Patents

Literature

375results about How to "Improve the effect of impurity removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrodewaxing catalyst and its preparation method

ActiveCN102451748AImprove the effect of impurity removalInhibit carbon depositionMolecular sieve catalystsRefining to eliminate hetero atomsImpurityChemistry

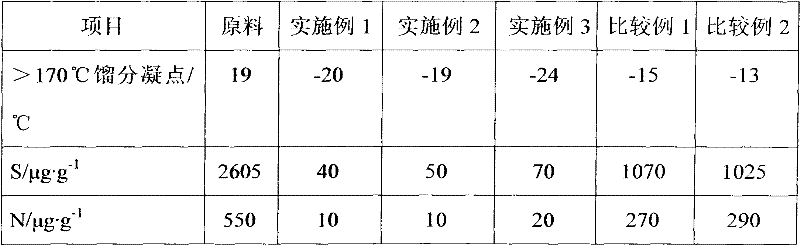

The invention discloses a hydrodewaxing catalyst and its preparation method. With the weight of the catalyst as the reference, the catalyst contains the following components of: by weight, 5-10% of tungsten oxide, 1-5% of nickel oxide, 40-50% of nanometer ZSM-5 molecular sieve, 10-40% of macroporous alumina and the balance being a binder. The catalyst is prepared by the following steps of: firstly kneading the nanometer ZSM-5 molecular sieve, macroporous alumina and the binder to prepare a carrier, dipping loaded active metal, and finally carrying out hydrothermal treatment. The hydrodewaxing catalyst provided by the invention has a good shape-selective catalysis function and simultaneously has a good hydrofinishing function, and is especially suitable for the hydrofinishing and pour point reduction processes of a waxy hydrocarbon oil material containing high content of impurities such as sulfur, nitrogen and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high purity quartz sand

InactiveCN101391871AImprove solubilityImprove the effect of impurity removalPolycrystalline siliconForeign matter

The invention relates to a preparation method of high-purity quartz sand. The method adopts quartz sand as basic raw material, removes ore foreign bodies on the surface of sand grains or inside the grains by carrying out roasting and water-granulating to blocky materials, removes certain soluble and flammable impurities in the quartz sand by carrying out the roasting and water-granulating again, and finally removes most of the ore foreign bodies by acid leaching to obtain the high-purity quartz sand. The quartz sand prepared by the method can be used for producing polysilicon materials.

Owner:晟茂(青岛)先进材料有限公司

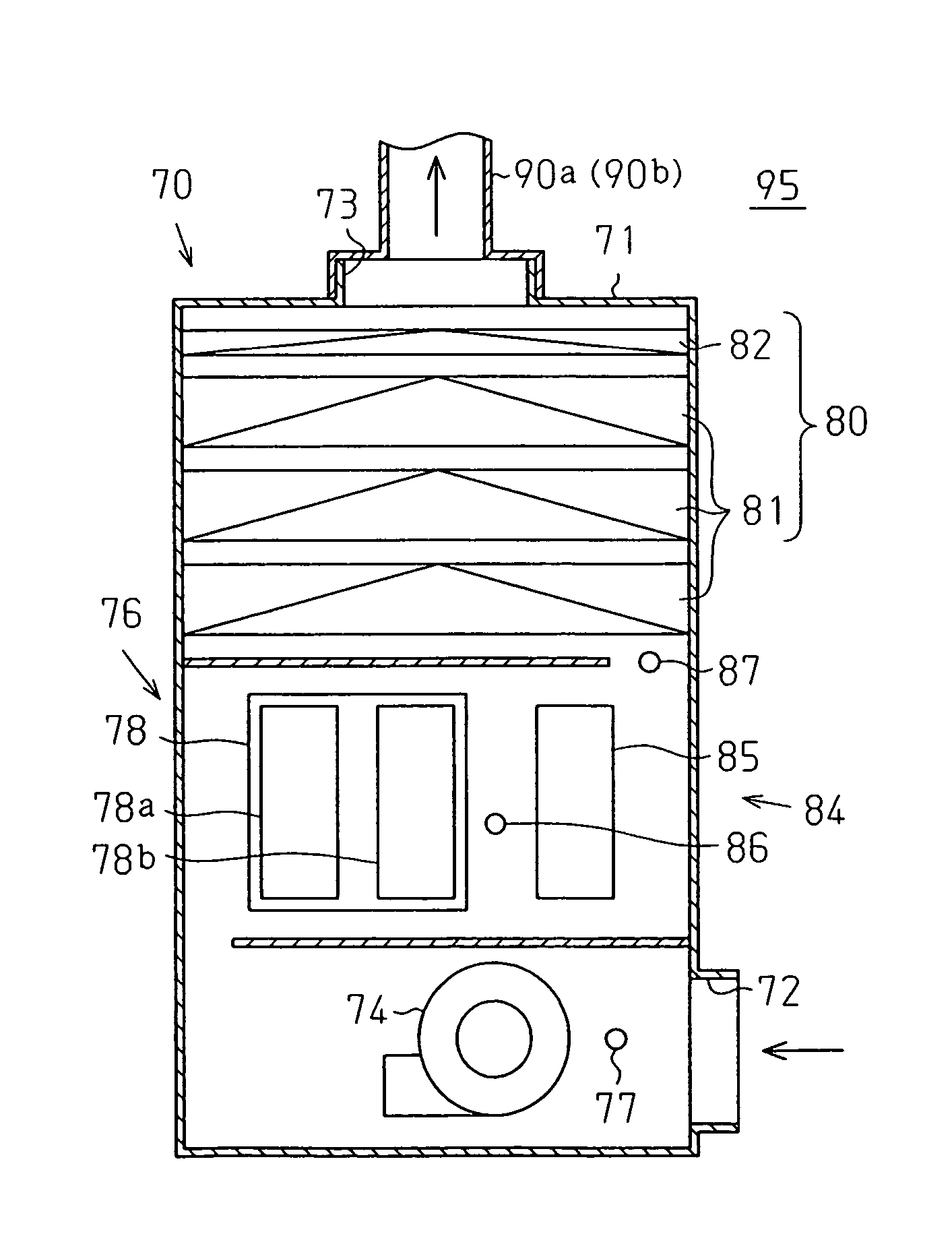

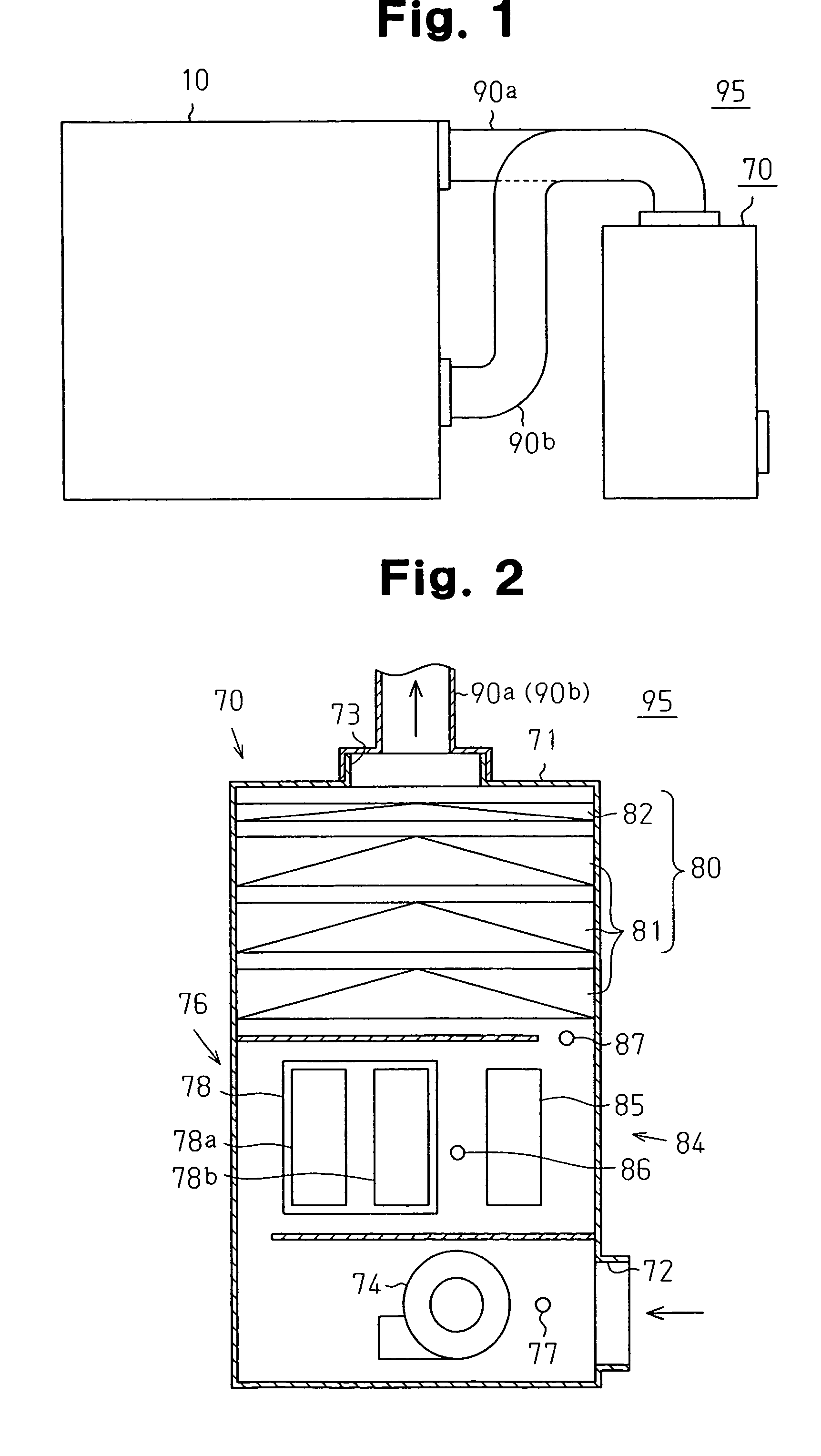

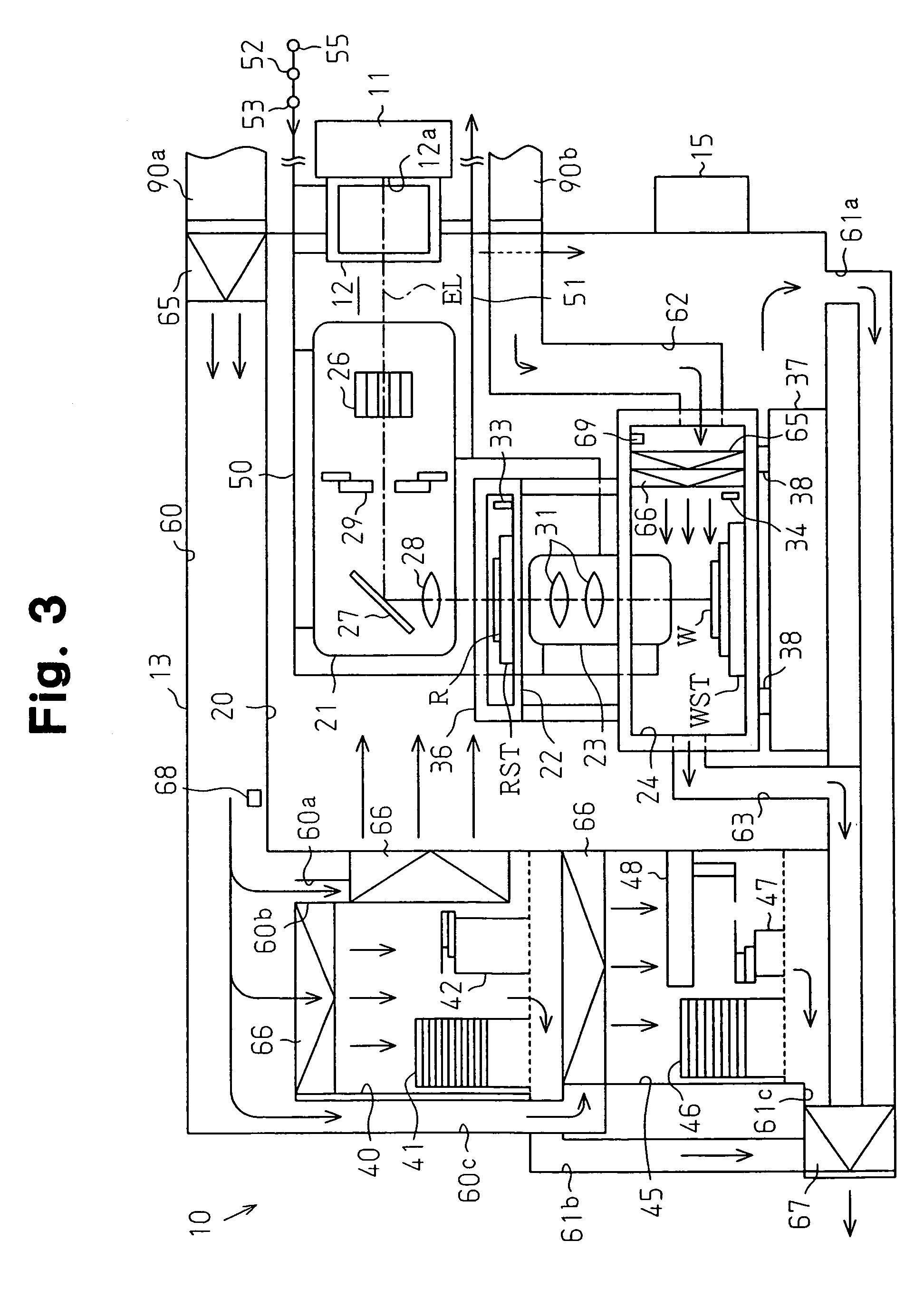

Filter apparatus, exposure apparatus, and device-producing method

ActiveUS20060156927A1Improve temperature stabilityImprove the effect of impurity removalCombination devicesAuxillary pretreatmentProcess engineeringHUMID WEATHER

