Patents

Literature

51results about How to "Hit evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

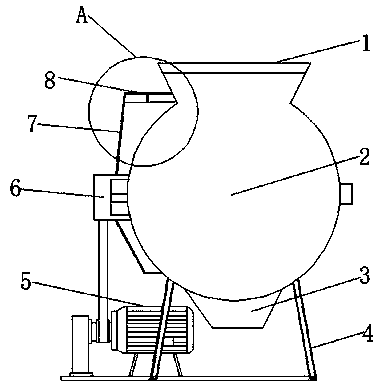

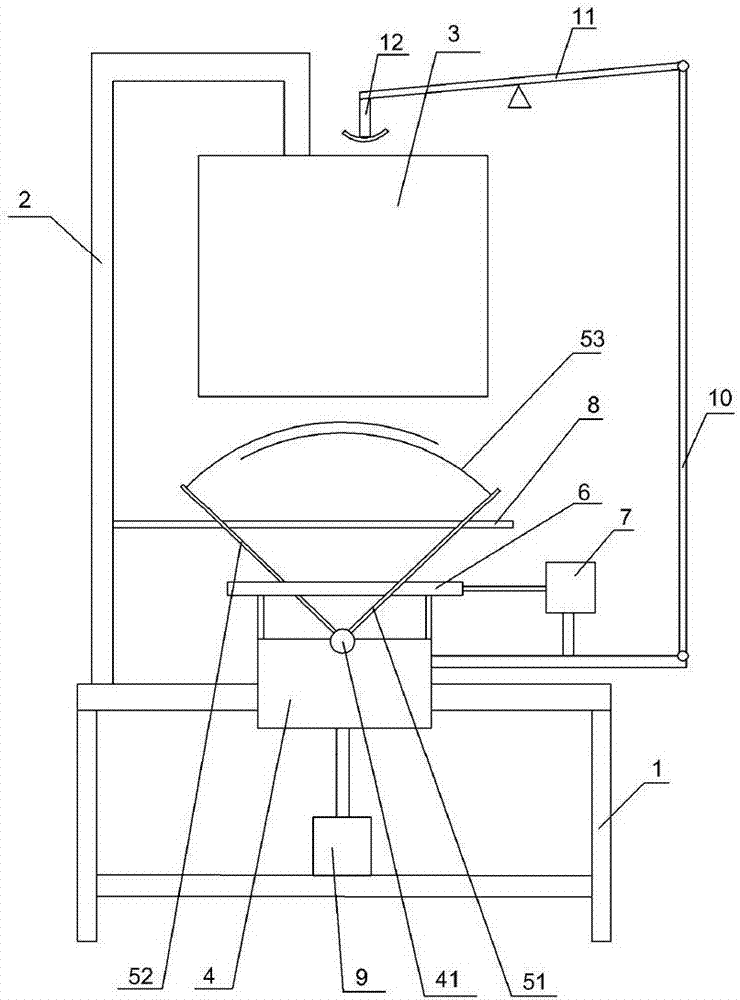

Flour mixing machine

InactiveCN107019010AIncrease elasticityUniform elasticityMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringMotor shaft

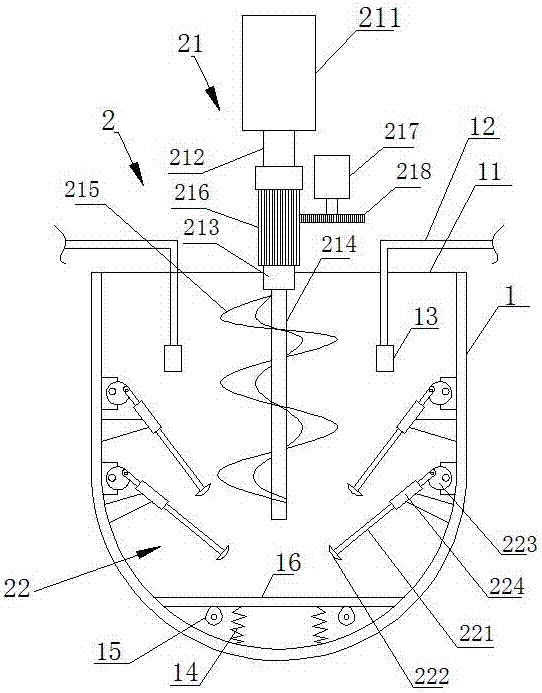

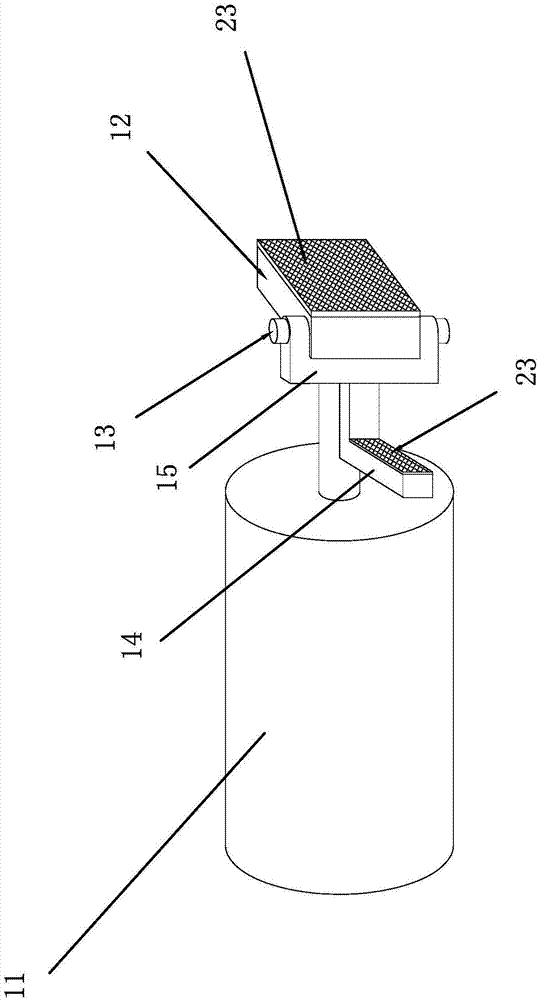

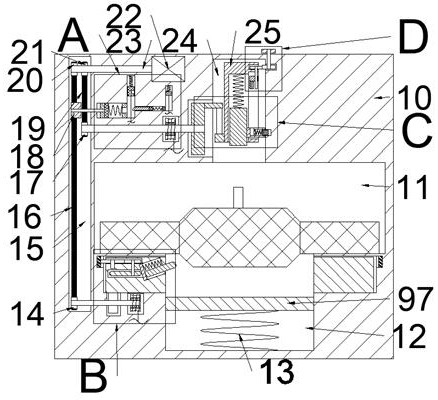

The invention relates to a noodle kneading machine, comprising a cylinder body and a dough kneading device arranged in the cylinder body; a dough inlet is arranged at the upper end of the cylinder body; a telescopic water inlet pipe which can be stretched The end is a cylindrical self-rotating nozzle; the kneading device includes a stirring device that can be raised and lowered as in the cylinder and a beating device that is evenly distributed on the inner periphery of the cylinder; the beating device includes a plurality of The stroke rod; one end of the stroke rod toward the center of the bottom of the cylinder is provided with a hemispherical hammer, and the other end is hinged on the outer periphery of a turntable; the turntable is driven by a first motor, and the motor shaft is eccentric on the turntable Setting; the middle part of the strike rod is slidingly sleeved in a limit sleeve.

Owner:林娜娜

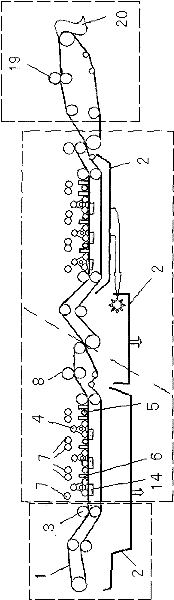

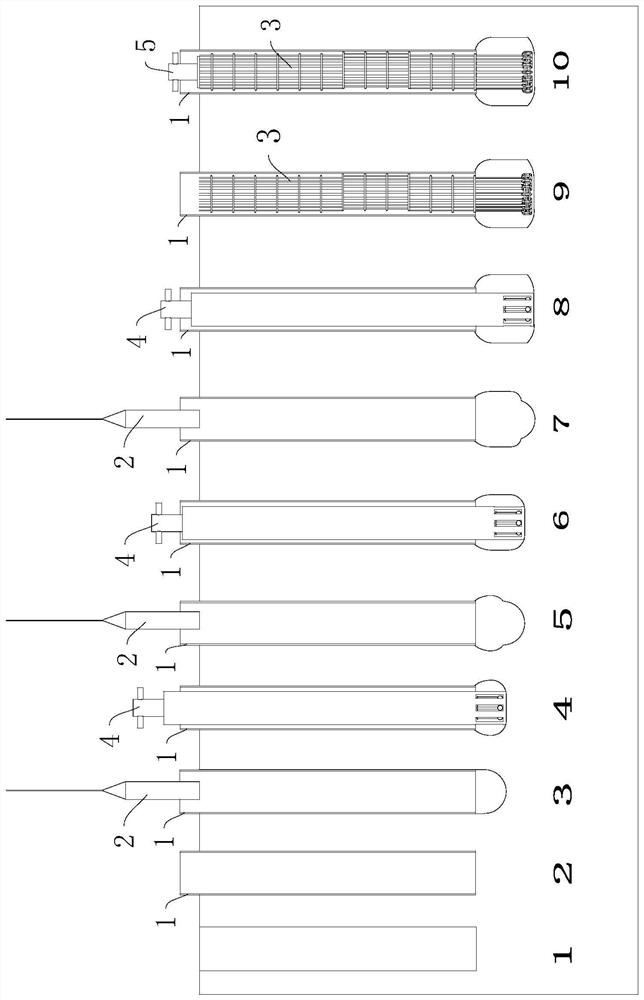

Processing system for processing hemp into hemp fiber

InactiveCN104562217AReduce stress and difficultyReduce processing timeMechanical impurity removalTextile/flexible product manufactureHemp fiberFineness

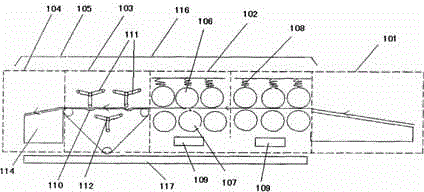

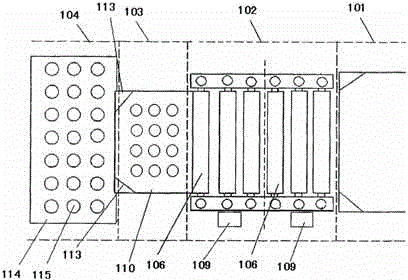

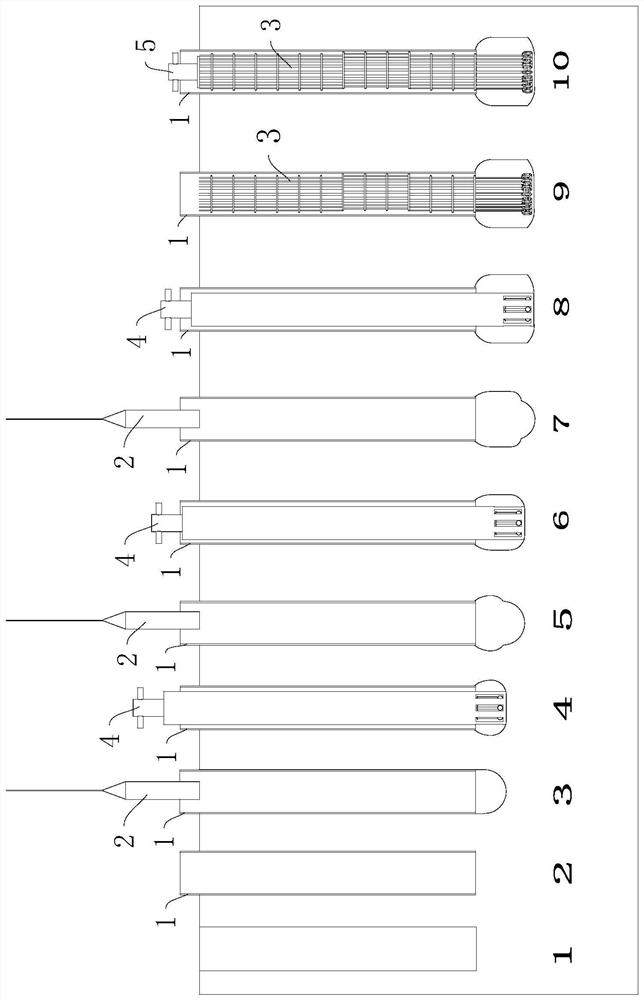

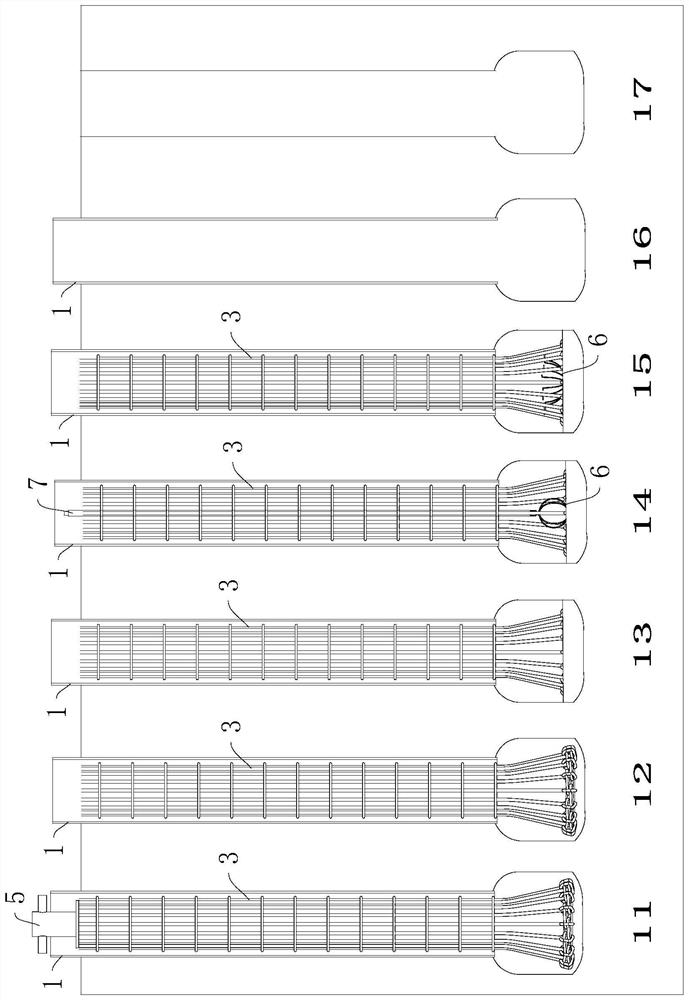

The invention relates to a hemp fiber manufacturing production line, in particular to a processing system for processing hemp into hemp fiber. The processing system for processing the hemp into the hemp fiber comprises devices for arranging hemp, degumming, dividing fiber and water washing, rinsing and softening, drying, softening and oiling, permeating and health maintaining, crush cutting and teasing, and combing and arranging; a degumming device comprises a mechanical degumming device, a biological degumming device and a high-temperature scouring-bleaching degumming device, and the device is special; a yarn hanging rack is composed of a hollow post and a plurality of hollow beams in a connecting mode, the hollow beams are provided with a plurality of hanging rods, and a plurality of holes are formed in the sides of the hanging rods; the crush cutting and teasing use a drafting roller set and a snapping roller set, and the drafting roller set and snapping roller set run in differential speeds and pressurize simultaneously. The combing and arranging use a round comb and a top comb to comb and a pulling vehicle to pull, along the rotating direction, the density of gill bars is increased gradually, and the fineness is reduced gradually. The processing system for processing the hemp into the hemp fiber changes a traditional hemp processing device, improves the long hemp yield and facilitates subsequent processing, and the produced hemp fiber is stable in quality.

Owner:王学钢

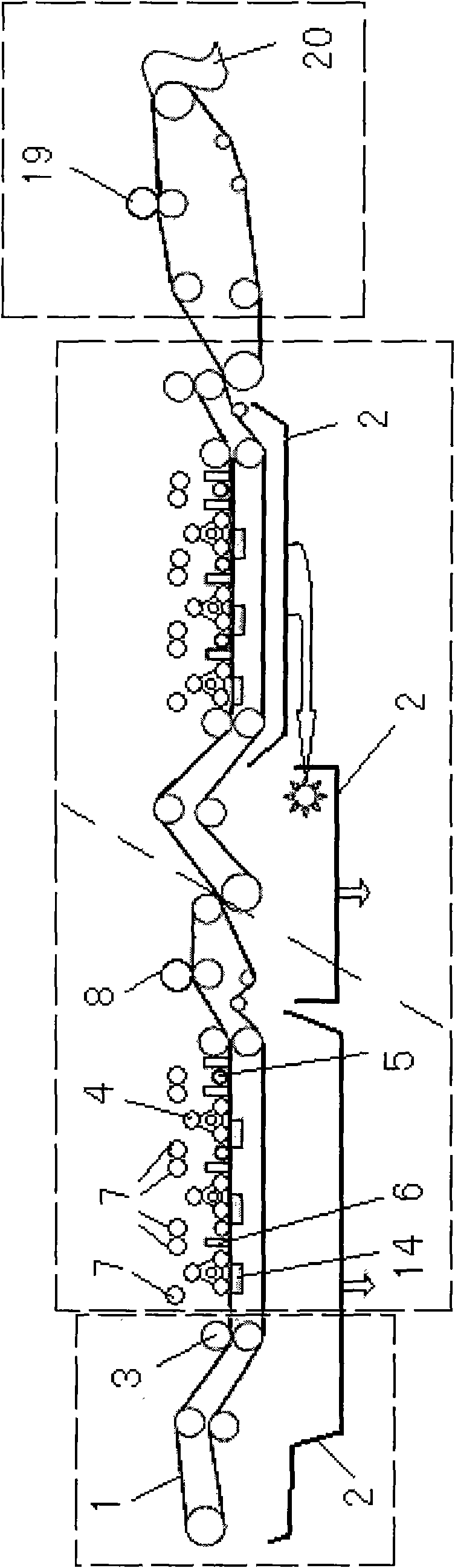

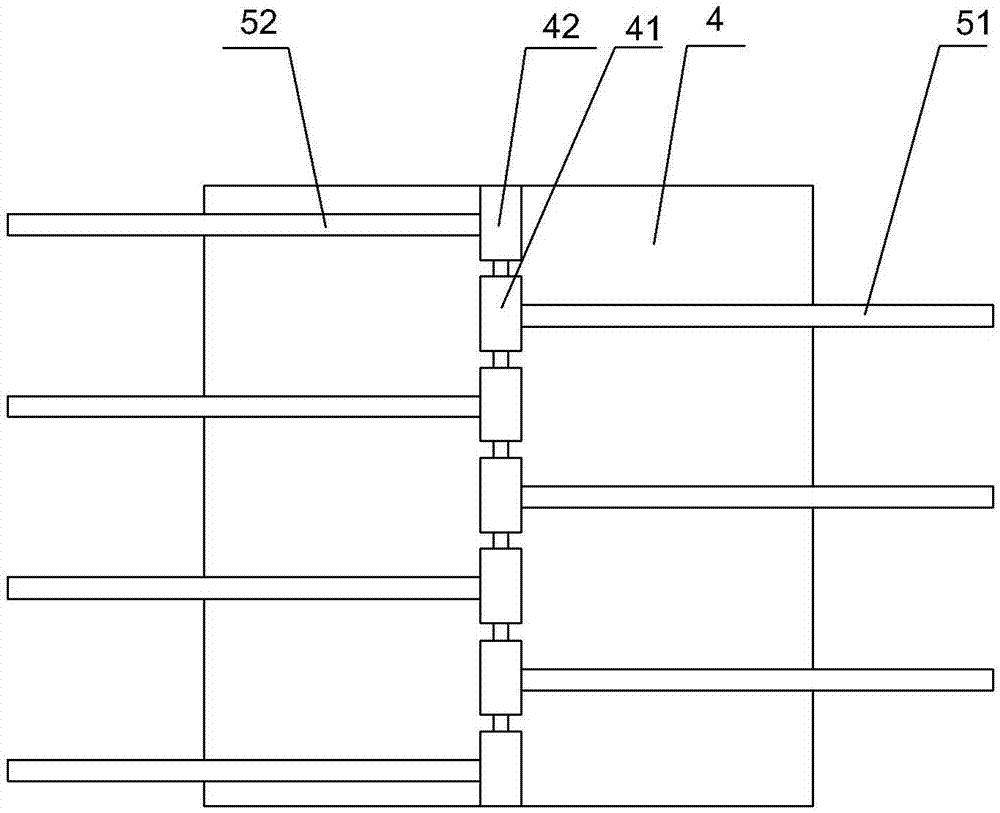

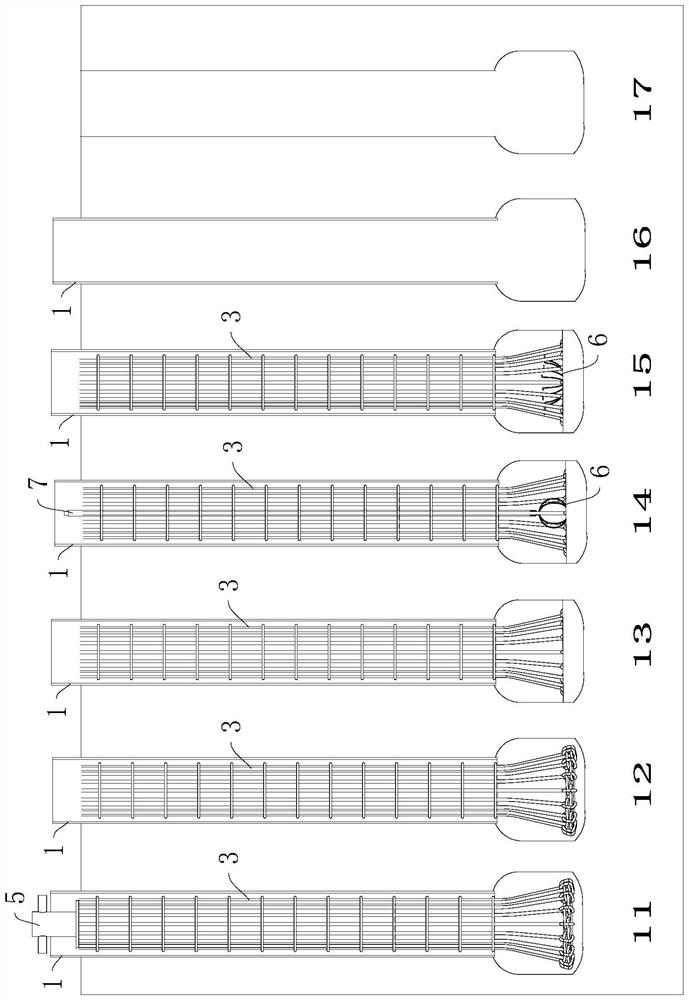

Fiber bundle dividing and washing method and device

ActiveCN101851789AGuaranteed cleanlinessHit evenlyMechanical treatmentFibre treatment to obtain bast fibreCardingFiber bundle

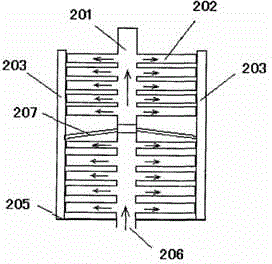

The invention relates to a fiber bundle dividing and washing method and a fiber bundle dividing and washing device. The method comprises the following steps of: 1) arranging a plurality of groups of fiber dividing and washing units and a fiber output unit on a frame, wherein each unit is provided with a running rotating crawler; 2) passing a feeding roller through a crawler input end of each fiber dividing and washing unit so as to convey the fiber bundle forward, making the fiber bundle enter a fiber dividing and washing area which is provided with a beater and a fiber dividing roller at intervals, simultaneously opening a high pressure water pipe which is arranged above the beater and the fiber dividing roller, and performing washing soaking, beating, carding and fiber dividing on the fiber bundle edges; 3) feeding the fiber treated by the previous fiber dividing and washing unit to the next fiber dividing and washing unit for continuous fiber dividing and washing; and 4) feeding the fiber treated by the last fiber dividing and washing unit into a fiber dividing input area, performing water squeezing operation through a squeezing roll, feeding the fiber into a cloth arrangement mechanism, arranging and folding the strip-shaped fiber through the cloth arrangement mechanism, and feeding the fiber into a fiber storage box. The fiber bundle dividing and washing method and the fiber bundle dividing and washing device can be widely applied to fiber dividing and washing treatment for various bast fibers, leaf fibers, and grass family fibers.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +3

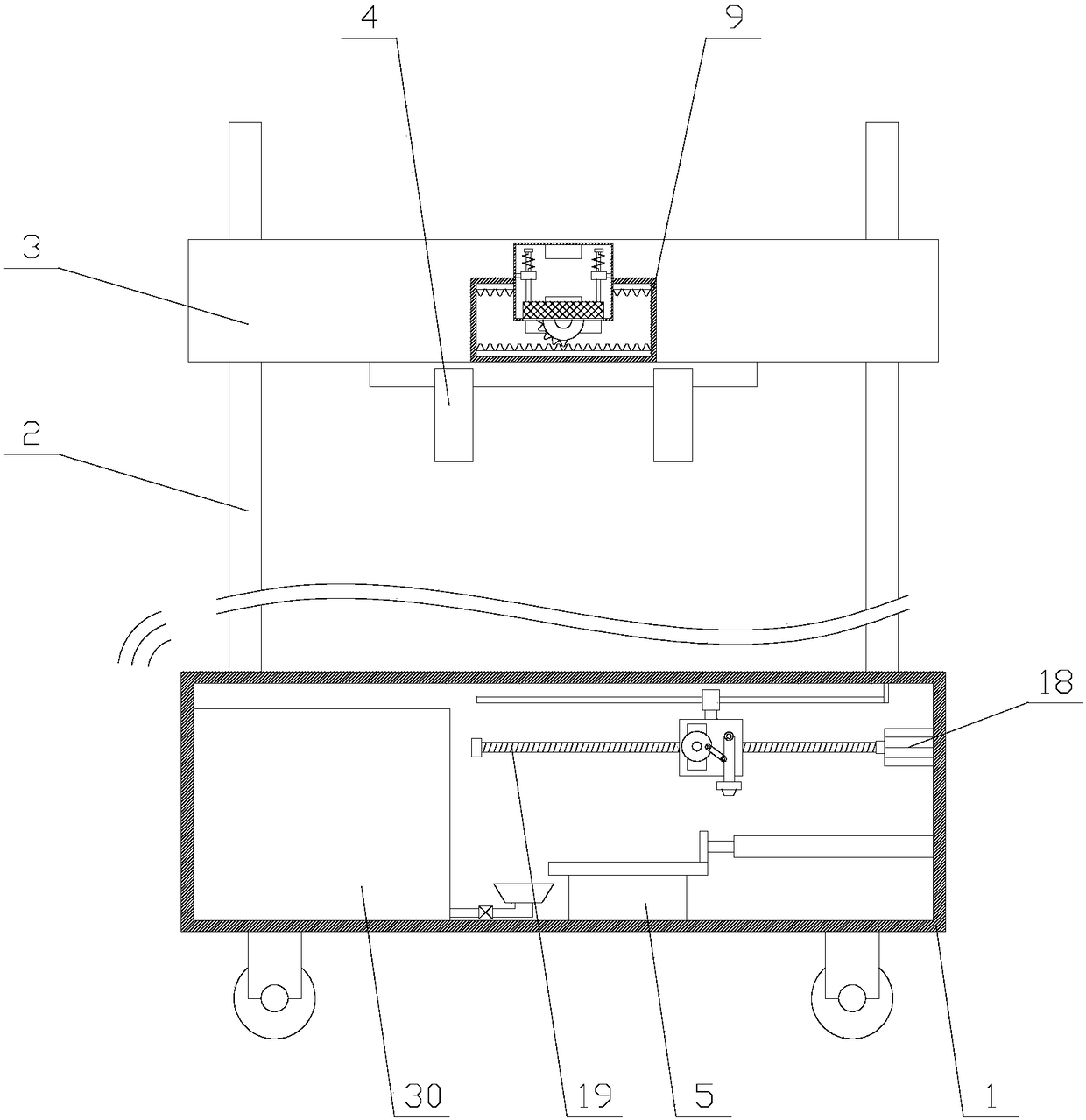

Wall building mechanical equipment with good using effect based on Internet of Things

The invention relates to wall building mechanical equipment with good using effect based on the Internet of Things. The wall building mechanical equipment comprises a base, stand columns, a lifting platform, clamping jaws, a material placing platform, a compaction mechanism and a material plastering mechanism. The compaction mechanism comprises a reciprocating component and a knocking component, and the material plastering mechanism comprises a material plastering component and a recycling component. According to the wall building mechanical equipment with the good using effect based on the Internet of Things, bricks can be knocked comprehensively and uniformly through the compaction mechanism, so that the upper and lower layers of bricks and cement between the bricks contact with each other fully, and compared with an existing automatic wall building machine, the bricks are bonded more tightly, so that the possibility of collapse caused by loose bricks is reduced; and the consumptionof cement resources is saved through the material plastering mechanism, the influence of external environmental factors on cement solidification is avoided, recycled cement is reused, compared with the existing automatic wall building machine, waste of the cement resources is avoided, the construction cost is reduced, and the practicability and reliability of the automatic wall building machine are improved.

