Patents

Literature

680results about How to "Easy installation and construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

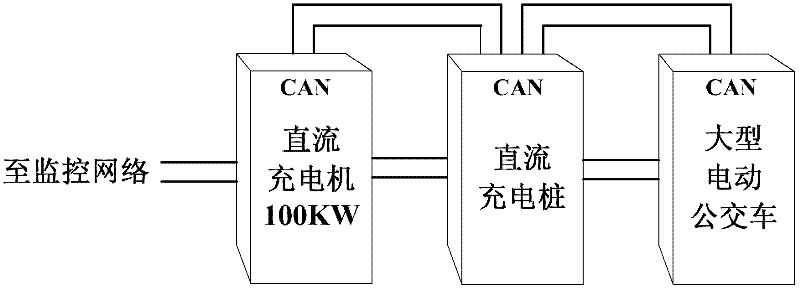

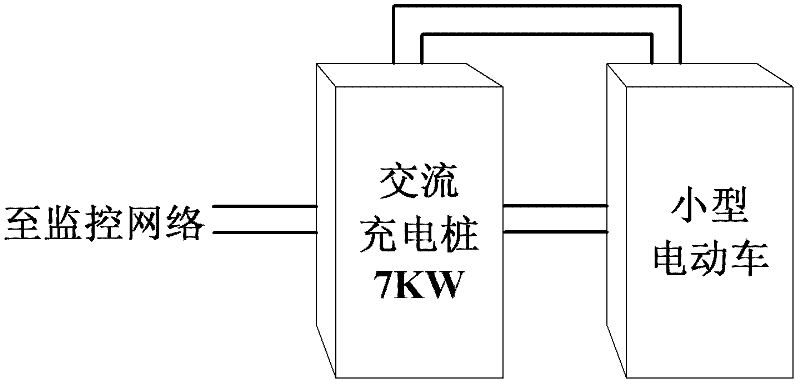

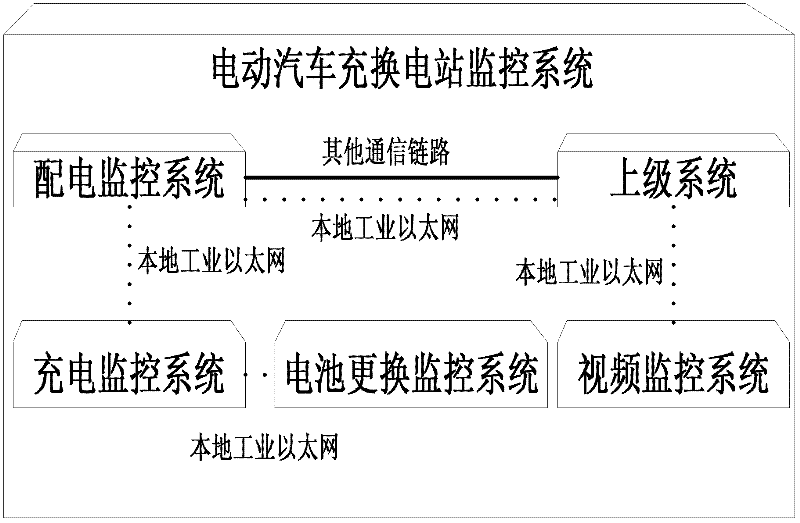

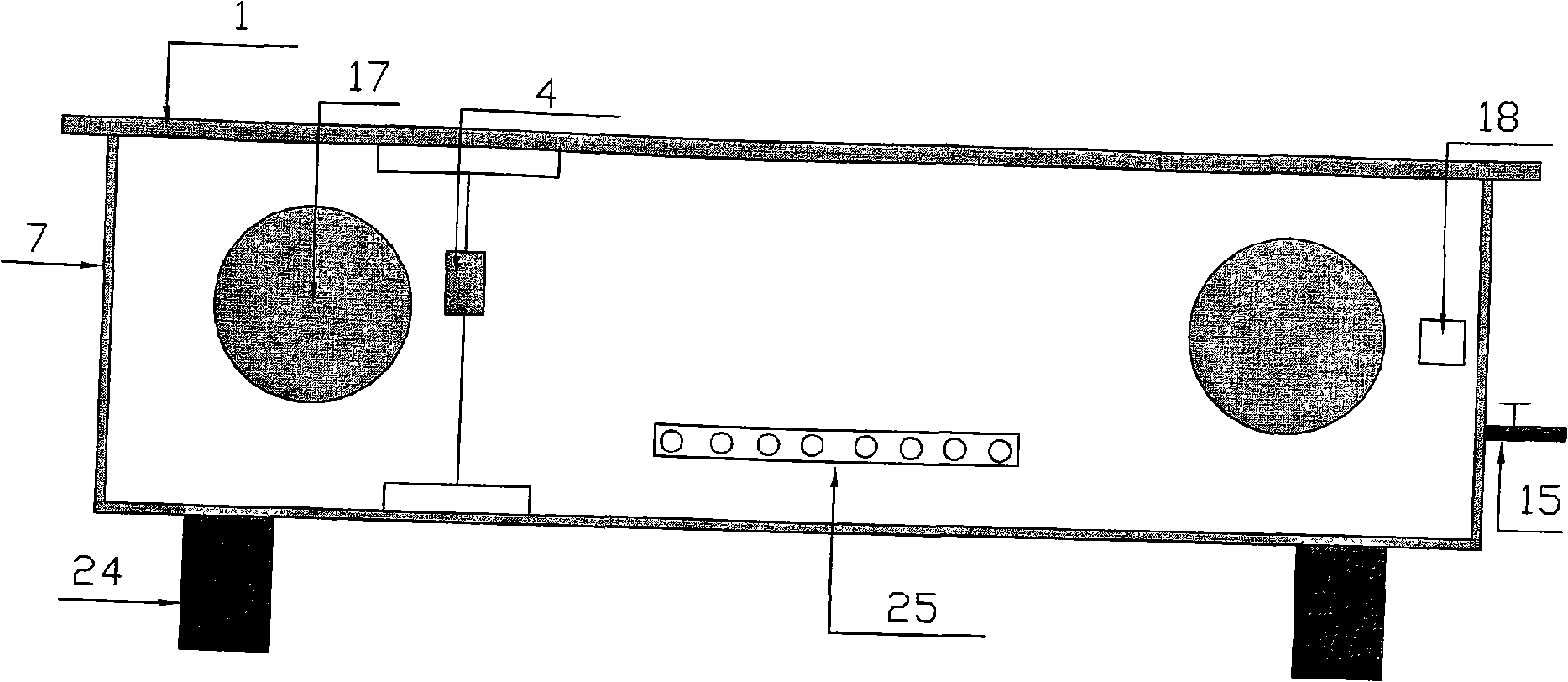

Monitoring system for electric automobile battery charging and replacing station

InactiveCN102315677ASolve the monitoring problem of compatible charging and swapping of large and small carsMeet the requirementsBatteries circuit arrangementsClosed circuit television systemsVideo monitoringDistribution power system

The invention relates to a monitoring system for an electric automobile battery charging and replacing station. The system comprises a superior system, an electricity distribution monitoring system, a charging monitoring system, a battery replacement monitoring system and a video monitoring system; a monitoring work station, a server, a printer, an electricity distribution system communication management machine and an electricity utilization information collecting terminal are connected with a network exchanger of the charging monitoring system through a local industrial Ethernet; a network exchanger of the electricity distribution monitoring system is connected with a communication gateway of the superior system through the local industrial Ethernet; an intelligent communication terminal of the battery replacement monitoring system is connected with the network exchanger of the charging monitoring system through the local industrial Ethernet; and a video server of the video monitoring system is connected with the communication gateway of the superior system through the local industrial Ethernet. The system can meet the requirement of electric energy complement of large commercial vehicles and small passenger vehicles and can realize omnibearing, effective and real-time monitoring on the battery charging and replacing of electric automobiles.

