Patents

Literature

1569results about How to "Guaranteed waterproof performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

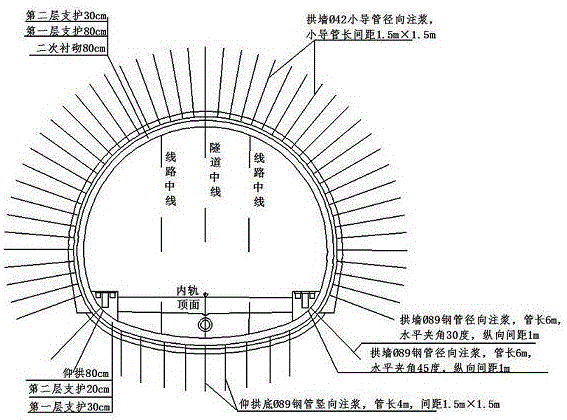

Construction method for soft rock deformation tunnel lining support dismantling-replacing arch

InactiveCN105781571AGuaranteed carrying capacityGuaranteed integrityUnderground chambersTunnel liningEngineeringLarge deformation

The invention provides a construction method for a soft rock deformation tunnel lining support dismantling-replacing arch. One-time whole section integral dismantling and replacing of a lining support is achieved. The construction method has the advantages that before dismantling and replacing, a lining which loses bearing capacity is subjected to grouting reinforcement treatment first, then a temporary cover arch is additionally arranged outside for reinforcement, and afterwards, the lining support is dismantled step by step, so that potential safety hazards caused by dismantling or removing of a temporary platform frame are avoided, and some security risks are avoided effectively. According to the construction method, the construction difficult problem of soft rock large deformation occurs during construction of a tunnel in special and complex geology is solved. Through the created novel construction method, the construction difficult problem of second lining cracking deformation needing remediation due to weak surrounding rock large deformation is solved. Through the construction method, safe, fast and economic treatment and remediation of the lining support and arch replacing construction are achieved, and the tunnel structure stability and construction safety are ensured effectively.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

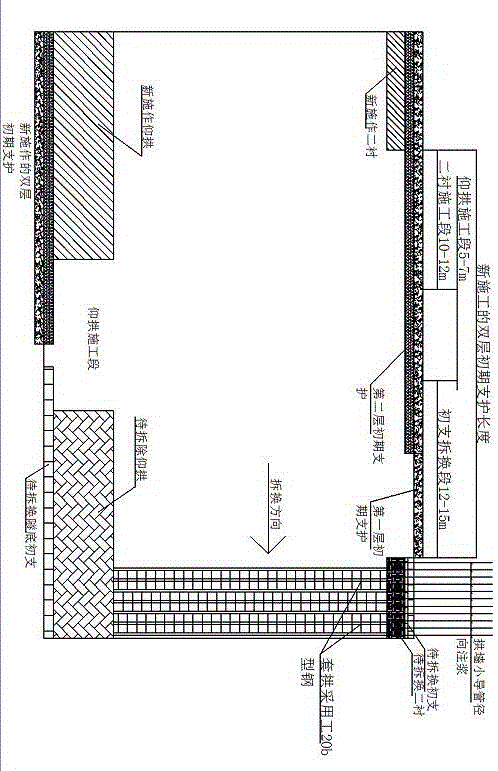

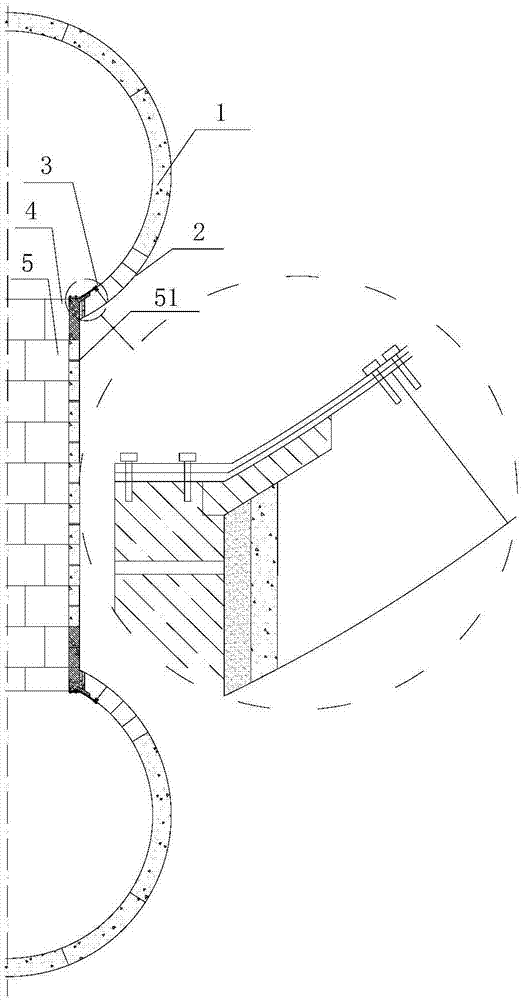

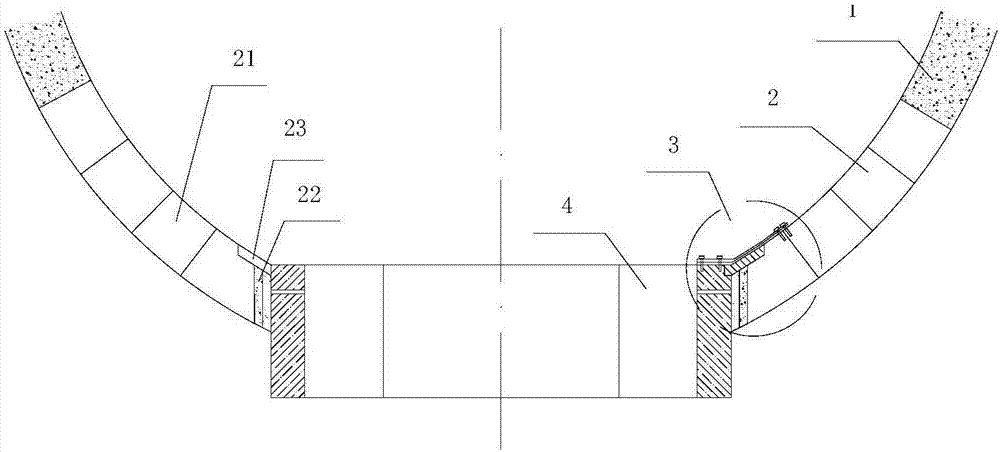

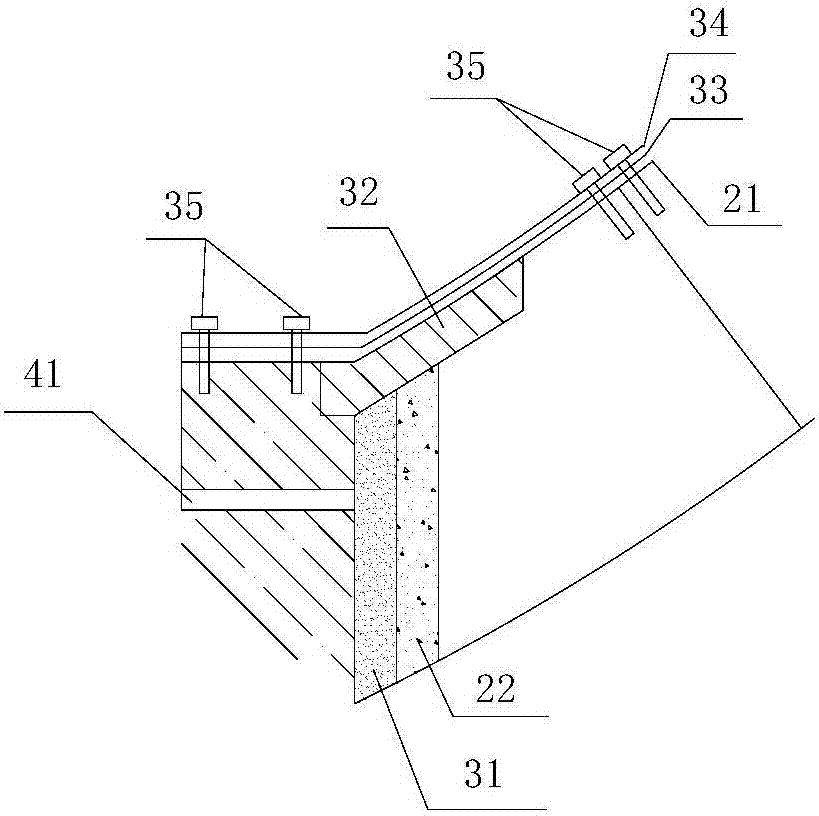

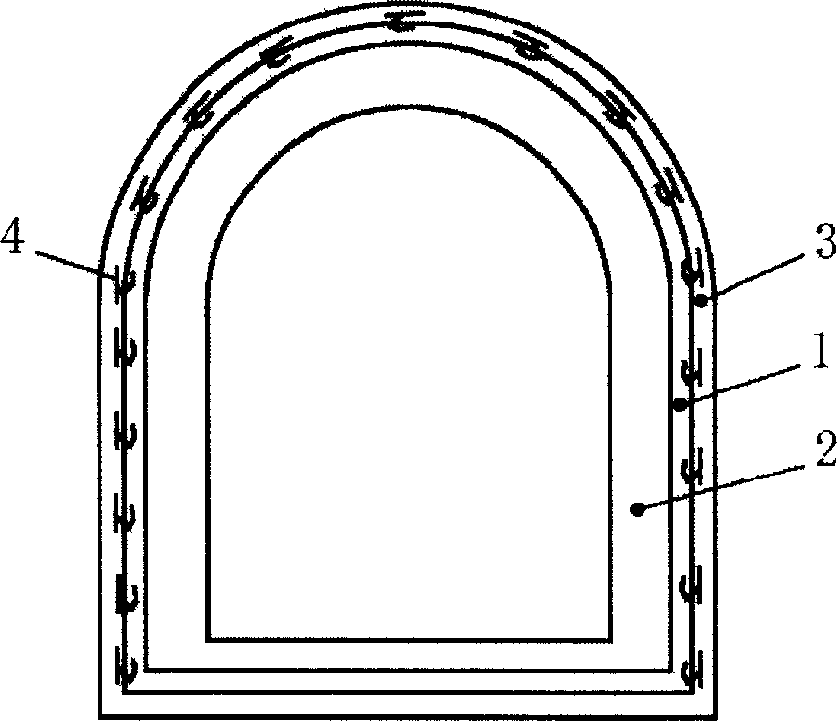

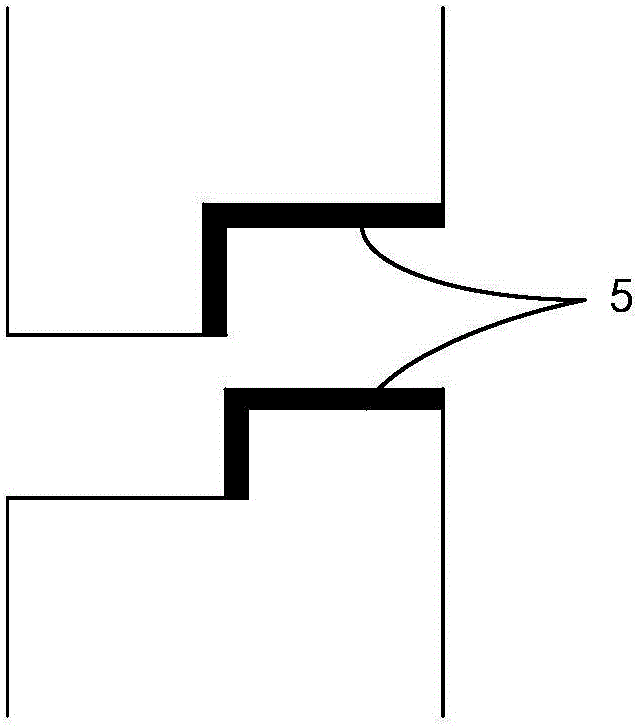

Assembling type connecting aisle structure and construction method thereof

ActiveCN106948833AGuaranteed waterproof performanceReduce disturbanceUnderground chambersTunnel liningBuilding construction

The invention discloses an assembling type connecting aisle structure and a construction method thereof. The assembling type connecting aisle structure is characterized by comprising a shield tunnel concrete segment, a shield tunnel composite segment, an inter-segment connecting system, a connecting aisle steel segment and a connecting aisle concrete segment. The shield tunnel composite segment comprises a composite segment steel segment section, a composite segment concrete segment section and a reserved reinforcing body box, the outer side of the composite segment steel segment section is connected with the shield tunnel concrete segment through connecting bolts in an assembling mode, the inner side of the composite segment steel segment section is integrally connected with the composite segment concrete segment section, and the inner side of the composite segment concrete segment section is connected with the connecting aisle steel segment through the inter-segment connecting system. According to the construction method, the mode of starting with a pipe jacking method and advancing with a shield method is adopted. The assembling type connecting aisle structure and the construction method thereof have the advantages the quality is controllable, the integrality with a shield tunnel is high, and joint waterproofness is high; and the starting problem of narrow and small spaces is solved, and the construction axis of a connecting aisle can also be easily controlled.

