Patents

Literature

34results about How to "High degree of assembly automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

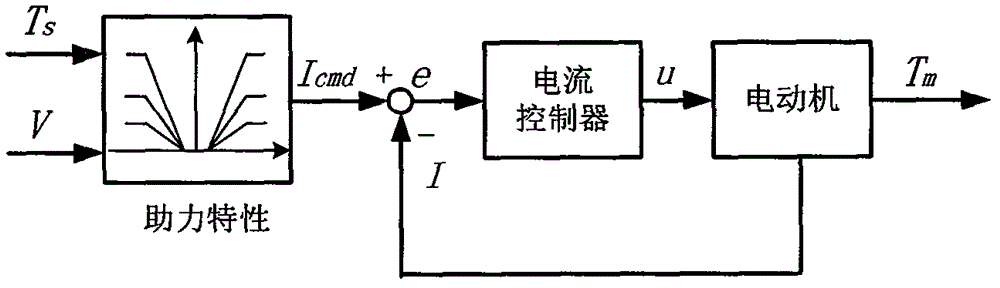

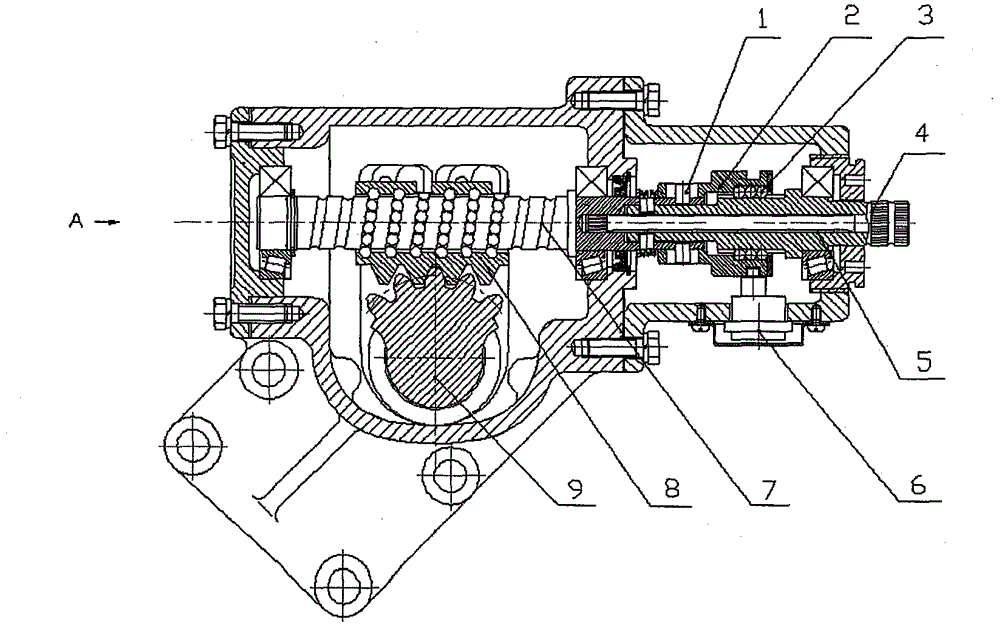

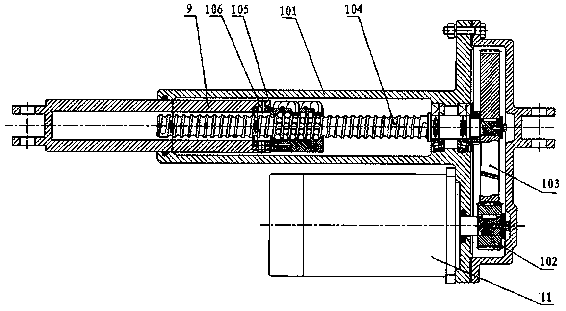

Circular ball type electric booster steering device

ActiveCN1647984AReduce disturbanceReduce pollutionMechanical steering gearsElectrical steeringElectric power steeringElectronic controller

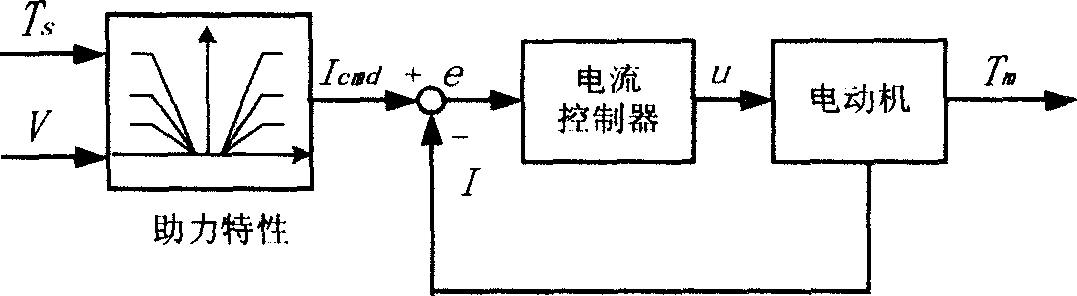

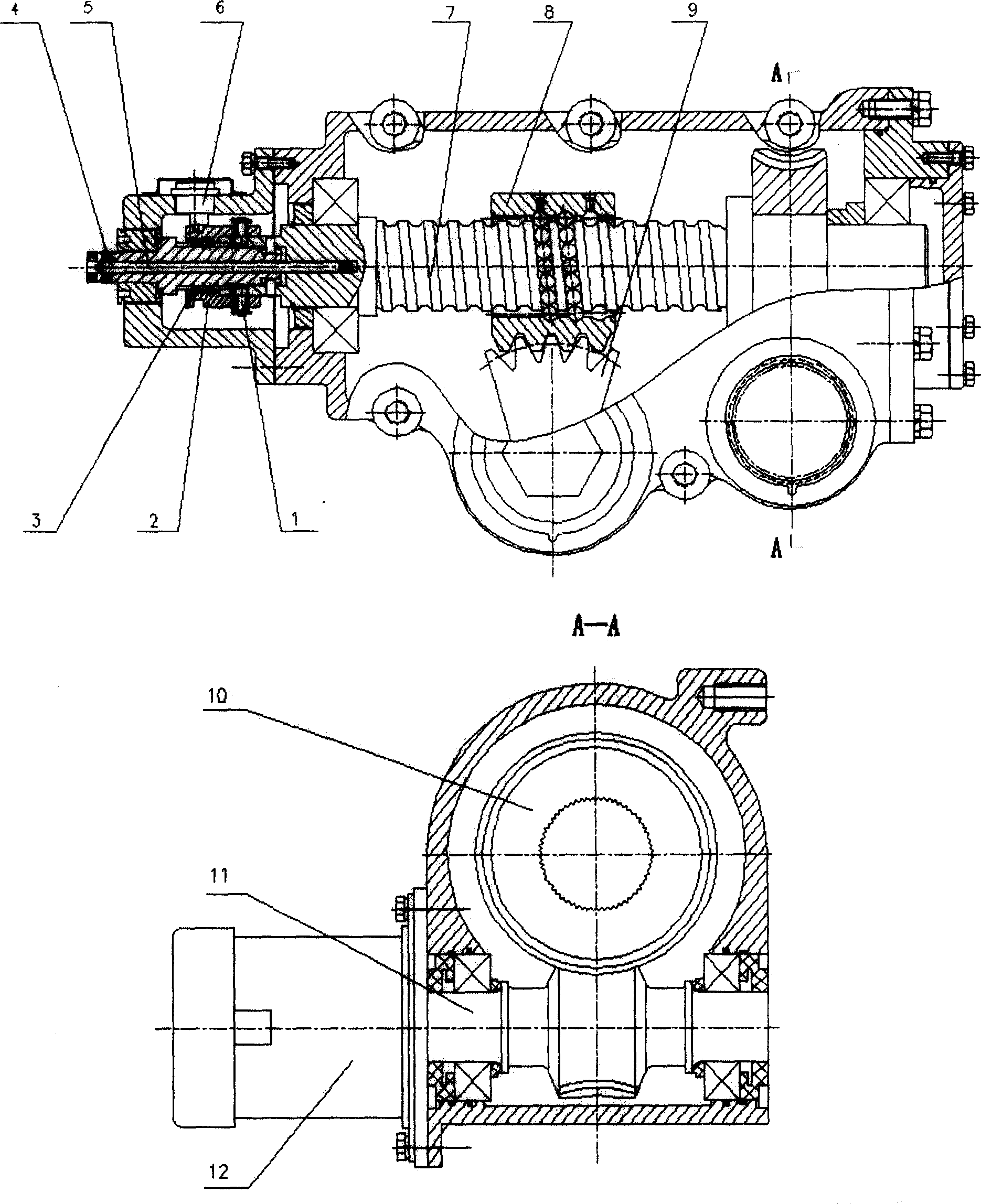

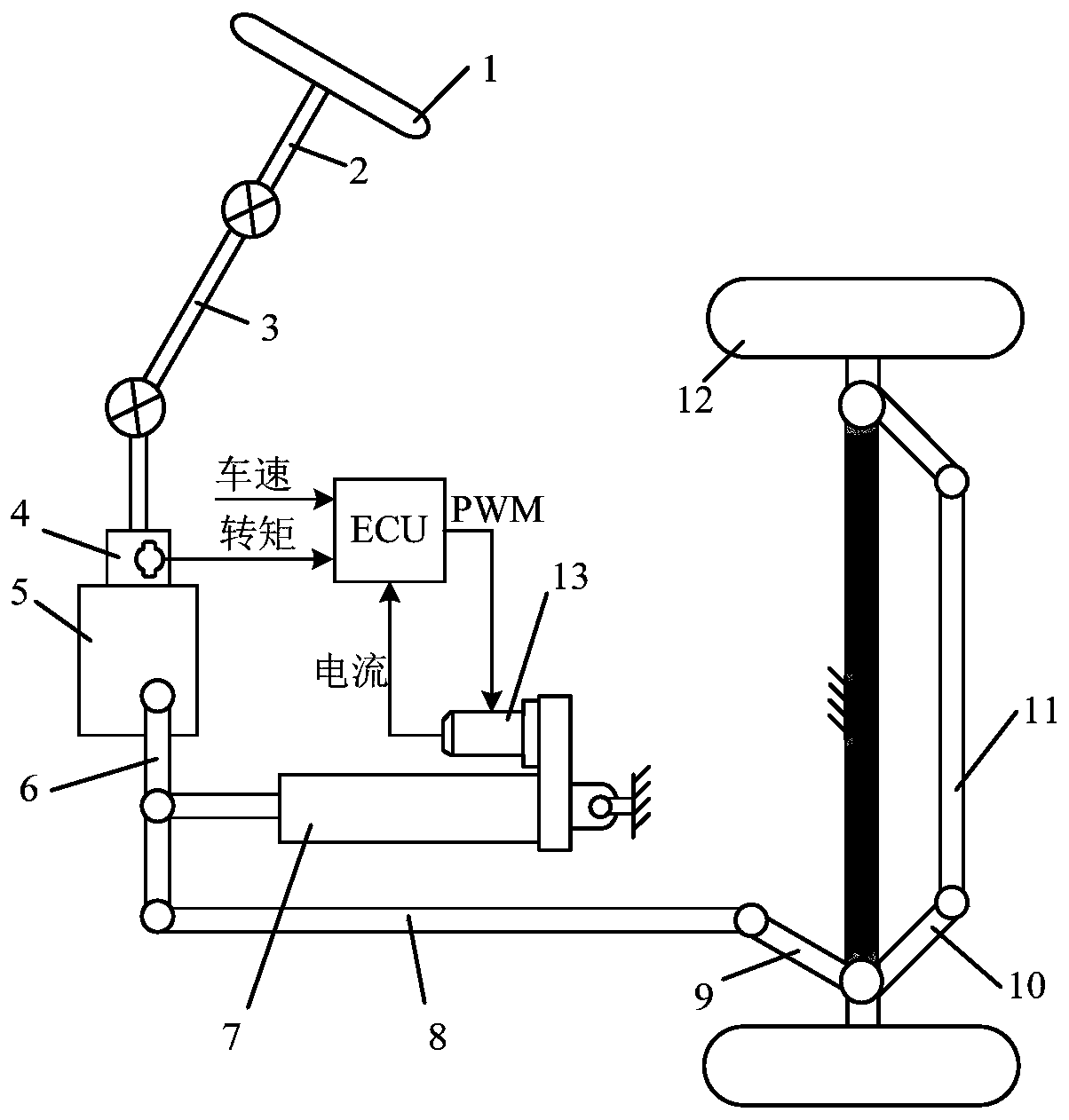

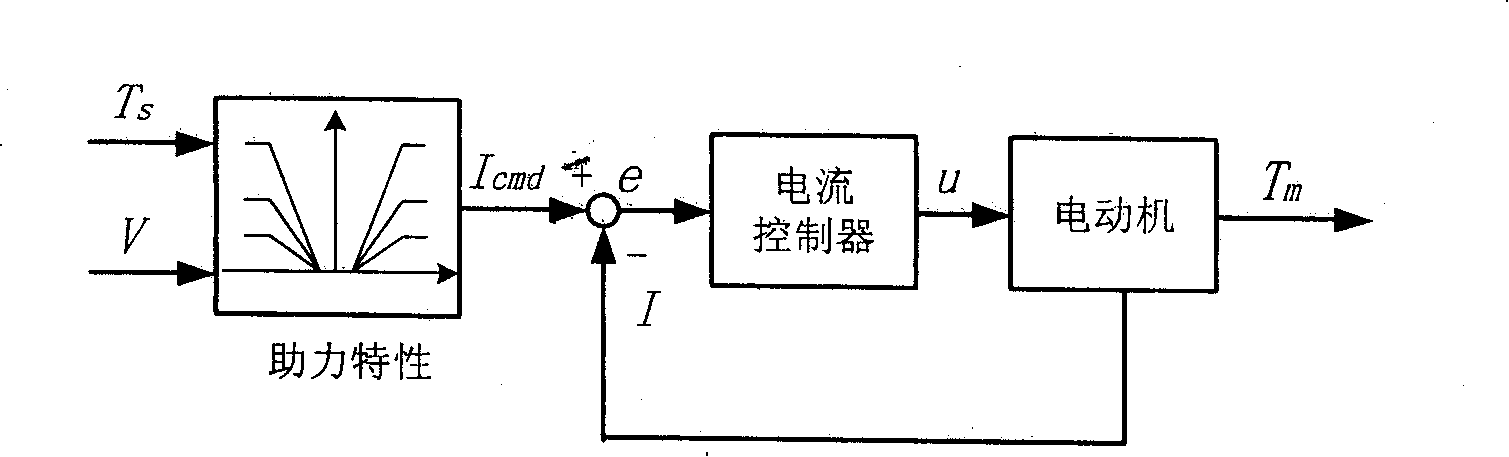

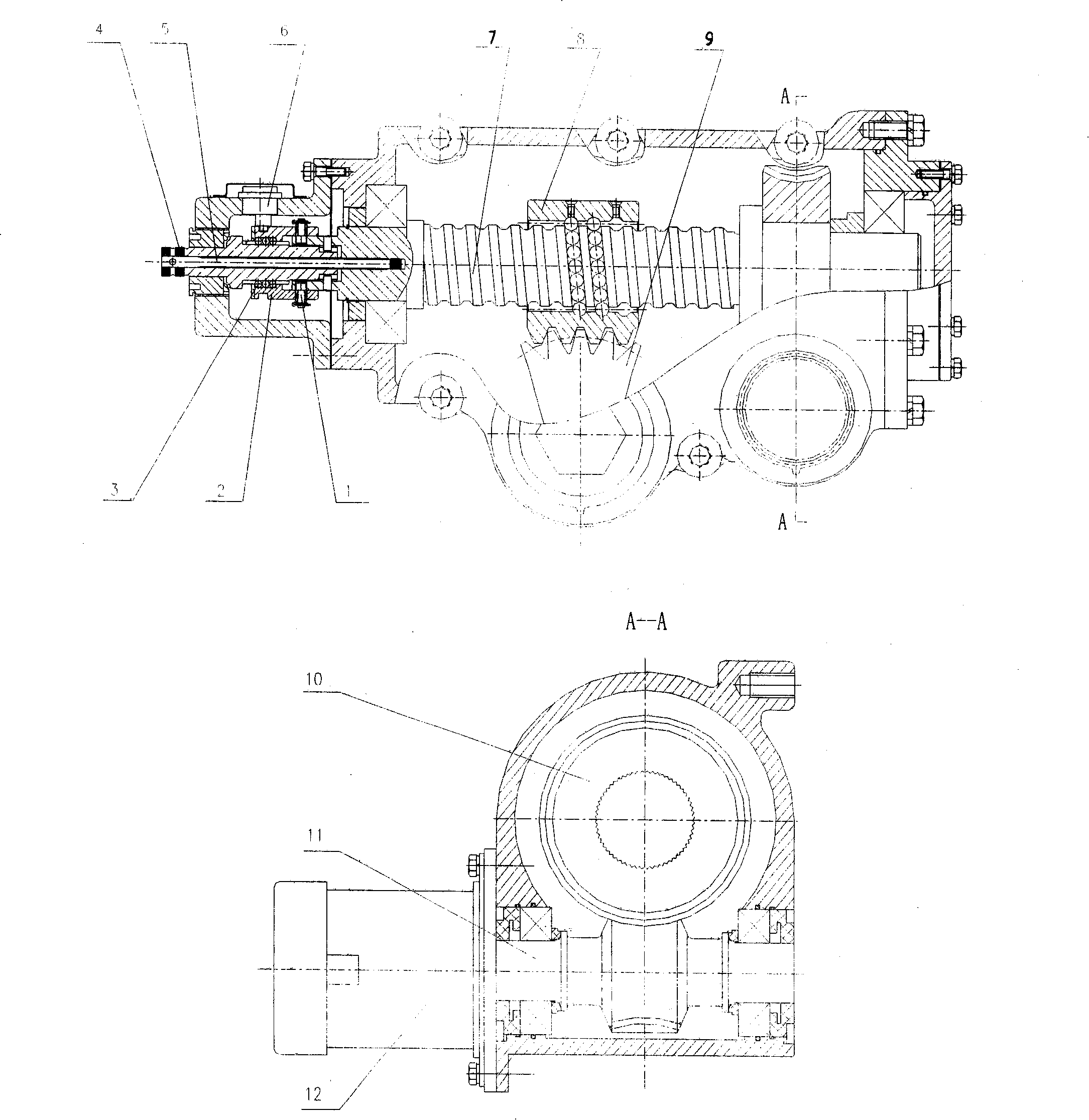

The circular ball type electric booster steering device has, except screw, nut, gear sector, steel ball and other mechanical parts, torque sensor, boosting motor, decelerating mechanism, electronic controller unit, etc. The electronic controller unit determines the target current of the motor based on the steering disc torque and the vehicle speed to complete the feedback tracking control of the motor current. The decelerating mechanism has input connected to the motor and output connected to the screw or gear sector shaft in the circular ball steering unit. The present invention has saving in energy, provides proper power force fitting different running conditions, and has less parts, light weight, compact structure and high automation.

Owner:BEIJING AUTONICS TECH

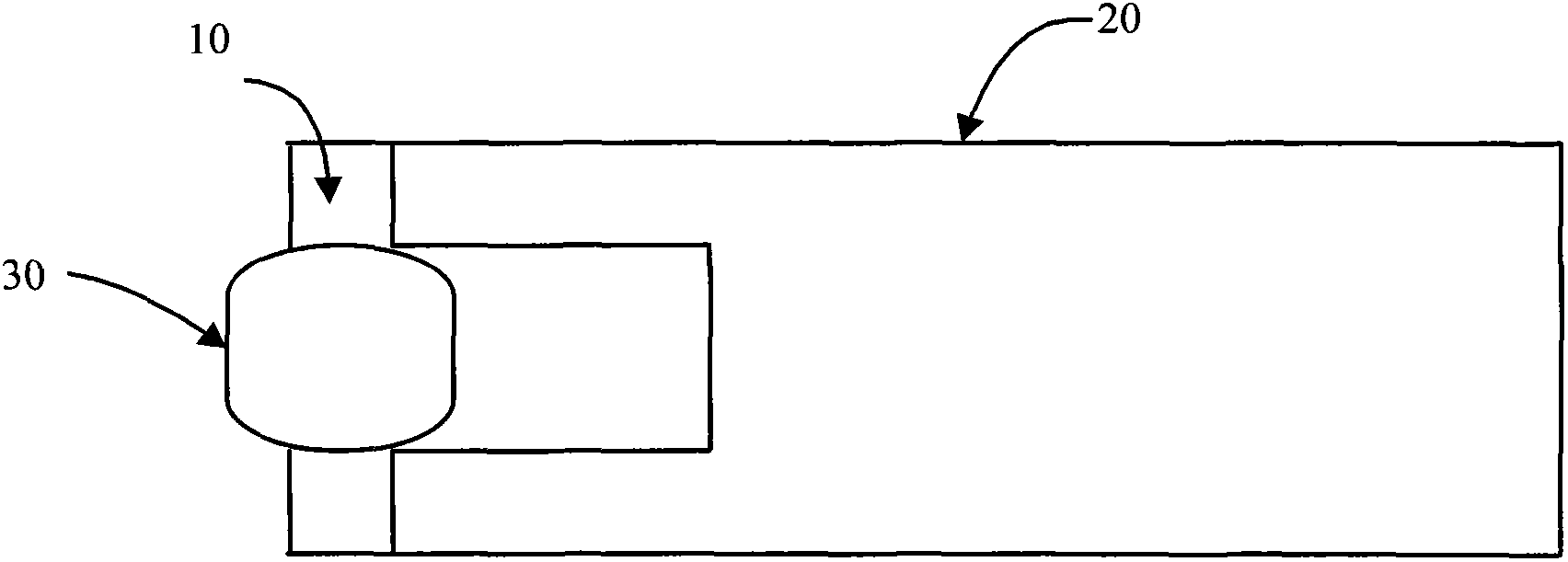

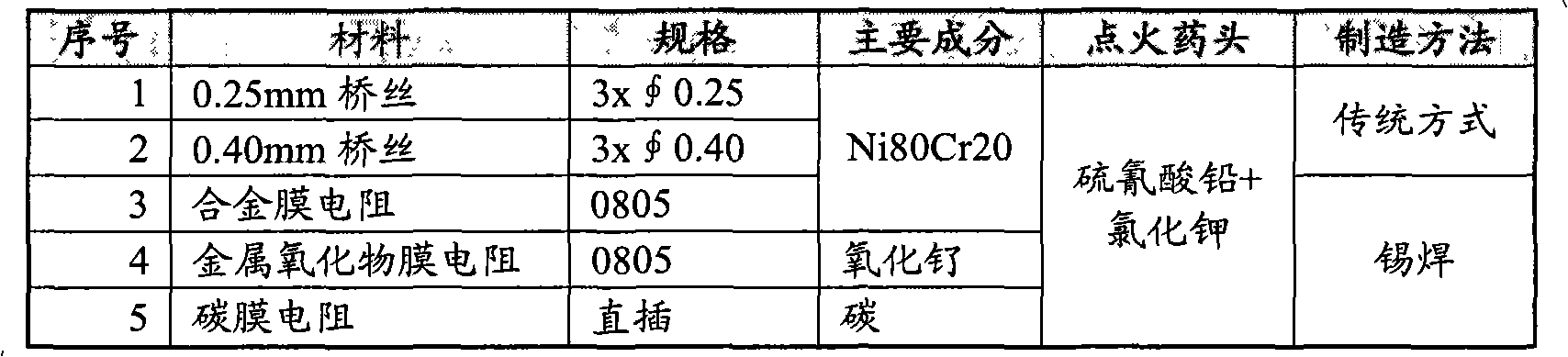

Electric fuse ignition device, electric detonator comprising electric fuse ignition device, electronic detonator comprising electric fuse ignition device, and manufacturing methods for electric detonator and electronic detonator

InactiveCN102878877AEasy to manufactureSimple preparation processBlastingAmmunition fuzesElectrical resistance and conductanceElectricity

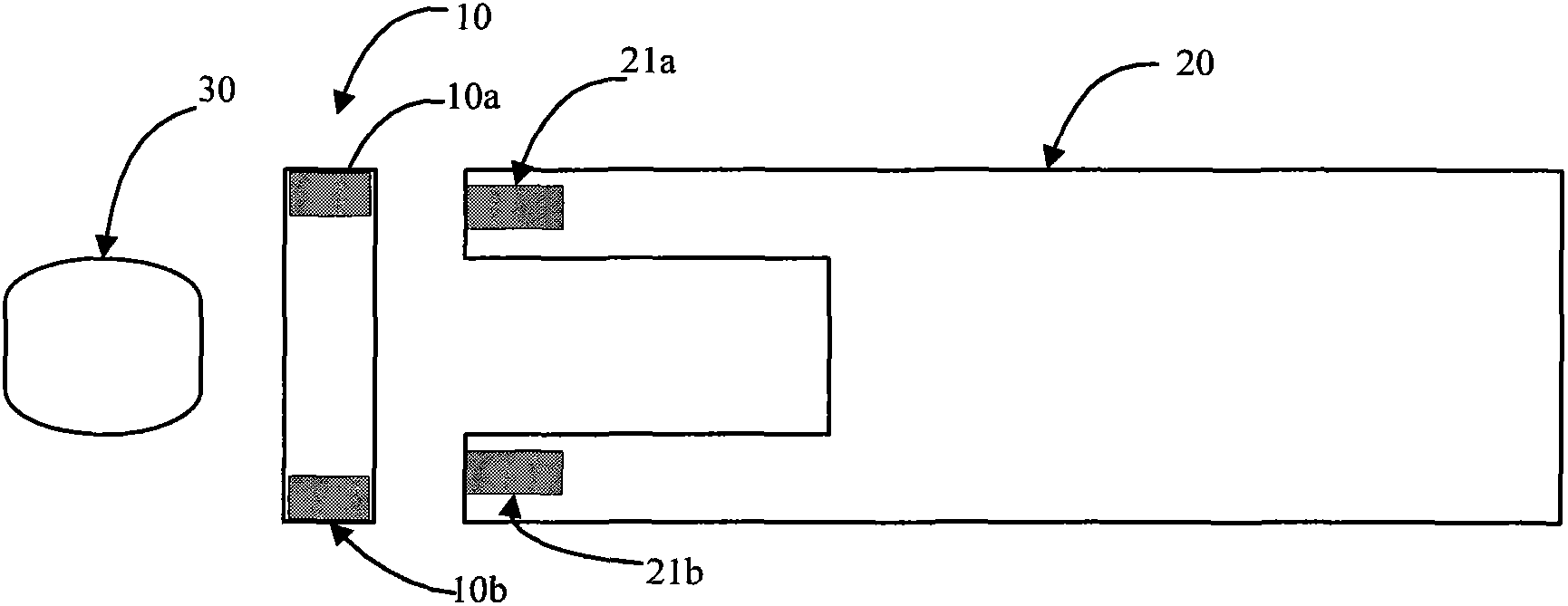

The invention provides an electric fuse ignition device. The electric fuse ignition device comprises a film resistor and an ignition explosive head wrapping the film resistor, wherein a power supply device can supply energy to the film resistor so that the film resistor generates enough joule heat and heats the ignition explosive head to a set temperature; and therefore, the ignition explosive head is lighted. The invention also provides an electric detonator comprising the electric fuse ignition device and an electronic detonator comprising the electric fuse ignition device. The invention also provides manufacturing methods for the electric detonator and the electronic detonator. According to the electric fuse ignition device provided by the invention, the film resistor is easy to manufacture, low in cost, high in yield, not easy to break and high in resistance precision, so that the electric detonator comprising the electric fuse ignition device and the electronic detonator comprising the electric fuse ignition device also have the advantages that the manufacturing is simple, the cost is low, the yield is high, the misfire rate is low, and the explosion precision is high. The manufacturing methods for the electric detonator and the electronic detonator are high in assembly automation degree, precise, reliable, high in yield and low in cost.