Owner:CHINA ELECTRIC POWER RES INST +1

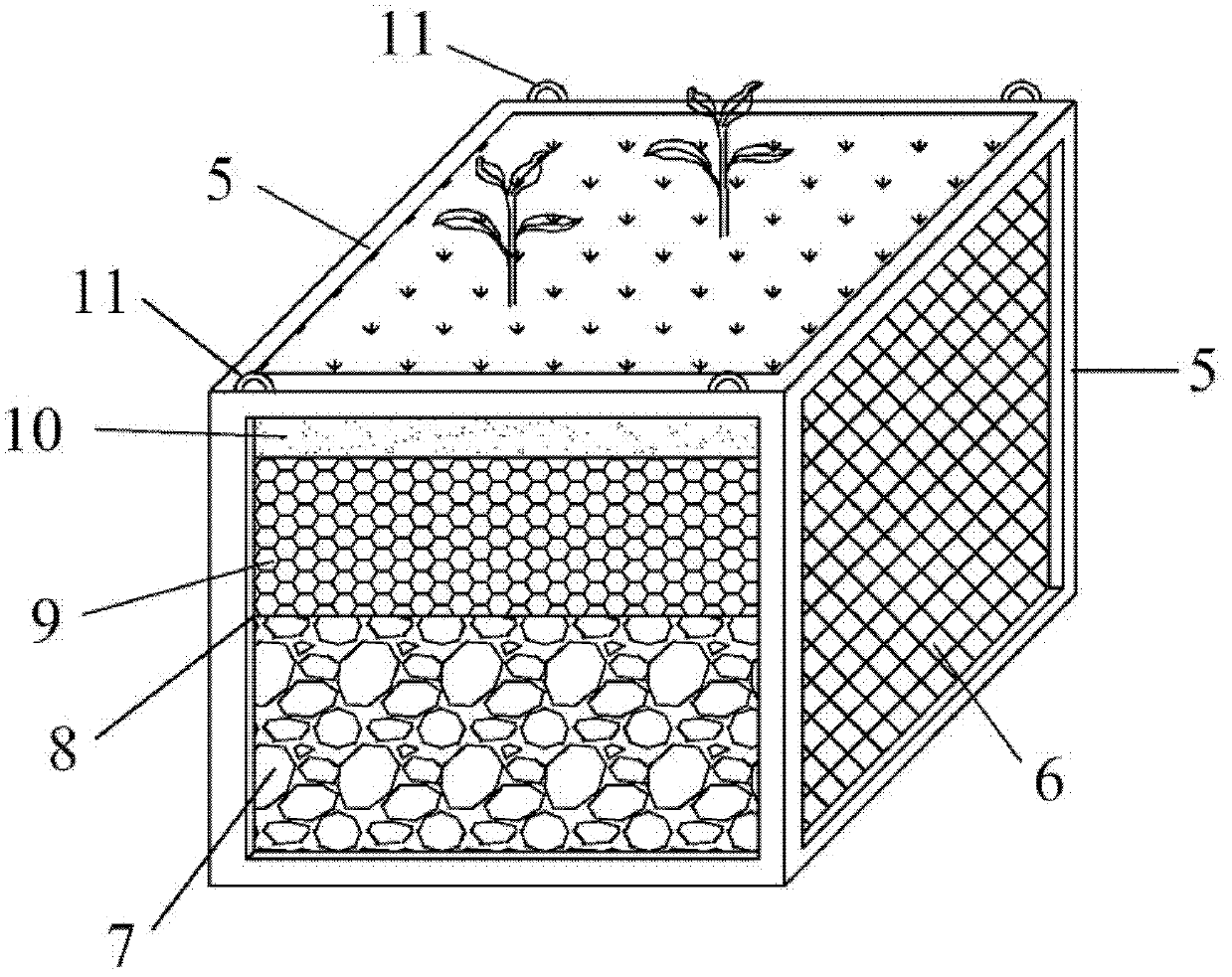

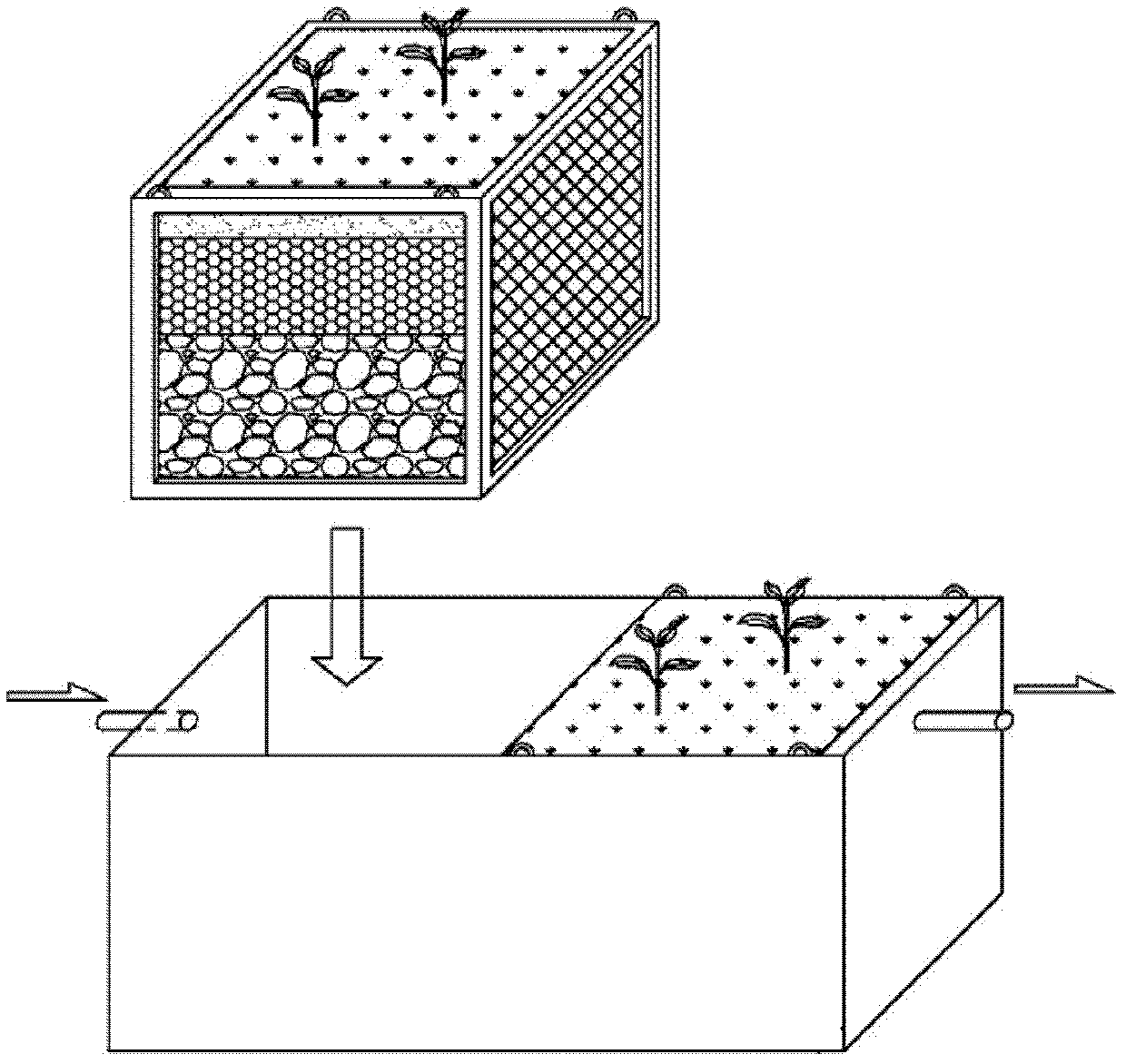

Modularized detachable constructed wetland

InactiveCN102603077ASimple structureEasy to installSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandWater quality

The invention discloses a modularized detachable constructed wetland, which is formed by a plurality of wetland modules, each module is relatively independent, and the module comprises a plurality of detachable filler units; each filler unit consists of a filler frame, a net separator and a filler layer, and the filler layer comprises a soil layer, a soil separation layer and a porous light filler layer from top to bottom. According to the water quality, the water yield and the water outlet requirement of the treated sewage, the wetland modules can be connected in series and in parallel or compositely connected to constitute a constructed wetland system. The modularized detachable constructed wetland has a simple structure, is convenient to install, is low in cost, and adapts to industrialized batch production. In the operation process of the wetland, the wetland modules and the filler units can be replaced and repaired at any time, the system is not blocked easily, the treatment effect is good, and the land can be reused.