Owner:NINGBO UNIV +2

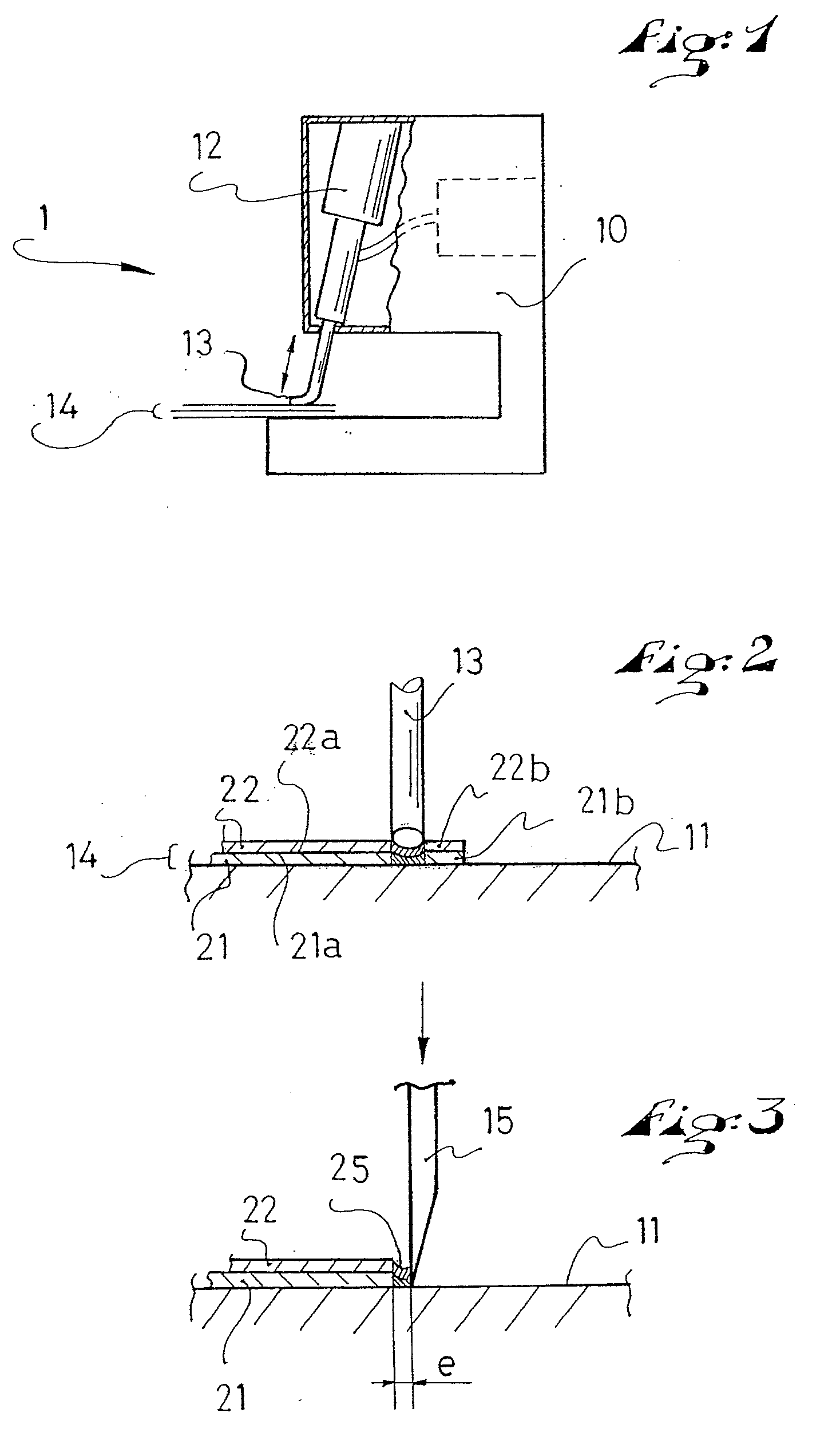

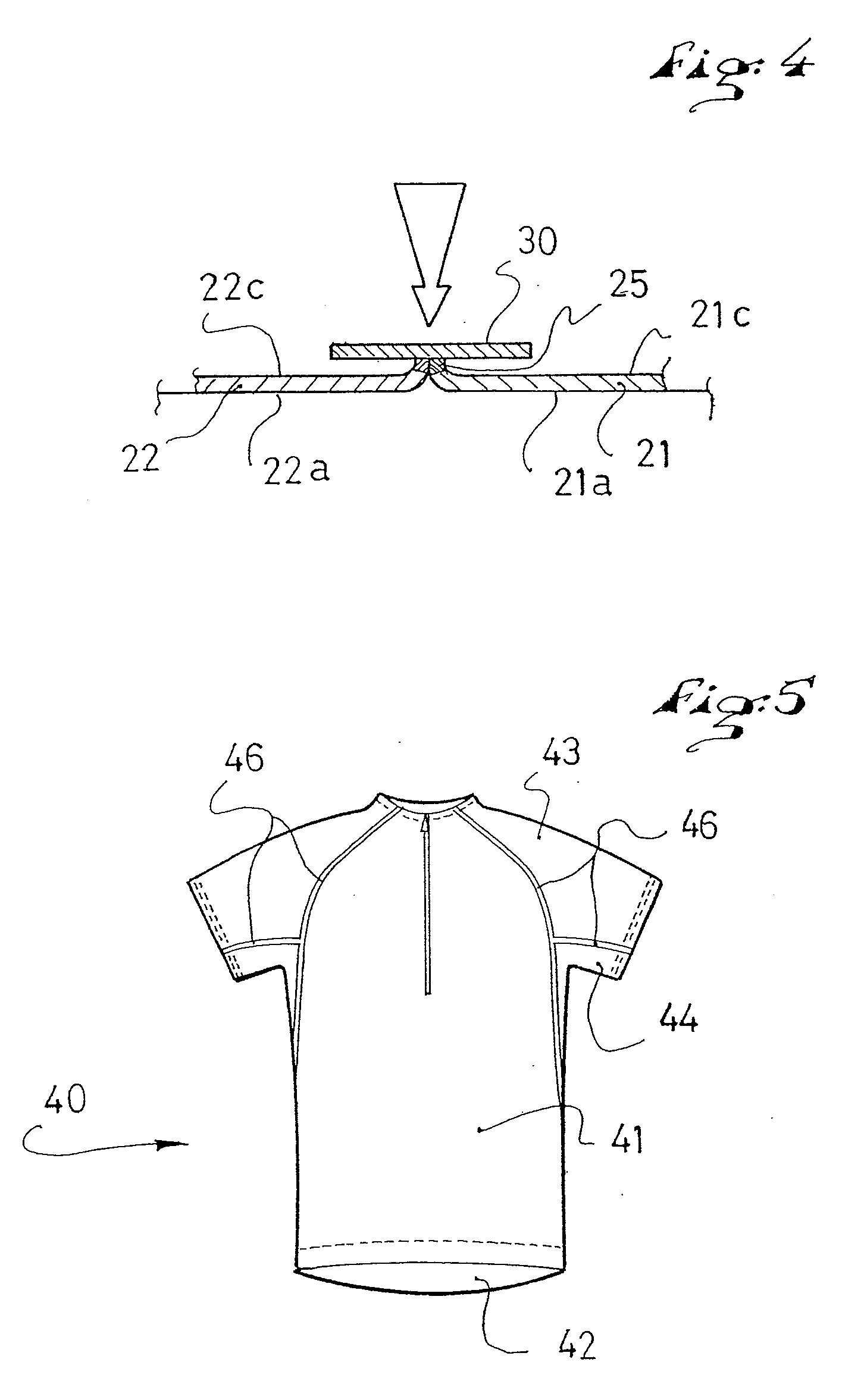

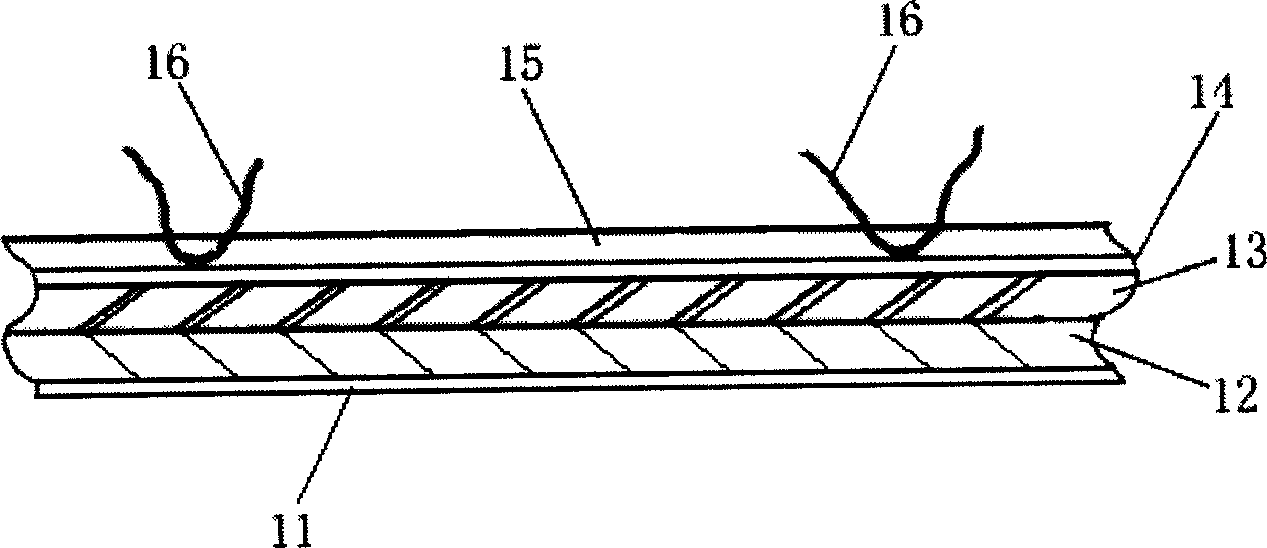

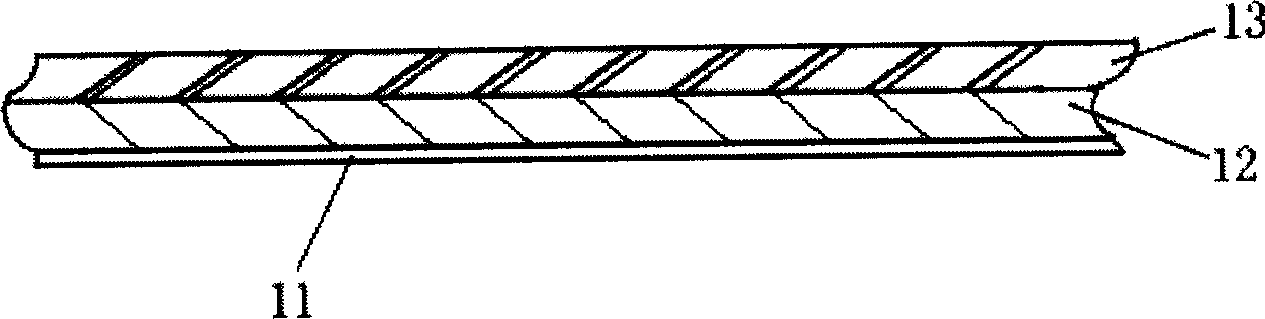

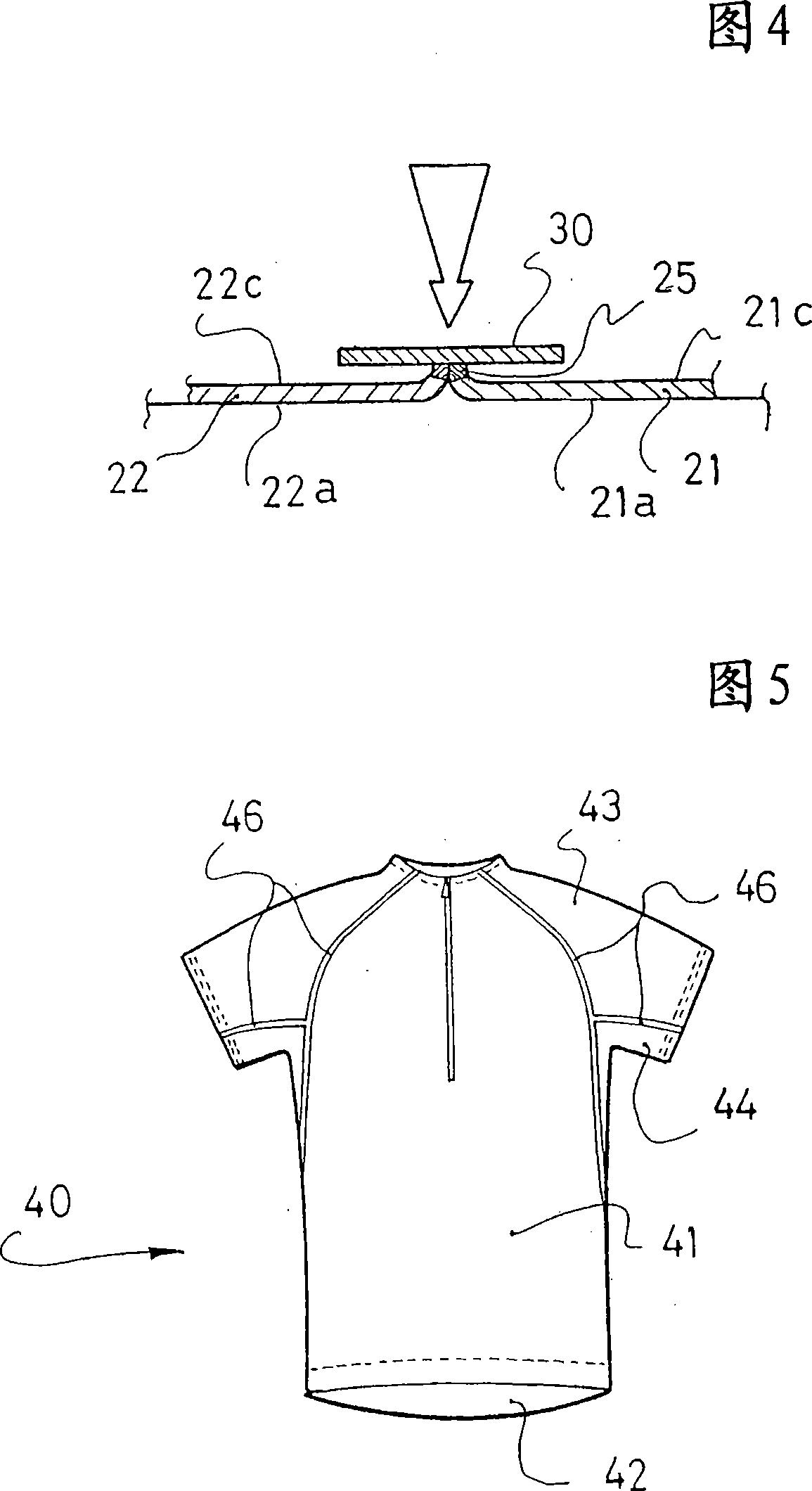

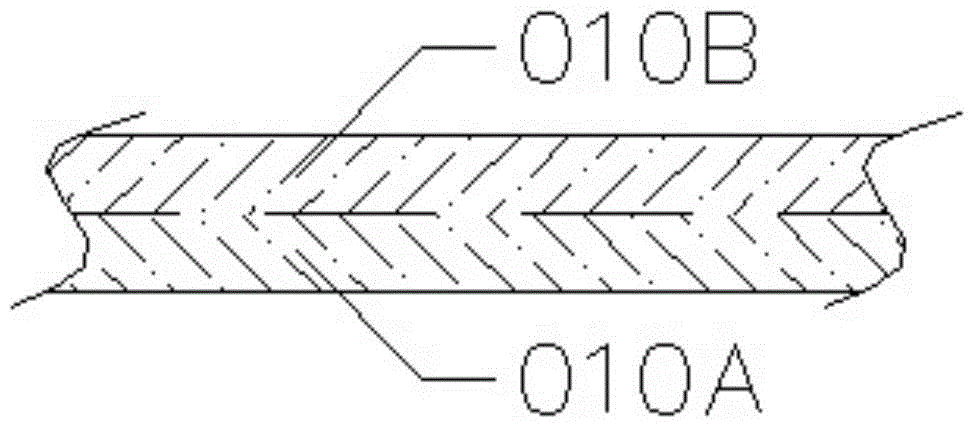

Laminated Fabric Panels and Method of Assembling Same

InactiveUS20080196136A1Easy to weldMinimizing abrasionLayered productsDomestic articlesEngineeringWeld line

Laminated fabric panels and a method of assembling such panels. A garment, for example, is made of first and second parts assembled to one another by superimposing the first part and the second part so that their inner surfaces face one another; welding the two parts along a weld line; flattening the two parts, the weld line being arranged on the outer side; applying a reinforcement strip to the welding line on the outer side of the garment.

Owner:SALOMON SA

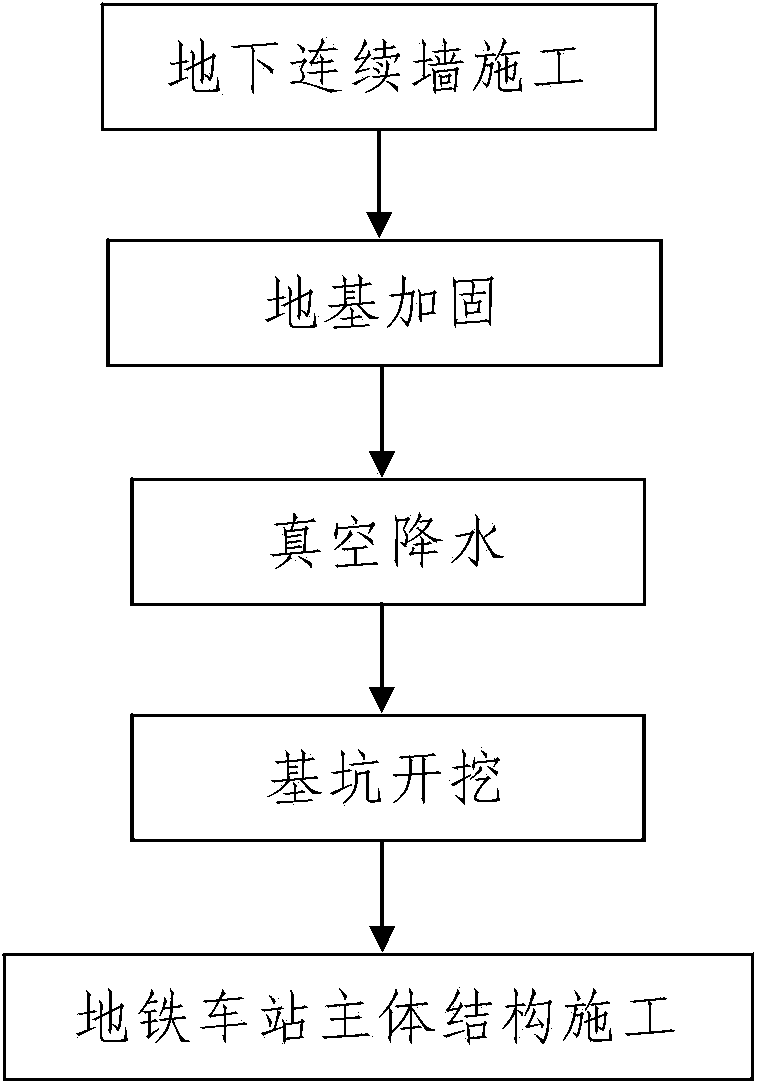

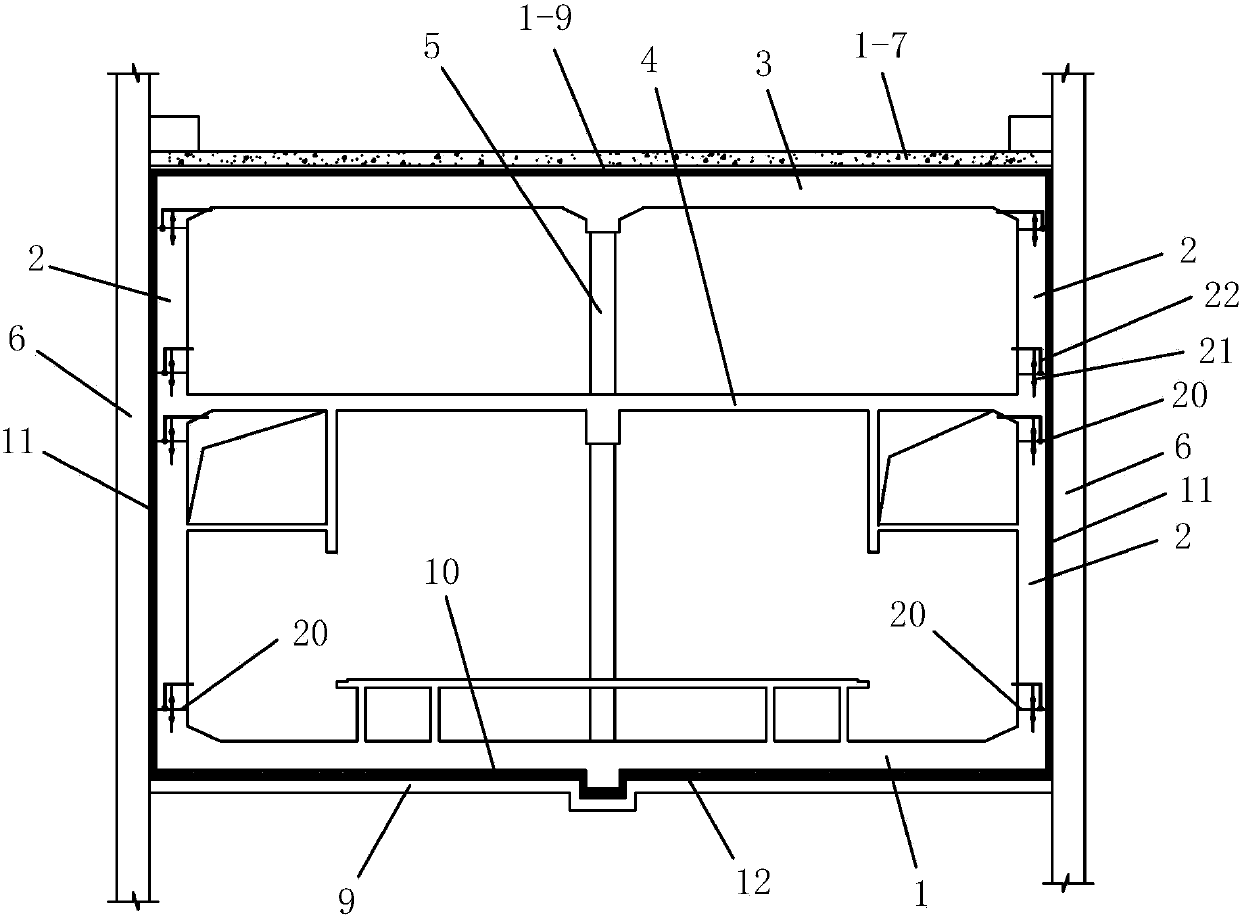

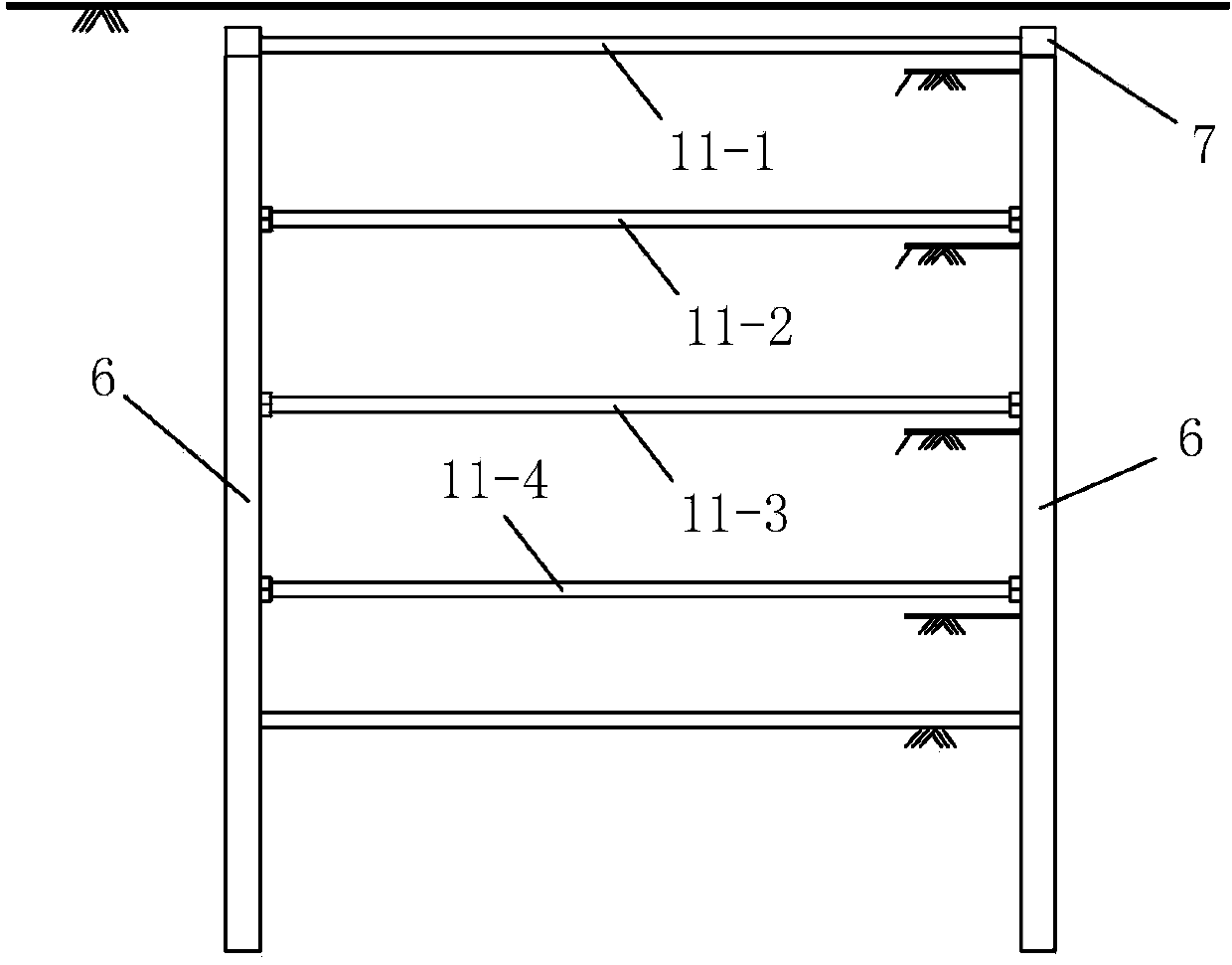

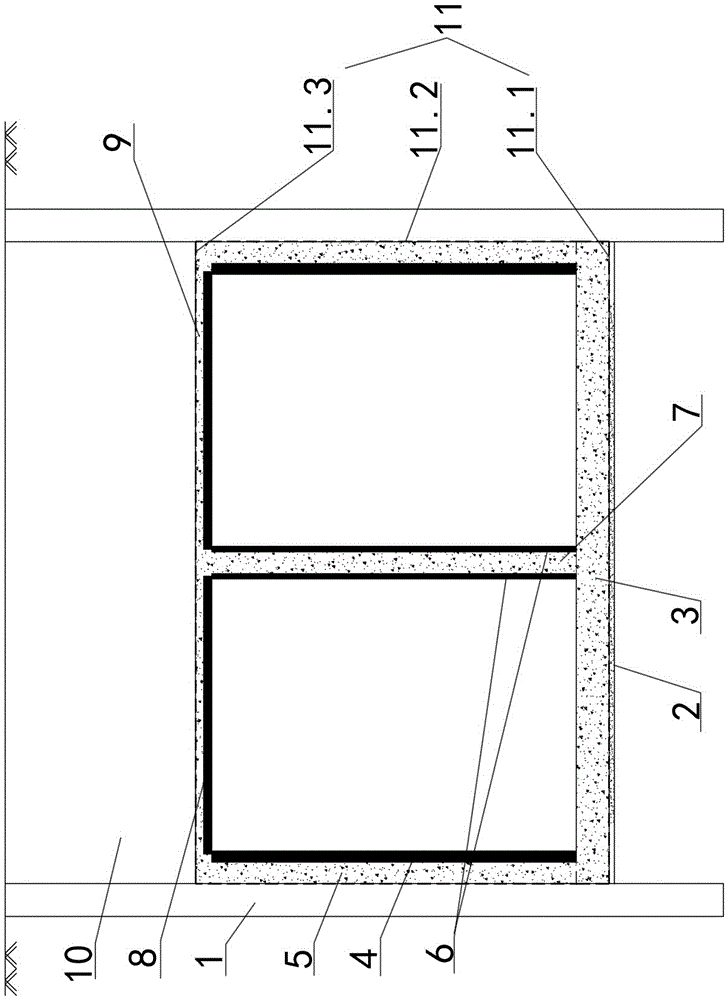

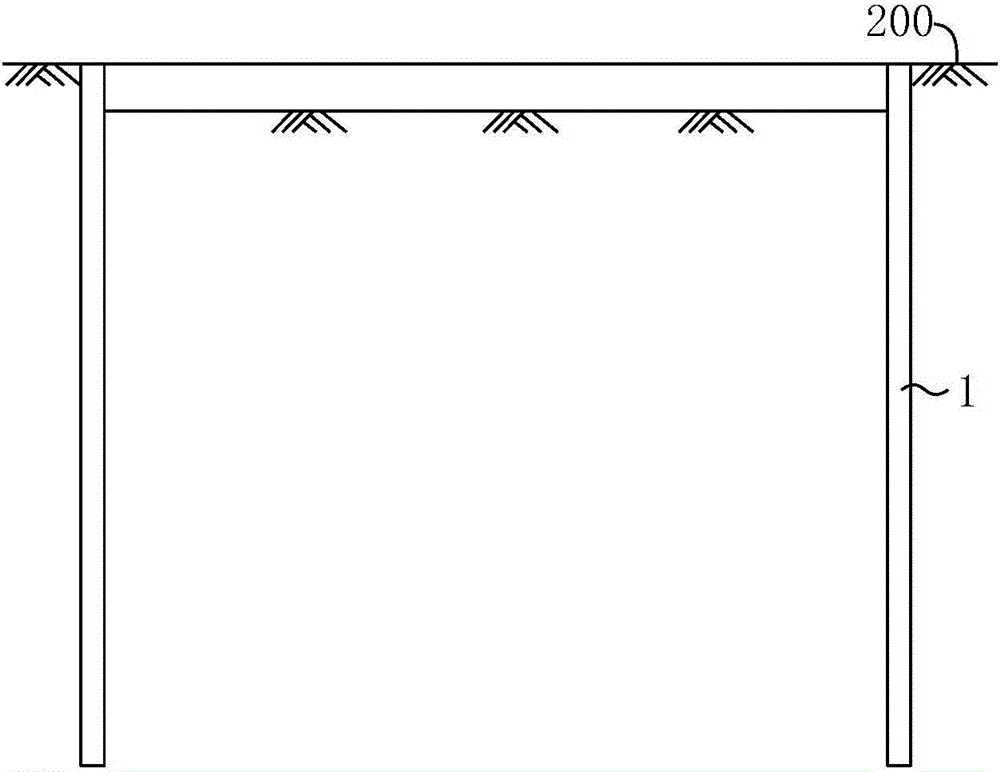

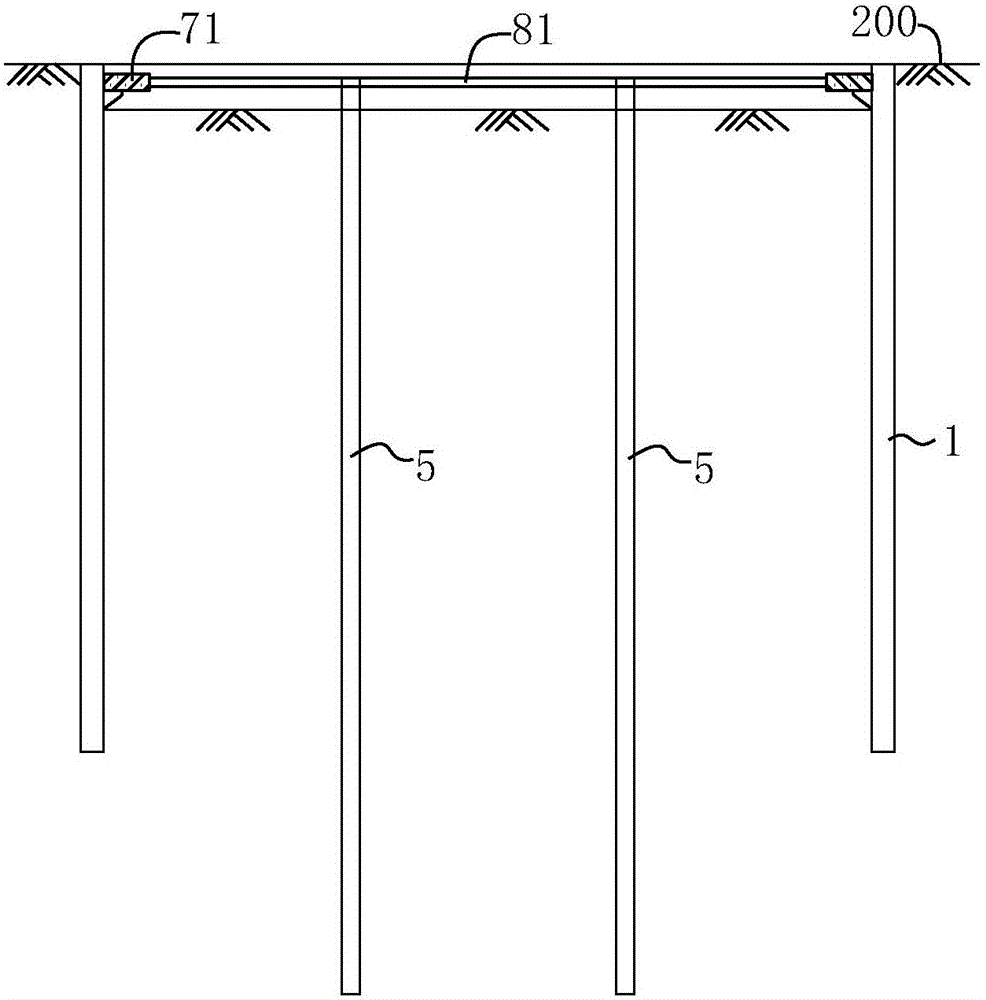

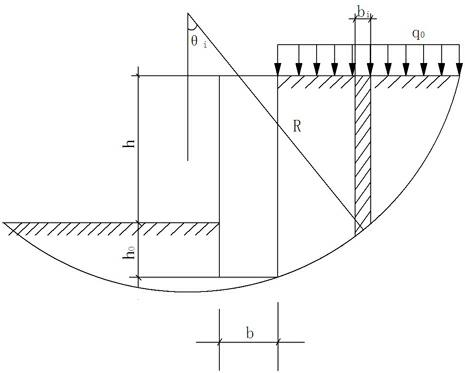

Peaty soft soil stratum subway station construction technology

ActiveCN103590425ASimplify construction stepsEasy constructionArtificial islandsProtective foundationSlurry wallReinforced concrete

The invention discloses a peaty soft soil stratum subway station construction technology. A main structure of a constructed subway station comprises base plates, side walls, top plates and middle plates distributed between the top plates and the base plates. Underground consecutive walls are arranged on outer sides of the two side walls. The base plates, the side walls, the middle plates and the top plates are all of a rebar concrete structure formed by pouring waterproof concrete. The subway station construction technology comprises the following steps: (1) underground consecutive wall construction, (2) foundation reinforcement, namely, three-shaft stirring piles are used for reinforcing the foundation of excavated foundation pits, (3) vacuum water falling, namely conducting vacuum well point water falling construction on the foundation pits needing excavating, (4) foundation pit excavation, namely, an open excavation method is used for conducting earthwork excavation on the foundation pits needing excavating with a plurality of excavating layers from top to bottom, (5) subway station main structure construction. The method is simple, convenient to realize, quick in construction speed, capable of being ensured in construction quality easily, and good in construction effect, and enables the subway station construction process of peaty soft soil stratum to be completed simply, quickly and with high quality.