Owner:南安市智德机械设备有限公司

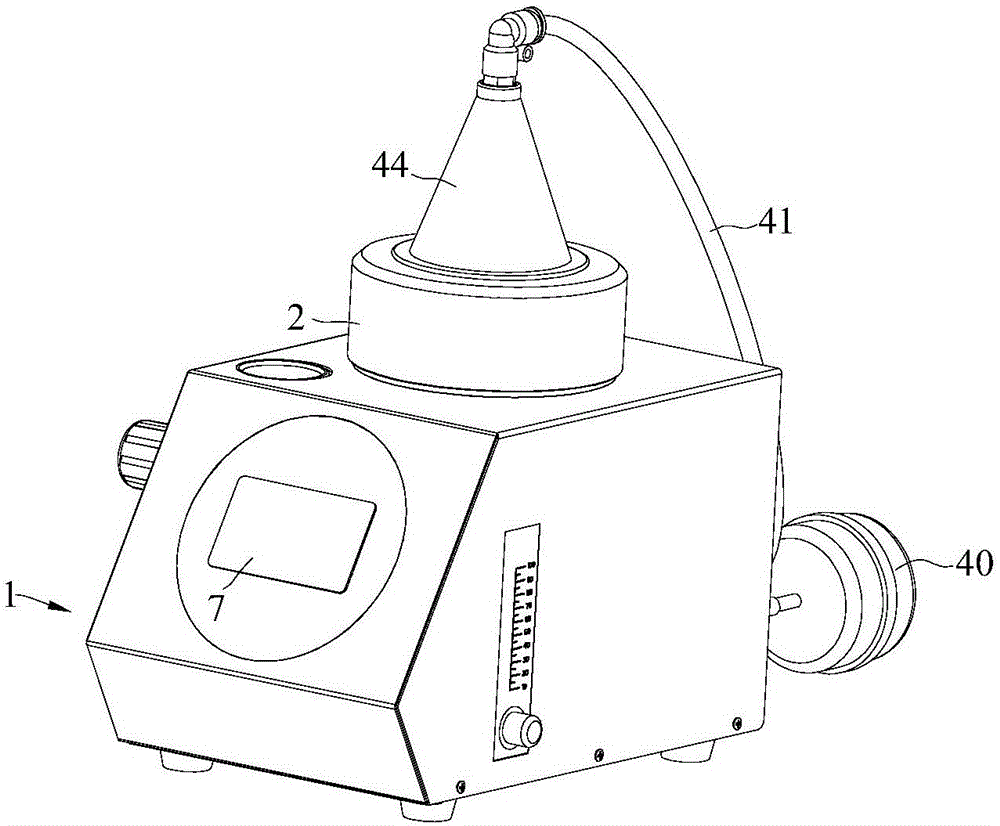

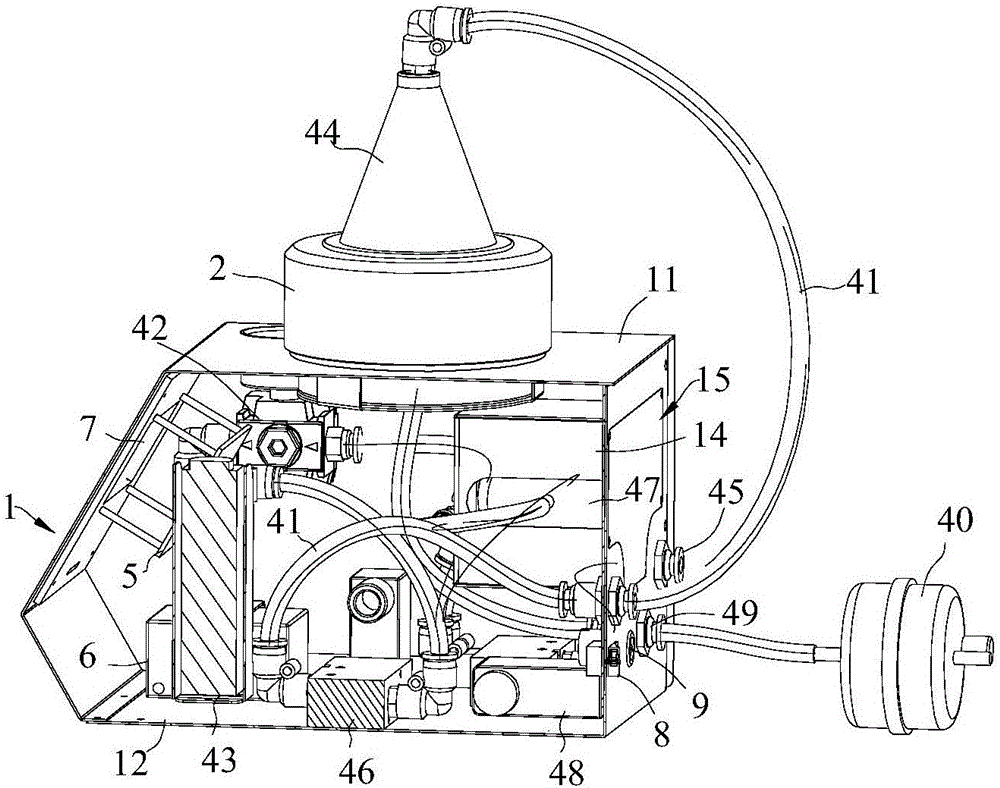

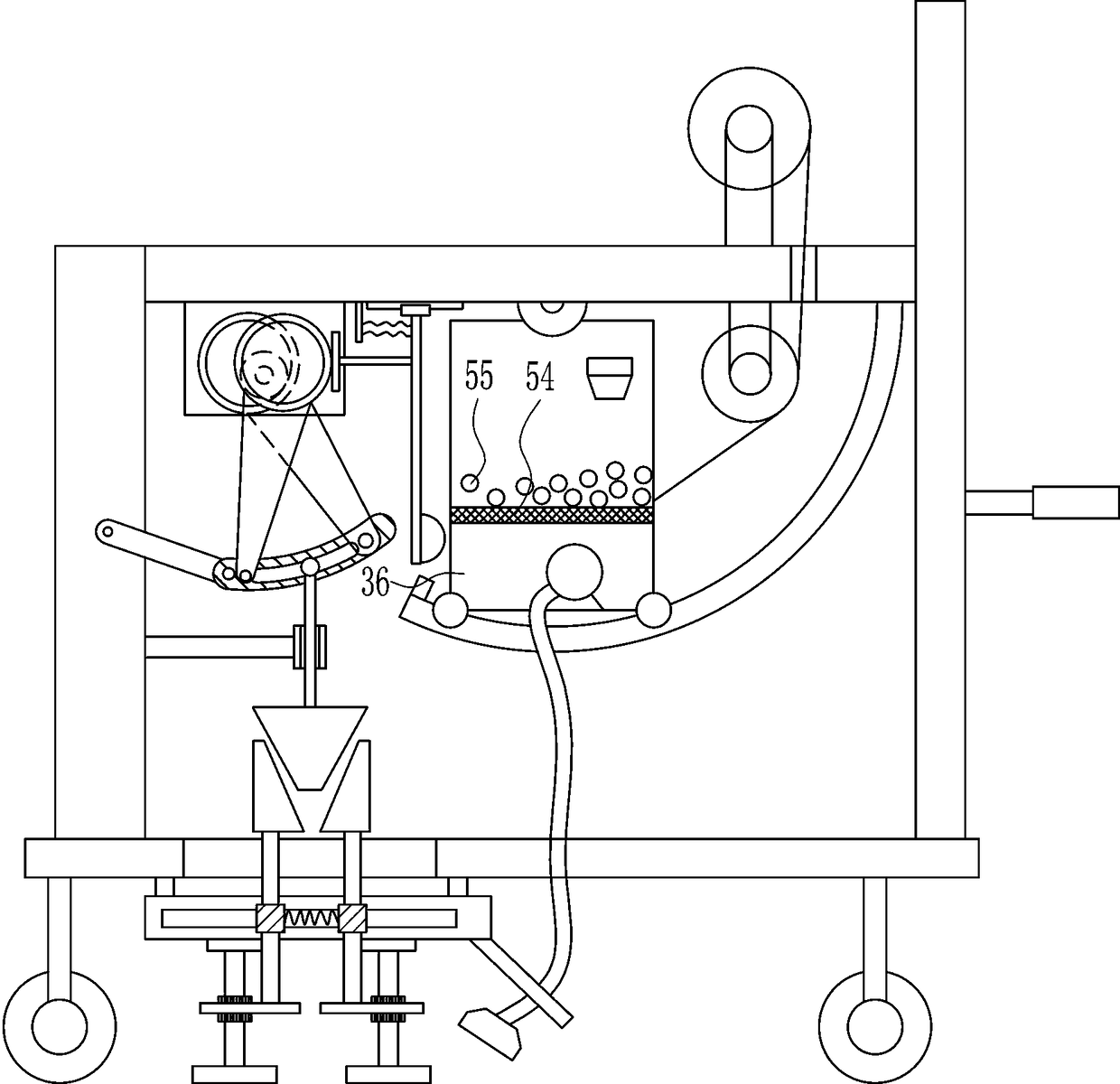

Flow-adjustable impact type compressed air microorganism sampler with sieve meshes

ActiveCN106479875AConstant sampling rateGuaranteed accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsInlet channelPerfect sampling

The invention discloses a flow-adjustable impact type compressed air microorganism sampler with sieve meshes, and is applied to the technical field of microorganism acquisition and quantity monitoring. The flow-adjustable impact type compressed air microorganism sampler comprises a shell, a sampling head and a controllable decompression gas circuit system. The sampling head is arranged on the top of the shell, the controllable decompression gas circuit system is arranged in the shell, an air inlet channel is arranged on the sampling head, a culture dish seat which directly faces the air inlet channel is arranged on the shell and is positioned below the sampling head, an air outlet channel is arranged on the culture dish seat, the controllable decompression gas circuit system comprises a gas circuit, a gas pressure regulating valve and a gas flow meter, the gas pressure regulating valve and the gas flow meter are arranged on the gas circuit, one end of the gas circuit on the shell is connected to a gas source connector, and the other end of the gas circuit is butted to the air inlet channel of the sampling head by a gas dispersing head. Compared with other treatment methods, the flow-adjustable impact type compressed air microorganism sampler has the advantages that the flow-adjustable impact type compressed air microorganism sampler is high in sampling speed and particle capture rate; the actual contents of bacteria in compressed air can be accurately expressed, and accordingly a perfect sampling method is proposed.

Owner:GUANGDONG HUANKAI MICROBIAL SCI & TECH

Rotating drying cylinder

InactiveCN103759519AAvoid depositionAvoid transportDrying solid materialsDrying machinesCombustorEngineering

The invention belongs to drying equipment for removing liquids from solid materials or products and discloses a rotating drying cylinder. The rotating drying cylinder comprises an outer cylinder and an inner cylinder, the inner cylinder is built in the outer cylinder, a heating channel is formed between the outer cylinder and the inner cylinder, the outer cylinder is connected with a combustor, rolling rings and teeth rings are fixed on an outer circle of the outer cylinder, protruded vibrating bands are arranged on the outer wall of the inner cylinder along an axial direction, inner cavities are mounted on the vibrating bands, and steel balls are placed at positions of the inner cavities. The rotating drying cylinder has the advantages that the structure is simple, material bonding can be effectively prevented, and normal conveying of materials can be guaranteed.

Owner:重庆信奇建材机械制造有限公司

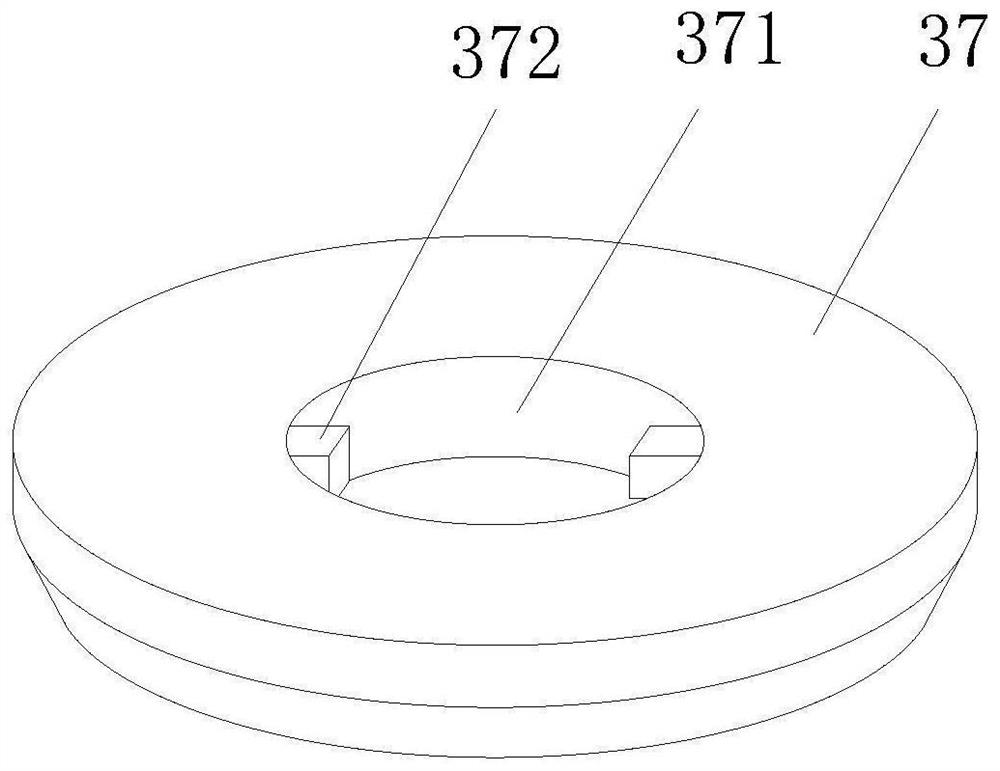

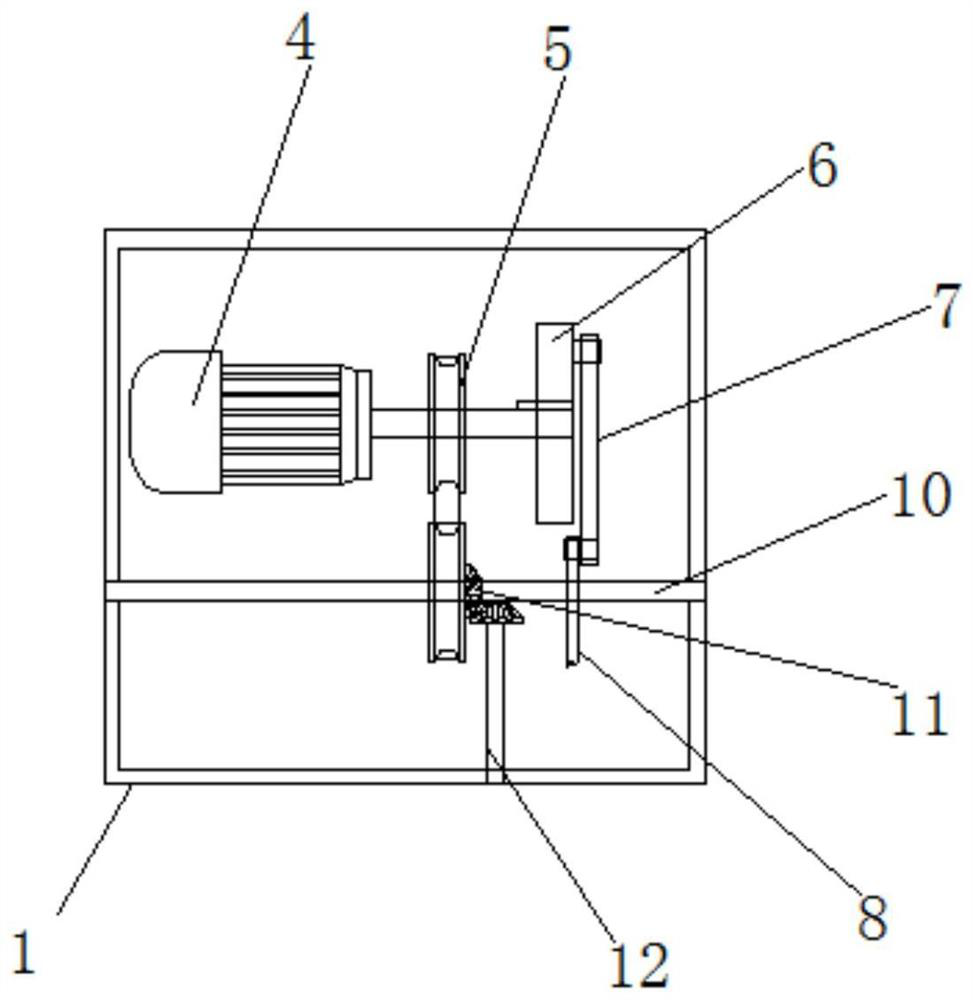

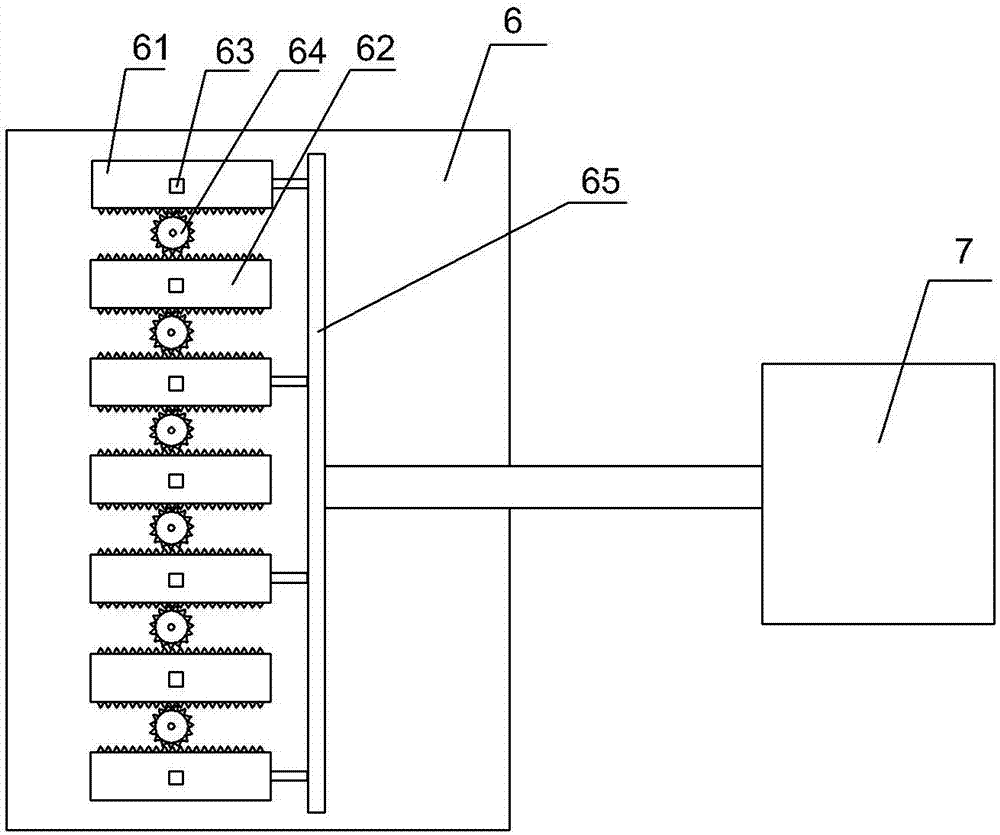

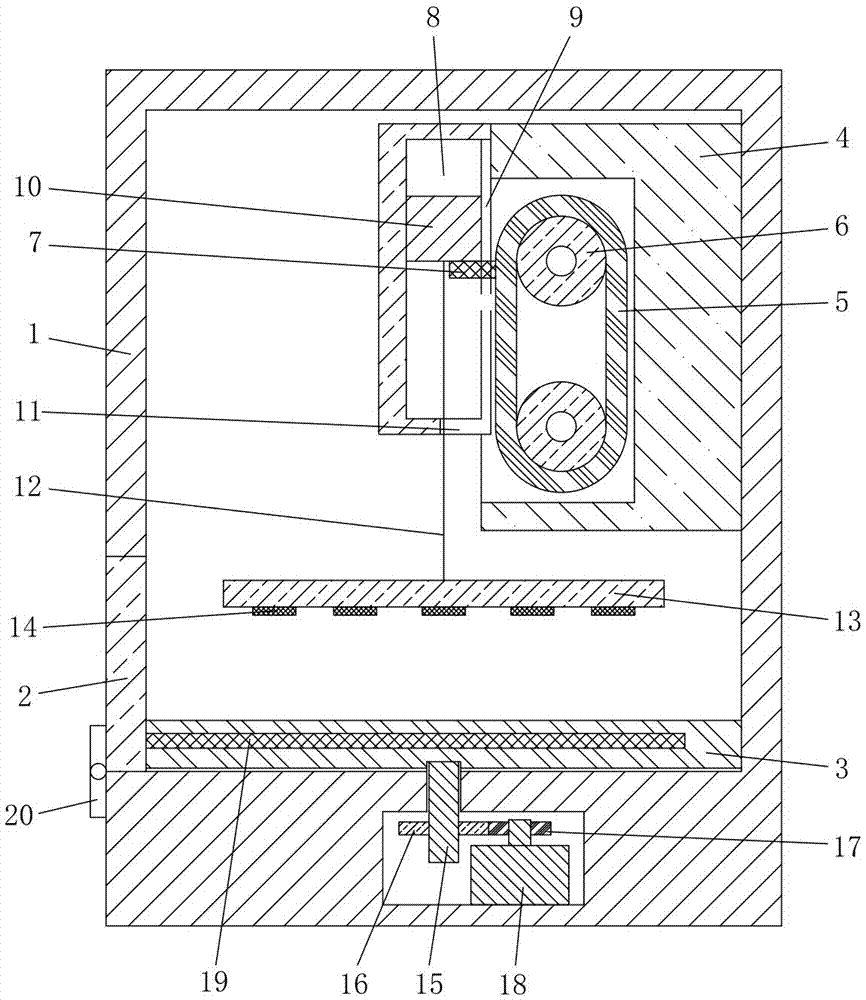

Beef knocking box used for beef barbecue

InactiveCN105557960AHit evenlySolve environmental problemsBeating-based meat tenderisingRaw beefElectric machinery

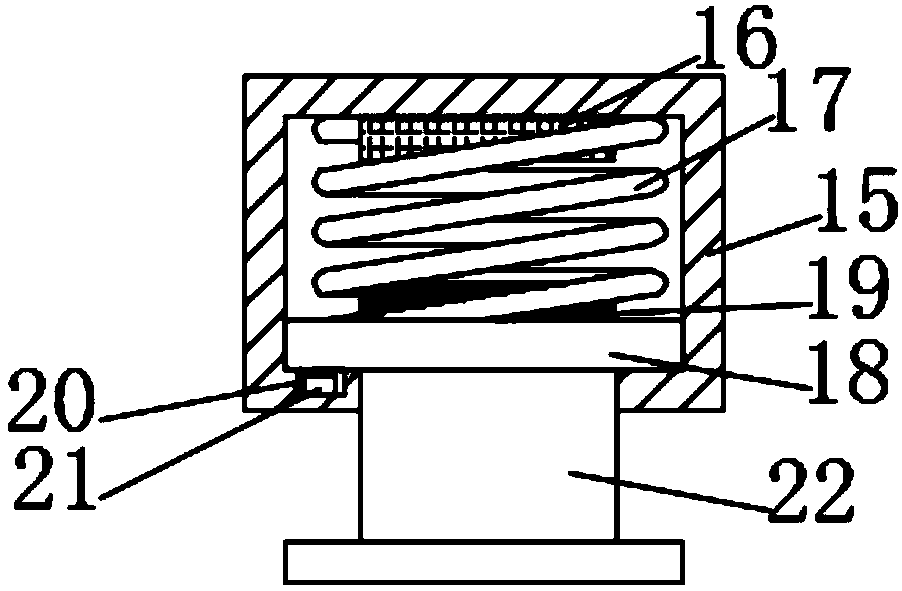

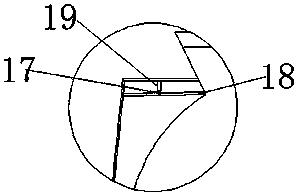

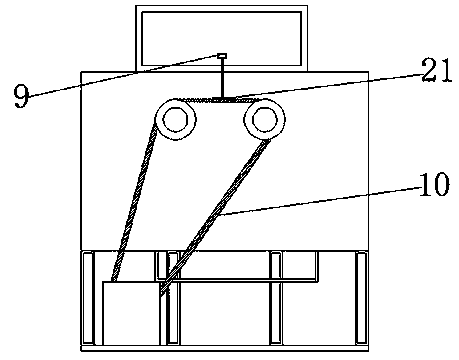

The invention discloses a beef knocking box used for a beef barbecue. The beef knocking box comprises a closed cylindrical box body; the side wall of the cylinder box body is provided with a movable openable and closeable door; the movable openable and closeable door is connected with the cylindrical box body through a hinge; a round turntable used for carrying raw beef is arranged in the cylindrical box body; a round cavity is formed in the round turntable; the side edge of the round turntable is provided with a rectangular cavity window; the round cavity is connected with outside through the cavity window; a length size of the cavity window is equal to a diameter size of the round cavity; ice is held in the round cavity; a knocking mechanism is arranged above the round turntable; the knocking mechanism comprises a support fixed on the inner wall face of the cylinder box body; the support is provided with a chain, chain wheels and a motor, wherein the chain wheels are connected with the chain, and the motor is used for driving the chain wheels; the chain is provided with a stopper. A beef knocking problem under a field environment is solved by the beef knocking box used for a beef barbecue provided by the invention.

