Patents

Literature

164results about How to "Large construction space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

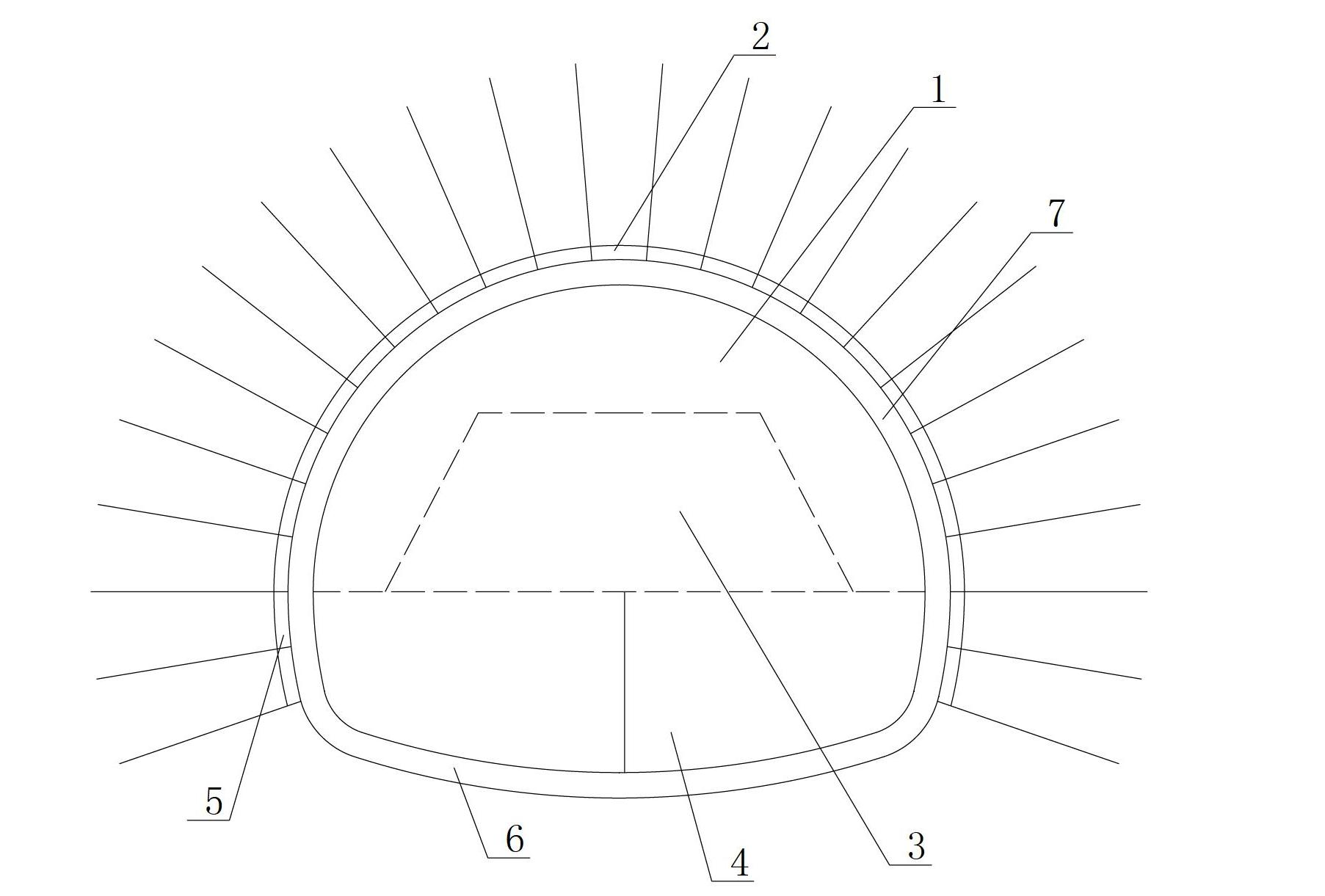

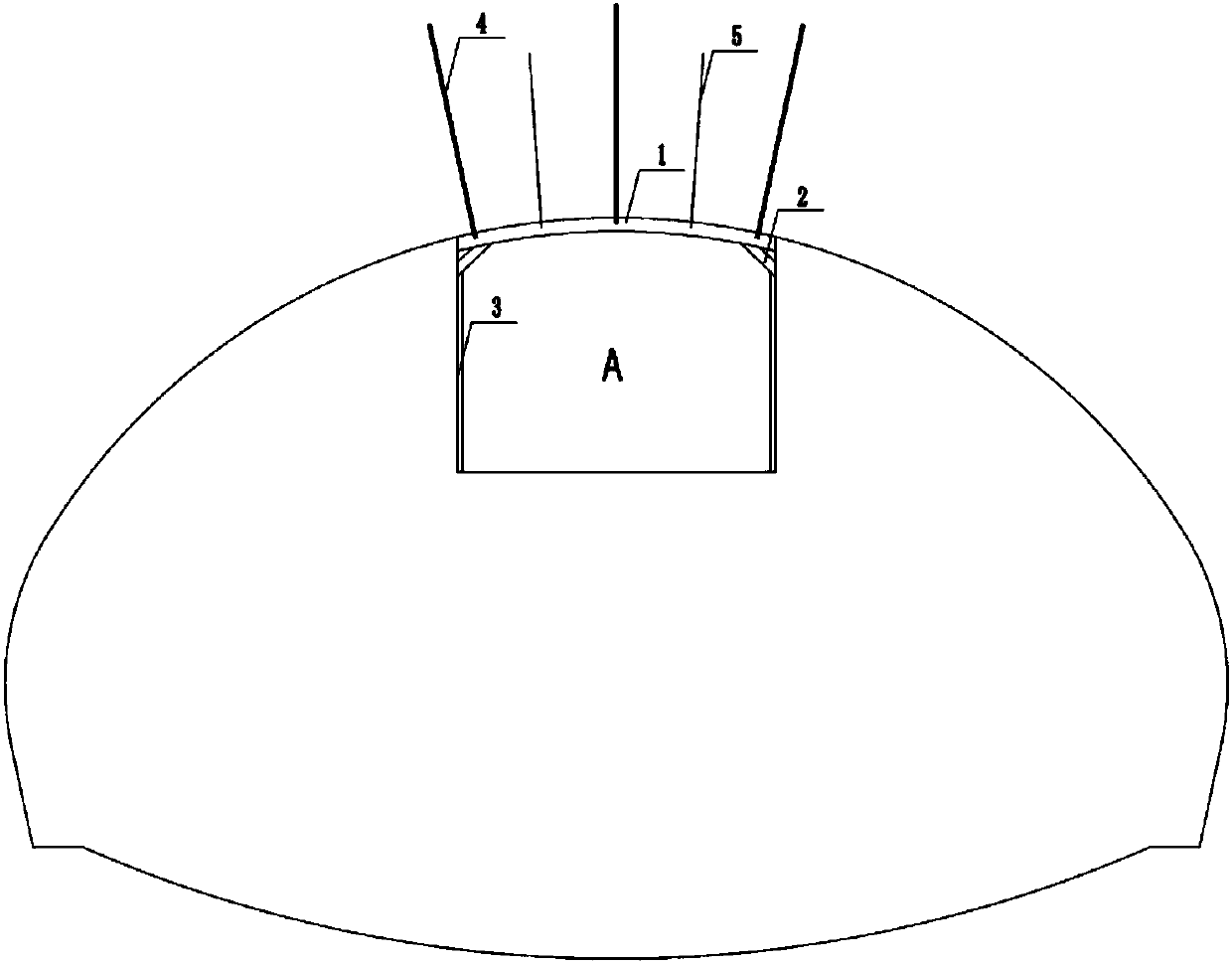

Tunnel dredging method suitable for railway large section IV, V class rock tunnel

ActiveCN101105131ASimple and fast operationLarge construction spaceUnderground chambersTunnel liningRailway tunnelRock tunnel

The invention relates to the technical field of railway tunnel construction, specifically a digging method of IV and V-class surrounding rock railway tunnel with large cross section, aiming to solve the problems of the existing railway tunnel digging method including narrow operation space, low work efficiency, inflexible construction method, instable construction progress, high deformation potential of surrounding rock, and inconvenient operation. The method comprises performing leading support, digging arc-shaped pilot tunnel and preserving core soil; staggeredly digging left / right side walls of middle sidestep and preserving core soil; staggeredly digging left / right side walls of lower sidestep and preserving core soil; sequentially digging upper, middle and lower sidesteps and preserving core soil; and digging inverted arch and carrying out preliminary support. The invention has large construction space and high work efficiency, and can perform multi-job parallel operation. When the geologic conditions are changed, the invention can be flexibly and timely converted to other construction method. Preservation of core soil and left / right staggeredly digging are helpful to the stability of the digging working face. When the surrounding rock has large deformation, the invention can adjust closure time as soon as possible under the prerequisite of assuring safety and meeting requirements of clearance cross section.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

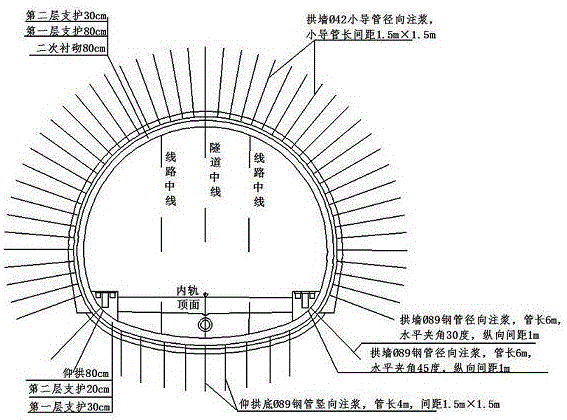

Construction method for soft rock deformation tunnel lining support dismantling-replacing arch

InactiveCN105781571AGuaranteed carrying capacityGuaranteed integrityUnderground chambersTunnel liningEngineeringLarge deformation

The invention provides a construction method for a soft rock deformation tunnel lining support dismantling-replacing arch. One-time whole section integral dismantling and replacing of a lining support is achieved. The construction method has the advantages that before dismantling and replacing, a lining which loses bearing capacity is subjected to grouting reinforcement treatment first, then a temporary cover arch is additionally arranged outside for reinforcement, and afterwards, the lining support is dismantled step by step, so that potential safety hazards caused by dismantling or removing of a temporary platform frame are avoided, and some security risks are avoided effectively. According to the construction method, the construction difficult problem of soft rock large deformation occurs during construction of a tunnel in special and complex geology is solved. Through the created novel construction method, the construction difficult problem of second lining cracking deformation needing remediation due to weak surrounding rock large deformation is solved. Through the construction method, safe, fast and economic treatment and remediation of the lining support and arch replacing construction are achieved, and the tunnel structure stability and construction safety are ensured effectively.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

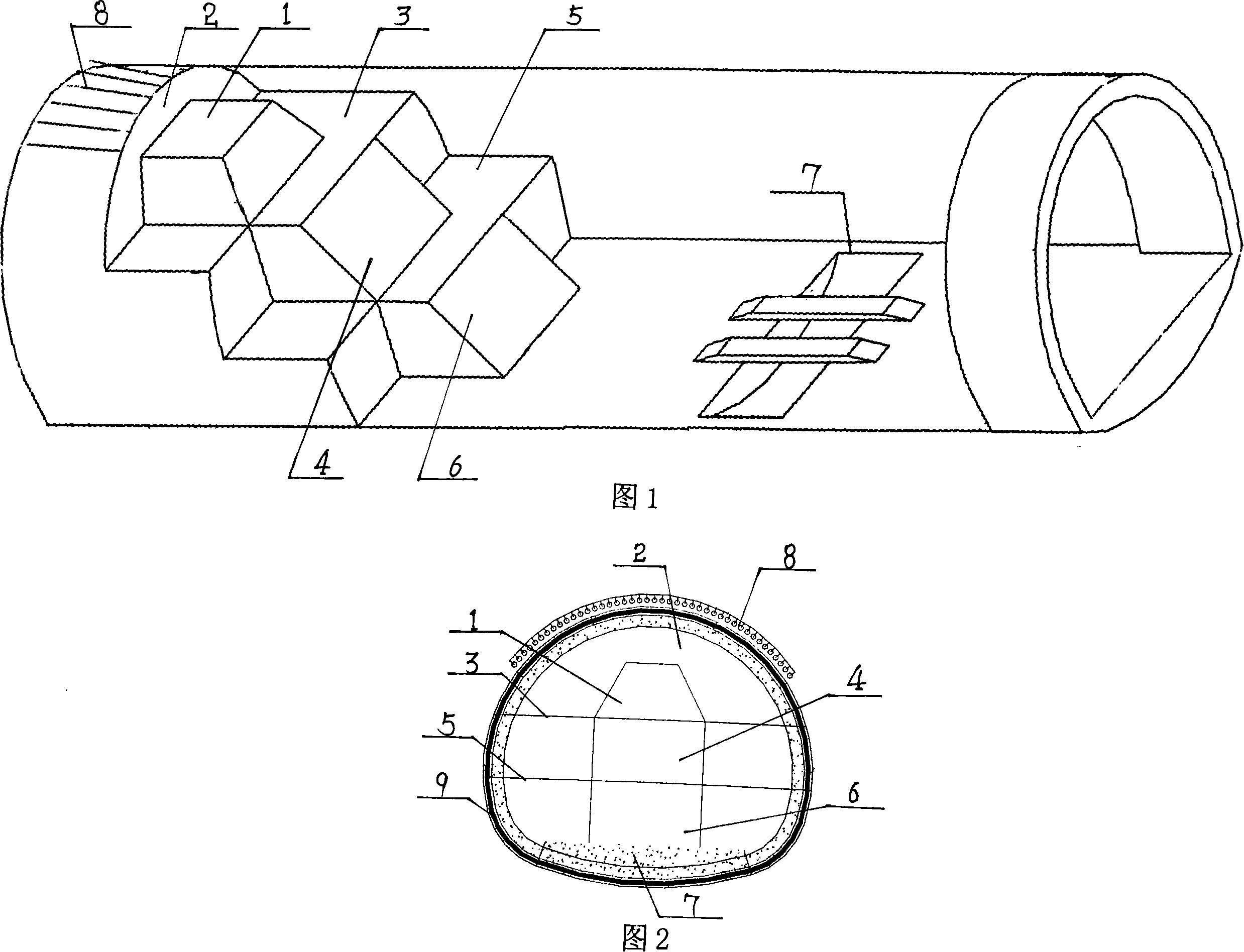

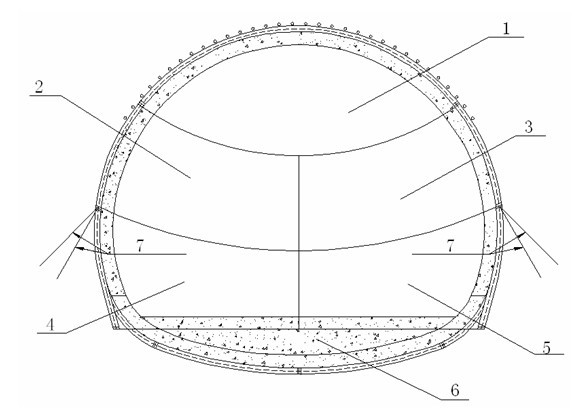

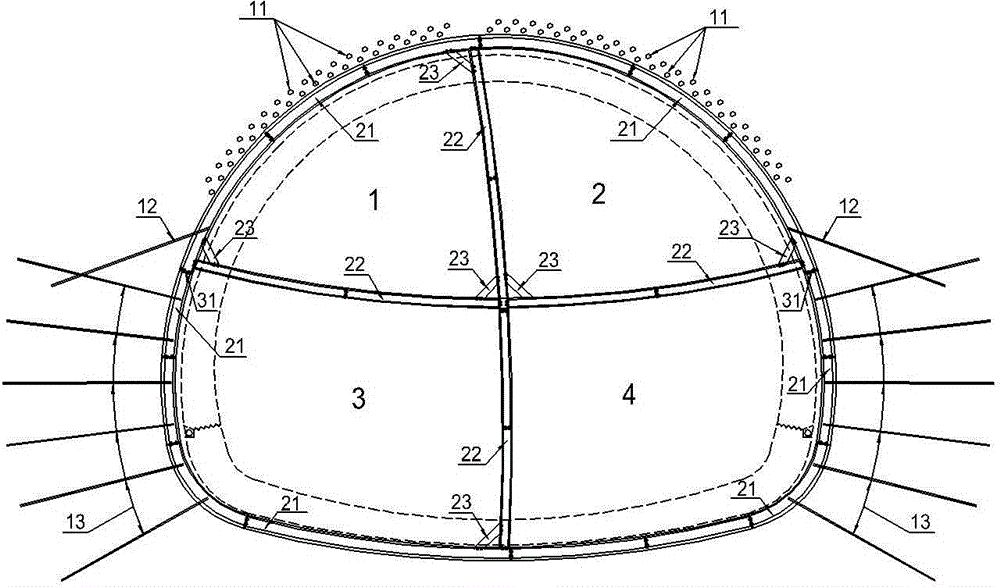

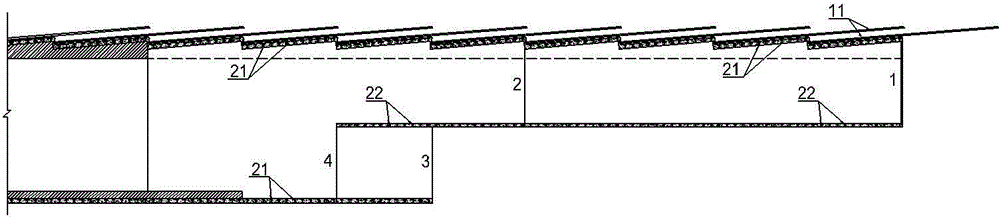

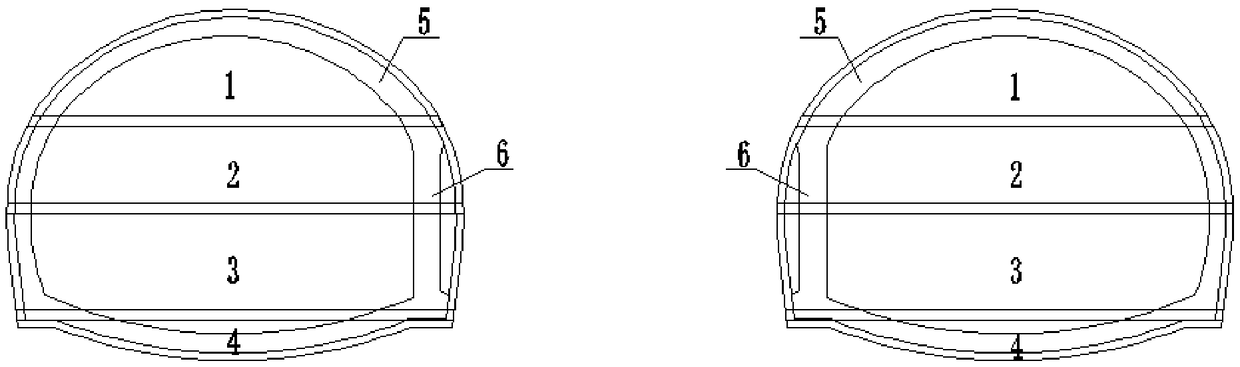

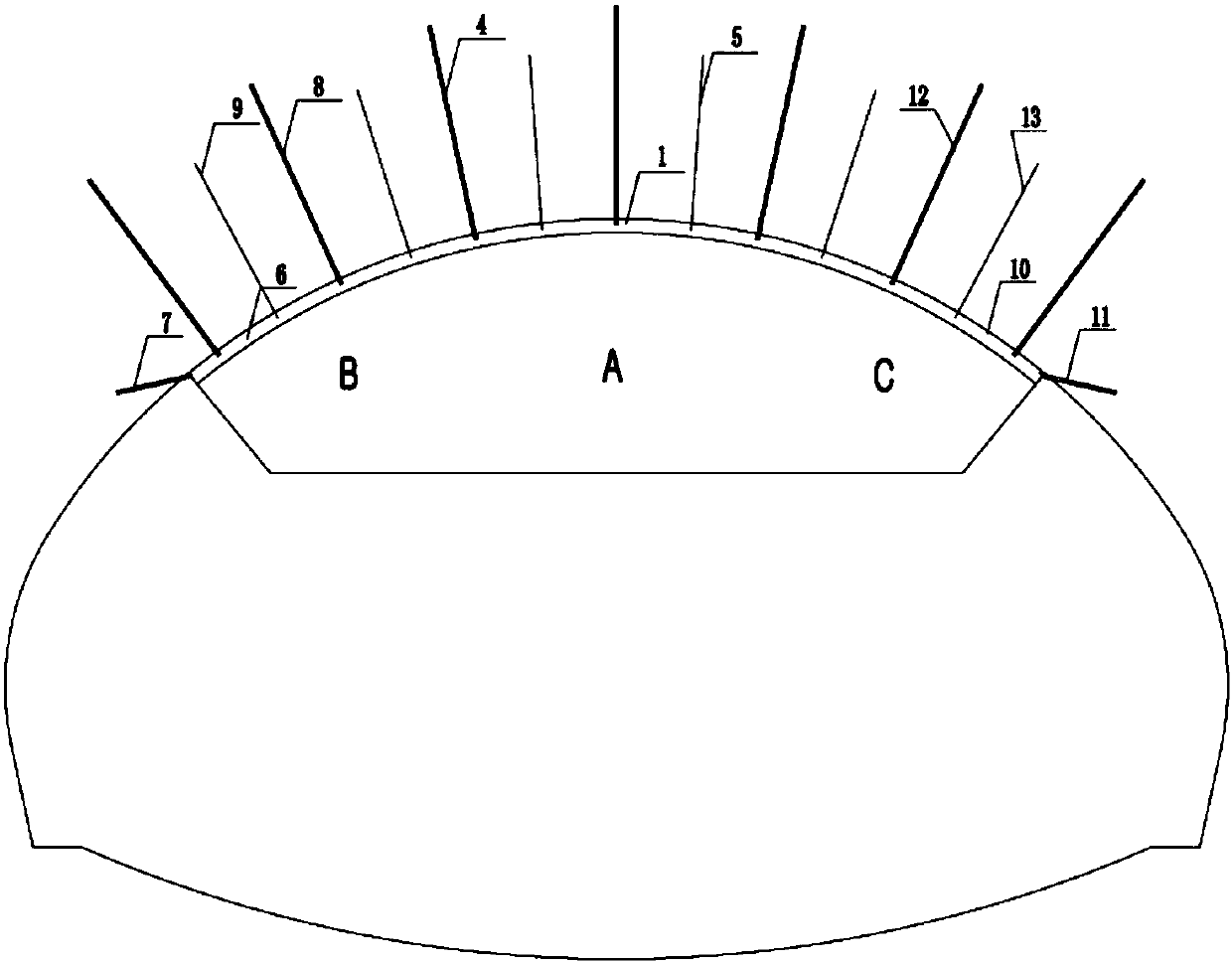

Large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method

ActiveCN102562075AMeet the requirements for enhanced controlsSpeed up early closure timesUnderground chambersTunnel liningShortest distanceRock tunnel

The invention discloses a large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method, which comprises the steps as follows: (1) annularly excavating an upper step of an upper part arc pilot tunnel, transferring excavated earthwork of the upper step to a lower step; (2) excavating a left part of a middle step about 4.5-5 meters behind the upper step, and transferring excavated earthwork to the lower step; (3) excavating a right part of the middle step about 3-4 meters behind the left part of the middle step, and transferring excavated earthwork to the lower step;(4) excavating a left part of the lower step about 6-8 meters behind the left part of the middle step or about 3-4 meters behind the right part of the middle step, and conveying excavated earthwork of the left part of the lower step out of the tunnel; (5) excavating a right part of the lower step about 3-4 meters behind the left part of the lower step, and conveying excavated earthwork of the lower step out of the tunnel; and (6) excavating the rest part of the tunnel bottom about 20-25 meters behind the right part of the lower step, excavating continuously according to the steps in a circulating and interlacing manner, and finally realizing tunnel excavating construction. The method can be used for building a large cross-section tunnel in a safe, rapid and economic manner.

Owner:CCCC SECOND HIGHWAY ENG CO LTD +1

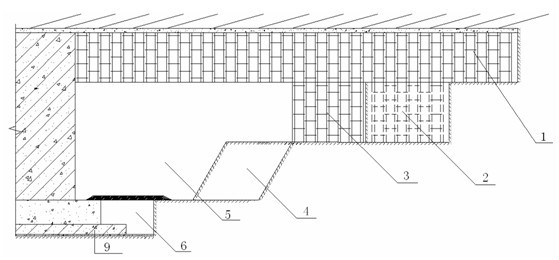

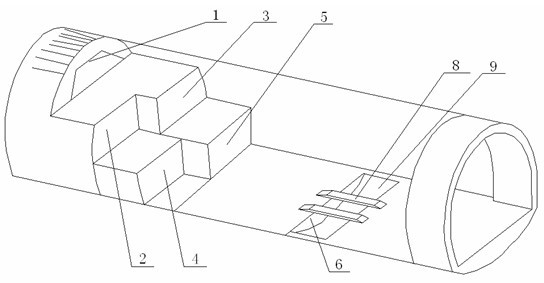

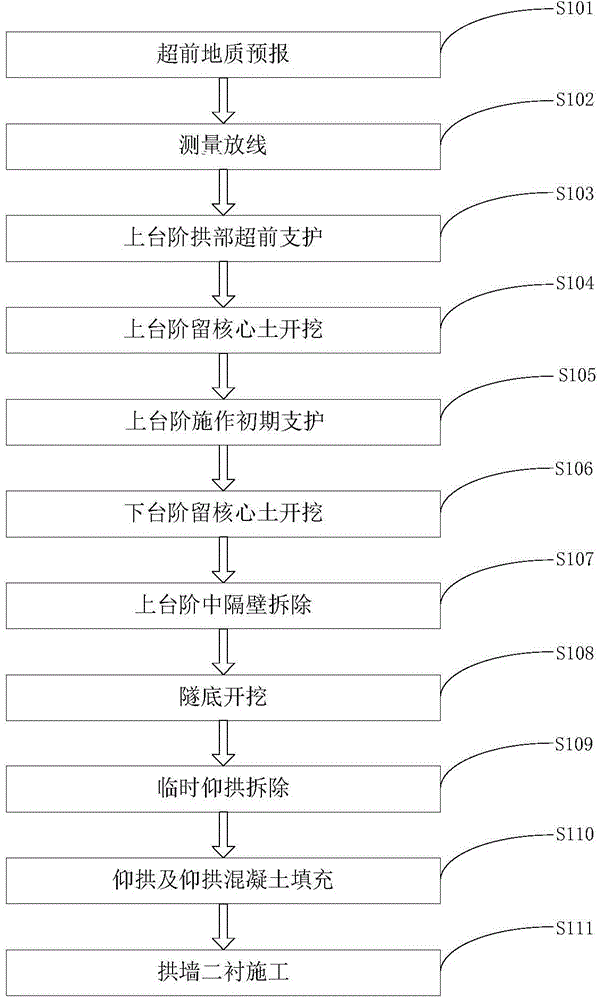

Method for constructing upper step middle partition wall of shallow-buried excavation tunnel

ActiveCN104612698ASuppression of extrusion displacementControl rear displacementUnderground chambersTunnel liningEconomic benefitsSupport materials

The invention discloses a method for constructing an upper step middle partition wall of a shallow-buried excavation tunnel. The method includes the steps of advanced geology forecast, measuring and setting-out, upper step arch advanced supporting, upper step excavation with core soil reserved, upper step application primary supporting, lower step excavation with core soil reserved, upper step middle partition wall detachment, tunnel bottom excavation, temporary inverted arch detachment, inverted arch and inverted arch concrete filling, and arch wall secondary lining construction. The method simplifies construction procedures, saves temporary supporting materials, accelerates the construction progress to 45-60 meters per month, reduces labor cost, effectively shortens the construction period, reduces engineering cost, solves various problems that the number of auxiliary procedures of shallow-buried excavation tunnel construction is large, construction process is slow and structure stress is complicate, reduces influences on surrounding environments, and achieves good social and economic benefits.

