Patents

Literature

242 results about "Industrial construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial construction is a specific form of building that requires expert training and highly experienced workers who can multi-task. Many industrial construction companies are large, multi-national firms. Projects are run by a bevy of managers, engineers and architects.

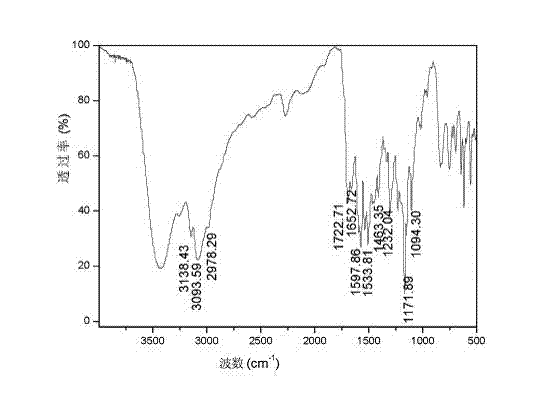

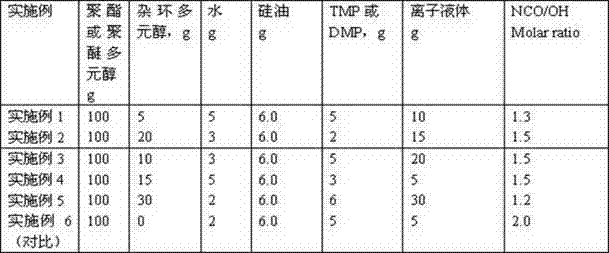

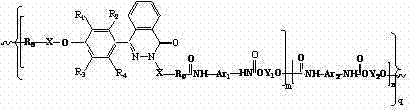

Flame-retardant heat-resistant polyurethane foaming plastic and preparation method thereof

ActiveCN103242647AImprove heat resistanceImprove mechanical propertiesPolyesterIndustrial construction

The invention belongs to high molecular materials and in particular relates to flame-retardant heat-resistant polyurethane foaming plastic. The polymer, namely the flame-retardant heat-resistant polyurethane foaming plastic, contains a residue structure obtained after reaction of heterocyclic polyol and polyisocyanate, and a flame retardant or flame-retardant polyol is added in the preparation process. The flame-retardant heat-resistant polyurethane foaming plastic is prepared by carrying out a reaction on heterocyclic substances, polyester or polyester polyol, polyisocyanate, flame-retardant polyol and the like, or adding the flame retardant instead of the flame-retardant polyol. As the heterocyclic structure is introduced in polyurethane, except for the characteristics of the common polyurethane foaming plastic, the flame-retardant heat-resistant polyurethane foaming plastic further has excellent heat resistance, corrosion resistance and more excellent mechanical property and is high-grade flame-retardant polyurethane foaming plastic; and a preparation process of the flame-retardant heat-resistant polyurethane foaming plastic is environment-friendly and non-toxic. The defects that the existing polyurethane is low in heat resistance, poor in flame retardance and the like are overcome; and the flame-retardant heat-resistant polyurethane foaming plastic can be dried at low temperature, is convenient to use and high in cost performance and can be widely applied to the fields of industrial construction materials, high-grade building materials, heat-preservation and heat-insulation materials and the like.

Owner:DALIAN UNIV OF TECH

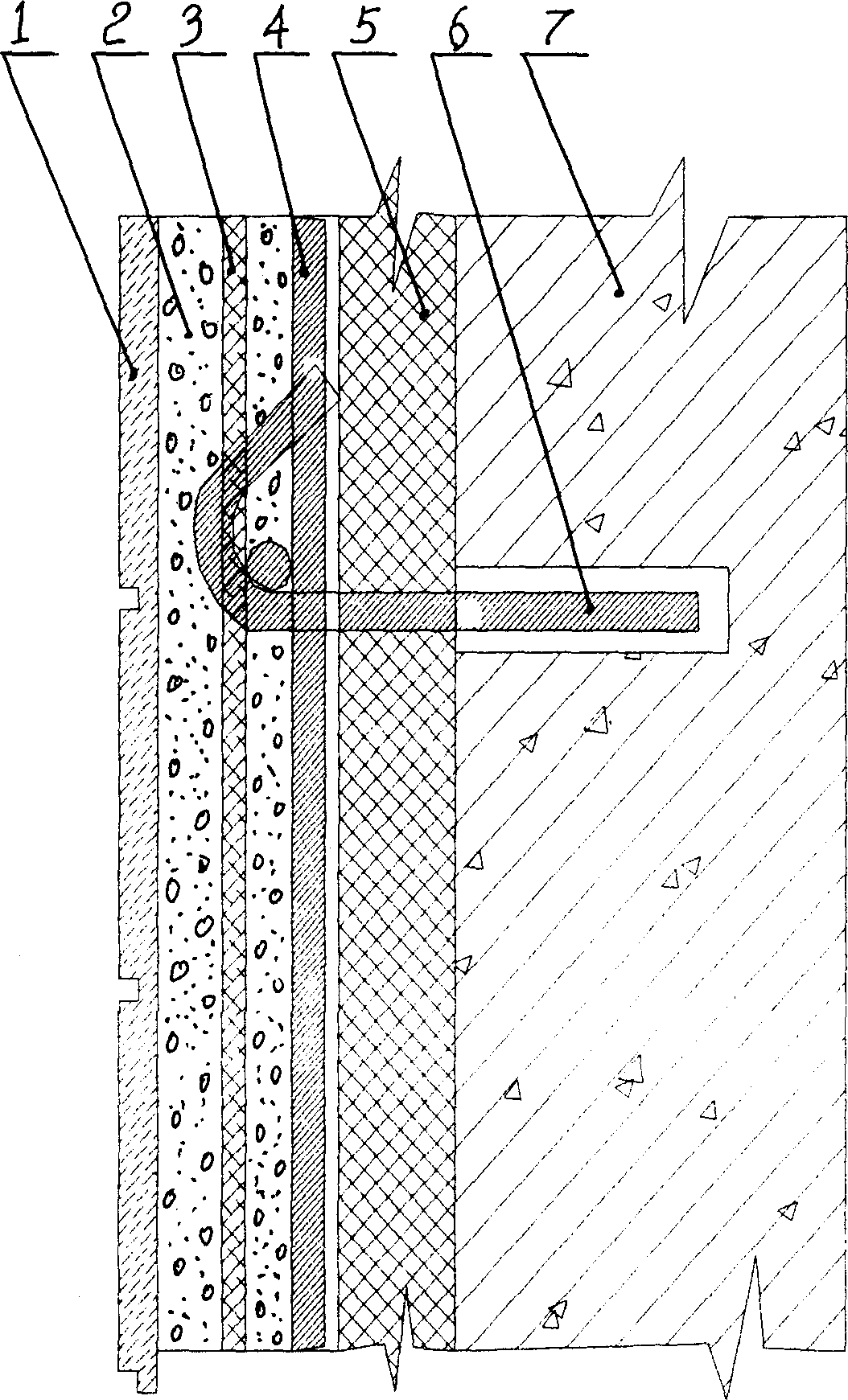

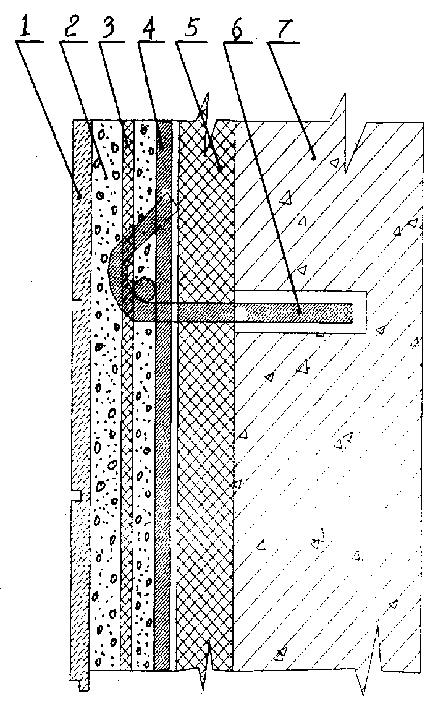

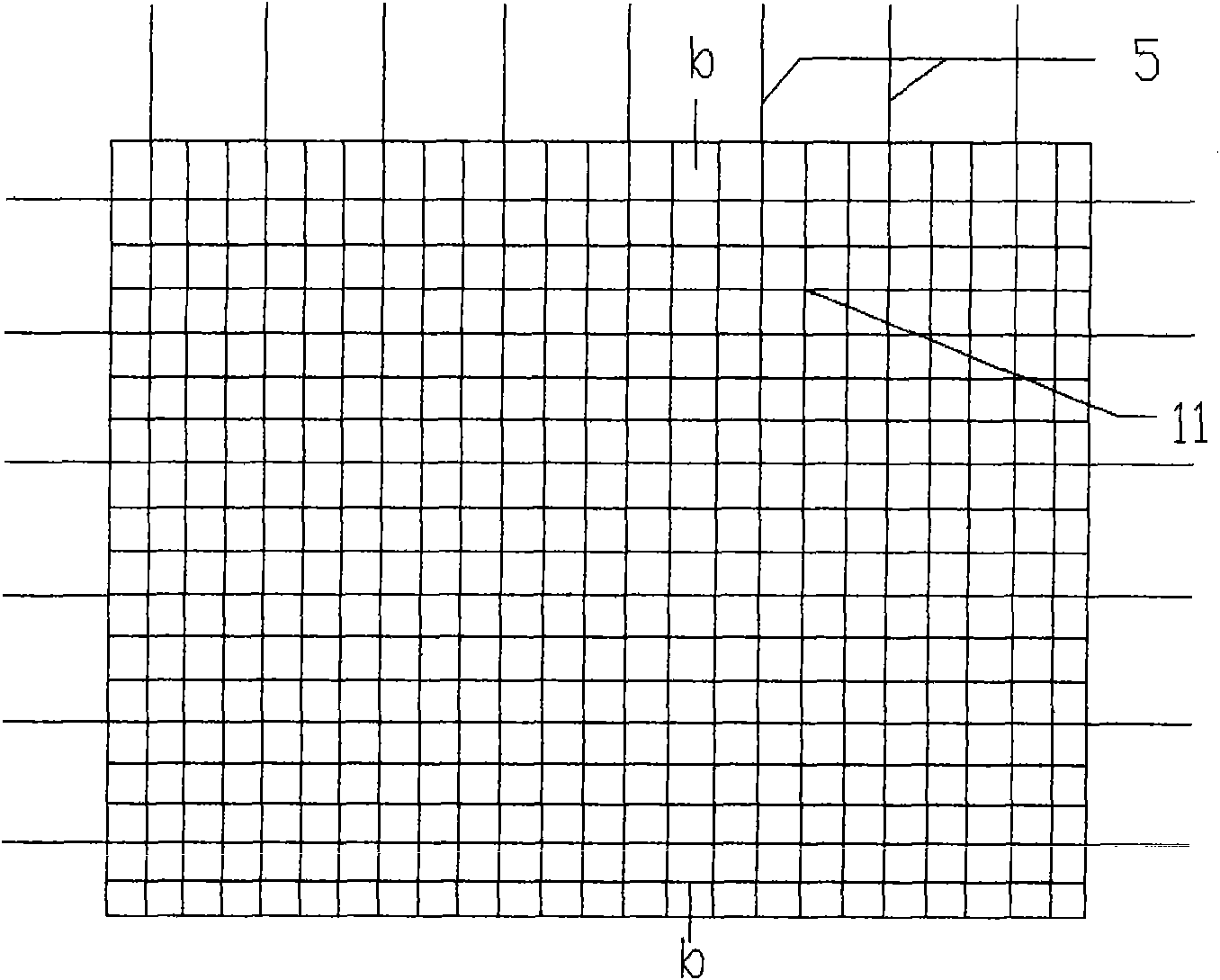

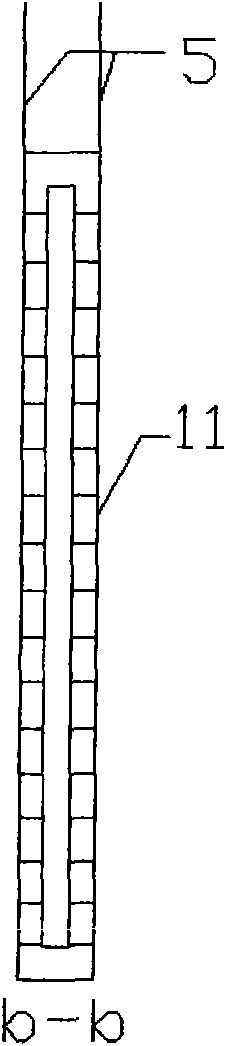

External insulating layer of external wall of ultra high-rise building and its making method

InactiveCN1442586AImprove energy savingGood energy saving effectCovering/liningsWallsIndustrial constructionSheet steel

A thermally insulating layer for the external surface of ultra-high building is composed of steel bars planted in said external surface, insualting boards, steel bar net, meshes steel sheet layer, concrete layer and decorative surface layer. Its technology includes such steps as planting steel bars in external surface, installing insulating boards, binding steel bar net and then meshed steel sheet layer, casting concrete, and applying decorative surface. Its advantages are high strength, not cracking and low cost.

Owner:NO 1 AUXILARY HOSPITAL NO 4 MILLITARY MEDICAL UNIV P L A

Interchangeable and removably connected geometric carpet sections

Owner:GALLAGER MICHAEL

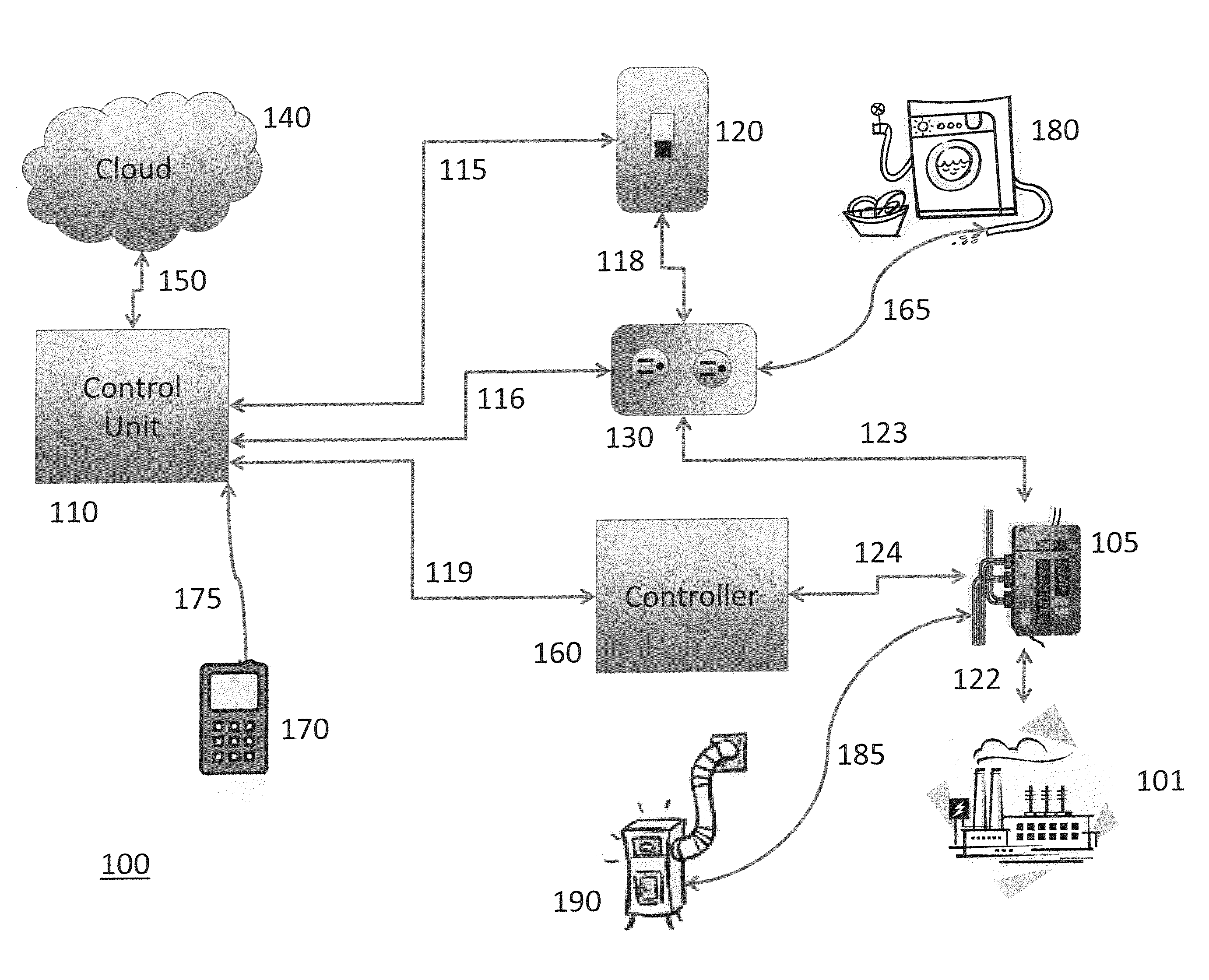

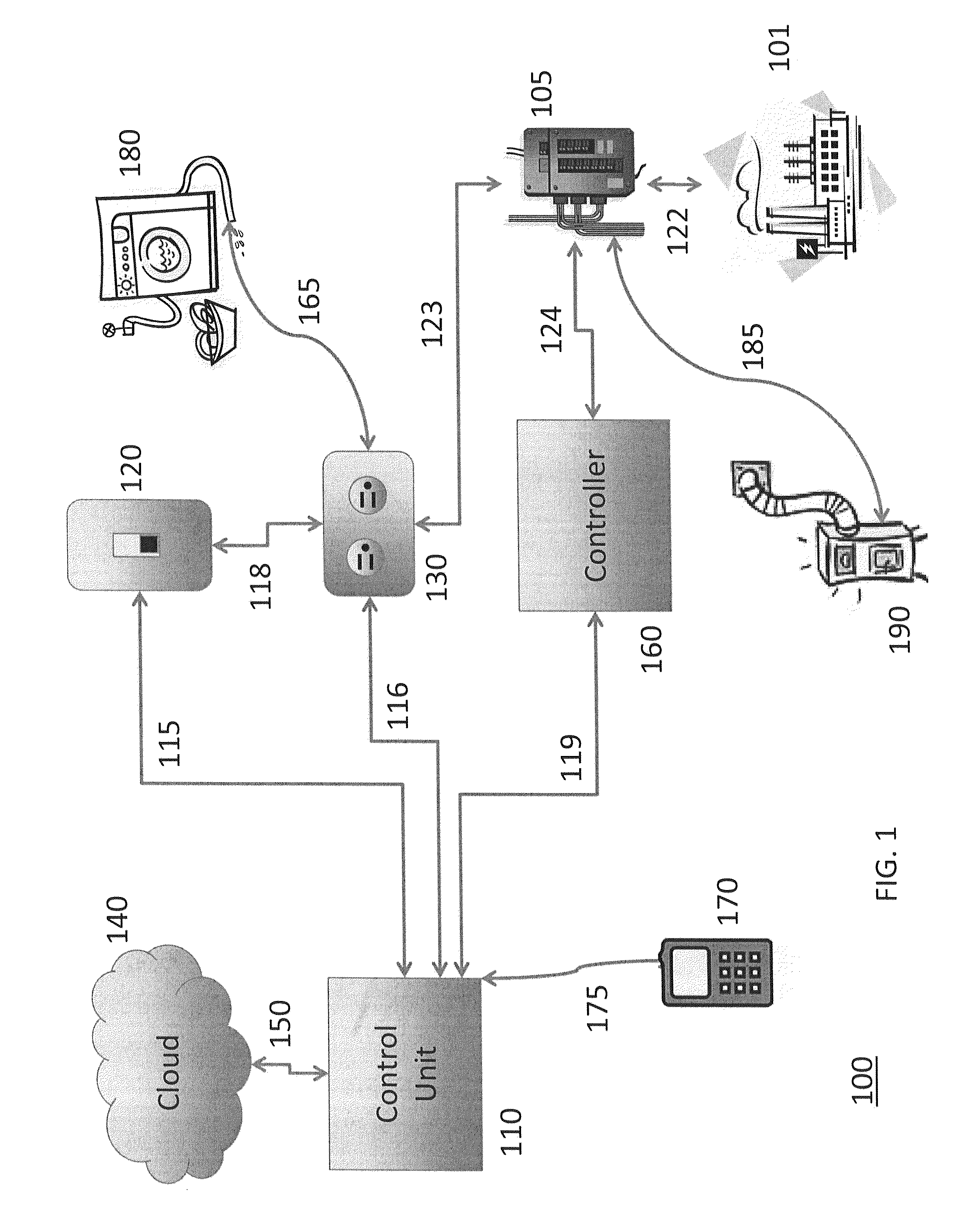

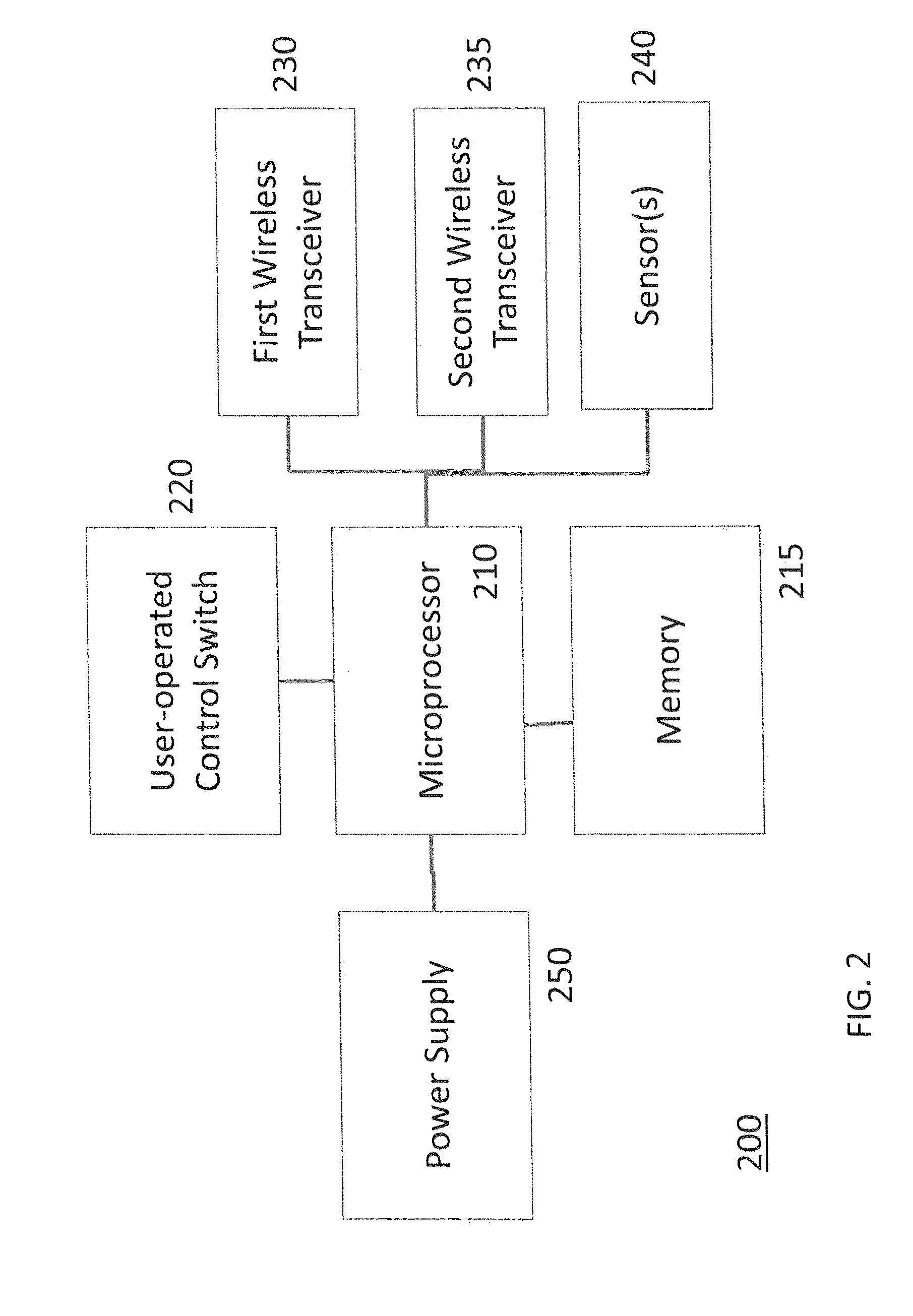

Systems, devices, and methods for reducing safety risk and optimizing energy use

InactiveUS20140316594A1Reduce loadMinimize security riskProgramme controlMechanical power/torque controlReliability engineeringAutomation

The present disclosure is generally directed to reducing a safety risk in an automation system such as an automated electrical system in a structure such as a residential, commercial, or industrial building. More particularly, the present disclosure includes systems, devices, and methods for intelligently monitoring and controlling conditions in components and / or wired connections of an automation system indicative of a potential fire hazard.