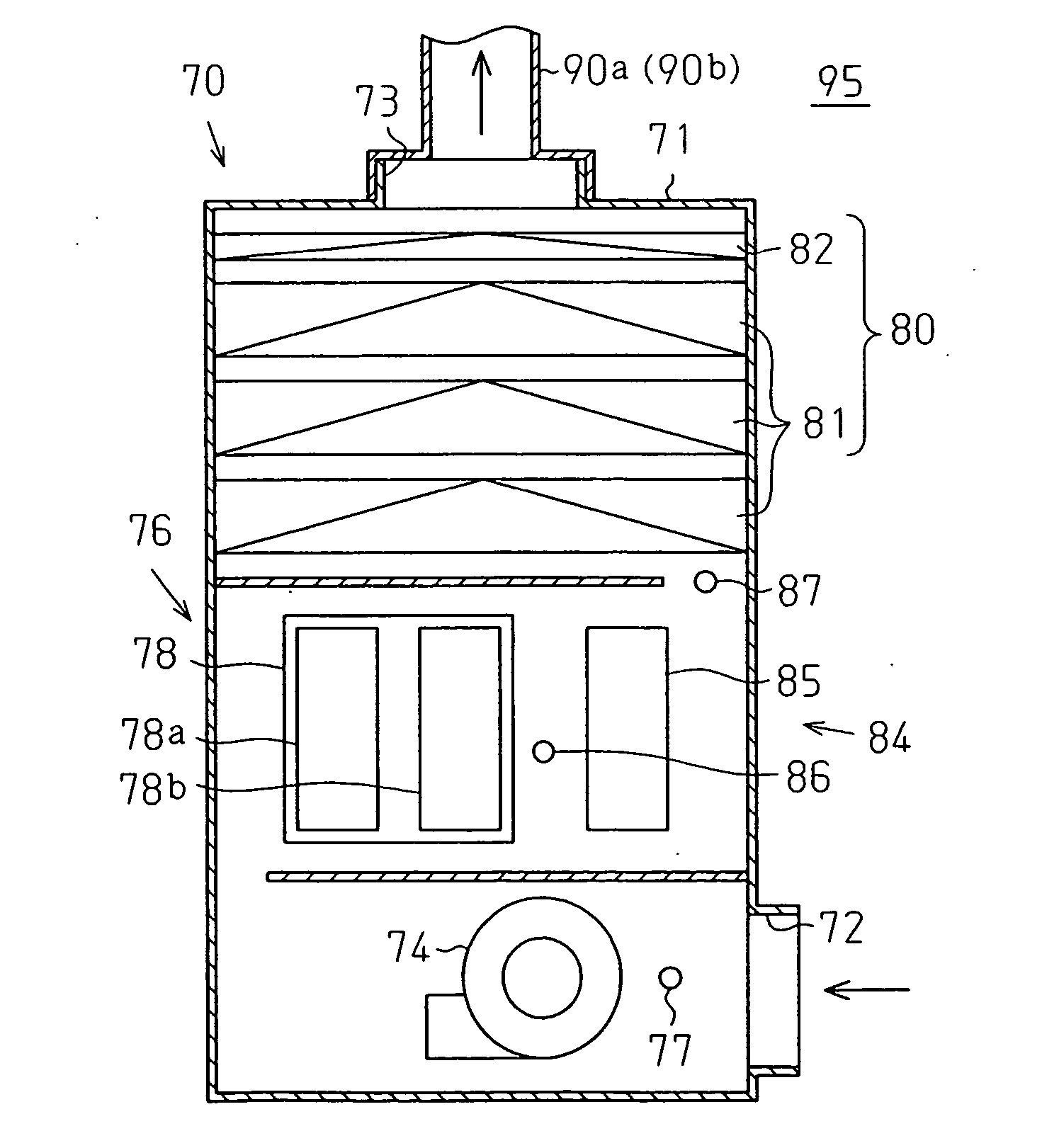

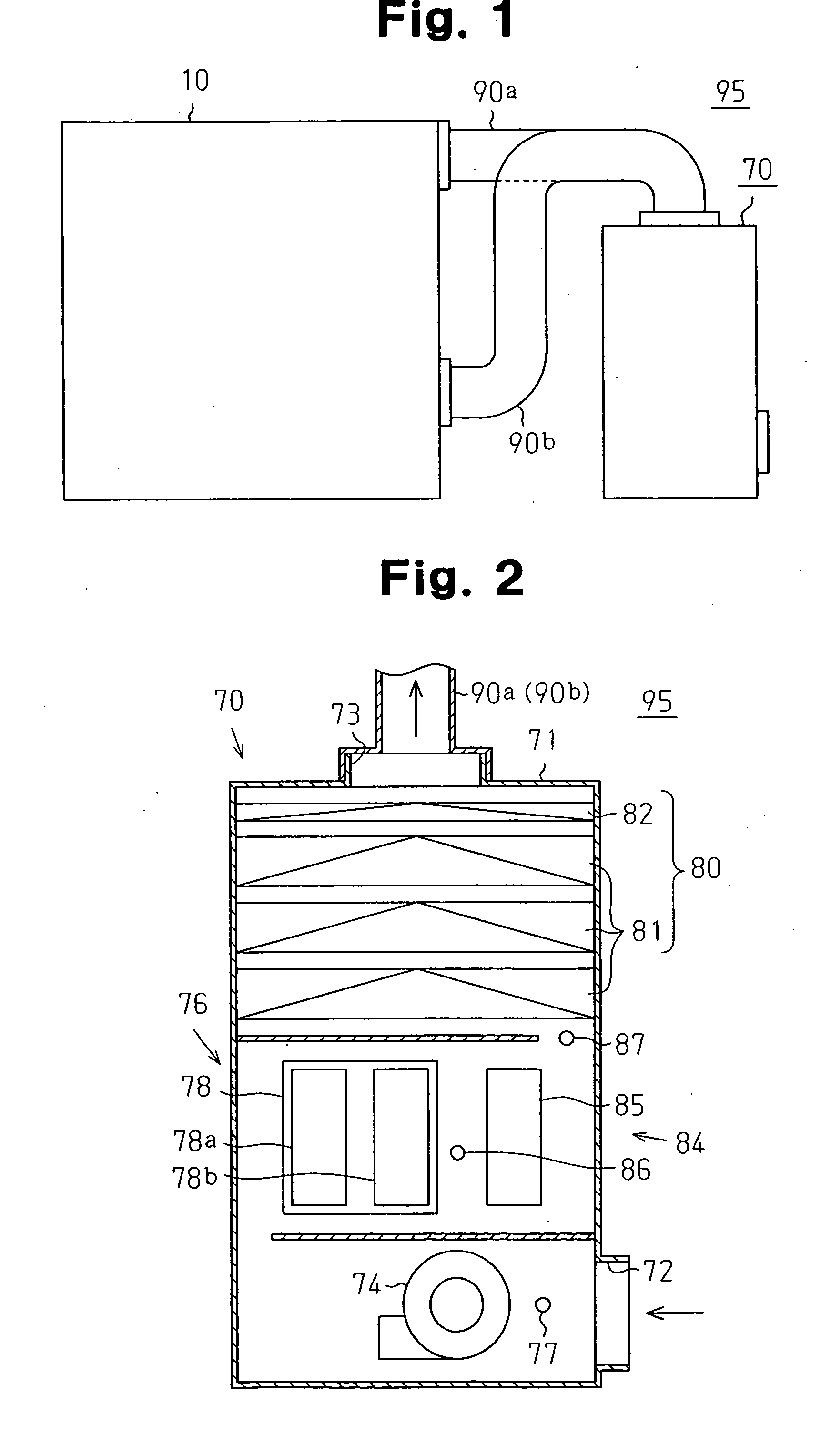

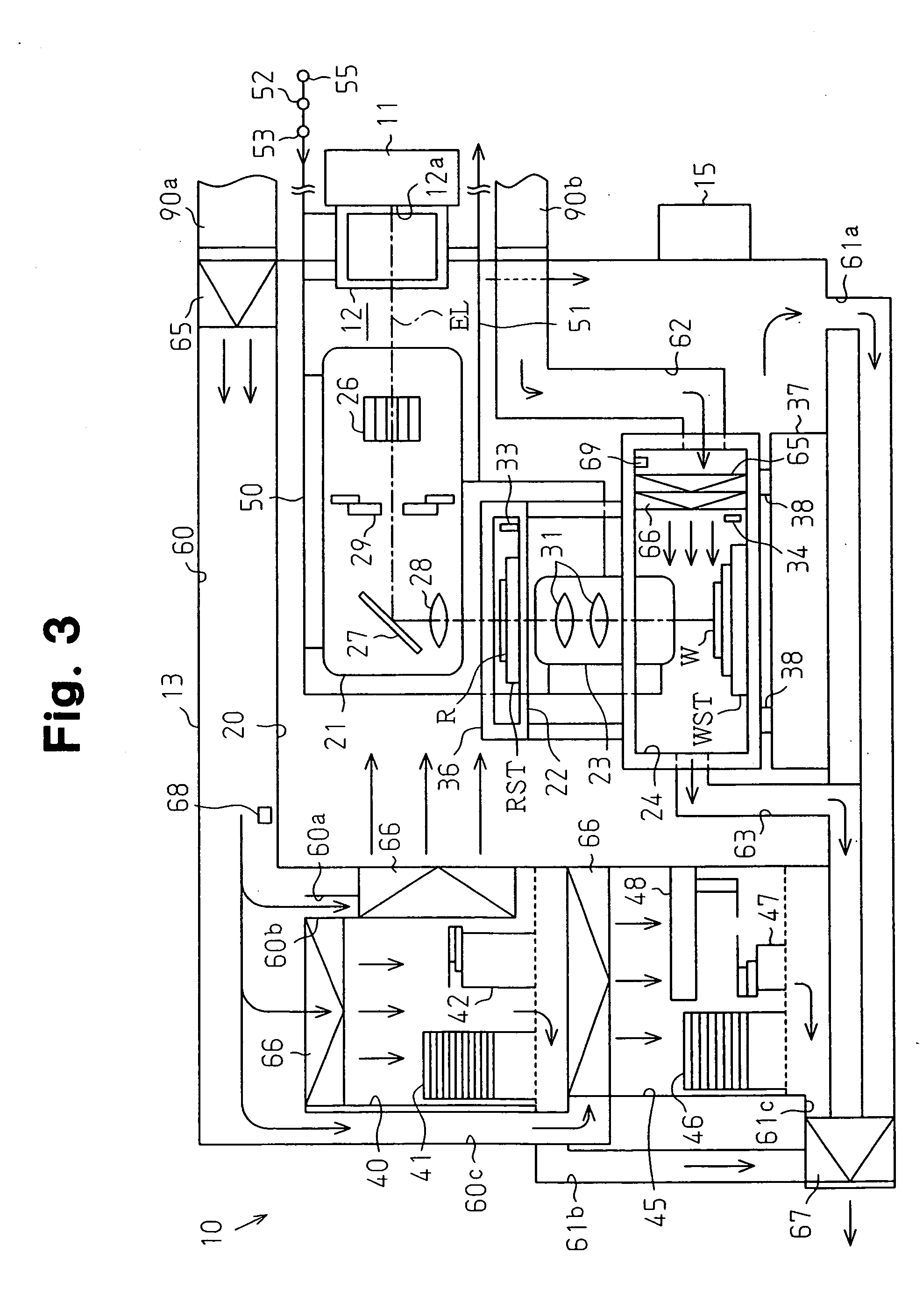

A filter apparatus for improving gas temperature stability while maintaining a high impurity removal capacity. The filter apparatus includes a filter for removing impurities from a gas and a temperature adjuster for adjusting the temperature of the gas to a predetermined temperature. The filter apparatus further includes a humidity detector, arranged at the upstream side of the filter, for adjusting the humidity of the gas before the gas passes through the filter.

Owner:NIKON CORP

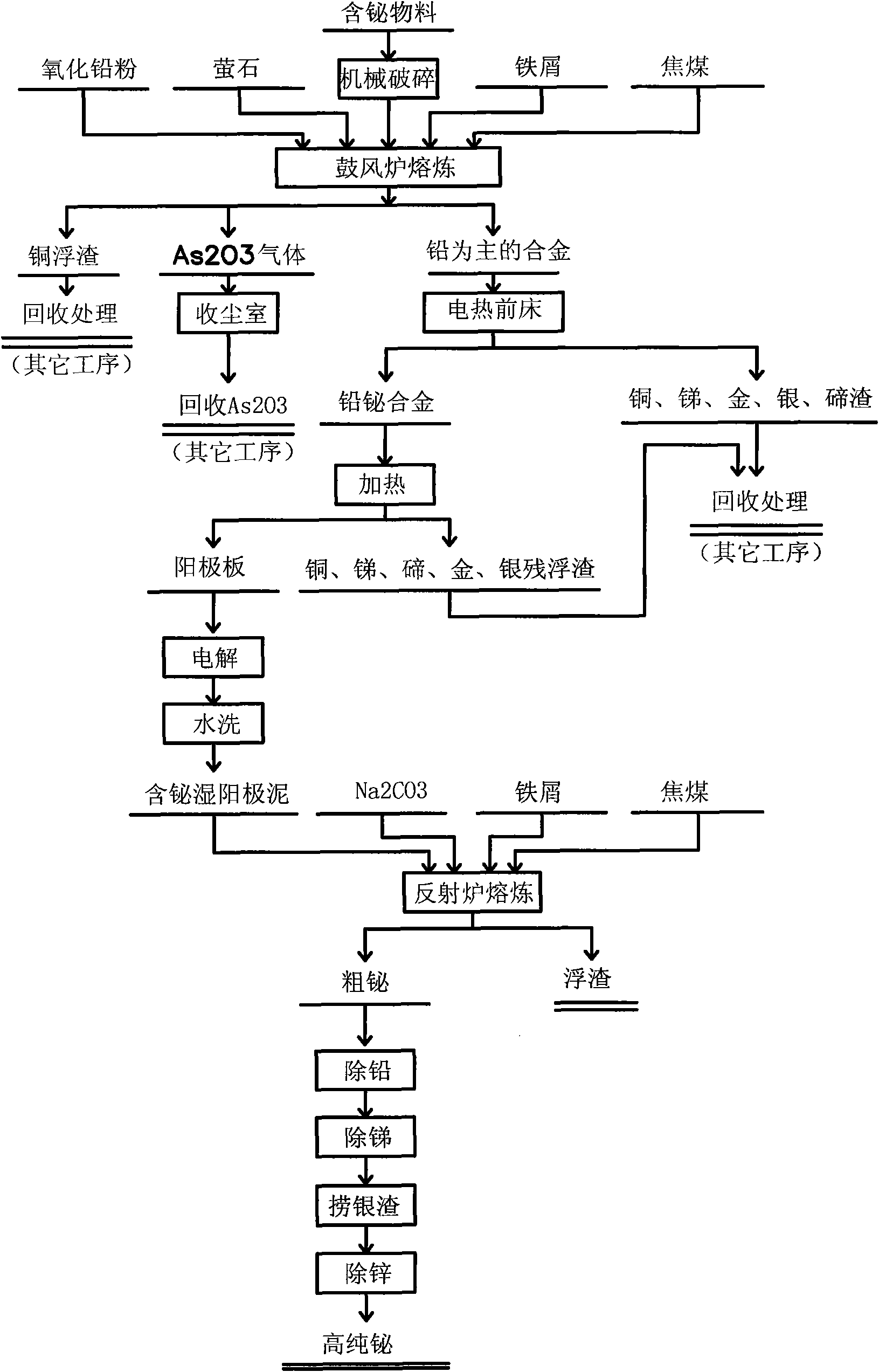

Process for refining high-purity bismuth from bismuth-containing material generated from anode mud recovery

ActiveCN101886174AReduction of Bismuth Content RequirementsExpand sourcePhotography auxillary processesProcess efficiency improvementTemperature controlBismuth

The invention relates to a process for refining high-purity bismuth from bismuth-containing materials generated from anode mud recovery, belonging to the technical field of processes of recovering smelting bismuth by combining a wet process and a pyrogenic process of non-ferrous metal. The process comprises the following steps of: firstly increasing the content of bismuth contained in the bismuth-containing materials to obtain crude bismuth by adopting an enrichment process; and then further refining and purifying the crude bismuth into the high-purity bismuth by adopting a selective accurate temperature-control smelting method according to different melting points of compounds between bismuth metal and impurity-containing metal. Compared with the prior art, the invention reduces the requirements for the content of the bismuth contained in raw materials and can realize the economic and high-efficiency recovery of the bismuth metal, refine the high-purity bismuth and reduce the environmental pollution.

Owner:郴州雄风环保科技有限公司

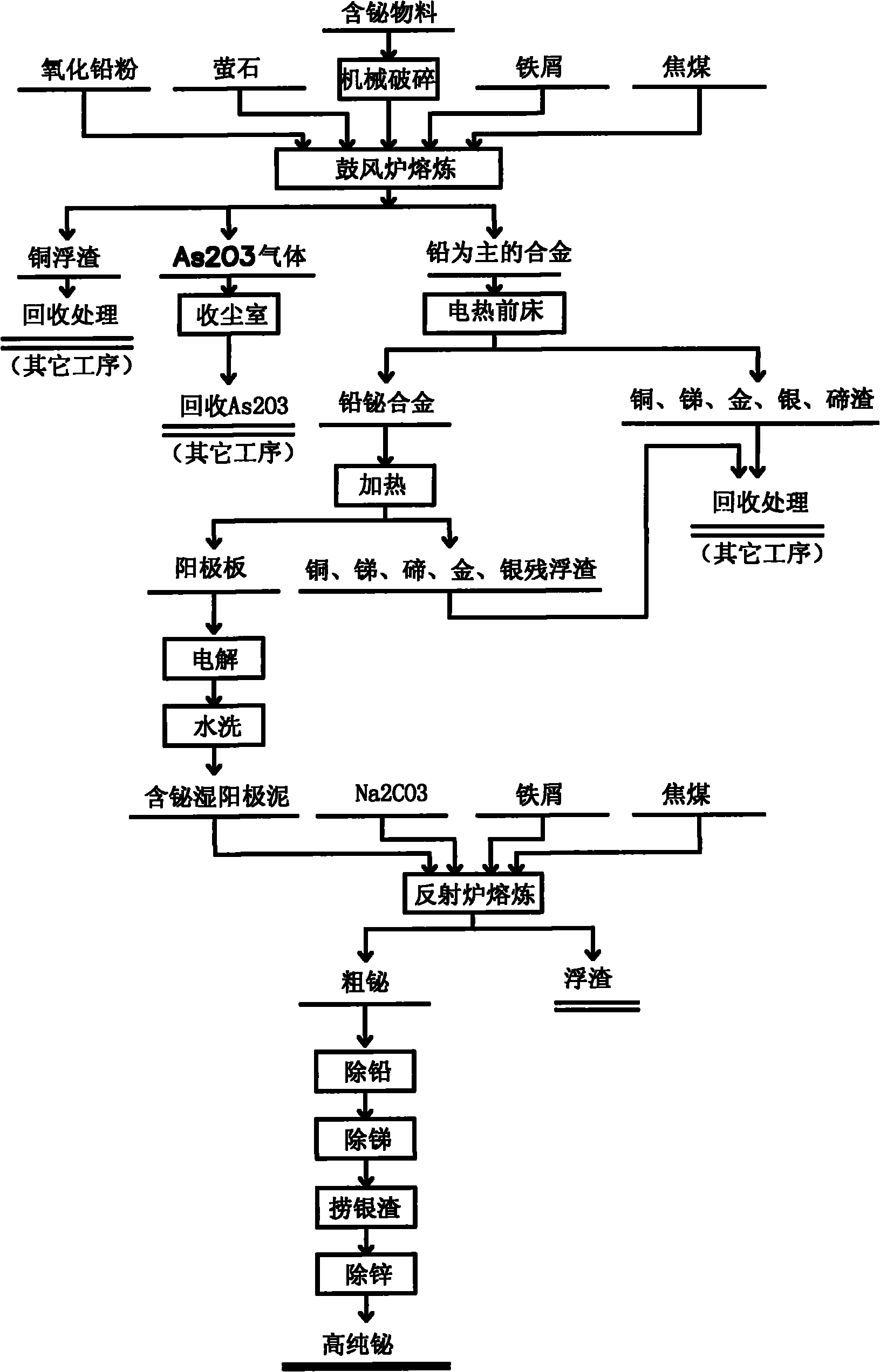

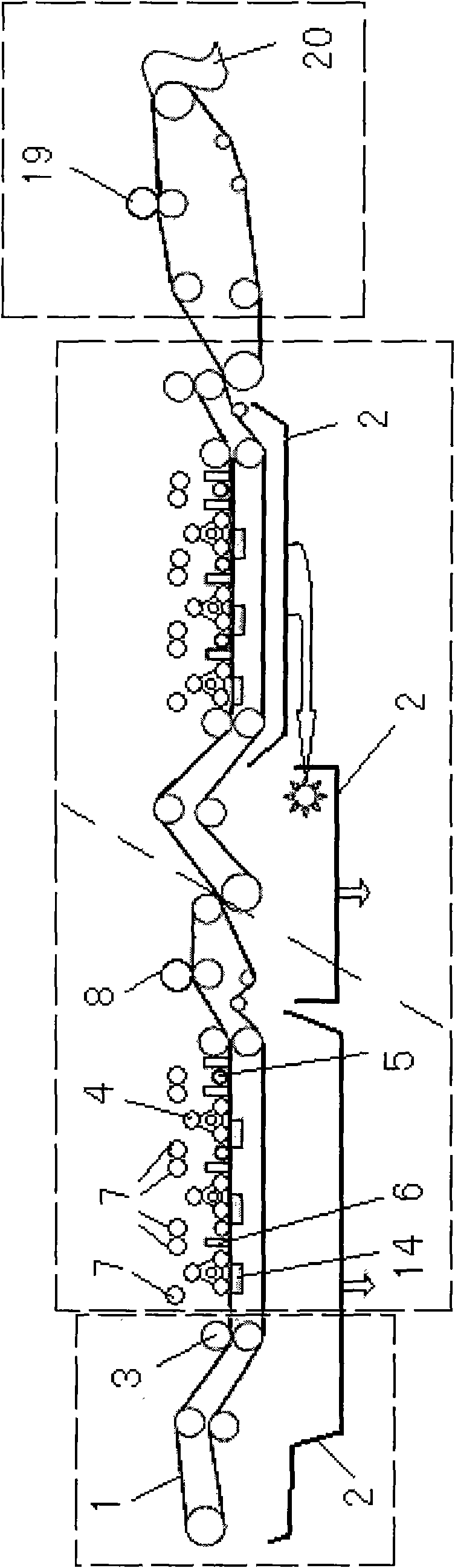

Six-column differential-pressure distillation device for extra edible alcohol and process therefor

ActiveCN1880435AImprove qualityEasy to excludeOrganic compound preparationGeneral water supply conservationDifferential pressureReboiler

The invention discloses a six-tower distilling device and technology of superfine edible spirit, which comprises the following parts: crude distillation column, vacuum aldehydo-removing column, water scrubber, fractionating tower, methanol column and recycling tower, wherein the mature ferment fermented glutinour rice is preheat in the ferment procedure, which enters into the top of crude distillation column; the crude distillation column is negative pressure, whose top wine gas enters in the vacuum aldehydo-removing column through separator after cooling sequently; the aldehydo-removing wine on the bottom is sent into feeder layer of water scrubber after preheating, which flows desalination wine after extracted by micro-negative pressure water in the fractionating tower to proceed positive pressure distillation; the spirit intermediate product is led into the methanol column from top wine hole of fractionating tower to remove menthol, which obtains superfine edible spirit; the steam condensate of fractionating tower reboiler is recycled in the autoclave of recycling tower after flash-boiling disposal, which flows through methanol column reboiler, water scrubber and crude distillation column to proceed secondary condensing by reboiler.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

Process for preparing crystal seed used for rutile type titanium dioxide production

InactiveCN1594103AShorten washing timeImprove the effect of impurity removalTitanium dioxideChemistryDecomposition

The invention discloses a process for preparing crystal seed used for rutile type titanium dioxide production which comprises the steps of alkali boiling reaction, dilution and hydrolytic decomposition, scouring edulcoration, neutralization with acids, acid solution, and cooling down, wherein the alkali-titanium ratio in the alkali boiling reaction is 1.7:1-1.9:1, and the scouring edulcoration is conducted with a press filtration mode.

Owner:湖南永利化工股份有限公司

Filter apparatus, exposure apparatus, and device-producing method

ActiveUS7416574B2Improve temperature stabilityStable and high precisionCombination devicesAuxillary pretreatmentEngineeringProcess engineering

A filter apparatus for improving gas temperature stability while maintaining a high impurity removal capacity. The filter apparatus includes a filter for removing impurities from a gas and a temperature adjuster for adjusting the temperature of the gas to a predetermined temperature. The filter apparatus further includes a humidity detector, arranged at the upstream side of the filter, for adjusting the humidity of the gas before the gas passes through the filter.