Owner:HANGZHOU TIANHENG INVESTMENT CONSTR MANAGEMENT +1

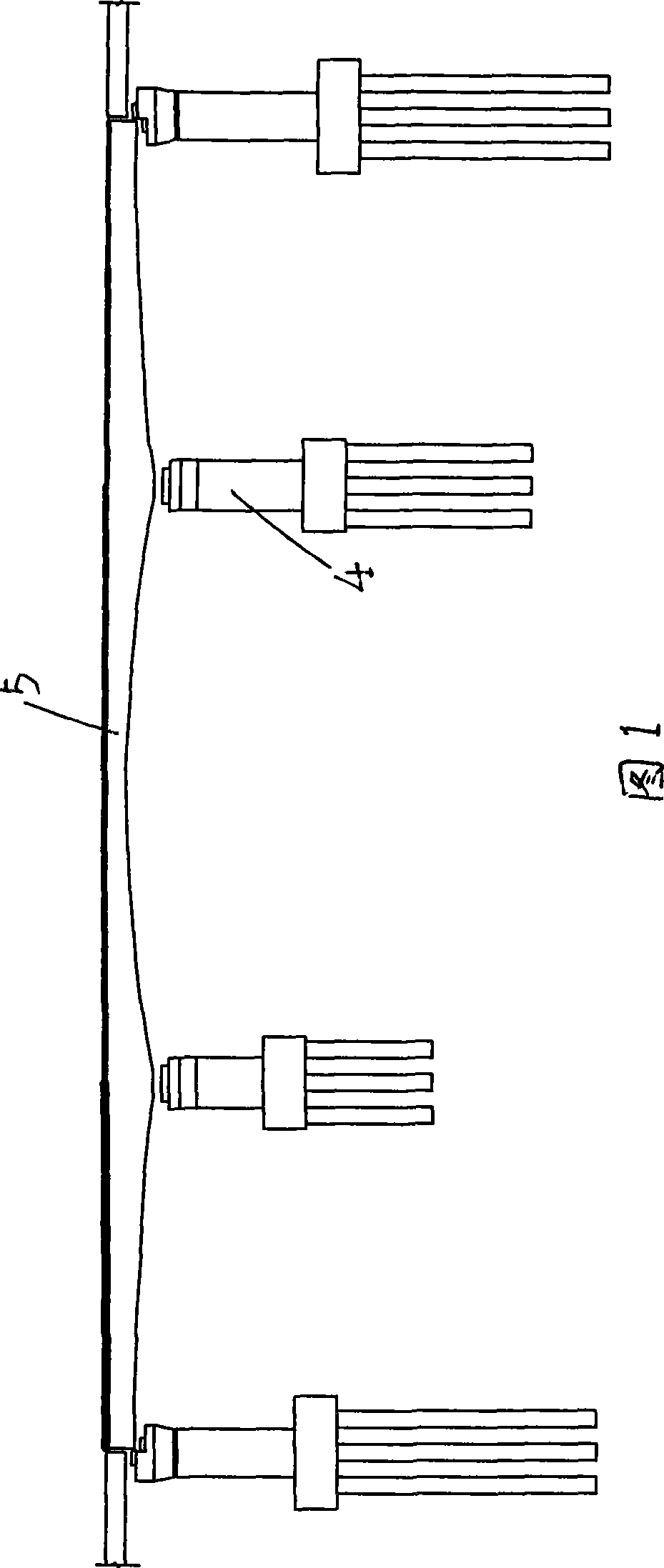

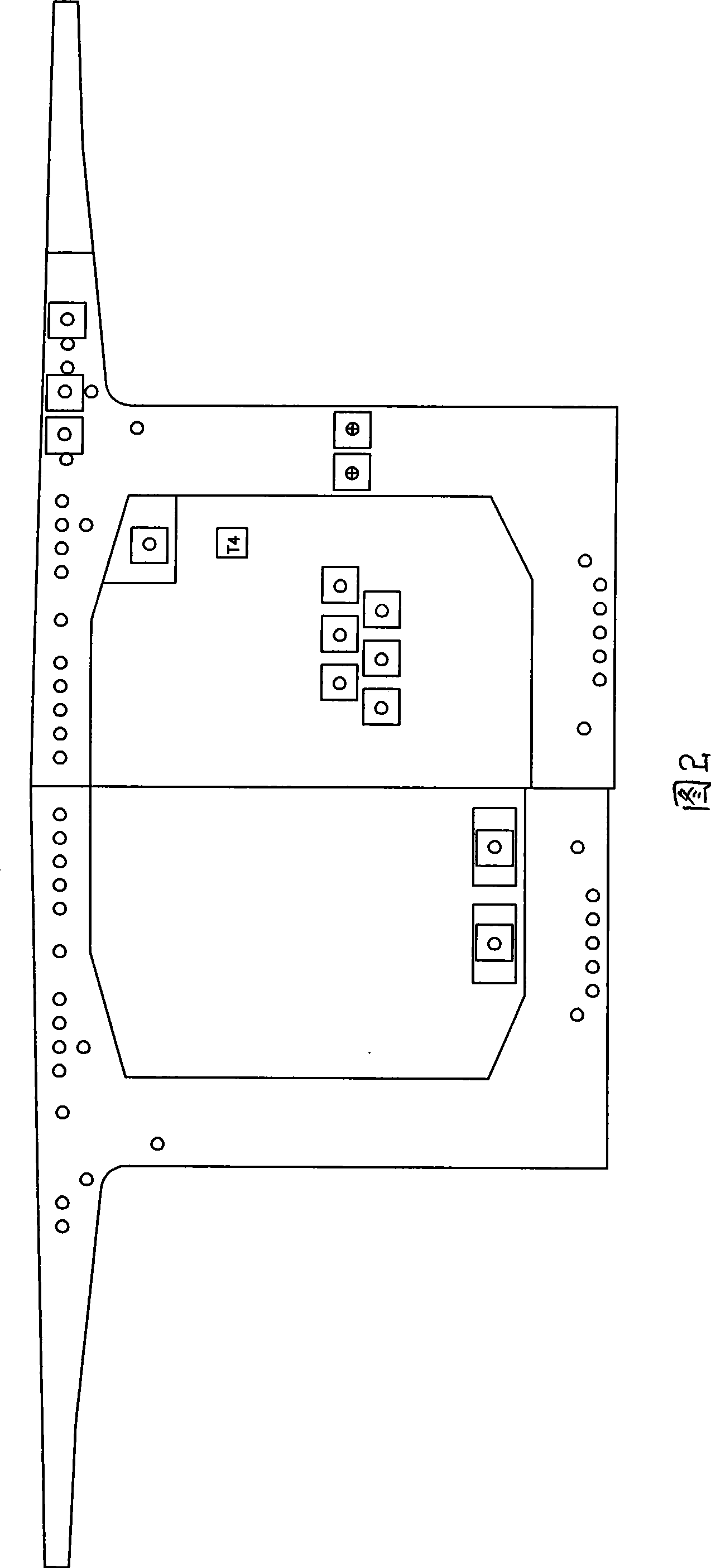

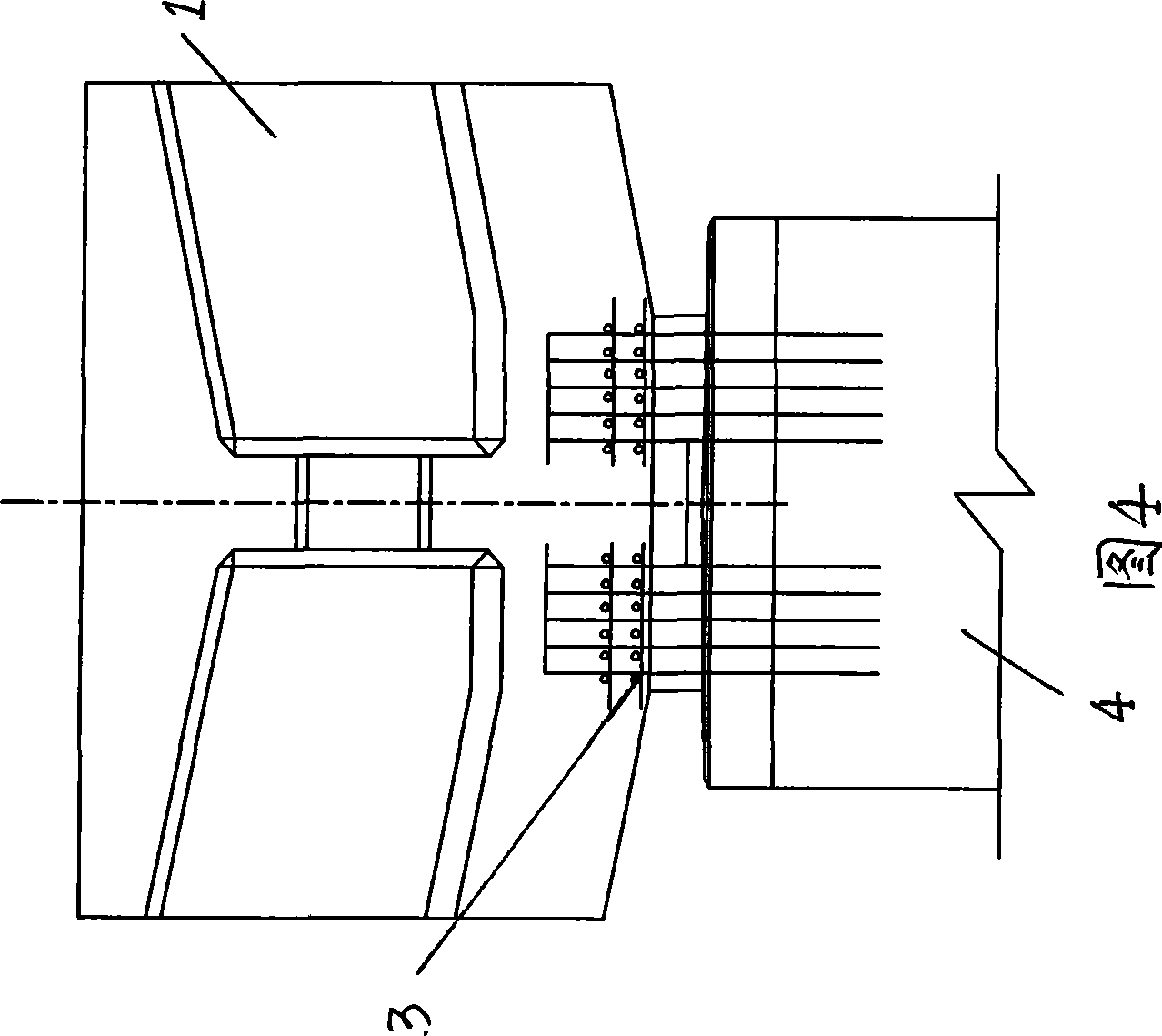

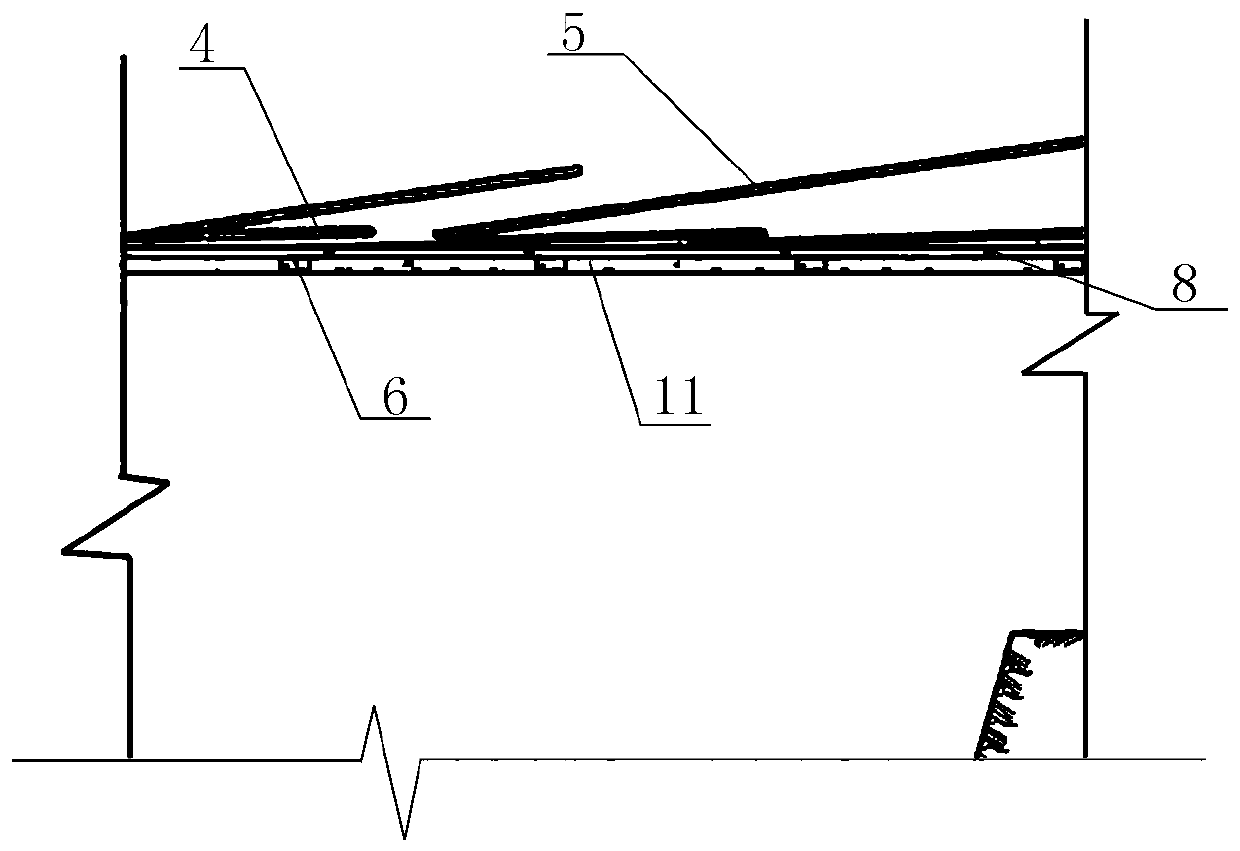

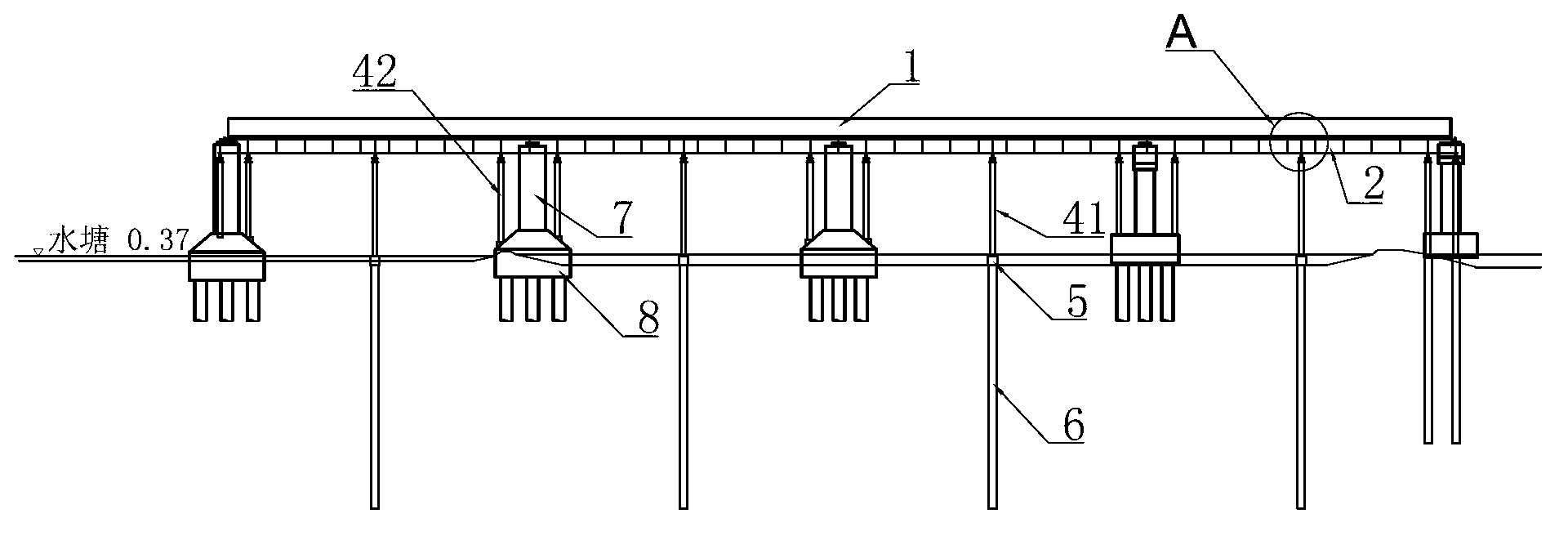

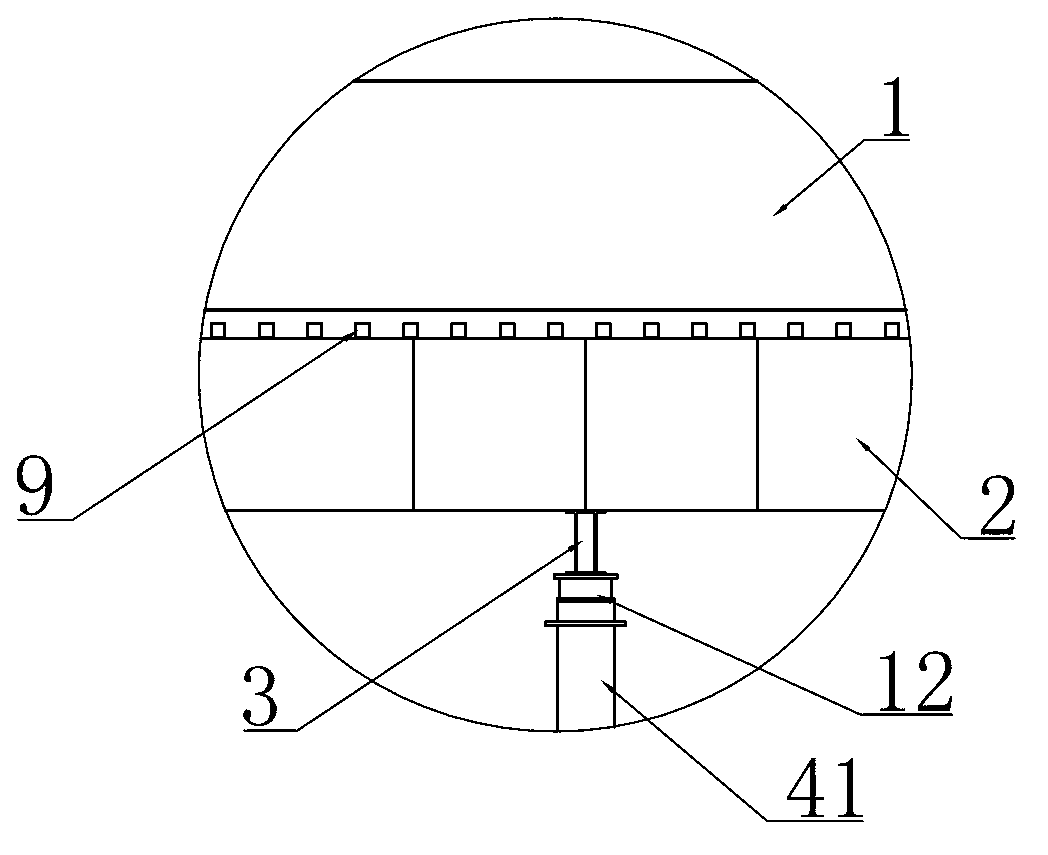

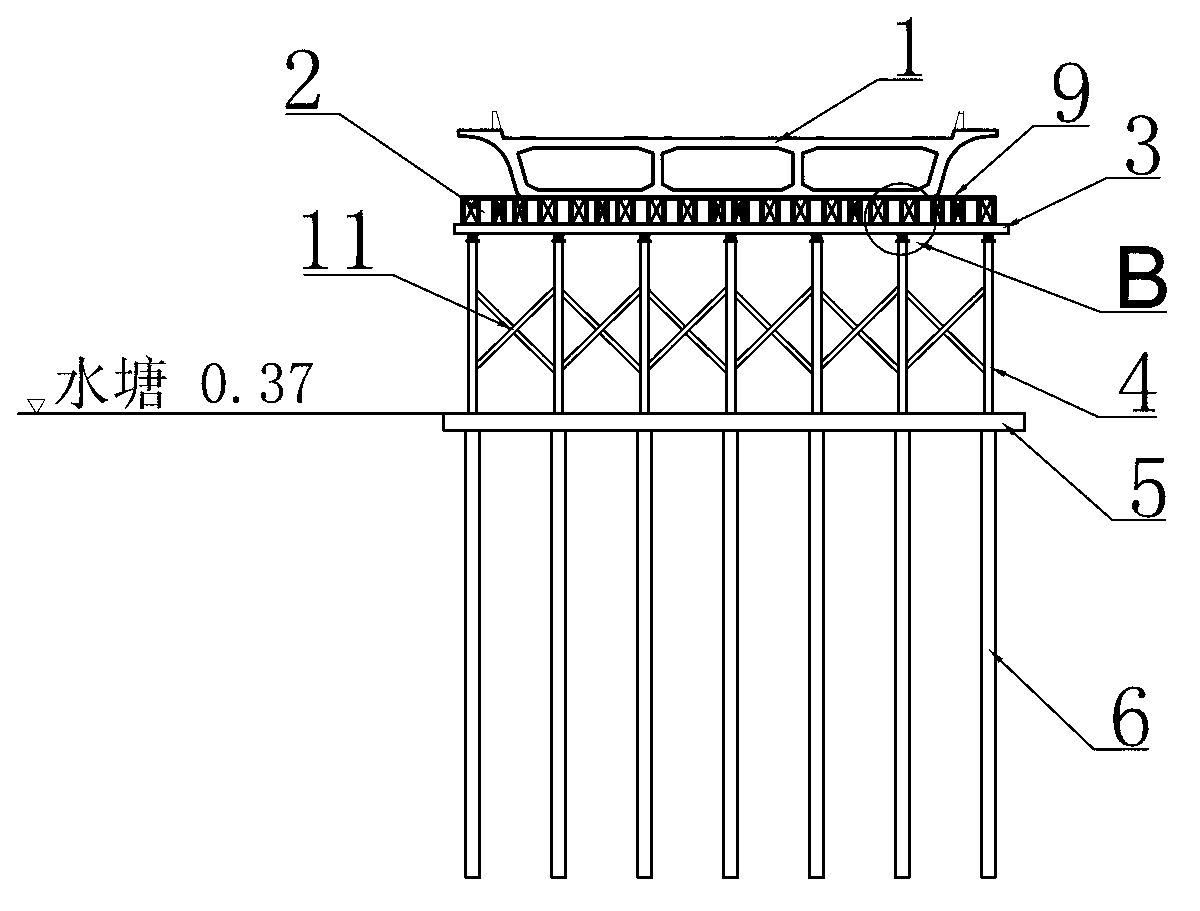

Cast-in-situ continuous beam construction method for special railway line stands

InactiveCN101368371AMeet the acceptance criteriaGood effectBridge erection/assemblyBridge materialsRebarPassenger transport

The invention relates to passenger dedicated railway line bridge construction field, in particular relates to a method for constructing a cast-in-site continuous girder on a passenger dedicated railway line, which is provided with brackets, solving the problems of narrow operation room, large equipment investment, large material consumption and trivial operation processes in bridge construction of a passenger dedicated railway line in the prior art. The method includes the following steps: groundsill treatment, frame linking, formwork fabrication, support preliminary compression, steel bar prefabrication, steel conduit and corrugated pipes installation, pedestal construction, concrete casting, and prestress construction. The pedestal construction includes temporary pedestal construction and permanent pedestal construction; the prestress construction includes tensioning and anchor seal. The prestressing tendon of the girder is pulled in the direction order of vertical, transverse and then vertical, and unshrinkable cement mortar is used during anchor seal. The construction space is big and a plurality of work surfaces can work in parallel or crosswise. The invention has the advantages of simple construction and wide applicability and is easy to operate. The invention is suitable for girders with different spans and structures and is simple in operation, small in material consumption, large in turnover frequency and low in work intensity and can save cost and is safe and reliable and easy to popularize.

