Method for excavating mountain tunnels in weak surrounding rock-fractured zones or shallow covered slope sections

A technology of weak surrounding rock and broken zone, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of slow construction speed, high cost, narrow working space, etc., and achieve fast construction progress, low project cost, and construction safety. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

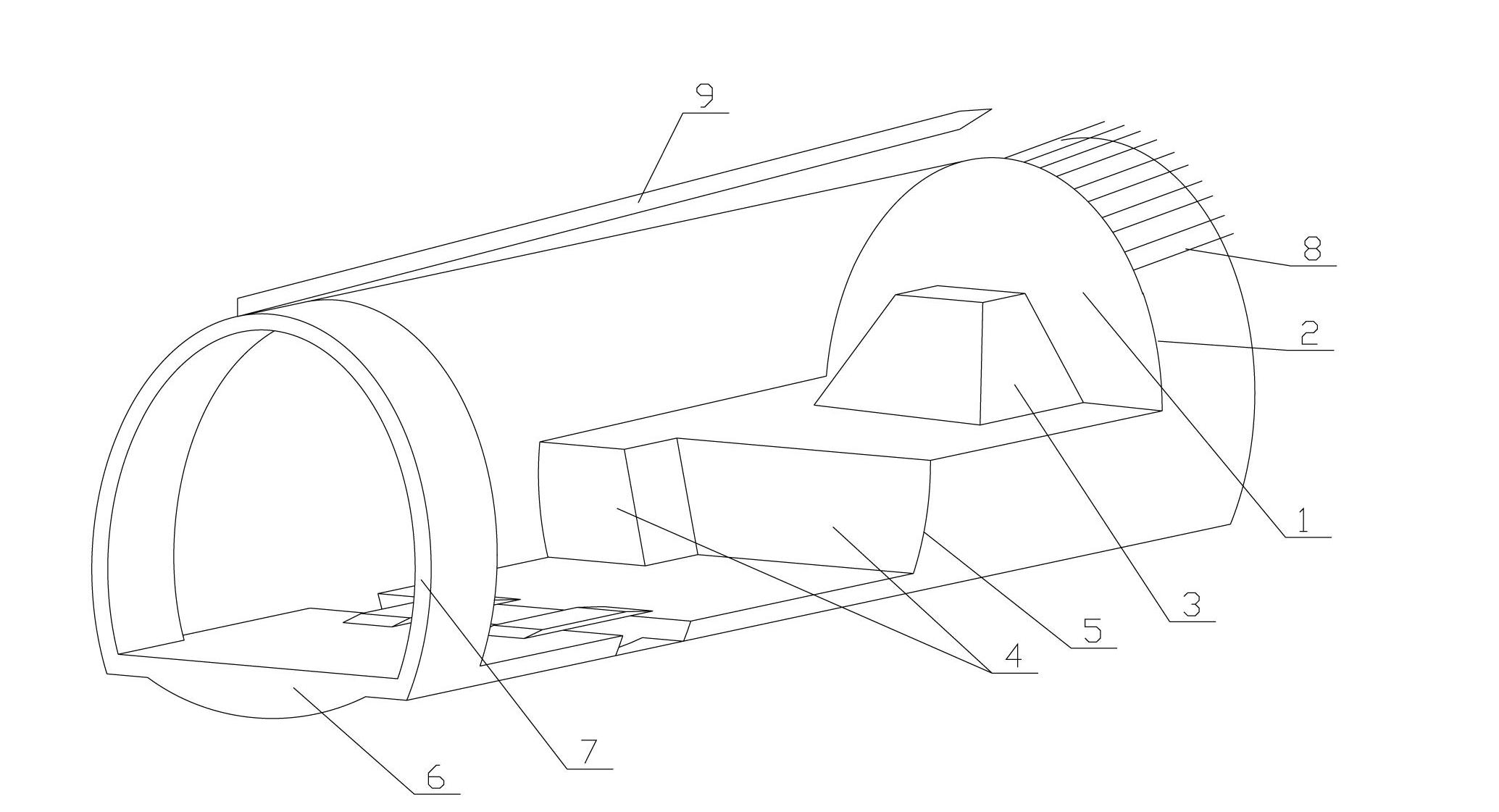

