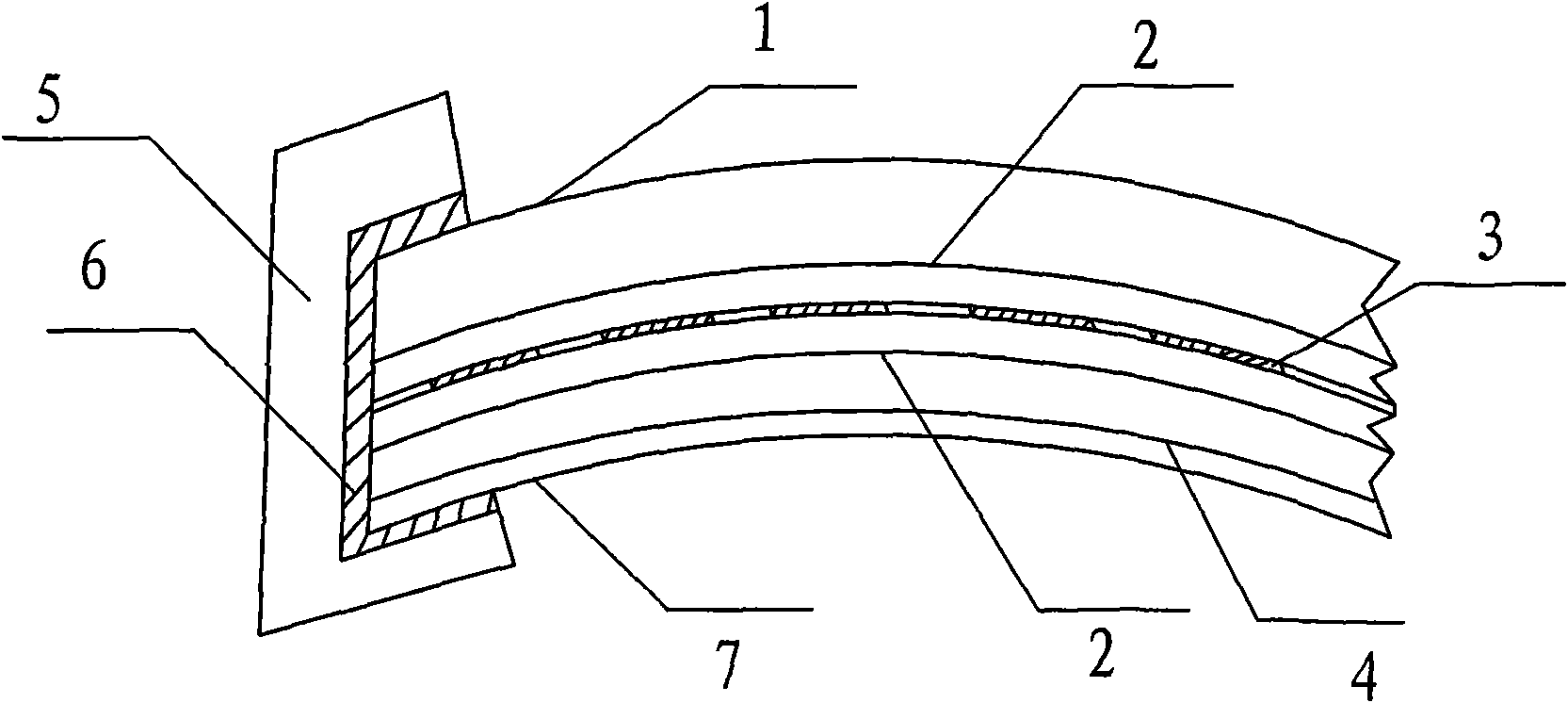

Airplane part reverse modeling method based on tangent plane mould line

ActiveCN103577630AImprove modeling accuracyQuick correctionSpecial data processing applicationsDistortion correctionLine drawings

The invention provides an airplane part reverse modeling method based on a tangent plane mould line according to the analog quantity airplane part improved design and the objective requirement of digitized manufacturing. An airplane part solid digifax conforming to the existing production coordinating relation can be more accurately built, a two-dimensional grating image is formed through scanning a tangent plane mould line drawing board of a part by a flat plate type scanning device, then distortion correction, vectorization and fitting fairing are carried out on the two-dimensional grating image by means of orthogonal grid lines, and finally, the solid modeling is carried out on the airplane part by fitting the tangent plane mould line.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

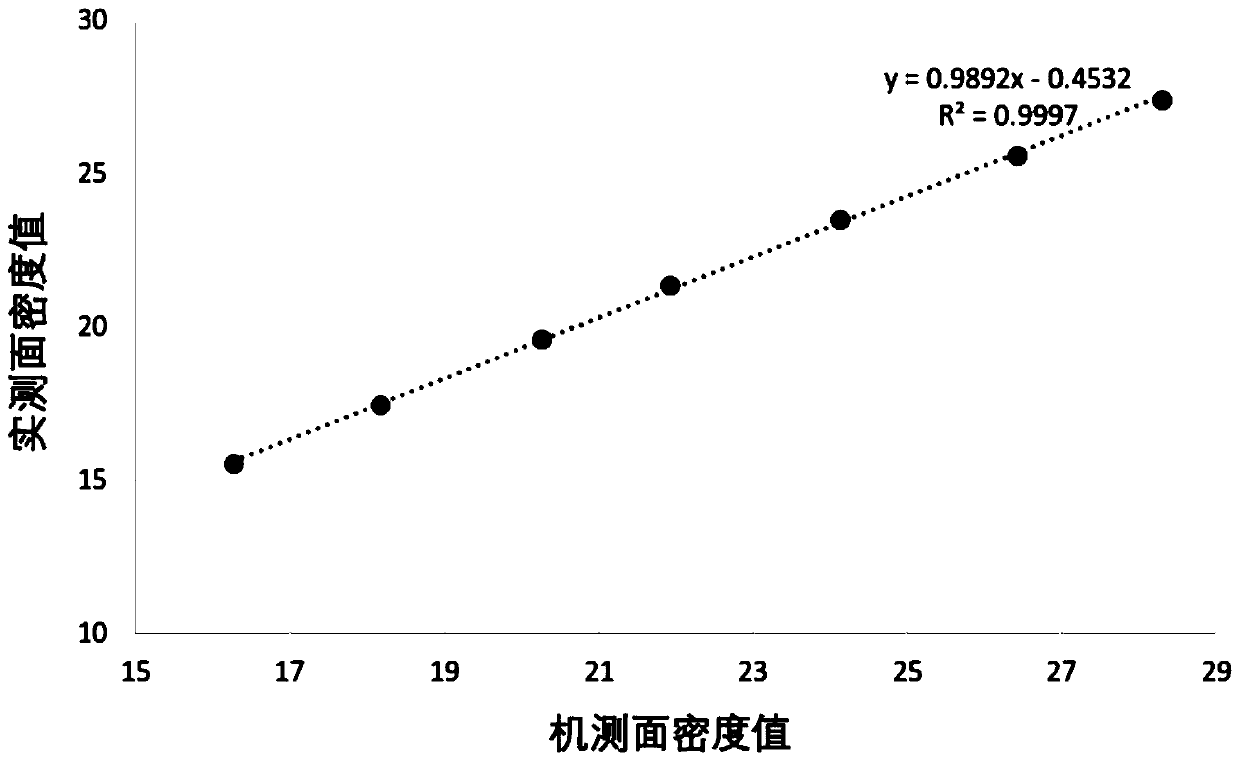

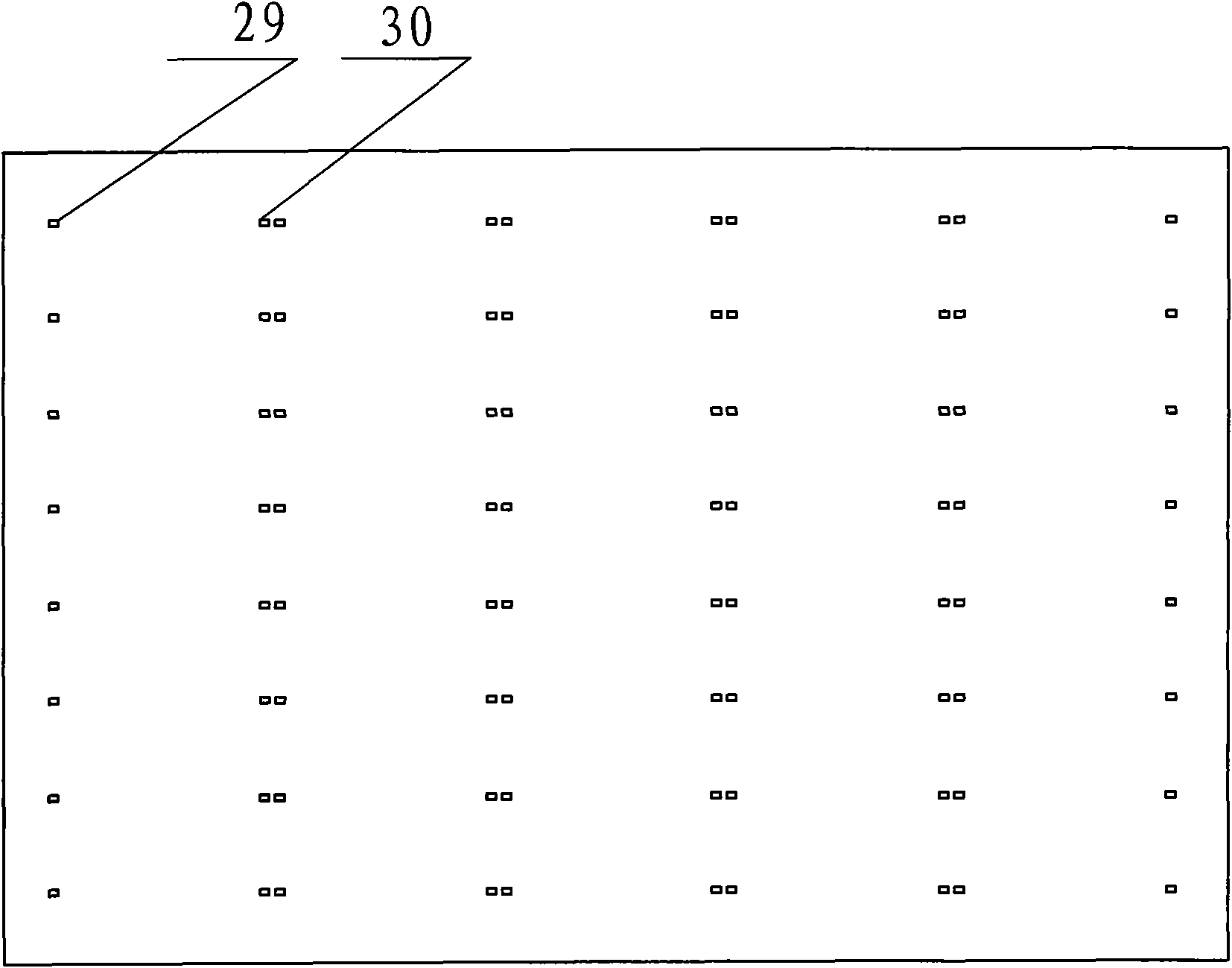

Calibration method of surface densitometer

InactiveCN110031359AImplement static detectionWill not cause scrapMaterial analysis by transmitting radiationMaterial analysis using radiation diffractionPole pieceDensitometer

The invention discloses a calibration method of a surface densitometer. The calibration method of the surface densitometer comprises the following steps of (1) preparing a standard pole piece having acoating with a known surface density value formed on the surface, wherein the standard pole piece has a diameter larger than that of the spot formed by the radiation emitted by the radiation source of the surface densitometer to be calibrated; (2) placing the standard pole piece under the radiation source so that the standard pole piece completely covers the spot; (3) measuring the surface density of the standard pole piece by using the surface densitometer to be calibrated to obtain a surface density machine measured value of the standard pole piece; and (4) calibrating the surface densitometer to be calibrated according to the surface density machine measured value and the known surface density value. The calibration method can easily and efficiently calibrate the surface densitometer,and has the advantages of high accuracy and low cost loss.

Owner:昆山聚创新能源科技有限公司

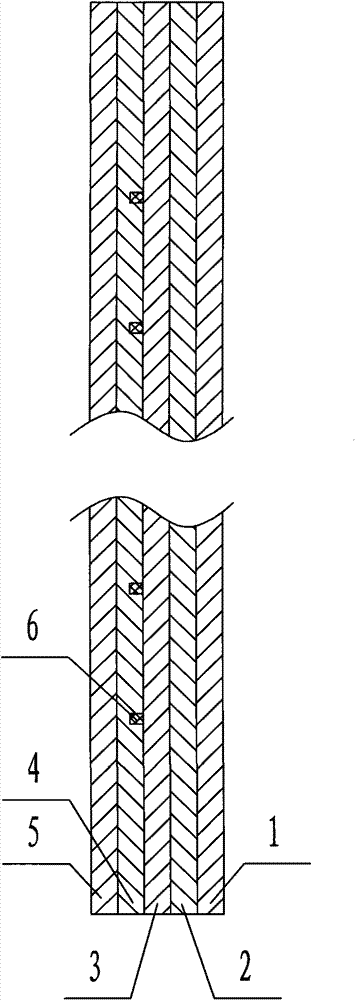

Self-positioning construction unit plate

InactiveCN103233548ANo step differenceEasy to processSheet joiningHeat proofingThermal insulationEngineering

The invention relates to a self-positioning construction unit plate, and solves problems such as complicated processing and difficult adjustment of existing spliced plates. The plate comprises a surface material and assembly components used for assembling adjacent surface materials. The invention has the technical points that: the surface material adopts a construction-use filling-type thermal-insulation load-bearing composite plate material; the assembly components comprise hitch devices composed of eccentric hook assemblies arranged in supporting frame blind hole hook slots of the surface material and U-shaped bolts arranged in supporting frame arc slots of an adjacent surface material, and self-positioning devices composed of positioning pins fixed on the surface material supporting frame and positioning holes provided on the supporting frame of an adjacent surface material; and with the hitching of the movable hooks and the U-shaped bolts of the hitch device, and with the cooperation of the positioning pins and the positioning holes of the self-positioning device, adjacent surface materials can be accurately spliced. The plate provided by the invention has reasonable structural design, and assists in realizing standardized production. Plate assembly and positioning are simple and fast, and self-positioning connection can be realized. Adjustment, transportation, and moving are convenient, such that construction quality and working efficiency are substantially improved.

Owner:SHENYANG THRIVE INDALIZED HOUSING

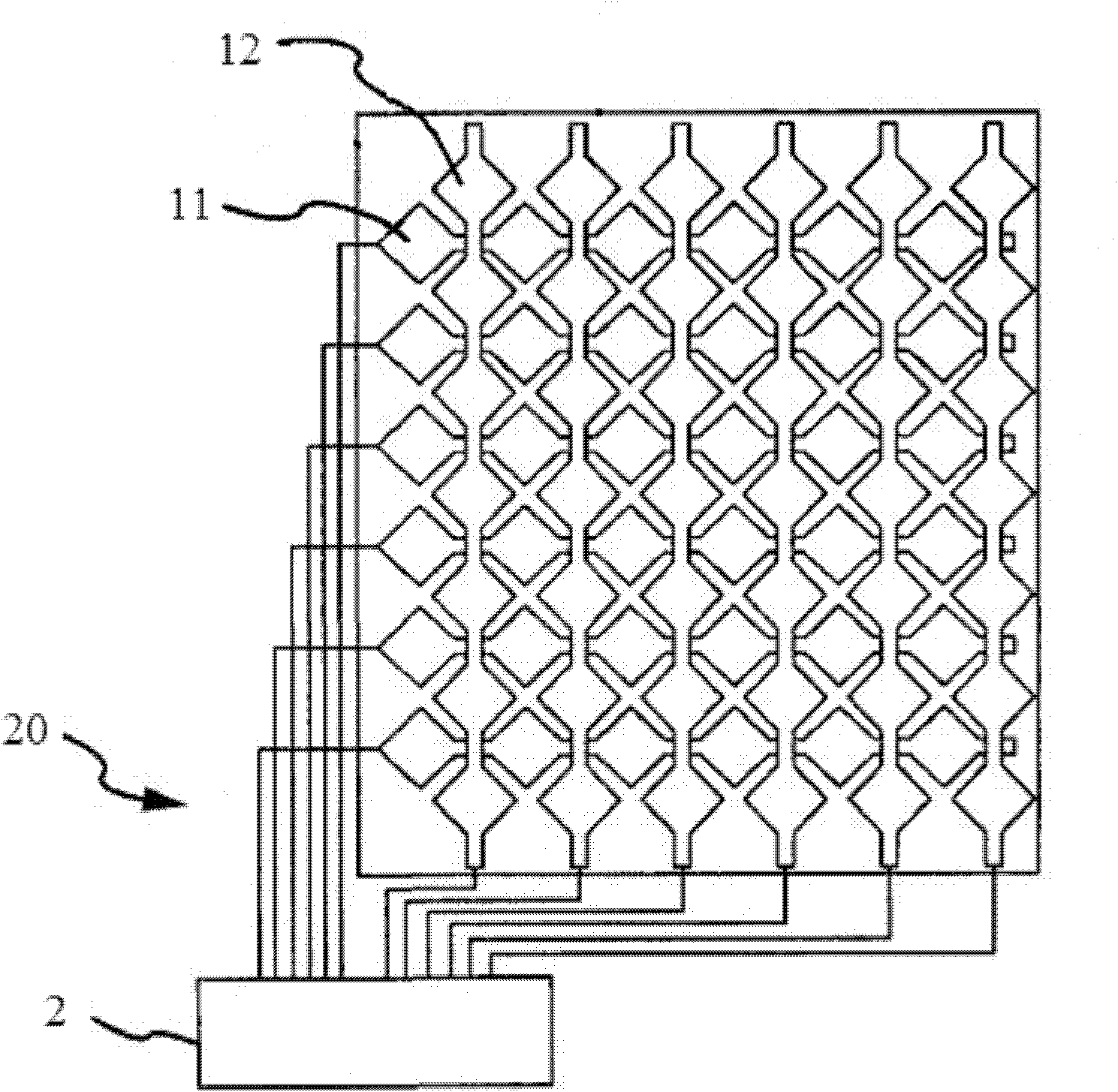

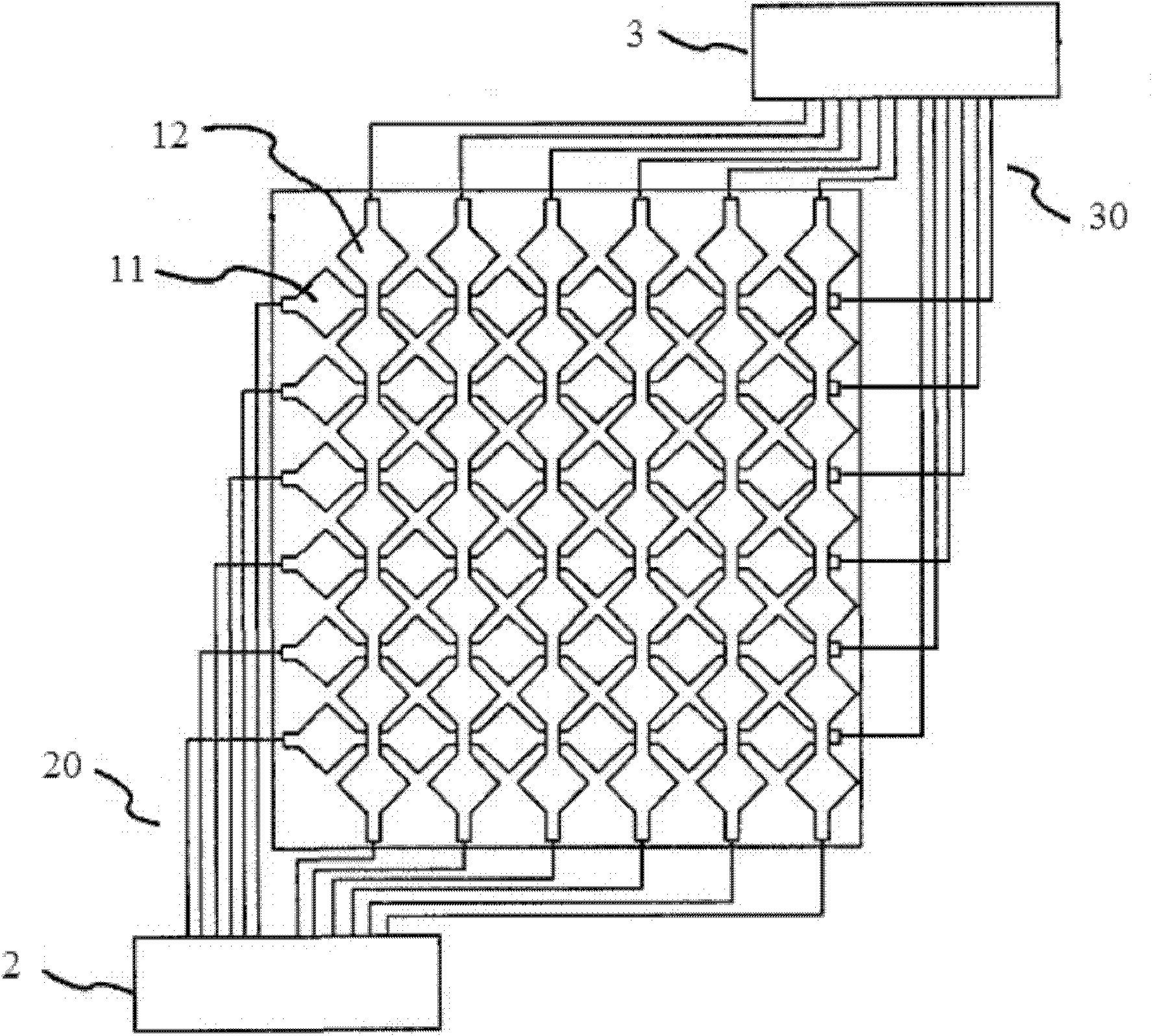

Capacitive touch screen

ActiveCN102646004AAvoid damageEasy to testInput/output processes for data processingElectricityTouchscreen

The invention discloses a capacitive touch screen, which comprises a substrate and at least one transparent conducting layer, wherein the transparent conducting layer comprises a plurality of electrode groups, and each electrode group comprises a plurality of electrodes which are connected in series. The capacitive touch screen also comprises two sets of leading wires, each set of leading wire in the two sets of leading wires is electrically connected with each electrode group, and the two sets of leading wires are respectively connected with connectors. Because the two sets of leading wires and the connectors are arranged, environment matching degree of the touch screen is guaranteed and improved, testing and debugging time is shortened, the availability of a product is improved, and the cost is reduced.