Owner:THE 2ND ENG OF THE 12TH BUREAU GROUP OF CHINA RAILWAY

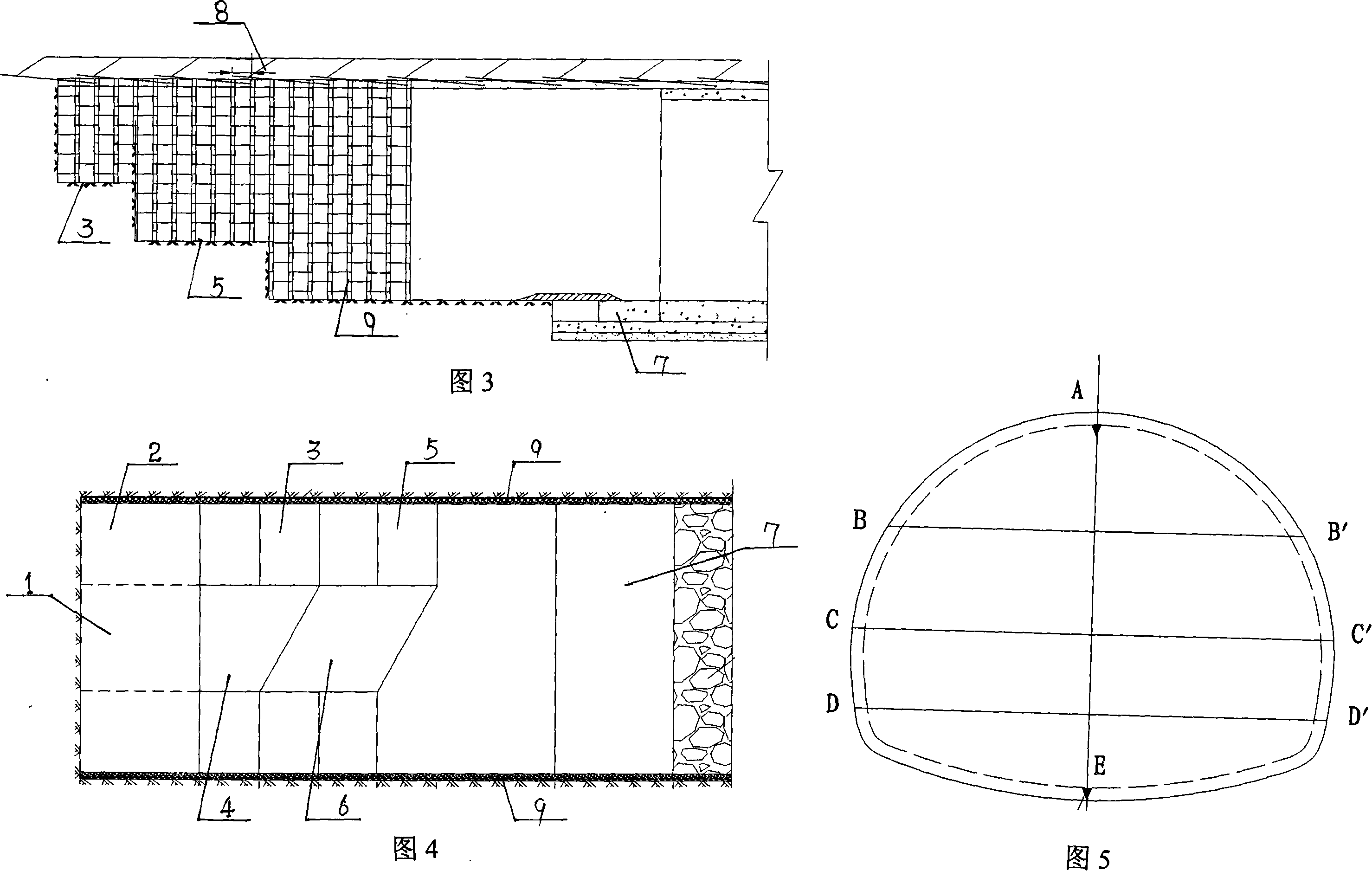

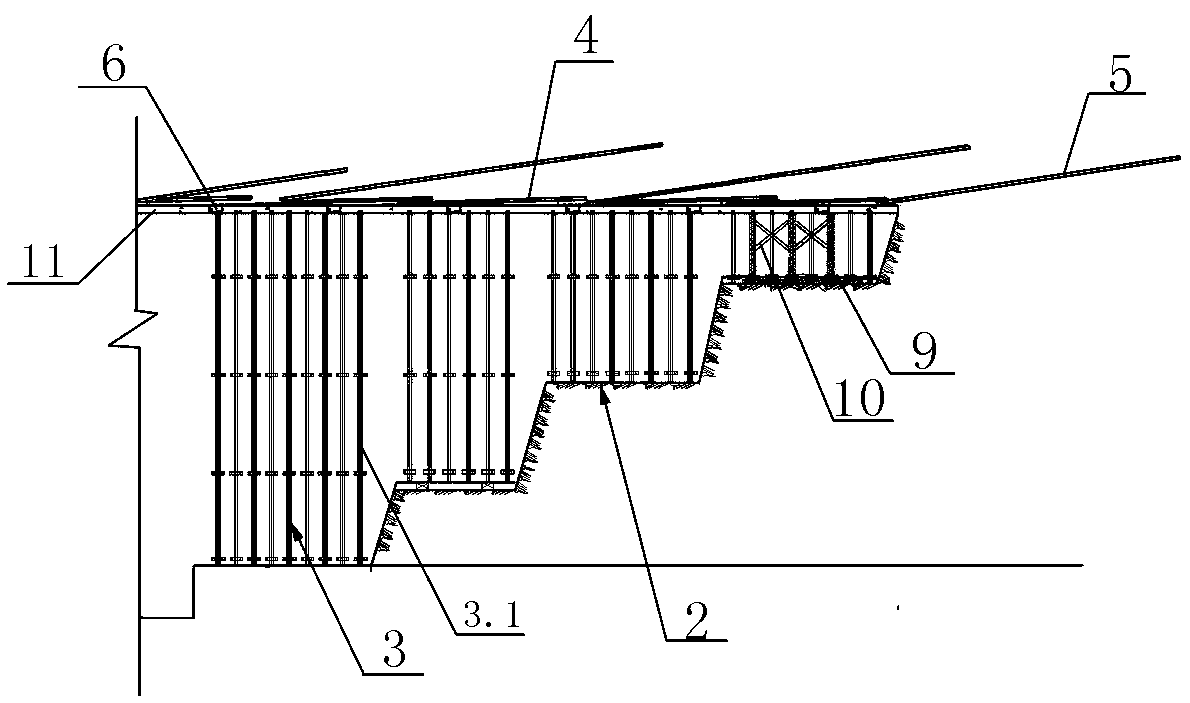

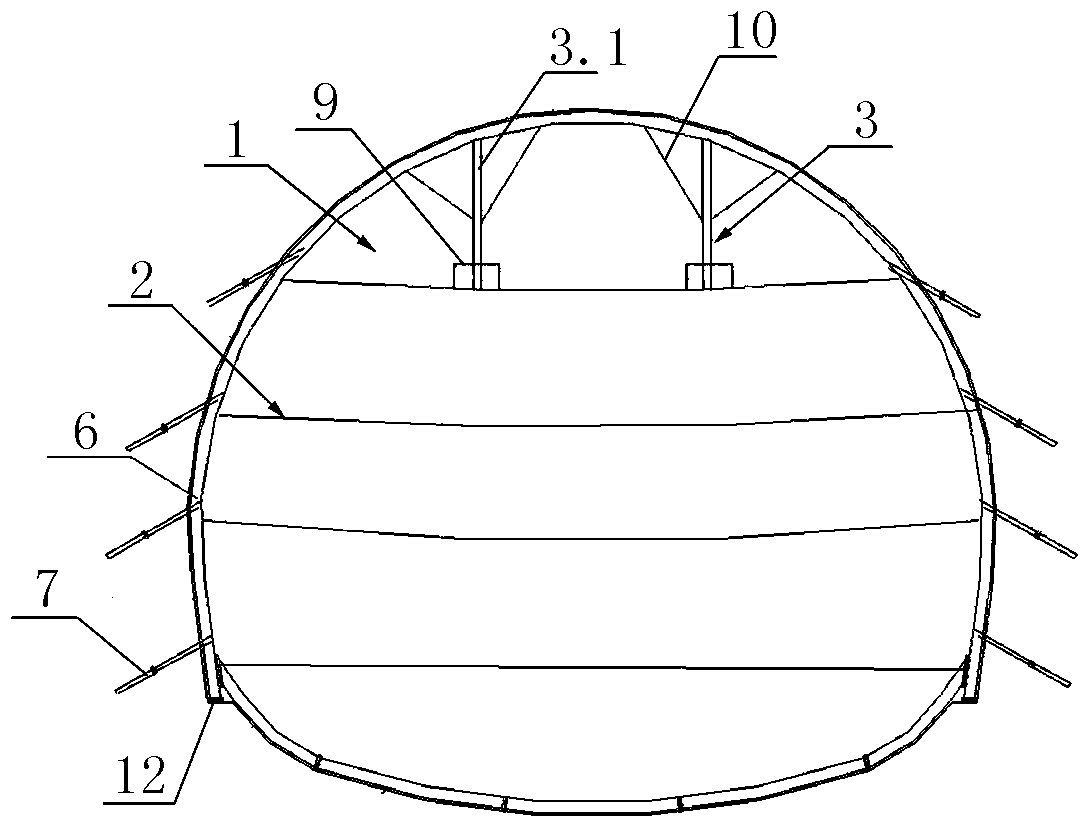

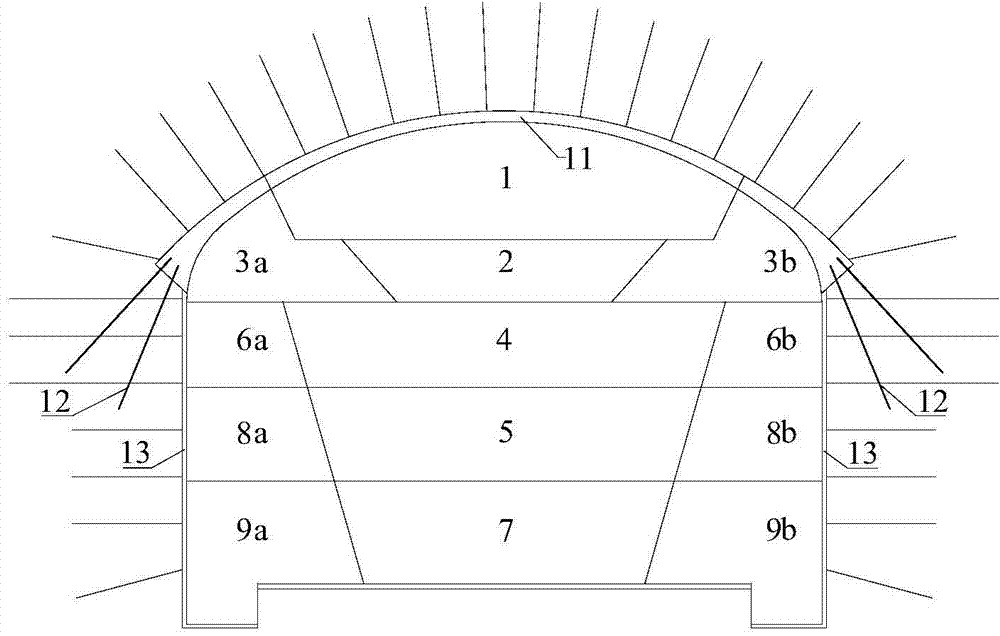

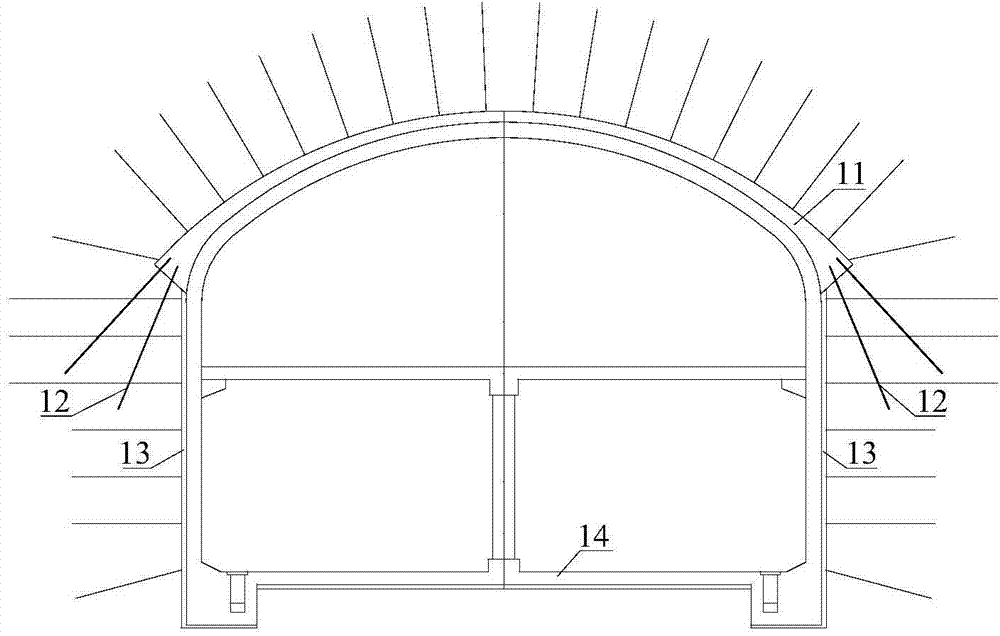

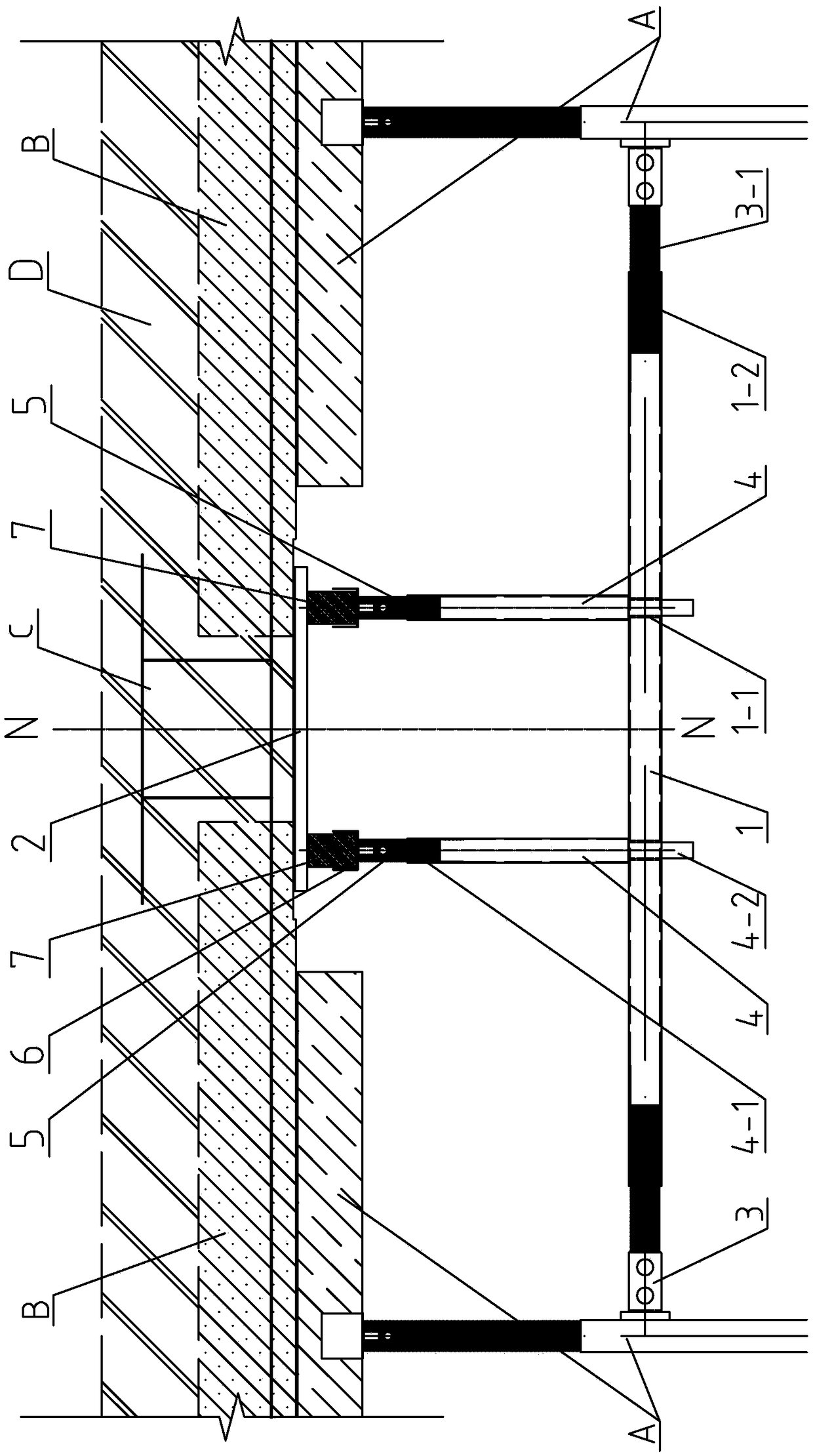

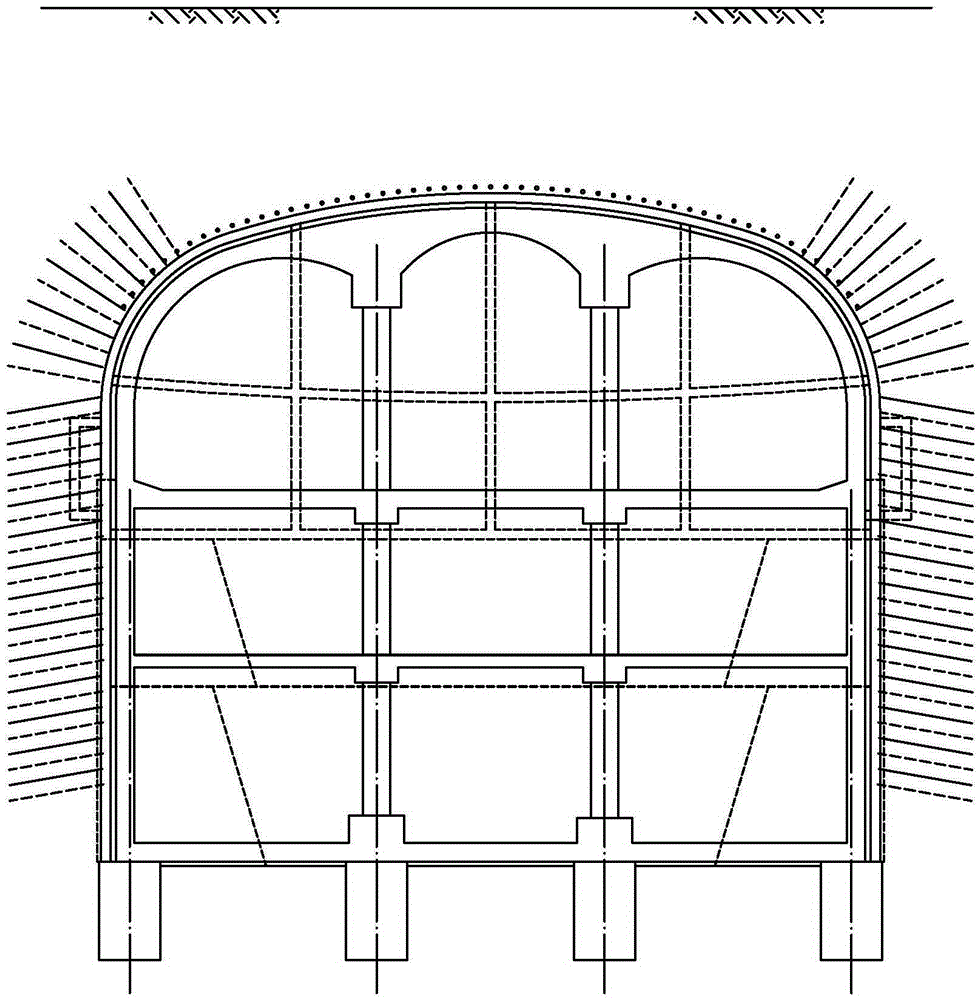

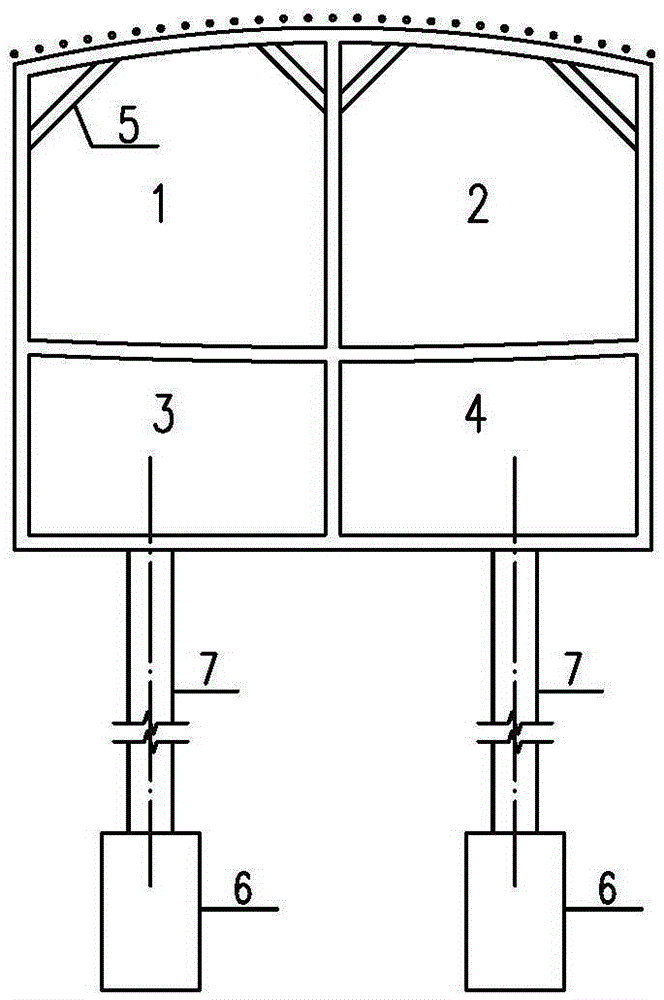

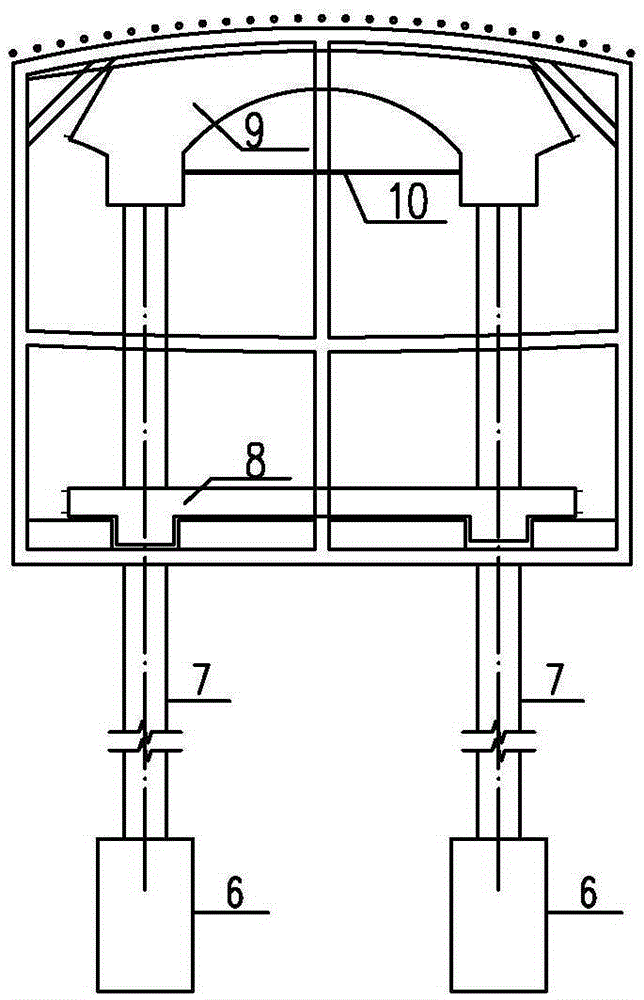

Excavation and supporting structure for weak surrounding rock super-large cross-section tunnel and construction method thereof

ActiveCN106351671ALarge construction spaceImprove ergonomicsUnderground chambersTunnel liningStructure of the EarthConductor pipe

The invention discloses anexcavation and supporting structure for a weak surrounding rock super-large cross-section tunnel and an operation method thereof. The weak surrounding rock super-large cross-section tunnel adopts six-step excavation and supporting for two side walls of an upper bench, and seven-step excavation and supporting based on a benching tunneling method are adopted for a lower bench. Before the excavation, an advanced small pipe is firstly adopted to perform an arch-part advanced support, and then a tunnel section is constructed in thirteen steps in a certain order. The excavation structure and method disclosed by the invention can ensure a large construction space for excavation, large-scale construction machinery can be introduced in each step, a plurality of construction sites can be constructed at the same time, so that high working efficiency is realized and construction progress is accelerated to a large extent, the number of temporary supports applied in a super-large cross-section construction process is reduced, the construction process is accelerated, temporary support removing process is simplified, safety is ensured, and efficiency is increased.

Owner:THE FIFTH ENGEERING OF CHINA RAILWAY 5TH BUREAU GROUP

Method for excavating mountain tunnels in weak surrounding rock-fractured zones or shallow covered slope sections

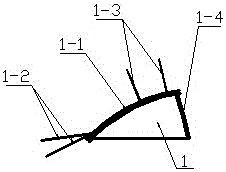

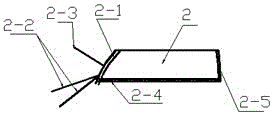

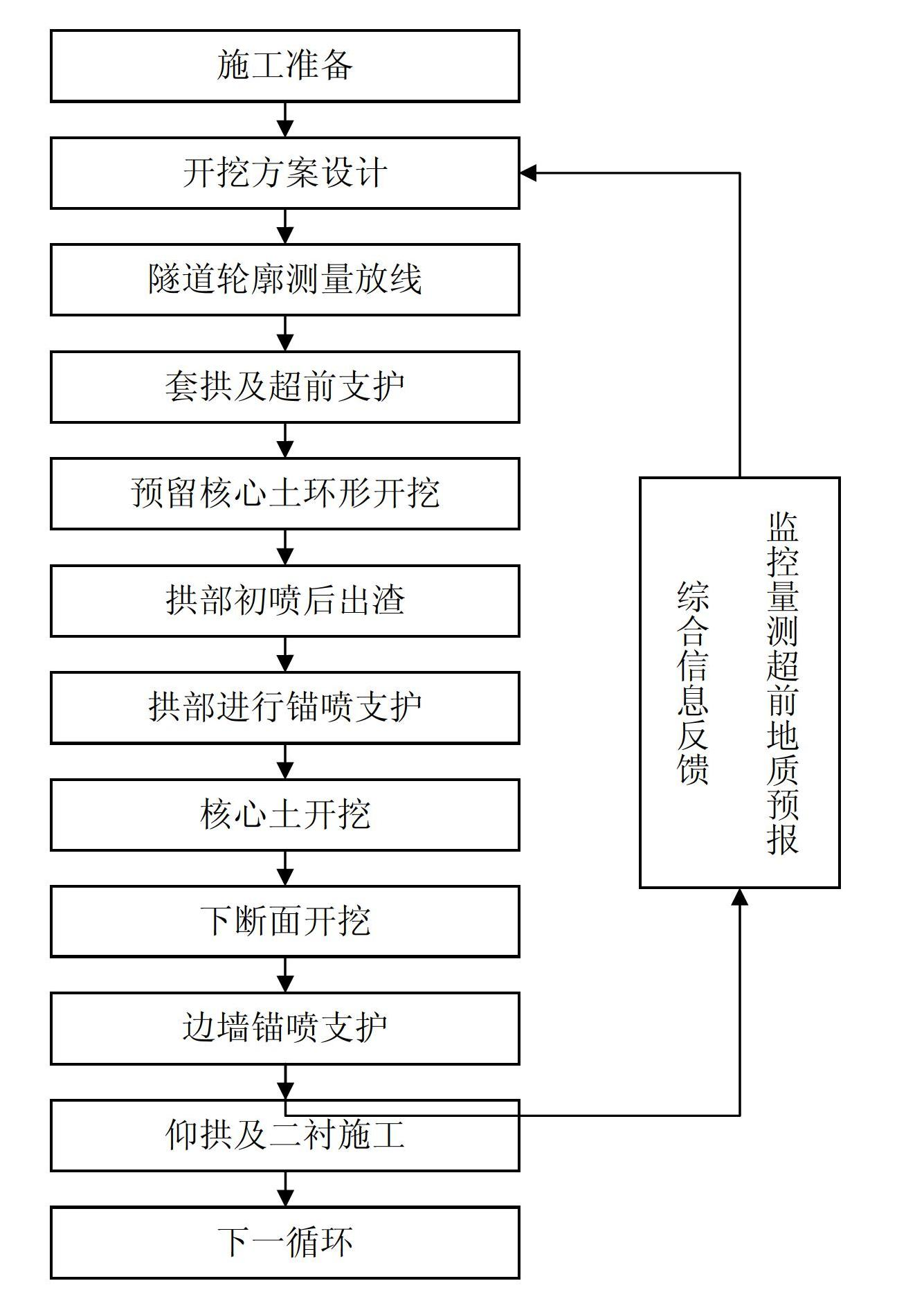

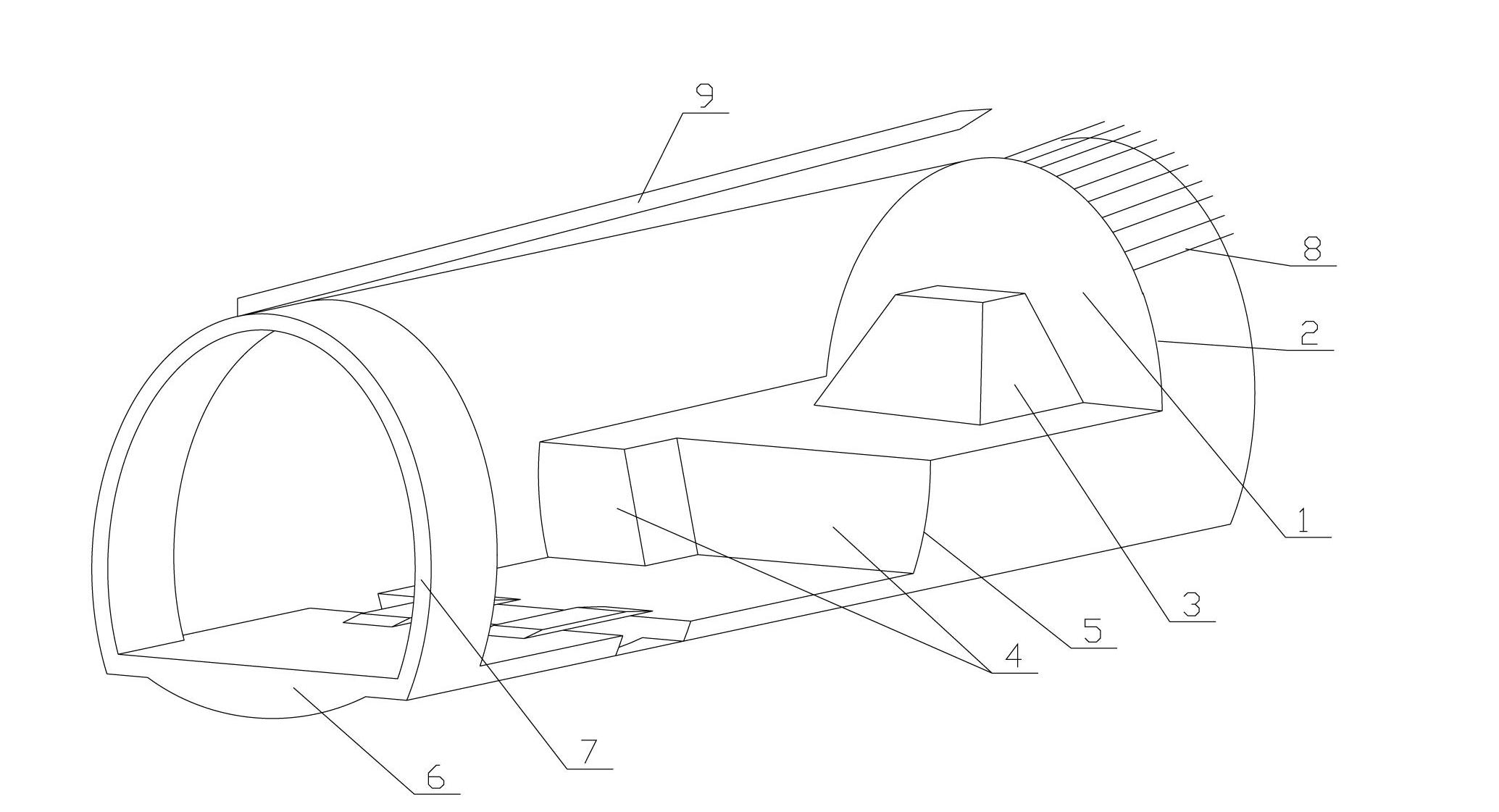

InactiveCN102678126AEasy to discharge slagImprove construction progressUnderground chambersTunnel liningShotcreteFracture zone

The invention discloses a method for excavating mountain tunnels in weak surrounding rock-fractured zones or shallow covered slope sections, which includes the following steps: (1) cover arch and forepoling; (2) tunnel cutting, including the following steps: (a) the annular part of the upper cross section of the portal of the buried tunnel is first cut, a core soil part is formed on the upper cross section, and an arch is formed; (b) combined bolting and shotcrete is carried out on the arch; (c) the core soil part is cut; (d) the lower cross section of the portal of the buried tunnel is cut; (e) first shotcrete and combined bolting and shotcrete are carried out on the left and the right sidewalls; (f) an inverted arch is lined and backfilled; (g) secondary lining is carried out; (3) step 2 is repeated until the leading pipe shed construction of the next tunnel section is carried out; (4) step 3 is repeated until the tunnel runs through the weak surrounding rock-fractured zone of a mountain. The construction space is large, multi-working face parallel operation can be carried out, and the working efficiency is high; and since the core soil is reserved on the upper cross section and the left and the right cross sections on the lower cross section are staggerly cut forward, the cut working face can be kept stable.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