Owner:重庆市老川牛食品有限公司

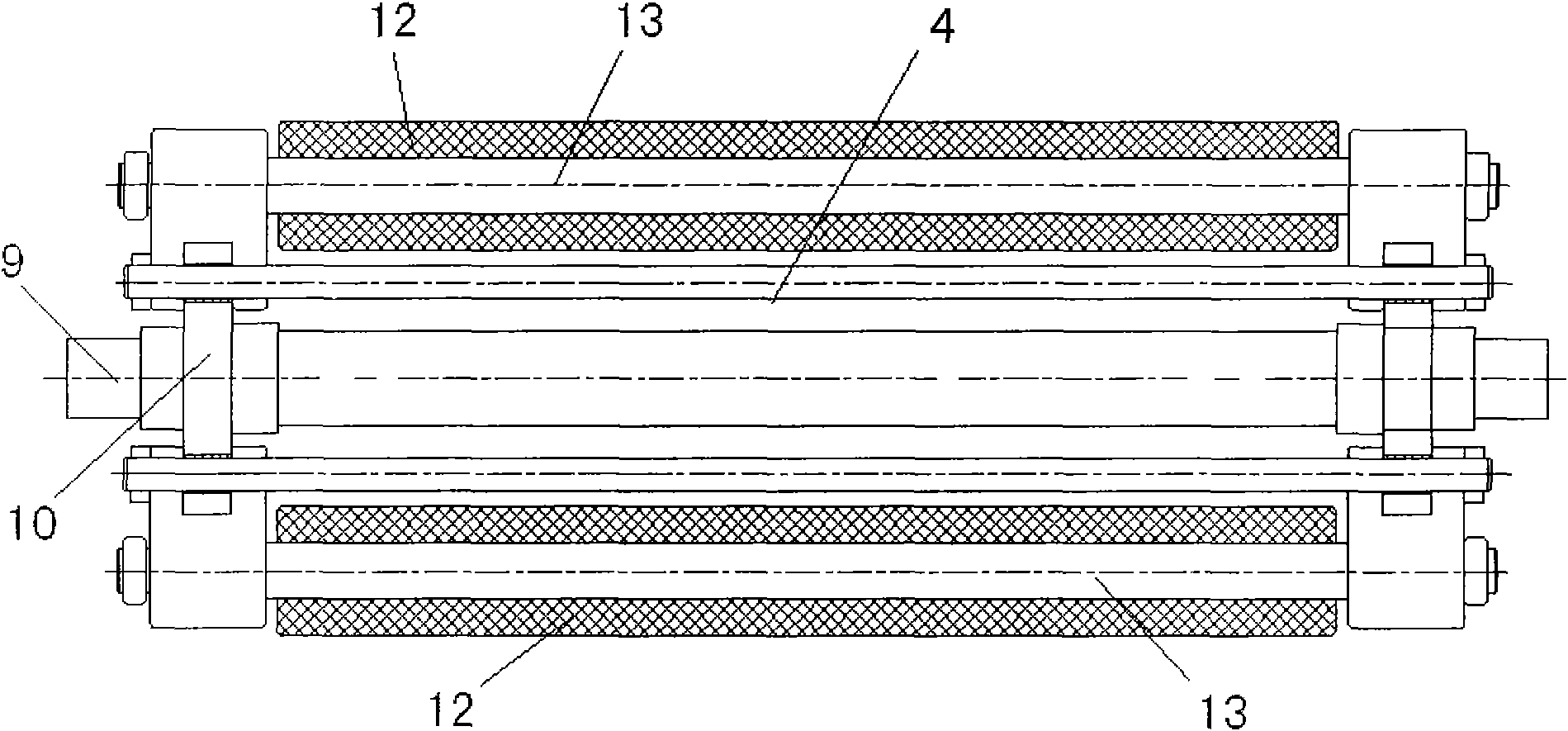

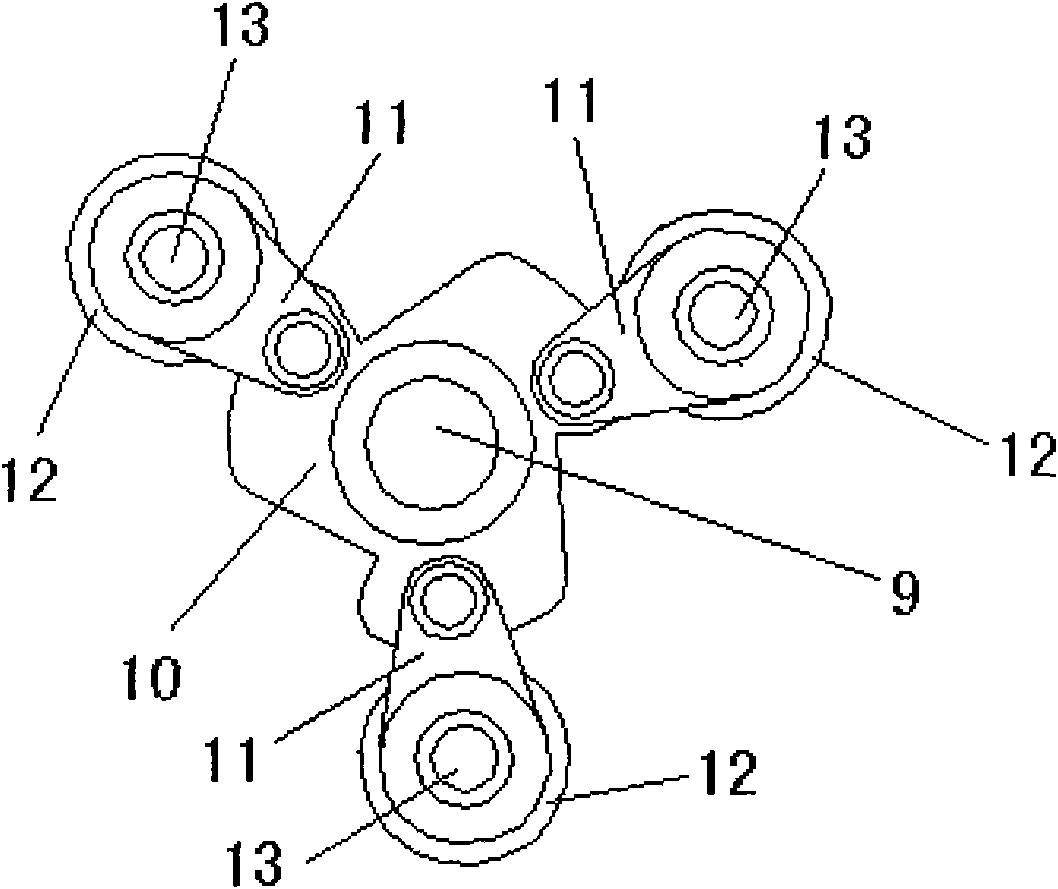

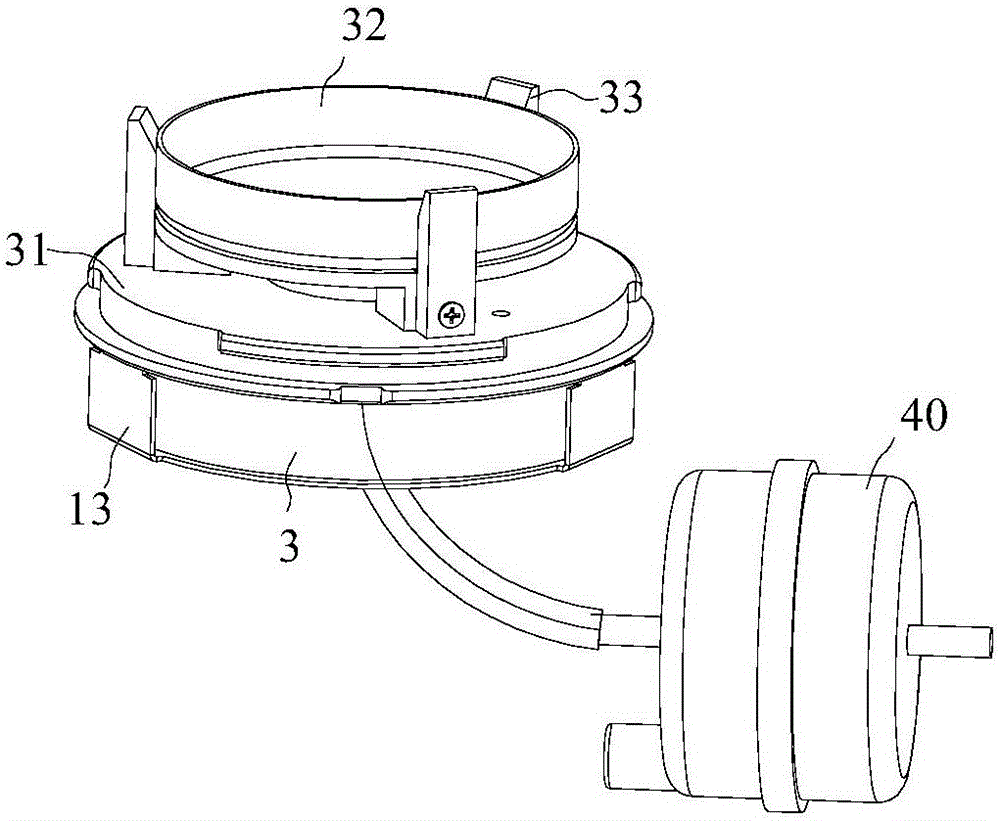

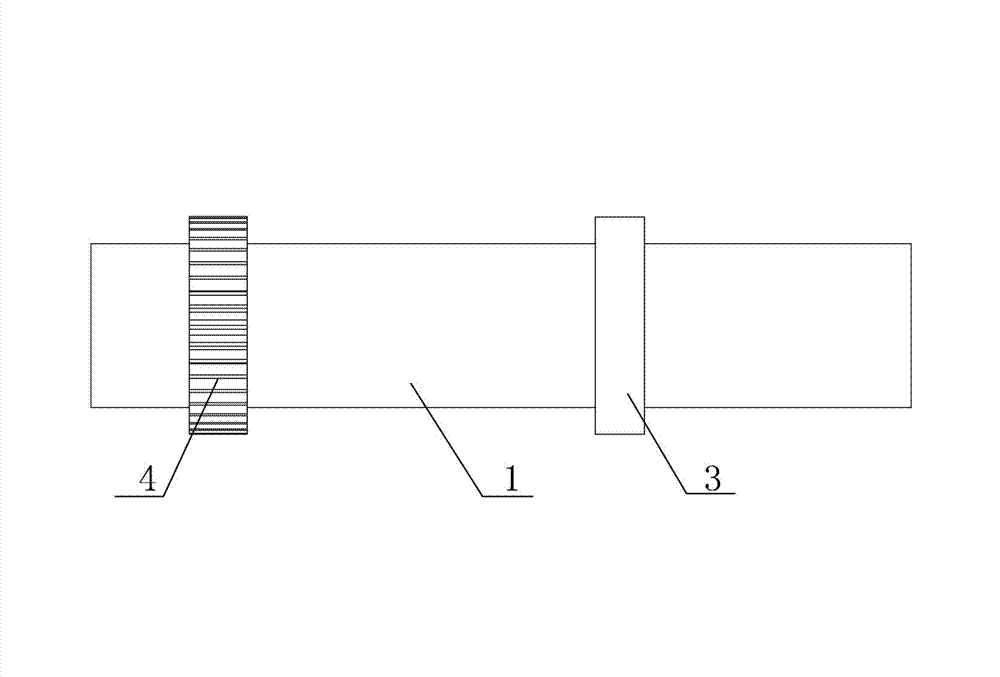

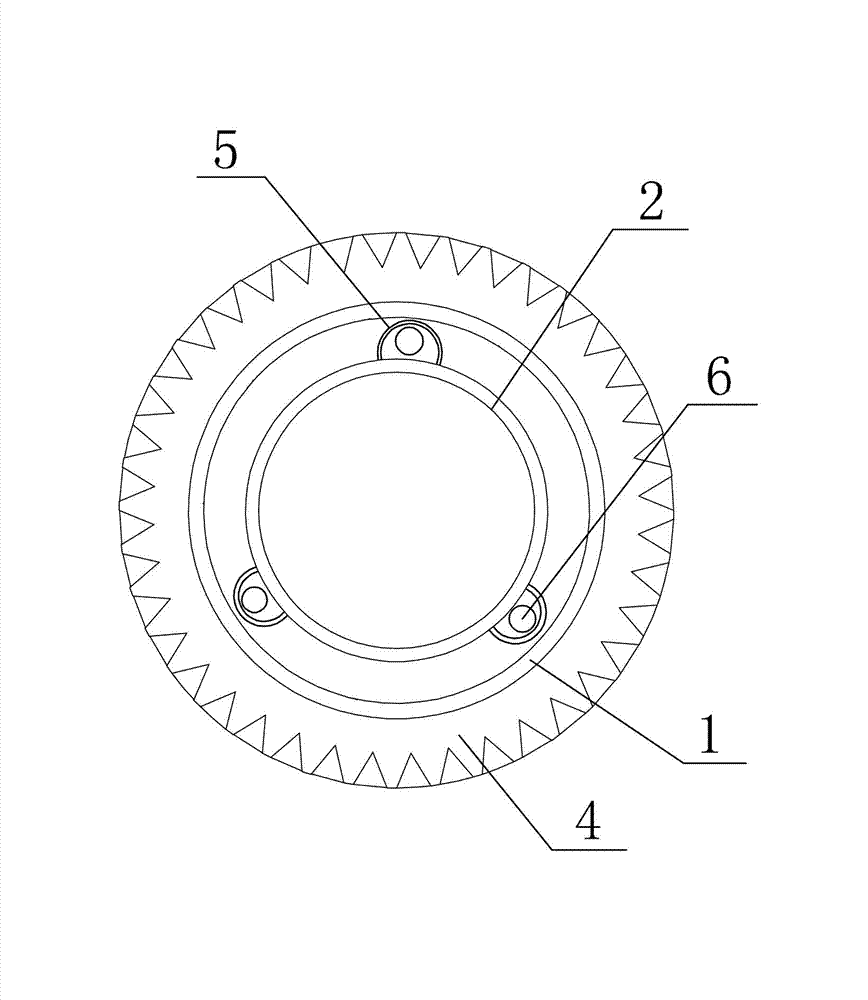

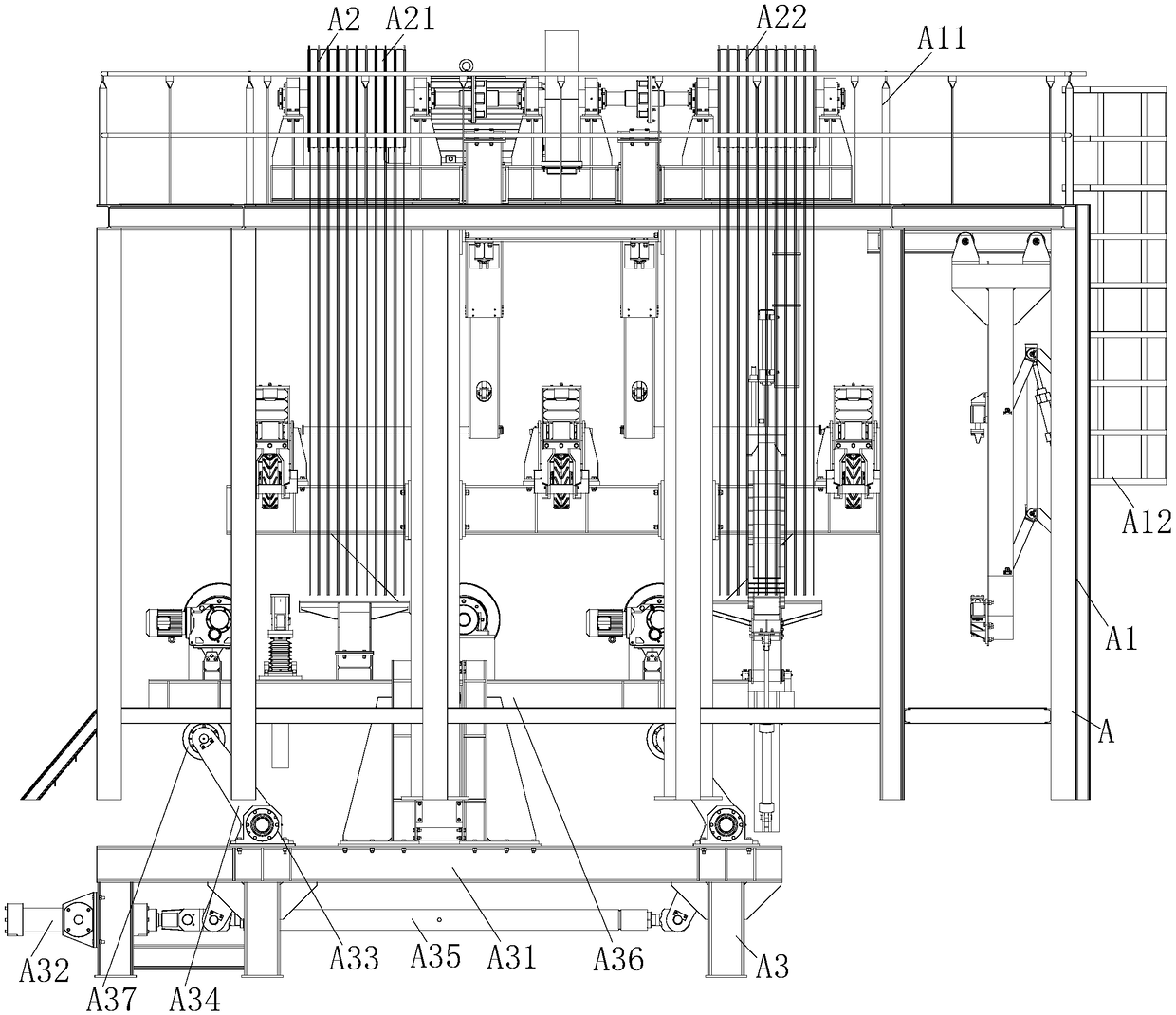

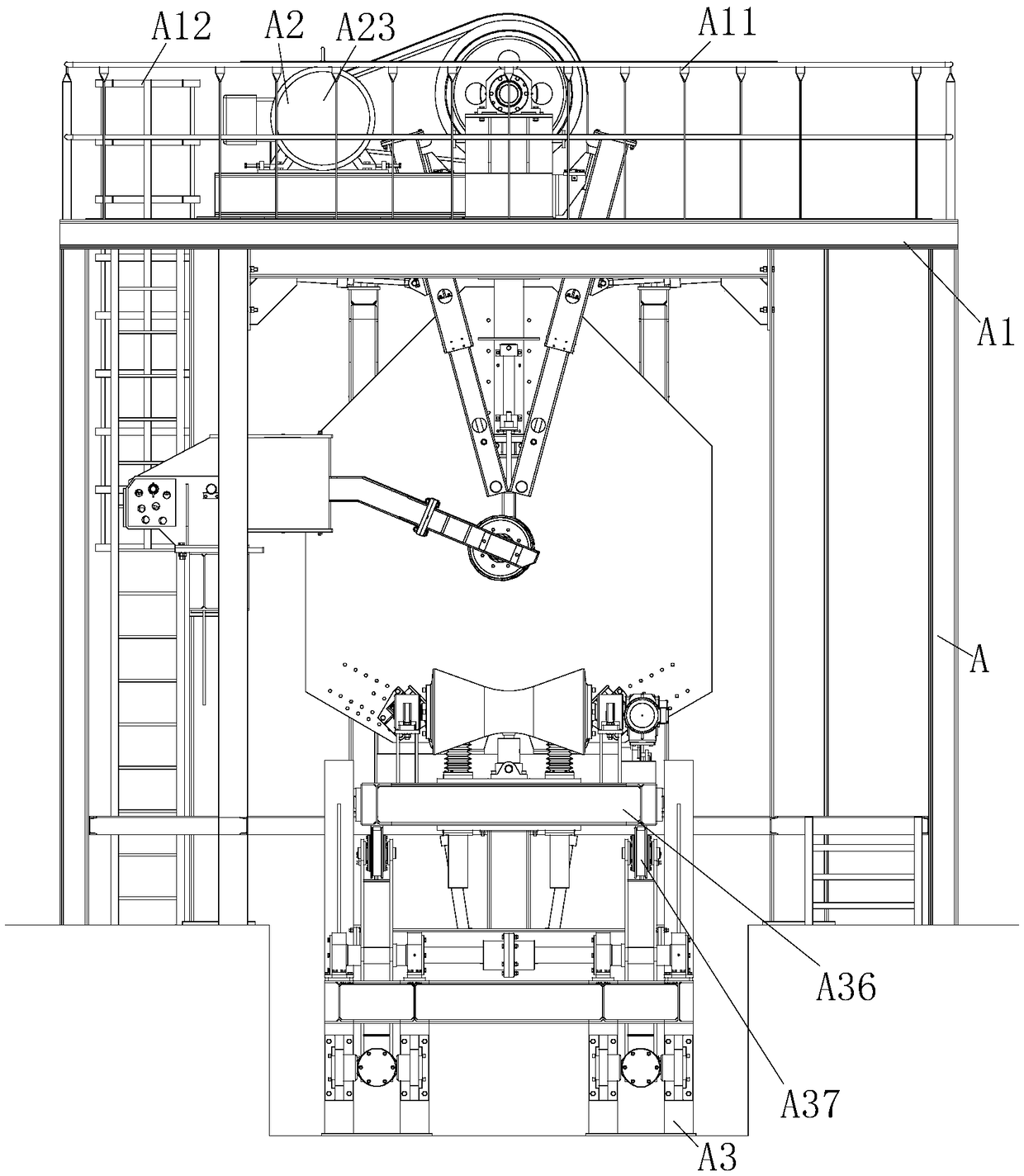

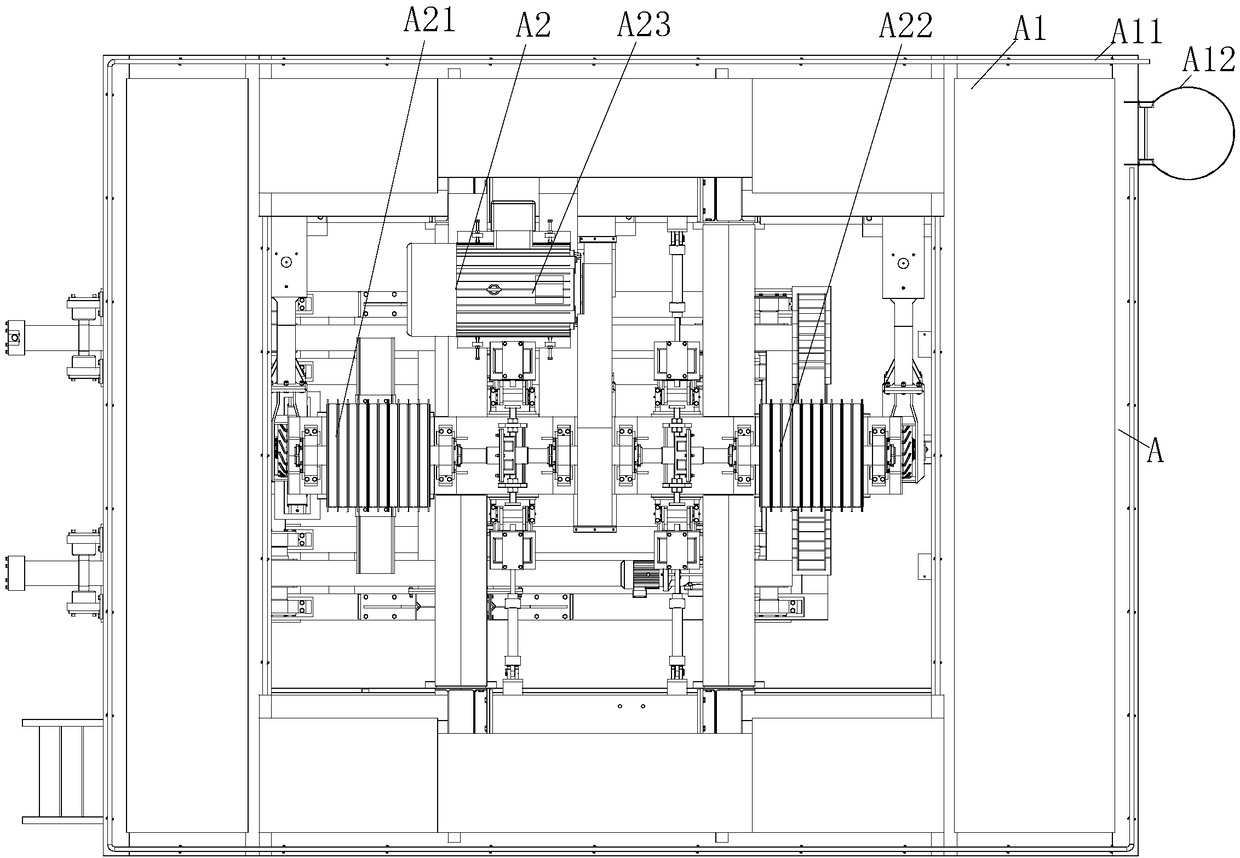

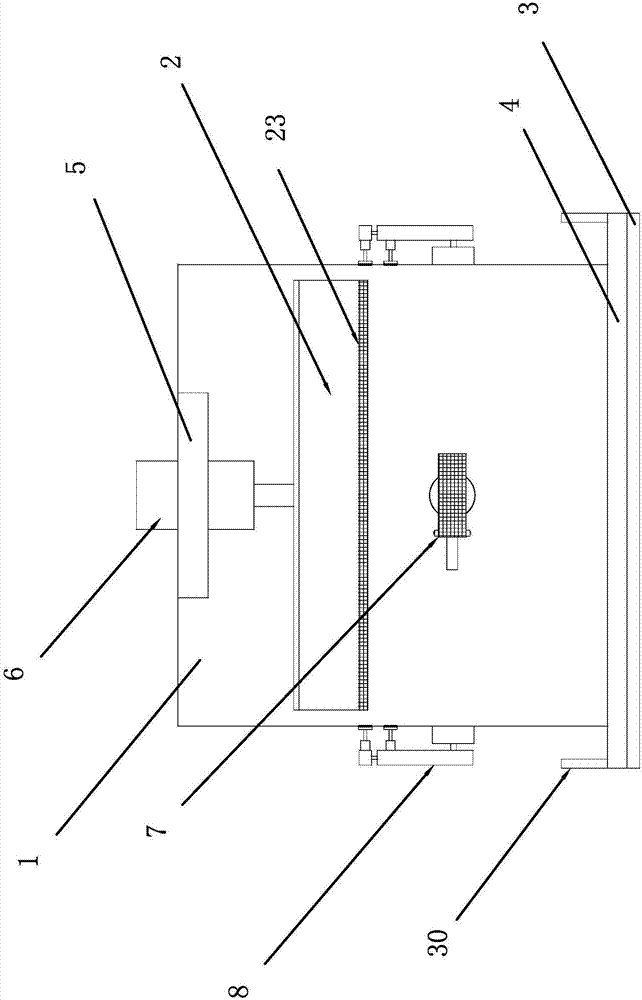

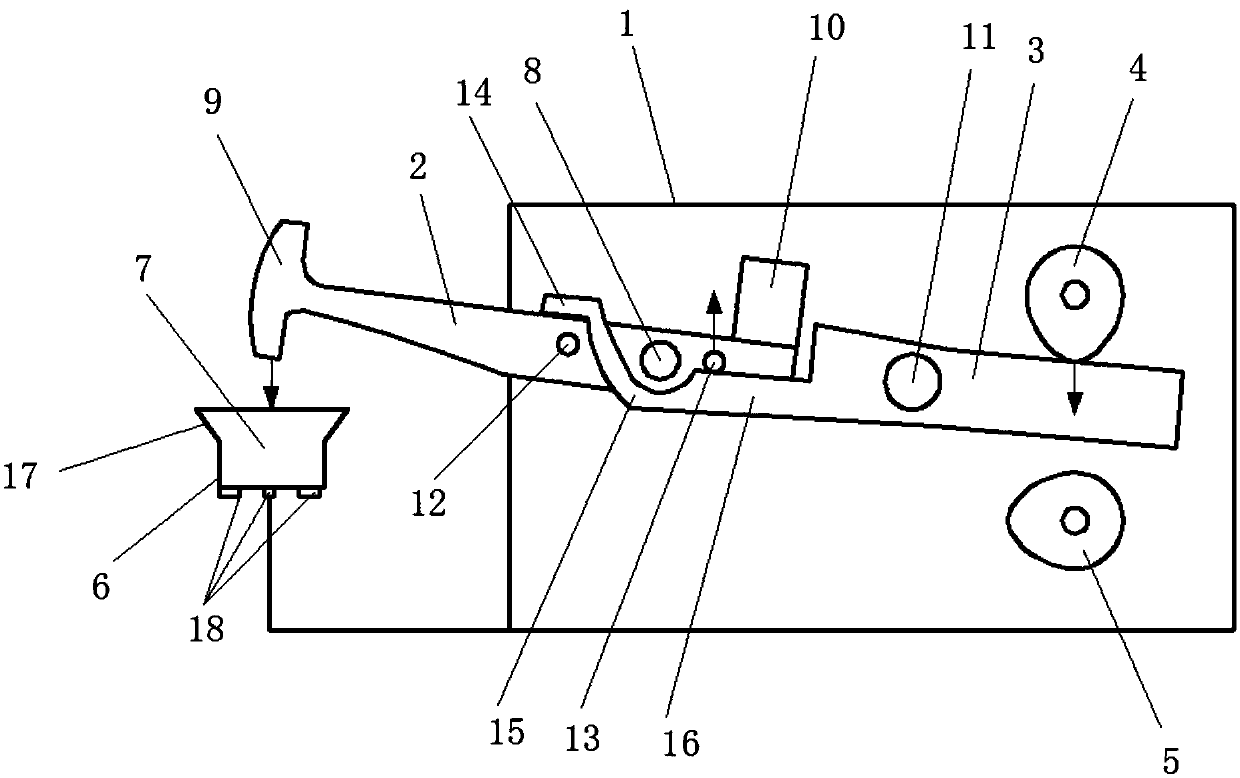

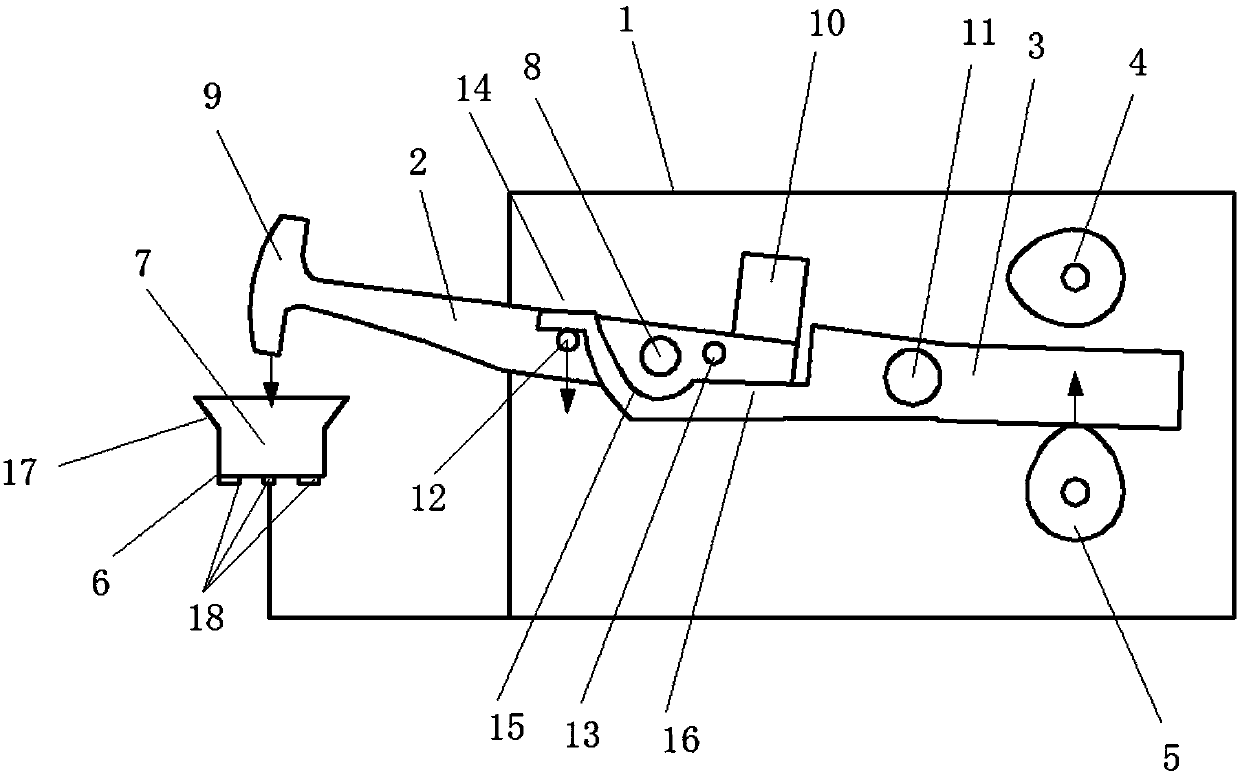

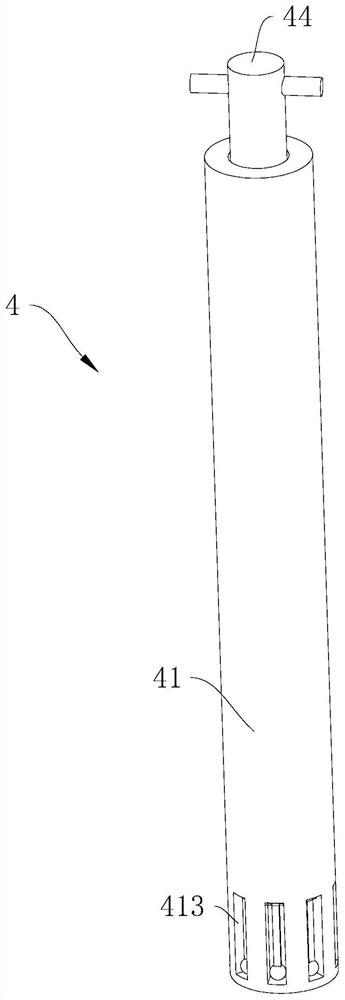

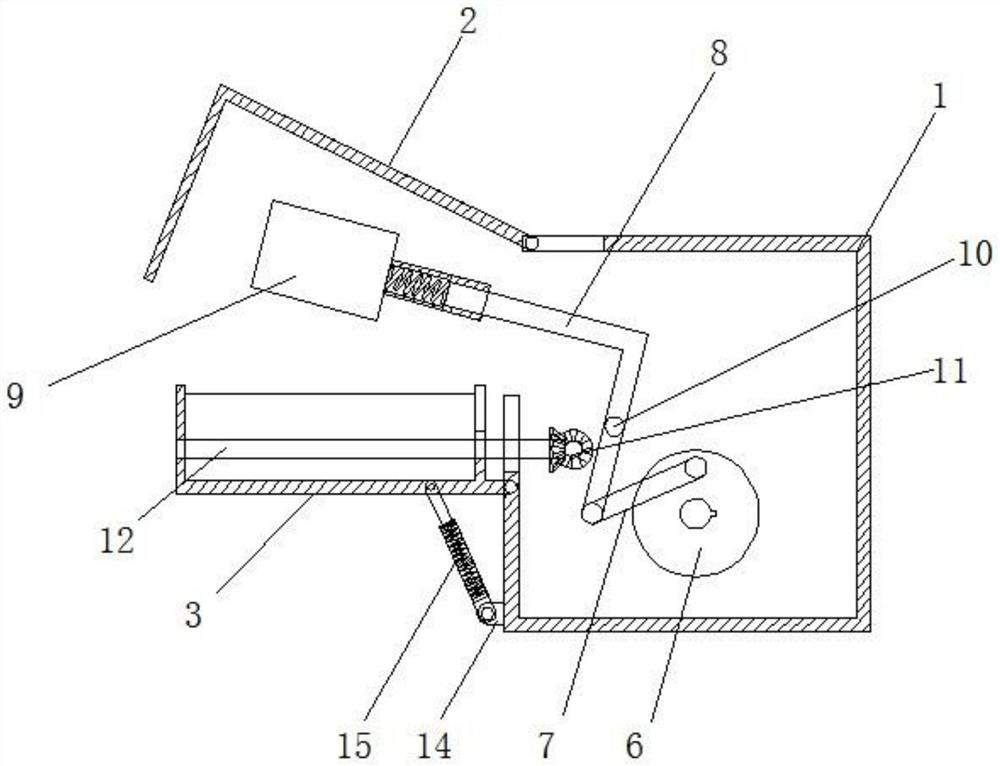

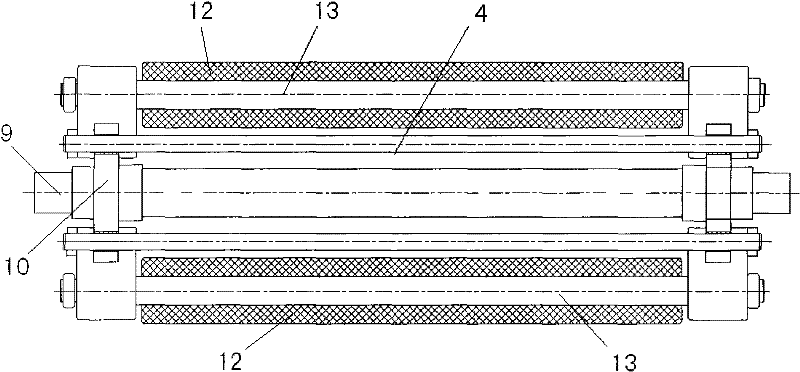

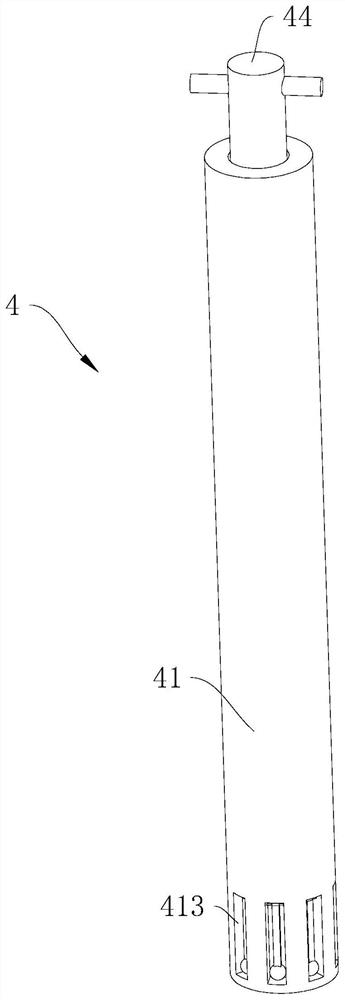

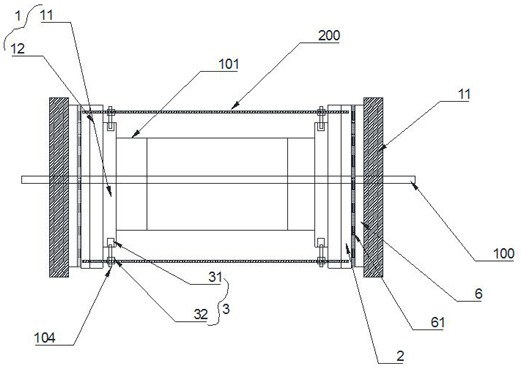

Green bodies shot-blasting equipment for sinter forging

InactiveCN102554801AHit evenlyEfficient removalAbrasive machine appurtenancesAbrasive blasting machinesEngineeringPeening

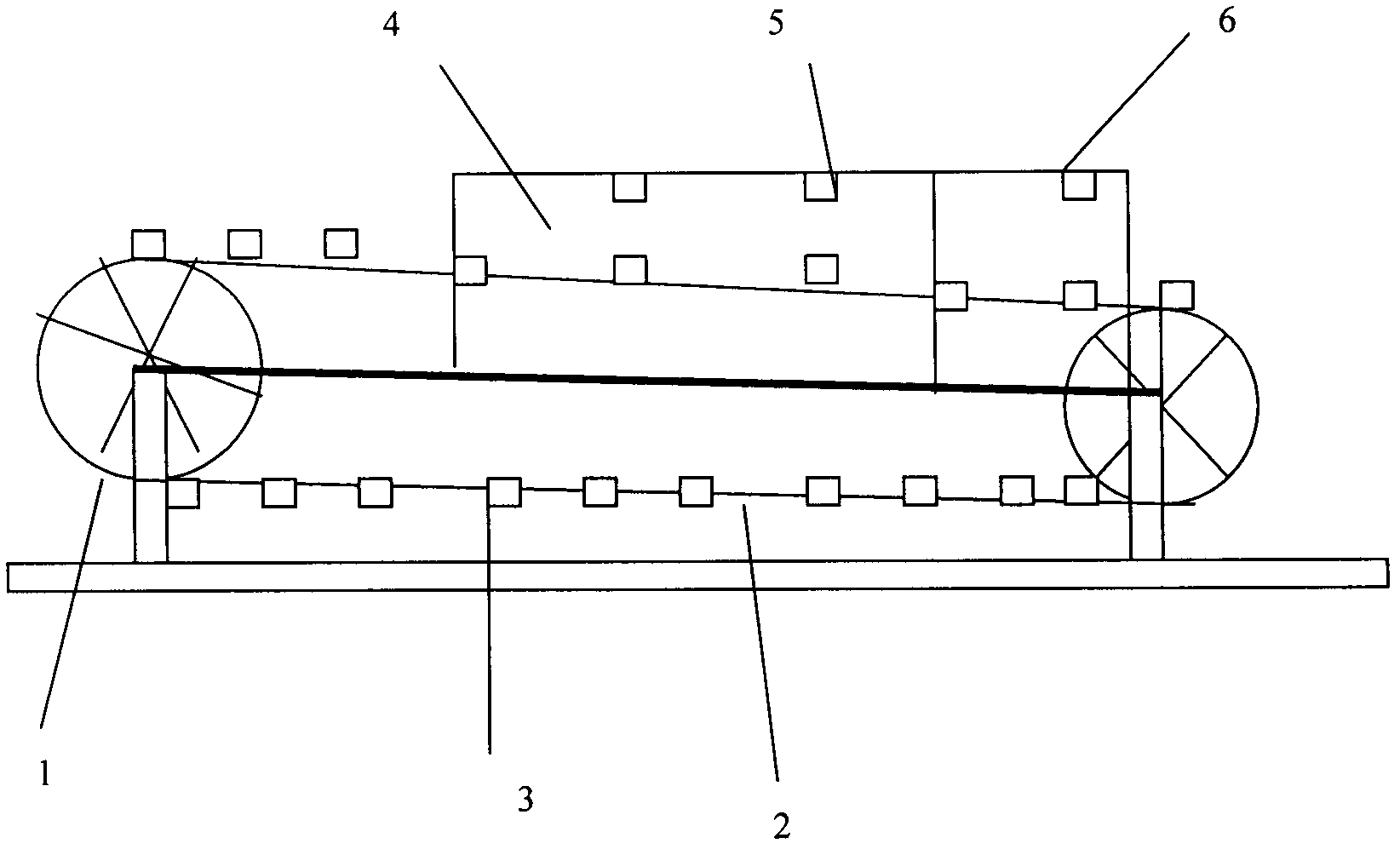

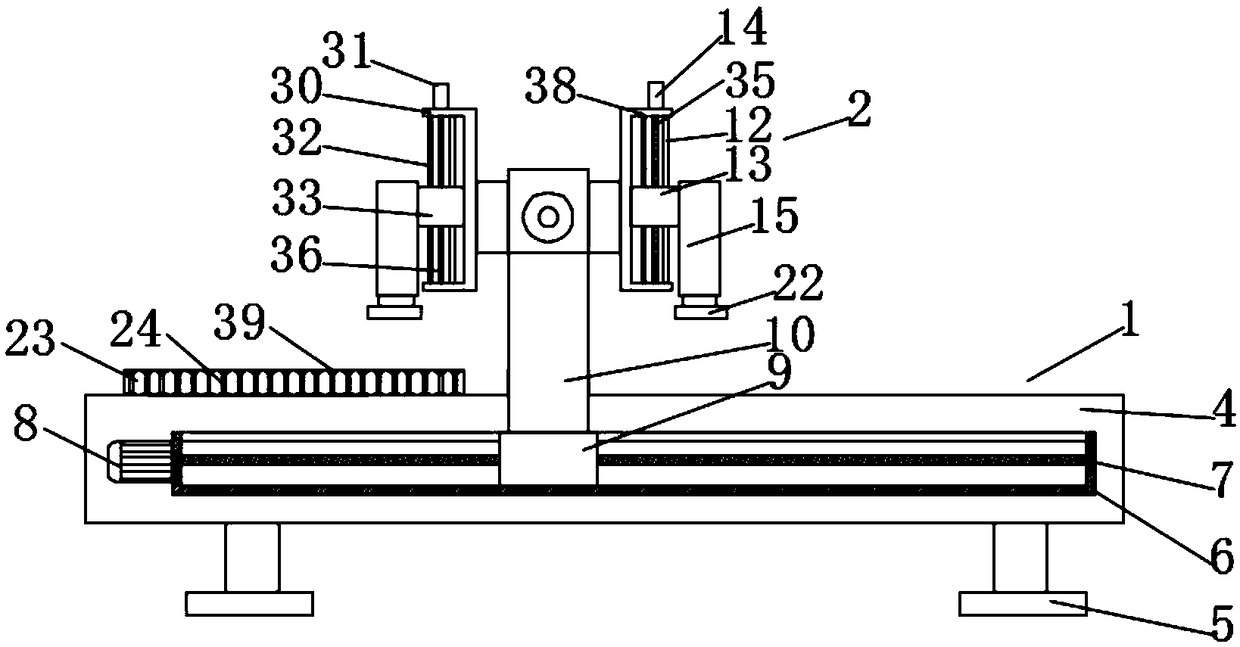

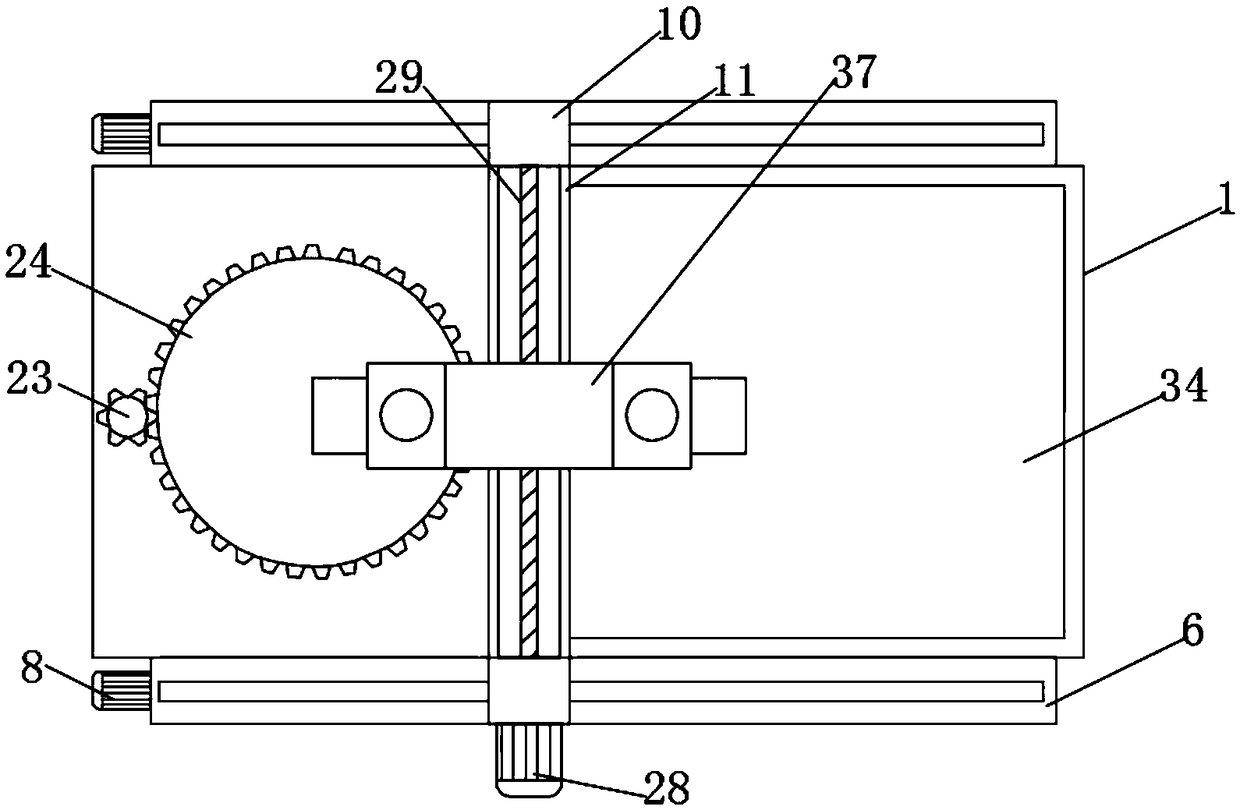

The invention relates to novel sinter forging equipment, particularly relates to green bodies shot-blasting equipment for sinter forging, and provides shot-blasting equipment of which the periphery of a product can be uniformly beaten by high-speed pellets. The green bodies shot-blasting equipment comprises a driving device (1), an automatic conveying mechanism and a shot-blasting mechanism (4), wherein the caterpillar track conveying mode is adopted by the automatic conveying mechanism, and comprises a caterpillar track conveying belt (2); a clamping frock (3) capable of movably rotating is arranged on the caterpillar track conveying belt (2); the clamping frock (3) is provided with a connecting rod movably connected; the shot-blasting mechanism (4) comprises a shot-blasting chamber; the caterpillar track conveying belt (2) passes through the shot-blasting chamber; a spray pipe (5) is fixed above the shot-blasting chamber, corresponding to the connecting rod; a cleaning room is arranged at the position of the caterpillar track conveying belt (2) after passing through the shot-blasting chamber; and a cleaning spray pipe (6) is fixed above the cleaning room, corresponding to the connecting rod. When passing the shot-blasting chamber, the periphery of the product can be uniformly beaten by high-speed pellets sprayed out by the spray pipe, so that the technological requirements can be met.