Owner:中铁二十局集团第五工程有限公司

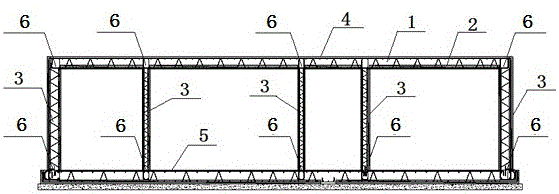

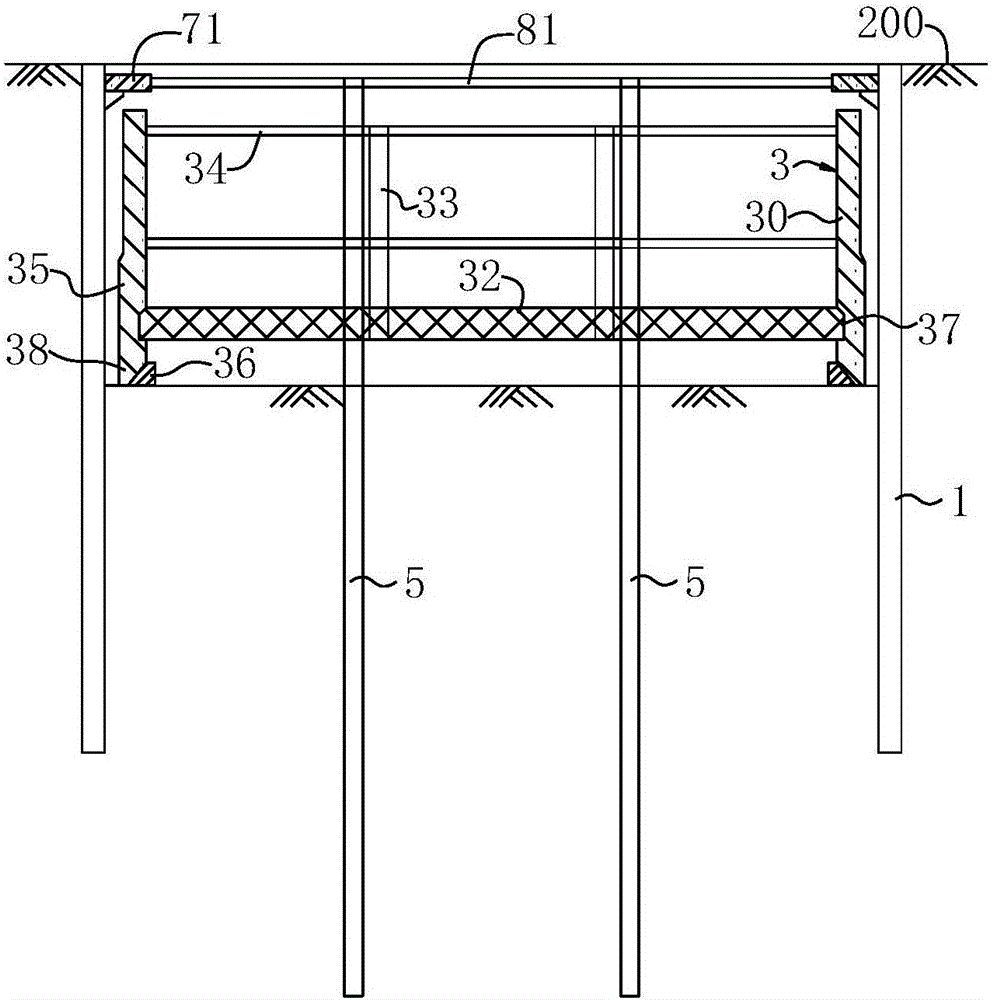

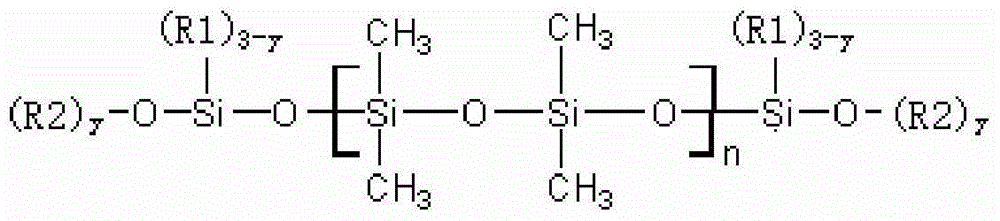

Overlapping integral type prefabricated assembly structure for comprehensive pipe gallery and construction method thereof

ActiveCN106013228ALarge working spaceActive connectionArtificial islandsUnderwater structuresEngineeringAssembly structure

The invention discloses an overlapping integral type prefabricated assembly structure for a comprehensive pipe gallery and a construction method thereof. The overlapping integral type prefabricated assembly structure comprises envelop enclosures, a pipe gallery prefabricated assembly structure body, a bottom plate cushion course and a completely outer-cladding waterproof layer, wherein the envelop enclosures are located in a foundation pit; the pipe gallery prefabricated assembly structure body is arranged between the envelop enclosures; the bottom plate cushion course is arranged under the pipe gallery prefabricated assembly structure body; and the completely outer-cladding waterproof layer is arranged on the outer side surface of the pipe gallery prefabricated assembly structure body in a cladding mode. The upper portion of the pipe gallery prefabricated assembly structure body is filled with backfill earth, and the completely outer-cladding waterproof layer is arranged on the outer side surface of an outer side cast-in-situ part of the pipe gallery prefabricated assembly structure body in a cladding mode. The construction method of the overlapping integral type prefabricated assembly structure comprises the steps of prefabricated component machining, foundation pit excavation, bottom plate pouring, side wall construction, mid-partition construction, top plate construction, earth backfilling and the like. According to the overlapping integral type prefabricated assembly structure for the comprehensive pipe gallery and the construction method thereof, the prominent problems of force bearing of joints, water seepage of connection seams and the like in the underground engineering prefabrication process are solved; and the structural modes of bottom plate casting in situ, side wall single-layer overlapping, mid-partition double-layer overlapping, top plate overlapping, all-joint casting in situ and completely outer-side waterproof layer cladding are adopted, so that effective connection and the waterproof function of the joints are ensured.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Wet coating self-adhering waterproof coiled material and producing method and construction method thereof

InactiveCN1888350AGood waterproof performanceHigh strengthLamination ancillary operationsRoof covering using flexible materialsSolventAsphalt

The present invention relates to a wet-stickable self-adhesive water-proof sheet material, its production method and construction method. It is characterized by that said invention uses butyl rubber and high-grade oxidated asphalt, makes them undergo the process of high-temperature mixing treatment, adds acryl water-absorbing resin, operation oil, filler and flow-resisting agent, makes them undergo the process of high-speed dispersion treatment so as to obtain self-adhesive seal water-proof material, dip-coating said self-adhesive seal water-proof material onto one surface of high-molecular water-proof sheet material carrier, then makes the above-mentioned material undergo the processes of calendaring, extruding and layering isolating layer as anti-adhesion layer, then makes a flexible protective layer be stuck on another surface of the above-mentioned high-molecular water-roof sheet material, so that the invented wet-stickable self-adhesive water-proof sheet material can be obtained.

Owner:北京中联天盛建筑工程有限公司

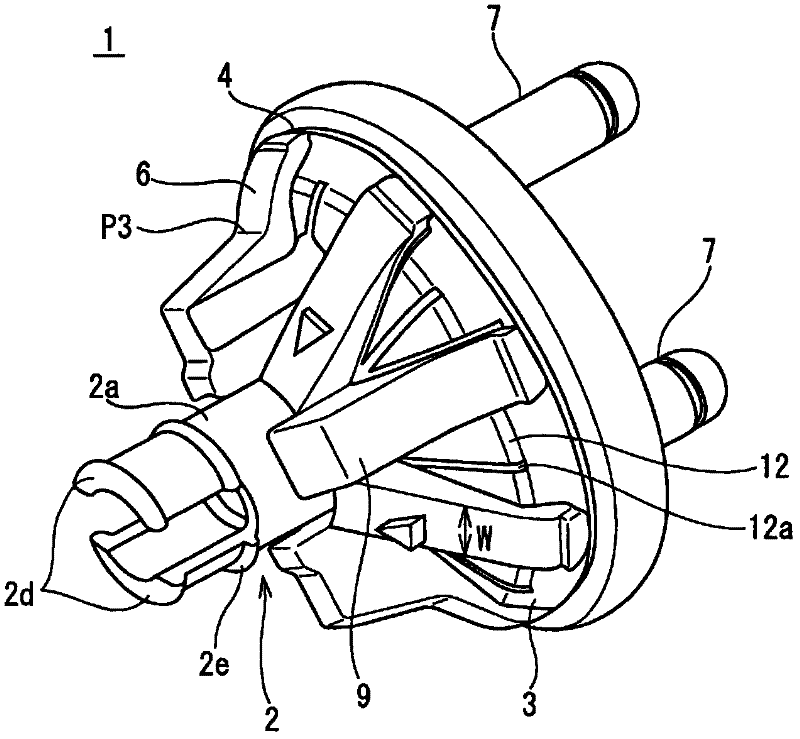

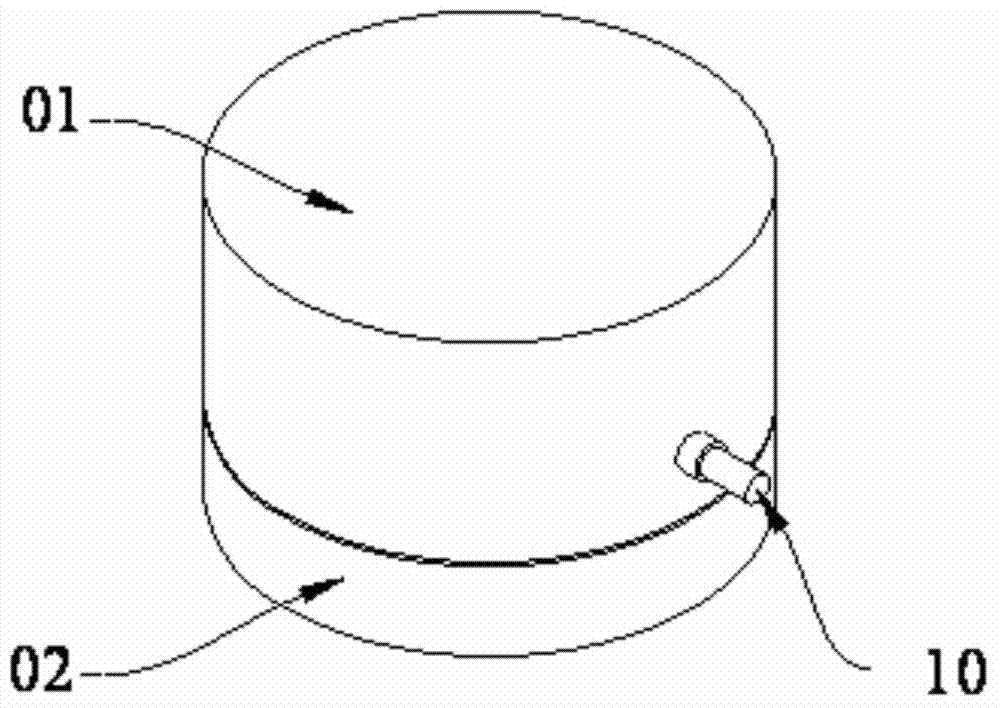

Grommet

InactiveCN102239617AReduce the number of winding operationsGood shape retentionElectric/fluid circuitInsulating bodiesEngineeringGrommet

A grommet mounted in a through-hole in a vehicle body panel and through which a wire harness is passed. Even if taping only one side, the grommet shape is retained and the grommet is prevented from deforming in the direction in which an engaging recess of the grommet separates from the peripheral edge of the through-hole. The grommet comprises: an enlarged-diameter tube which connects to the outer periphery of the longitudinal intermediate section of a small-diameter tube through which wires are tightly passed, and which is enlarged in diameter to surround the other side of the small-diameter tube; an engaging recess which is annularly formed in the outer peripheral surface of the enlarged-diameter tube on the large diameter side thereof; inner ribs provided at intervals in the circumferential direction and connecting between the inner periphery of the enlarged-diameter tube and the outer peripheral surface of the other side of the small-diameter tube; and wire insertion tubes which connect to through-holes for wires formed in the enlarged-diameter tube and which extend through the inside of the enlarged-diameter tube and project from the opening end on the large-diameter side. The inner ribs stick out with a clearance from the inner peripheral surface of the enlarged-diameter tube from the position where the enlarged-diameter tube contacts the inner peripheral surface of the through-hole of the vehicle body panel to a position facing the engaging recess.

Owner:SUMITOMO WIRING SYST LTD

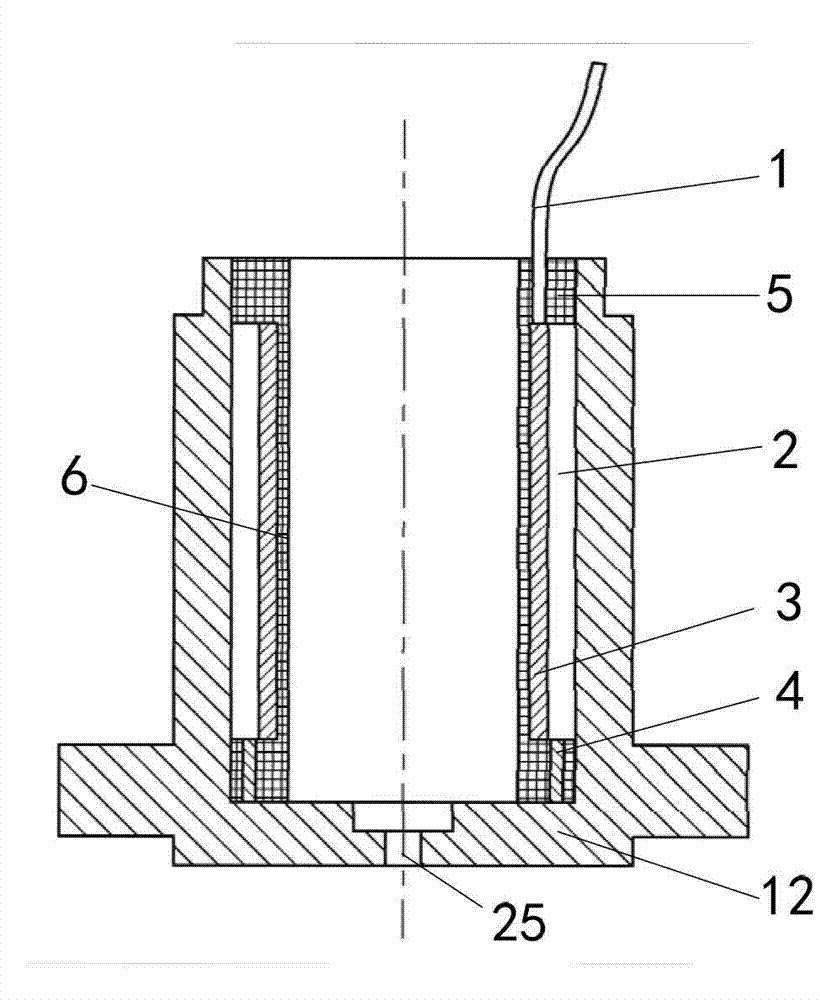

Concrete stress sensor by piezoelectric properties of PVDF (polyvinylidene fluoride) film

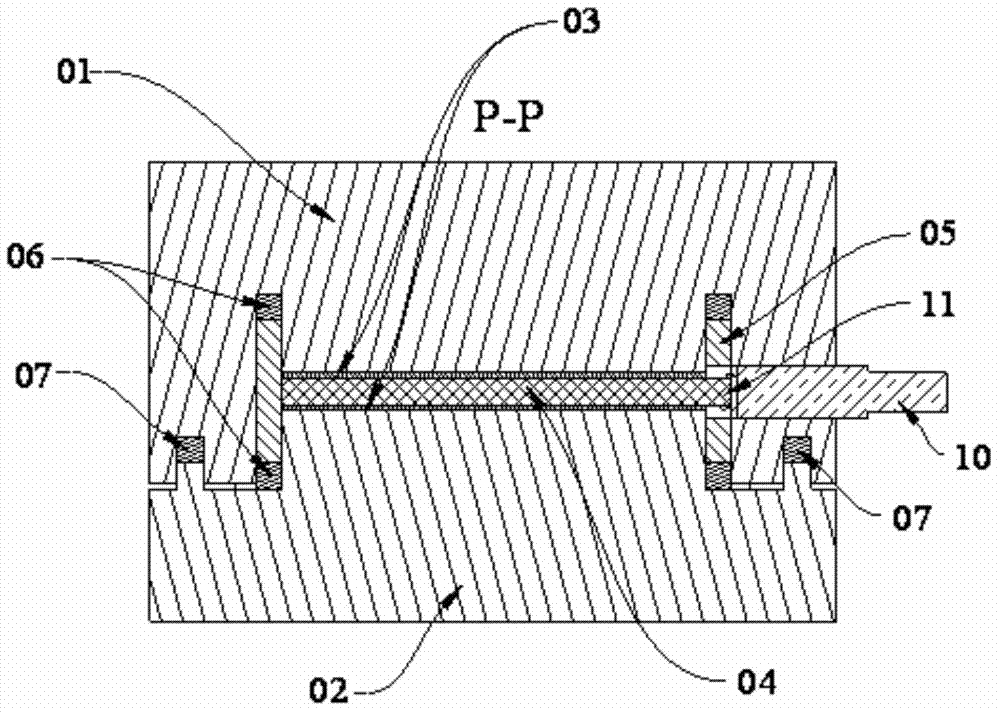

InactiveCN103674353AGood flexibilityHigh mechanical strengthForce measurement using piezo-electric devicesStrength propertiesPolyvinylidene difluorideEngineering

The invention discloses a concrete stress sensor by piezoelectric properties of a PVDF (polyvinylidene fluoride) film. The concrete stress sensor comprises an upper sensor shell, a lower sensor shell and the PVDF piezoelectric film, the upper sensor shell and the lower sensor shell are buckled together, the PVDF piezoelectric film is arranged between the upper sensor shell and the lower sensor shell, a nylon sleeve is sleeved on the periphery of the PVDF piezoelectric film, so that the PVDF piezoelectric film is positioned on a boss, insulating layers are respectively arranged on the upper end face and the lower end face of the PVDF piezoelectric film and closely contact with the upper sensor shell and the lower sensor shell, the nylon sleeve and the insulating layers form a sealed insulating space, so that a PVDF piezoelectric film and the sensor shells are separated in an insulating manner, and connection electrodes are respectively arranged on the upper surface and the lower surface of the PVDF piezoelectric film, so that piezoelectric signals are led to the outside of the sensor. The PVDF piezoelectric film is clamped between the two metal shells, a load is transmitted to the PVDF film by the aid of the sensor metal shells, the concrete stress sensor is sensitive in sensing, simple in structure, convenient to package and small in size, and can be embedded into concrete materials to finish an impact stress test.