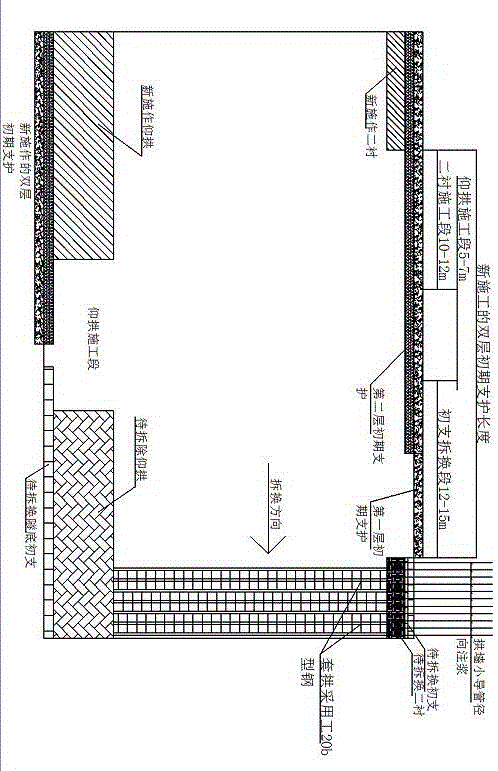

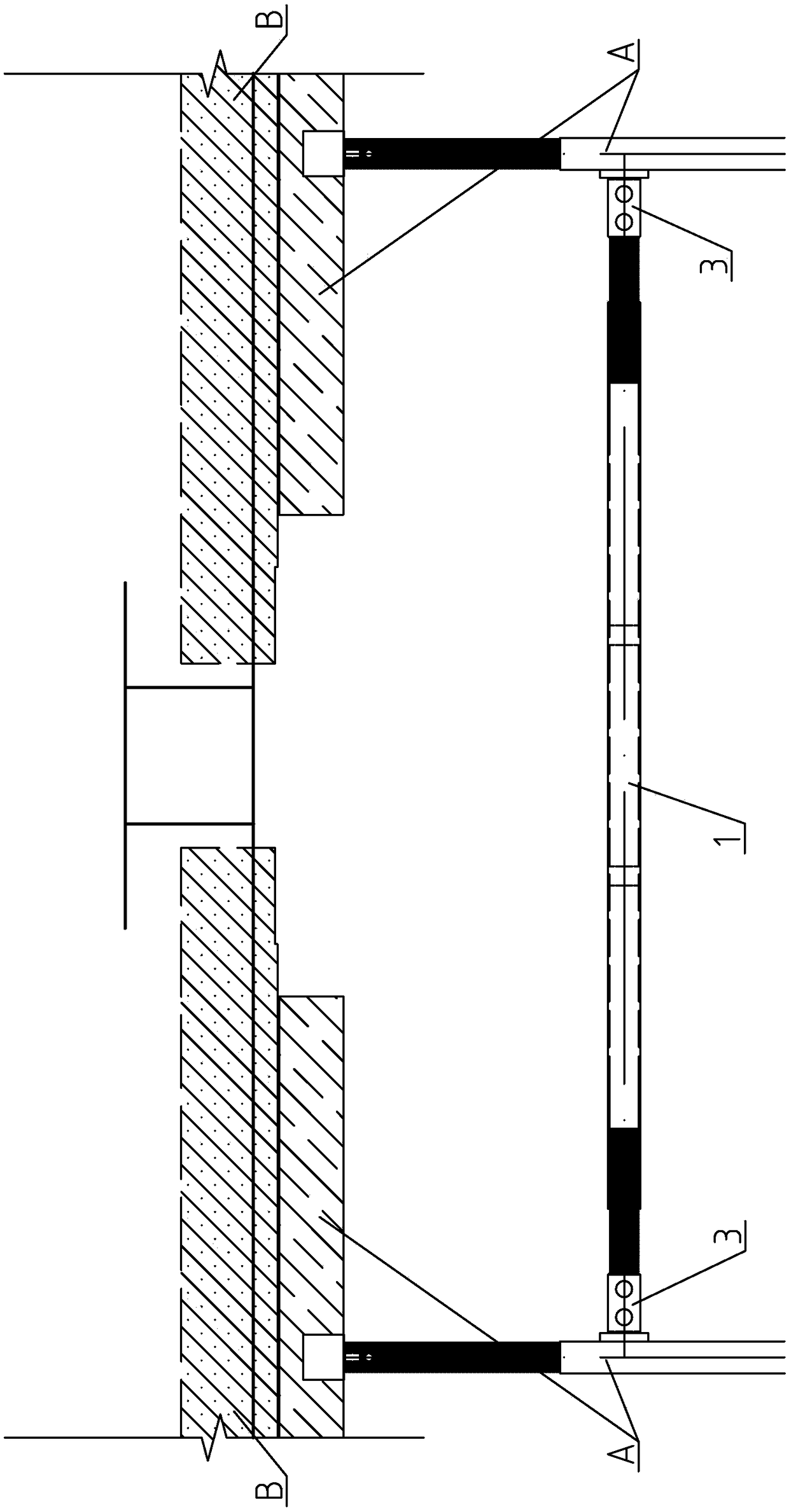

Support structure for preventing settlement deformation of tunnels and construction method thereof

InactiveCN104989421ASimplify the construction processLarge construction spaceUnderground chambersTunnel liningArchitectural engineeringPipe

The invention relates to a support structure for preventing settlement deformation of tunnels and a construction method thereof. Long pipe shed method and center cross diagram method generally use constant section tunnel construction during excavation; owing to a triangular area soil body between pipe sheds and a primary support, the primary support fail to be attached to the long pipe sheds tightly, which is unfavorable for the stress of the long pipe sheds and primary support combination. The support structure comprises an annular permanent steel arch in a tunnel; the annular permanent steel arch is composed of a plurality of parallel multi-ring variable section units in the longitudinal direction of the tunnel, the longitudinal section being zigzag in shape; a temporary steel arch is arranged between sectional pilot tunnels; long pipe sheds are uniformly distributed on the top of the arch portion of the permanent steel arch; small grouting guide pipes are uniformly arranged on the outside of the two side walls of the permanent steel arch. A variable section mode is adopted in the longitudinal direction of tunnels, and the primary support can be tightly attached to the long pipe sheds; the primary support and the long pipe sheds are combined for support, thereby being capable of controlling settlement. The structure process is simple; the operation space is large; the support structure is in favor of mechanical construction and prevents the increase of construction cost.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

Supporting system of water-rich drifting sand stratum full-weathering surrounding rock tunnel and construction method

InactiveCN110541721ASettlement controlEnsure stability and securityUnderground chambersDrainageSupporting systemStructure of the Earth

The invention discloses a supporting system of a water-rich drifting sand stratum full-weathering surrounding rock tunnel and a construction method. At least four layers of steps are arranged in a tunnel. Steel row frame supports are arranged between the steps and the top of the tunnel. An advanced small guide pipe and an advanced pipe shed are arranged at the top of the tunnel. A group of steel arch frames are arranged in the tunnel and are arranged at intervals in the longitudinal direction. The shapes of the steel arch frames are matched with the shape of the section of the tunnel. Pipe shed lock feet are arranged on the two sides of each layer of steps and on the steel arch frames respectively. Steel bar mesh pieces are laid and hung on the portions, between adjacent steel arch frames,of the inner lateral side of the tunnel. Concrete layers fully sprayed on the outer sides of the steel arch frames and the steel bar mesh pieces. Bar-shaped foundations are arranged on the positions,corresponding to the steel row frame supports, of the horizontal planes of the steps. Inclined supports are arranged between the steel row frame supports and the steel arch frames. The supporting system of the water-rich drifting sand stratum full-weathering surrounding rock tunnel and the construction method solve the technical problems that a traditional construction method easily causes settlement of an integral initial support structure, the construction space is small, steel frame arch foot pipe shed locking feet cannot be reinforced, the risk of median septum dismantling is large, the working procedures are complex and the construction speed is low.

Owner:中国建筑土木建设有限公司

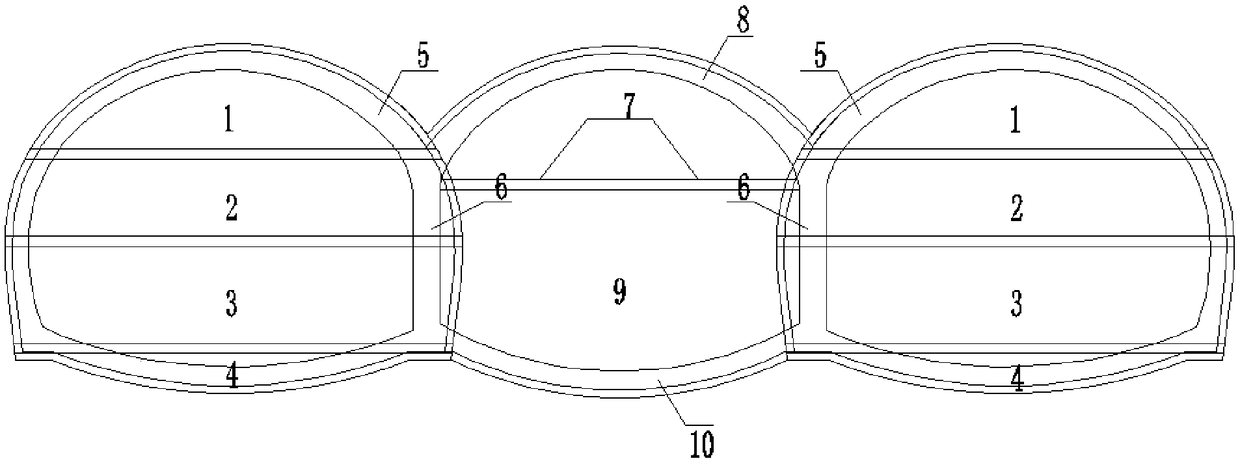

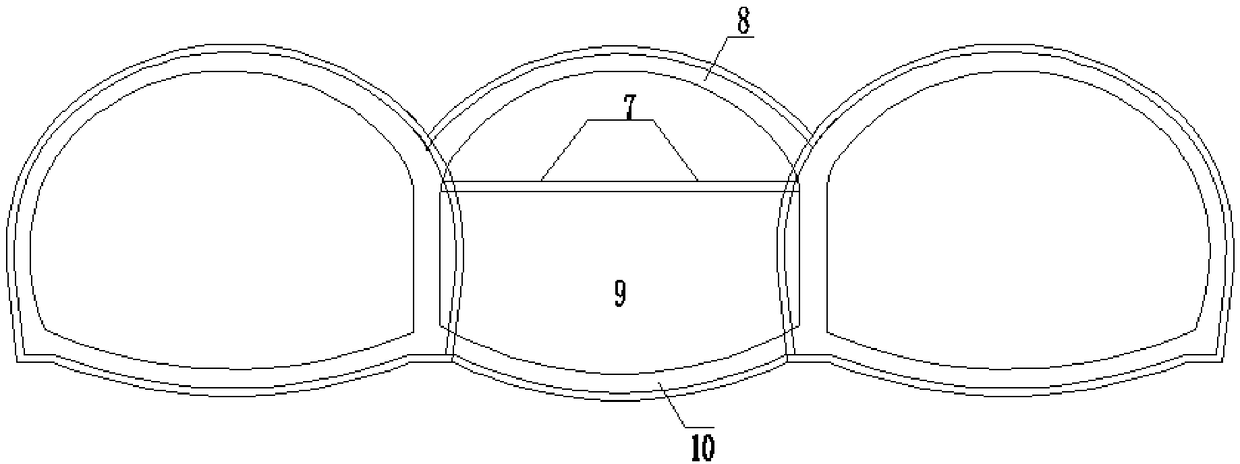

Three-arched tunnel construction method

InactiveCN109488311ALarge construction spaceImprove ergonomicsUnderground chambersTunnel liningTunnel constructionBuilding construction

The invention relates to a three-arched tunnel construction method. The three-arched tunnel construction method comprises the following steps that a left opening is first excavated, the complete crosssection of the left opening is preliminarily supported and close to form a ring, then a right opening is excavated, and the staggering distance of excavation of the left opening and the right openingis greater 15 meters; after secondary lining and a middle partition wall of the left opening and the right opening are completed, a middle opening is excavated; when the middle opening is excavated,an upper half cross section is firstly excavated, then arch lining is executed, the lower portion is excavated after the arch lining is completed, and finally an inverted arch of the middle opening isconstructed. The three-arched tunnel construction method has the advantages of few working processes, few surrounding rock disturbance times, good safety, high working efficiency, high construction progress and the like.

Owner:THE 4TH ENG OF CHINA RAILWAY 5TH ENG GROUP +1

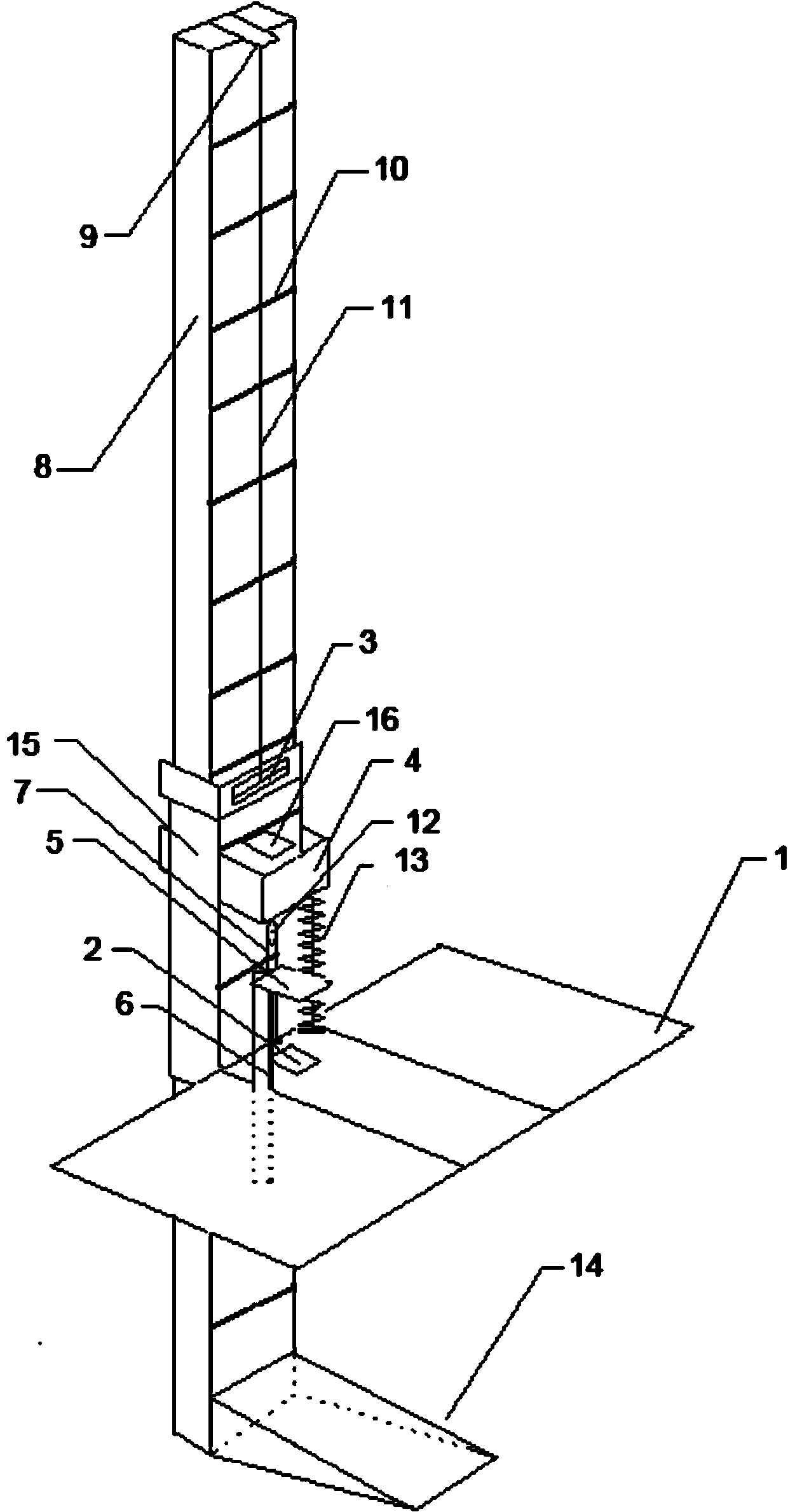

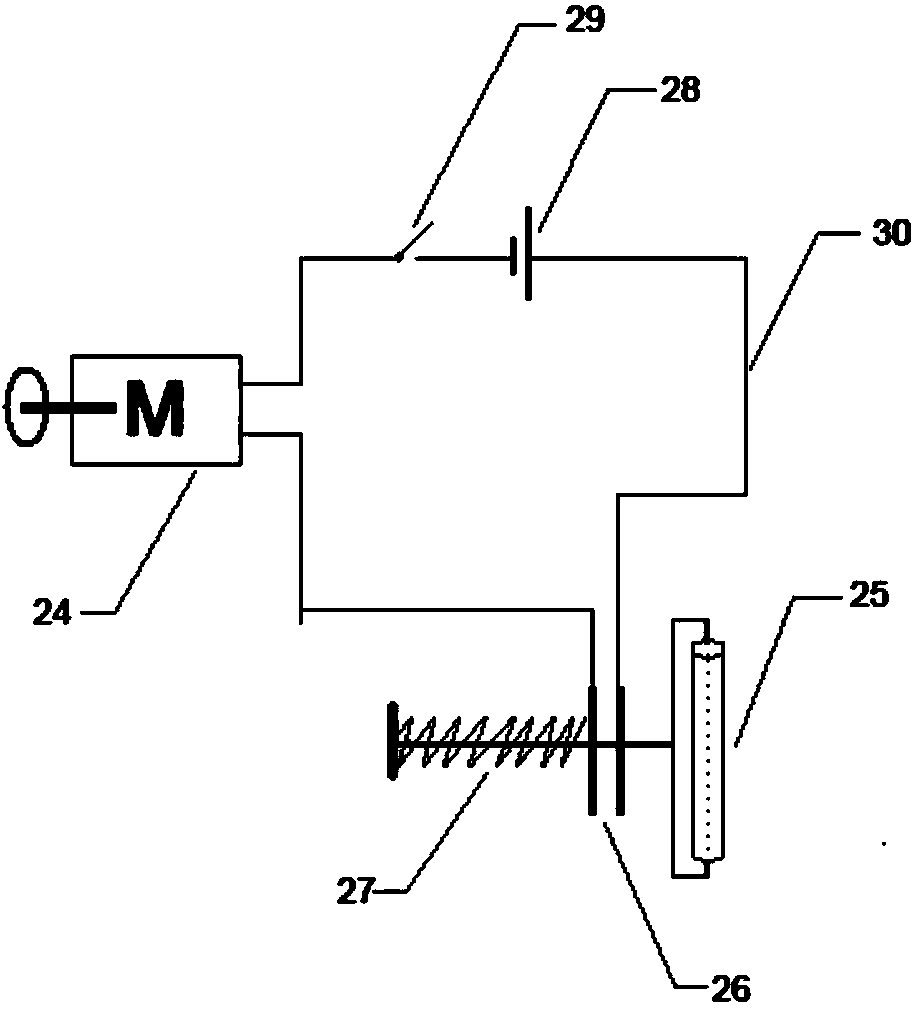

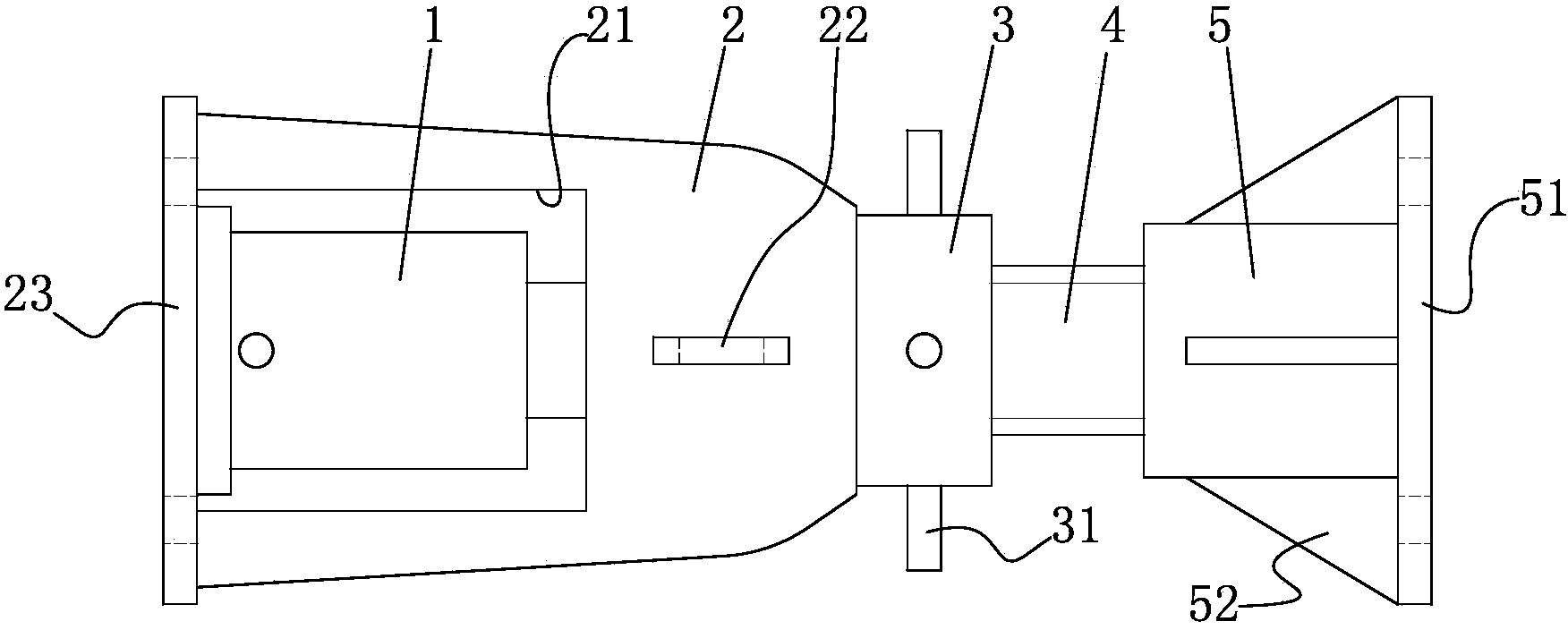

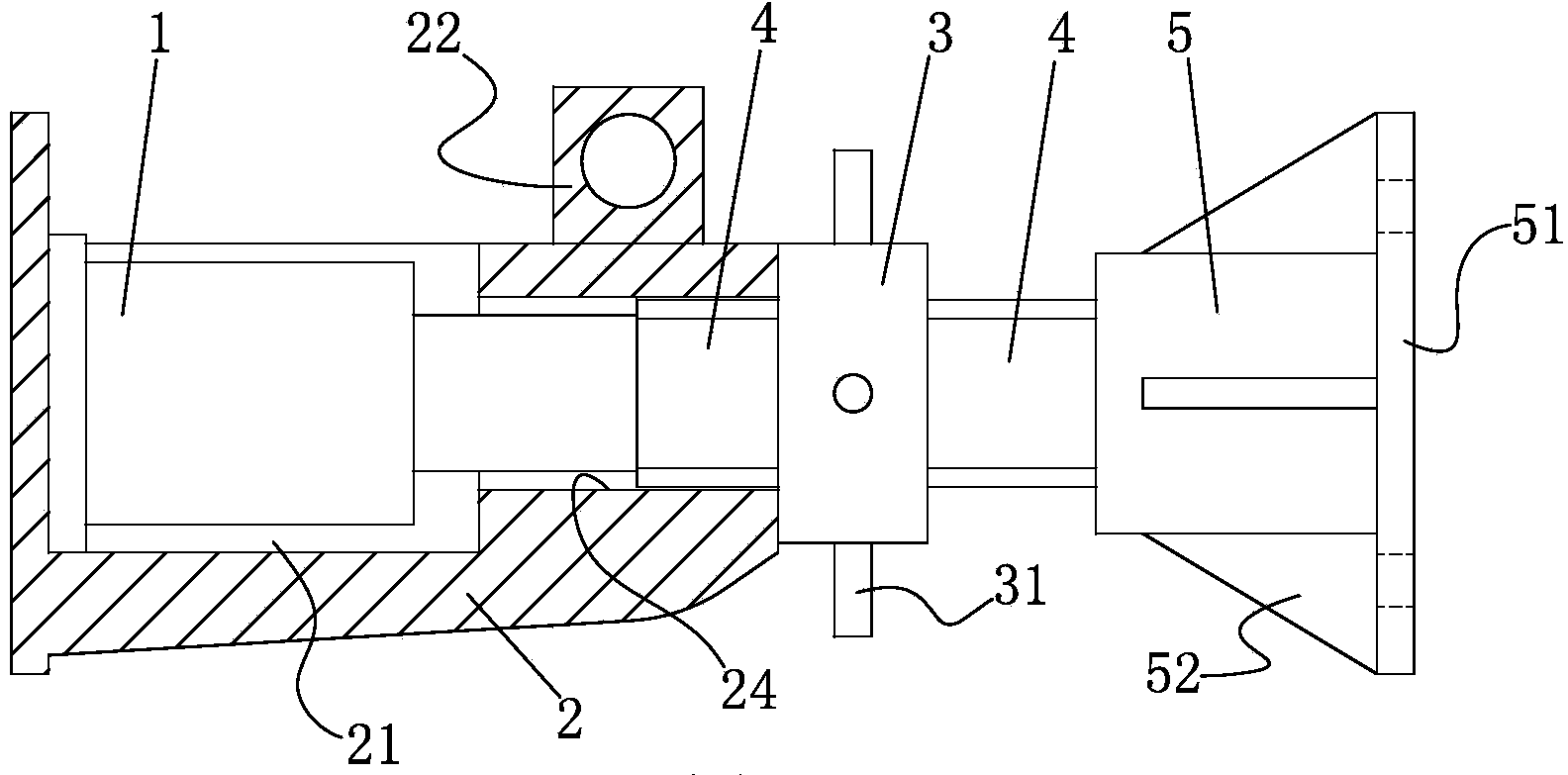

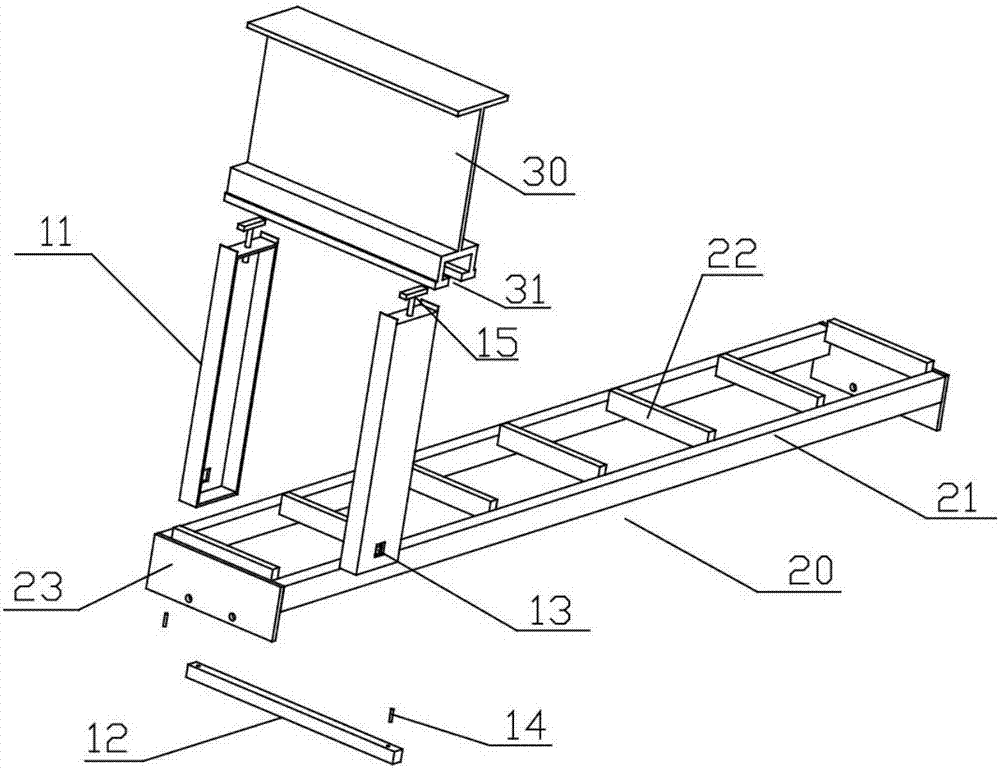

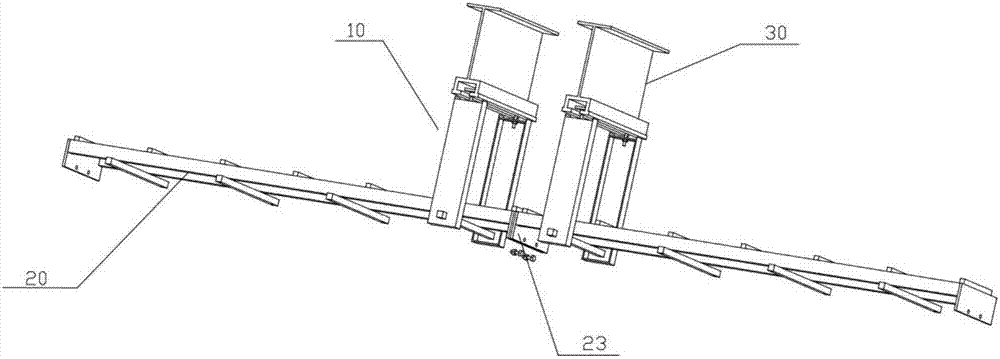

Stepping type hoisting platform

The invention relates to the technical field of hoisting devices and particularly relates to a stepping type hoisting platform. The stepping type hoisting platform comprises a working table board, positioning locks, a moving bracket, a pedal, a pedal bracket, a steel cable, a supporting framework, a steel cable connector, crosspieces, a pulley, a resetting spring and a table board bracket, the platform is characterized in that the supporting framework is provided with the plurality of crosspieces; the table board bracket is sleeved on the supporting framework; the moving bracket is mounted in the table board bracket and is sleeved on the supporting framework; the working table board is fixedly connected with the table board bracket; the working table board is provided with a first positioning block and the moving bracket is arranged above the working table board; the moving bracket is provided with a second positioning lock; one end of the resetting spring is connected with the bottom of the moving bracket; the pedal is arranged between the moving bracket and the working table board. Compared with the prior art, the stepping type hoisting platform has the advantages of simple structure, low construction cost, accordance with human engineering, capability of meeting the requirements of different working types, high safety, light weight, convenience for carrying, high working efficiency and convenience for installation.