Owner:BOE TECH GRP CO LTD

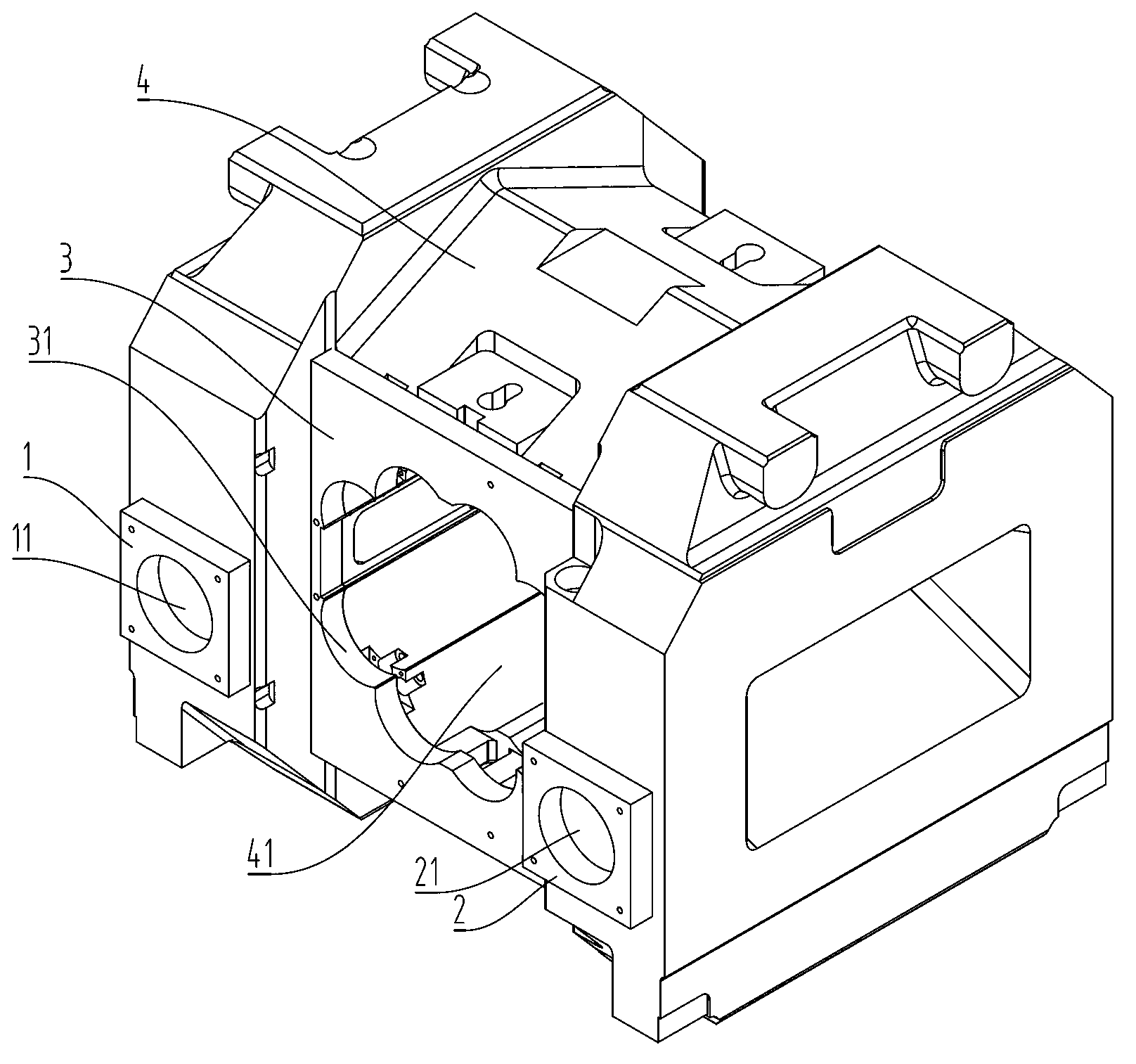

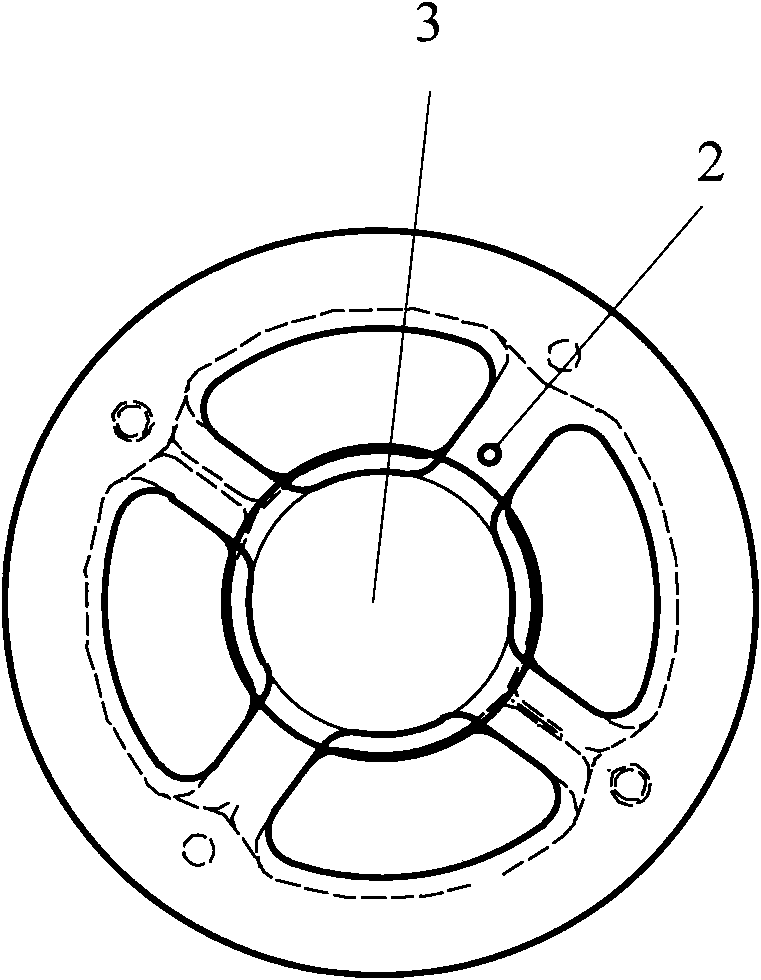

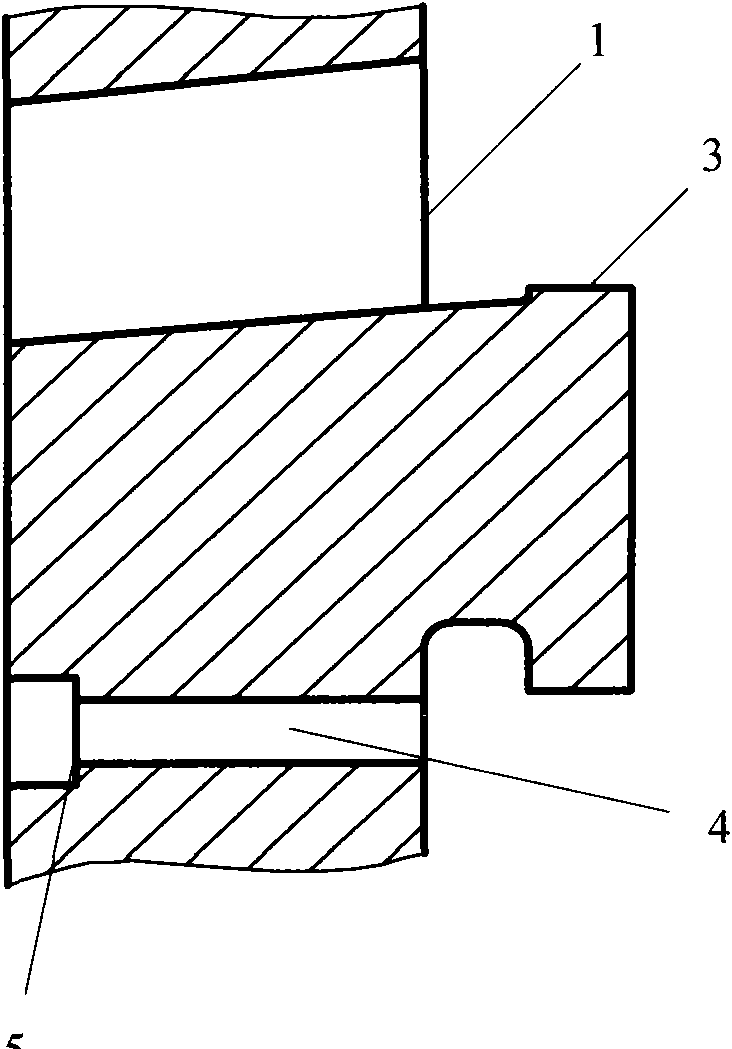

Processing method of mill housing

The invention discloses a processing method of a milling housing. A first plum blossom hole is formed in the housing and formed through cutting machining and abrasive machining on a housing substrate. The processing method is characterized in that during the cutting, the empirical formula of a cutting speed is as follows: V=3.14*D*n*eta<2> / 1000, wherein V represents the cutting speed with a unit of m / min; n represents the revolving speed of a machine tool spindle with a unit of rpm; D represents a cutting radius ranging from 260mm to 360mm; eta<2> is a coefficient ranging from 0.05 to 0.08; the smaller the difference between the size of the plum blossom hole and a design value is, the larger the value of the plum blossom hole is; and otherwise, the value of the plum blossom hole is smaller. By means of the processing method of the mill housing, the mill housing which meets the accuracy requirement can be processed. According to the processing method, the dimensional tolerance of diagonal plum blossom holes of the mill housing are smaller than or equal to 0.01mm, the total tolerance is smaller than or equal to 0.02mm, and the straightness of each hole is smaller than or equal to 0.01mm. With the adoption of the method for processing the housing, under the condition that smooth and efficient processing is guaranteed, the housing substrate cannot be scrapped, and the scrappage rate is zero under the condition that the processing efficiency is improved by over 20%.