Owner:王启明

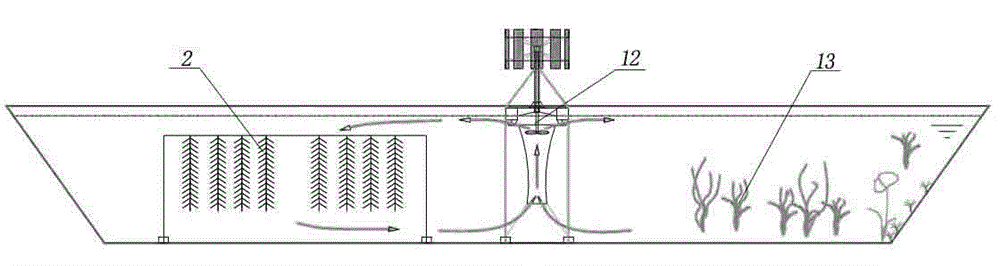

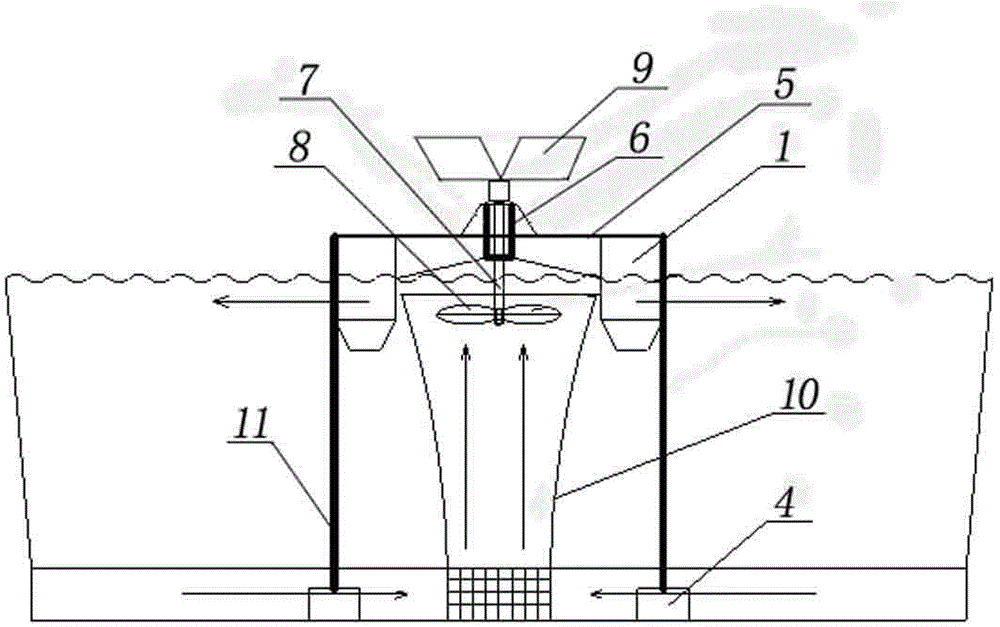

Technology for direct in-situ treatment and ecological restoration of polluted water body

InactiveCN102874934ALow investment costLow running costWater resource protectionEnergy based wastewater treatmentEutrophicationAquatic animal

The invention discloses a technology for direct in-situ treatment and ecological restoration of polluted water body, belonging to the field of environment protection. The technology is a systems engineering which synthesizes three contents: 1, a water flow stirring elevator for generating high-flow water flow is installed, fixed and used in water body, so that the water body which is free of flowability or very low in flowability is changed into running water from dead water, and the biochemical reaction environment of water body can be improved; 2, biological membrane fillers which are provided or enriched with a mass of microbial community are arranged in river and lake water body which is preferably oxygenated, so that the organic pollutants or the other microorganism-degradable pollutants in water can be effectively removed in a degradable way; and 3, aerobiont contact oxidation reaction in polluted and nutrition-enriched river and lake water body is carried out, the aquatic plants are planted and the aquatic animals are bred, and the pollutants in the river and lake water body are biologically degraded and purified, so that the in-situ treatment and purification of the polluted river and lake water body can be realized.