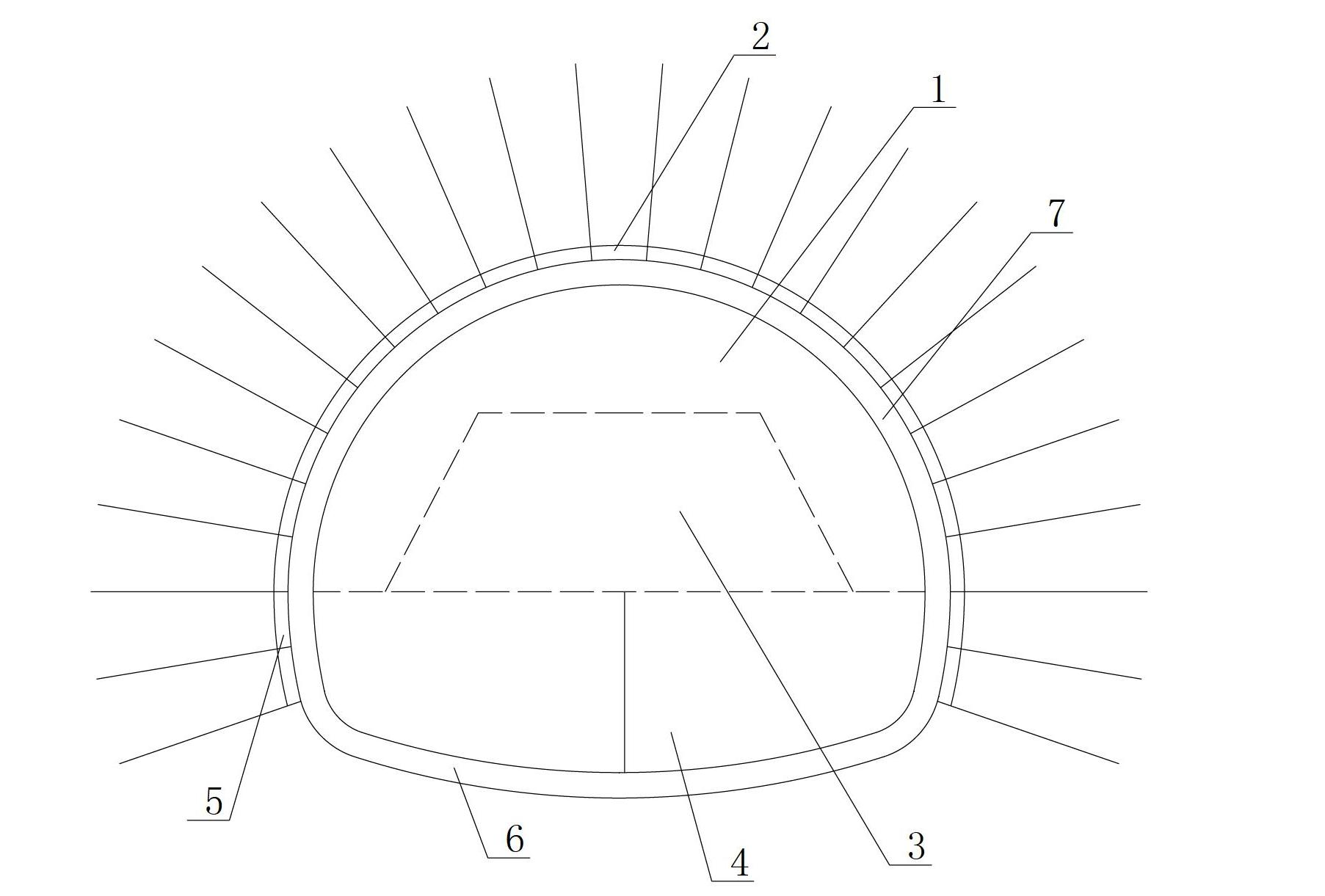

[0032] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

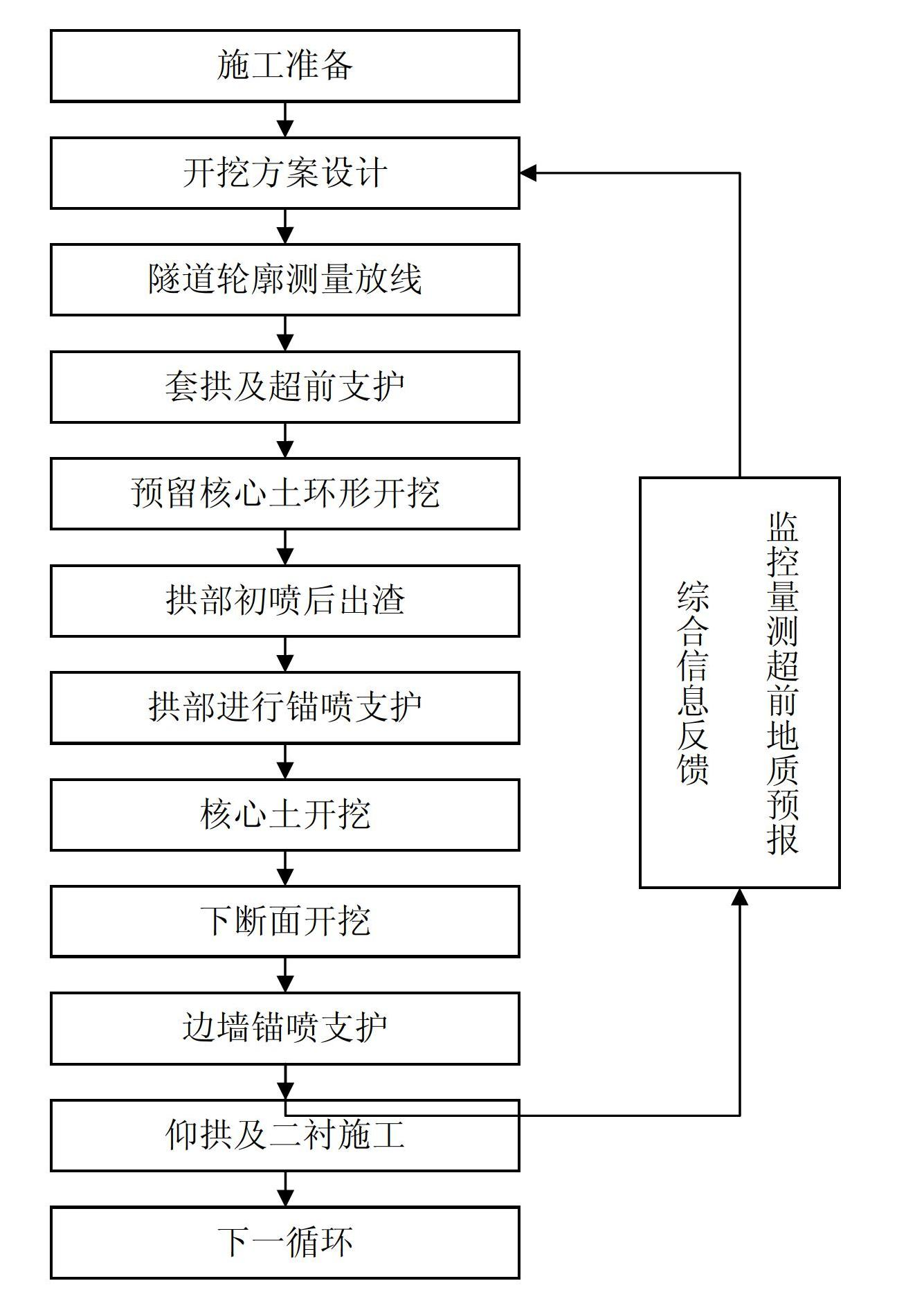

[0033] see Figure 1 to Figure 4 , an excavation method for a weak surrounding rock fracture zone and a shallow buried biased section of a mountain tunnel, comprising the following steps:

[0034] 1) Arch set and advance support, including the following steps:

[0035] 1) Excavation and formation of the uphill slope at the mountain side of the cave entrance: After the position of the tunnel entrance is determined, the open excavation forming operation platform makes the tunnel dark cave entrance appear;

[0036] 2) Arch construction:

[0037] When the excavation of earth and stone at the entrance of the open tunnel reaches the junction of the open and dark tunnels, the excavation of earth and stone will be suspended, and the position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com