Owner:NIKON CORP

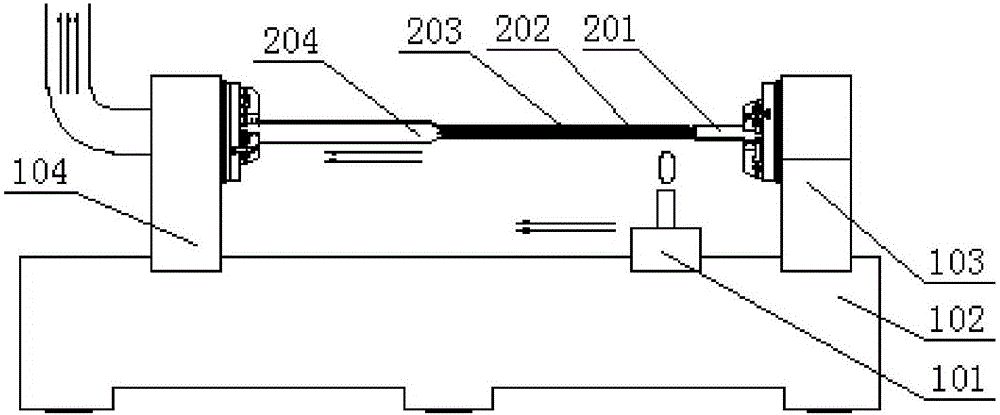

Method for preparing doped optical fiber outer cladding layer

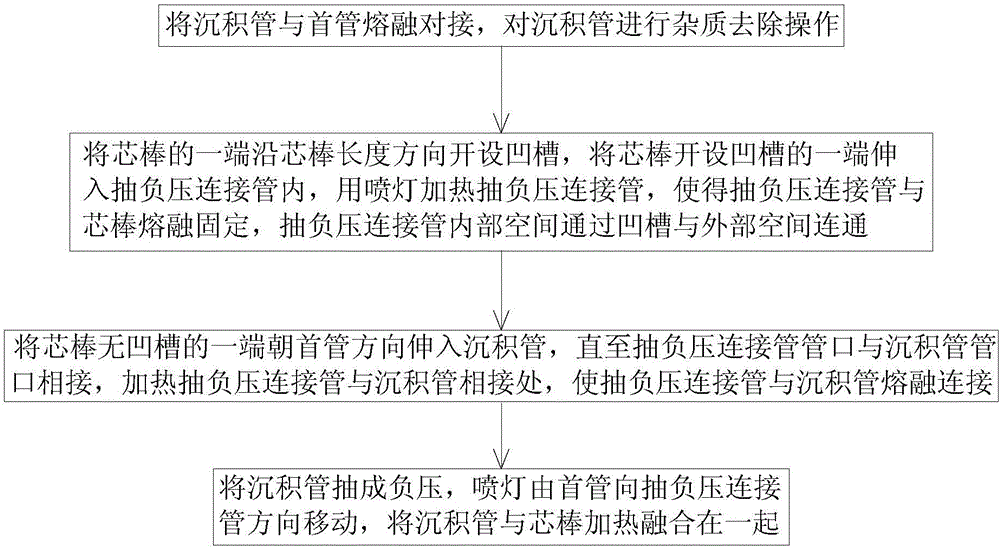

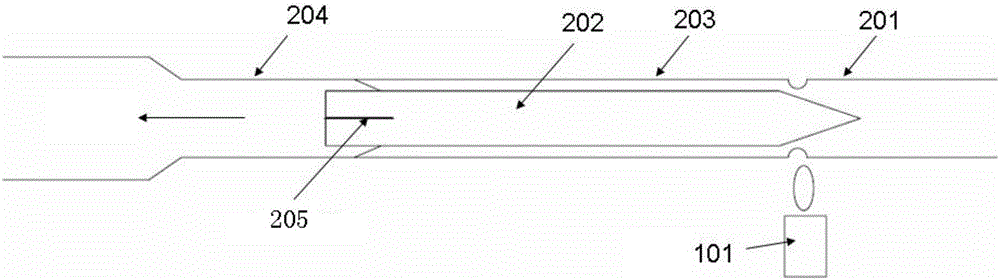

ActiveCN106242262AQuality assuranceImprove the effect of impurity removalGlass making apparatusPressure systemEngineering

The invention discloses a method for preparing a doped optical fiber outer cladding layer, and the method comprises the following steps: 1) a deposition tube and a head tube are butted by fusion, and impurities are removed; 2) one end of a core rod is provided with a groove along the length direction of the core rod, the end, which is provided with the groove, of the core rod stretches into a negative pressure suction connection pipe, and the negative pressure suction connection pipe is heated for fusion fixing with the core rod; 3) one end, which is not provided with the groove, of the core rod stretches into the deposition tube toward the direction of the head tube, and the opening of the deposition tube is heated for sealed connection of the negative pressure suction connection pipe and the deposition tube; 4) the pressure of the deposition tube is pumped to a negative pressure, a blast burner moves from the head tube to the direction of the negative pressure suction connection pipe for heating to fuse the deposition tube and the core rod together. Through arrangement of the groove on one end of the core rod, when air is pumped, the groove plays a key role, air between the deposition tube and the core rod enters the negative pressure suction connection pipe through the groove, and a negative pressure system is formed in the deposition tube, so that the deposition tube and the core rod can be reliably fused.

Owner:ZHEJIANG FUTONG OPTICAL FIBER TECH +1

Production process for preparing high-purity quartz powder from quartzite

InactiveCN104556047ALoose structureGuaranteed structural porositySilicon compoundsStrong acidsMetal impurities

The invention discloses a production process for preparing high-purity quartz powder from quartzite. The production process comprises the following steps: 1) soaking; 2) smashing; 3) calcining; 4) water quenching; 5) grinding; 6) magnetic separation; 7) elestrostatic separation; 8) acid pickling; 9) cleaning by deionized water; 10) drying. According to the production process, the contamination particles are eluted via gradient acidity distribution; before the smashing, strong acid is used for soaking so as to remove the impurities on the surface of the quartzite; during the water quenching, medium / strong acid is used for removing the metal impurities wrapped in the quartzite; during the grinding, in order to protect the equipment from erosion, medium / weak acid is used for removing the impurities during the grinding, and a ball grinding mill is utilized to increase the contact probability and contact area between the acid liquor and the impurities so as to increase the impurity removal efficiency; during the final acid pickling, weak acid is used for further removing a small quantity of residual contamination particles which are not reacted completely; the afterheat generated during the calcination is collected and used for the final drying, so that the energy consumption is reduced and the production cost of the enterprise is decreased.

Owner:新沂市永恒熔融石英有限公司

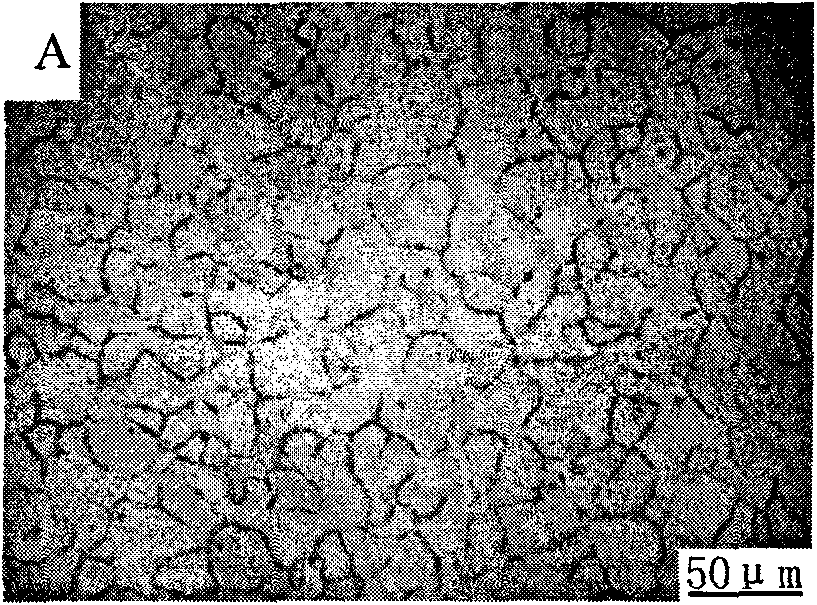

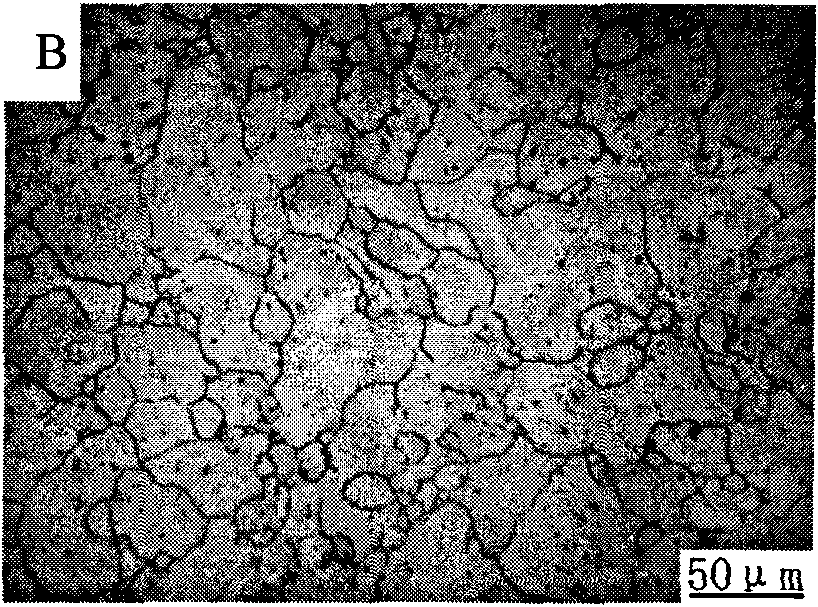

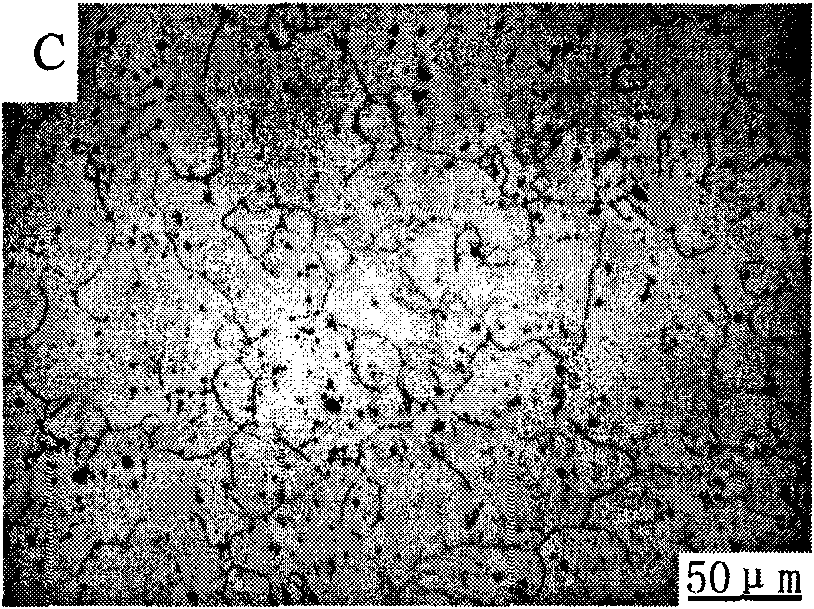

Graphene/flax composite fiber preparation method

InactiveCN106120333AHigh strengthImprove toughnessBiochemical treatment with enzymes/microorganismsWet spinning methodsYarnGraphene

The invention discloses a graphene / flax composite fiber preparation method, which comprises: 1) preparing a compound enzyme refining agent; 2) pre-treating flax fiber; 3) refining, wherein the prepared flax fiber is immersed into the compound enzyme refining agent and soaked, and washing and dewatering drying are performed to prepare the modified flax fiber; and 4) uniformly mixing the modified flax fiber and graphene fiber. According to the present invention, the flax fiber is mixed with the graphene fiber, such that the strength and the toughness of the blended yarn of the flax fiber can be improved, and the resistivity of the mixed fiber achieves 10-103 [omega].m while the resistivity of the conventional fiber is about 10-14 [omega].m, wherein the resistivity is improved by more than 10 magnitude orders; the flax fiber is subjected to the modification treatment with the biological enzyme so as to improve the dyeing effect of the yarn; and the impurity pectin removing effect and the impurity lignin removing effect are good with the selected compound enzyme refining agent, and the chelating agent is increased so as to further enhance the impurity removing effect of the compound enzyme.