Owner:上海山弈冶金技术有限公司

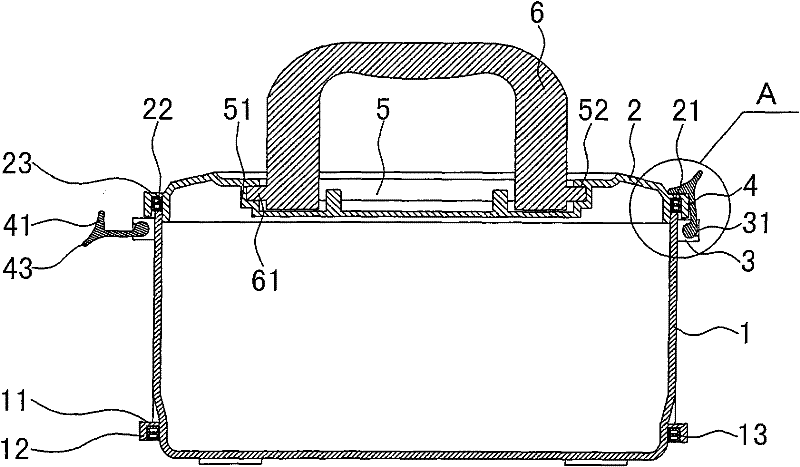

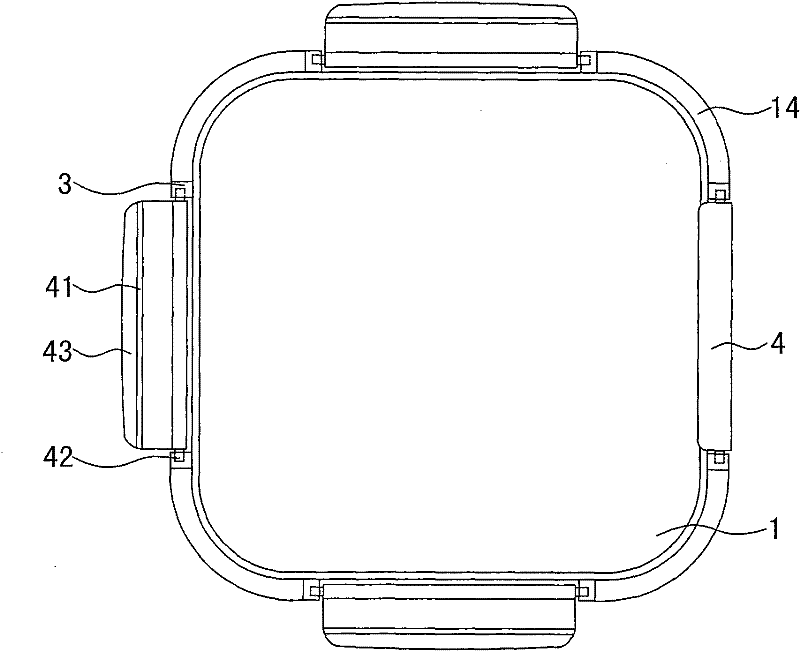

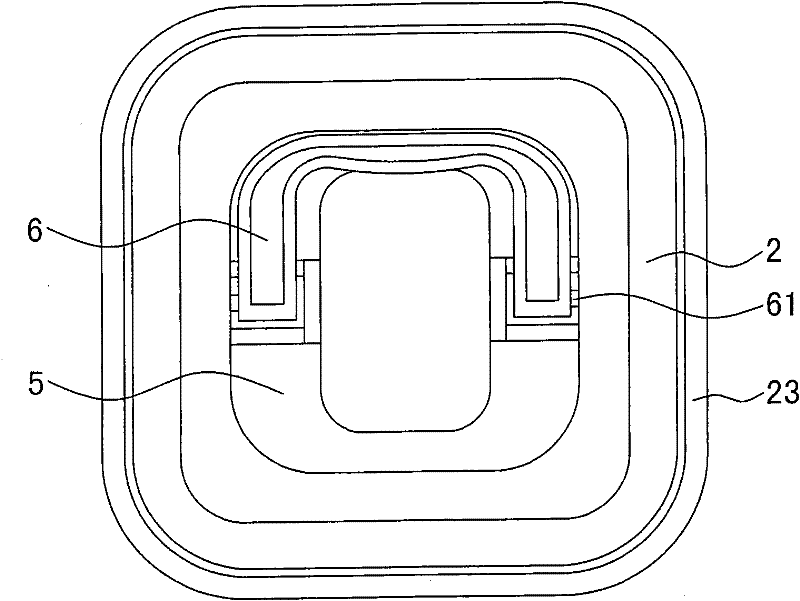

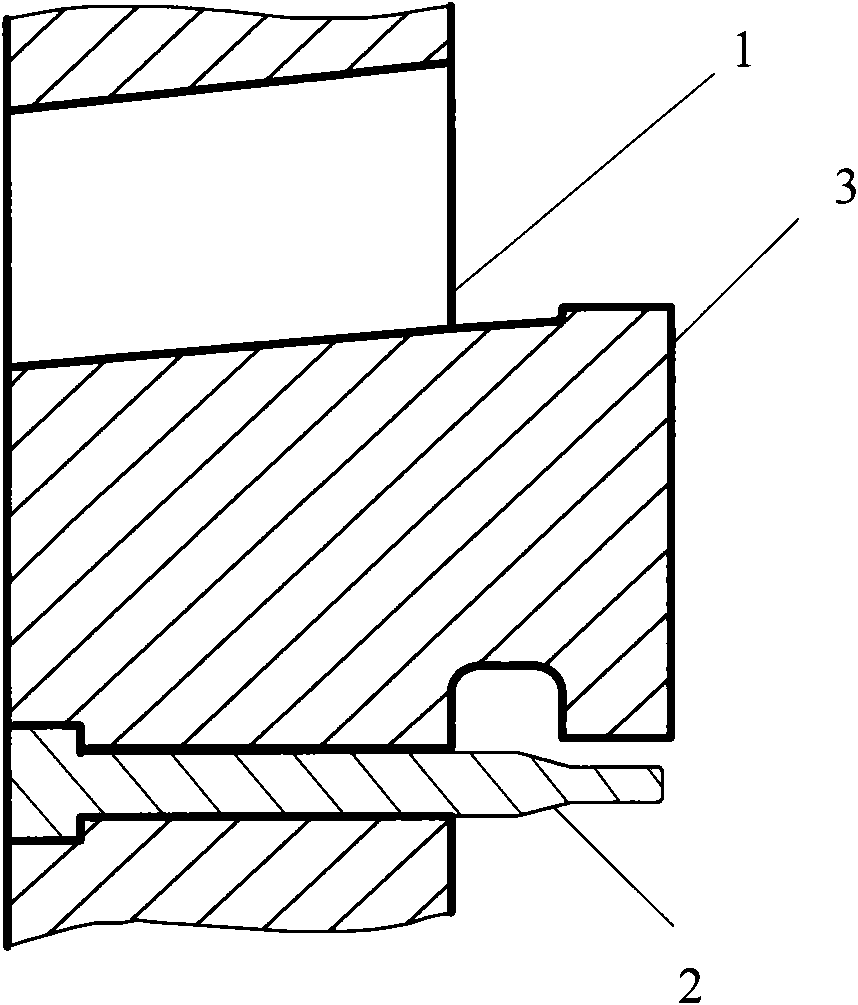

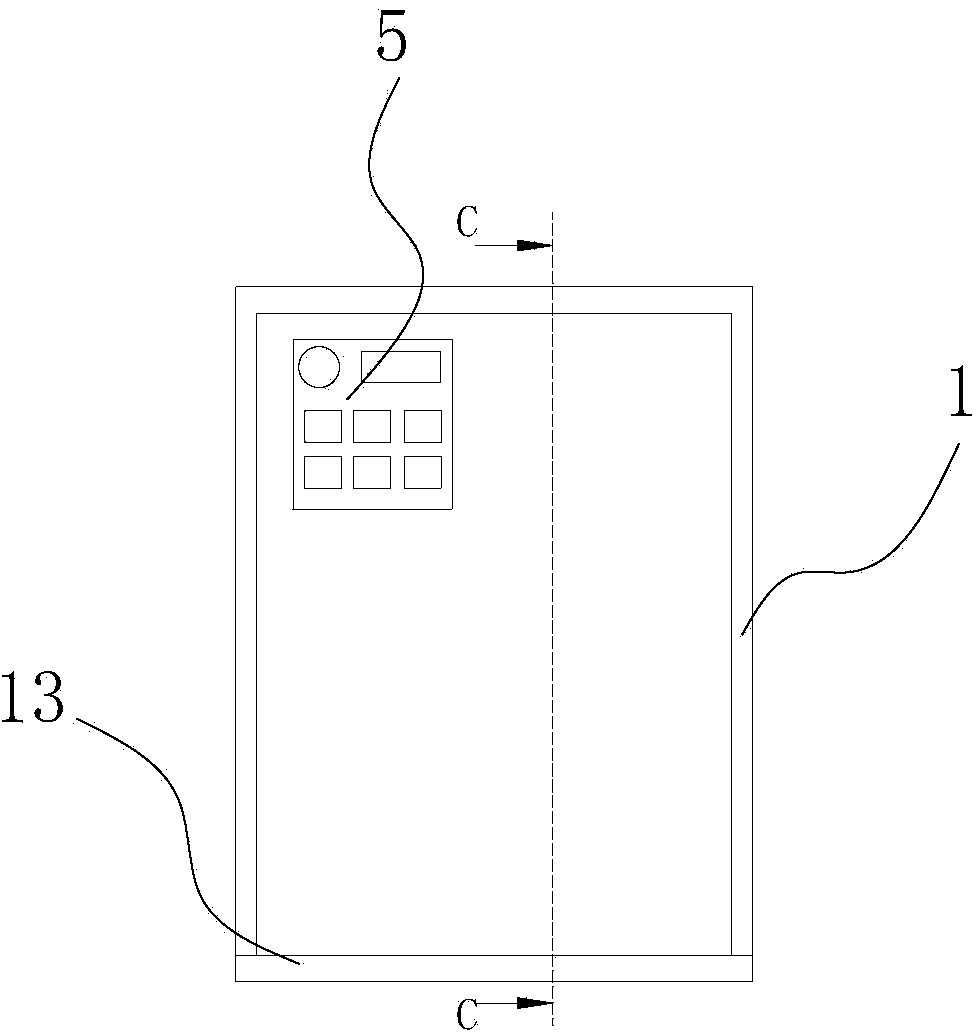

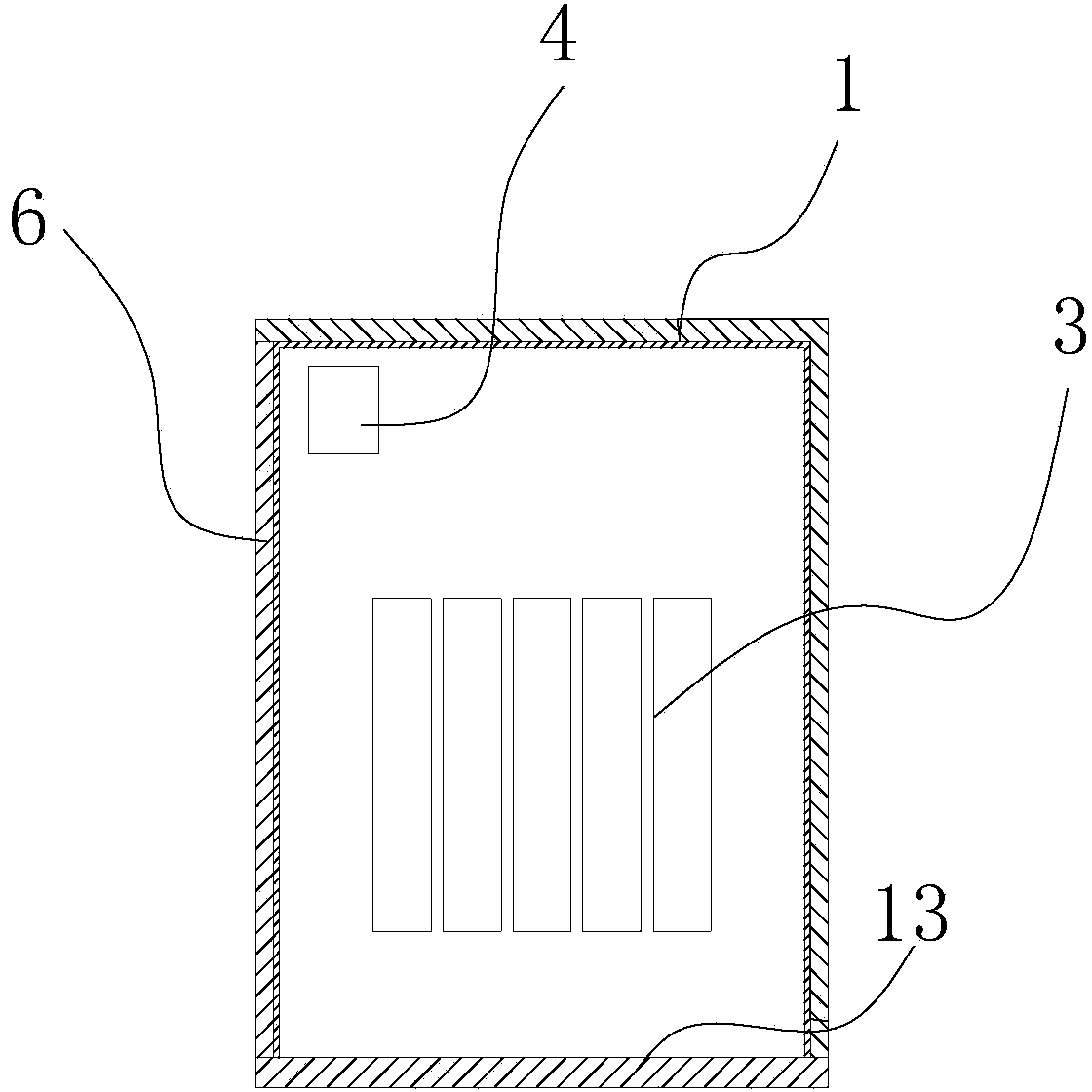

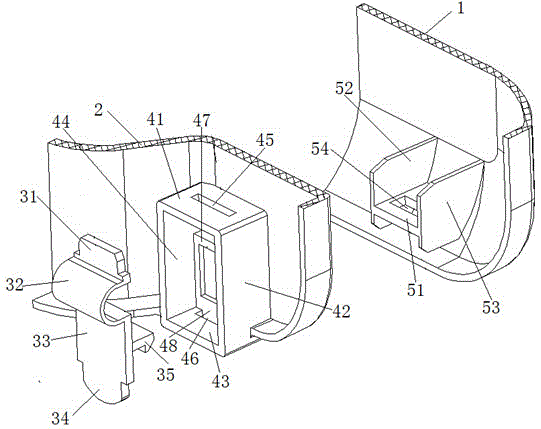

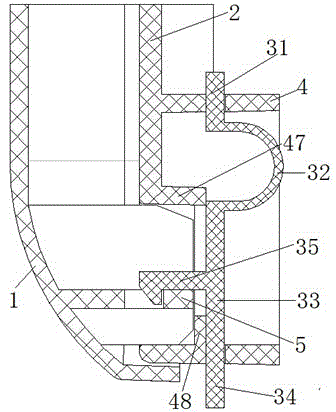

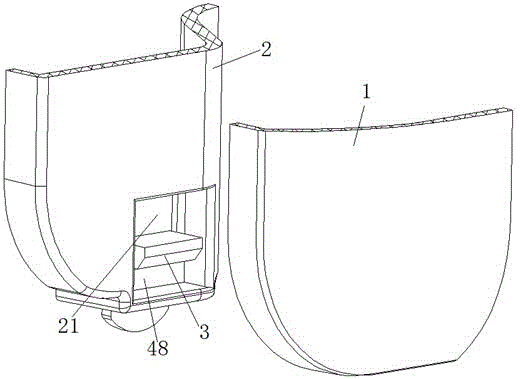

Split-type wrenching-type preservation box

InactiveCN102219082AWill not be scrappedWill not cause scrapSealingRigid containersEngineeringInjection moulding

The invention relates to a split-type wrenching-type preservation box, comprising a box body and a box cover, wherein a fixed slot is arranged below the box cover, the fixed slot is provided with a seal ring, and the seal ring is sealed with the opening of the box body. The split-type wrenching-type preservation box is characterized in that the outer wall of the box body is provided with a connection block, the connection block is provided with a connecting slot, the connecting slot is internally provided with a wrench, the two ends of the wrench are provided with blocking tenons, the blocking tenons are movably connected with the connecting slot in the connection block, the wrench is provided with a clip, the box cover is provided with a fixed side, and the clip of the wrench is clamped and matched with the fixed side. The outer side of the box body is provided with the connection block, the connection block is provided with the connecting slot, the connecting slot and the wrench are connected, the wrench is independently injected and moulded, the two ends of the wrench are provided with the blocking tenons, and the wrench is arranged in the connecting slot of the box body by virtue of the blocking tenons, thus mounting is convenient, the generality is good, the blocking tenons and the connecting slot are connected in a rotating way by virtue of spindle and can not rebound or slip off, the influence of repeated rotation is avoided, the service life is long, the wrench and the box body or box cover are in a split structure, a die is easy to make, a demoulding mechanism is simple, the rejection rate is low, and the production efficiency is high.

Owner:张胜伟

Solar battery assembly

InactiveCN102005490APrevent movementAvoid damagePhotovoltaic energy generationSemiconductor devicesElectricityPower flow

The invention provides a solar battery assembly comprising a light-transmission upper cover plate, a plurality of solar battery slices, an adhesive and a carrier, wherein the plurality of solar battery slices are positioned between the light-transmission upper cover plate and the carrier; the adhesive is filled between the light-transmission upper cover plate and the carrier; the plurality of solar battery slices are connected with each other in series, in parallel or in series and parallel; positive and negative extraction electrodes for extracting current are arranged on the solar battery slices, wherein the positive and negative extraction electrodes on the solar battery slices are connected to the carrier to be used as positive and negative electrode connection points, and the positive and negative electrode connection points on the carrier are electrically connected for realizing the series connection, parallel connection or mixed connection of the solar battery slices. The positive and negative extraction electrodes of the solar battery slices are directly connected to the carrier so that the solar battery assembly has simple process and firm connection. The solar battery assembly can be repaired, and the voltage of a battery is adjustable.

Owner:BYD CO LTD

Rubber sealing ring molding trimming treatment machinery and treatment method thereof

InactiveCN110682486AFast trimmingEnsure smoothness and uniformityDomestic articlesStructural engineeringMechanical engineering

Owner:胡帆

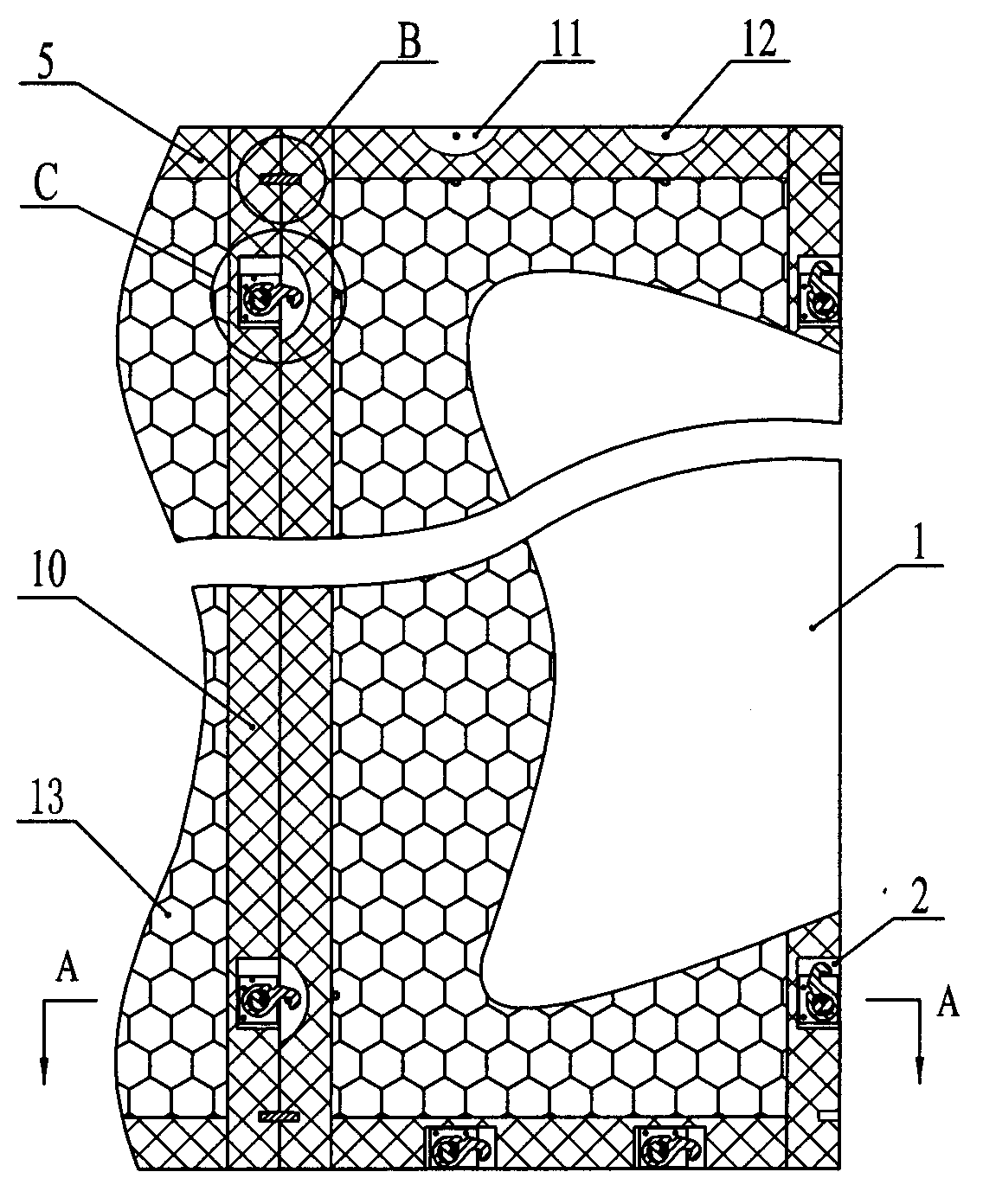

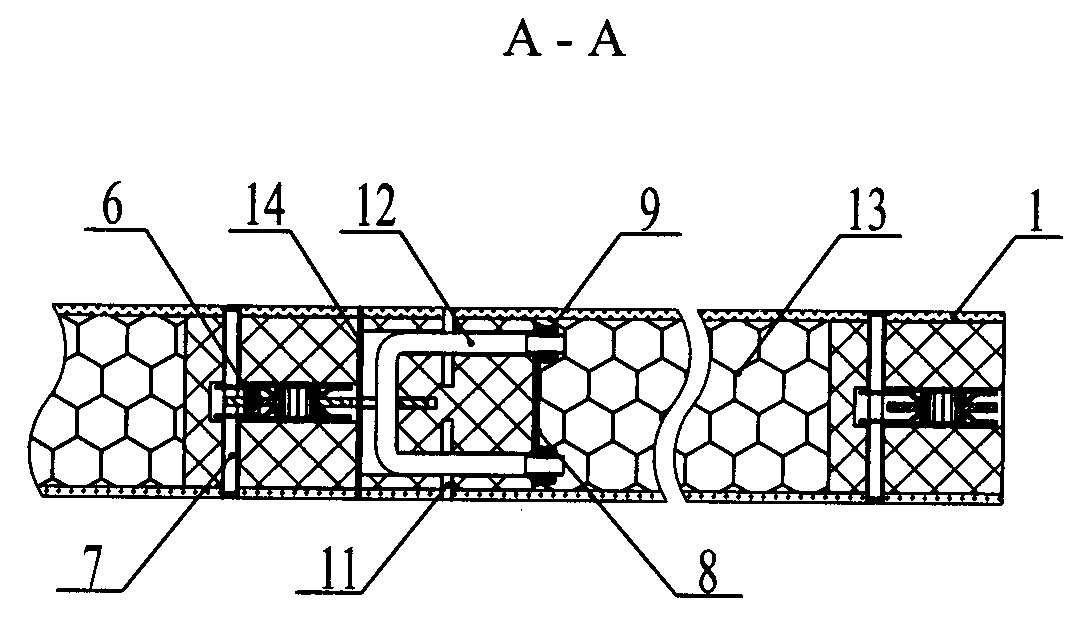

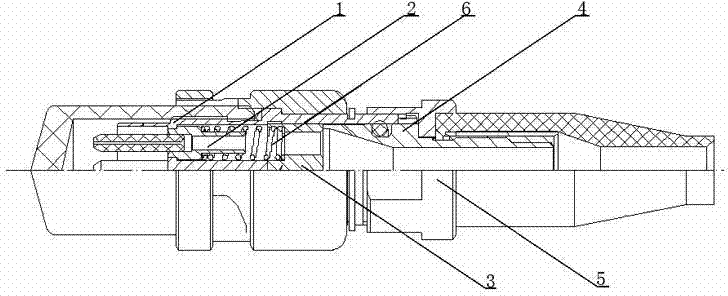

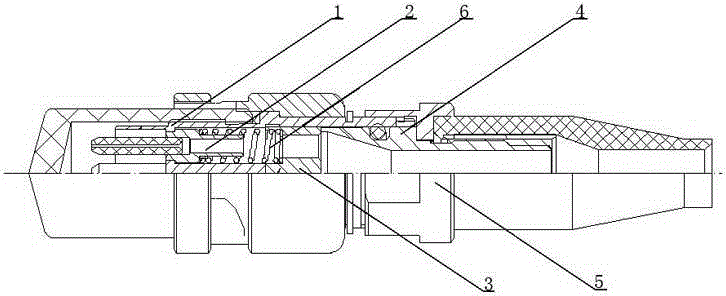

Small high-density multi-core optical fiber connector

ActiveCN103901554AShort lengthEasy to disassembleCoupling light guidesOptical fiber connectorComposite material

The invention relates to a small high-density multi-core optical fiber connector. A plurality of contact pin parts are arranged in a spline shell of a plug, contact pin pressing plates are arranged on the tail portions of the contact pin parts, springs are arranged between the contact pin parts and the contact pin pressing plates, a fastening nut is arranged at the tail of the spline shell, and the fastening nut tightly ejects the contact pin pressing plates through a rear ejector sleeve. A metal shell of a socket is installed in an outer shell, each cavity of the metal shell is provided with a ceramic bushing, contact pin pieces are arranged in the ceramic bushings, ceramic bushing pressing plates are installed on the tail portions of the ceramic bushings, and a tail nut tightly ejects the ceramic bushing pressing plates through a contact pin ejector plate. The optical fiber connector is small in size and high in integration level, and can be used in small space. A viscose structure is not arranged inside a shell of the optical fiber connector, so that the optical fiber connector is convenient to disassemble, the whole internal structure can be taken out only by disassembling the tail of the optical fiber connector in the maintenance process, if some parts are damaged, only the damaged parts need to be replaced, other parts cannot be scraped, and therefore maintenance cost is low.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

