Light sound insulation wallboard and preparation method thereof

A wallboard, lightweight technology, applied in the direction of clay preparation equipment, chemical instruments and methods, manufacturing tools, etc., can solve the problems of poor sound insulation effect, and achieve the effect of improving sound insulation effect, light weight, and good structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

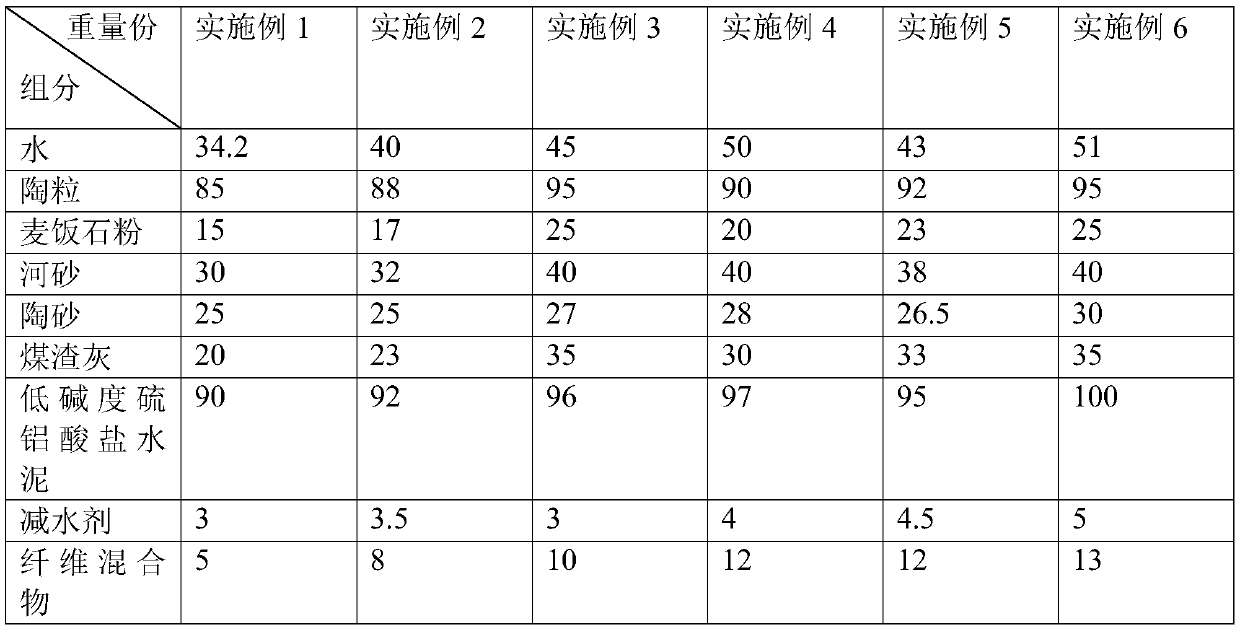

[0064] A lightweight sound-insulating wallboard is prepared from the components shown in Table 1 and their parts by weight.

[0065] In this embodiment, the mesh number of the medical stone powder in Table 1 is 200 mesh.

[0066] The fly ash in Table 1 comes from the solid waste discharged from thermal power plants, and the mesh number of the fly ash is 180 mesh.

[0067] The fiber mixtures in Table 1 consisted of low carbon steel fibers mixed with glass fibers at a weight ratio of 1:0.5.

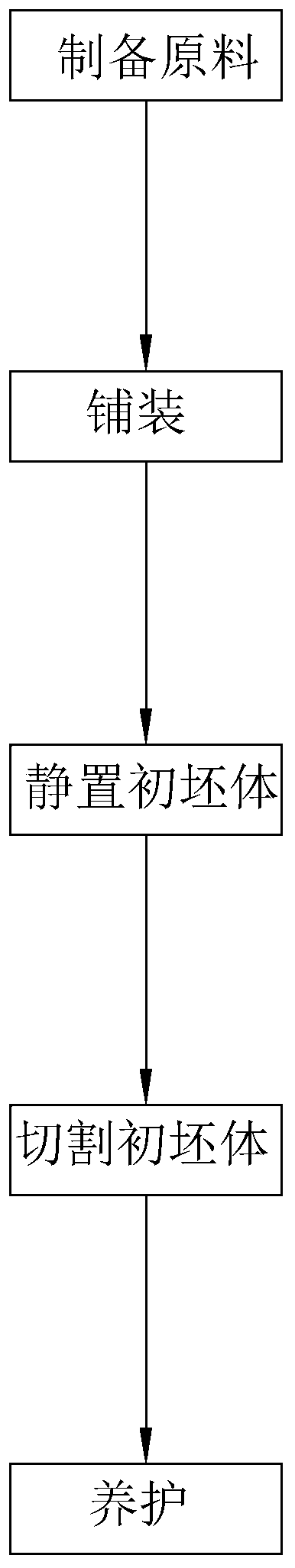

[0068] A preparation method for a lightweight sound-insulating wallboard, comprising the following steps:

[0069] S1. Preparation of raw materials: Take corresponding parts by weight of ceramsite, river sand, fly ash, pottery sand and sepiolite and mix and stir for 30 minutes to prepare mixture A. Take corresponding parts by weight of water and low-alkalinity sulphoaluminate cement Stir and mix for 20 minutes to obtain mixture B, take corresponding weight parts of sodium lignosulfonate, wa...

Embodiment 2

[0075] A lightweight sound-insulating wallboard, which differs from Example 1 in that it is made from the components shown in Table 1 and their parts by weight.

[0076] In the present embodiment, the medical stone powder in Table 1 is modified medical stone powder, and the preparation method of modified medical stone powder is as follows:

[0077] A1, the medical stone is soaked in 8% hydrochloric acid for 3 hours with a volume fraction, washed with deionized water, then calcined at 400°C for 4 hours, after cooling, soaked with 10% hydrogen peroxide solution for 3 hours, and washed with deionized water until Neutral, tumble dry.

[0078] A2, adding 2,4,6-tris(dimethylaminomethyl)phenol, 0.5 part of ethyl cyanoacrylate, 0.25 part of cross-linking agent TAC in 0.25 parts by weight, high speed 4500 rpm After 20 minutes, it was dried and pulverized to obtain modified medical stone powder.

[0079] In this embodiment, the mesh number of medical stone powder is 300 mesh.

[0080...

Embodiment 3

[0090] A lightweight sound-insulating wallboard, which differs from Example 2 in that it is made from the components shown in Table 1 and their parts by weight.

[0091] In this embodiment, the medical stone powder in Table 1 is modified medical stone powder, and the preparation method of modified medical stone powder is as follows: A1, the medical stone is soaked with 10% hydrochloric acid for 3.5 hours, washed with deionized water , then calcined at 420° C. for 4.5 hours, cooled, then soaked in 15% hydrogen peroxide solution for 3.5 hours, washed with deionized water until neutral, and dried.

[0092] A2, adding 0.3 parts of 2,4,6-tris(dimethylaminomethyl)phenol, 0.6 parts of ethyl cyanoacrylate, 0.3 parts of crosslinking agent TAC, high speed 4600 rpm After 25 minutes, it was dried and pulverized to obtain modified medical stone powder.

[0093] In this embodiment, the mesh number of medical stone powder is 300 mesh.

[0094] The fly ash in Table 1 comes from the solid wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com