High-performance thermoplastic polyolefin waterproof coiled material with high scrap rubber powder doping amount

A thermoplastic polyolefin and waterproof coiled material technology, which is applied in rubber layered products, synthetic resin layered products, chemical instruments and methods, etc. The mechanical properties remain stable, the welding peel strength is large, and the strength is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The high-performance thermoplastic polyolefin waterproof membrane with high waste rubber powder content of the present invention will be further described below in combination with examples and comparative examples.

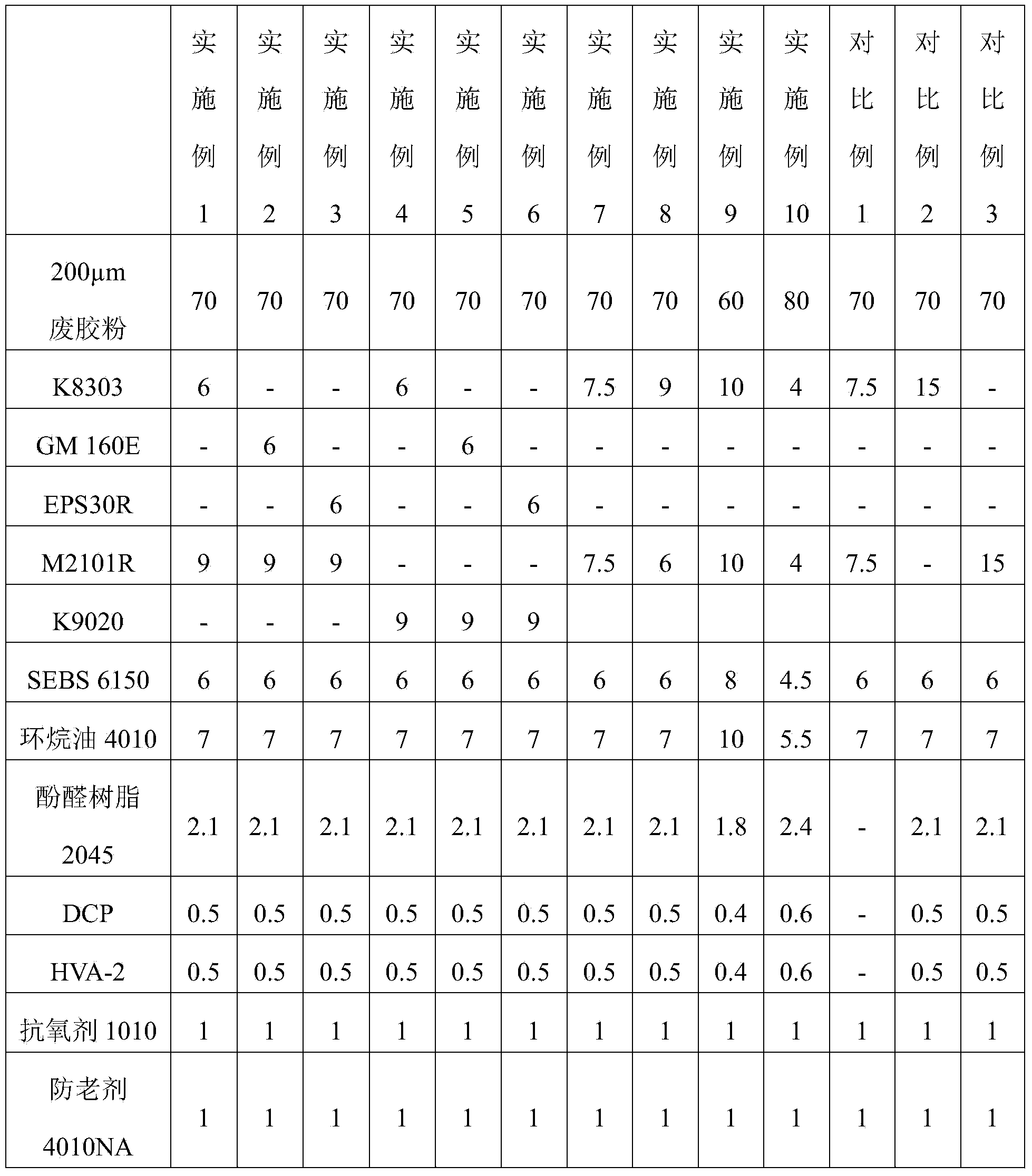

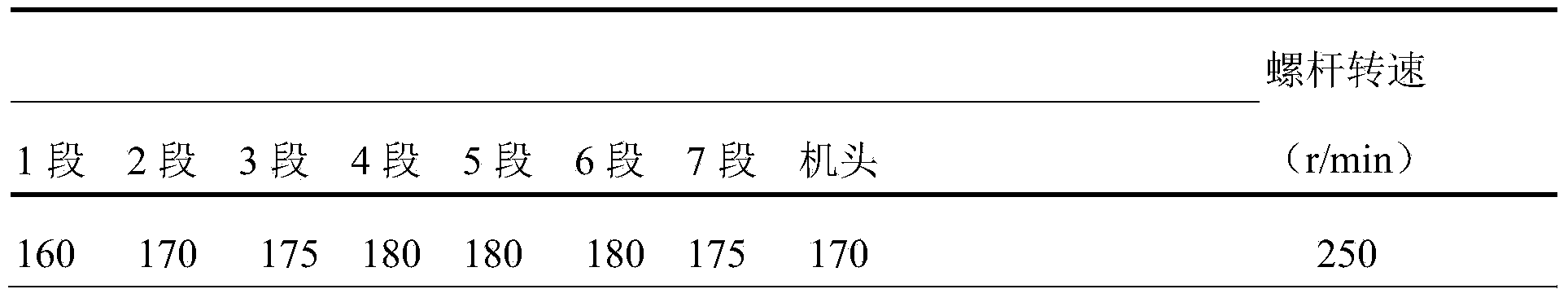

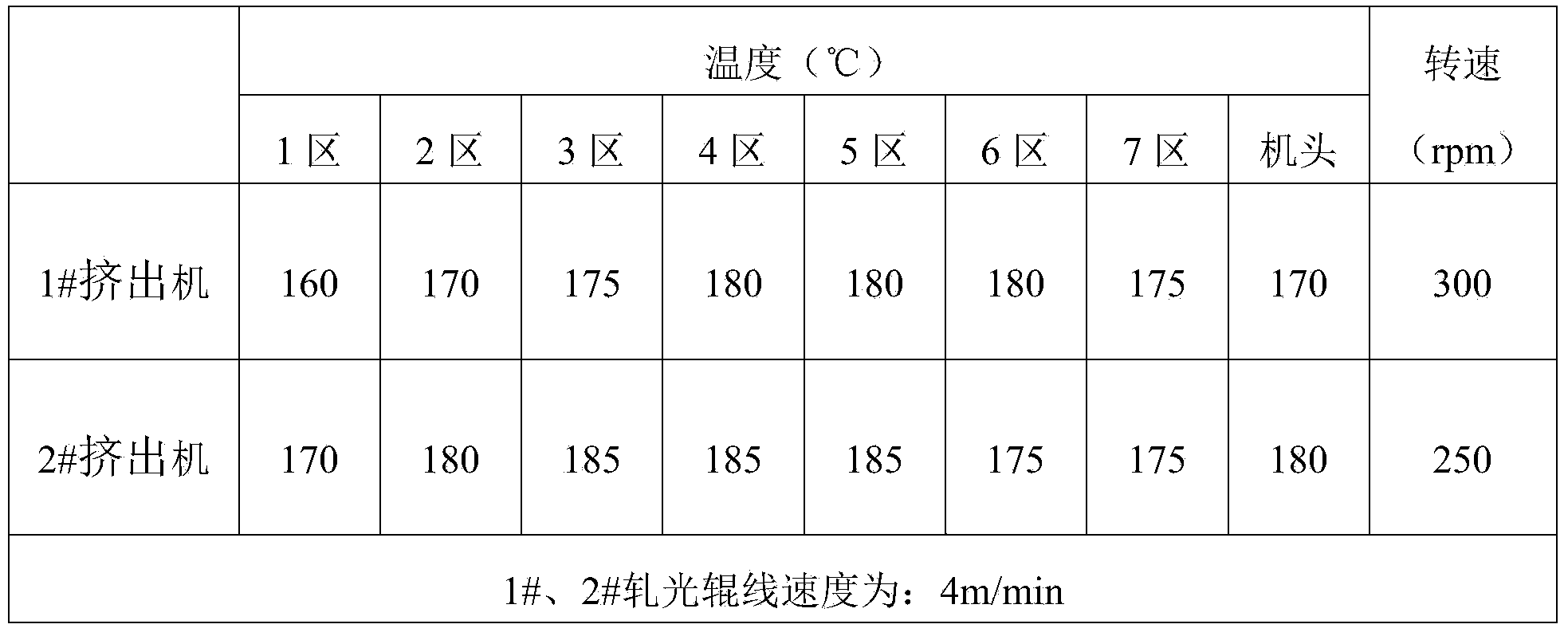

[0029] The raw material formulas of waste rubber powder-based thermoplastic elastomer implementation cases 1-10 of the present invention are listed in Table 1. Unless otherwise specified, the data in Table 1 are all parts by mass. The waste tire rubber powder with an average particle size of 200 μm was purchased from Jiangyin Anqiang High Wear-resistant Rubber Powder Co., Ltd.; the polypropylene with a yield strength > 24 MPa was selected from Yanshan Petrochemical K8303, Shanghai Petrochemical GM 160E and Maoming Petrochemical EPS30R, with a melt index > 5g / The 10-minute polypropylene uses Shanghai Petrochemical M2101R and Yanshan Petrochemical K9020; SEBS uses Formosa Plastics 6150; phenolic resin chooses HY-2045 from Shanxi Rubber Auxiliary Factory; fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com