Owner:武汉昌宝环保工程有限公司

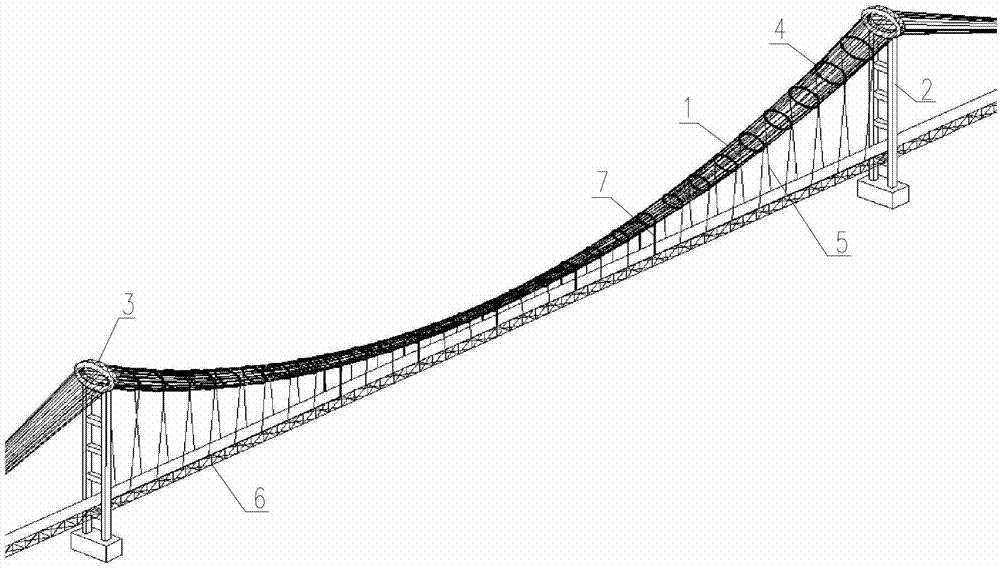

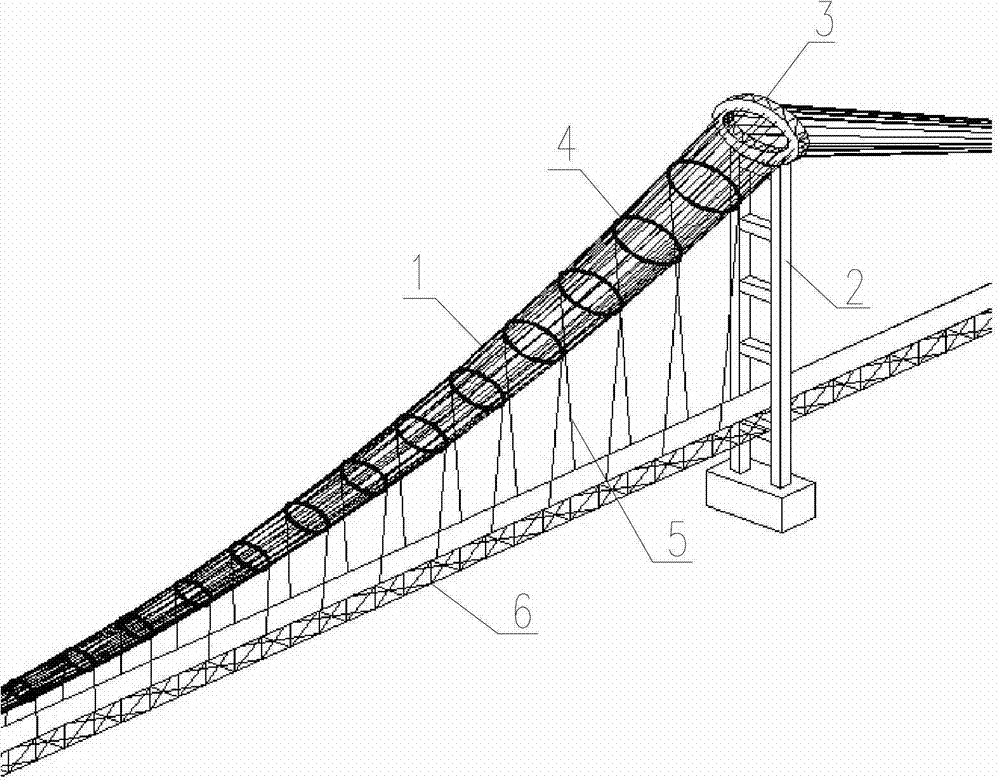

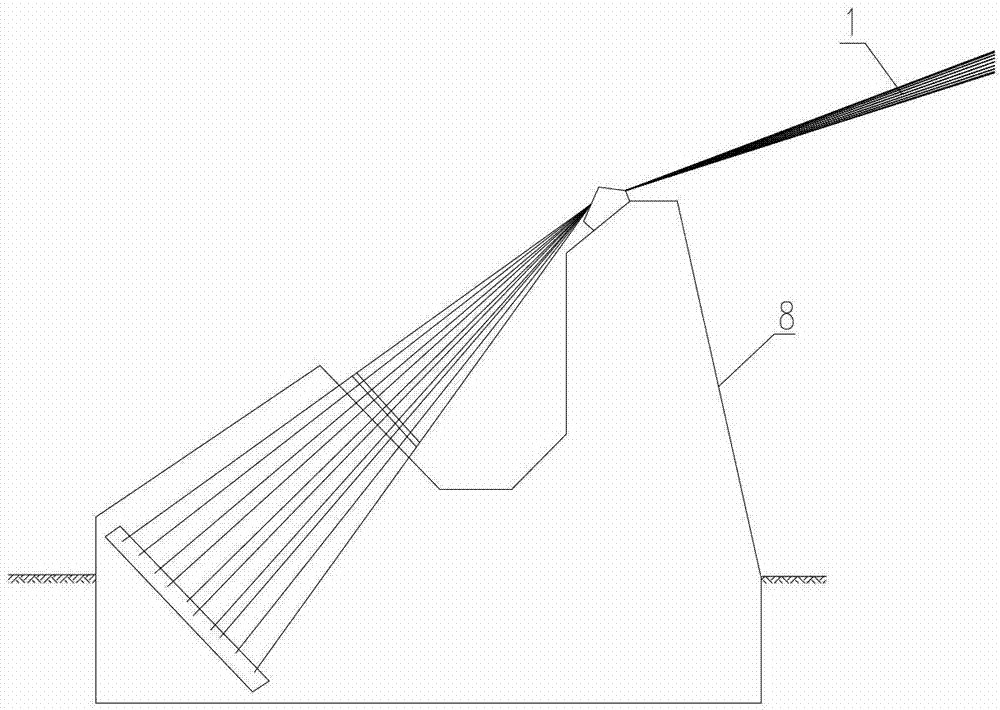

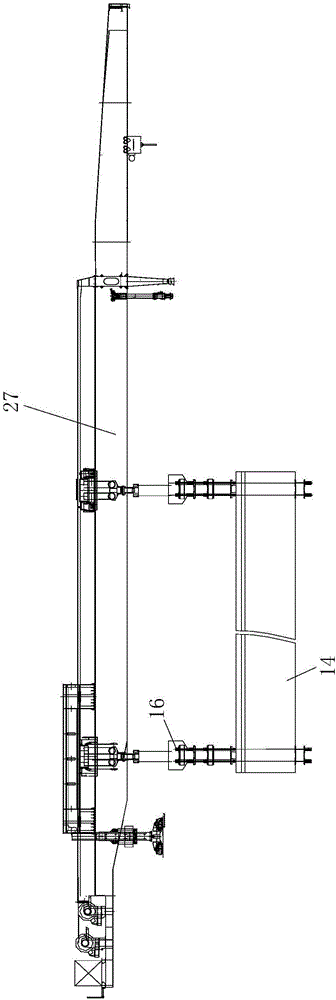

Especial-big span suspension bridge of uniparted hyperboloid space rope net main cable and construction method thereof

InactiveCN103088750AHigh lateral stiffnessLarge anti-lateral static wind load capacitySuspension bridgeBridge erection/assemblyHyperboloidSpatial structure

The invention provides an especial-big span suspension bridge of a uniparted hyperboloid space rope net main cable and a construction method thereof. A straight line character of the uniparted hyperboloid is used to change a vertical parallel cable rope system of an original suspension bridge. A thick and heavy centralized cable rope is changed into a dispersive space steel wire cable rope. Multiple strand of steel wire cable ropes are arranged in a cross mode. Space rope net main cable-cross nodes are fixed to form a space cable rope system of the uniparted hyperboloid type. An oval steel strengthening ring beam is arranged. A suspender and a stiffening beam are installed. A gate-type rigidity middle buckle is arranged. The especial-big span suspension bridge of the uniparted hyperboloid space rope net main cable system is built. The especial-big span suspension bridge of the uniparted hyperboloid space rope net main cable system has the advantages of being strong in span capacity, large in space structure rigidity, high in screw frequency ratio, good in wind resistance stability and the like. The novel space main cable system suspension bridge is capable of radically saving the problem of the wind resistance stability of the big span suspension bridge and used for projects of a striding sea connected island. The especial-big span channel suspension bridge of 3000-5000 meters is built.

Owner:SOUTHEAST UNIV

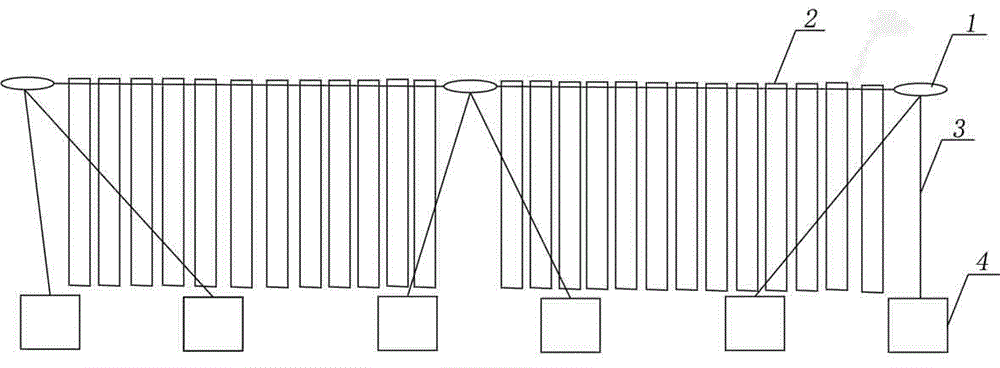

Jet printing type steel guard rail

ActiveCN101265694AImprove structural strengthAvoid deformationTraffic signalsRoad signsVertical barEngineering

The invention discloses a spraying type steel barrier, which comprises columns, upper cross bars, lower cross bars and vertical bars. The main bodies of the columns, the upper cross bars, the lower cross bars and the vertical bars are all integrated style steel works. The columns are made from the galvanized steel strip, made into steel pipe of a certain shape and sprayed with plastic or paint; the upper cross bars, the lower cross bars and the vertical bars are integrated parts which the upper cross bars, the lower cross bars and the vertical bars are respectively made from the galvanized steel strip, steel pipes of a certain shape are made through extrusion forming of the steel pipe stock mould, seam welding of the high frequency induction welder and extrusion forming of the steel pipe shaping mould and the integrated parts are formed by placing the vertical bars between the upper cross bars and the lower cross bars, welding and fixing, and at last spraying plastic or paint on the exterior surface of the integrated parts. The spraying type steel barrier has the advantages of high structural strength, deformation resistance, beautiful and clean barrier surface, rustiness resistance, easy cleaning, greatly reduced maintenance cost, both the beautiful appearance of the PVC plastic steel barrier and the high strength of the assembly type barrier.