Owner:信义集团公司

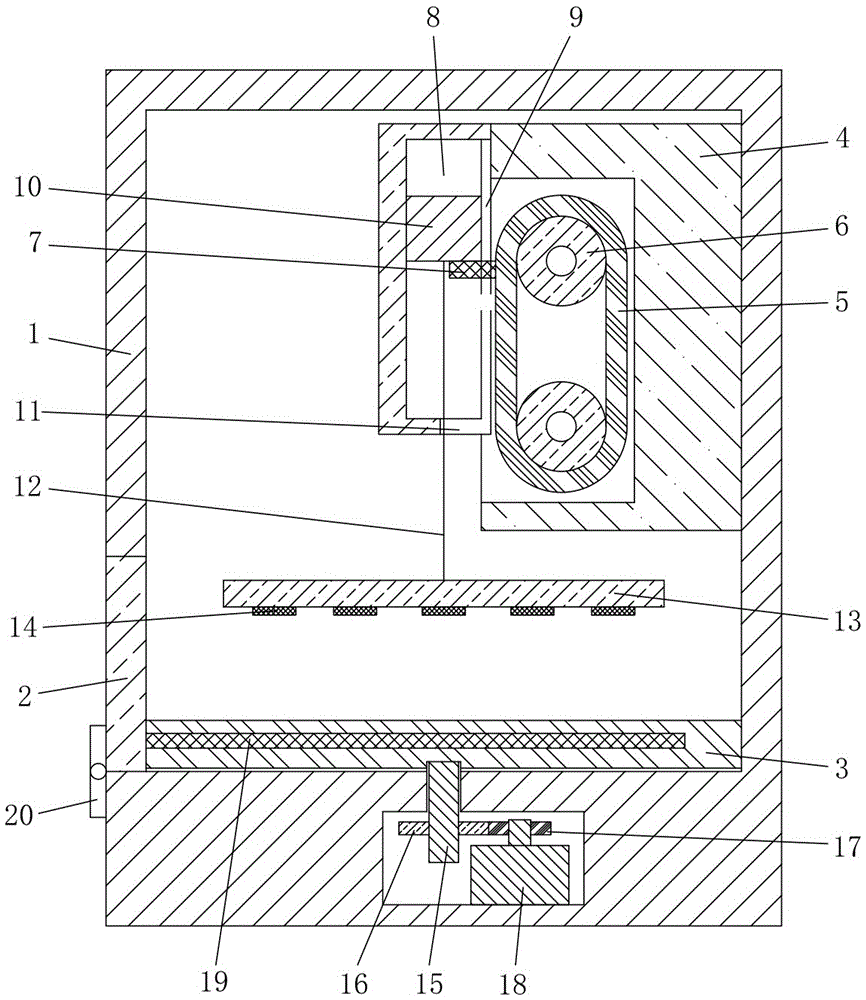

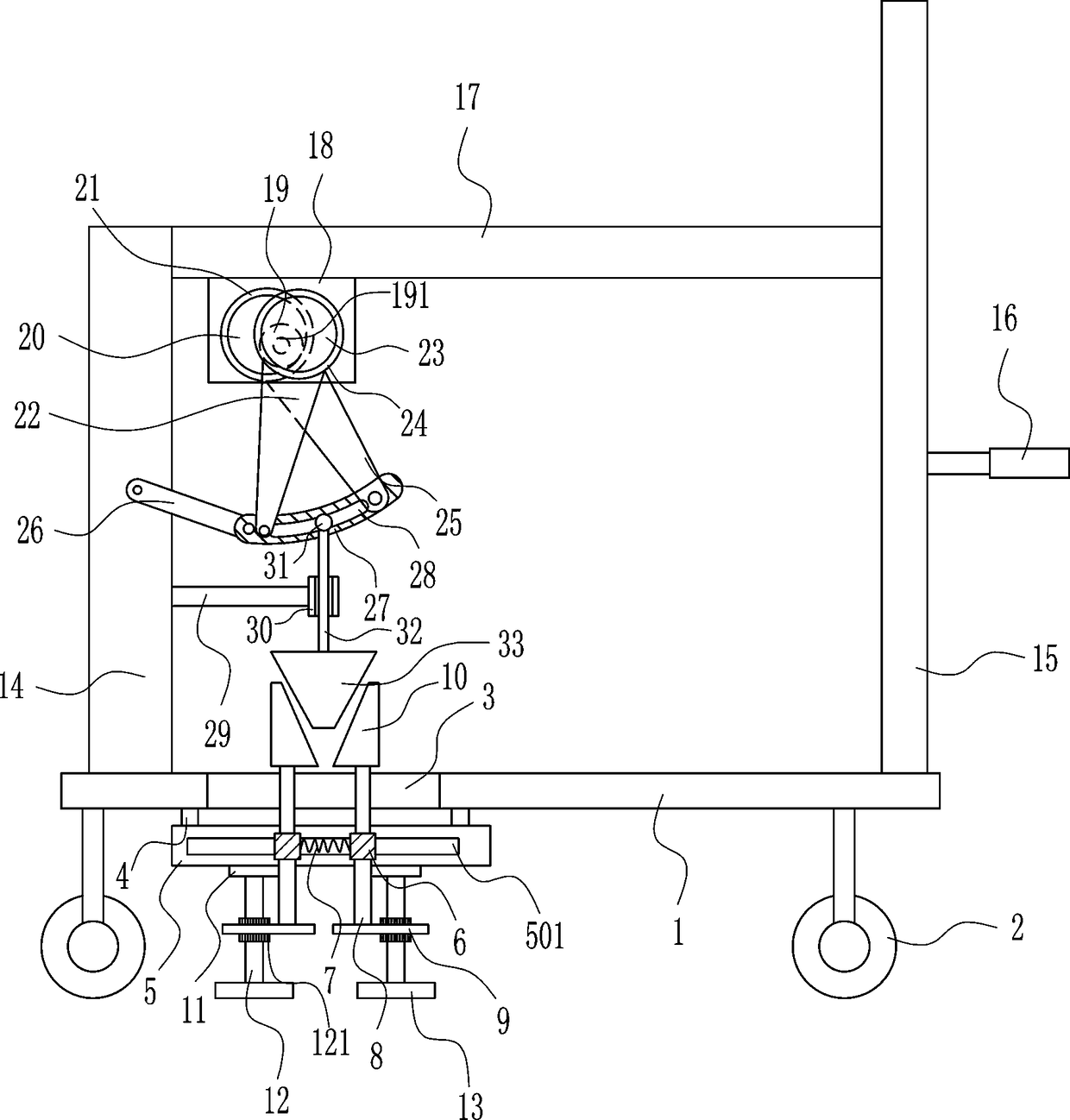

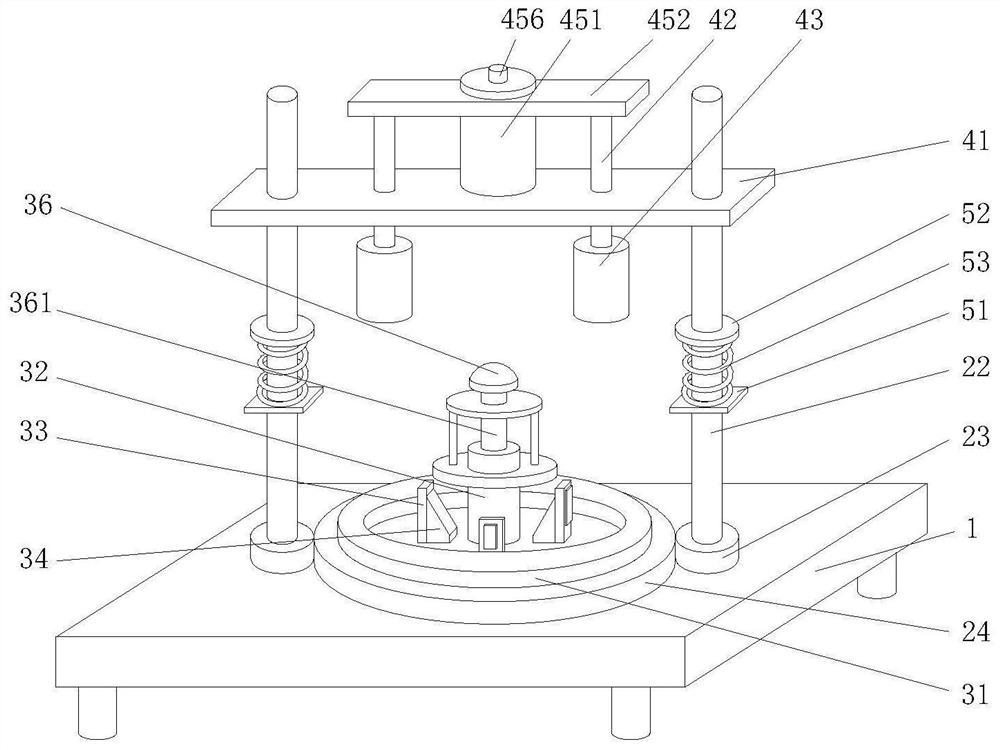

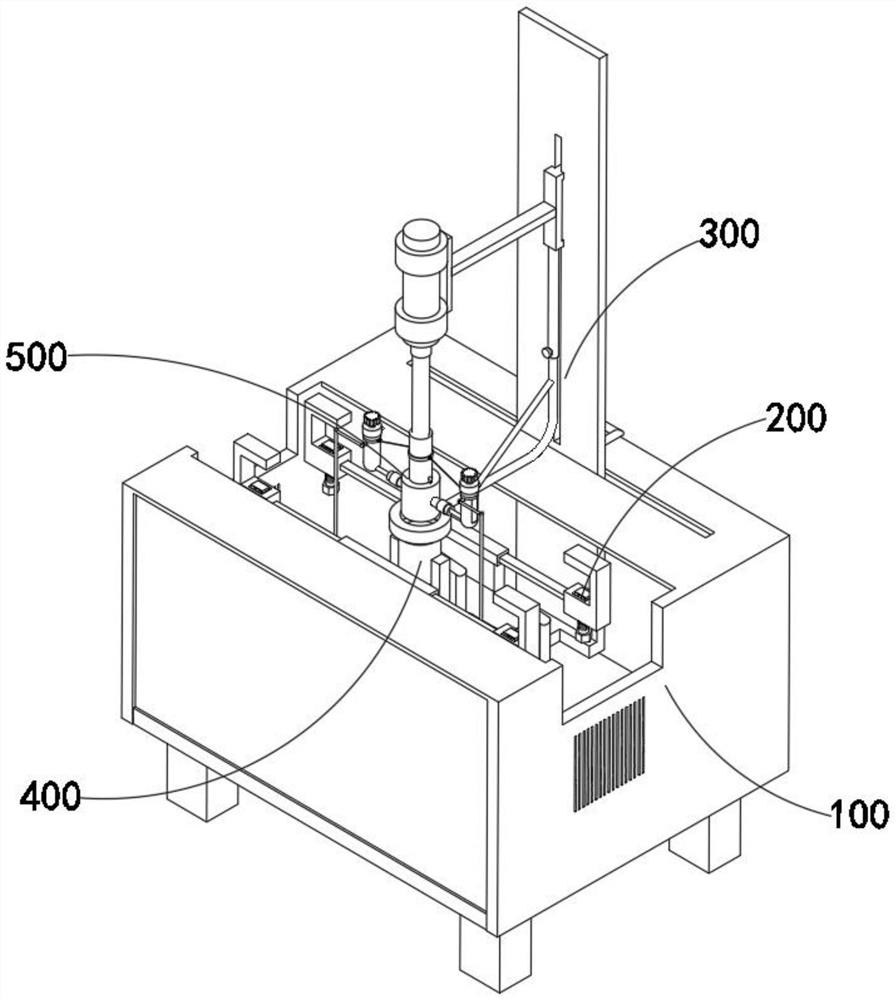

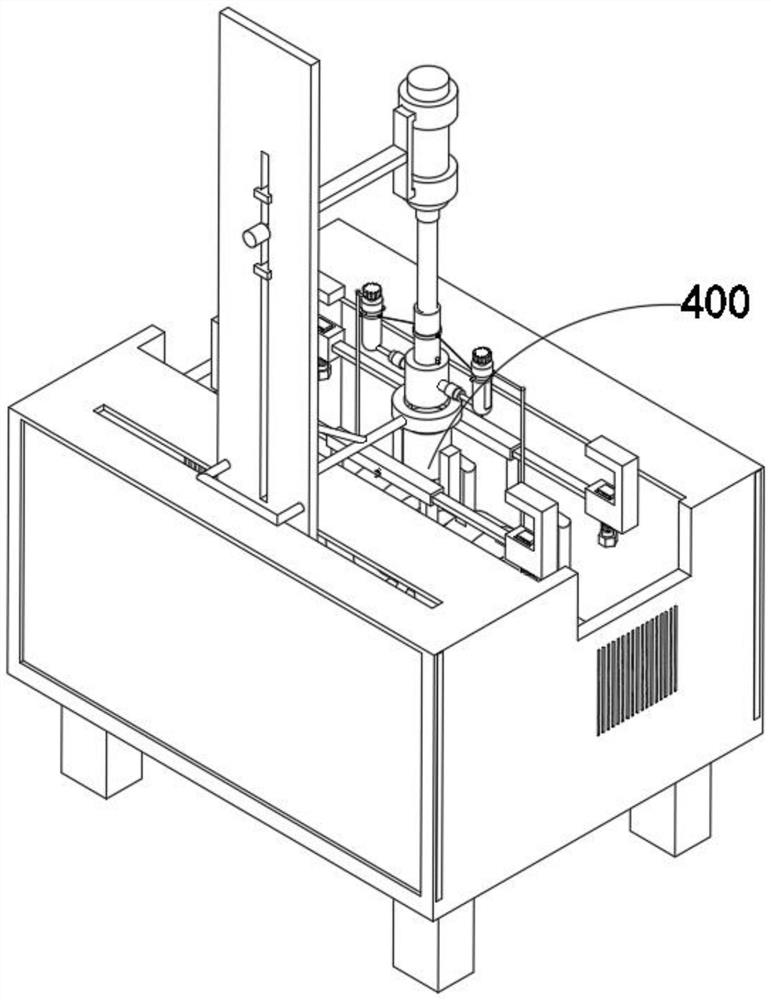

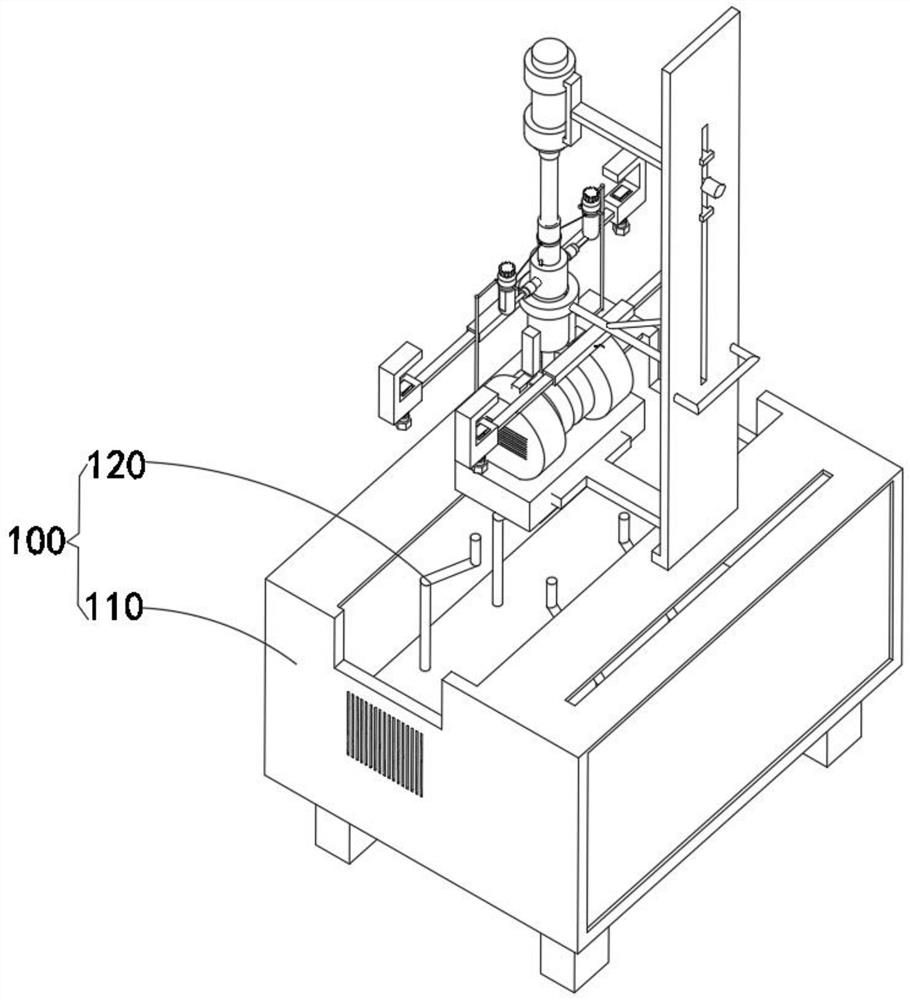

Rutting plate specimen compaction instrument and compaction method

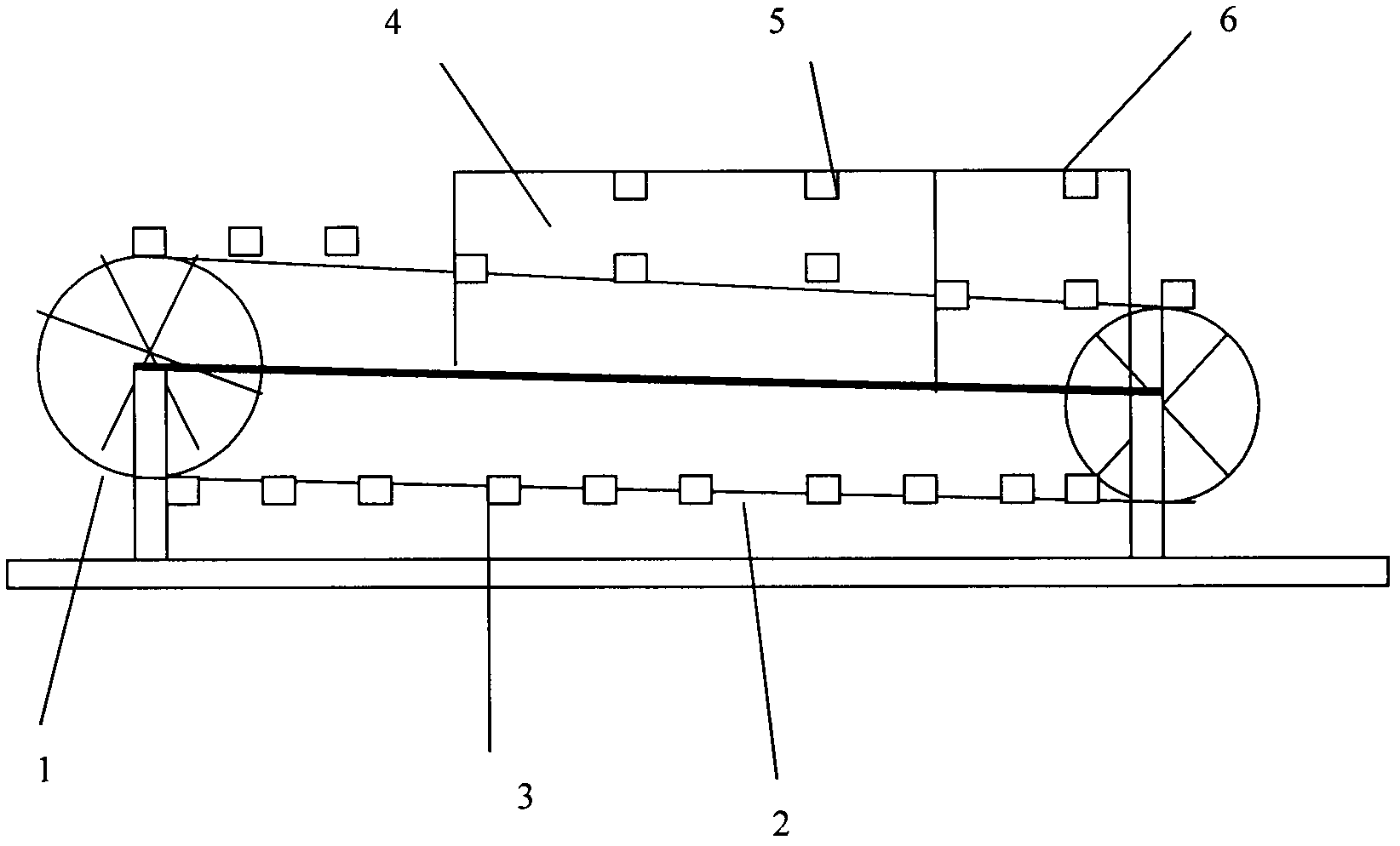

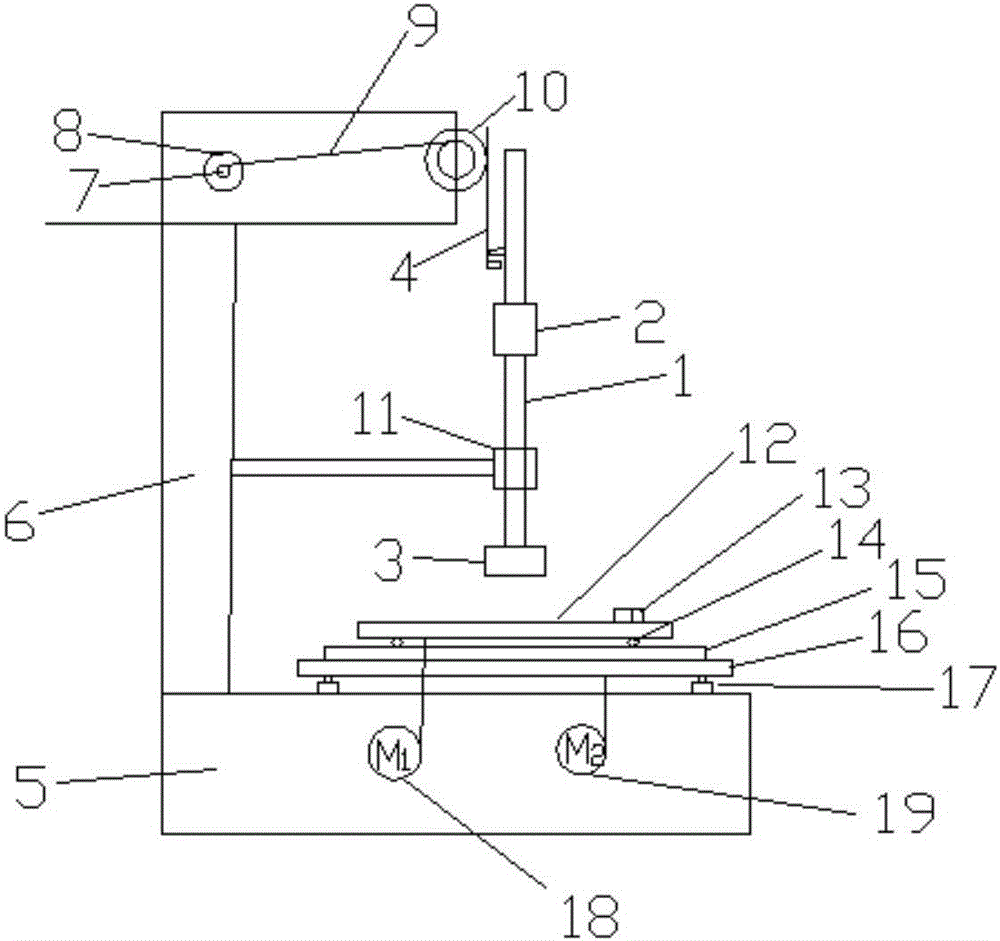

ActiveCN106706391AQuality improvementImprove uniform densityClimate change adaptationPreparing sample for investigationTemperature controlEngineering

The invention relates to a rutting plate specimen compaction instrument and compaction method, wherein the device comprises a base; the base is provided with a bracket and a test mold fixing frame which can move on the base, and the bracket is provided with a compaction device; the compaction device comprises a compaction rod which can move up and down, the upper end of the compaction rod is connected with a power device, and the lower end of the compaction rod is connected with a compaction head; the compaction head is internally provided with a heating and temperature controlling device; the compaction head is located above the test mold fixing frame. The compaction head can be heated and the temperature can be accurately controlled, so the quality of an indoor molded rutting plate specimen is improved, and the accuracy of a test is ensured; the compaction rod in the compaction device can move up and down, drives the compaction head to repeatedly hit mixed materials in the test mold, hitting is uniform, the efficiency is high, the manual compaction is not required, and the scalding is avoided; by setting the test mold fixing frame, the test mold can move on the base, a hitting position can be changed, the uniform compactness of the mixed materials is improved.

Owner:CHANGAN UNIV

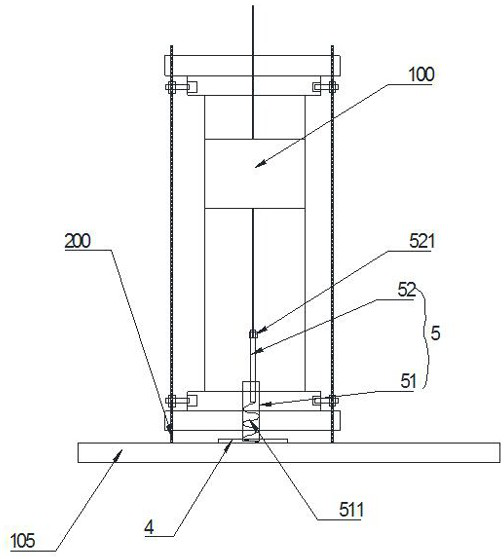

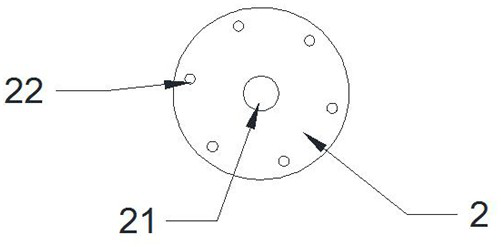

Pipe fitting lining system and lining method thereof

ActiveCN108656338AStir wellPrevent solidificationHydro energy generationFeeding arrangmentsPipe fittingCement mortar

The invention relates to a pipe fitting lining system and a lining method thereof, and belongs to the field of pipe fitting equipment. In the prior art, due to that that a nodular cast iron pipe usually has ovality, the nodular cast iron pipe vibrates or bounces when rotating, consequently, cement mortar arranged on the inner wall of the nodular cast iron pipe in a lined manner is not uniform, andthe strength and corrosion resistance of a pipe fitting are reduced. The pipe fitting lining system comprises a lining machine, a press wheel and a distribution device. The press wheel is mounted onthe lining machine. The distribution device is located on one side of the lining machine. The pipe fitting is lifted through a lifting band for lining, the pipe fitting and the lifting band are flexibly connected, the ovality of the pipe fitting can be remedied, the pipe fitting is knocked through the press wheel, and the cement mortar in the pipe fitting can be lined more uniformly; and cement mortar in a stirring tank is stirred by a stirring paddle, and the cement mortar is prevented from being solidified.