Owner:SUZHOU YUXI NEW MATERIAL TECH

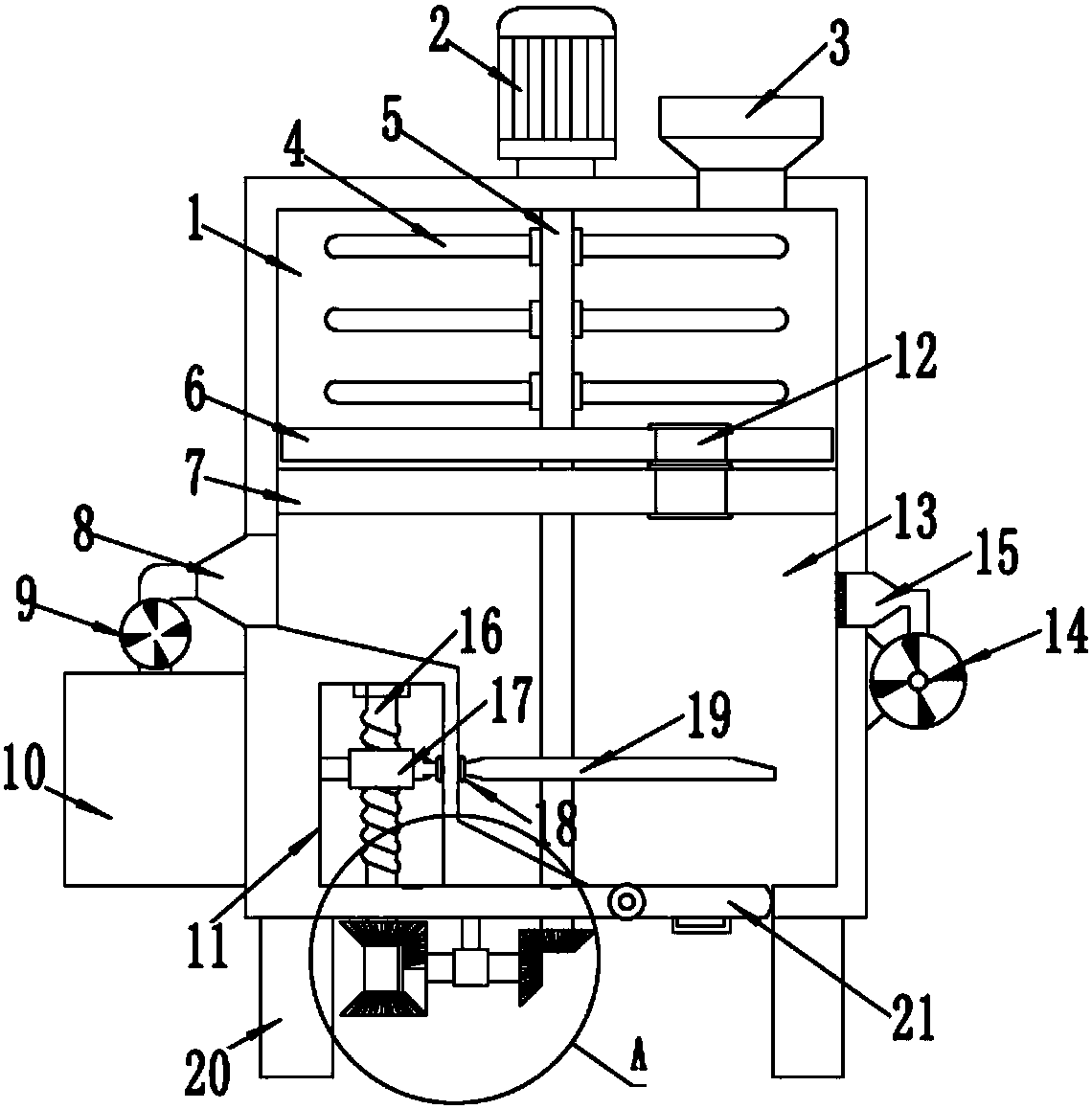

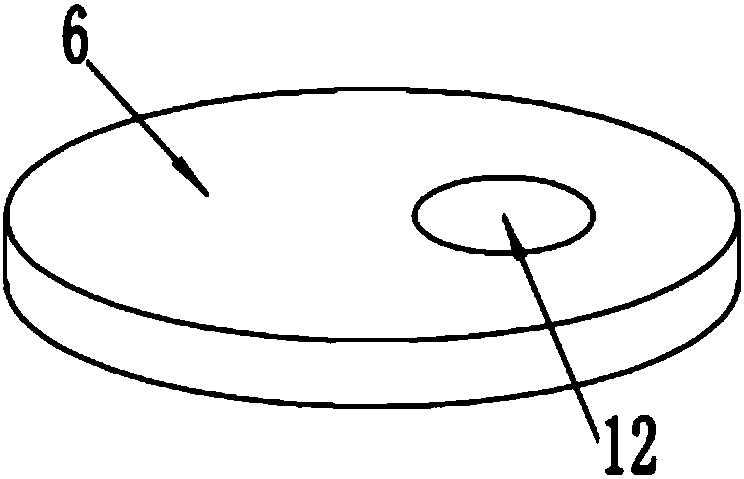

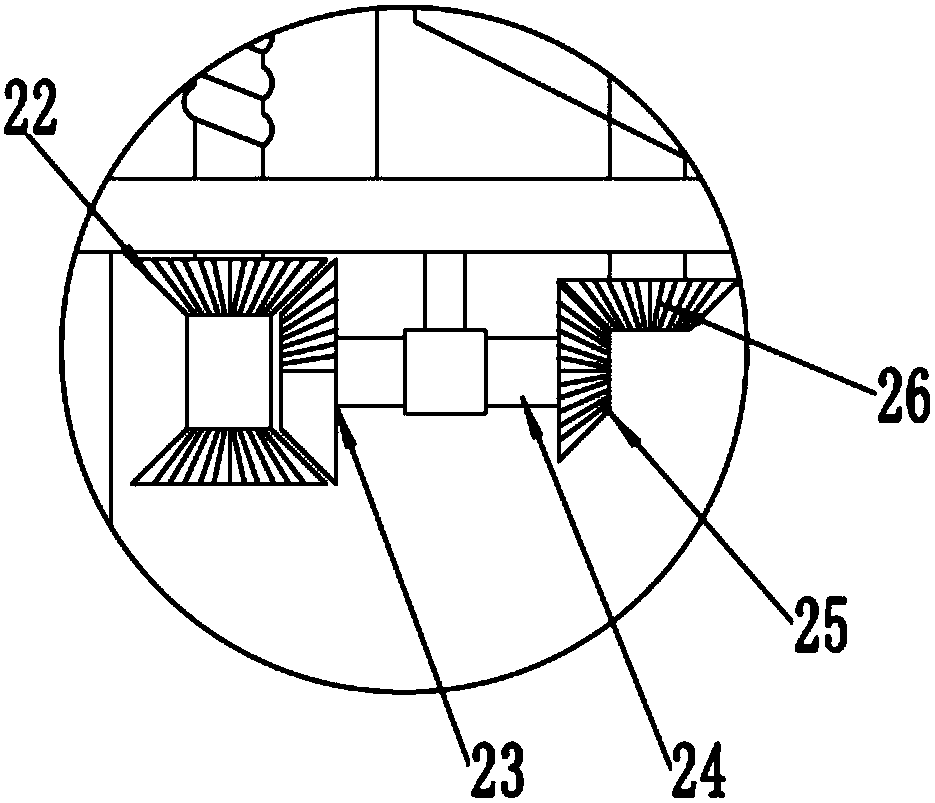

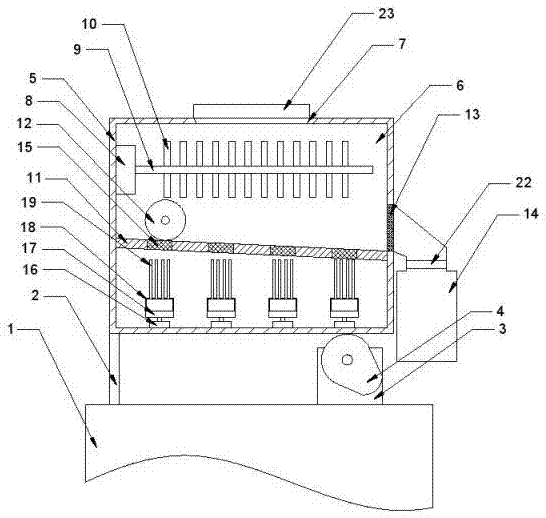

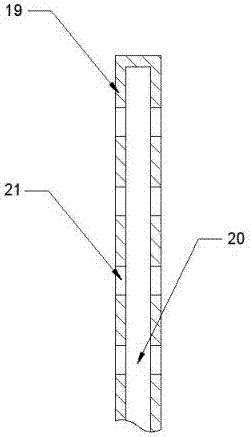

Screening machine for tea leaf processing

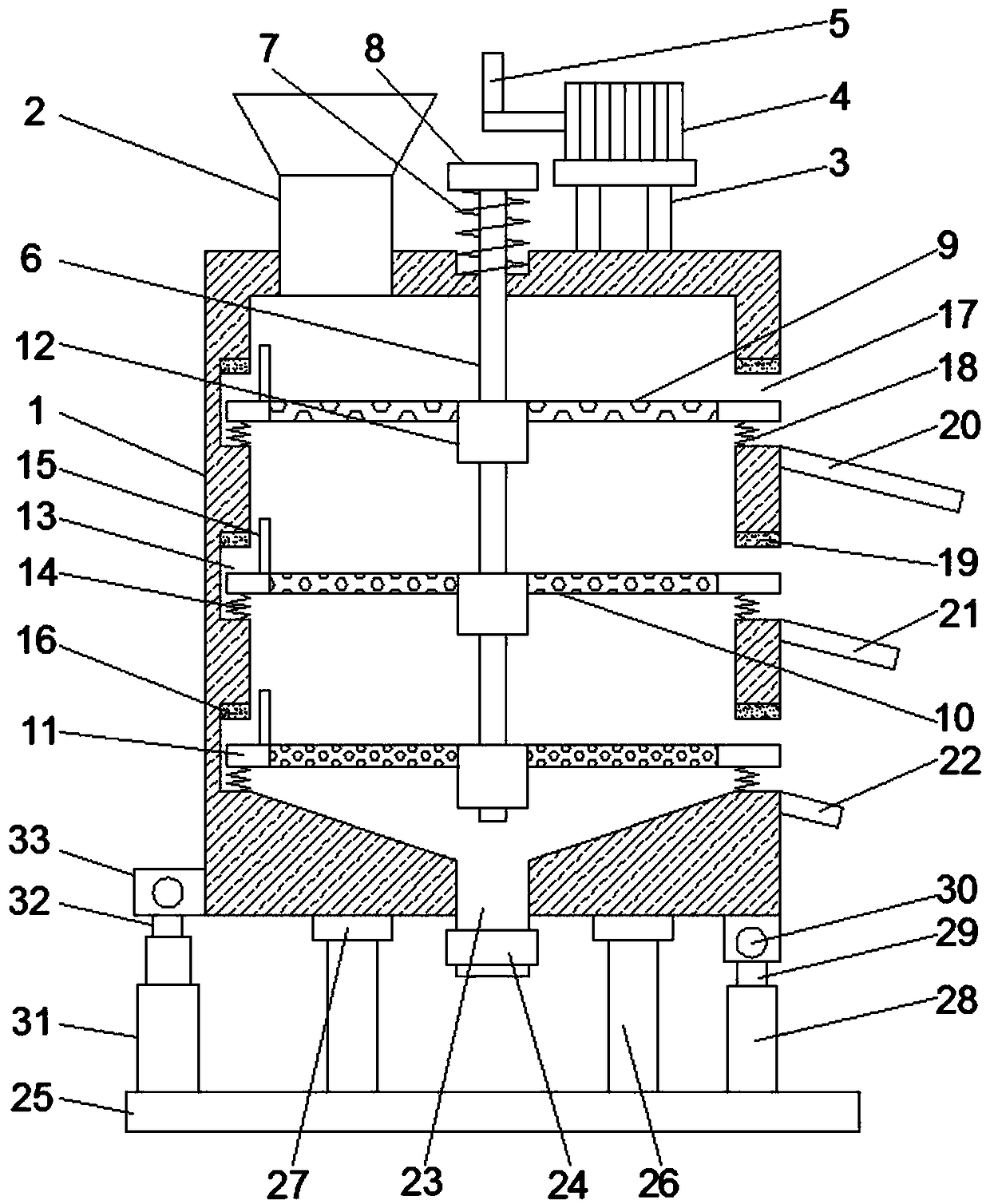

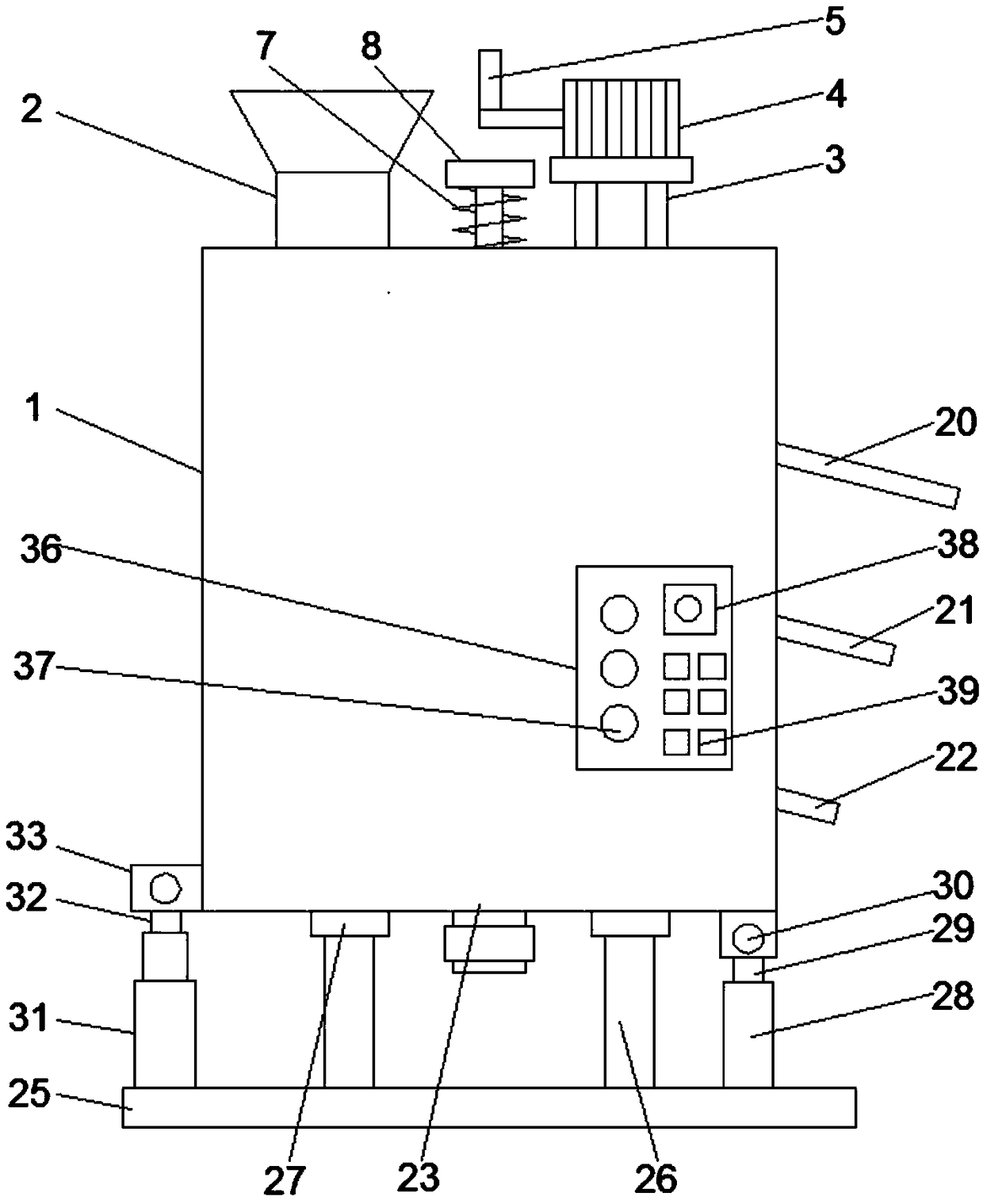

InactiveCN108940839AIncrease vibration amplitudeImprove screening efficiencySievingPre-extraction tea treatmentMotor shaftEngineering

The invention discloses a screening machine for tea leaf processing. The screening machine for tea leaf processing comprises a box body and a bottom plate, a feeding pipe is arranged on the left sideof the upper end of the box body, a motor frame is arranged on the right side of the upper end of the box body, a motor is arranged at the upper end of the motor frame, a cam is connected to the leftend of the motor through a motor shaft, a movable rod is arranged in the middle of the upper end of the box body, and a pressing block is arranged at the upper end of the movable rod. According to thescreening machine for tea leaf processing, the motor works to enable the cam to act on the pressing block, and the movable rod is made to move downwards; when the cam moves to another position, the movable rod rebounds under the action of second springs, and the movable rod can move up and down so as to drive a coarse screen plate, a middle screen plate and a fine screen plate to shake up and down, and therefore the tea leaves can be screened; the screen plates are in sliding connection with the movable rod through a movable frame, the vibration frequency and the vibration amplitude of the screen plates are further improved, therefore the tea leaf screening efficiency of the screen plates is improved; and different material guide plates are arranged on the right side of the box body corresponding to different screen plates, and therefore collection is facilitated after screening is completed by the screen plates.

Owner:ANHUI XINXUTANG TEA CO LTD

Soybean processing device for agricultural product processing

InactiveCN108393258AReduce transportationSmall footprintSievingScreeningMaterial resourcesSmall footprint

The invention discloses a soybean processing device for agricultural product processing, and relates to the technical field of production equipment. The soybean processing device comprises an impurityremoval device and a cleaning device; the top of the cleaning device is fixedly connected with the bottom of the impurity removal device; the bottom of the cleaning device communicates with a water circulation device; a dust removal device is fixed to one surface of the cleaning device; the impurity removal device comprises a storage tank, and a rotating shaft penetrates through the side face ofthe storage tank; and the cleaning device comprises a cleaning box, a supporting frame is fixed to the top of the cleaning box, and a first motor is fixed to the top of the cleaning box. Through combination use of the impurity removal device and the cleaning device, soybeans can immediately enter the cleaning device to be cleaned after being screened, thus the transport process is omitted, screening equipment and cleaning equipment do not need to be purchased correspondingly, the occupied area is small, the cost, manpower, material resources and time are saved, and the work efficiency is improved.

Owner:饶琼仙

Enzyme scouring agent for linen fibers

ActiveCN103469600AImprove the effect of impurity removalReduce usageBiochemical fibre treatmentVegetal fibresFiberPectinase

The invention discloses an enzyme scouring agent for linen fibers. The enzyme scouring agent contains 2%-3% by volume of pectinase, 2%-4% by volume of glucanase, 2%-3% by volume of cellulose, as well as a 4-5g / L surfactant scouring agent and a 2-3g / L chelating agent, wherein a bath ratio is 1:30. The linen fibers are scoured by compound enzyme, so that the effect of removing impurities of pectin and lignin is very good; besides, the surfactant scouring agent and the chelating agent are added, thereby further reinforcing the impurity removing effect of the compound enzyme and effectively reducing the use amount of the compound enzyme; in addition, the scoured linen fibers achieve a degumming degree of 20%-23% and have a good handfeel, excellent whiteness and a fine capillary effect.

Owner:山东信开源科技创新发展有限责任公司

Ultralow-metal-content high-purity silica sand preparation method

The invention discloses an ultralow-metal-content high-purity silica sand preparation method. The ultralow-metal-content high-purity silica sand preparation method mainly comprises the technologies ofmaterial selection, first-time burning, water quenching, smashing, magnetic separation, electric separation, second-time calcining, water quenching, acid pickling, flotation, washing and the like; asodium hydroxide solution is adopted for water quenching after first-time burning is carried out, sodium hydroxide solid is mixed in the second-time calcining process, a formic acid solution containing 2,2'-dipyridyl is adopted as an acid pickling solution for acid pickling, and an significant improvement is made for the floatation process in the aspect of a collecting agent. According to the silica sand purification process, common silica sand with the SiO2 content smaller than or equal to 98% can serve as a raw material to obtain ultralow-metal-content high-purity silica sand with the SiO2 content larger than or equal to 99.97% and the impurity metal total amount smaller than or equal to 30ppm, cost is saved, and the technologies are more environment-friendly.

Owner:江苏凯达石英股份有限公司

High-intensity high-damping deforming magnesium alloy with rear earth yttrium

The invention discloses a high-intensity high-damping deforming magnesium alloy with rear earth yttrium, which is characterized by comprising the following components by weight percent: 2.9-3.1 percent of Al, 0.9-1.1 percent of Zn, 0.5-2 percent of Y, 0.29-0.31 percent of Mn and the rest of Mg and unavoidable impurities. The high-intensity high-damping deforming magnesium alloy with rear earth yttrium can greatly increase the mechanical property and the damping performance of the high-intensity AZ series deforming magnesium alloy, successfully solve the conflict of the mechanical property andthe damping performance of the magnesium alloy and satisfy the actual requirements for a high-intensity high-damping light-weight material in the fields of very high-speed trains, automobiles, aerospace, national defense war industry, and the like, moreover, the magnesium alloy material has lower cost, and a technical device is the normal universal device with strong portability and easy operation.

Owner:CHONGQING UNIV

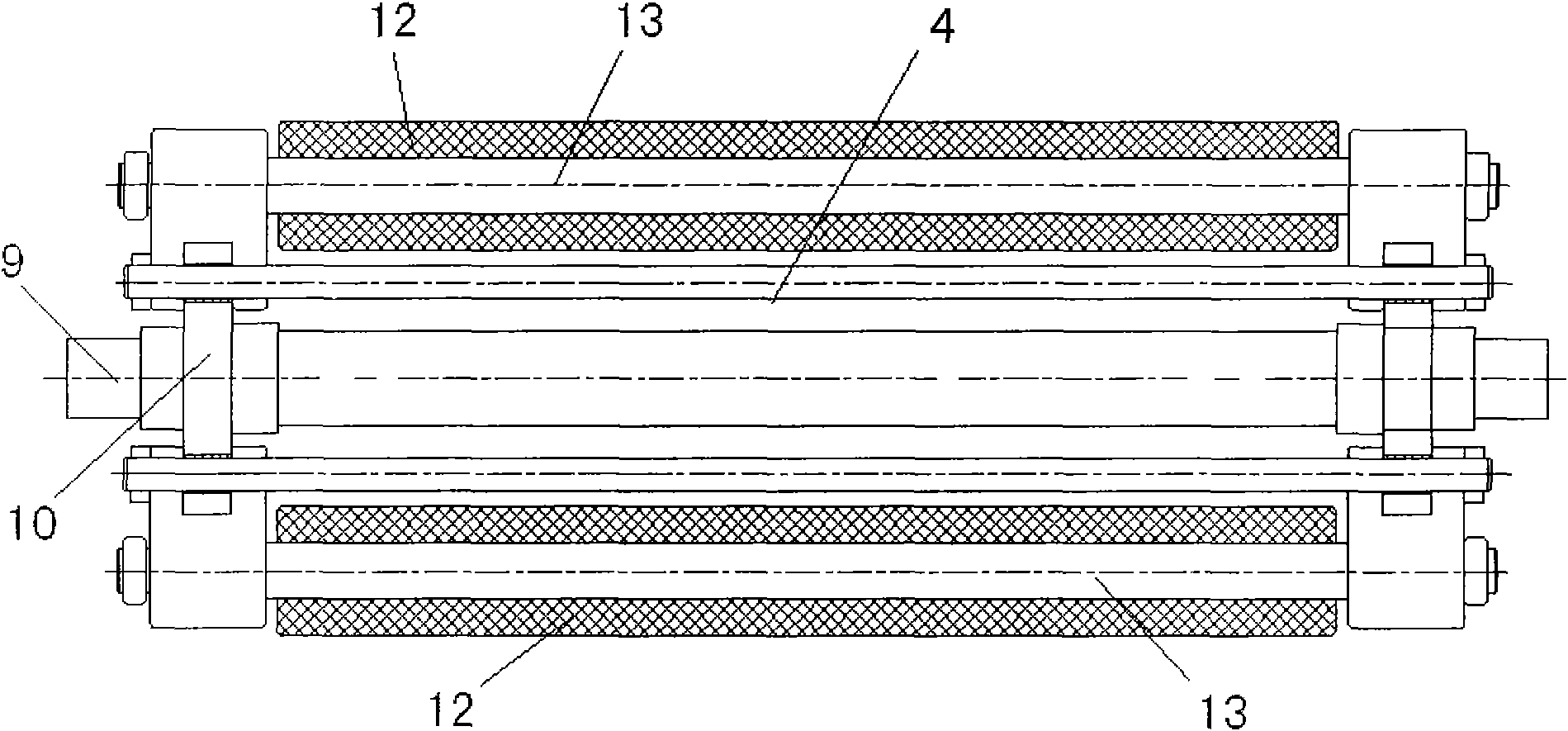

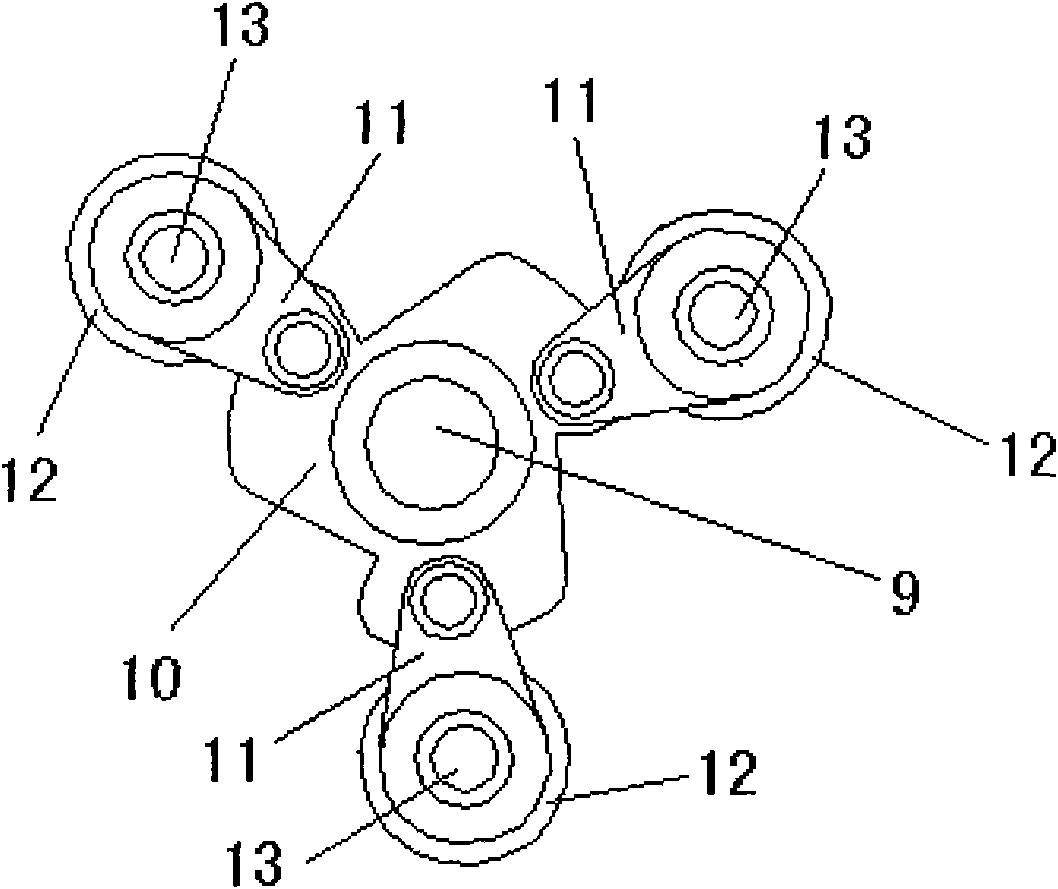

Fiber bundle dividing and washing method and device

ActiveCN101851789AGuaranteed cleanlinessHit evenlyMechanical treatmentFibre treatment to obtain bast fibreCardingFiber bundle

