Patents

Literature

170 results about "Reverse modeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

What is Reverse Modeling. 1. Is the activity that allows you to generate a mathematical model from the scan of the actual item. The first step in the activity is the partial or total survey of the object to be reconstructed: this step acquires particular efficiency through the use of optical techniques for 3D contactless digitization.

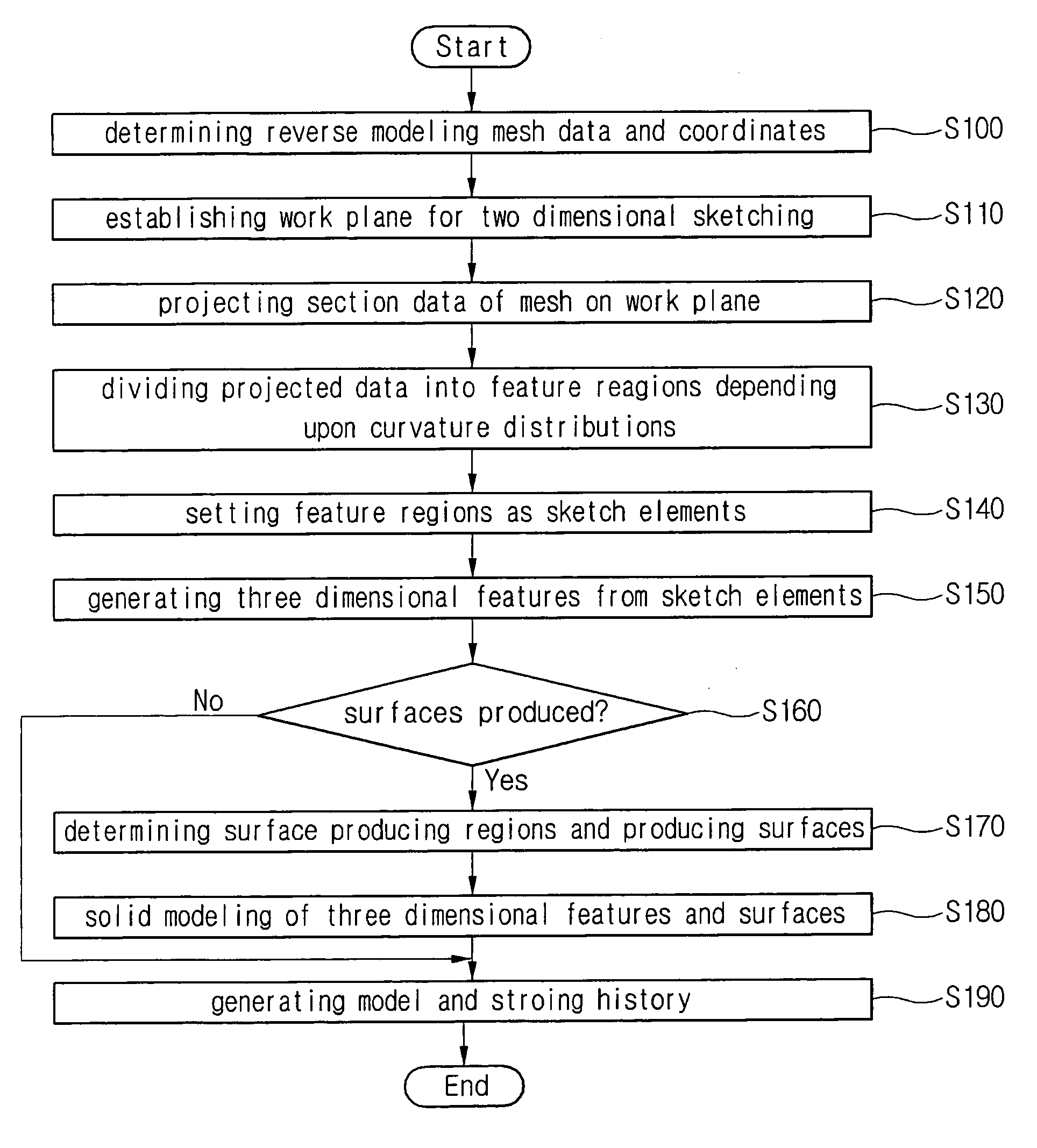

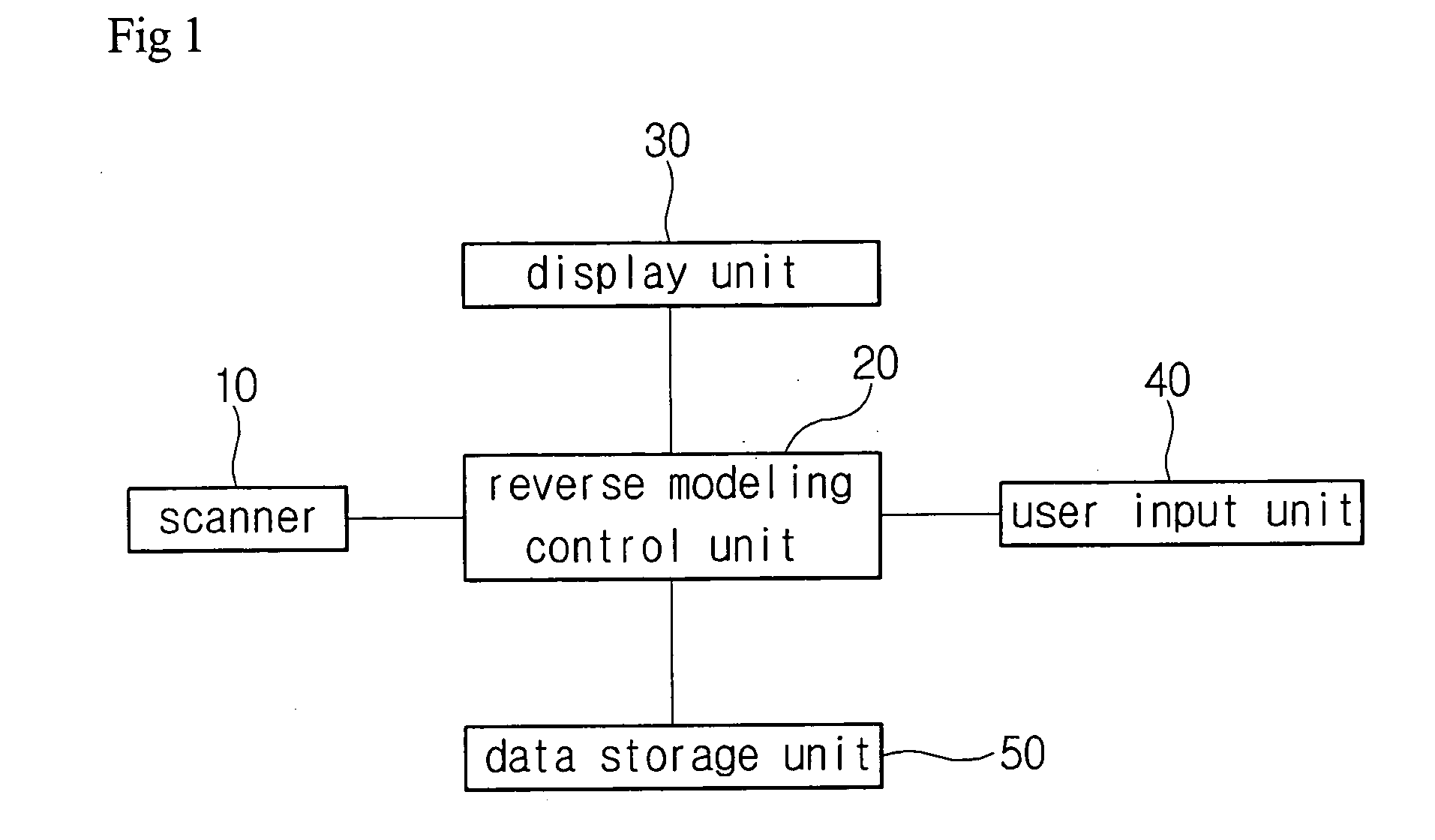

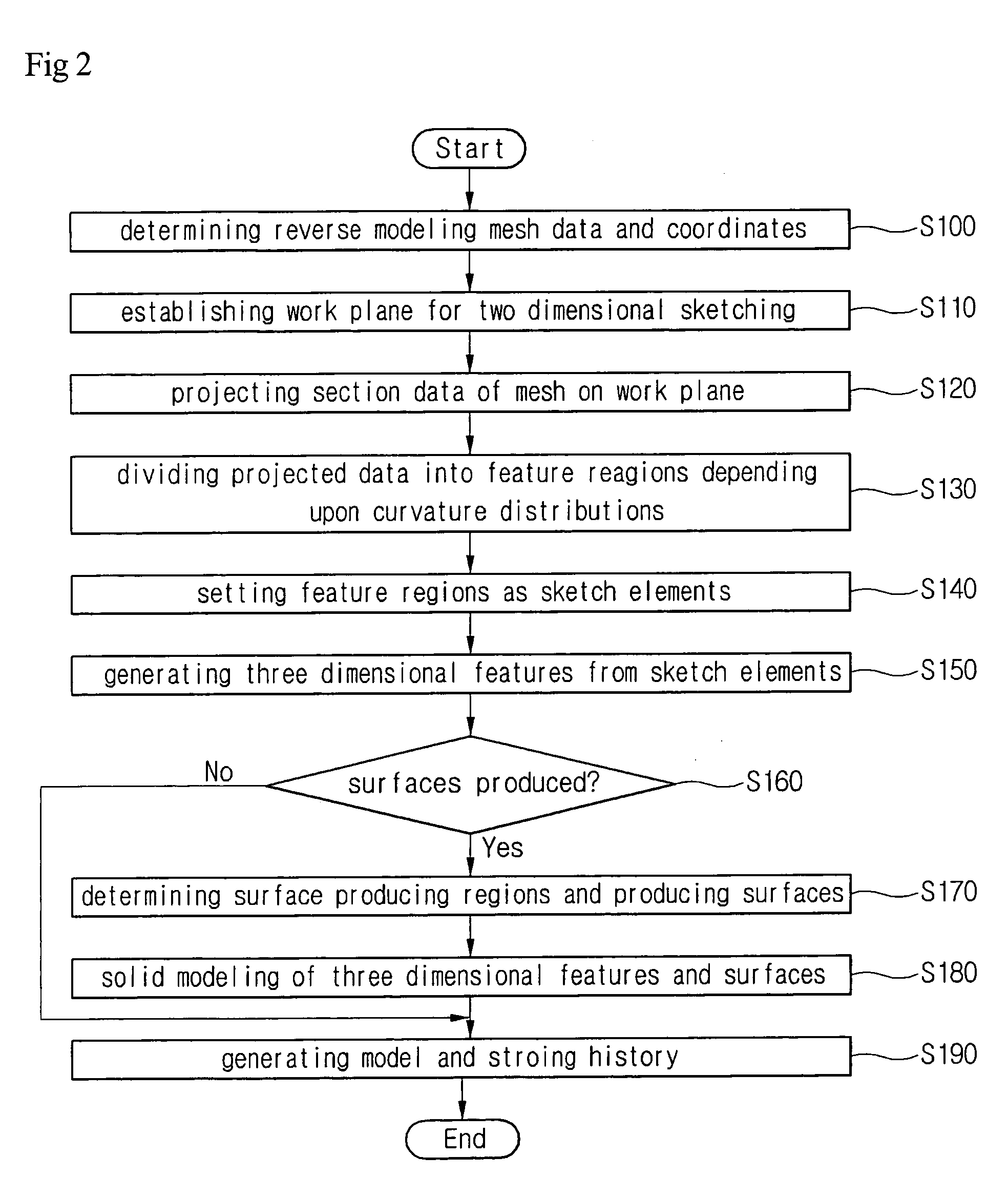

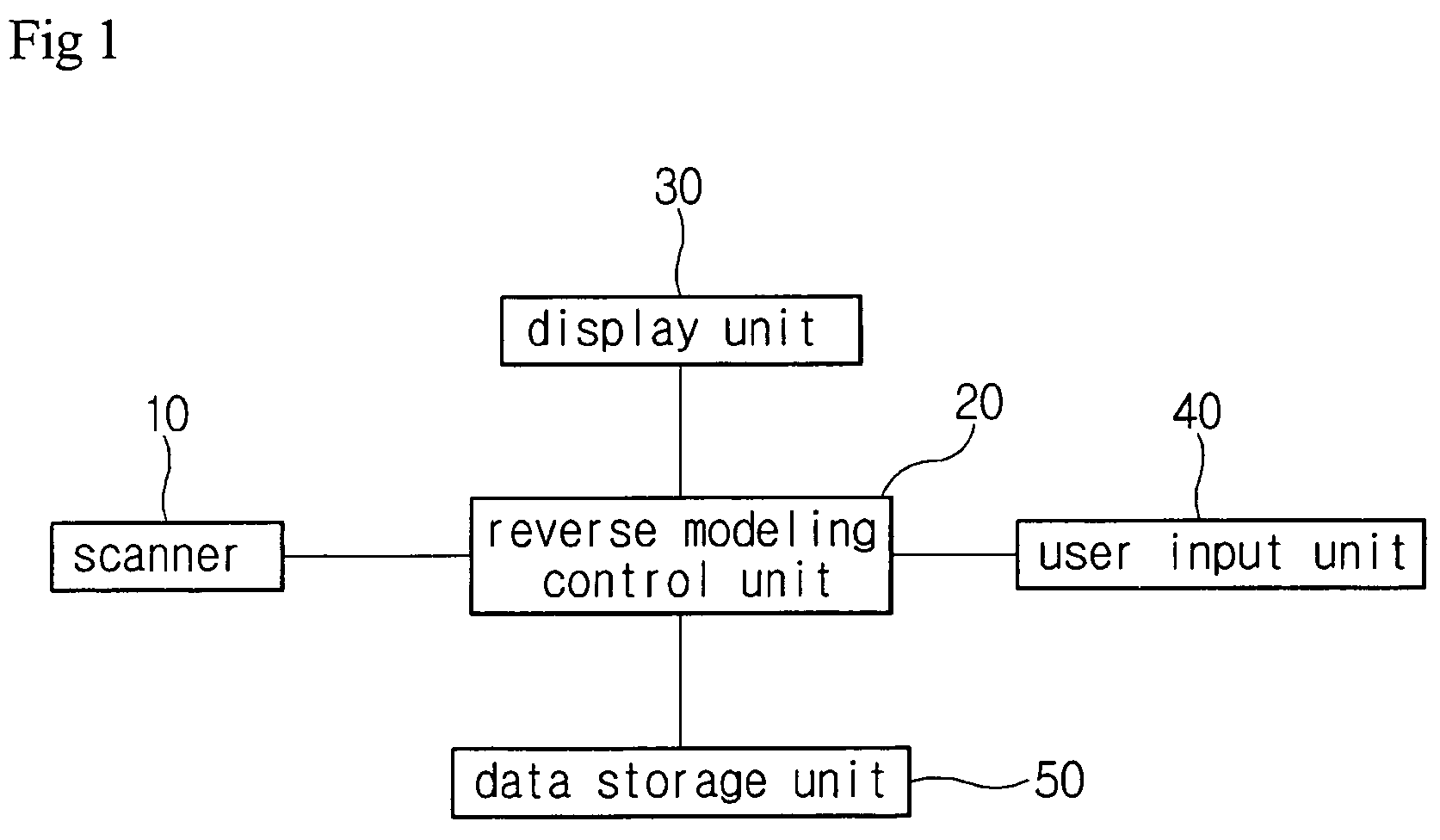

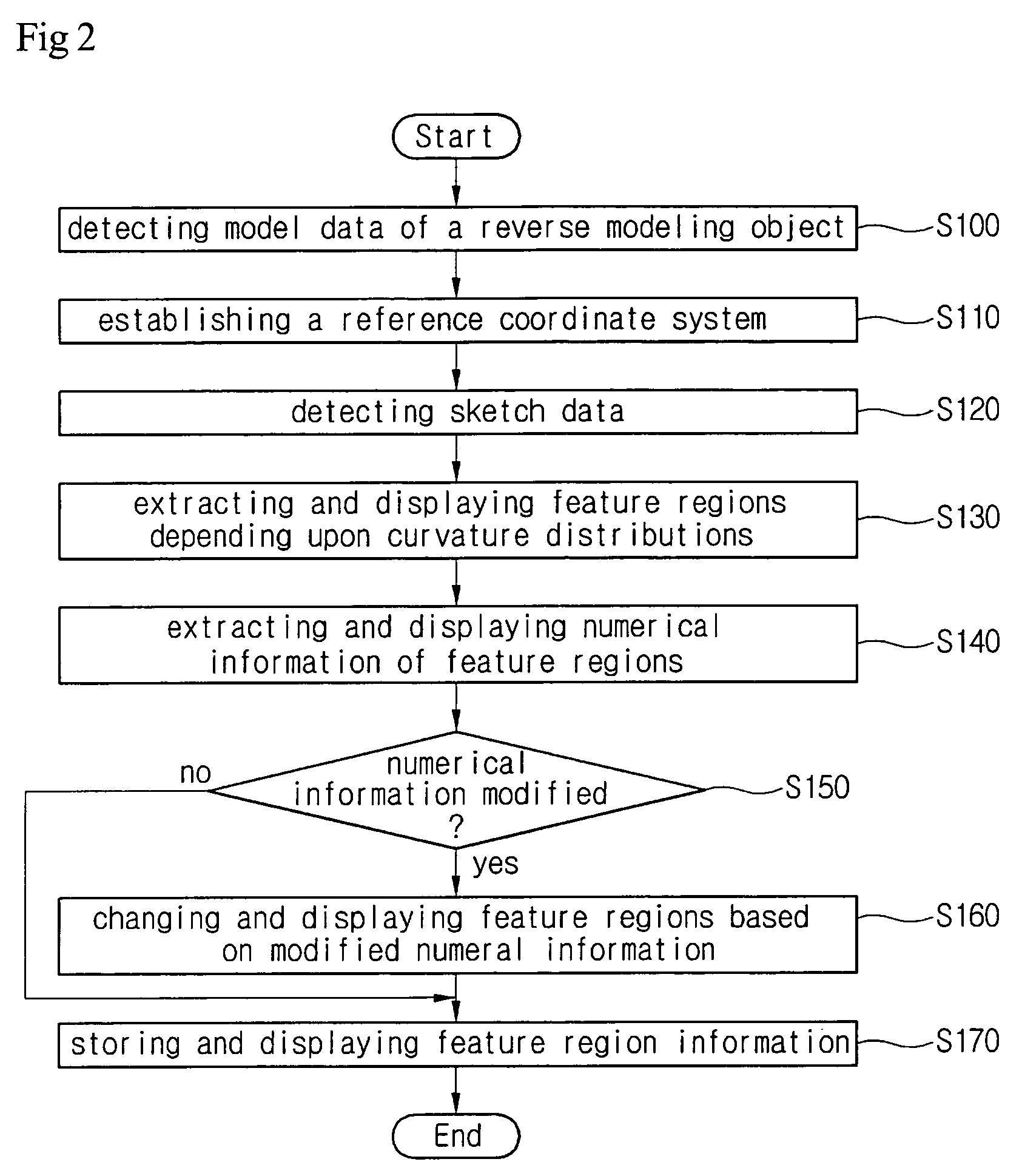

Reverse modeling method using mesh data as feature

InactiveUS20070285425A1Drawing from basic elementsComputer aided designComputer graphics (images)Reverse modeling

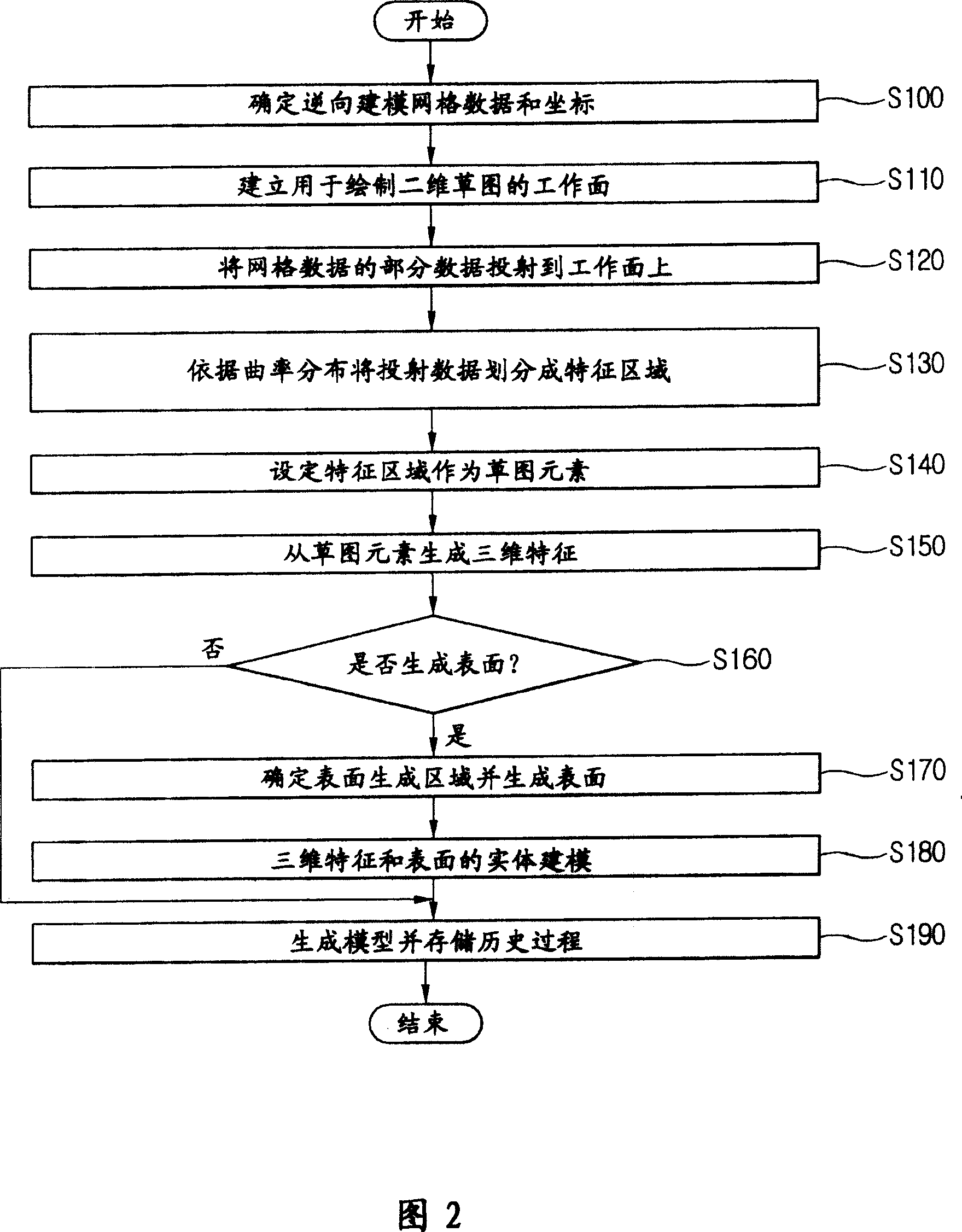

A reverse modeling method using mesh data as a feature to allow reverse modeling to be conducted by following a procedure of an original designer includes the steps of detecting optional model data, setting the model data as a feature, and establishing a reference coordinate system of set mesh data; establishing a work plane on which a sketch of the set mesh data can be projected; projecting section data of the mesh data on the work plane; dividing data projected on the work plane into feature segments depending upon curvature distributions, and producing divided segments as sketch data; and producing a three dimensional feature from the sketch data which corresponds to a shape of the mesh data, and storing the produced three dimensional feature as model data, wherein the produced sketch data and three dimensional feature are parametrically connected with each other.