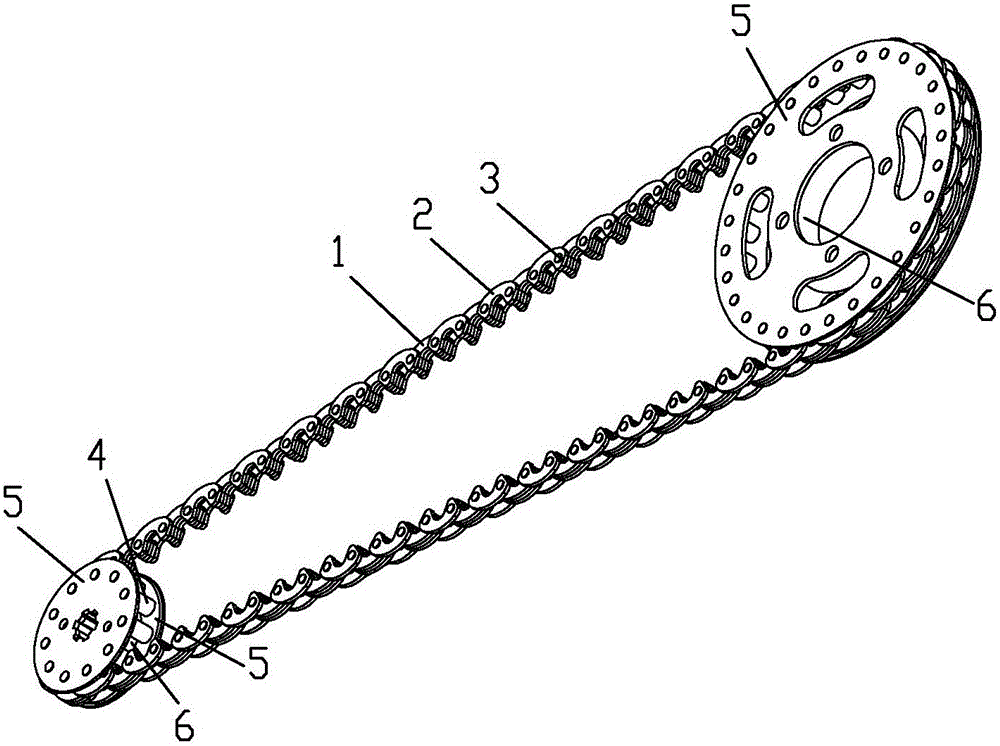

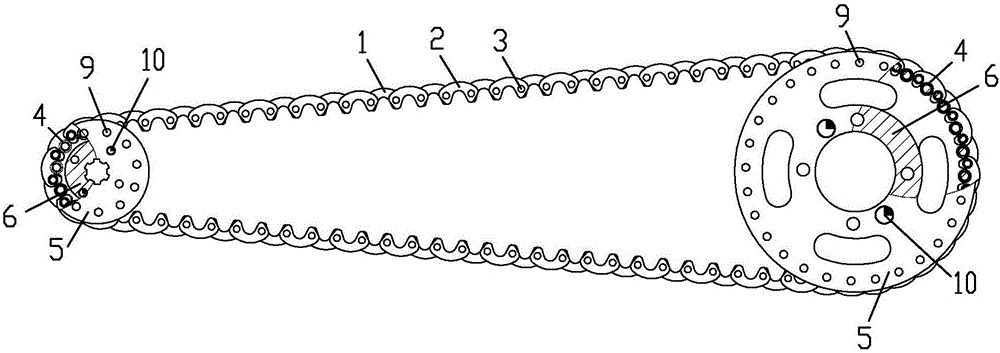

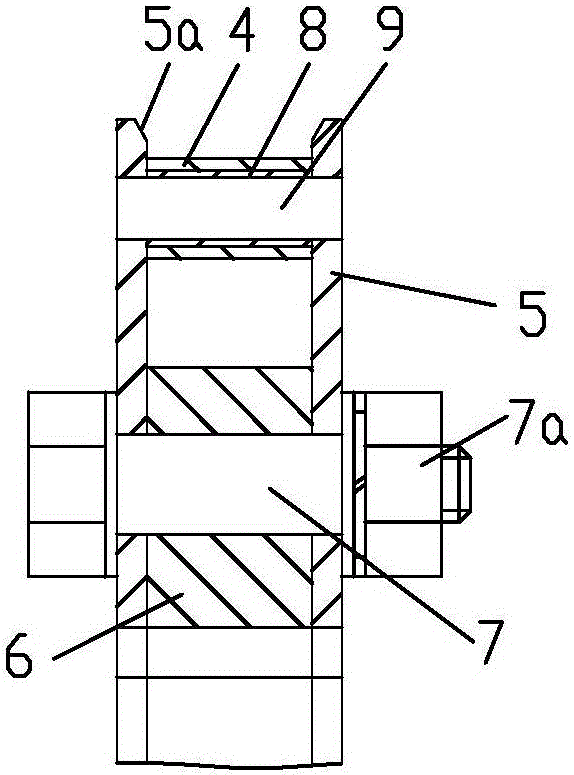

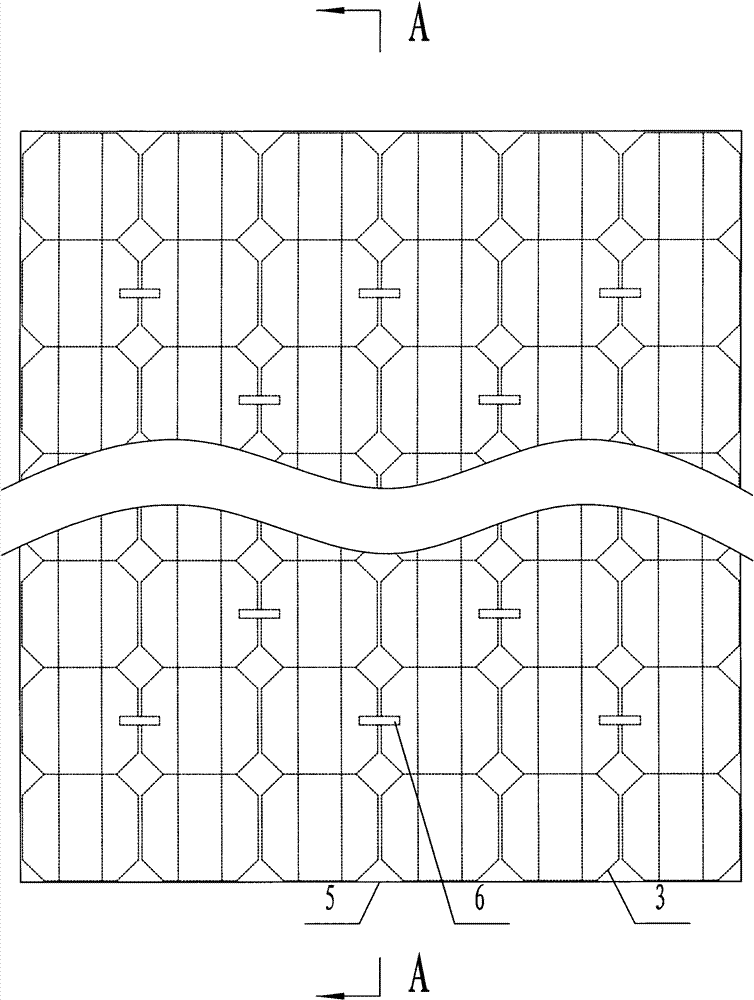

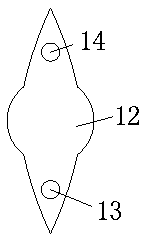

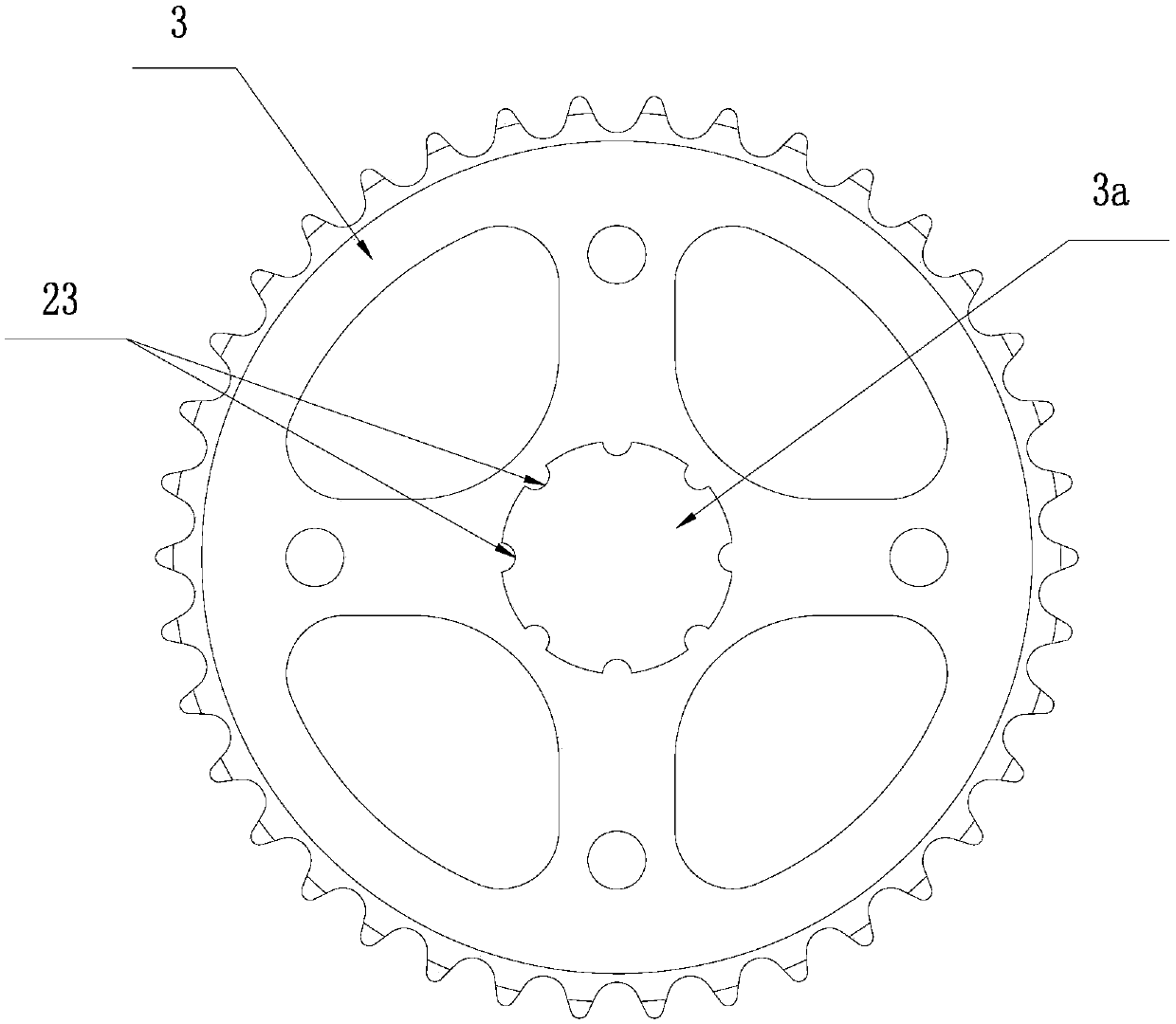

Chain transmission system

InactiveCN105864376AImprove carrying capacityWill not cause scrapGearingPortable liftingEngineeringSprocket

The invention discloses a chain transmission system, which comprises a driving sprocket, a driven sprocket and a chain with an annular closed structure. Constitutes an internally meshing toothed chain, the first chain link and the second chain link are staggered and hinged to each other through the pin shaft; the driving sprocket and the driven sprocket both include two end disks, and the two end disks are connected through the middle of the middle There are a plurality of rollers constituting chain teeth evenly distributed on the circumference between the two end disks connecting the outer circumference of the cylinder in the middle, and the two end disks also form side slip restrictions on the internal meshing toothed chain. The invention has the beneficial effects of small frictional resistance, low noise, high transmission efficiency, simple structure, low manufacturing difficulty, and low manufacturing and use costs.

Owner:张应新

Structure of solar battery module

ActiveCN102064218BWill not cause scrapNot easy to shiftPhotovoltaic energy generationSemiconductor devicesLap jointSolar battery

Owner:苏州潞能能源科技有限公司

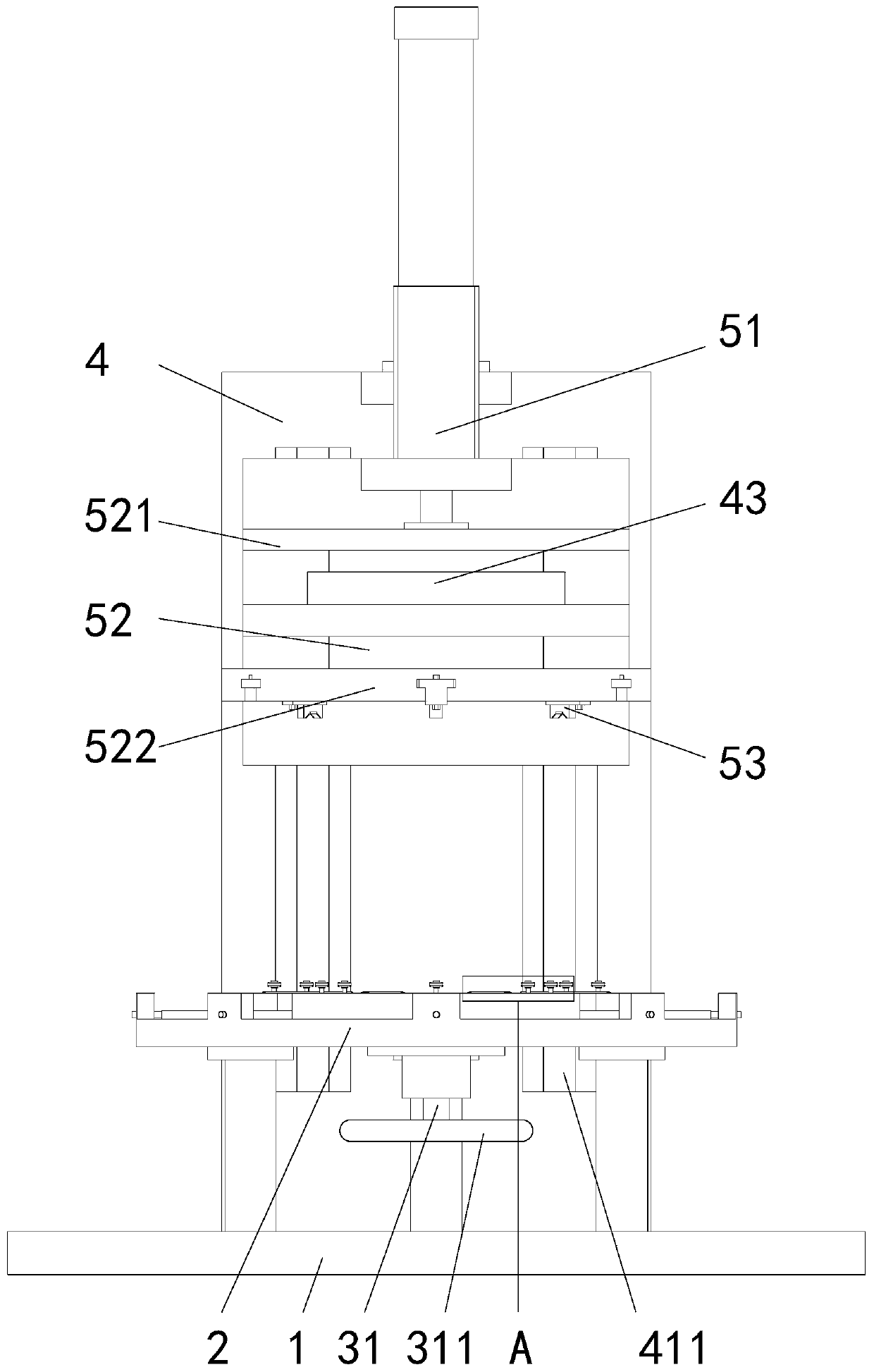

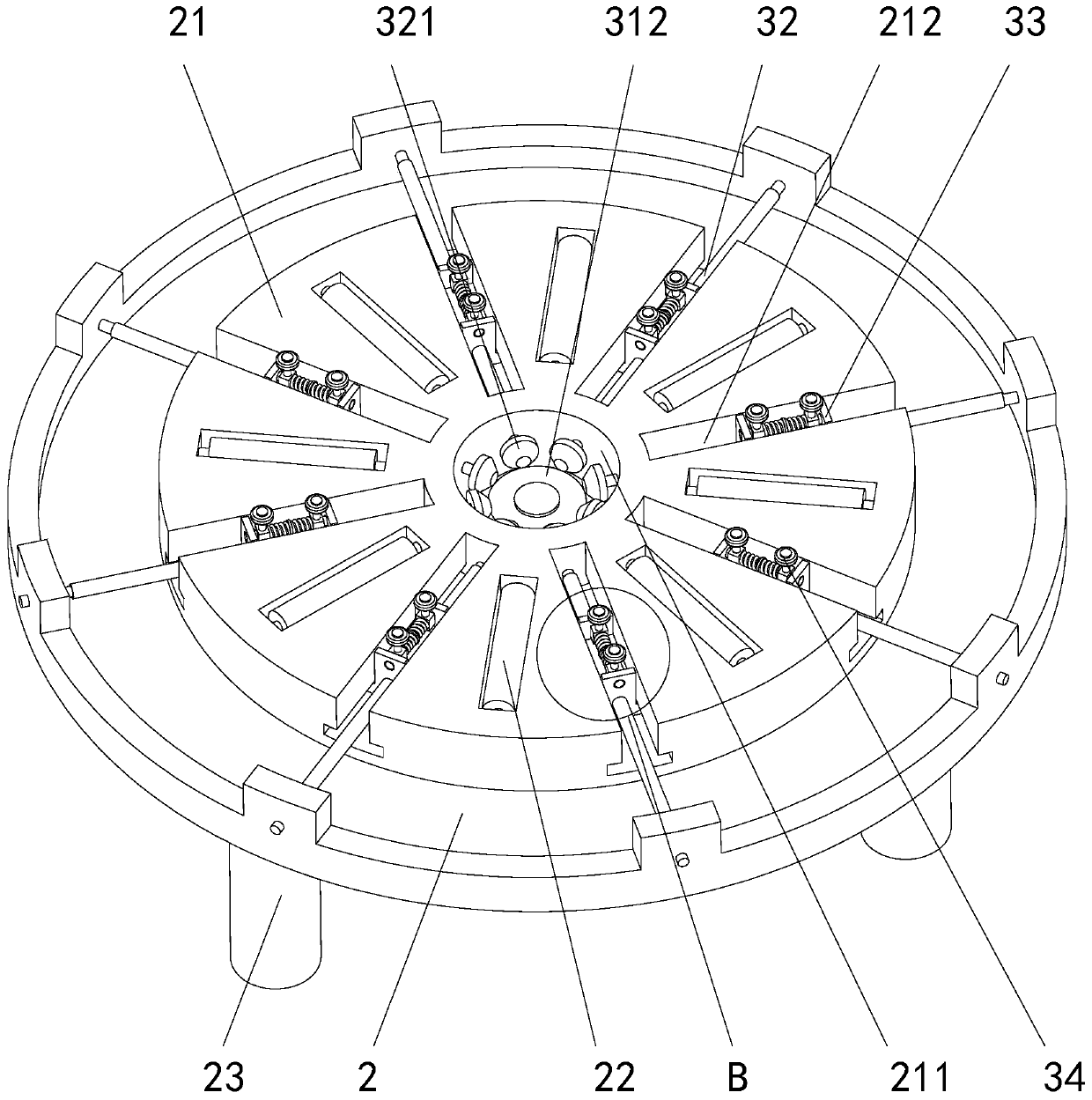

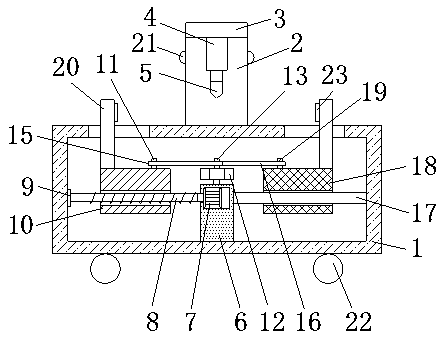

Punching device for three-phase asynchronous motor production

InactiveCN108435884AImprove punching efficiencyEasy to moveMetal-working feeding devicesLighting elementsThree phase asynchronous motorIndustrial engineering

The invention discloses a punching device for three-phase asynchronous motor production. The punching device comprises a base; the top of the base is fixedly connected with a supporting plate, and a supporting block is fixedly connected to the top of the front face of the supporting plate; a hydraulic lifting column is fixedly connected to the bottom of the supporting block, and a punching head isfixedly connected to the bottom of the hydraulic lifting column; and a fixed block is fixedly connected to the bottom of an inner cavity of the base, and a motor is fixedly connected into the fixed block. According to the punching device for three-phase asynchronous motor production, through cooperative using of the fixed block, the motor, a threaded rod, a bearing, a first movable block, a firstfixed column, a rotary block, a second fixed column, a third fixed column, a first movable rod, a second movable rod, a fixed rod, a second movable block, a fourth fixed column and clamping blocks, the punching device for three-phase asynchronous motor production is high in punching efficiency, the situation that punching of a punched workpiece is inaccurate, and the workpiece is scrapped is avoided, and people using is facilitated.

Owner:陈建民

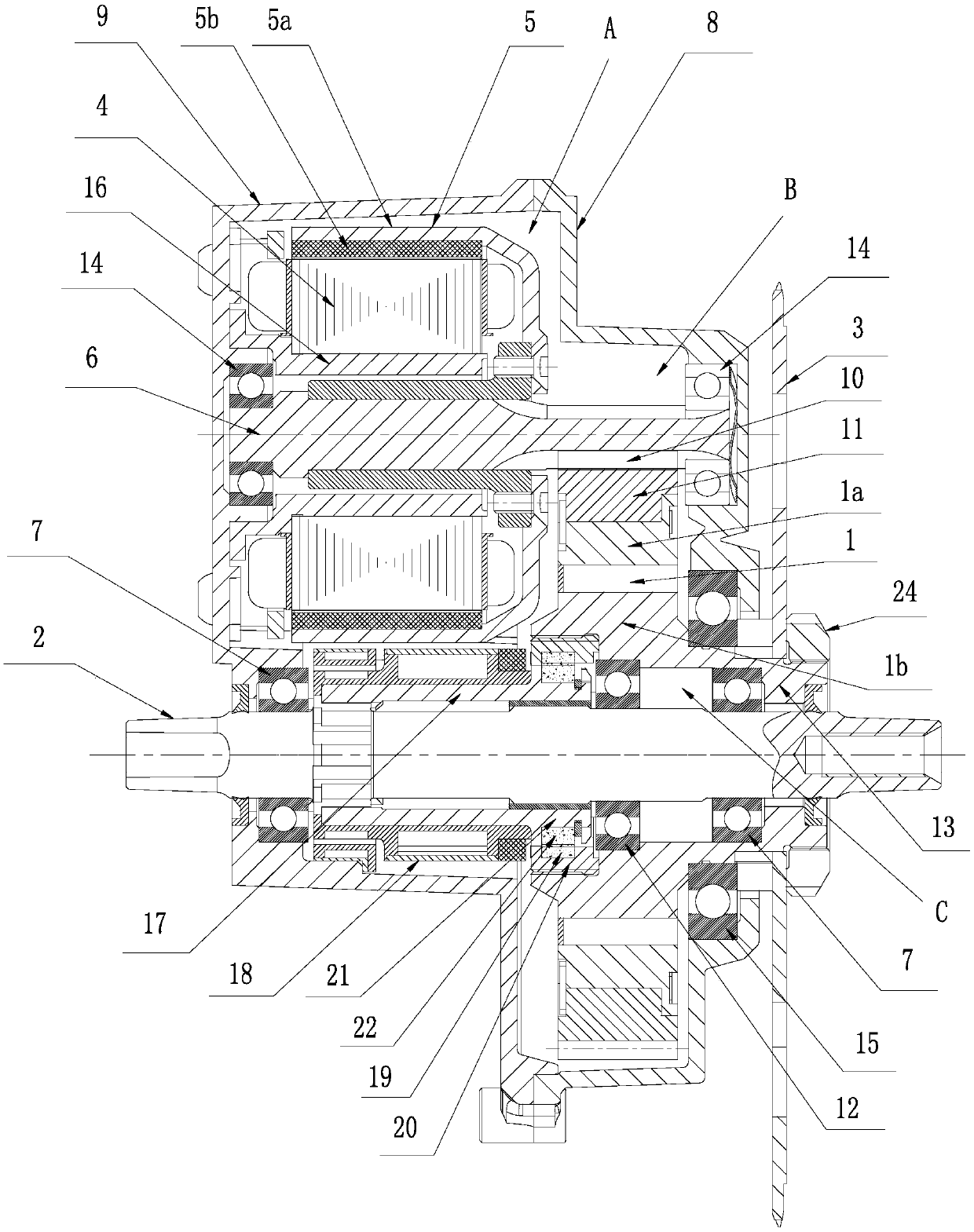

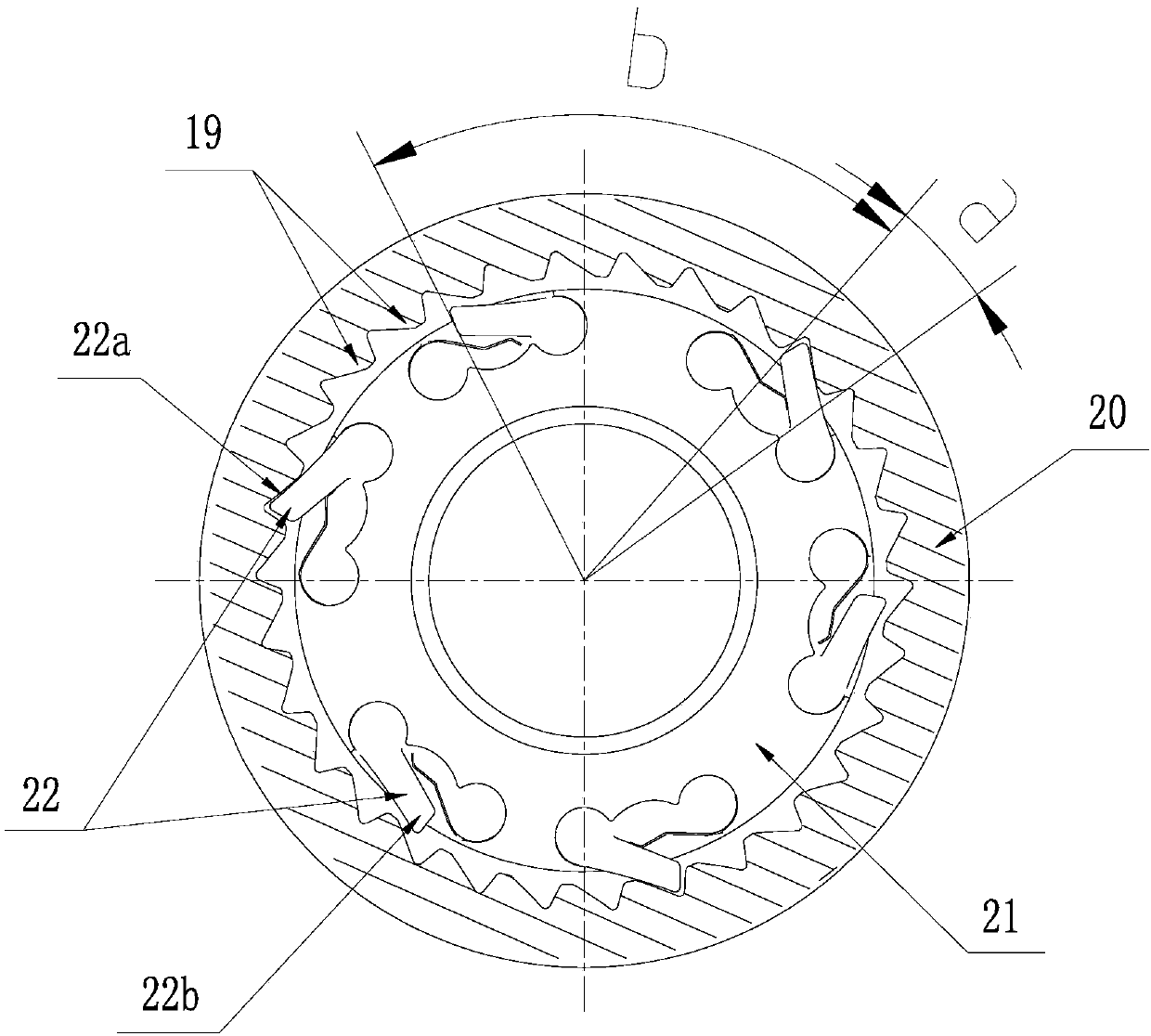

Primary-gear-gearing-down compact-type mid-motor

PendingCN109625146AImprove user experienceEasy to operateWheel based transmissionMechanical energy handlingClutchStator

The invention discloses a primary-gear-gearing-down compact-type mid-motor. The primary-gear-gearing-down compact-type mid-motor comprises a shell, a motor body, a clutch, a gear reducing mechanism, acenter shaft and a chain wheel, wherein the motor body comprises a stator, a rotor and a core shaft; the center shaft penetrates through shaft holes in the two ends of the shell, supporting and positioning are carried out through center shaft bearings arranged in the shell, and the core shaft and the center shaft are parallelly arranged; the primary-gear-gearing-down compact-type mid-motor is characterized in that the shell is formed by buckling and fixing a motor front cover and a motor back cover, the motor body is of an outer-rotor inner-stator structure, the gear reducing mechanism comprises a small gear fixed or integrally arranged on the core shaft and a large gear engaged with the small gear, an inner ring of the large gear and an outer ring of the clutch are fixed or integrally formed, an inner ring of the clutch is installed on the center shaft through a clutch bearing, and a chain-wheel positioning sleeve extending out of the shaft holes of the shell is integrally formed atthe front end of the inner ring of the clutch to fix the chain wheel. The motor structure is more compact, smaller in size and much less in part, and is particularly suitable for an electric bicycle with the small motor design power, and the production cost can be greatly saved.