Owner:张辉

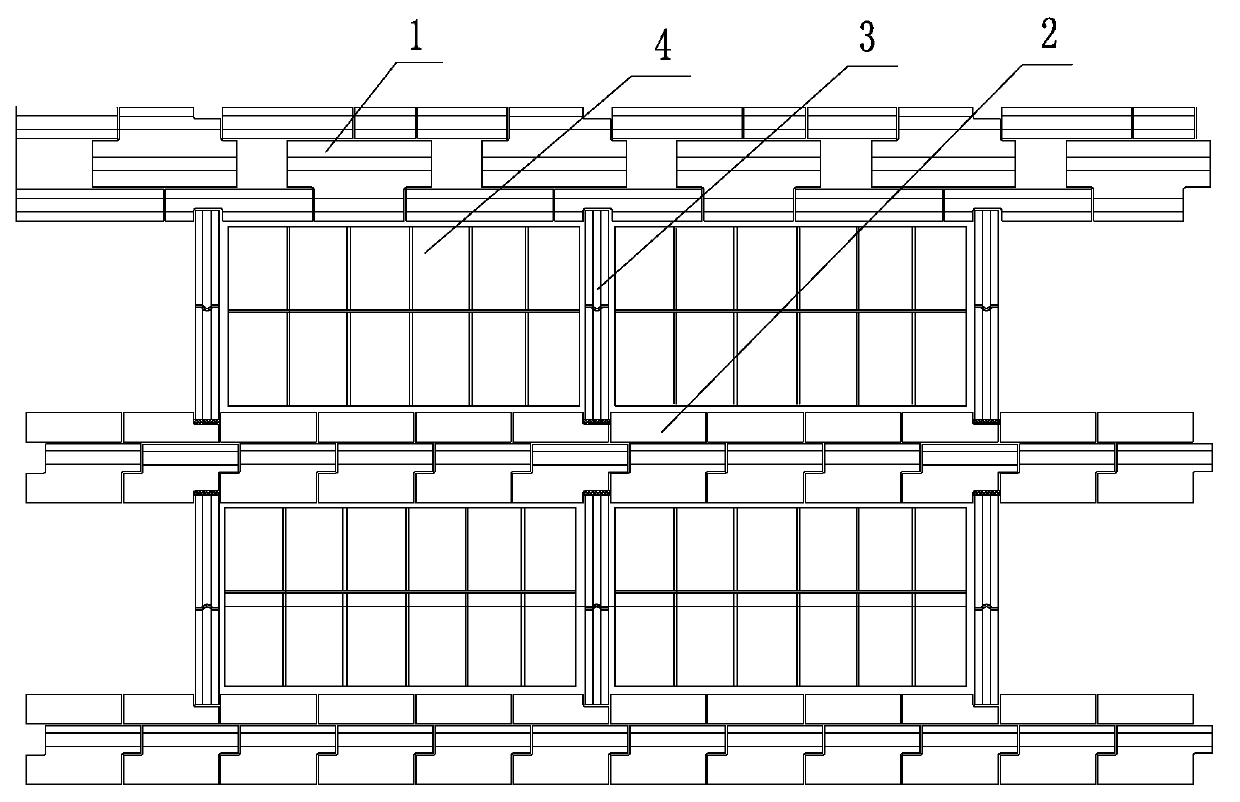

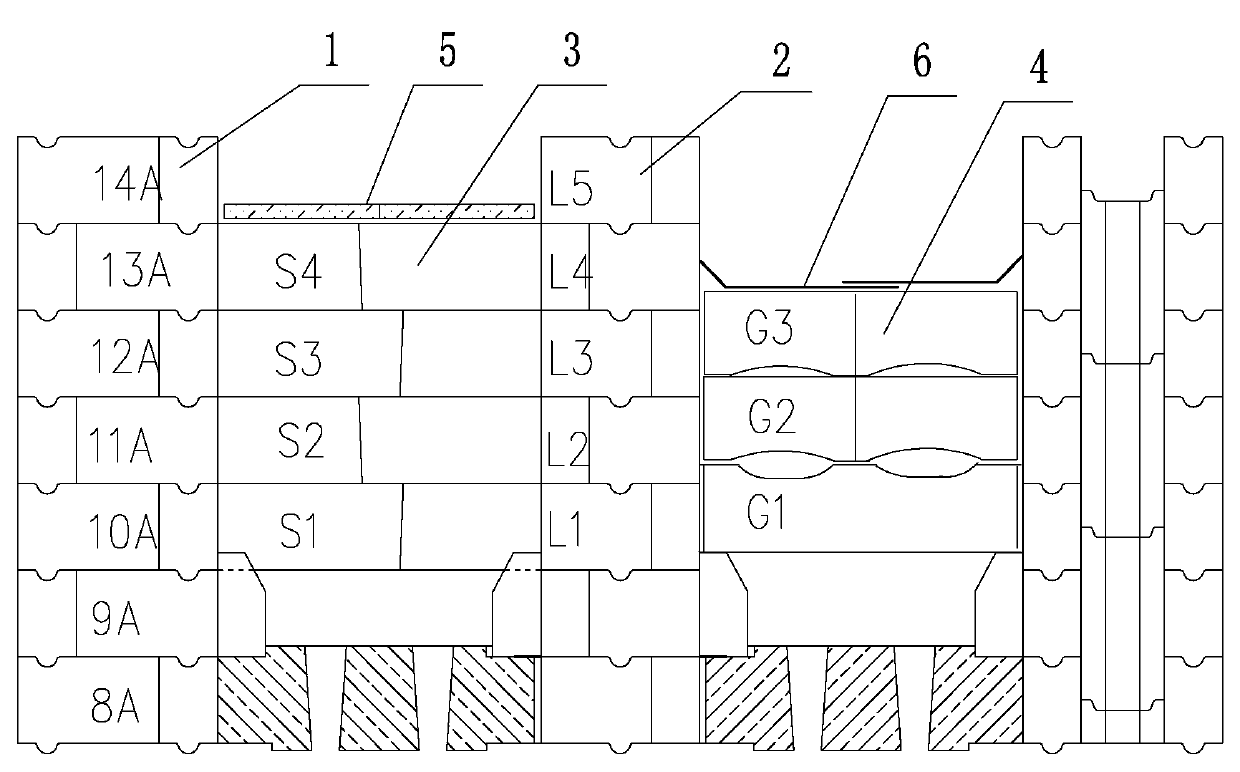

Method for building cellular regenerative chamber of coke oven

The invention discloses a method for building a cellular regenerative chamber of a coke oven. The method is characterized by comprising the following steps of: a, building a main wall and a single wall of the regenerative chamber; b, building a small cross wall of the regenerative chamber; c, building lattice bricks; d, placing rubber skins and wood boards for protection; and e, repeating the steps a-d until the building design height of the cellular regenerative chamber of the coke oven is reached. The method for building the cellular regenerative chamber of the coke oven, disclosed by the invention, has the advantages of being reasonable in construction step design and simple in operation, changing a conventional building method, being large in construction space and orderly in management of refractory materials, being capable of immediately monitoring the building quality, being safe and reliable in project quality, increasing labor efficiency, greatly reducing the construction period and lowering the project cost.

Owner:MCC5 GROUP CORP SHANGHAI

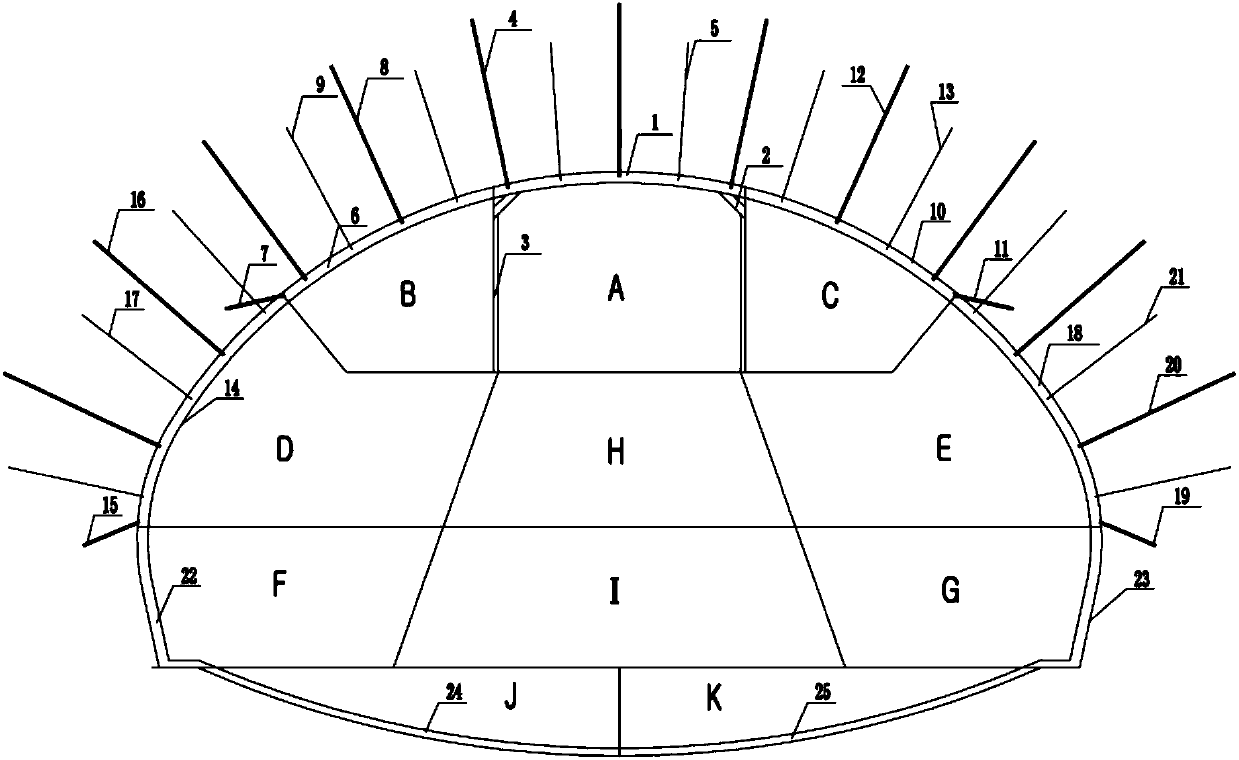

Super-long span tunnel excavation and support construction method

ActiveCN108131145ALarge construction spaceSimple construction methodUnderground chambersTunnel liningSupporting systemEngineering

The invention relates to a super-long span tunnel excavation and support construction method. The method comprises the steps of top hole advancing, stratified excavation, core reservation and key anchoring; according to the principle that the transverse direction and the vertical direction are basic uniform, the super cross-section tunnel is divided into eleven parts to be excavated, and a top layer middle hole is dug; all parts on the two sides are excavated in a left-right alternate and stratified mode from top to bottom, and initial support is conducted after each part is excavated; finallycore soil and an inverted arch are excavated gradually by layers, and a closed ring support system is formed. The method has the advantages of being simple in construction method, less in in processtransformation, safe and reliable in construction, high in degree of mechanization and capable of organizing safe and rapid construction.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

Large-span subway station underground excavation construction method for hard rock stratum

ActiveCN104847362AGood for subsidence controlAvoid impact damageUnderground chambersTunnel liningClerestoryGeomorphology

Disclosed is a large-span subway station underground excavation construction method for a hard rock stratum. The large-span subway station underground excavation construction method for the hard rock stratum is used for effectively reducing the excavation construction risk and improving the excavation construction efficiency. The large-span subway station underground excavation construction method for the hard rock stratum comprises the following steps that the arch portion middle of a station is divided into two steps to be excavated, a tunnel arch portion middle upper step is excavated, and an initial support arch cover of the tunnel arch portion middle is constructed; a tunnel arch portion middle lower step is excavated; a tunnel arch portion left side portion and a tunnel arch portion right side portion are excavated, feet-lock bolts are constructed at the arch foot positions, the initial support arch cover on the arch top is lengthened through connection, and construction of the initial support arch cover is accomplished; a rock mass arranged below the station is excavated in a slot broaching mode under the protection action of the initial support arch cover, nine portions including upper steps on the left portion, the middle portion and the right portion, middle steps on the left portion, the middle portion and the right portion and lower steps on the left portion, the middle portion and the right portion are excavated, and side wall initial supports of corresponding sections are constructed until the rock mass is excavated to the bottom; and a station body structure is sequentially constructed from bottom to top, and station construction is accomplished.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Construction method for cast-in-place of continuous beam at turnout junction for passenger transport line in seawall area by false work method

InactiveCN102797223AMeet the acceptance criteriaEfficient constructionBridge erection/assemblyBridge materialsPre stressContinuous beam

The invention provides a construction method for cast-in-place of a continuous beam at a turnout junction for a passenger transport line in a seawall area by a false work method. The construction method comprises the steps of processing a foundation, erecting a bracket, pressing the bracket in advance, mounting a support base, mounting a template, processing and mounting reinforcing steel bars, distributing corrugated pipes, casting concrete, constructing prestress, grouting a pipeline and sealing anchor. According to the construction method, the false work is applied to the construction of the continuous beam at the turnout junction of the passenger transport line engineering in the seawall area along the coast, the work procedures of bracket construction and prestress construction are innovated according to the geological conditions and self characteristics of the continuous beam, and by the proving of the practice, the construction of the continuous beam for the passenger transport line in the seawall along the coast achieves good effects, and the acceptance standard of the passenger transport line is met.

Owner:NO 7 ENG CO LTD OF CHINA RAILWAY 19 BUREAU GRP

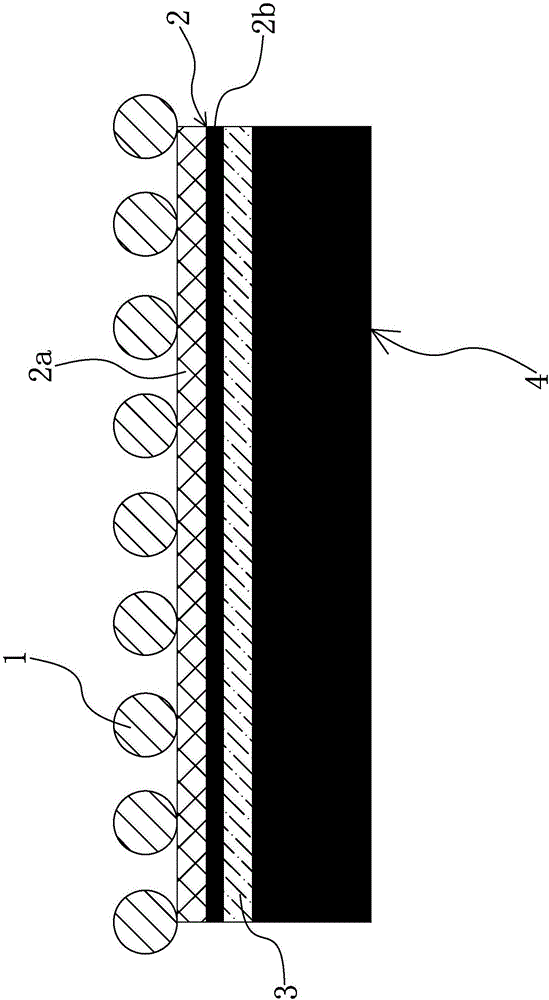

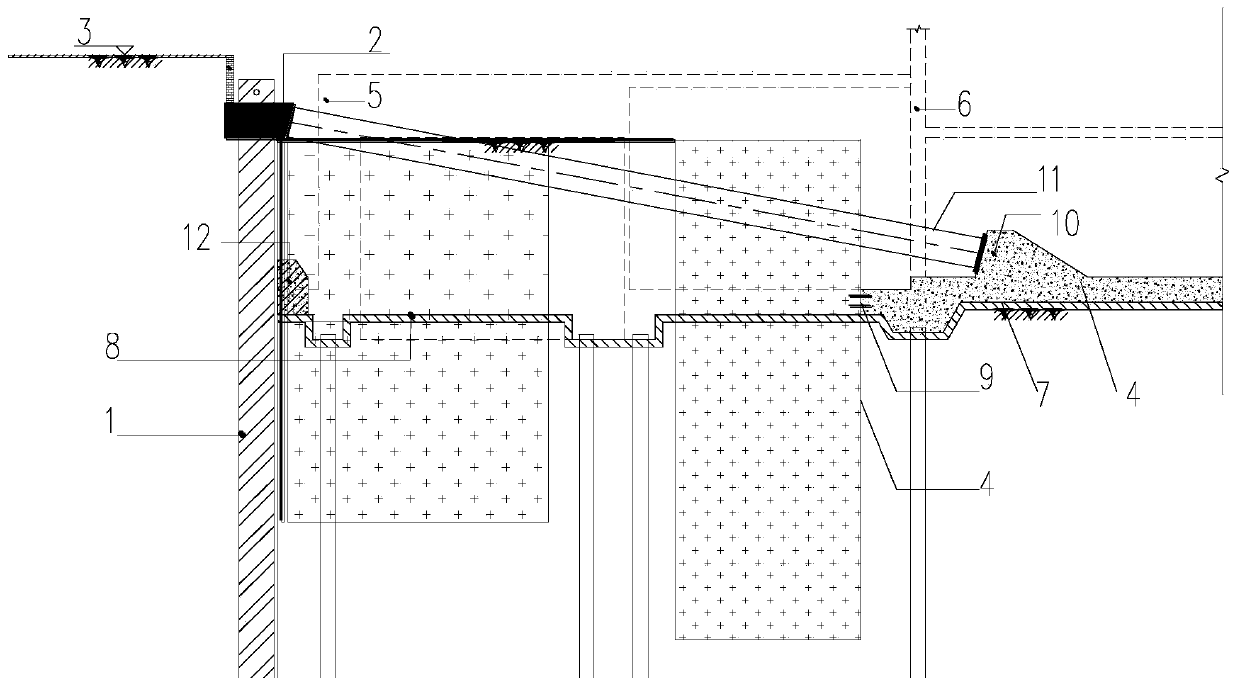

Basement exterior wall waterproof structure and construction method thereof

InactiveCN106759843AImprove construction qualityImprove waterproof performanceCellarsBuilding insulationsBasementArchitectural engineering

The invention provides a basement exterior wall waterproof structure and a construction method thereof, and belongs to the technical field of building construction. The technical problem that an existing waterproof structure and a construction method are poor in waterproof quality and low in construction efficiency is solved. According to the technical scheme, the basement exterior wall waterproof structure comprises multiple fender posts, an exterior formwork, a waterproof layer and an exterior wall, the fender posts are erected inside a base pit and located outside an outside base line of the exterior wall, the multiple fender posts are arranged at intervals, and the distances between the base line and the fender posts are the same; the exterior formwork is connected with the sides, opposite to the base line, of the fender posts, the waterproof layer is arranged on the surfaces, opposite to the base line, of the exterior formwork, the exterior wall is arranged between the waterproof layer and the base line, one surface of the exterior wall is tightly attached to the waterproof layer, and the other surface coincides with the base line; the waterproof layer can be constructed in advance, construction is convenient, the construction cost is low, the waterproof layer is constructed in advance, the construction quality of the waterproof layer is high, and the waterproof effect of the waterproof layer is better.