Owner:INUS TECH

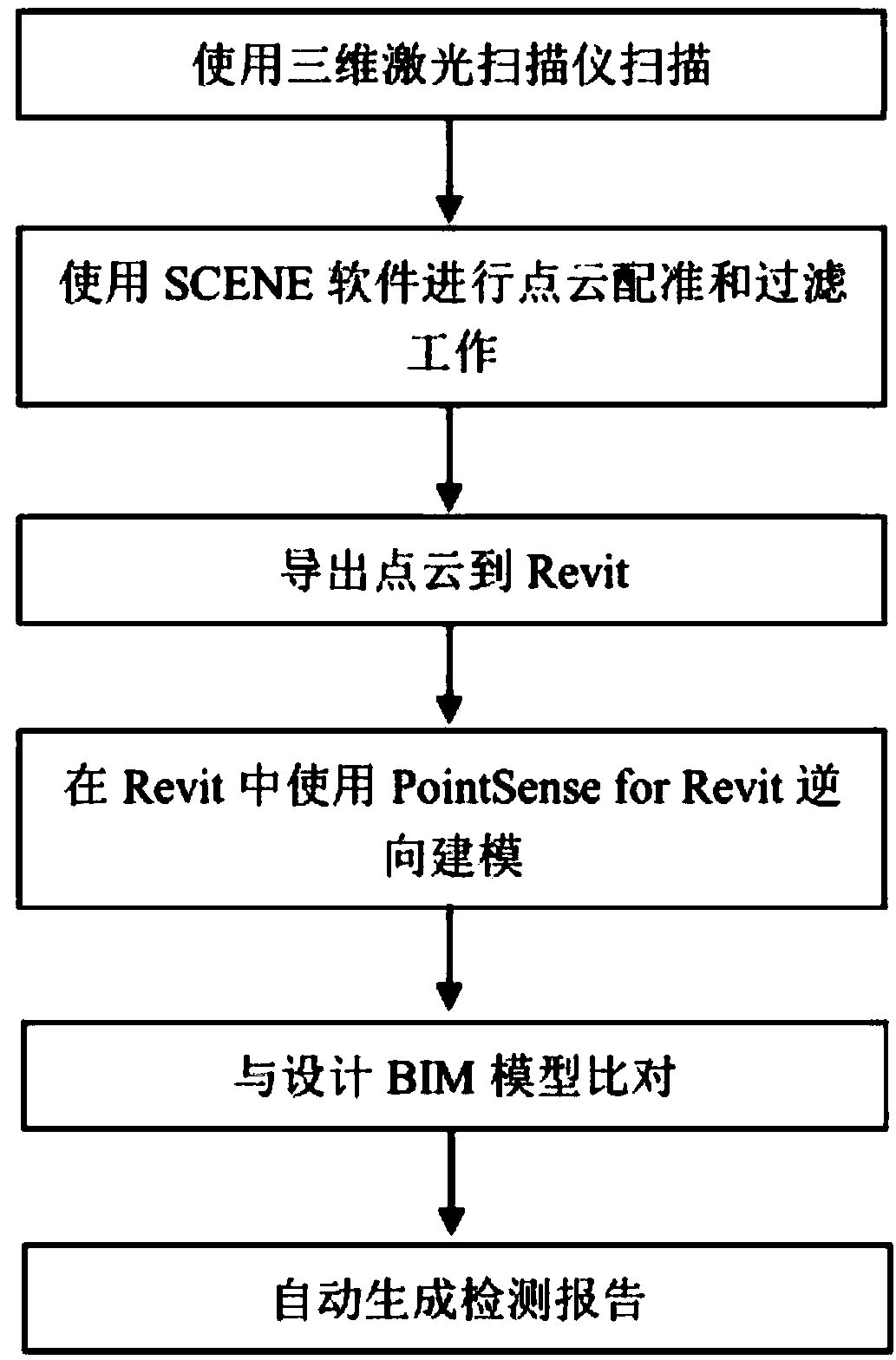

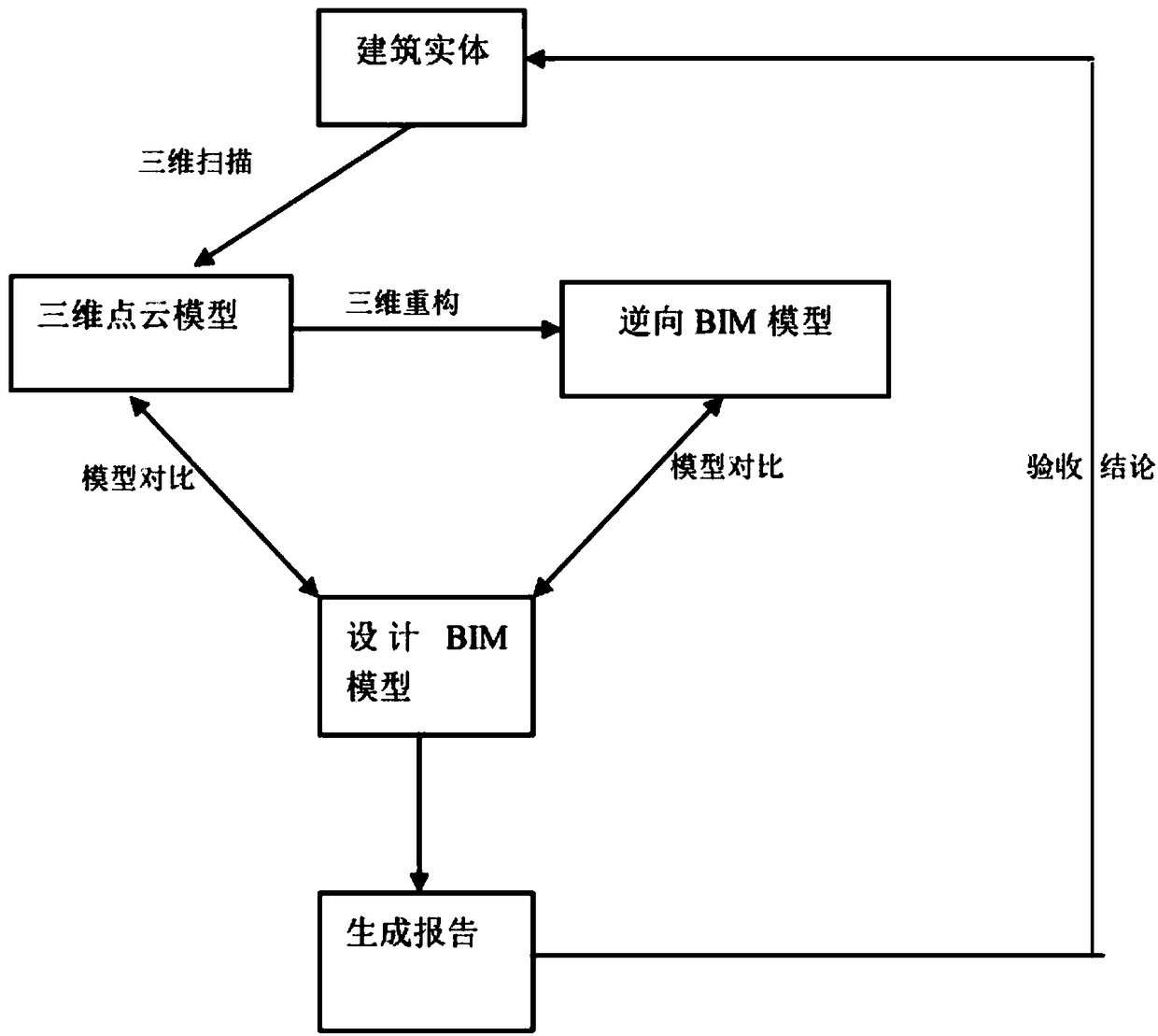

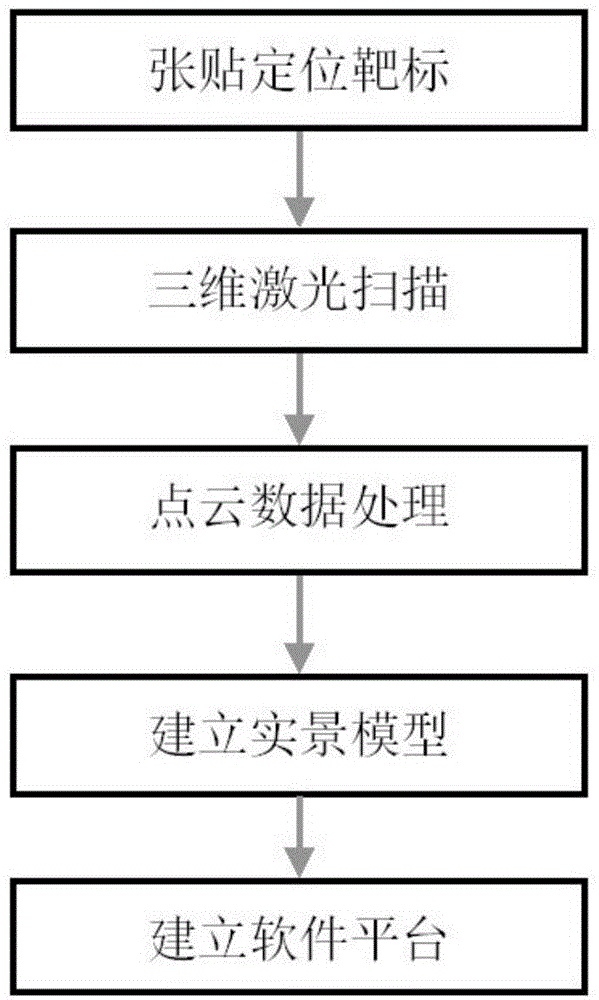

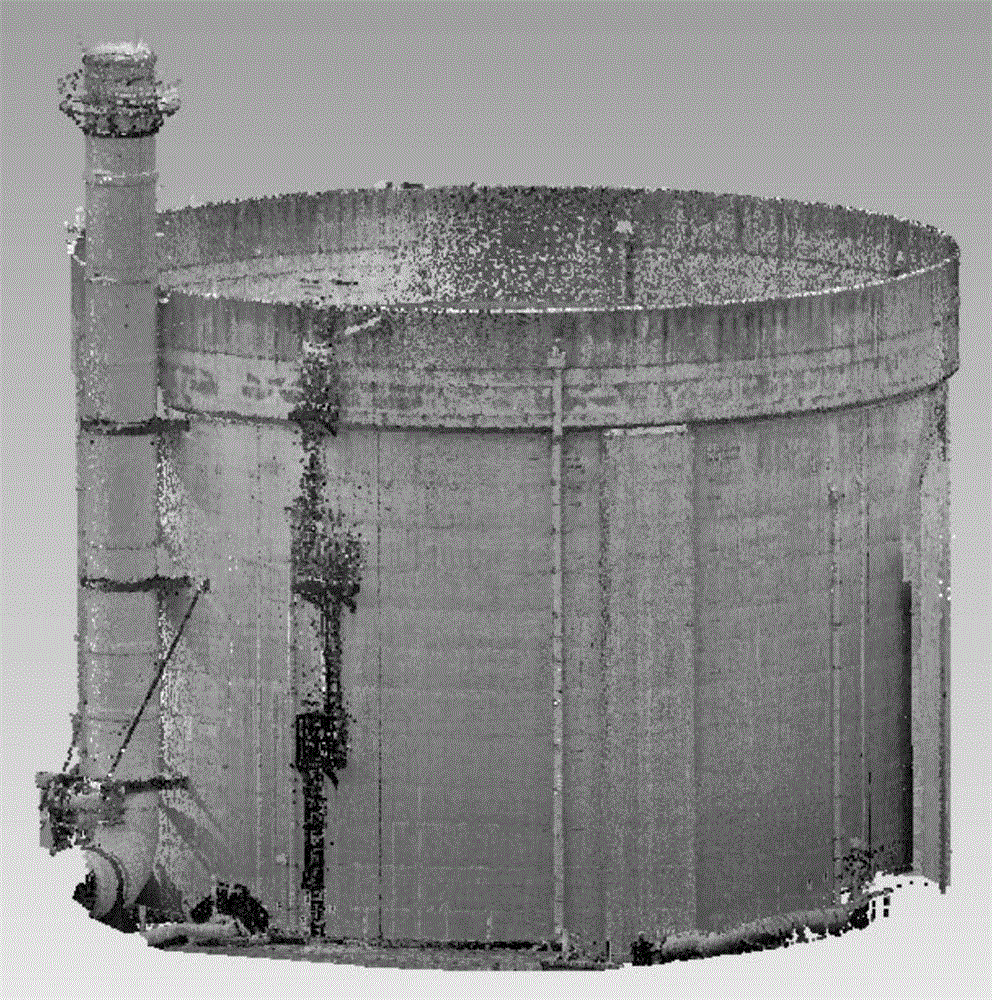

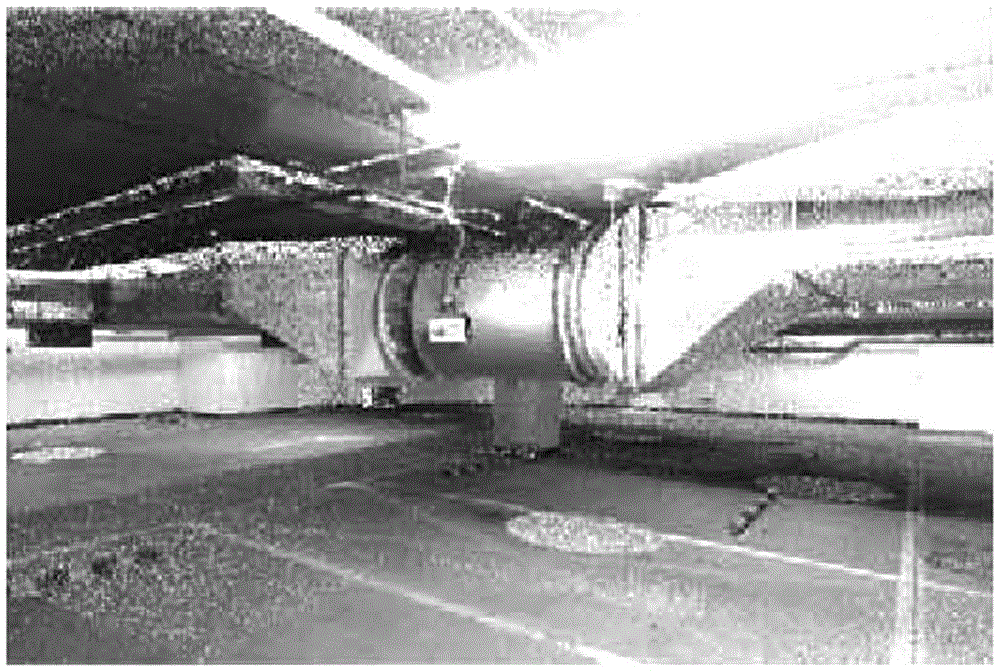

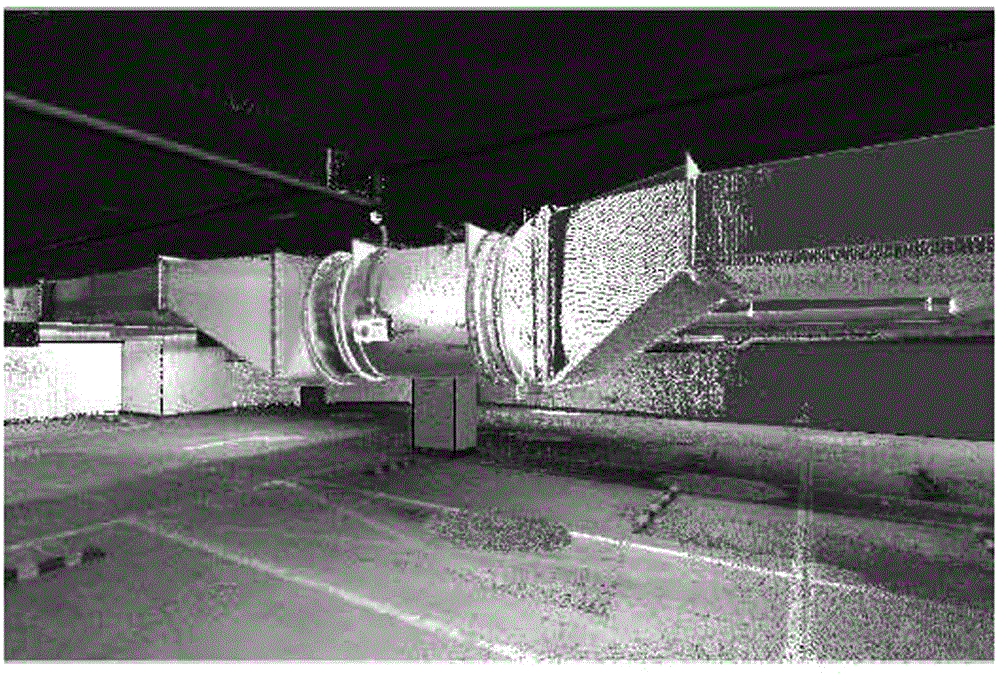

Application of modeling reverse engineering technology based on laser scanning in construction supervision

InactiveCN108090284AAccurate analysisQuality improvementGeometric CADSpecial data processing applicationsPoint cloudQuality control

The invention discloses application of a modeling reverse engineering technology based on laser scanning in construction supervision. The technology comprises the steps that a supervision station is built, scanning parameters are set, the supervision station is spliced, point cloud data is processed, the earthwork volume is calculated, the quality is controlled, and concealed works and completiondata of a project are subjected to supervision operation such as three-dimensional digitizing archiving by using digital scanning modeling reverse engineering. According to the application, traditional construction supervision means are improved, three-dimensional laser scanning and reverse modeling are applied to the construction supervision process, a supervision engineer can conduct three-dimensional scanning and reverse BIM modeling on building entities, models of reverse BIM modeling are compared with models of design BIM modeling, data analysis is conducted, problems or deviations in theconstruction process are discovered, modification is conducted in time, supervision analysis is more accurate, and the management quality and the project management efficiency are improved.

Owner:建基工程咨询有限公司

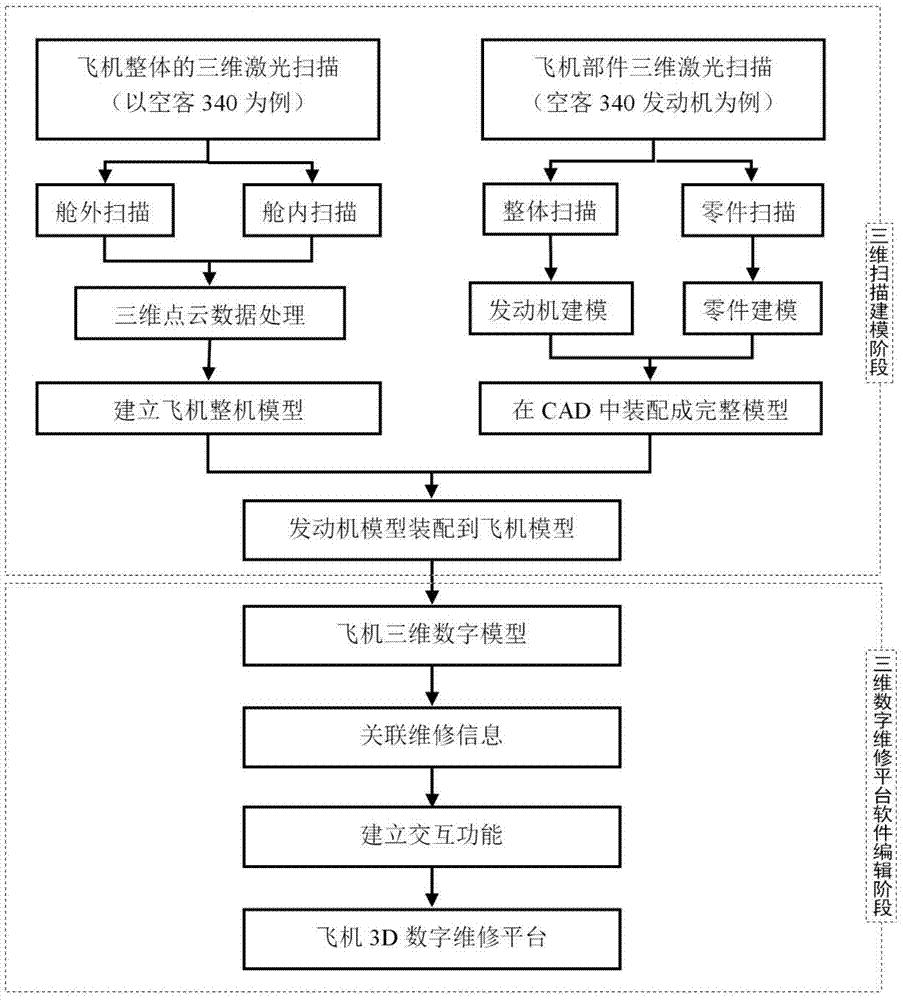

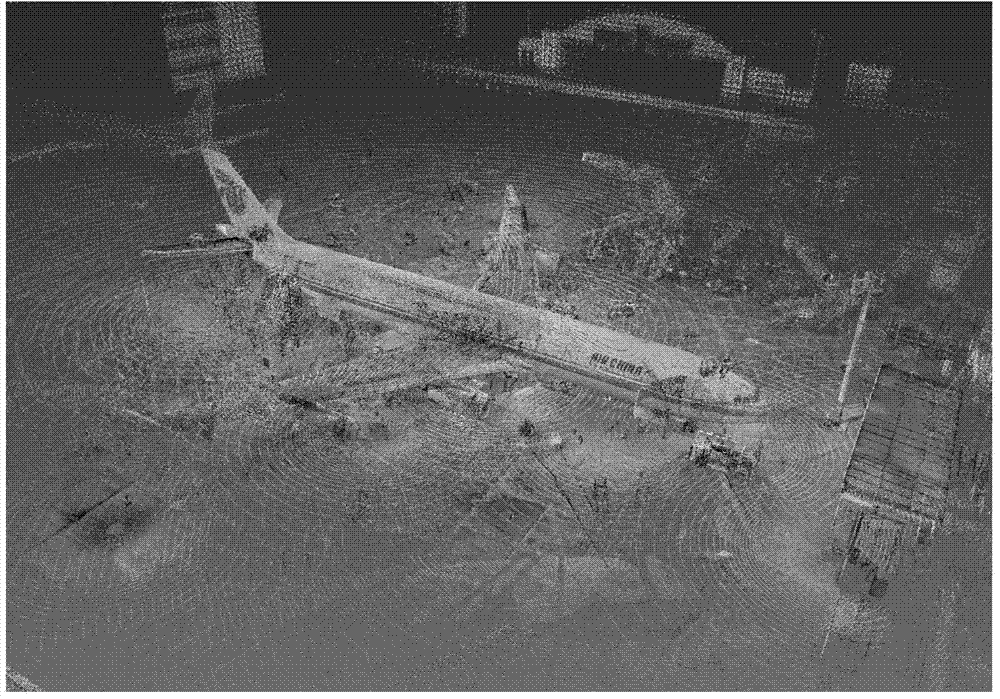

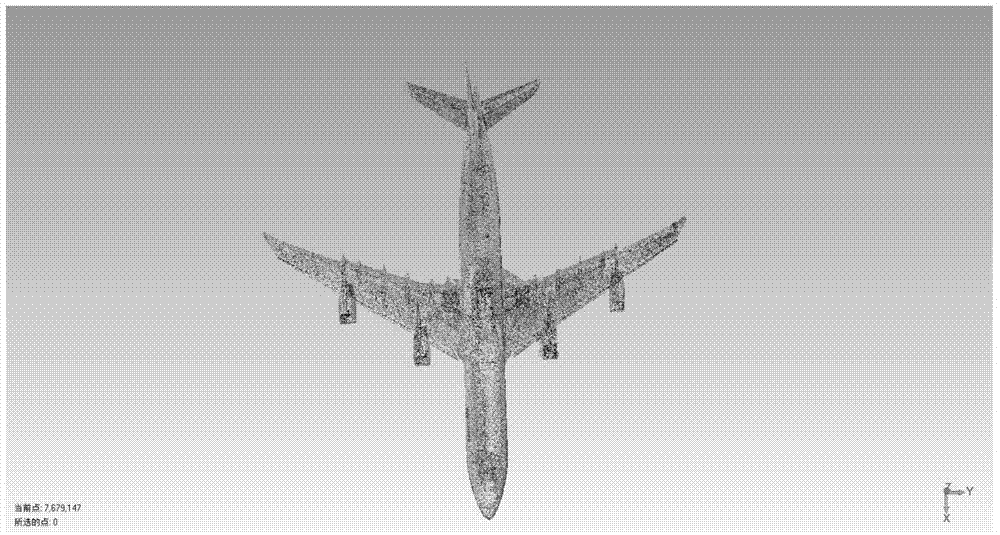

Method for establishing 3D digital maintenance platform of aircraft based on 3D laser scanning technology

