Airplane part reverse modeling method based on tangent plane mould line

A technology of cutting die line and reverse modeling, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of improving efficiency and accuracy, avoiding the image correction process, and simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

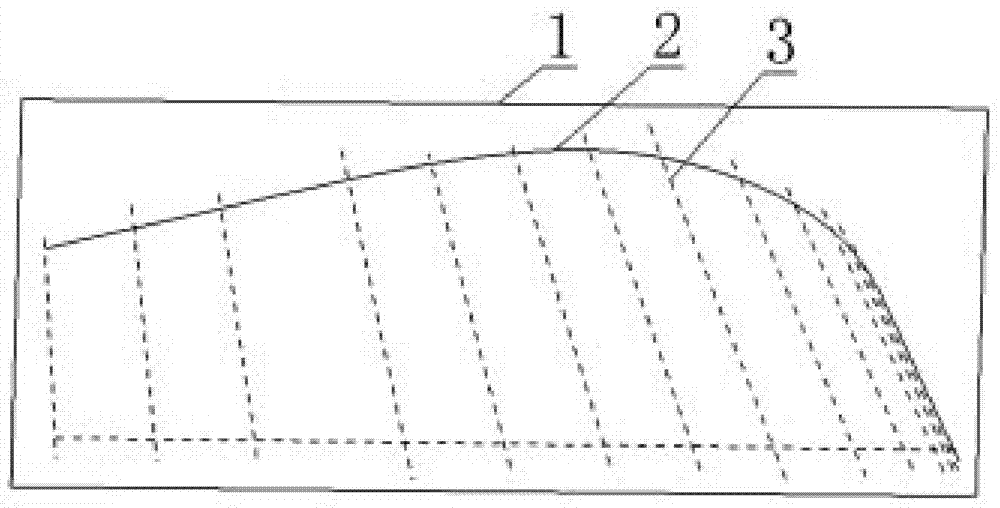

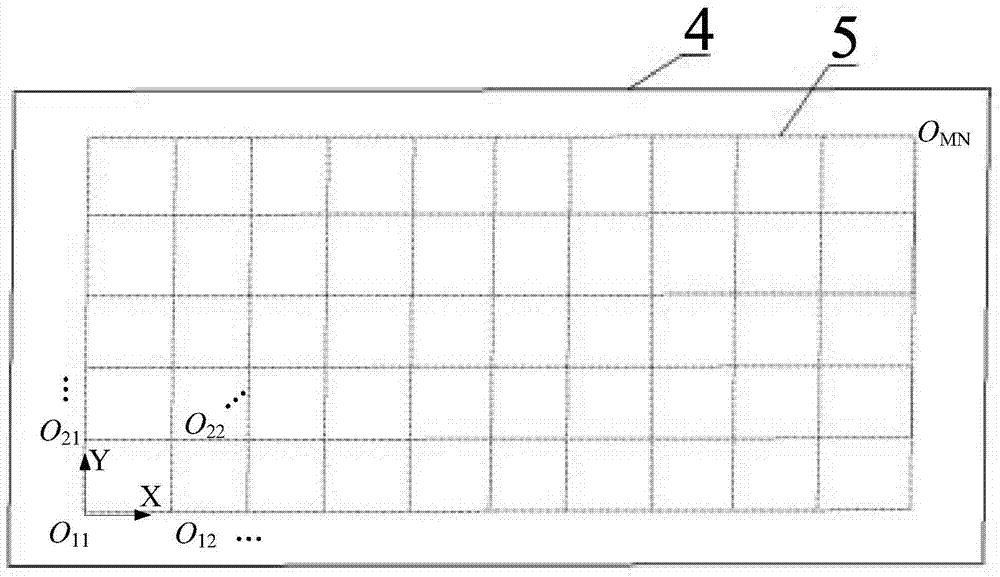

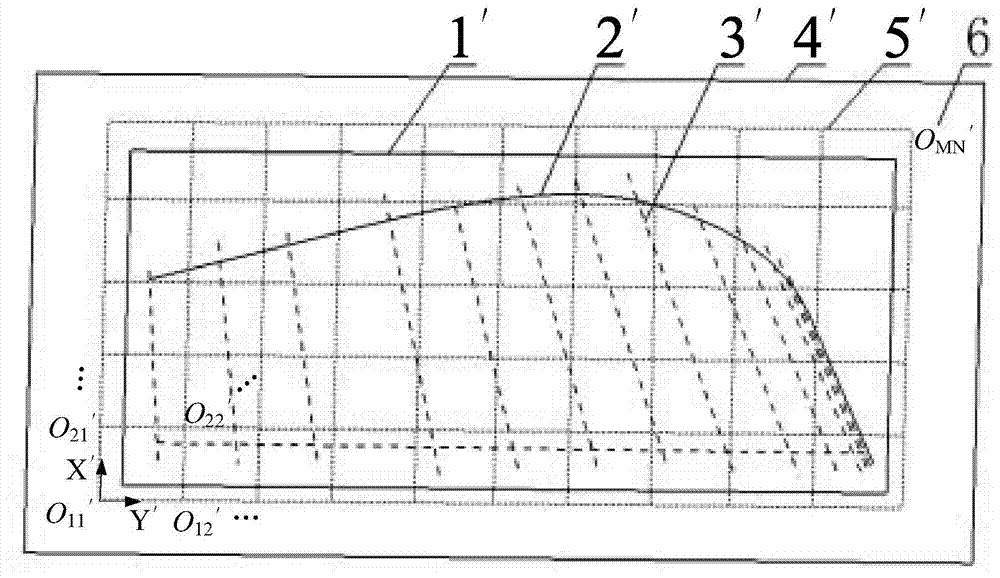

Method used

Image

Examples

Embodiment Construction

[0036] In order to realize the beneficial effects of the present invention, ensure that the established part entity digital model conforms to the existing production coordination relationship, and avoid the scrapping of existing tooling, the following principles should be followed in the process of implementing the present invention:

[0037] (1) The original definition remains unchanged. The reverse modeling process should fully respect the original design concepts and schemes, and should not destroy the boundary lines specified in the original aircraft part theory diagram, and should not destroy the original definition types of curves and surfaces.

[0038](2) The principle of unchanged coordination relationship. The established physical digital model of the part should conform to the existing production coordination relationship, and the shape of the part should be consistent with the relevant manufacturing basis and assembly state.

[0039] (3) The principle that the mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com