Owner:XINJIANG CHUANGANDA ELECTRONICS TECH DEV

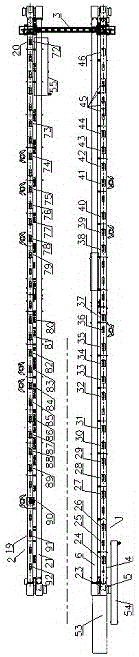

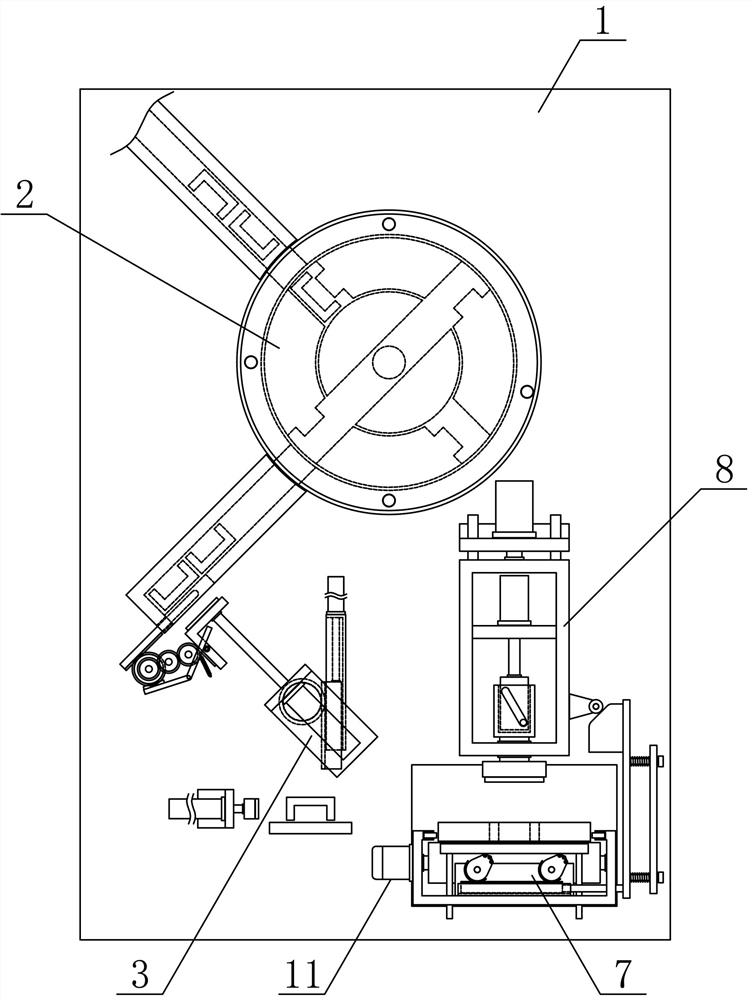

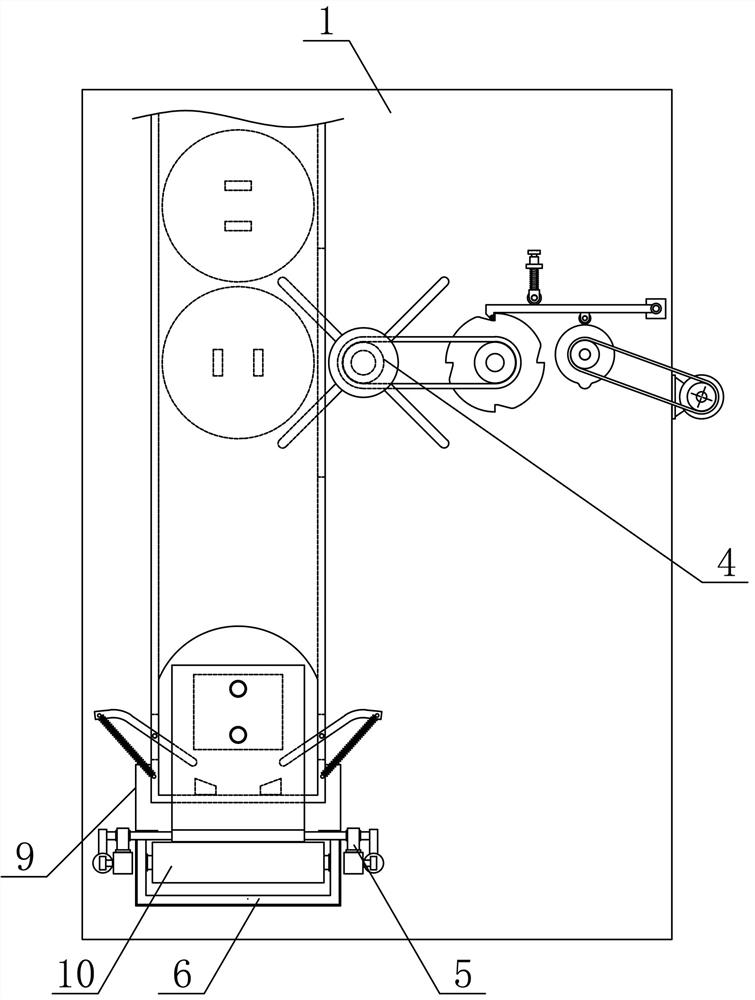

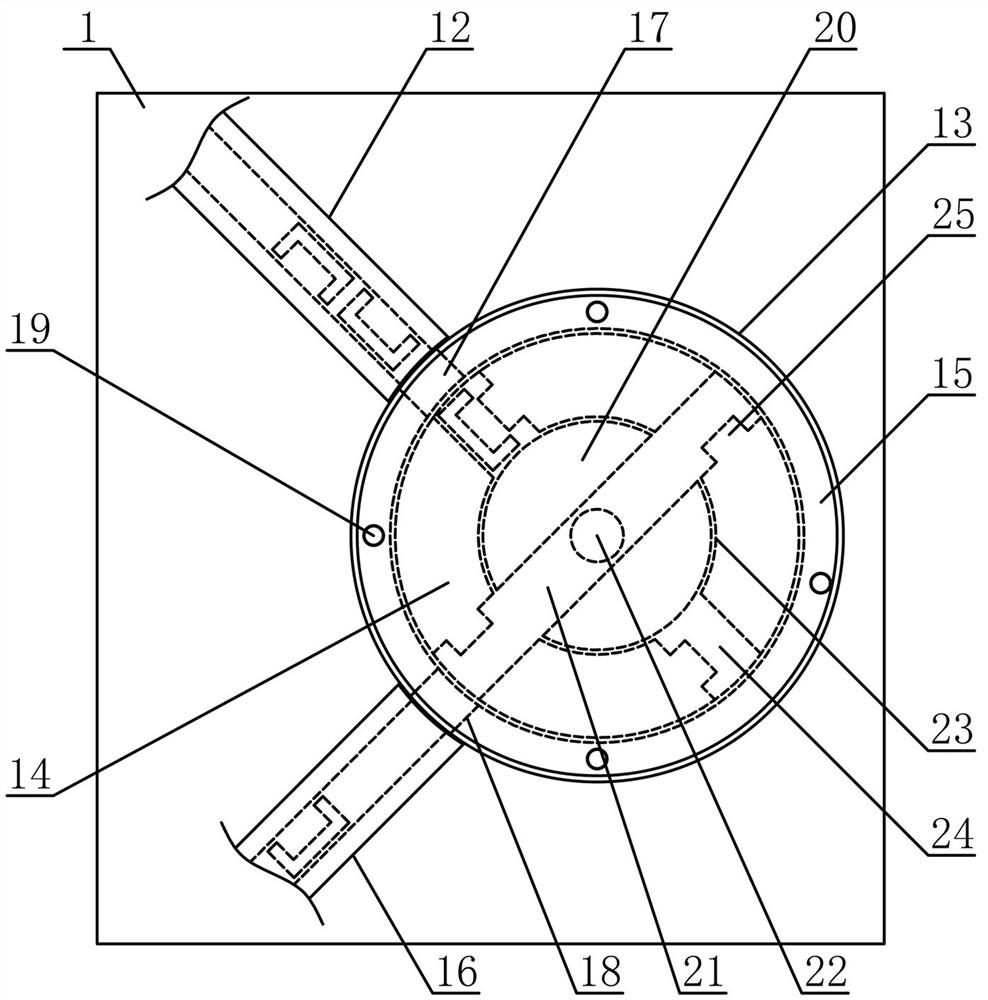

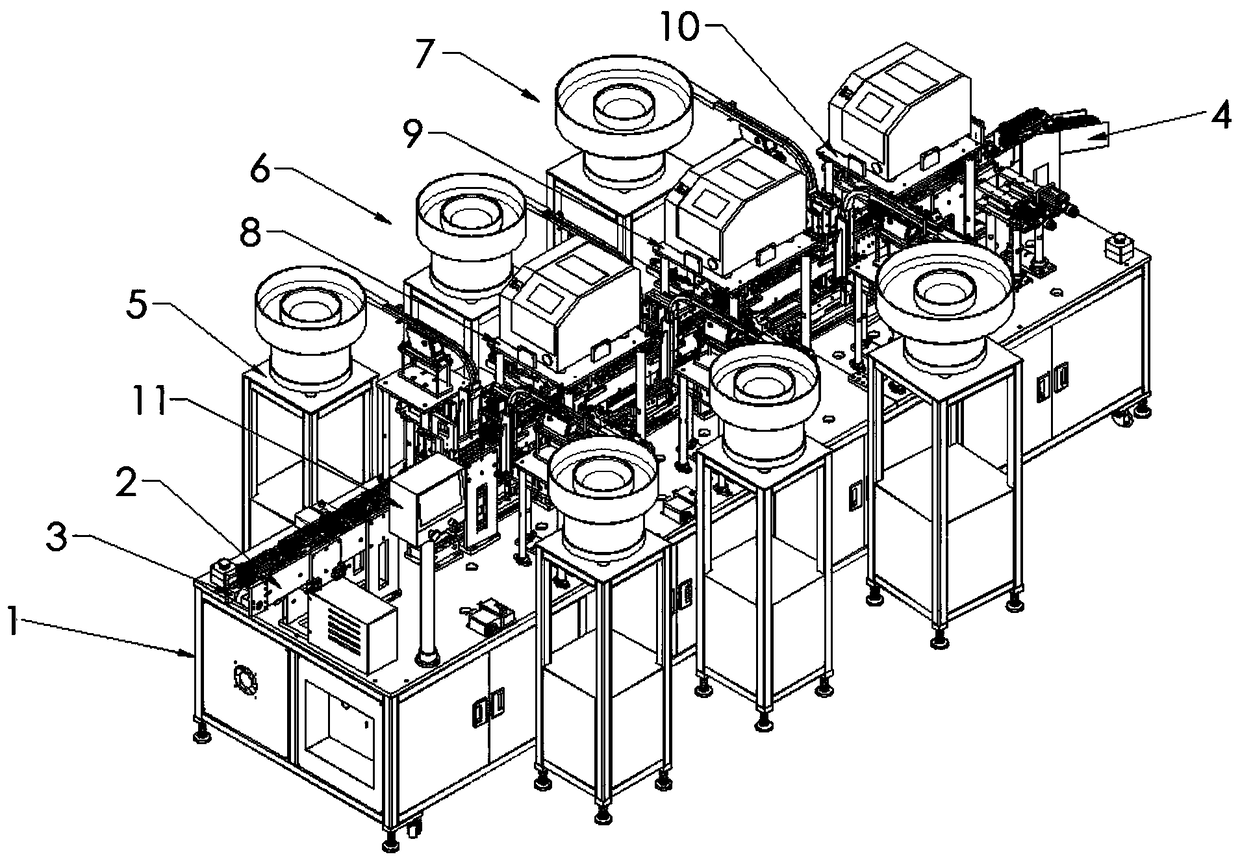

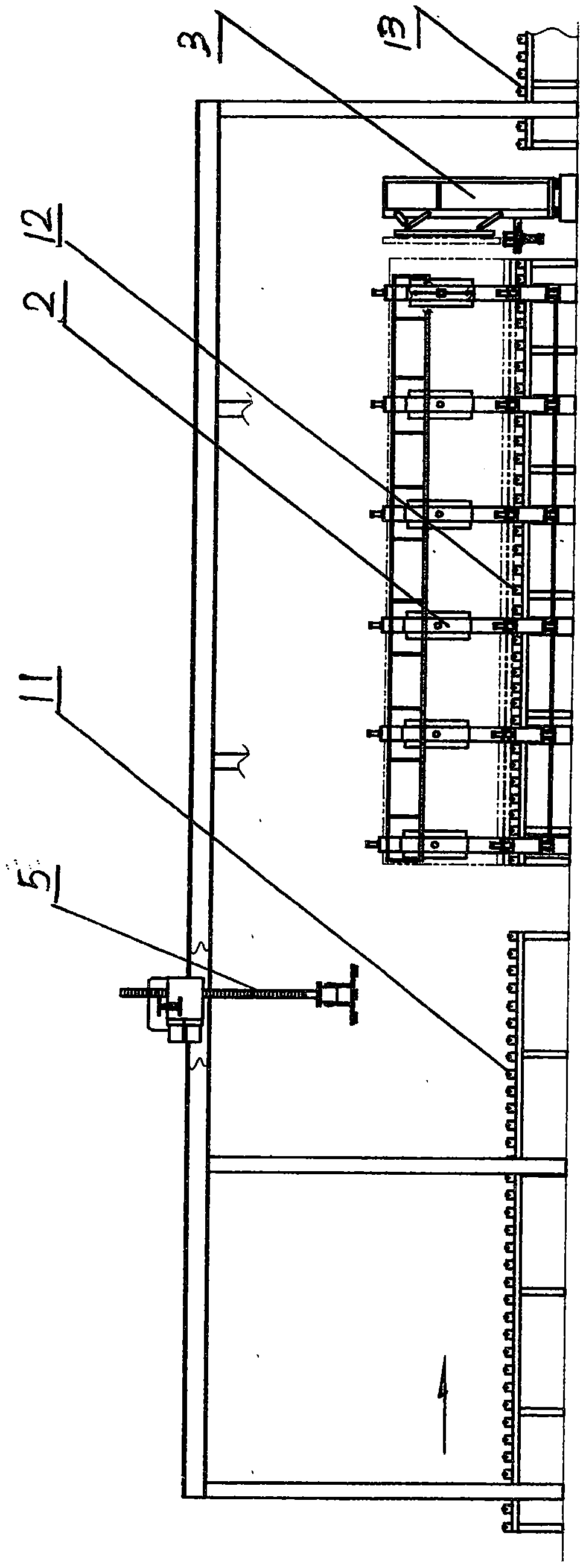

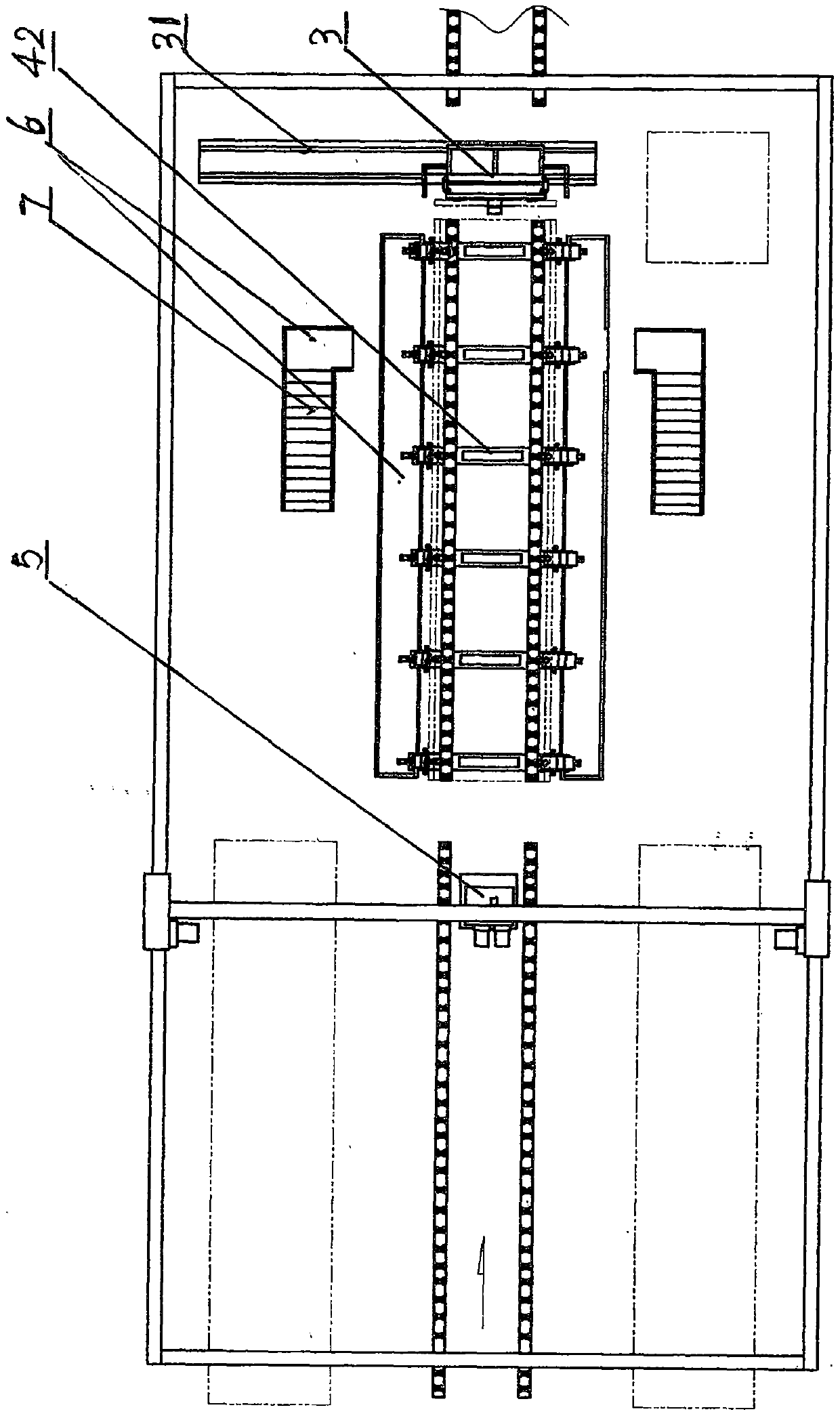

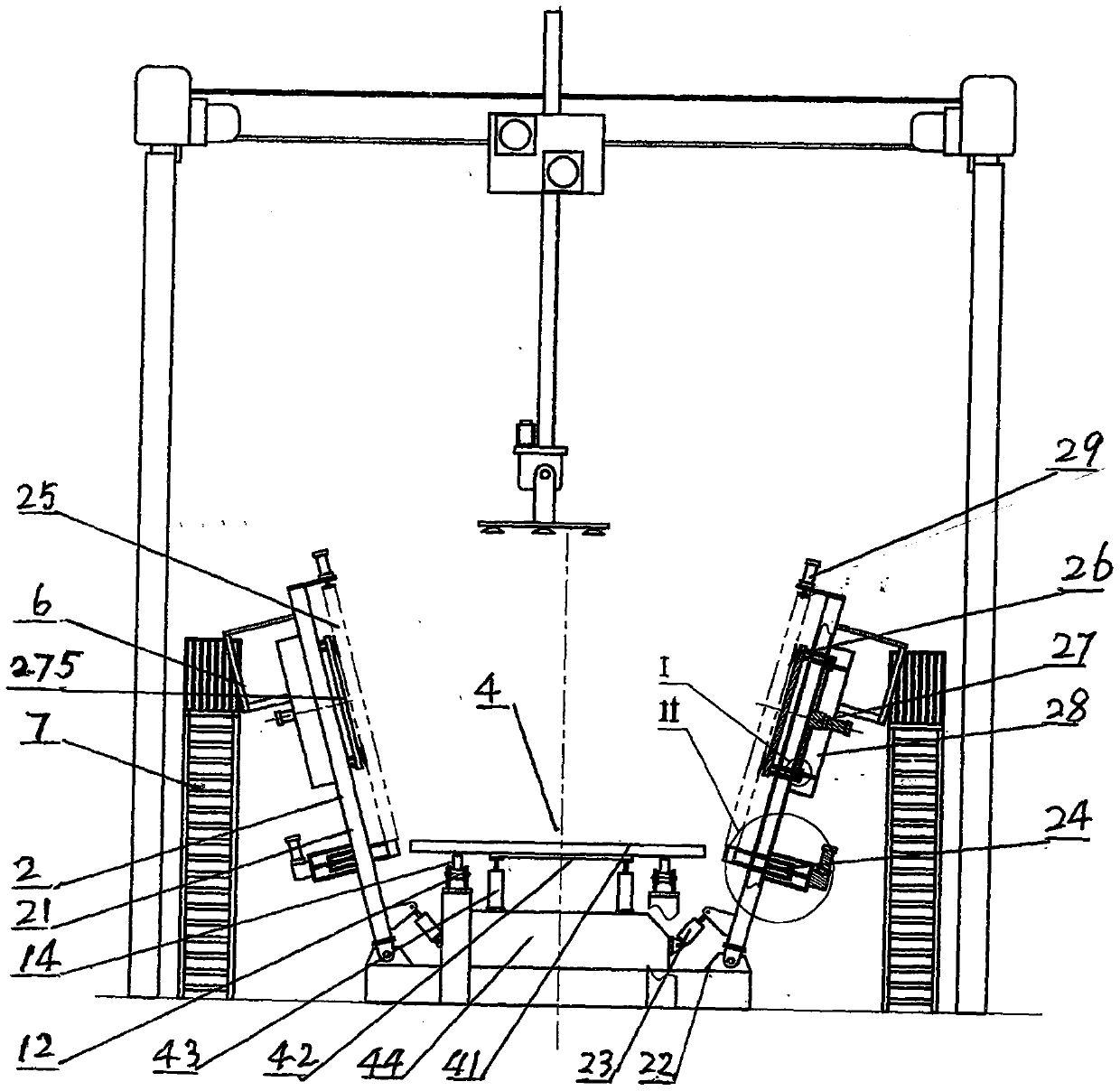

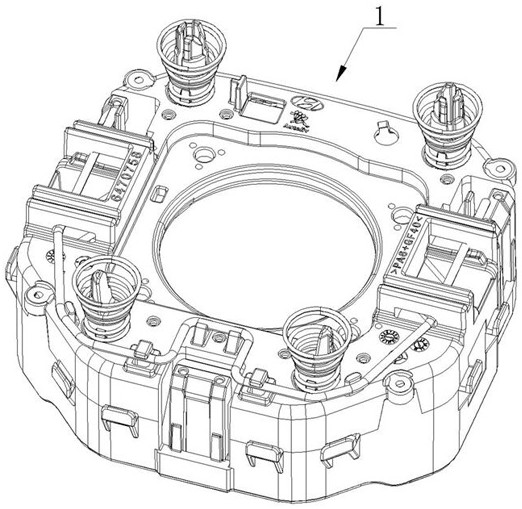

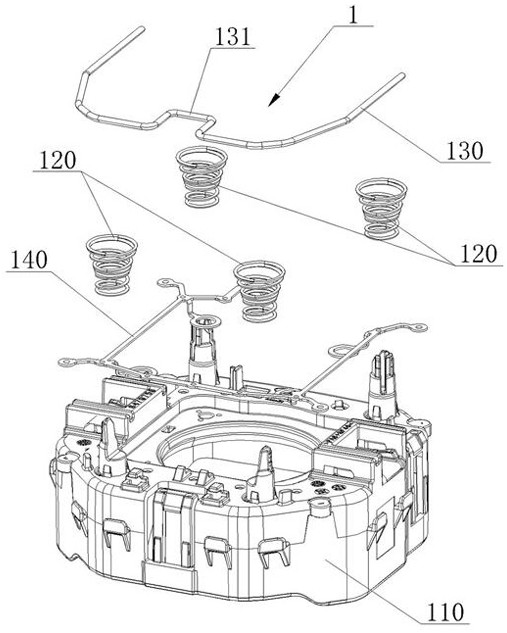

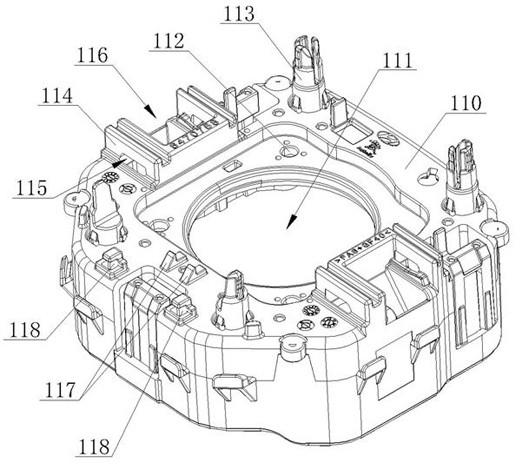

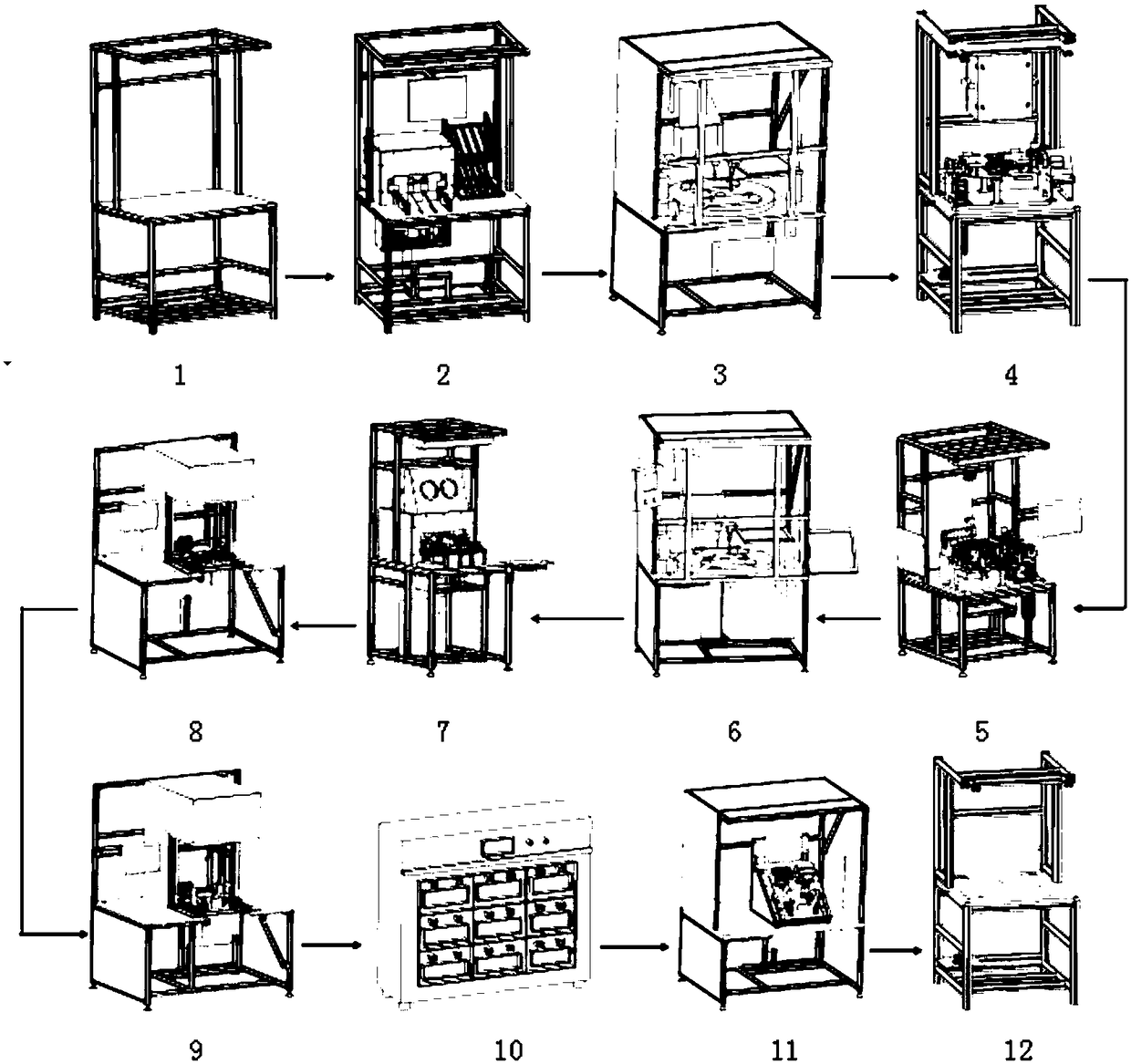

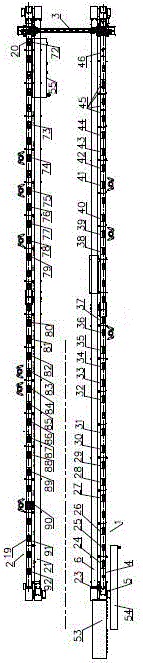

Automatic assembling line for washing machine clutch

InactiveCN105149943AHigh degree of assembly automationReduce demandAssembly machinesEngineeringAssembly automation

The invention relates to an automatic assembling line for a washing machine clutch. The automatic assembling line comprises an automatic shaft assembly assembling line, a clutch final assembly automatic line and a jumper wire transplanting device. The automatic shaft assembly assembling line comprises a shaft assembly assembling conveying line, a shaft assembly assembling carrier and an automatic shaft assembly assembling carrier returning line. The clutch final assembly automatic line comprises a clutch final assembly conveying line, a clutch final assembly carrier and an automatic clutch final assembly carrier returning line. The shaft assembly assembling conveying line and the clutch final assembly conveying line are provided with a plurality of stations sequentially distributed from the initial end to the tail end and online special machines arranged on the stations. The assembling of the washing machine clutch is finished when the shaft assembly assembling carrier and the clutch final assembly carrier pass the stations and the online special machines in sequence. The automatic assembling line has the beneficial effects that the assembling automation rate of the washing machine clutch is greatly increased, the labor intensity of workers is relieved, and the requirement for assembling workers is lowered.