Owner:SUZHOU SHENGYI MOTOR

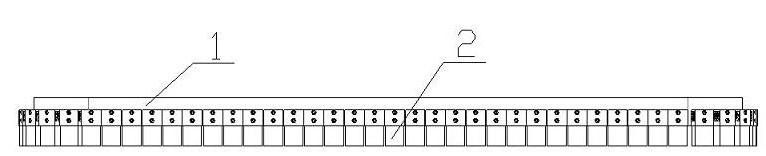

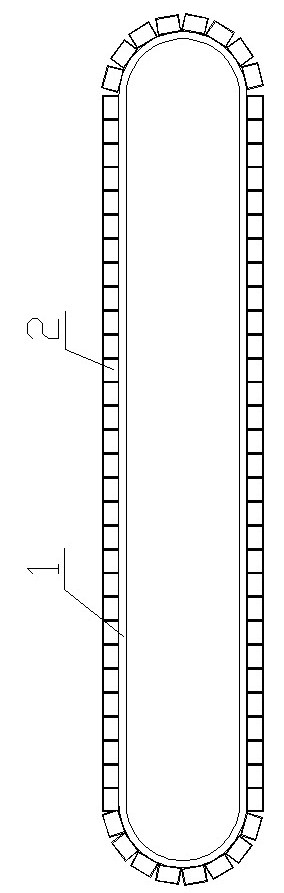

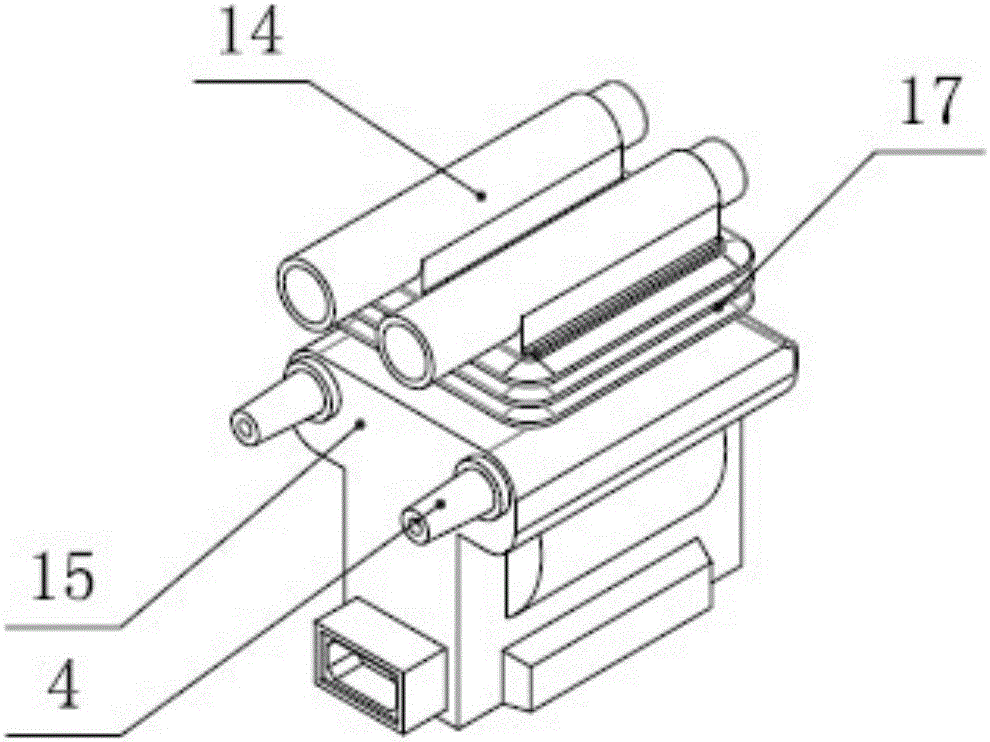

Deburring machine material grinding belt with replaceable polishing head

The invention relates to a deburring machine material grinding belt with a replaceable polishing head, which is characterized in that an annular polishing belt substrate surface is laterally and annularly transmitted to drive a deburring head in the polishing head on the annular polishing belt substrate surface to vertically polish relatively to the workpiece, and the polishing efficiency is high. The deburring machine material grinding belt comprises an annular polishing base belt, wherein the side surfaces of a plurality of polishing heads are connected with the surface of the annular polishing base belt at equal interval or unequal interval. The deburring machine material grinding belt has the advantages that polishing distance can be regulated because the polishing belt can be vertically regulated, and therefore the deburring machine material grinding belt can be used for polishing and deburring workpieces of different thicknesses, and has good applicability; and in addition, the polishing belt is transmitted once to finish two-time polishing and deburring, and therefore the deburring machine material grinding belt has high polishing and deburring efficiency.

Owner:HANGZHOU XIANGSHENG ABRASIVE MACHINE MFG

Method for molding simulated thread high-pressure injection die

The invention discloses a method for molding a simulated thread high-pressure injection die. The method comprises the following steps: modeling a required 3D (three-dimensional) model by utilizing 3D design software, wherein the digital model comprises thread slot models, thread models and detailed characteristics of threads; dividing male and female dies by die designers according to the digital model, and designing the structure of the die; engraving various required thread textures by using a numerical control processing center; manufacturing a cavity, and performing texture engagement treatment on the cavity; assembling the cavity to the female die, and locking the cavity and the female die together by bolts; directly carrying out injecting molding on a plastic product with simulated threads by a die with the cavity. The method is easy to operate, has the advantages that adverse results caused by man-made reasons can be reduced and products are completely the same to realize seamless lap joint with opponent pieces, is strong in dimension stability, adhesive omission, more environmental-friendliness and low in manual and equipment cost.

Owner:QUANXING TOOLING EQUIP NANJING

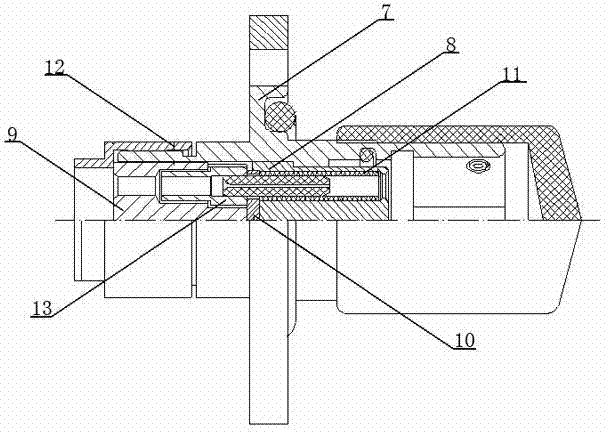

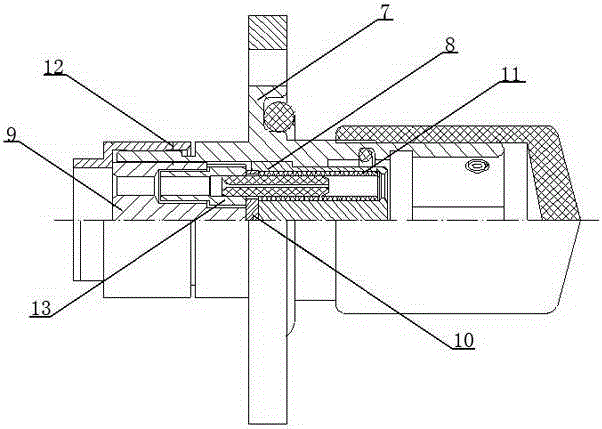

Voltage transformer with elbow plug

ActiveCN106683862AConducive to miniaturization designEasy to useTransformersTransformers/inductances coils/windings/connectionsTransformerElectric cables

The invention provides a voltage transformer with an elbow plug. An independent fuse seat is integrally arranged at the top of a cable socket; a fuse cavity accommodating a fuse protector is arranged in the fuse seat; an open end of the fuse cavity and the cable socket are located at the same side; an embedded part is arranged at the tail end of the fuse cavity; a detachable fixed plate is arranged at the open end of the fuse cavity; the fuse protector is arranged between the embedded part and the fixed plate; one end of the fuse protector is propped against a spring; the fuse protector is electrically connected with the embedded part and the fixed plate; a primary terminal is embedded into the cable socket; a primary conductive rod is arranged on an elbow cable plug; and when the elbow cable plug is inserted into the cable socket, the primary conductive rod is electrically connected with the primary terminal through a pressure spring and the primary terminal is connected with a primary coil through the fuse protector of the fuse cavity. When the fuse protector is replaced, the complicated process of disassembling and assembling the plug is avoided, the operation is simple and convenient, the work efficiency is improved, a lot of replacement time is shortened and the voltage transformer has very high popularization and application value.

Owner:ZHEJIANG HORIZON INSTR TRANSFORMERS

A small high -density multi -core optical fiber connector

ActiveCN103901554BReduce sizeHighly integratedCoupling light guidesHigh densityOptical fiber connector

The invention relates to a small high-density multi-core optical fiber connector. A plurality of pin parts are arranged in the spline housing of the plug, a pin pressing plate is arranged at the tail of the pin parts, and a There is a spring, and the fastening nut is arranged at the tail of the spline housing, and the fastening nut tightens the pin pressing plate through the rear top sleeve; the metal shell of the socket is installed in the outer shell, and each chamber of the metal shell is installed There is a ceramic sleeve, and a pin insert is also arranged in the ceramic sleeve, a ceramic sleeve pressure plate is installed at the tail of the ceramic sleeve, and the tail nut tightens the ceramic sleeve pressure plate through the pin top plate. The optical fiber connector of the present invention is small in size and high in integration, and can be used in a small space. There is no adhesive structure inside the housing of the optical fiber connector, and it is easy to disassemble. When maintaining, only the tail part needs to be removed to remove the entire internal structure. Taken out, if a part is damaged, only the part needs to be replaced, and the rest of the parts will not be scrapped, and the maintenance cost is low.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

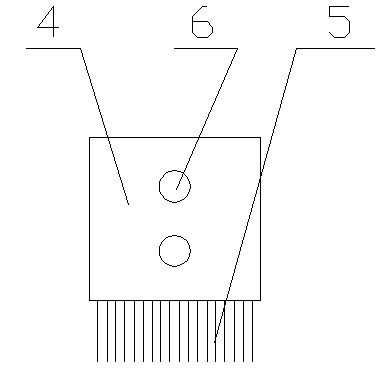

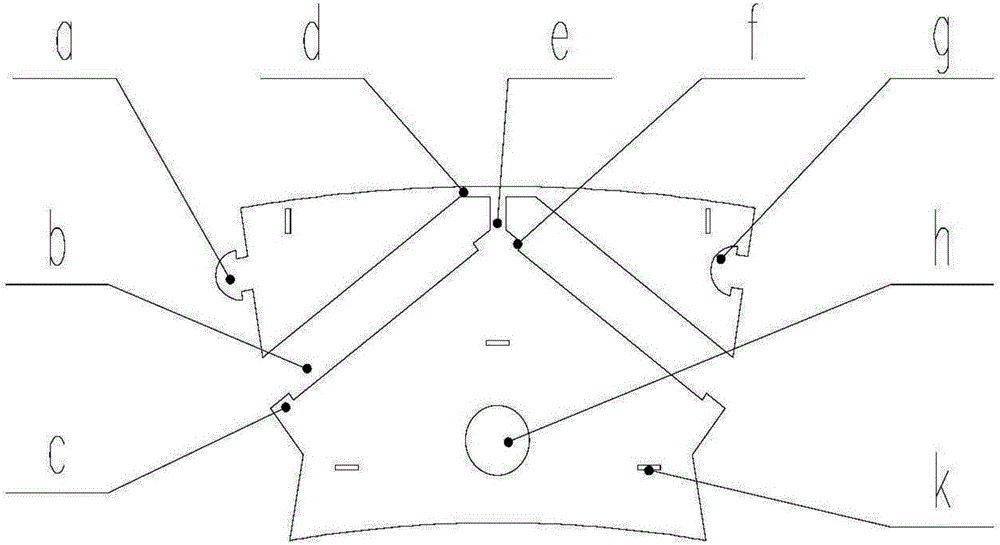

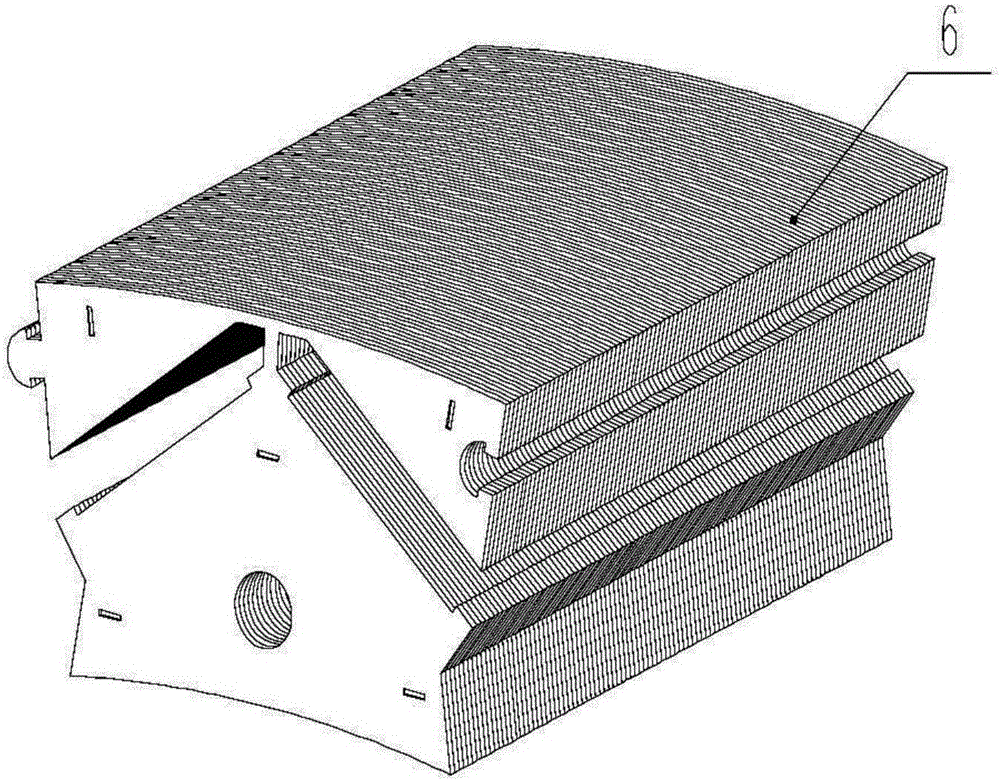

Integral multi-core upper die

InactiveCN101648230AEasy to processShorten the production cycleExtrusion diesEngineeringProduction cycle

Owner:SOUTHWEST ALUMINUM GRP

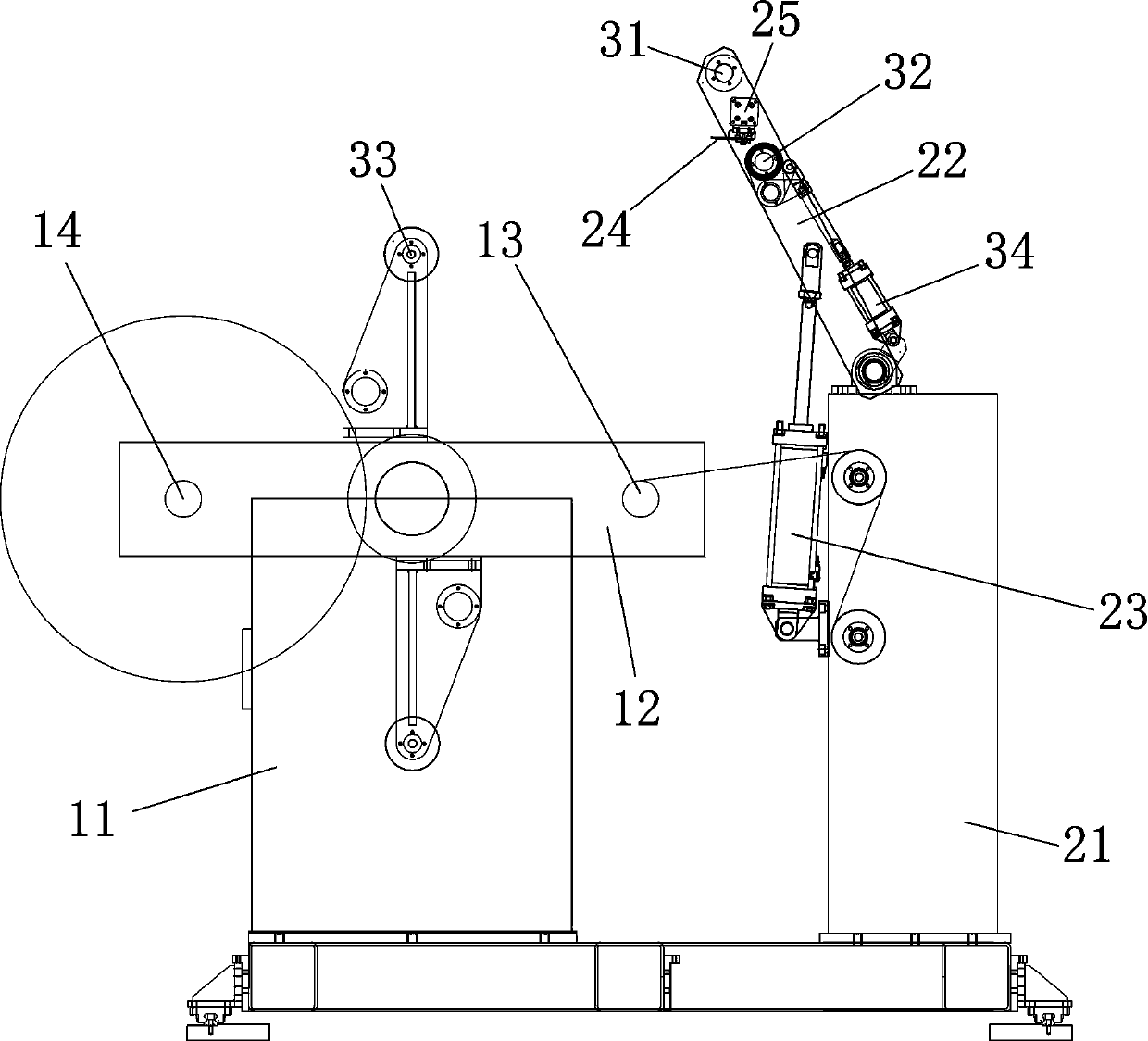

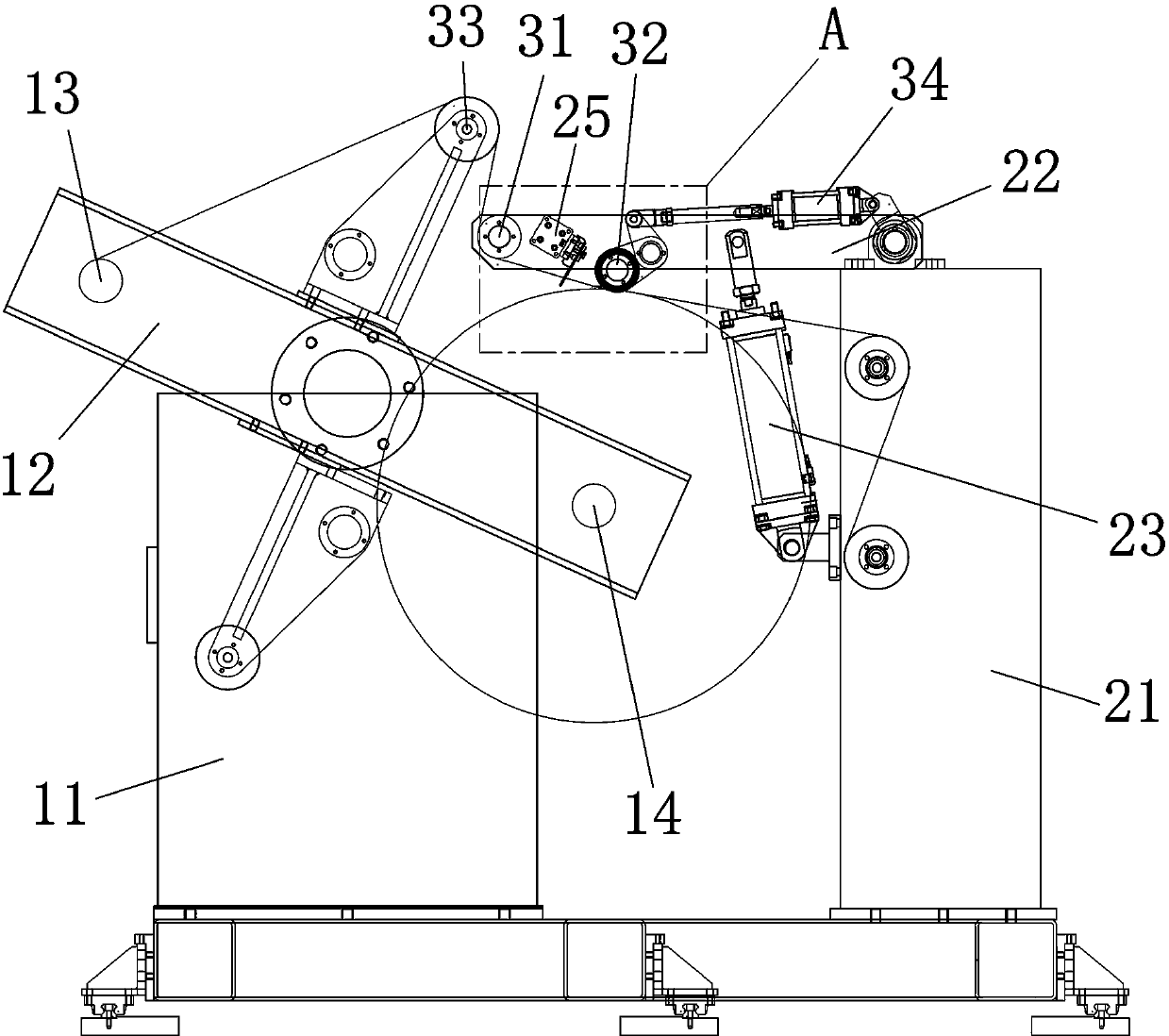

Automatic cutting and unwinding equipment

The invention discloses automatic cutting and unwinding equipment. The automatic cutting and unwinding equipment comprises an unwinding mechanism, a tensioning mechanism and a cutting mechanism. The unwinding mechanism comprises at least two winding drums, wherein the winding drum completing unwinding is an old-coil winding drum, and the winding drum provided with coiled materials is a new-coil winding drum. The tensioning mechanism comprises a compression roller device and a first bypass roller device. The cutting mechanism comprises a cutter and a cutter drive device. The cutter is arranged between the compression roller device and the first bypass roller device. When the cutting mechanism performs cutting, the unwinding mechanism rotates to make the new-coil winding drum be located at the unwinding position, the coiled materials between the new-coil winding drum and the old-coil winding drum are pressed by the first bypass roller device so that the coiled materials can be tightened, and the coiled materials on the old-coil winding drum are compressed and fixed to the coiled materials of the new-coil winding drum through the compression roller device. The cutter is controlled by the cutter drive device to transversely cut the coiled materials between the first bypass roller device and the new-coil winding drum.