InactiveCN104778742AIncrease valueNon-contactSpecial data processing applications3D modellingInformatizationSimulation

The invention relates to a method for establishing a digital maintenance platform of an aircraft based on a real 3D space point cloud by using a 3D laser scanning technology and a reverse modeling technology. The method disclosed by the invention comprises the following steps: firstly, obtaining point cloud data of the aircraft and parts thereof through a 3D laser scanner, and then on the basis of the point cloud data, generating the 3D digital model through data processing and reverse modeling. Based on the 3D digital model, a set of visualized operational software platforms in butt joint with the maintenance work of the aircraft is established, so that massive maintenance information can be related and integrated, and efficient convenient interactive functions can be established. The aircraft model data in the method is the real 3D point cloud information of the aircraft, and the aircraft model data can be used as maintenance information storage and maintenance interactive platforms and can complete space measurement, drawing extraction, staff training, maintenance simulation and the like in software, so that the aircraft maintenance work is greatly improved in the respects of digitalization, informatization, intelligentization and visualization.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

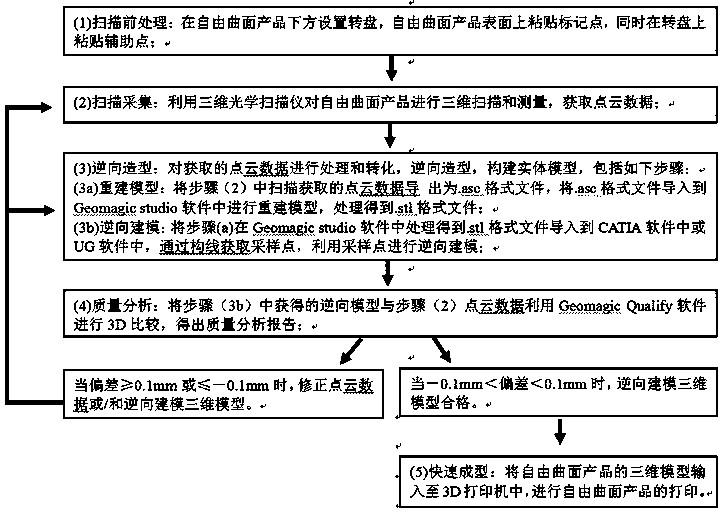

Free curved surface product reverse engineering modeling prototyping method based on three-dimensional optical scanning

InactiveCN107818590ALight and dark effects are smallHigh speed3D modellingPoint cloudOptical scanners

The invention discloses a free curved surface product reverse engineering modeling prototyping method based on three-dimensional optical scanning. The free curved surface product reverse engineering modeling prototyping method based on three-dimensional optical scanning includes over-scanning, reverse modeling, quality analysis, rapid prototyping, and printing of the final three-dimensional model,and is characterized by pasting mark points on the front and back surfaces of a free curved surface product and setting a rotating disk at the same time, realizing integrity and accuracy of scanningby means of auxiliary paste points on the rotating disk, utilizing a non-contact three-dimensional optical scanner to easily scan the full view of a multi-curved-surface product at higher speed, afterreverse modeling, utilizing Geomagic Qualify software to perform 3D comparison of the sampling point on the obtained reverse model and the point cloud data in the step (2), and according to the analysis and comparison situation, continuously correcting and scanning the point cloud data or the reverse three-dimensional model, so that the free curved surface product reverse engineering modeling prototyping method based on three-dimensional optical scanning has the advantages of guaranteeing the quality of the output product, improving the work efficiency, being low in the product quality reworkrate and saving printing of consumables.

Owner:童和平 +1

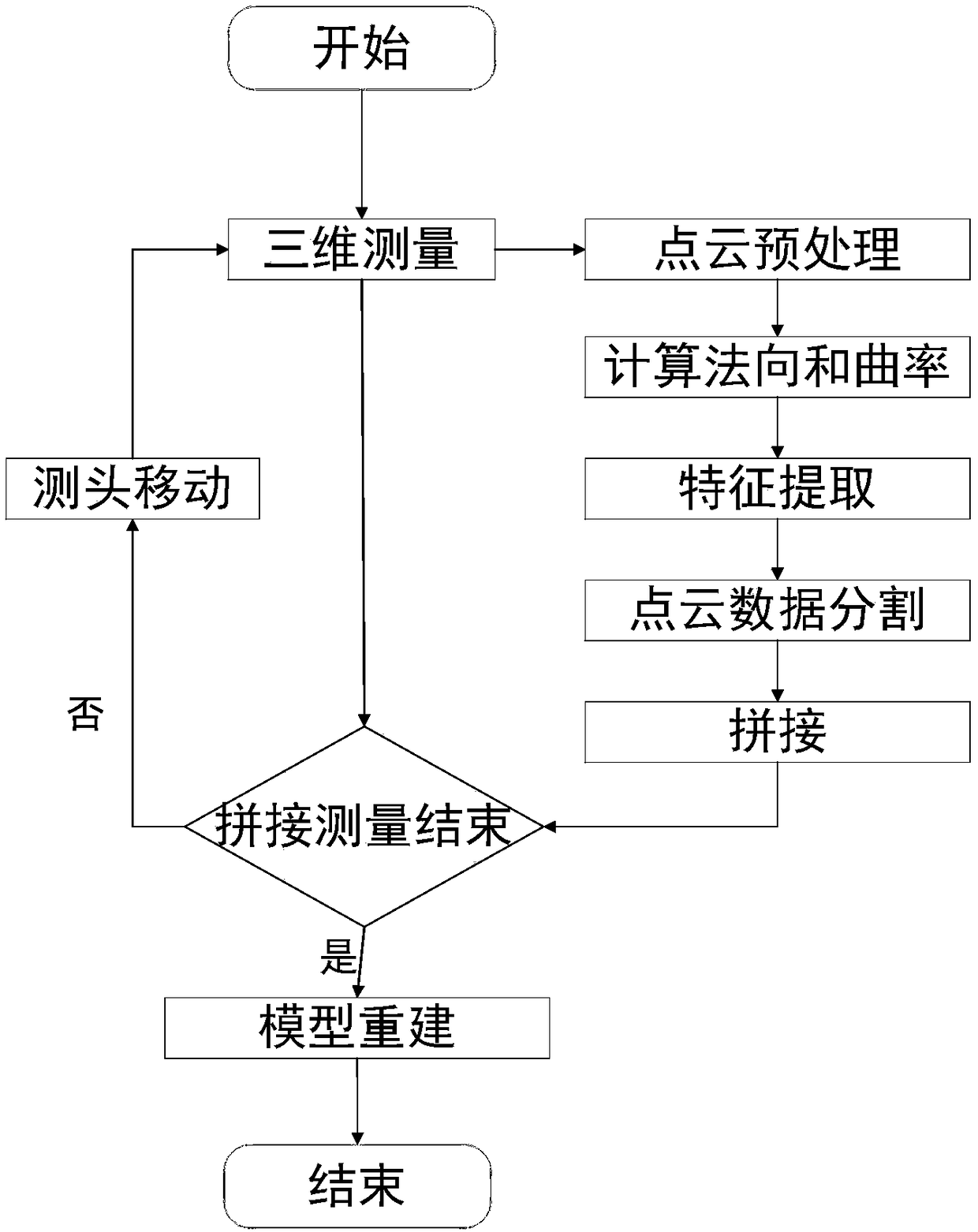

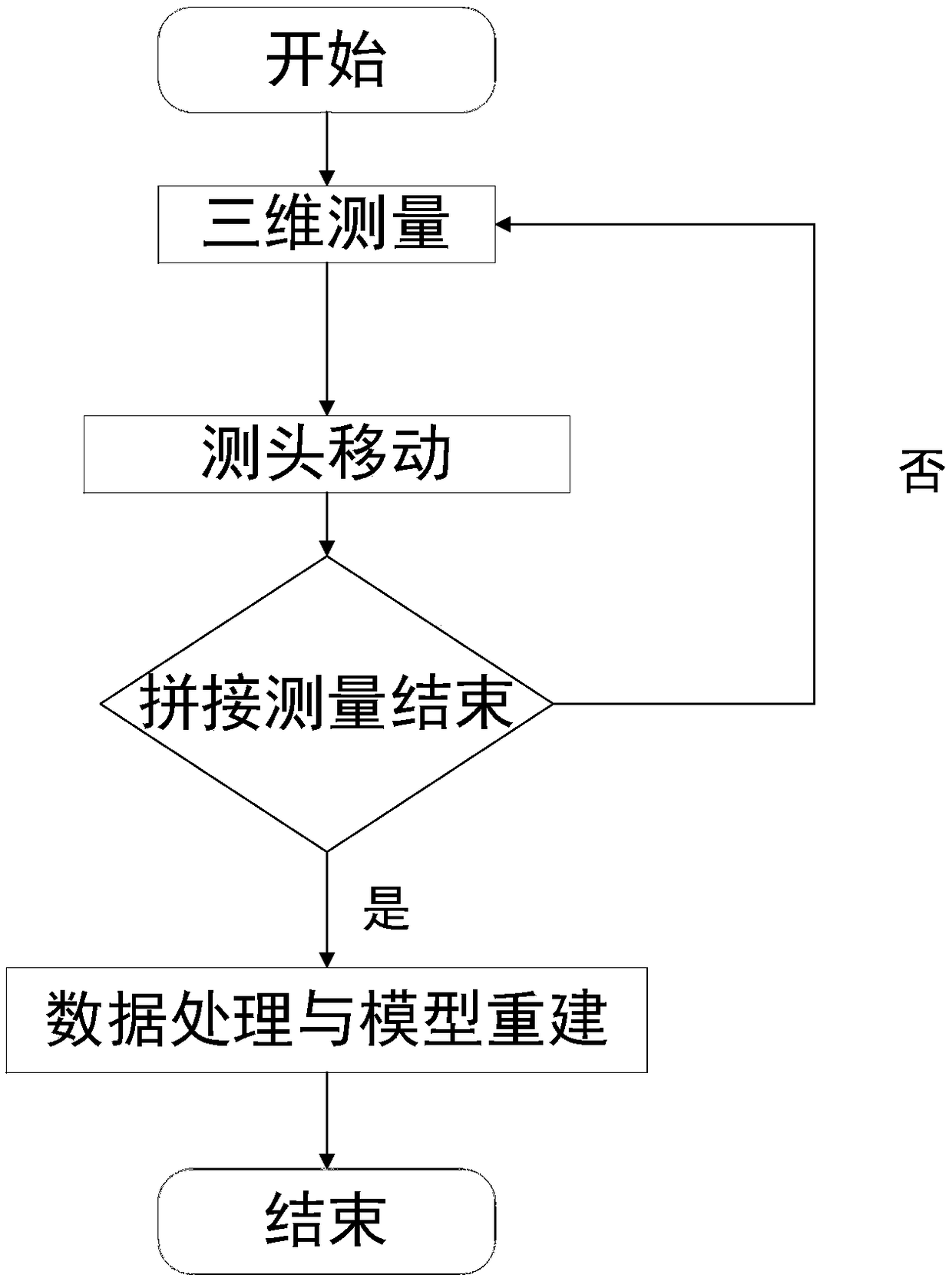

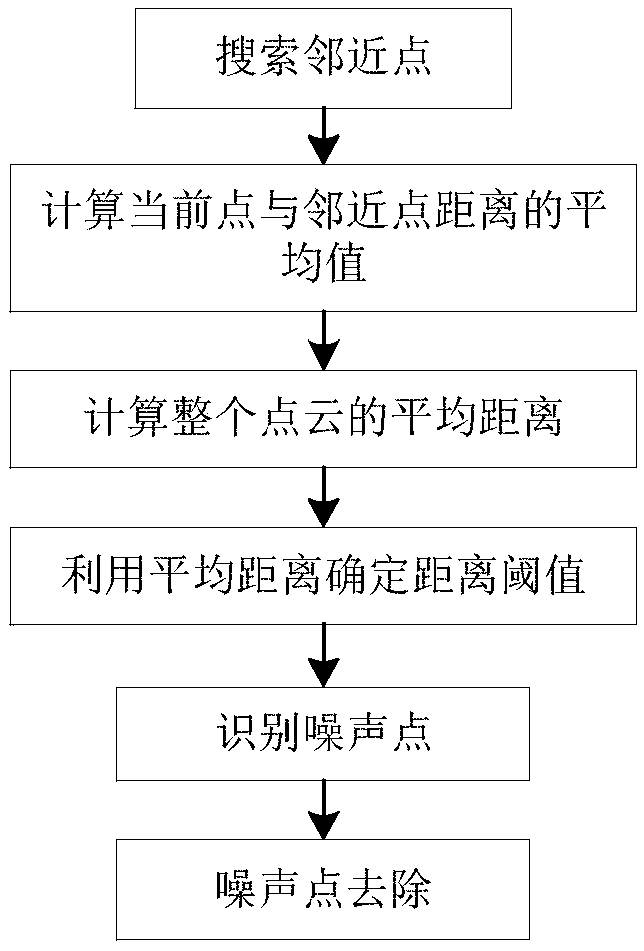

Fast reverse modeling method based on three-dimensional feature extraction

PendingCN109118574AExtended processing timeReduce difficultyImage enhancementImage analysisProcess optimizationPoint cloud

A fast reverse modeling method based on three-dimensional feature extraction is proposed, which utilizes the characteristics of large-scale structural parts splicing measurement and realizes the rapidreverse modeling of large-scale structural parts at the same time of splicing measurement. As the splice measuring probe moves, the noise of measuring point cloud in single field of view of large-scale structure is reduced, filter preprocessing is performed, then the 3D features are extracted by using the curvature and normal vector information of point cloud, the point cloud data is segmented, the stitching parameters are calculated according to the segmentation results, and several single-field data are quickly stitched, and the point cloud data processing is synchronized with the stitchingmeasurement of multiple fields of view, so as to realize the rapid reverse modeling, and guide the production processing and process optimization. The point cloud data processing method of the invention not only has high speed, but also retains the three-dimensional characteristics of the point cloud, can realize the simultaneous processing of the point cloud data and the splicing measurement, and meets the requirements of rapid model reconstruction.