Owner:CENT SOUTH UNIV

Construction and manufacturing process of total-prefabricated superimposed assembly type underground pipe gallery

ActiveCN105839667AOutstanding FeaturesHighlight significant effectArtificial islandsUnderwater structuresPrefabricationBuilding construction

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

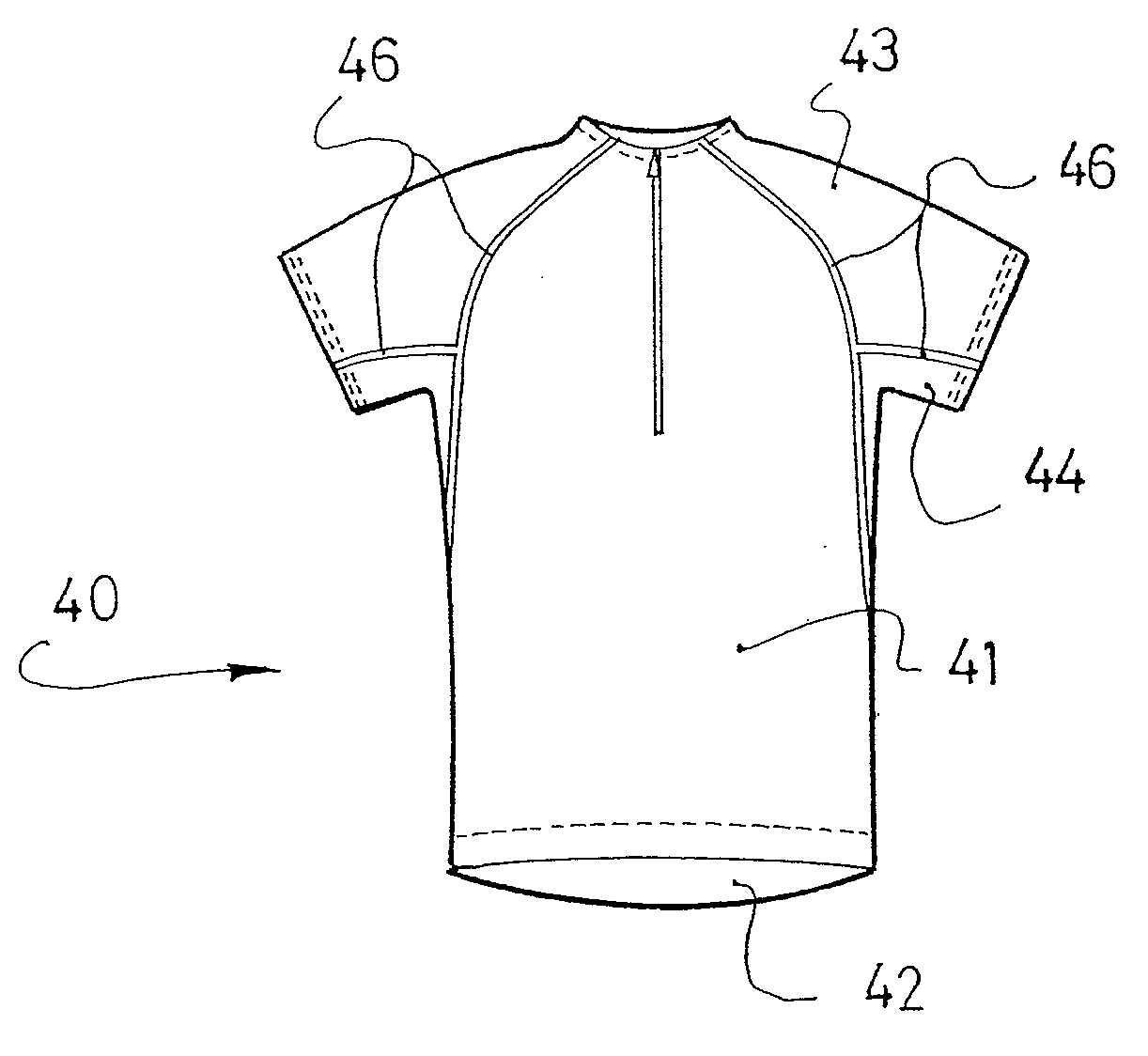

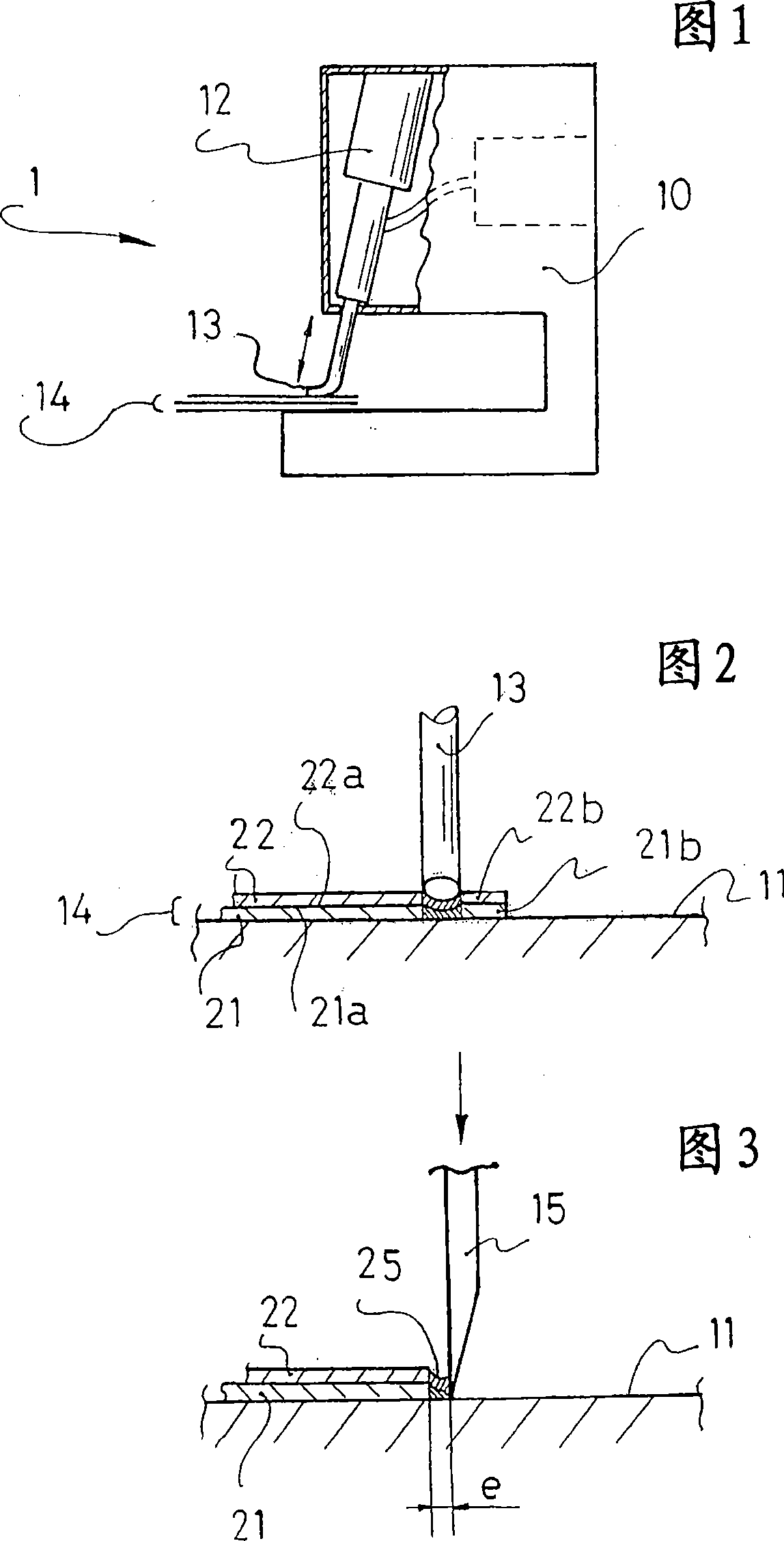

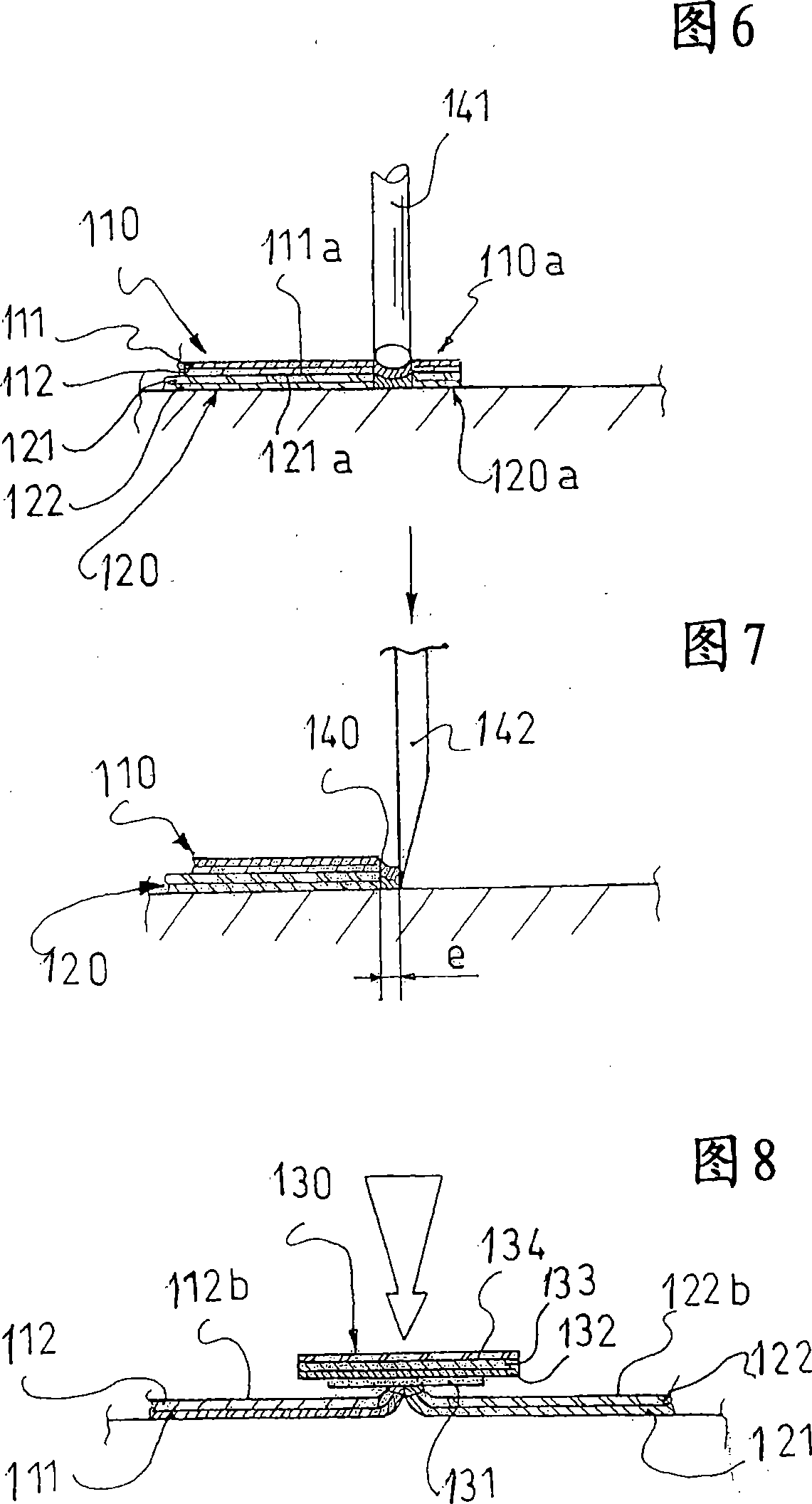

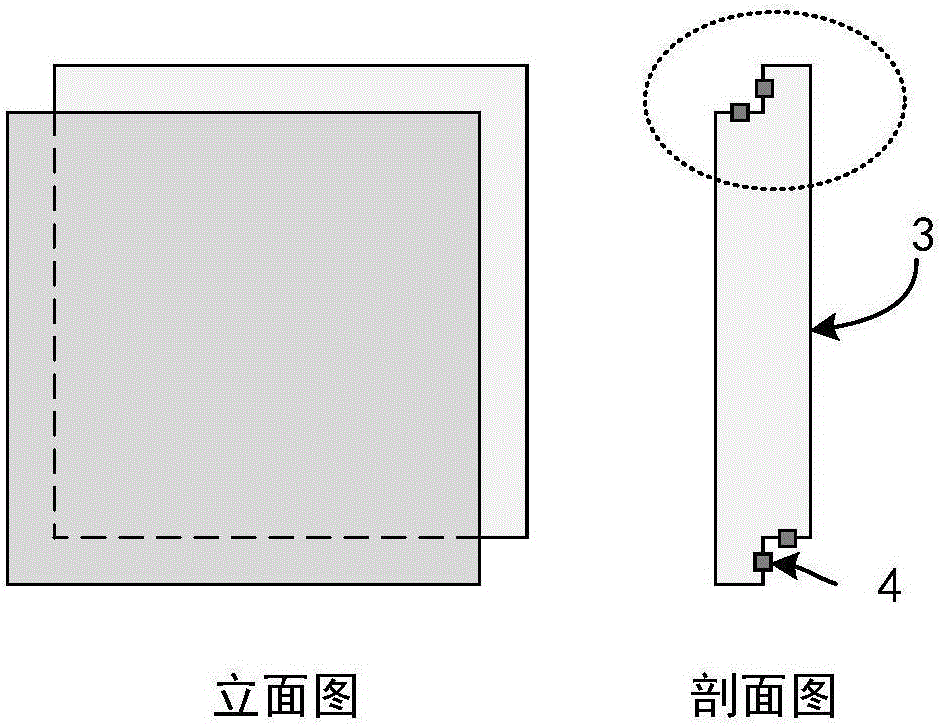

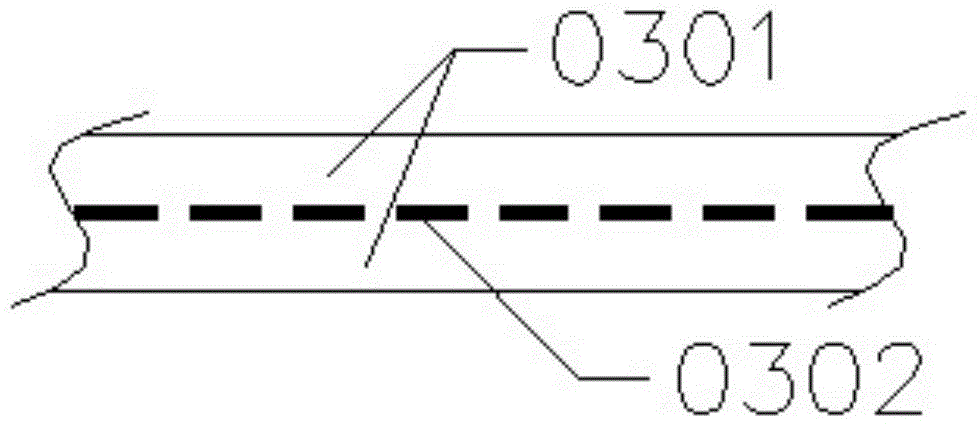

Method for assembling fabric panels and product obtainable by said method

InactiveCN101001546AGuaranteed tightnessGuaranteed waterproof performanceGarmentsDomestic articlesEngineeringMechanical engineering

The inventive method for assembling parts of a clothing article consisting of at least one first (21) and one second (22) parts assembleable with each other consists in superimposing the first (21) and second (22) parts in such a way that the respective internal surfaces thereof (21a, 21b) are placed oppositely to each other, in welding the parts (21, 22) along a determined seam (25), in laying flat said two parts in such a way that the seam (25) is disposed on the external side and in applying a strip (30) reinforcing the seam (25) to the external side of the article. The thickness of the seam is approximately equal to 1 mm.

Owner:SALOMON SA

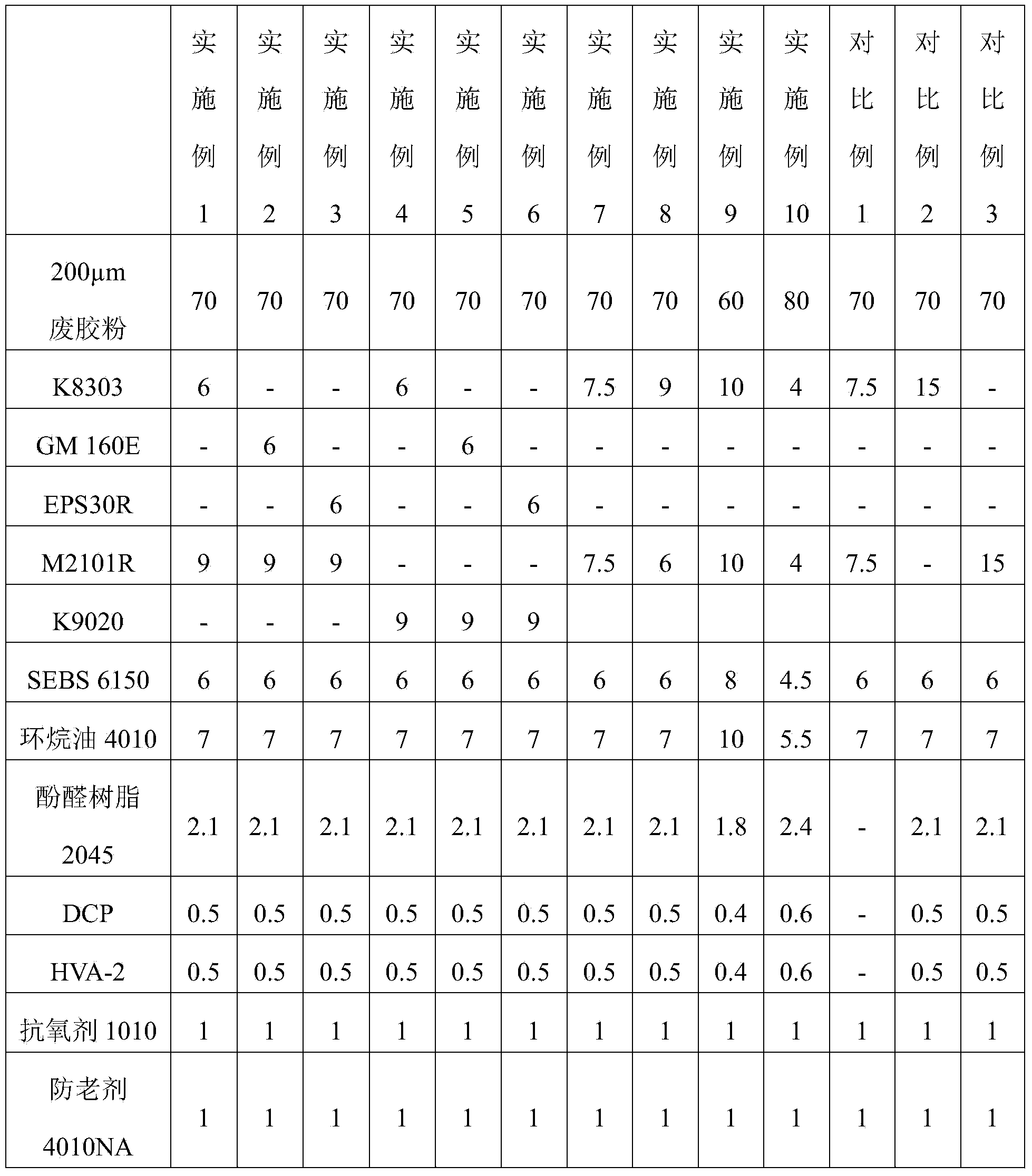

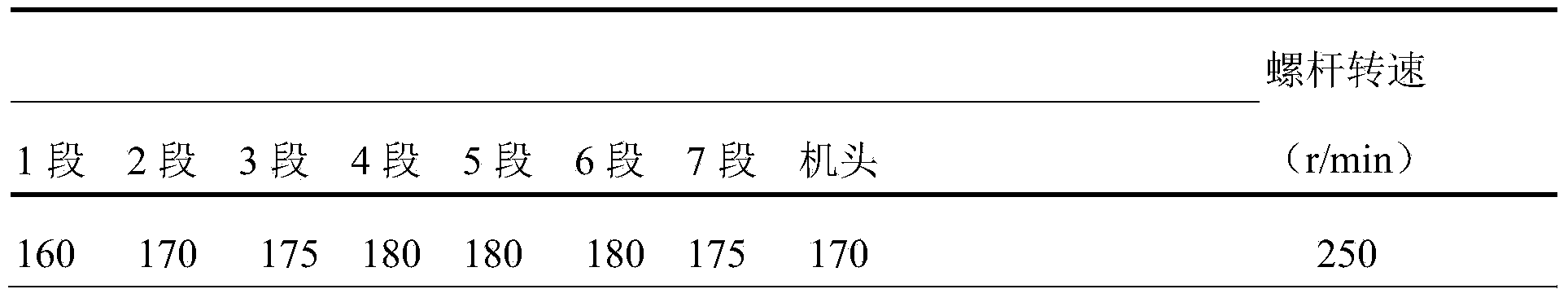

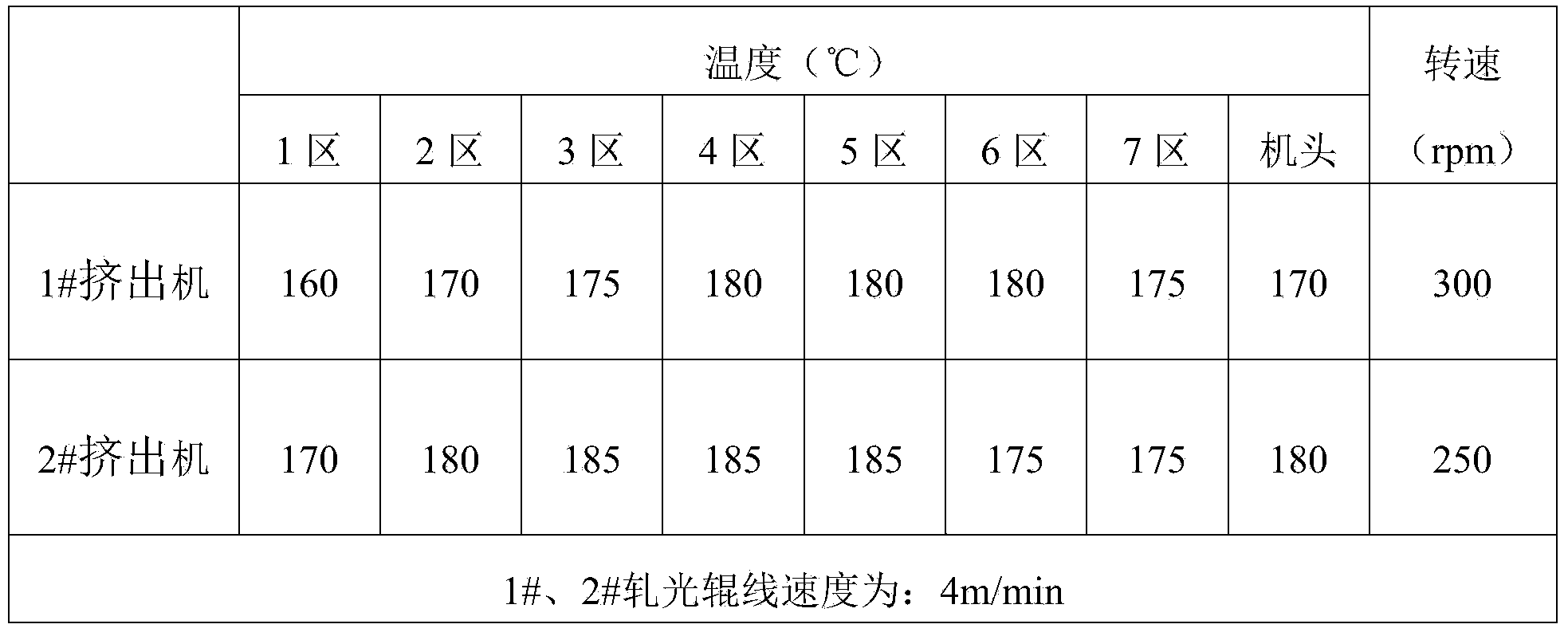

High-performance thermoplastic polyolefin waterproof coiled material with high scrap rubber powder doping amount

ActiveCN104260504AWide variety of sourcesLow priceSynthetic resin layered productsConstructions elementsThermoplasticPolymer science

The invention relates to a high-performance thermoplastic polyolefin waterproof coiled material with a high scrap rubber powder doping amount. The high-performance thermoplastic polyolefin waterproof coiled material is formed by compounding an upper surface thermoplastic polyolefin (TPO) coiled material layer, an intermediate fiber fabric enhancement layer and a lower surface scarp rubber powder-based thermoplastic elastomer (WRTPE) coiled material layer. The composite waterproof coiled material disclosed by the invention is high in tensile strength and high in breakage ductility; all the coiled material layers are tightly combined, and all properties are higher than the indexes of enhancement coiled materials in a fabric GB 27789-2011; the composite coiled material is convenient to construct, and the cost of the composite coiled material is lowered by 20-30 percent when compared with the cost of a TPO enhanced coiled material with the same thickness; the high-performance thermoplastic polyolefin waterproof coiled material has a wide application prospect.