Owner:杭州春风机械工程股份有限公司

Rotary weeding equipment for garden

Owner:湖州达立智能设备制造有限公司

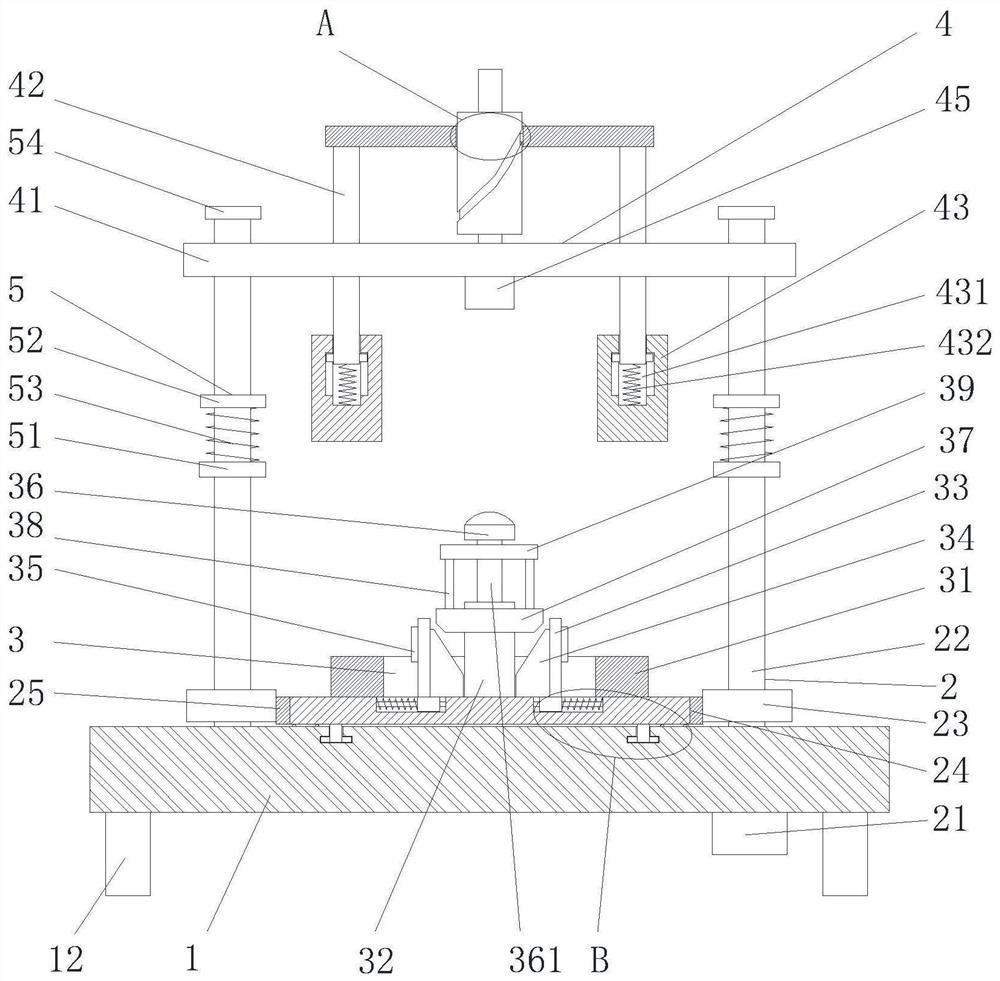

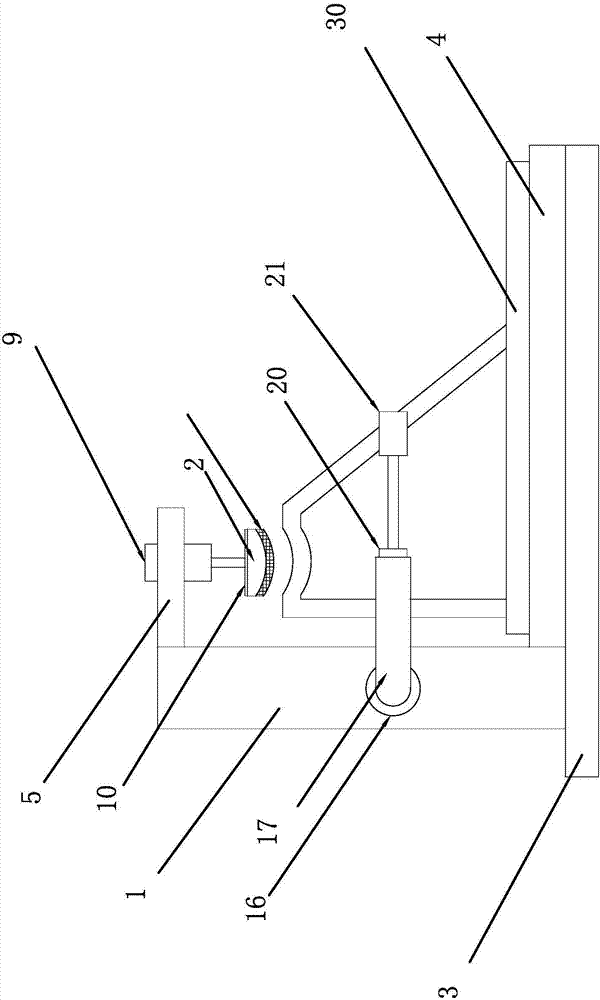

Steel automobile hub shape-righting repairing machining equipment and method

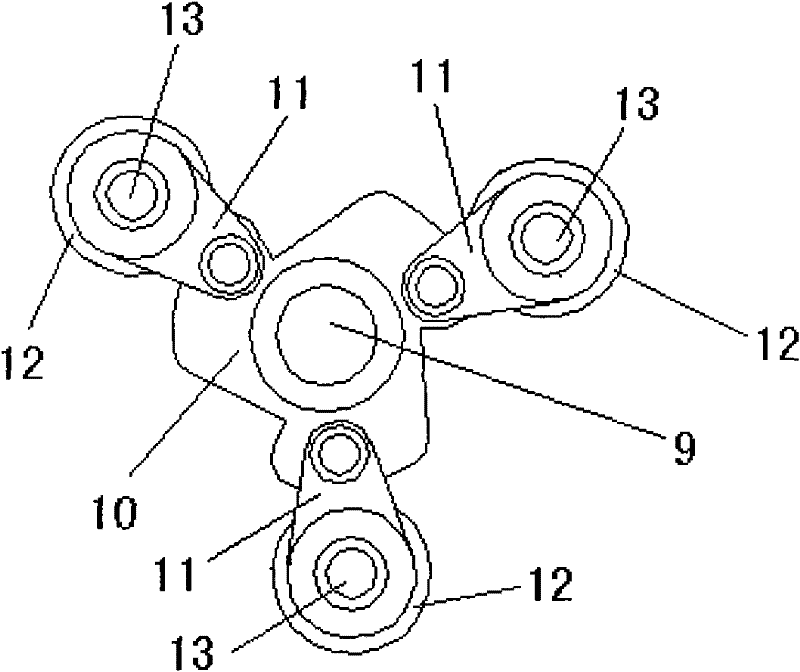

InactiveCN113102558AQuick Squeeze FixRepair processing is even and smoothMetal-working feeding devicesPositioning devicesGear wheelElectric machinery

The invention relates to steel automobile hub shape-righting repairing machining equipment and method. The steel automobile hub shape-righting repairing machining equipment comprises a base, a lifting mechanism, a clamping mechanism, knocking correcting sets and a buffering mechanism. Four symmetrically-arranged supporting legs are mounted on the lower end face of the base. Two symmetrically-arranged supporting rods are mounted on the upper end face of the base through bearings. The knocking correcting sets are mounted on the two supporting rods in a threaded mode. The buffering mechanism is mounted on the supporting rods. The clamping mechanism is mounted on the upper end face of the base. The lifting mechanism comprises a first motor, two supporting rods, two gears and a bottom plate. According to the steel automobile hub shape-righting repairing machining equipment and method, the problems that existing hub shape-righting repairing machining equipment cannot conveniently and rapidly fix a hub, the fixed position of the hub is prone to skewing and deviating during fixing, uniform hammering cannot be conducted when the hub is repaired and knocked, the knocking forces at different places are prone to being different, the knocking position is prone to being uneven, and consequently the repairing quality is not high enough can be solved.

Owner:安徽诺玛嘉新材料有限公司

Detection device for stability of solar water heater support

ActiveCN107462381AImprove robustness detectionHigh precisionElasticity measurementSolar waterEngineering

The invention provides a detection device for stability of a solar water heater support, and belongs to the technical field of solar detection. The detection device comprises a detection rack, a simulation water tank and a base. The detection rack is installed on the upper end of the base. A detection platform where the solar water heater support is placed is arranged on the base. A fixed rack extending to one side of the solar water heater is arranged on the upper end of the detection rack. A pressure imposing structure 1 is arranged on the fixed rack. The simulation water tank is fixed on the pressure imposing structure 1. A pressure imposing structure 2 is arranged in the middle part, close to one side of the solar water heater support, of the detection rack. Pressure imposing structures 3 are arranged on adjacent two sides of the pressure imposing structure 2 on the detection rack. Force sensors are arranged on the pressure imposing structure 1, the pressure imposing structure 2 and the pressure imposing structures 3. Stopping plates corresponding to two sides of the pressure imposing structure 2 are arranged on the detection platform. According to the invention, a point place where the solar water heater support bears the pressure is simulated and stability detection of the solar water heater support is improved.

Owner:浙江省太阳能产品质量检验中心

Surface knocking device for mechanical components of building equipment

The invention discloses a surface knocking device for mechanical components of building equipment. The surface knocking device comprises a support mechanism, a knocking mechanism and a rotary mechanism. The rotary mechanism is arranged on the top of the support mechanism, the knocking mechanism is arranged above the support mechanism, the support mechanism comprises a worktable, fixing props, movable slide grooves, movable lead screws, movable motors, a movable slider, a driving gear, an outer gear ring, a rotary shaft, a rotary motor, a speed reducer and an adjusting motor, and the movable slide grooves are symmetrically fixedly connected with the outer side of the worktable. The surface knocking device has the advantages that the surface knocking device is provided with the adjusting motor, accordingly, knocking columns can conveniently move, different workpieces can be conveniently repeatedly knocked, the time and labor can be saved, the knocking efficiency can be improved, and theproblem of inflexible structures of existing knocking devices can be solved by the aid of the surface knocking device; the surface knocking device is provided with a rotary disc, the circular workpieces can rotate by the aid of the rotary motor, can be simultaneously conveniently knocked by the aid of the rotary motor and can be uniformly knocked, the shapes of the different workpieces can be pertinently machined, and accordingly the practicality of the surface knocking device can be greatly improved.

Owner:温州洪升建筑机械有限公司

Protective automatic dismounting device for electric vehicle motor

InactiveCN112059589AAchieve disassemblyEasy to disassembleElectric machinesManufacturing dynamo-electric machinesElectric machineElectric cars

The invention relates to the relevant field of electric vehicle power devices, and discloses a protective automatic dismounting device for an electric vehicle motor. The protective automatic dismounting device for the electric vehicle motor comprises a main box body, wherein a dismounting cavity with a forward opening is formed in the main box body; the lower side of the dismounting cavity communicates with a falling cavity; the outer side of the falling cavity communicates with an annular box body cavity formed in an annular mode; the side wall of the annular box body cavity is connected withan annular box body in a rotating fit manner; the tail end of the upper side of the side wall of the annular box body cavity outwards communicates with an annular inner gear ring cavity; the annularbox body drives a knocking block to rotate, so that uniform knocking at each part of the motor in the circumferential direction is realized; the motor is loosened relative to a hub; and the motor canbe favorably dismounted in the subsequent process; an impact block impacts the upper end surface of a motor main shaft under the effect of an impact spring; dismounting of the motor is realized; and the magnitude of accumulated force of the impact spring is changed by adjusting the position of an impact magnet, and the damage to the motor due to excessive dismounting force is avoided as much as possible.

Owner:福州勃楠电子科技有限公司

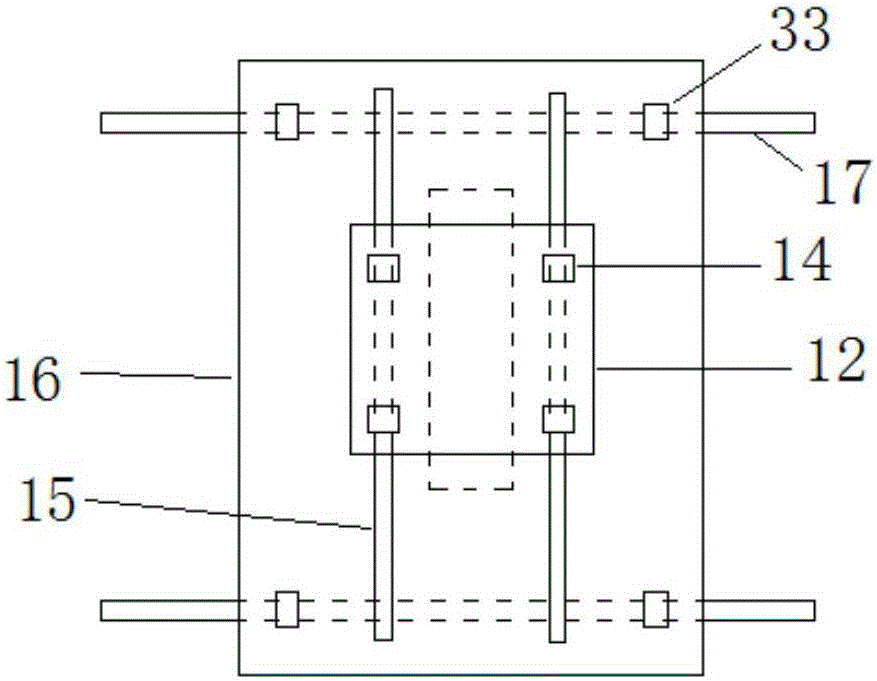

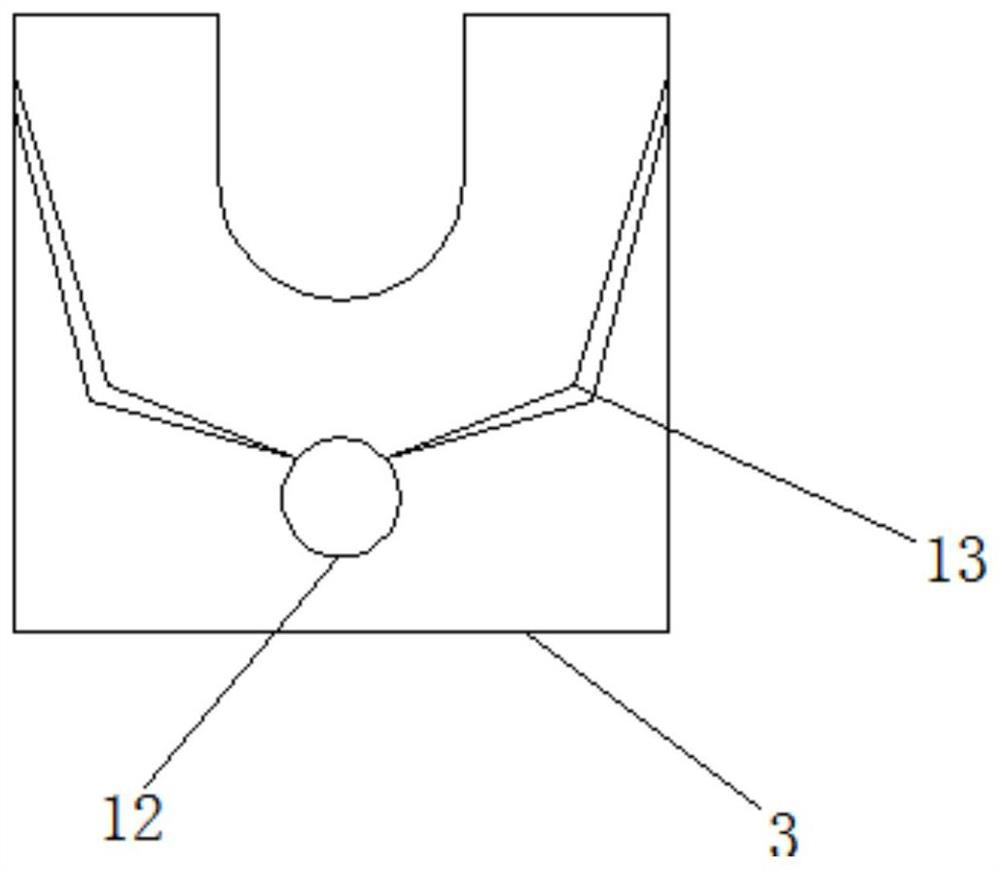

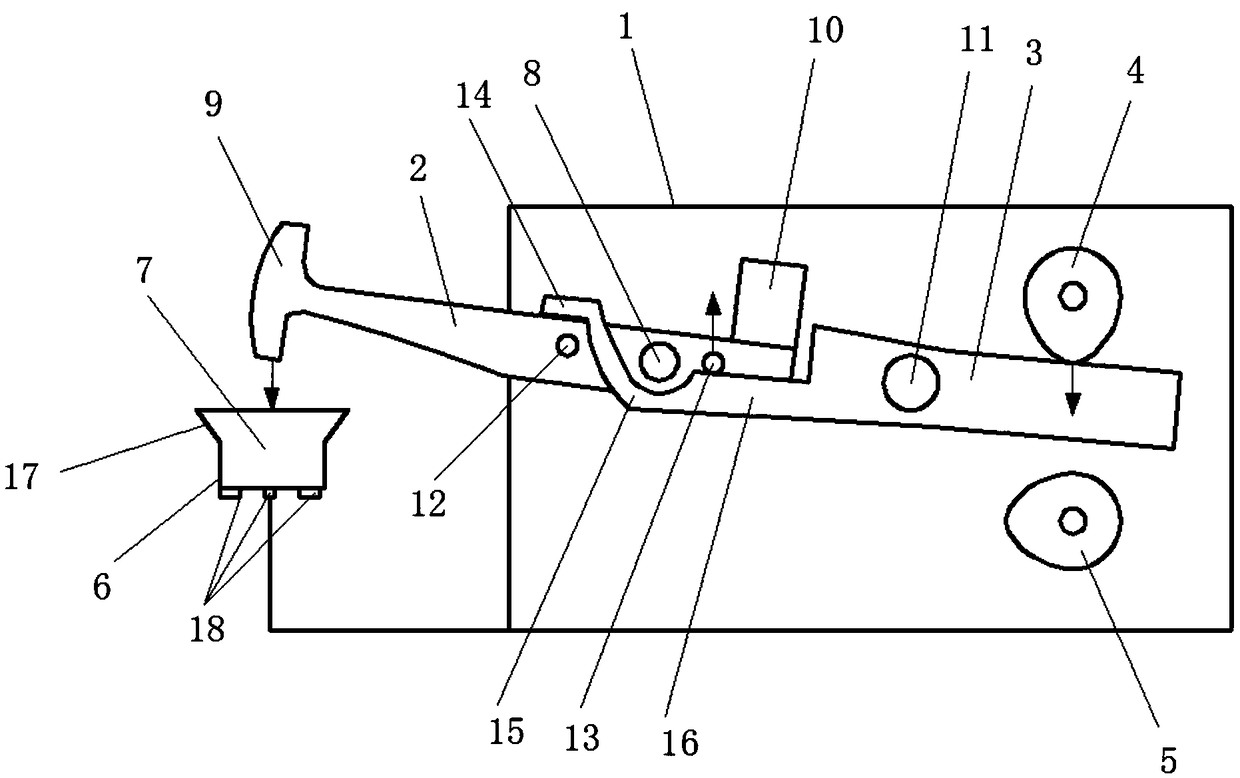

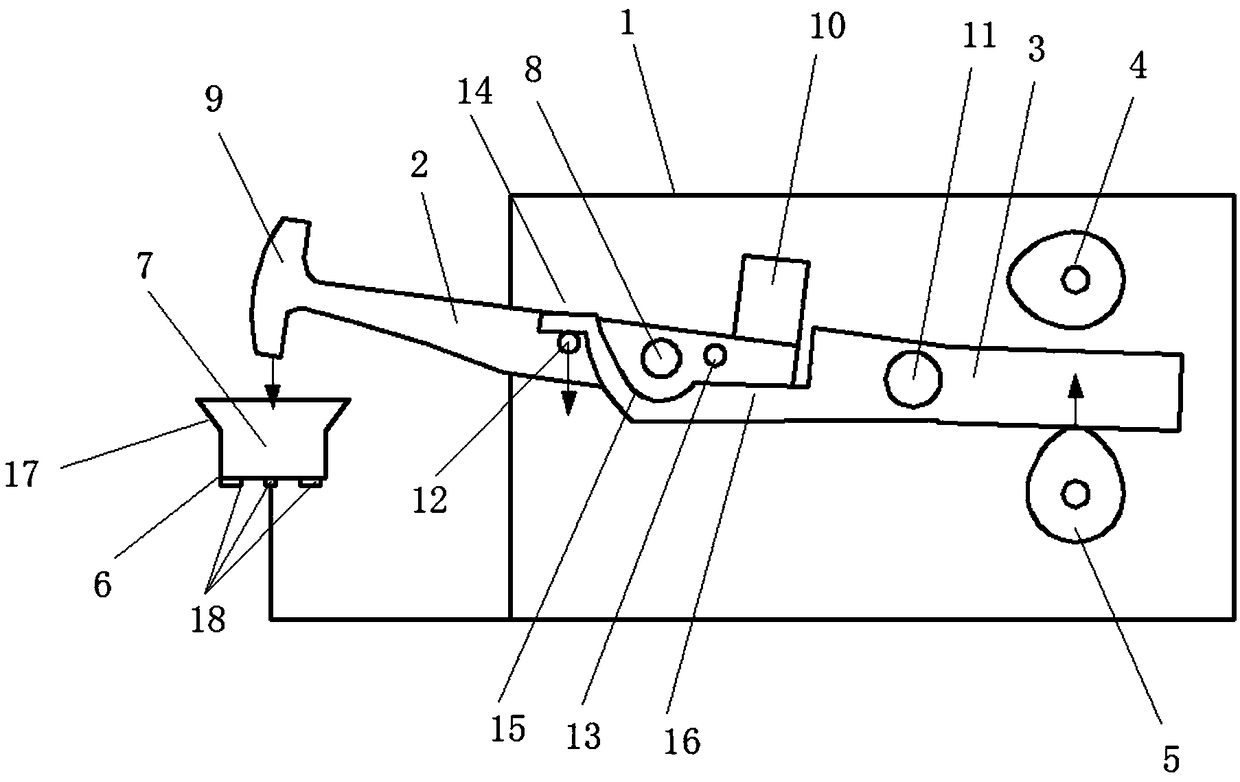

Drug smashing device

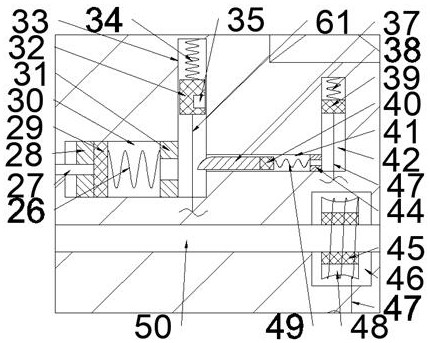

ActiveCN107597264AHit evenlyThe power on the strike rod can make the hammer head strike down evenlyGrain treatmentsEngineeringCam

The invention relates to a drug smashing device. The drug smashing device comprises a shell, a beating bar, a driving rod, a first cam and a second cam. The first cam and the second cam are oppositelylocated above and below the rear end of the driving rod separately. The first cam and the second cam press the rear end of the driving rod downwards or eject the rear end of the driving rod upwards alternately under the driving action of a motor, so that the front portion of the driving rod swings up and down continuously. Therefore, a hammer swings up and down around a first rotating pin so thatthe inside of a beating cavity can be beaten up and down continuously. The drug smashing device replaces manual work to smash drugs, and drug smashing work efficiency is improved. In addition, the drugs in the beating cavity are moved to the two sides from the middle position and then are moved to the middle position from the two sides, cyclic motion is made continuously, the hammer can beat thedrugs more evenly, and the quality of obtained drug powder is made higher.

