Modeling and compensation method of heat error of numerical control machine tool

A numerical control machine tool, thermal error technology, applied in simulators, program control, computer control, etc., can solve the problems of missing the best temperature measurement point, low stability, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

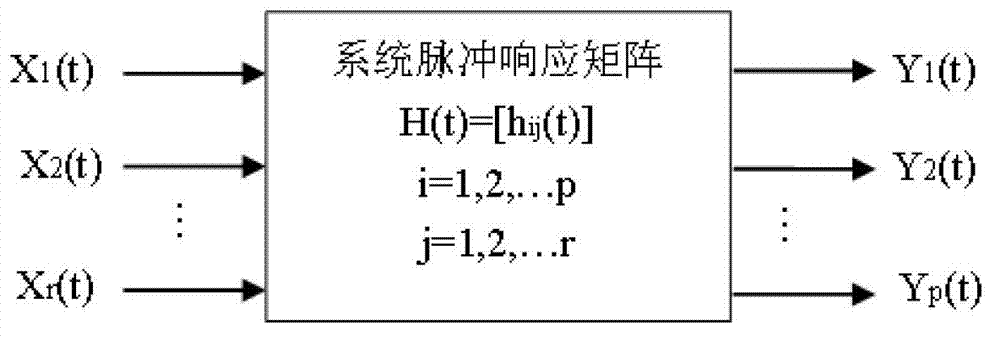

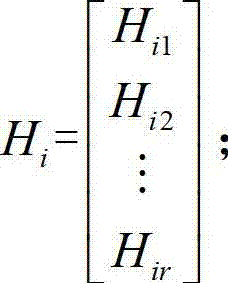

Method used

Image

Examples

Embodiment

[0055] Z-direction thermal error modeling analysis of a VMT80 CNC machining center turntable.

[0056] The infrared imager model is FLIR A315; the axial thermal expansion data of the machine tool turntable is collected by an eddy current displacement sensor (model DT3010-M / U05(09)); the temperature variable is collected by two surface magnetic adsorption temperature sensors (model MG- 22K-TS5-W); finally connect the signal conditioning circuit (model is HIOKI8423) and the computer to complete the data collection.

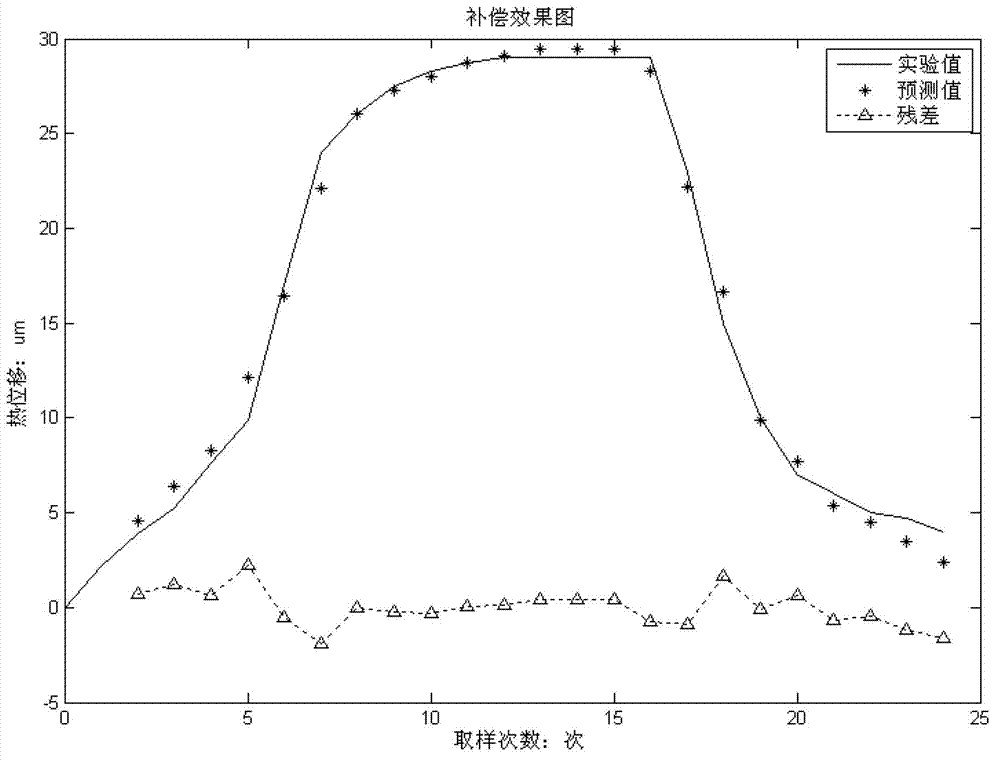

[0057] According to step 1, select the temperature measurement point of the machine tool, and install a temperature sensor at the bearing at the front end of the turntable; according to step 2, test various data and establish a thermal impulse response model of the turntable system; follow step 3, use the model established in step 2 to predict the thermal error of the turntable, and let the turntable Run at different speeds for a total of 3 hours, then stop the mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com