Owner:BEIJING UNIV OF CHEM TECH

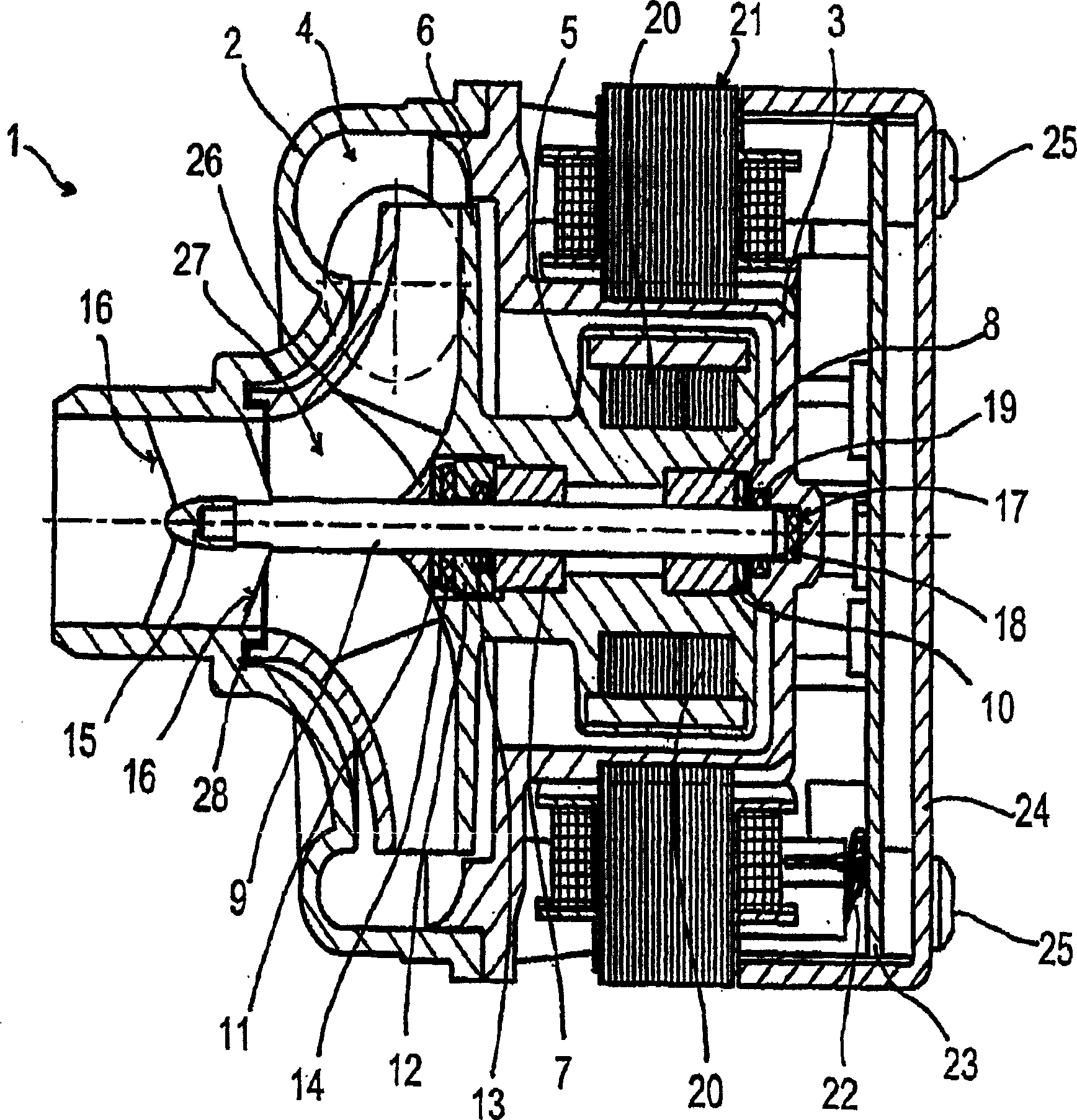

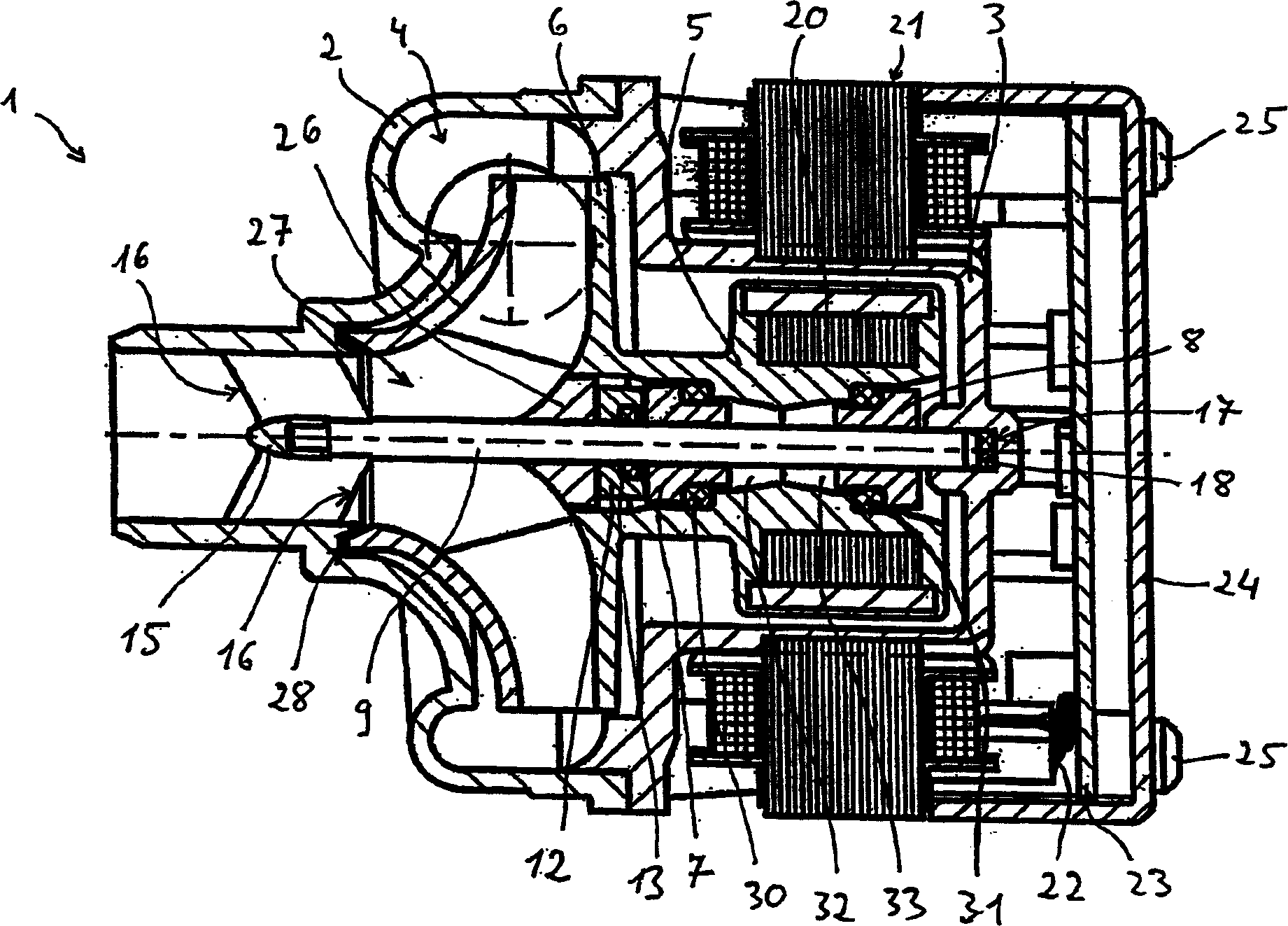

Pump comprising an integrated engine

ActiveCN1826470AImprove utilizationReduced vibration damping requirementsPump componentsPump installationsPhysicsElectric motor

Owner:BOSCH SIEMENS HAUSGERATE GMBH

Steel sheet pile and open caisson combined underground garage and construction method thereof

ActiveCN106013052AHigh strengthTightly boundArtificial islandsExcavationsReinforced concreteEngineering

The invention discloses a steel sheet pile and open caisson combined underground garage. A body structure of the underground garage comprises an external wall and an external wall supporting structure; the external wall is composed of an upper external wall body and a lower external wall body which are connected in an up-down manner; the upper external wall body is a steel plate pile wall formed by connecting steel plate piles with one another; the lower external wall body is a reinforced concrete well wall of an open caisson; and the external wall supporting structure serves as a supporting structure of a parking platform of the underground garage at the same time. The external wall of the underground garage adopts a compounded external wall composed of the steel plate pile wall and the well wall of the open caisson, and the beneficial effects of the steel plate pile wall and the well wall of the open caisson are combined. The invention further discloses a construction method of the underground garage. According to the construction method, firstly, the steel plate piles sink to form the steel plate pile wall; and then the open caisson is poured in the steel plate pile wall and sinks. By means of the construction method, the building cost of the underground garage is successfully reduced, and the building time of the underground garage is successfully shortened.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

Telescoped type waterproof sealed wallboard

ActiveCN106193444AGuaranteed waterproof performanceImprove integrityWallsArchitectural engineeringWall plate

Owner:TSINGHUA UNIV

Construction method for foundation pit in Larson steel sheet pile retaining and protecting river

ActiveCN102587387AGuaranteed waterproof performanceReduce construction costsExcavationsCofferdamSheet pile

The invention relates to a construction method for a foundation pit in a river, in particular to the construction method for the foundation pit in a Larson steel sheet pile retaining and protecting river. The construction method mainly solves the technical problems that according to the prior art, when the foundation pit in the river is excavated, firstly a cofferdam needs to be constructed, but the construction cost of the cofferdam is higher and the cost for retaining and protecting the foundation pit in the cofferdam weir is higher. The construction method comprises the following steps of carrying out construction calculation and construction preparation, internally supporting a first layer, inserting and piling steel sheet piles, pumping, carrying out earth cutting, internally supporting a second layer, carrying out earth cutting, internally supporting a third layer, sealing the bottom, constructing a bearing platform, and dismantling the internal support and removing the steel sheet piles.

Owner:浙江国丰建设有限公司 +2

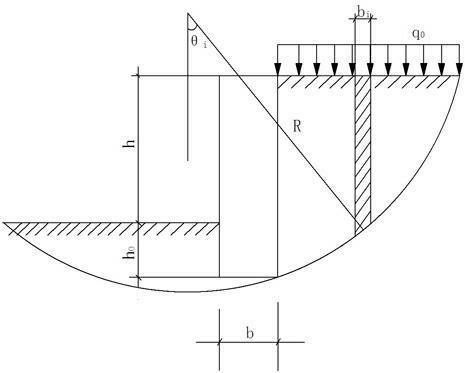

Transparent organic silicon LED light bar pouring sealant and preparation method thereof

ActiveCN104017534AHigh light transmittanceLight transmittance does not affectNon-macromolecular adhesive additivesLED lampDimethyl siloxane

The invention discloses a transparent organic silicon LED light bar pouring sealant and a preparation method thereof. The pouring sealant is prepared from a component (A) and a component (B), wherein the component (A) comprises the following components in parts by weight: 100 parts of polysiloxane base polymer, 0.1-100 parts of alpha, omega-alkoxy capped polydimethylsiloxane, 0-80 parts of reinforcing resin and 0-40 parts of silicone oil; the component (B) comprises the following components by weight: 100 parts of alpha, omega-alkoxy capped polydimethylsiloxane, 0-100 parts of silicone oil, 0-50 parts of reinforcing resin, 0-50 parts of a crosslinking agent, 0.5-15 parts of a thickening agent and 0.001-3 parts of a catalyst. The pouring sealant is a product with high light transmittance and strength, excellent adhesion and yellowing resistance, quick deep solidification and stable storage, can be used for pouring electronic appliances, can fulfill places requiring high light transmittance and high strength. The preparation method is simple, adjustable in solidification time and convenient to operate.

Owner:深圳市百丽春粘胶实业有限公司

Plugging structure for large-drawdown pipe well and construction method thereof

InactiveCN103993615AEasy to operateShorten the construction periodProtective foundationSealing/packingSteel tubeSteel plates

The invention relates to a plugging structure for a large-drawdown pipe well and a construction method thereof, and belongs to the field of building construction. The plugging structure for the large-drawdown pipe well comprises a no-sand cement pipe and a steel casing pipe. A steel plate water stop ring is welded to the steel casing pipe. The portion, located on the bottom elevation portion of an under layer, of the steel casing pipe is connected with a slip-preventing water stop ring in a welded mode. A water stop steel plate with a screw thread steel pipe and the steel casing pipe are welded for stopping water. An end cap with screw threads and threads of the water stop steel plate with the screw thread steel pipe are connected and sealed in a threaded mode. A thickened water stop plugging steel plate is welded to the top of the steel casing pipe. Expansive imperious concrete is poured in the portion between the water stop steel plate and the plugging steel plate of the steel casing pipe. Expansive water stop strips winding around the steel casing pipe are arranged on the connecting portion of the no-sand cement pipe and the steel casing pipe. The invention further discloses a construction method of the plugging structure for the large-drawdown pipe well. Operation is easy to carry out, and the construction period is shortened; as measures of adopting a plurality of waterproof structures are taken, the waterproof effect of a concrete bottom plate can be ensured, and more economic benefits and social benefits can be achieved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

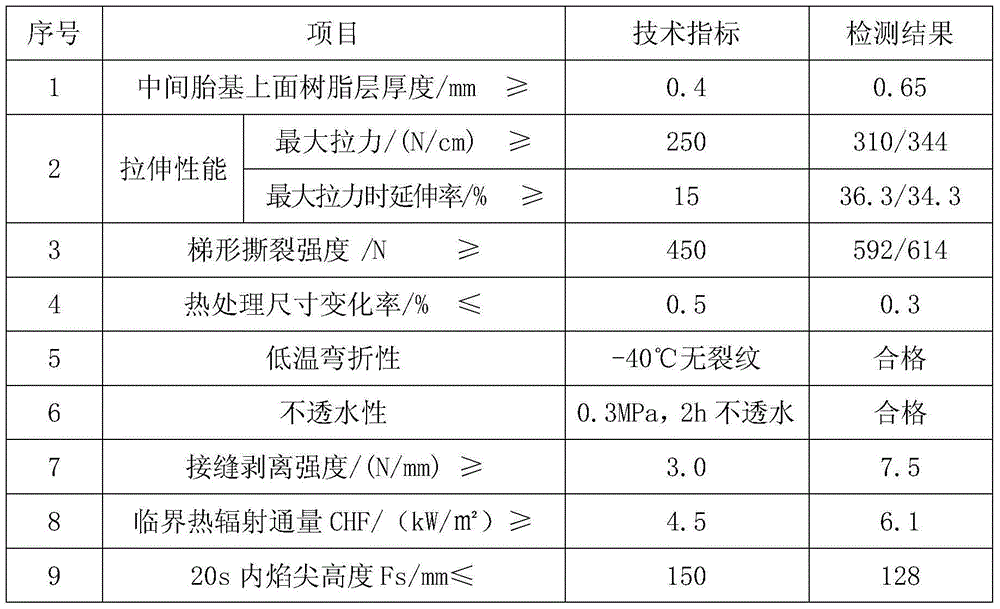

Fire-retardant thermoplastic polyolefin waterproof roll and preparation method thereof

InactiveCN104441887AImprove flame retardant performanceHave synergistic effectSynthetic resin layered productsGlass/slag layered productsFiberPolyolefin

The invention discloses a fire-retardant thermoplastic polyolefin waterproof roll, which is of a three-layer composite structure, wherein a middle layer is a fiber fabric layer; an upper surface layer and a lower surface layer are fire-retardant TPO roll layers; a fire-retardant TPO resin layer is prepared from TPO resin as a base material, a composite fire retardant as an assistant and other auxiliary materials; the composite fire retardant is composed of decabrominated dipheny ethane (DBDPE), magnesium hydrate, antimonous oxide and zinc borate; and the auxiliary materials are selected from one or a mixture of more than one of packing, titanium dioxide, a compatilizer, an antioxidant, an ultraviolet absorbent, a light stabilizer and black master batches. According to the waterproof roll disclosed by the invention, through use of the composite fire retardant, the defect that an existing TPO waterproof roll is inflammable is solved; the fire-retardant target is achieved under the premise of ensuring the welding construction and waterproof effect reliability of the product; and through use of the composite fire retardant, the combustion performance of the TPO roll belonging to inflammable materials can be up to A grade maximally, and reaches the non-inflammable grade.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH

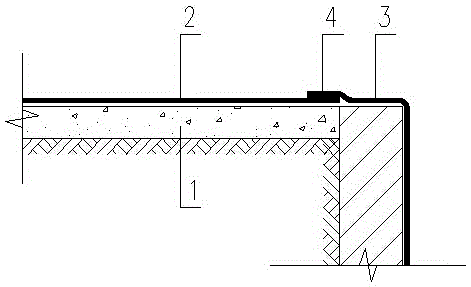

Integration construction method for basement soleplate and waterproof roll as well as waterproof structure

ActiveCN105544617AGuaranteed waterproof performancePrevent infiltrationProtective foundationBasementBituminous waterproofing

The invention discloses an integration construction method for a basement soleplate and a waterproof roll as well as a waterproof structure. The waterproof structure is characterized in that a pre-paving type self-adhered membrane waterproof roll is paved on the horizontal plane of a pad layer of the basement soleplate; self-adhered modified asphalt waterproof rolls are paved on internal and external corners of the structure; a cement binding agent coats on a lap-joint part of the pre-paving type self-adhered membrane waterproof roll and the self-adhered modified asphalt waterproof rolls; and the basement soleplate is cast to upper portions of the pre-paving type self-adhered membrane waterproof roll and the self-adhered modified asphalt waterproof rolls to form an integrated waterproof layer. According to the integration construction method and the waterproof structure, two different waterproof rolls are paved on the pad layer of the basement soleplate to carry out waterproof construction, so that the roll waterproof layers are tightly combined with the soleplate structure to the form the integrated waterproof layer, and therefore, water can be completely prevented from entering gaps between the waterproof rolls and the structure.