Owner:江西高馨中药材有限公司

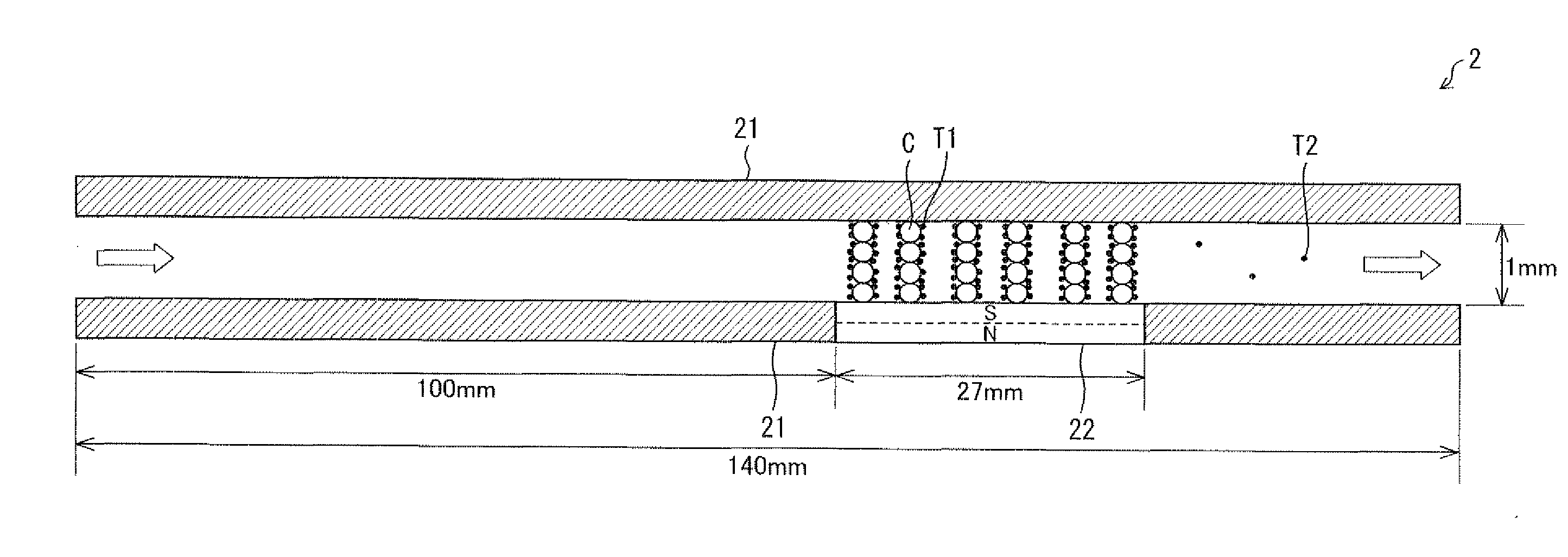

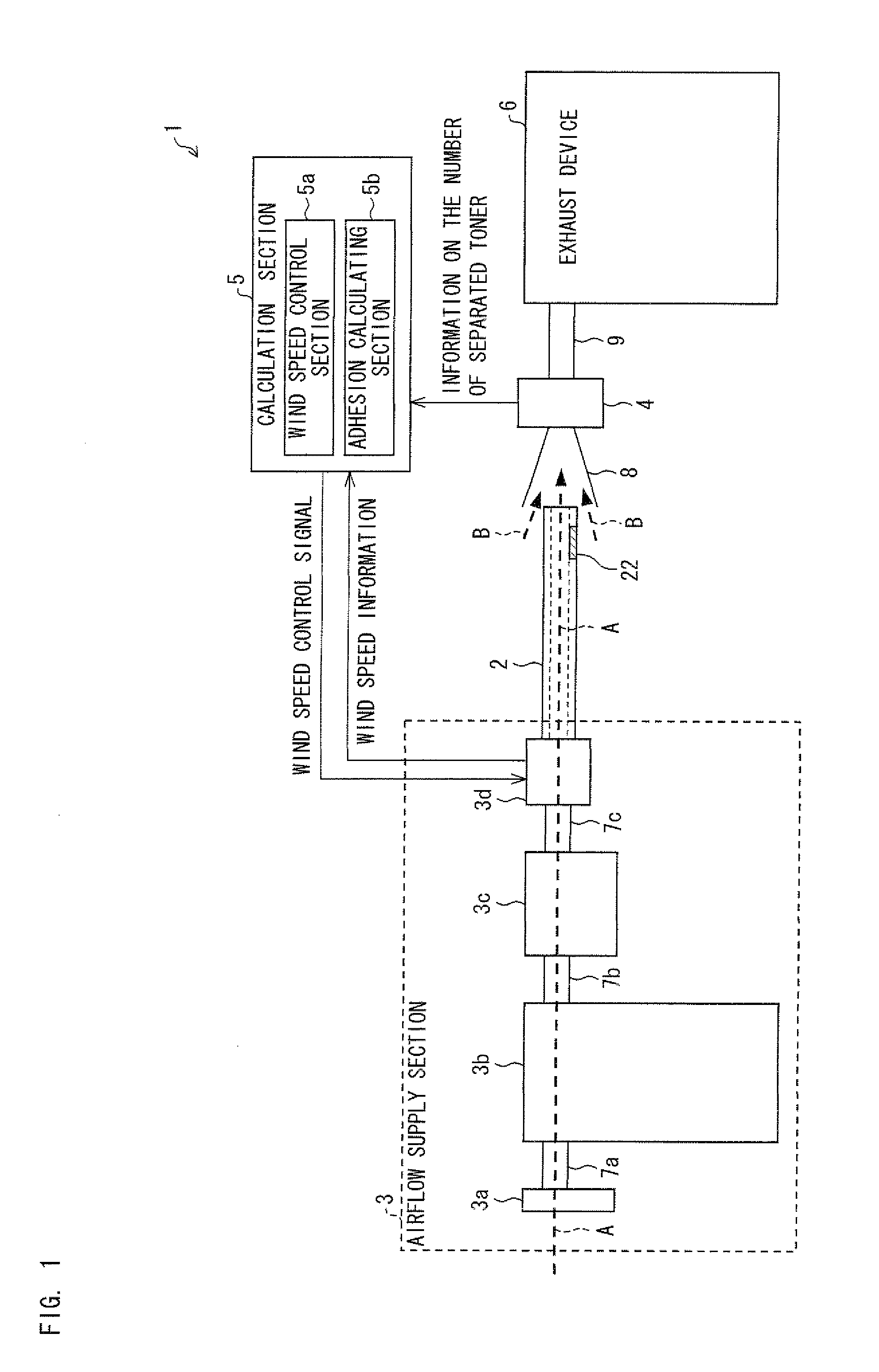

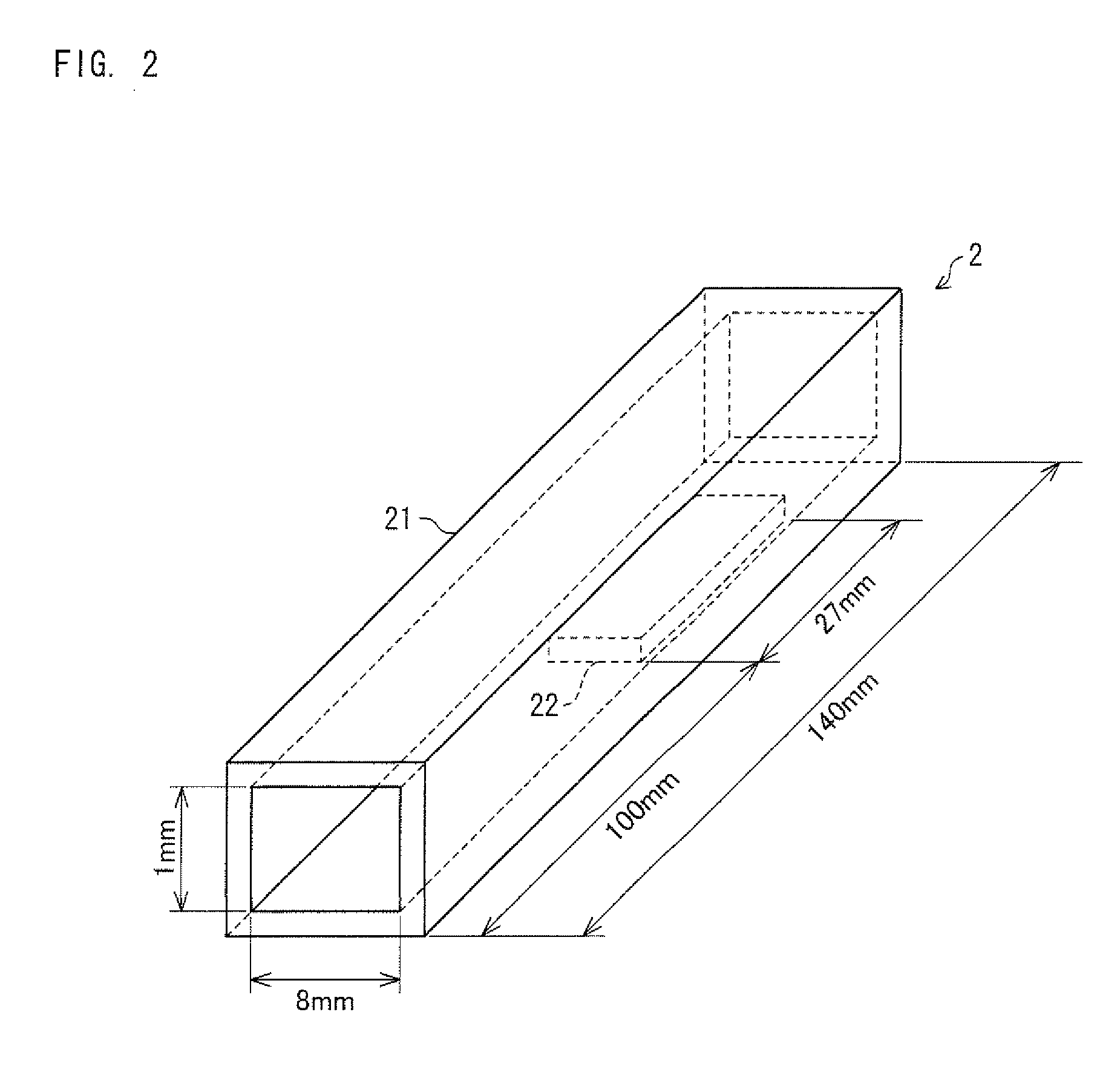

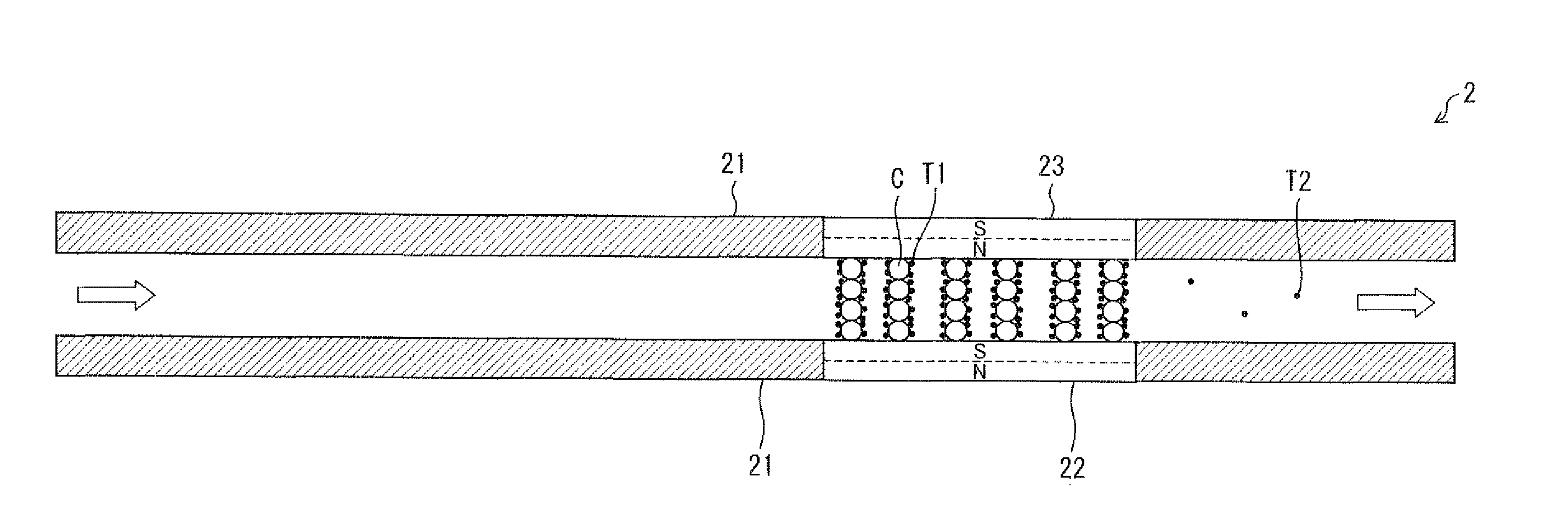

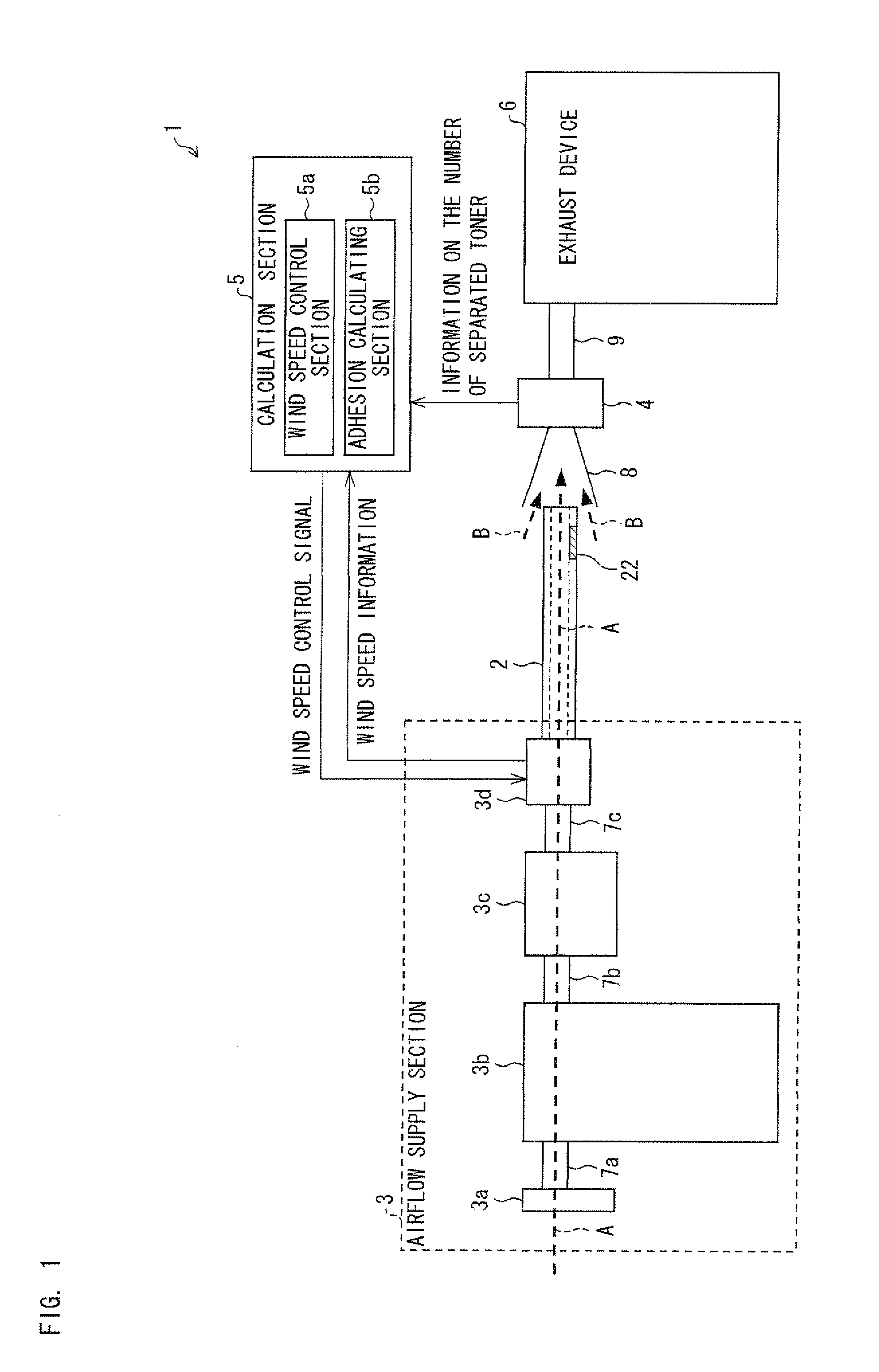

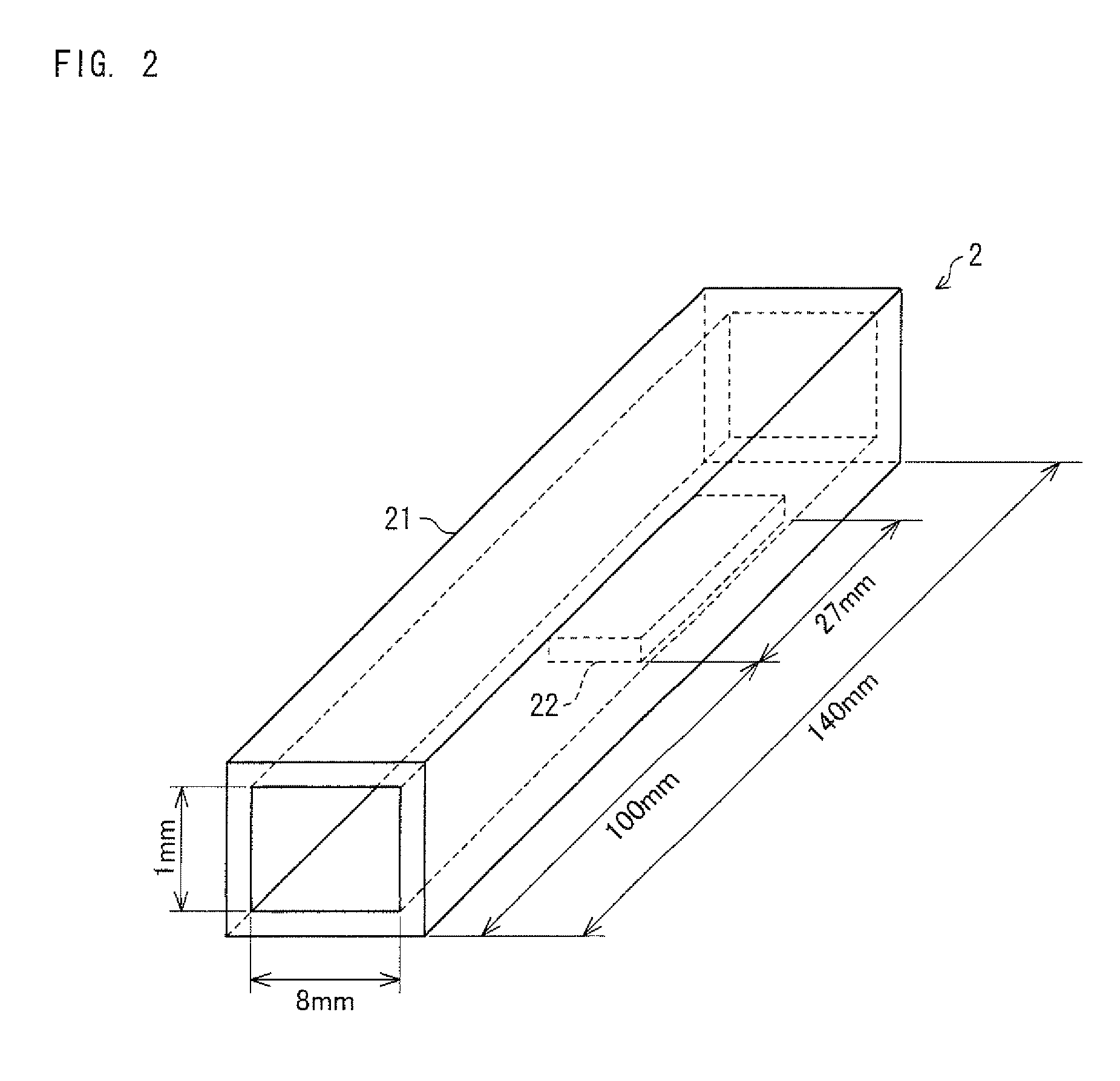

Device and method for measuring toner adhesion

ActiveUS20110265561A1High reproducibilityGood reproducibilityUsing mechanical meansStrength propertiesAirflowMagnet

A device for measuring adhesion of toner to carrier containing a magnetic component, the toner and the carrier being contained in a two-component developer, includes: a developer holding section including a first magnet for holding the two-component developer by a magnetic force; an airflow supply section for supplying airflow to the two-component developer held by the first magnet; a separated toner detecting section for detecting the number of toner separated from the carrier by the airflow; and an adhesion calculating section for calculating the adhesion of the toner to the carrier or an index of the adhesion, based on wind speed of the airflow and the detected number of the separated toner. Thus, the device can measure the adhesion of the toner to the carrier with high reproducibility and exactness.

Owner:SHARP KK

Sheet metal part straightening device

ActiveCN113351690AAvoid heatingHigh precisionShaping toolsMetal-working feeding devicesStructural engineeringMovement control

The invention discloses a sheet metal part straightening device which comprises a protection assembly, a limiting and clamping mechanism, a transverse movement control assembly, a turbine power mechanism and a heating mechanism. The protection assembly is used for containing sheet metal parts; the limiting and clamping mechanism comprises a reverse transmission part and a clamping part; and the clamping part comprises a pressing block, a cushion piece assembly in threaded connection with the interior of the pressing block, and an elastic pressing piece assembly installed in the cushion piece assembly. A spray head and a flame spray gun are arranged over an annular gasket at the bottom end of a telescopic pressing piece; when a sliding plate is manually pushed, flames sprayed by the flame spray gun can pass through a notch in the bottom end of the spray head to conduct high-temperature heating on a bulge on a sheet metal part; and when the bottom end of the spray head is located on the inner side of the annular gasket at the bottom end of the telescopic pressing piece, flames sprayed from the bottom of the spray head can be effectively blocked, so that the flames sprayed from the bottom of the spray head are prevented from heating the intact part near the bulge of the sheet metal part, and the processing accuracy of the bulge position of the sheet metal part is greatly improved.

Owner:江苏铭瀚智能科技有限公司

Feed grinder uniform in discharging

The invention relates to the technical field of machinery, and discloses a feed grinder uniform in discharging. The feed grinder comprises a grinder box. A feed port is fixedly connected with the topof the grinder box. A discharge port is fixedly connected with the bottom of the grinder box. Six supporting legs are fixedly connected with the outer wall of the grinder box. A motor is arranged on the rear lower side of the grinder box. A belt is movably connected with a rotating shaft of the motor. A rotating bearing is fixedly connected with one side of the grinder box. A rotating latch is arranged on the position, on the same side as the rotating bearing, of the grinder box and fixedly provided with a vertical rod. A filter screen on the lower side of the feed port does clockwise circularmotions, so feed entering the feed port more evenly enters the upper side of the rotating bearing in a more layered mode than traditional feed, and bulky feed entering the feed port does circular motions to be decomposed into small blocks to enter the grinder box.

Owner:朱爱芳

Concrete construction device and method

The invention relates to a concrete construction device. The concrete construction device comprises an outer pipe, an inner rammer, a steel reinforcement cage, a soil expander, a rib expander and an expansion steel bar ball, and further comprises a concrete construction method which comprises the following steps that 1) a pile hole is pre-excavated; 2) the outer pipe is sunk into the pile hole; 3)the inner rammer freely falls to expand and punch the bottom space of the outer pipe; 4) the soil expander is put into the outer pipe for soil expansion; 5) the soil expander is taken out, and the bottom space is expanded and punched through free falling of the inner rammer; 6) the step (4) and the step (5) are repeated to expand and punch an expanded head space; 7) the soil expander and the inner rammer are taken out, and the soil expander and the inner rammer are put into the steel reinforcement cage; 8) the rib expander is placed into the outer pipe for rib expansion; 9) a layer of cementis poured into the expanded head space; 10) the expansion steel bar ball is placed into the expanded head space, and a binding rope is pulled out; 11) the opened expansion steel bar ball is adjusted through an adjusting rod; 12) concrete is poured into the outer pipe to the top of a pile; and 13) the outer pipe is lifted out, and the dense concrete is vibrated. The construction method has the effect that the constructed pile is high in anti-pulling capacity.

Owner:ZHEJIANG XINZHONGYUAN CONSTR

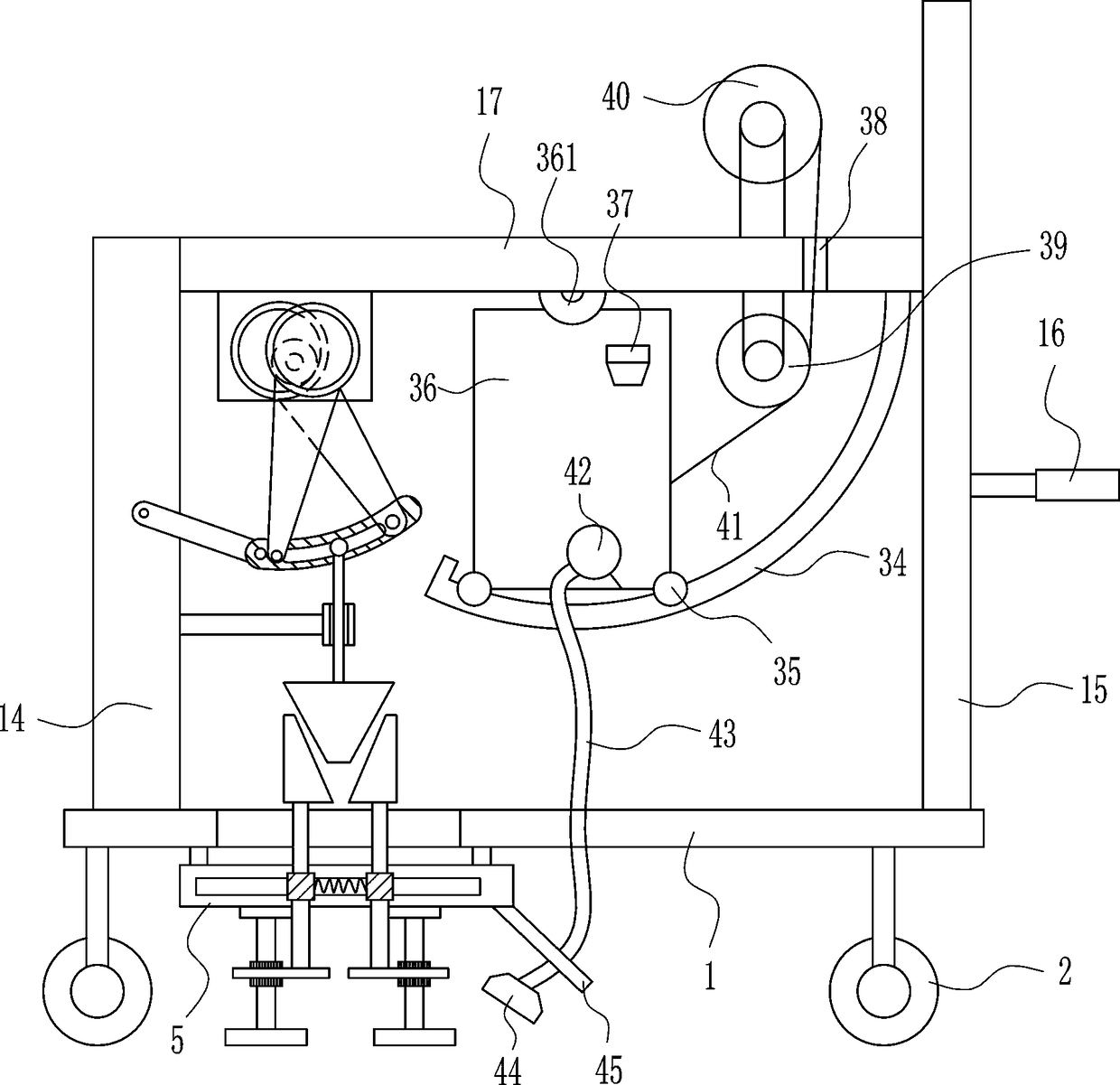

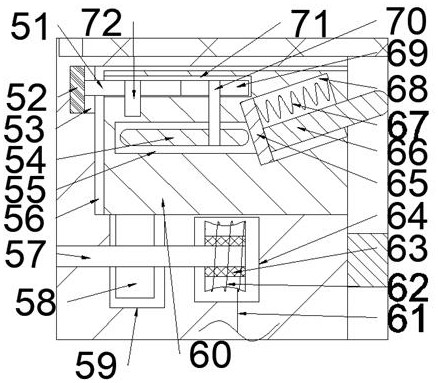

Meat beating machine

InactiveCN114145332AGood hitting effectIncrease inertial forceBeating-based meat tenderisingVibration suppression adjustmentsMachining vibrationsEngineering

The invention relates to the technical field of food processing, and discloses a meat beating machine which comprises a machine box, the left end of the top of the machine box is movably connected with a cover plate, the left end face of the machine box is movably connected with a workbench, the interior of the machine box is fixedly connected with a motor, and the surface of an output shaft of the motor is fixedly connected with a belt pulley. The end, away from the belt wheel, of the motor is fixedly connected with a rotating disc, the protruding position of the right end face of the rotating disc is movably connected with a connecting rod, the other end of the connecting rod is movably connected with a swing rod, the end of the swing rod is fixedly connected with a hammer rod, a rotating shaft is movably installed in the machine box, and the outer side face of the rotating shaft is fixedly connected with a bevel gear. A rolling shaft is movably installed in the workbench, a scraping plate is fixedly installed on the inner wall of the workbench, a support is fixedly connected to the lower left portion of the outer portion of the machine box, and through the design, the effects of saving manpower, being high in efficiency and even in beating and reducing machine vibration are achieved.