Owner:北自精工机械(常州)有限公司

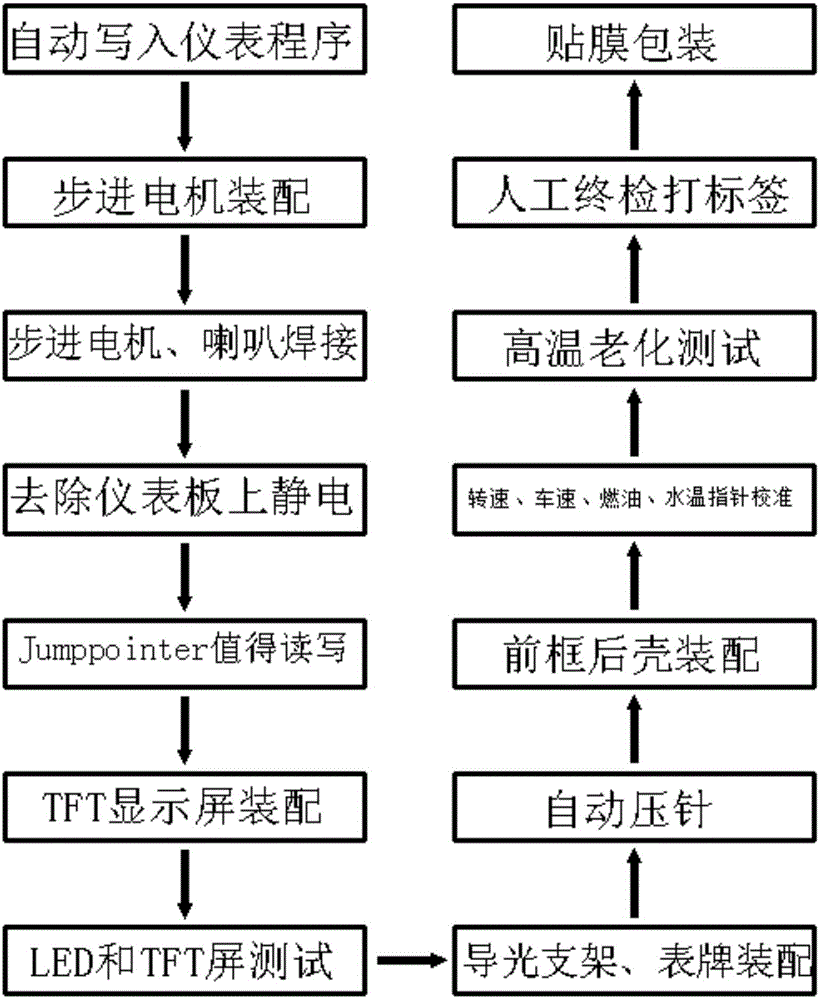

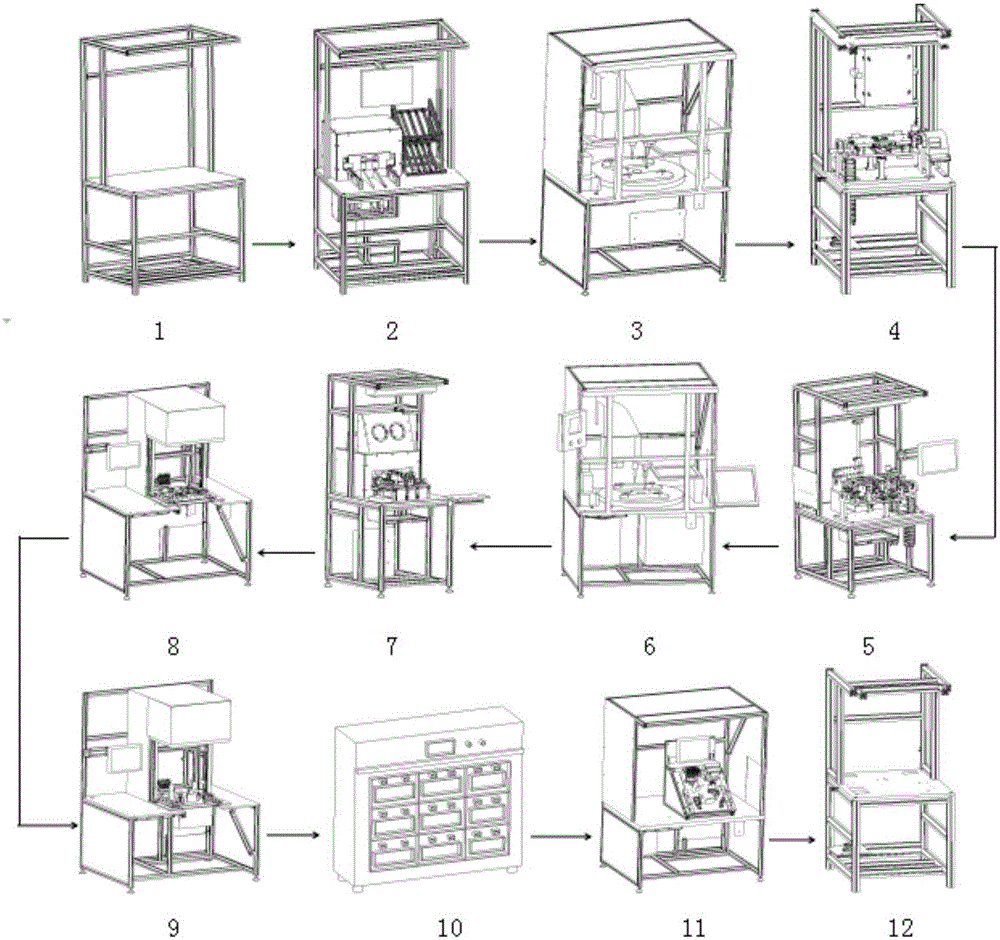

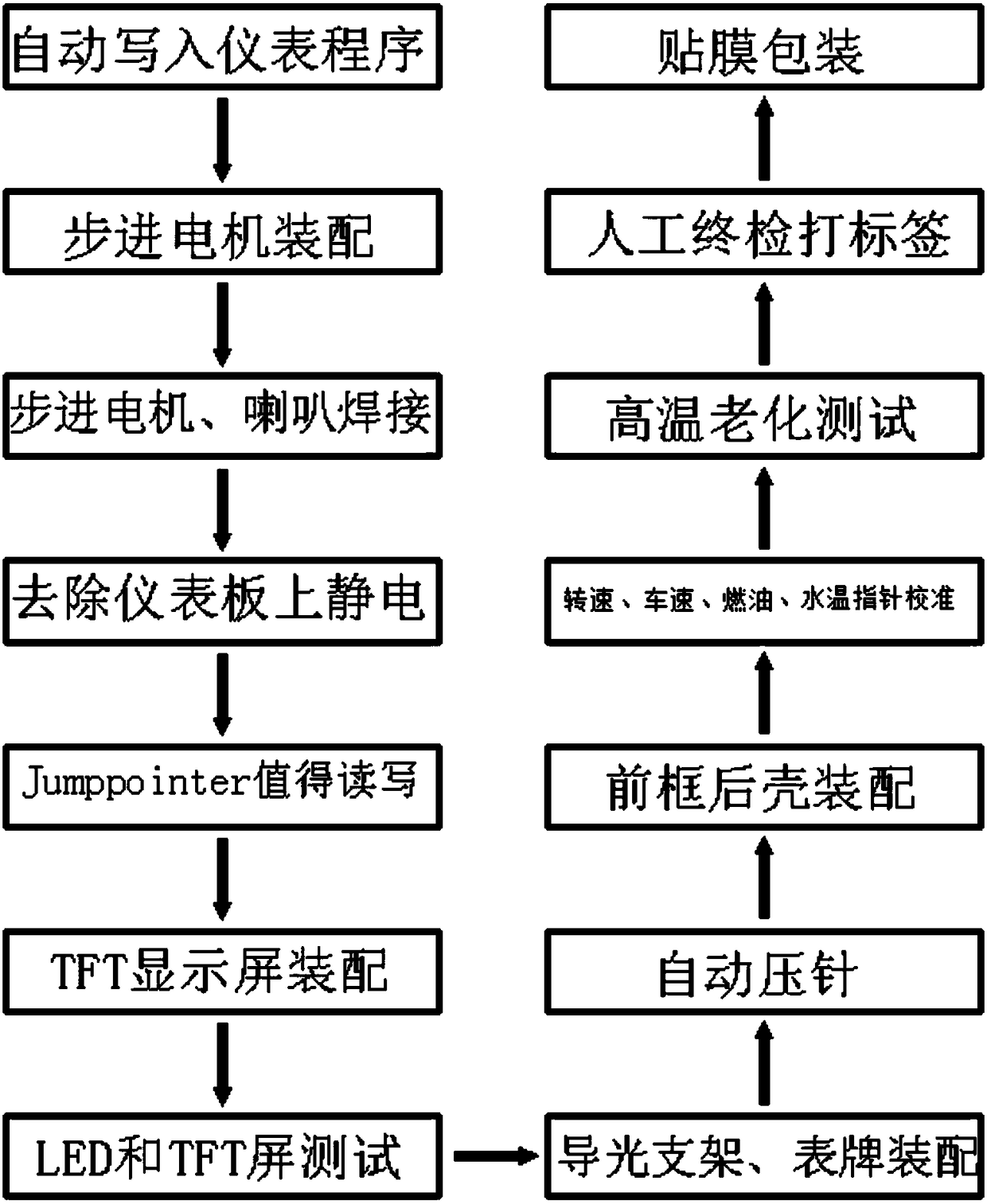

Assembly line for automobile combination dashboards and assembly method thereof

InactiveCN105904209AHigh degree of assembly automationHigh degree of automationAssembly machinesProduction lineDashboard

The invention discloses an assembly line for automobile combination dashboards and an assembly method thereof. The production flow roughly comprises the steps of automatically writing values in dashboard programs, assembling stepping motors, welding the stepping motors and horns, removing static electricity on dash boards, reading and writing Jumppointer values, assembling TFT display screens, testing LEDs and the TFT screens, assembling light guide supports and board plates, automatically pressing pins, assembling front frames and rear shells, calibrating rotation speed pointers, automobile speed pointers, fuel oil pointers and water temperature pointers, testing the high temperature aging performance, carrying out final inspection manually and labeling and transferring the dashboards to film pasting and packaging stations. According to the assembly line and the assembly method, the production safety is improved, the assembly work efficiency of the automobile combination dashboards is greatly improved, and the product quality and the qualification rate are guaranteed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

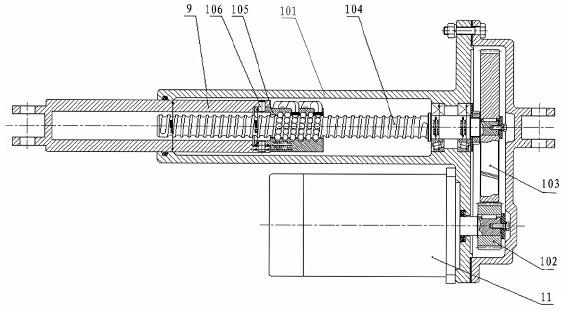

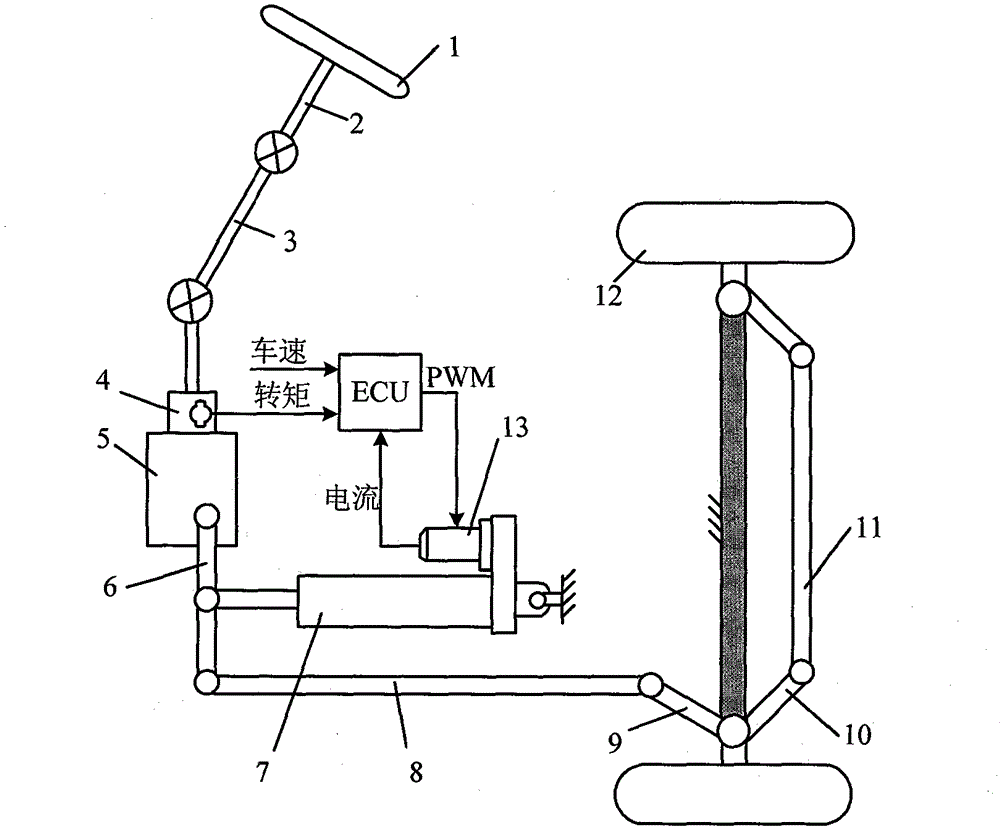

Push rod type electric power steering device for commercial vehicle

PendingCN110871841AReduce energy consumptionReduce occupancyMechanical steering gearsElectrical steeringElectric power steeringVehicle frame

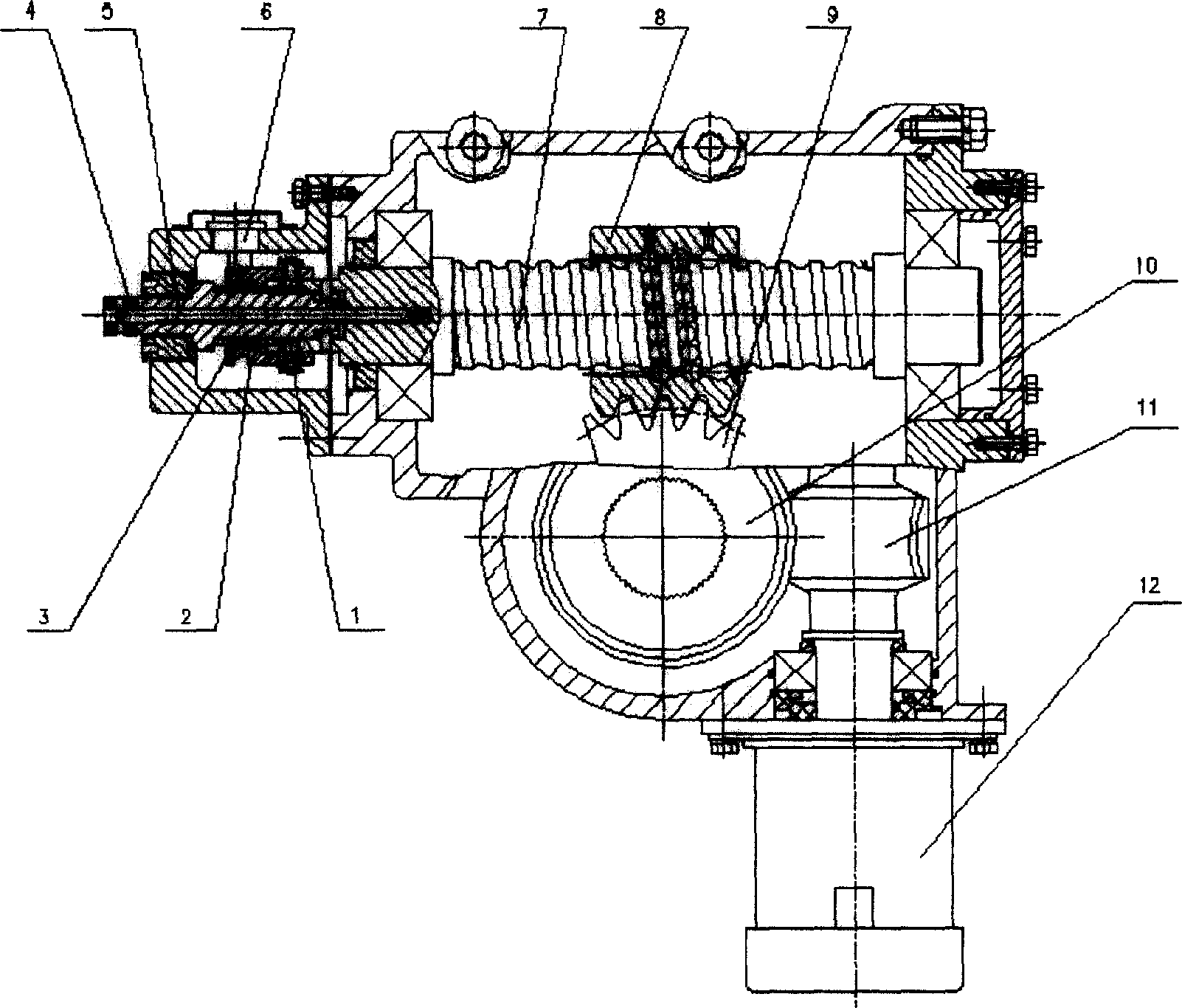

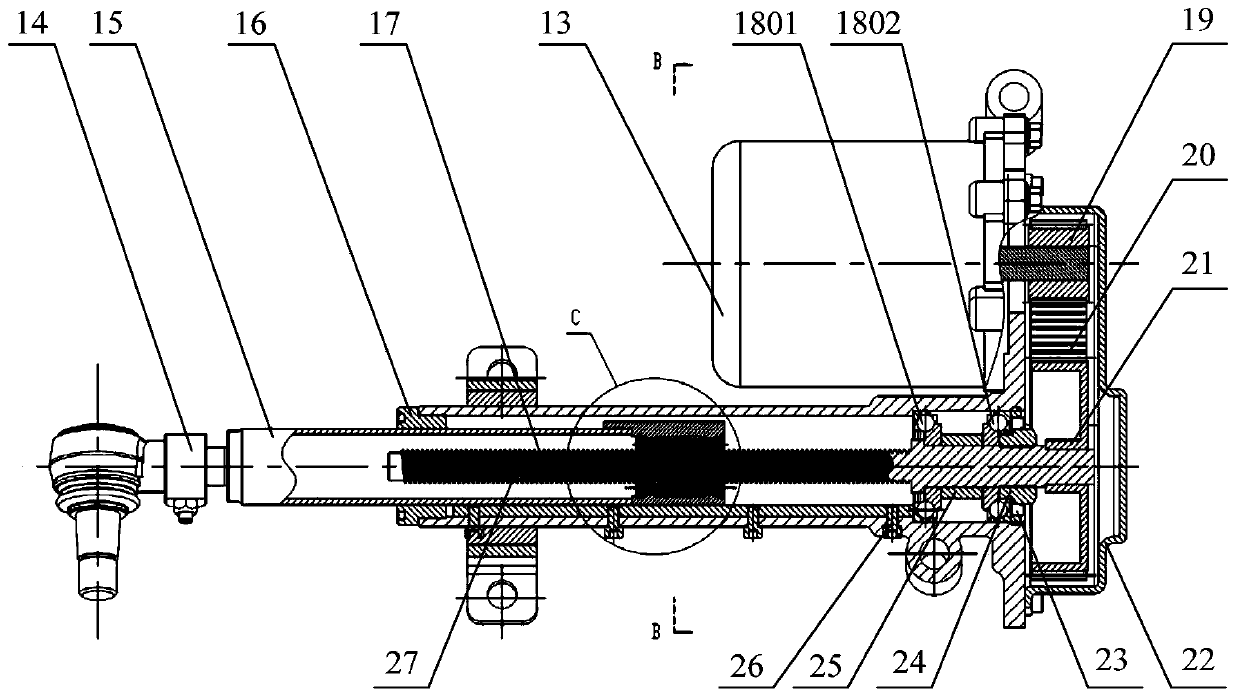

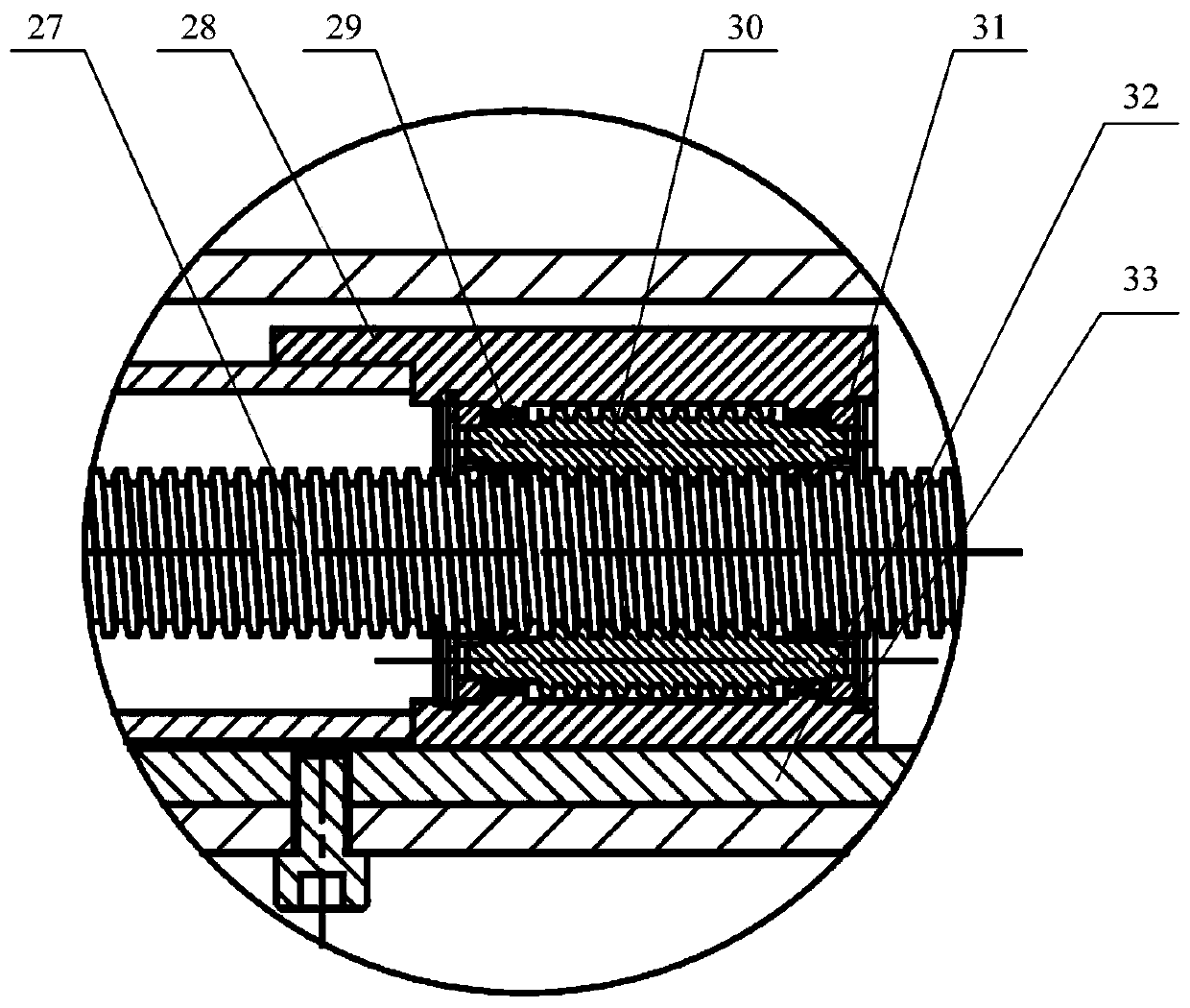

The invention discloses a push rod type electric power steering device for a commercial vehicle. The device comprises a circular ball type steering gear provided with a steering wheel torque and corner sensor, a planetary rolling column screw type electric push rod power steering mechanism and an electronic control unit. The steering wheel torque and corner sensor is used for detecting torque anda steering wheel corner acting on a steering wheel and is arranged on the input end of the circular ball type steering gear, the planetary rolling column screw type electric push rod power steering mechanism comprises a motor, a synchronous belt speed reduction mechanism, a planetary rolling column screw transmission pair, a linear guide rail, a push rod and the like, a motor output shaft is connected with a small belt wheel, a motor outputs torque and transmits the torque to a planetary rolling column screw through a synchronous belt, a large belt wheel inner hole is connected with a screw inthe planetary rolling column screw, the output torque is transmitted and amplified through the planetary rolling column screw transmission pair, and a steering rocker arm shaft is pushed to rotate. One end of the planetary rolling column screw type electric push rod power steering mechanism is connected with a steering rocker arm, the other end of the planetary rolling column screw type electricpush rod power steering mechanism is connected with a vehicle frame, through planetary rolling column screw transmission, large thrust steering assistance is obtained, and pure electrification and intelligence of a heavy commercial vehicle steering system can be achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