Owner:孟昊

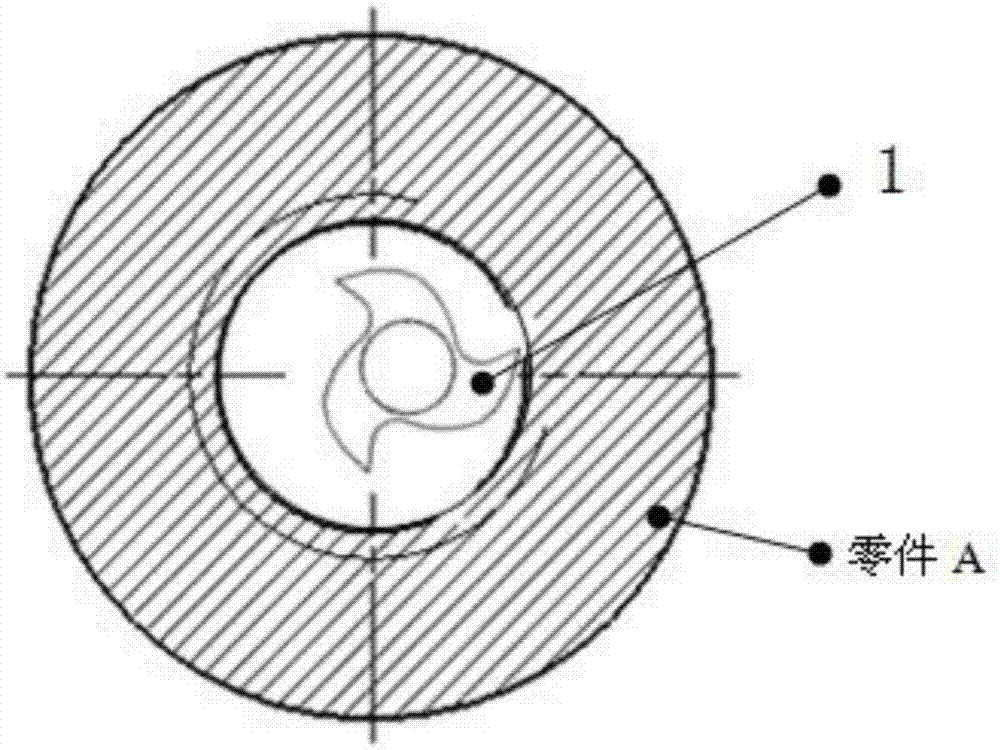

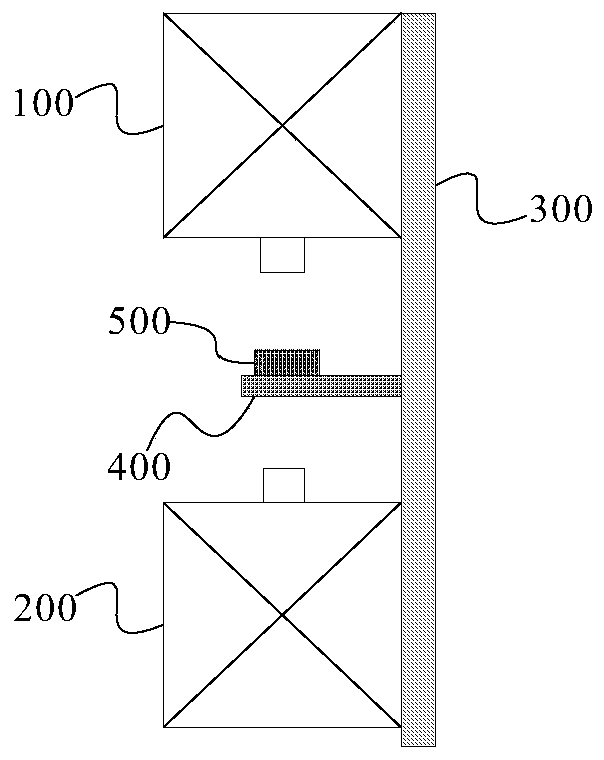

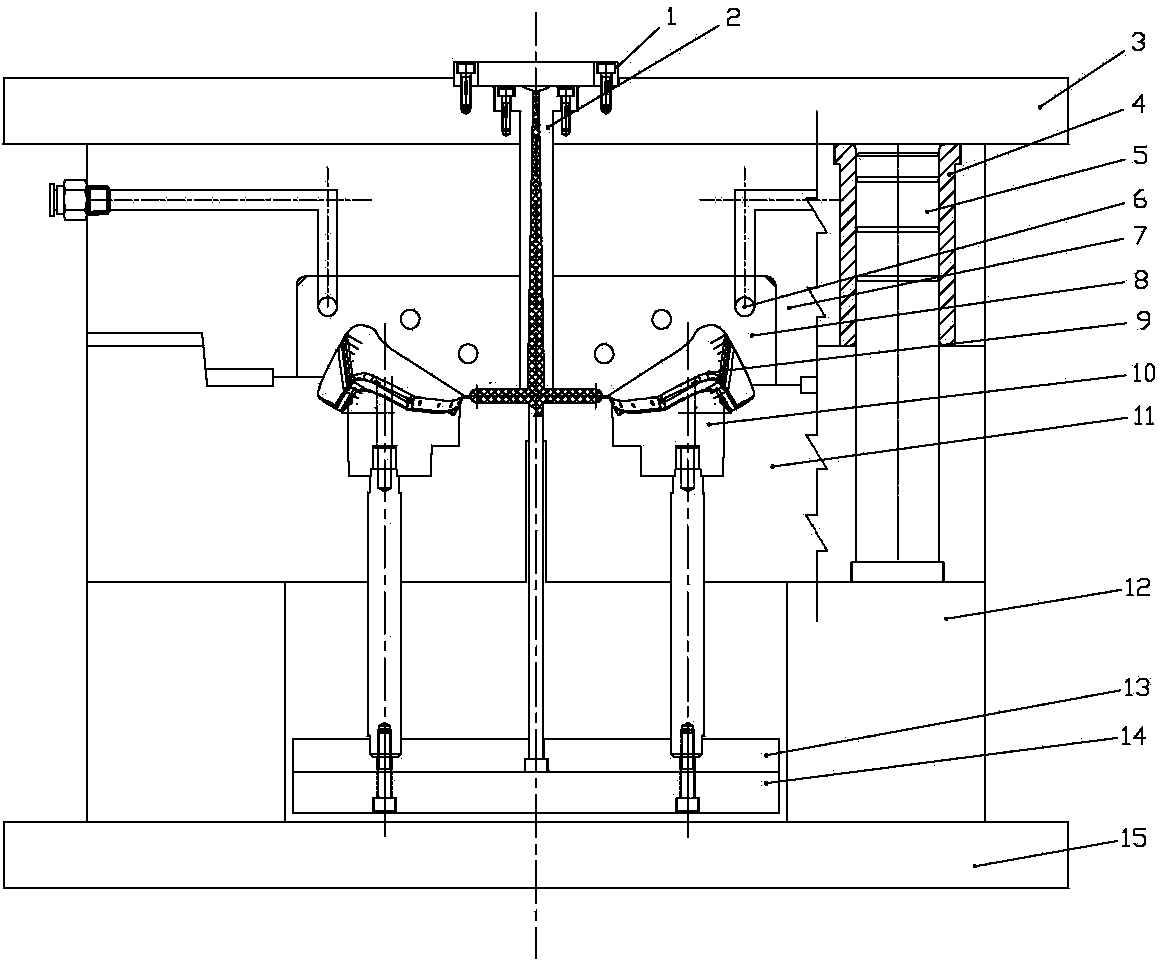

End face superfinishing machine

ActiveCN105196141AReduce hardnessWill not cause scrapGrinding drivesBelt grinding machinesEngineeringImpurity

An end face superfinishing machine comprises a rack and a worktable. The worktable is provided with a lower center, an abrasive belt guide rail, an abrasive belt lower clamping plate, an abrasive belt longitudinal driving mechanism, a stand frame, a center guide rail, a center sliding table and a center vertical moving driving mechanism, and the abrasive belt lower clamping plate is provided with a lower U-shaped groove. An abrasive belt upper clamping plate is arranged above the abrasive belt lower clamping plate, and the abrasive belt upper clamping plate is provided with an upper U-shpaed groove. An abrasive belt is arranged between the abrasive belt upper clamping plate and the abrasive belt lower clamping plate in a penetrating mode and provided with a plurality of notches, and the abrasive belt upper clamping plate is further provided with an abrasive belt locking device. The center sliding table is provided with an upper center. A swing sleeve is rotationally installed outside the upper center and internally provided with a fixing hole, and a swing driving mechanism is further arranged outside the swing sleeve. The end face superfinishing machine has the advantages that the end face superfinishing machine is simple and compact in structure, convenient to operate and stable and reliable in overall operation; due to the fact that the abrasion belt is low in hardness and has few impurities, the polishing precision is high, and scraps of step type centrifugal type shaft parts can be avoided.

Owner:宁波华表机械制造有限公司

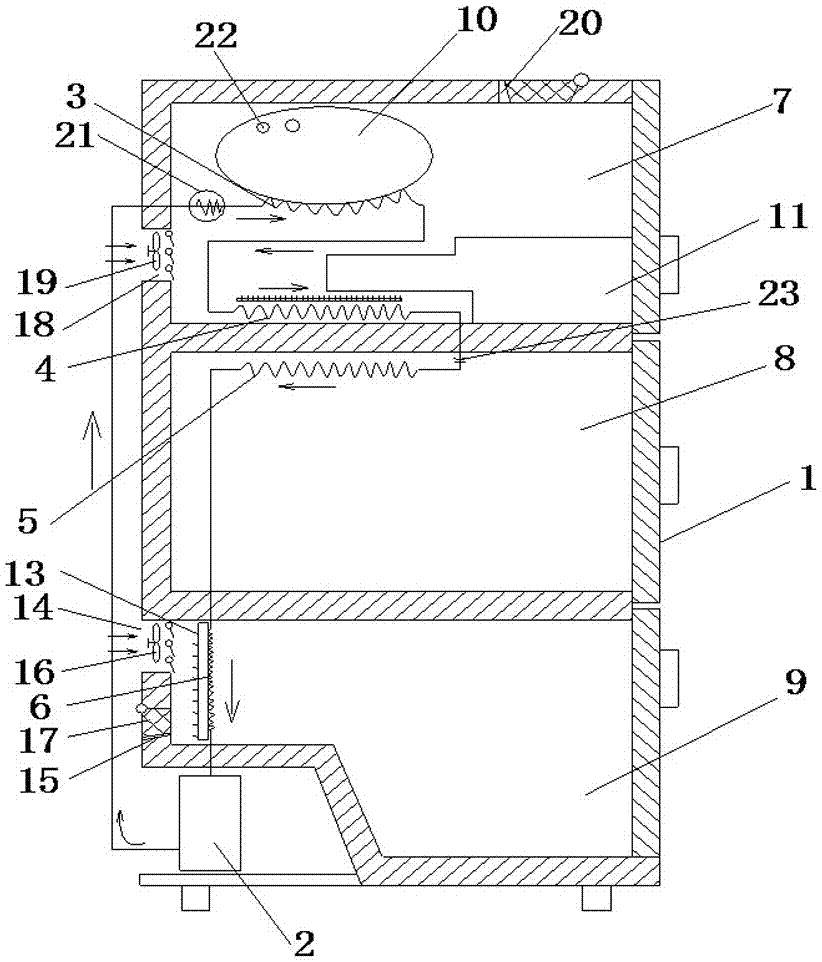

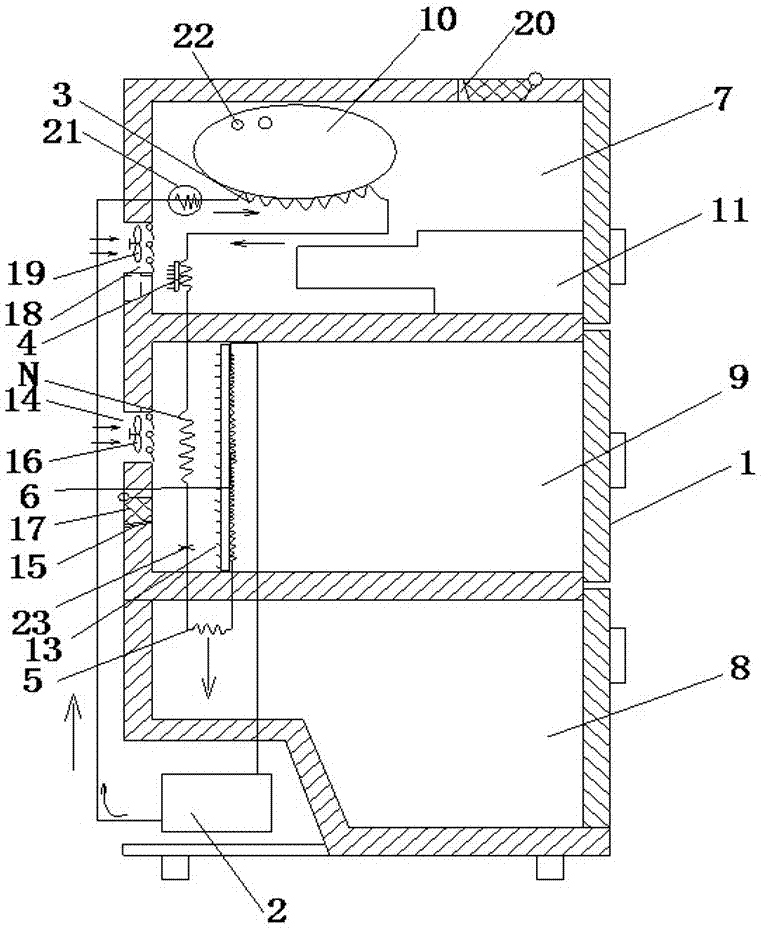

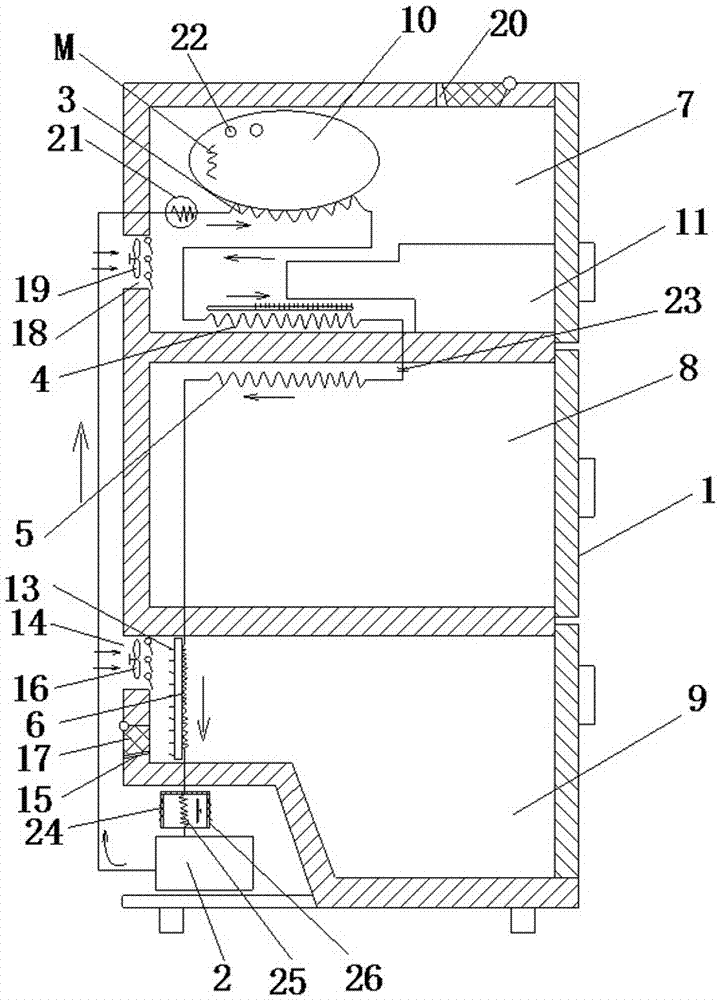

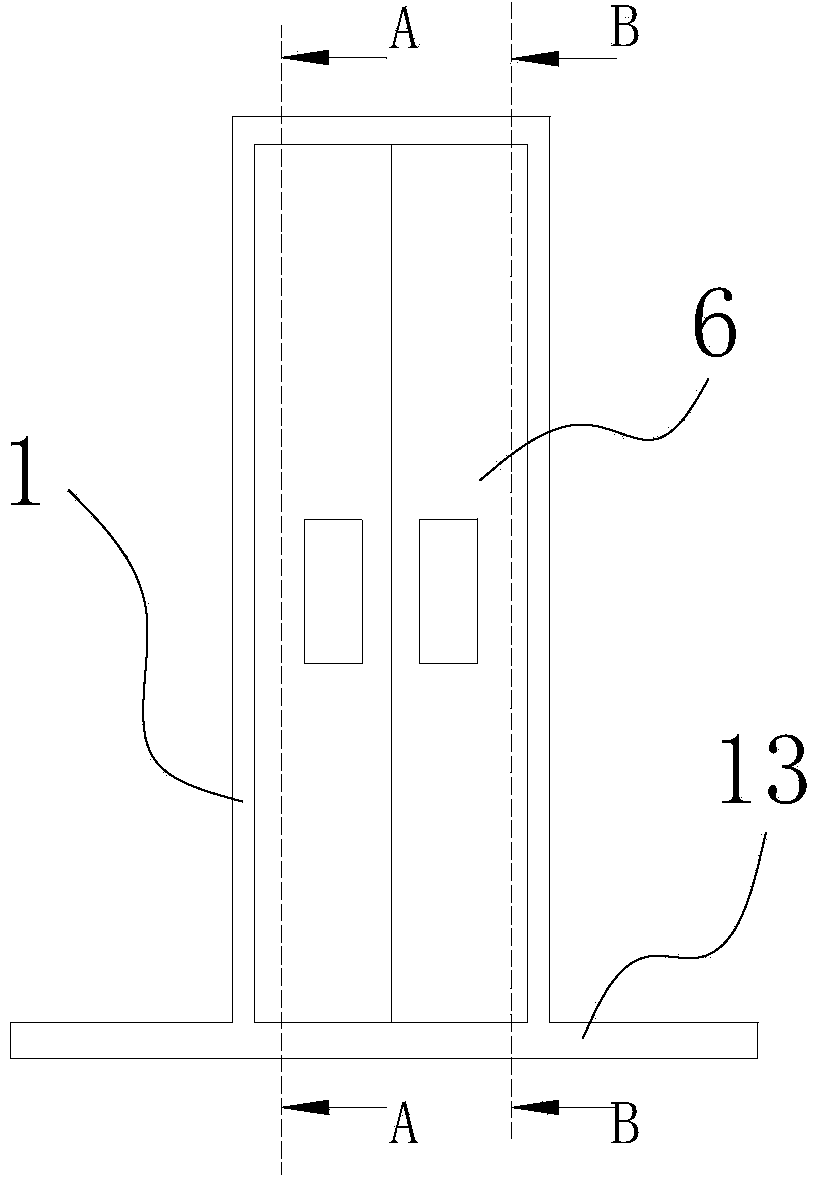

Refrigerating chamber heat-exchange refrigerator integration all-in-one machine and working method thereof

ActiveCN106871537AThe purpose of creating high-efficiency and energy-savingChange using a single functionLighting and heating apparatusDomestic refrigeratorsIceboxCool storage

The invention relates to a refrigerating chamber heat-exchange refrigerator integration all-in-one machine and a working method thereof. The refrigerating chamber heat-exchange refrigerator integration all-in-one machine is characterized by comprising a refrigerator body, and a compressor, a water tank condenser, a heat-insulation condenser, a freezing evaporator and a refrigeration evaporator sequentially connected and arranged at the back face of the refrigerator body. a heat-insulation chamber, a freezing chamber and a refrigeration chamber are arranged in the refrigerator body from top to bottom; a water tank and a heat-insulation cavity are arranged in the heat-insulation chamber; the water tank condenser covers the lower surface of the water tank; the heat-insulation condenser is arranged at the wall face of the heat-insulation cavity; the freezing evaporator is arranged in the freezing chamber; the refrigeration evaporator is arranged in the refrigeration chamber; a heat absorption fin is arranged at the back face of the refrigeration evaporator; and a first air inlet and a first air outlet are formed in positions, directly facing the heat absorption fin, on the refrigerator body. The refrigerating chamber heat-exchange refrigerator integration all-in-one machine provided by the invention is simple in structure and reasonable in design, integrates hot water, heat insulation and refrigeration into a whole, and is convenient to use.

