Concrete construction device and method

A construction device and construction method technology, applied in earthwork drilling, foundation structure engineering, drilling equipment, etc., can solve the problems of different degrees of bending of steel bars, uneven distribution of steel bar skeletons, and insufficient pull-out resistance of concrete piles, etc., to achieve Easy to adjust and good pull-out resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

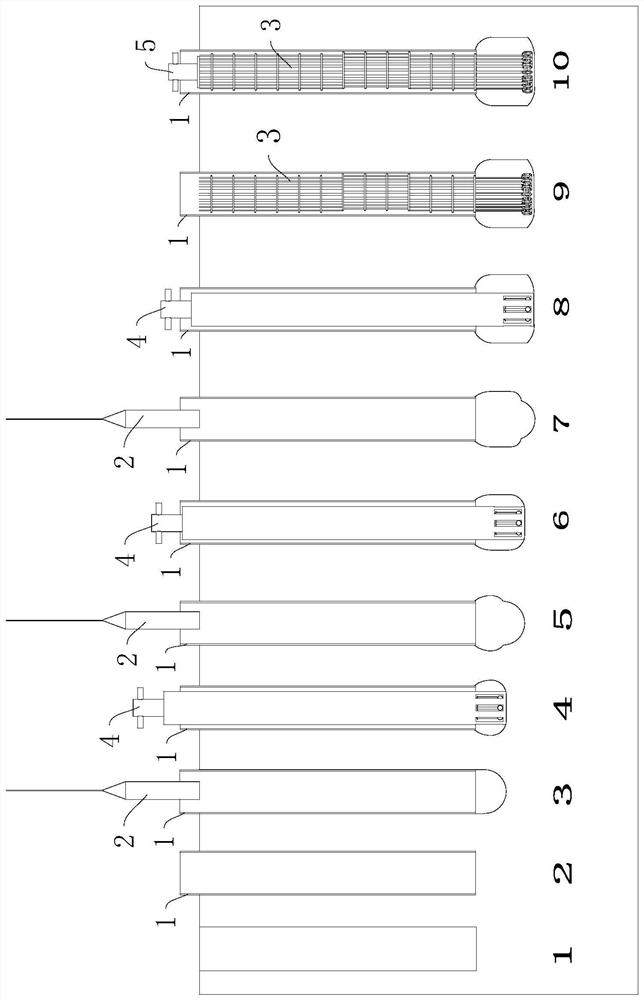

[0059] refer to figure 1 , is a concrete construction device disclosed in the present invention, comprising an outer pipe 1 , an inner rammer 2 , a reinforcement cage 3 , a soil expander 4 , a reinforcement expander 5 , an expanded steel ball 6 and an adjustment rod 7 . The outer pipe 1 is a steel pipe or a cement pipe with a designed length, and in this embodiment, a cement pipe is used; the material of the inner tamper 2 can be cast steel, and the weight of the inner tamper 2 can be adjusted by adjusting the length of the inner tamper 2. The upper part of the inner rammer 2 can be connected with a crane by a steel cable, and the inner rammer 2 is lifted by the crane.