The invention relates to a fiber bundle dividing and washing method and a fiber bundle dividing and washing device. The method comprises the following steps of: 1) arranging a plurality of groups of fiber dividing and washing units and a fiber output unit on a frame, wherein each unit is provided with a running rotating crawler; 2) passing a feeding roller through a crawler input end of each fiber dividing and washing unit so as to convey the fiber bundle forward, making the fiber bundle enter a fiber dividing and washing area which is provided with a beater and a fiber dividing roller at intervals, simultaneously opening a high pressure water pipe which is arranged above the beater and the fiber dividing roller, and performing washing soaking, beating, carding and fiber dividing on the fiber bundle edges; 3) feeding the fiber treated by the previous fiber dividing and washing unit to the next fiber dividing and washing unit for continuous fiber dividing and washing; and 4) feeding the fiber treated by the last fiber dividing and washing unit into a fiber dividing input area, performing water squeezing operation through a squeezing roll, feeding the fiber into a cloth arrangement mechanism, arranging and folding the strip-shaped fiber through the cloth arrangement mechanism, and feeding the fiber into a fiber storage box. The fiber bundle dividing and washing method and the fiber bundle dividing and washing device can be widely applied to fiber dividing and washing treatment for various bast fibers, leaf fibers, and grass family fibers.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +3

Suspension bed residual oil hydrogenation-catalytic cracking combined technological process

ActiveCN101434867AAppropriate mode of operationLower conversion rateTreatment with hydrotreatment processesHydrogenation reactionResidual oil

The invention discloses a combination process of hydrogenation-catalytic cracking used for suspension bed residual oil. The method comprises the steps as follows: residual oil and catalytic cracking decanted oil enter a suspension bed hydrogenation reaction device and carry out hydrogenation reaction with the presence of hydrogen and a catalyst; the vacuum distillate oil gained during the hydrogenation reaction enters a catalytic cracking device, the vacuum residual oil is circulated back to the suspension bed hydrogenation device, and the catalytic cracking decanted oil and heavy circular oil can wholly or partly enter the suspension bed hydrogenation device which adopts a relatively moderate operation condition. The method organically combines the suspension bed hydrogenation device with the catalytic cracking device, and therefore not only ensures the stable running of the suspension bed hydrogenation device, but also improves the impurity removal capability of the suspension bed hydrogenation device, improves the raw material quality of the catalytic cracking device, and increases the yield of the light oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

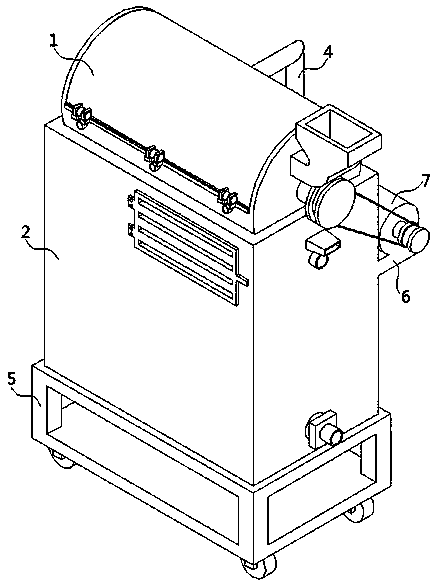

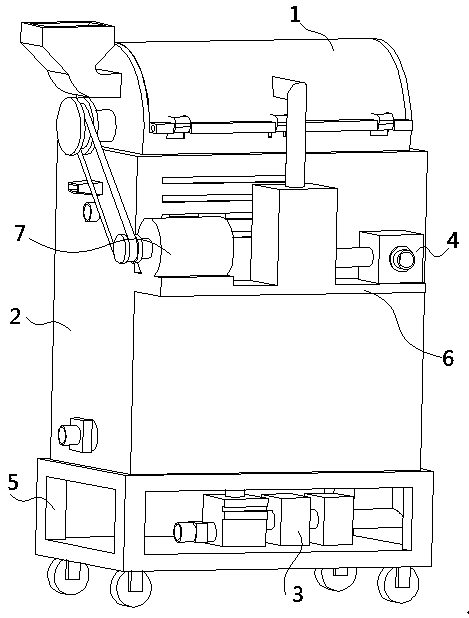

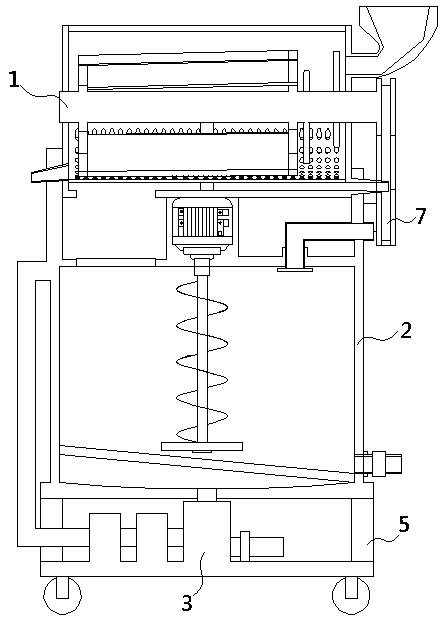

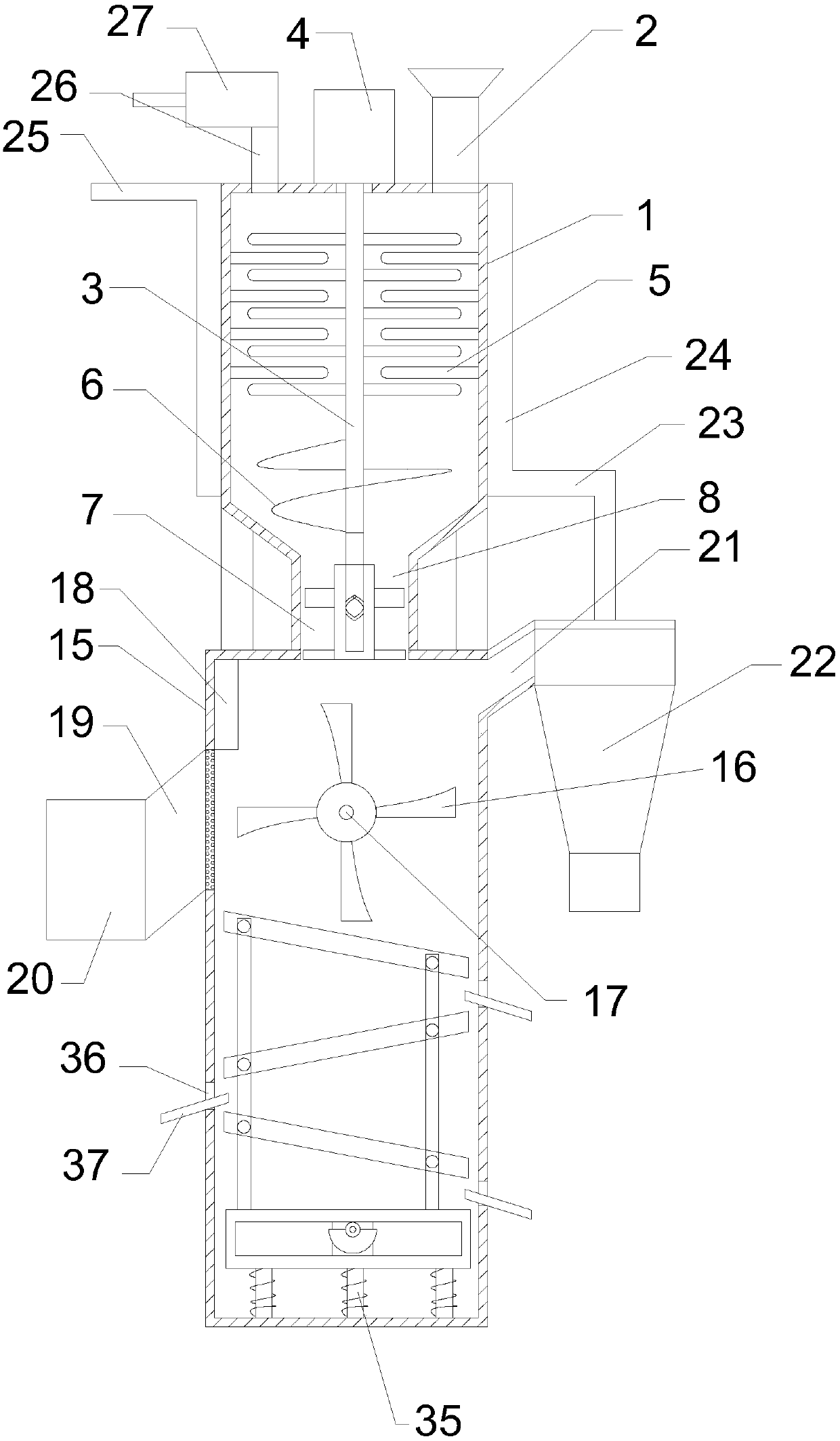

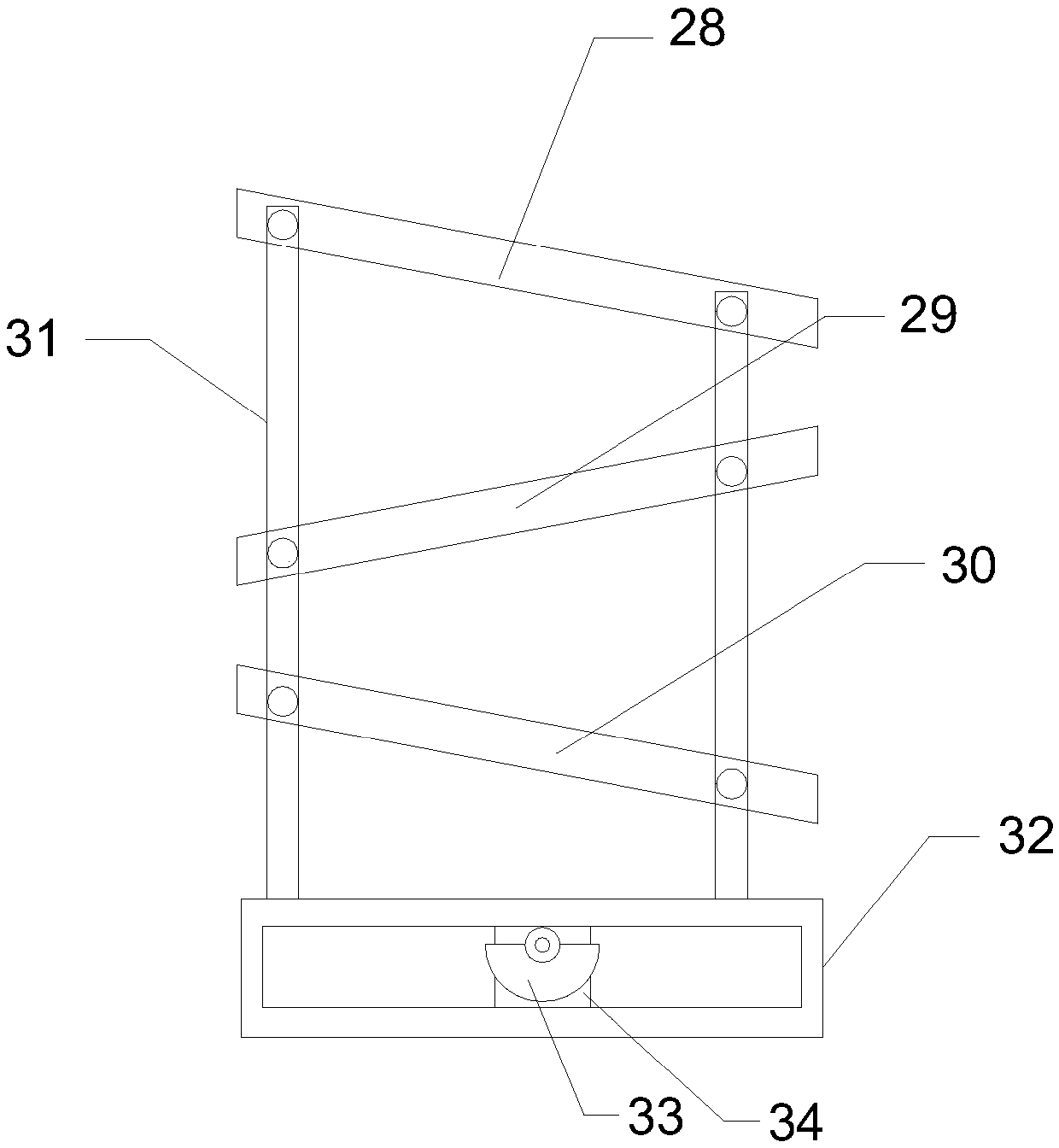

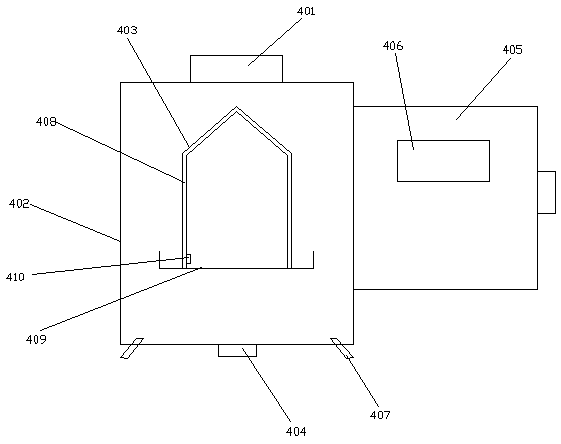

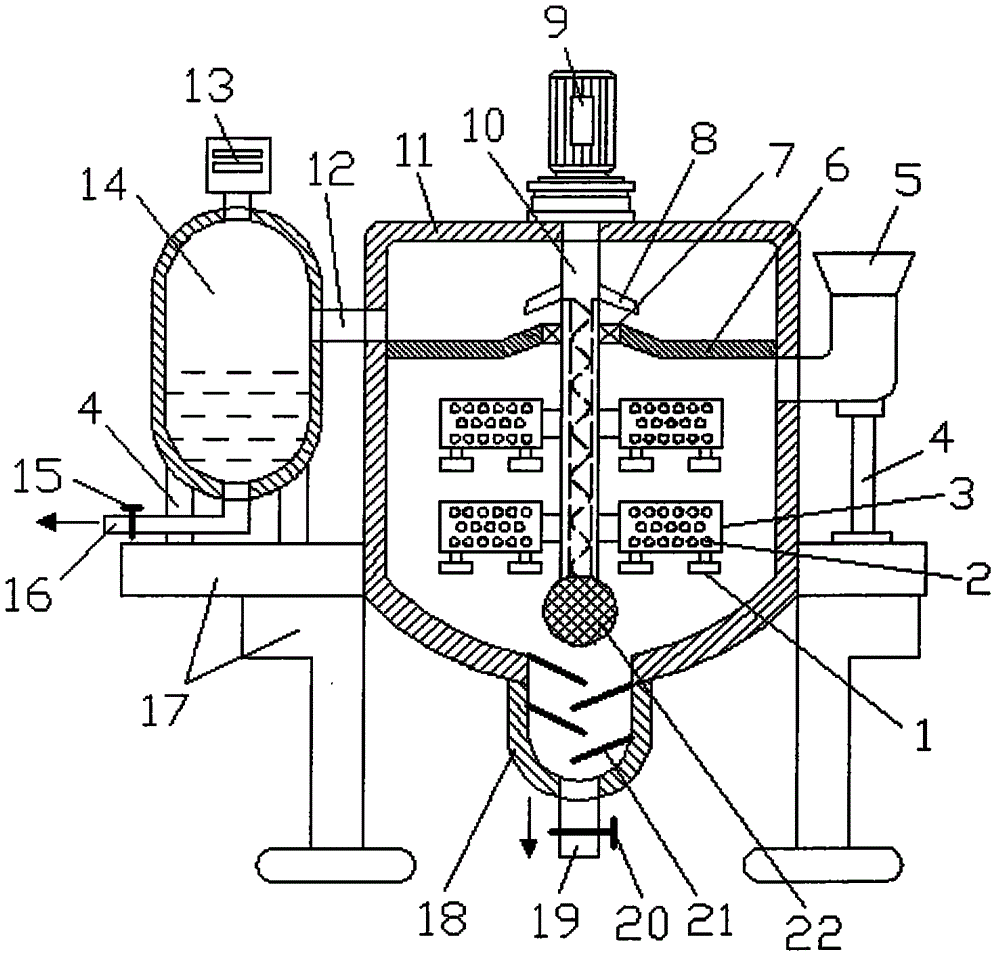

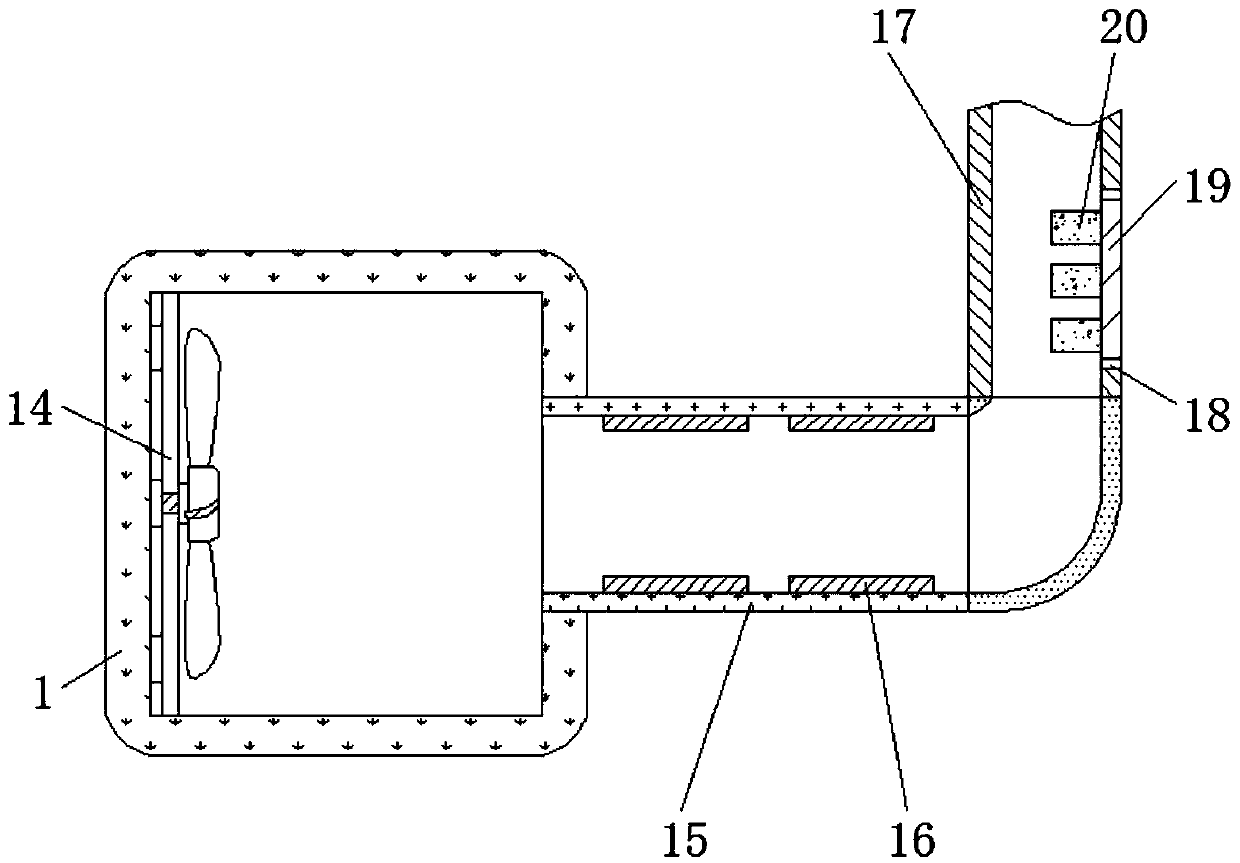

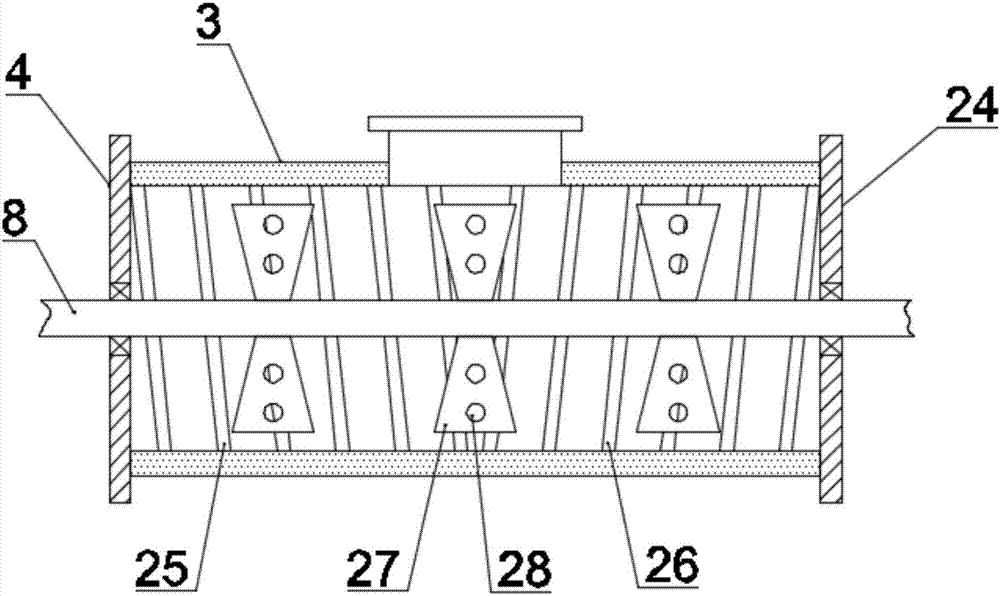

Efficient grain impurity-removing and drying device with pre-heating function

InactiveCN107560407AEfficient separationFor subsequent screeningSolid separationDrying gas arrangementsHuskAgricultural engineering