Owner:黄安东

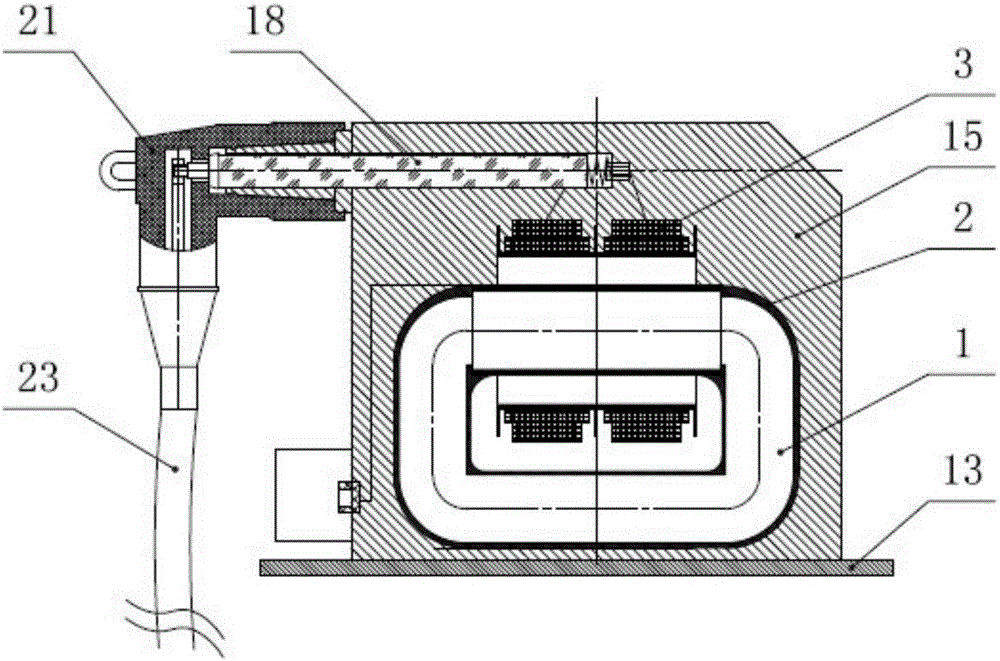

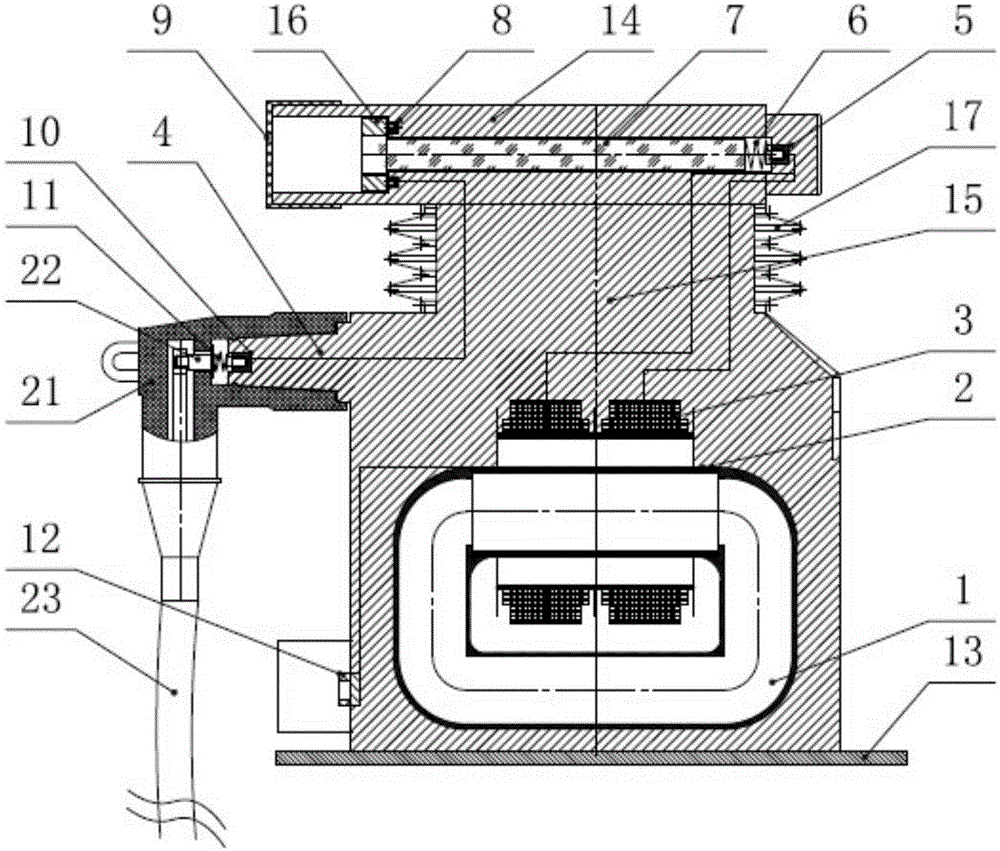

Heating device for blade of circle shear

ActiveCN104191159AHeating evenlyReduce replacement timeMetal working apparatusElectricityElectrical resistance and conductance

The invention discloses a heating device for a blade of a circle shear. The heating device can be used for heating the blade of the circle shear, and the blade of the shear is heated to expand according to the expansion and contraction principle, so that the blade of the shear is convenient to replace. The heating device comprises a heating box, wherein the heating box is provided with an inner cavity, a bracket is arranged on the bottom surface of the inner cavity of the heating box, electric resistance heating pieces are arranged on the inner wall of the inner cavity of the heating box or both on the inner wall and on the top surface of the inner cavity of the heating box, a shear blade inlet is formed in the heating box, the shear blade inlet is provided with an openable door used for closing the shear blade inlet, a power switch is arranged on the outer surface of the heating box, and the electric resistance heating pieces are connected with the power switch. By the adoption of the heating device, the workload can be lightened, the shear blade replacement time is shortened, working efficiency is improved, and a traditional shear blade replacement method is changed; meanwhile, the blade of the shear can be evenly heated during heating, and thus the situation that the blade of the shear is scraped due to deformation caused by heating is avoided.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Separated type elastic buckle device for domestic appliance

Owner:WHIRLPOOL CHINA

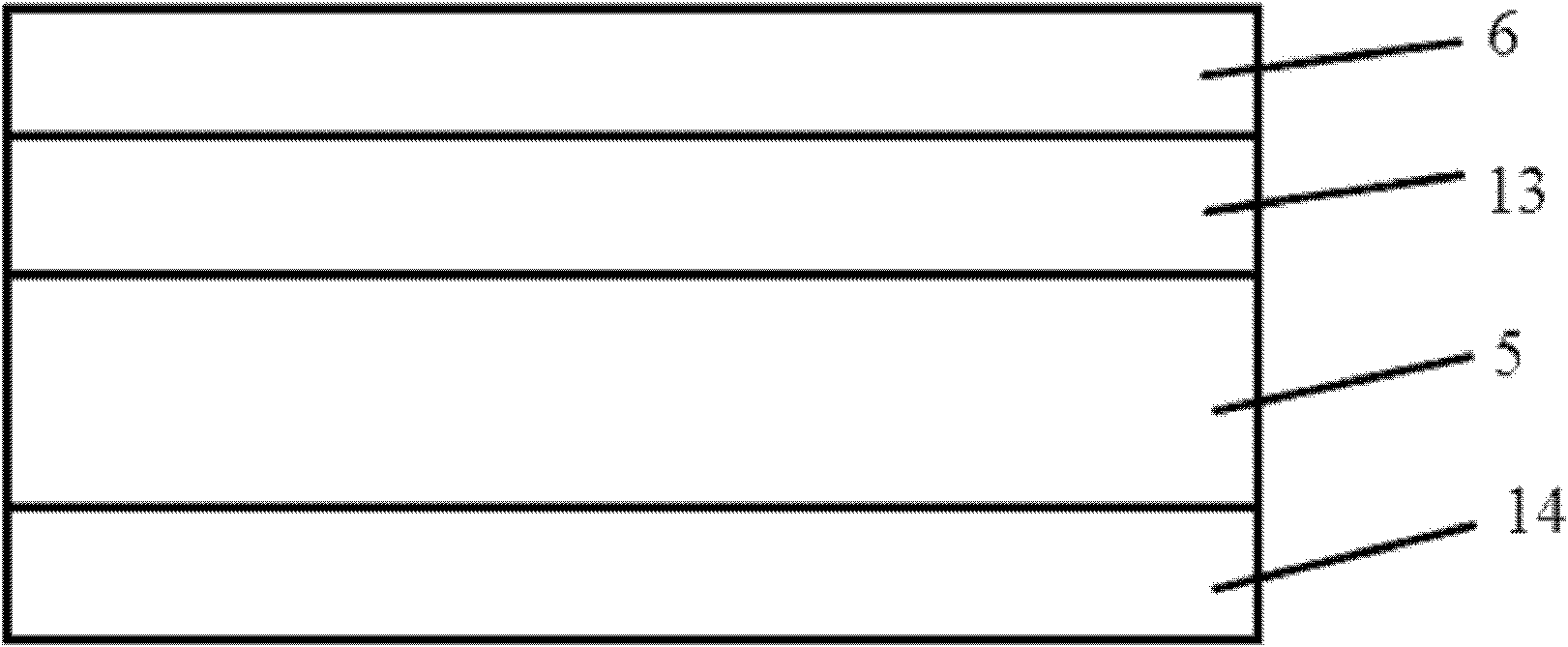

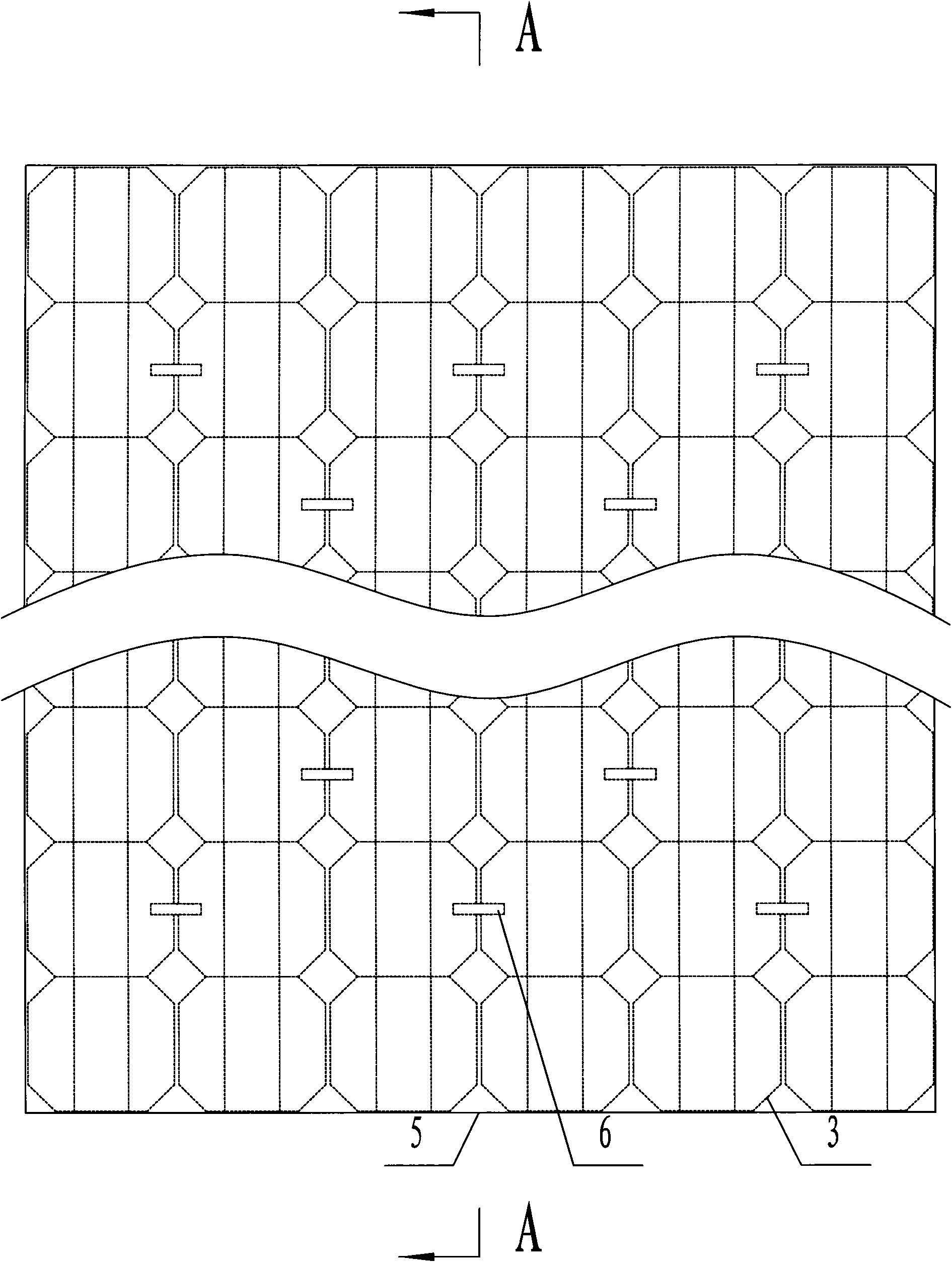

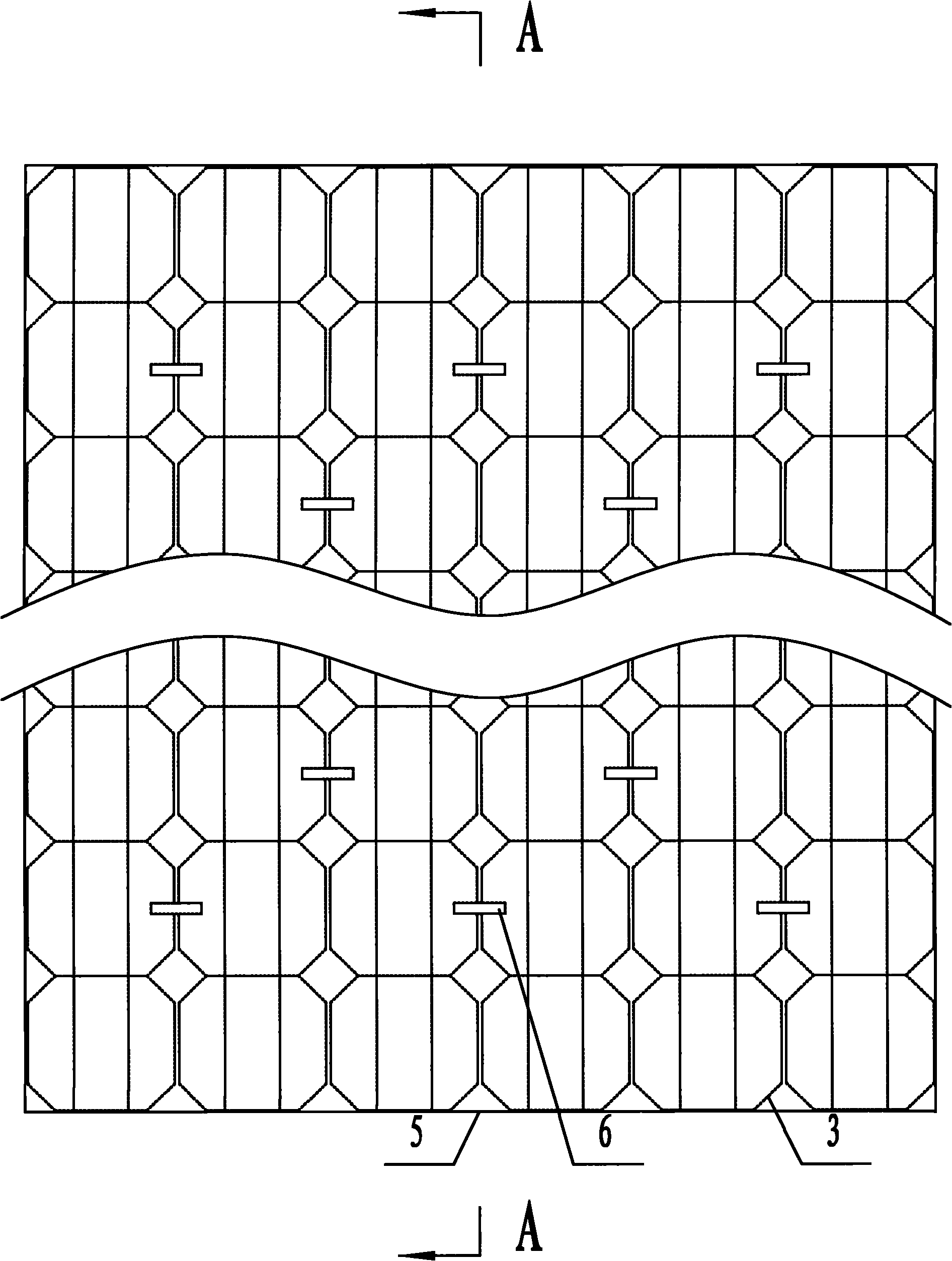

Structure of solar battery module

ActiveCN102064218AWill not cause scrapNot easy to shiftPhotovoltaic energy generationSemiconductor devicesLap jointEngineering

The invention relates to a structure of a solar battery module. The structure of the solar battery module comprises a back panel positioned at the bottom, wherein a lower ethylene-vinyl acetate copolymer (EVA) layer is positioned above the back panel; a battery string layer is positioned above the lower EVA layer; an upper EVA layer is positioned above the battery string layer; a toughened glass layer is positioned above the upper EVA layer; the battering string layer comprises at least two battery strings arranged adjacently; and a connecting body is in lap joint with a junction of the obverse sides or the reverse sides of the adjacent battery strings. The invention provides a production process of the solar battery module. In the process of transferring and laminating stacked modules, the battery strings are difficult to displace and the adjacent battery strings are not extruded with each other, so that the structure of the solar battery module cannot be scrapped.

Owner:苏州潞能能源科技有限公司

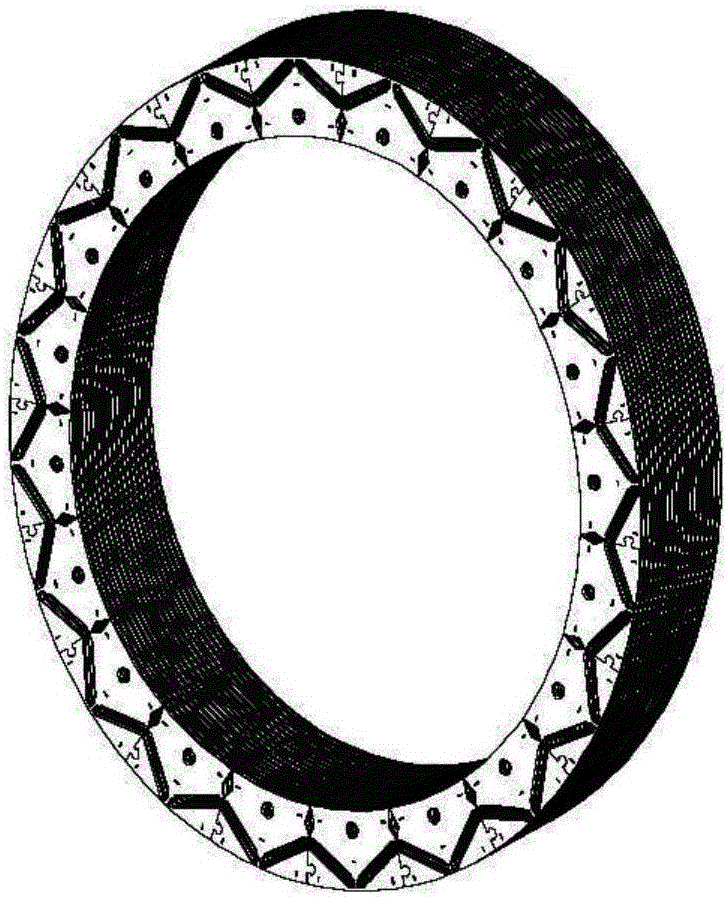

Permanent magnet motor rotor punching sheet assembling unit and assembled rotor

ActiveCN106169823AReduce wear and tearLow manufacturing process requirementsMagnetic circuit rotating partsPunchingRotor magnets

The invention discloses a permanent magnet motor rotor punching sheet assembling unit and an assembled rotor. Multiple assembling units are laminated to form blocks through self-pierce rivets, assembling unit laminated blocks are assembled with other same assembling unit laminated blocks through left-side bosses and right-side bosses of the assembling units so as to form an annular rotor magnet yoke. The permanent magnet motor rotor punching sheet assembling unit and the assembled rotor have the advantages that the size of the assembling unit is small, requirements of the manufacturing technique are relatively lower, a failure to manufacture the rotor punching sheet assembling unit will not cause scrapping of overall rotor punching sheets, and wastes can be largely reduced.

