Overlapping integral type prefabricated assembly structure for comprehensive pipe gallery and construction method thereof

A technology of prefabricated assembly and integrated pipe gallery, which is applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve problems such as water seepage and water leakage in the joints of prefabricated components, and the inability to ensure the safety of force between nodes. Strengthen strength and rigidity, save construction period and cost, and ensure the effect of effective connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

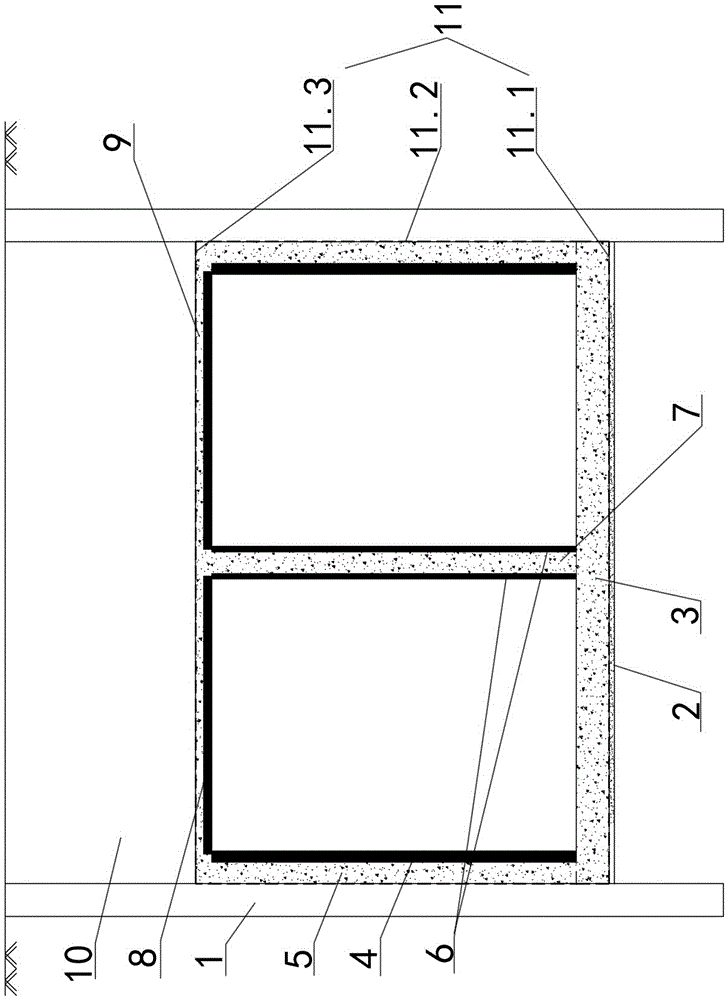

[0046] Examples see figure 1 As shown, a prefabricated assembly structure of a superimposed integral comprehensive pipe gallery is the construction of the main structure of a single-layer double-span comprehensive pipe gallery.

[0047] The prefabricated assembly structure includes the enclosure structure 1 located in the foundation pit, the prefabricated assembly structure of the pipe gallery arranged between the enclosure structures 1, the floor cushion 2 under the prefabricated assembly structure of the pipe gallery, and the outer surface cladding of the prefabricated assembly structure of the pipe gallery The fully outsourcing waterproof layer 11, the top of the pipe gallery prefabricated assembly structure is filled with backfill cover soil 10, and the bottom plate cushion layer 2 is laid horizontally along the lower side of the pipe gallery prefabricated assembly structure;

[0048] The prefabricated assembly structure of the pipe gallery is composed of a cast-in-place b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com