Flame-retardant heat-resistant polyurethane foaming plastic and preparation method thereof

A technology of foamed plastics and polyurethane, applied in the field of polyurethane foamed plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

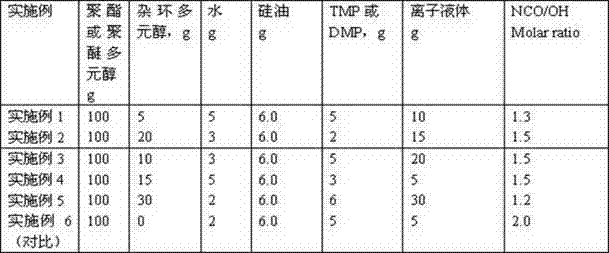

Embodiment 1

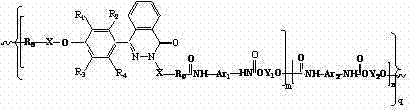

[0044] Proportionally mix polyester polyol and heterocyclic polyol A (G=H, X, R 8 , R 9 Both are chemical bonds), catalyst A-33 0.5g, dibutyltin dilaurate 0.5g, silicone oil, flame retardant polyol FRC-6 10g, TMP and water into the reaction kettle, mix well at 50°C, add TDI and mix well , injected into a mold for foaming, and then cured in an oven at 50°C for 2 hours to obtain a flame-retardant heterocyclic polyurethane foam product. The limiting oxygen index LOI is 28.

[0045] The obtained product is detected by the following test methods:

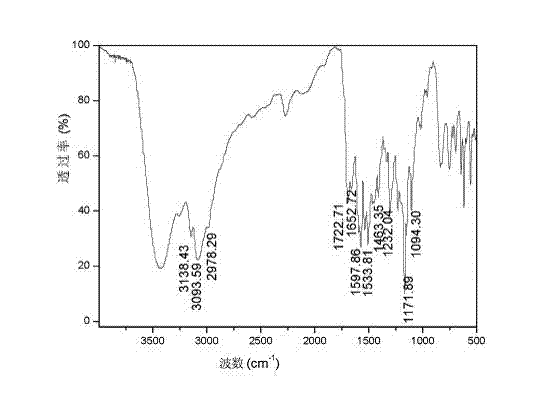

[0046] Infrared spectrum test: FTIR-430 Spectrometer produced by Japan JASCO Company was used to test the infrared spectrum of polyurethane foam plastics by film reflection or potassium bromide tablet method.

[0047] The limiting oxygen index is tested according to ASTM D-2863 standard.

[0048] figure 1 Medium 3138.43cm -1 It is the C-H stretching vibration absorption peak on the benzene ring; 3093.59cm -1 and 2978.29cm -1 at ...

Embodiment 2

[0050] Add polyether polyol 4110, heterocyclic polyol B, dibutyltin dilaurate and triethanolamine 0.2g, bromobutylmethylimidazolium salt, silicone oil, 30g flame retardant polyol Fyrol-6, DMP and water into the reactor, Mix well at 50°C. Add PAPI, stir and mix, pour into a mold for foaming, and then mature in an oven at 60° C. for 1 hour to obtain a flame-retardant heterocyclic polyurethane foam product. The limiting oxygen index LOI is 27.

Embodiment 3

[0052] Polyether polyol 4110, heterocyclic polyol A (G=H, X, R 8 , R 9 Both are chemical bonds), catalyst A-33 0.6g, dibutyltin dilaurate 0.3g, phosphorus hexafluoride butylmethylimidazolium salt, silicone oil, 30g flame retardant polyol FRC-6, TMP and water were added to the reactor, at 50 °C and mix well. Add MDI-100, stir and mix, pour into a mold for foaming, and then mature in an oven at 80°C for 2 hours to obtain a flame-retardant heterocyclic polyurethane foam product. The limiting oxygen index (LOI) is 30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com