Preparation method of lithium thionyl chloride power type battery positive electrode

A lithium thionyl chloride power and battery cathode technology, which is applied in electrode manufacturing, battery electrodes, lithium storage batteries, etc., can solve problems such as transformation of the production process of power-type cathodes, and achieve convenient operation, improve overall consistency, and good uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Powder pretreatment

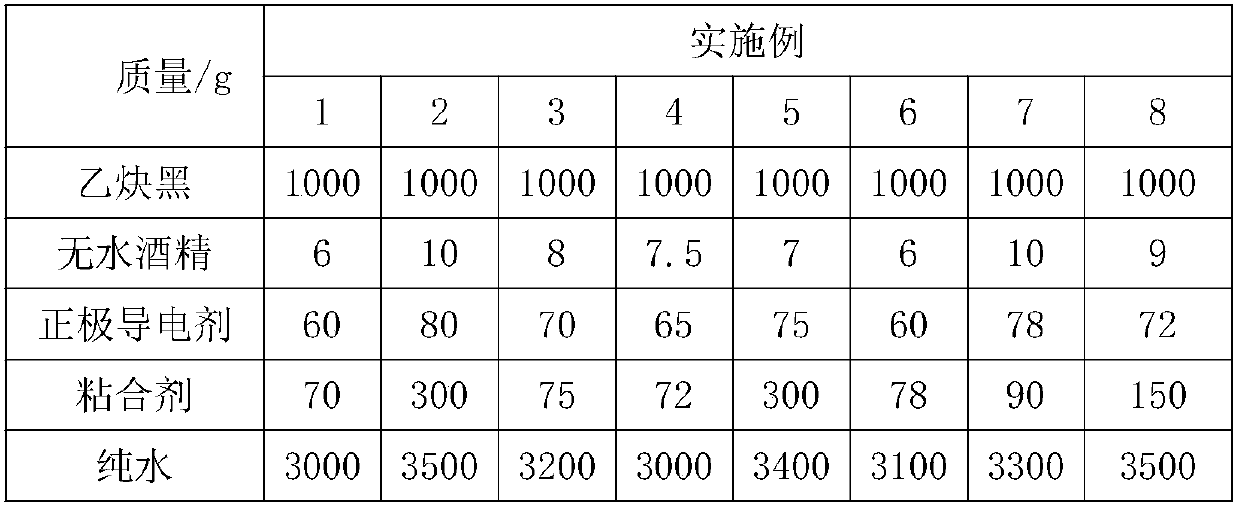

[0035] As shown in table 1, 1000g acetylene black, 6g absolute alcohol, 60g positive electrode conductive agent copper powder, 70g polytetrafluoroethylene emulsion binder, 3000g pure water are mixed into wet material and stir;

[0036] The wet material enters the extrusion machine with a sieve aperture of 0.5mm for extrusion, and obtains a strip material with a length of 1-2cm;

[0037] The strip material enters the centrifugal pellet machine to obtain fine pellets with a particle size of 0.5 mm;

[0038] The fine pellets were dried in a vacuum oven at 100°C for 8 hours;

[0039] 2) powder online

[0040] The obtained dried fine pellets are crushed into fine powders with a particle size of 0.1-0.2 μm;

[0041] Mix the powder with a 50% alcohol solution in a mass ratio of 1:2.2 to form a semi-dry powder;

[0042] The semi-dry powder is evenly sprinkled on both sides of the nickel expanded grid through the impeller feeder, and the powder is bo...

Embodiment 2

[0046] 1) Powder pretreatment

[0047] As shown in table 1, 1000g acetylene black, 10g absolute alcohol, 80g positive electrode conductive agent nickel powder, 300g vinylidene fluoride emulsion binder, 3500g pure water are mixed into wet material and stir;

[0048] The wet material enters the extrusion machine with a sieve aperture of 1.5mm for extruding, and obtains a strip material with a length of 1-2cm;

[0049] The strip material enters the centrifugal pellet machine to obtain fine pellets with a particle size of 1.5mm;

[0050] The fine pellets were dried in a vacuum oven at 100°C for 9 hours;

[0051] 2) powder online

[0052] The obtained dried fine pellets are crushed into fine powders with a particle size of 0.1-0.2 μm;

[0053] Mix the powder with a 70% alcohol solution in a mass ratio of 1:1.5 to form a semi-dry powder;

[0054] The semi-dry powder is evenly sprinkled on both sides of the nickel expanded mesh through the impeller feeder, and the powder is bonde...

Embodiment 3

[0060] 1) Powder pretreatment

[0061] As shown in table 1, 1000g acetylene black, 8g absolute alcohol, 70g positive electrode conductor platinum powder, 75g polyacrylic acid emulsion adhesive, 3200g pure water are mixed into wet material and stir;

[0062] The wet material enters the extrusion machine with a sieve aperture of 1.5mm for extruding, and obtains a strip material with a length of 1-2cm;

[0063] The strip material enters the centrifugal pellet machine to obtain fine pellets with a particle size of 1.2mm;

[0064] The fine pellets were dried in a vacuum oven at 100°C for 10 hours;

[0065] 2) powder online

[0066] The obtained dried fine pellets are crushed into fine powders with a particle size of 0.1-0.2 μm;

[0067] Evenly mix the powder with a 99% alcohol solution in a mass ratio of 1:2 to form a semi-dry powder;

[0068] The semi-dry powder is evenly sprinkled on both sides of the nickel screen through the impeller feeder, and the powder is bonded to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com