The invention discloses an efficient grain impurity-removing and drying device with pre-heating function. The efficient grain impurity-removing and drying device comprises a pre-heating box; and a discharging pipe is arranged under the pre-heating box, a impurity-removing box communicates the lower portion of the discharging pipe, and a throwing hopper is arranged on the position, below the discharging pipe, of the impurity-removing box. According to the efficient grain impurity-removing and drying device, rolling rollers and a heating cover are arranged so that hardened grain blocks can be efficiently broken, subsequent screening and dust-removing processes can be facilitated, meanwhile, grain undergo the pre-heating process, and the high-efficiency utilization of the heat energy is realized; the throwing hopper and a cyclone dust collector are arranged, the grain is thrown into the air so that the grain can be in full contact with hot air, the drying efficiency can be improved, drying can be more thorough, and meanwhile, light garbage and flat husks of grains can be cleared; a sealing cover driven by a groove roller and a variable frequency motor are arranged so that the grain falling speed can be controlled conveniently, and the processing effect can be guaranteed; and two stages of sieve plates are arranged, high-efficiency separation can be carried out on solid waste withrelatively large quality in the grain, and the impurity-removing effect can be improved.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

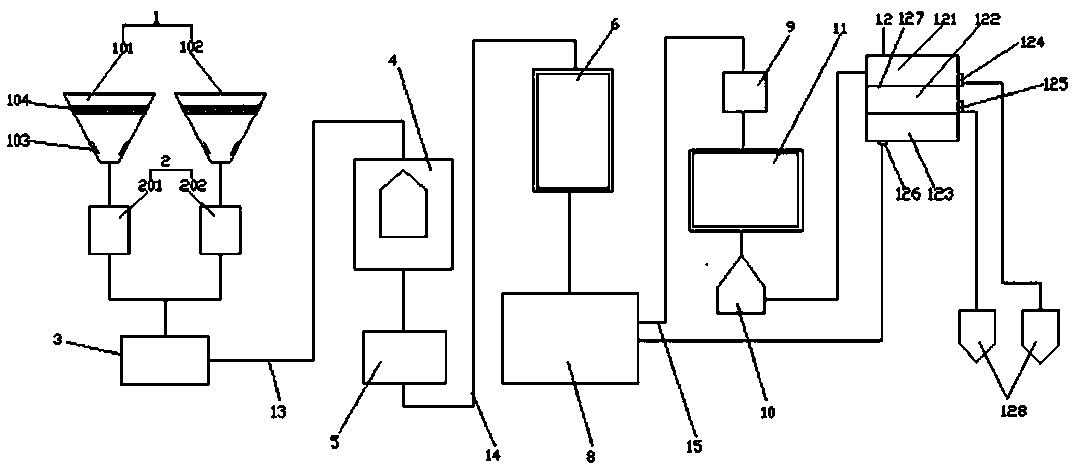

Granulated feed producing and processing equipment and method

PendingCN109480319AMessy layoutHigh energy consumptionFeeding-stuffProcess equipmentProcess engineering

The invention relates to granulated feed producing and processing equipment and method. The granulated feed producing and processing equipment comprises a raw material receiving system, a crushing system, a mixing machine, a granulating system and a quantitative packaging system, wherein the raw material receiving system comprises a feeding device, a dosing device, a stirring barrel, an impurity removing device and a dust removing device; the crushing system comprises a crusher and an ozone generating device; the granulating system comprises a conditioning device, a granulator and a cooler; and the quantitative packaging system comprises a sorting machine and a quantitative packaging mechanism. Through adoption of the granulated feed producing and processing equipment disclosed by the invention, the defects that in the prior art, a set of perfect feed producing and processing equipment does not exist, most conventional equipment has single equipment working procedure, the equipment layout is in disorder, the energy consumption is high, the production process is complex, the production efficiency is low, and the product quality cannot be guaranteed, are solved; and the granulated feed producing and processing equipment disclosed by the invention is high in automation degree, simple in structure, high in production efficiency and low in cost, and can produce multi-grade products,and the grade quality is high.

