Screwing type hard seal ball valve

A hard-sealed, ball valve technology, applied in valve details, valve devices, cocks including cut-off devices, etc., can solve the problem of not being able to ensure the seal on a regular basis, and achieve the effect of easy maintenance and replacement, easy installation and construction, and easy positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

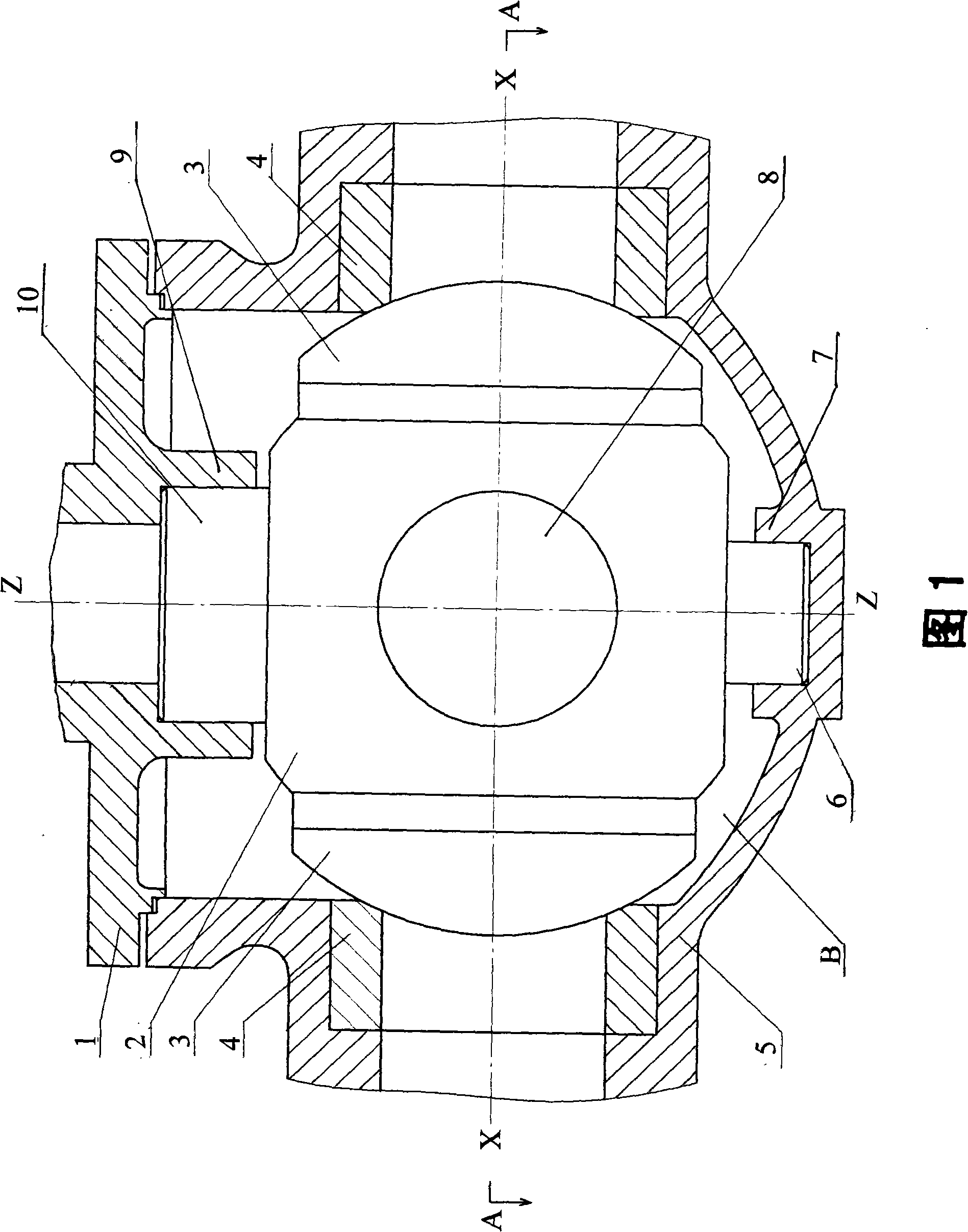

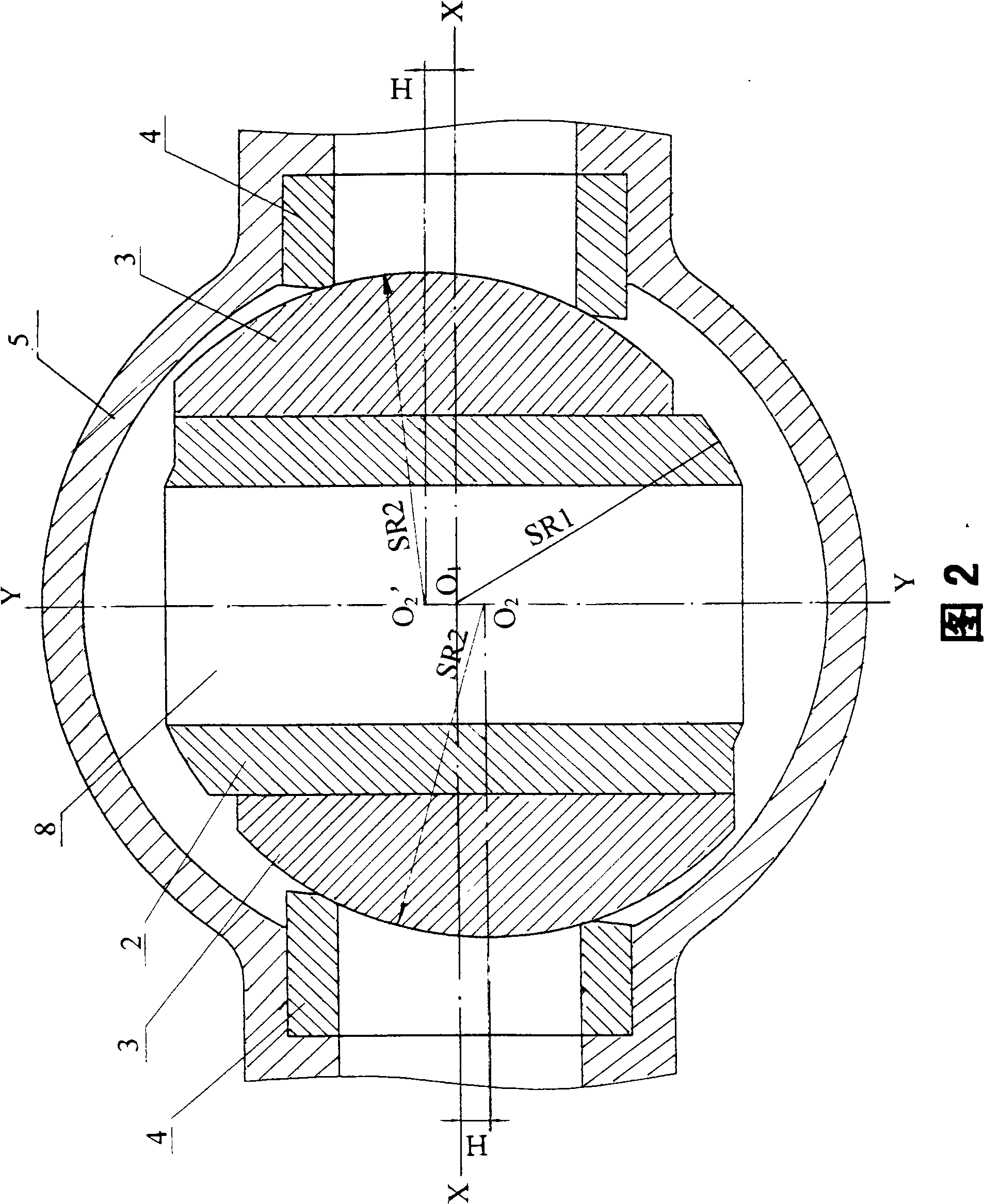

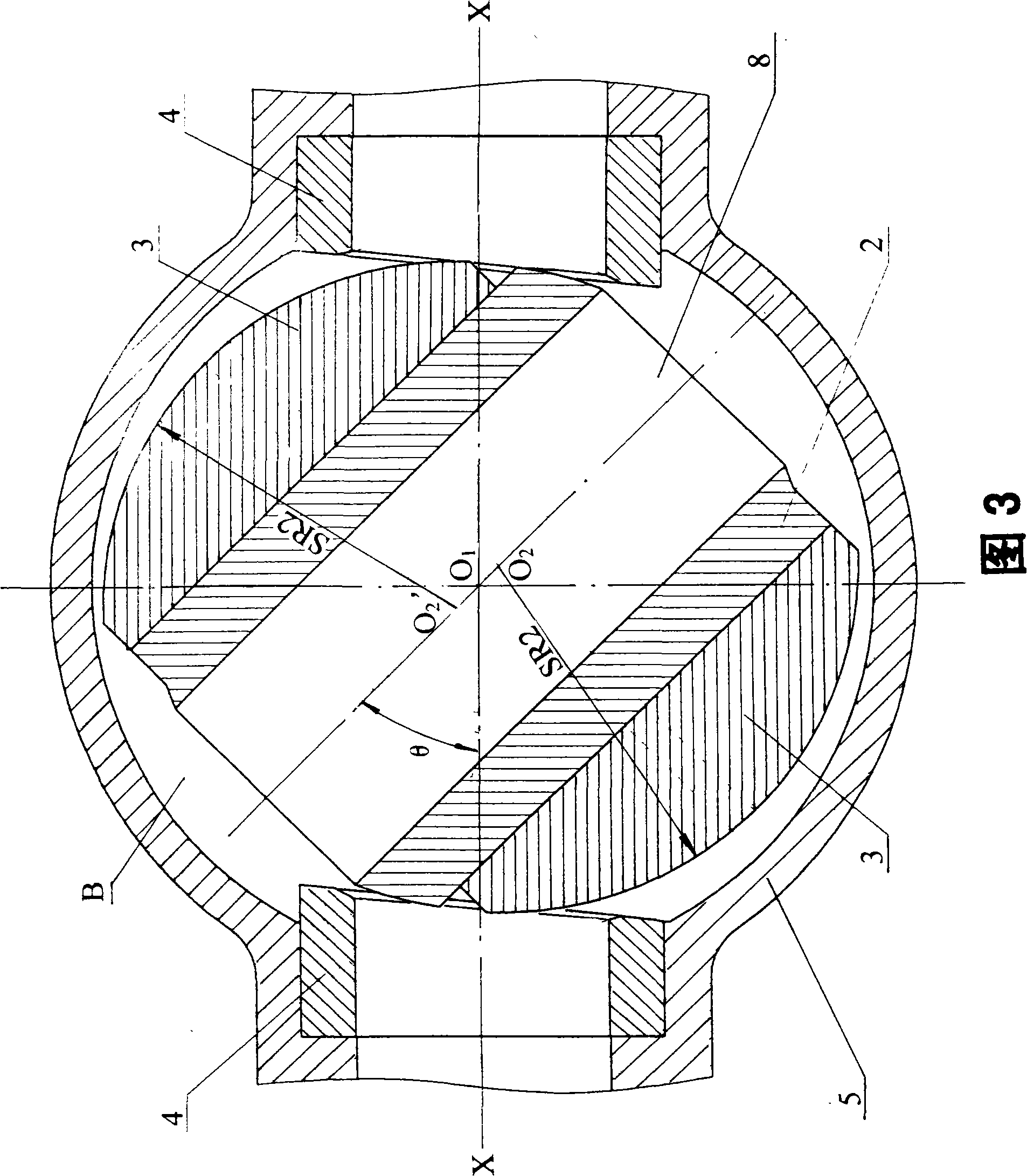

[0020] Please refer to Fig. 1, the present invention is a screw-on hard-sealed ball valve, which includes a valve seat 4 and a valve core, and the valve core is connected to the upper surface of the valve cover 1 with its upper fixed journal 10 and lower fixed shaft 6 respectively. The bearing seat 9 cooperates with the lower bearing seat 7 of the valve body 5 to be supported in the valve cavity B formed by the valve cover 1 and the valve body 5, and rotates around the vertical axis Z-Z of the ball valve. The spool is a spheroid composed of a metal ball body 2 and two metal spherical caps 3 offset on both sides of the ball body 2, the radius SR1 of the ball body 2 (see Figure 2) is smaller than the radius of the metal spherical cap 3 SR2, the radial through hole 8 is located on the ball main body 2. When the ball valve is fully open, the axis of the radial through hole 8 is coaxial with the horizontal longitudinal axis X-X of the valve body (see Figure 4); the two metal spheric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com