Method for assembling fabric panels and product obtainable by said method

An assembling method and cutting technology, applied in the field of clothing or clothing products and/or bags, can solve the problems of complex and difficult adjustment and achieve the effect of strengthening the assembly seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

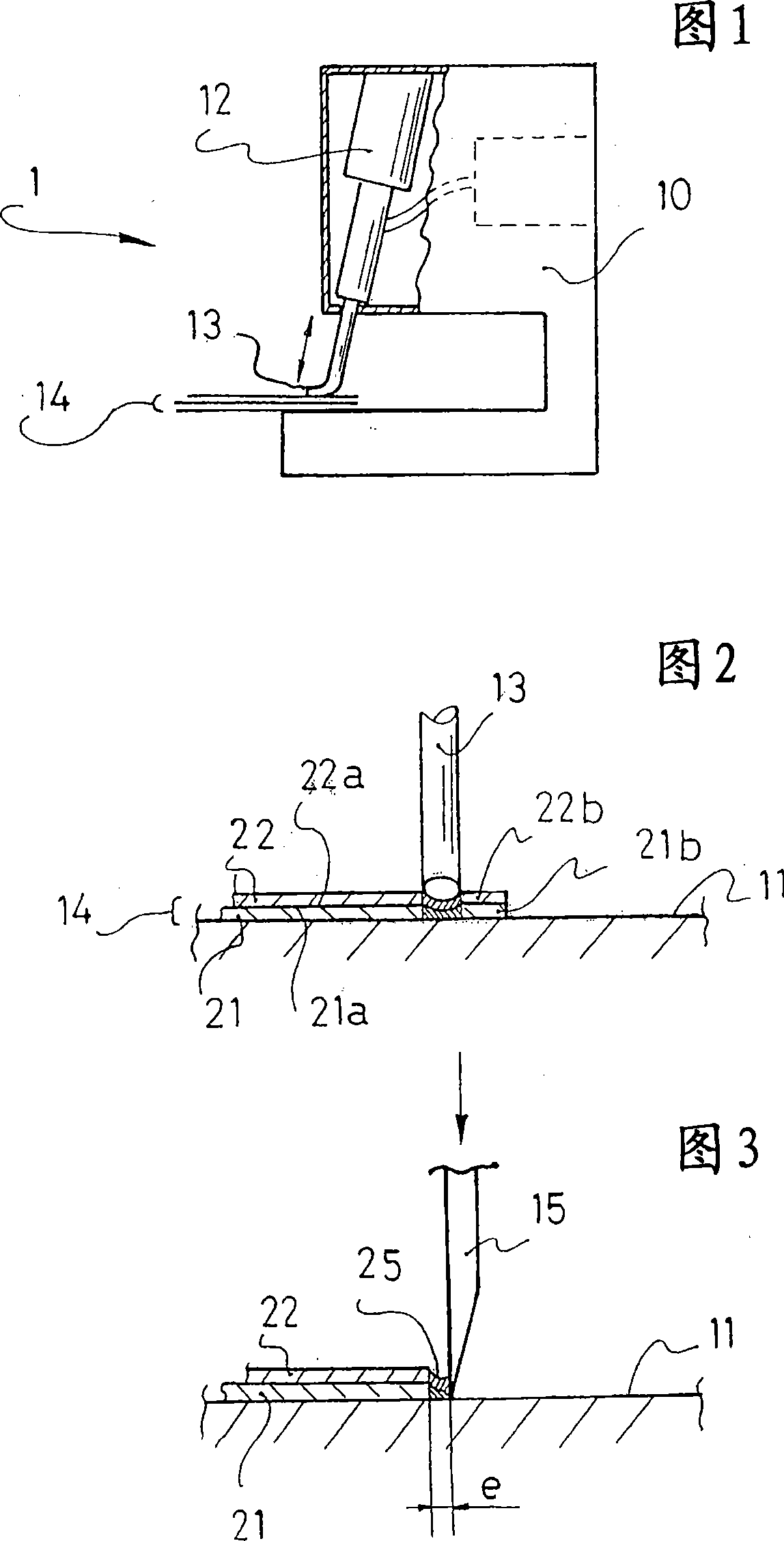

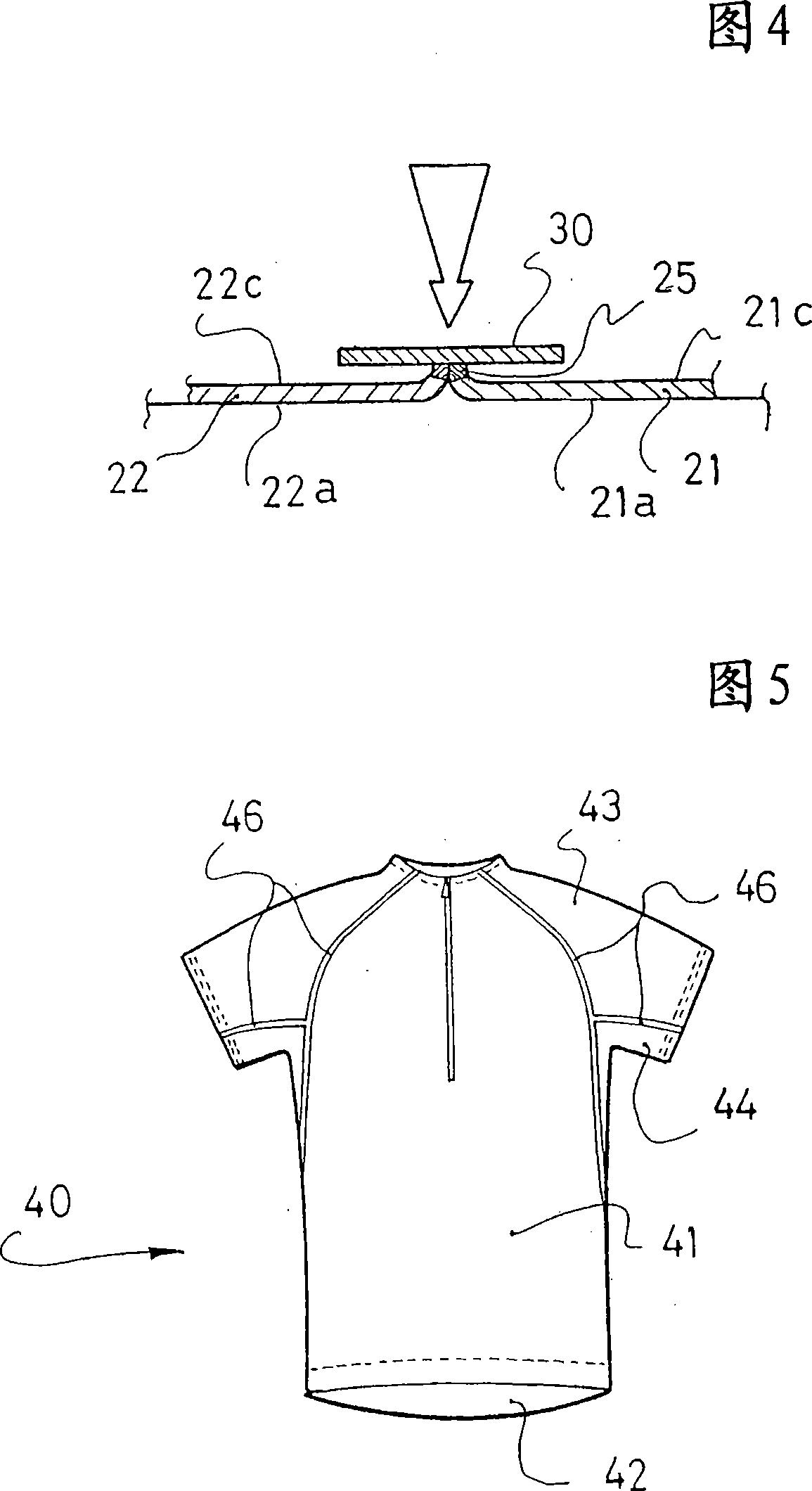

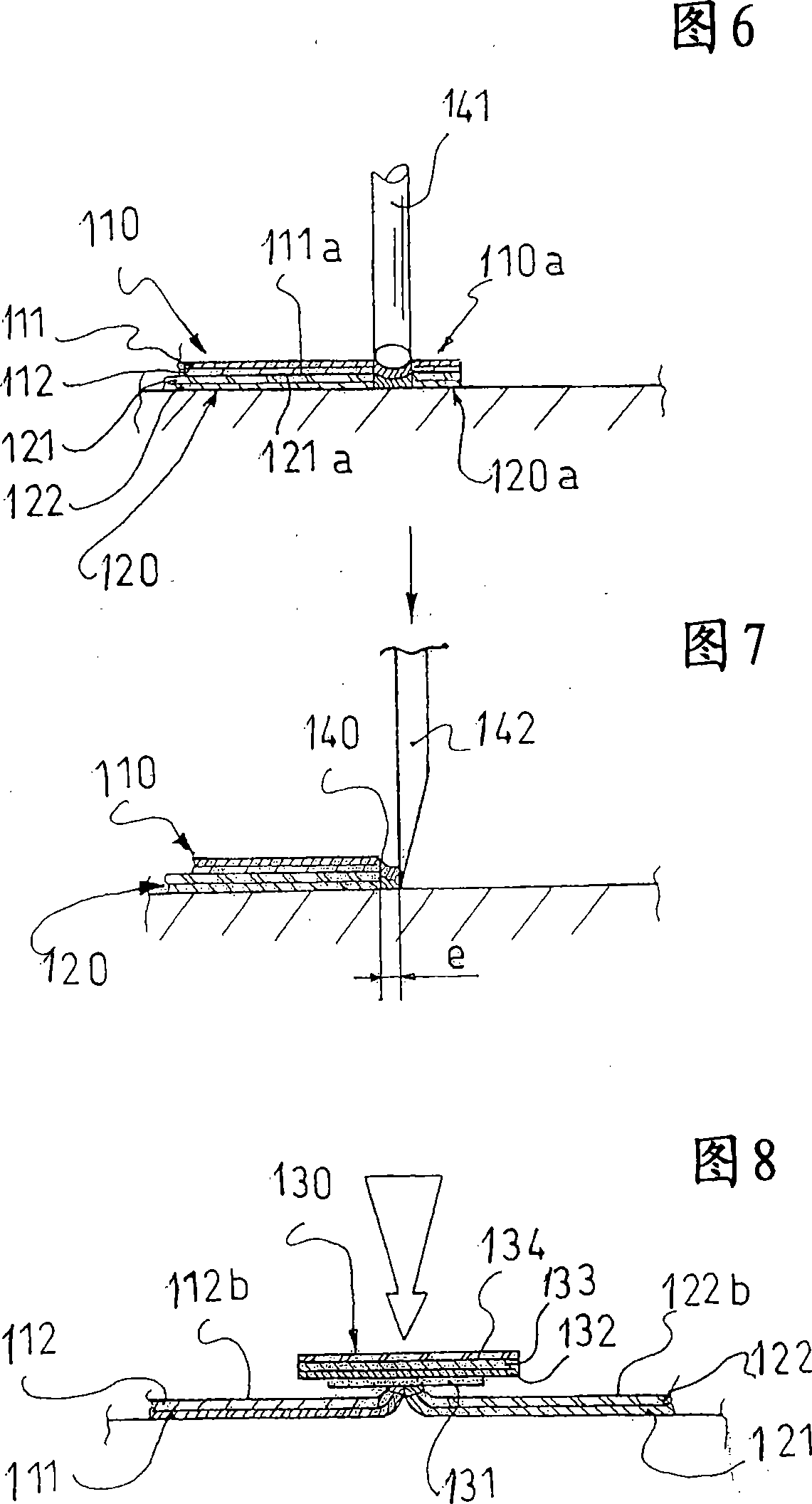

[0054] [54] FIGS. 1 to 4 show the different steps of the assembly method given in accordance with the first embodiment of the present invention by means of an ultrasonic fusion machine 1 .

[0055] [55] Such machines are known, for example, from patent US 3,817,802 and will therefore not be described in detail. The machine comprises: a frame 10 supporting the ultrasonic motor or vibrator 12 ; a support plate 11 for objects 14 to be fused; and a fusion device 13 .

[0056] [56] There are also other ultrasonic fusion machines in which, at a pressure of a few bars, the elements to be fused are advanced between two rotating fusion tools, which can accomplish the assembly in the form of a sewing machine.

[0057] [57] In the principle of ultrasonic fusion, vibrations with a frequency between 20 and 30 KHz are applied to the fusion tool by the vibrator. The vibrations heat the two layers of the material to be assembled and cause them to fuse to each other.

[0058] [58] Of course,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com