Owner:JIANGSU AIKEQING IND

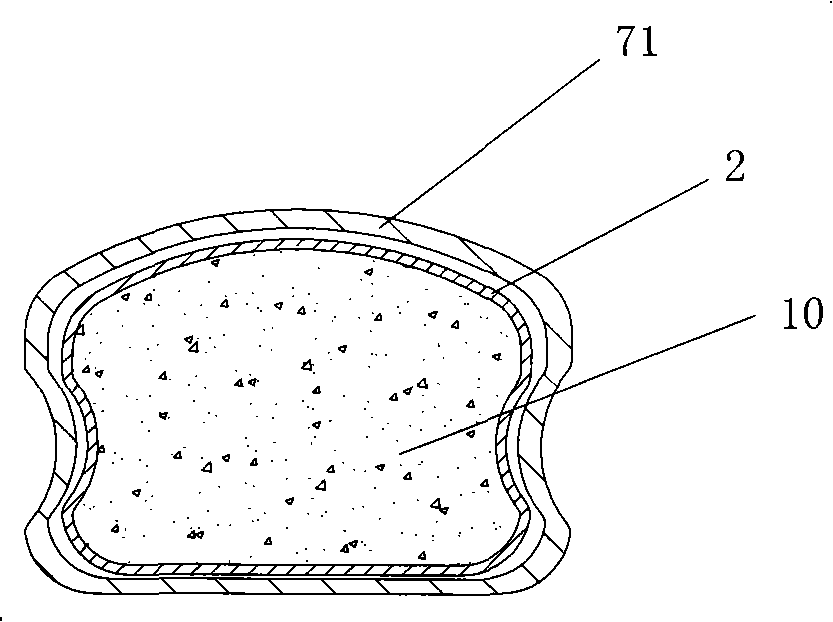

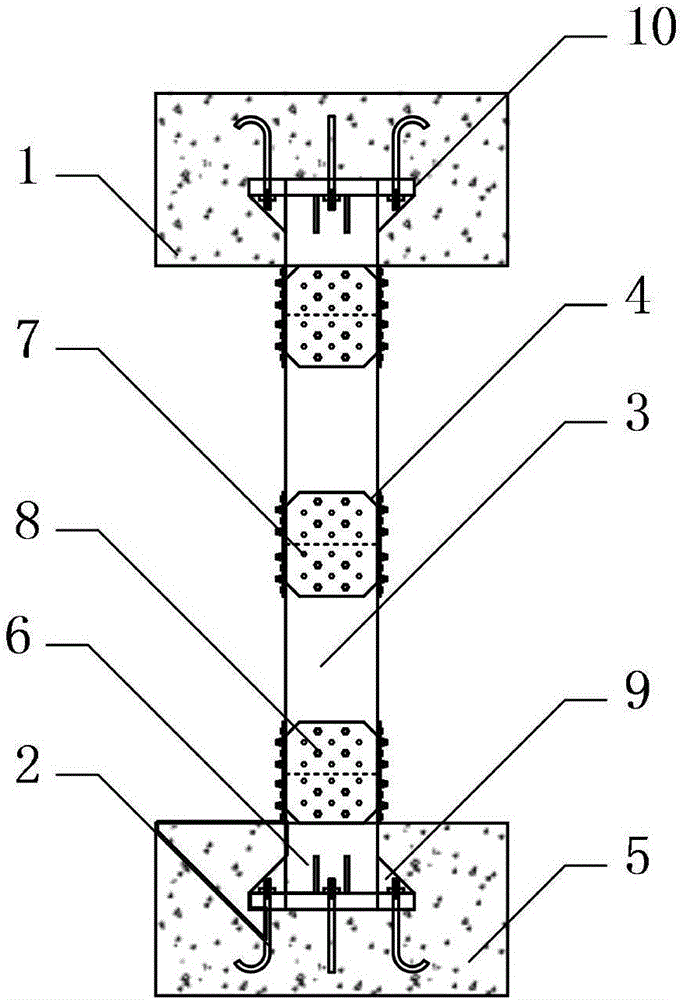

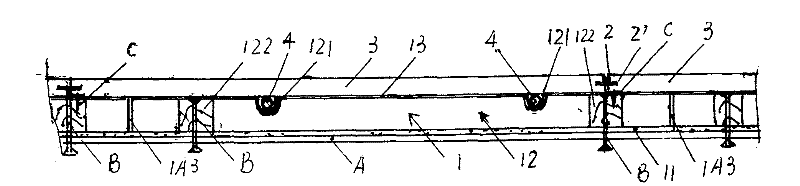

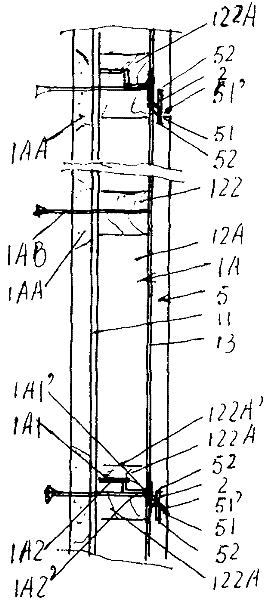

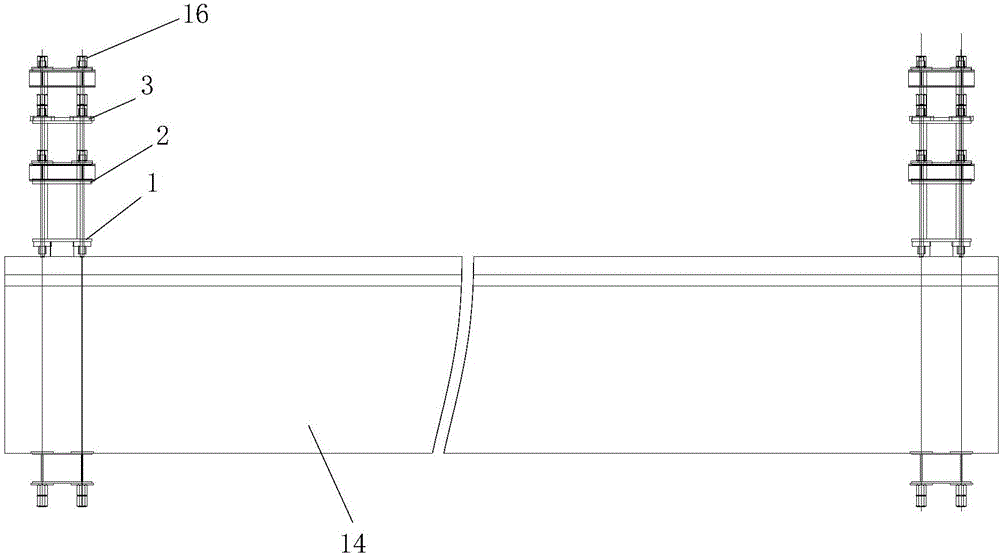

Bolt connection-based rapid assembling precast rectangular concrete filled steel tube bridge pier

ActiveCN105735112AImprove stress resistanceImprove carrying capacityBridge structural detailsBridge erection/assemblyBridge engineeringPolyvinyl chloride

The invention discloses a bolt connection-based rapid assembling precast rectangular concrete filled steel tube bridge pier, and belongs to the field of bridge engineering. The bolt connection-based rapid assembling precast rectangular concrete filled steel tube bridge pier comprises precast rectangular concrete filled steel tube sections, pre-buried nodes, connecting plates, high-strength bolts and core penetration bolts; each precast concrete filled steel tube section consists of a steel tube section, concrete, reserved core penetration bolt hole channels, reserved bolt holes, precast screw caps, a sealing material and PVC (Polyvinyl Chloride) tubes; each pre-buried node consists of a precast rectangular concrete filled steel tube section, a foot plate, outside-stiffened ribs and anchor bolts; bolt holes and core penetration bolt holes are formed in each connecting plate according to bolt design positions; adjacent precast concrete filled steel tube sections are connected with each other by the connecting plates, the high-strength bolts and the core penetration bolts. The bolt connection-based rapid assembling precast rectangular concrete filled steel tube bridge pier has the characteristics of high anti-pressure and anti-shear bearing capacity, excellent anti-seismic property, easiness in factory production, convenience and rapidness in site operation, energy conservation, environmental friendliness and the like.

Owner:BEIJING UNIV OF TECH

Novel multi-purpose fireproof composite heat-insulation plate

InactiveCN102304969APlay a role in strengthening supportMake up for the defect of low compressive strengthCovering/liningsSustainable buildingsCompound aSurface layer

The invention relates to a novel multi-purpose fireproof composite heat-insulation plate comprising a fireproof composite heat-insulation plate body, a fastener and a heat storage substrate plate or a surface-layer veneer plate, wherein the fireproof composite heat-insulation plate body sequentially is formed by sequentially compounding a protective layer, a composite heat-insulation plate or a heat-insulation plate and a fireproof antiflaming reflecting layer or a reflecting layer from bottom to top; an underfloor heating pipe groove is arranged at the upper end of the composite heat-insulation plate or the heat-insulation plate; and the heat storage substrate plate or the surface-layer veneer plate and a supporting base in the composite heat-insulation plate are anchored on the fireproof composite heat-insulation plate body and an underfloor heating pipeline by using the fastener and a bolt or using the bolt directly. The novel multi-purpose fireproof composite heat-insulation plate is suitable for dry-type or wet-method low-temperature radiation heating of floors of various structural forms including steel structures and the like and inner and outer walls and roof heat insulation, improves the fireproof property of the composite heat-insulation plate, ensures that the composite heat-insulation plate can meet the new fireproof requirement and ensures the fire safety of building heat-insulation materials, and has the advantages of simplicity and convenience for installation, lower cost, economy and practicability, broad application and better decoration effect.