Owner:CCFED THE FIRST CONSTR & ENG

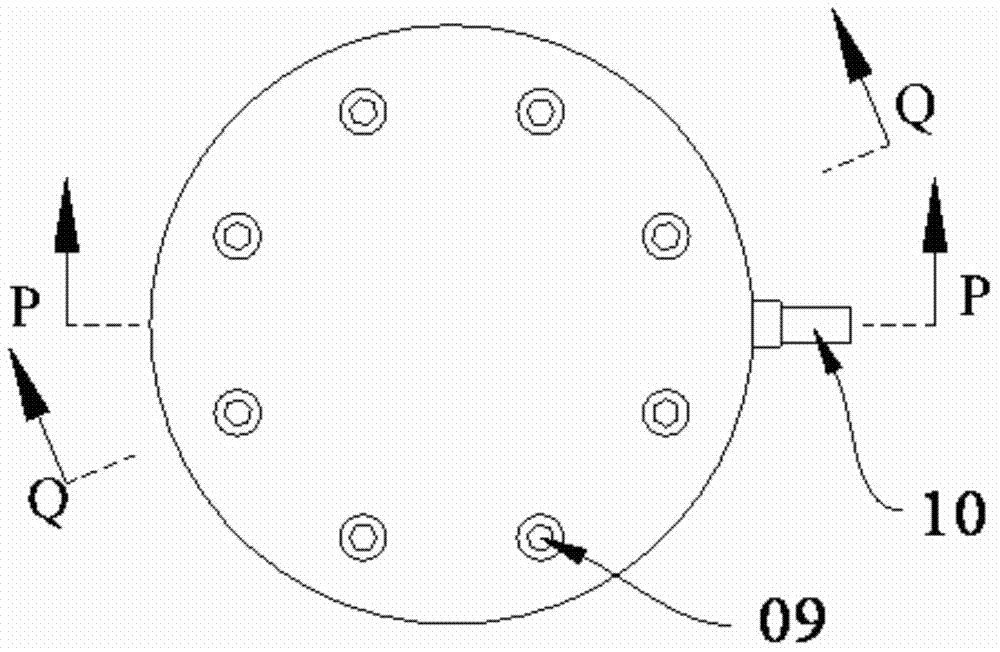

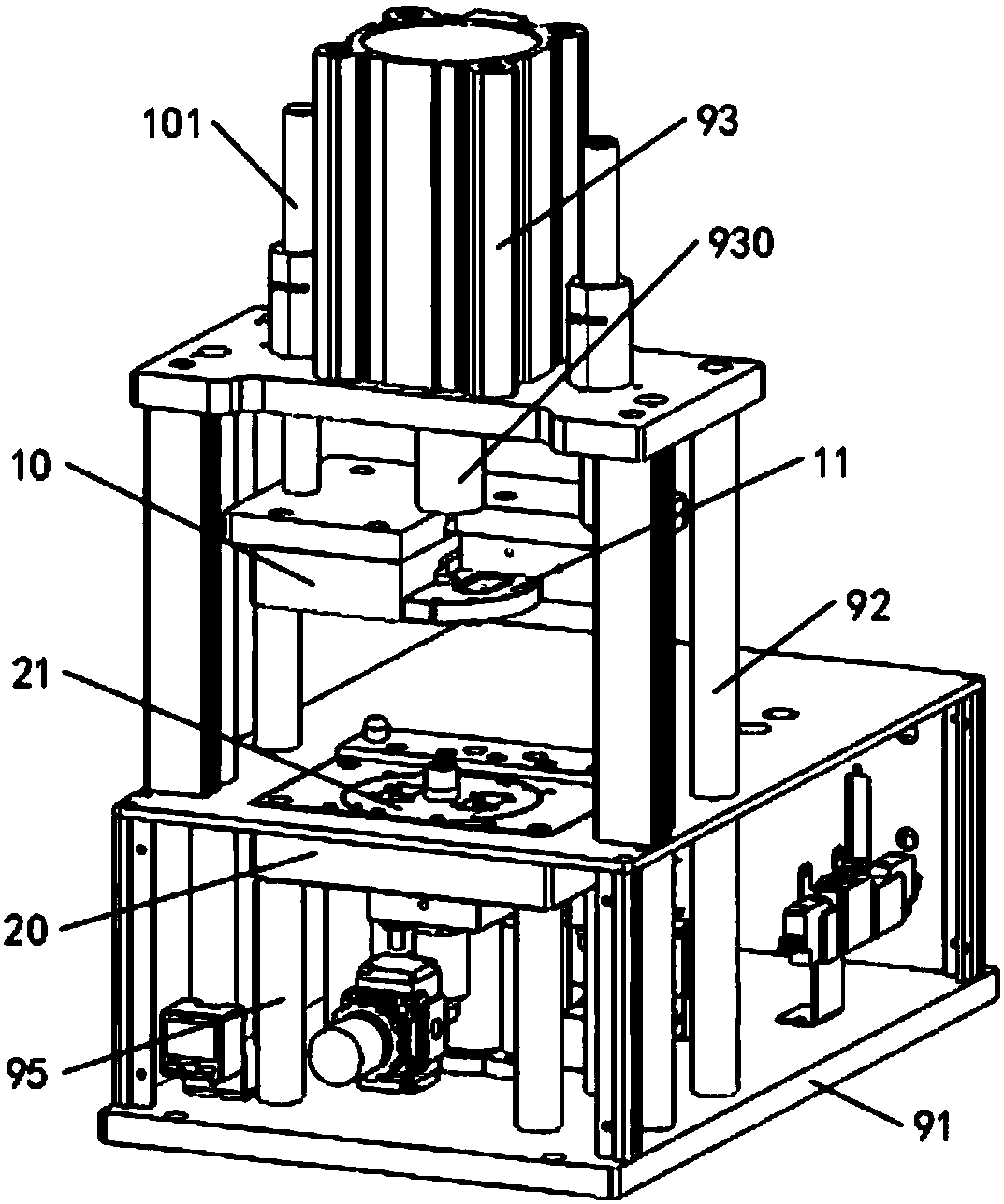

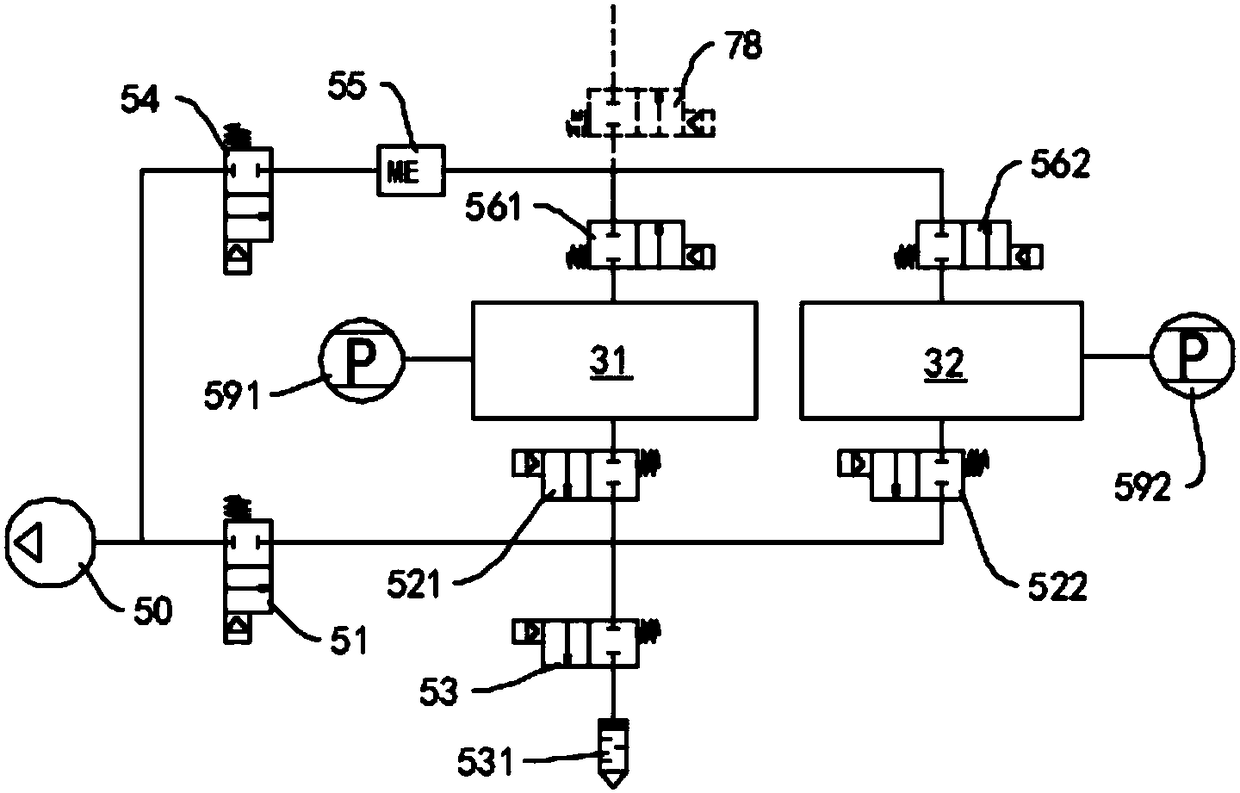

Method and device for waterproof test of breathable film

PendingCN108362620AGuaranteed to meet the requirementsGuaranteed waterproof performanceMeasurement of fluid loss/gain ratePermeability/surface area analysisWater leakageVacuum pressure

The invention provides a method for the waterproof test of a breathable film. The method comprises the following steps: arranging a breathable film part to be detected in a test tool in a closed manner, arranging a water chamber at one side of the breathable film, and arranging a vacuum chamber at the other side of the breathable film; injecting a pressure into the water chamber, vacuumizing the vacuum chamber through a first vacuum loop, and performing test and determination; performing pressure retaining, detecting the vacuum pressure, and performing determination; and vacuumizing the vacuumchamber through a second vacuum loop provided with a mass flow meter, detecting slight leakage, and performing determination. The invention also provides a device for the waterproof test of the breathable film. The method and the device for the waterproof test of the breathable film can achieve high-efficiency and high-precision detection on the waterproof film part of an electronic device, can detect the obvious water leakage phenomenon, and also can detect the slight leakage condition to ensure the waterproof performance of the electronic device.

Owner:常州北埠电子技术有限公司

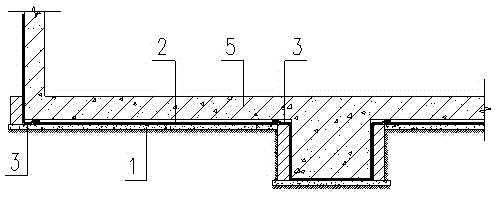

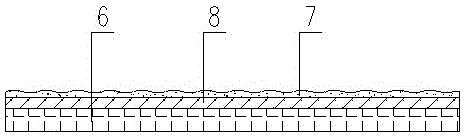

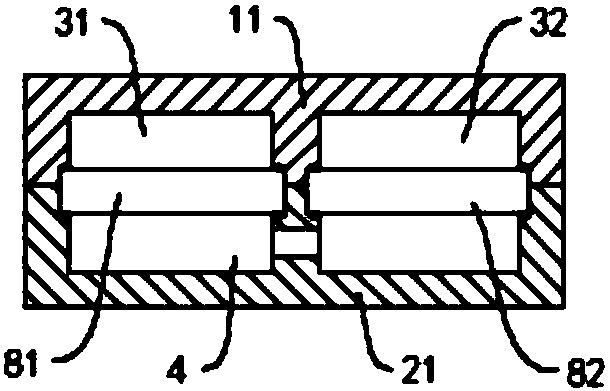

Polyurethane waterproof roll, production equipment and process, composite waterproof layer and practice thereof

InactiveCN105089208ABroad application spaceVersatileLiquid surface applicatorsRoof covering using flexible materialsButt jointUltimate tensile strength

The invention provides a polyurethane waterproof roll, production equipment and process, a composite waterproof layer and practice thereof. A method of achieving the composite waterproof layer comprises the steps that firstly, underlayer polyurethane waterproof coating is manufactured, then the upper-layer polyurethane waterproof roll is manufactured, and the coating and the roll are bonded into an organic integrity which has certain interface shearing and peeling strength by the coating. Through the polyurethane waterproof roll, the solidification and film forming process of the polyurethane waterproof coating which is achieved at the construction site previously is moved forward, the polyurethane waterproof roll is produced ready in a factory through special equipment, the thickness is uniform and consistent, and the category and function are diversified. By means of seamless connection characteristic of the coating and uniform thickness characteristic of the roll, quality of a waterproofing project can be improved. The practice has the advantages that the coating and the roll are compatible in material property, the coating is smooth to cure and large in cohesive force, the cohesion between the coating and a substrate is powerful, the roll is tight to overlap or in butt joint, the coating is bonded to the roll sufficiently, the construction site demands no open fire or electrical heating operation, the safety, energy conservation and environmental protection are achieved, and the characteristic of 'liquid rubber' of the polyurethane material is given full play.

Owner:辛永刚 +1

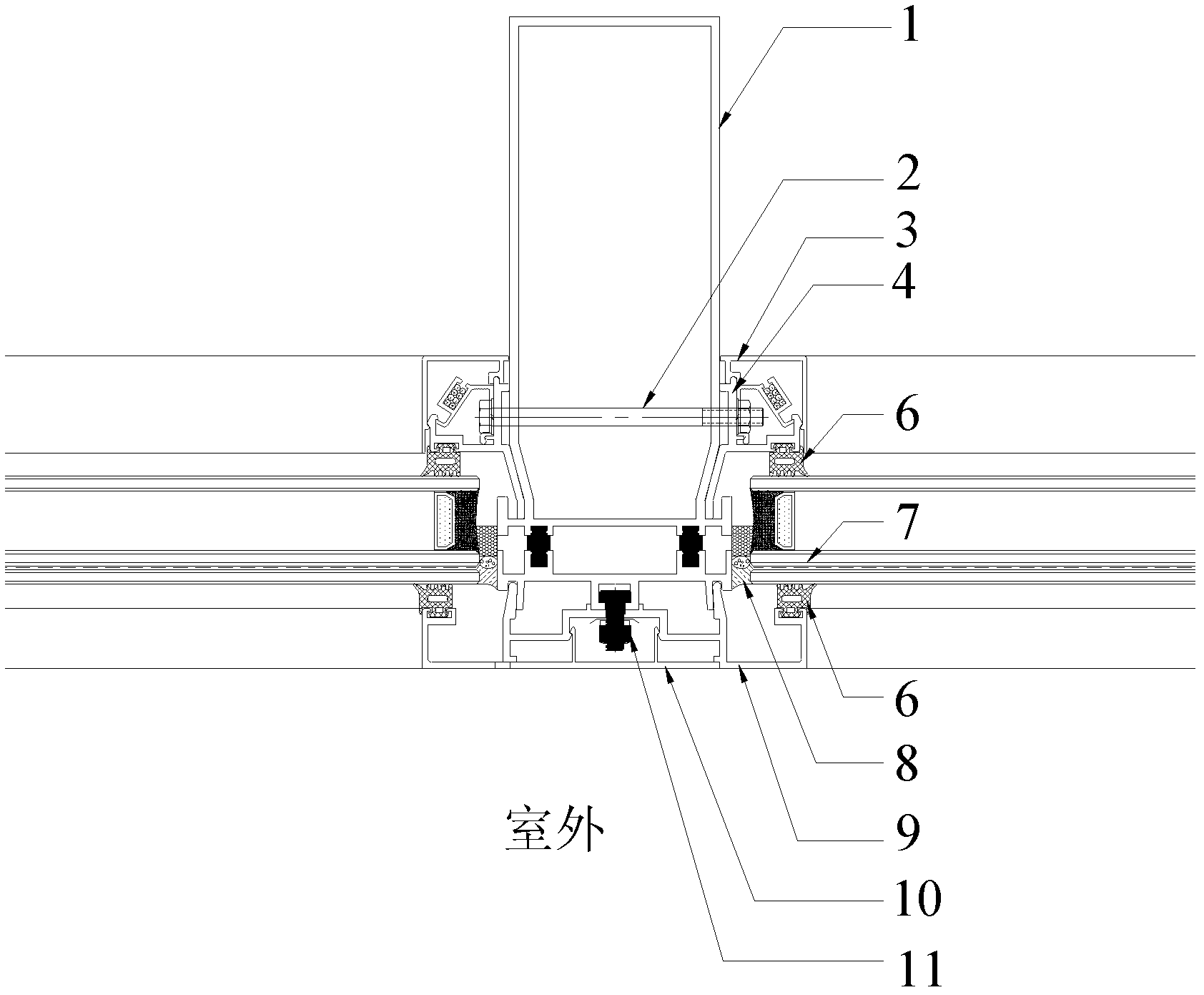

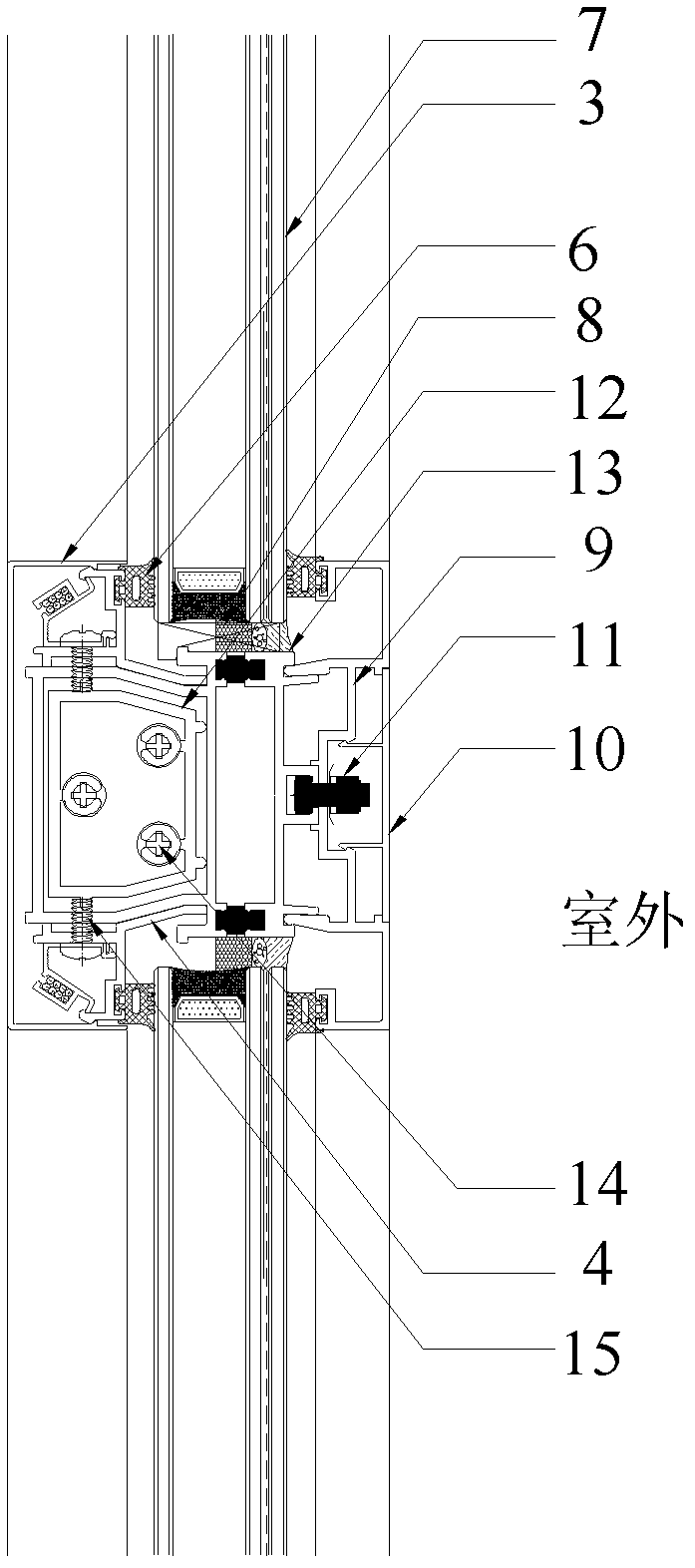

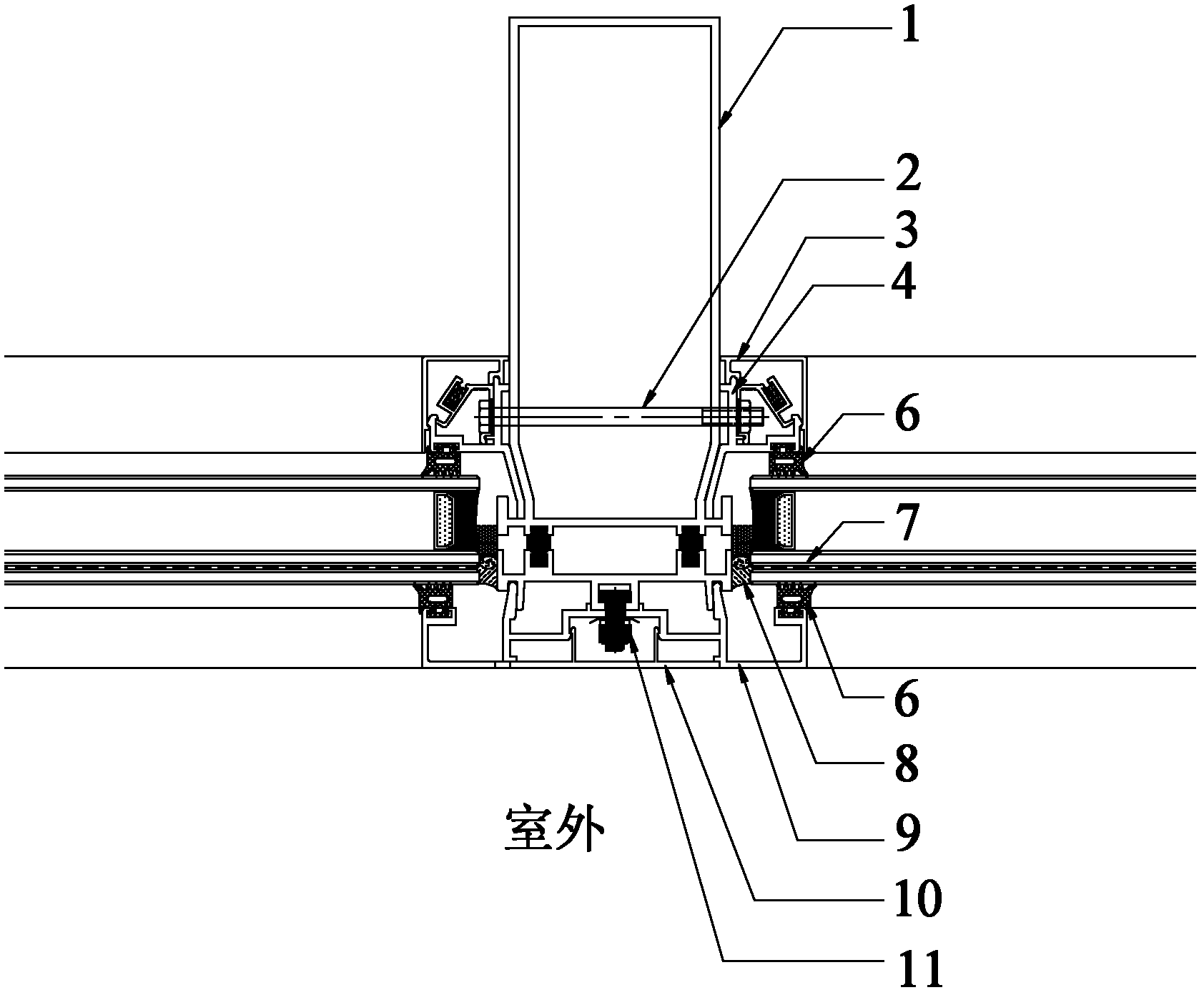

Glass curtain wall structure for indoor maintenance and change

The invention relates to a curtain wall structure for indoor maintenance and change. The curtain wall structure comprises a curtain wall framework consisting of an aluminum alloy vertical keel and an aluminum alloy transverse keel which are connected each other, wherein an aluminum subframe is fixed on a master keel through machine wires or through bolts, and a rubber bar is inserted into the aluminum subframe; and a glass plate block is pushed into the subframe from the outer side, and is effectively connected with the master keel through an external decoration bar so as to be limited and fixed. Compared with the prior art, the curtain wall structure has the advantages that: the glass plate block can be changed or maintained in a room; the efficiency is improved; convenience and quickness are realized, and the maintenance cost of a curtain wall plate block is reduced greatly; and great breakthrough is supplied to maintenance and change of the curtain wall plate block.