Owner:GREEN EDGE TECH

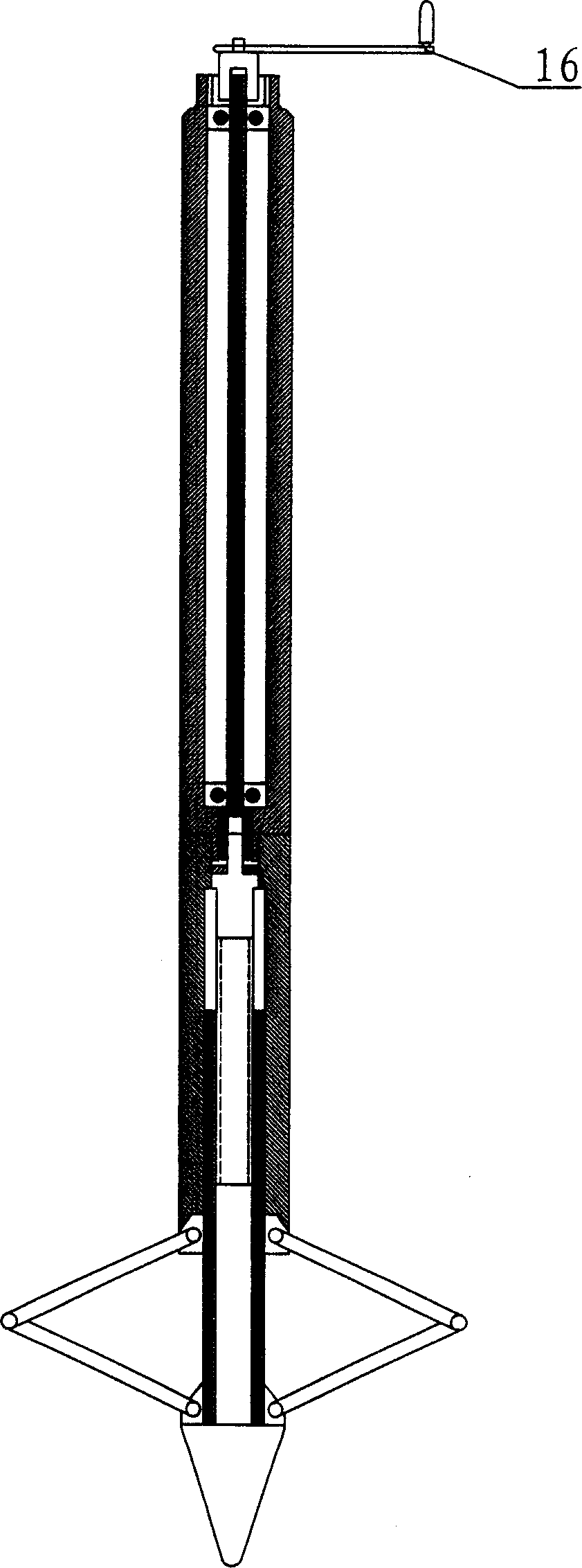

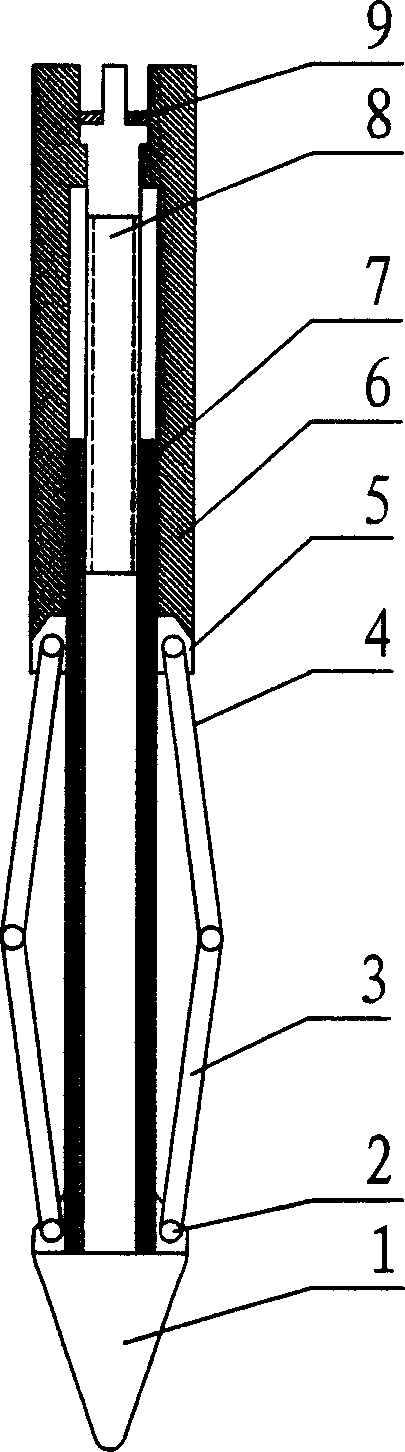

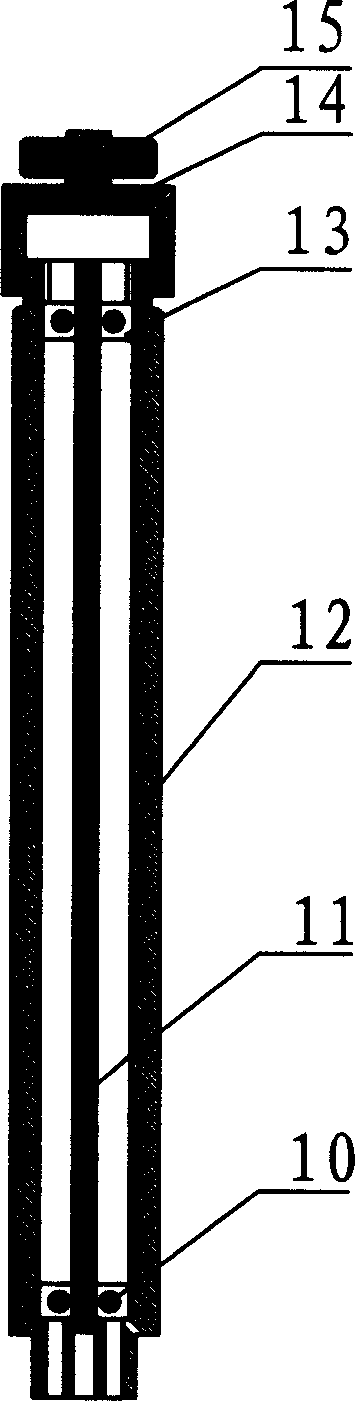

Apparatus of anchoring capable of repeating use and its construction method

InactiveCN1786352AReduce pollutionReduce anchoring costsBulkheads/pilesUpper jointMetallic materials

The invention relates to repeated use anchor fitting and its construction method. It is applied in foundation ditch anchoring, slope protection anchoring, electric force transporting tower wind proofing, large-scale billboard and temporary anchoring, road, bridge, and railway signs anchoring in industrial and civil architecture. Anchor fitting is made up of squeezing enlarging machine, connection link and spanner. The upper joint of the squeezing enlarging machine is connected to inner pipe, and connected to the under joint by axle pin. The under joint is connected to the outer pipe. The connection link outer pipe is connected by bearing and roll bearing. The spanner is connected to roll bearing. The invention presses metal anchor bar into soil and opens the squeezing enlarging machine to greatly increase anchoring force while anchoring. The anchor bar is metal, not need concrete pouring, so it is environmental protection. When the anchoring is finished, the squeezing enlarging machine can reclaim to use repeatedly. Thus it can save cost, and has no needless barrier left above or under ground.

Owner:北京中阔地基基础技术有限公司

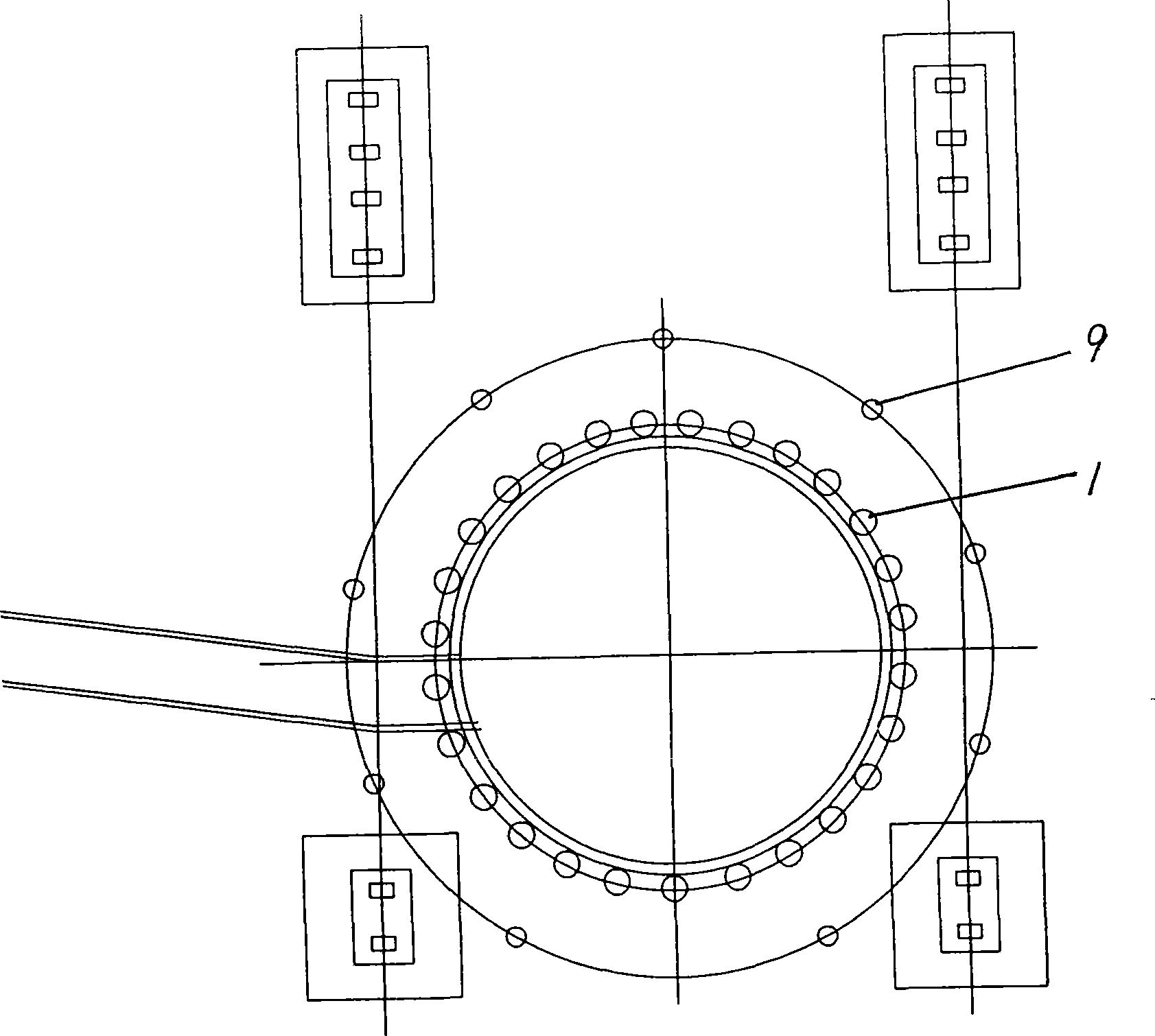

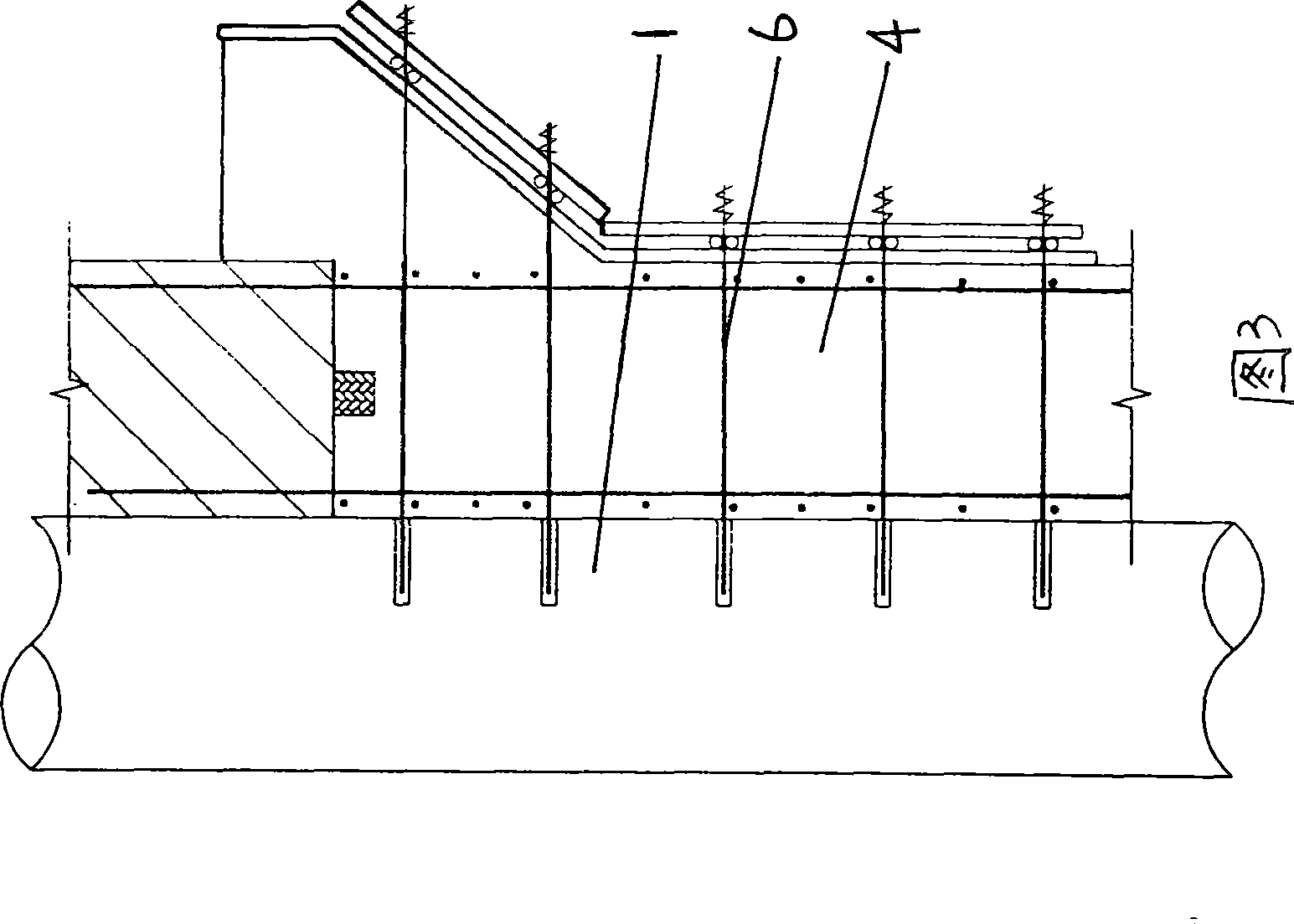

Circular deep foundation ditch concrete pile arranging support and major structure inversing construction method

InactiveCN101457526AEasy constructionFast progressExcavationsBulkheads/pilesIndustrial constructionSoil horizon

The invention belongs to the construction method of a deep foundation pit of industrial construction, particularly relates to a reverse operating construction method of a round deep foundation pit concrete piling support and a main structure and solves the problem that the existing construction method of the deep foundation pit is not suitable for complex geological condition and the construction cost is too high. The construction method comprises the following steps: the center of the foundation pit is adopted as the center and the outer sides of the position of the main structure are respectively distributed with pilings; the top parts of the pilings are poured with crown bore beams which connects the top parts of the pilings into one body; the first section of the foundation pit is excavated, reverse operation is carried out to the outer layer of the first section of the main structure; the outer layer of the first section of the main structure and the pilings are integrated by the crown bore beams so as to form a primary support of the foundation pit; the foundation pit is excavated by sections, reverse operating construction of the outer layer of the main structure is carried out by sections, which form a foundation pit support together; and normal operating construction is carried out to the inner layer of the main structure. The invention is applicable to poor geological condition and is particularly applicable to structural diversity of the soil layer in the depth range of excavation of earthwork, thus ensuring the stability of the soil body of the main structure in the construction period, greatly reducing the cost of construction measures and improving the construction speed.

Owner:MCC TIANGONG GROUP

Metallized polymeric film reflective insulation material

ActiveUS20070248805A1Improve flame retardant performanceRaise the fireAdhesive processesMechanical working/deformationLacquerExpanded polystyrene

A method of thermally insulating an object that requires a Class A standard insulation material, said method comprising suitably locating a metallized polymeric reflective insulation material adjacent said object, wherein said polymeric material is selected from a closed cell foam, polyethylene foam, polypropylene foam, expanded polystyrene foam, multi-film layers assembly and a bubble-pack assembly. The object is preferably packaging, a vehicle or a residential, commercial or industrial building or establishment. The polymeric material may contain a fire-retardant and the bright surface of the metallized layer has a clear lacquer coating to provide anti-corrosion properties, and which maintains satisfactory reflectance commercial criteria.

Owner:PROMETHEAN INSULATION TECH

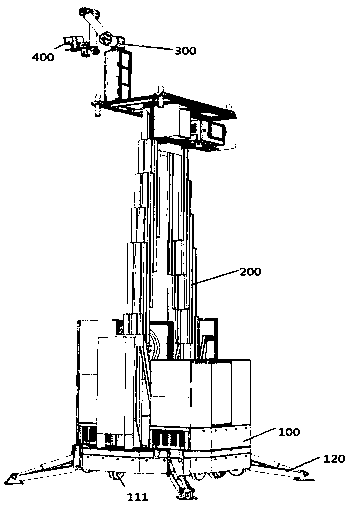

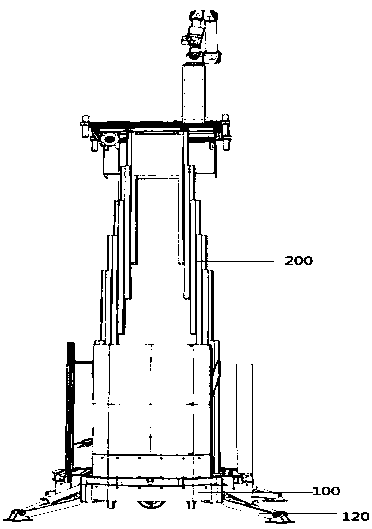

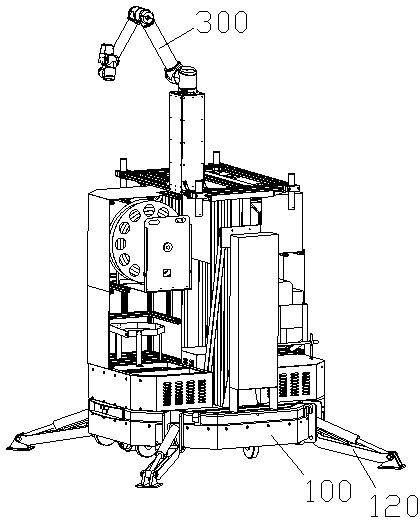

High-wall surface painting system and method for industrial buildings

InactiveCN109306794AReduce generationReduce Risk of Exposure to Harmful Coating ChemicalsBuilding constructionsIndustrial constructionHuman exposure

The invention discloses a high-wall surface painting system and method for industrial buildings. A moving base is arranged to drive the whole high-wall surface painting system for the industrial buildings to achieve autonomous navigation and movement in a work space, a two-bar telescopic lifting mechanism is used for driving a mechanical arm to ascend and descend for painting of a high-rise region, the mechanical arm drives a spray gun to achieve multiple degree-of-freedom angle and position adjustment so as to meet the requirements of different painted positions; the whole painting process isautomatically completed by the high-wall surface painting system for the industrial buildings, time and labor are saved, the efficiency is high, the high-wall surface painting system for the industrial buildings can achieve painting of the top of an area up to 13 meters, and the painting requirements of high-rise areas are met. The thickness of paint is accurate and uniform, the painted surface is evenly distributed, and the quality of painting is ensured. The high-wall surface painting system for the industrial buildings can obviously reduce paint dust produced in the painting process, thusreducing the risk of human exposure to harmful paint chemicals.