Owner:NINGBO XINDA ELEVATOR FITTINGS FACTORY

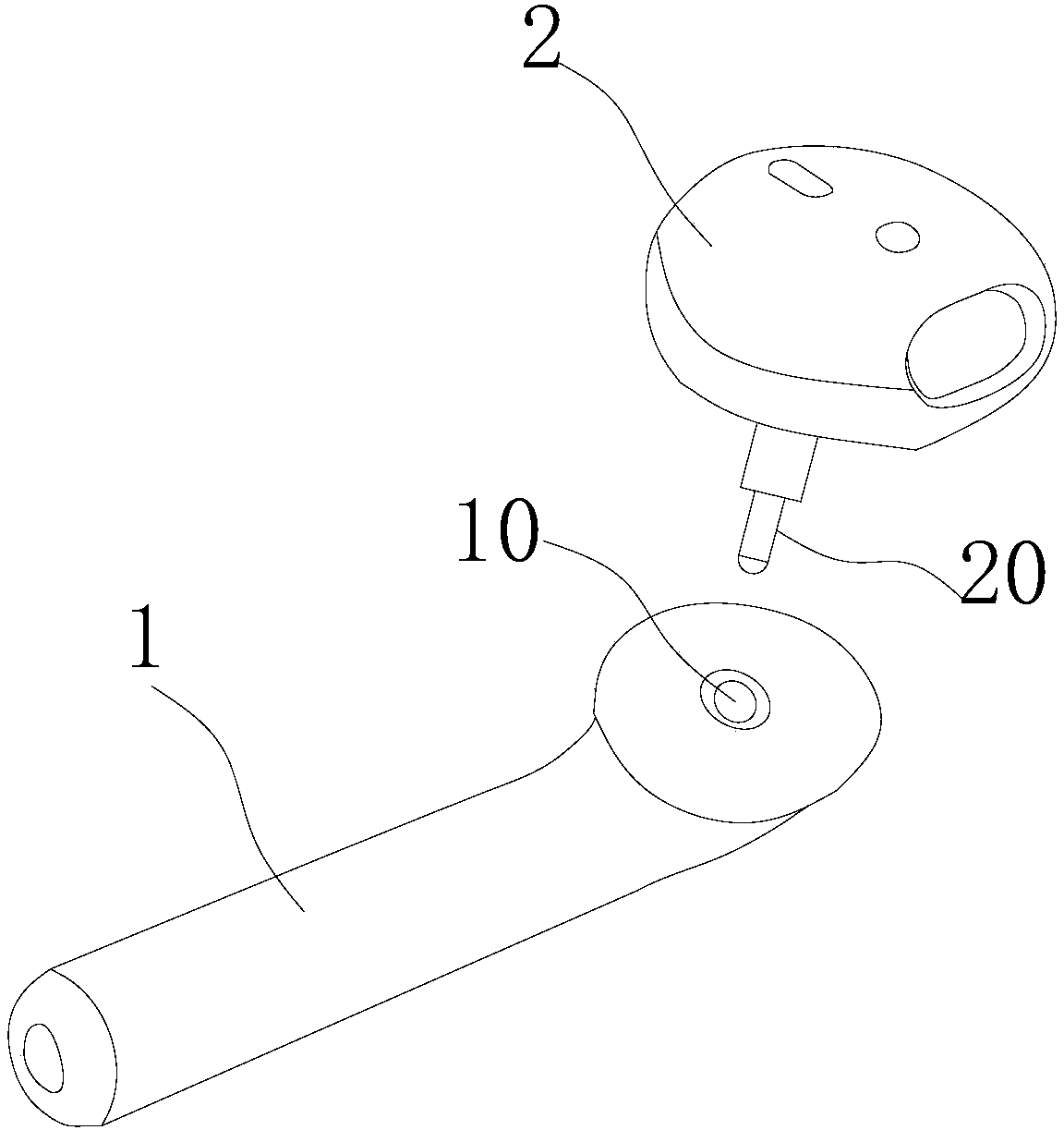

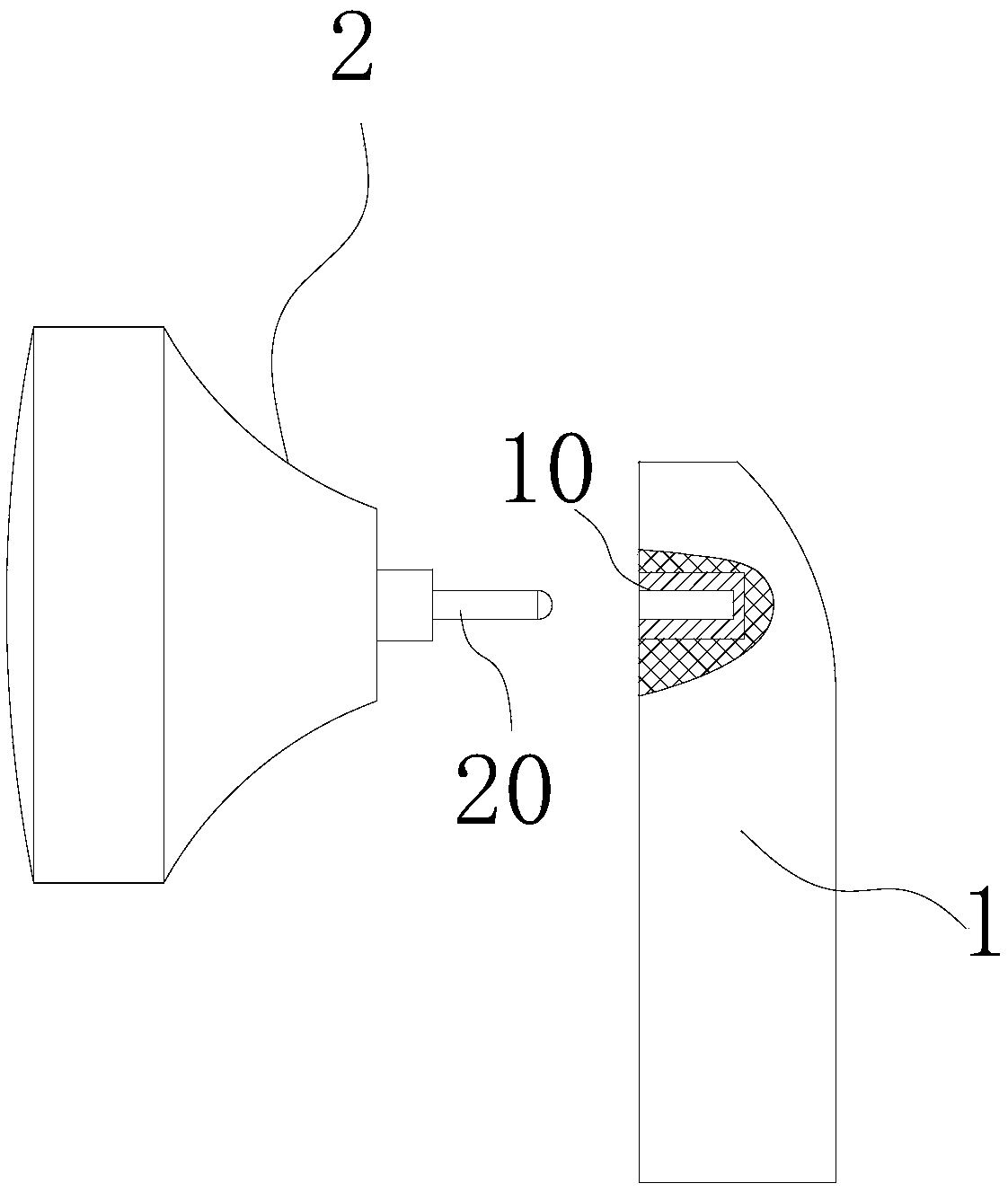

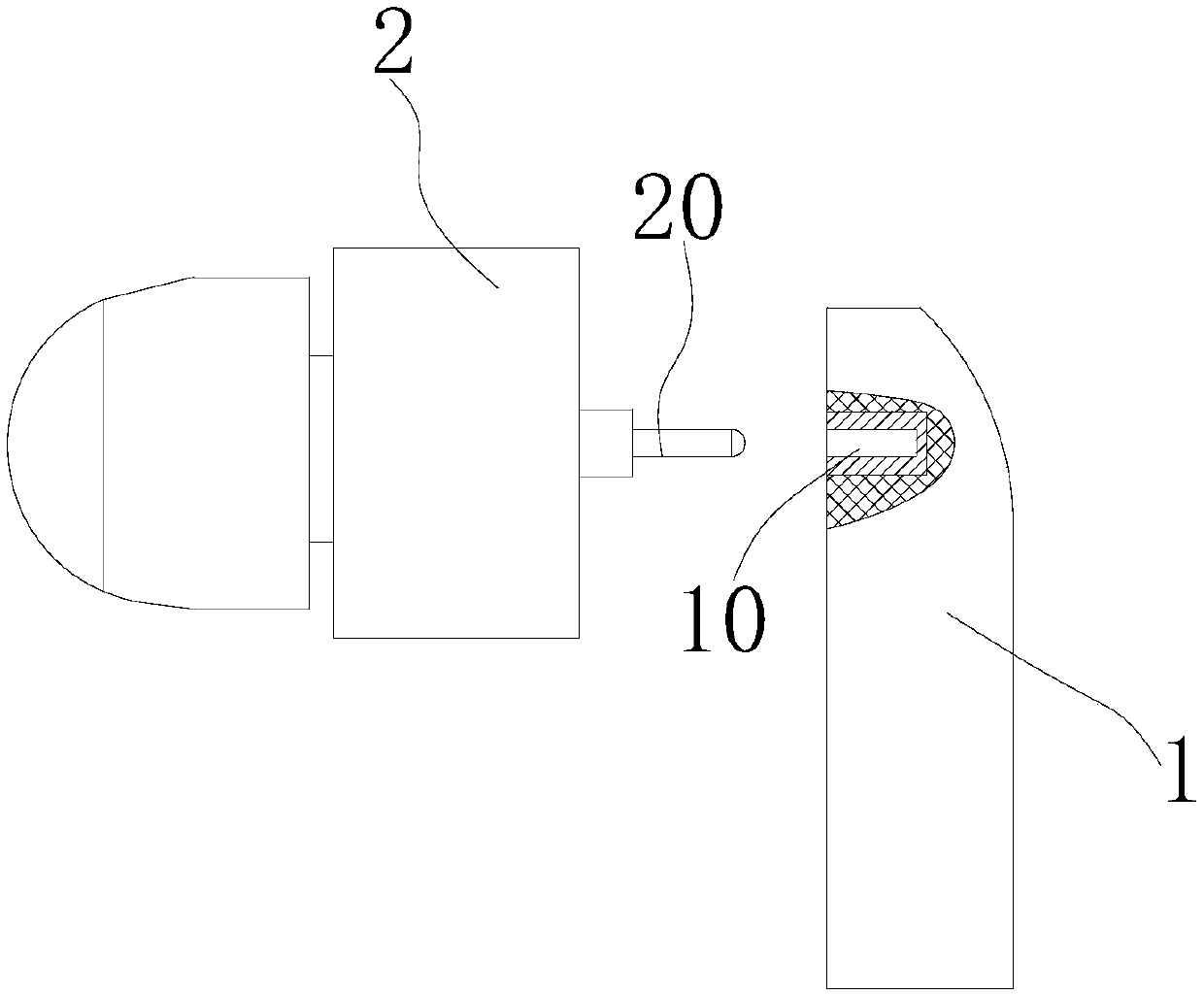

Multifunctional earphone with replaceable earphone head

PendingCN109640210AMeet the needs of useWill not cause scrapMicrophonesLoudspeakersEngineeringHeadphones

The invention discloses a multifunctional earphone with a replaceable earphone head, and particularly relates to the field of earphones. The multifunctional earphone with the replaceable earphone headcomprises an earphone body, wherein the earphone body can replace the earphone heads with different wearing modes. People can replace earphone heads with different wearing modes according to own needs, so that the different requirements of people can be met; after the earphone head or the earphone body is damaged, one of the earphone head and the earphone body can be replaced, so that the whole earphone cannot be scrapped; when a consumer purchases the earphone, the earphone heads with different wearing modes can be matched according to the own needs; the earphone body of one model can be produced and the earphone heads with different wearing modes can be matched in a production process of the earphone, so that the production cost can be reduced, and the production inventory can be reduced.

Owner:成都法兰特科技有限公司

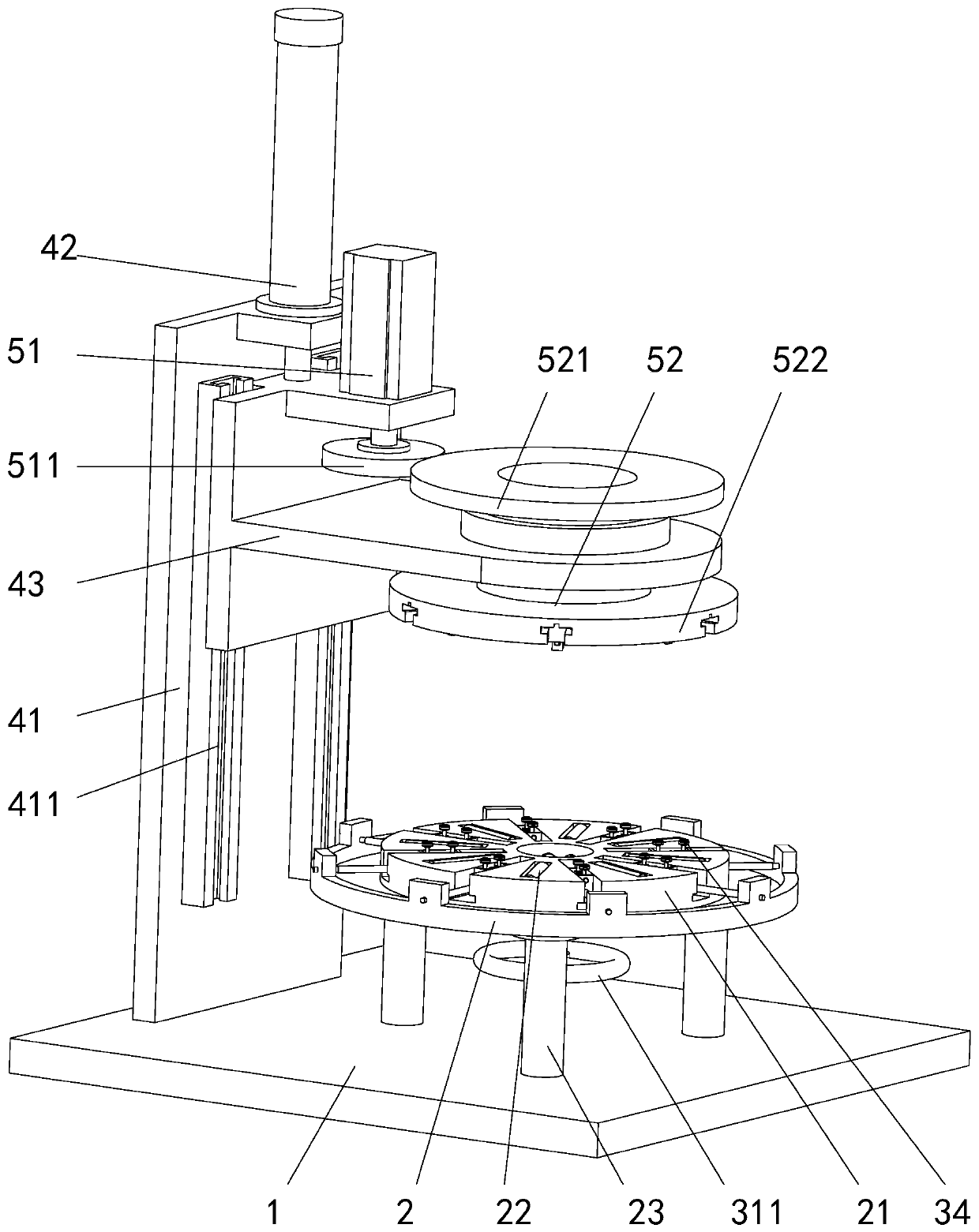

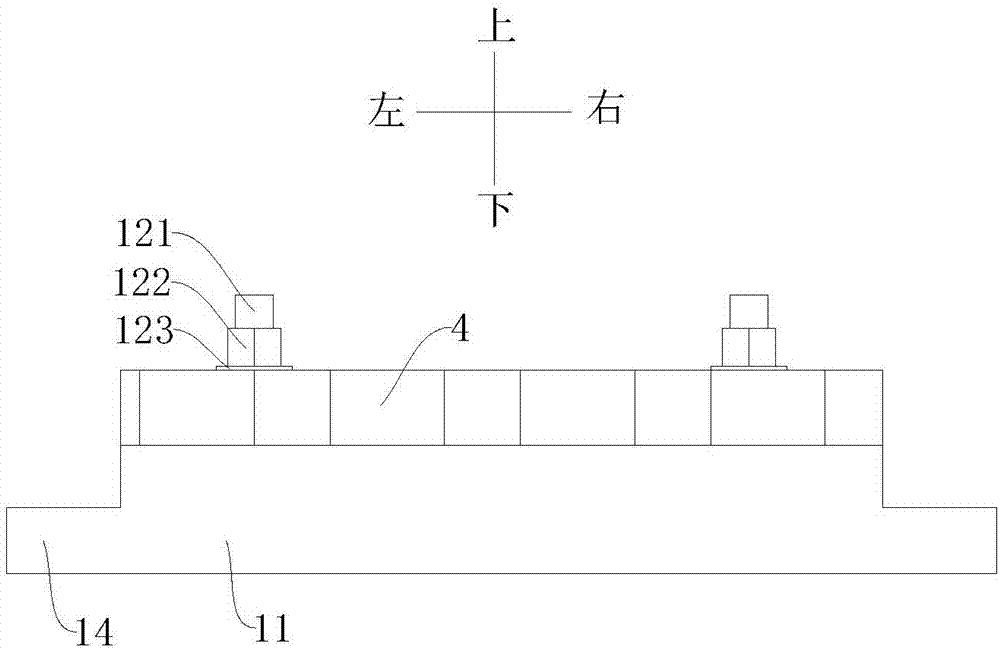

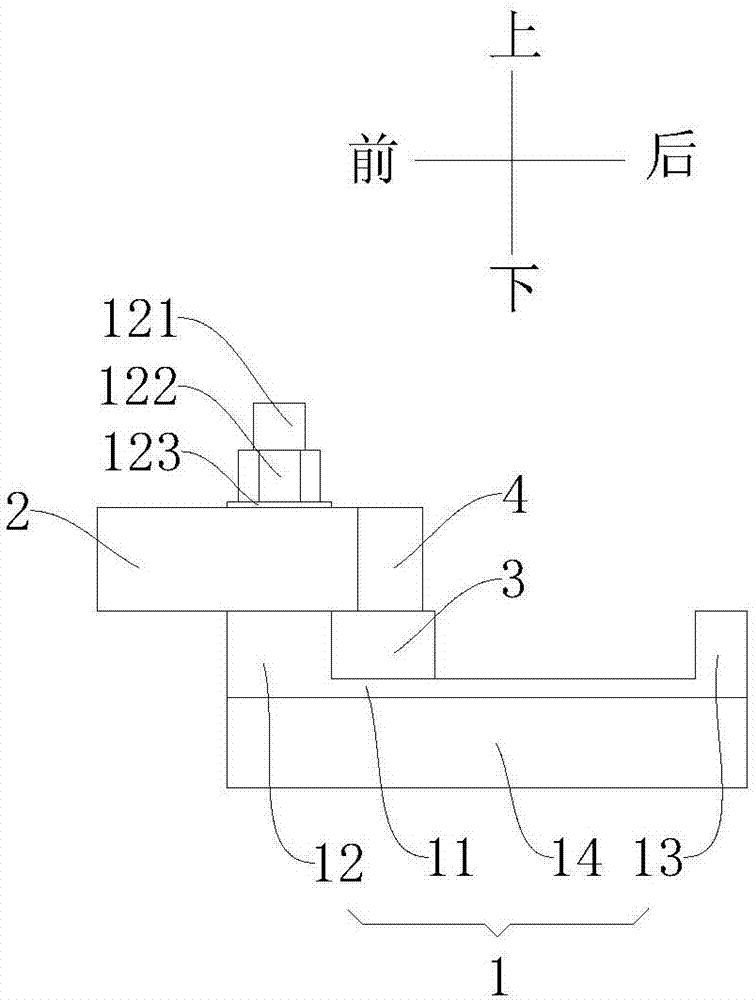

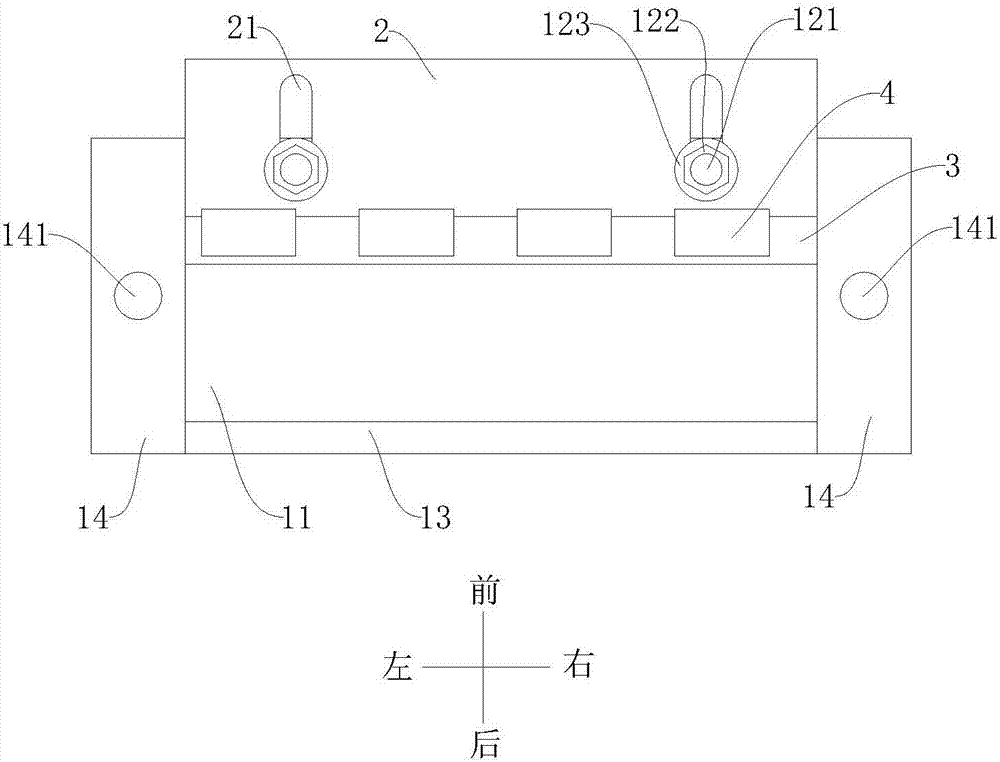

Positioning device for processing of motor magnetic sheets

PendingCN107297552APrecise positioningHigh precisionManufacturing stator/rotor bodiesElectrical-based auxillary apparatusElectric machineStructural engineering

The invention discloses a positioning device for processing of motor magnetic sheets. The positioning device is mounted on a workbench and comprises a lower support, an upper support and a processing plate. The lower support is of a square grooved structure and comprises a bottom plate, a first side board and a second side board; the first side board and the second side board are formed on two sides of the bottom plate integrally. The upper support is of a rectangular block structure. The upper support is fixedly connected with the lower support. The back end surface of the upper support is parallel to the internal side surfaces of the first side board and the second side board of the lower support, and is provided with clamp slots at intervals along the left to right direction. The processing plate is of a cuboid structure disposed in the square groove of the lower support; the front side surface and the back side surface of the processing plate are parallel with the internal side surfaces of the first side board and the second side board; the vertical height of the processing plate is not higher than the height of the first side board; the front side surface of the processing plate is abutted against the first side board. By the positioning device, the motor magnetic sheets can be positioned on the processing plate accurately; the products have high precision, scrap is avoided, resources are saved, and production cost is reduced.

Owner:徐州给力磁业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com