Owner:SHANGHAI BRIGHT INTELLIGENT CURTAIN WALL

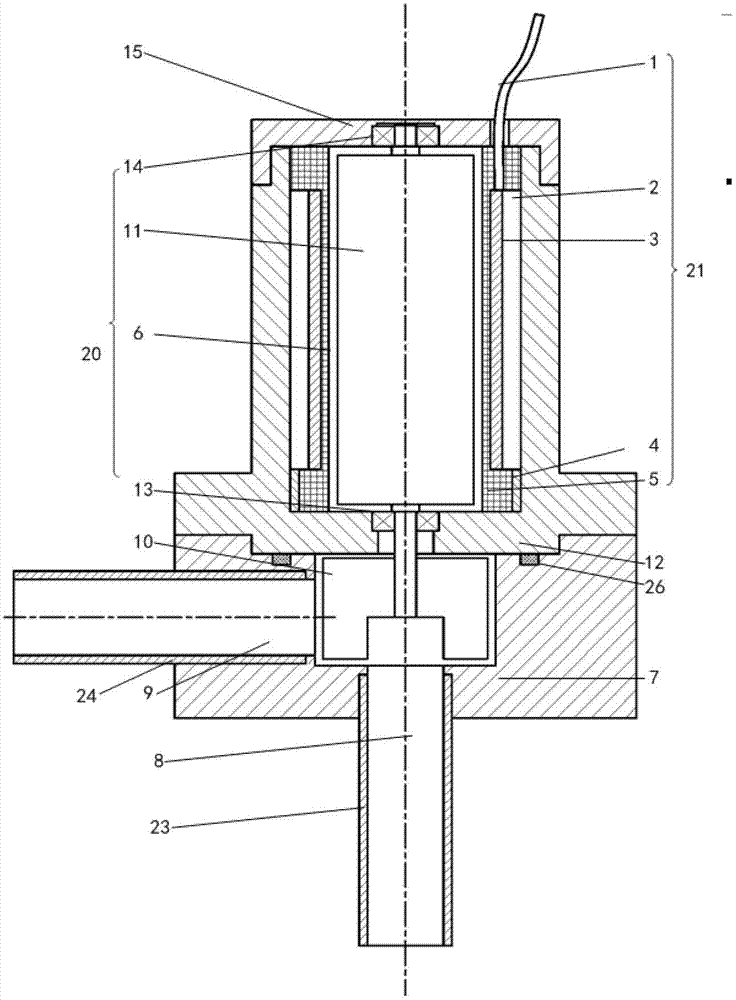

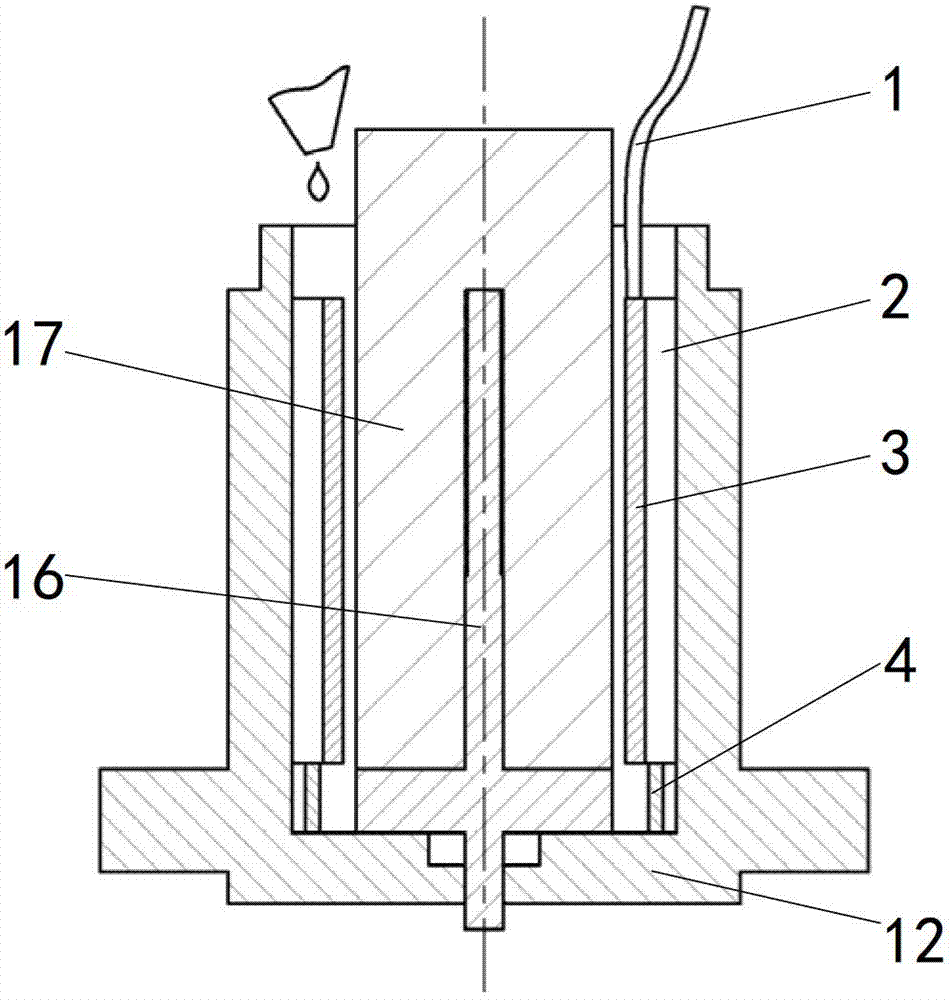

High-reliability miniature mechanical pump

ActiveCN102788022AImprove potting effectImprove operational conveniencePump componentsPump installationsMotor protectionImpeller

The invention discloses a high-reliability miniature mechanical pump which comprises a pump body, pump chambers, a fluid inlet, a fluid outlet, an impeller and a brushless motor, wherein the pump body is formed in such a manner that a volute, a motor protection housing and a motor cover plate are connected with one another, and the pump chamber for accommodating the impeller and the pump chamber for accommodating the brushless motor are formed. The fluid inlet and the fluid outlet are formed in the volute and communicated with the pump chambers. The brushless motor is arranged in the pump chamber in the motor protection housing and the motor cover, an output shaft of the brushless motor is connected with a spindle of the impeller, and the brushless motor comprises a permanent magnet rotor assembly and a winding coil stator assembly, wherein a metal sleeve is arranged between the rotor assembly and the stator assembly, and a waterproof sealant layer is formed on the surface of a stator coil to wrap and seal the stator coil. The invention further discloses other structural adjustment. With the adoption of the high-reliability miniature mechanical pump, the water tightness of the motor can be achieved, the heat dissipation performance of the motor can be improved, the spare part structure of the pump can be further simplified and compact, the effective seal of the pump chambers and the precise concentric positioning of the impeller can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

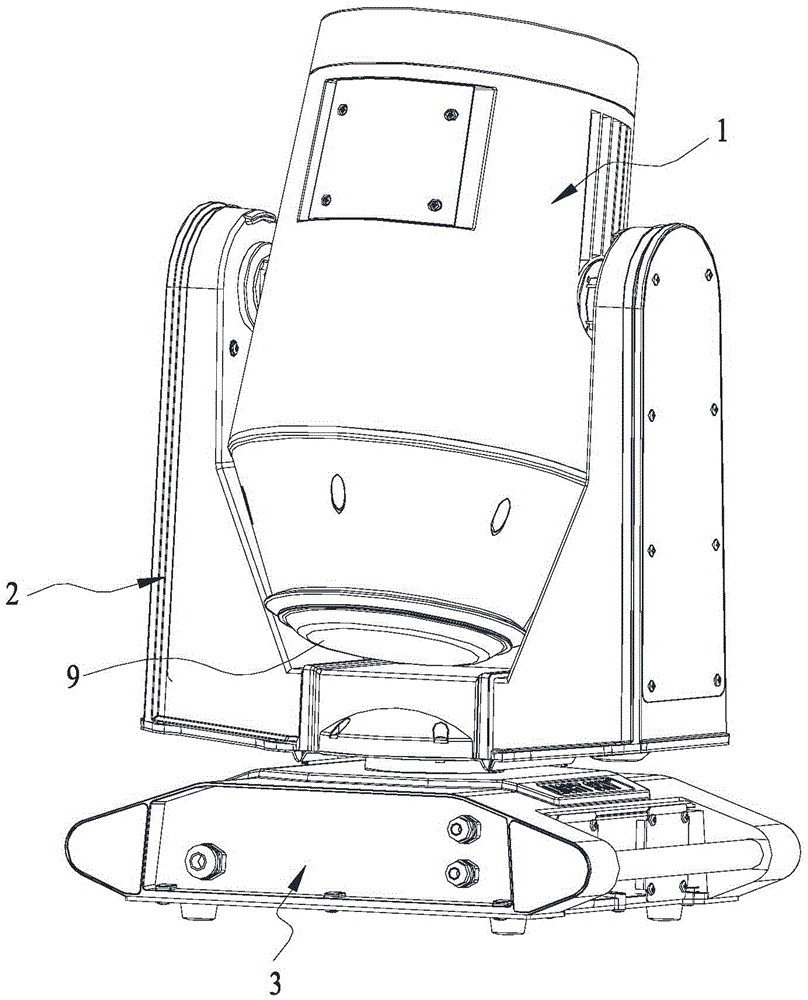

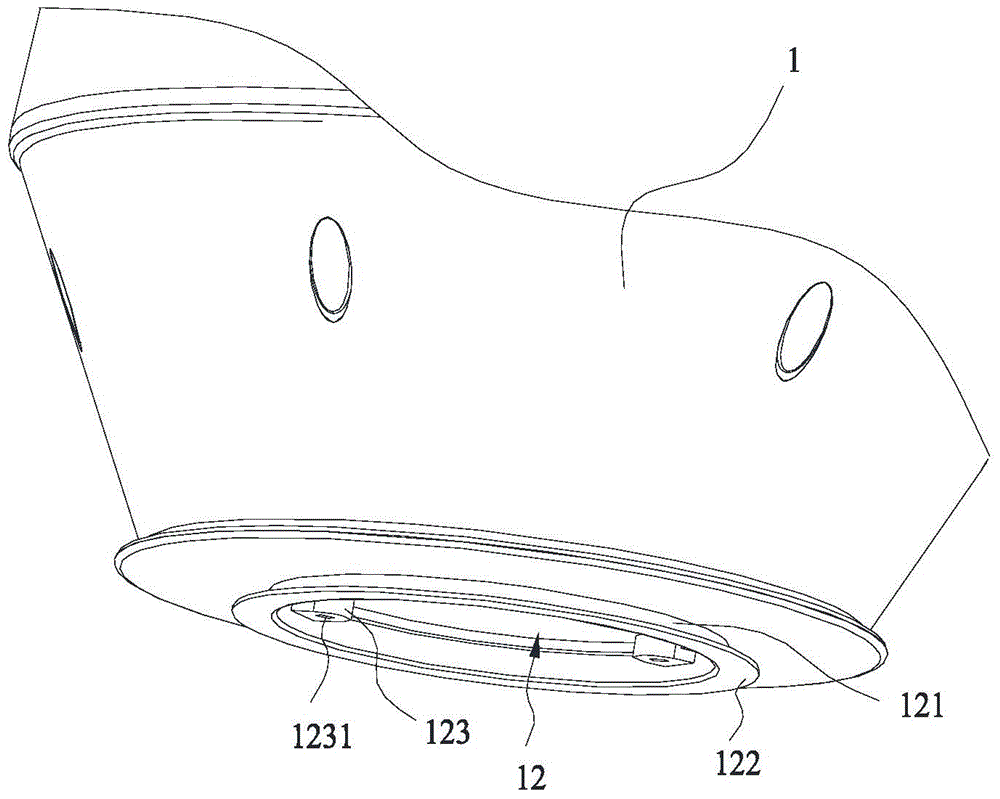

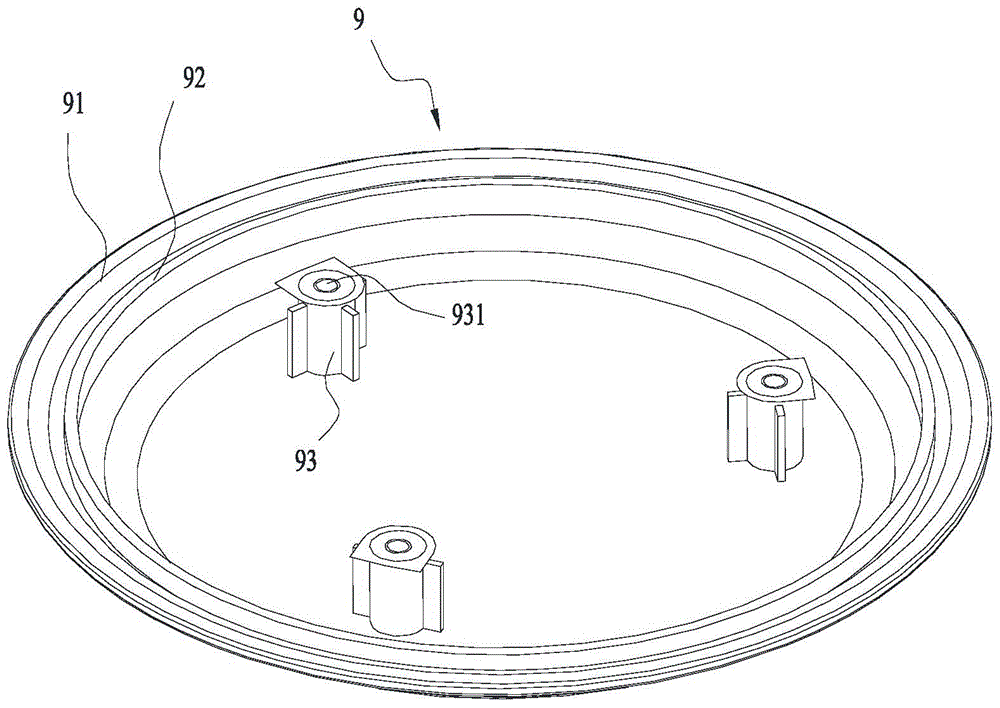

Novel waterproof stage lamp

ActiveCN104566035AEffective circulationGuaranteed liquidityLighting applicationsMechanical apparatusEngineering

The invention discloses a novel waterproof stage lamp which comprises a lamp holder, a U-shaped frame, a bottom box and a sealing cover. Two sides of the lamp holder are pivotally connected to the U-shaped frame, the bottom of the U-shaped frame is pivotally connected to the bottom box, a radiating opening is formed in the tail of the lamp holder, the periphery of the opening extends out along the central axis of the lamp holder to form a supporting ring, a first annular water retaining portion projects over the outer edge of the supporting ring and perpendicular to the supporting ring, the sealing cover is fixedly matched with the opening, the outer periphery of the sealing cover extends out to form an arc portion bent towards the opening, the arc portion is separated from the tail of the lamp holder, and a second annular water retaining portion projects over the inner side face of the sealing cover on the inner side of the arc portion along the central axis of the lamp holder, is positioned on the periphery of the first annular water retaining portion and is separated from the first annular water retaining portion to form a first radiating channel. A waterproof function can be effectively provided based on guarantee of radiating.

Owner:GUANGZHOU FLY DRAGON LIGHTING EQUIP

Tent fabrics and preparation method thereof

InactiveCN104859231AKeep warmGood dyeing effectSynthetic resin layered productsVegetal fibresHemp fiberPolyester

The invention discloses tent fabrics and a preparation method of the tent fabrics. The tent fabrics comprise base cloth and waterproof coating. The base cloth comprises, by weight 50-65% of polyester fiber, 15-25% of hemp fiber is, 10-20% of bamboo fiber and 5-10% of wool fiber. The tent fabrics adopt special waterproofing treatment and dyeing processing, not only ensure the waterproof washing color fastness, the color fastness to light and the waterproof effect, but also ensure the wearability to the largest extent through the fiber blending weaving, and enable the blending fibers to have good-strength, anti-bacteria, heat-insulation, uvioresistant and anti-static effects.

Owner:湖州丝葳纺织有限公司

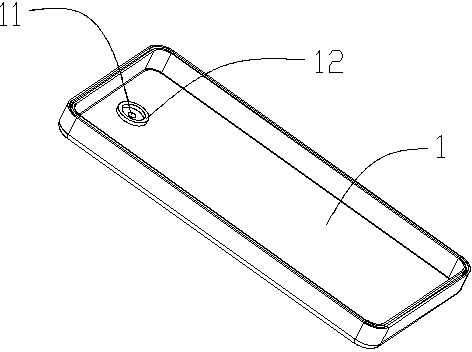

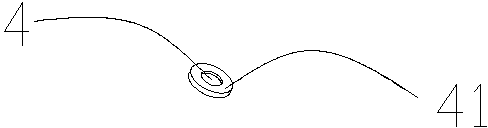

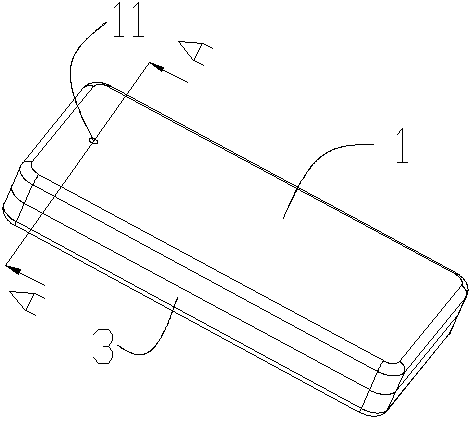

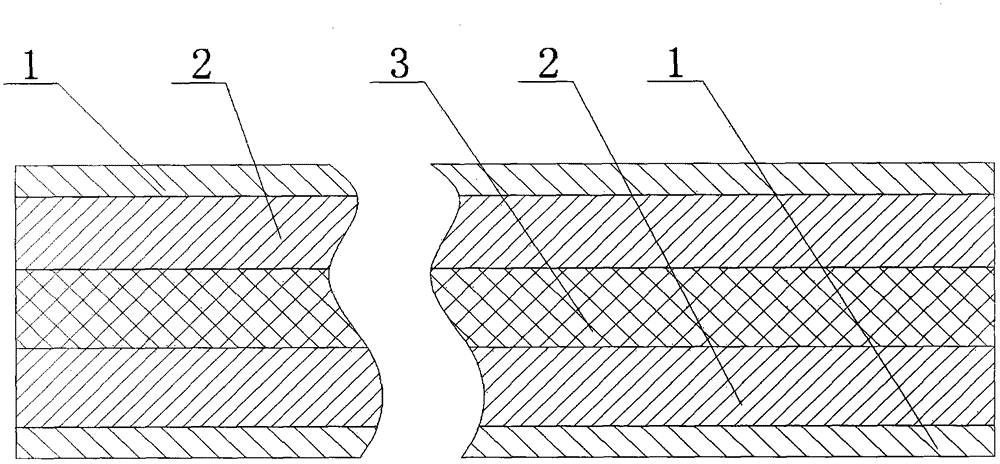

Electronic device with pressure relief structure

InactiveCN103974604AGuaranteed waterproof performanceGuaranteed functionCasings/cabinets/drawers detailsTelephone set constructionsEngineeringAtmospheric pressure

The invention relates to an electronic device with a pressure relief structure. The device comprises a first shell, a sealing part and a second shell, the sealing part is arranged between the first shell and the second shell, the first shell and the second shell are arranged on the sealing part in a press fitting mode until the first shell and the second shell are deformed to be assembled together, a sealing space is formed between the first shell and the second shell, the pressure relief structure comprises at least one ventilation waterproof film and at least one pressure relief hole, the pressure relief hole is formed in at least one of the first shell or the second shell, and the ventilation waterproof film is arranged on the pressure relief hole and is sealed with the edge of the pressure relief hole. Therefore, when the device is used for the different environments with the large temperature or pressure changes, the pressure relief structure can keep connectedness and consistency of the shell sealing space and the external temperature and pressure all the time, so that the electronic device can be normally used in the different environments with the rapid changes of temperature and pressure.

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

Ultra-low-temperature SBS modified bitumen waterproof membrane

InactiveCN104859217AReasonable structureImprove adhesionSynthetic resin layered productsBituminous layered productsIsolation layerCold area

The invention relates to an ultra-low-temperature SBS modified bitumen waterproof membrane. The ultra-low-temperature SBS modified bitumen waterproof membrane comprises a base layer. The upper and the lower surfaces of the base layer are provided with a hot melt or self-adhesive layer. The outer surface of the hot melt or self-adhesive layer is provided with an isolation layer. The ultra-low-temperature SBS modified bitumen waterproof membrane is reasonable in structure, good in adhesion and resistant to low temperature, can still maintain waterproof performance at the temperature of -50 DEG C, has good adhesion at low temperature and is especially suitable for cold areas and winter waterproof construction.