Owner:冯刚克

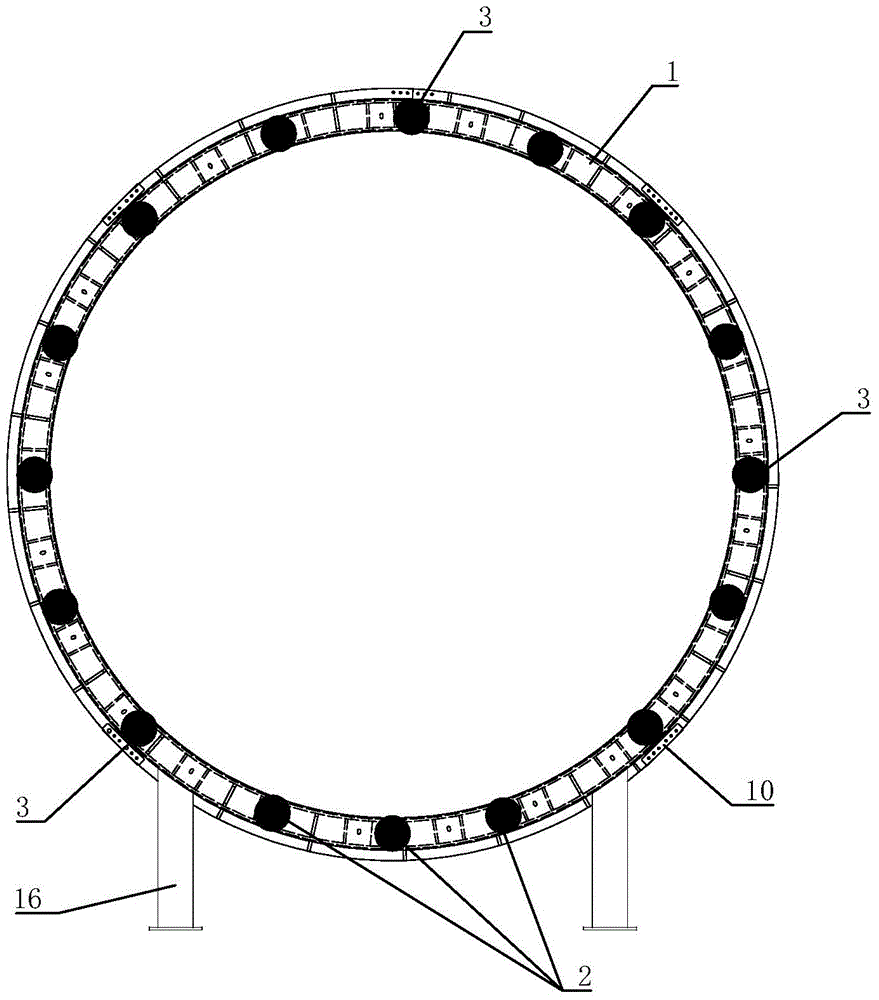

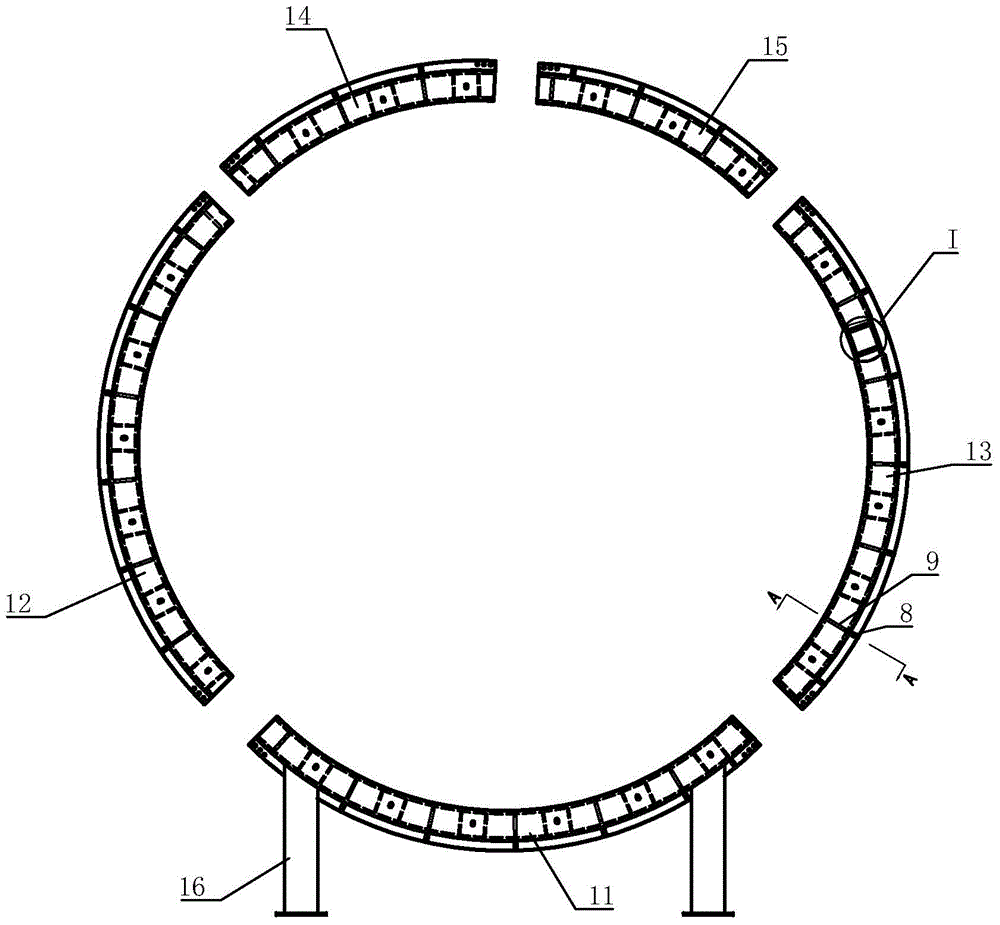

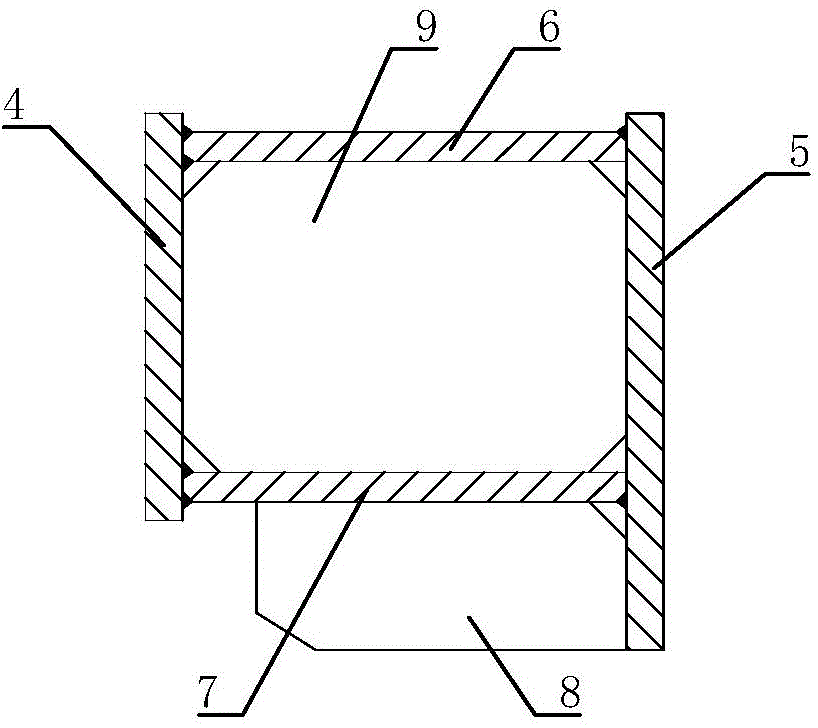

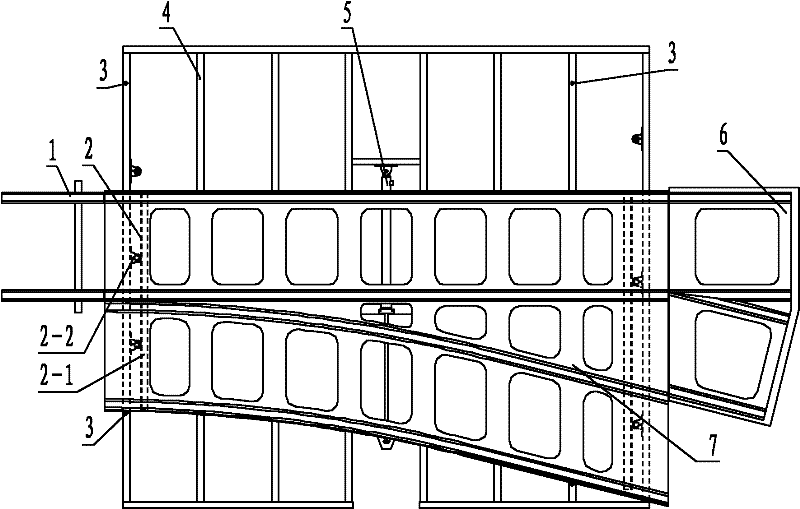

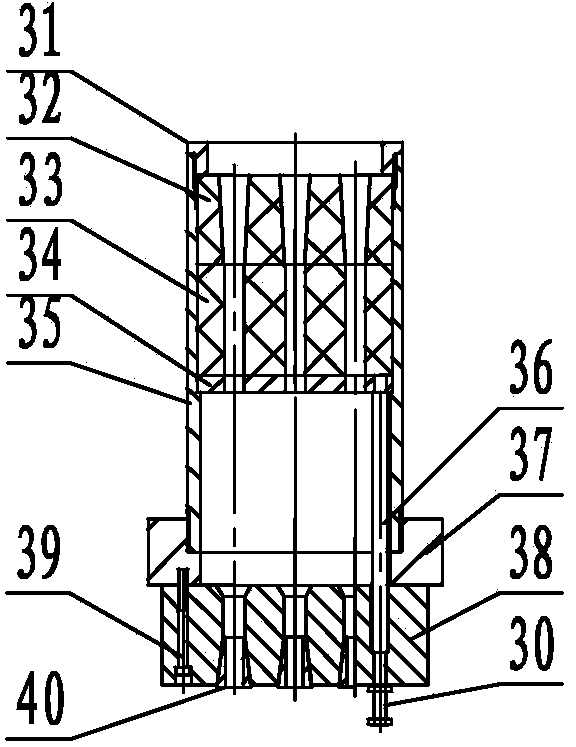

Shield launching counter-force frame and installation and use method thereof

ActiveCN103953353AIncreased driving safetyImprove stress environmentTunnelsShield tunnelingUltimate tensile strength