Owner:BEIHANG UNIV +2

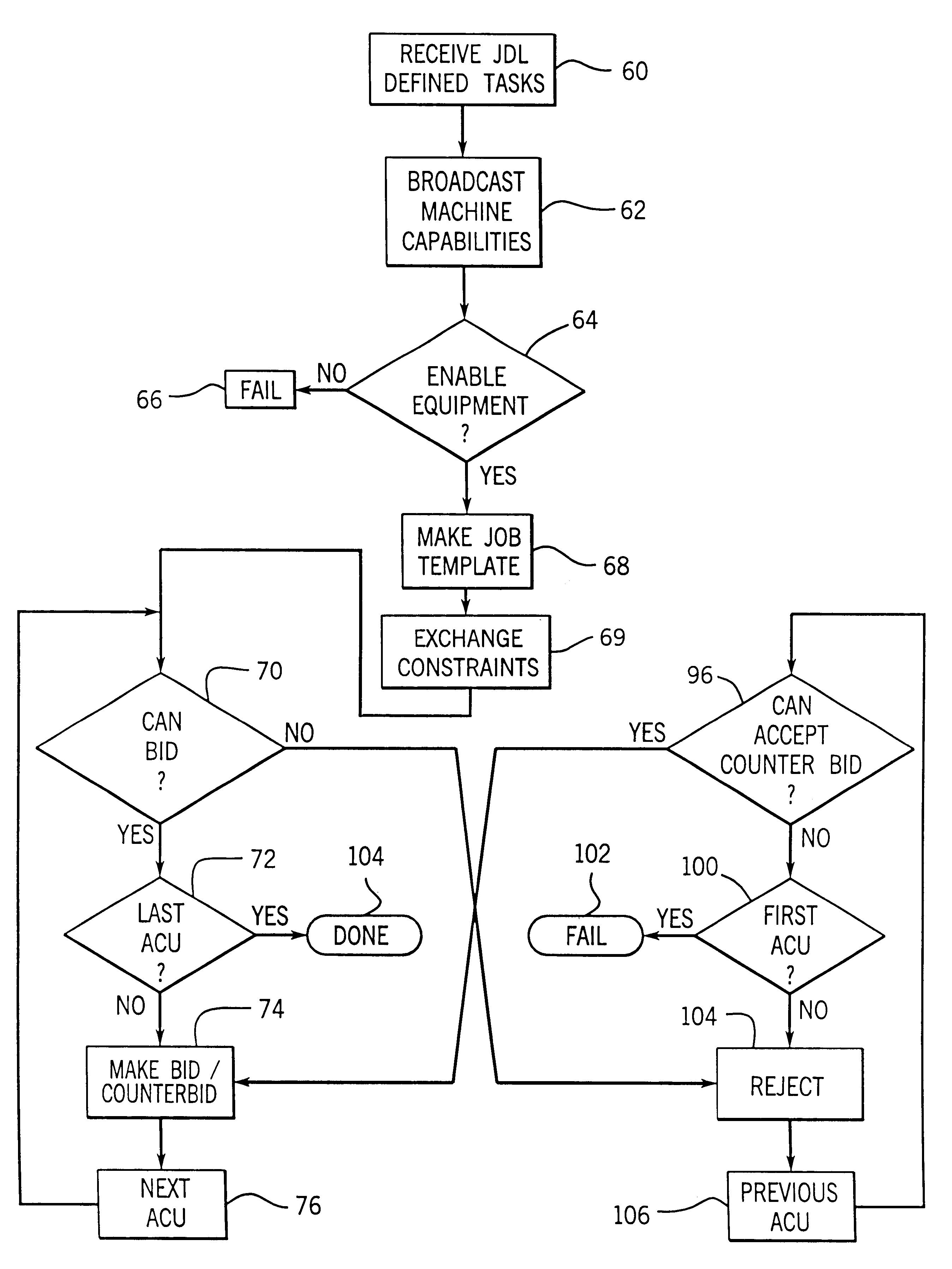

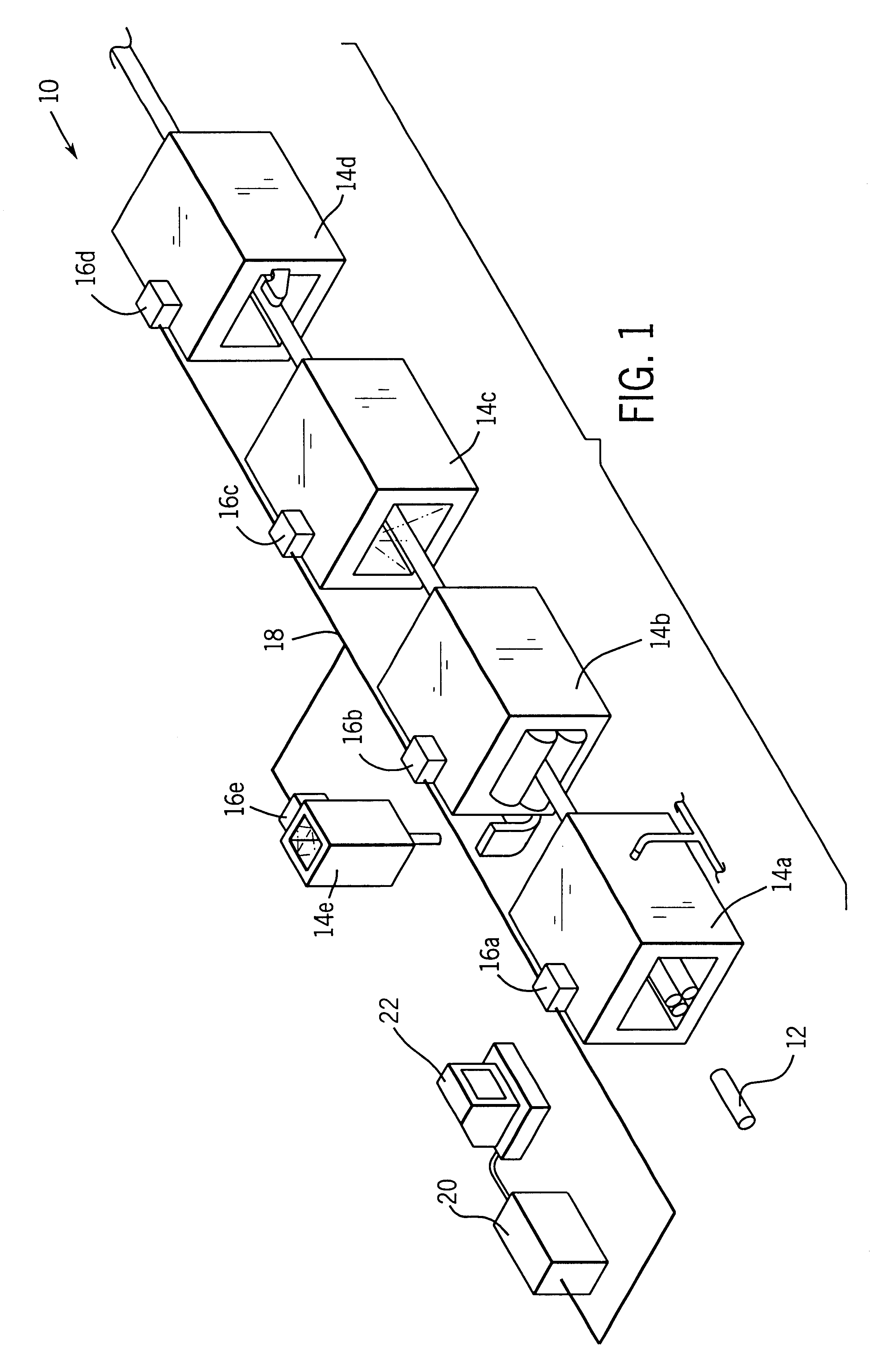

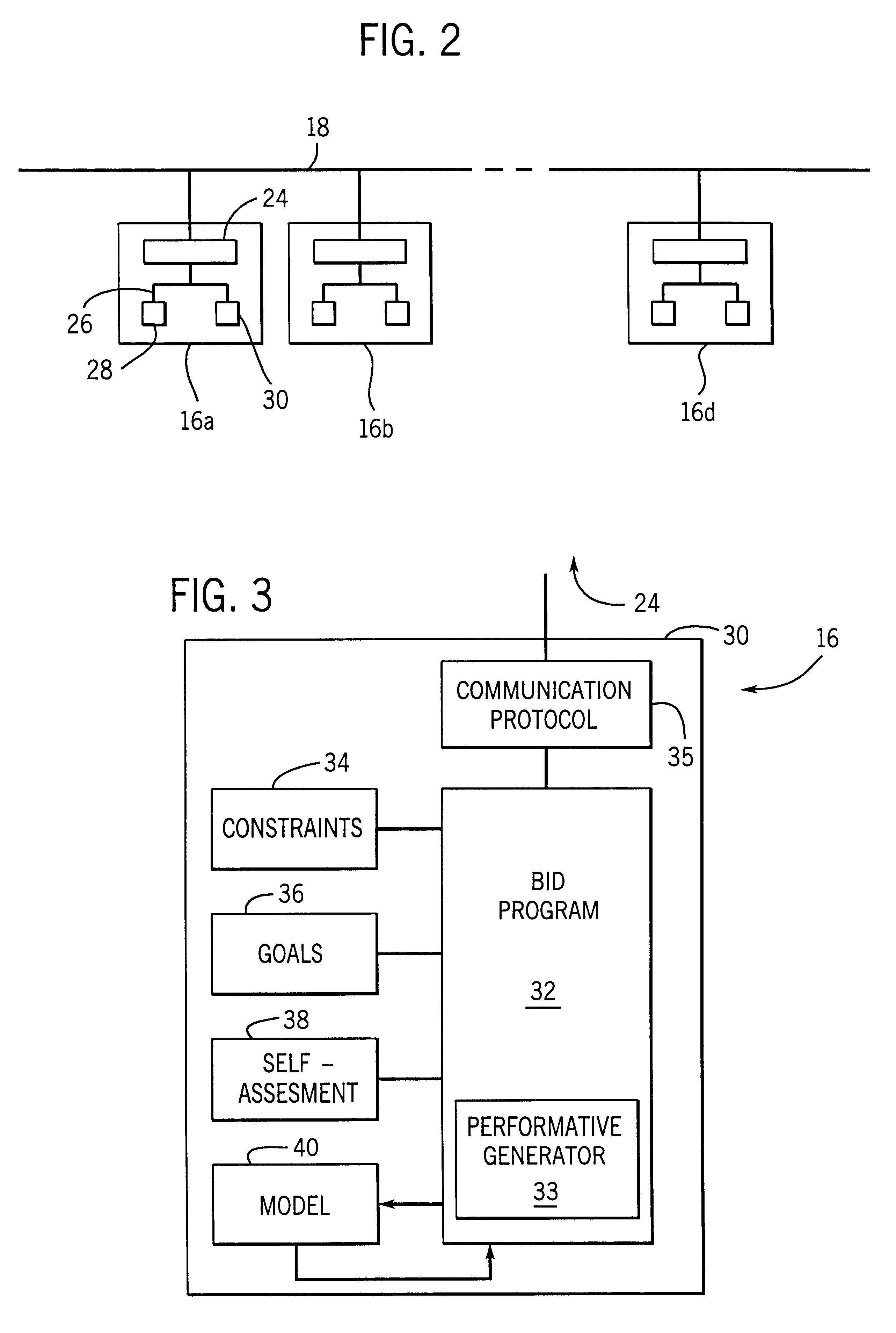

Self-organizing industrial control system using iterative reverse modeling to evaluate bids

InactiveUS6430454B1Shorten the timeEfficiently traverseResourcesSpecial data processing applicationsMulti inputReverse modeling

An industrial control system uses a number of autonomous control units, each associated with one piece of equipment in an industrial process. The autonomous control units negotiate by bidding among themselves to determine a common set of input and output values for the interconnected machines with which they are associated. Each autonomous control unit determines whether input values are acceptable by using a model of its associated equipment. The model provides anticipated output values based on given input values and is effectively operated in reverse for external counterbids proposing output values and needing to know input values, or internal counterbids seeking to optimize counterbid input values against output based goals. The reverse modeling iteratively applies inputs to the model until the desired output is attained. The inputs may be constrained by predefined intermediate constraints and may be changed in a binary search pattern. In multi-input models, one input may be specified for iteration.

Owner:ALLEN-BRADLEY CO LLC

Space synchronous positioning and information recording system based on three-dimensional real scene model

The invention relates to a space synchronous positioning and information recording system, which can be mainly applied to carrying out positioning on the located position in a three-dimensional real scene model when information is acquired in a building structure and recording the acquired information at the corresponding position. According to the system provided by the invention, three-dimensional point cloud data of the surface of an observed object is acquired at first through a three-dimensional laser scanner, a three-dimensional real scene model with three-dimensional coordinate information is acquired through processing the three-dimensional point cloud data by point cloud data processing software and reverse modeling software, and a computer terminal software platform is established based on the three-dimensional real scene model; and the three-dimensional real scene software platform of the computer terminal is connected to a universal cradle head positioning instrument, thereby being capable of aiming at any positions on the observed object. The positioning instrument takes a universal cradle head and a laser emission instrument as a basis, the universal cradle head positioning instrument capable of carrying an information acquisition instrument is established, and a data processing, storage and transmission module is arranged inside at the same time. Finally, the universal cradle head positioning instrument and the three-dimensional real scene software platform carry out matching on the three-dimensional real scene model and the actual space according to a space matching method, thereby becoming a system with space synchronous positioning and information recording functions.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

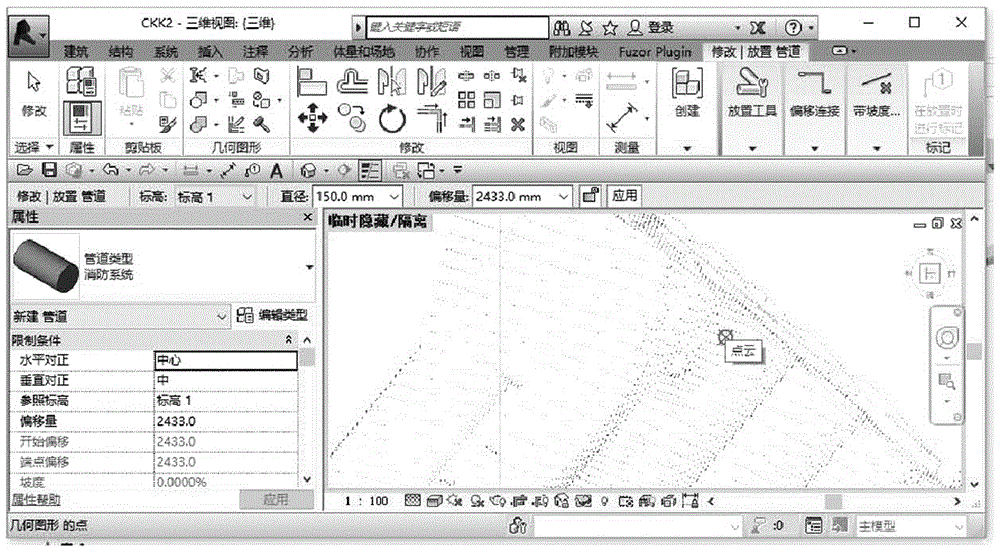

Method for reverse establishment of BIM model by using three-dimensional point cloud data

InactiveCN106484988AImprove efficiencyDesign optimisation/simulationSpecial data processing applicationsPoint cloudReverse modeling

The invention provides a method for reverse establishment of a BIM model by using three-dimensional point cloud data. The method is applied to the construction industry; and for seamless integration with a BIM technology, reverse modeling engineering of the point cloud data is tried to be finished in REVIT software. Modeling is not carried by in a point, line and plane mode in the REVIT software, but is realized through positioning by using the point cloud data and importing the point cloud data into the REVIT software successfully through format transformation by combining with professional components such as a base, a structure, windows and doors, curtain walls, stairs, heating and ventilation, electrics and water supply and drainage commonly used in the building and integrated in the software; and in addition, each point in the point cloud data can be identified by the REVIT software, and the point cloud data of a real scene can be transformed into the BIM model. The model can form one-one mapping with the building components in the real world, so that the efficiency of reverse modeling is greatly increased, and a series of construction production activities can be assisted via a means of information management.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

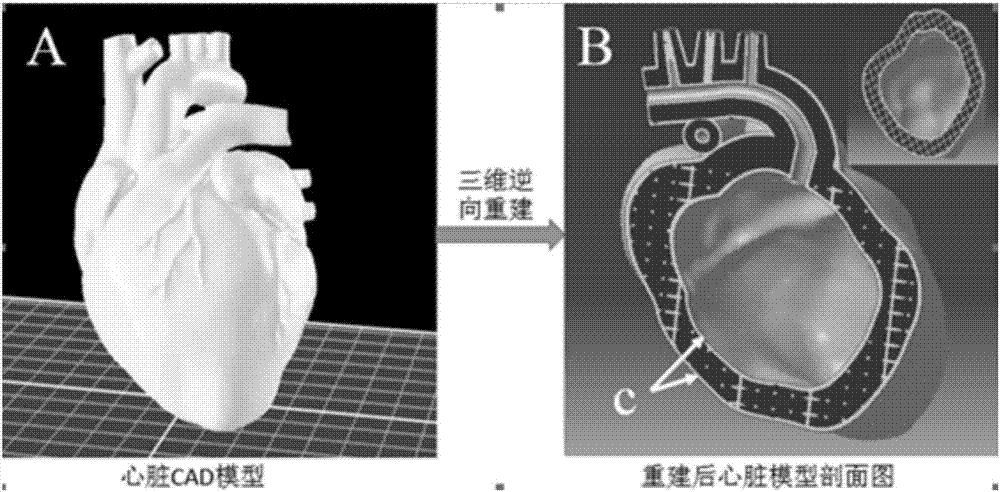

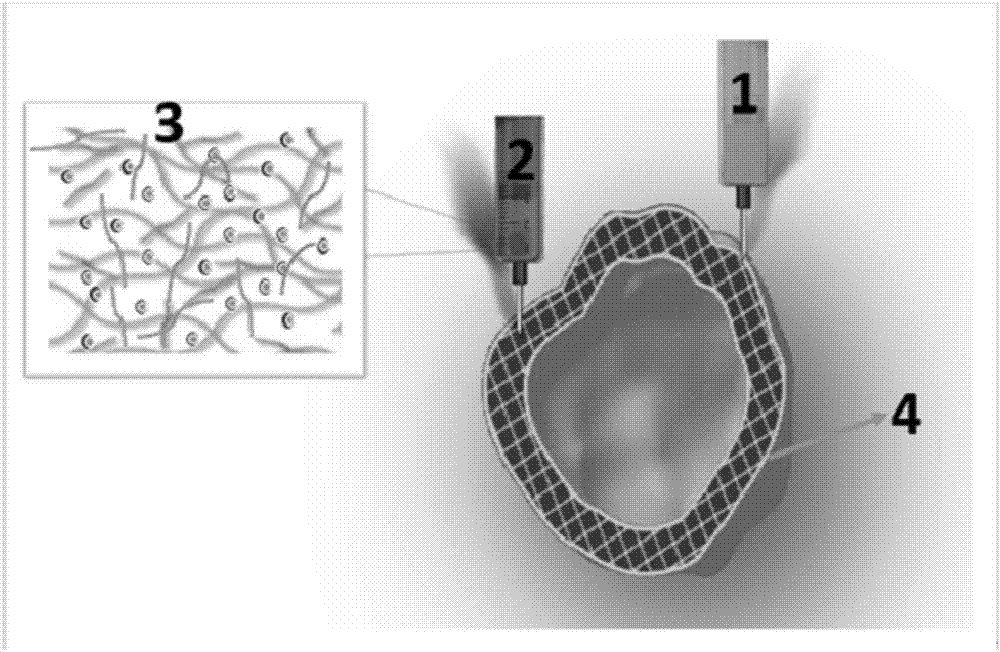

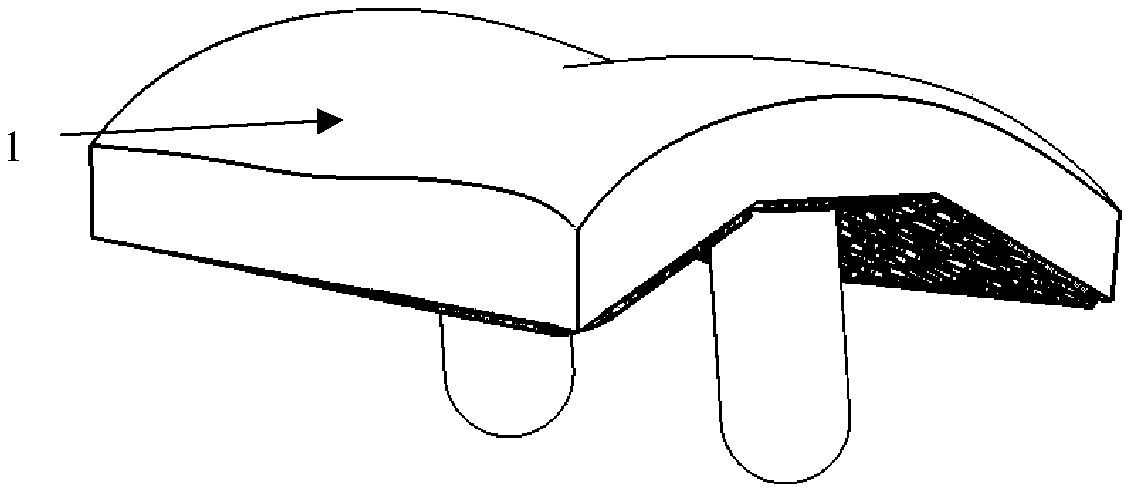

Method for building hollow vascularized heart based on 3D biological printing technology and hollow vascularized heart

ActiveCN107164318ASolve the poor effect of mechanical supportEasy to shapeCell culture supports/coatingSkeletal/connective tissue cellsCell activityReverse modeling

The invention provides a method for building a hollow vascularized heart based on the 3D biological printing technology and the hollow vascularized heart and relates to the technical field of tissue engineering and biology. The method includes: performing reverse modeling to build a heart three-dimensional grid model, importing the data of the heart three-dimensional grid model into a double-nozzle biological printing machine, and driving the nozzles of the printing machine to move according to a predesigned CAD digital model and selected forming parameters, wherein the nozzle 1 of the printing machine is loaded with sacrificial materials and used for printing a support framework, the nozzle 2 of the printing machine sprays biological ink to obtain building bodies, and the effective components of the biological ink comprise hydrogel, platelet-rich plasma, third-generation human umbilical vein endothelial cells and SD rat primary cardiomyocytes; crosslinking and cleaning the building bodies, and performing three-dimensional culture to form the hollow vascularized heart. The method has the advantages that the problem that a large-size hollow vascularized heart is hard in integrated printing, and the hollow vascularized heart built by the method is high in cell activity and has certain functions.

Owner:叶川 +2

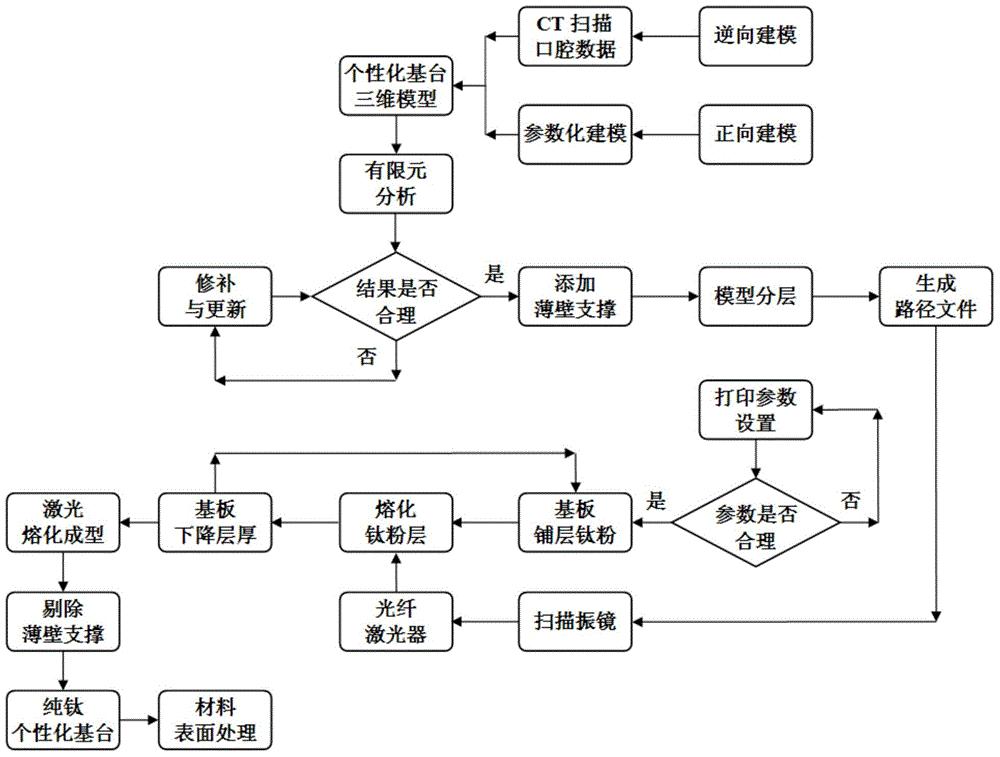

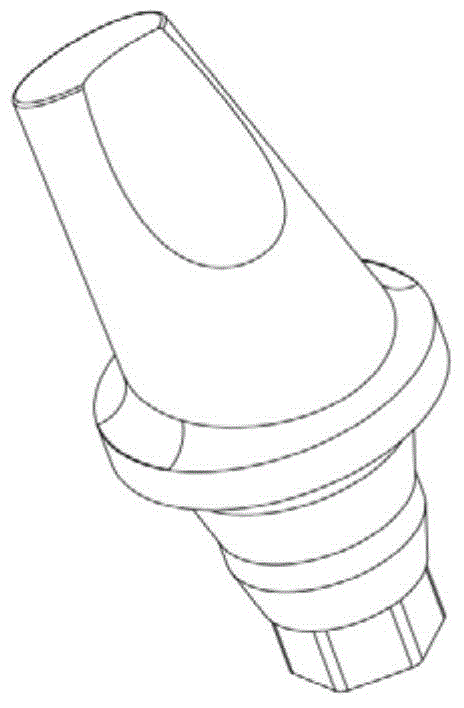

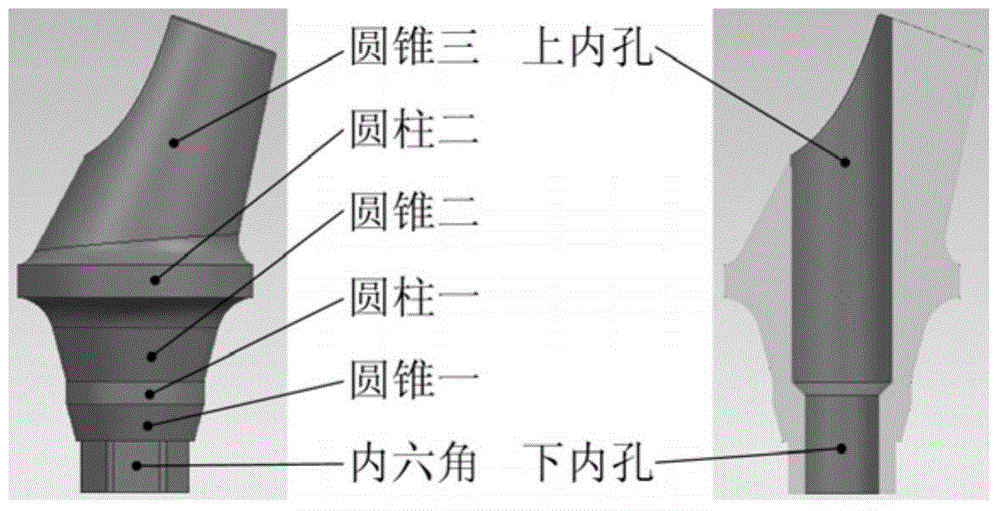

Individual abutment and manufacturing method thereof

ActiveCN105055037AFit closelyImplement a parametric design processDental implantsImpression capsSelective laser meltingComputed tomography

The invention relates to an individual abutment and a manufacturing method thereof. The manufacturing method comprises the following steps: carrying out reverse modeling through CT scanning and carrying out parametrization design on a model through Unigraphics NX, implementing precise repairing on the abutment model, carrying out simulation analysis on the abutment model by virtue of a finite element analysis method, and implementing model optimization design according to a finite element stress analysis result so as to meet the attributes of an abutment material; carrying out three-dimensional hierarchical slicing treatment on the abutment model meeting the attributes of the abutment material, and promoting the generation of a corresponding path file; and according to the path file, reasonably controlling the parameters of selective laser melting equipment and molding so as to obtain the individual abutment. The manufacturing method disclosed by the invention can be used for effectively guaranteeing the accuracy of stress direction and size of the abutment as well as the precision of molding, and the manufactured individual abutment can fit to jaw characteristics of a patient more precisely compared with the prior art, so that comfort in use is improved and the service life of the abutment is prolonged.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

