Precast concrete parapet wall component and connecting structure thereof

A technology of precast concrete and connecting structure, applied in snow traps and other directions, can solve the problems of complicated construction process, limited popularization and application, etc., and achieve the effects of simple construction, convenient installation and reasonable stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

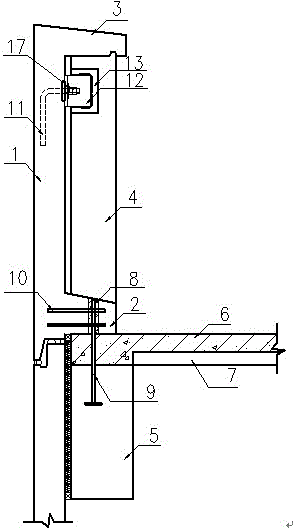

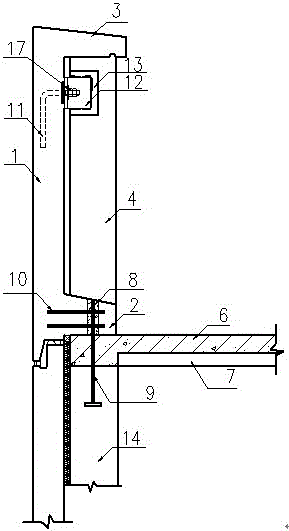

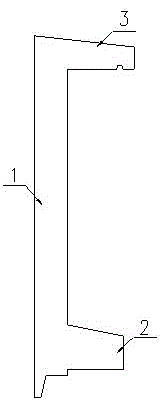

[0018] The prefabricated concrete parapet component of the present invention includes a parapet wall body 1 , a corbel 2 and a parapet top 3 , and the parapet top 3 and the corbel 2 are connected through the parapet wall body 1 .

[0019] In this embodiment, the three parts of the parapet wall body 1 , the corbel 2 and the parapet top 3 are poured into prefabricated reinforced concrete components at one time.

[0020] In this embodiment, the cross-section of the prefabricated reinforced concrete member cast in three parts, the parapet wall body 1, the corbel 2 and the parapet top 3, is groove-shaped.

[0021] In the connection structure of the precast concrete parapet components of the present invention, the two ends of the precast concrete parapet components are provided with precast concrete structural columns 4 connected to the main structural components, and the precast concrete structural columns 4 are used as horizontal connection supports for the precast concrete parapet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com