Owner:TRANSFORMA ROBOTICS PTE LTD

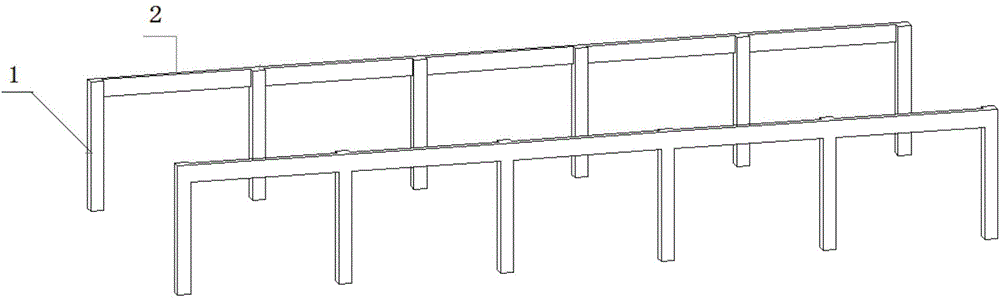

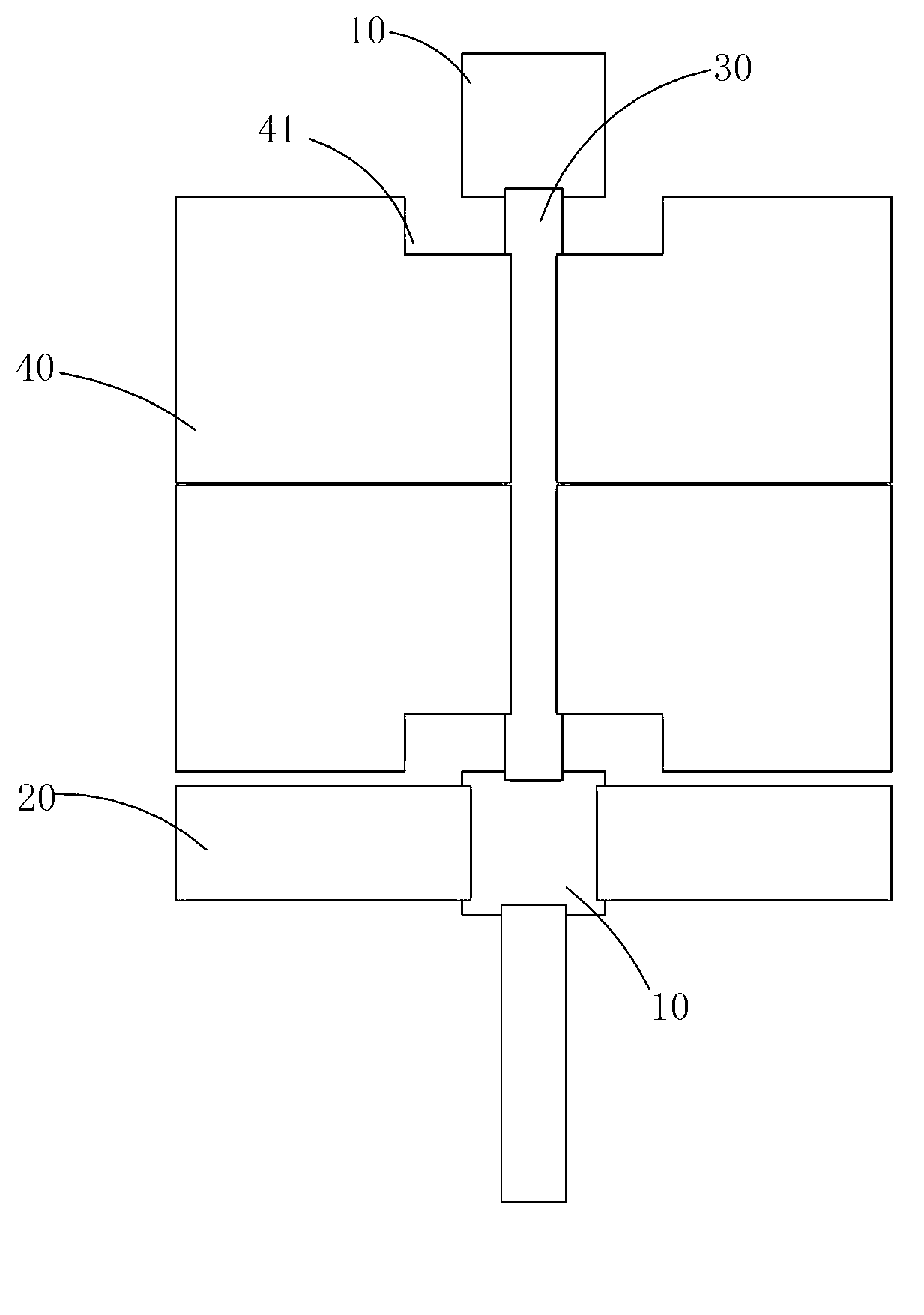

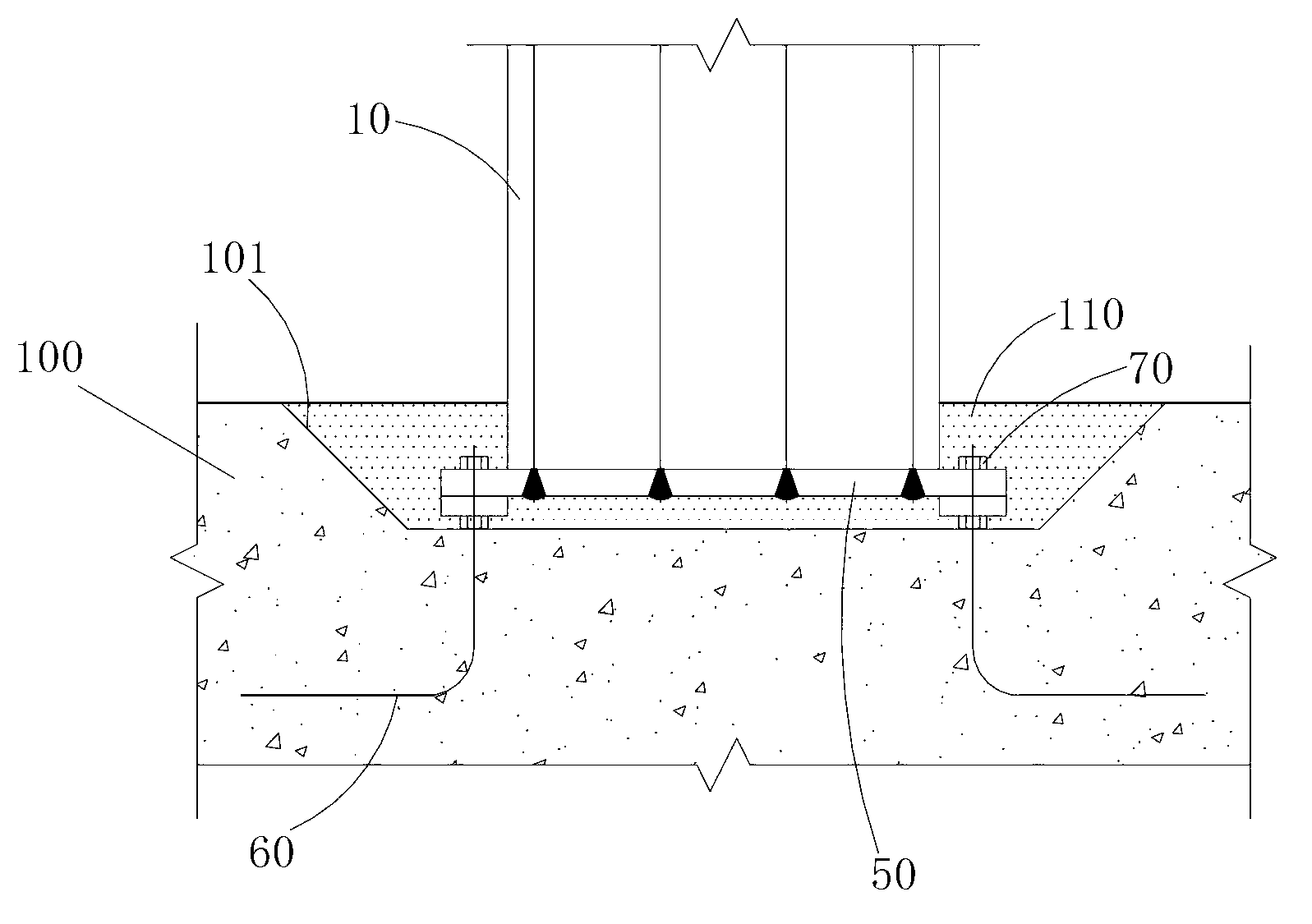

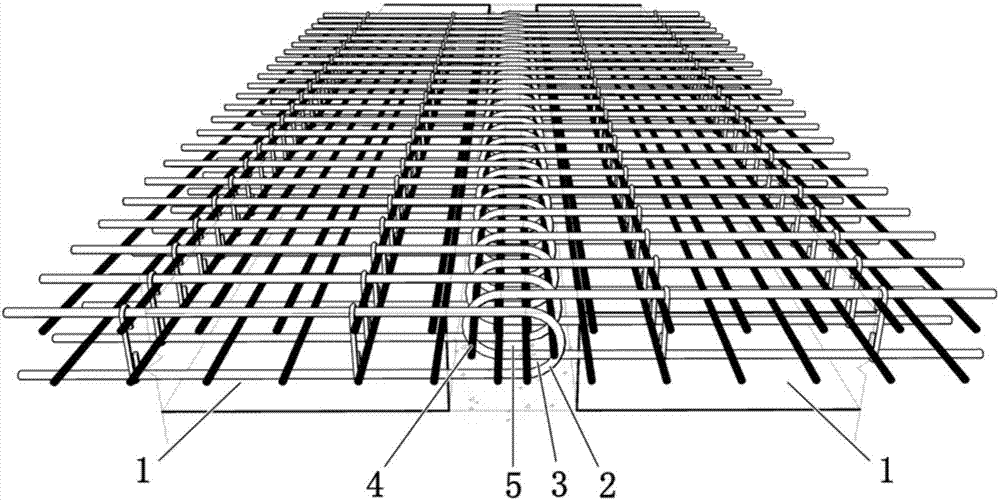

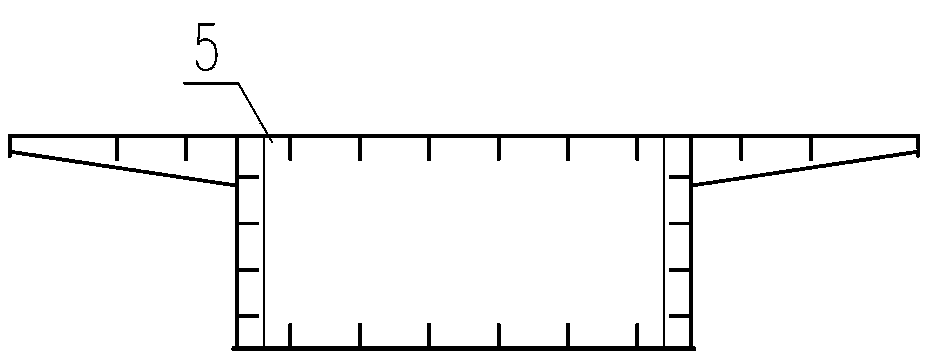

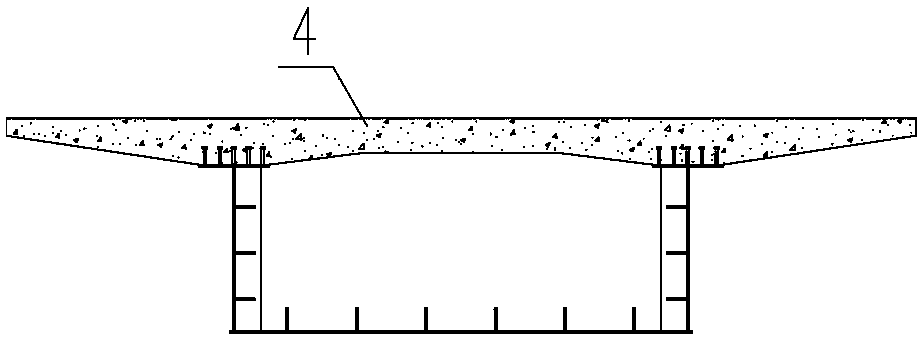

Assembled monolithic concrete large-span frame structure system and assembling method thereof

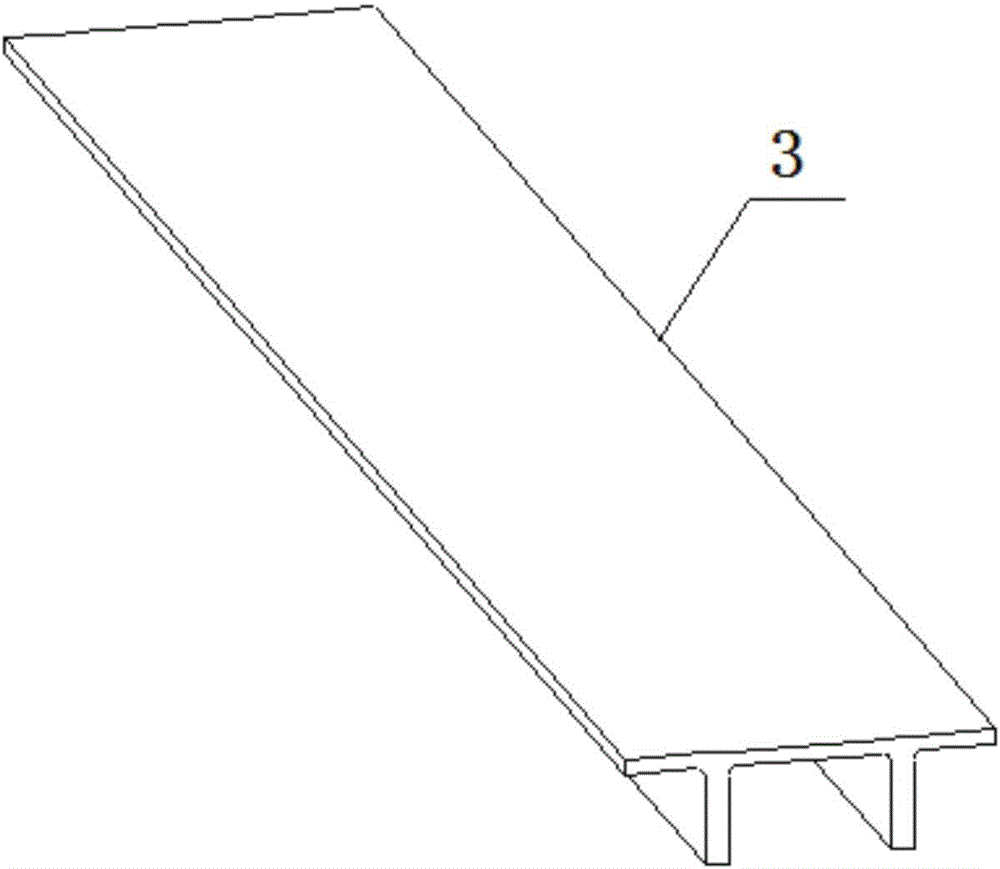

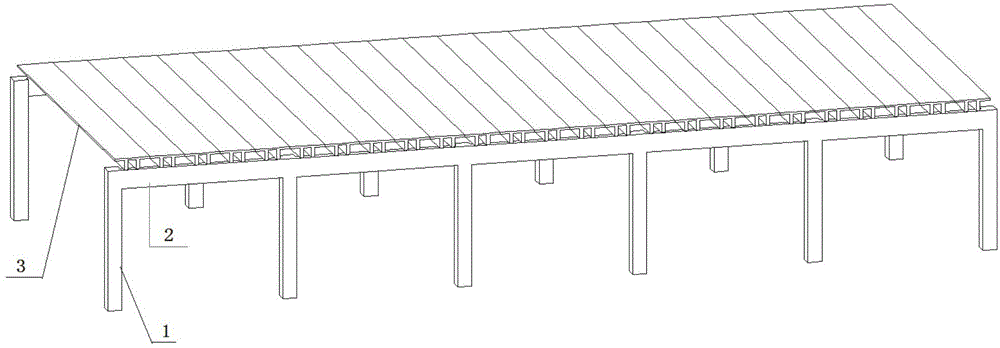

ActiveCN104612246AEasy to useLow costConstruction materialStrutsIndustrial constructionEconomic benefits

The invention provides an assembled monolithic concrete large-span frame structure system and an assembling method thereof. The assembled monolithic concrete large-span frame structure system comprises prefabricated frame columns, prefabricated frame beams, prefabricated truss beams and prefabricated plates. The prefabricated frame columns are connected with the prefabricated frame beams and the prefabricated truss beams respectively. The prefabricated plates are connected with the prefabricated frame beams. The assembled monolithic concrete large-span frame structure system comprises the prefabricated frame columns, the prefabricated frame beams, the prefabricated truss beams and the prefabricated plates, and all the components are prefabricated and produced in factories; the assembled monolithic concrete large-span frame structure system can be spliced on a construction site; the span of 40 meters or lower can be achieved, the requirement for functions of various public buildings and industrial buildings is met, and cost is greatly reduced; in addition, as an advanced industrial building, the assembled monolithic concrete large-span frame structure system comprises the components which are all prefabricated and produced in factories, and therefore the workloads on the construction site are greatly reduced, the construction period is greatly shortened, and good economic benefits are achieved.

Owner:青岛九屋建筑安装有限公司

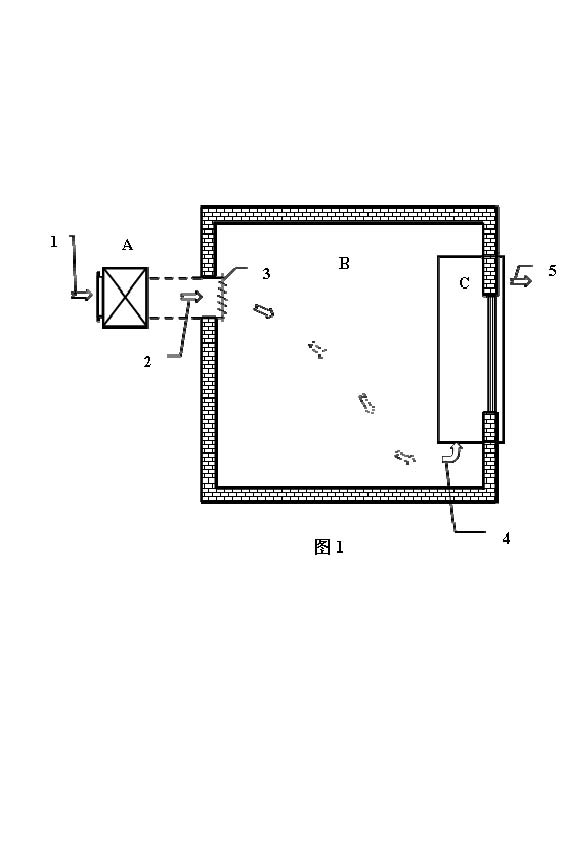

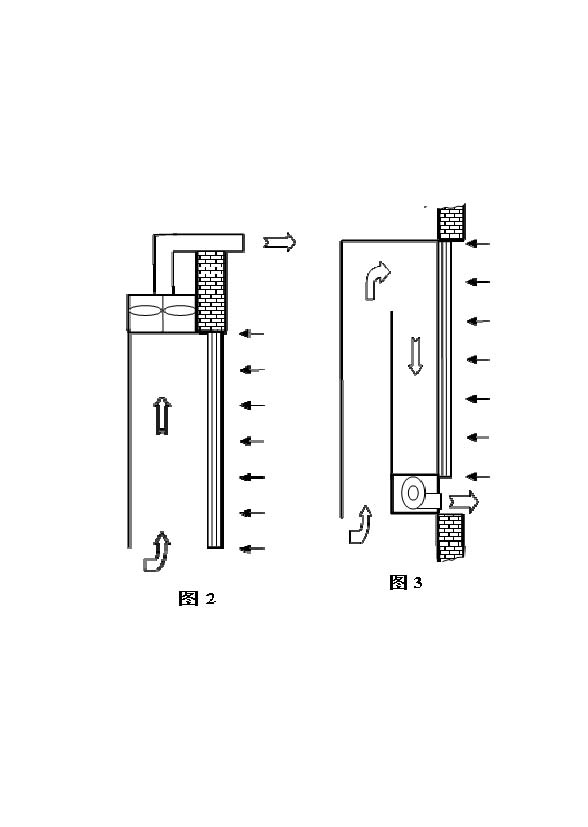

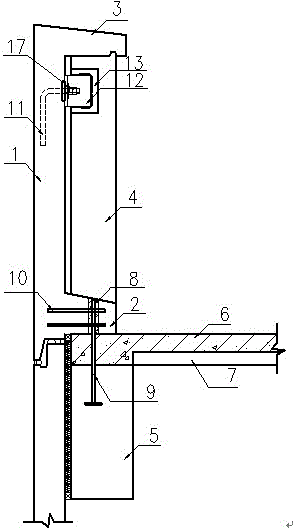

Passive cooling air conditioning method and device thereof

ActiveCN101922775AReduce heat gainReduce loadEnergy recovery in ventilation and heatingHeat recovery systemsIndustrial constructionActive cooling

The invention discloses a passive cooling air conditioning method and a device thereof. The passive cooling air conditioning method is as follows: air out of an air conditioning area is processed by an air processer to be sent into the air conditioning area, and exhausted air in the air conditioning area is discharged out of the air conditioning area after passing through the exhausted air cavity of a passive cooling integration device. The invention can be applied in various air conditioning systems, can combine active cooling and passive cooling into a whole, takes the active cooling mode to carry out air conditioning in the air conditioning area and drastically adsorbs the solar radiation energy of translucency building envelope in a passive cooling mode, thus effectively lowering indoor air conditioning load; air output is lowered, the overall dimension of the unit is reduced, the section surface of the air hose is lowered, so that the air hose is easy to cooperate with building space, and cost is low. The invention is suitable for air conditioning in rooms of various living buildings, public buildings, industrial buildings and the like and is especially applied in various buildings of dry and tropic regions.