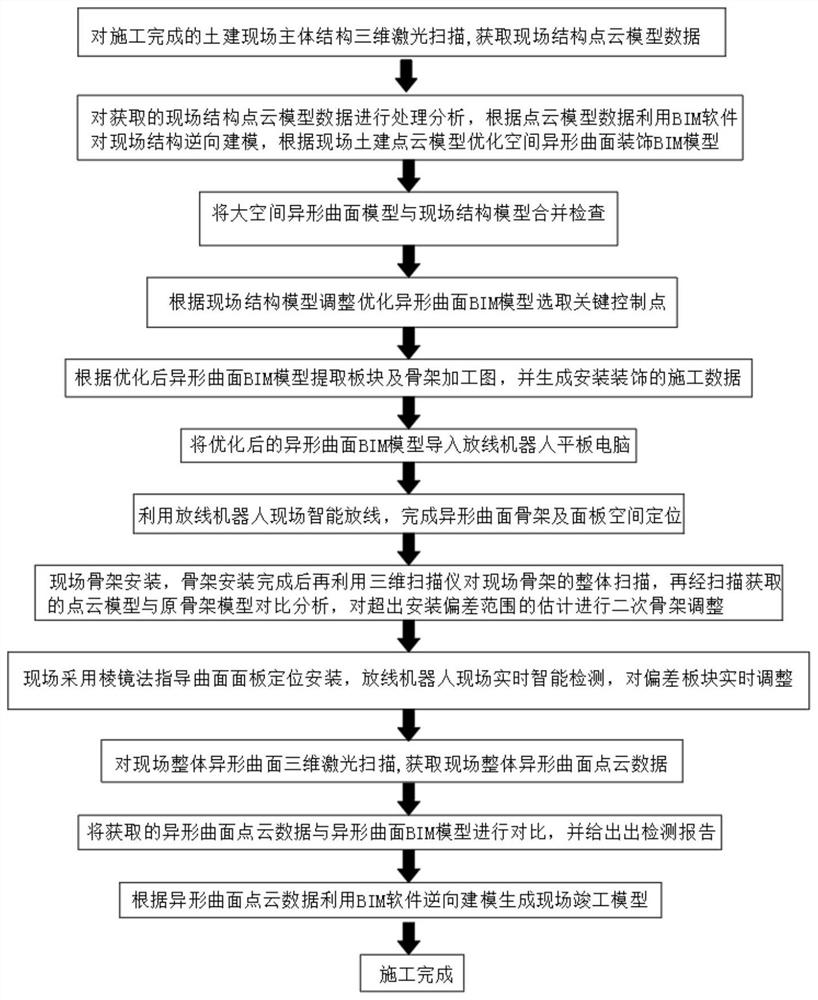

Construction method for intelligently controlling large-space special-shaped curved surface based on BIM technology

PendingCN111709074AEfficient measurementHigh precision measurementGeometric CADData processing applicationsPoint cloudSimulation

The invention discloses a construction method for intelligently controlling a large-space special-shaped curved surface based on a BIM technology, and relates to the technical field of BIM application, and the method is characterized by comprising the following steps: S1, carrying out the three-dimensional laser scanning of a civil engineering field main structure after construction, and obtainingthe point cloud model data of the field structure; and S2, processing and analyzing the acquired point cloud model data of the field structure, performing reverse modeling on the field structure by utilizing BIM software according to the point cloud model data, and optimizing a spatial special-shaped curved surface decoration BIM model according to a field civil engineering point cloud model. According to the invention, three-dimensional scanning is carried out on the civil engineering; buried point measurement does not need to be conducted on site manually, constructed civil engineering canbe measured efficiently with high precision, an accurate and visual construction deviation analysis result is obtained rapidly, installation and real-time adjustment are guided through lofting of thepay-off robot and on-site real-time monitoring, error accumulation is avoided, and the decoration construction efficiency is improved.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

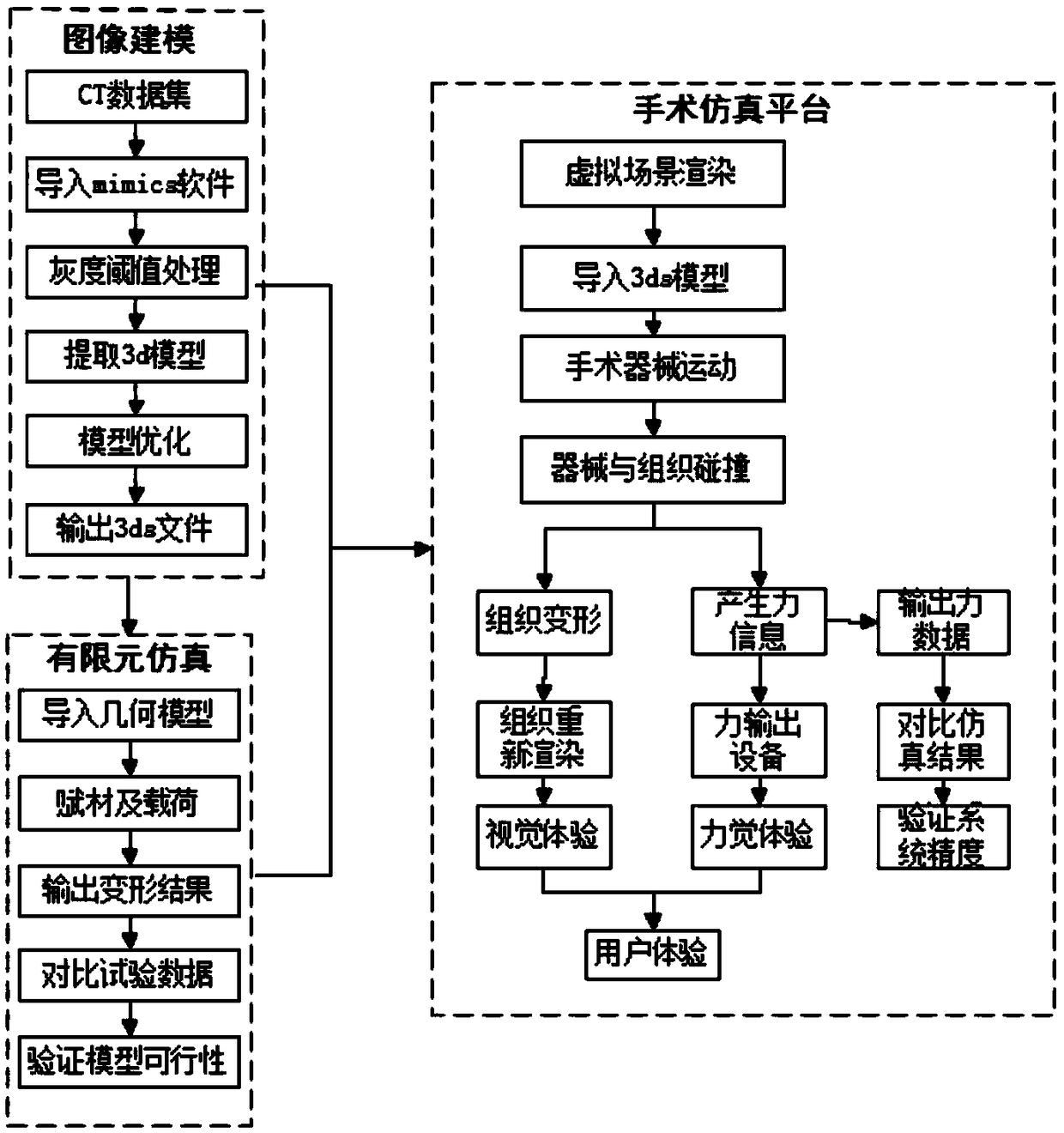

A training method of soft tissue minimally invasive surgery based on virtual reality

PendingCN109308739AGuaranteed accuracyGuaranteed force experience3D modellingFinite element algorithmVoxel

The invention discloses a soft tissue minimally invasive surgical training method based on virtual reality, which can enable a user to operate a force feedback device to perform minimally invasive puncture or forceps pulling on the soft tissue, comprising the following steps: 1, reverse modeling the abdominal CT image of a patient; 2, optimize that model; 3, carry out finite element puncture simulation on that model; 4, that finite element simulation result are processed in Matlab software to verify the correctness of the model by compare with the experimental results; 5. Complete the module design of model import, scene rendering, collision detection, deformation algorithm, data input and output of force feedback device in Microsoft Visual Studio 2013 software, and realize the function ofinteraction between user and virtual scene through force feedback device. The invention can improve the system accuracy through modeling and simulation, adopt voxel octree and finite element algorithm, improve the collision and deformation accuracy and real-time, accurately perceive the virtual force through the external force feedback device, and effectively enhance the immersion feeling.

Owner:NANJING INST OF TECH

Laser-cladding cobalt-base alloy powder and repairing method for repairing damaged expander blade

ActiveCN105349995AImprove corrosion resistanceImprove hardenabilityMetallic material coating processesMo elementLaser scanning

The invention discloses laser-cladding cobalt-base alloy powder and a repairing method for repairing a damaged expander blade. The laser-cladding cobalt-base alloy powder comprises the following raw materials in percentage by mass: 20.0% to 50% of Co, 1.0% to 3.0% of W, 2.0% to 5.0% of Mo, 20.0% to 26.0% of Cr, 19.0% to 45.0% of Fe, 0 to 9% of Ni and the balance of Si. The repairing method comprises the following steps: pre-treating the damaged expander blade before laser cladding; performing reverse modeling by three-dimensional laser scanning; determining the to-be-repaired position and size of the blade; performing multi-track lapped laser cladding repair on the damaged expander blade by using the laser-cladding cobalt-base alloy powder. The laser-cladding cobalt-base alloy powder disclosed by the invention adopts austenite as a main phase; Co and Ni elements are used for stabilizing the main phase; W and Mo elements are added, and meanwhile, the content of Si and B elements is reduced, so the toughness and corrosion resistance are improved, and the phenomenon of cracking generated during multi-track lapping of a laser cladding layer is reduced. The alloy powder component has the effects of lowering the cost and improving the stability of a cladding technique, and the laser repair quality and the effective service life of the blade of an energy recycling turbo expander are guaranteed.

Owner:汉中艾斯达特新材料科技有限公司

Method for machining bolt holes in hanging subassembly of aircraft engine by using numerical control equipment

InactiveCN103785874AImprove production efficiencyHigh degree of assembly automationNumerical controlReverse analysis

The invention belongs to the field of numerical control machining methods, and particularly relates to a method for machining bolt holes in a hanging subassembly of an aircraft engine by using mechanical control equipment. The method comprises the following steps of preassembling the hanging subassembly by using an assembling tool; positioning the hanging subassembly on a special machining supporting clamp; performing measurement and reverse analysis and adjusting numerical control machining programs; positioning the subassembly and the clamp on a machine tool in an integrated manner; automatically forming holes by using the machine tool and examining a machining result; preassembling the hanging subassembly by using a small number of bolts; establishing a measuring benchmark on the product under aircraft axes; positioning the product on the special machining supporting clamp and then examining the appearance error and the location degree of the product; performing reverse modeling and analysis by using CATIA (computer-graphics aided three-dimensional interactive application) software; adjusting a normal tolerance point of a curved surface of the subassembly; correcting a hole-forming machining program; and positioning the whole pre-assembled hanging subassembly by using the benchmark of the special machining clamp on the machine tool as a tool setting benchmark and using the measuring benchmark established on the subassembly as an examination point, and then forming the holes on the subassembly in a machining manner.

Owner:AVIC SAC COMML AIRCRAFT

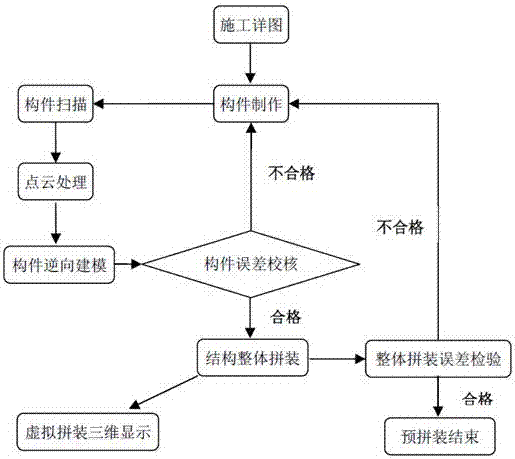

Digital pre-assembling method of building steel structure based on three-dimensional scanning and reverse modeling

InactiveCN107292947AReduce the burden onImprove pre-assembly efficiencyGeometric CADSpecial data processing applicationsError checkingReverse modeling

The invention relates to a digital pre-assembling method of a building steel structure based on three-dimensional scanning and reverse modeling. The method comprises the following steps: step one, carrying out component manufacturing; step two, carrying out component scanning, step three, carrying out point cloud processing; step four, carrying out reverse modeling of a component; step five, carrying out component error checking; step six, carrying out structural assembling; step seven, carrying out overall assembling error checking; and step eight, finishing pre-assembling. According to the invention, all information of components including a bolt hole and small hidden parts can be reflected completely; with reverse modeling, massive stored point cloud data are processed by fitting to obtain an entity model; the data volume is reduced for follow-up pre assembling and entity model displaying; the computer burden is reduced; and the pre assembling efficiency of the computer is improved substantially. On the basis of the optimization-algorithm-based digital pre assembling technique, optimized pre assembling is carried out on the fitted entity component model.

Owner:SHANGHAI BAOYE GRP CORP

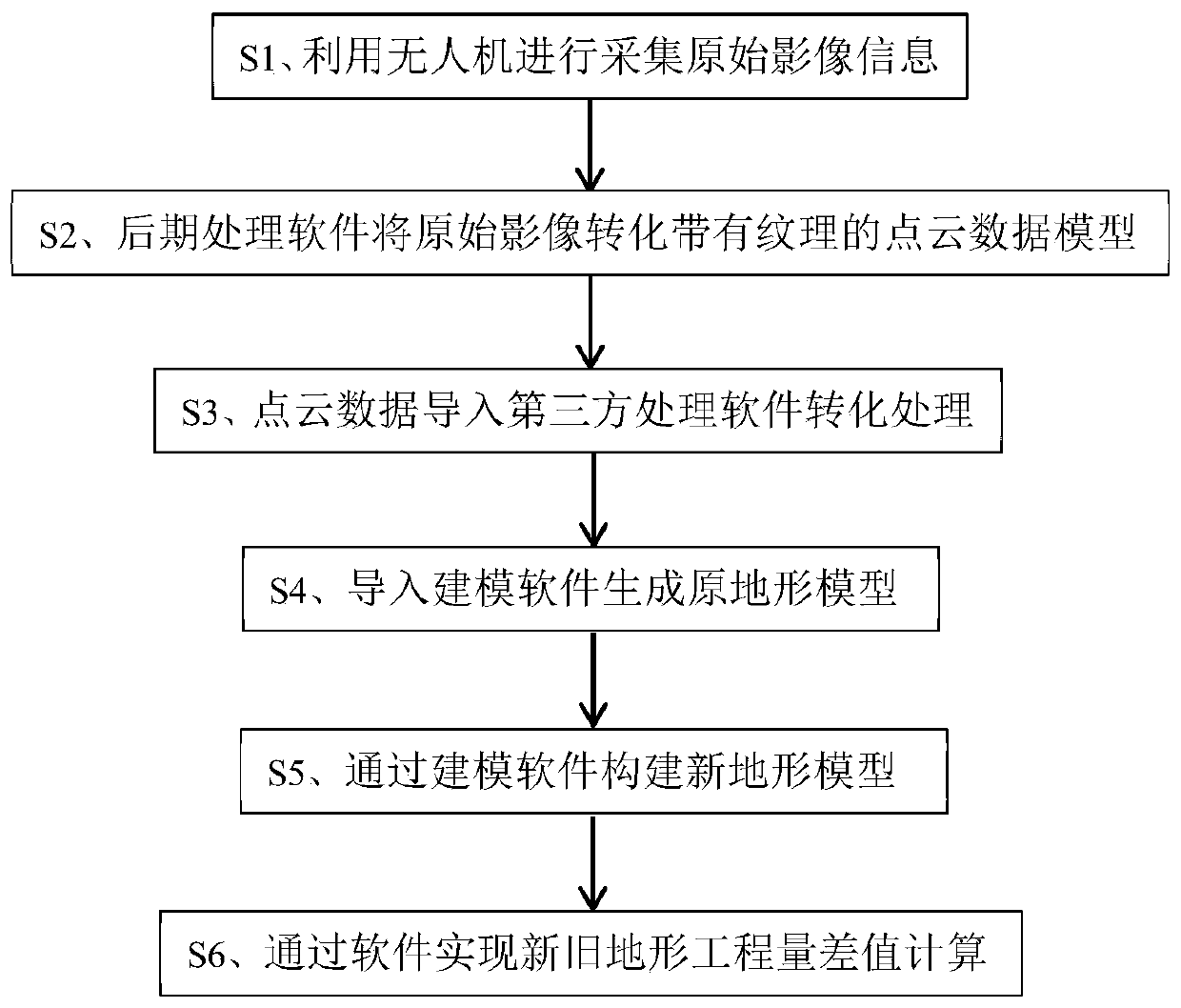

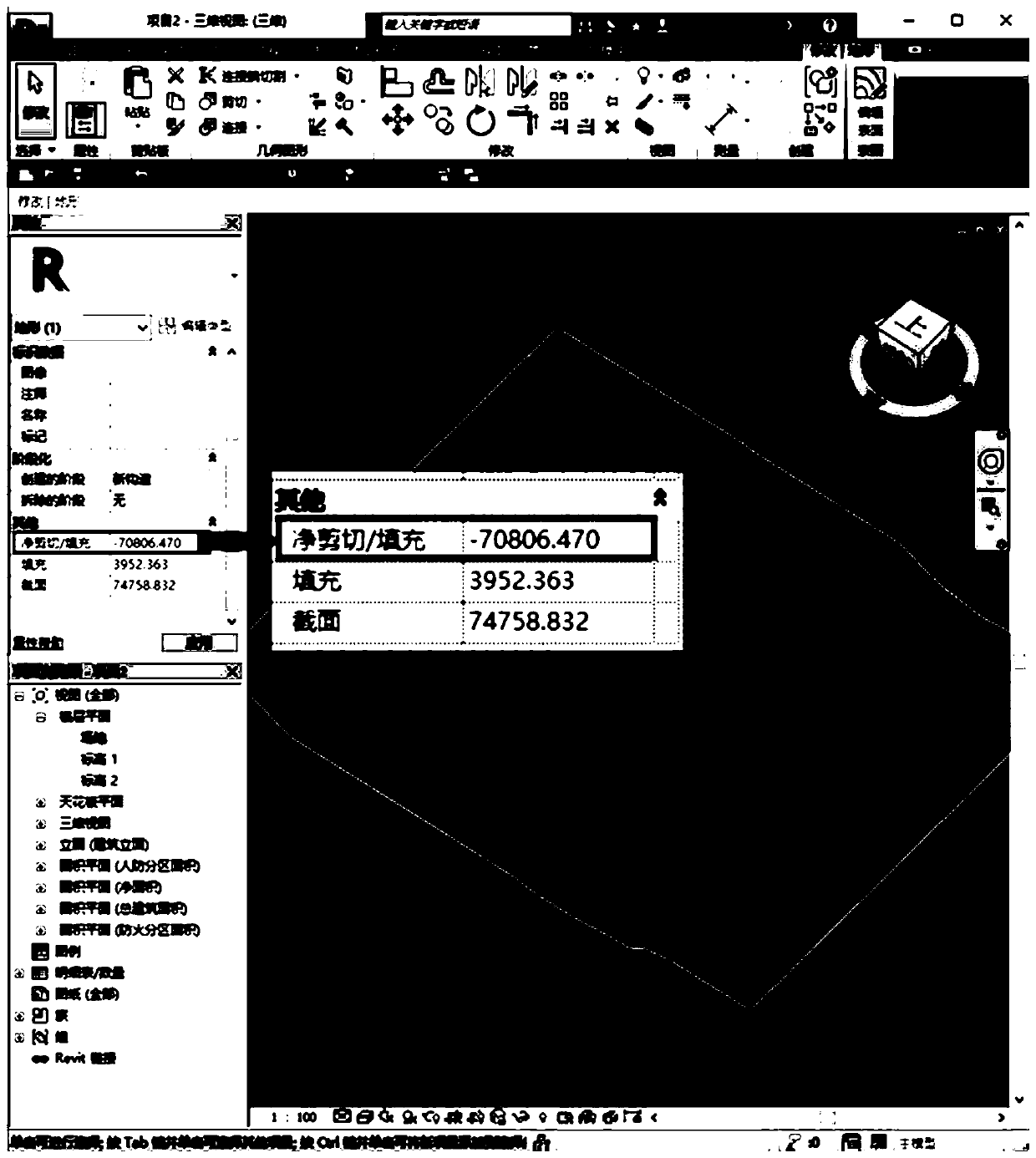

Aerial photography and BIM (Building Information Modeling) combination-based earthwork project amount calculation method

InactiveCN110083903AImprove measurement efficiencyImprove modeling efficiencyGeometric CADPhotogrammetry/videogrammetryTerrainData file

The invention discloses an aerial photography and BIM (Building Information Modeling) combination-based earthwork project amount calculation method. The method comprises the following steps of (1) performing original image information acquisition by utilizing aerial photography of an unmanned aerial vehicle; (2) converting the original image into a point cloud data model with textures through surveying and mapping post-processing software; (3) importing the point cloud data into third-party processing software for conversion processing; (4) importing the converted data file into modeling software to construct an original terrain model; and (5) establishing a new terrain plane or terrain model on the basis of the original terrain model through modeling software; (6) extracting an engineering quantity difference value between the new terrain and the original terrain. According to the invention, based on a mode of combining the aerial photography technology and the BIM technology, the unmanned aerial vehicle is utilized to obtain the original terrain data, the original terrain data is processed through the reverse modeling technology, and the BIM software is utilized to obtain the three-dimensional model, so that not only is the measurement time saved, but also the modeling efficiency is improved, and meanwhile, the data precision is ensured.