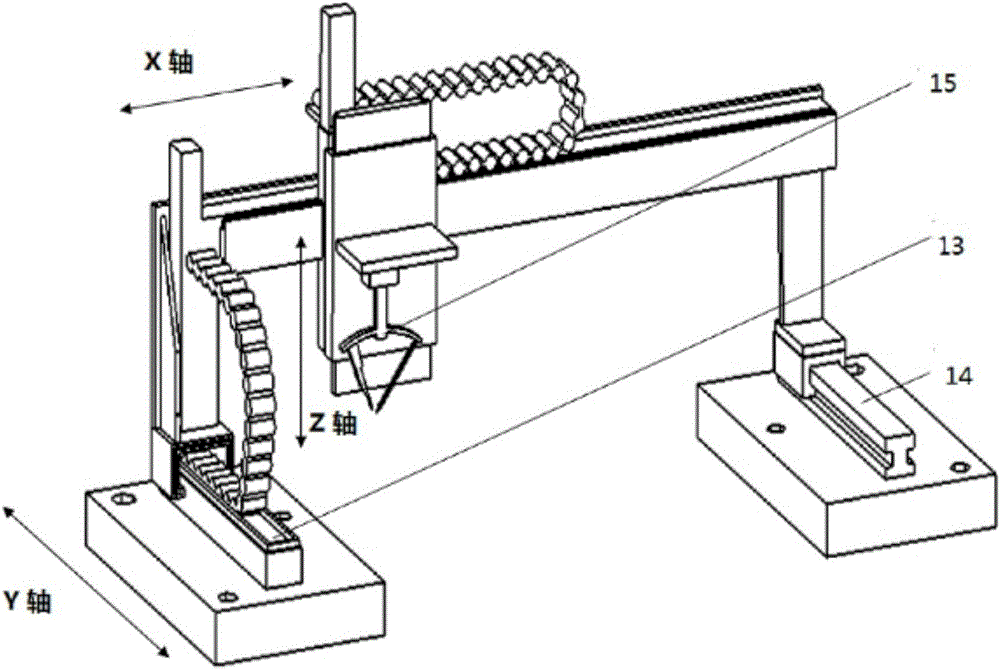

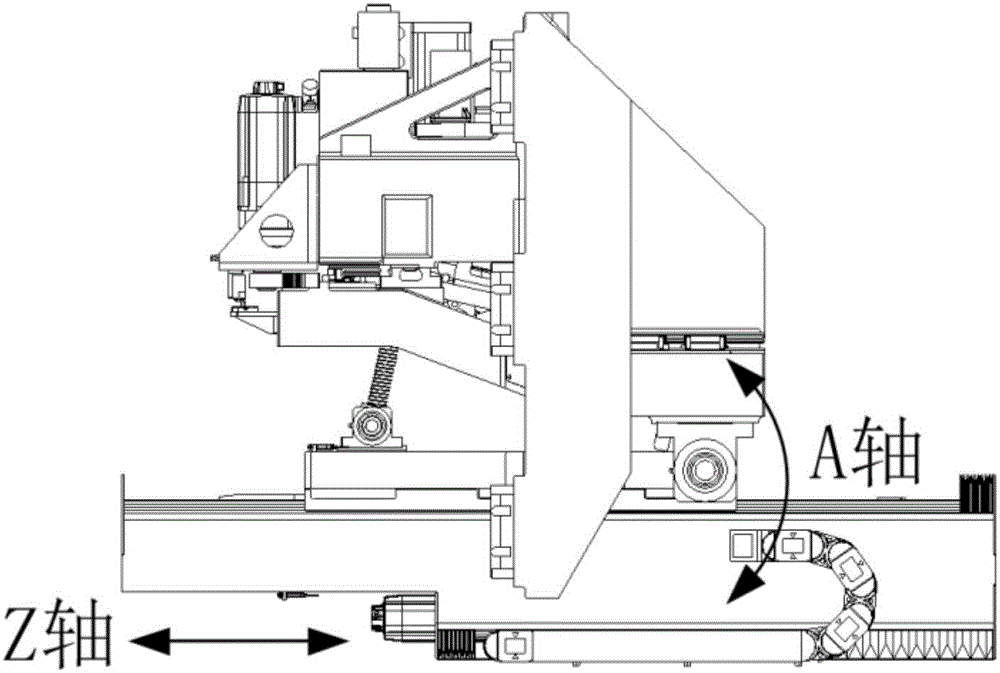

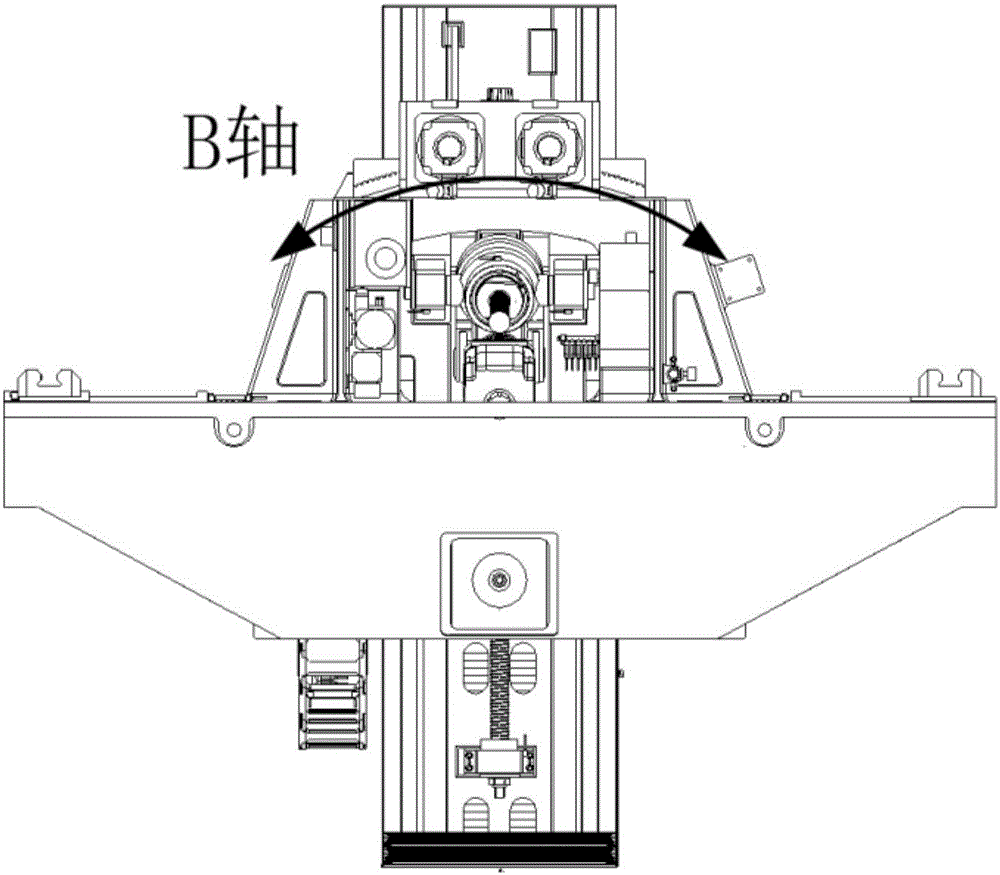

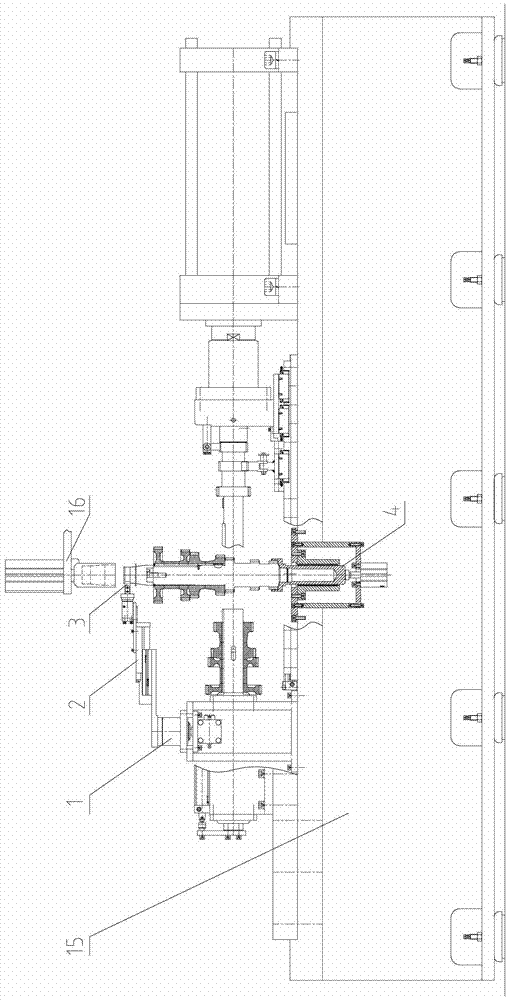

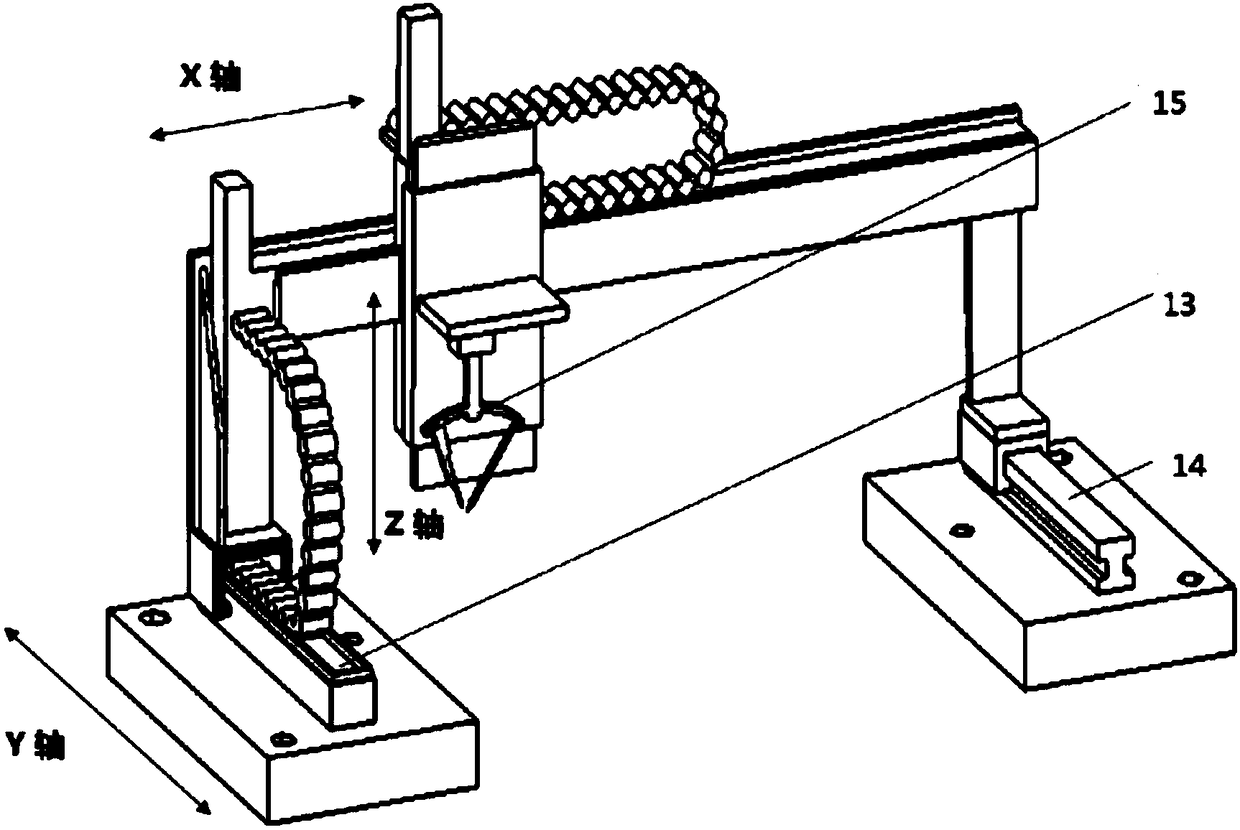

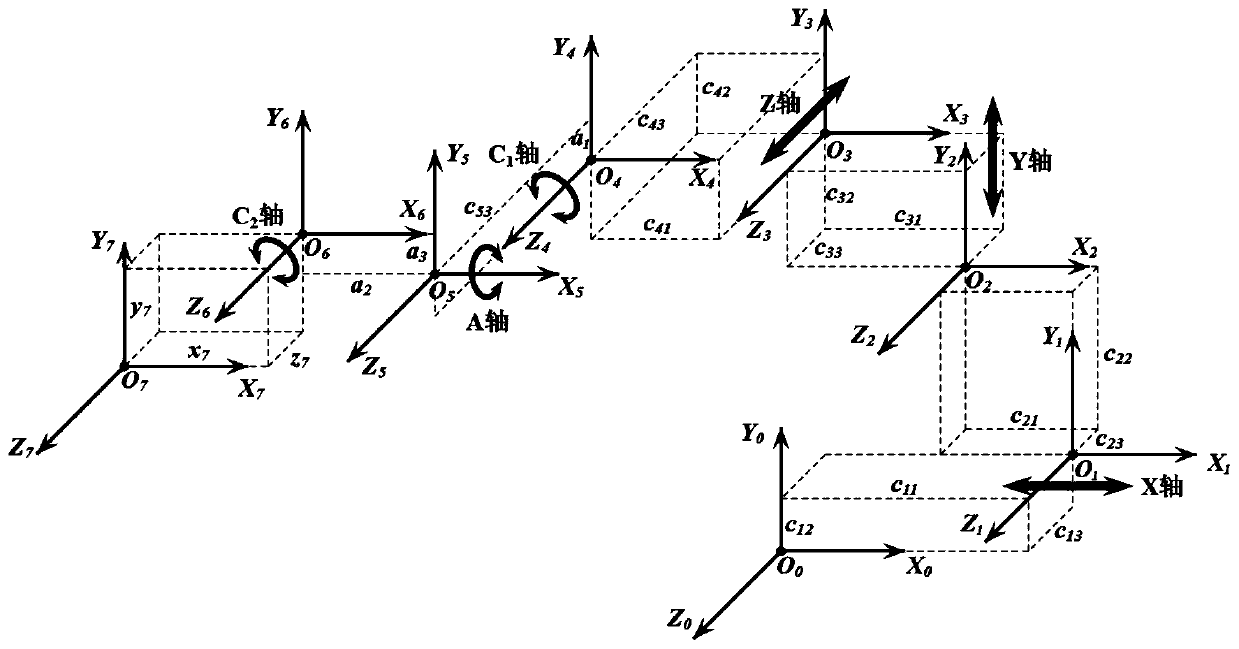

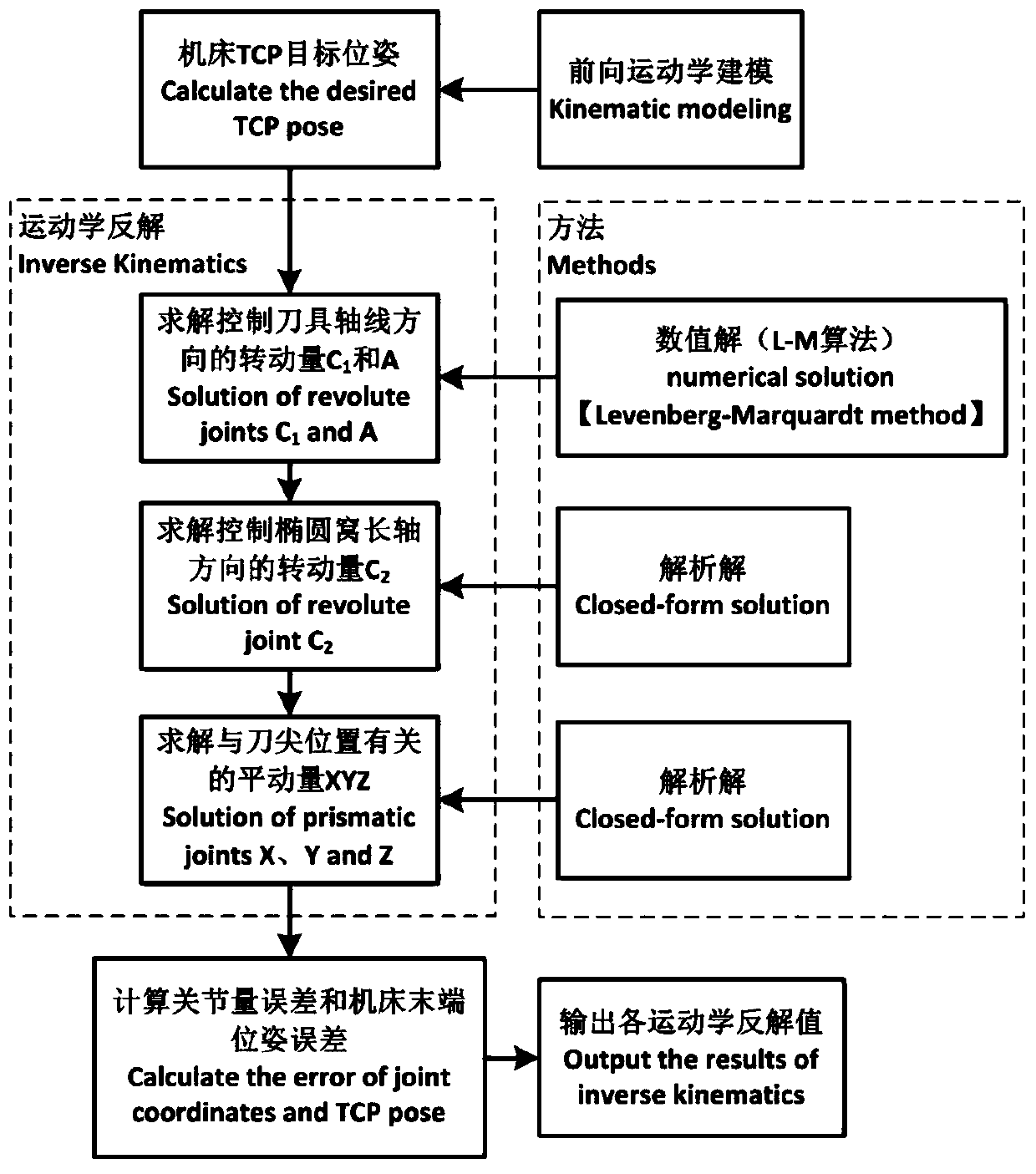

Forward and inverse solution method of five-shaft numerical control drilling machine tool with feed shaft swinging wit AB shaft

ActiveCN106843151ARealize positive and negative solutions of kinematicsHigh degree of assembly automationProgramme controlComputer controlNumerical controlEngineering

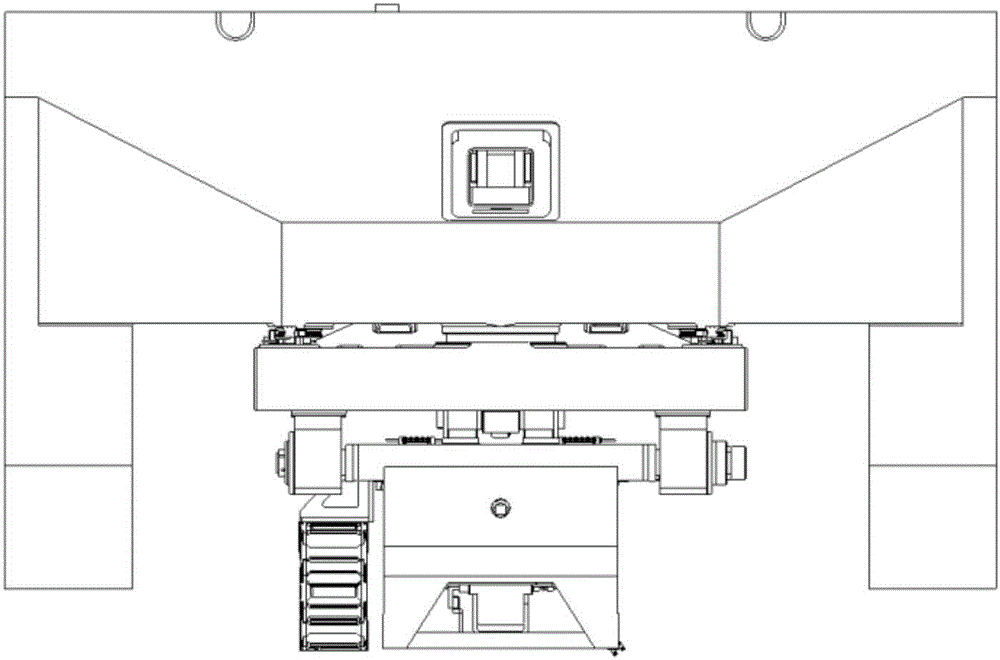

The invention discloses a forward and inverse solution method of a five-shaft numerical control drilling machine tool with a feed shaft swinging with an AB shaft. The method comprises the following steps: (1) establishing an equipment base coordinate system, respective motion shaft sub coordinate systems and a cutter coordinate system in a profiled five-shaft numerical control drilling machine tool; drawing a coordinate system definition diagram in order that respective sub coordinate systems and the equipment base coordinate system has a consistent coordinate axis direction. (2) performing kinematics analysis on the profiled five-shaft numerical control drilling machine tool, and establishing a forward kinematic model; (3) according to the target pose and the forward kinematic model of the profiled five-shaft numerical control drilling machine tool, establishing an equation set of joint quantity and deriving an inverse kinematics model. The method realizes the kinematic forward and inverse solution of the five-shaft numerical control drilling machine tool with a feed shaft swinging with an AB shaft, and lays the foundation for the machine tool motion control.

Owner:ZHEJIANG UNIV

Electric drive pusher type steering system controlled by coupling force and displacement and control method

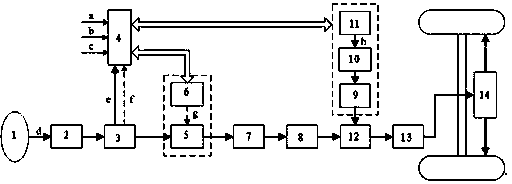

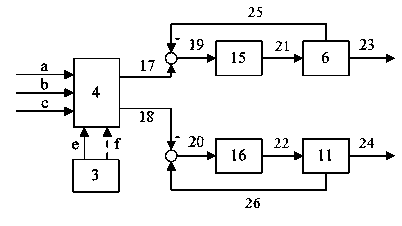

InactiveCN102632921AReduce disturbanceImprove steering characteristicsSteering linkagesAutomatic steering controlActive safetyLow speed

The invention relates to an automobile steering assistant-control system and a control method and in particular relates to an electric drive pusher type steering system controlled by coupling force and displacement and a control method. The moment output end of a driving mechanism, connected with a steering motor, is connected with a worm crankpin steering gear through an output shaft; a steering rocker arm on the worm crankpin steering gear is used for controlling a steering knuckle arm; the steering knuckle arm is connected with a steering trapezium rod; an assistant motor is connected with and drives a speed reducing mechanism; the speed reducing mechanism drives an electric drive pusher; and the assistant motor is controlled by an ECU (Electronic Control Unit). The steering assistant-control system provides appropriate assistance under various driving conditions to reduce disturbance caused by an uneven road surface to the steering system, improves steering characteristics of an automobile, decreases the steering operation force of the automobile traveling at a low speed, enhances the steering stability of the automobile traveling at a high speed to further enhance the driving safety of the automobile and meets the requirements of different using objects by setting different steering hand power characteristics.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