Owner:于向阳

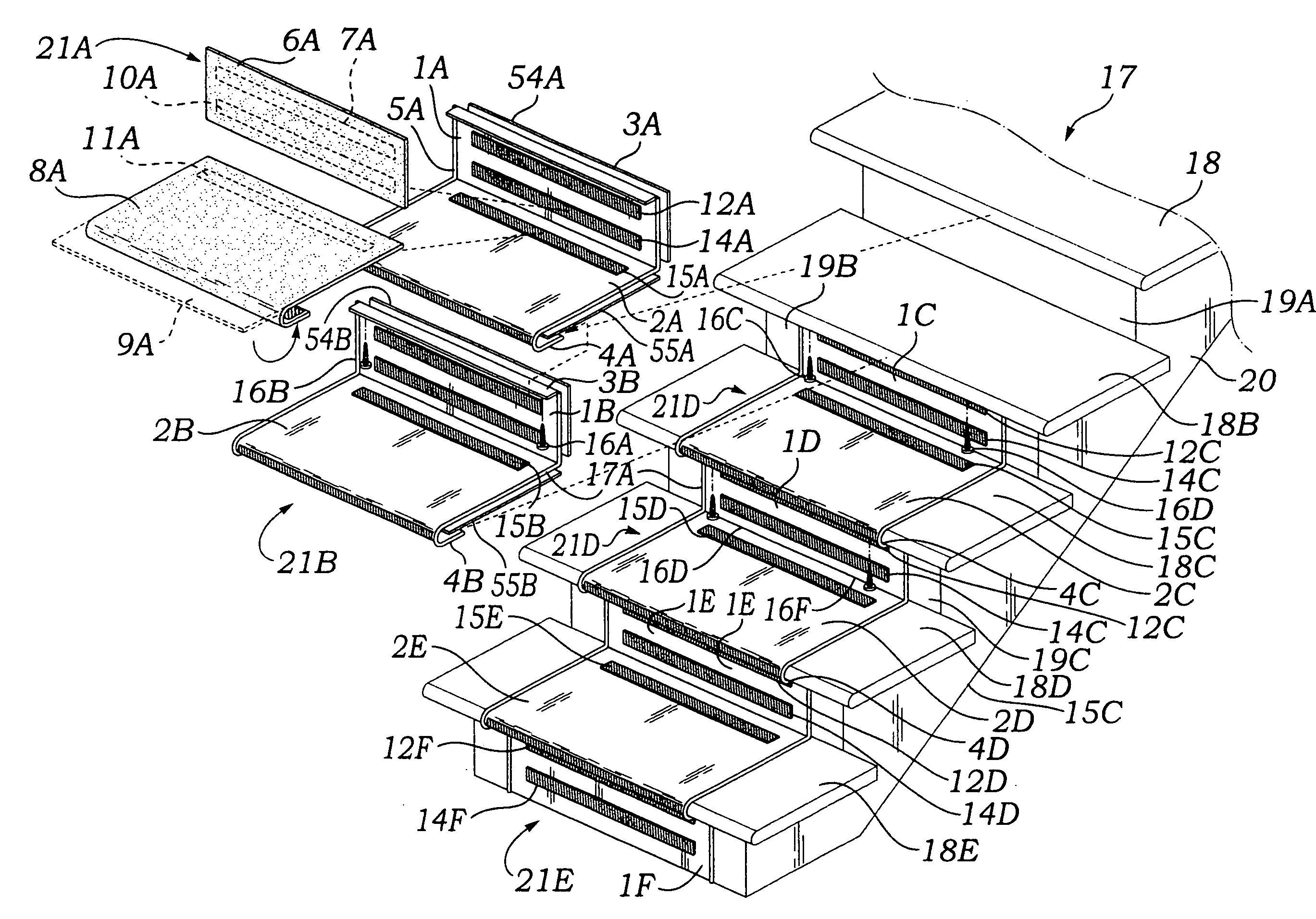

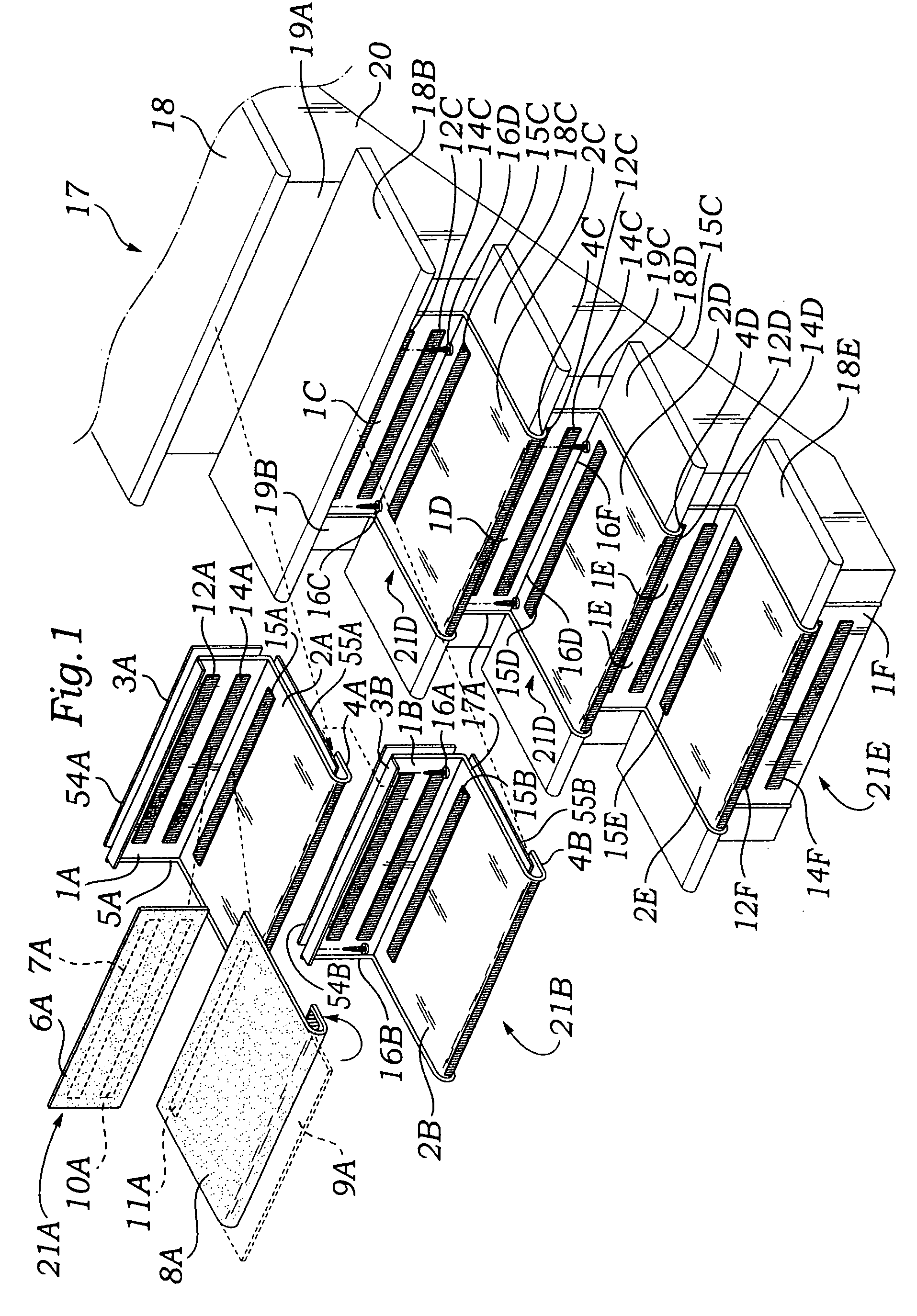

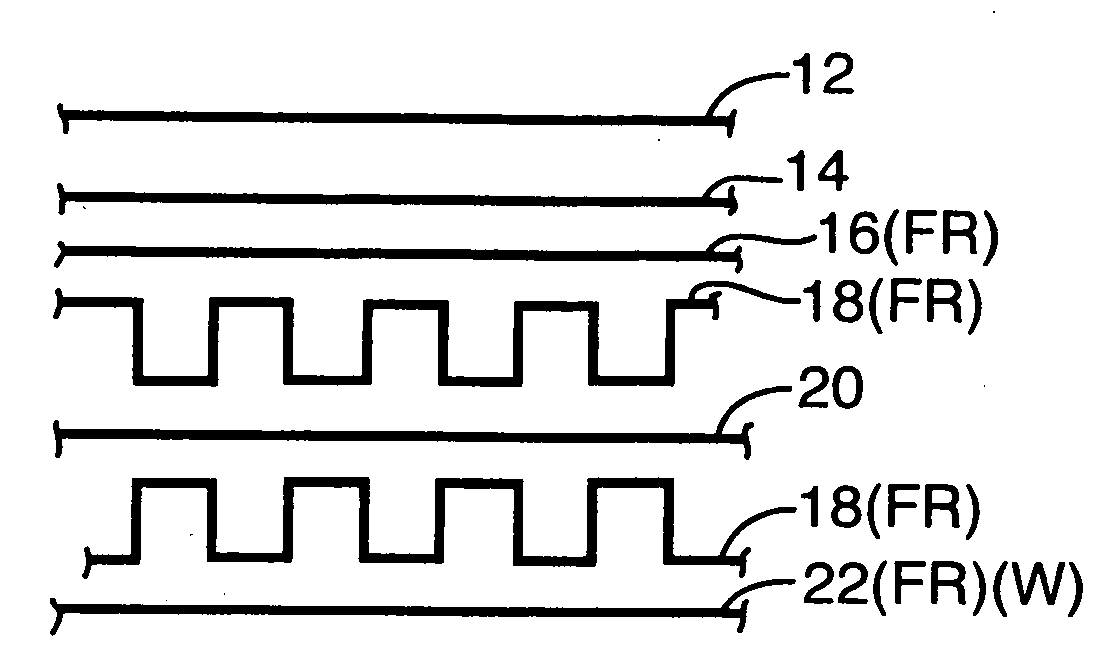

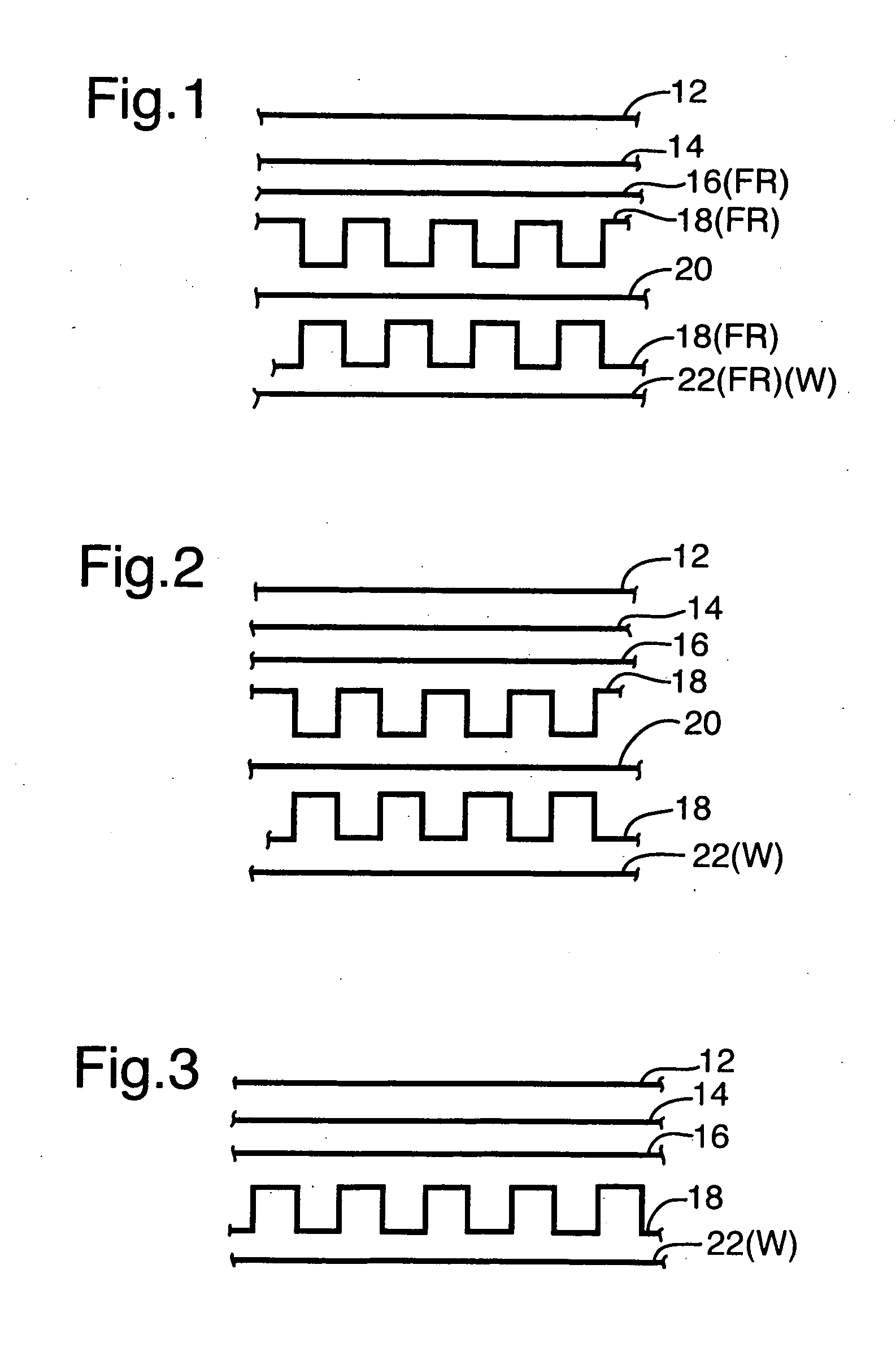

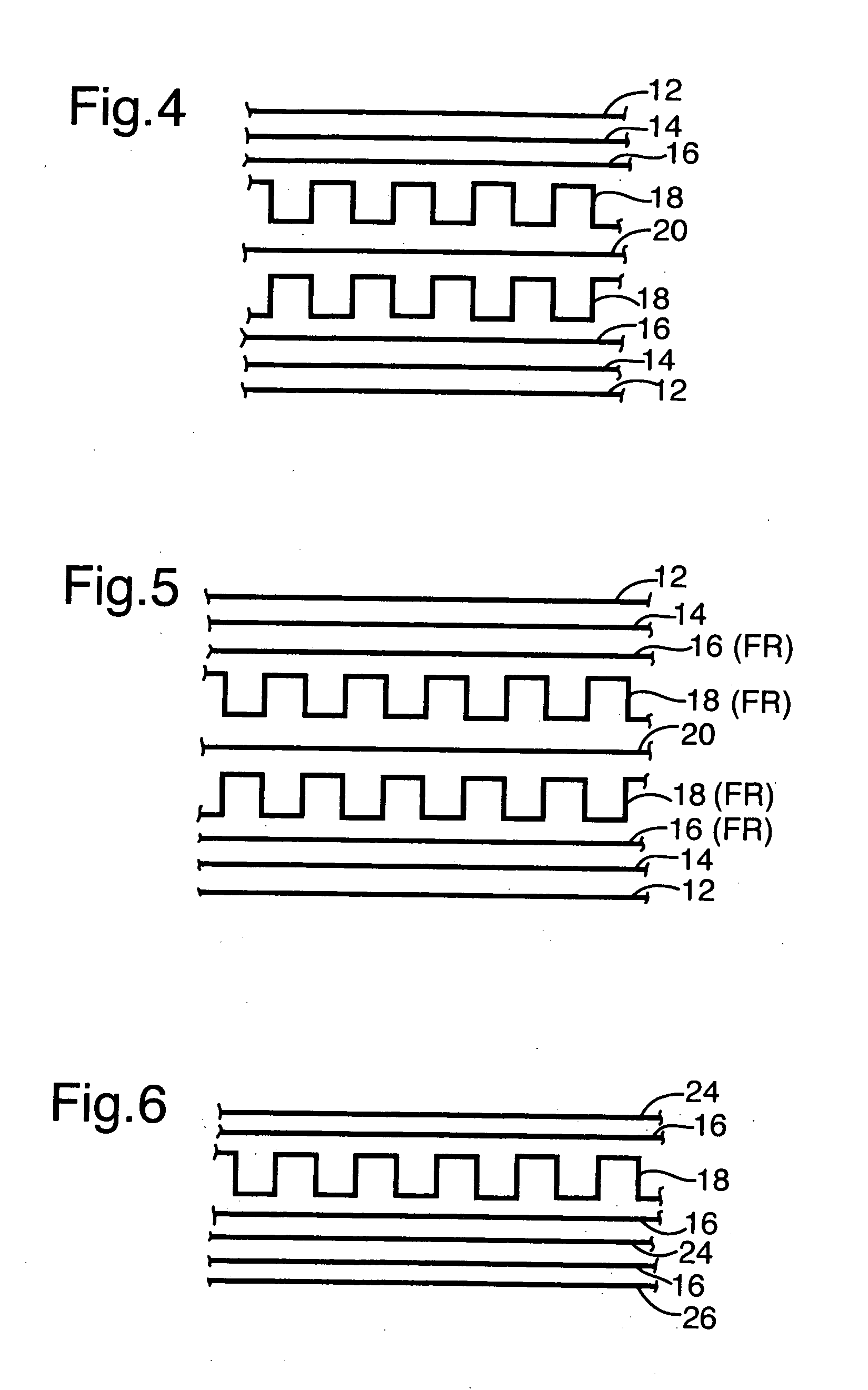

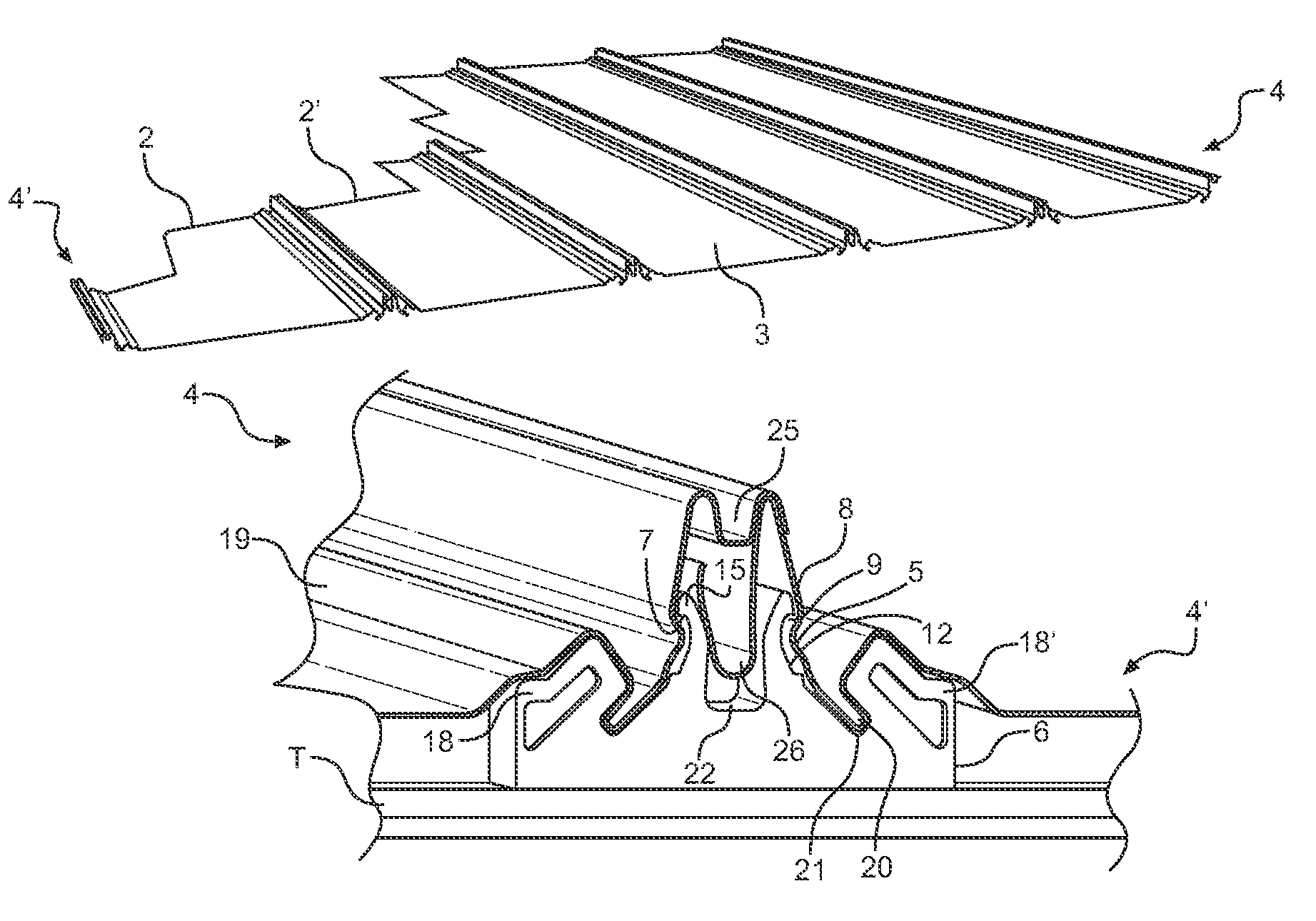

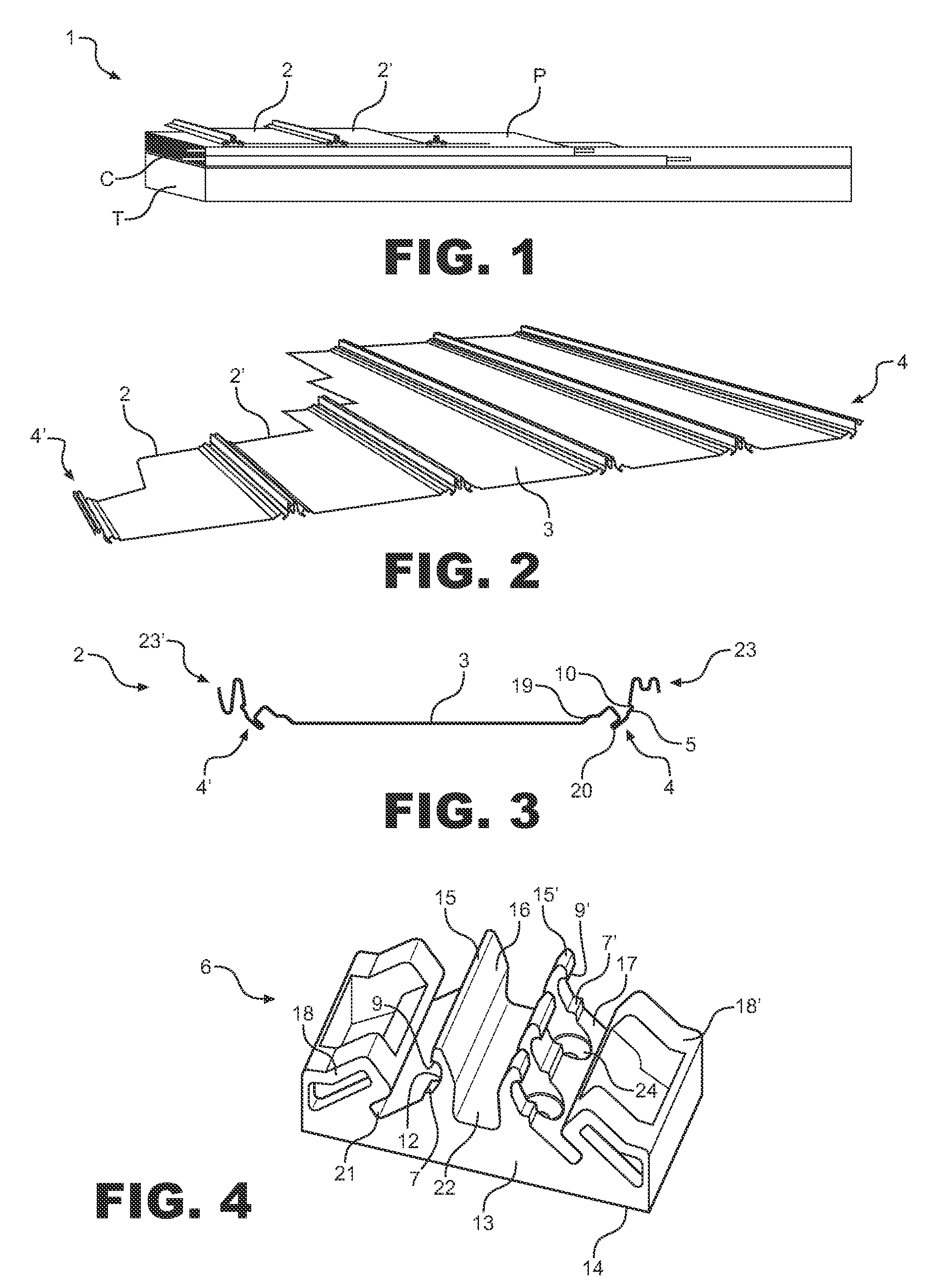

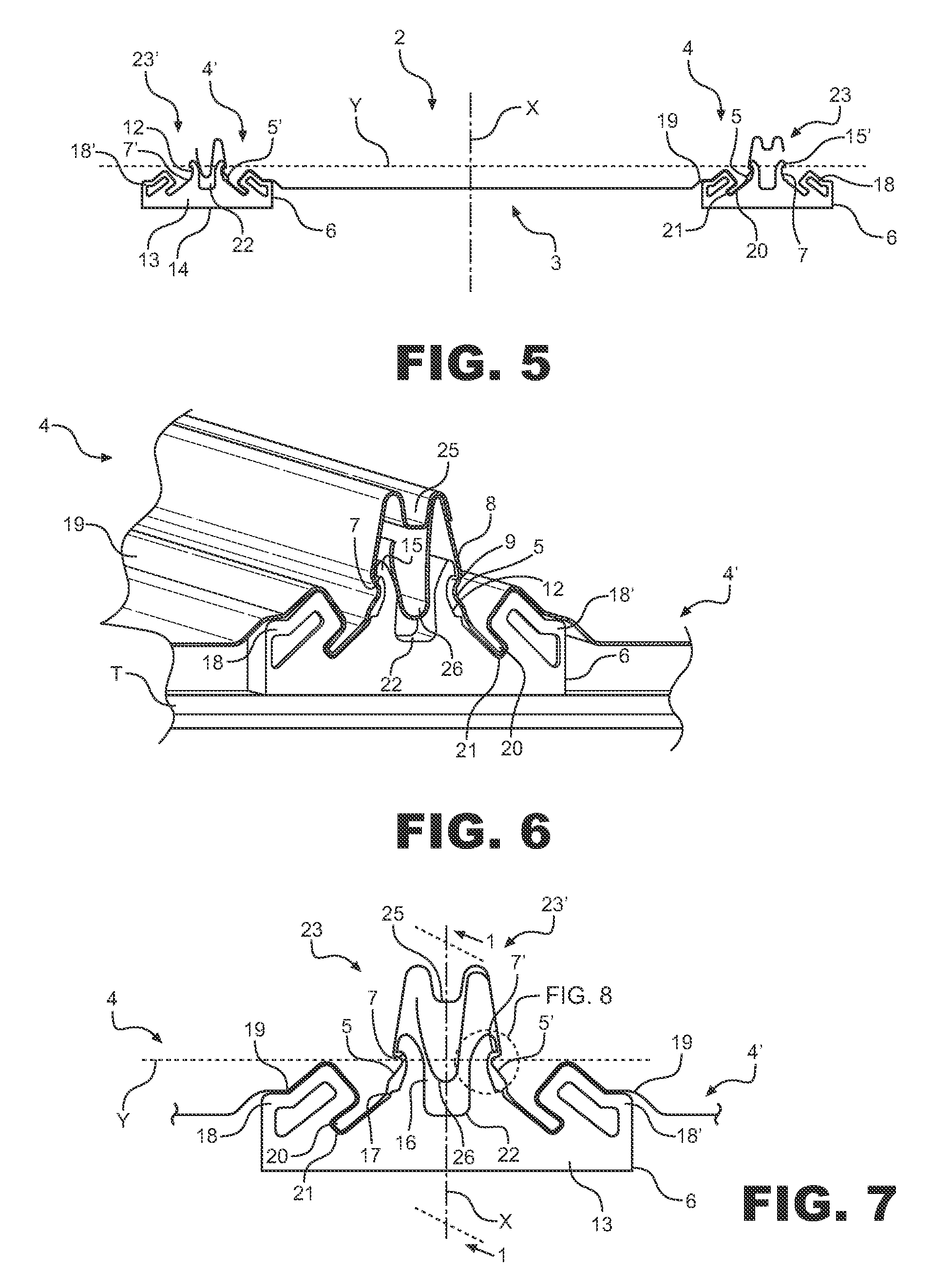

Roofing assembly including sheet panels having side edge portions with projections mating with grooves on brackets anchored to roof

ActiveUS7712278B2Improve efficiencyRelatively cost-effectiveRoof covering using slabs/sheetsRoof covering using tiles/slatesIndustrial constructionHigh resistance

A roofing structure for buildings, and more particularly a roofing assembly having high resistance, especially for use with roofs of residential and industrial buildings. The assembly comprises a plurality of sheet panels to be interconnected along side edge portions shaped to define a first longitudinal projection facing laterally outwards, and multiple mounting brackets to be anchored to a roof. Each bracket has at least one longitudinal groove to house in a snap fit relationship the first longitudinal projections of adjacent panels, so that the first longitudinal projections and the groove have opposing upper surfaces at least partly flat and substantially parallel or slightly inclined, in order to enhance the retaining action of the brackets and increase the separation load causing the separation of the edge portions from the brackets.

Owner:ISCOM SPA

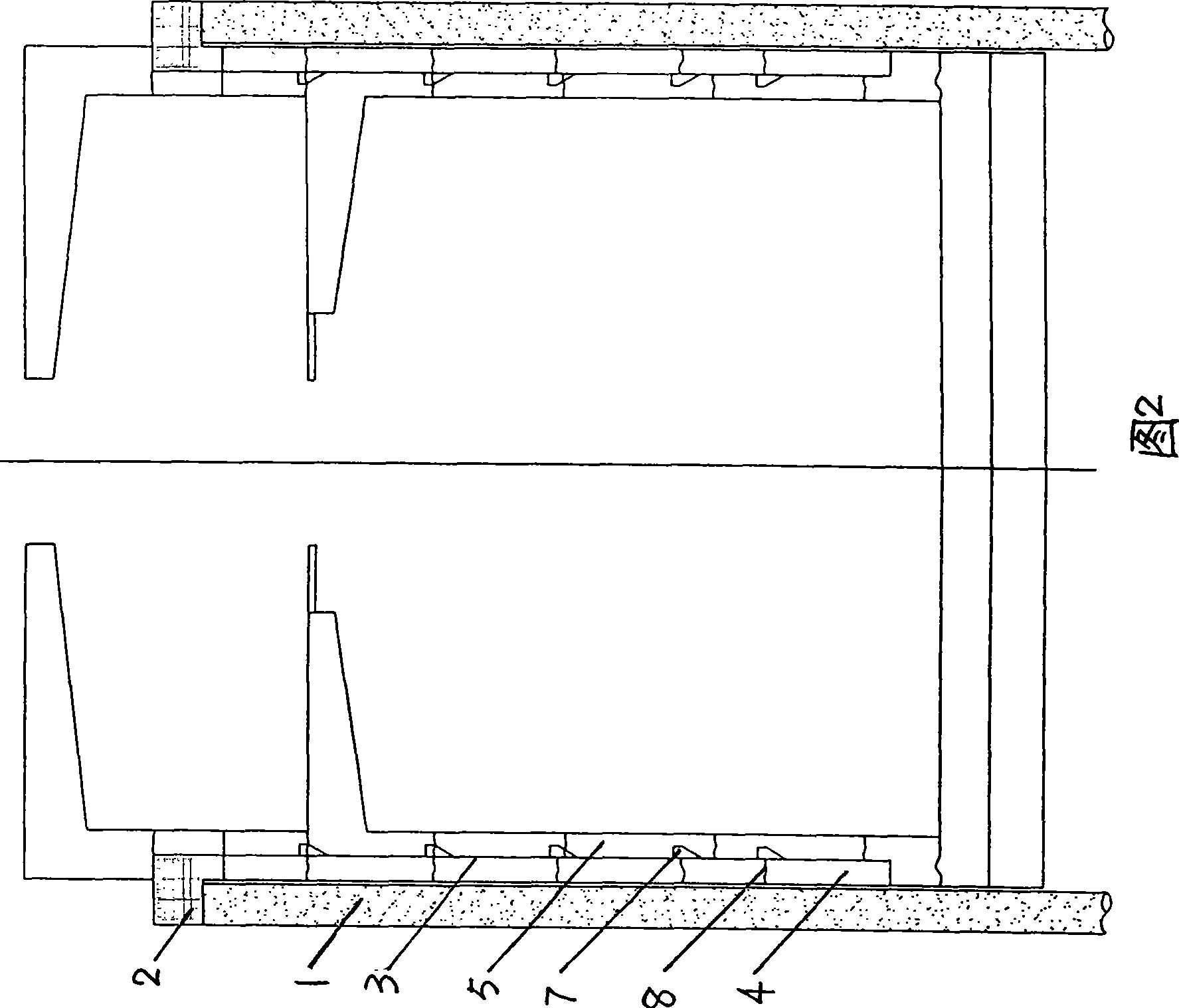

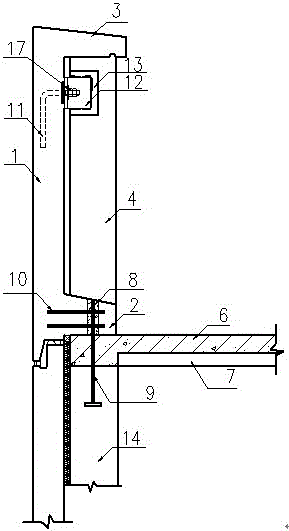

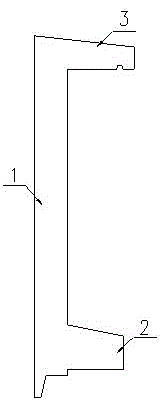

Industrial construction method for multistory residence system with clamp die frame core wall self-bearing structure

ActiveCN102140842AImprove insulation effectLight weightWallsBuilding material handlingIndustrial constructionEarthquake resistance

The invention relates to an industrial construction method for a multistory residence system with a clamp die frame core wall self-bearing structure. The construction of a bearing wall comprises the following steps of: (1) pre-embedding connecting steel bars on a footing of the bearing wall and a concrete foundation beam; (2) arranging a precast wall plate with a light core material between the connecting steel bars of the foundation beam in an aligned mode; (3) respectively arranging the stressed steel bars of a constructional column and a beam, respectively connecting the connecting steel bars of the constructional column and the beam, and arranging the clamp dies of the constructional column and the beam to ensure that the left and right ends and / or the upper end of the wall plate is coated in the clamp die of the constructional column and / or the clamp die of the beam; and (4) spraying concrete onto surfaces on the two sides of the wall plate, and casting the constructional column and the beam in situ. By the construction method, a large number of templates can be saved, the construction speed is obviously increased, the construction period is shortened, cost is reduced, the strength, impact resistance, earthquake resistance and overall performance of the constructed multistory residence system are obviously improved, the dead weight of the system is reduced, and the systemhas good energy conversation, heat insulation and sound insulation effects.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +1

