Precast side wall splicing construction method for open-cut assembled subway station

A construction method and prefabricated technology, which is applied in the field of prefabricated side wall assembly construction of open-cut subway prefabricated stations, can solve the problems of high demand for on-site labor force, low degree of engineering mechanization, and high demand for construction turnover materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

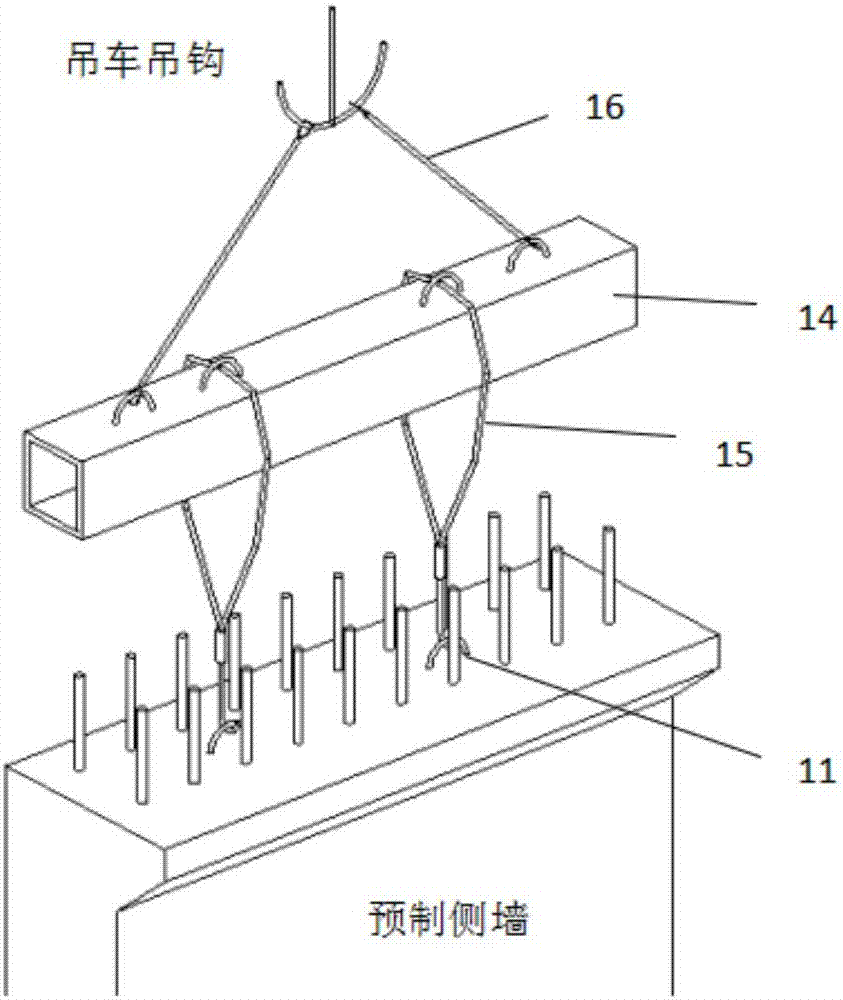

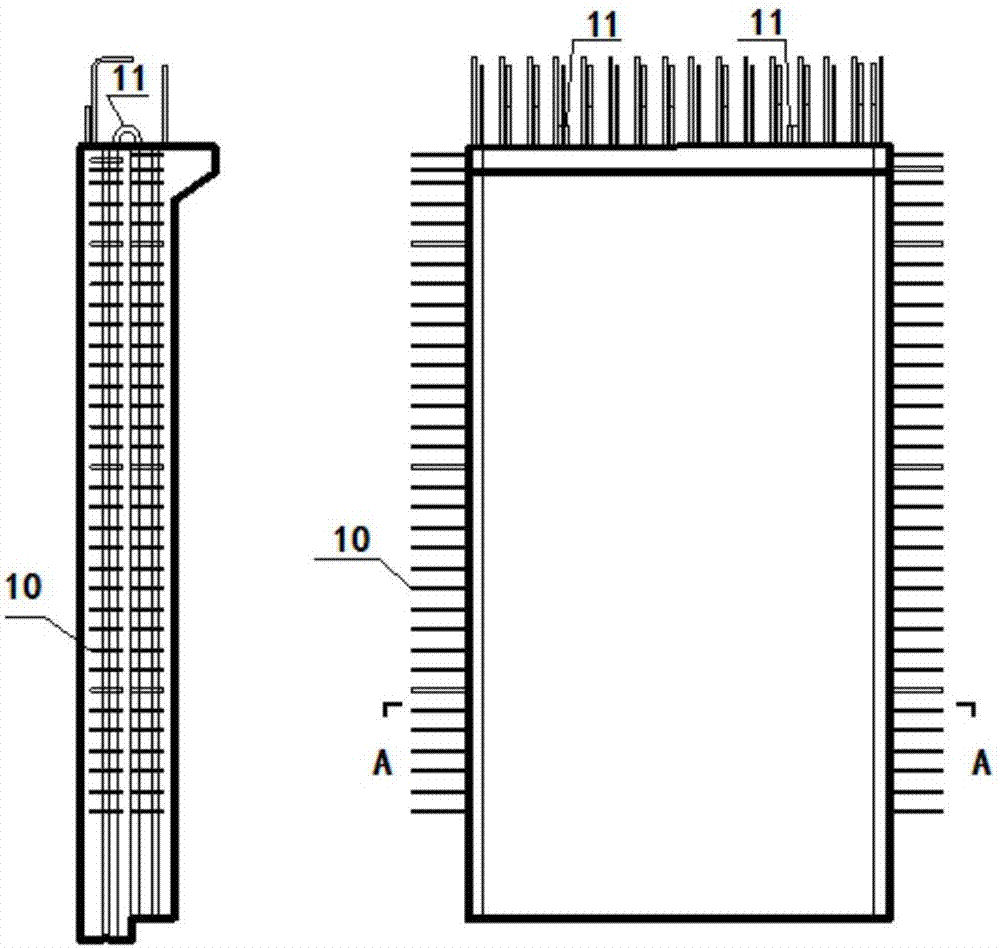

[0036] The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0037] The technology for hoisting the prefabricated side wall of the open-cut subway prefabricated station is characterized in that it includes the following steps:

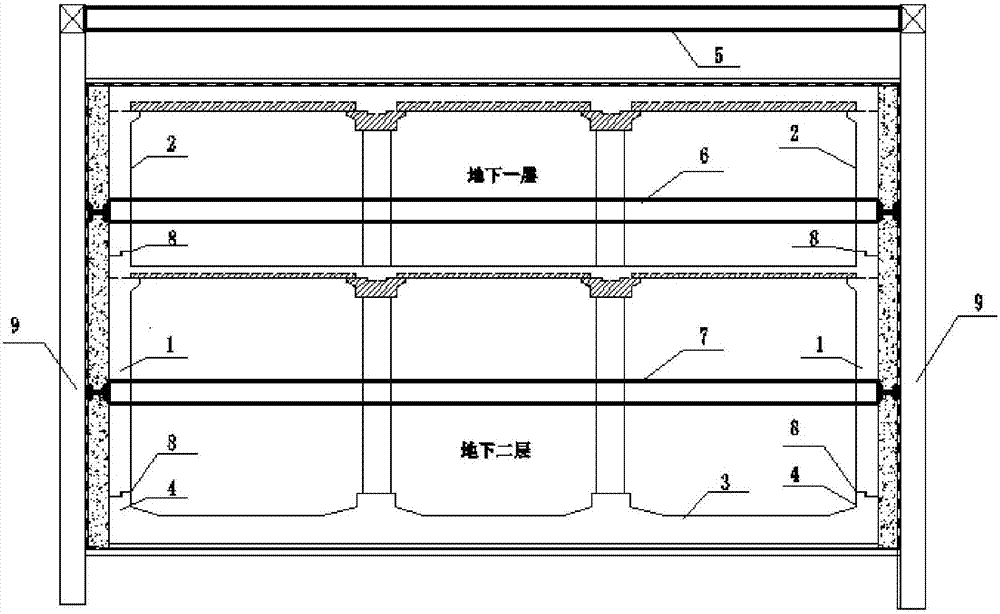

[0038] ①Floor construction: The open-cut assembly integral structure subway station adopts a pile support system. After the excavation and support of the foundation pit is completed, three horizontal steel supports (5), (6), (7) ( The steel support is divided into upper, middle and lower three, and each steel support has multiple steel supports, which are evenly arranged). Firstly, the bottom slab (3) is constructed, and the bottom slab (3) adopts a cast-in-place concrete structure, that is, after the bottom slab (3) is bound with steel bars and the formwork is installed, the concrete of the bottom slab (3) is poured, and the steel bar positioning for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com