Spring composite disc

A technology of spring seat and interference fit, which is applied in the field of auto parts, can solve the problems of heavy spring combination plate, unreasonable combination structure, spring misalignment and falling off, etc., and achieve the effect of good symmetry, high degree of automation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through examples.

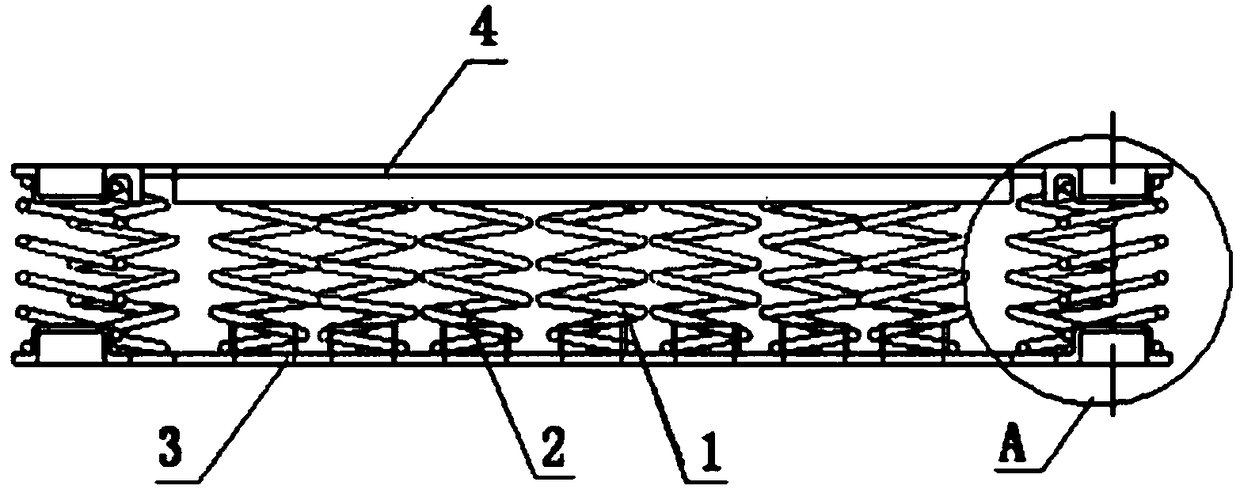

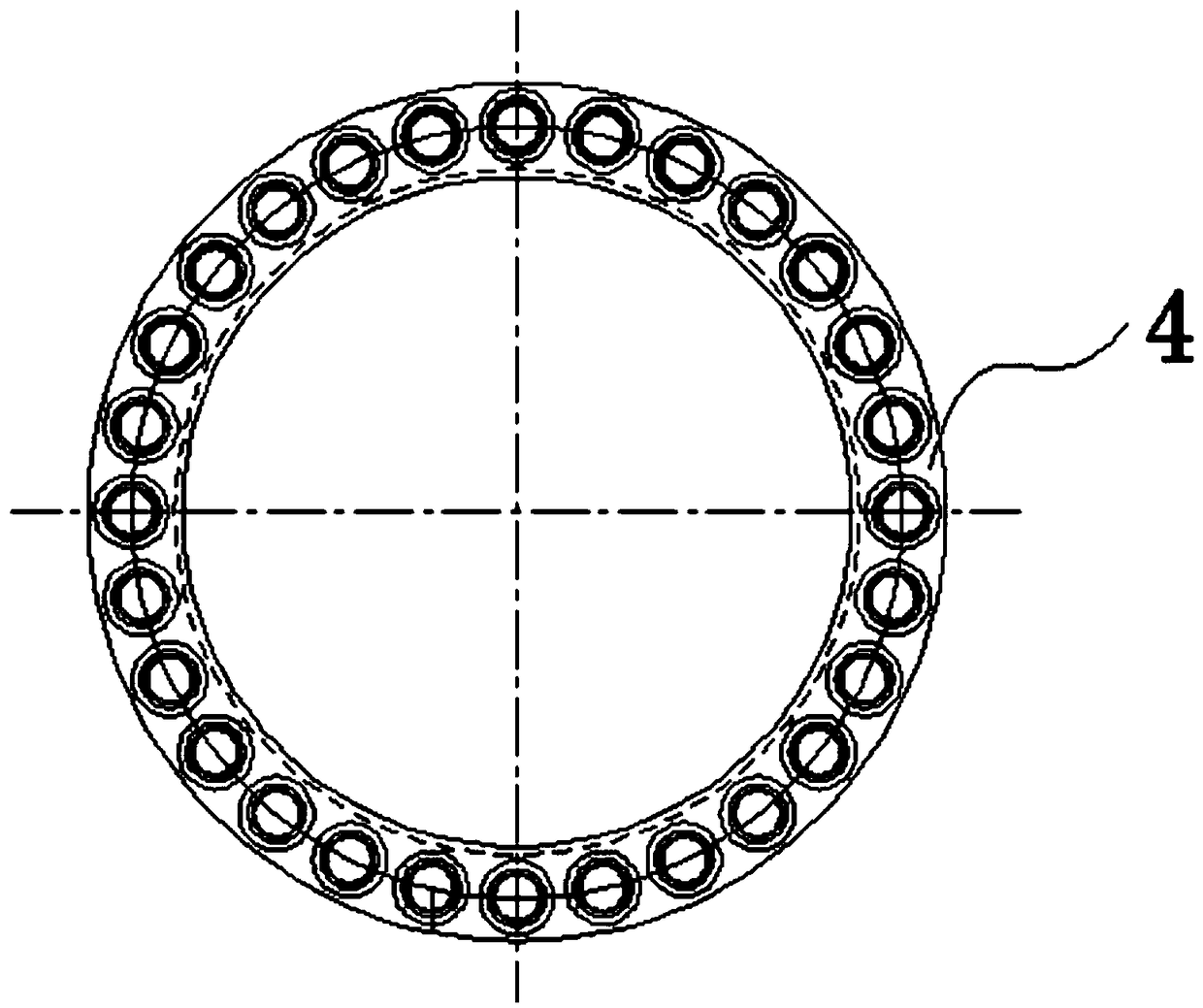

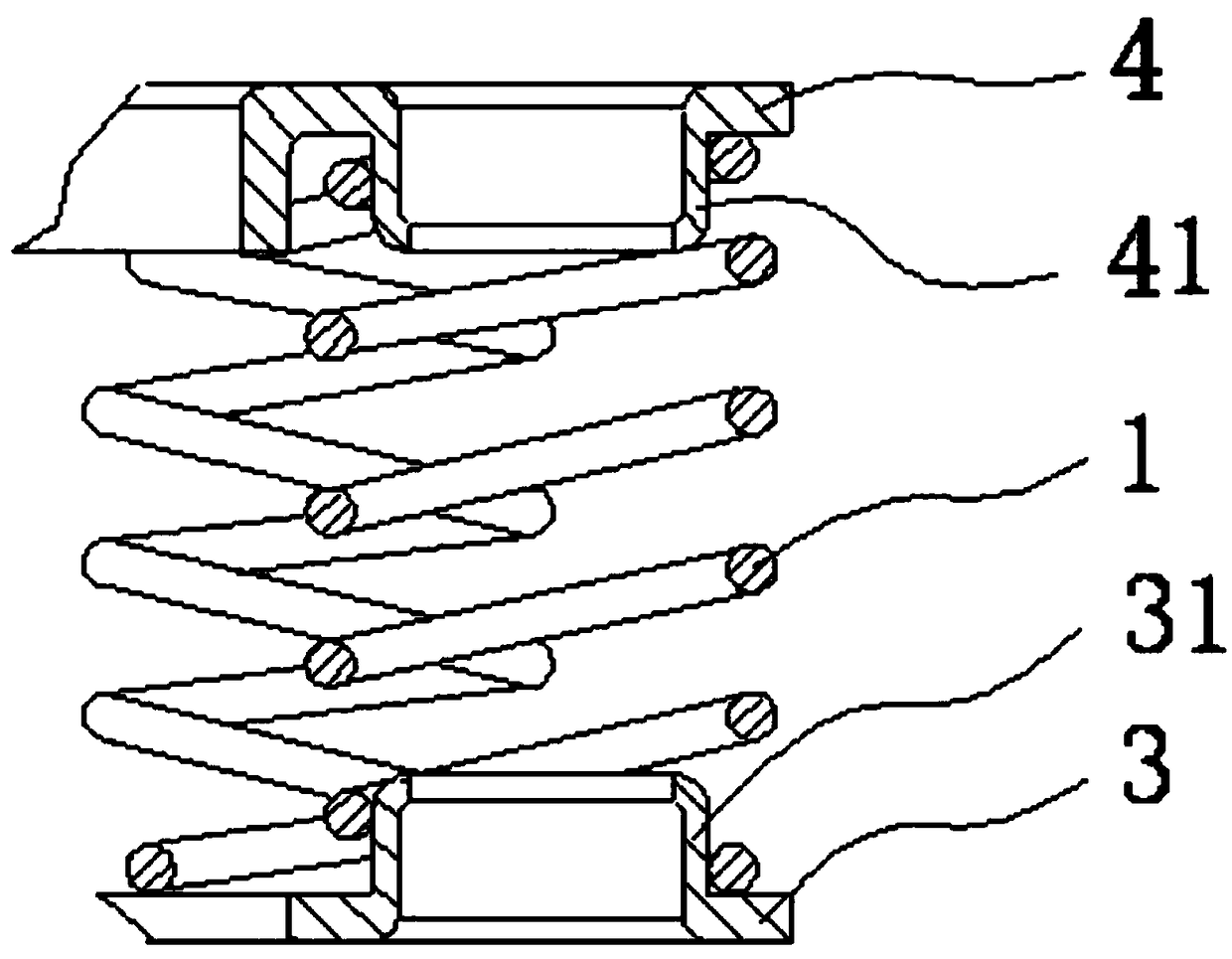

[0021] see figure 1 , figure 2 , the present embodiment is a combination spring disc, including a ring-shaped lower thrust ring and a ring-shaped upper thrust ring, and the upper and lower thrust rings are stretched and formed by thin plate materials. Be provided with 28 lower spring seats 31 in the lower thrust ring 3, be provided with 28 upper spring seats 41 in the upper thrust ring 4, as image 3 As shown, a spring is arranged between the lower spring seat 31 and the upper spring seat 41, and the centerlines of the upper spring seat 41 and the lower spring seat 31 coincide.

[0022] Springs are divided into left-handed spring 2 and right-handed spring 1. On the upper spring seat 41 and lower spring seat 31 of the upper and lower thrust rings, left-handed spring 2 and right-handed spring 1 are arranged at intervals, that is, one left-handed spring 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com