Owner:浙江二十冶建设有限公司 +1

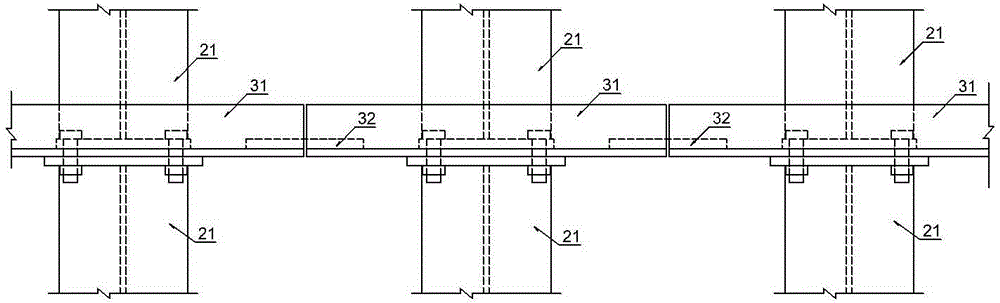

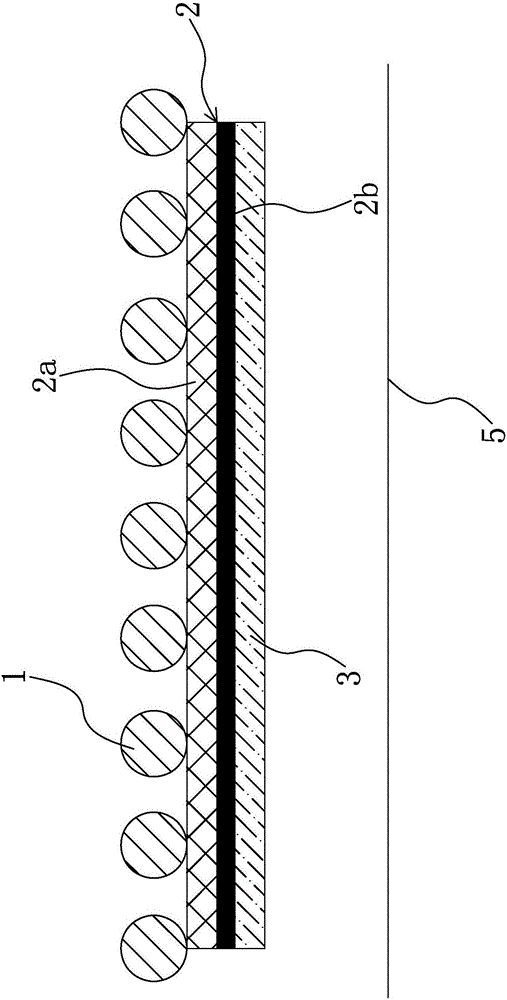

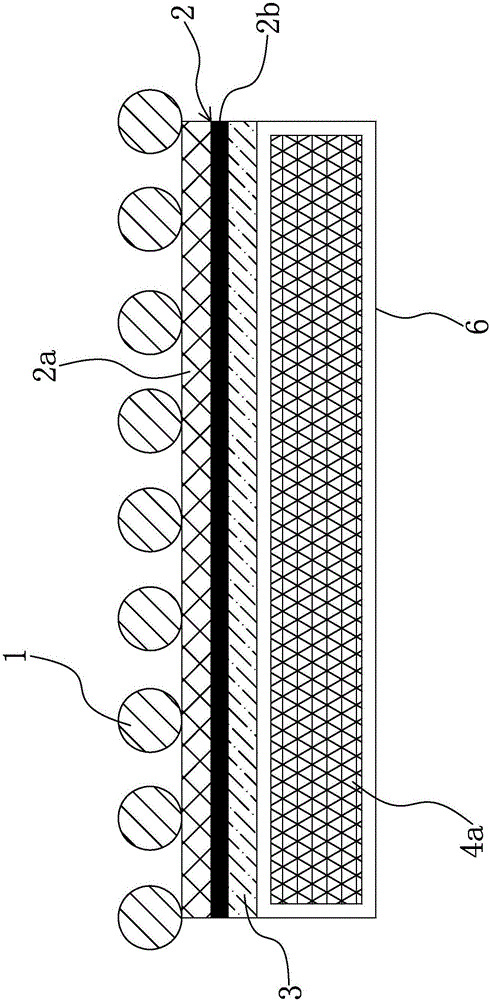

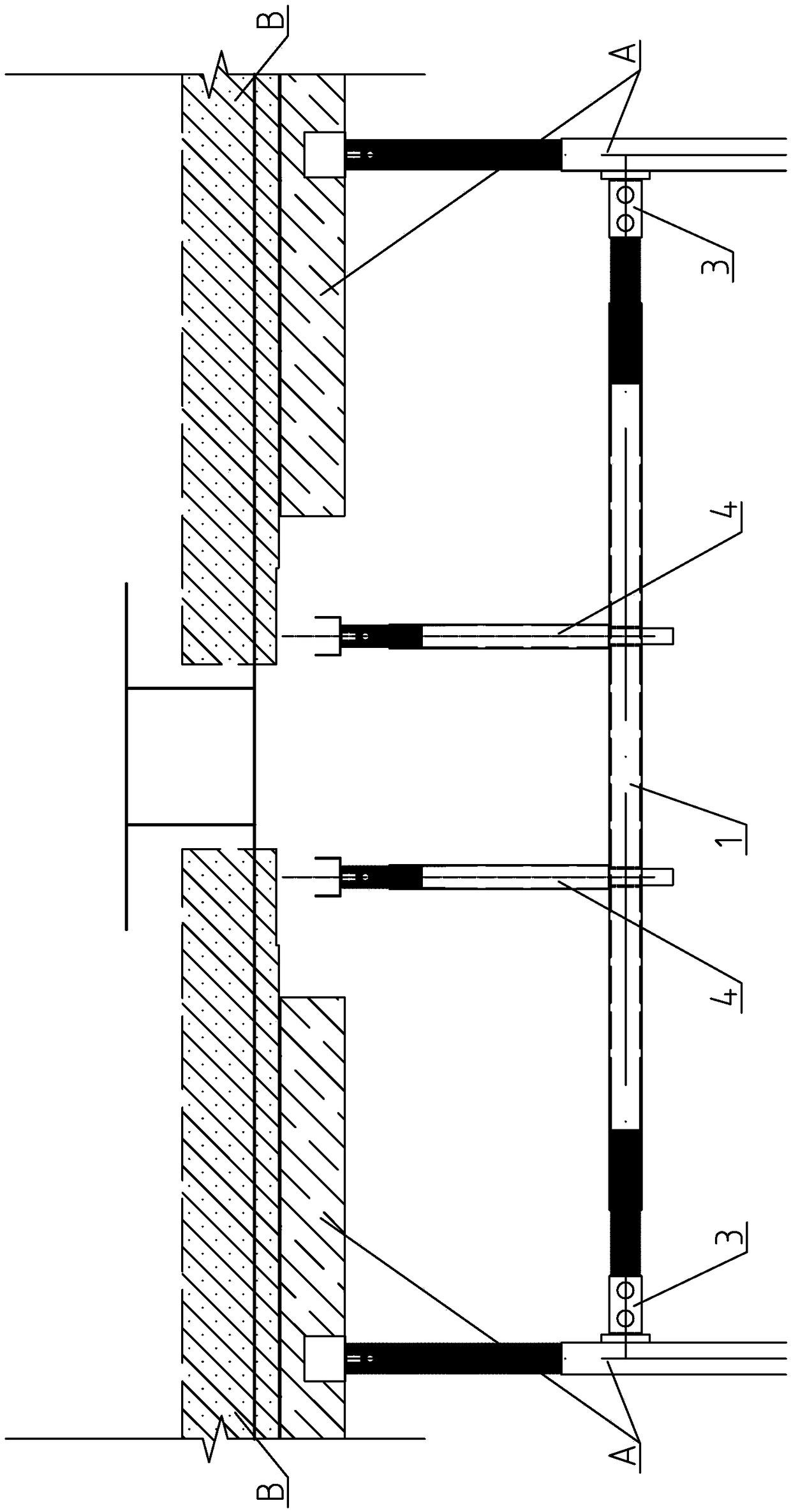

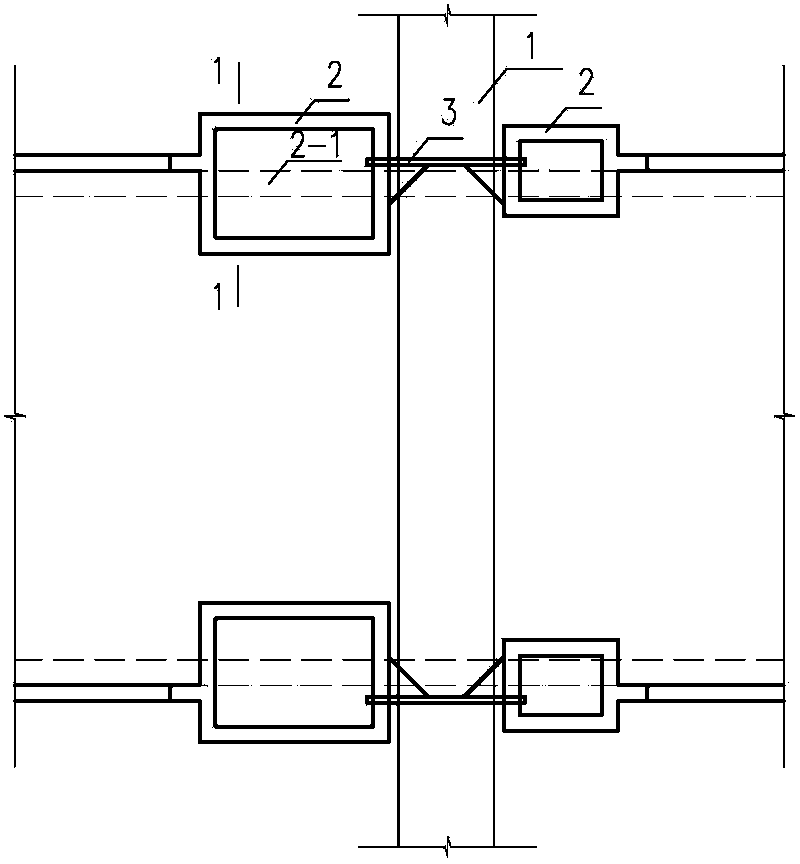

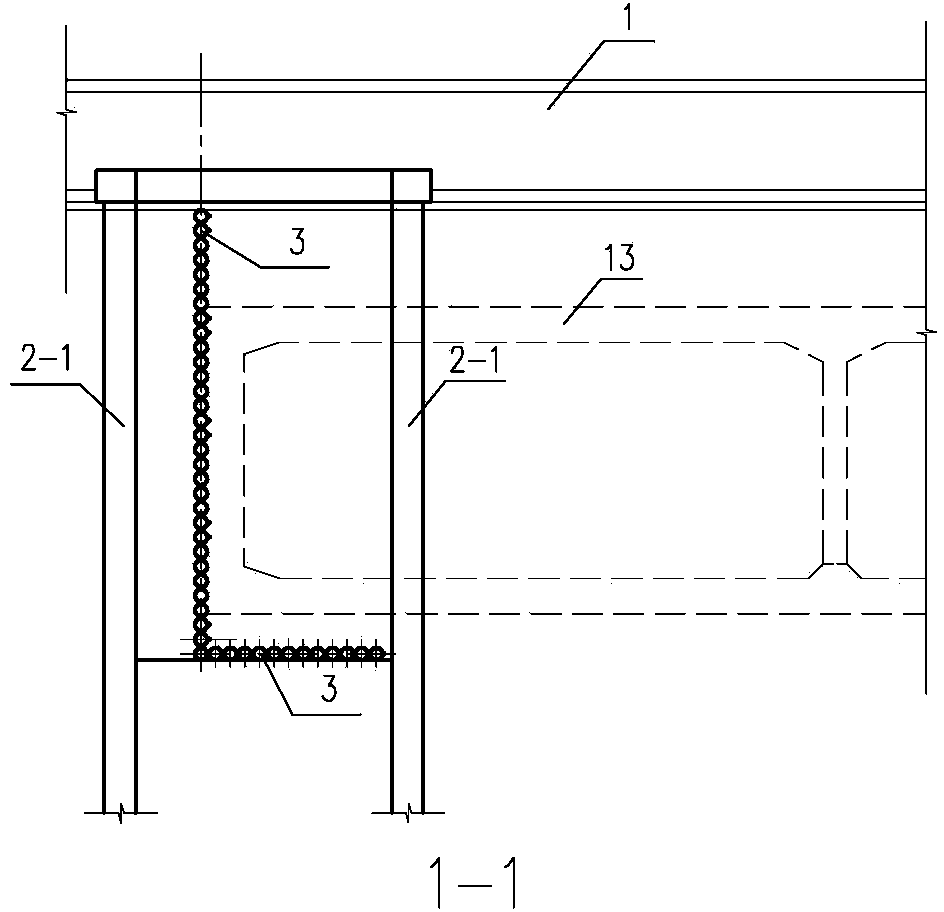

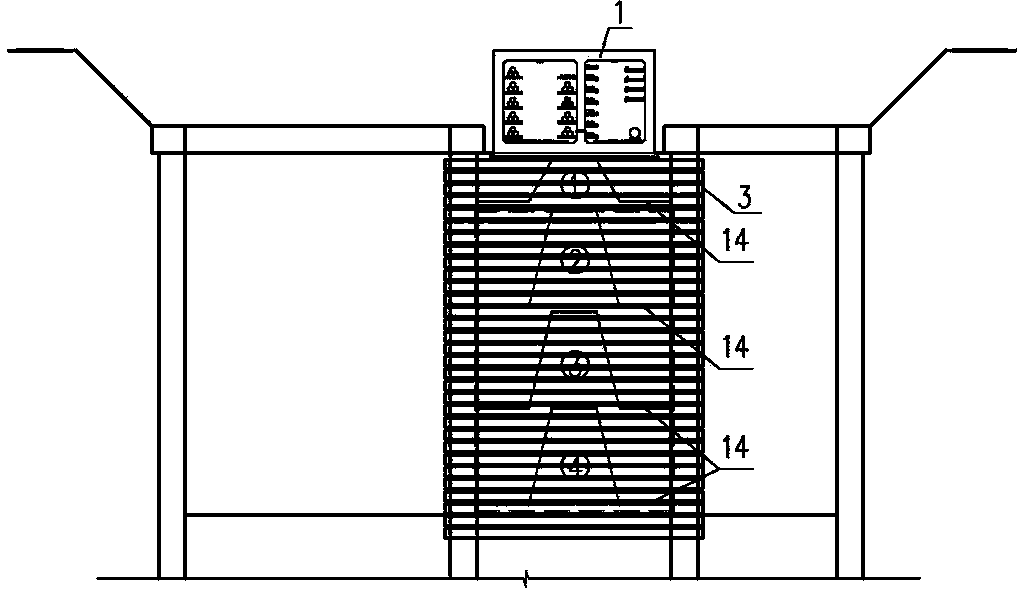

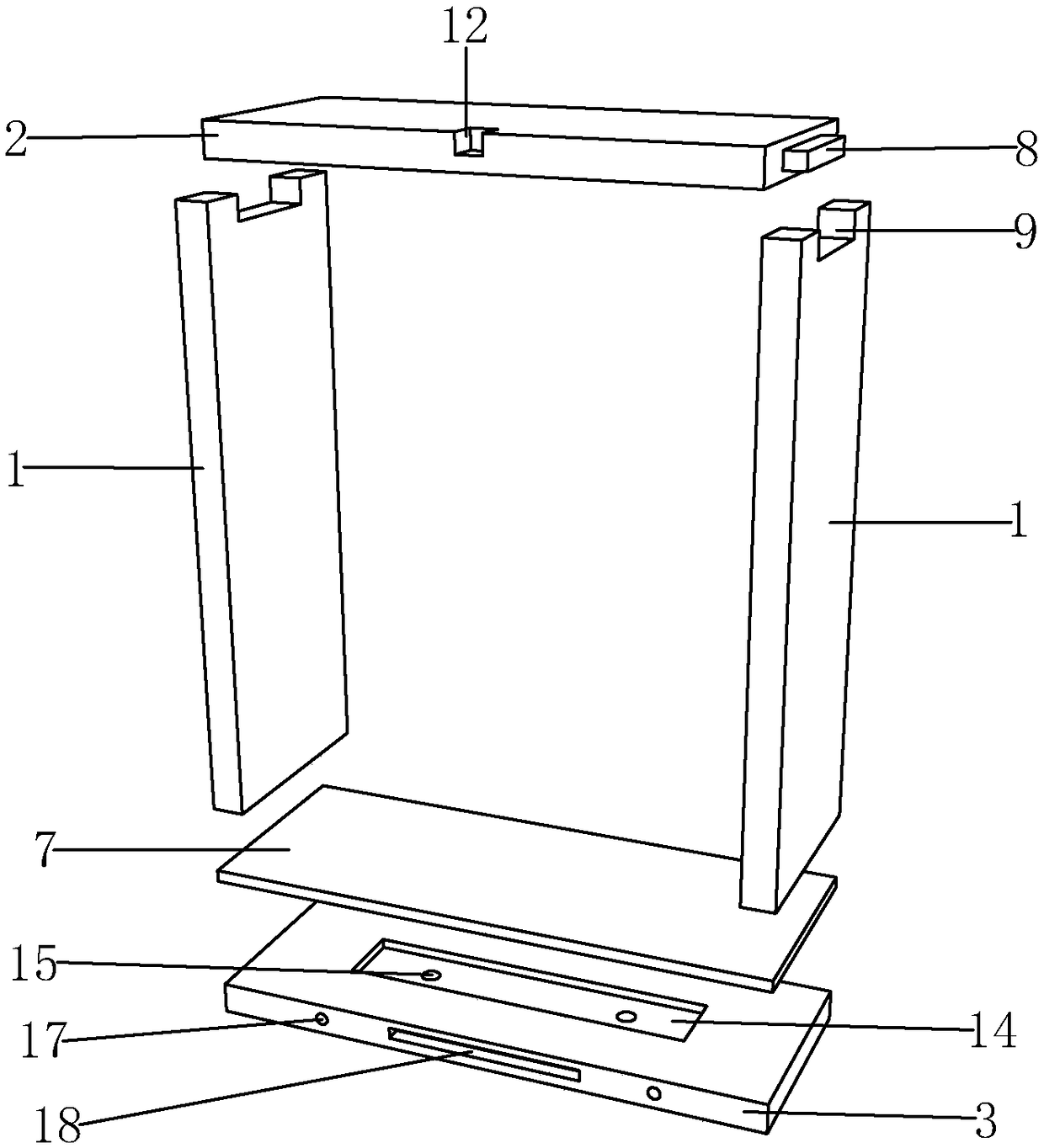

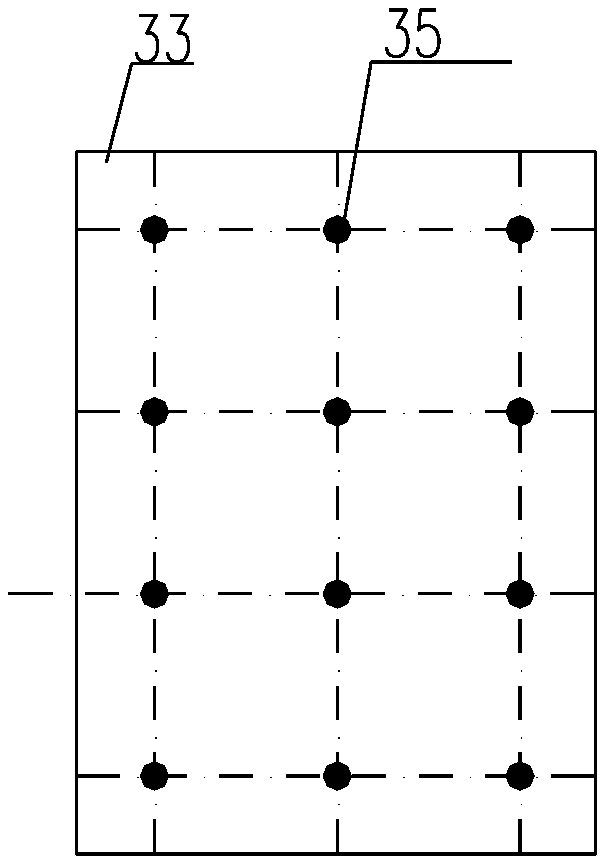

Tool type concrete composite slab cast-in-situ connecting section formwork supporting device

The invention discloses a tool type concrete composite slab cast-in-situ connecting section formwork supporting device. The tool type concrete composite slab cast-in-situ connecting section formwork supporting device solves the problem that existing concrete composite slab cast-in-situ connection adopts a hanging formwork or a traditional full-hall support method and the problems that connection section formwork support and prefabricated part support interfere with each other, supporting materials are large in dosage and the mounting accuracy and installation quality of the formwork are difficult to guarantee exist. Two supporting stand column inserting holes are formed in the middle portion of a supporting cross beam, two transverse adjusting pieces are symmetrically arranged at the two ends of the supporting cross beam, the transverse adjusting pieces are connected with the supporting cross beam in a threaded mode, two supporting stand columns correspond to the two supporting stand column inserting holes in a one-to-one mode, and the supporting stand columns are connected with the supporting cross beam in an inserting mode. Vertical adjusting pieces are connected to the upper ends of the supporting stand columns in a threaded mode, U-shaped brackets are connected to the upper ends of the vertical adjusting pieces in a threaded mode, the U-shaped brackets are internally provided with formwork supporting beams, and a bottom formwork is arranged above the two formwork supporting beams. The tool type concrete composite slab cast-in-situ connecting section formwork supportingdevice is used in the construction of fabricated composite concrete floor.

Owner:HARBIN UNIV

Foundation pit supporting method used below existing comprehensive pipe rack

ActiveCN104358263AReduce construction proceduresReduce investmentExcavationsUnderwater structuresUtility tunnelCulvert

The invention discloses a foundation pit supporting method used below an existing comprehensive pipe rack and relates to existing comprehensive pipe racks and to-be-built tunnel box culverts crossed below the existing comprehensive pipe racks. The foundation pit supporting method is characterized by comprising the following steps: at the crossed position, at least one working well is arranged on each of two sides of a comprehensive pipe rack, a longitudinal pipe-roof is arranged in each of the working wells, and a horizontal pipe-roof is arranged at the bottom of each of the working wells, and the longitudinal and horizontal pipe-roofs are jacked into soil between the working wells on the two sides in the longitudinal direction of the to-be-built tunnel box culvert; after that, the to-be-built tunnel box culvert is constructed. The foundation pit supporting method has the advantages that the construction environment is good, the risk is relatively low, the deformation is controllable, and influence on the existing comprehensive pipe rack above is avoided.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

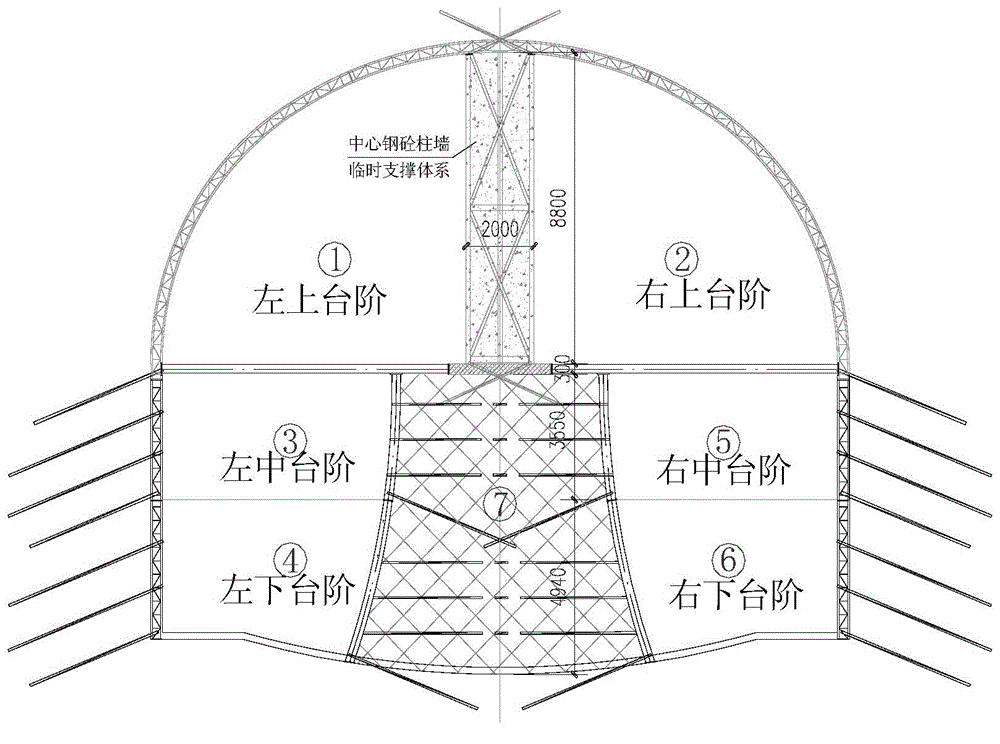

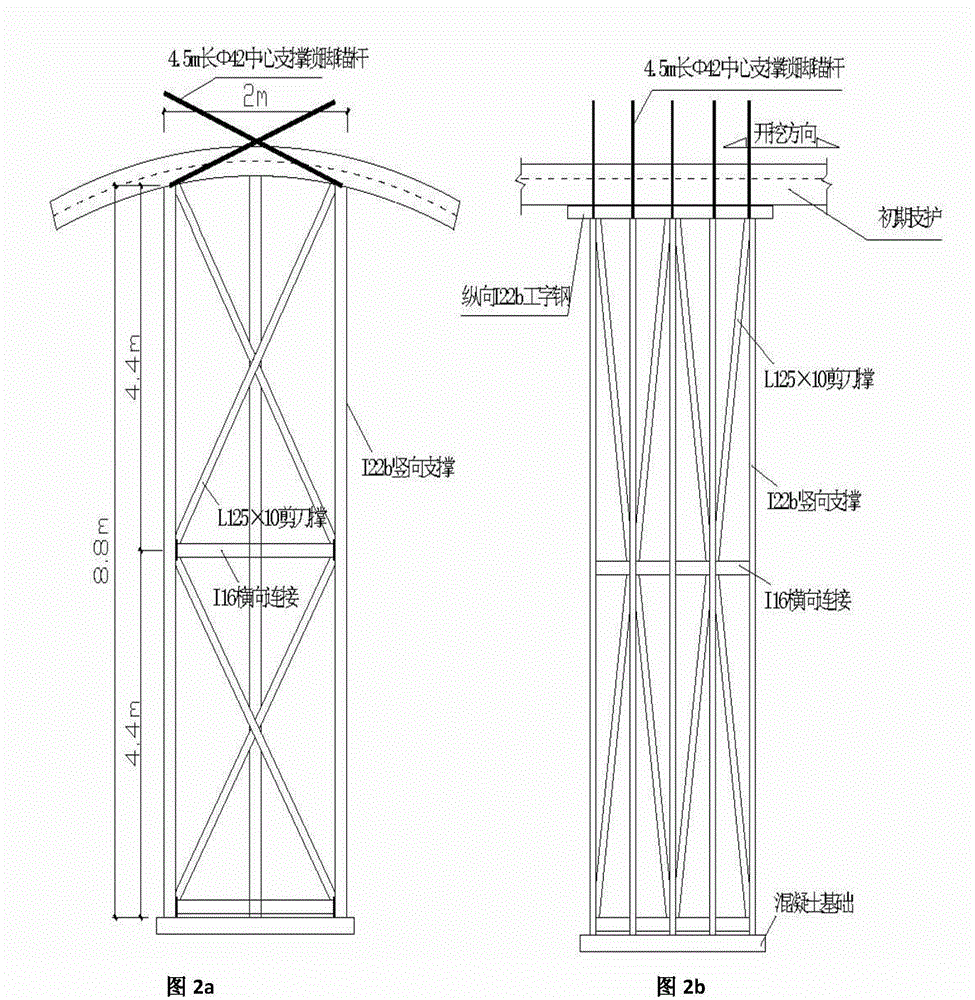

Construction technology of step temporary support and partial double side walls

InactiveCN103334778ASpeed upEasy to doTunnelsProtective coversReinforced concrete columnSupporting system

The invention relates to a construction technology of a step temporary support and partial double side walls. The construction technology is characterized in that an upper half cross section is excavated by a step method; a center reinforced concrete column wall temporary support system is constructed; and a lower half cross section adopts the double side walls. For the center reinforced concrete column wall temporary support system, a plurality of rows of vertical steel supports are arranged vertically; the distances between the vertical steel supports are 1.0m; the vertical steel supports are internally provided with cross connections, longitudinal connections and bridgings; feet-lock bolts are constructed at vaults on the two sides of the vertical steel supports; mortar bolts are constructed at arch springs on the two sides of the vertical steel supports; the vertical steel supports, the cross connections, the longitudinal connections, the bridgings, the feet-lock bolts and the mortar bolts form a reinforcement framework; the reinforcement framework is poured with concrete to form a concrete solid column in size of 2.0*2.0m-4.0*4.0m; the interval between every two concrete solid columns in a whole tunnel is 4-8m; and a steel arch injection concrete enclosed wall body is arranged between every two concrete solid columns. With the adoption of the technology, on the premise that construction safety is ensured, the construction period of a project is shortened by 15% entirely, and construction cost is saved by 6% approximately.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

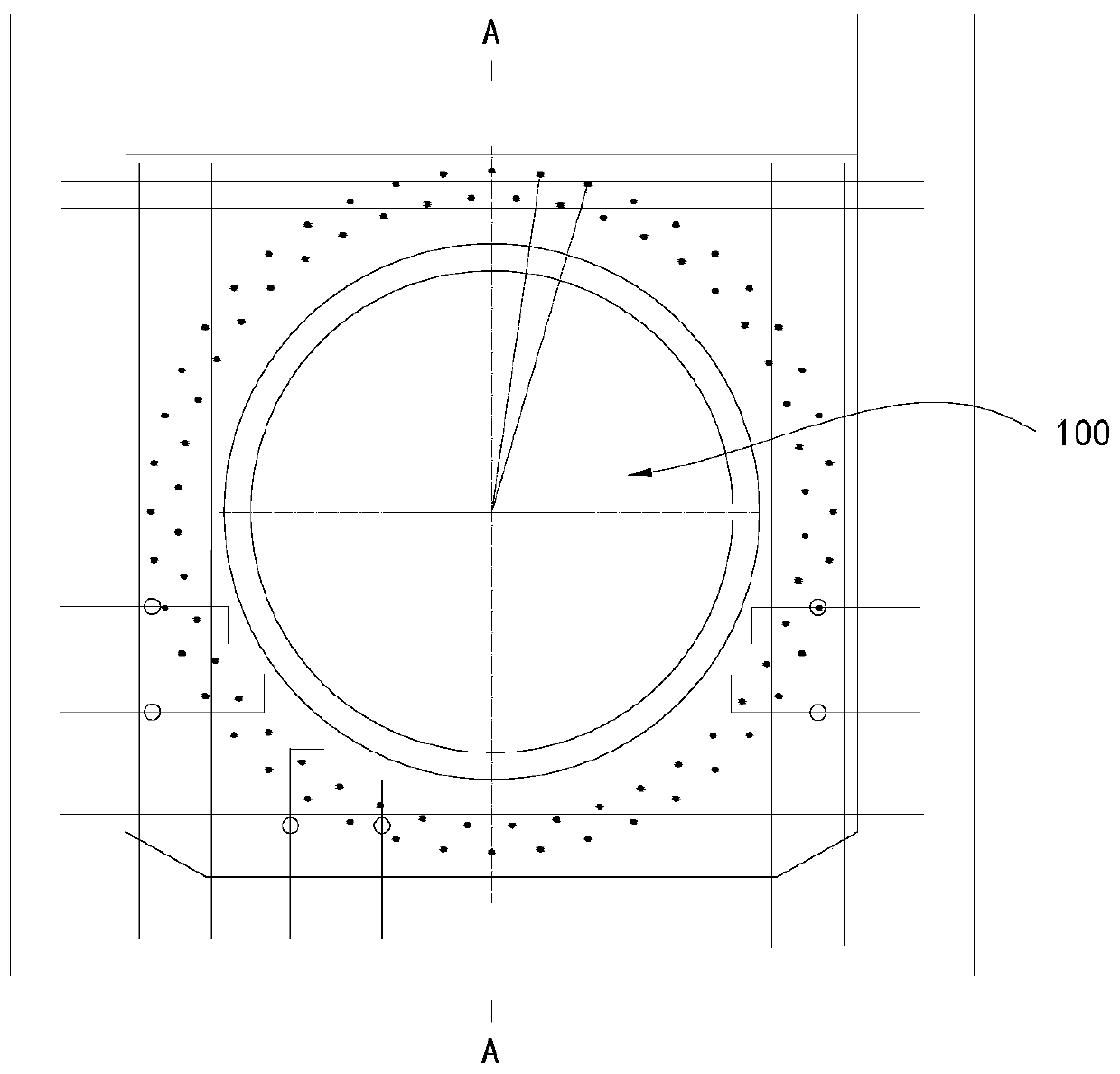

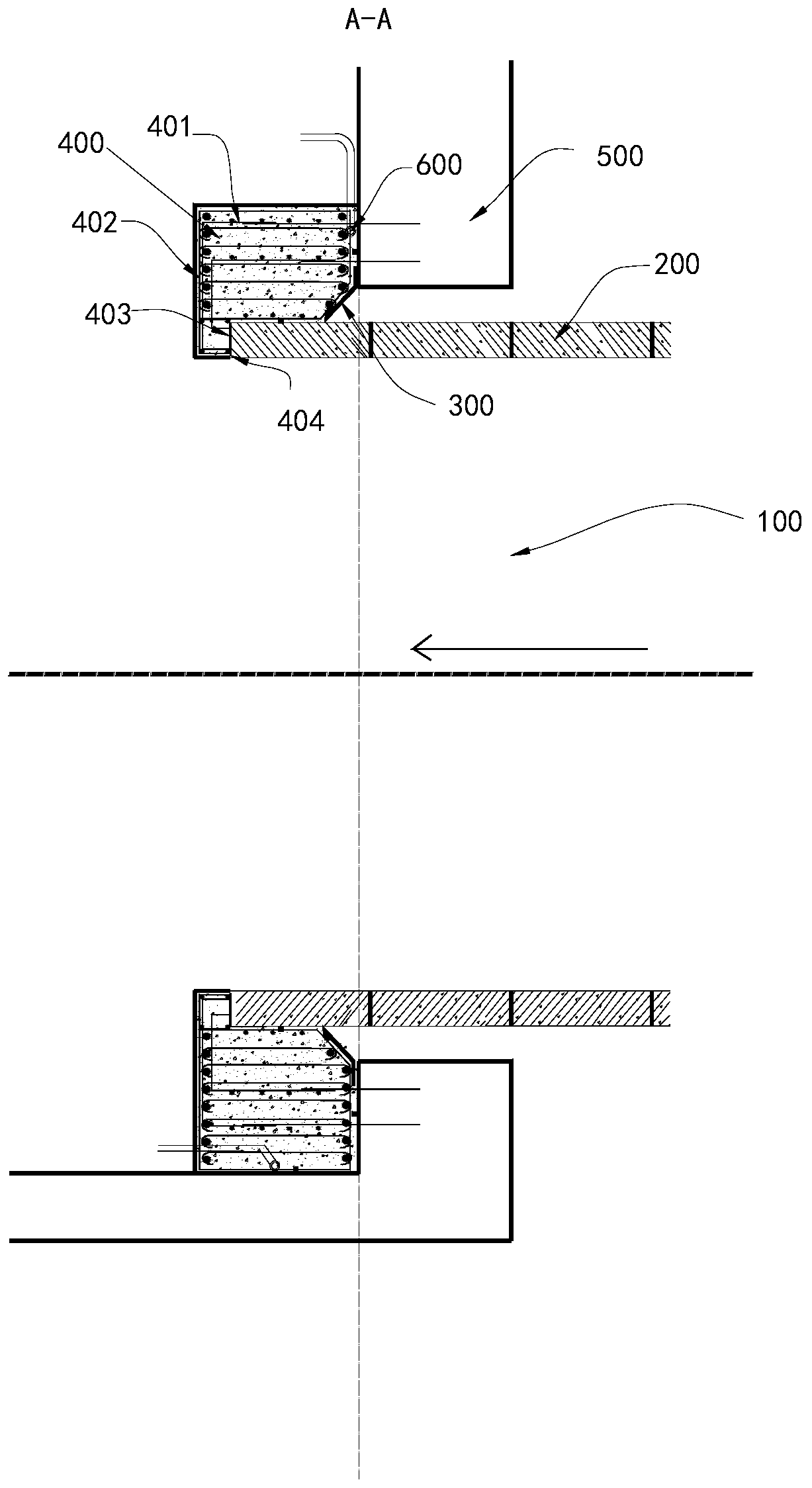

Construction method of external-wrapping tunnel portal ring beam in water-rich stratum shield interval

InactiveCN110966017AConstruction quality is safe and reliableSafe and reliable structureUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a construction method of an external-wrapping tunnel portal ring beam in a water-rich stratum shield interval. By improving the construction method of a traditional tunnel portal ring beam, the construction quality of the tunnel portal ring beam is safer and more reliable than that of a traditional internal-lining ring beam by adopting the method of the external-wrapping ring beam without being affected by the length of an original tunnel outing cave ring segment extending out of a tunnel portal end wall, an original segment in a tunnel does not need to be damaged, water flush accidents due to detaching of the segment are avoided, the construction risk is reduced, the construction space is large, the concrete can be vibrated and compacted, the method is easy to conduct, the structure is more safe and reliable, and the quality is more guaranteed; and the construction method is used in the technical field of underground engineering construction.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

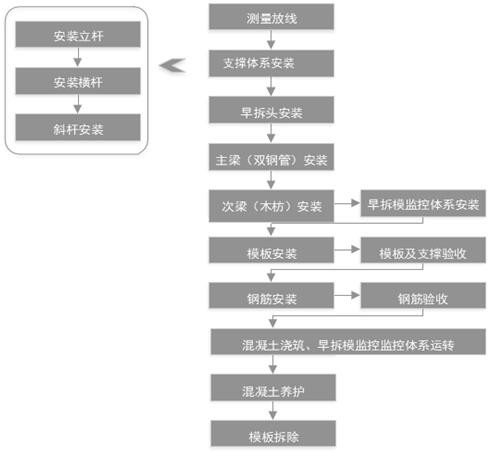

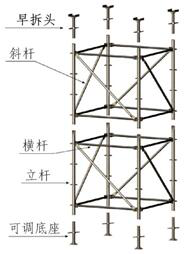

Construction method of intelligent construction site frog early-dismantling support real-time monitoring system

InactiveCN112360147AFlexible layoutEasy constructionMeasurement devicesForms/shuttering/falseworksSupporting systemConstruction engineering

The invention discloses a construction method of an intelligent construction site frog early-dismantling support real-time monitoring system. The construction method comprises the following steps of surveying and setting out, support system installation, double-nut early-dismantling head installation, primary beam and secondary beam installation, early-dismantling support real-time monitoring system installation, formwork installation and acceptance, rebar installation and acceptance, concrete pouring and maintenance and formwork dismantling. The construction method has the advantages that a socket-type frog type steel pipe support is adopted, a double-nut early-dismantling head is arranged at the top of a vertical rod, and the construction method has the characteristics of being flexiblein arrangement, safe, reliable and convenient and quick to construct; a primary beam, a secondary beam and a formwork can be repeatedly used in a turnover mode, the turnover efficiency is improved, investment of consumed materials such as the formwork and turnover materials is reduced, accordingly the cost is reduced, and the construction period is shortened; and the early-dismantling support real-time monitoring system can achieve frame body deformation monitoring and alarming, the safety and stability of formwork support are ensured, if the early-dismantling support real-time monitoring system is applied and popularized in a large area, the total social demand of related materials can be reduced, and loss of materials such as steel and frogs is reduced.