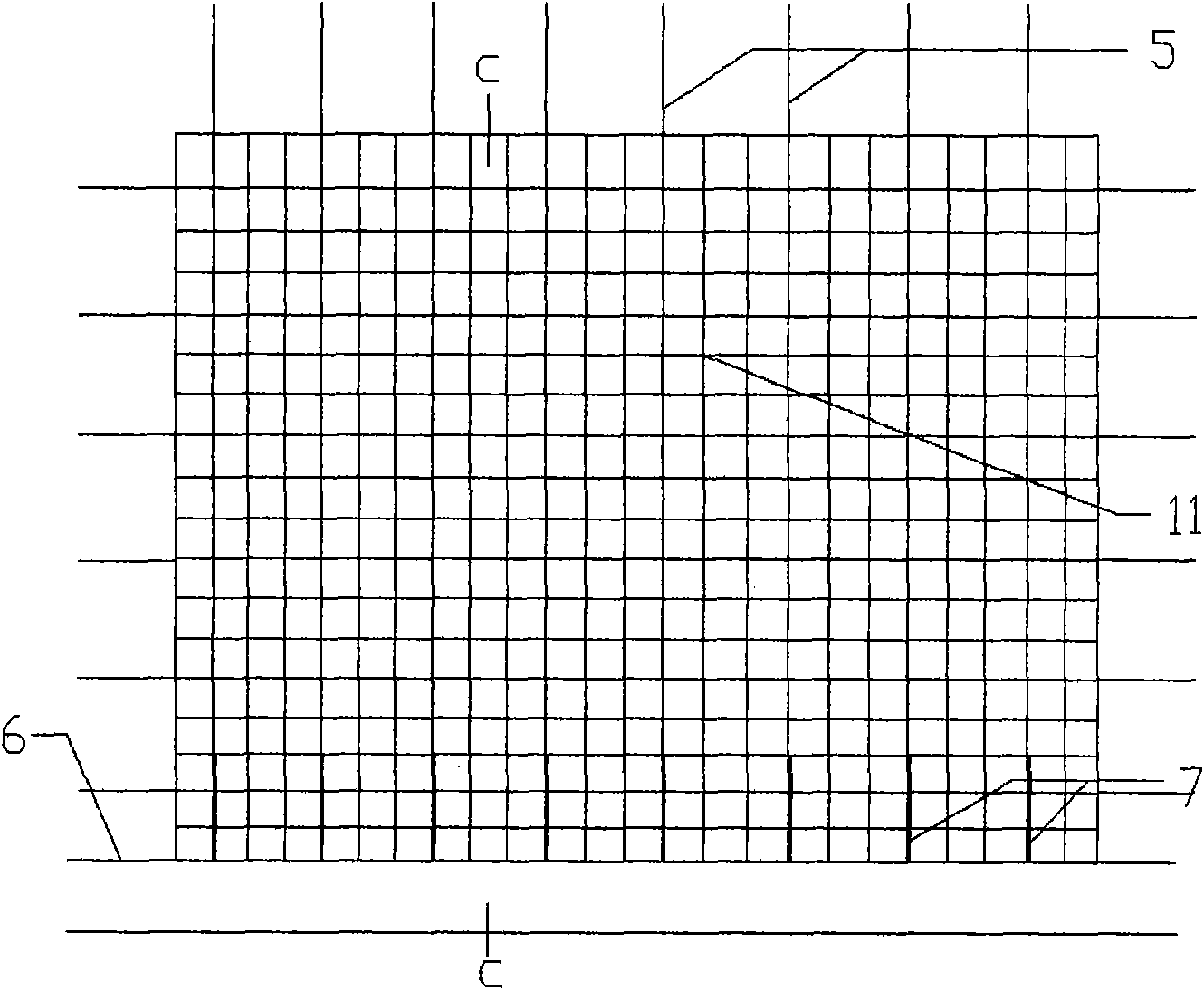

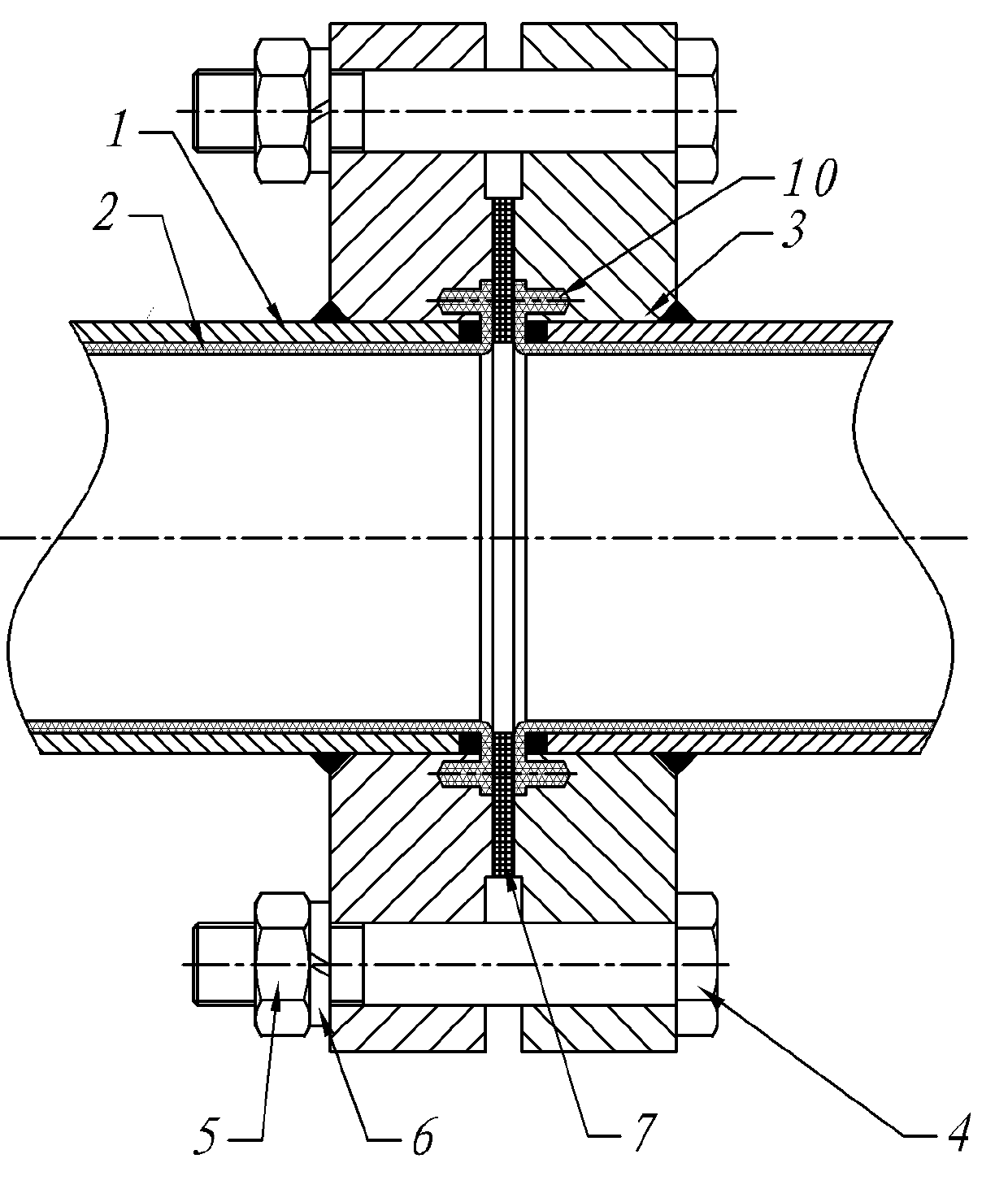

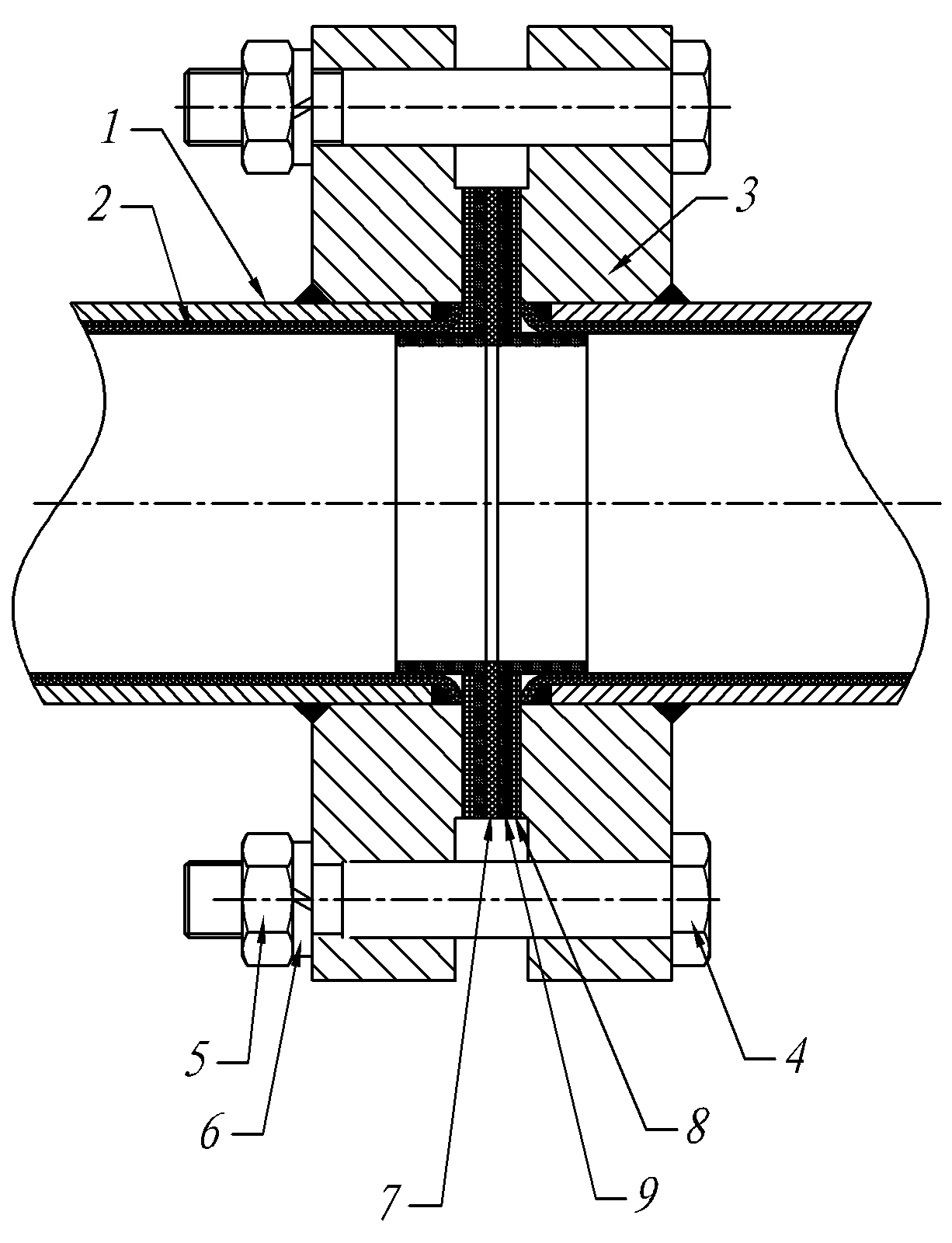

Crack-prevention intelligent pipeline connecting equipment used for large and smart city industrial buildings

ActiveCN105526459APrevent frost crackingImprove securityFlanged jointsThermal insulationIndustrial constructionThermal insulation

The invention discloses crack-prevention intelligent pipeline connecting equipment used for large and smart city industrial buildings. The crack-prevention intelligent pipeline connecting equipment comprises a first connecting sleeve and a second connecting sleeve, wherein both the first connecting sleeve and the second connecting sleeve adopt hollow structures, the exteriors of the first connecting sleeve and the second connecting sleeve are sleeved with protection covers, heating slots arranged spirally are formed in the inner walls of the protection covers, heating wires are arranged in the heating slots, each protection cover adopts an inner-outer two-layer structure, the heating slots are positioned in the inner walls of the inner layer structures of the protection covers, a cavity is arranged between the inner layer and the outer layer of each inner-outer two-layer structure, thermal insulation sponges are respectively adhered to the end surfaces, in opposite direction, of the inner-outer two-layer structures, mutual connection of two sections of pipelines is achieved through the first connecting sleeve and the second connecting sleeve, moreover, the protection covers and the heating wires are adopted, heating to pipelines to increase the temperature is achieved, and pipeline cracks under a low temperature state are avoided.

Owner:天津市景联科技有限公司

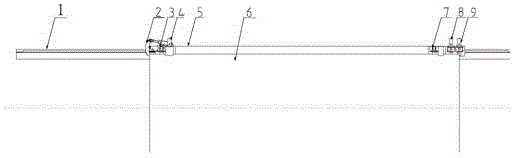

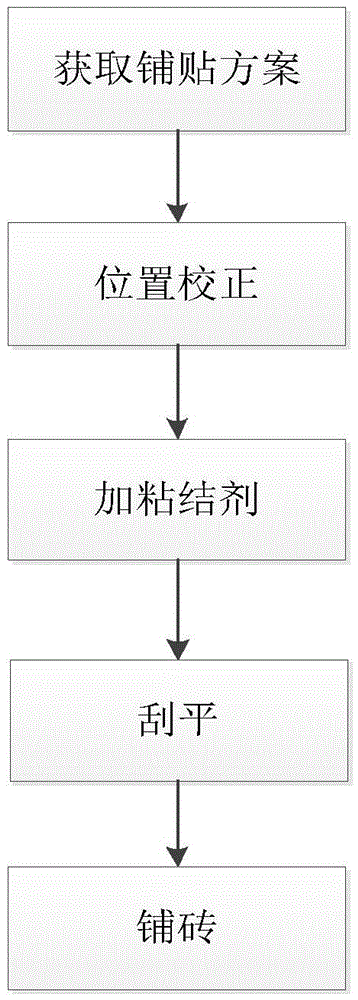

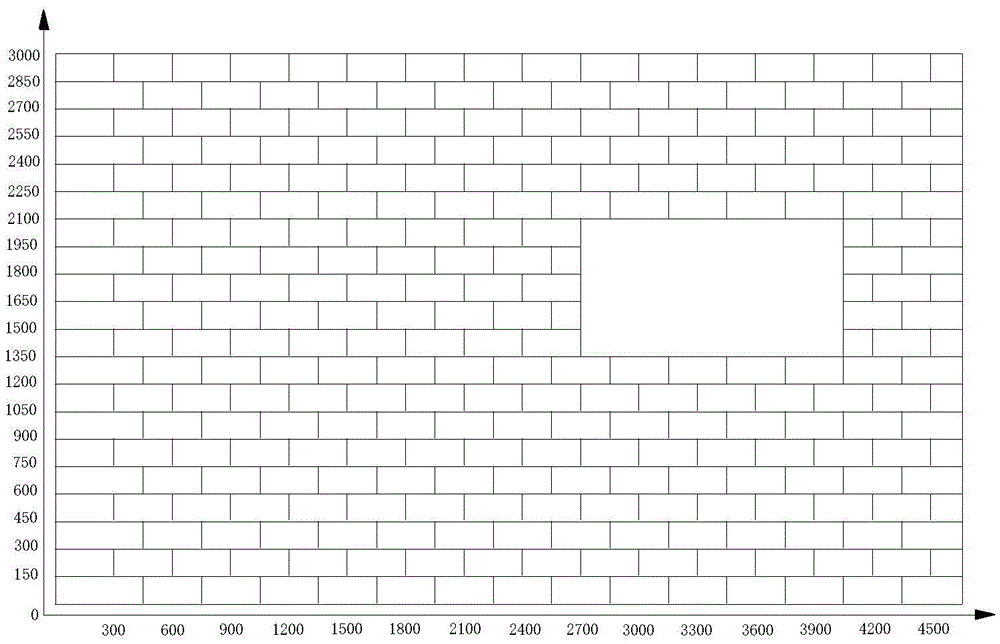

Tiling method

ActiveCN105644124AImprove tiling accuracyImprove tiling efficiencyLamination ancillary operationsLaminationProduction lineIndustrial construction

The invention discloses a tiling method. The method comprises steps as follows: a tiling scheme is obtained, wherein the tiling scheme comprises coordinate information of tiles arranged at to-be-tiled parts; tiling is performed, tiling equipment tiles the to-be-tiled parts with the tiles according to the coordinate information on the basis of the tiling scheme. According to the tiling method, the accurate coordinate information of the tiles at the to-be-tiled parts is acquired, then the tiling equipment is controlled to tile coordinate-determined specific positions with the tiles, the method is suitable for industrial construction, in particularly to the tiling of prefabricated parts on a prefabricated part production line, the tiling efficiency of the prefabricated parts can be improved, and the tiling effect of the prefabricated parts is tidier and more attractive.

Owner:SANY AUTOMOBILE MFG CO LTD

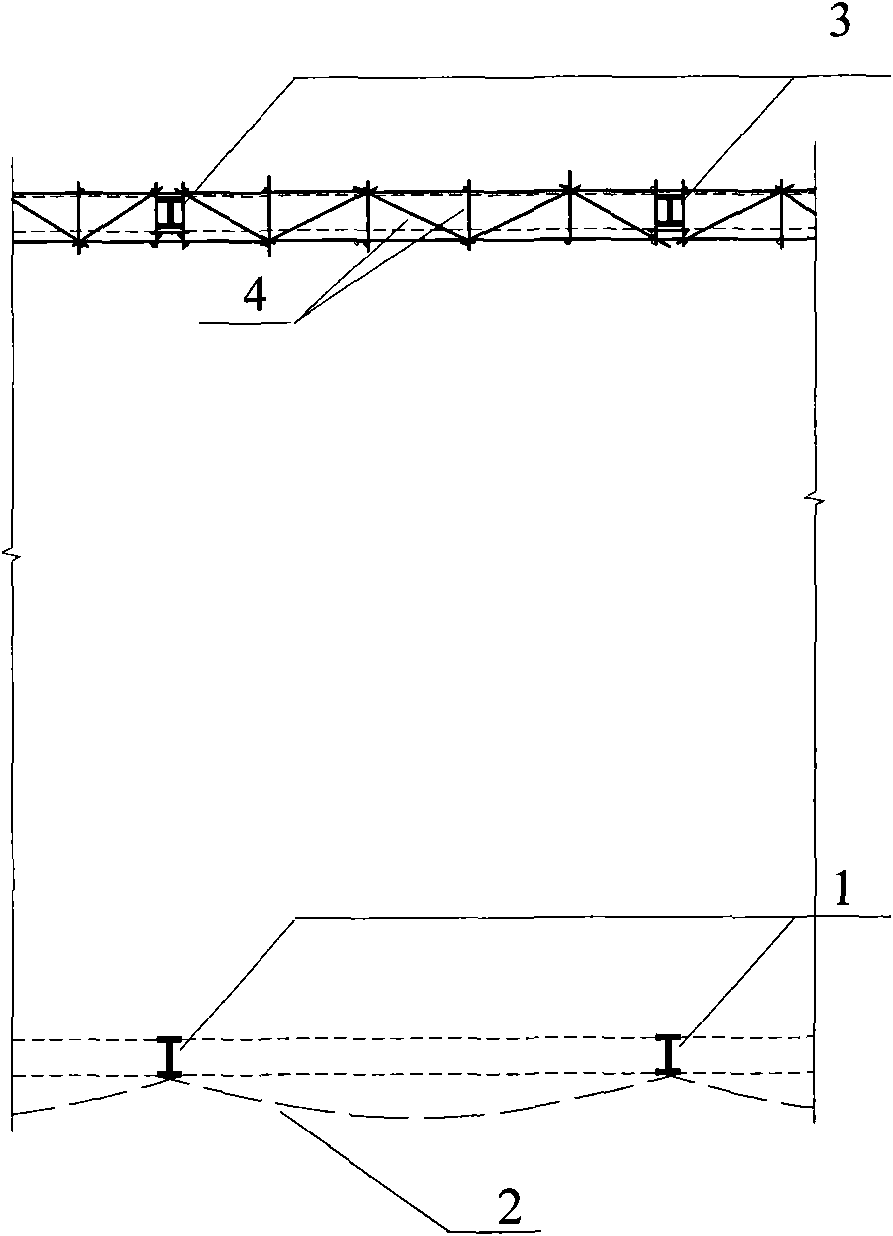

Method for installing pipeline scaffold of steel roof equipment and rigid suspended scaffold

InactiveCN101775896AImprove structural rigidityImprove stabilityBuilding support scaffoldsIndustrial constructionArchitectural engineering

The invention discloses a method for installing a pipeline scaffold of steel roof equipment and a rigid suspended scaffold. The rigid suspended scaffold comprises a plurality of steel pipe upper trusses with same structures and a plurality of suspended scaffolds with same structures, wherein each steel pipe upper truss is built between at least two upper chords of a steel roof along the vertical running direction of an equipment pipeline, and the steel pipe upper trusses are connected with each other into a whole; each suspended scaffold is suspended and built below each steel pipe upper truss along the running direction of the equipment pipeline, and the length of a suspended overhead corridor formed by the longitudinal connection of the suspended scaffolds is the same as that of the corresponding equipment pipeline. In the invention, building floor type scaffolds is not needed, and high-performance special installing machinery is not needed, thereby saving construction period and cost. The invention is suitable for public buildings, such as long-spun sports and culture stadiums and the like, and equipment pipeline construction in the steel roofs of large-scale industrial buildings and the like.

Owner:ZHEJIANG UNIV +2

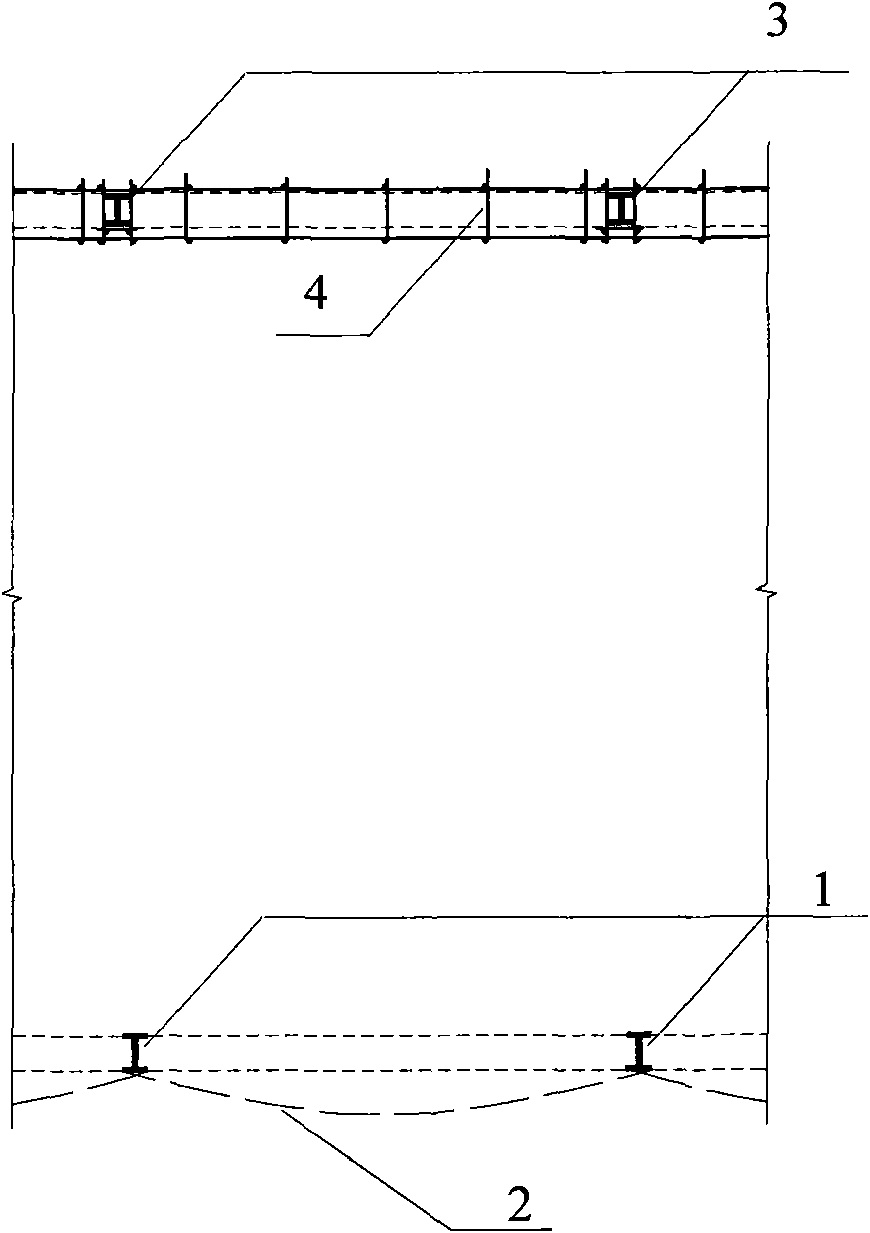

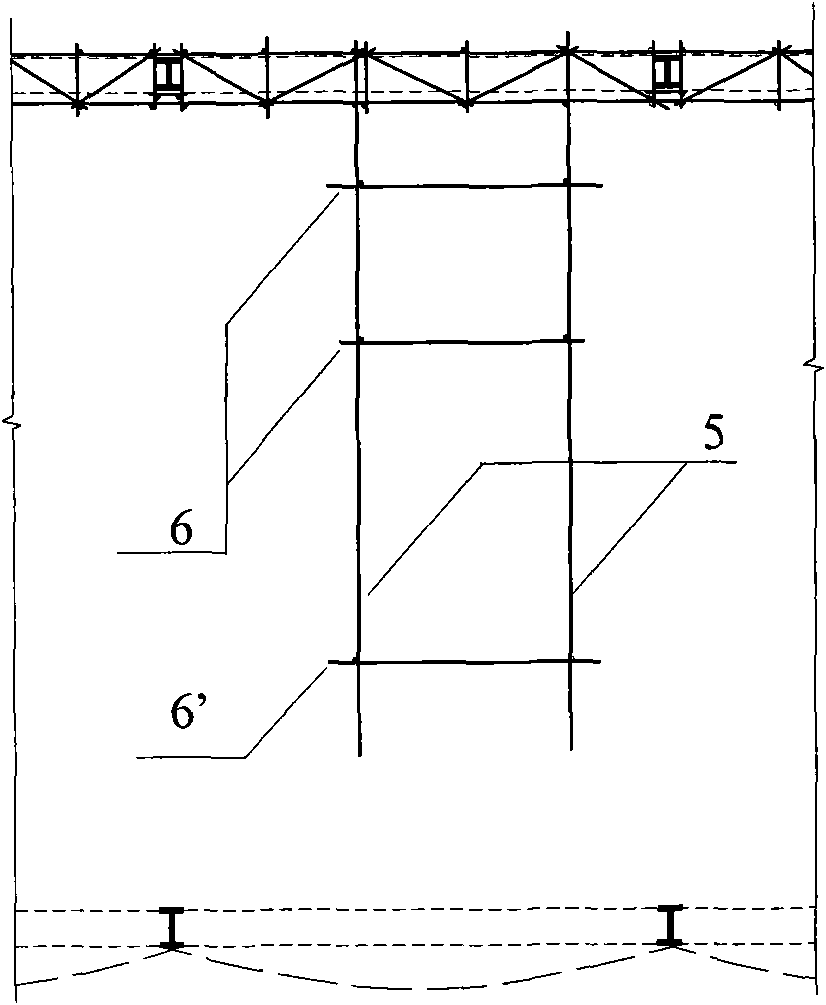

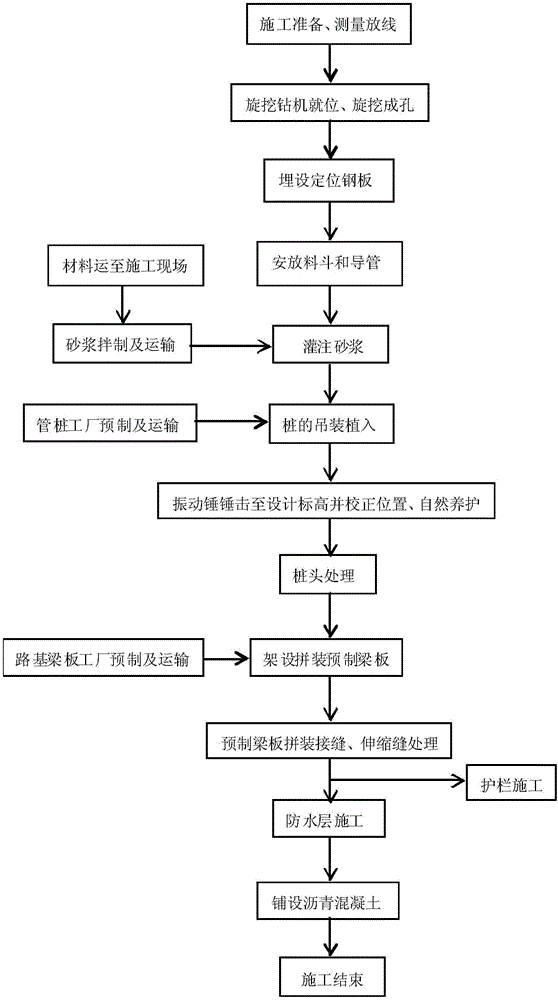

Construction process for pile slab type non-soil roadbed highway

ActiveCN106320120AShorten the construction periodImprove project qualityRoadwaysBulkheads/pilesIndustrial constructionExpansion joint

The invention relates to a construction process for a pile slab type non-soil roadbed highway. In the process, a rotary drilling rig is used for rotary drilling to form holes, after the holes are formed, cement mortar is poured into the pile holes, then prefabricated tubular piles are vertically hoisted and then are implanted into the pile holes, a vibratory hammer is started to hammer so that the tubular piles are effectively in contact with the bottoms of the pile holes, then natural curing is carried out after perpendicularity and plane positions of the tubular piles are corrected, pile heads are treated, prefabricated beam slabs are erected and assembled, assembling joints and expansion joints of the prefabricated beam slabs are treated, a waterproof layer is constructed, in the period, guard bars are mounted, asphalt concrete is paved, and then construction is finished. The construction process has the outstanding advantages that a roadbed does not require to be heightened by soil, a large use amount of earthwork is reduced, and meanwhile, permanent occupation of a highway roadbed is reduced. The process conforms to development tendency of industrial construction, standard design, industrial production and specialized construction can be realized, moreover, a construction period is greatly shortened, engineering quality is improved, construction cost is reduced, and working hours can be shortened by about 20%.