Owner:中铁十八局集团第五工程有限公司 +1

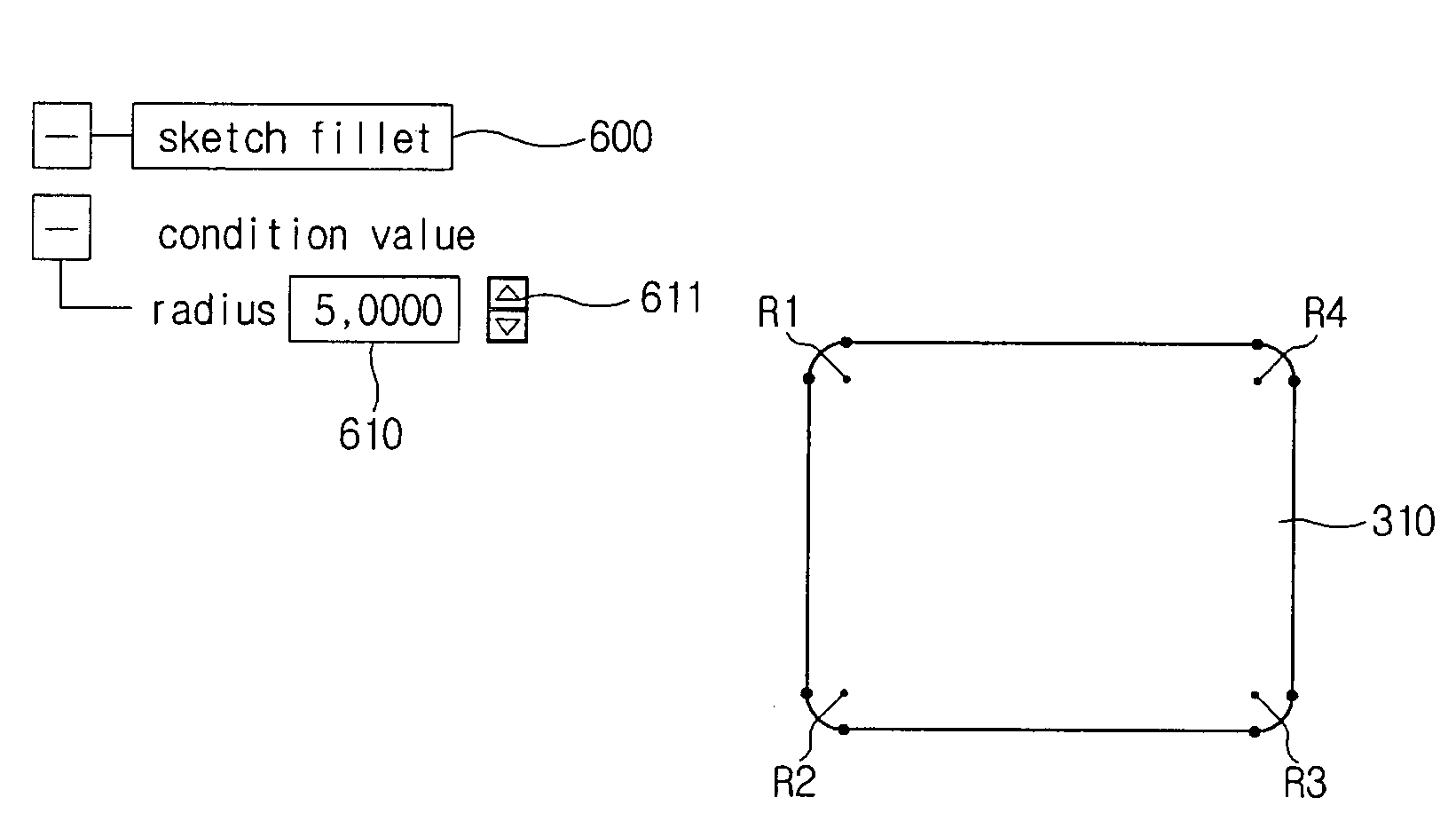

Method for detecting two dimensional sketch data from source model data for three dimensional reverse modeling

ActiveUS20080049046A1Precise sectionGeometric CADCathode-ray tube indicatorsPolygonal lineUser input

A method for detecting two dimensional sketch data from source model data for three dimensional reverse modeling. The method includes the steps of detecting optional model data, establishing X-axis, Y-axis and Z-axis of the model data depending upon a reference coordinate system information inputted from a user, and setting a work plane for detecting two dimensional section data of the model data; projecting, on the work plane, two dimensional section data to be detected from the model data or polylines detected by designating a detection position; detecting two dimensional projected section data of the model data projected on the work plane, and dividing the two dimensional projected section data into feature segments depending upon a curvature distribution; and establishing a constraint and numerical information in accordance with connection of the divided feature segments of the two dimensional projected section data, and creating two dimensional sketch data.

Owner:3D SYST KOREA INC

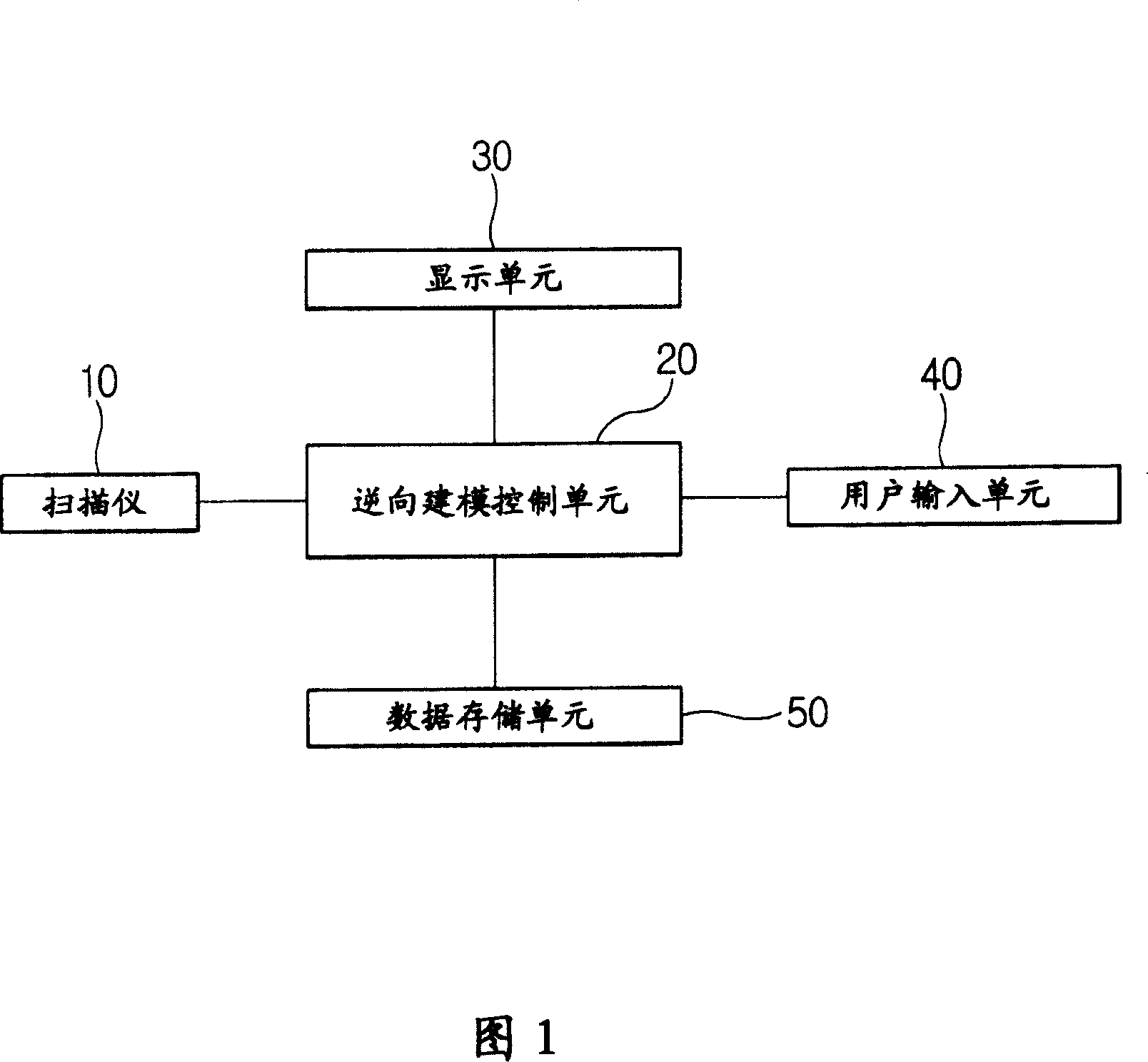

Reverse modeling method using mesh data as feature

ActiveCN101086789AComputer aided designSpecial data processing applicationsComputer graphics (images)Reverse modeling

A reverse modeling method using mesh data as a feature to allow reverse modeling to be conducted by following a procedure of an original designer includes the steps of detecting optional model data, setting the model data as a feature, and establishing a reference coordinate system of set mesh data; establishing a work plane on which a sketch of the set mesh data can be projected; projecting section data of the mesh data on the work plane; dividing data projected on the work plane into feature segments depending upon curvature distributions, and producing divided segments as sketch data; and producing a three dimensional feature from the sketch data which corresponds to a shape of the mesh data, and storing the produced three dimensional feature as model data, wherein the produced sketch data and three dimensional feature are parametrically connected with each other.

Owner:INUS TECH

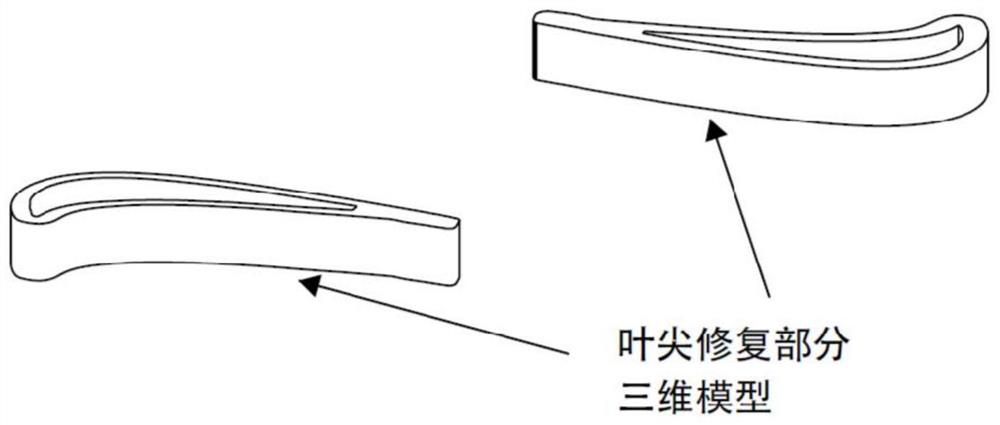

Single crystal and directional solidification material turbine rotor blade tip repairing method and tool

ActiveCN112077310AControl Positioning AccuracyImprove efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyAviationEngineering

The invention belongs to the technical field of aero-engine hot end part repairing, and relates to a single crystal and directional solidification material turbine rotor blade tip repairing method andtool. According to the method, a laser selective melting or electron beam selective melting process is adopted for completing repairing, a blade can be placed in a forming area of laser selective melting or electron beam selective melting equipment through the tool and is formed at the blade tip, data are obtained through three-dimensional scanning for reverse modeling to obtain a model needing to be repaired and formed and related position information, the corresponding tool and blade clamping are designed, the structure and form of the tool are not limited, and the tool can be used for completing blade clamping, auxiliary positioning and position calibration; printing repairing forming is carried out after positioning calibration, and finally aftertreatment and detection are completed;and the positioning precision of blade repairing is well controlled, and the beneficial effects that heat input is small, grains are fine, the mechanical property is good, deformation is small, the surface roughness is good, the size precision is high, near-net forming does not need machining, and forming is rapid and efficient are achieved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

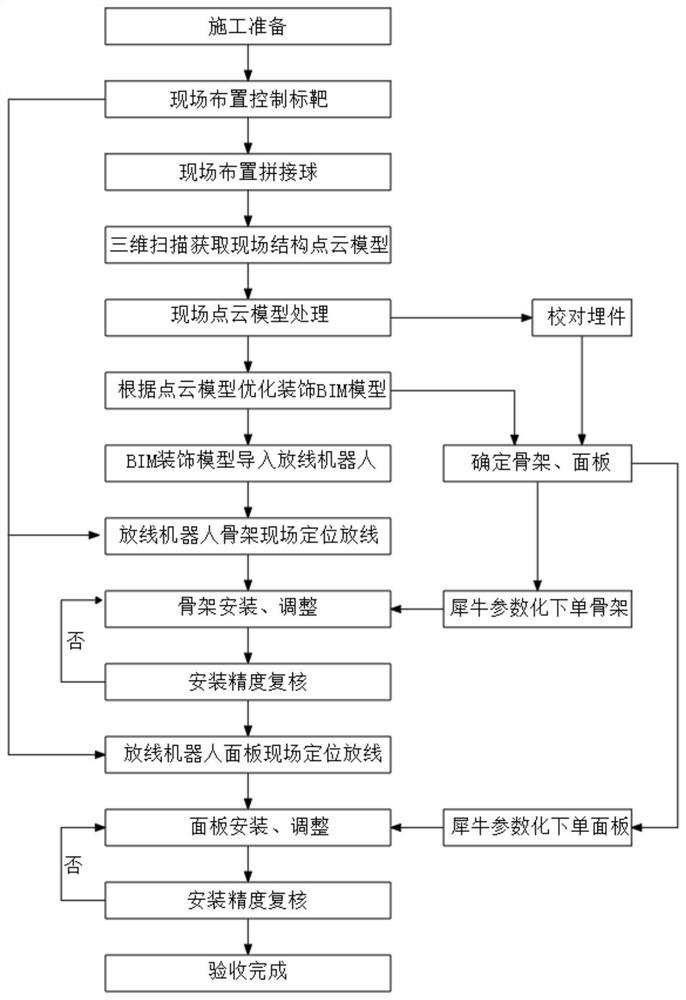

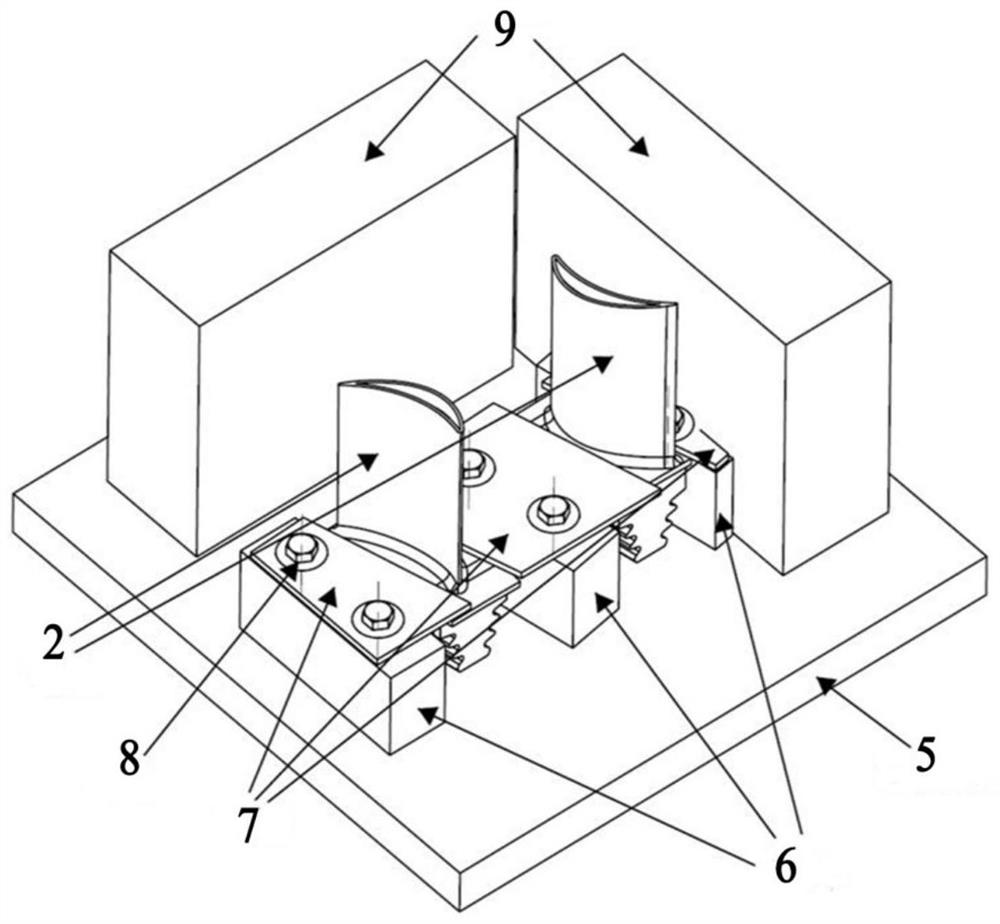

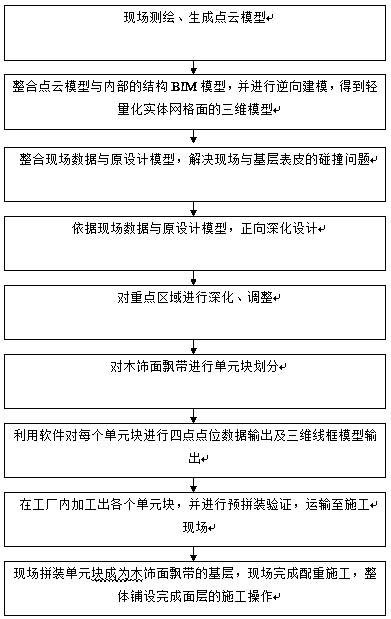

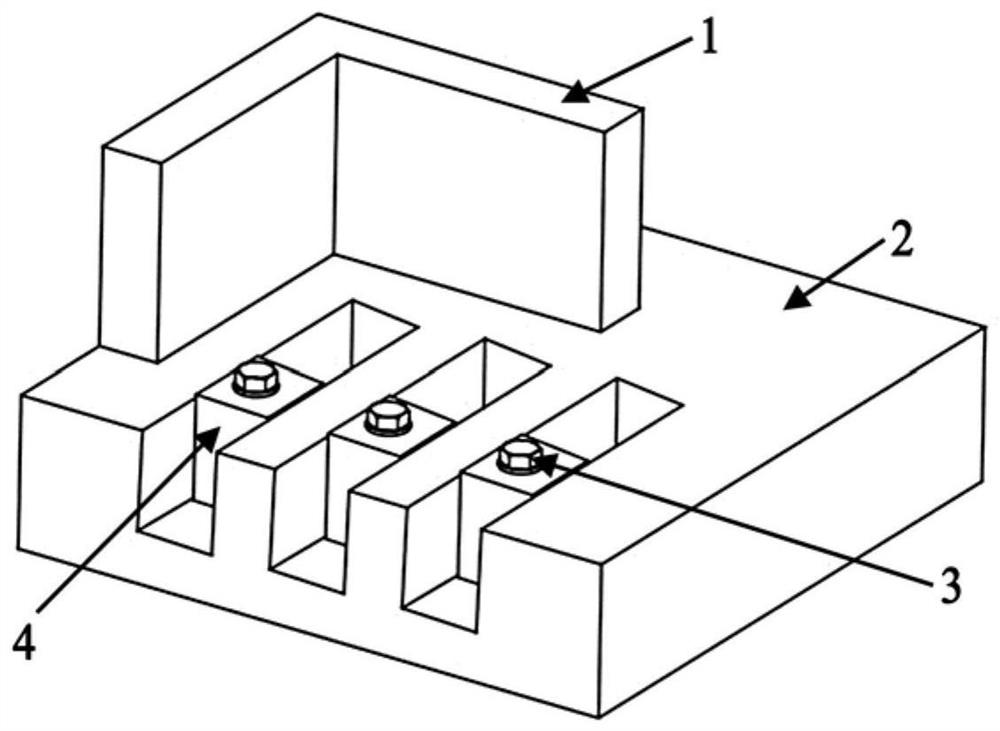

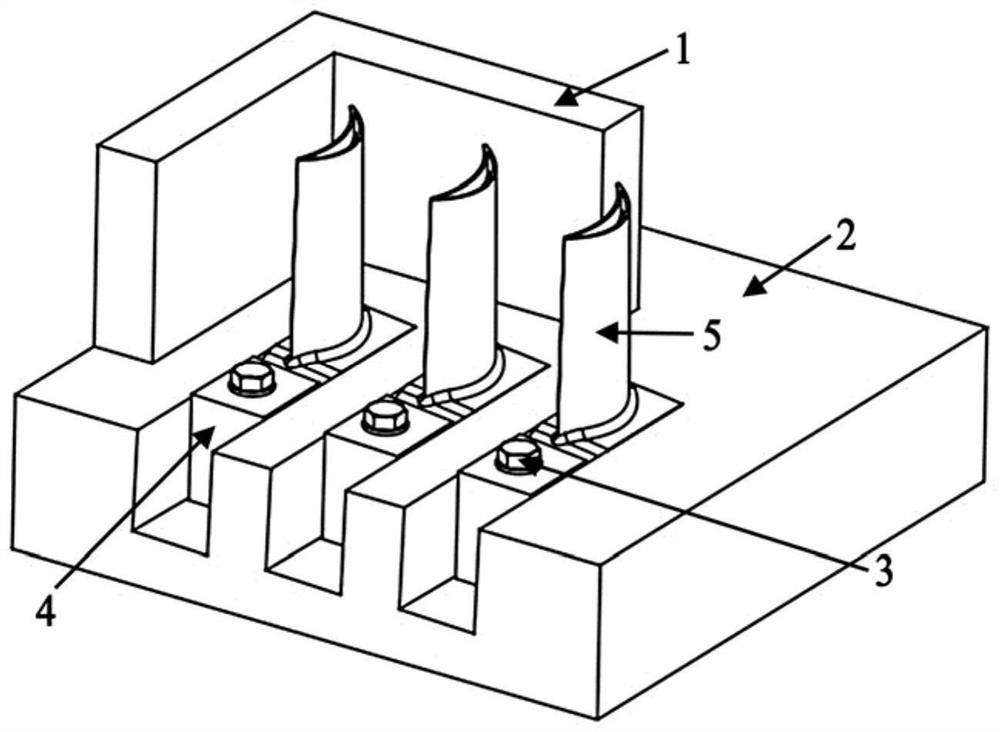

Digital construction auxiliary construction method suitable for complex multi-curve components of architectural decoration engineering

ActiveCN111062069AGuaranteed structural performanceWarranty requirementsGeometric CADDetails involving processing stepsPoint cloudProcess engineering

The invention relates to a digital construction auxiliary construction method suitable for complex multi-curve components of architectural decoration engineering, and belongs to the field of architectural design and construction. The auxiliary construction method comprises the following steps of performing space surveying and mapping on the interior of a large-scale stadium completed through civilengineering, and generating a point cloud model; integrating the point cloud model with a BIM model, and determining a deviation position for reverse modeling; integrating the field data and the decoration model to solve the problem of collision between the field and the decoration surface layer; deepening the coordination problem of design adjustment and other professions in the forward direction; deepening the whole base layer skin of the complex special-shaped decorative surface, dividing and numbering unit blocks of the base layer skin, outputting point positions and three-dimensional wireframe models by utilizing software, processing and verifying in a factory, transporting to a site, and installing according to numbers. The auxiliary construction method for digital construction of the complex special-shaped decorative surface in the large venue has the advantages of being high in design precision, capable of coping with various complex decorative surface models and achieving perfect matching of various decorative materials and efficient in construction.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

Cast isometric crystal high-temperature alloy turbine rotor blade tip repairing method and tool

ActiveCN112045186AOvercoming positioningOvercoming the lack of fusion at the repair interfaceAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringReverse modeling

The invention belongs to the technical field of aero-engine maintenance, and relates to a cast isometric crystal high-temperature alloy turbine rotor blade tip repairing method and tool. According tothe method, repairing is completed through a laser selective melting or electron beam selective melting process, a blade can be placed in a forming area of laser selective melting or electron beam selective melting equipment and formed at a blade tip through the tool, data are obtained through three-dimensional scanning for reverse modeling, a model needing to be repaired and formed and related position information are obtained, the corresponding tool and blade clamping are designed, the structure and form of the tool are not limited, and the tool can be used for completing blade clamping, auxiliary positioning and position calibration; printing repairing forming is conducted after positioning calibration, and finally aftertreatment and detection are completed; and the positioning precision of blade repairing is well controlled, and the beneficial effects that the cast isometric crystal high-temperature alloy turbine rotor blade tip repairing method and tool is small in heat input, fine in grains, excellent in mechanical property, small in deformation, excellent in surface roughness and high in size precision, near-net forming does not need machining, and forming is rapid and efficient are achieved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