Owner:中如建工集团有限公司

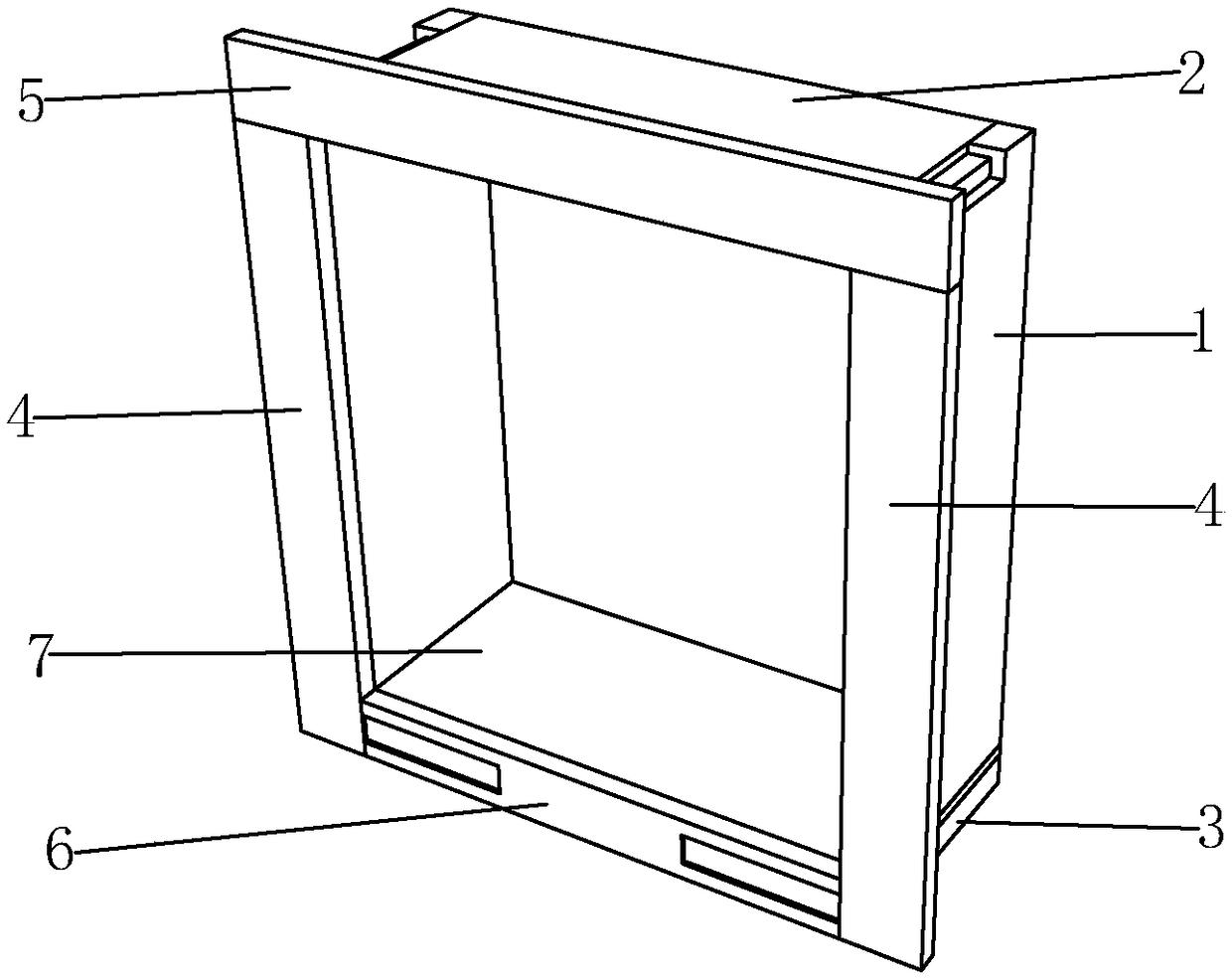

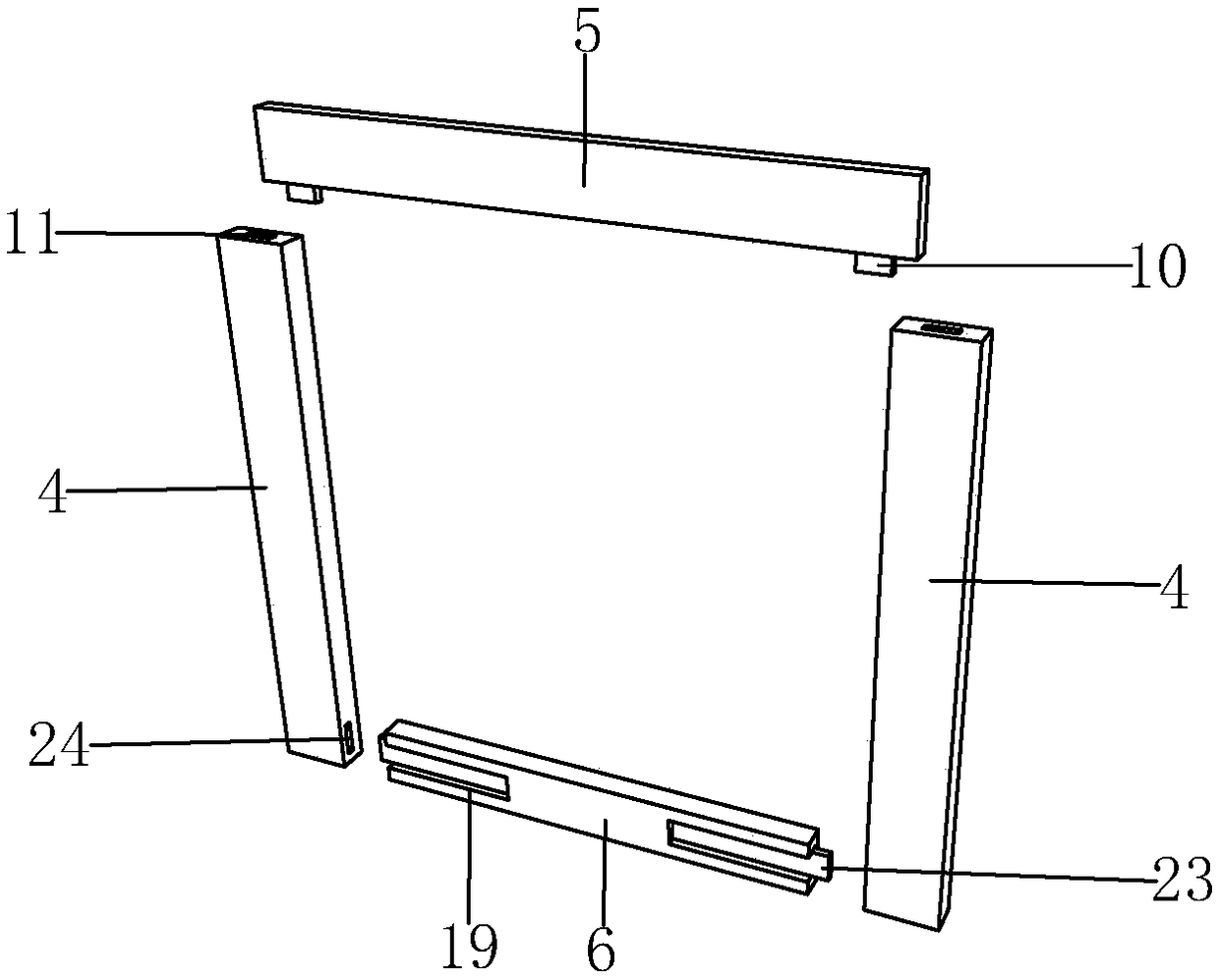

Combined window casing and installation method thereof

ActiveCN108825054ASimple structureEasy to transportFrame fasteningWindow/door framesWindow openingUltimate tensile strength

The invention discloses a combined window casing and an installation method thereof. The window casing comprises side table plates, a top table plate, a lower table plate, side attaching panels, a topattaching panel, a lower attaching panel and a base plate, wherein the top table plate is arranged between the side table plates, the top attaching panel is arranged between the side attaching panels, the side attaching panels are arranged on the two sides of the lower attaching panel, the side table plates are symmetrically distributed on the lower table plate, and the base plate is located between the lower table plate and the side table plates. The installation method comprises the following steps of (a) window opening base surface treatment; (b) supporting and positioning; (c) gluing andfixing; (d) edge line installation; and (e) installing and forming. The window casing is simple in structure, convenient to transport, rapid and convenient during field construction, flexible to assemble and easy to adjust, and the surface does not expose nail holes and is flat and uniform; the attractiveness is high, the later maintenance is facilitated, the installation method is reasonable andorderly, saves labor and is convenient, construction intensity is low, the operation is simple, the construction space is large, the control and the adjustment are easy, and the installation accuracyand the overall attractiveness can be improved.

Owner:浙江图森定制家居股份有限公司

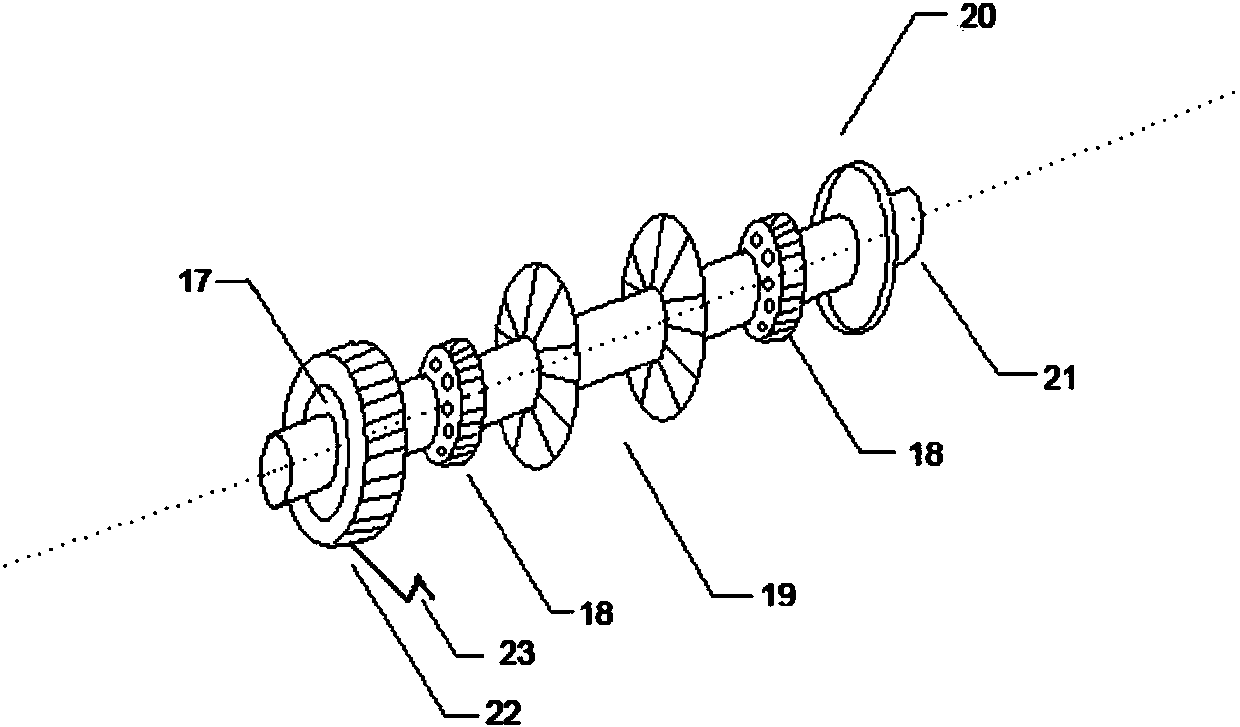

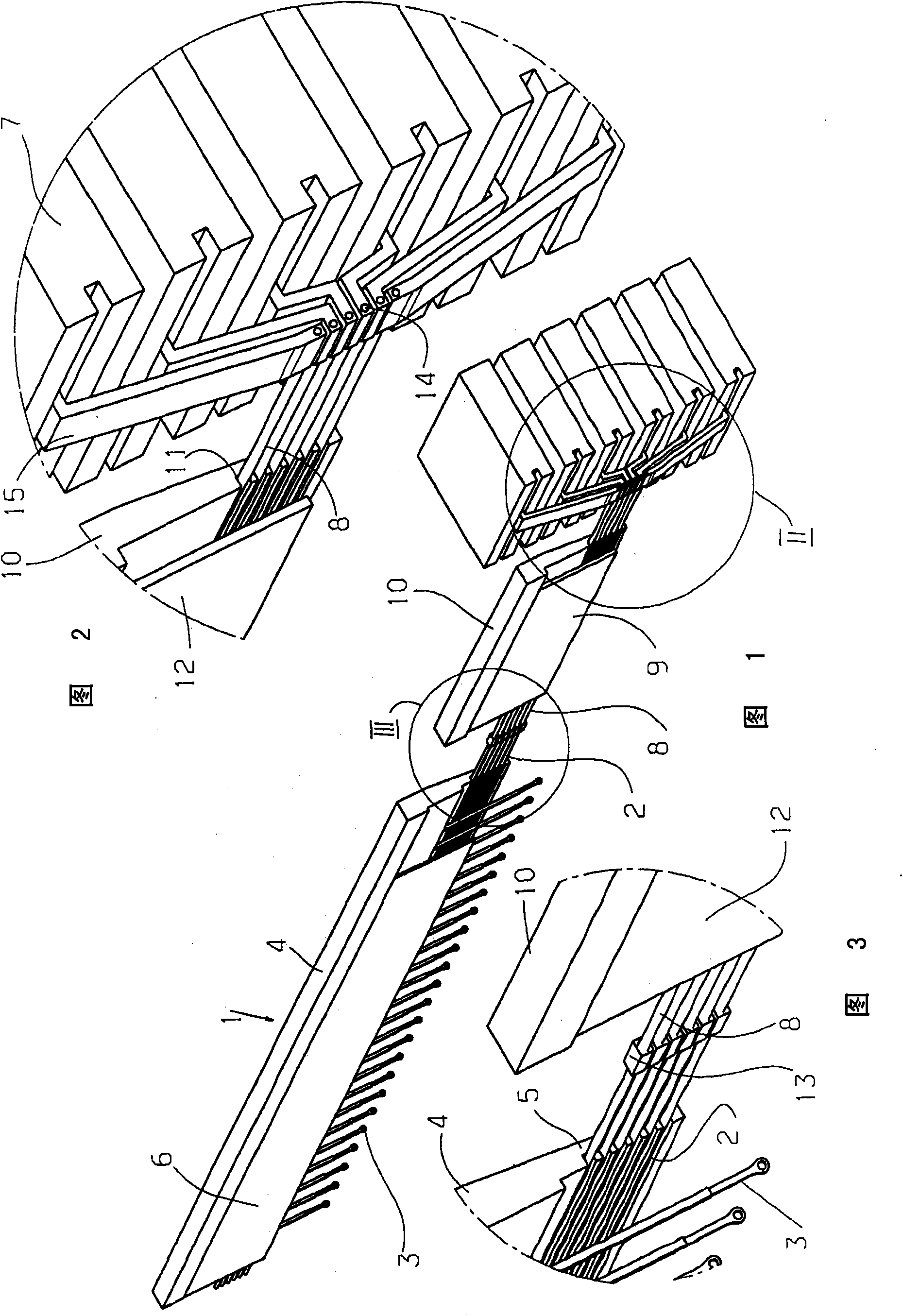

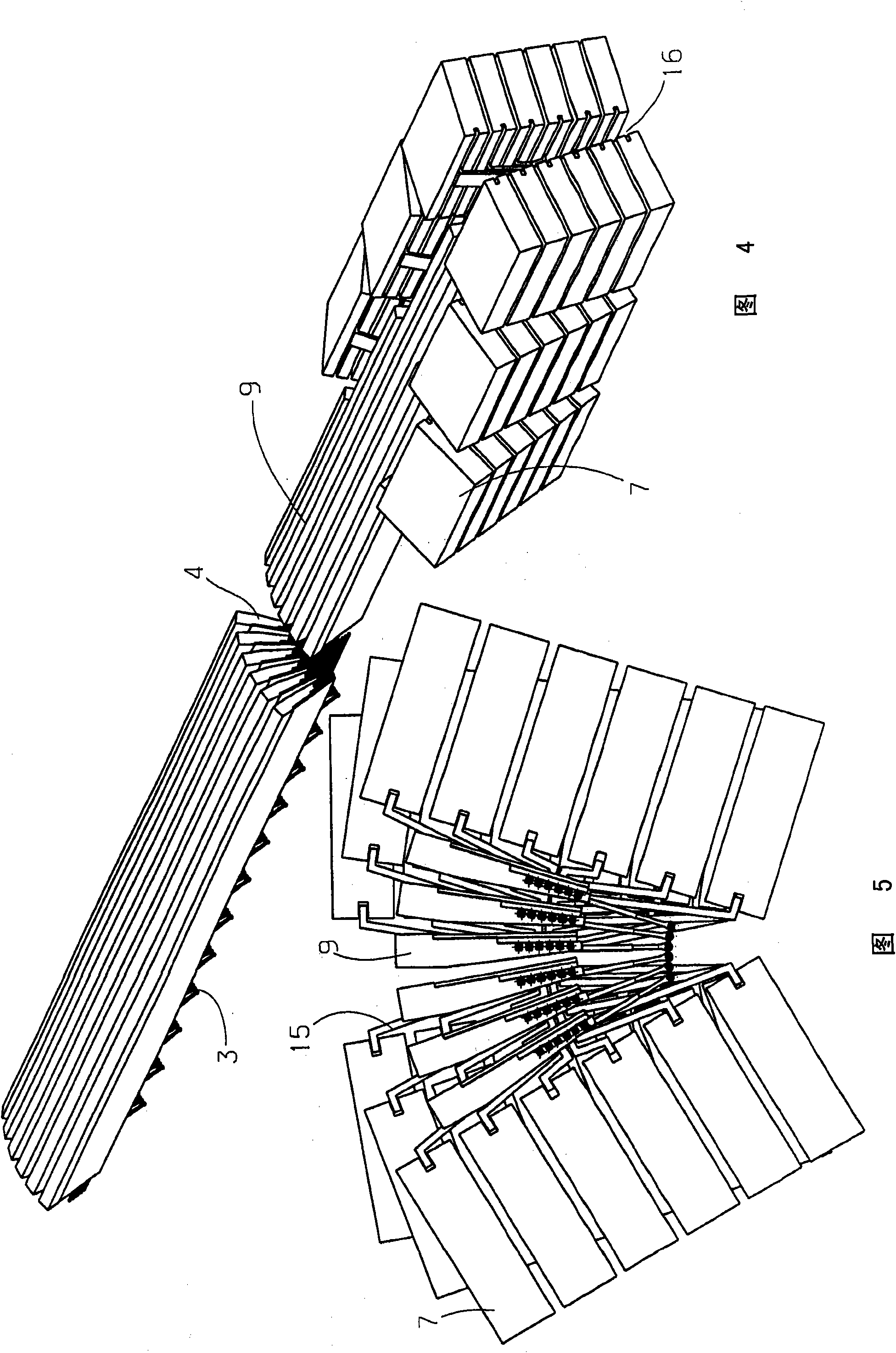

Raschel machine

The invention relates to a Raschel machine, which comprises a plurality of flower guide bars (2) forming at least one cluster, wherein each flower guide bar is provided with a shifting driving device (7) and the flower guide bars (2) of one cluster are superposed on a piling direction. In order to achieve the purpose of acquiring a Raschel machine having simple structure, each flower guide bar (2) is connected to the shifting driving device (7) through a prolonging element (8) which has a function of guiding in a guiding device (9).

Owner:KARL MAYER TEXTILMASCHFAB GMBH

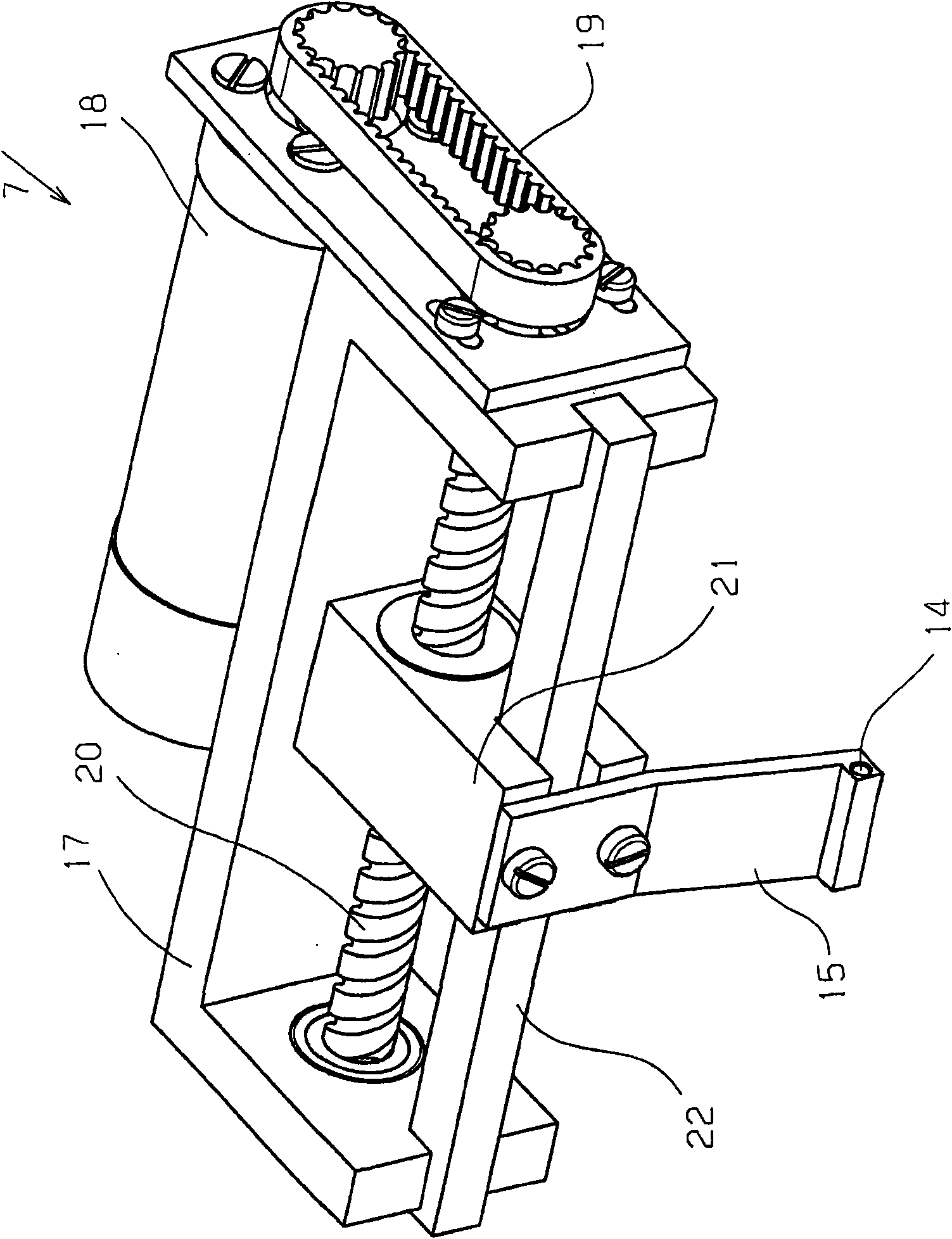

Prestress loading device connecting part

The invention discloses a prestress loading device connecting part which comprises a loading base, a nut, a screw rod and a screw rod base. A groove for placing a jack is formed in the loading base. A screw rod inserting hole is formed in one side of the groove. A connecting flange A is arranged on the opposite side of the screw rod inserting hole of the loading base. One end of the screw rod is inserted into the screw rod inserting hole. The other end of the screw rod is fixedly connected with the screw rod base which is provided with a connecting flange B on the side opposite to the side connected with the screw rod. The connecting flange B and the nut which abuts against the loading base can be in thread connection with the portion, except the screw rod inserting hole, of the screw rod. According to the technical scheme, prestress is exerted on a whole supporting-protecting structure, the overall intensity of a supporting-protecting system is improved, assembling and disassembling are convenient, multi-time repeated using can be achieved, and the purpose that construction cost is saved, and construction is convenient is achieved.