Owner:安徽省经工建设集团有限公司

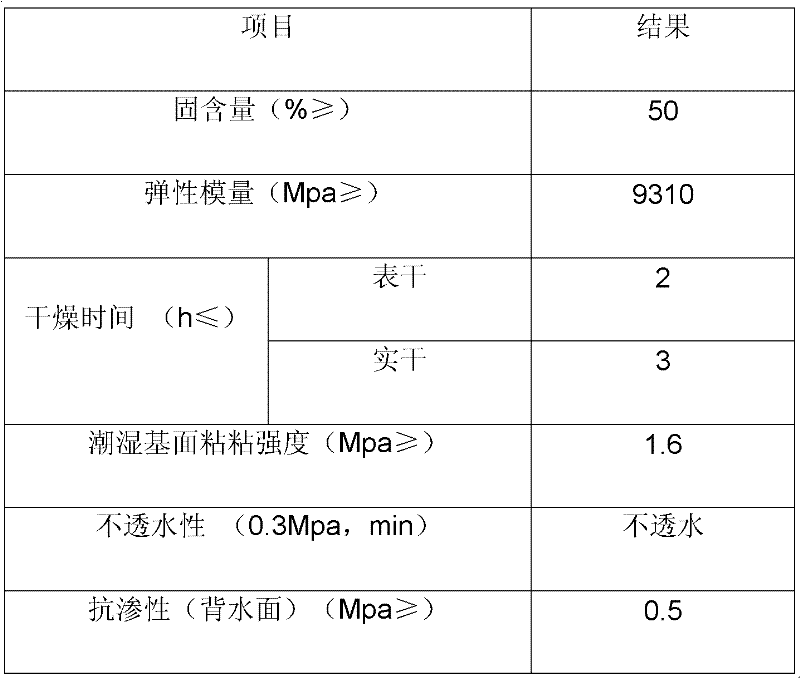

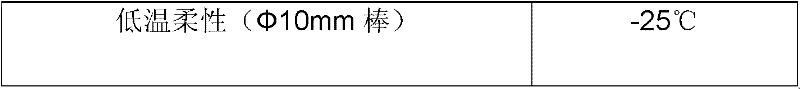

Polymer cement waterproof material and preparation method thereof

InactiveCN102173683AGood compatibilityAvoid demulsificationSolid waste managementIndustrial constructionFiber

The invention relates to a polymer cement waterproof material and a preparation method thereof. The polymer cement waterproof material comprises silicate cement, a polyacrylate / polyurethane composite emulsion, a water reducing agent, fibers, river sands and other materials according to a certain weight proportion. The polymer cement waterproof material has the characteristics, such as high strength and easiness of adhesion to wet substrate, of cement gel materials, and also has the characteristics, such as high elasticity and good water resistance, of polymer coatings. The polymer cement waterproof material is mainly applied to waterproofing in various industrial constructions, civil constructions, bridges, tunnels, traffic transportation and other industries and fields.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

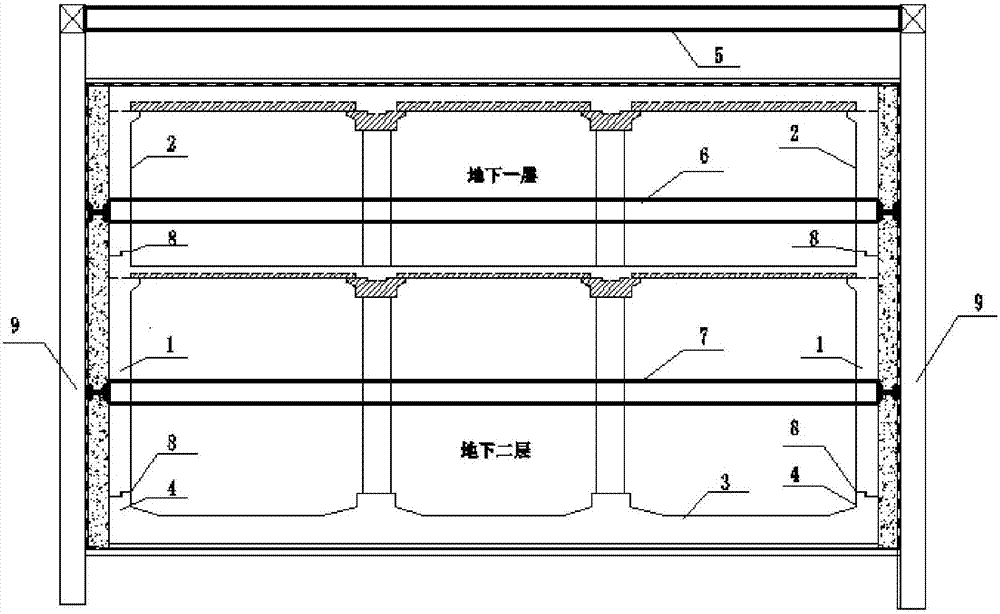

Industrial construction method of building

ActiveCN103306483AReduce in quantityReduce pollutionBuilding material handlingIndustrial constructionFloor slab

The invention discloses an industrial construction method of a building, which comprises the following steps that S1, a prefabricated member is fabricated in advance; S2, the prefabricated member fabricated in advance is transported to a construction site; S3, a prefabricated column is mounted; S4, a prefabricated beam is mounted; S5, a prefabricated floor slab is mounted; S6, concrete is poured and covered at the top of the prefabricated column, on the prefabricated beam and the prefabricated floor slab, and among the prefabricated column, the prefabricated beam and the prefabricated floor slab; the prefabricated beam and the prefabricated floor slab are connected to form a top slab which is fixed at the top of the prefabricated column; and S7, a prefabricated external wall is mounted: the prefabricated external wall is positioned and mounted on the prefabricated beam and the prefabricated column at the periphery of the top slab. According to the method, each member of the building is industrially produced in advance, then is transported to the construction site for mounting, and finally is connected into a whole by casting joints in place, so that the construction difficulty is reduced, the construction progress is increased, industrial production and mounting are realized, the efficiency and the quality are improved, and the engineering cost and the material consumption are reduced.

Owner:CHINA STATE CONSTR HAILONG TECH CO LTD

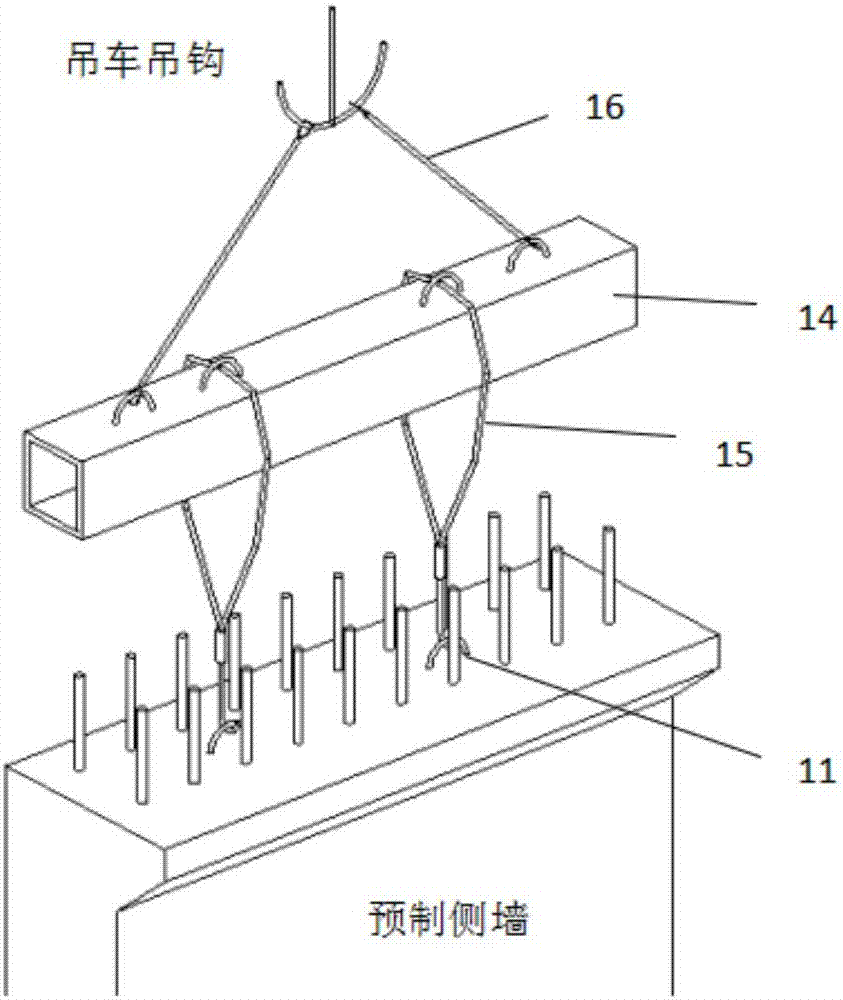

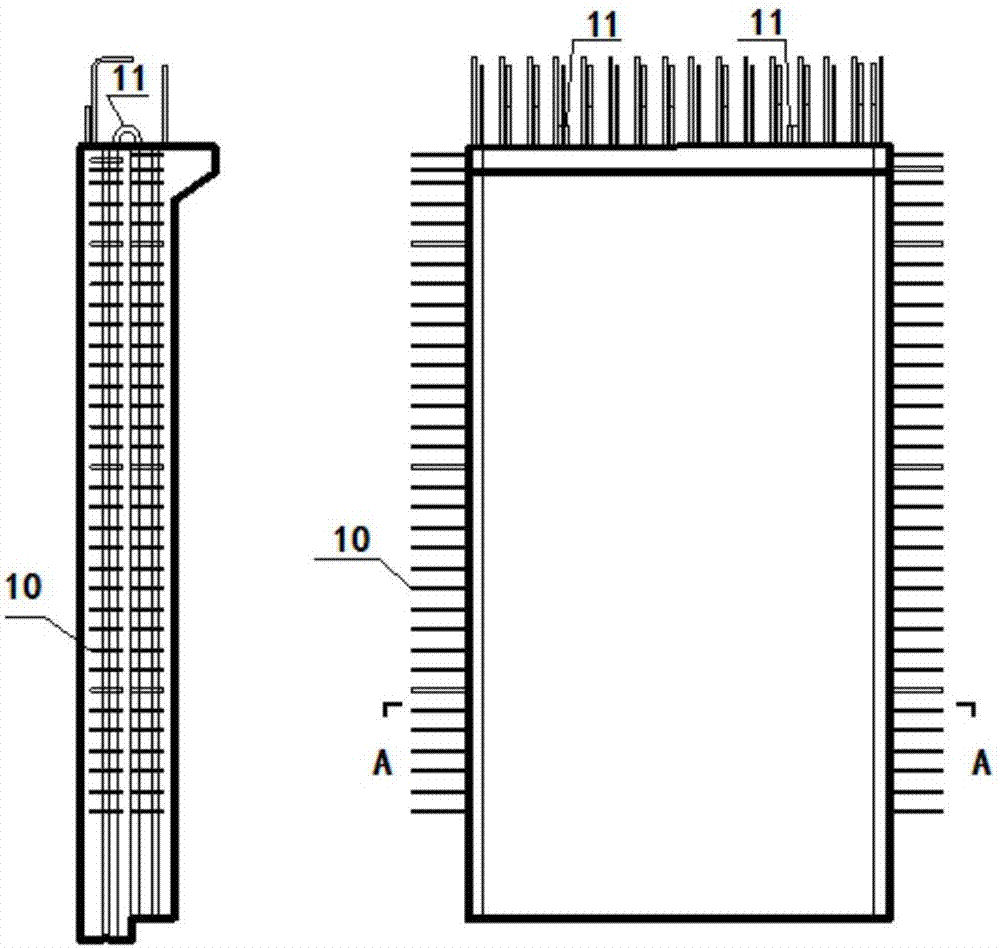

Precast side wall splicing construction method for open-cut assembled subway station

The invention provides a precast side wall splicing construction method for an open-cut assembled subway station. By adoption of the precast side wall splicing construction method, the demand on the labor force and the consumption of on-site building turnovers of traditional subway station cast-in-place side wall construction are greatly lowered, wet-working operation on the construction site is greatly reduced, such pollution as dust raising, noise and the like of the construction site are relieved, and the influence on the ambient environment of the construction site is reduced. On the construction site, a precast side wall splicing trolley is adopted to guarantee accurate aligning and splicing of side walls, so that the mechanical degree of construction is improved, and the project demand on the labor force is lowered. Owing to use of lots of precast members, the overall construction quality and the construction efficiency of related projects are remarkably improved, and a foundation is laid for industrial construction popularization.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +2

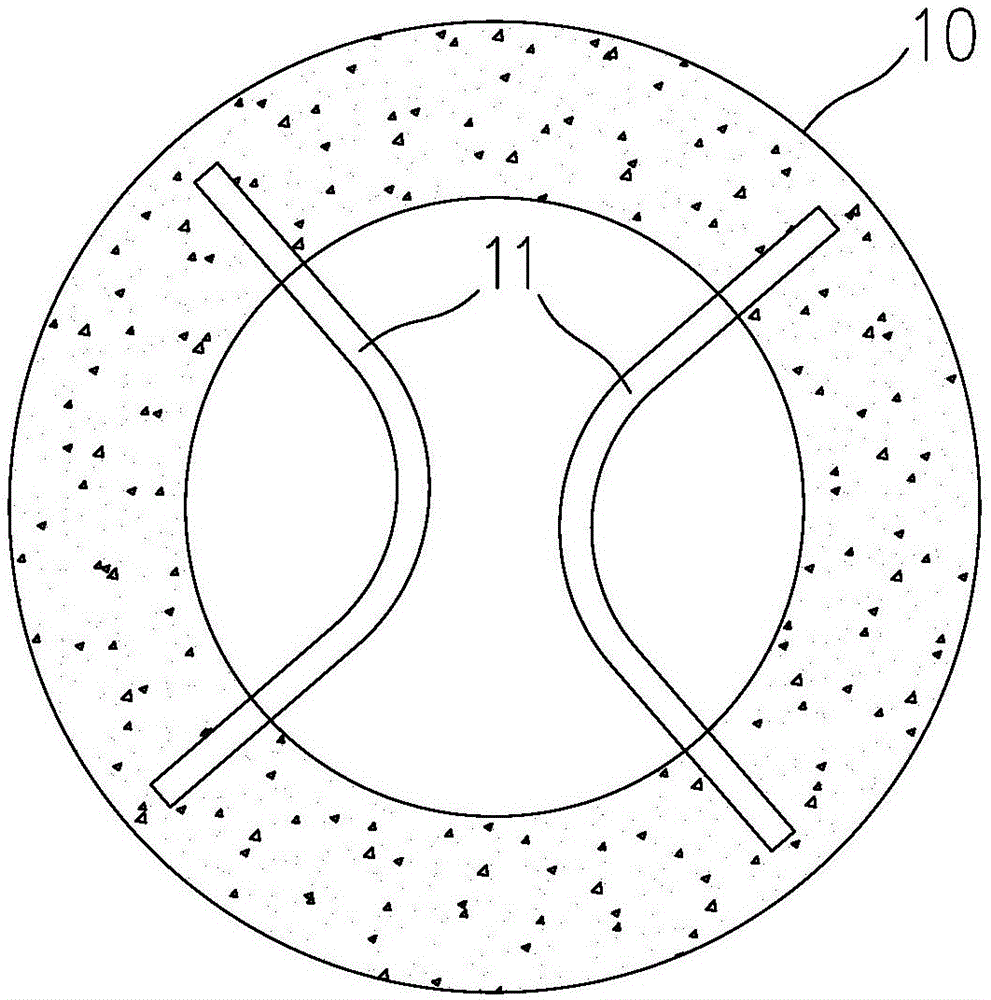

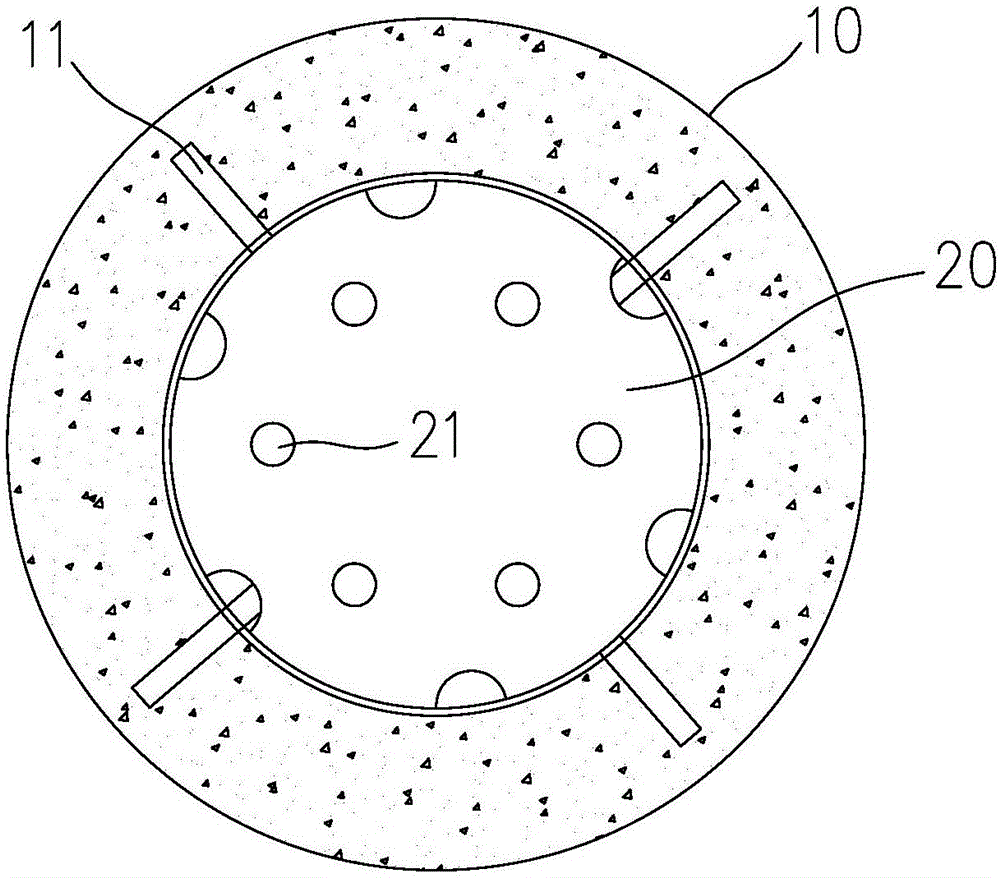

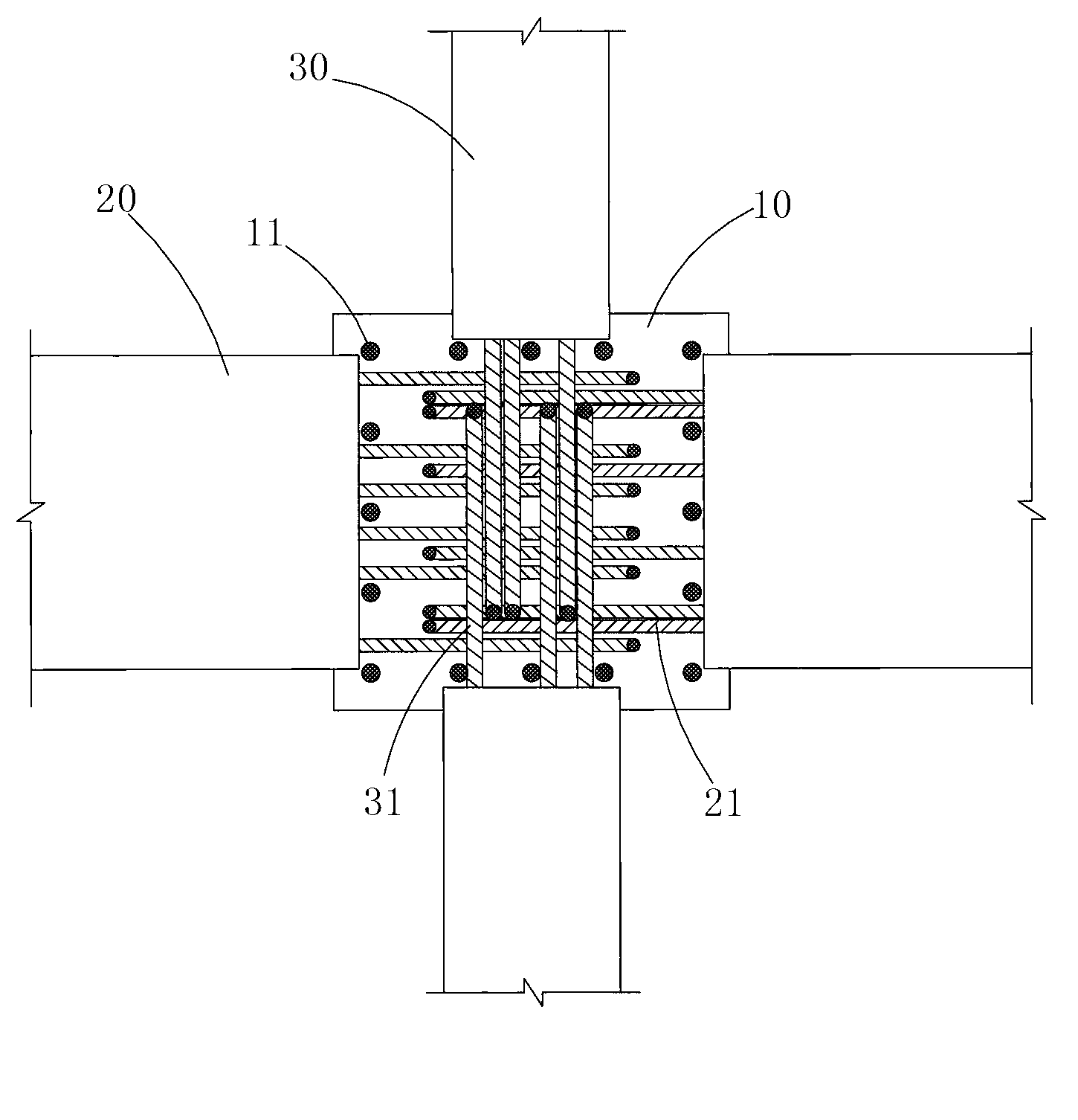

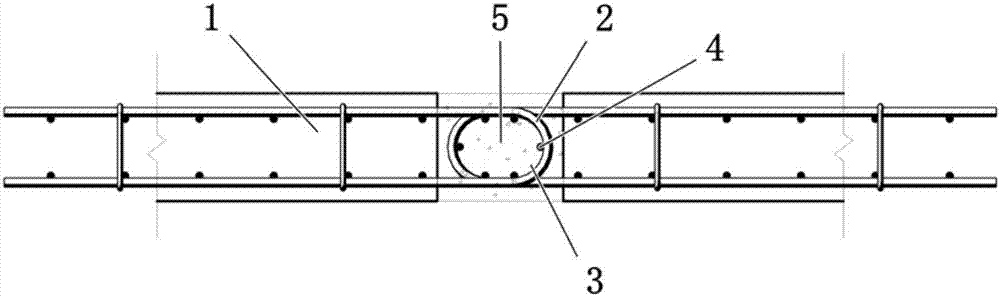

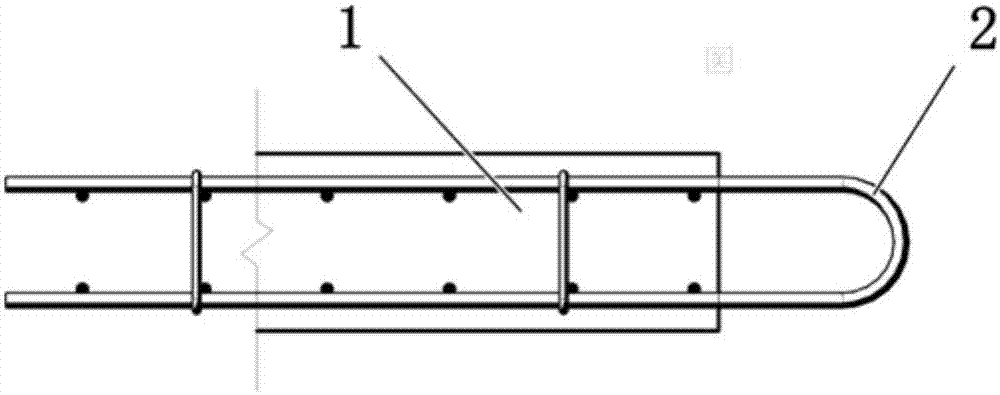

O-shaped steel bar connecting structure

InactiveCN106948494AFirmly connectedUnique working principleBuilding reinforcementsIndustrial constructionSteel bar