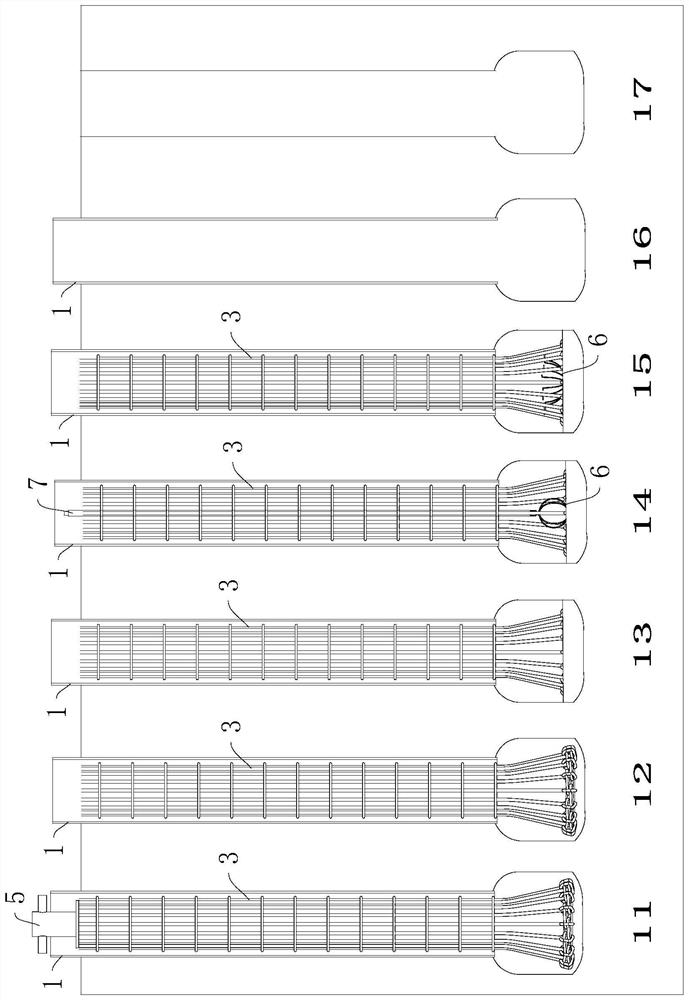

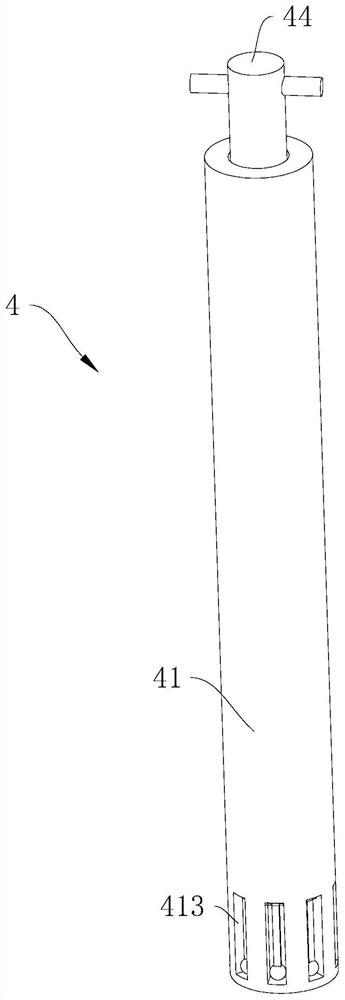

[0060] refer to figure 2 with image 3 The soil expander 4 includes a casing 41, a hammer 42, a push rod 43 and a drive rod 44. The casing 41 is provided with a sliding chamber 411 with an upper opening, and the bottom of the sliding chamber 411 is vertically provided with a limit post 412, and the driving ...

Embodiment 2

[0069] refer to Figure 9 The difference between this embodiment and Embodiment 1 is that the puller is a stay cord 732, there are several stay cords 732, and several stay cords 732 are arranged at interval angles along the circumferential direction of the slip sleeve 72, and one end of the stay cord 732 is fixed to the slip sleeve 72 , the other end of the stay rope 732 is fixed with the tie rope 63.

Embodiment 3

[0071] refer to figure 1 , a concrete construction method, the method adopts the above-mentioned concrete construction device, and the method comprises the steps of:

[0072] 1) Select the location where piling needs to be driven, and pre-dig the pile hole with the design depth at the pile location;

[0073] 2) sink the outer tube 1 into the pile hole;

[0074] 3) Put the inner rammer 2 into the outer tube 1, and expand the space at the bottom of the outer tube 1 through the free fall movement of the inner rammer 2 in the outer tube 1 until the bottom of the inner rammer 2 is located on the outer tube 1 A certain distance below is 17cm to 33cm in the present embodiment, and the weight and falling position of the internal rammer 2 are determined according to the actual soil quality;

[0075] 4) Put the expander 4 into the outer tube 1 as a whole, push and pull the drive rod 44 up and down, rotate the expander 4 at a certain angle every few times, until the drive rod 44 can slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com