Owner:新晃老蔡食品有限责任公司

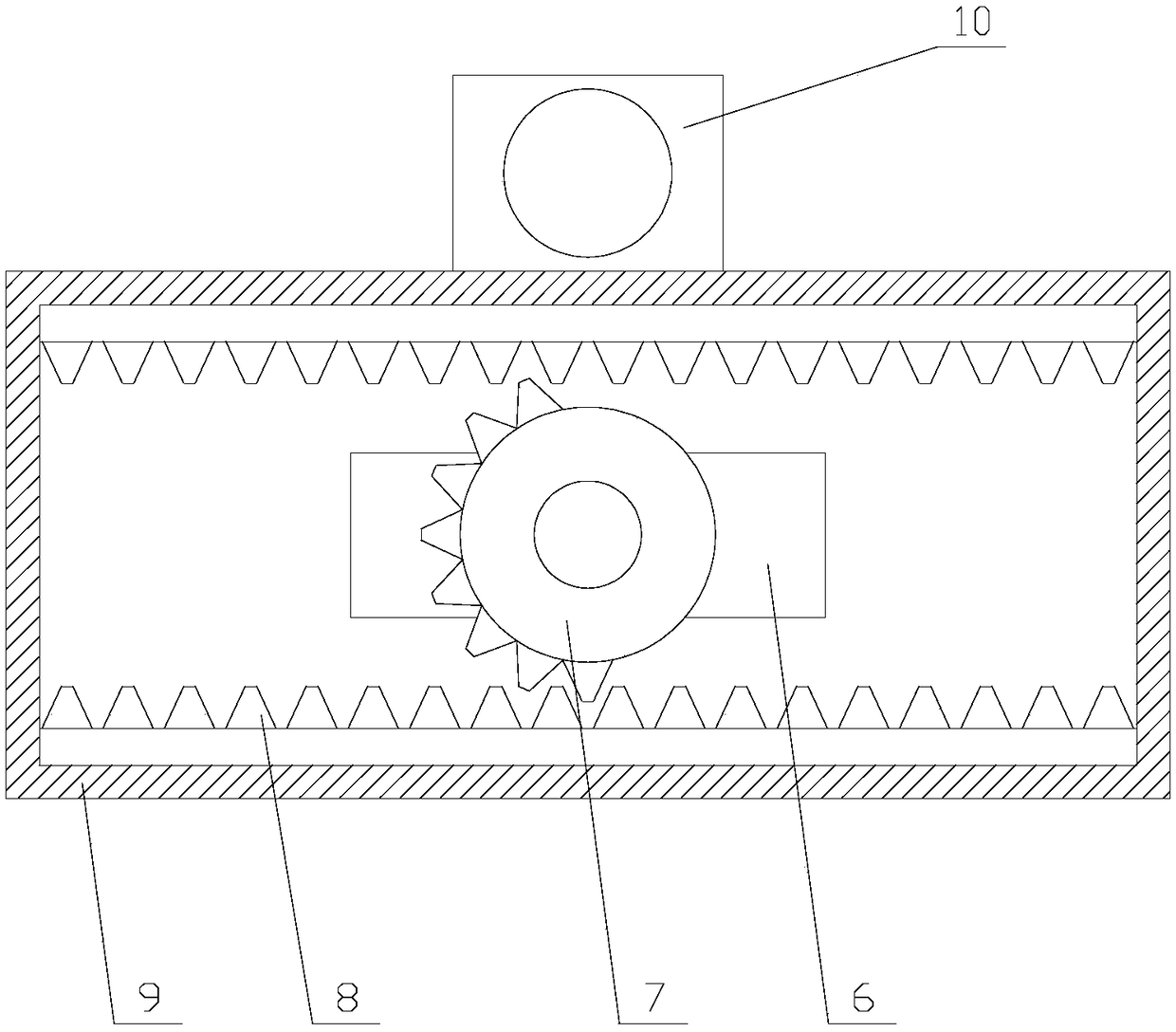

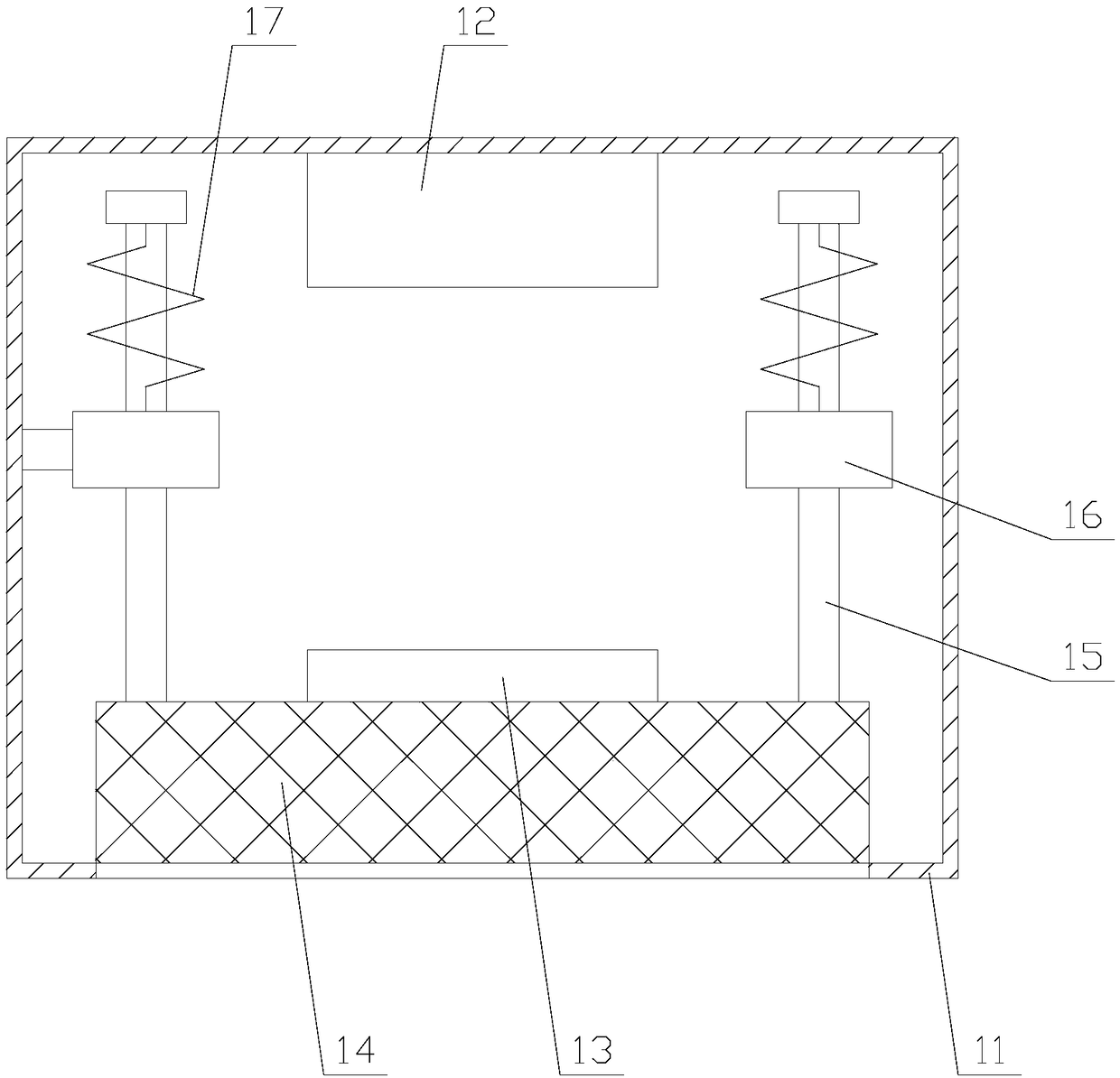

Demoulding equipment for Hechuan sliced meat

The invention belongs to the field of food processing, and particularly discloses demoulding equipment for Hechuan sliced meat. The demoulding equipment comprises a machine frame, wherein a clamping mechanism, a punching mechanism and an actuating mechanism are arranged on the machine frame; the actuating mechanism comprises a mounting seat; a mounting seat driving mechanism is arranged on the machine frame; left rotating shafts and right rotating shafts are rotatably connected to the mounting seat; a left pendulum rod is fixedly connected to each left rotating shaft; a right pendulum rod is fixedly connected to each right rotating shaft; arc-shaped demoulding needles are respectively and fixedly connected to the free end of each left pendulum rod and the free end of each right pendulum rod; the swinging center of each left pendulum rod coincides with an arc center of the corresponding demoulding needle, and the swinging center of each right pendulum rod coincides with an arc center ofthe corresponding demoulding needle; a swinging seat which is fixedly connected with the mounting seat is arranged on the mounting seat; left racks and right racks which are arranged in a spaced manner are in sliding connection to the swinging seat; a swinging driving mechanism is arranged on the swinging seat; and a gear is meshed between each left rack and the adjacent right rack. Through the adoption of the demoulding equipment for the Hechuan sliced meat disclosed by the invention, the demoulding efficiency can be improved when the Hechuan sliced meat is processed.

Owner:CHONGQING NIANJI FOOD

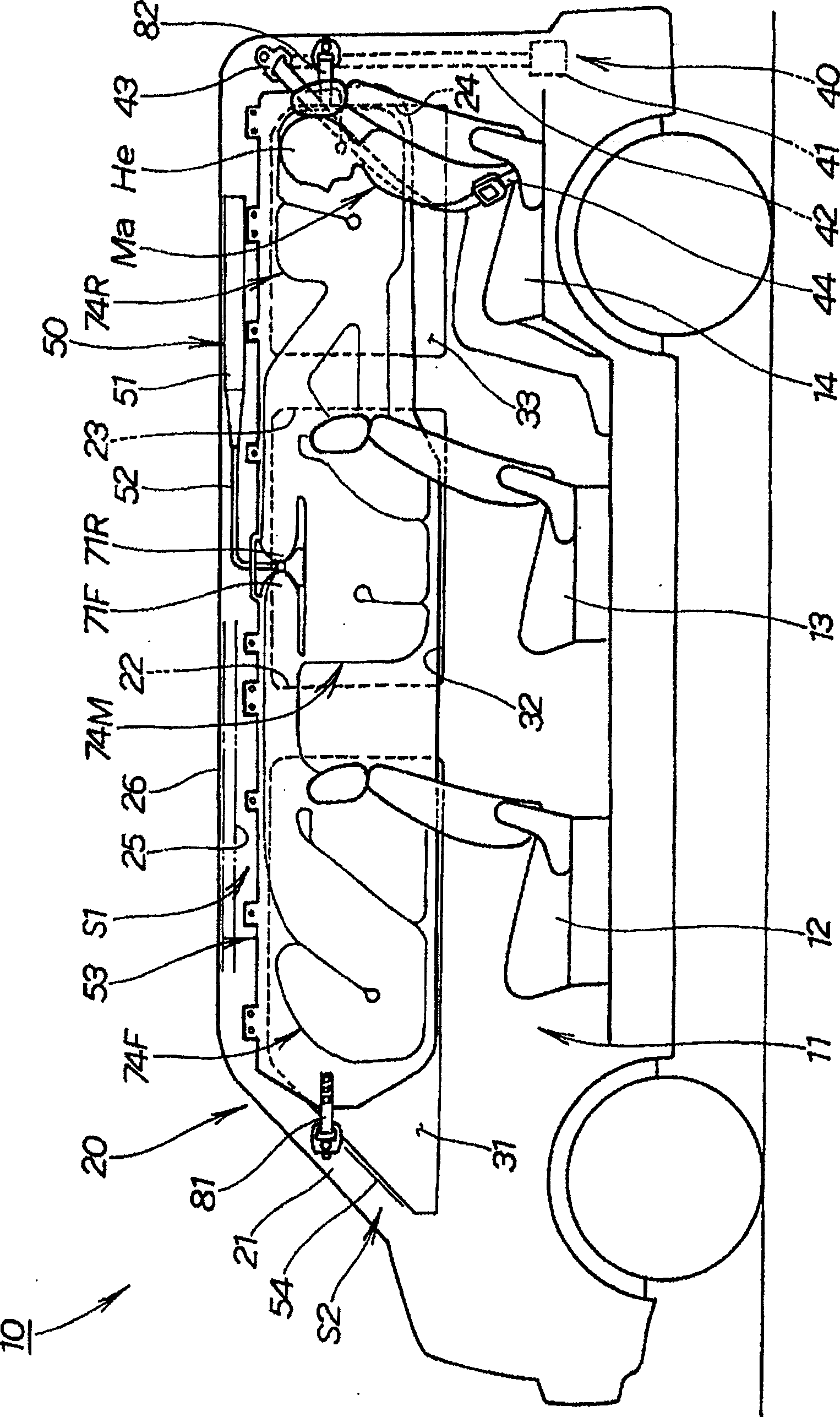

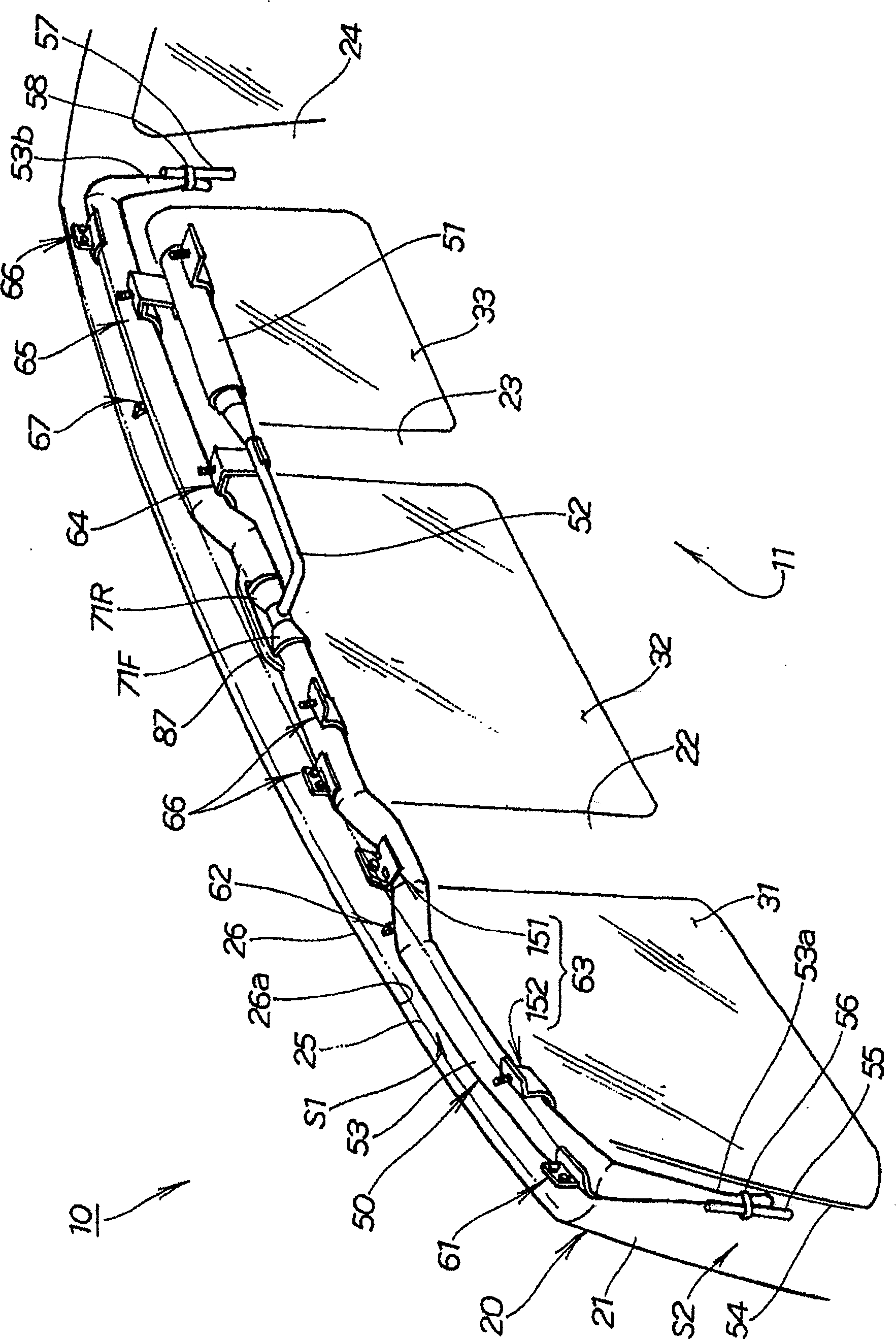

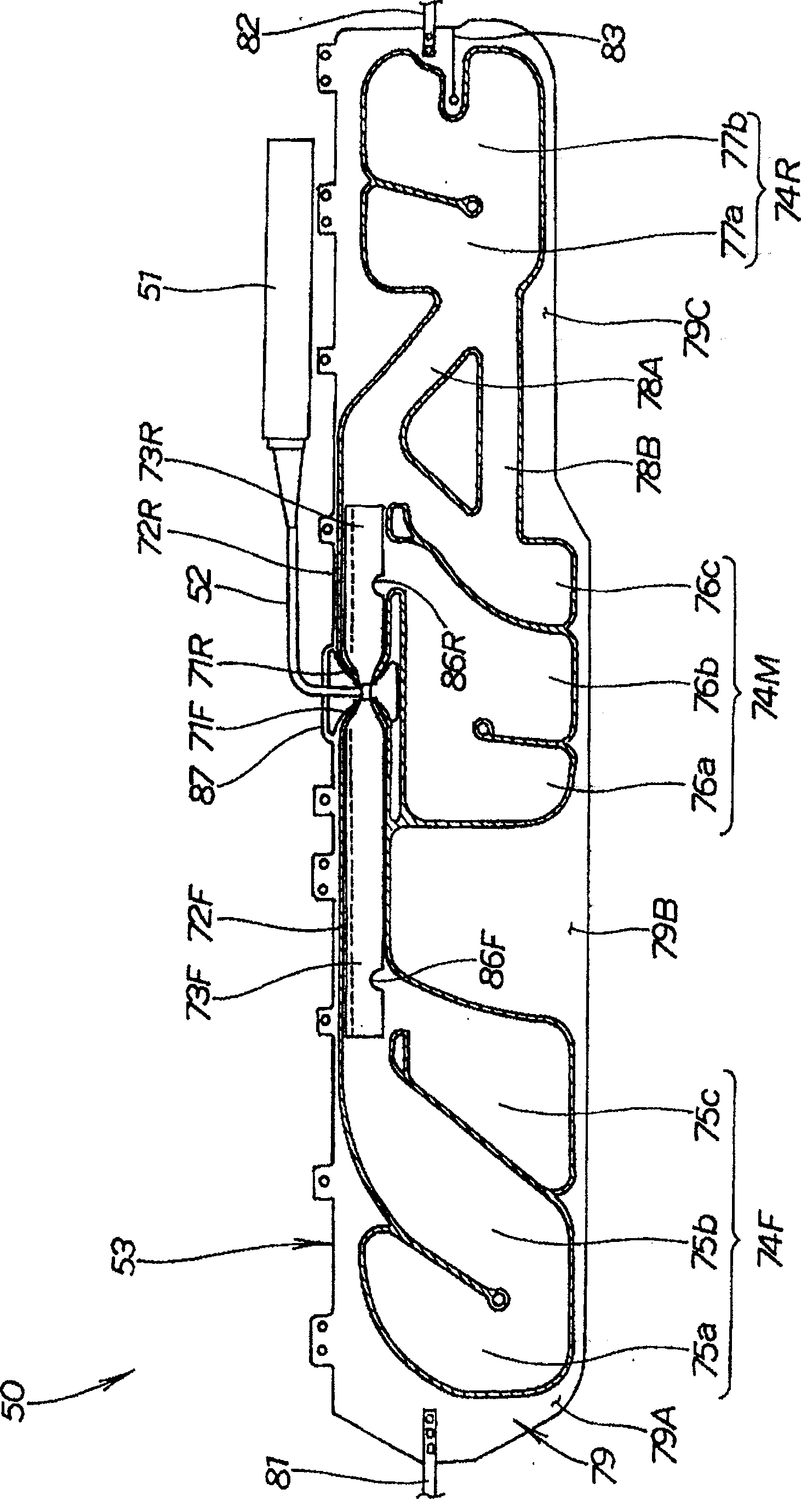

Vehicle occupant protection device

InactiveCN100542856CShorten the inflow pathSmall pressure lossPedestrian/occupant safety arrangementEngineeringAirbag deployment

Owner:HONDA MOTOR CO LTD

Fiber bundle dividing and washing method and device

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +3

A Knock Meat Box for Beef BBQ

The invention discloses a beef knocking box used for a beef barbecue. The beef knocking box comprises a closed cylindrical box body; the side wall of the cylinder box body is provided with a movable openable and closeable door; the movable openable and closeable door is connected with the cylindrical box body through a hinge; a round turntable used for carrying raw beef is arranged in the cylindrical box body; a round cavity is formed in the round turntable; the side edge of the round turntable is provided with a rectangular cavity window; the round cavity is connected with outside through the cavity window; a length size of the cavity window is equal to a diameter size of the round cavity; ice is held in the round cavity; a knocking mechanism is arranged above the round turntable; the knocking mechanism comprises a support fixed on the inner wall face of the cylinder box body; the support is provided with a chain, chain wheels and a motor, wherein the chain wheels are connected with the chain, and the motor is used for driving the chain wheels; the chain is provided with a stopper. A beef knocking problem under a field environment is solved by the beef knocking box used for a beef barbecue provided by the invention.

Owner:重庆市老川牛食品有限公司

Concrete construction device and construction method

ActiveCN111676962BImprove pullout resistanceCavity wall denseDrill bitsBulkheads/pilesSteel ballRebar

The invention relates to a concrete construction device, which includes an outer pipe, an inner rammer, a reinforcement cage, a soil expander, a reinforcement expander and an expanded steel ball, and also includes a concrete construction method, the steps of which are: 1), pre-excavation piles 2), the outer pipe sinks into the pile hole; 3), the inner rammer free falls to expand the space at the bottom of the outer pipe; 4), put the expander into the outer pipe to expand the soil; 5), take out the expander, pass The internal rammer falls freely to expand the bottom space; 6), repeat steps 4 and 5 to expand the head space; 7), take out the soil expander and internal rammer, and put them into the reinforcement cage; 8), put the expander Enter the outer pipe to expand the reinforcement; 9), pour a layer of cement in the expansion head space; 10), put the expanded steel ball into the expansion head space, and pull out the binding rope; 11), adjust the expanded expanded steel ball with the adjustment lever; 12) 1. Pour concrete into the outer pipe to the top of the pile; 13) Lift the outer pipe and vibrate the dense concrete. The invention has the effect that the constructed pile has stronger pull-out resistance.

Owner:浙江新甬城建设有限公司

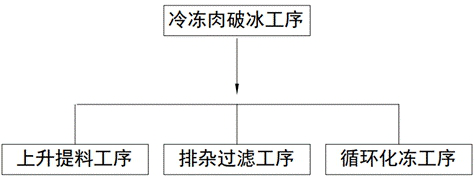

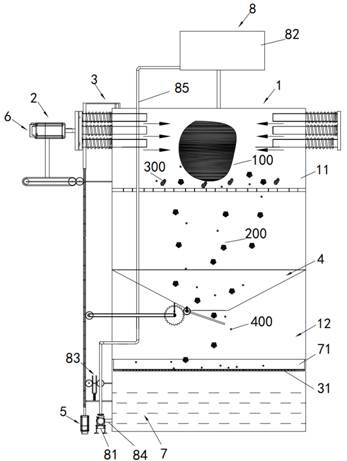

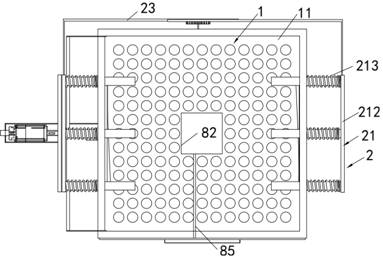

Thawing method for frozen meat

PendingCN114468028AProcess method is environmentally friendlyThe process is sustainableMeat/fish preservation by freezing/coolingStationary filtering element filtersBiotechnologyWater storage tank

The invention provides a frozen meat unfreezing method, which comprises an icebreaking process, a material lifting process, a filtering process and a circulating process, and the material lifting process comprises the following steps: step 1, a frozen meat icebreaking process: putting frozen meat on a material lifting mechanism, and then knocking the frozen meat by a knocking assembly; step 2, a lifting process: driving an ice breaking mechanism to horizontally move towards the frozen meat through a first driving mechanism, so that a beating assembly can sufficiently beat the outside of the frozen meat; step 3, impurity removal and filtration, wherein ice cubes and impurities knocked off from the frozen meat fall into a filter bin below through a filter plate; and step 4, circulating thawing process: pumping the filtered water at the bottom of the thawing bin into a water storage tank right above the thawing bin under the action of a circulating water pump to complete the thawing work, so that the problems that the surface of the frozen meat is easily polluted by bacteria, a large amount of nutritional ingredients in the frozen meat are lost in the thawing process and the meat quality is reduced are solved.

Owner:安徽腾翔食品有限公司

Assembly process of oil-free vacuum pump

The invention discloses an assembly process of an oil-free vacuum pump. The assembly process specifically comprises the following steps that S1, opening positions at the two ends of a cylinder body are sleeved with annular step surfaces protruding outwards, a plurality of clamping rods are connected to the two annular step surfaces, the clamping rods are circularly arranged on the outer side of the cylinder body in a surrounding mode and are coaxially arranged with the cylinder body, and the clamping rods extend to the outer sides of the annular step surfaces; S2, the clamping rods are used as suspended stress points, and a rotor is uniformly knocked into the cylinder body; S3, masking paper sequentially penetrates through the rotor and the clamping rods and is attached to openings in the two ends of the cylinder body; and S4, a front cover plate and a rear cover plate are pre-positioned and abut against the masking paper and are fixedly connected with the annular step surfaces. According to the assembly process, the connecting efficiency between the front cover plate or the rear cover plate and the openings of the cylinder body is improved, and the front cover plate or the rear cover plate can be accurately positioned and connected to the openings of the cylinder body.

Owner:NANTONG BEIKE VACUUM MACHINERY CO LTD

A drug crushing device

The invention relates to a drug smashing device. The drug smashing device comprises a shell, a beating bar, a driving rod, a first cam and a second cam. The first cam and the second cam are oppositelylocated above and below the rear end of the driving rod separately. The first cam and the second cam press the rear end of the driving rod downwards or eject the rear end of the driving rod upwards alternately under the driving action of a motor, so that the front portion of the driving rod swings up and down continuously. Therefore, a hammer swings up and down around a first rotating pin so thatthe inside of a beating cavity can be beaten up and down continuously. The drug smashing device replaces manual work to smash drugs, and drug smashing work efficiency is improved. In addition, the drugs in the beating cavity are moved to the two sides from the middle position and then are moved to the middle position from the two sides, cyclic motion is made continuously, the hammer can beat thedrugs more evenly, and the quality of obtained drug powder is made higher.

Owner:江西高馨中药材有限公司

Device and method for measuring toner adhesion

ActiveUS8590372B2Good reproducibilityHit evenlyUsing mechanical meansStrength propertiesMagnetic tension forceEngineering

A device for measuring adhesion of toner to carrier containing a magnetic component, the toner and the carrier being contained in a two-component developer, includes: a developer holding section including a first magnet for holding the two-component developer by a magnetic force; an airflow supply section for supplying airflow to the two-component developer held by the first magnet; a separated toner detecting section for detecting the number of toner separated from the carrier by the airflow; and an adhesion calculating section for calculating the adhesion of the toner to the carrier or an index of the adhesion, based on wind speed of the airflow and the detected number of the separated toner. Thus, the device can measure the adhesion of the toner to the carrier with high reproducibility and exactness.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com