Owner:杭州爱默乐实验设备有限公司

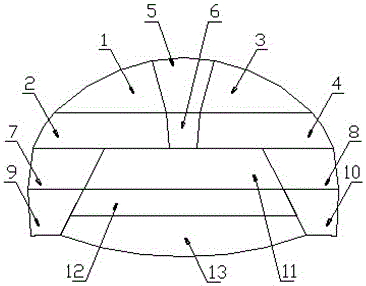

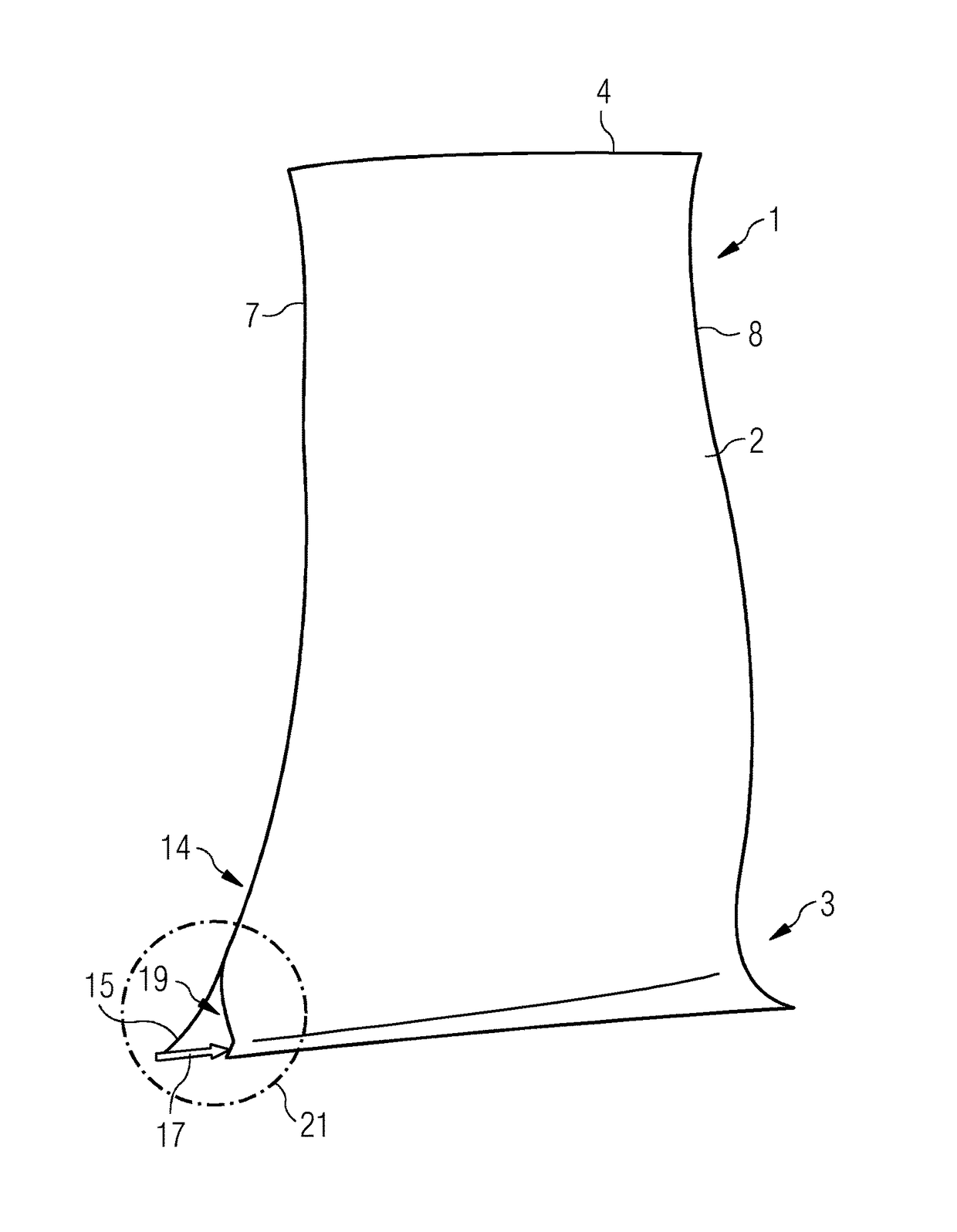

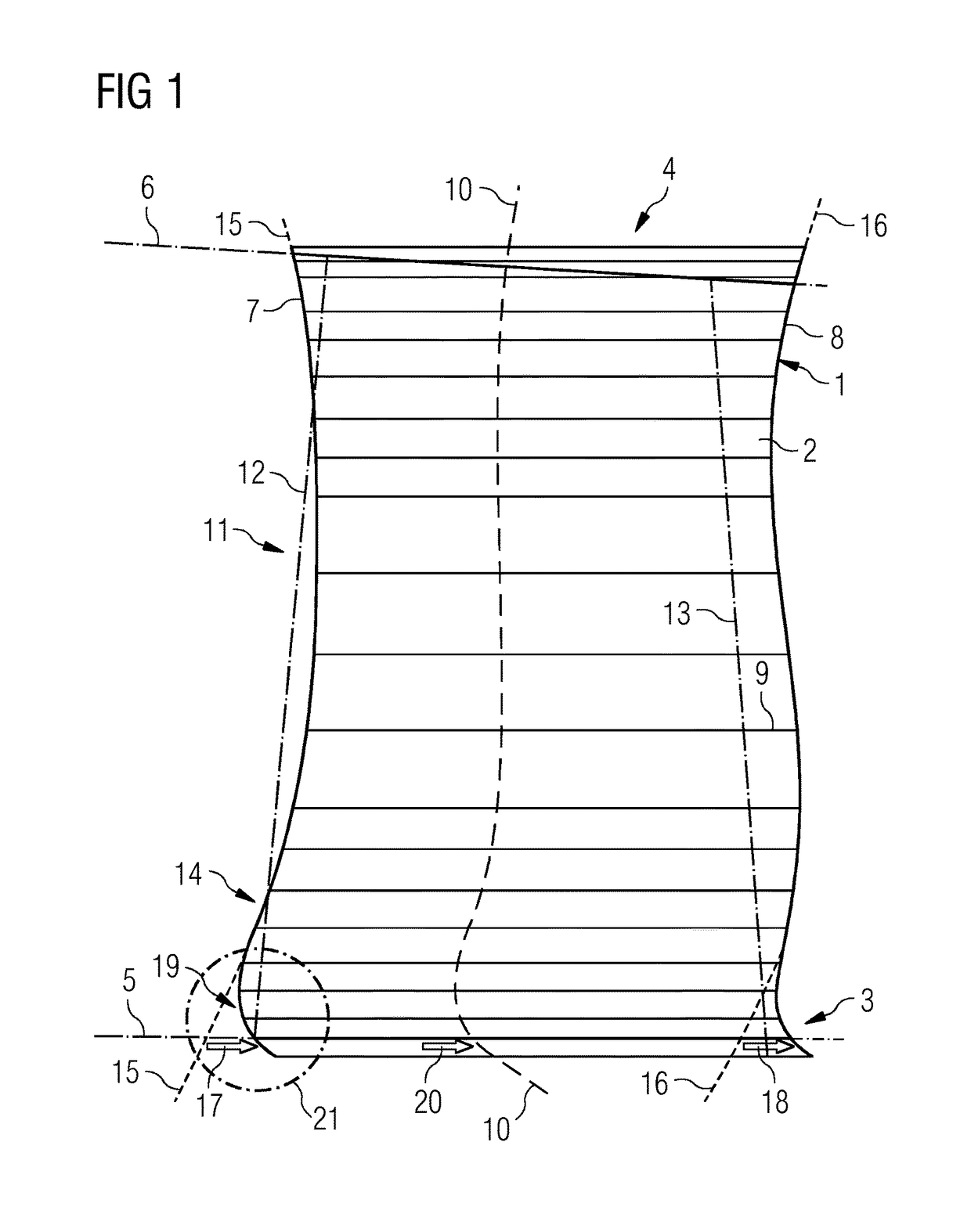

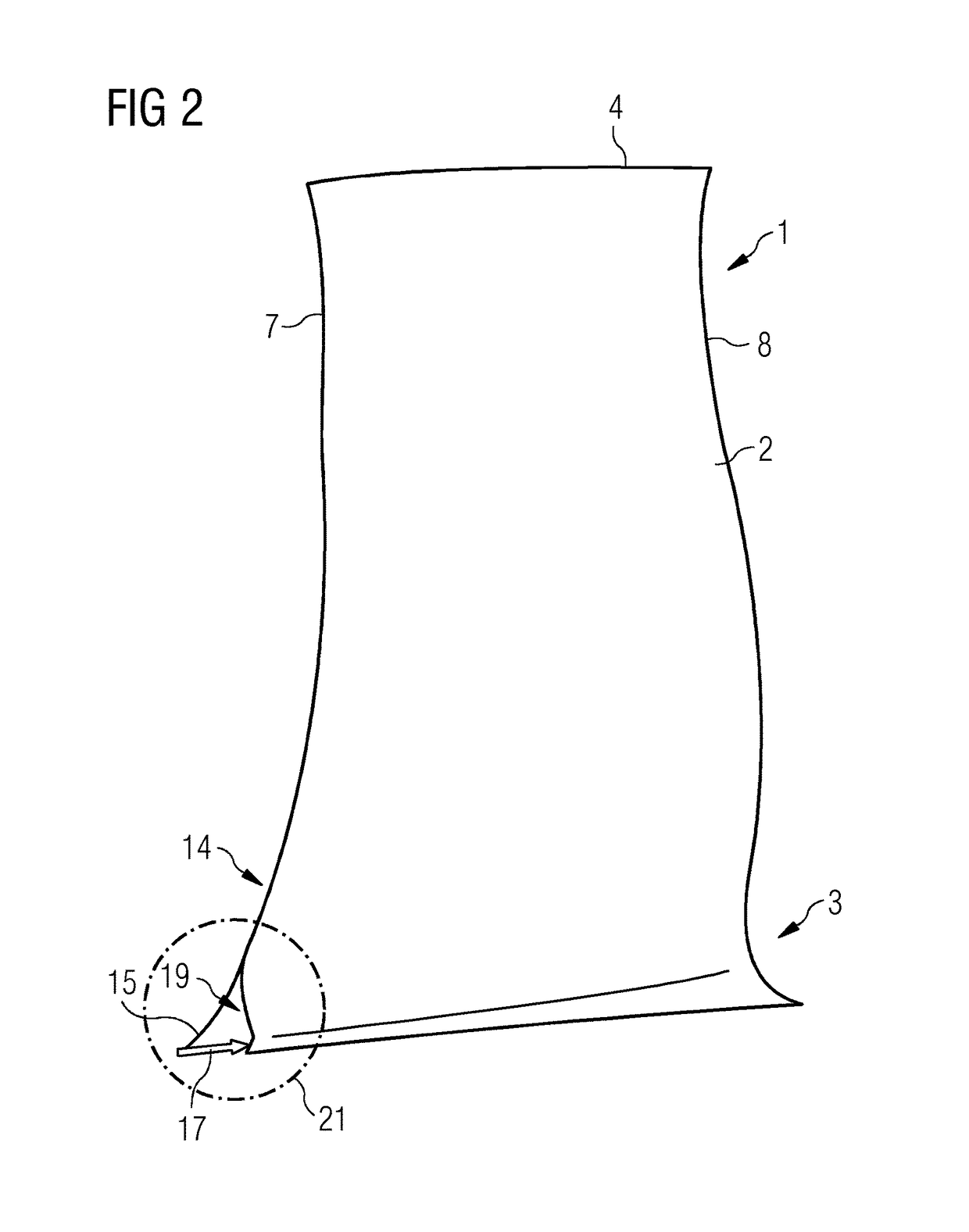

Method for profiling a replacement blade as a replacement part for an old blade for an axial-flow turbomachine

ActiveUS9771803B2Improve efficiencyLarge construction spaceBlade accessoriesStatorsLeading edgeEngineering

A method for profiling a replacement blade for an axial turbomachine is provided. The method includes: measuring hub contour geometry and housing contour geometry of the flow channel of the old blade and the axial position of the centre of gravity of the blade aerofoil of the old blade; laying out geometry of the blade aerofoil of the replacement blade, the blade aerofoil having a rearward sweep on its leading edge; defining a region of the blade aerofoil near the mounting and in which positive influence of the rearward sweep on the degree of stage efficiency is rated as low; and axially displacing the replacement blade aerofoil section arranged outside this region in the upstream direction, until the axial position of the centre of gravity of the blade aerofoil of the replacement blade coincides with the old blade. In the region from the mounting-side section to the displaced blade aerofoil section of the replacement blade, the leading edge is inclined downstream towards the mounting such that the blade aerofoil has a transition sweep in this region.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

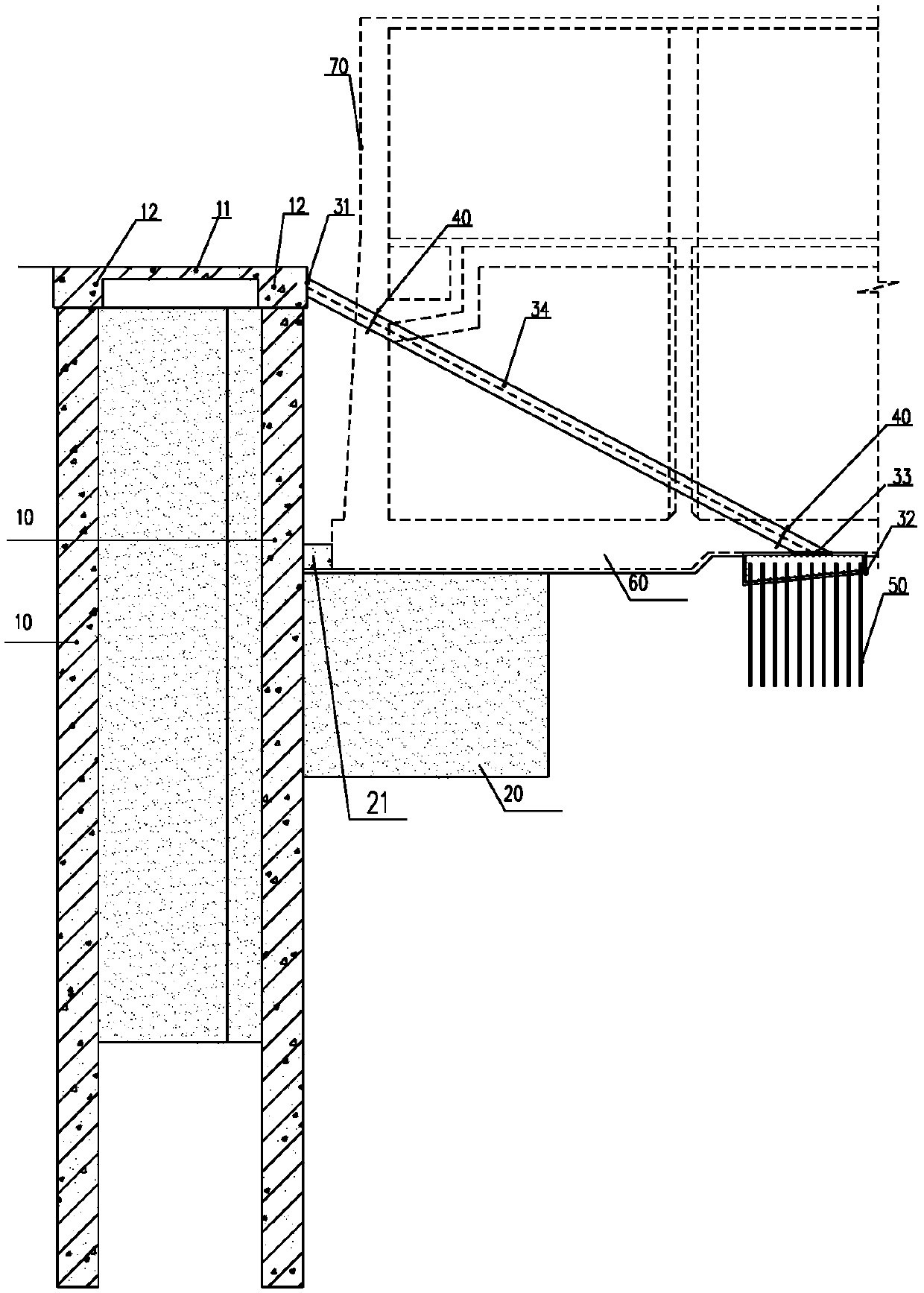

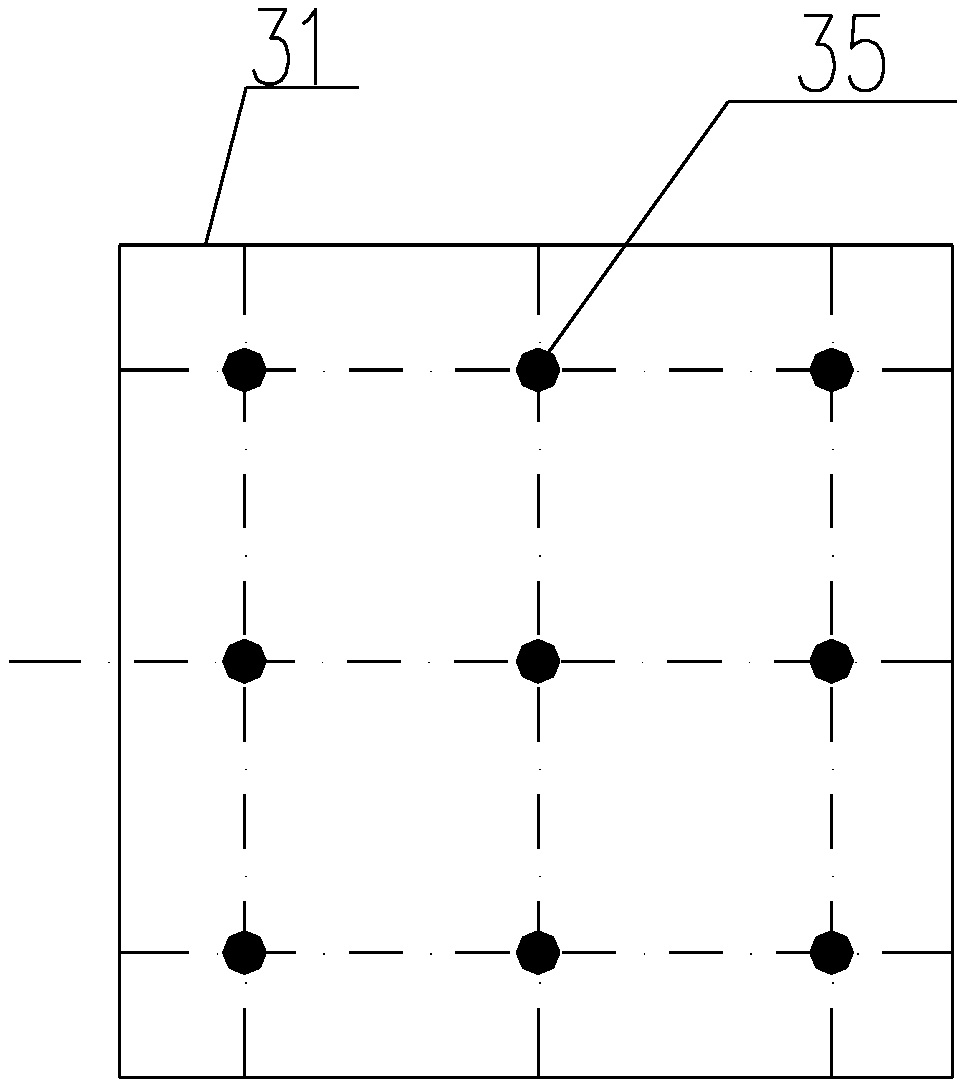

Combined supporting system for foundation pit central island basin type excavation and construction method thereof

The invention provides a combined supporting system for a foundation pit central island basin type excavation and a construction method thereof. A grid type double-shaft cement-soil mixing pile gravity type enclosure wall is added to replace a soil body to slope, steel inclined struts are arranged after overall pouring of a tower bottom plate is completed, and follow-up construction work is carried out. The double-shaft cement-soil mixing pile gravity type enclosure wall is used for replacing the soil body slope, so that the length of the steel inclined struts can be properly shortened, and the influence of the steel inclined struts on foundation pit deformation is reduced; a foundation bottom plate of a tower extends to the position, close to the edge side of a foundation pit, of part ofa foundation bottom plate of a basement to be constructed, the problem of tower bottom plate cutting caused by central island basin type earth excavation is solved, the foundation bottom plate of thetower can be integrally poured, integrity and continuity of the tower structure are guaranteed, and other quality problems such as water leakage caused by improper later construction joint treatment are avoided.

Owner:SHANGHAI CONSTRUCTION GROUP

Quick emergency diagonal bracing for foundation pit salvage, and construction method

PendingCN109555129AShorten emergency rescue timeShorten the construction periodExcavationsCushionPre embedding

The invention provides a quick emergency diagonal bracing for foundation pit salvage, and a construction method, and belongs to the technical field of building construction. The quick emergency diagonal bracing is used for effectively relieving the situation that during large-area, deep-foundation-pit and support-free earth excavation, the stress and deformation speed of a foundation pit enclosurewall are too large, and thus the potential safety hazard to a site is generated. According to the quick emergency diagonal bracing, a first pre-embedded piece is mounted on the side wall, close to the inner side of a foundation pit, of a retaining type enclosure structure at a foundation pit platform in the vertical direction of the retaining type enclosure structure, a second pre-embedded pieceis mounted on a thickened cushion layer at the bottom of the foundation pit, then the two ends of a profile steel support manufactured by a plant are connected with the first pre-embedded piece and the second pre-embedded piece in a full weld mode correspondingly to form the diagonal bracing, and thus the diagonal bracing serve as an emergency rescue measure of the foundation pit; the profile steel support can effectively shorten the emergency salvage time so as to shorten the construction period; the large construction space is saved for construction of a structure body; and the stress form of the profile steel support is good, the stress of the foundation pit enclosure wall and the stress of soil body bulges are counteracted mutually, and the foundation pit enclosure form can be reinforced effectively.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

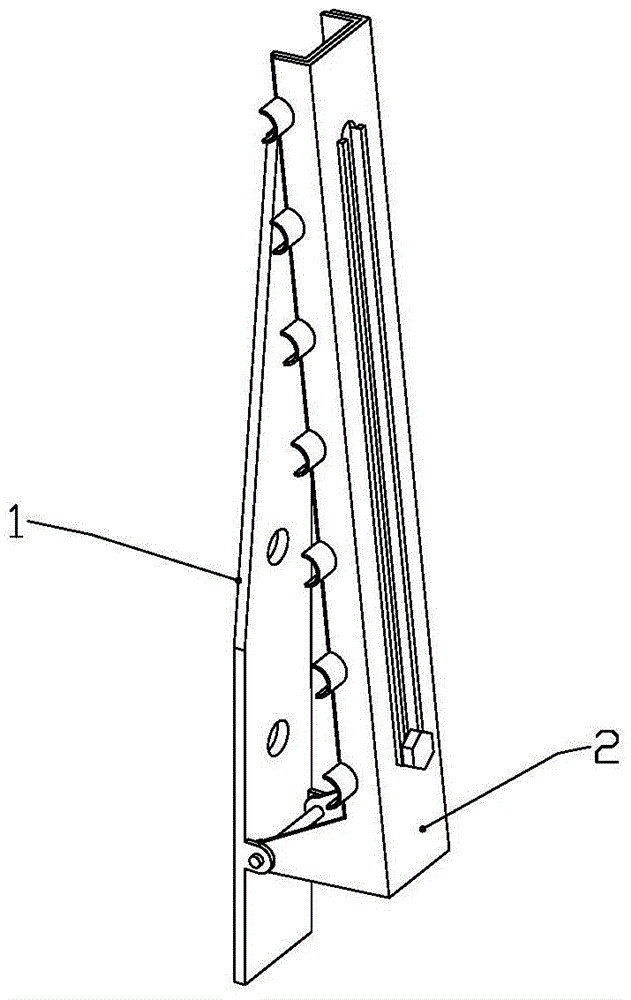

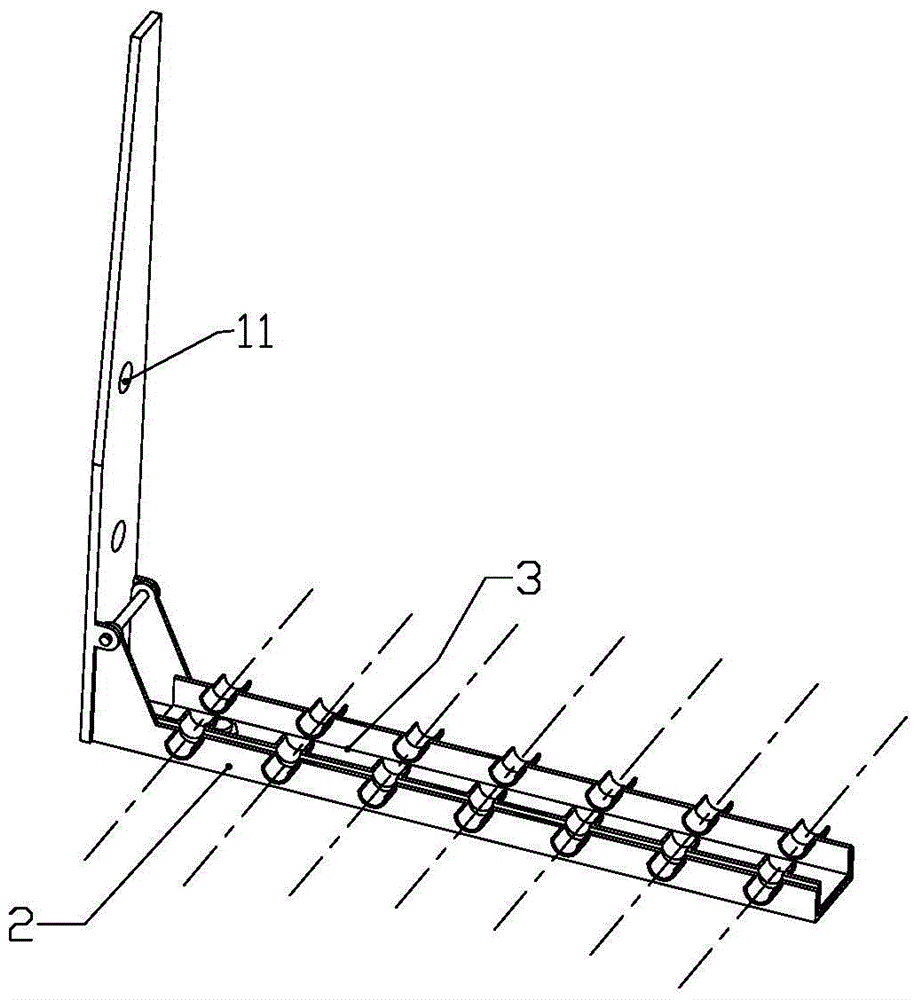

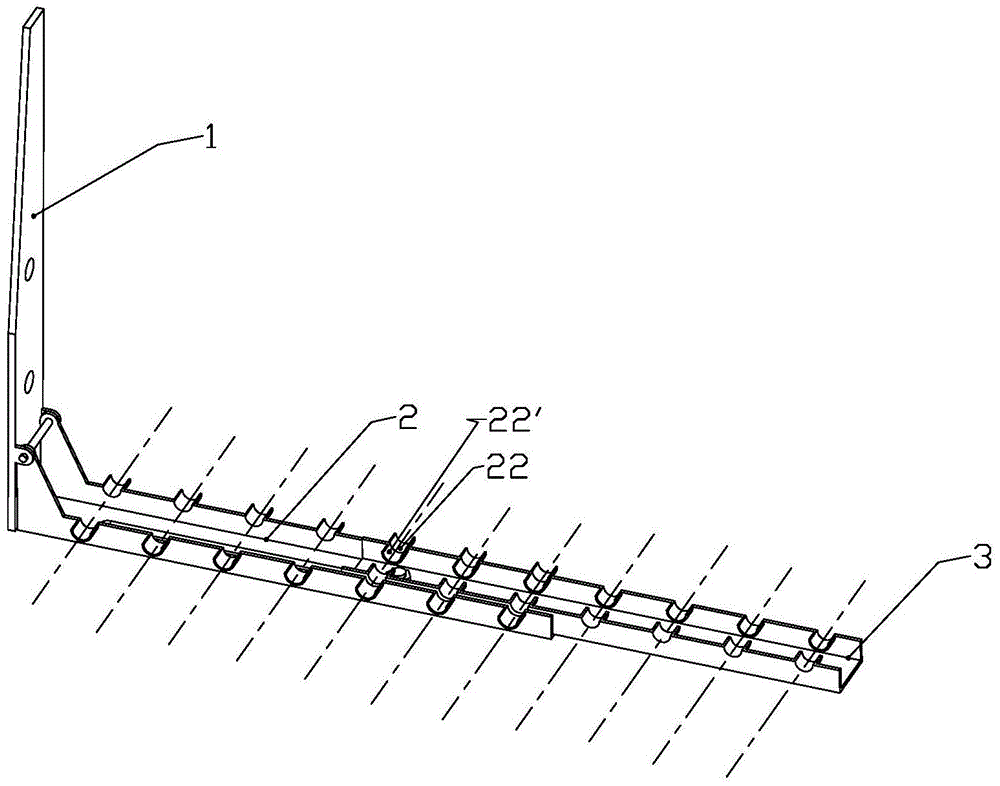

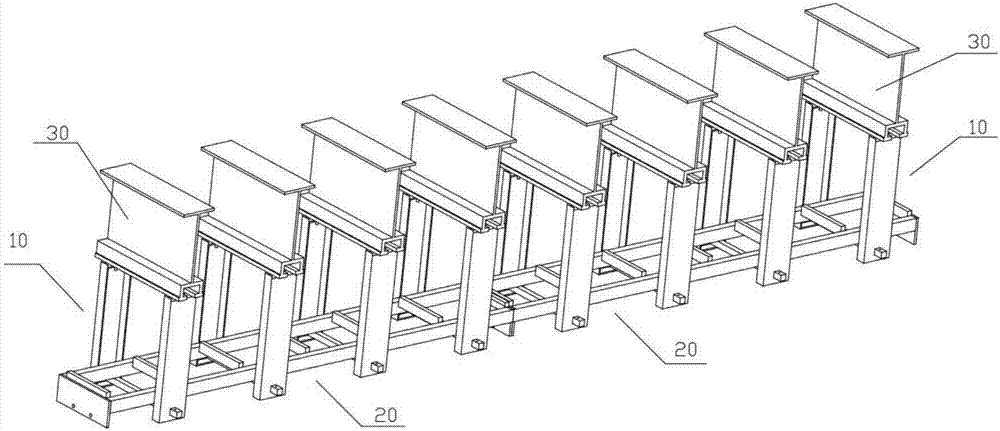

Folding telescopic cable rack

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

Arch column method for building large-scale underground structure in shallow buried rock stratums

ActiveCN105386779ALow costShorten the construction periodUnderground chambersStructure of the EarthDeformation control

The invention relates to an arch column method for building a large-scale underground structure in shallow buried rock stratums. The method comprises the following steps of: 1, separately excavating underground one-storey middle pilot tunnels, constructing primary supports, and constructing pile foundations and steel pipe columns at the positions of middle columns; 2, constructing secondary linings including underground one-storey floors, steel pipe columns, roof timbers, roof arches and the like, and waterproof layers in middle tunnels; 3, symmetrically excavating underground one-storey two-side pilot tunnels, constructing primary supports, and constructing pile foundations and side columns under side walls; 4, constructing secondary linings including floors, vertical walls, edge arches and the like in side tunnels and waterproof layers, and disassembling temporary supports; 5, under the protection of underground one-storey structures, downwards excavating an underground second-storey structure with large-scale machinery, besides, constructing side wall bolt spray supports or slab rib type anchored bolt retaining wall supports, and pouring underground second-storey floors, side walls and waterproof layers; and 6, sequentially downwards excavating a plurality of underground storeys, besides, constructing side wall supports, and pouring floors, side walls and waterproof layers of corresponding storeys. The method disclosed by the invention is convenient to construct, high in efficiency, small in construction risks, good in stratum deformation control, and low in building cost.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

Wire groove mounting, dismounting and suspending device for railway vehicles

ActiveCN107161037ASave human effortSave moneyElectrical apparatusPower railsMarine engineeringMaterial resources

The invention relates to the technical field of railway vehicles, and discloses a wire groove mounting, dismounting and suspending device for the railway vehicles. The wire groove mounting, dismounting and suspending device comprises a plurality of groups of suspending and supporting frames and a bearing bracket, wherein the bearing bracket is used for penetrating through the suspending and supporting frames and is arranged on the bottom surfaces of the suspending and supporting frames; the suspending and supporting frames are arranged at the bottom of a vehicle body at intervals, and the upper ends of the suspending and supporting frames are connected with mounting beams of the vehicle body; and the bearing bracket and the suspending and supporting frames can move relatively. According to the wire groove mounting, dismounting and suspending device disclosed by the invention, after a wire groove is dismounted from the railway vehicle, the wire groove can move along with the vehicle body, so that a fixed platform is not occupied, and the platform can be provided for subsequent vehicles for repair; and according to production needs, streamline operation is performed, so that a lot of manpower and material resources are saved, and the production efficiency is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com