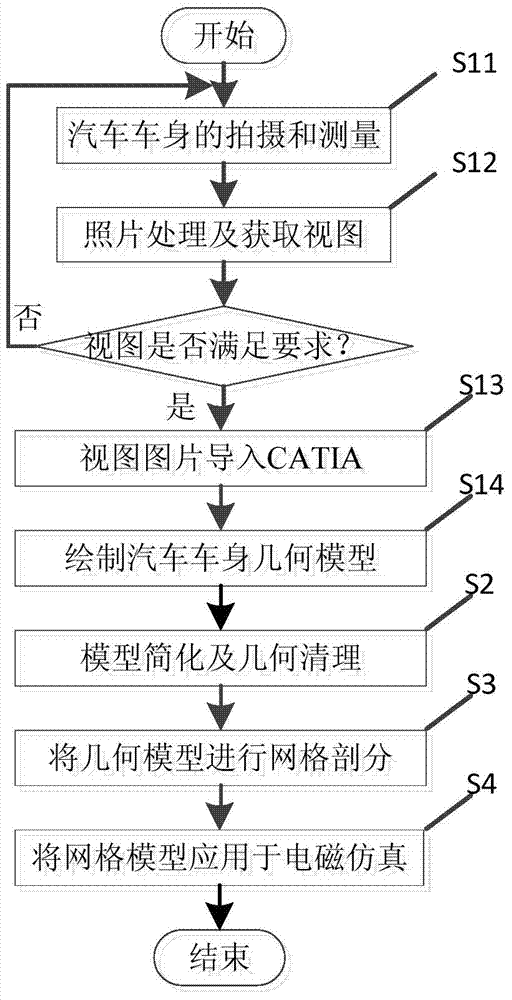

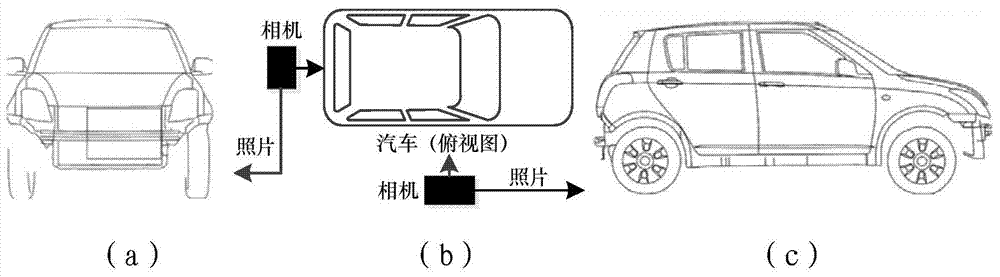

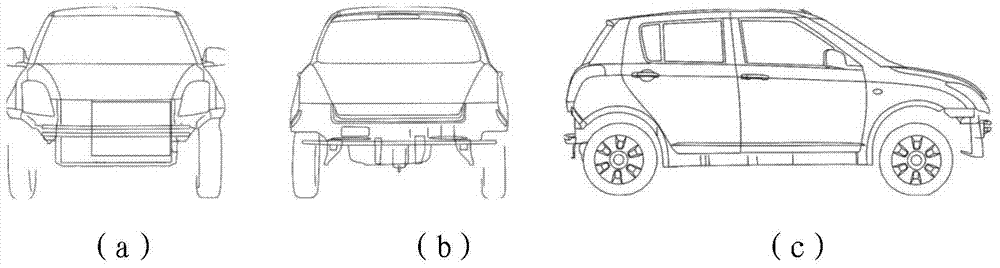

Finished automobile electromagnetic stimulation reverse modeling method

The invention provides a finished automobile electromagnetic stimulation reverse modeling method. The method includes the following steps that views in various directions are obtained according to shot pictures of an automobile body, modeling software is imported, a curved surface partitioning technology is utilized to divide the finished automobile body into curved surface blocks with continuous curvatures , and all the curved surface blocks are spliced and sewn to form a finished automobile model; the finished automobile model is simplified; mesh generation is conducted on the simplified model; the generated finished automobile mesh model is imported into the electromagnetic stimulation software for conducting stimulation analysis on finished automobile electromagnetic performance. According to the finished automobile electromagnetic stimulation reverse modeling method, the finished automobile electromagnetic stimulation model is established under the condition that a sample automobile is possessed, so that automobile electromagnetic performance stimulation analysis operation does not need to depend on finished automobile original automobile data any longer; when the finished automobile original automobile data are not available, expensive three-coordinate scanning does not need to be conducted on the sample automobile, the pictures obtained by simple and feasible shooting are used as data sources for conducting reverse modeling, on the premise that accuracy of the model is guaranteed, cost of finished automobile reverse modeling is greatly reduced, the modeling workload is effectively reduced, and time needed for modeling is effectively shortened.

Owner:CHINA AUTOMOTIVE ENG RES INST +1

Automatic repairing and remanufacturing method of turbine blade

The invention discloses an automatic repairing and remanufacturing method of a turbine blade and relates to the technical field of repairing and remanufacturing of turbine blades. The automatic repairing and remanufacturing method comprises the technological steps of scanning an original blade, establishing a three-dimensional model, conducting reverse modeling through a computer, planning a cutting area and a cutting path, conducting cutting, scanning a gap, conducting reverse modeling, conducting gap overlaying planning, conducting printing overlaying, conducting heat treatment, conducting nondestructive examination, conducting machining and conducting scanning. The determined blade is scanned through a robot 3D scanning system, the 3D model of the blade is obtained through software treatment, the to-be-cut area and the cutting path are defined on the model, and then the damaged portion is completely removed or an area to be manufactured is established. By the adoption of the technical scheme, the problems of water erosion damage repair of the blade, repair and upgrading of the blade and the like can be rapidly and efficiently solved at a high quality; and compared with traditional machining, the automatic repairing and remanufacturing method simplifies the machining technology, greatly improves the on-site machining efficiency of the blade and determines a new direction forefficient and intelligent repairing and remanufacturing for the damage of the turbine rotor blade.

Owner:DONGFANG ELECTRIC WUHAN NUCLEAR EQUIP

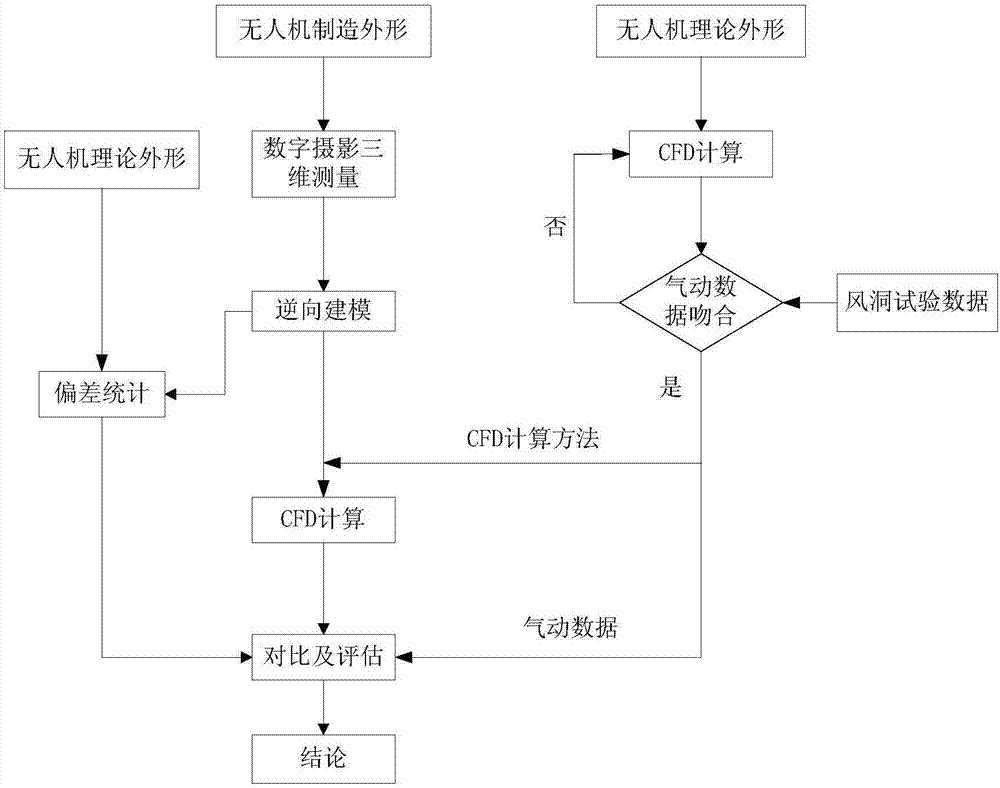

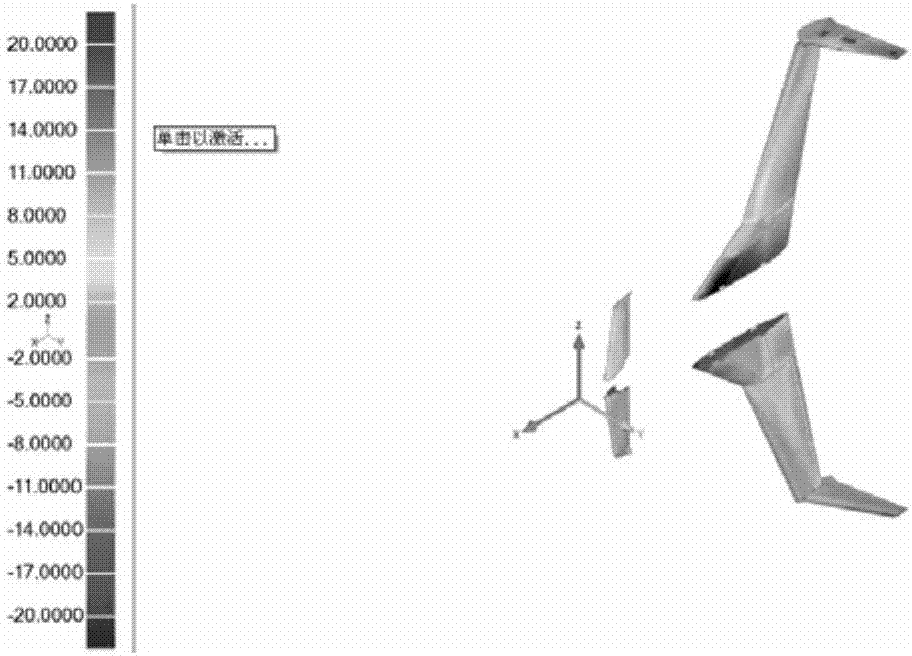

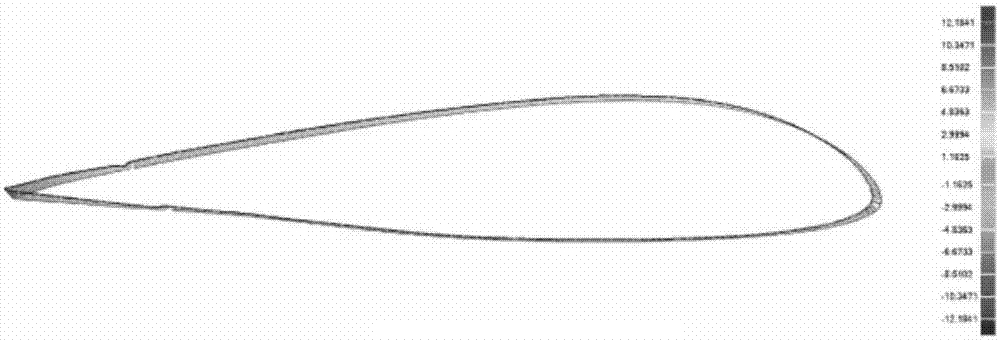

Method for evaluation of pneumatic deviation of manufactured outline of unmanned aerial vehicle

ActiveCN106864770AAvoid Flight Safety RisksImprove efficiencyGeometric CADAerodynamic testingPoint cloudUncrewed vehicle

A method for evaluation of the pneumatic deviation of the manufactured outline of an unmanned aerial vehicle comprises the following steps that (1) firstly through combination of wind tunnel test data according to the theoretical outline of the unmanned aerial vehicle, according to the curvature tolerance of pneumatic data and the wind tunnel test data which are obtained by means of the method that the unmanned aerial vehicle theory is subjected to CFD calculation, a CFD calculation method suitable for the theoretical outline of the unmanned aerial vehicle is finally determined, and secondly according to the manufactured outline of the unmanned aerial vehicle, the point cloud data of the manufactured outline of the unmanned aerial vehicle are obtained, so that reverse modeling is conducted, and a three-dimensional model is obtained; (2) the theoretical outline of the unmanned aerial vehicle and the three-dimensional model are subjected to deviation statistics, and geometric deviation value distribution of the theoretical outline of the unmanned aerial vehicle and the three-dimensional model is obtained, the obtained three-dimensional model is calculated through the determined CFD calculation method, and the pneumatic data of the manufactured outline are obtained; and (3) according to the pneumatic data obtained through CFD calculation of the manufactured outline and the theoretical outline, the pneumatic deviation of the unmanned aerial vehicle is compared, if the pneumatic data are deviated within a preset range, the manufactured outline of the unmanned aerial vehicle meets the requirement, and otherwise, the fact that the pneumatic deviation exists in the manufactured outline of the unmanned aerial vehicle is affirmed.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

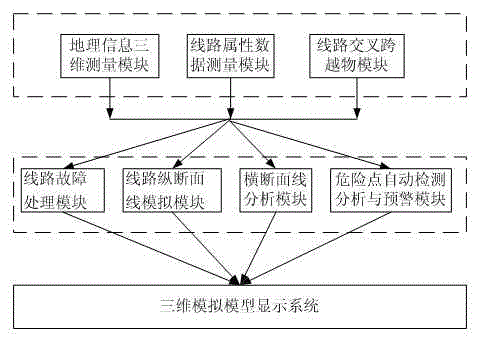

Three-dimensional visualized intelligent monitoring system for extra-high voltage transmission line

ActiveCN102946069AThree-dimensional visualization intelligent monitoring realizationRealize section analysisApparatus for overhead lines/cablesThree dimensional simulationData simulation

The invention discloses a three-dimensional visualized intelligent monitoring system for an extra-high voltage transmission line. The three-dimensional visualized intelligent monitoring system comprises an extra-high voltage transmission line data collecting system, a three-dimensional simulation model, a line data analog system and a three-dimensional simulation model display system, wherein the extra-high voltage transmission line data collecting system is used for obtaining basic geographic data along the line of an extra-high voltage direct-current transmission line and line attribute data, the three-dimensional simulation model is used for building real scenes of the extra-high voltage transmission line, and the line data analog system forms extra-high voltage transmission line monitoring signals. A three-dimensional laser radar measuring technology and a three-dimensional reverse modeling technology are adopted, a three-dimensional visualized intelligent monitoring platform is established, and three-dimensional monitoring of a direct-current extra-high voltage transmission line corridor is achieved. Automatic detection analysis and early warning of dangerous points are achieved. Cross section analysis of the line, ground feature and earth surfaces is achieved, a powerful analysis tool can be provided for overhauling, rebuilding and expanding and the like of the extra-high voltage transmission line, massive devices and channel resources are saved, share of information resources is achieved, and application of information resources is facilitated.

Owner:MAINTENANCE BRANCH OF STATE GRID CHONGQING ELECTRIC POWER +1

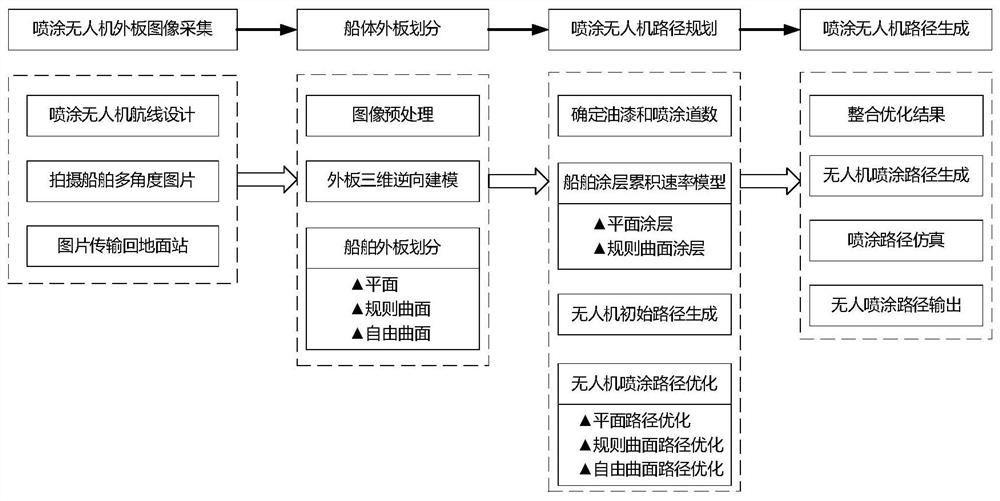

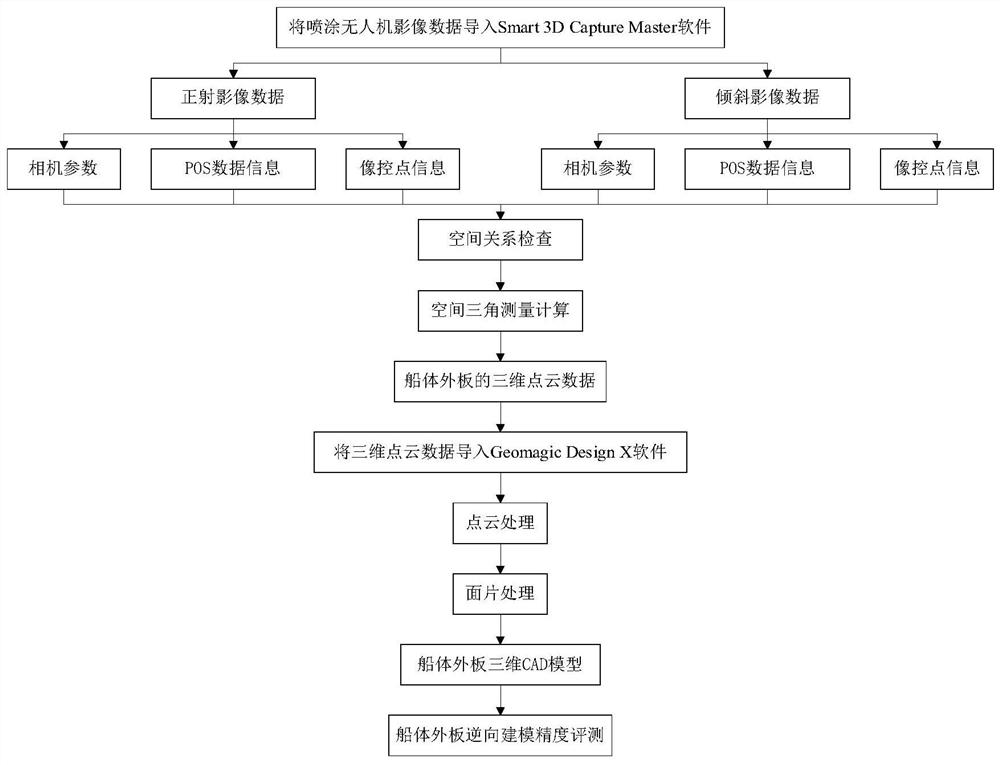

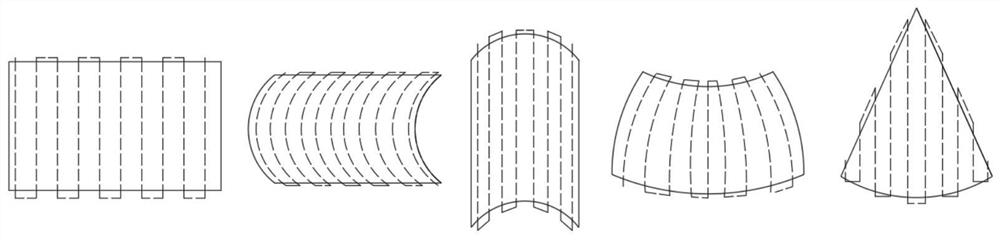

Automatic planning method for intelligent spraying path of ship outer plate based on unmanned aerial vehicle

ActiveCN112917486AImprove spray qualityImprove resource utilizationProgramme-controlled manipulatorSpraying apparatusUncrewed vehicleFlight velocity

The invention discloses an automatic planning method for an intelligent spraying path of a ship outer plate based on an unmanned aerial vehicle. The method comprises the following steps of: (1) collecting an image of the ship outer plate by using the unmanned aerial vehicle; (2) performing three-dimensional reverse modeling on the ship outer plate, and classifying the ship outer plate model according to the regularity of the shape; (3) respectively planning the flight times and spraying path of the spraying unmanned aerial vehicle for a plane, a regular curved surface and a complex curved surface; and (4) generating the spraying path of the spraying unmanned aerial vehicle and the operation parameters of the unmanned aerial vehicle. According to the automatic planning method disclosed by the invention, the three-dimensional model of the ship outer plate is quickly generated, the flight speed, spraying pressure, spray gun distance and spraying path spacing of the spraying unmanned aerial vehicle for the plane, the regular curved surface and the complex curved surface are respectively optimized by a multi-objective particle swarm algorithm, and the automatic planning method has important significance for improving the spraying quality, resource utilization rate and operation efficiency of the spraying unmanned aerial vehicle.