The invention relates to an O-shaped steel bar connecting structure. The O-shaped steel bar connecting structure comprises two rows of U-shaped steel bars arranged on different concrete components. The two rows of the U-shaped steel bars are oppositely overlapped and crossed to form the O-shaped steel bar structure which is internally provided with a plurality of supporting cushion steel bars and forms anchorage-type connecting through pressure-bearing concrete pouring. According to the O-shaped steel bar connecting structure, a traditional mode and a force-transferring mechanism of steel bar connecting are changed, the width of a wet joint formed by connecting is greatly reduced to be less than half of the width of a non-welding wet joint of a traditional steel bar, steel bar connecting and component jointing are simplified, material using is reduced, engineering cost is reduced, the workload is greatly reduced, construction site quick connecting of factory precast concrete components is achieved, and development of a bridge girder industrial construction technology is promoted.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

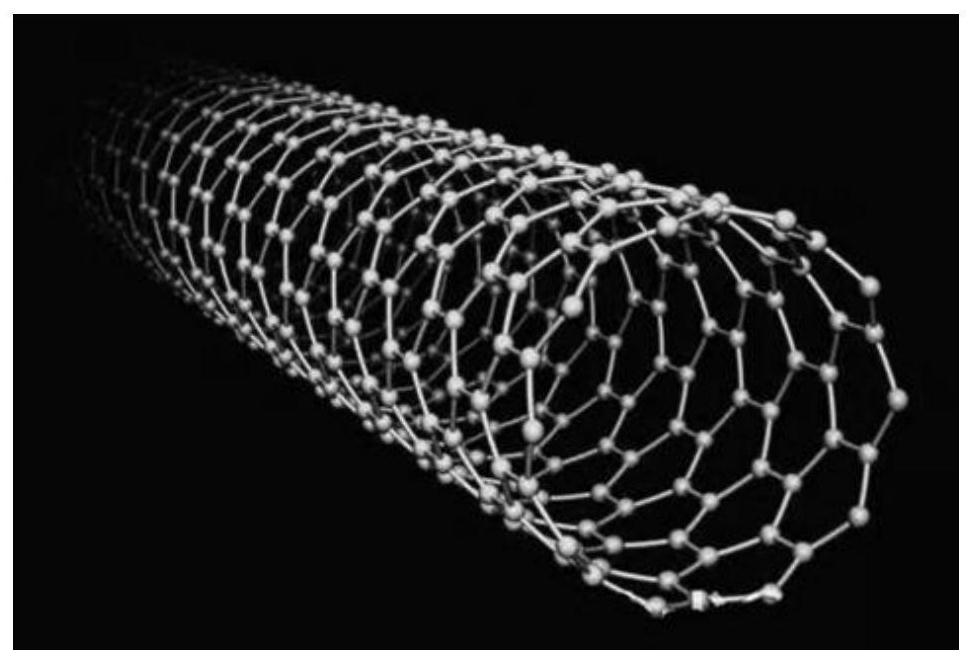

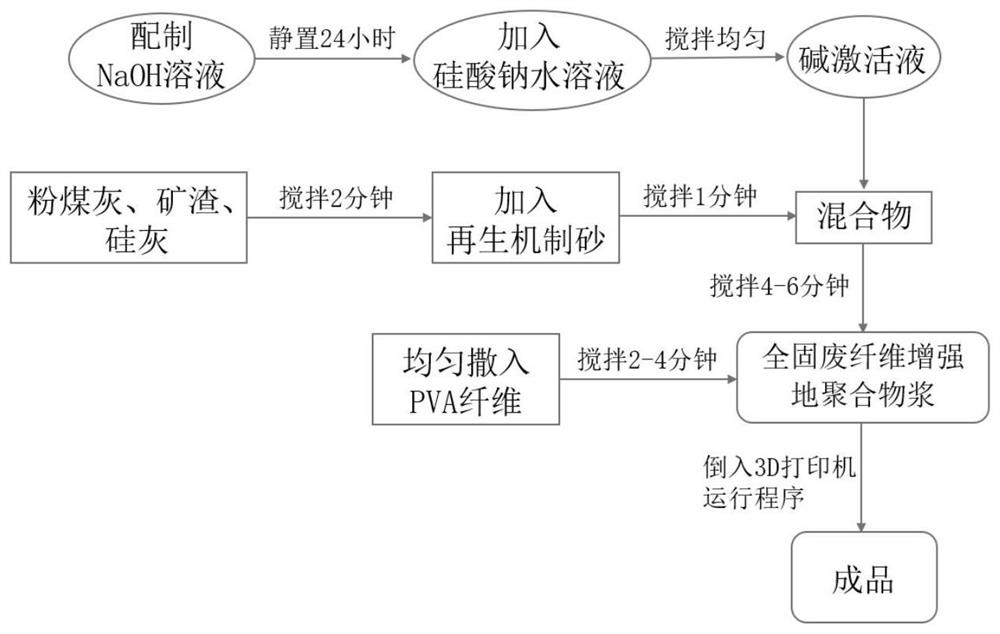

All-solid waste fiber reinforced geopolymer composite material suitable for 3D printing technology

ActiveCN113754359AImprove sustainabilityEasy to handleAdditive manufacturing apparatusCement productionIndustrial constructionAggregate (composite)

The invention relates to the technical field of solid waste resource utilization and geopolymer concrete preparation, in particular to an all-solid waste fiber reinforced geopolymer composite material suitable for a 3D printing technology. The all-solid waste fiber reinforced geopolymer composite material comprises the following raw materials in parts by mass: 20-30 parts of aggregate, 70-80 parts of a cementing material, carbon nanotubes, PVA fibers and an alkali activator, wherein the cementing material comprises the following components in percentage by mass: 15-30% of fly ash, 55-65% of slag and 10-25% of silica fume; and the aggregate is regenerated machine-made sand. The all-solid-waste ultra-high-performance geopolymer concrete provided by the invention can reach initial setting within 10-25 minutes after being discharged, and meets the 3D printing requirement. Besides, the fly ash, the slag and the regenerated machine-made sand are all derived from industrial building solid wastes, so that the waste of the solid wastes can be effectively reduced, the sustainability of the building is improved, and an efficient, environment-friendly and energy-saving solution is provided for treatment after the building is demolished.

Owner:无锡初如企业管理合伙企业(有限合伙)

Precast concrete parapet wall component and connecting structure thereof

ActiveCN106703306AEasy installation and constructionAvoid Temporary SupportSnow trapsIndustrial constructionPrecast concrete

The invention relates to a precast concrete parapet wall component and a connecting structure thereof. The parapet wall component comprises a parapet wall body, a bracket and a parapet wall coping; and the parapet wall coping is connected with the bracket through the parapet wall body. According to the connecting structure of the precast concrete parapet wall component, precast concrete constructional columns which are connected with a main body structural component are arranged at two ends of the precast concrete parapet wall component, and are used as horizontal connecting supports of the precast concrete parapet wall component, and the bottom and two ends of the precast concrete parapet wall component are connected with the main body structural component through connecting pieces. Reliable connection between the precast concrete parapet wall component and the main body structural component can be guaranteed, the overturning effect of the horizontal load to the precast concrete parapet wall component can be resisted effectively, and the precast concrete parapet wall component is convenient and speedy to construct and mount, and is suitable for industrial construction.

Owner:香港华艺设计顾问(深圳)有限公司

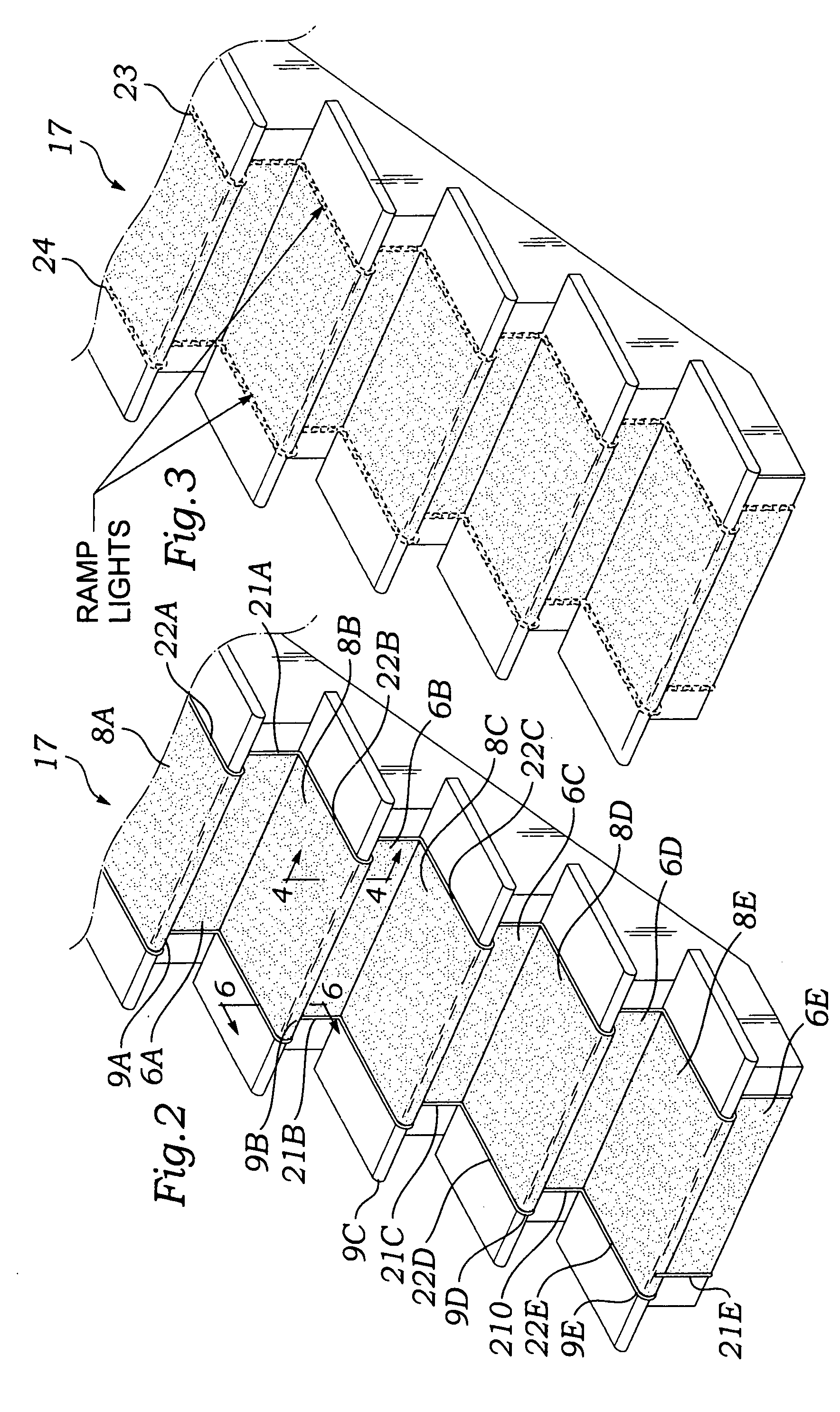

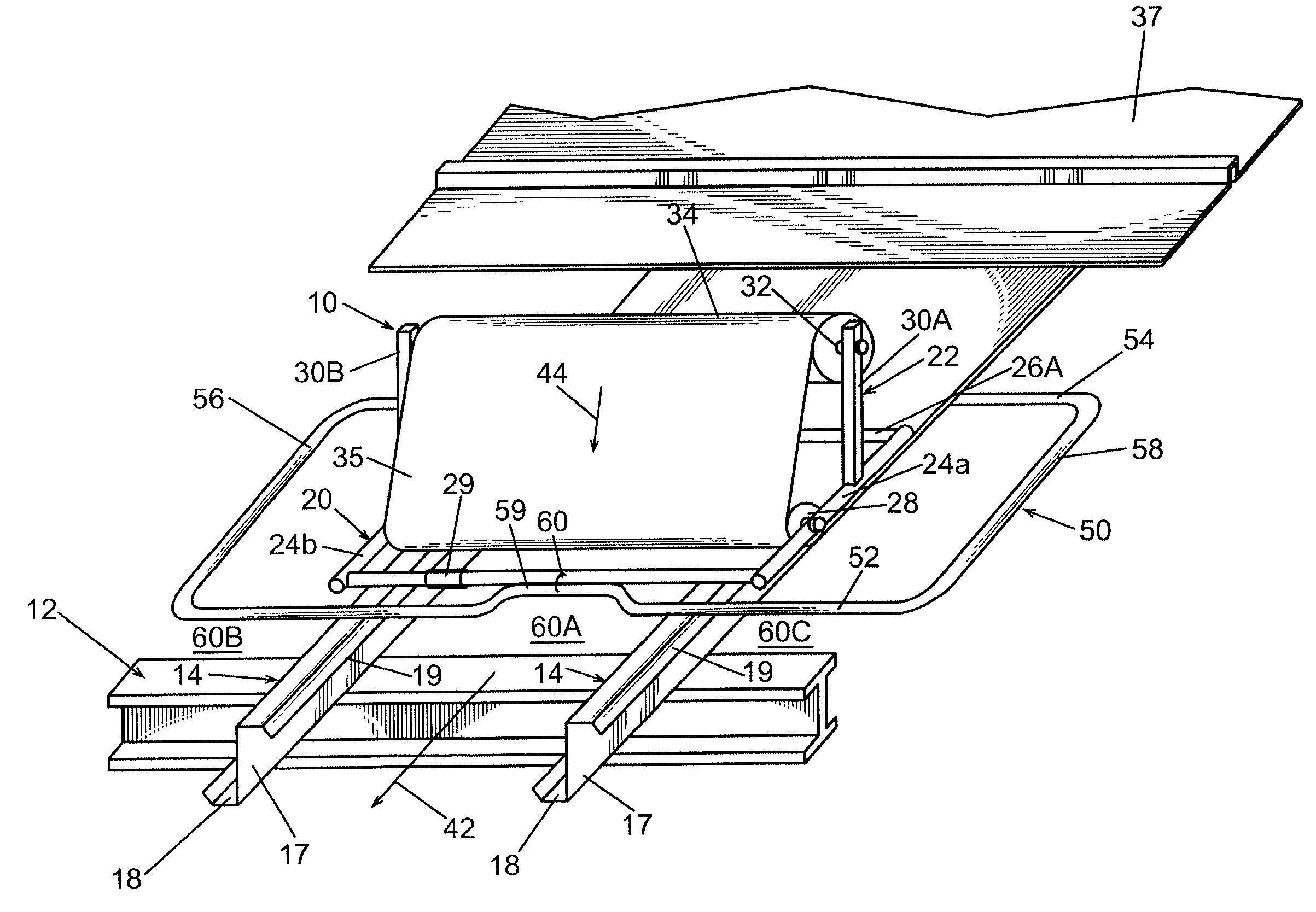

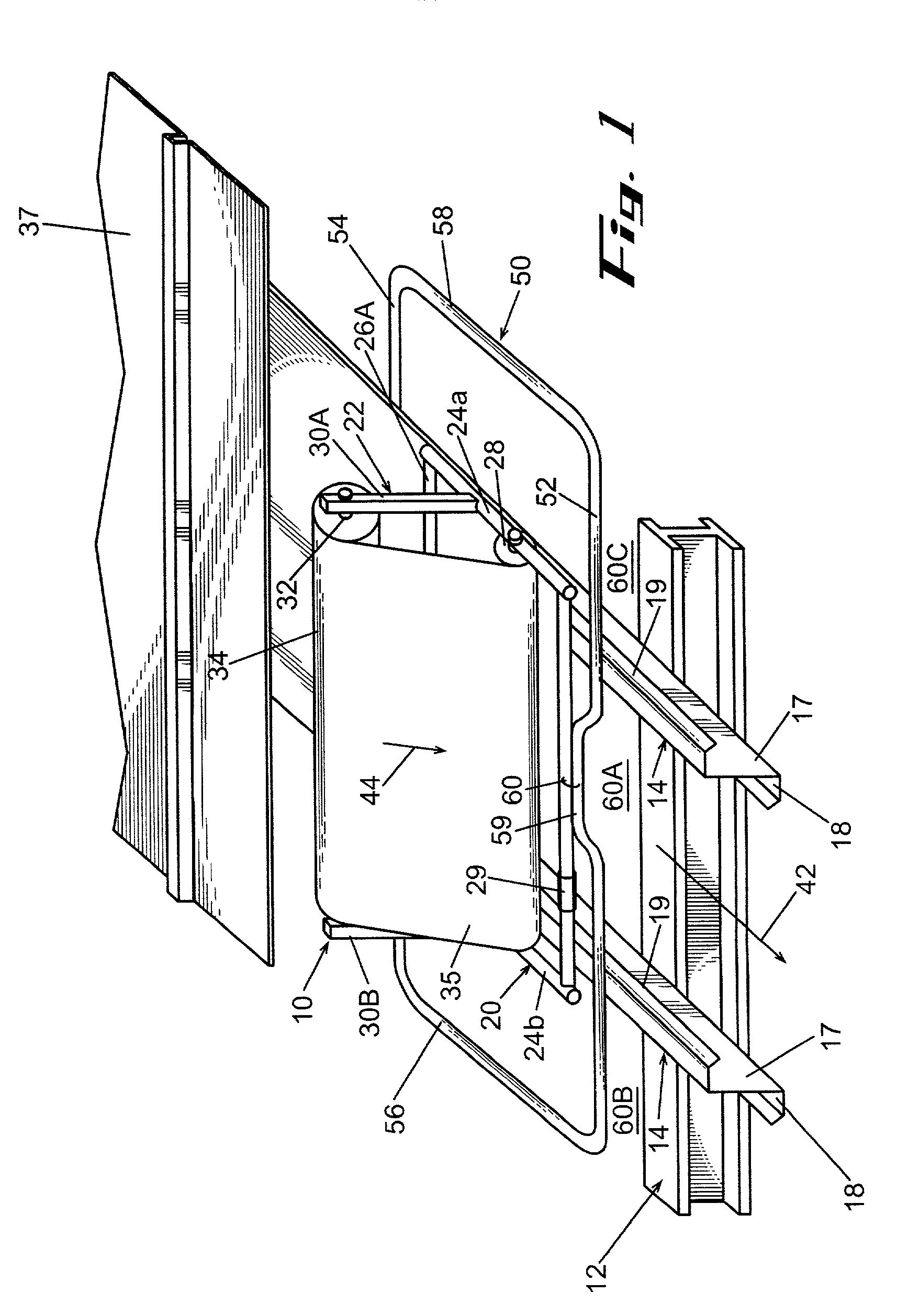

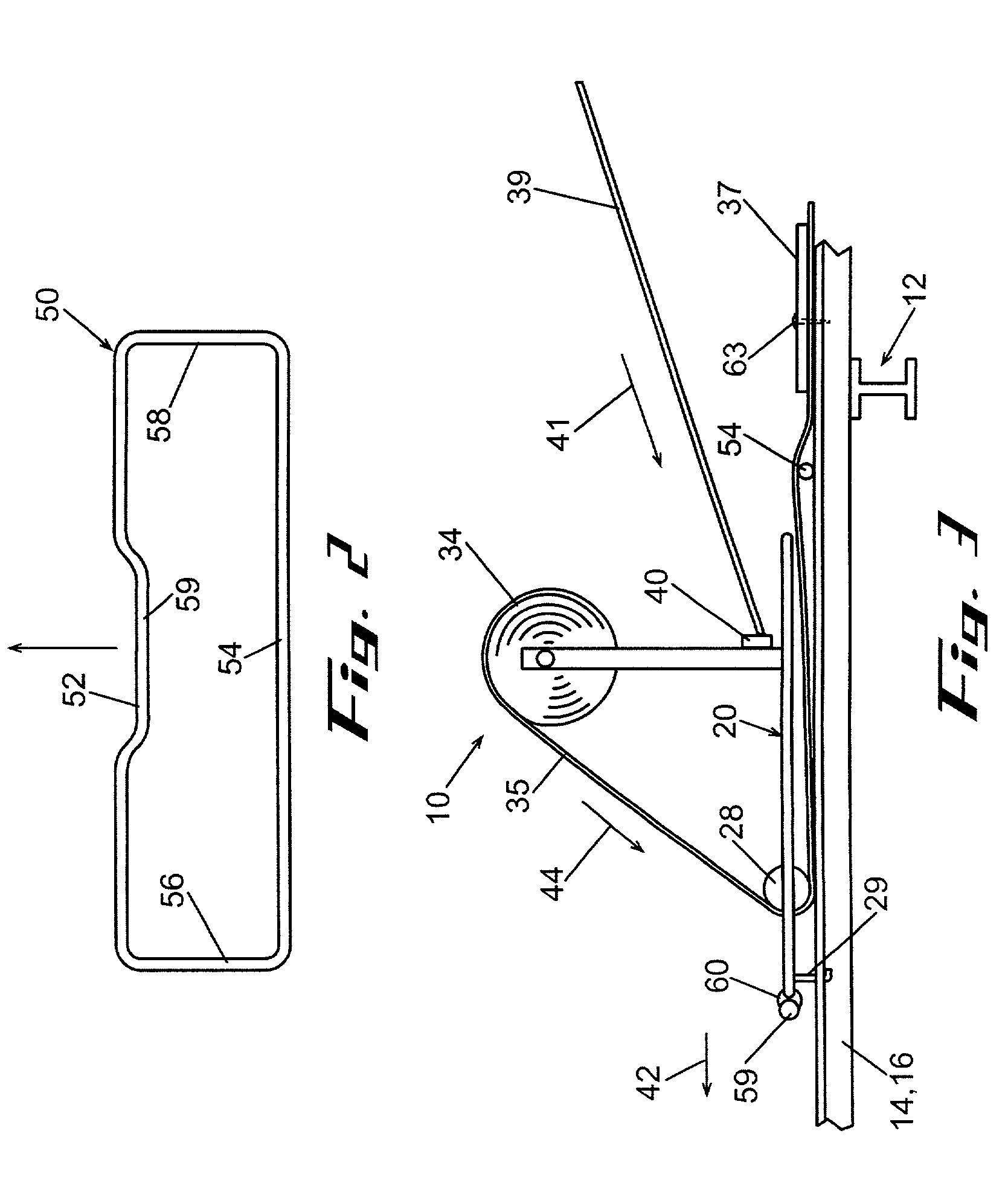

Insulation support for roof insulation applicator

InactiveUS6955018B2Less effortPrecise supportBuilding repairsRoof toolsPurlinIndustrial construction

A plurality of sheet supports 50 or 70 of approximate rectangular configuration are placed on adjacent purlins 14 of a partially completed roof of an industrial building, about the second row of roof insulation support carriages 10. When the carriages are advanced along the lengths of the purlins to apply the sheet material 34 to the purlins, the sheet supports 50 or 70 move in unison with the carriages of the second row of carriages and the rear segment 54 supports the sheet material in the spaces 60 over which the carriage is mounted and the side segments 56 and 58 support the sheet material extending from the first row of carriages in the next adjacent spaces between the purlins. This avoids the sagging of the sheet material between the purlins at the time when the hard roof panels 37 are fastened to the purlins.