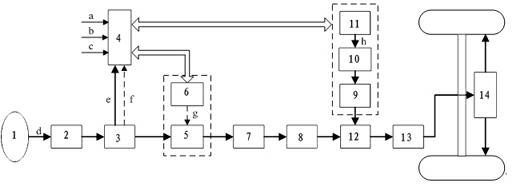

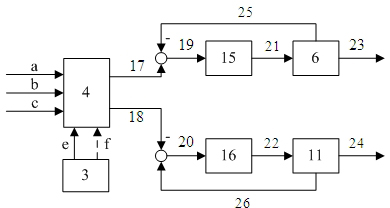

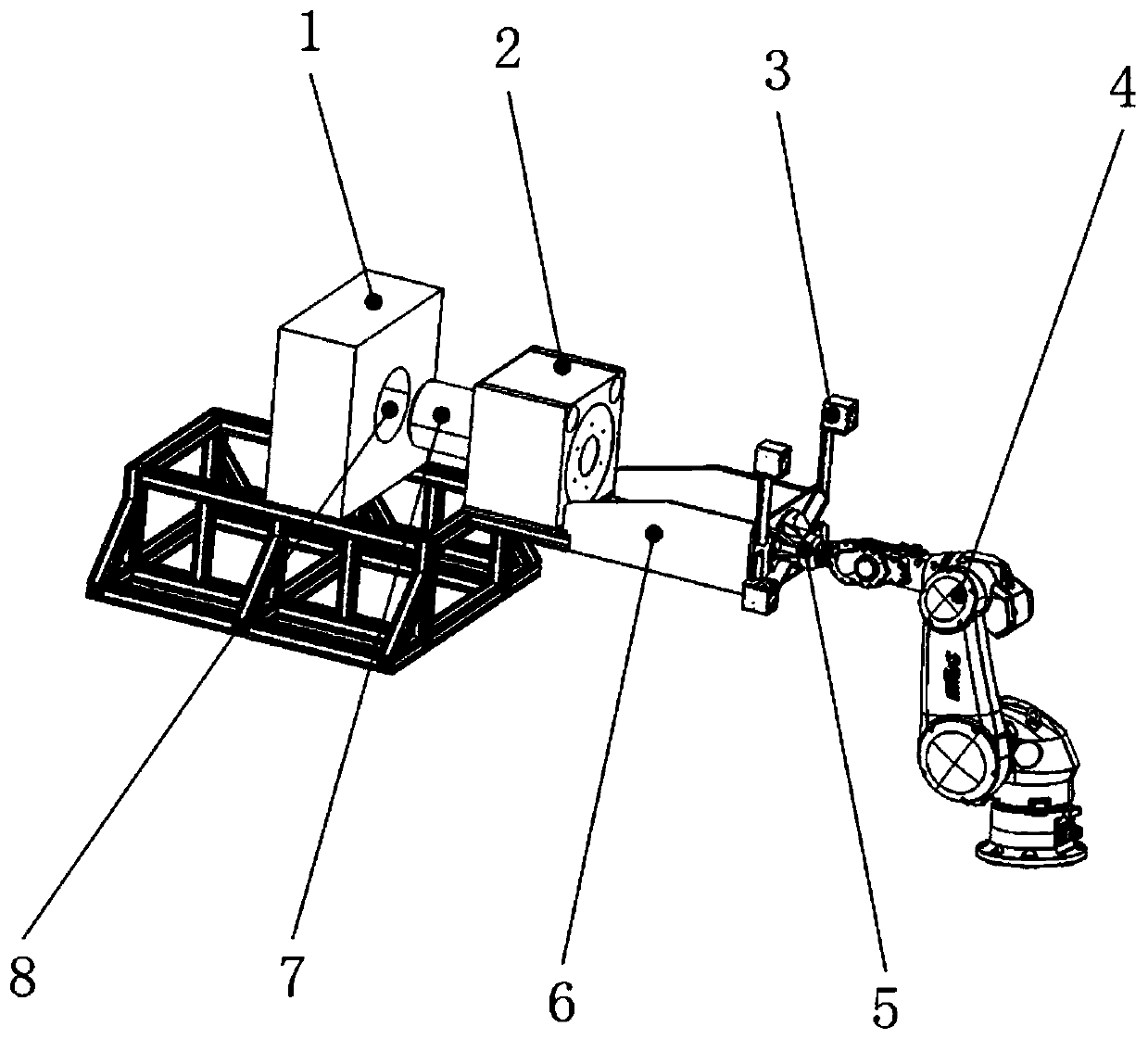

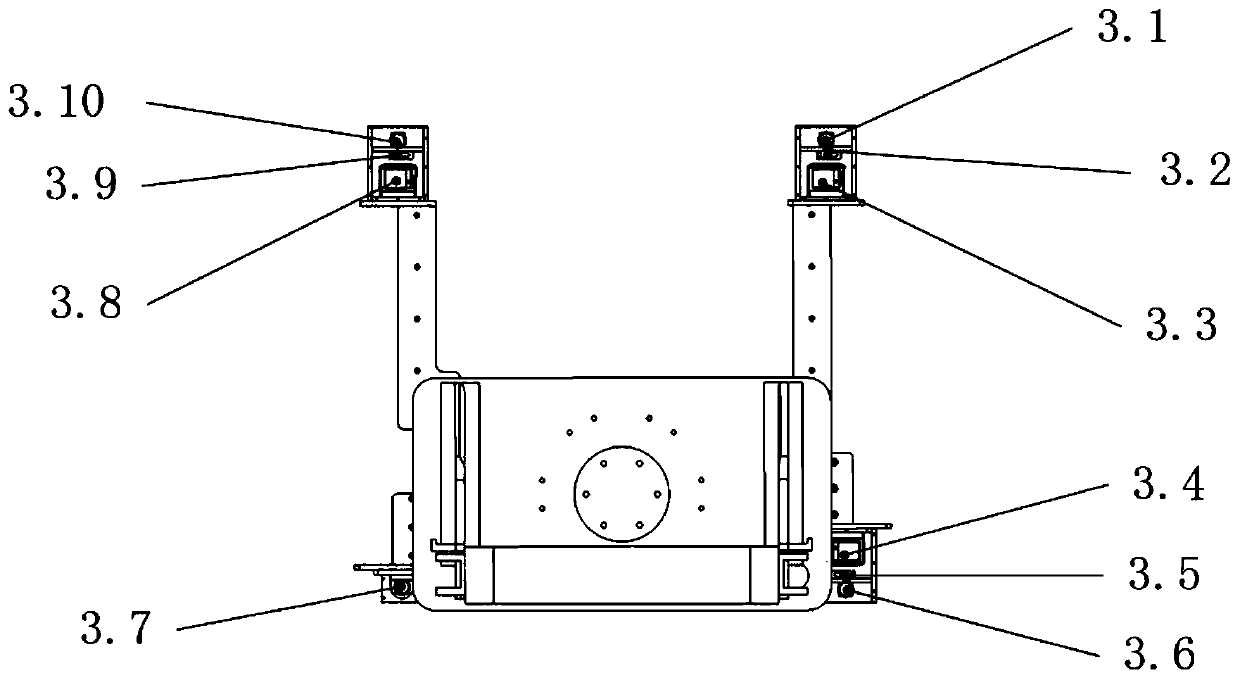

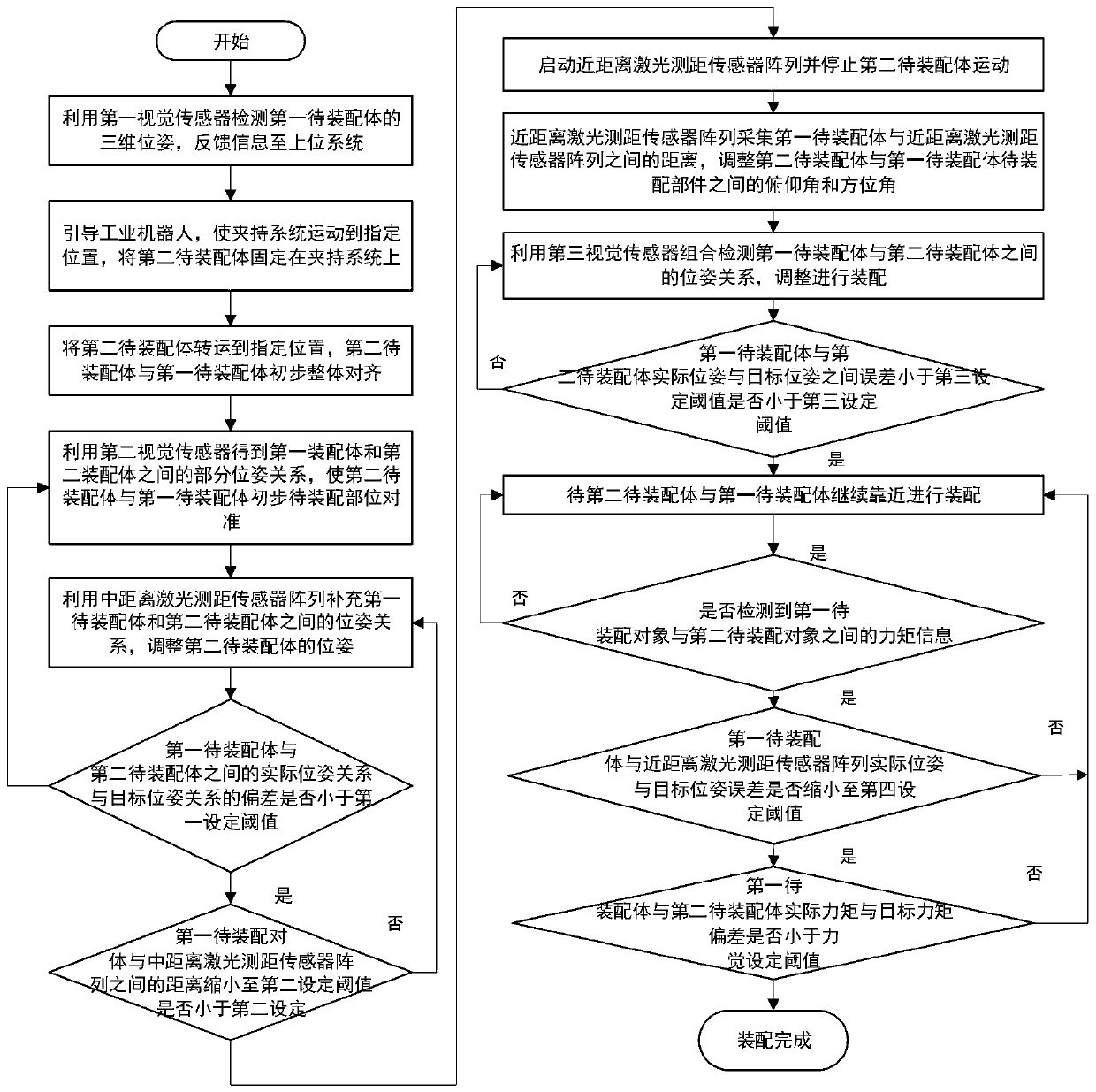

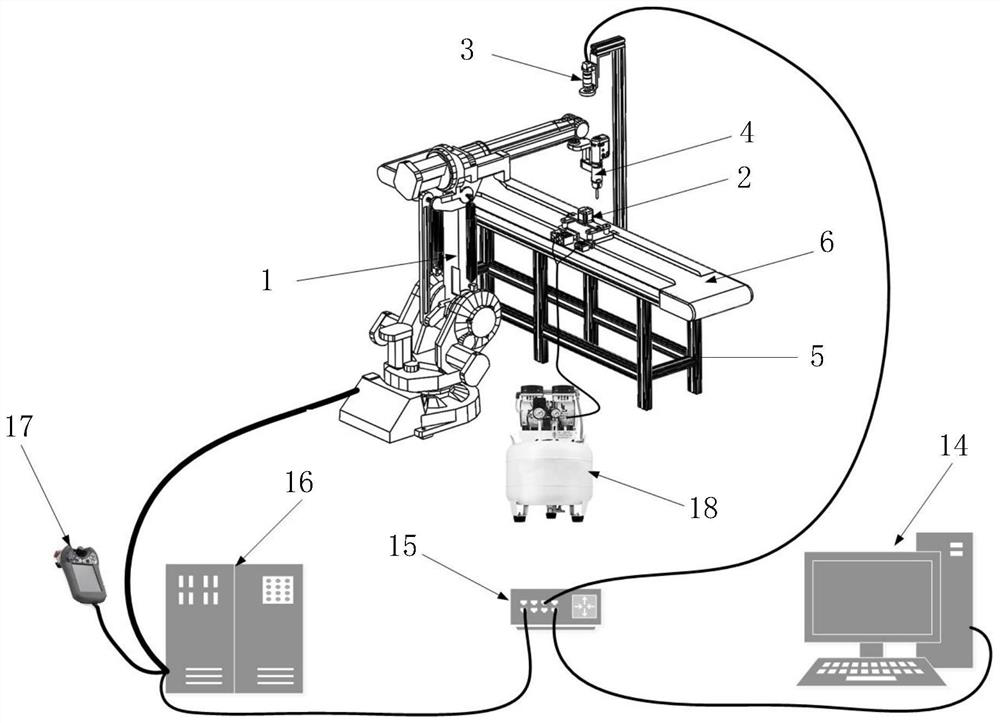

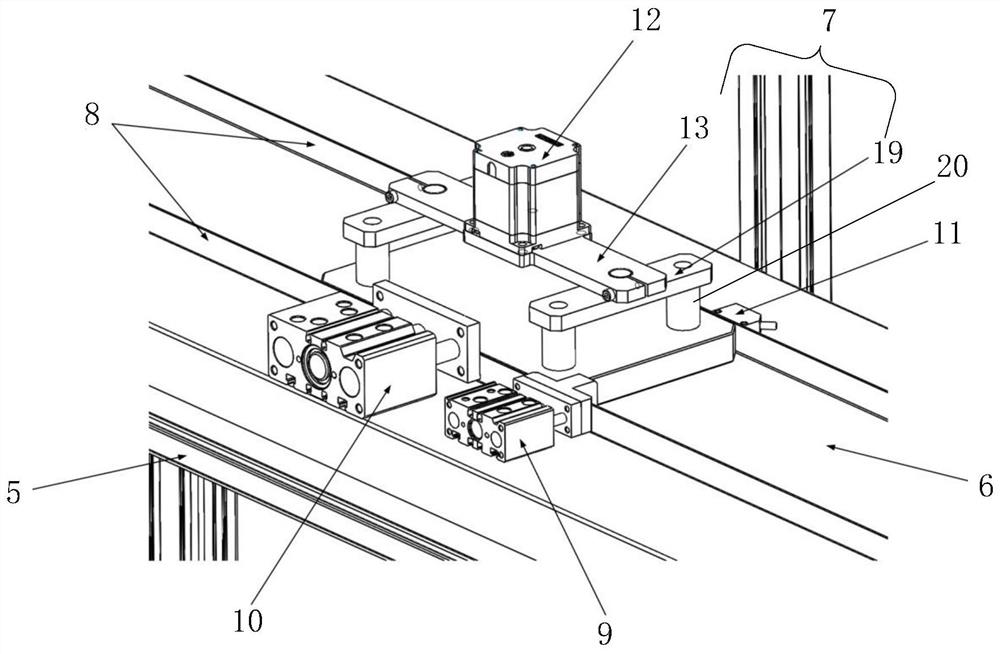

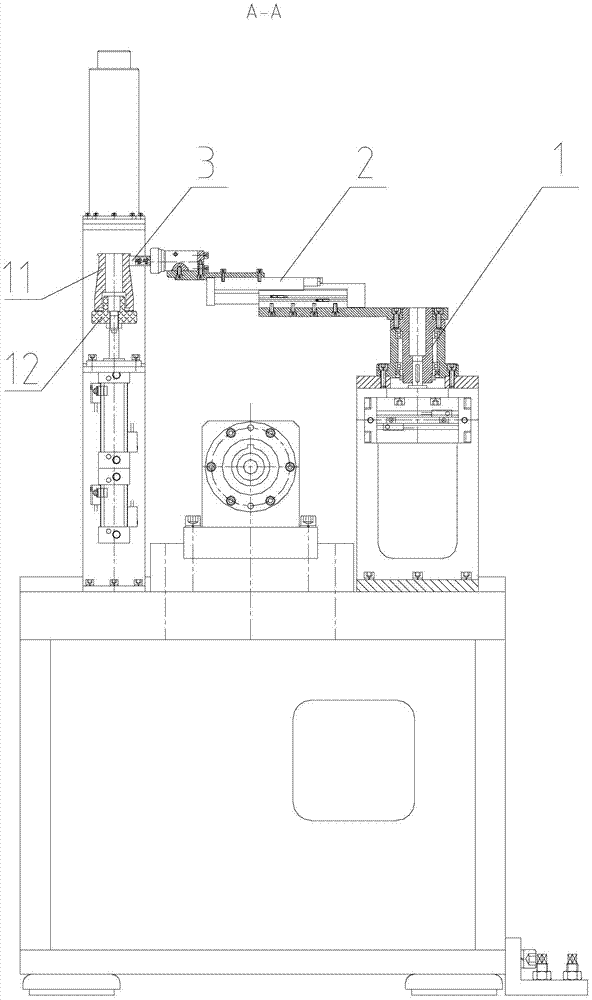

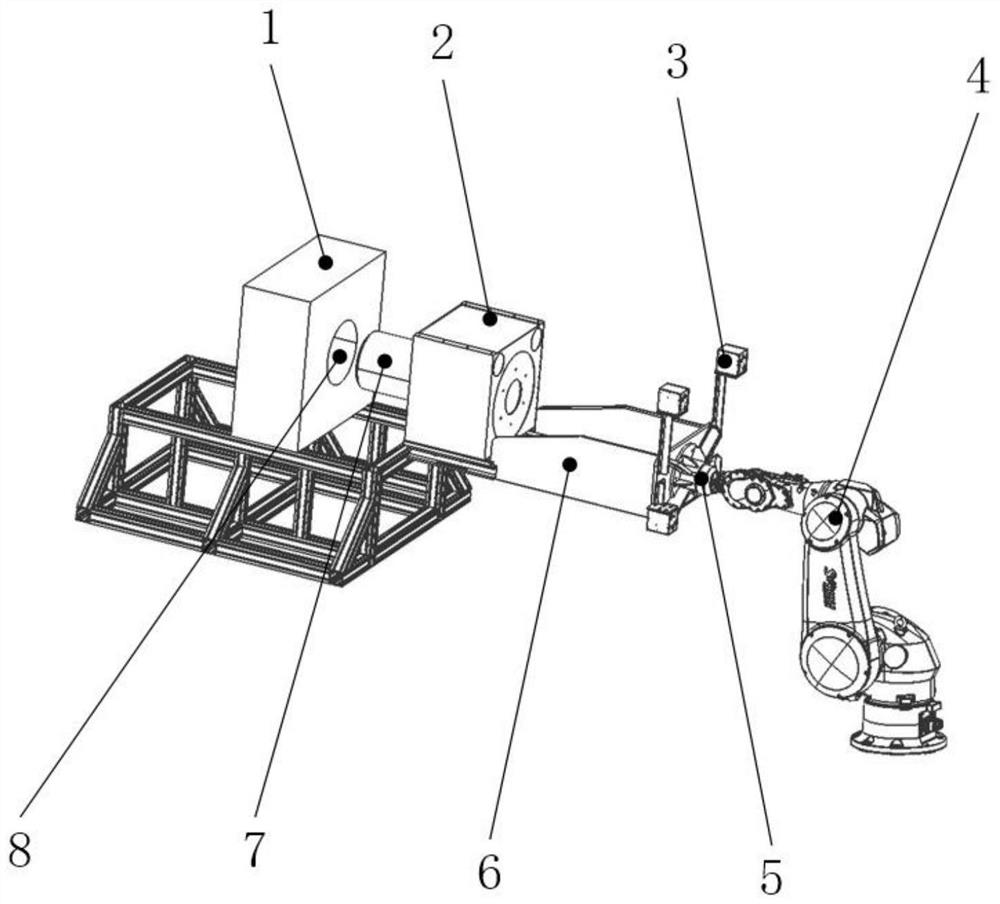

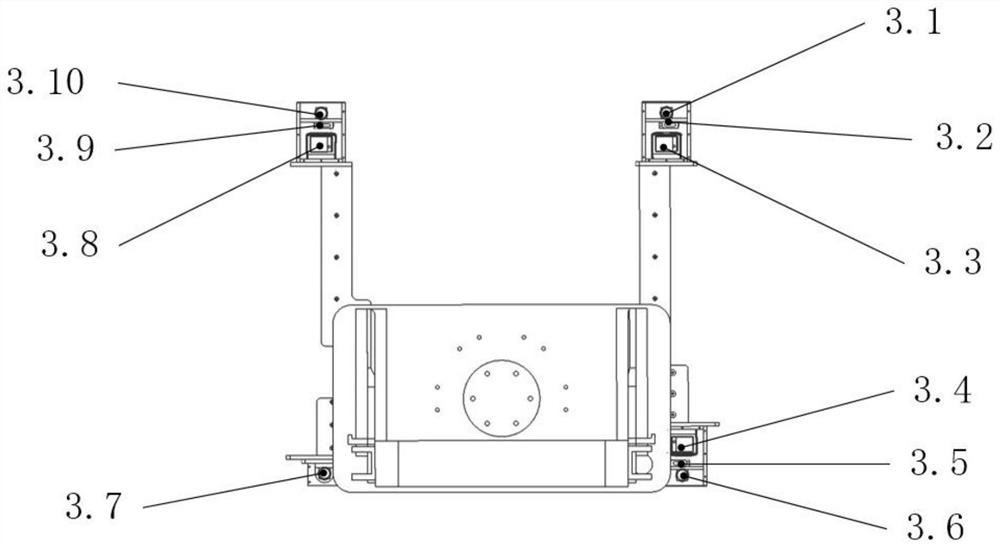

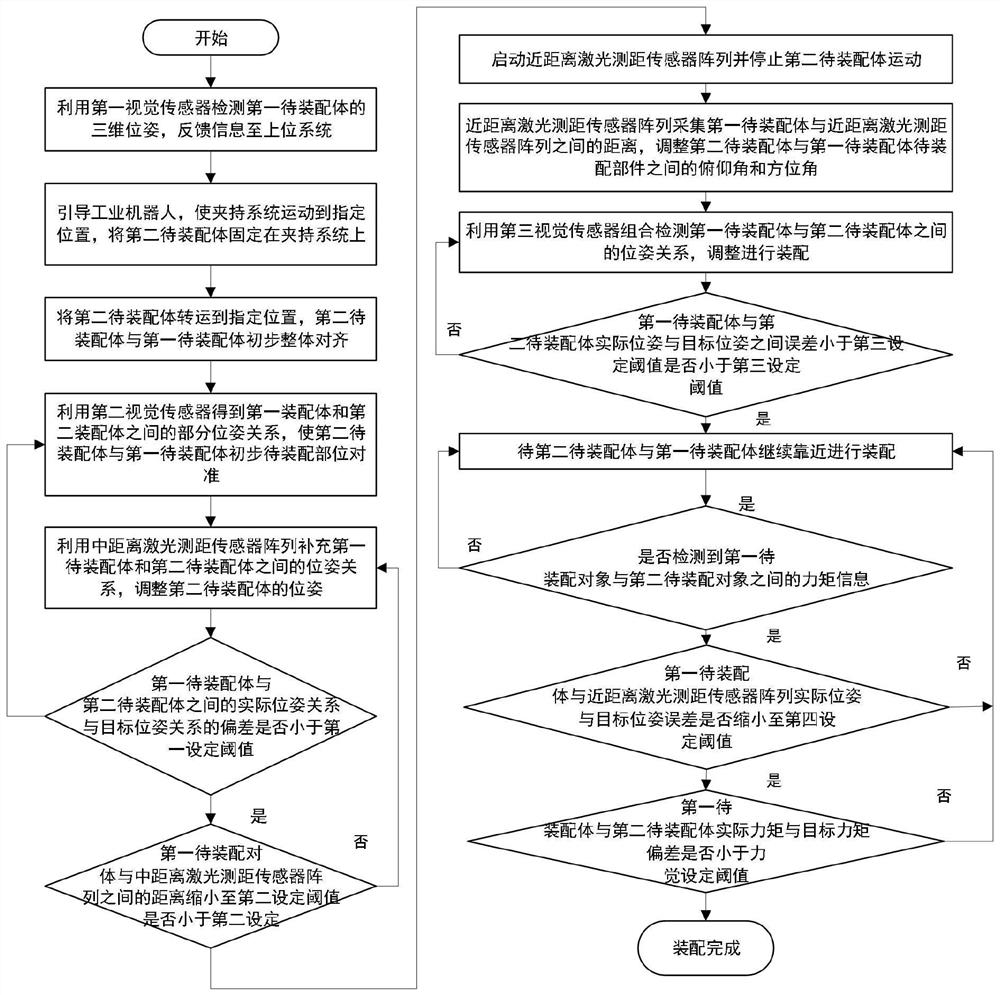

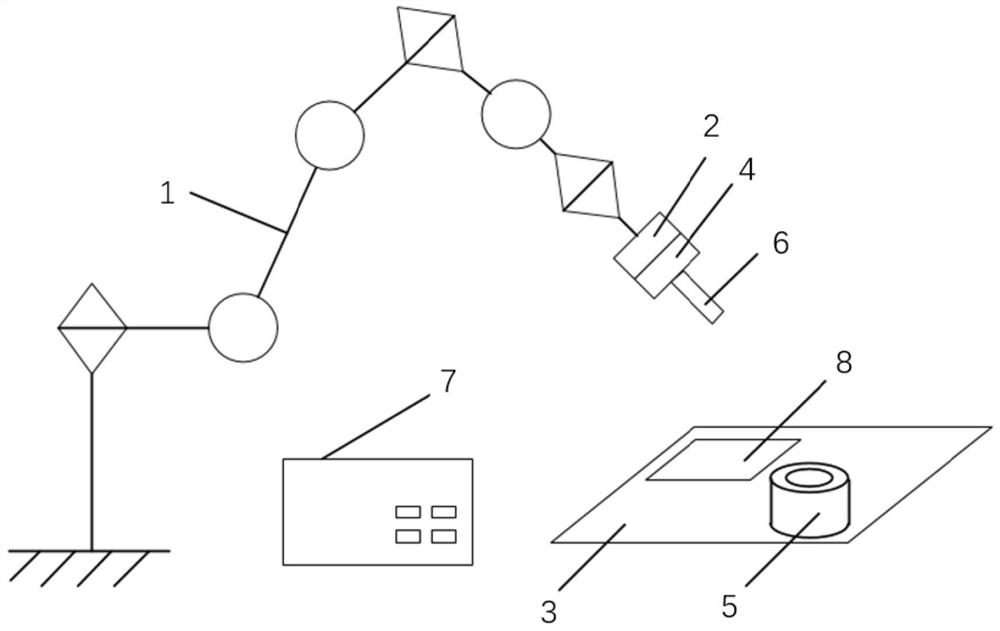

Method and device of robot automatic assembly based on multisensor fusion

ActiveCN110340630AHigh positioning accuracyPrecise positioningMetal working apparatusSimulationMultiple sensor

The embodiment of the invention relates to the technical field of automatic assembly, and discloses a method and device of robot automatic assembly based on multisensor fusion. The invention solves the problemsthatthe positioning range of a system is small, the positioning precision is not accurate and the detection information is incompletein the prior art, according to the technical scheme, thesystem comprises an upper computer system, an industrial robot, a clamping system, a multisensor system and to-be-assembled bodies, wherein the upper computer system is used for acquiring measurementdata of the multisensor system and performing calculation, planning the movement of the robot according to acalculation result and feeding back the movement of the robot to the industrial robot; the industrial robot is used for conveying the to-be-assembled bodies,the clamping system is used for clamping the to-be-assembled bodies,and the multisensor system is used for obtaining the pose relationship and contact force information among the assembly bodies. According to the method and the device, the assembly process is planned according to theaccurate detection of the multisensor fusedmulti-parameter data of the to-be-assembled bodies, so that high-precision automatic assembly of acomplex large body is realized, the system positioning range is expanded, and the positioning precision is improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

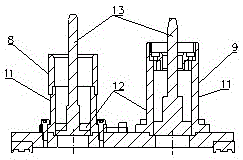

Working method of workpiece conveying and assembling equipment

InactiveCN113084510ASmooth and smooth slideEasy to useAssembly machinesMetal working apparatusEngineeringMechanical equipment

The invention discloses a working method of workpiece conveying and assembling equipment, and belongs to the field of workpiece machining mechanical equipment. A U-shaped workpiece guiding mechanism and a disc cover workpiece blanking mechanism are vertically arranged on the two sides of a workpiece assembling support respectively, a U-shaped workpiece transferring mechanism is arranged on the workpiece assembling support on the lower side of the U-shaped workpiece guiding mechanism, a disc cover workpiece transferring mechanism is arranged on the workpiece assembling support on one side below the disc cover workpiece blanking mechanism, a disc cover workpiece conveying support is horizontally and fixedly arranged in a disc cover workpiece conveying channel, a disc cover workpiece bearing mechanism is horizontally arranged on the disc cover workpiece conveying support on the lower side of a workpiece assembling mechanism, and a plurality of disc cover conveying guide rollers are sequentially and rotationally connected to the disc cover workpiece conveying support in the horizontal direction. The working method is reasonable in structural design, two kinds of workpieces can be efficiently and smoothly conveyed and guided one by one, the two workpieces can be stably and accurately pressed and machined, the workpiece assembling automation degree is improved, and the machining and using requirements are met.