Owner:JIANGSU UNIV OF SCI & TECH

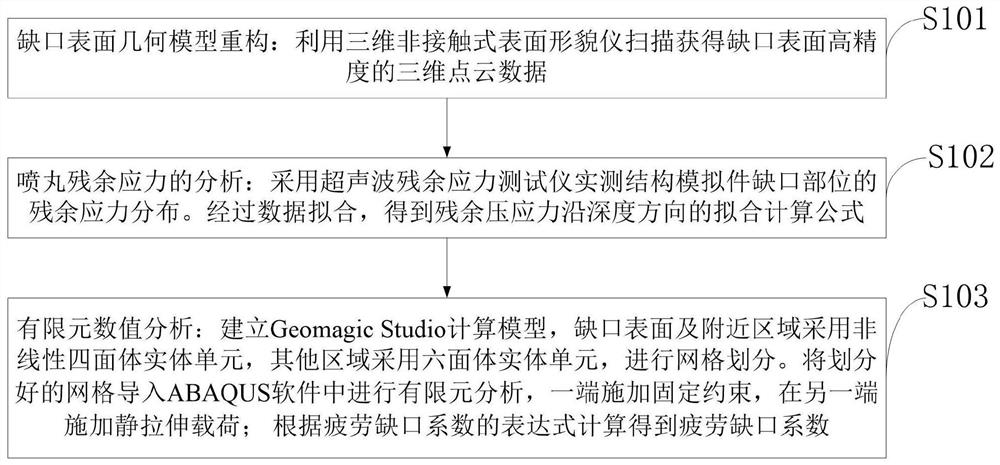

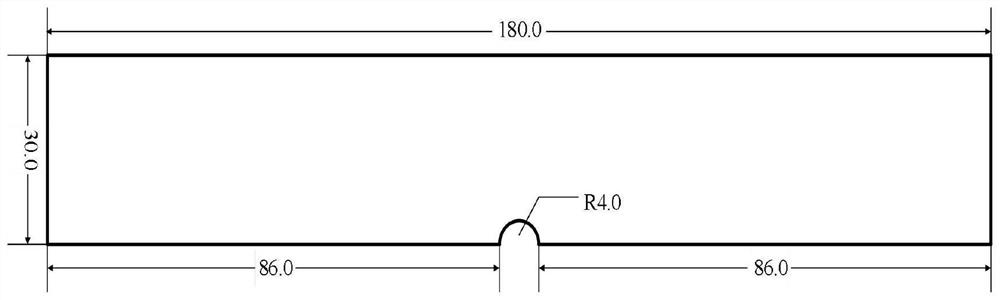

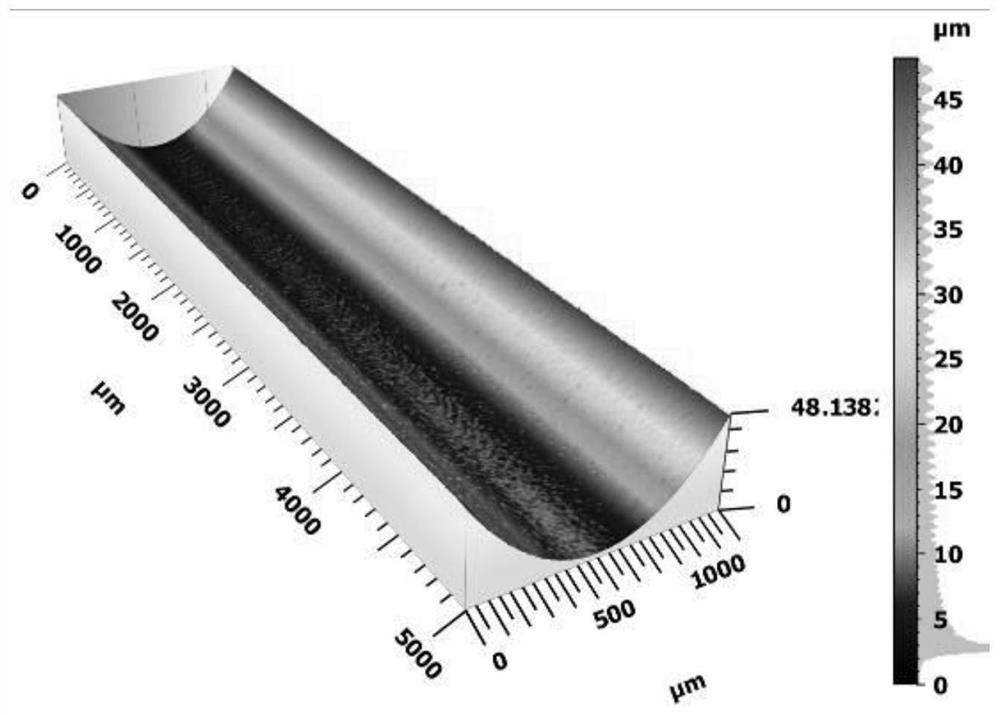

Fatigue notch coefficient data processing method considering corrosion and residual stress

ActiveCN111625985AImprove forecast accuracyImprove universalityDesign optimisation/simulationProcess efficiency improvementStress concentrationTester device

The invention belongs to the technical field of structural life reliability evaluation in a corrosive environment, and discloses a fatigue notch coefficient data processing method considering corrosion and residual stress. The method includes: reconstructing a notch surface geometric model; actually measuring the residual stress distribution of the notch part of the structural simulation piece byadopting an ultrasonic residual stress tester; obtaining a fitting calculation formula of the residual compressive stress along the depth direction through data fitting; establishing a finite elementtheoretical analysis model by adopting a reverse modeling technology, carrying out mesh generation, and obtaining a stress concentration coefficient through analysis; and obtaining the stress concentration coefficient under the corrosion condition based on analysis. The theoretical calculation method provided by the invention better conforms to the actual condition of structure service, and the prediction precision of the fatigue life is obviously improved. According to the method, the influences of corrosion damage and residual stress caused by the microstructure, the structural boundary dimension and the environment of the material can be considered, and the fatigue notch coefficient calculation method provided by the invention is wider in application range and good in universality.

Owner:恒创联拓(青岛)航空科技有限公司

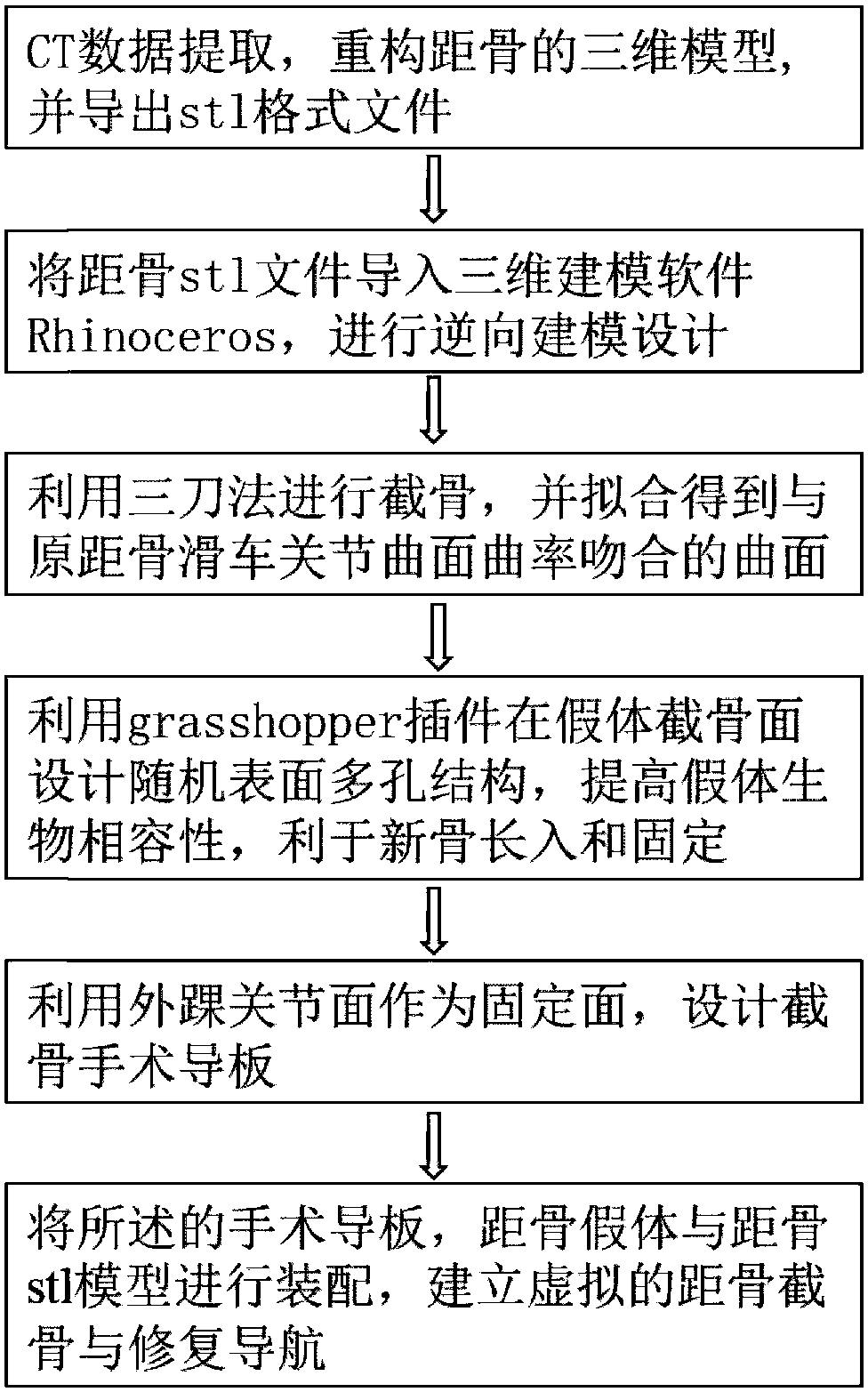

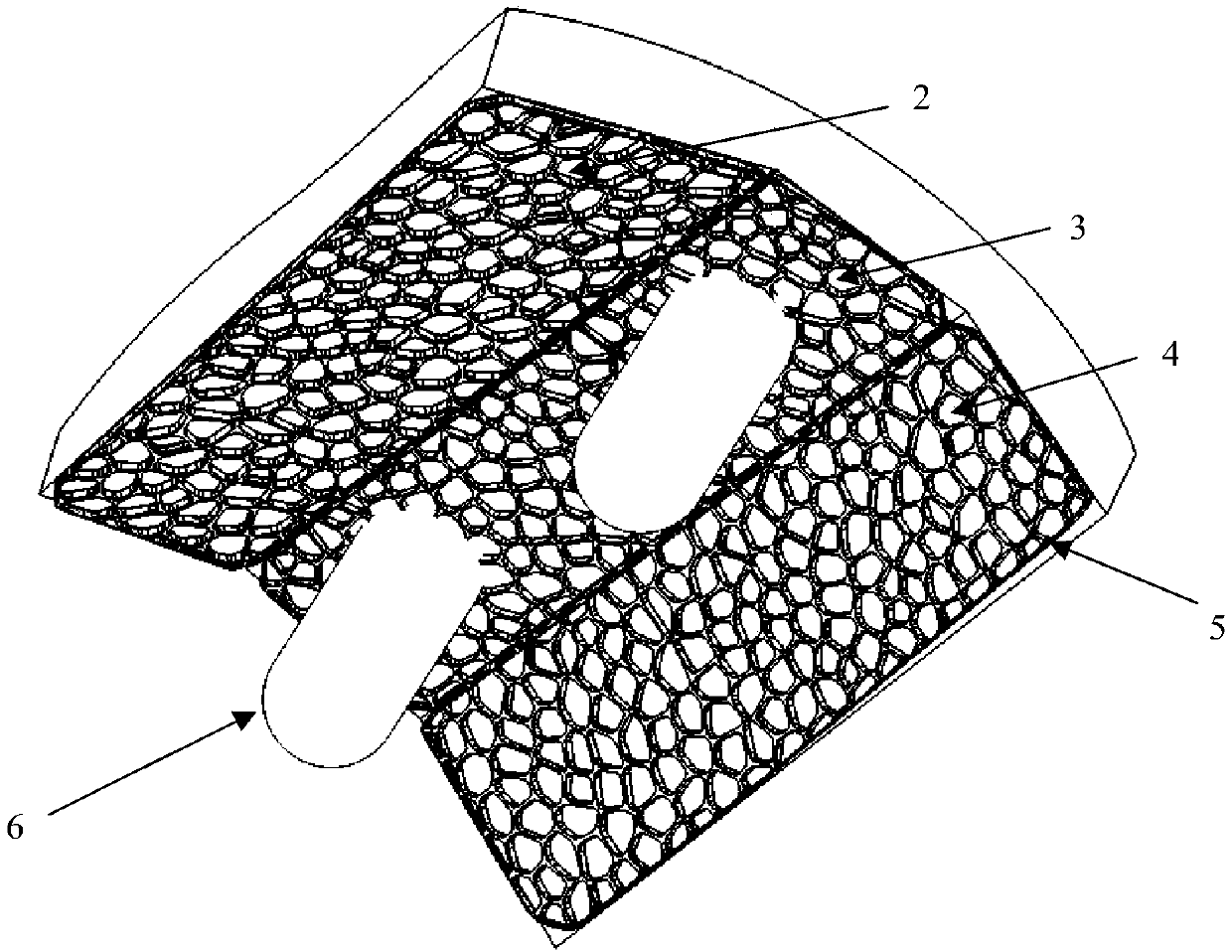

Personalized porous structure astragalus restoration, osteotomy surgical guide plate and design method thereof

PendingCN108030532AHigh degree of reductionImprove adaptabilityBone drill guidesArticular surfacesArticular surface

The invention discloses a personalized porous structure astragalus restoration, an osteotomy surgical guide plate and a design method thereof. The design method comprises the following steps of extracting CT data, reconstructing a three-dimensional model of astragalus, and exporting a stl format file; importing the stl file into a three-dimensional modelling software Rhinoceros for an inverse modeling design; using a three-knife method to perform osteotomy, and obtaining a curved surface fitted with curvature of a curved surface of an original astragalus hinge joint through matching; using a grasshopper plug-in to design a random surface porous structure on a prosthesis osteotomy surface, improving the biocompatibility of a prosthesis, facilitating new bone ingrowth, fixedly using a lateral malleolus articular surface as a fixing surface, and designing the osteotomy surgical guide plate; assembling the surgical guide plate, the astragalus prosthesis and a astragalus styl model, and establishing a virtual astragalus osteotomy and repair navigation. The method is based on the CT data of the astragalus of a patient, and combined with the reverse modeling design and an forward modelingdesign to design the astragalus restoration and the osteotomy navigation.

Owner:SOUTH CHINA UNIV OF TECH

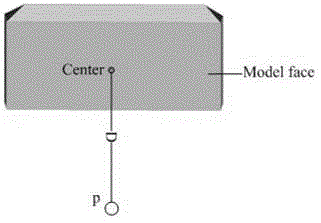

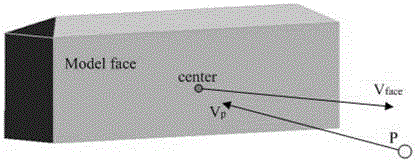

Full-automatic texture mapping method based on vehicle-mounted laser measurement system

InactiveCN103955959AImproved texture efficiencySave human resourcesImage analysis3D modellingPoint cloudData modeling

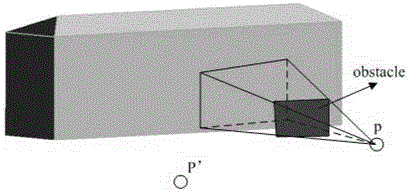

The invention relates to the technical field of surveying and mapping data modeling and computer graphics and particularly relates to a full-automatic texture mapping method based on a vehicle-mounted laser measurement system. For three-dimensional model faces generated from vehicle-mounted laser point clouds, through analysis of the position and attitude of a camera which takes a plurality of pictures along the way, a picture which has a highest effective pixel value relative to a corresponding texture model face is automatically selected and then a texture pixel area corresponding to the model face is captured and stored as a final texture file and then a texture coordinate (u,v) is calculated. The method is capable of realizing automatic selection of a texture picture with the highest quality, corresponding to each model face, and calculation of a corresponding texture coordinate under a condition that vehicle-mounted laser point clouds and camera internal and external orientation elements are given so that automatic three-dimensional model mapping is completed. For a three-dimensional reverse modeling problem which needs to use live-action mapping, the method effectively shortens the time of a texture mapping step in a modeling overall process so that a traditional manual mapping process can be substituted completely; and the method is an obvious improvement of a three-dimensional reverse modeling working process.

Owner:BEIJING TOVOS TECH

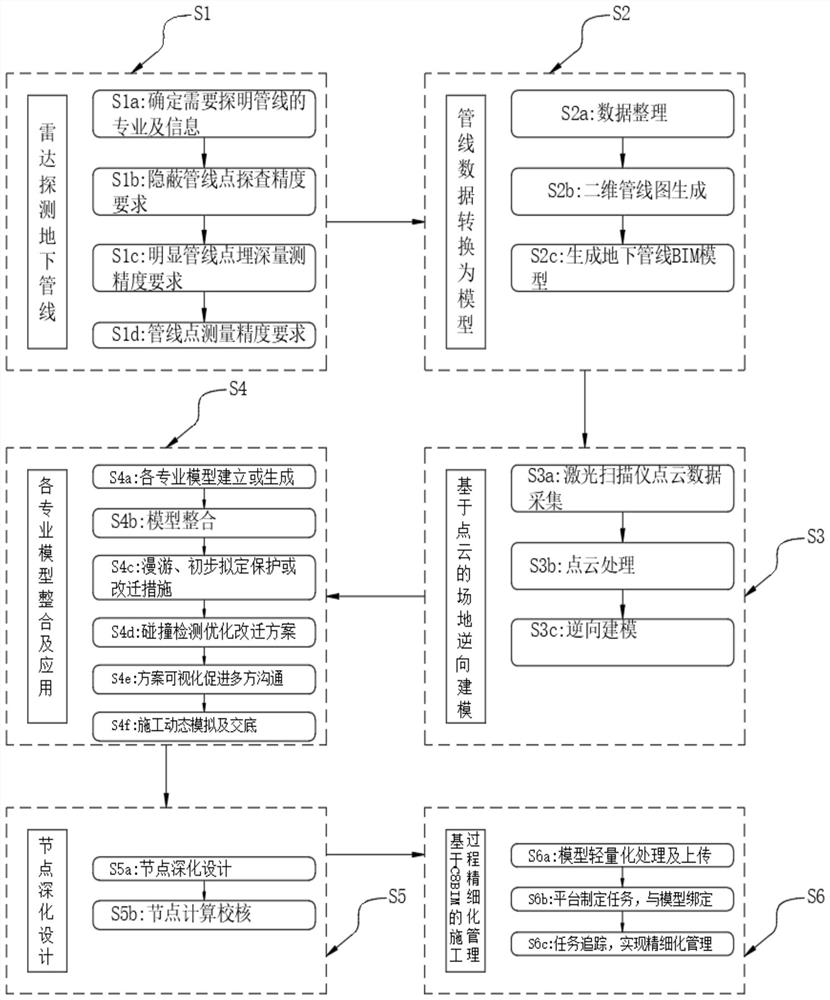

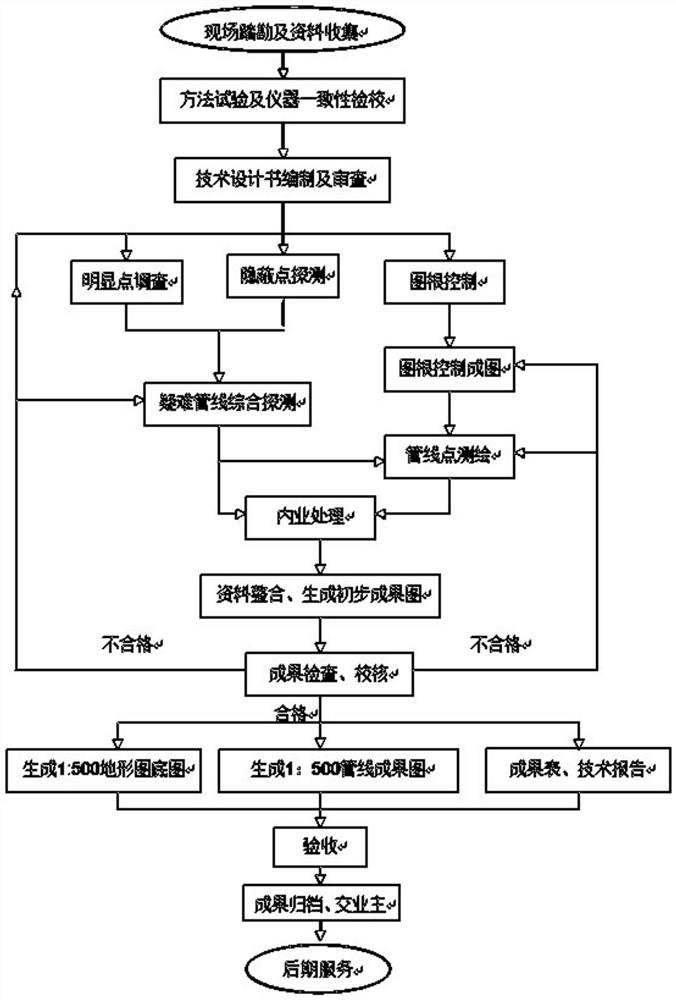

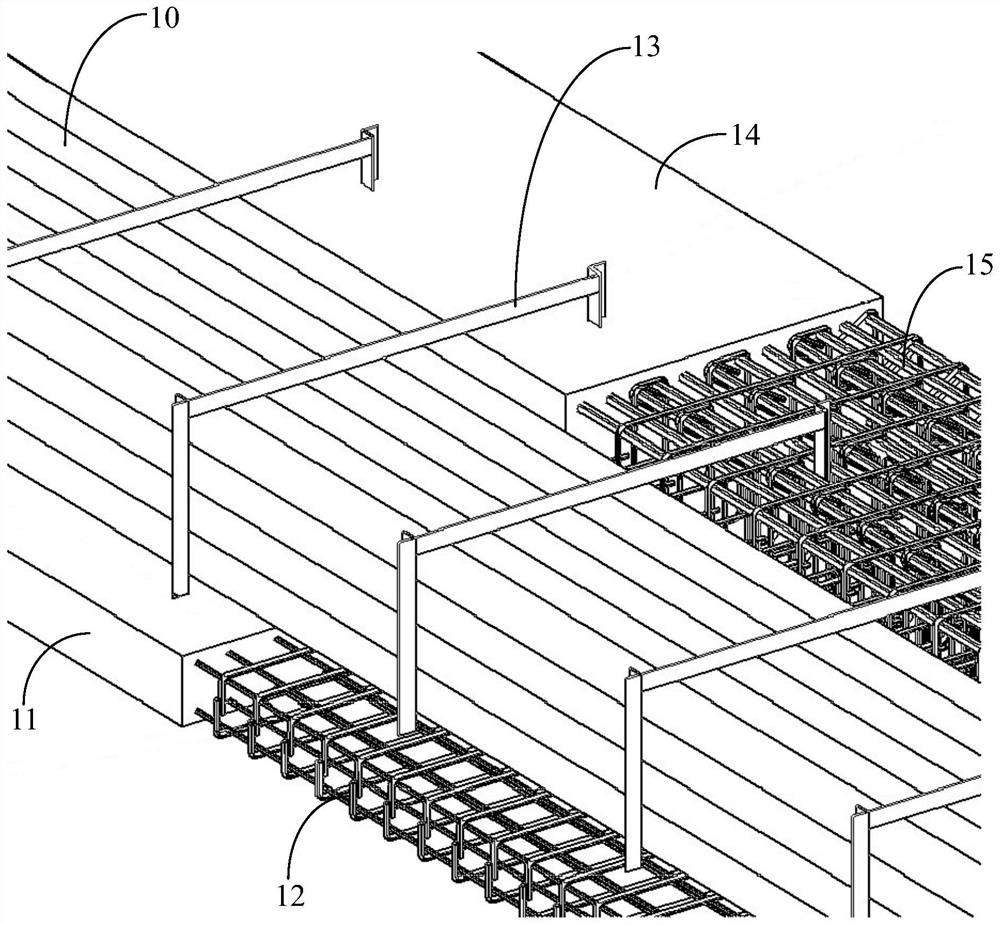

BIM-based metro station municipal pipeline relocation construction method

PendingCN112989532ASolve rationalityAddress riskGeometric CADVirtual/augmented realityMetro stationScanner

The invention discloses a BIM (Building Information Modeling)-based metro station municipal pipeline relocation construction method. The method mainly comprises the following steps: detecting underground municipal pipelines in a construction area by using a radar; building an underground pipeline model by using the BIM; using a laser scanner to generate point cloud data to perform reverse modeling on the terrain and surrounding environment of the construction area; building a construction site, a station main body and an enclosure structure model of each stage, and preliminarily drawing up a pipeline relocation scheme of each stage in combination with the underground comprehensive pipeline model; optimizing a migration and modification scheme through dynamic migration and modification simulation; visually displaying the installation node deepening design through BIM; and in combination with a collaborative management platform, carrying out accurate management and control on the relocation process. The invention aims to solve the problems that the pipeline cannot be accurately positioned on the drawing, the construction communication coordination difficulty is high, the construction efficiency is low and the like.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com