Construction method for soft rock deformation tunnel lining support dismantling-replacing arch

A construction method and lining technology, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc., can solve problems such as unsafe construction, and achieve the effects of large construction space, saving construction period, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

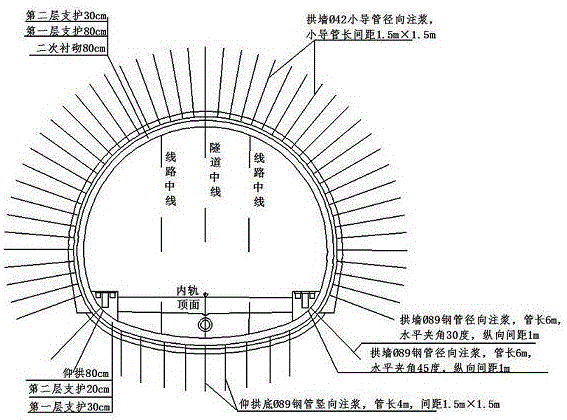

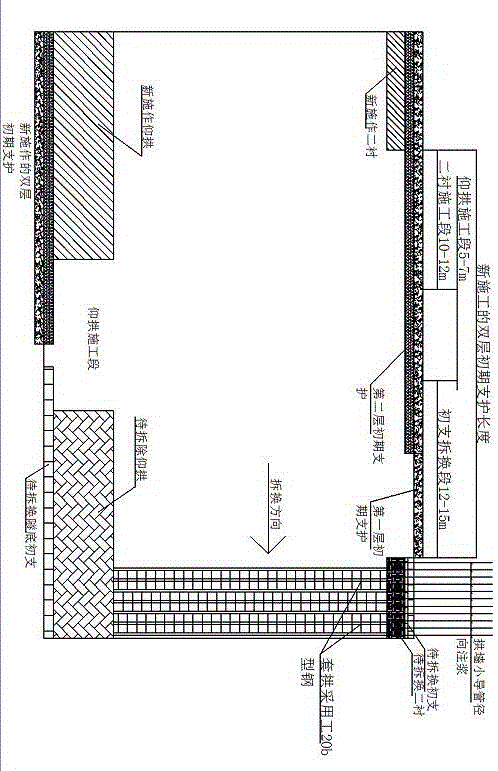

[0040] In order to overcome the problem that the existing method cannot dismantle and replace the lining support of the whole section at one time, and the construction is unsafe, the present invention provides such figure 1 , figure 2 Shown is a construction method for removing and replacing arches for the lining support of soft rock deformation tunnels. The present invention does not set a pedestal for reinforcing the lining, but adopts temporary arches, which has a large construction space and is conducive to rapid mechanized construction. The original bearing capacity, integrity, erosion and waterproof and anti-seepage properties of the lining structure; construction workers can work safely under effective protection, which can effectively avoid and reduce the risk of top falling blocks or landslides during the removal of the initial support Danger, shorten the operation cycle time, and gradually advance the operation in depth, which speeds up the construction progress and...

Embodiment 2

[0063] On the basis of Example 1, in the third step in this example, before removing the primary support to be replaced, the arch wall is reinforced by radial drilling and grouting on the lining surface with a φ42 small conduit. The length of the small conduit is 5.5m , spacing 1.5m×1.5m, quincunx layout, grouting pressure 1.0MPa-3MPa, design grouting amount per linear meter is 3.5m 3 ;Use φ89 steel pipes on the top surface of the inverted arch filling to carry out vertical drilling and grouting reinforcement on the base of the inverted arch. The length of the steel pipes is 5.2-6.5m, and the spacing is 1.5m×1.5m. Eyes, the diameter of the eye hole is 10-16 mm, and the length of the tail is not less than 100 cm without drilling.

[0064] Use section steel to carry out arch reinforcement work for the second lining to be removed. Before demolition, temporary arch reinforcement should be erected on the arch wall. The arch is made of I-20b section steel with a spacing of 1 榀 / 0.6m....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com