Owner:于金亚

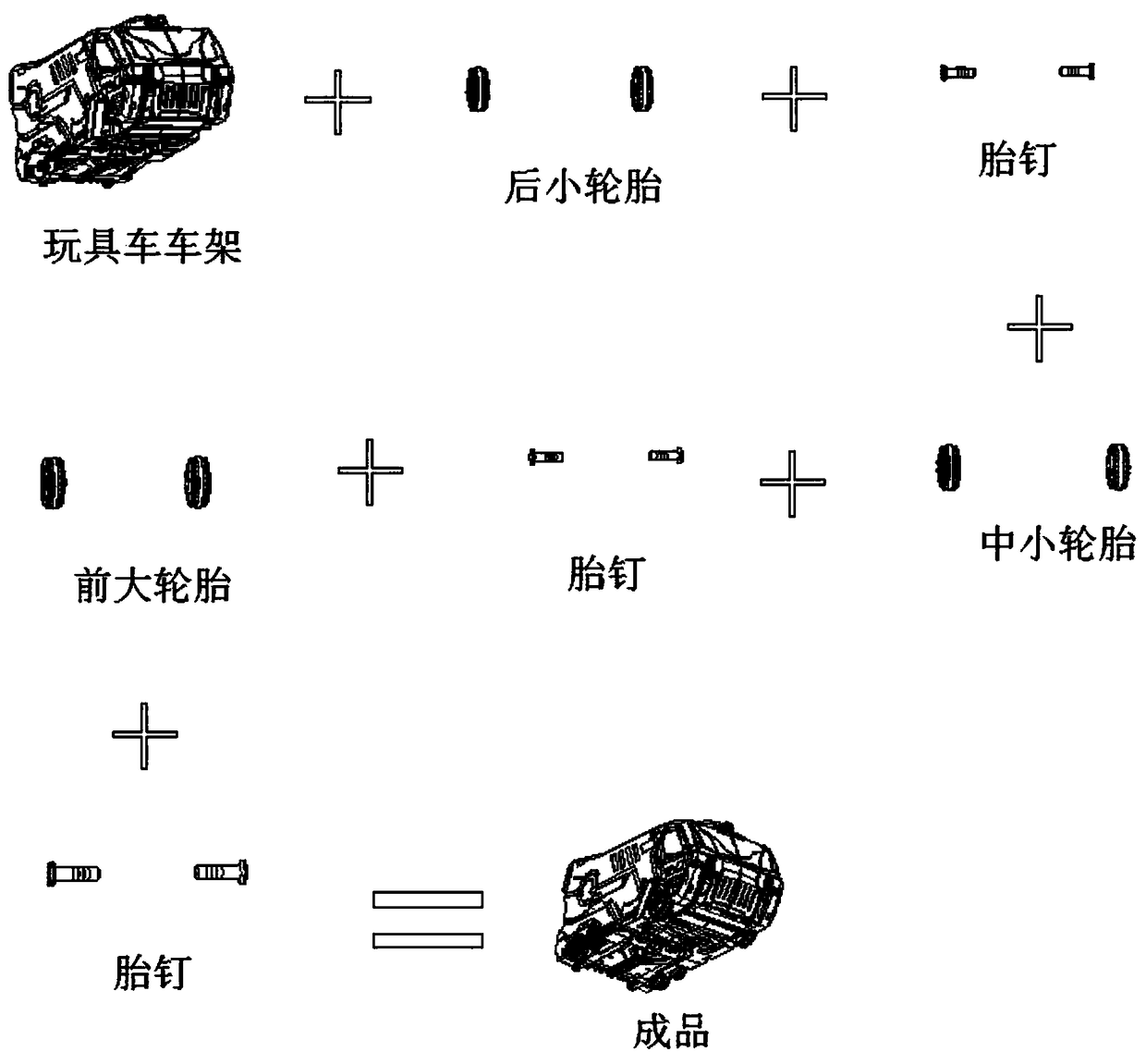

Automatic assembling machine for toy car

The invention relates to the field of toy processing, and in particular discloses an automatic assembling machine for a toy car. The automatic assembling machine comprises a stand, a feed mechanism and a control touch screen, and further comprises a rear small tire loading structure, a middle small tire loading structure, a front big tire loading structure, a rear small tire nail applying structure, a middle small tire nail applying structure and a front big tire nail applying structure, wherein the feed mechanism is horizontally arranged on the stand; the control touch screen is fixedly arranged on the stand; one end of the feed mechanism is arranged as a material inlet and the other end is arranged as a material outlet; and tires are arranged on a car frame by virtue of the tire loadingstructures and the tires are fixed by virtue of the tire nail applying structures. According to the automatic assembling machine provided by the invention, the car frame of the toy car is placed on the feed mechanism, and the toy car can be automatically assembled along with moving of the feed mechanism; the plurality of tires of the toy car can be rapidly assembled, so that an assembling automation degree is improved, labor is saved and production efficiency of the toy car is improved; and in addition, the tires are firmly fixed and are prevented from getting fallen easily.

Owner:DONGGUAN XINLIANGDIAN AUTOMATION EQUIP TECH

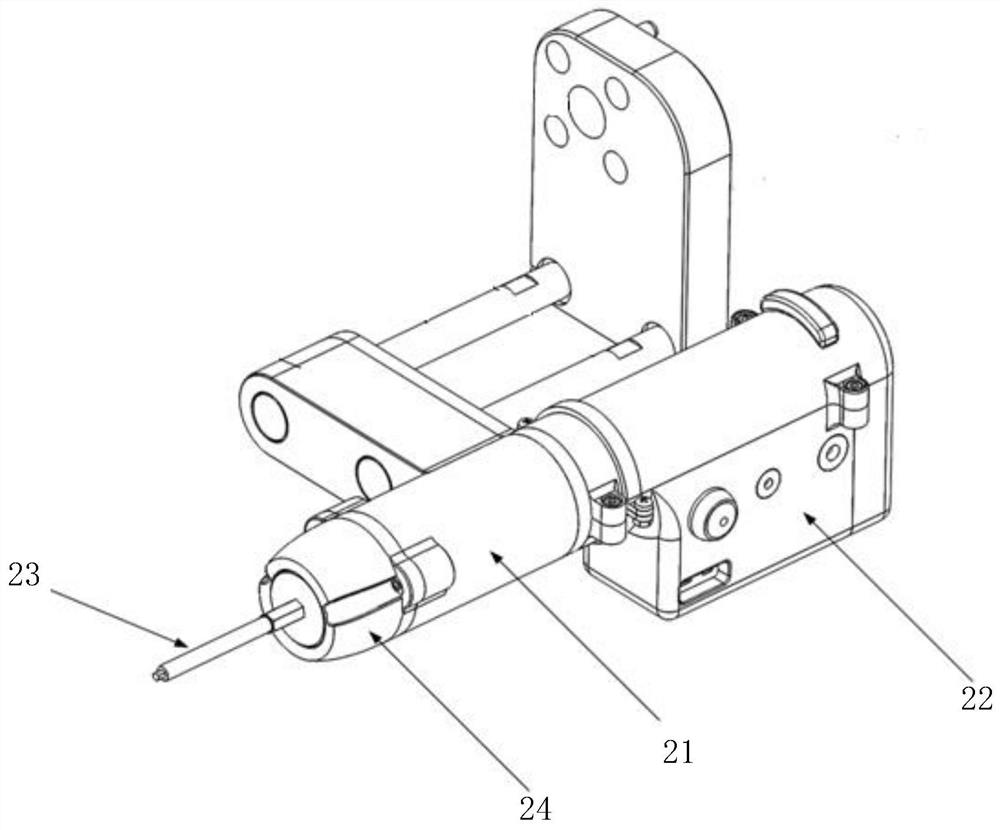

Thread tightening device based on visual positioning and control method

PendingCN113714789AIncrease productivityReduce manufacturing costMetal working apparatusTotal factory controlVision basedProcess engineering

The invention discloses a thread tightening device based on visual positioning and a control method. The device comprises a robot, a control system, a feeding mechanism, a visual measurement module and a tightening tool, wherein the control system is in communication connection with the robot and the tightening tool; the feeding mechanism comprises a rack, a conveying belt, a material disc, material baffles, a blocking air cylinder, a clamping air cylinder and a photoelectric sensor, the conveying belt is installed on the rack, the material disc is placed on the conveying belt, the material baffles are installed on the two sides of the conveying belt, the blocking air cylinder and the clamping air cylinder are installed on the same side of the material baffles, and the photoelectric sensor is installed on the opposite side of the blocking air cylinder; and the vision measurement module is installed on the rack, the tightening tool is installed on a flange of a sixth shaft of the robot, and the vision measurement module is located above a tightening operation area. According to the thread tightening device based on visual positioning and the control method, the positions of a plurality of bolts can be rapidly positioned, the tightening torque is controlled through programming, the thread tightening control precision is improved, and the expected tightening effect of thread connection can be achieved.

Owner:SHENZHEN POLYTECHNIC

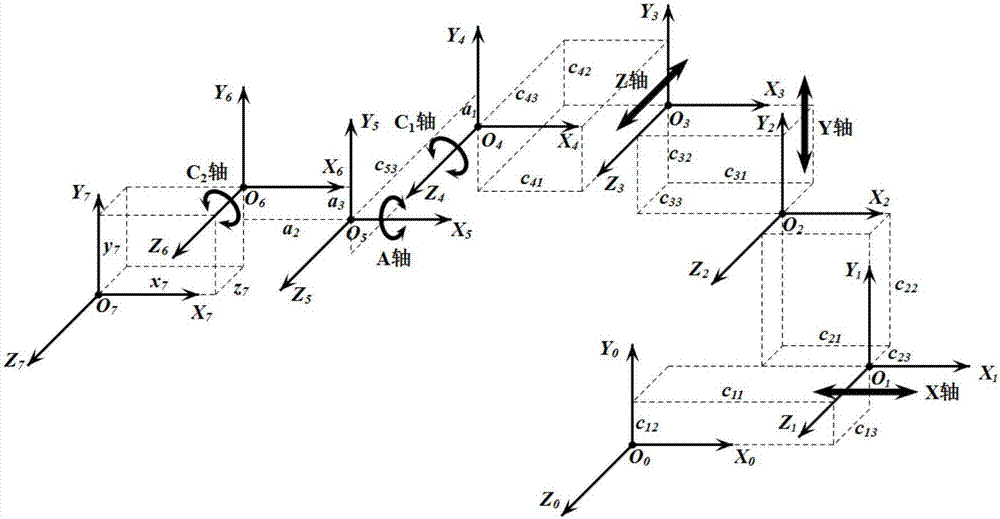

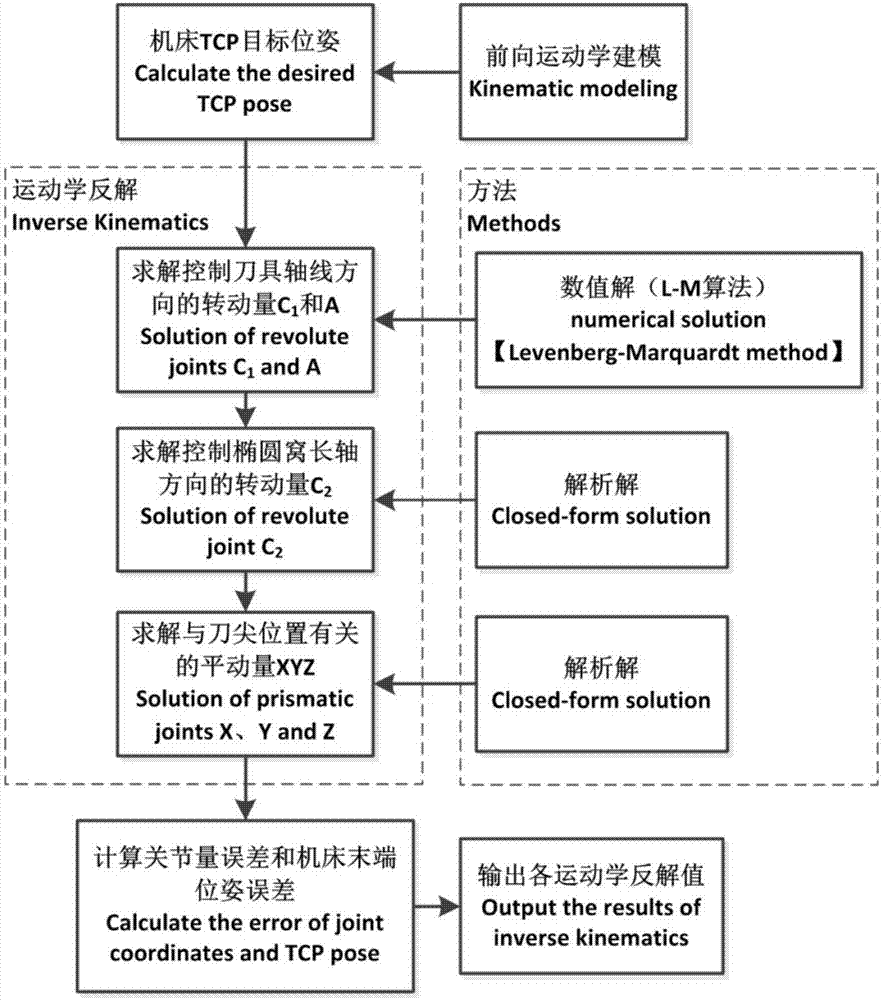

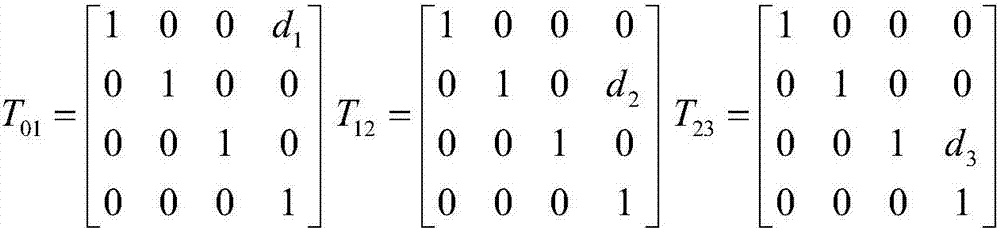

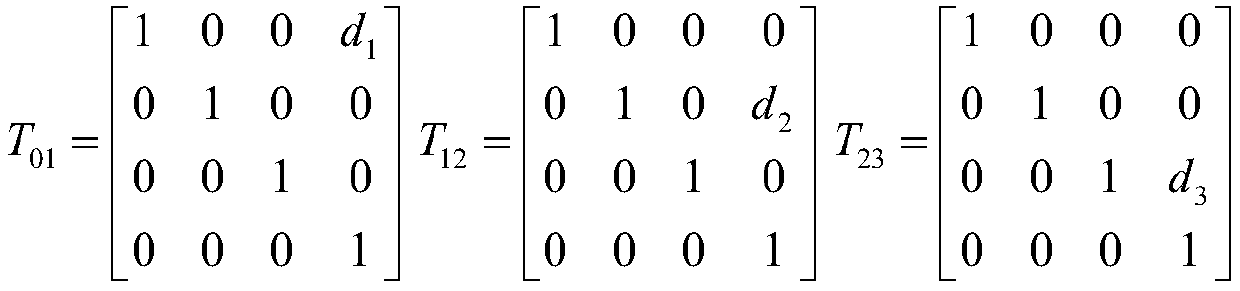

Kinematic inverse solving method for six-shaft automatic drilling and dimpling machine tool comprising double C shafts

ActiveCN106980751AGuaranteed accuracyGuaranteed stabilitySpecial data processing applicationsInformaticsEngineeringMovement control

The invention discloses a kinematic inverse solving method for a six-shaft automatic drilling and dimpling machine tool comprising double C shafts. The method comprises the steps that (1) an equipment base coordinate system, all moving shaft sub-coordinate systems and a tool coordinate system are established in the six-shaft automatic drilling and dimpling machine tool, a coordinate system definition diagram is drawn, and all the sub-coordinate systems and the equipment base coordinate system are made to keep consistent in coordinate axis direction; (2) kinematic analysis is performed on the six-shaft automatic drilling and dimpling machine tool, and a forward kinematic model is established; and (3) an equation set of joint quantities is established according to a target pose and the forward kinematic model of the six-shaft automatic drilling and dimpling machine tool, a kinematic inverse solving strategy for separate solving of the joint quantities is proposed, and an analytical method and a numerical method are combined to solve all the joint quantities to obtain an inverse kinematic model. Through the method, kinematic forward / inverse solving of the six-shaft automatic drilling and dimpling machine tool can be realized, the accuracy of machine tool movement control can be guaranteed, and automatic machining of an elliptical dimple is realized.

Owner:ZHEJIANG UNIV

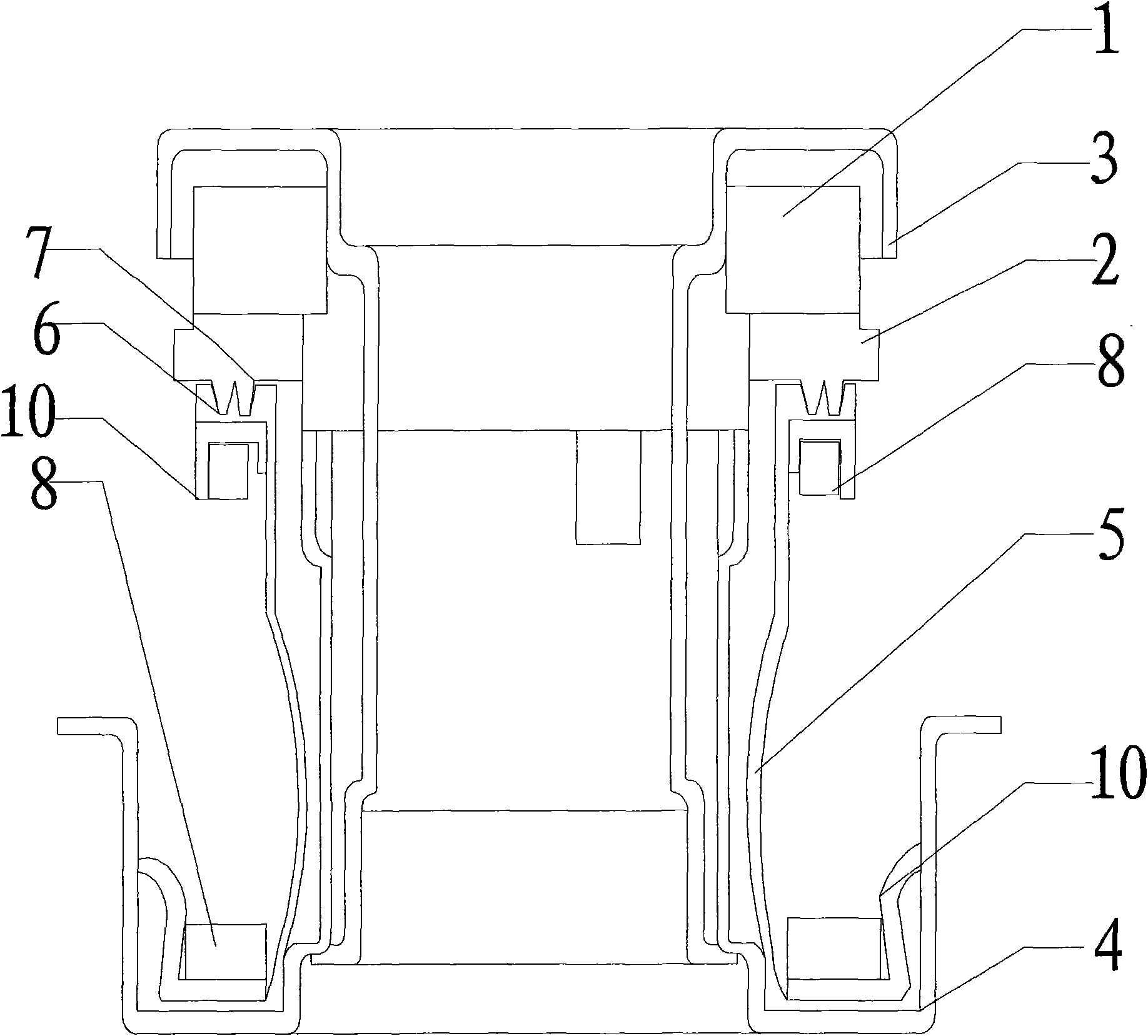

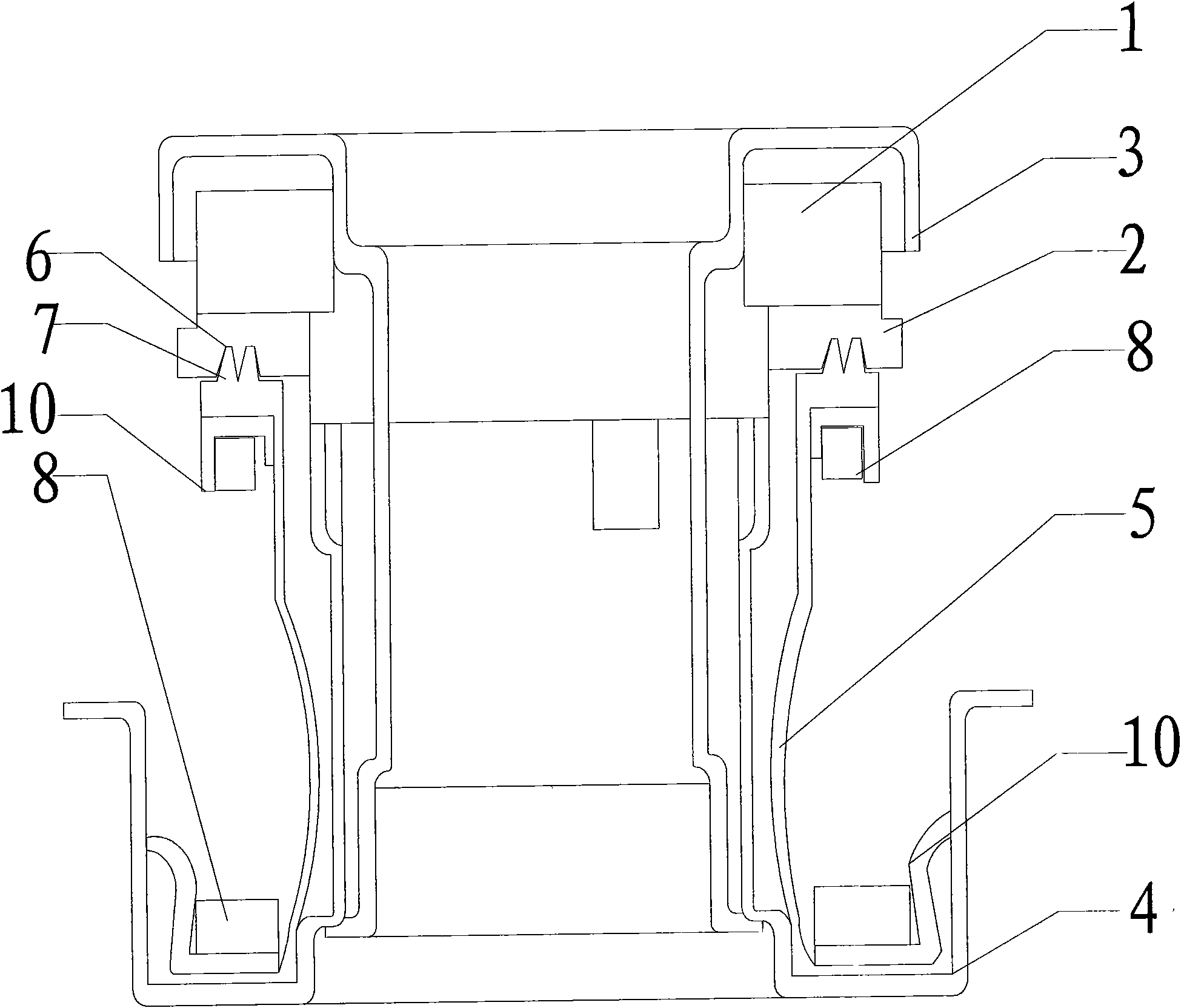

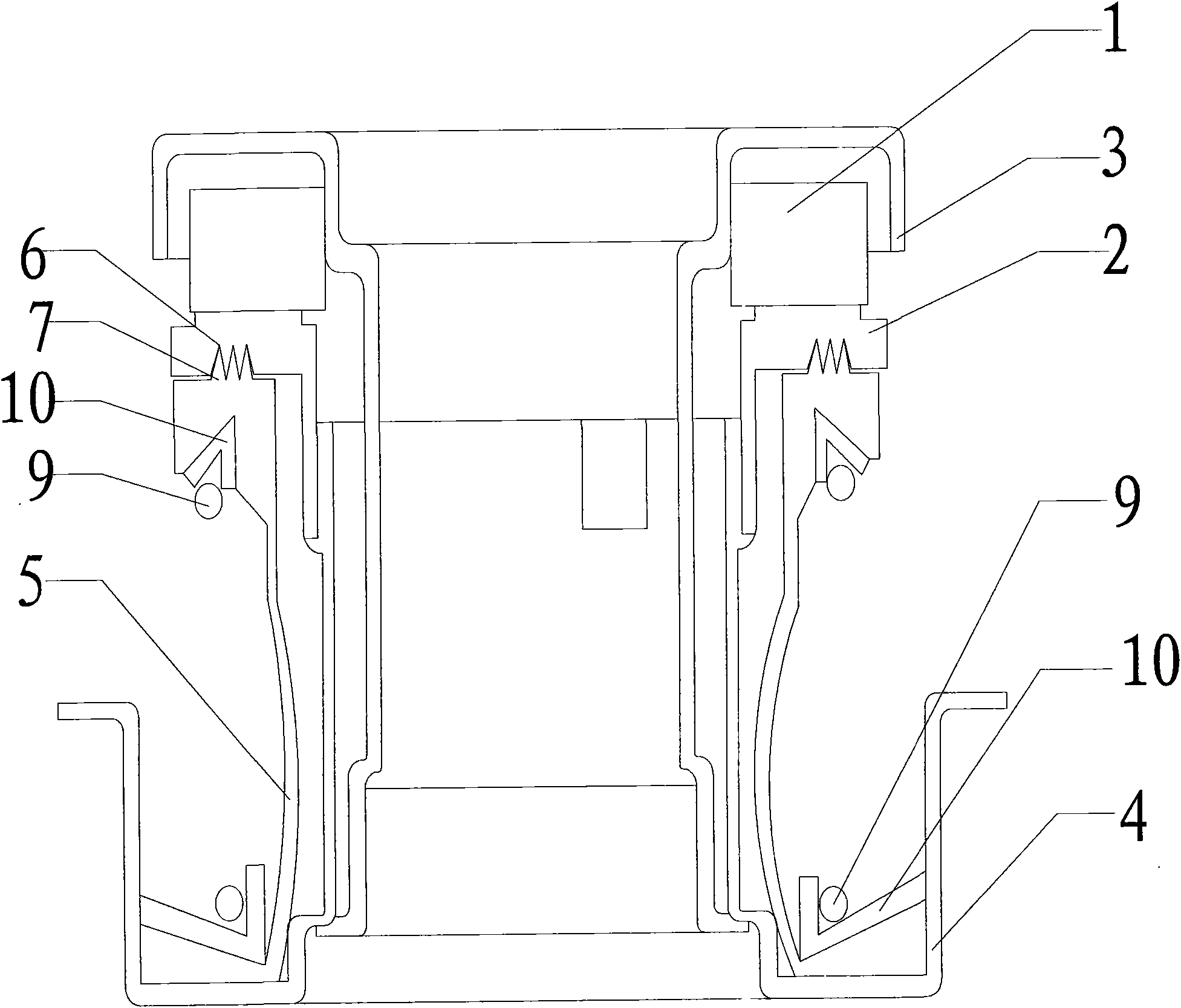

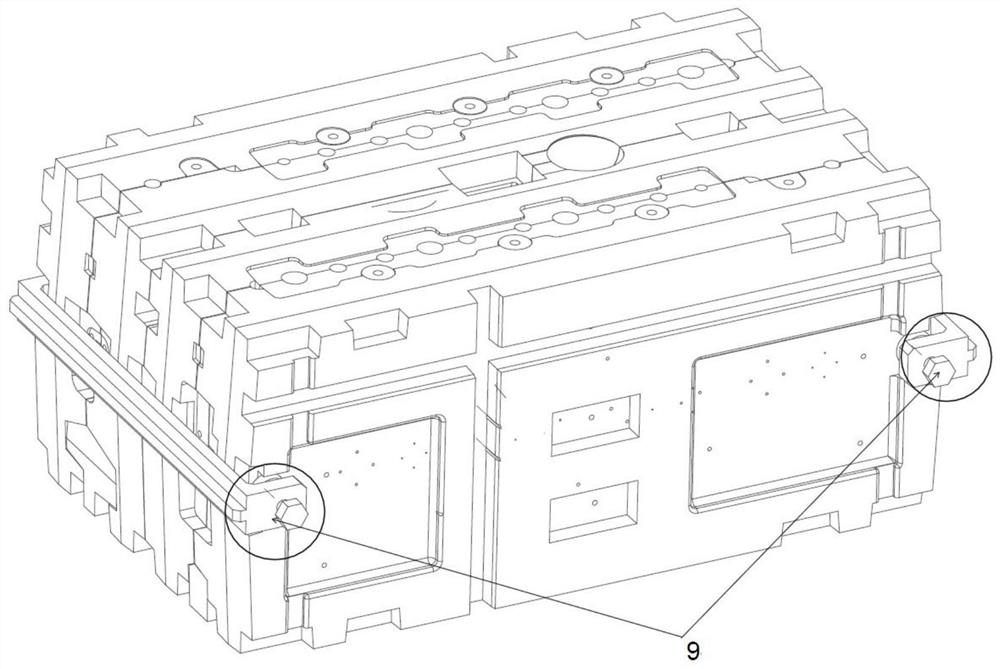

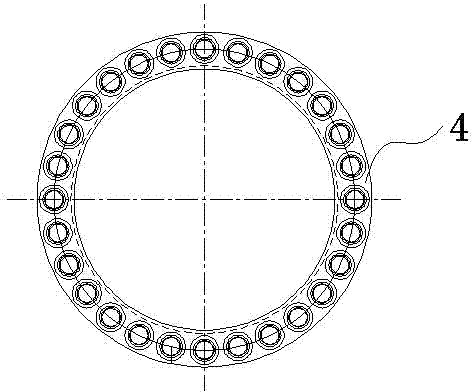

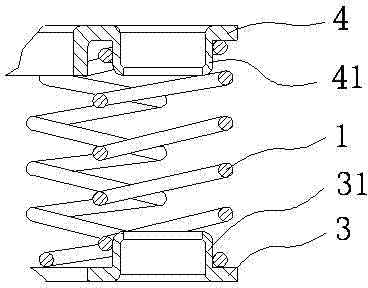

Sealing part assembly

InactiveCN101619766ASimple manufacturing processHigh degree of assembly automationEngine sealsPump componentsEngineeringMagnet

The invention discloses a sealing part assembly which comprises a movable ring body, a stationary ring body, a movable ring shaft sleeve base, a stationary ring shaft sleeve base, a rubber sealing sleeve and two groups of fixed frameworks. The upper surface of the rubber sealing sleeve is matched with the lower surface of the static ring body; the lower end part of the rubber sealing sleeve is sleeved in the stationary ring shaft sleeve base; and the lower surface of the movable ring body is matched with the upper surface f the stationary ring body. The sealing part assembly is characterized in that the upper surface of the rubber sealing sleeve and the lower surface of the stationary ring body are matched in a manner of a convex body with a taper and a groove with a taper; and springs or magnets are sleeved on the fixed frameworks at the upper end and the lower end on the outer surface of the rubber sealing sleeve. The invention has the advantages of simple manufacturing process, strong university, reliable sealing performance and long service life.