Owner:韶关正邦农牧科技有限公司

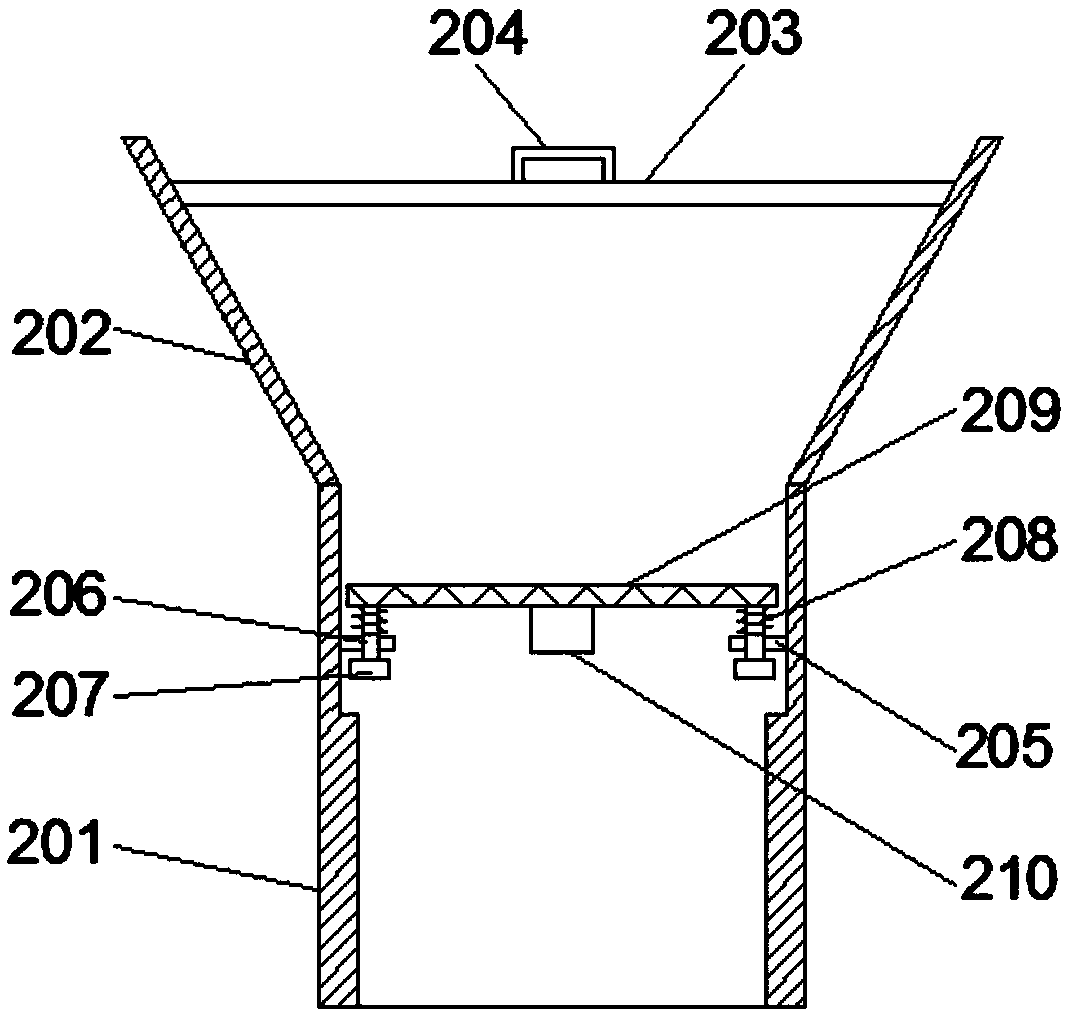

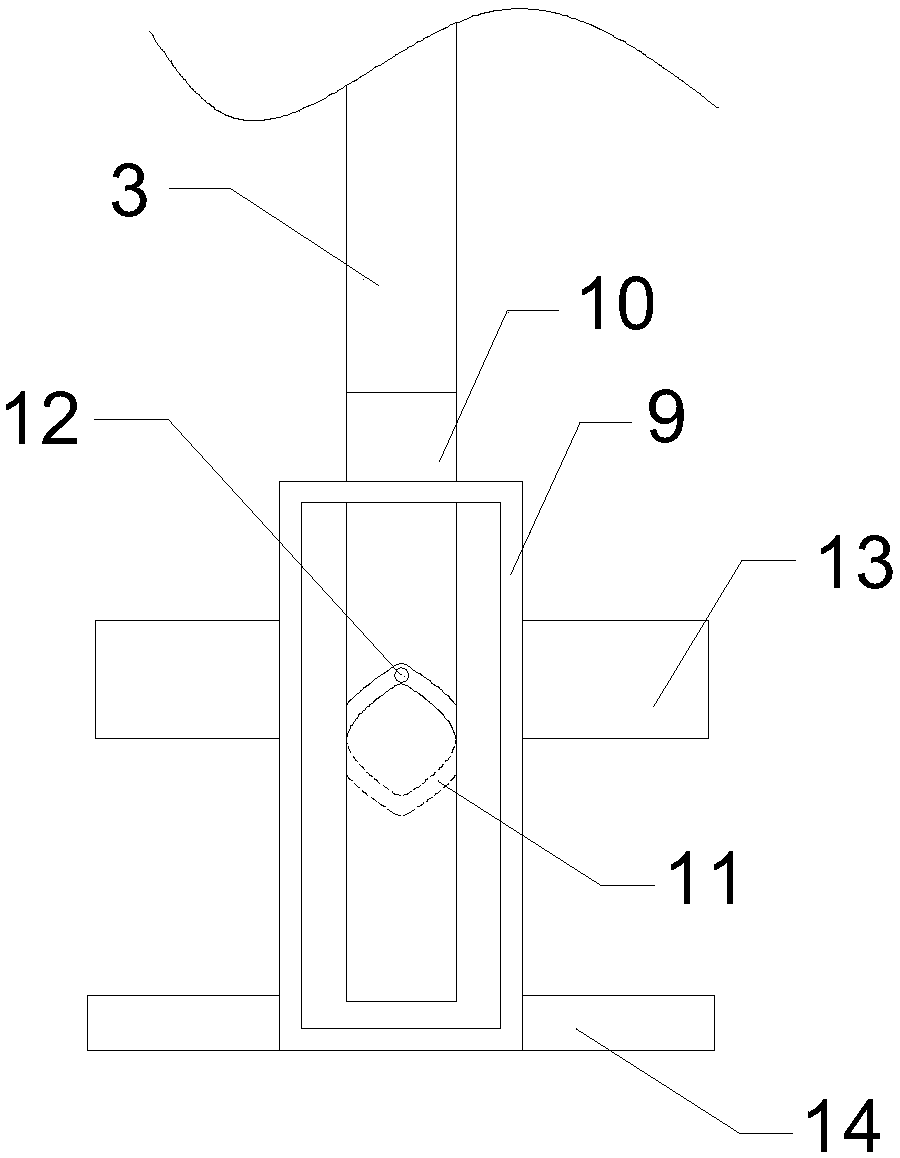

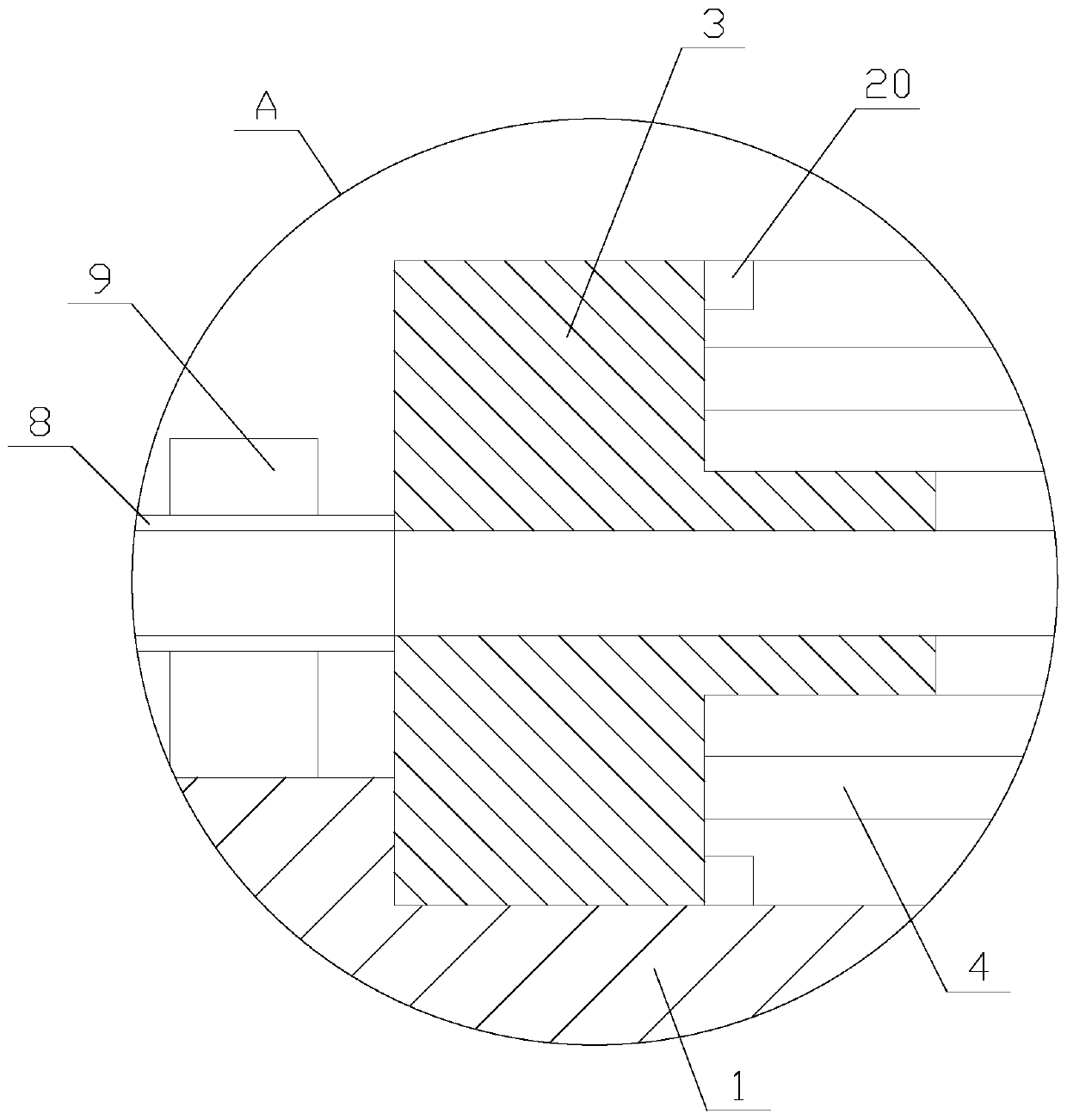

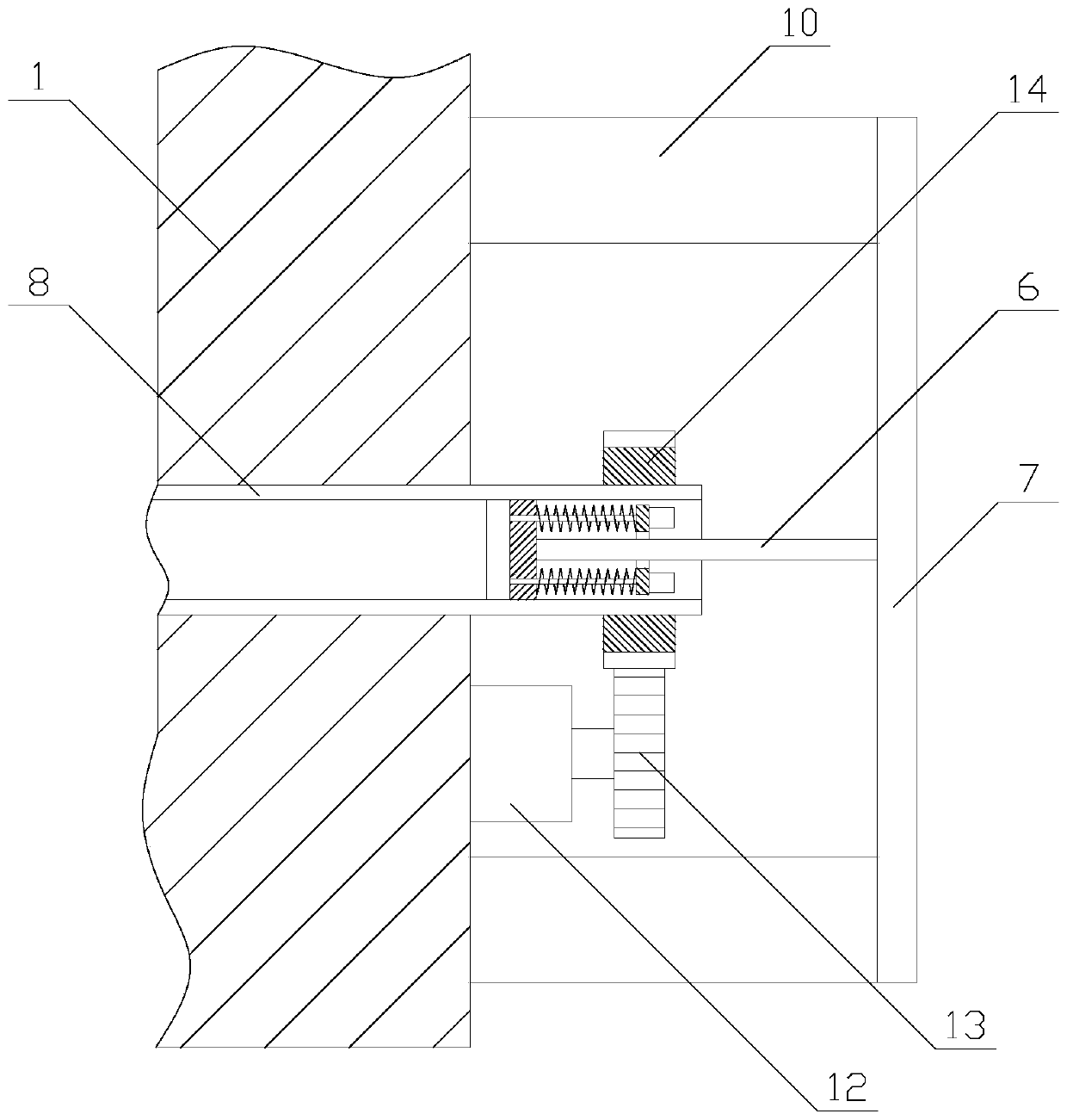

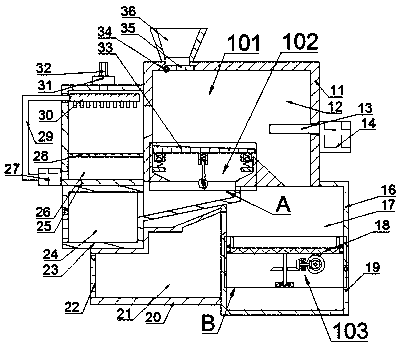

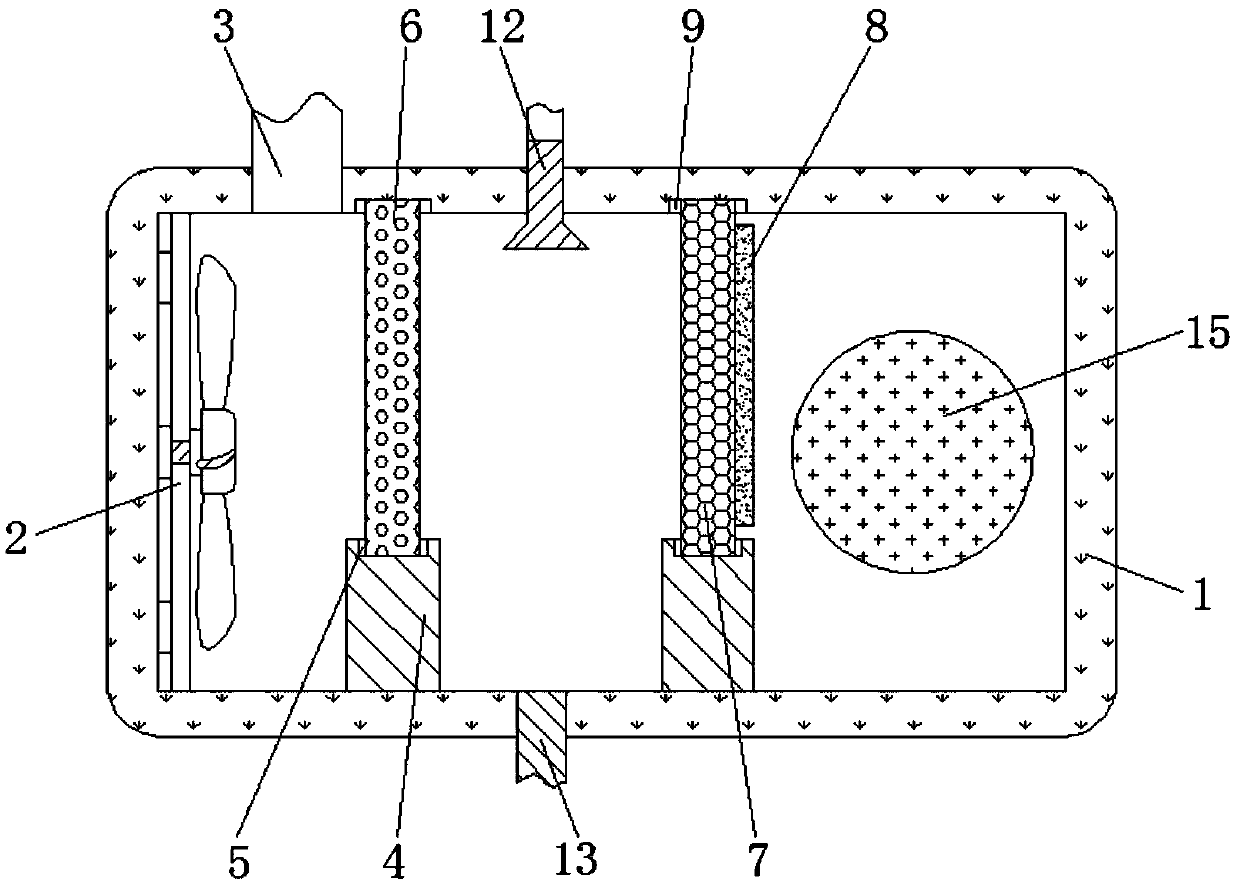

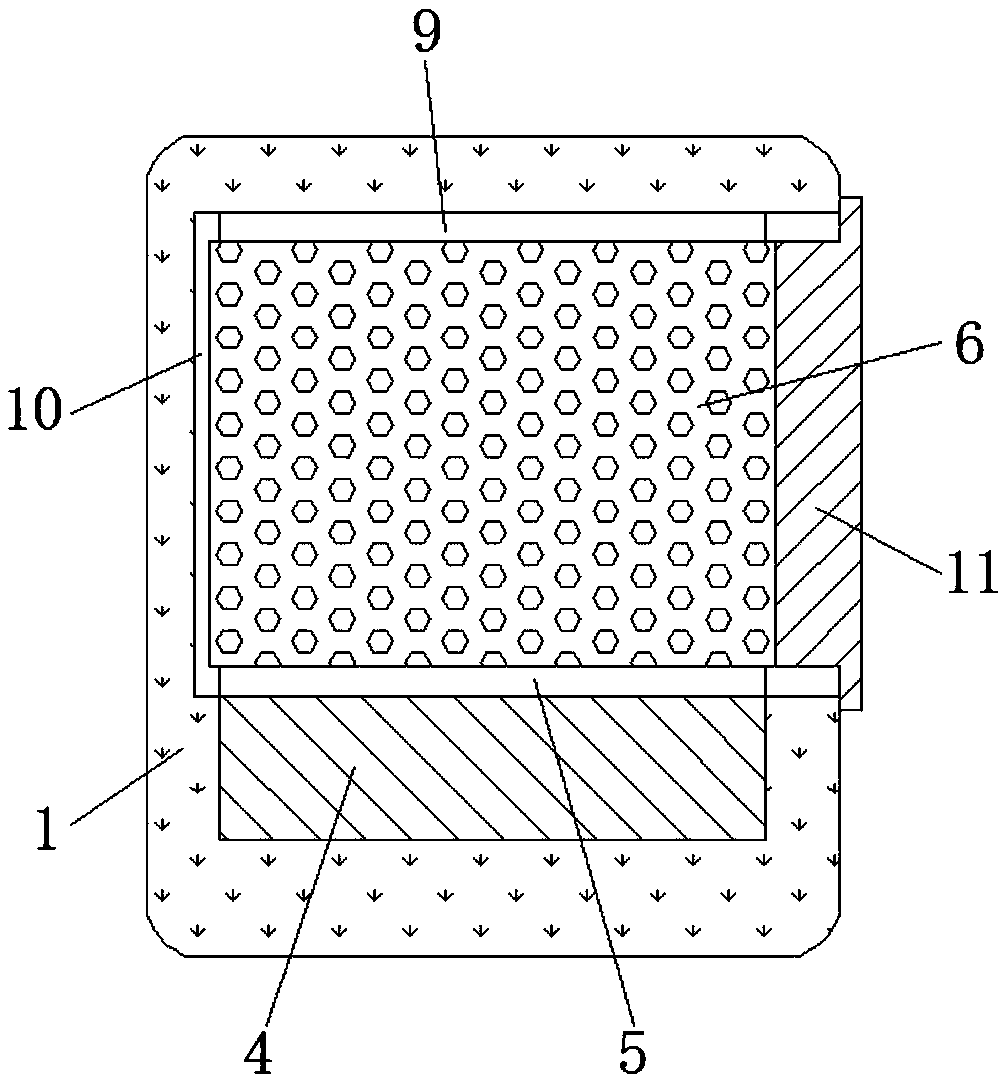

Hand lifting-copied cereal impurity removing device

InactiveCN108580283AImprove the effect of impurity removalAvoid affecting the effect of dustGas current separationArchitectural engineeringImpurity

The invention discloses a hand lifting-copied cereal impurity removing device. The hand lifting-copied cereal impurity removing device comprises a stirring cavity, a motor, a base plate, a collectingcavity, a transmission cavity and an impurity removing cavity; the stirring cavity is arranged at the upper end of the impurity removing cavity, and is separated through a base plate; a feed hopper isarranged at the upper end of the stirring cavity; the motor is arranged on the left side of the feed hopper; an output end of the motor is fixedly connected with a rotating shaft; a baffle plate is fixedly mounted on the rotating shaft at the lower end of the inner side of the stirring cavity; a transmission cavity is formed in the left end of the inner side of the impurity removing cavity; a thread rod on the inner side of the transmission cavity is in threaded connection with a thread sleeve; and the right side of the thread sleeve is hinged with a poking plate. The hand lifting-copied cereal impurity removing device is novel in design; when a blanking hole is staggered from or overlapped with a blanking hole on the base plate, cereals fall down through the blanking holes; and when thetwo blanking holes are staggered from each other, the cereals are stopped from falling to achieve an intermittent unloading effect and to effectively prevent influence on the dust flying effect due tosynchronous falling of excessive cereals.

Owner:台州来智科技有限公司

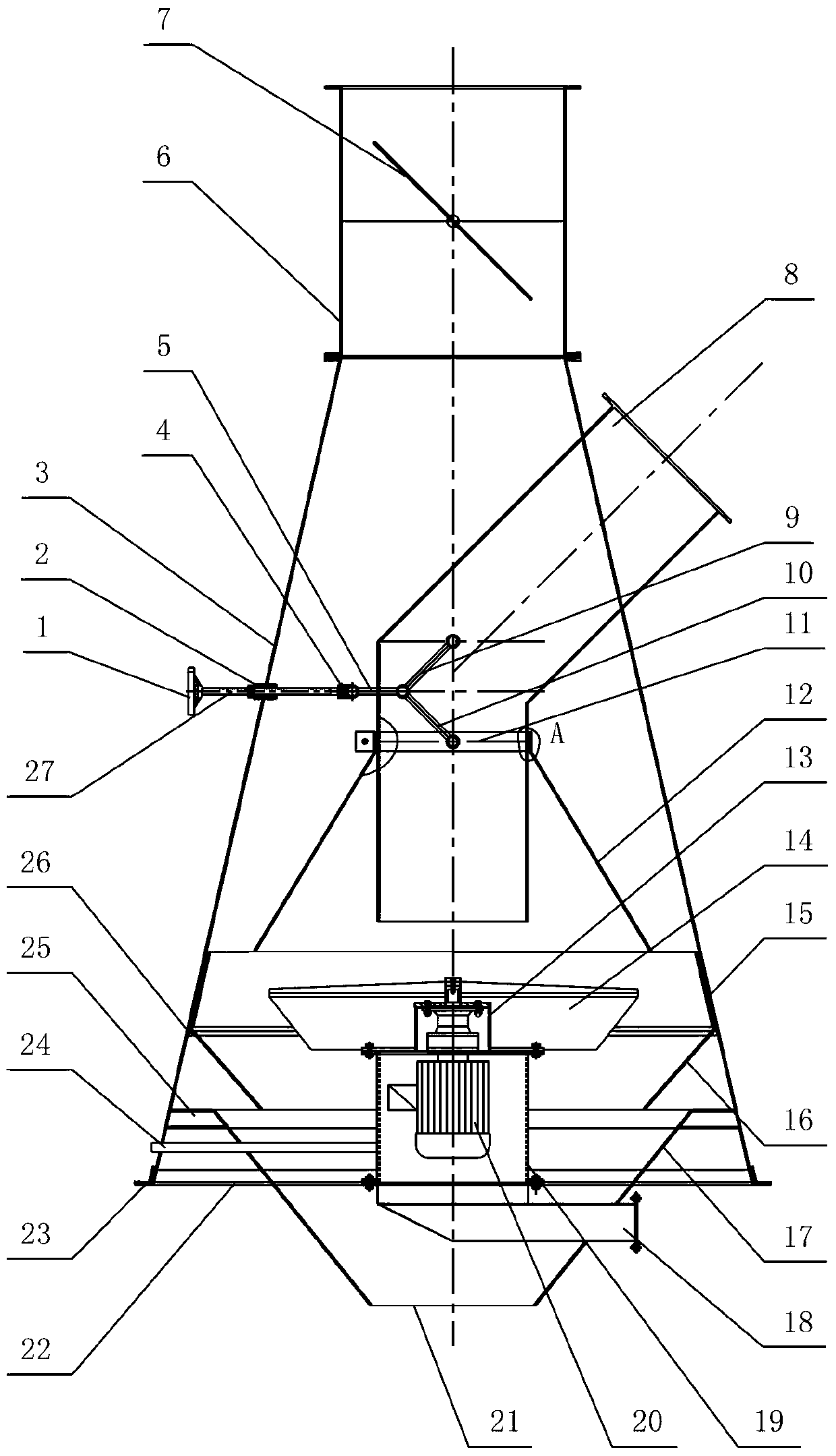

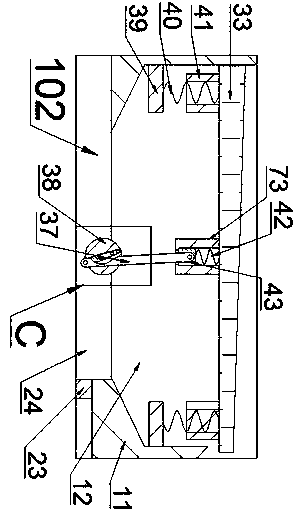

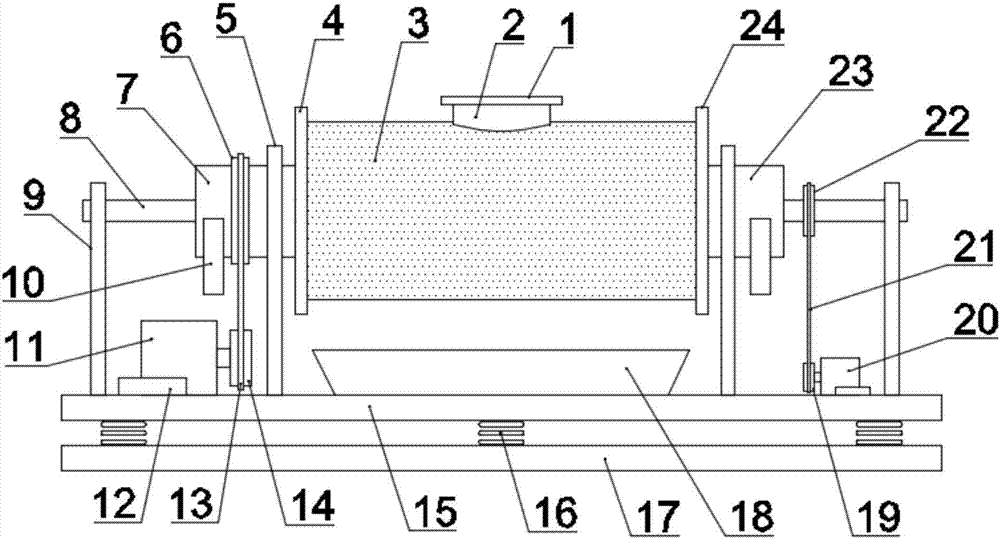

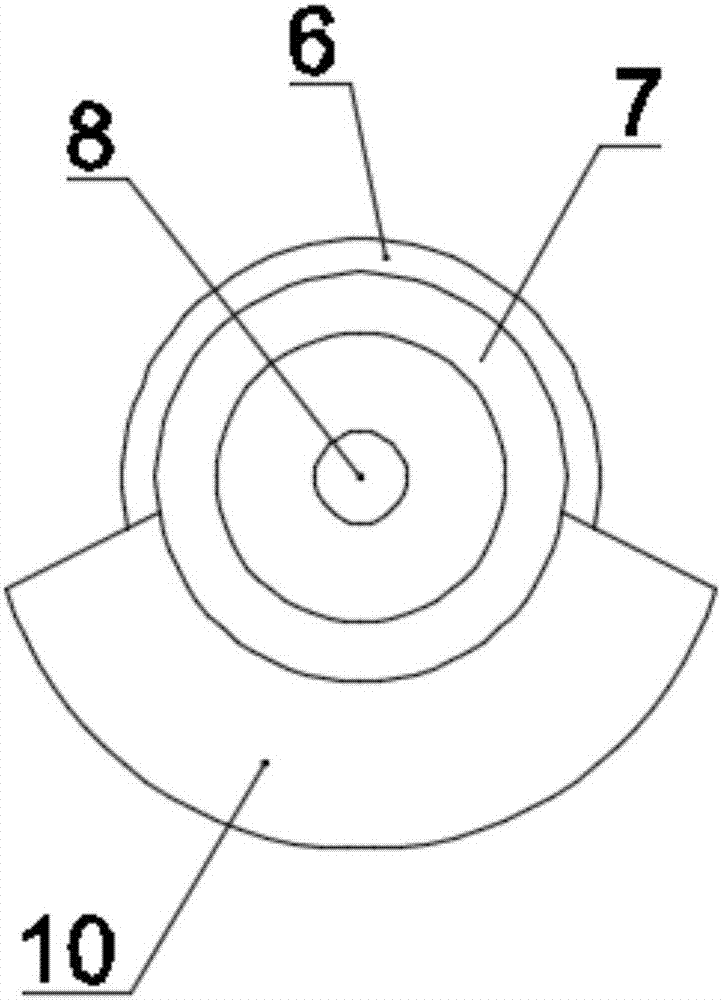

Rotary type grain separating device

ActiveCN103341445AConvenient and smooth flowReduce falling speedGas current separationEngineeringResidence time

The invention relates to a grain separating device, in particular to a grain winnowing separating device and belongs to the field of grain machinery. The rotary type grain separating device comprises a shell body, a rotary disc and a discharging tube. The rotary disc is arranged in the shell body; the discharging tube is arranged above the rotary disc; a motor is connected with the axial position of the rotary disc; a material collecting structure is arranged above the rotary disc; a winnowing region is formed among the rotary disc, the shell body and the material collecting structure; the opening portion of the shell body is connected with a wind power device. The rotary type grain separating device is reasonable in structure, small in size and occupied space, convenient to transport and suitable for application of a peasant household and small-sized operation. Grain is evenly distributed in the winnowing region, the residence time of the grain in the winnowing region is improved, the impurity removing efficiency is greatly improved, and the impurity removing efficiency is improved to 85% from 70%.

