novel Steel-Concrete Composite Continuous Box Girder Bridge and Its Scaffolding-Free Industrial Construction Method

A technology of steel box girders and combined boxes, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of unreasonable structural stress in the negative bending moment area and ineffective control measures for bridge deck cracks, and shorten the construction period and work The effect of small amount and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

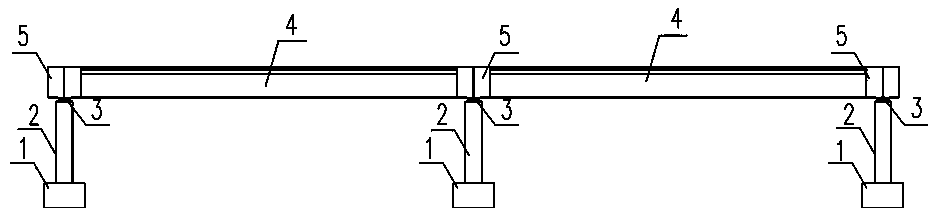

[0030] Such as figure 1 As shown, the novel steel-concrete composite continuous box girder bridge of the present invention includes caps 1 poured at intervals and piers 2 fixedly placed on each cap 1, and supports are installed on the top of each pier 2 3. A steel-concrete composite box girder segment 4 is erected between two adjacent supports 3; a steel box girder segment 5 is hoisted on the top of each support 3, and a steel-concrete composite box girder segment 4 In the joint with the steel box girder section 5, the web and the bottom plate are connected by high-strength bolts + double-sided spliced plates with fillet welds, while the top plate is connected by a steel cell structure filled with concrete.

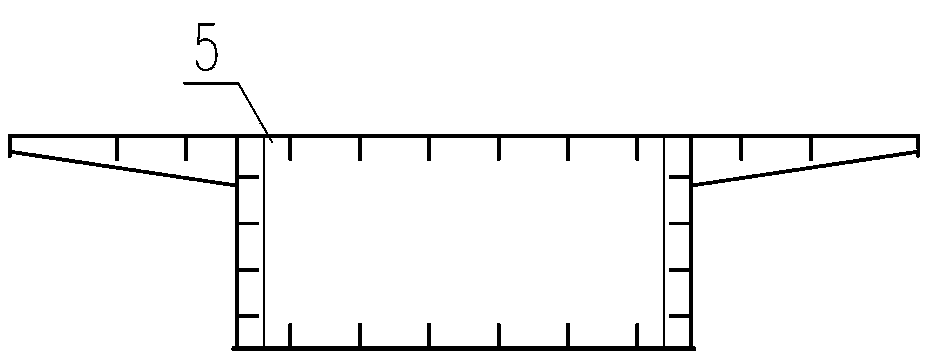

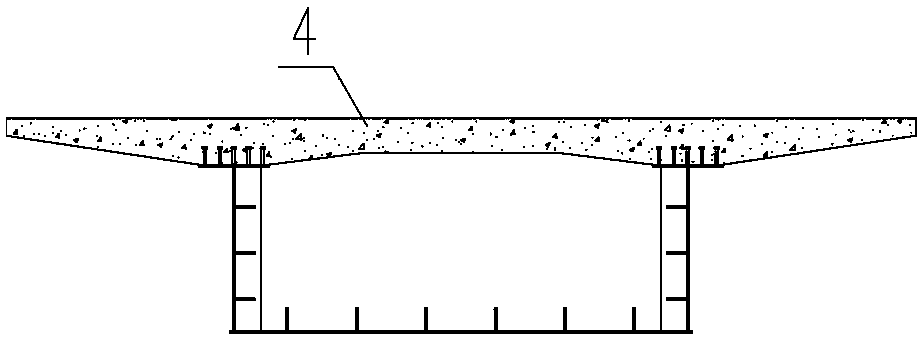

[0031] The section structure of steel box girder segment 5 used in the present invention is as figure 2 As mentioned above, the section structure of steel-concrete composite box girder section 4 is as follows image 3 shown;

[0032] Steel-concrete composite box gir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com