Owner:江雪忠

Insulated van carriage assembly frame

PendingCN111250947ATooling layout design is scientific and reasonableHigh degree of assembly automationMetal working apparatusRefrigerator carCarriage

Owner:QINGDAO GUOSEN MACHINERY

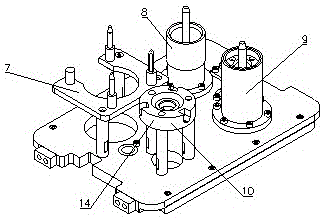

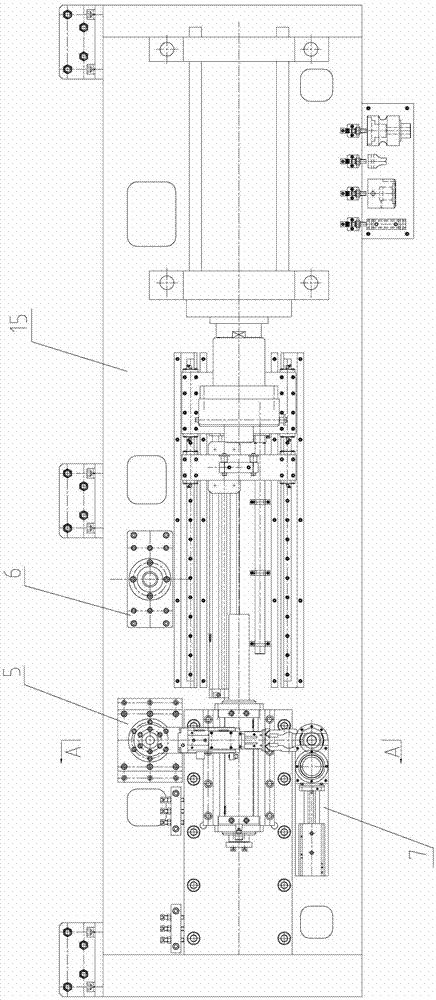

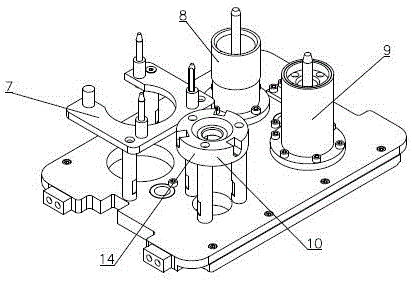

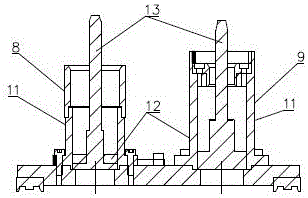

Transmission intermediate shaft circlip automatic feeding and pressing mechanism

InactiveCN103846658BHigh degree of assembly automationNo manual operationAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention belongs to the technical field of transmission assembly and particularly relates to an automatic loading pressing mechanism for an intermediate shaft snap spring of a transmission. The mechanism comprises a body, a pressing unit and a snap spring loading delivery mechanism. The snap spring loading delivery mechanism comprises a snap spring mounting mechanism, a snapping rotation mechanism, a snap spring sleeve tooling, a snap spring sleeve tooling location mechanism and an intermediate shaft lifting mechanism. The snap spring sleeve tooling is located on the snap spring sleeve tooling location mechanism, the snap spring mounting mechanism is arranged above the snap spring sleeve tooling, the intermediate shaft on which the snap spring is to be pressed, is arranged on the intermediate shaft lifting mechanism vertically. The snap spring to be pressed is sleeved on the snap spring sleeve tooling through the snap spring mounting mechanism, the snapping rotation mechanism snaps and delivers the snap spring sleeve tooling with the snap spring sleeved to the upper portion of the intermediate shaft on which the snap spring is to be pressed, the intermediate shaft rises to be located with the snap spring sleeve tooling through the intermediate shaft lifting mechanism, and the pressing unit presses the snap spring sleeved on the snap spring sleeve tooling in a snap spring groove of the end of the intermediate shaft. By means of the mechanism, automatic loading, location and pressing of the snap spring are achieved, and the problem of the difficulty in prior manual assembly of snap springs is solved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

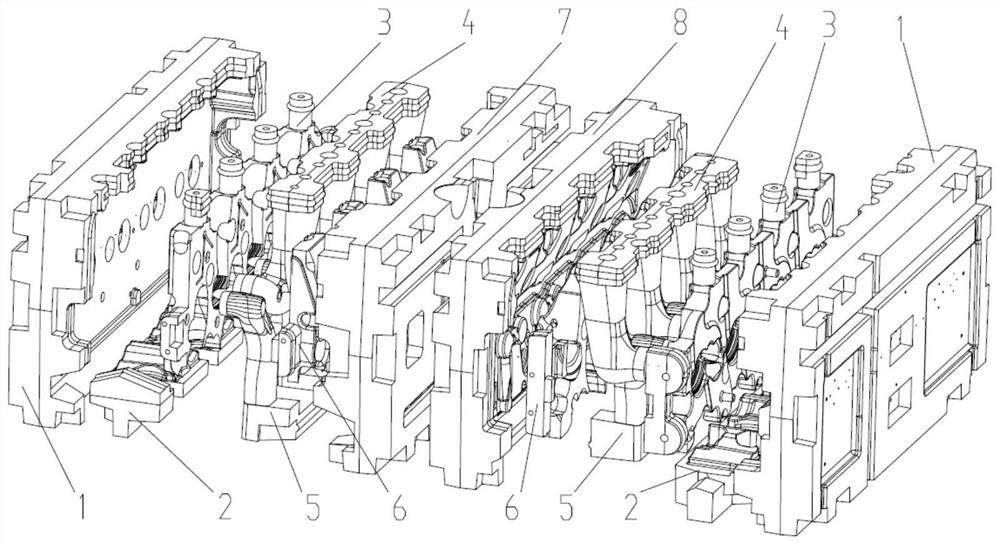

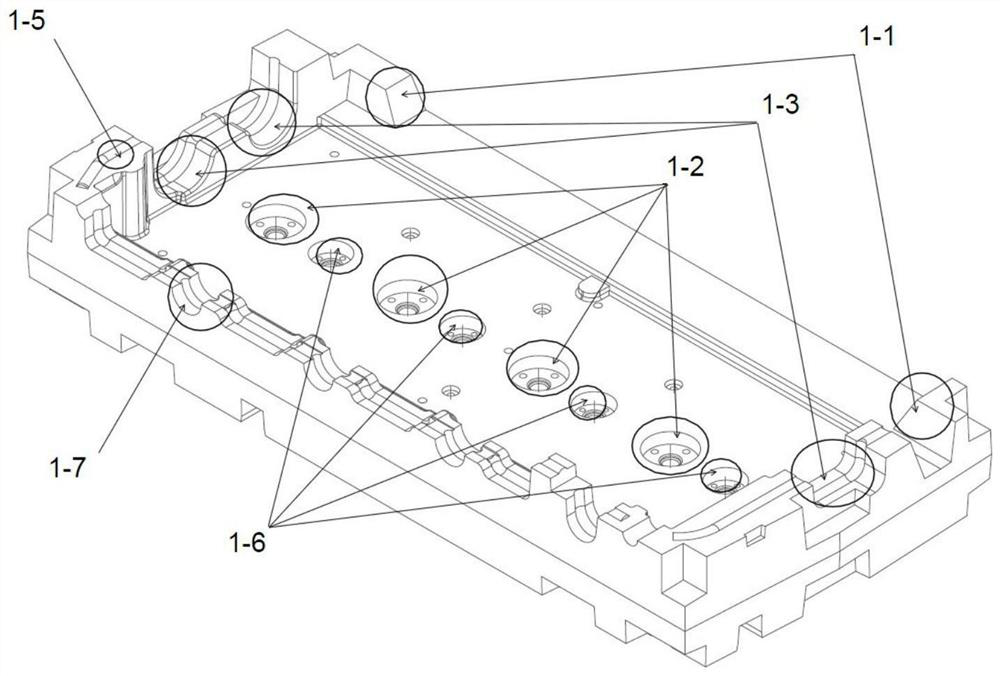

Casting structure and method for diesel engine cylinder cover core assembly vertical casting process sand core combination

ActiveCN113579165ARealize coringRealize handlingFoundry mouldsProcess efficiency improvementDieselingStructural engineering

The invention discloses a casting structure and method for a diesel engine cylinder cover core assembly vertical casting process sand core combination. The structure comprises tray cores on the two sides, lower water jacket cores arranged on the tray cores on the two sides, exhaust passage core seats arranged on the tray cores on the two sides, exhaust passage cores arranged on the tray cores on the two sides and the exhaust passage core seats, air inlet passage cores arranged on the tray cores, upper water jacket cores arranged on the lower water jacket cores, a left top cover core and a right top cover core, wherein the left top cover core and the right top cover core are arranged on the tray cores on the two sides respectively, the left top cover core and the right top cover core are matched with the tray cores on the two sides to form the shape of the top face of a cylinder cover; and all sand cores are compressed through a compressing device, the casting structure of the sand core combination is formed, and two cylinder covers can be formed at a time. The size precision, the process yield and the inner cavity quality of the cylinder covers are improved.

Owner:KUNMING YUNNEI POWER

Robot automatic assembly method and device based on multi-sensor fusion

ActiveCN110340630BHigh positioning accuracyPrecise positioningMetal working apparatusControl engineeringProcess engineering

The embodiment of the invention relates to the technical field of automatic assembly, and discloses a method and device of robot automatic assembly based on multisensor fusion. The invention solves the problemsthatthe positioning range of a system is small, the positioning precision is not accurate and the detection information is incompletein the prior art, according to the technical scheme, thesystem comprises an upper computer system, an industrial robot, a clamping system, a multisensor system and to-be-assembled bodies, wherein the upper computer system is used for acquiring measurementdata of the multisensor system and performing calculation, planning the movement of the robot according to acalculation result and feeding back the movement of the robot to the industrial robot; the industrial robot is used for conveying the to-be-assembled bodies,the clamping system is used for clamping the to-be-assembled bodies,and the multisensor system is used for obtaining the pose relationship and contact force information among the assembly bodies. According to the method and the device, the assembly process is planned according to theaccurate detection of the multisensor fusedmulti-parameter data of the to-be-assembled bodies, so that high-precision automatic assembly of acomplex large body is realized, the system positioning range is expanded, and the positioning precision is improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

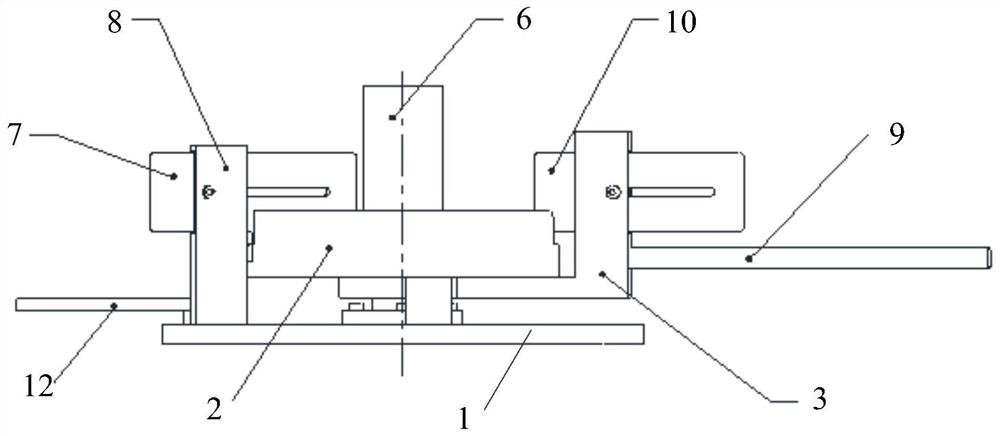

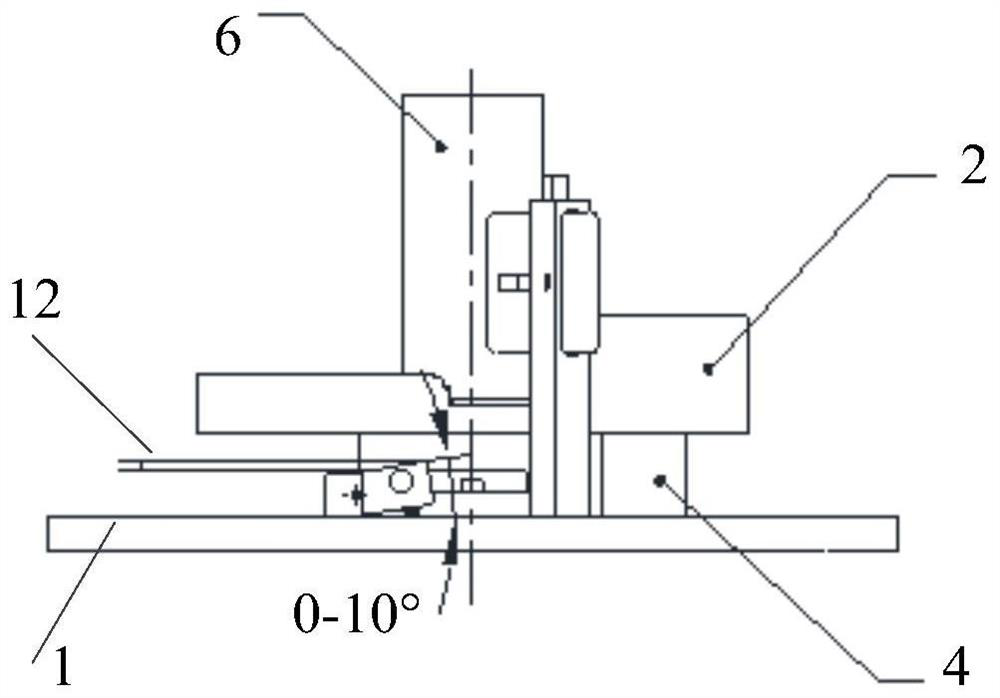

Motor push rod type power-assisted steering apparatus

ActiveCN101450677BReduce disturbanceReduce pollutionElectrical steeringElectric power steeringVehicle frame

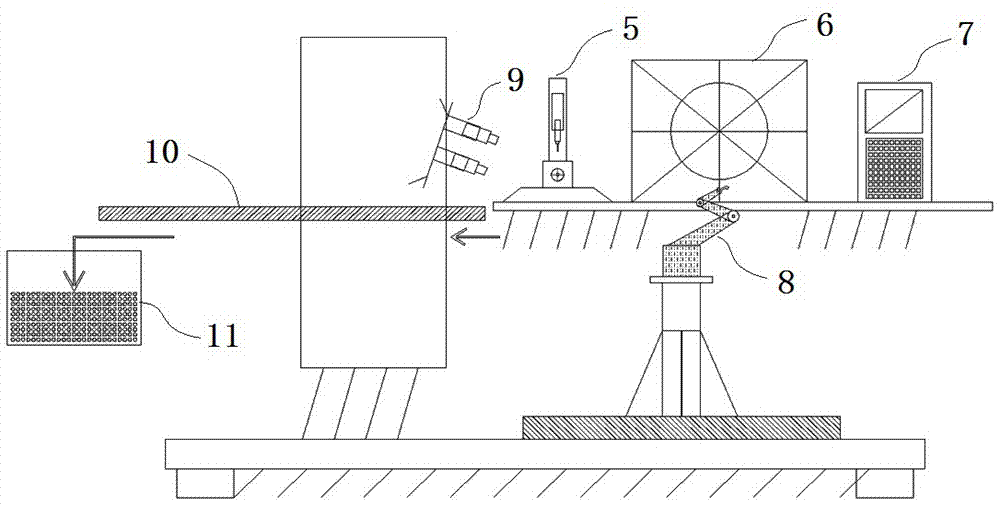

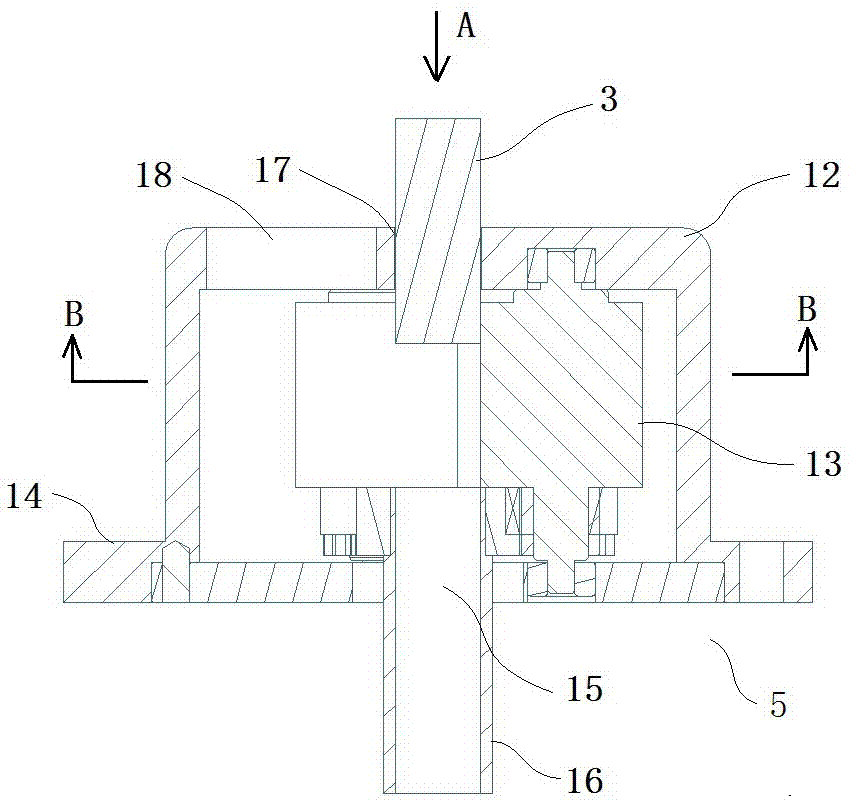

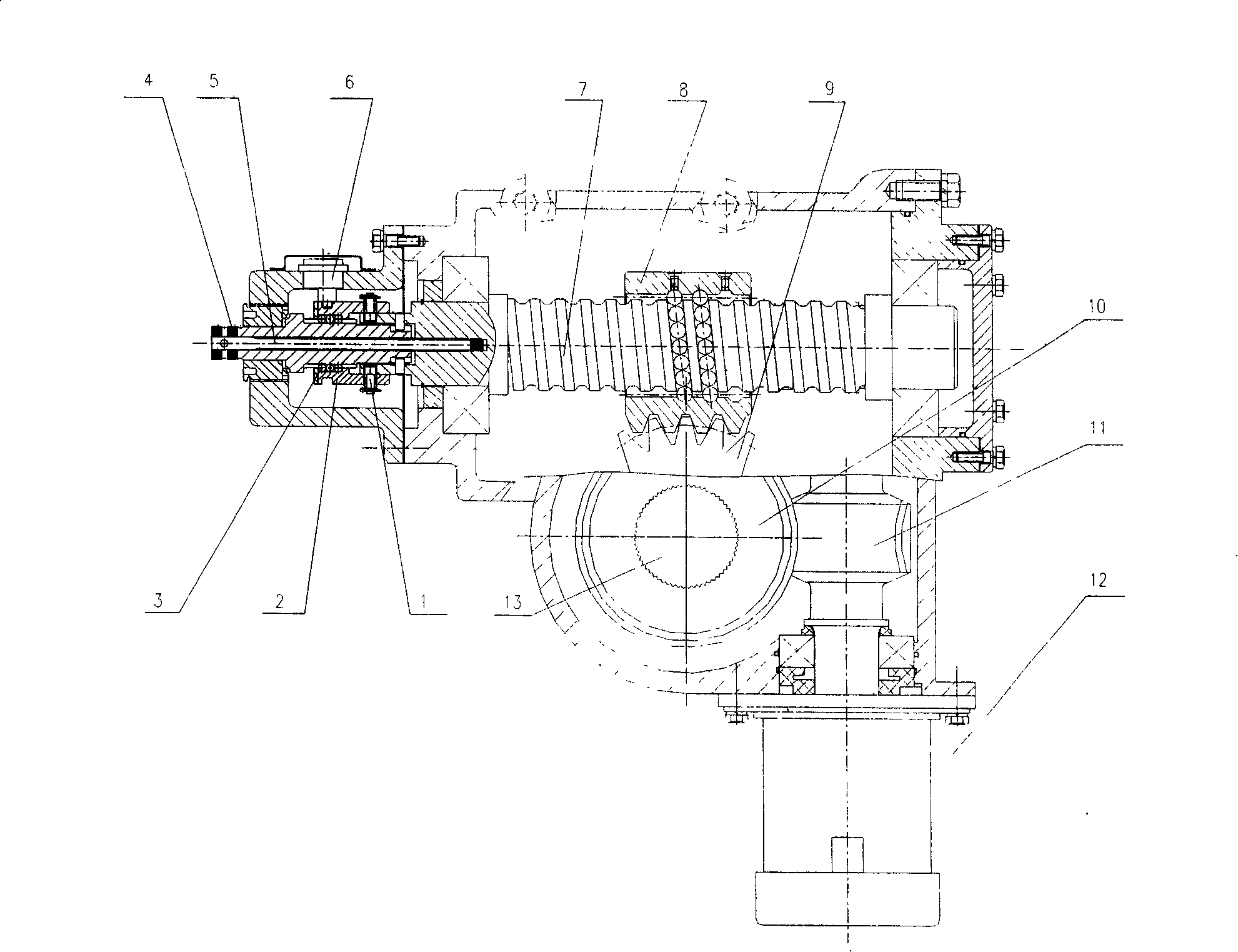

The invention relates to an electrical push rod type electrical power-assisted steering device, which comprises a recirculating ball steering gear provided with a torque sensing device, an electrical push rod and an electronic control unit, wherein the torque sensing device is used for detecting moment acted on a steering wheel, and is arranged on an input shaft of the recirculating ball steering gear. One end of the electrical push rod is connected with a steering rock arm, and the other end of the electrical push rod is connected with a vehicle frame. The electrical push rod comprises a power-assisted motor and a speed reducing mechanism, a push rod and so on. An input shaft of the speed reducing mechanism of the power-assisted motor is connected with an output shaft of the power-assisted motor, an output shaft of the speed reducing mechanism is connected with a screw rod of the push rod, and the moment output by the power-assisted motor pushes a rock arm shaft to rotate through a screw nut transmission pair. The electronic control unit is used for controlling the current of the power-assisted motor according to signals of the torque of the steering wheel and the vehicle speed and so on. The steering device can save energy, provide proper power assistance under various running work conditions, has fewer parts, light weight, compact structure and high assembly automatic degree, and is a steering mechanism of vehicle power with energy conservation, safety and environmental protection.