Owner:ALDERMAN ROBERT J

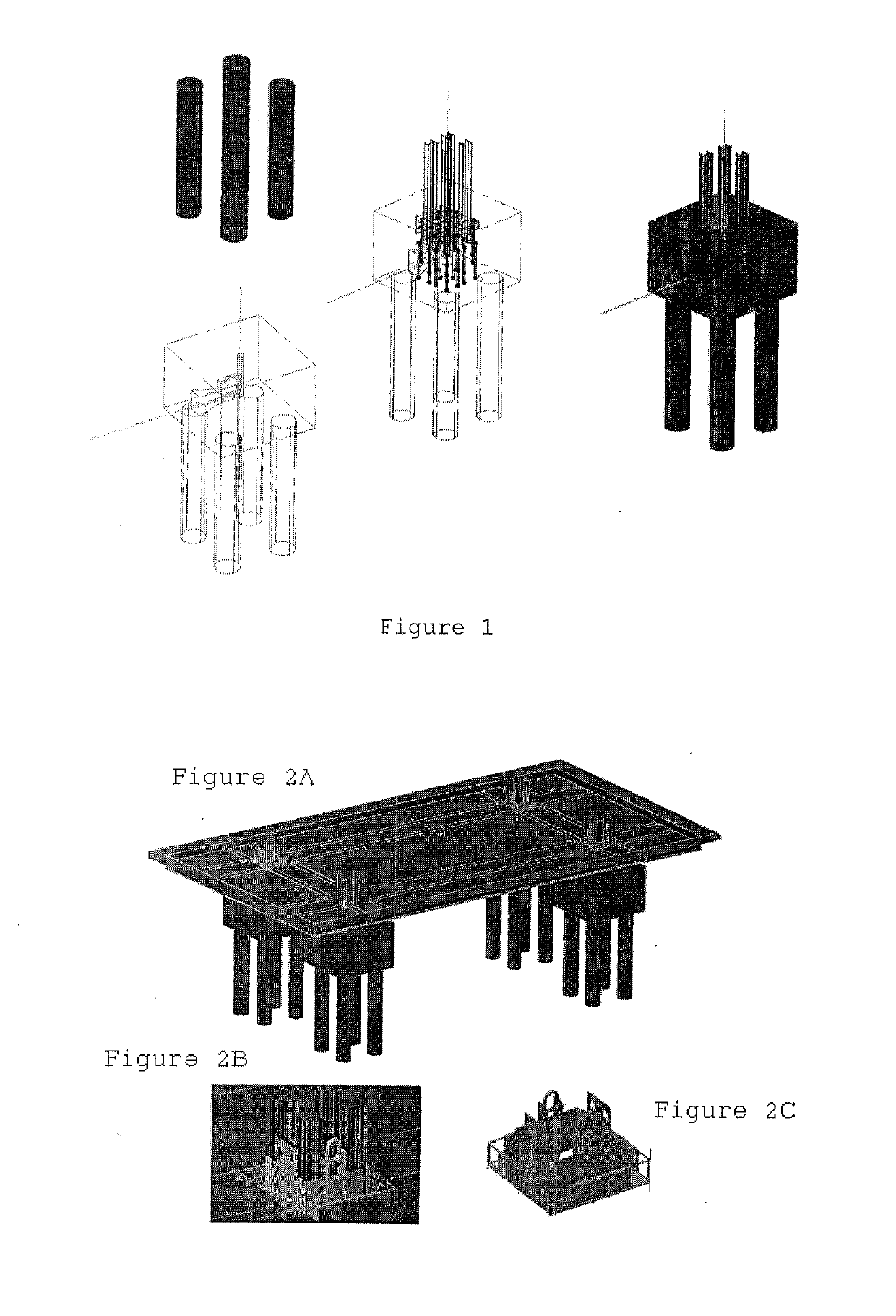

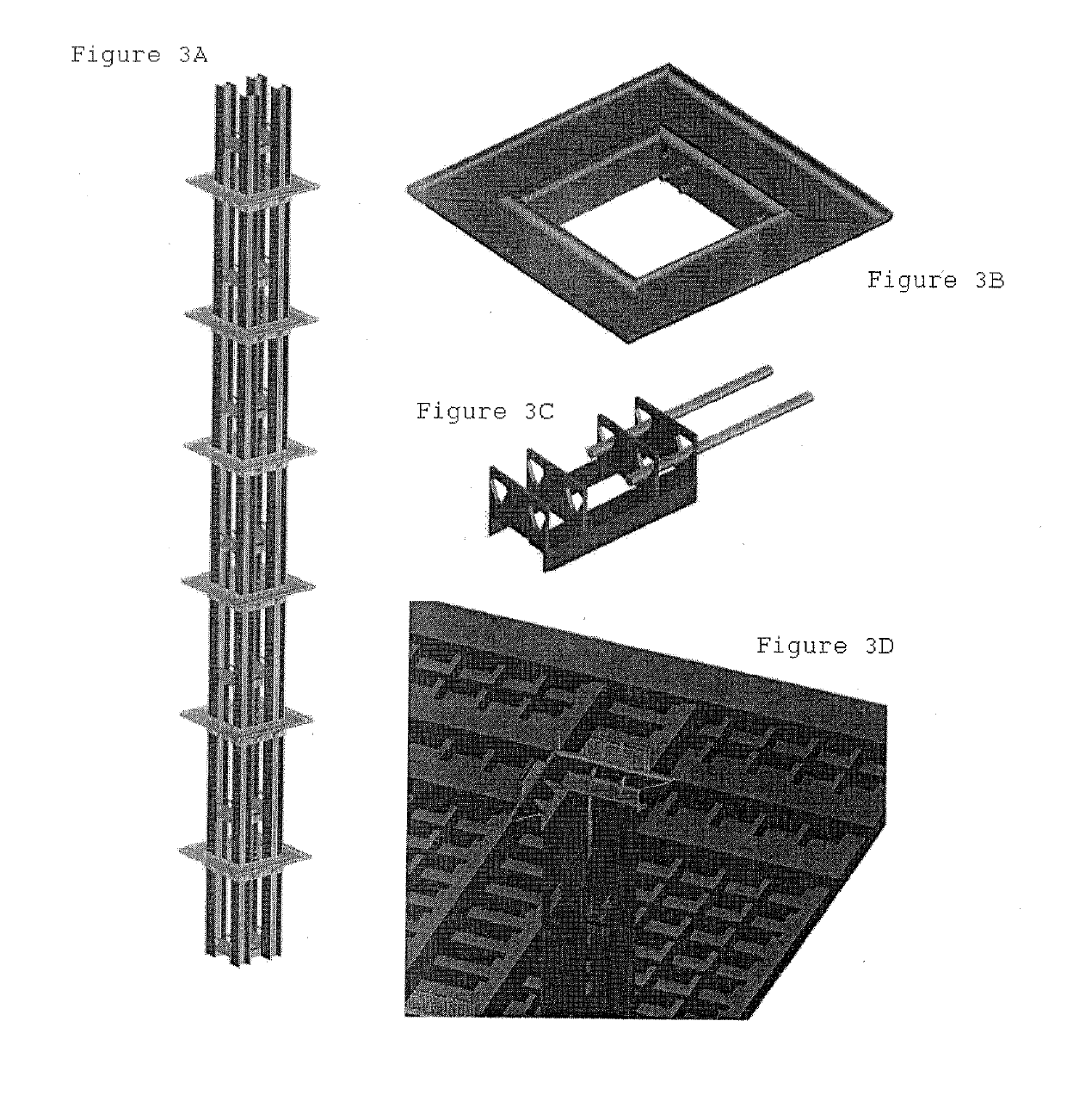

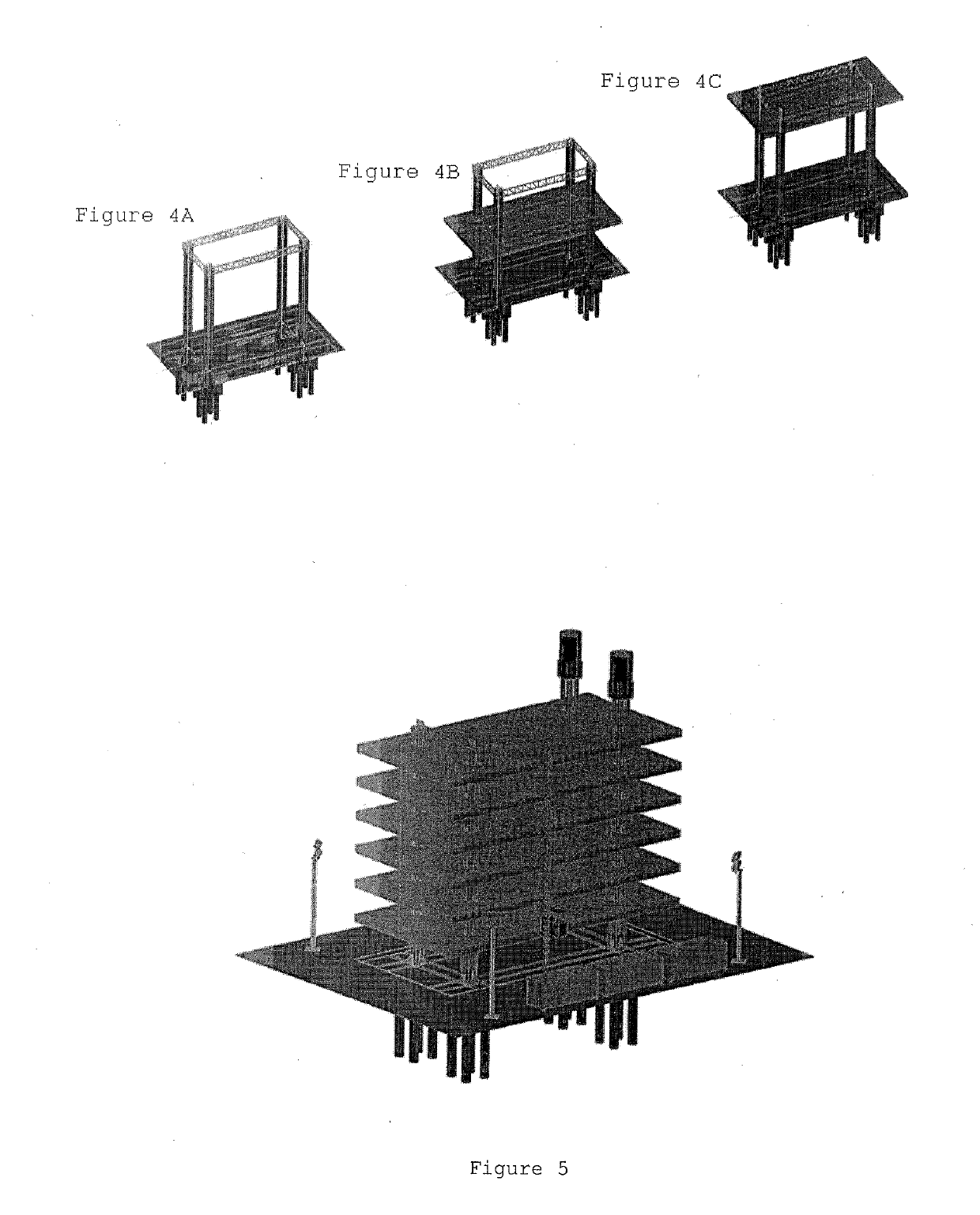

Industrial building construction process

InactiveUS20190106877A1Easy and fast cleaningArtificial islandsFoundation engineeringProduction lineIndustrial construction

The present disclosure relates to a construction process, the so-called “Zaina” process, which was designed to industrialize the construction of buildings. The Zaina construction process operates like an industry that receives raw materials and transforms them into a product; it establishes an analogous vertical production line, the end product of which is a building. It is an industrial process implemented at the delivery site of the product, that is to say, the building.

Owner:RINALDO ZAINA ENGENHARIA CONSULTORIA E PROJETOS INDIS S S LTDA ME

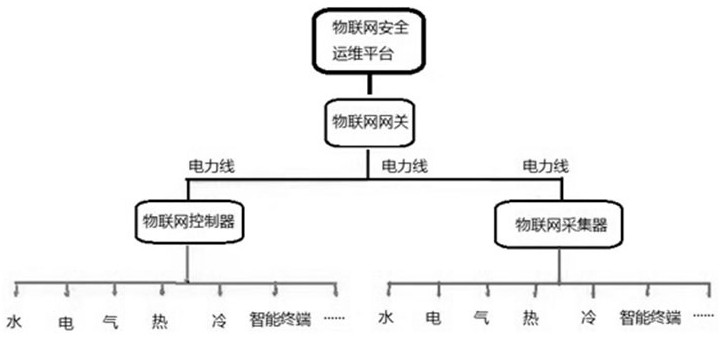

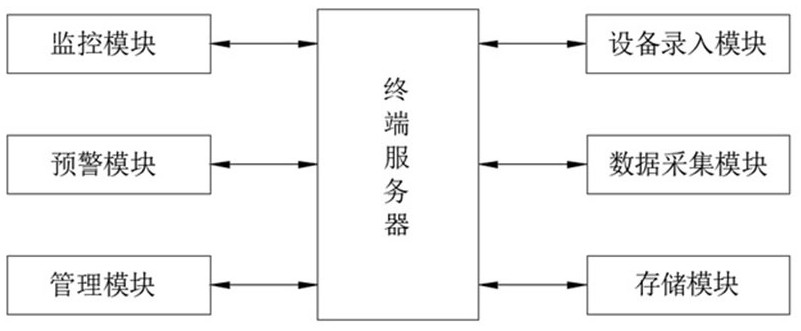

Smart park safety operation and maintenance system

ActiveCN112862118AAchieve high efficiency and energy savingFulfillment requirementsData processing applicationsMeasurement devicesIndustrial constructionComputer network

A smart park safety operation and maintenance system comprises an Internet of Things safety operation and maintenance platform, an Internet of Things gateway, an Internet of Things controller and an Internet of Things collector. The system can not only realize real-time detection and presentation of energy consumption information of each region in a park, but also detect energy consumption abnormity in real time, such as positioning fault equipment, determining equipment operation conditions and the like; therefore, faults can be eliminated in time, maintenance is simple and convenient, and safe operation management of energy consumption and equipment of public buildings, industrial buildings, municipal facilities, civil air defense facilities and the like in the whole park is guaranteed.

Owner:安徽德诺科技股份公司 +1

Low-thermal conductivity composite foam material and preparation method thereof

The invention discloses a low-thermal conductivity composite foam material, which is prepared by the following steps: uniformly mixing resin, hollow microspheres, thermal expansion microspheres, a curing agent, an accelerant, a coupling agent, a toughening agent and a flame retardant in proportion, and filling a mold with the mixed slurry for molding and curing to obtain a resin-based foam matrix;and uniformly mixing a silicon source, ethanol, water and a catalyst to obtain silica sol, impregnating the resin-based foam matrix with the silica sol, and carrying out gelatinization treatment, aging and drying to obtain the low-thermal conductivity composite foam material. By adding the hollow microspheres, the problems that traditional aerogel is low in mechanical strength and poor in toughness are solved, the operability of the aerogel serving as a thermal insulation material in construction application is improved, and the mechanical properties of the aerogel material are greatly improved. The prepared low-thermal conductivity composite foam material has good heat insulation and sound insulation characteristics and mechanical properties, is simple in forming process and convenient to operate, and can be widely applied to the requirements of industries, buildings and aerospace for heat insulation and heat preservation components.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

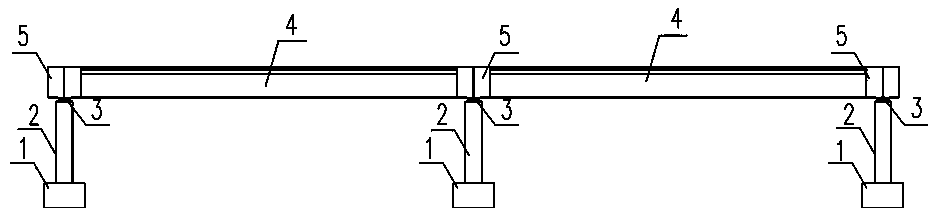

novel Steel-Concrete Composite Continuous Box Girder Bridge and Its Scaffolding-Free Industrial Construction Method

PendingCN108978434AReasonable structureFast construction on siteBridge structural detailsBridge erection/assemblyFillet weldIndustrial construction

The invention discloses a novel stee-concrete composite continuous box girder bridge, including spaced cast caps and piers fixed on each caps, each pier top mounted with bearings and steel erected between two adjacent bearings. Mixed composite box girder segments; Steel box girder segments are hoisted at the top of each bearing. The web plate and bottom plate of the joint part of the composite boxgirder segment and the steel box girder segment adopt the high-strength bolt + double-sided splice plate fillet welding connection structure, and the top plate adopts the steel cell structure filledwith concrete. The invention also discloses a support-free industrial construction method of the bridge. The whole bridge structure of the invention is reasonable, the main structural parts can be prefabricated in advance, assembled on the spot, and the field construction speed is fast, which accords with the development trend of bridge industrialization construction. The pier top adopts steel boxgirder, and the whole bridge has steel. The structural advantages of concrete composite continuous box girder bridges can also effectively overcome the shortcomings of The stee-concrete composite continuous box girder bridge. The problem that the negative moment zone near the pivot of concrete composite continuous box girder bridge is unreasonable is resolved.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

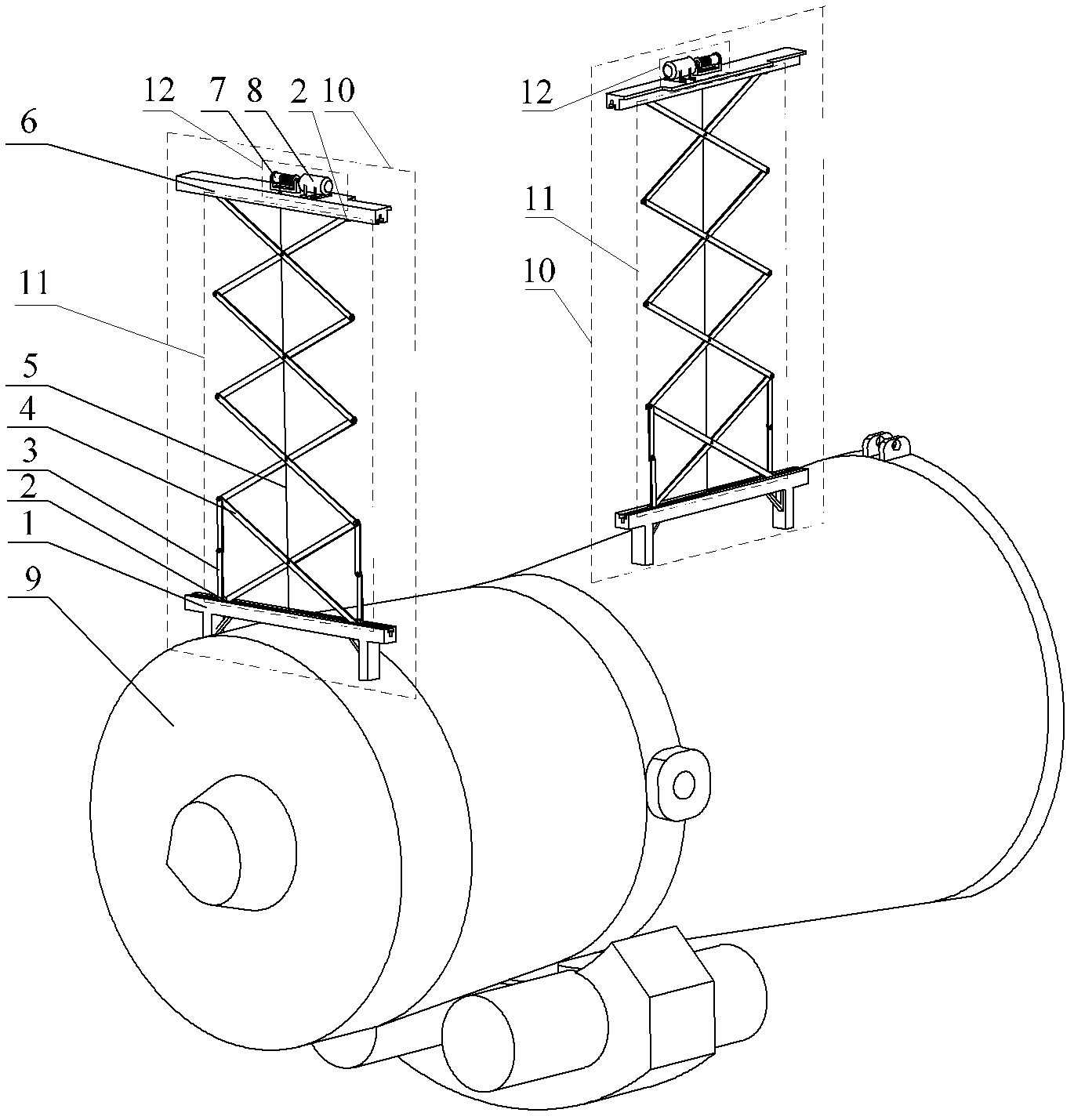

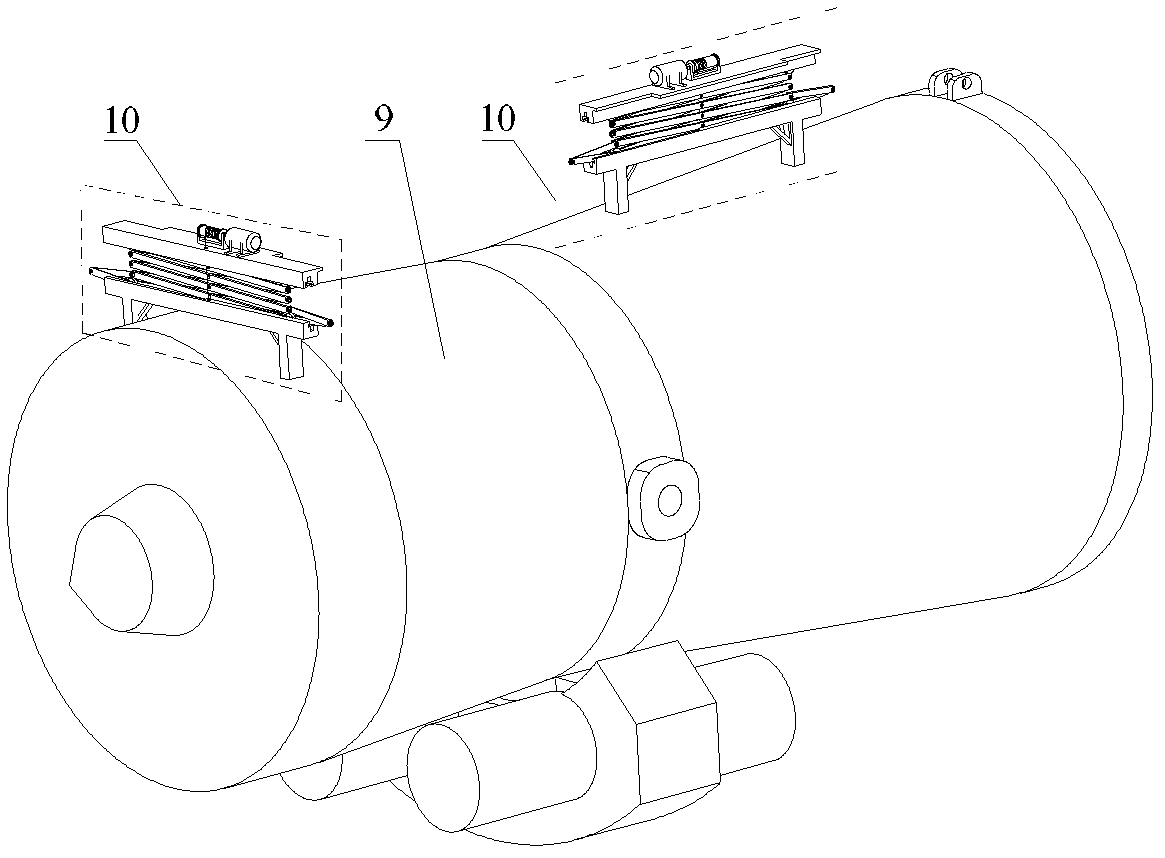

Lifting device for mounting and maintaining aero-engine

ActiveCN103318415AEasy maintenanceLarge folding ratioPower plant constructionAviationIndustrial construction

A lifting device for mounting and maintaining an aero-engine is characterized by comprising lower guide rails, rollers, short rods, long rods, guy cables, upper guide rails, winding drums, motors, an engine, unfoldable mechanisms, scissors fork mechanisms and drive control mechanisms; the two lower guide rails, the rollers, the scissors fork mechanisms, the upper guide rails and the drive control mechanisms form the two independent unfoldable mechanisms together; the two independent unfoldable mechanisms are perpendicularly arranged at the front end and the back end of the engine; the lower guide rails are fixedly connected with the engine; the upper guide rails are fixedly connected with an airplane; the drive control mechanisms comprise the guy cables, the winding drums and the motors. The lifting device has the advantages that the folding ratio is large, the radial direction space between the engine and the airplane can be effectively utilized under a completely gathering condition, meanwhile accurate positioning can be formed with a main mounting part of the engine, and the quick mounting is facilitated; during the expansion process, the expansion is stable, the perturbation is small, and the device is not only suitable for the aero-engine, but also can be applied to a crane for industrial buildings and an escaping device for fire hazard.

Owner:AECC SHENYANG ENGINE RES INST

Device and method for connecting and sealing steel-plastic composite steel pipe, flange metal pipe and pipe fitting

ActiveCN103123024AImprove sealingEasy to installFlanged jointsCorrosion preventionIndustrial constructionPipe fitting

The invention provides a method for connecting and sealing a steel-plastic composite steel pipe, a flange metal pipe and a pipe fitting, and further provides a device for connecting and sealing the steel-plastic composite steel pipe, the flange metal pipe and the pipe fitting. The method comprises that at least one rabbet is formed on the periphery of the outer end surfaces of flange gaskets of the steel-plastic composite steel pipe; hot melt adhesive is coated on the outer layer of an inner liner plastic pipe layer of the steel-plastic composite steel pipe; the steel-plastic composite steel pipe with the hot melt adhesive coated on the outer layer of the steel-plastic composite steel pipe is embedded in an outer layer pipeline, and the inner liner plastic pipe layer is extended and coated on the end surface of the outer layer pipeline; and a silica gel gasket is arranged between end surfaces of two flange gaskets. The device for connecting and sealing the steel-plastic composite steel pipe, the flange metal pipe and the pipe fitting is simple in sealing and connecting method, reliable, stable and strong in sealing ability, and has prominent and active effects for engineering applications in the fields such as subways, industrial architecture and drinking water.

Owner:JIANGDONG SHENGFENG STEEL PLASTIC PIPE MFG FACTORY NINGBO

Waterproof nanometer anticorrosive coating and preparation method thereof

InactiveCN106189710AImprove waterproof performancePrevent infiltrationAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

Disclosed is a waterproof nanometer anticorrosive coating. The waterproof nanometer anticorrosive coating is prepared from, by mass, 28-39% of modified epoxy resin, 18-28% of a water repellent agent, 8-13% of hydrophobic nano-silica, 8-14% of glass flakes, 3-7% of isophthalic acid ester, 5-14% of diethanol amine, 2-3% of bentonite, 8-15% of nanometer calcium oxide and 5-8% of polyaniline. The water repellent agent is an organic silicon water repellent agent or a wax water repellent agent or a water-based nanometer water repellent agent. The invention further discloses a preparation method of the nanometer anticorrosive coating. The method comprises the three steps totally. The nanometer anticorrosive coating has the good waterproof performance and anticorrosive performance, is high in compactness and has the higher stability and reliability. The waterproof nanometer anticorrosive coating can be applied to seaborne facilities, industrial buildings and various mechanical devices, and has the wide development prospect.

Owner:陈曦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com