Owner:LIAONING BENTENAI TECH DEV

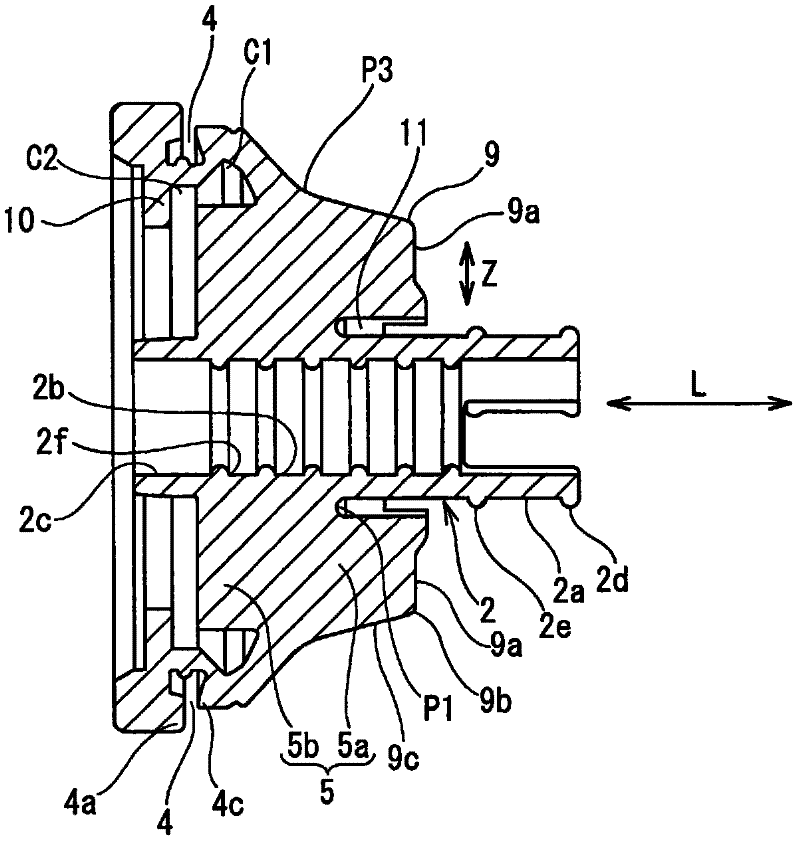

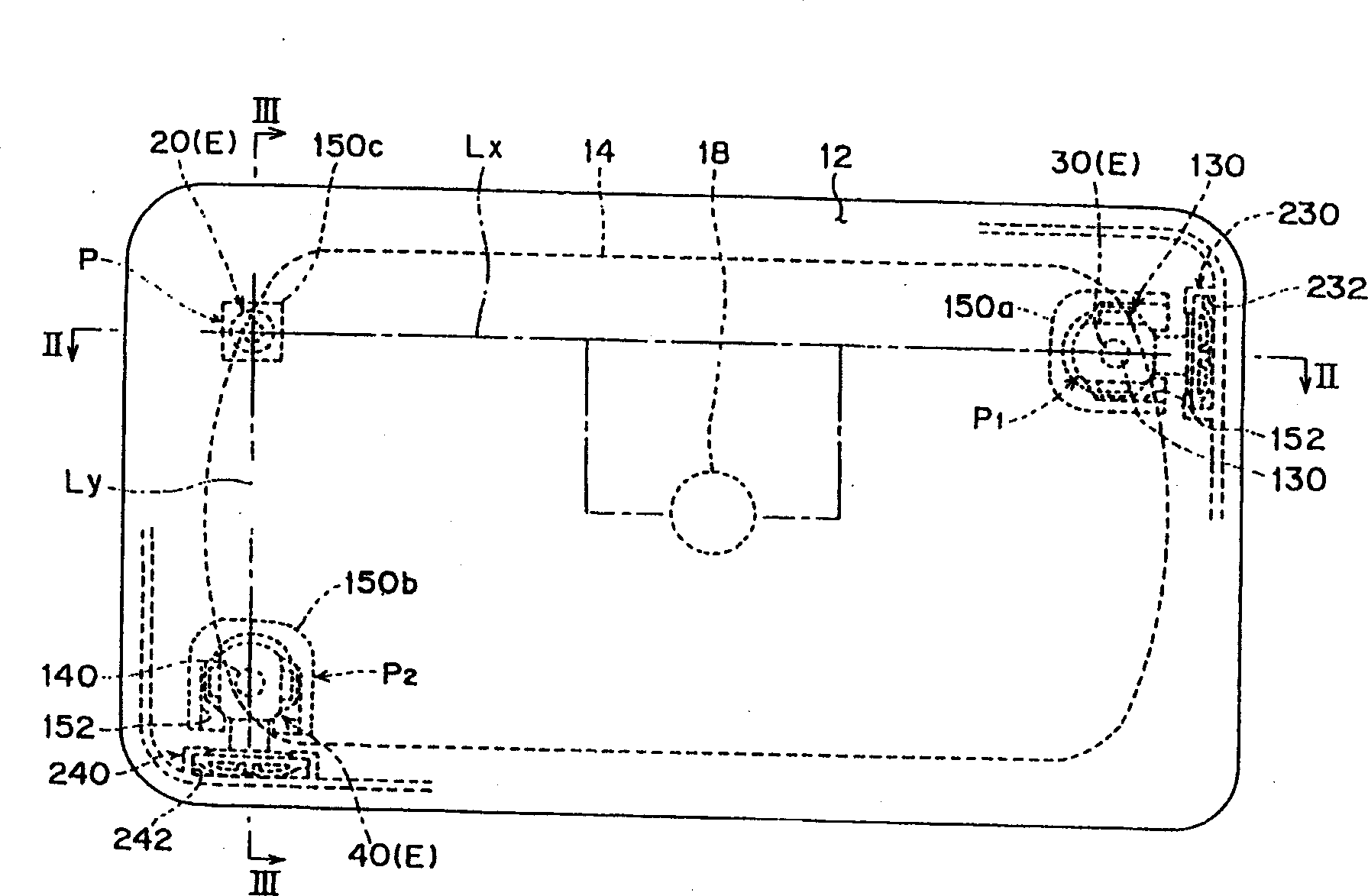

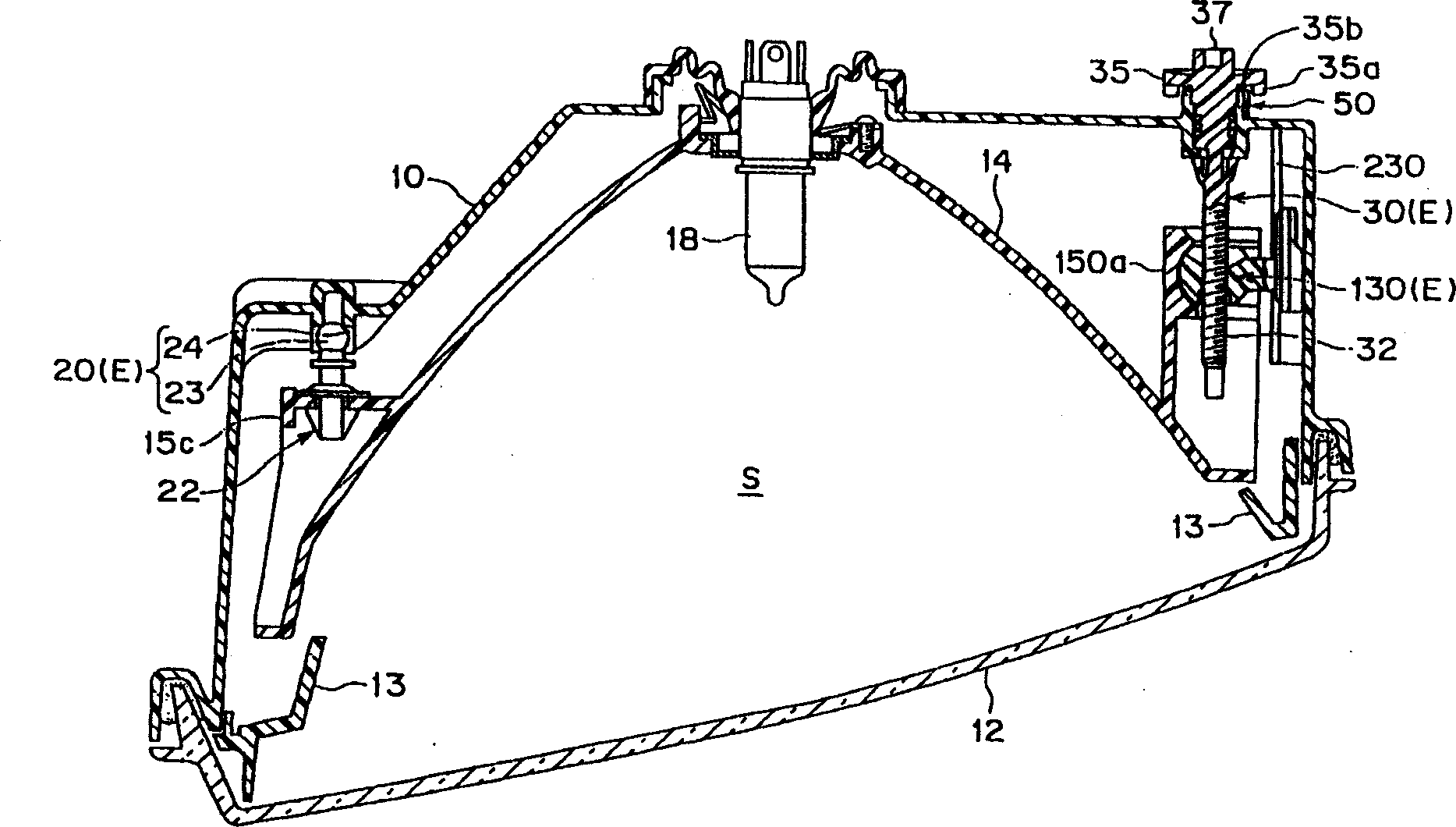

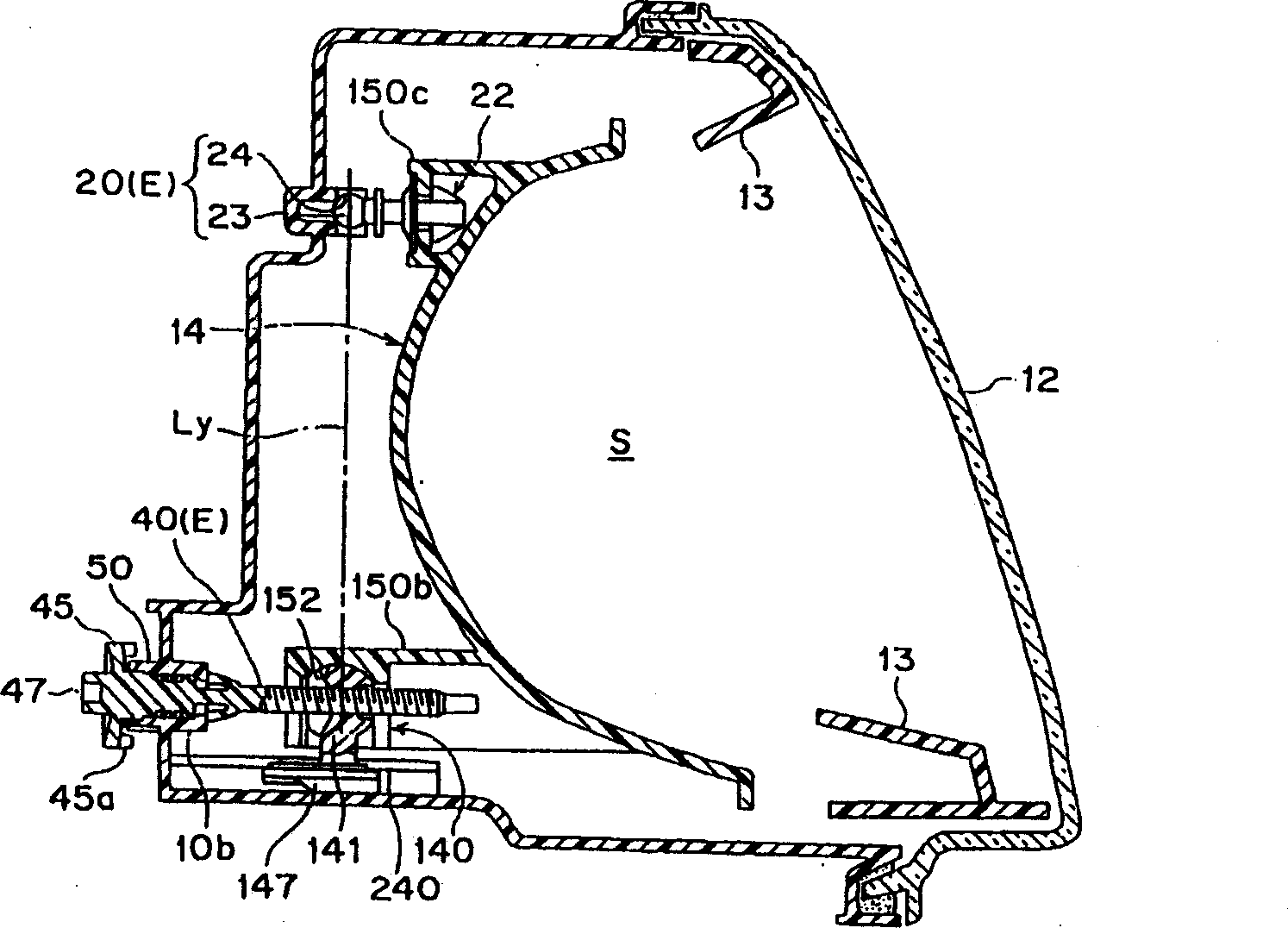

Reflector-movable front-lighting lamp for automobile

InactiveCN1362594ADoes not hinder rotationGuaranteed normal slidingVehicle headlampsPoint-like light sourceMovable typeMiniaturization

The invention provides a compact head lamp for reflector movable type automobile capable of preventing vibrations of a reflector and smoothly rotating an aiming screw. In this head lamp, a nut sliding guide 230 equipped to a bracket 150a in a reflector 14 side, screwed with a screw 30, and guides a nut member 130 moving forward / backward in relation to rotations of the screw 30 is provided on a lamp body. A stress releasing means having a ball joint structure is provided between the nut member 130 composing a aiming point P1 and the bracket 150a. The sliding guide 230 carries the weight of the reflector 14, guarantees sliding of the nut member 30. Torsional moment is not generated on the nut member 30, so that vibrations of the reflector 14 can be suppressed, and smooth rotations of the screw can be ensured.

Owner:KOITO MFG CO LTD

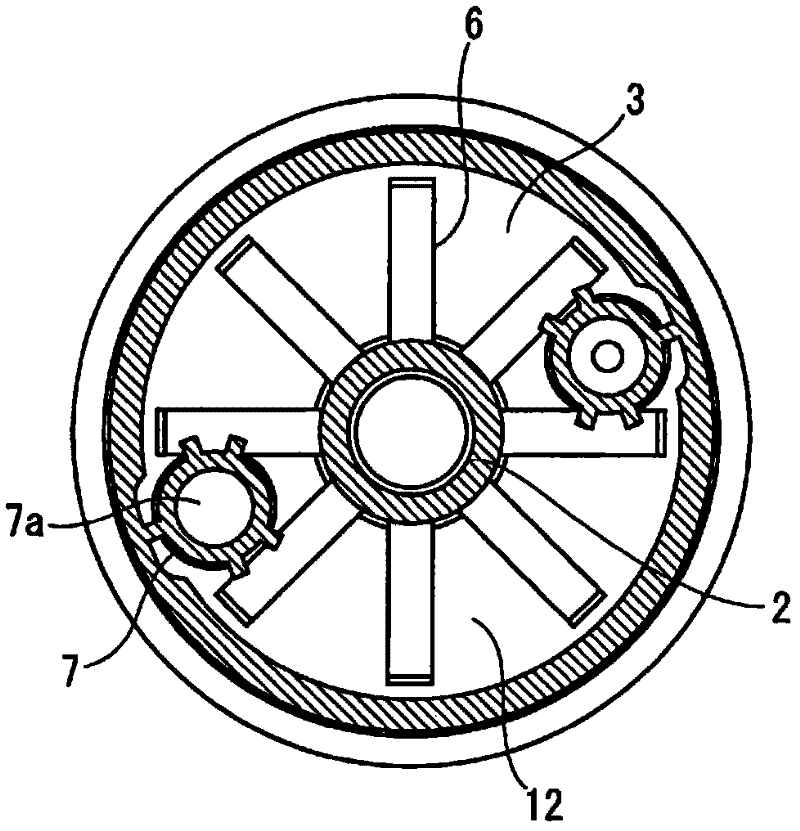

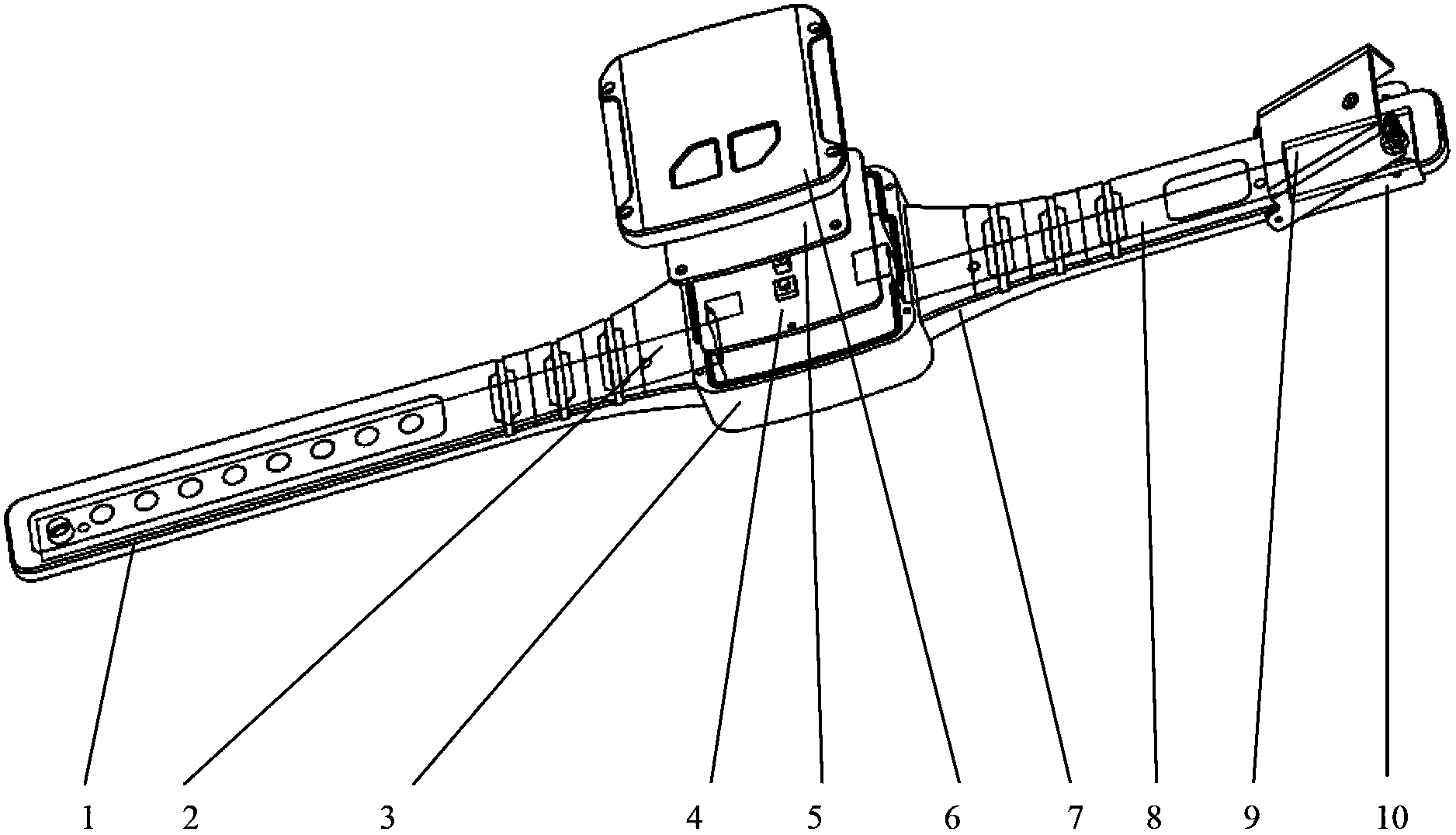

Wearing-type anti-dismantling alarm apparatus

ActiveCN103794022AWon't breakApplicableAlarmsRecord carriers used with machinesFlexible circuitsEngineering

The invention discloses a wearing-type anti-dismantling alarm apparatus. The wearing-type anti-dismantling alarm apparatus comprises a gauge head 3, a top cover 6 (provided with a top cover PCB 5), an electronic label 4, a gauge band including a long gauge band 1 and a short gauge band 7, a long flexible circuit board 2, a short flexible circuit board 8, and a gauge buckle including an upper gauge buckle 9 and a lower gauge buckle 10. When an active alarm device is started, an alarm signal is generated; when the long gauge band is destroyed, an anti-dismantling alarm circuit is disconnected, and an alarm signal is generated; when the short gauge band is destroyed, a sensing type anti-dismantling alarm circuit is disconnected, and an alarm signal is generated; and when the upper gauge buckle, the lower gauge buckle or the top cover are opened in unauthorized cases, the sensing type anti-dismantling alarm circuit generates the alarm signal. The wearing-type anti-dismantling alarm apparatus is provided with waterproof and super-low power consumption functions and the like, therefore, the service life is longer, and the adaptability is higher. At the same time, the wearing-type anti-dismantling alarm apparatus also has the advantages of dismantling alarm, wrong alarm prevention and the like.

Owner:BEIJING INST OF COMP TECH & APPL

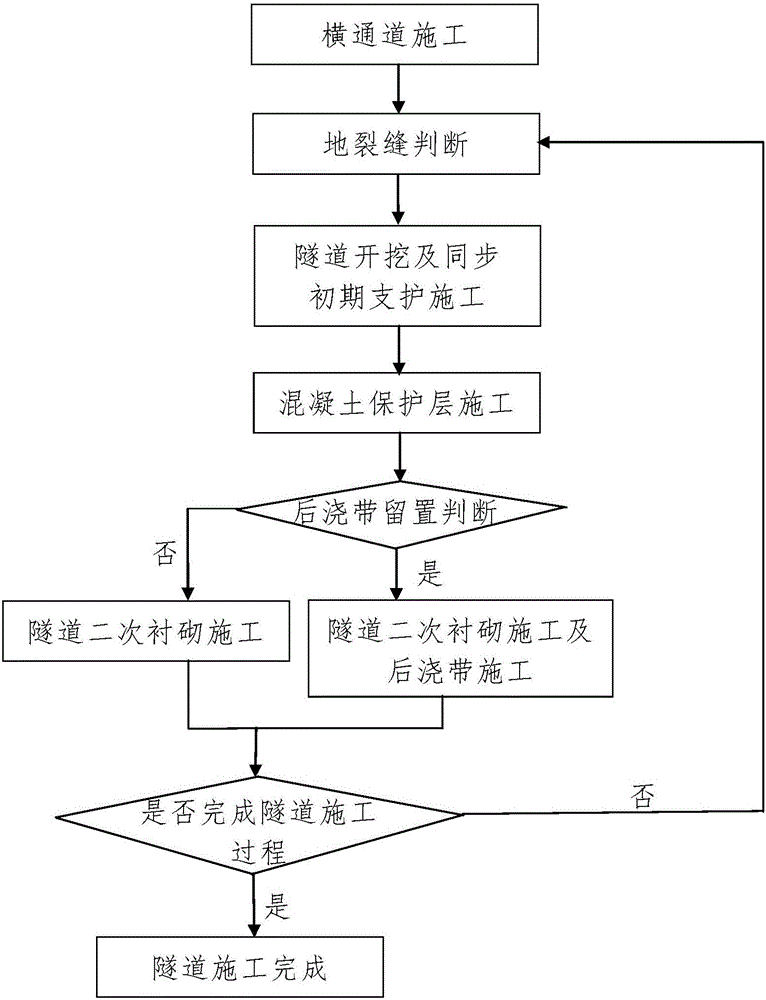

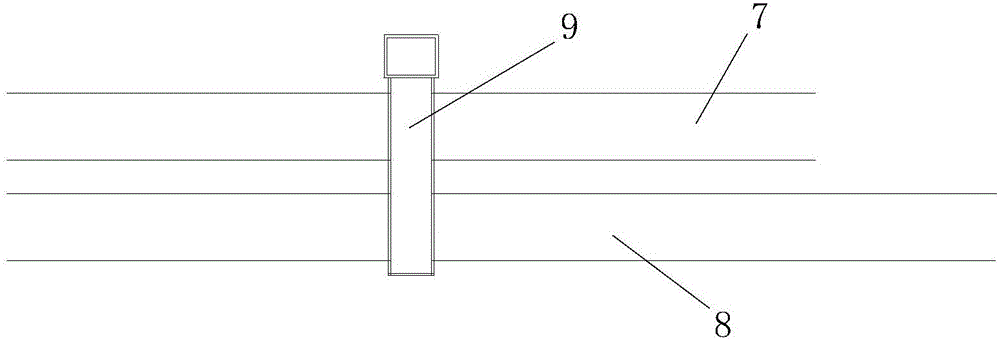

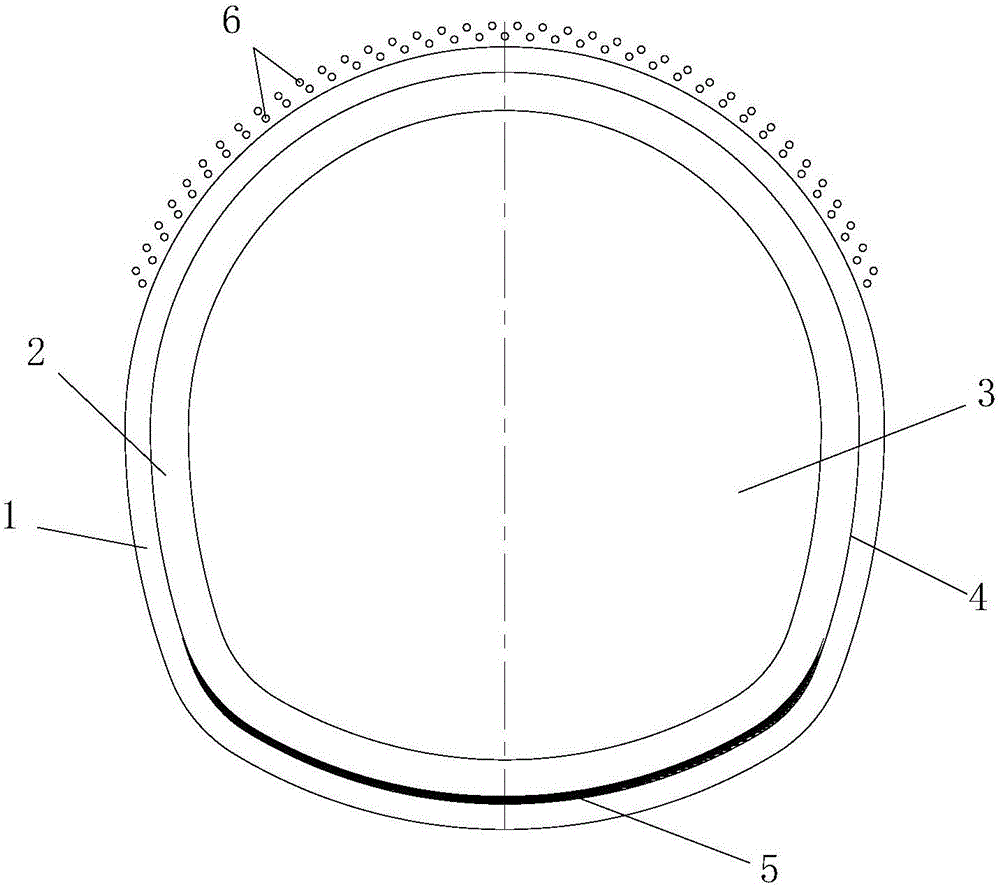

Ground fracture crushed zone passing construction method for shallow-buried tunnel excavation

ActiveCN106437726AThe method steps are simpleReasonable designUnderground chambersTunnel liningProtection layerTunnel construction

The invention discloses a ground fracture crushed zone passing construction method for shallow-buried tunnel excavation. A constructed shallow-buried excavation tunnel comprises a left line tunnel and a right line tunnel which are communicated through a transverse channel. During construction of the constructed shallow-buried excavation tunnel, the method comprises the steps that 1, transverse channel construction is performed; 2, tunnel construction is performed, wherein the two tunnel sections of the left line tunnel and the right line tunnel are constructed through the transverse channel, the construction is performed in the mode of multiple tunnel sections in the longitudinal extending direction of the tunnel from back to from during construction of any one tunnel section, and the construction of any one tunnel section includes the processes of ground fracture judgement, tunnel excavation and synchronous preliminary bracing construction, concrete protection layer construction, post-cast strip retention judgement, secondary tunnel lining construction and post-cast strip construction. The method includes simple steps and is reasonable in design, convenient to construct, good in construction effect, capable of simply and conveniently completing the shallow-buried tunnel excavation construction process of a ground fracture crushed zone and safe and reliable in construction process.

Owner:中铁二十局集团第五工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com