Owner:BEIJING AUTONICS TECH

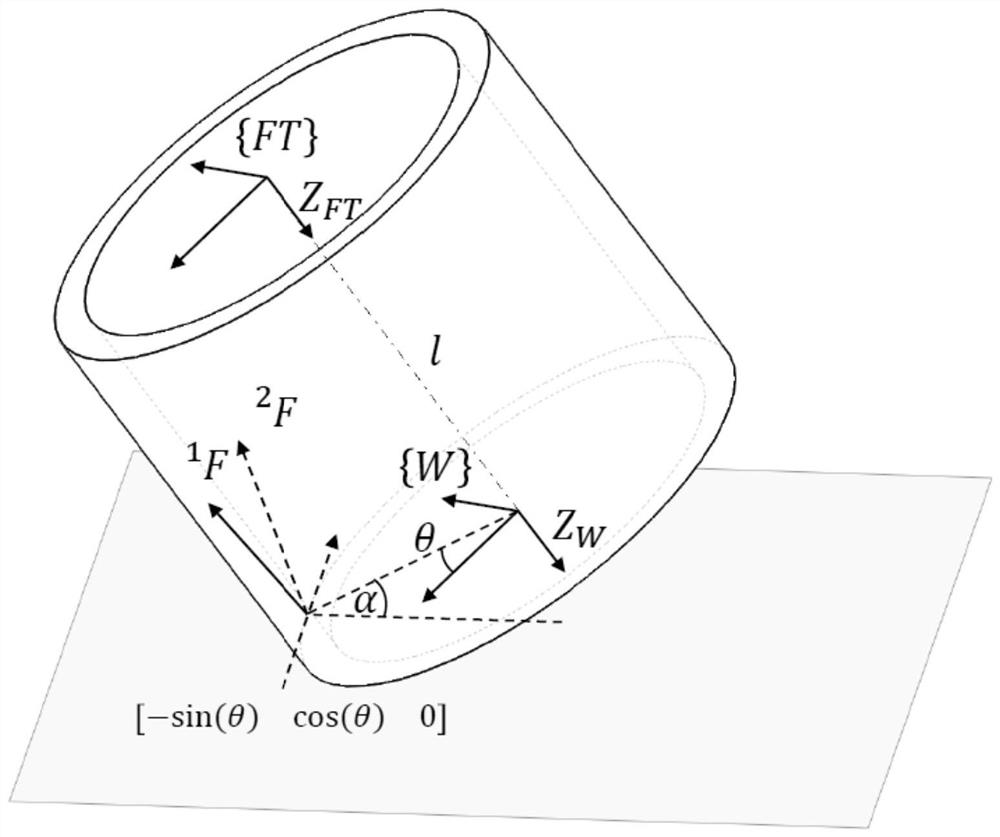

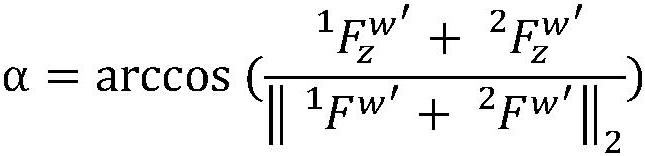

Method and system for automatic shaft hole axis alignment of robot based on plane surface friction

ActiveCN112223303BHigh degree of assembly automationLess teaching processArmsEngineeringContact force

The invention discloses a robot automatic shaft hole axis alignment method and system based on plane surface friction. The shaft to be assembled is taught above the plane, and the plane is perpendicular to the axis of the hole to be assembled placed on the shaft hole assembly platform; The shaft to be assembled is in contact with the plane; the shaft to be assembled is moved back and forth on the plane, and a force sensor is used to measure the contact force and moment of the shaft to be assembled in contact with the plane According to the size of the contact force and moment, the inclination angle and direction of the shaft to be assembled are calculated; according to the angle of inclination and the direction of inclination, the axis of the shaft to be assembled is aligned with the axis of the hole to be assembled Axis aligned. The invention can improve the automation degree of the shaft hole assembly operation and improve the assembly efficiency.

Owner:XI AN JIAOTONG UNIV

An automatic assembly system for an airbag housing

The application discloses an automatic assembly system for an airbag housing, which includes an assembly platform; an operating platform is provided at one end of the assembling platform, and the operating platform is used to place torsion springs and springs on the housing body to form a housing to be assembled One side of the assembly platform is equipped with a torsion spring installation mechanism, a spring installation mechanism, a conduction detection mechanism, and a code scanning and dotting mechanism; a conveying device is also installed on the assembly platform, and the conveying device is suitable for driving through the carrier plate to be assembled The shell assembly moves along the assembly platform; so that the shell assembly to be assembled passes through the torsion spring installation mechanism, the spring installation mechanism, the conduction detection mechanism and the scanning code marking mechanism. Beneficial effects of the present application: the detection mechanism of the shell assembly is set on the assembly platform, and the shell assembly is driven circularly by the conveying device to complete the processes of torsion spring installation detection, spring installation detection, power-on detection, and information recording in sequence, thereby improving the shell assembly. The degree of automation in the assembly of body components.

Owner:NINGBO SHUANGLIN MOULD CO LTD

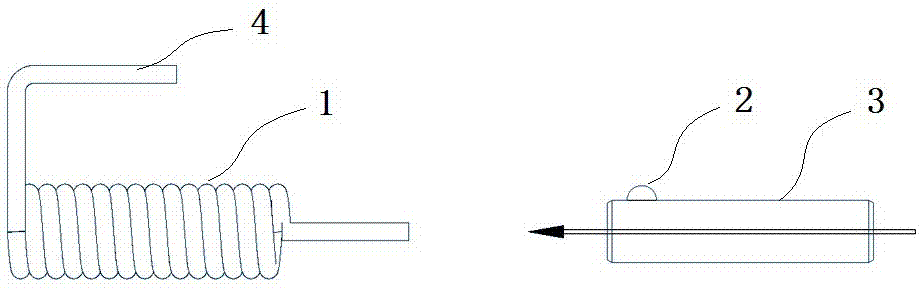

A kind of automatic assembly mechanism and working method of automobile inductance

ActiveCN105931826BSimple structureHigh degree of assembly automationInductances/transformers/magnets manufactureFixed signal inductancesEngineeringInductor

The invention discloses an automatic assembling mechanism for an automobile inductor, and an operating method of the automatic assembling mechanism, and relates to assembling between coils and magnetic cores. The automatic assembling mechanism is characterized by comprising a coil clamping apparatus and an assembling headstock, wherein the assembling headstock comprises a base, a magnetic core clamping wheel group which is perpendicularly arranged on the base, and a cover body for packaging the magnetic core clamping wheel group; a magnetic-core passing-through hole is formed in the upper end plane of the cover body; the magnetic core clamping wheel group comprises at least three adhesive wheels which are distributed at intervals along the magnetic-core passing-through hole. The automatic assembling mechanism has the advantages of simple structure, high assembling automatic degree, less working procedures, convenient control and operation, and capabilities of improving the assembling efficiency and the mass and lowering the production cost, avoiding the problems of low efficiency and difficulty in ensuring the quality existing in the conventional manual assembling of the automobile inductors, as well as overcoming the shortcomings of deformation, clamping and the like existing in the conventional coil assembling by adopting a vibrating plate structure.

Owner:上海奇开电器有限公司

Electric drive pusher type steering system controlled by coupling force and displacement and control method

InactiveCN102632921BReduce disturbanceImprove steering characteristicsSteering linkagesAutomatic steering controlActive safetyLow speed

The invention relates to an automobile steering assistant-control system and a control method and in particular relates to an electric drive pusher type steering system controlled by coupling force and displacement and a control method. The moment output end of a driving mechanism, connected with a steering motor, is connected with a worm crankpin steering gear through an output shaft; a steering rocker arm on the worm crankpin steering gear is used for controlling a steering knuckle arm; the steering knuckle arm is connected with a steering trapezium rod; an assistant motor is connected with and drives a speed reducing mechanism; the speed reducing mechanism drives an electric drive pusher; and the assistant motor is controlled by an ECU (Electronic Control Unit). The steering assistant-control system provides appropriate assistance under various driving conditions to reduce disturbance caused by an uneven road surface to the steering system, improves steering characteristics of an automobile, decreases the steering operation force of the automobile traveling at a low speed, enhances the steering stability of the automobile traveling at a high speed to further enhance the driving safety of the automobile and meets the requirements of different using objects by setting different steering hand power characteristics.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

An assembly line for an automobile combination instrument

InactiveCN105904209BHigh degree of assembly automationHigh degree of automationAssembly machinesProduction lineDashboard

The invention discloses an assembly line for automobile combination dashboards and an assembly method thereof. The production flow roughly comprises the steps of automatically writing values in dashboard programs, assembling stepping motors, welding the stepping motors and horns, removing static electricity on dash boards, reading and writing Jumppointer values, assembling TFT display screens, testing LEDs and the TFT screens, assembling light guide supports and board plates, automatically pressing pins, assembling front frames and rear shells, calibrating rotation speed pointers, automobile speed pointers, fuel oil pointers and water temperature pointers, testing the high temperature aging performance, carrying out final inspection manually and labeling and transferring the dashboards to film pasting and packaging stations. According to the assembly line and the assembly method, the production safety is improved, the assembly work efficiency of the automobile combination dashboards is greatly improved, and the product quality and the qualification rate are guaranteed.

Owner:ANHUI POLYTECHNIC UNIV

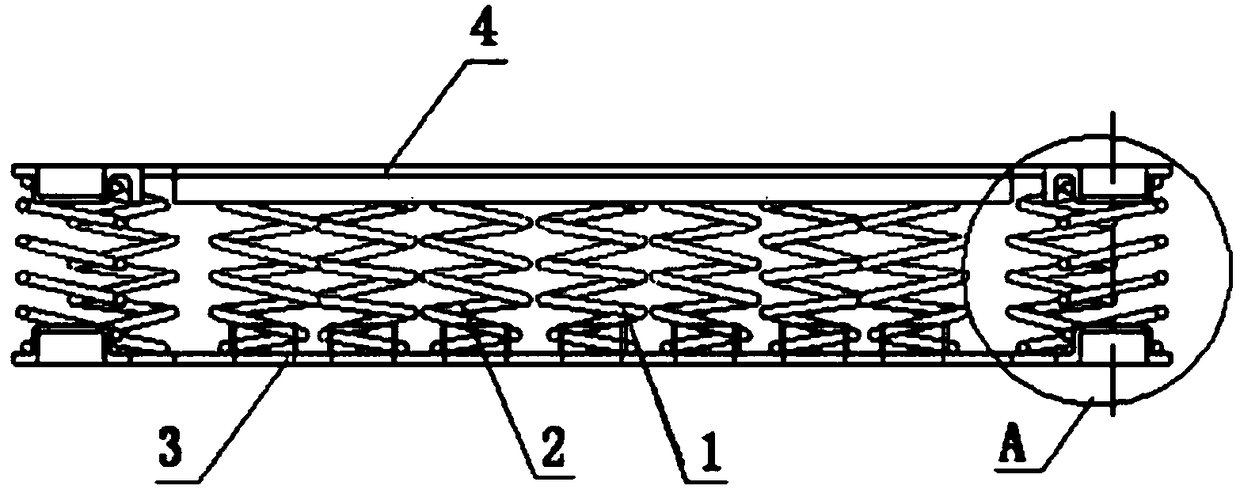

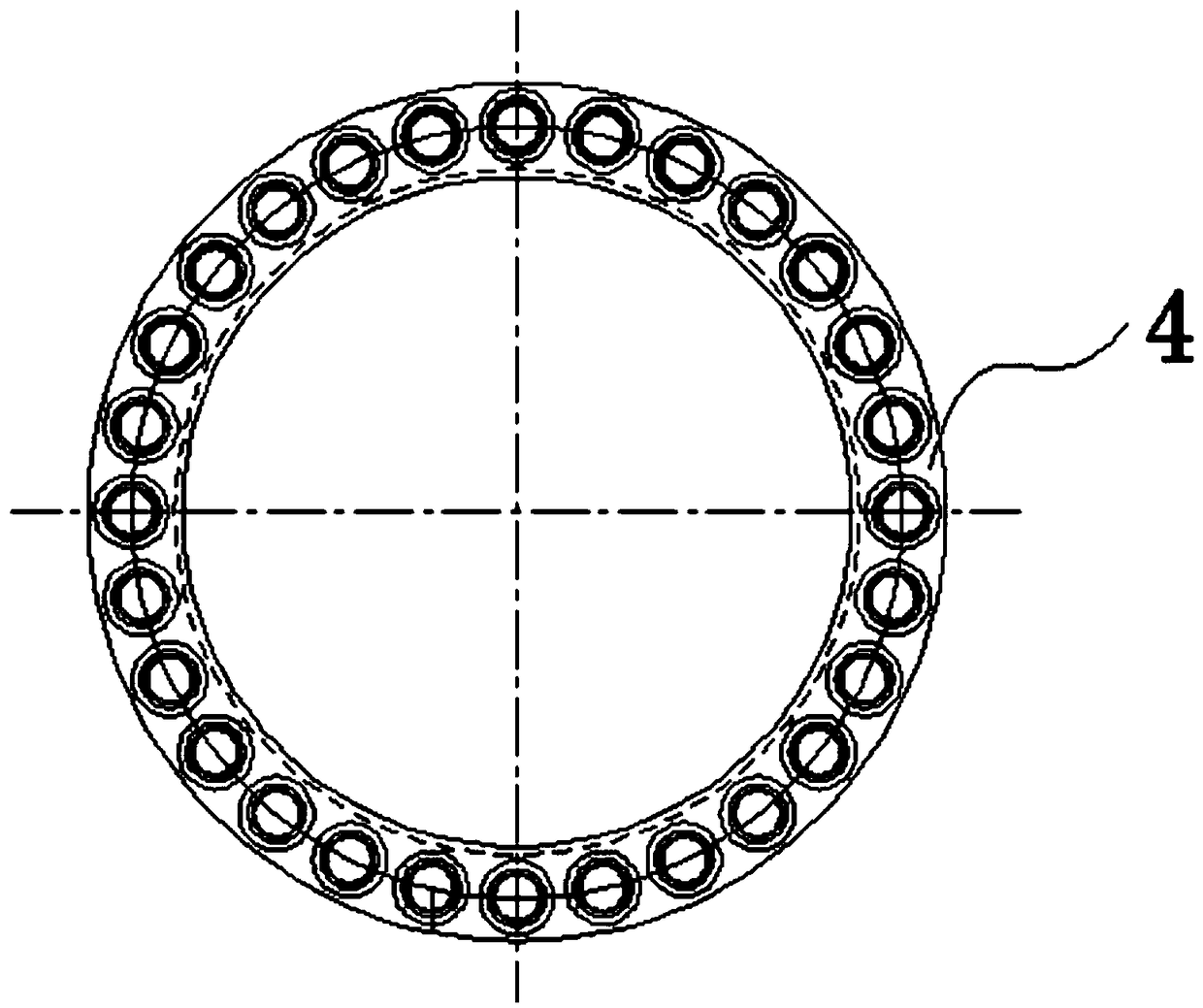

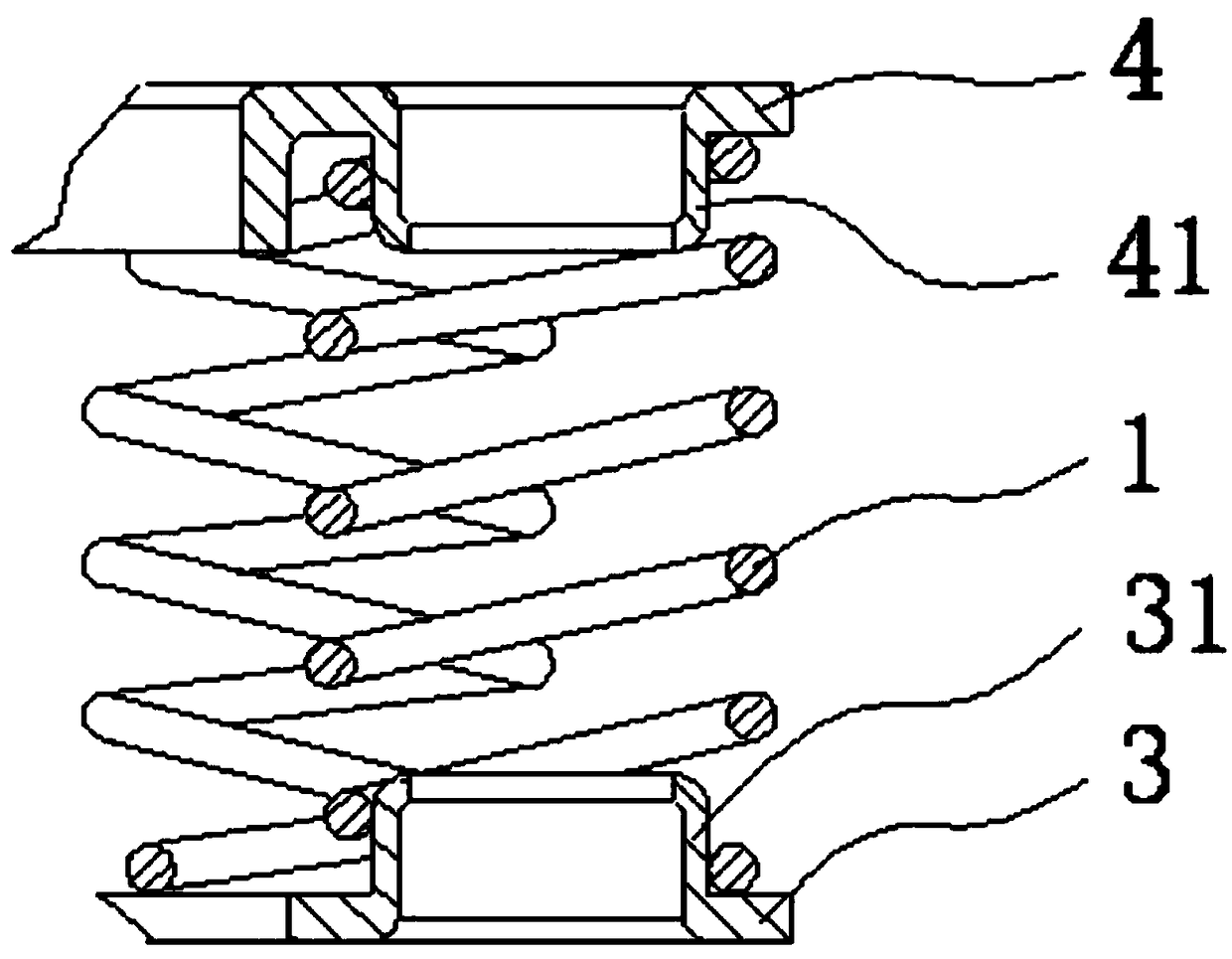

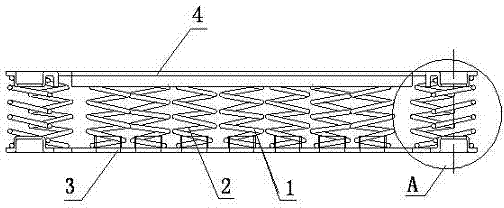

Spring composite disc

The invention relates to an auto part technology, in particular to a spring composite disc. The spring composite disc solves the unsafe problems that an automobile clutch spring composite disc is notreasonable in structure, and consequently springs are staggered and fall and a foundation frame deforms. The spring composite disc comprises upper and lower thrust rings in ring shapes, a plurality oflower spring bases are arranged in the lower thrust ring, a plurality of upper spring bases are arranged in the upper thrust ring, springs are arranged between the lower spring bases and the upper spring bases, the quantity of the lower spring bases is the same as that of the upper spring bases, the quantity is an even number, and center lines of the lower spring bases and the upper spring basesare coincident; and the springs comprise the left-hand springs and the right-hand springs, and the left-hand springs and the right-hand springs are arranged in a spaced manner. The springs comprise the left-hand springs and the right-hand springs, it is guaranteed that the composite disc cannot twist or incline in the compressed process, the lower spring bases and the upper spring bases directly conduct expansive interference fit assembly on the left and right springs under the effect of a special compression device, the springs and the thrust rings are completely combined into a whole, and the good structure strength is achieved.

Owner:JIANGSU XIANGYING HARDWARE SPRING CO LTD

A kinematic inverse solution method of a six-axis automatic hole-making and spot-sinking machine tool with double c-axes

ActiveCN106980751BGuaranteed accuracyGuaranteed stabilityInformaticsSpecial data processing applicationsEngineeringMovement control

The invention discloses a kinematic inverse solving method for a six-shaft automatic drilling and dimpling machine tool comprising double C shafts. The method comprises the steps that (1) an equipment base coordinate system, all moving shaft sub-coordinate systems and a tool coordinate system are established in the six-shaft automatic drilling and dimpling machine tool, a coordinate system definition diagram is drawn, and all the sub-coordinate systems and the equipment base coordinate system are made to keep consistent in coordinate axis direction; (2) kinematic analysis is performed on the six-shaft automatic drilling and dimpling machine tool, and a forward kinematic model is established; and (3) an equation set of joint quantities is established according to a target pose and the forward kinematic model of the six-shaft automatic drilling and dimpling machine tool, a kinematic inverse solving strategy for separate solving of the joint quantities is proposed, and an analytical method and a numerical method are combined to solve all the joint quantities to obtain an inverse kinematic model. Through the method, kinematic forward / inverse solving of the six-shaft automatic drilling and dimpling machine tool can be realized, the accuracy of machine tool movement control can be guaranteed, and automatic machining of an elliptical dimple is realized.

Owner:ZHEJIANG UNIV

Washing machine clutch assembly automatic line

InactiveCN105149943BHigh degree of assembly automationReduce demandAssembly machinesEngineeringAssembly line

The invention relates to an automatic assembling line for a washing machine clutch. The automatic assembling line comprises an automatic shaft assembly assembling line, a clutch final assembly automatic line and a jumper wire transplanting device. The automatic shaft assembly assembling line comprises a shaft assembly assembling conveying line, a shaft assembly assembling carrier and an automatic shaft assembly assembling carrier returning line. The clutch final assembly automatic line comprises a clutch final assembly conveying line, a clutch final assembly carrier and an automatic clutch final assembly carrier returning line. The shaft assembly assembling conveying line and the clutch final assembly conveying line are provided with a plurality of stations sequentially distributed from the initial end to the tail end and online special machines arranged on the stations. The assembling of the washing machine clutch is finished when the shaft assembly assembling carrier and the clutch final assembly carrier pass the stations and the online special machines in sequence. The automatic assembling line has the beneficial effects that the assembling automation rate of the washing machine clutch is greatly increased, the labor intensity of workers is relieved, and the requirement for assembling workers is lowered.

Owner:北自精工机械(常州)有限公司

Spring combined disk

InactiveCN101788033BHigh precisionGood symmetryVibration suppression adjustmentsInterference fitEngineering

The invention relates to the technology of automobile parts, in particular to a spring combined disk, solving the problems that the spring is staggered and falls off, a base frame is deformed and the like caused by unreasonable structure of a spring combined disk of an automobile clutch. The spring combined disk comprises an annular upper and an annular lower push rings, wherein the lower push ring is internally provided with a plurality of lower spring seats; the upper push ring is internally provided with a plurality of upper spring seats; springs are arranged between the upper spring seatsand the lower spring seats; the number of the lower spring seats is equal to the number of the upper spring seats and is an even number; center lines of the lower spring seats and the upper spring seats are superposed; and the springs comprise left-handed springs and right-handed springs which are arrayed at intervals. Since the springs comprise the left-handed springs and the right-handed springs, the combined disk cannot be twisted and tilted in the compressed process; the lower spring sets and the upper spring seats directly carry out expansible interference fit assembly on the left-handedsprings and the right-handed springs, so that the springs and the push rings are completely combined into a whole; and the invention has favorable structural strength.

Owner:钱江弹簧(北京)有限公司

A method for machining bolt holes of aircraft engine suspension components using numerical control equipment

InactiveCN103785874BImprove production efficiencyHigh degree of assembly automationNumerical controlReverse analysis

The invention belongs to the field of numerical control machining methods, and particularly relates to a method for machining bolt holes in a hanging subassembly of an aircraft engine by using mechanical control equipment. The method comprises the following steps of preassembling the hanging subassembly by using an assembling tool; positioning the hanging subassembly on a special machining supporting clamp; performing measurement and reverse analysis and adjusting numerical control machining programs; positioning the subassembly and the clamp on a machine tool in an integrated manner; automatically forming holes by using the machine tool and examining a machining result; preassembling the hanging subassembly by using a small number of bolts; establishing a measuring benchmark on the product under aircraft axes; positioning the product on the special machining supporting clamp and then examining the appearance error and the location degree of the product; performing reverse modeling and analysis by using CATIA (computer-graphics aided three-dimensional interactive application) software; adjusting a normal tolerance point of a curved surface of the subassembly; correcting a hole-forming machining program; and positioning the whole pre-assembled hanging subassembly by using the benchmark of the special machining clamp on the machine tool as a tool setting benchmark and using the measuring benchmark established on the subassembly as an examination point, and then forming the holes on the subassembly in a machining manner.

Owner:AVIC SAC COMML AIRCRAFT

Circular ball type electric booster steering device

ActiveCN100398373CReduce disturbanceReduce pollutionMechanical steering gearsElectrical steeringElectric power steeringElectronic controller

Owner:BEIJING AUTONICS TECH

Vertical winding coil forming tool and method

PendingCN114765093ARealize the processing effectSimple Forming ToolingInductances/transformers/magnets manufactureStructural engineeringMechanical engineering

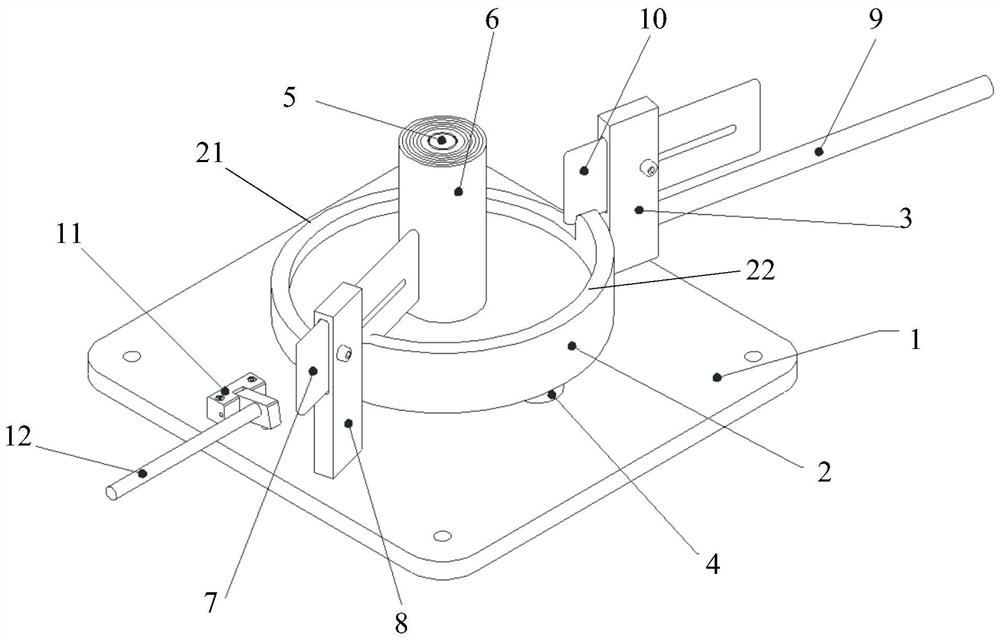

The invention provides a vertically-wound coil forming tool and method, and relates to the technical field of machining and assembling. The forming tool comprises a base; the forming disc is arranged on the base; the shaft sleeve is arranged at the central position of the forming disc; the rotating structure is rotationally connected with the base; wherein the forming disc is provided with a first limiting wall and a second limiting wall, and the rotating structure can rotate between the first limiting wall and the second limiting wall around the shaft sleeve. The forming tool is simple in structure, high in assembly automation degree, convenient to control and operate, capable of effectively improving the assembly efficiency, the quality progress and the production cost and capable of solving the problems that in the prior art, vertically-wound coils are complex in forming and low in efficiency, and procedures are reduced.

Owner:特富特电磁科技(洛阳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com