Owner:山东聚阳智能装备有限公司

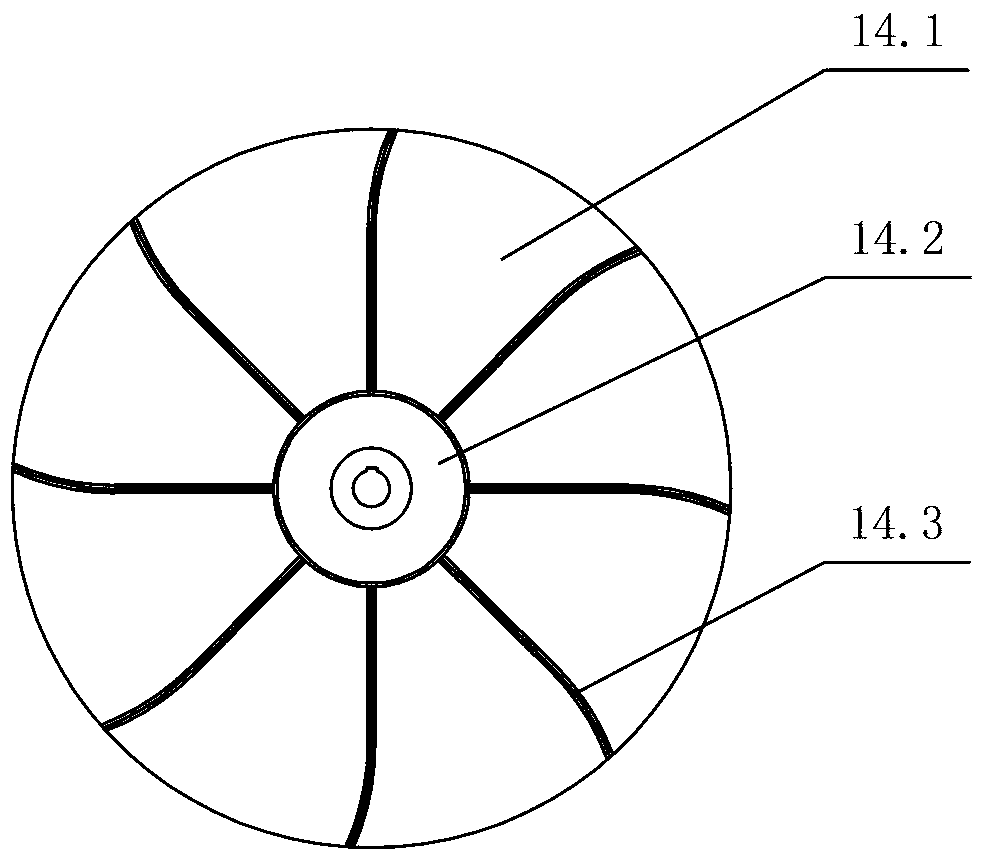

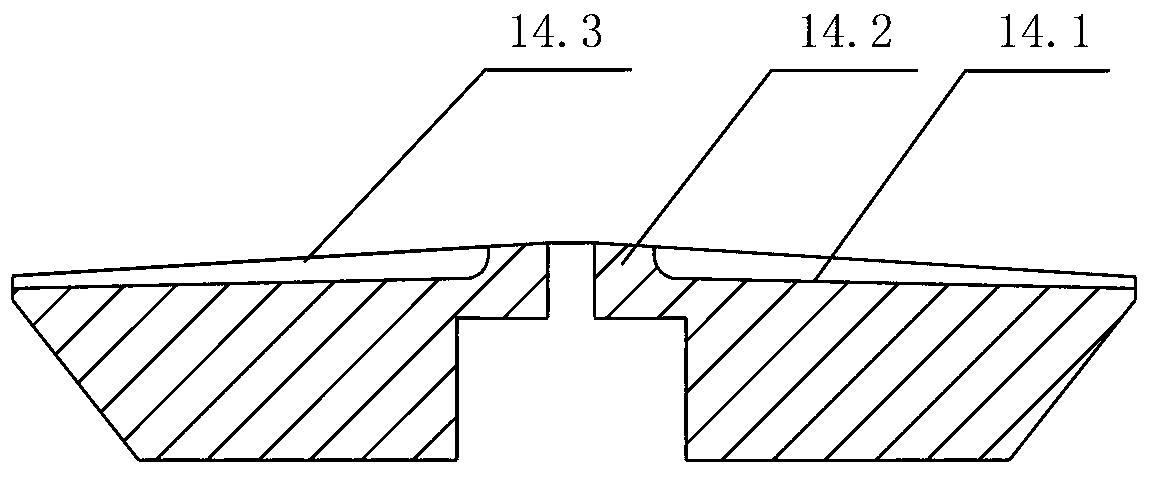

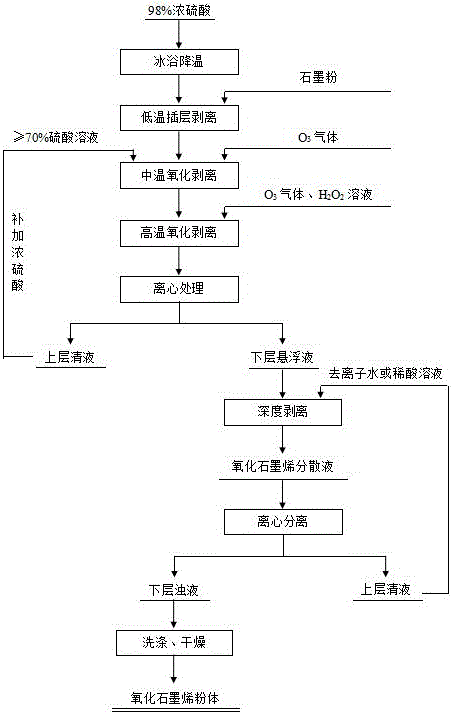

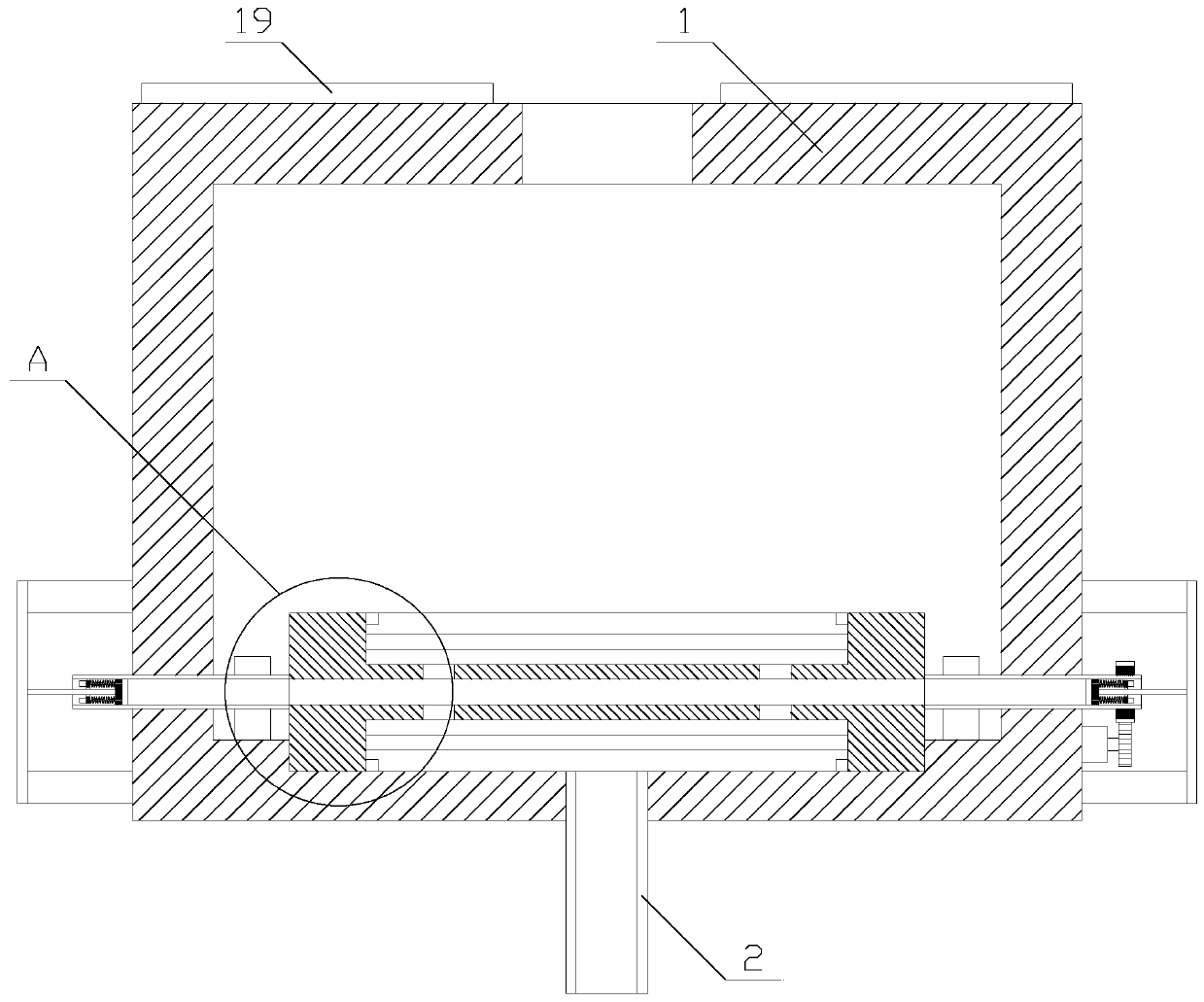

Method for preparing oxidized graphene

ActiveCN106395808AReduce the introductionOvercome Difficult Cleaning ProblemsGraphenePreparation proceduresHot Temperature

The invention discloses a method for preparing oxidized graphene. The method includes steps of adding graphite powder into concentrated sulfuric acid at the low temperature and carrying out ultrasonic treatment under a stirring condition; adding sulfuric acid solution into obtained mixed solution, continuously filling the mixed solution with gas containing ozone, then gradually increasing the temperature until moderate-temperature environments are created and carrying out constant-temperature stirring reaction; continuously filling reaction products with gas containing ozone, starting to add strong oxidizing agent solution into the reaction products, gradually increasing the temperature until high-temperature environments are created and carrying out constant-temperature stirring reaction; carrying out high-temperature oxidation exfoliation to obtain mixed liquid, carrying out centrifugal treatment on the mixed liquid, separating upper-layer clear liquid from lower-layer suspension, deeply exfoliating the lower-layer suspension to obtain dispersion liquid containing the oxidized graphene, or carrying out deep exfoliation, centrifugal separation, washing and drying treatment on the lower-layer suspension to obtain oxidized graphene powder. The method has the advantages that the oxidized graphene prepared by the aid of the method is high in purity, good in safety and large in laminar structure distance, waste acid can be recycled, and preparation procedures are green and environmentally friendly.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Recovery method of waste SCR denitration catalyst

ActiveCN110817944AGood removal effectImprove permeabilityAlkaline earth titanatesTungsten compounds preparationPtru catalystTungstate

The invention belongs to the field of non-ferrous metal recovery, and particularly relates to a recovery method of a waste SCR denitration catalyst. The recovery method comprises the steps of pretreatment, TiO2 separation, extraction and purification, titanium recovery, vanadium recovery, tungsten / molybdenum recovery and the like. The recovery method is capable of recycling a several precious recovery products such as V2O5, ammonium tungstate / ammonium molybdate and BaTiO3 from the waste SCR denitration catalyst. The invention provides an effective technical scheme, and efficient resource utilization of the waste SCR denitration catalyst can be realized.

Owner:北京华电光大环境股份有限公司

Drip irrigation device with speed regulating function and used for vegetable planting base

InactiveCN110622830AAvoid blockingImprove reliabilityClimate change adaptationWatering devicesWater volumeDrip irrigation

The invention relates to a drip irrigation device with a speed regulating function and used for a vegetable planting base. The drip irrigation device comprises a cuboid water tank and a drip pipe, thetop of the water tank is provided with a water inlet hole, and the drip tube is perpendicular to a plane of the bottom of the water tank, arranged at the bottom of the water tank and communicated with the water tank. A control mechanism and a regulation mechanism are arranged in the water tank; the control mechanism comprises a rotating pipe, a power component, two supporting components and two control components; each control component comprises a slide groove, a moving plate and two through holes; each supporting component comprises a moving plate, a pull rod, a push plate, a supporting pipe, a bearing, a mounting hole and at least two expansion blocks. The drip irrigation device with the speed regulating function and used for the vegetable planting base has advantages that by the control mechanism, a function of adjusting water volume in drip irrigation according to the environment temperature is realized, and moreover, by the regulation mechanism, the drip pipe can be protected from being blocked by impurities.

Owner:广州市沙唯士电子科技有限公司

Rice processing device

The invention discloses a rice processing device. The rice processing device comprises a machine seat which is provided with a bracket and an intermittent mechanism; a box body is hinged to the bracket; the intermittent mechanism comprises a driving motor and a cam fixedly connected with the motor; the box body is internally provided with a processing chamber, and the top of the box body is provided with a feeding inlet; the inner wall of the box body is provided with a rotary motor, a circular shaft is fixedly connected to the rotary motor, and a plurality of magnet rods are arranged on the circular shaft in the circumferential direction; an inclined plate is arranged in the box body, located below the circular shaft and provided with a gear; the side wall of the box body is provided with a discharging outlet, and a screen net is arranged at the discharging outlet and connected with a collecting box; a plurality of through holes are formed in the inclined plate, and each through hole is provided with an air net; the bottom of the box body is provided with a plurality of anti-blocking devices; each anti-blocking device comprises an air cylinder and an air blower, the air blower is provided with an blower cover, and an anti-blocking rod is arranged on the blower cover; and each anti-blocking rod is provided with an air chamber and an air exhaust hole. According to the scheme, the problem that existing rice impurity removal modes are poor in impurity removal effect is mainly solved.

Owner:通道福香米业有限公司

Honey stirring purification device

ActiveCN104857772AImprove qualityImprove the efficiency of impurity removalFiltration circuitsFood preparationAgricultural engineeringSelf-absorption

The invention discloses a honey stirring purification device which comprises a stirring tank, wherein a honey discharge hopper is arranged at the top of a hollow pipe of a stirring shaft in the stirring tank in a communicating manner; a drainage plate is fixed on the stirring shaft on the lower side of the honey discharge hopper via a bearing; a first stirrer and a second stirrer are fixed on the left side and the right side of the stirring shaft on the lower side of the drainage plate; a filter bulb is arranged at the bottom end of the stirring shaft; the top of the stirring tank is connected with a motor via a speed changer at the top end of the stirring shaft; a sediment tank is arranged in the middle of the bottom of the stirring tank in a communicating manner; and the upper side of the drainage plate is connected with a honey tank via a communicating pipe on the left side of the stirring tank. The device is compact in structure, small in floor area, better in honey quality and high in purification efficiency, and purifies honey via self-absorption and drainage.

Owner:枣庄科顺数码有限公司

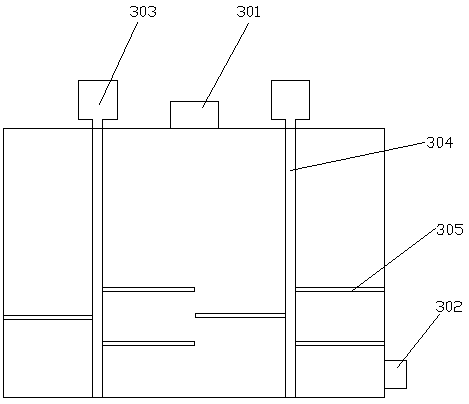

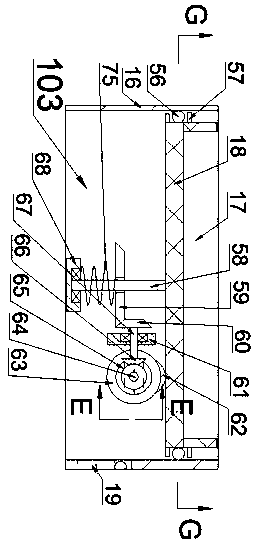

Impurity removing equipment for grain processing

InactiveCN110639811AImprove adaptabilityQuickly adjust the amplitudeSievingGas current separationVibration amplitudeCrank

The invention discloses impurity removing equipment for grain processing. The equipment comprises a vibration box; a vibration cavity is formed in the vibration box; a dust removing device for removing dust by using air currents is arranged on the left side of the vibration box; a vibration device is arranged in the vibration cavity; a screening box is fixedly connected to the lower side end surface of the vibration box; a screening cavity communicating with the dust removing device is arranged in the screening box; a screening device is arranged in the screening cavity; and the screening device uses rotary vibration for removing impurities larger than grain particles. A primary vibration screening device can quickly adjust the length of a crank in a crank slide block mechanism through rotation of a knob, so that the vibration amplitude adjusting function is achieved, operators conveniently adjust the vibration amplitude, the impurity removing adaption to different grains is improved,the impurity removing effect is improved, and meanwhile, dust generated by screening can be removed.

Owner:永康串行电子有限公司

Waste gas purification equipment with filtering function for chemical machine production

PendingCN108671662AImprove filtering effectQuality assuranceDispersed particle filtrationTransportation and packagingProduct gasEngineering

The invention discloses waste gas purification equipment with a filtering function for chemical machine production. The waste gas purification equipment comprises a purification box, wherein the innerwall of one side of the purification box is provided with a first fan through a bolt; one side, which is near the first fan, on the outer wall of the top of the purification box is provided with an air inlet pipe through a bolt; two sides of the inner wall of the bottom of the purification box are respectively provided with a supporting substrate through bolts; the outer walls of two ends of thesupporting substrate are respectively connected with the inner walls of two ends of the purification box through bolts; the outer wall of the top of each supporting substrate is provided with a connecting groove. According to the waste gas purification equipment, a first filtering screen plate and a second filtering screen plate of different net holes are used for carrying out dual filtering to remove larger impurity particles in waste gas, alkaline liquid is sprayed into waste gas through a shower nozzle to carry out neutral reaction with acid gas in the waste gas so as to filter the acidic components of the waste gas, oil stain in the waste gas is adsorbed and filtered by oil adsorption cotton so as to improve the waste gas filtering effect of the device, and waste gas filtering qualityis ensured.

Owner:ZHENGZHOU UNIV

Novel process for processing chicken manure through aerobic fermentation

InactiveCN109180236AImprove the environmentSoft textureBio-organic fraction processingExcrement fertilisersBacillus licheniformisHealth index

The invention discloses a novel process for processing chicken manure through aerobic fermentation. A high-efficiency, green chicken manure fermented bio-organic fertilizer is developed by using a rapid fermentation process of mixed bacteria solids. The compound microbial agents include bacillus coagulans, bacillus licheniformis, thermophilic heterotrophic ammonia-oxidizing bacteria, aspergillus niger and the like. The process adopts multi-bacterium mixed fermentation, through the combination of different metabolic abilities, the complex metabolic effects that are difficult to complete by a single strain can be completed, through the synergistic fermentation between microorganisms, the effective conversion of chicken manure is realized, the health indexes meet the national standards, and the product maturity and growth promotion indexes are significantly improved. The fermentation process is simple and efficient, has good deodorizing and sterilizing effect, has low production cost, andis easy for industrial large-scale production.

Owner:山东惠民禽乐畜牧机械有限公司 +1

Crop combined cleaning device

InactiveCN107096708AConducive to spoilerImprove work efficiencySievingScreeningAgricultural engineering

The invention discloses a crop combined cleaning device, comprising a screen filter net drum; a left sealing plate and a right sealing plate are respectively arranged on the left and right ends of the screen filter net drum; a left sleeve and a right sleeve are respectively mounted on the left side of the left sealing plate and the right side of the right sealing plate, a first support is arranged on each of the right side of the left sleeve and the left side of the right sleeve, the left sleeve is provided with a first belt wheel, the first belt wheel is connected to a second belt wheel mounted on a first motor output shaft by a first driving belt, a transverse shaft is arranged in the middle of the inner side of the screen filter net drum, a second support is arranged on each of the right end and the left end of the transverse shaft, the right side of the right sleeve is provided with a fourth belt wheel on the transverse shaft, the fourth belt wheel is connected to a third belt wheel mounted on a second motor output shaft by a second driving belt, and a plurality of stirring blades are mounted on the transverse shaft in the screen filter net drum. The crop combined cleaning device is reasonable in structural design and has better cleaning effect by combining a plurality of modes and working efficiency is improved.

Owner:刘冬明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com