The invention relates to a shield launching counter-force frame. Counter-force is supplied for launching of a shield tunneling machine in a formed circular tunnel by means of an annular steel ring body favorably, thus the stress environment of the counter-force frame is improved well, the transmission pathway of the counter-force is transformed, 16 steel supports are arranged on the steel ring body, the steel supports act on the steel ring body simultaneously, the integral strength, stiffness and stability of the counter-force frame are improved, the stress of the counter-force frame is reduced, meanwhile, the steel ring body is formed by splicing multiple arc segments, thus installation and construction of the counter-force frame in the tunnel are facilitated, the risk of construction work is reduced, and the safety of the shield tunneling is increased. The invention also relates to an installation and use method of the shield launching counter-force frame. The shield launching counter-force frame and the installation and use method thereof can be applied to shield construction of the circular tunnel.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP

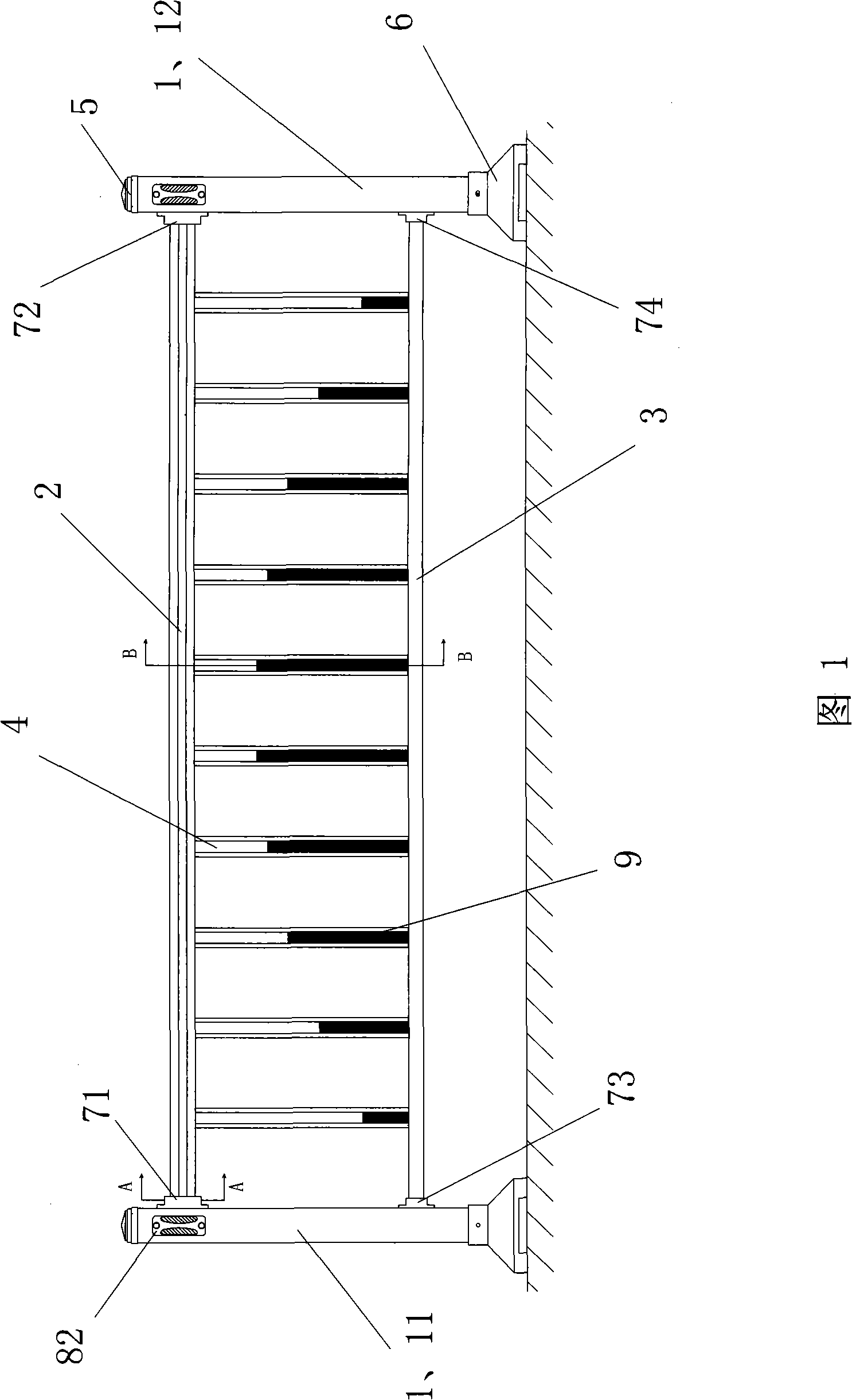

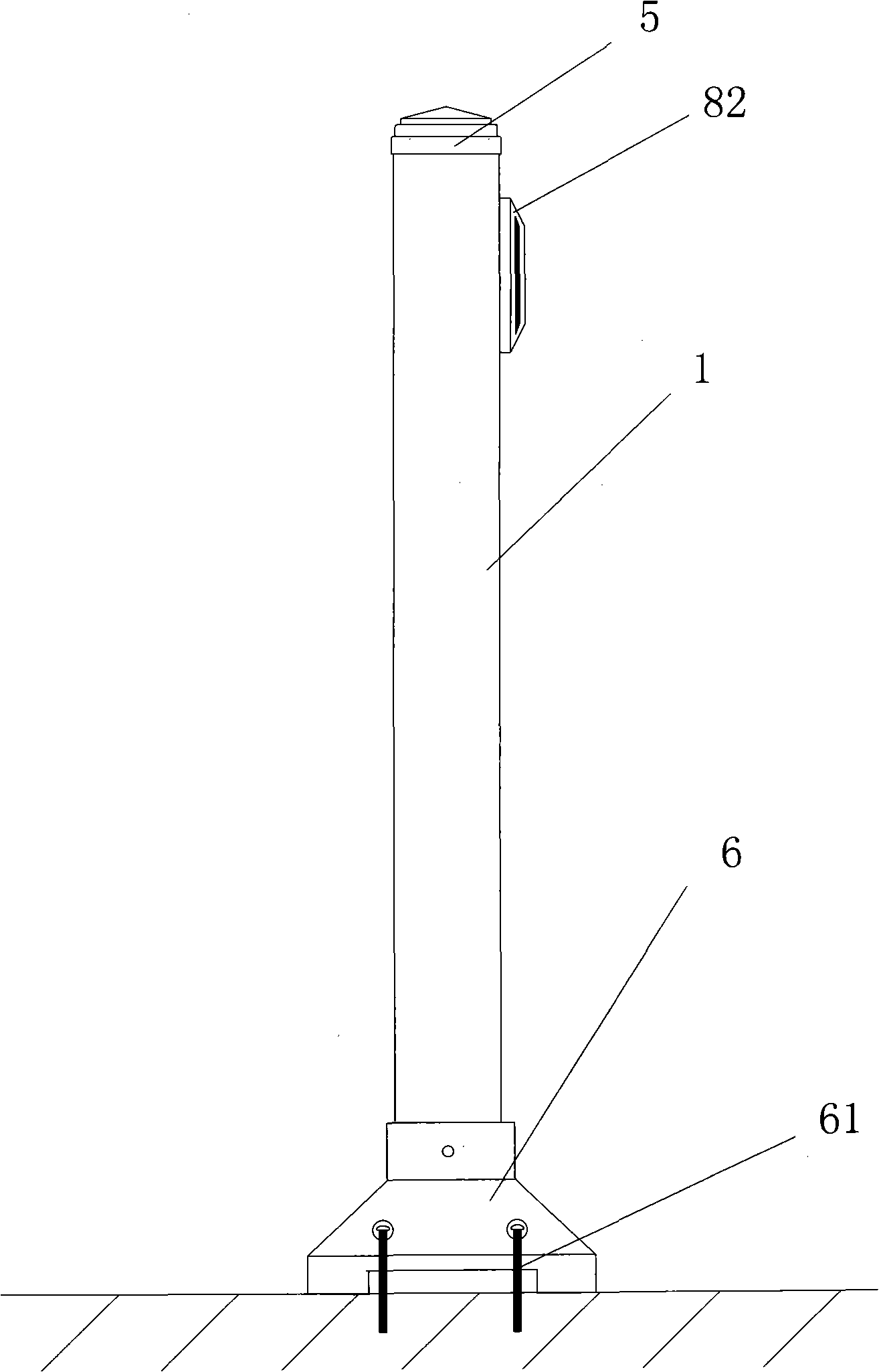

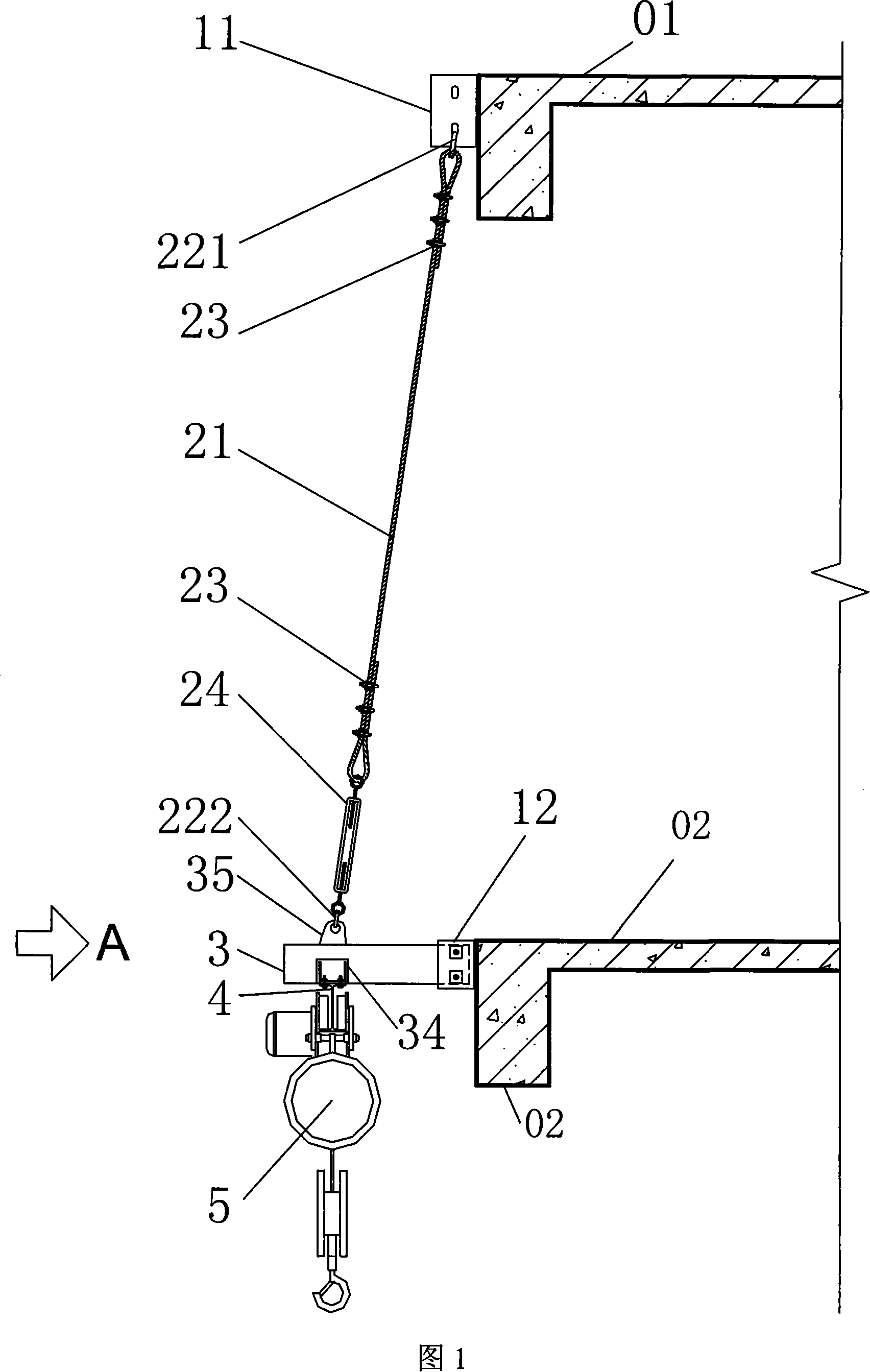

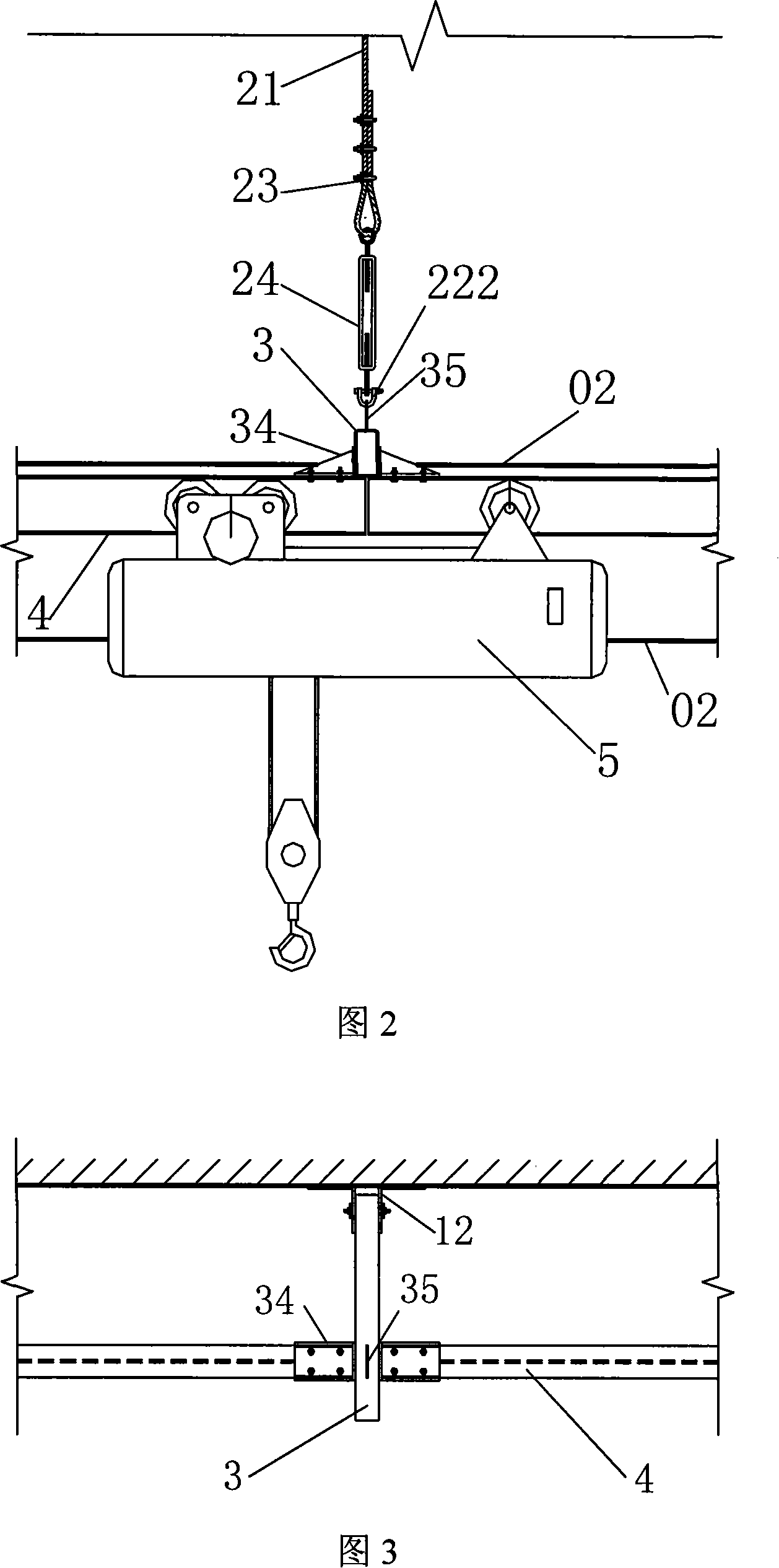

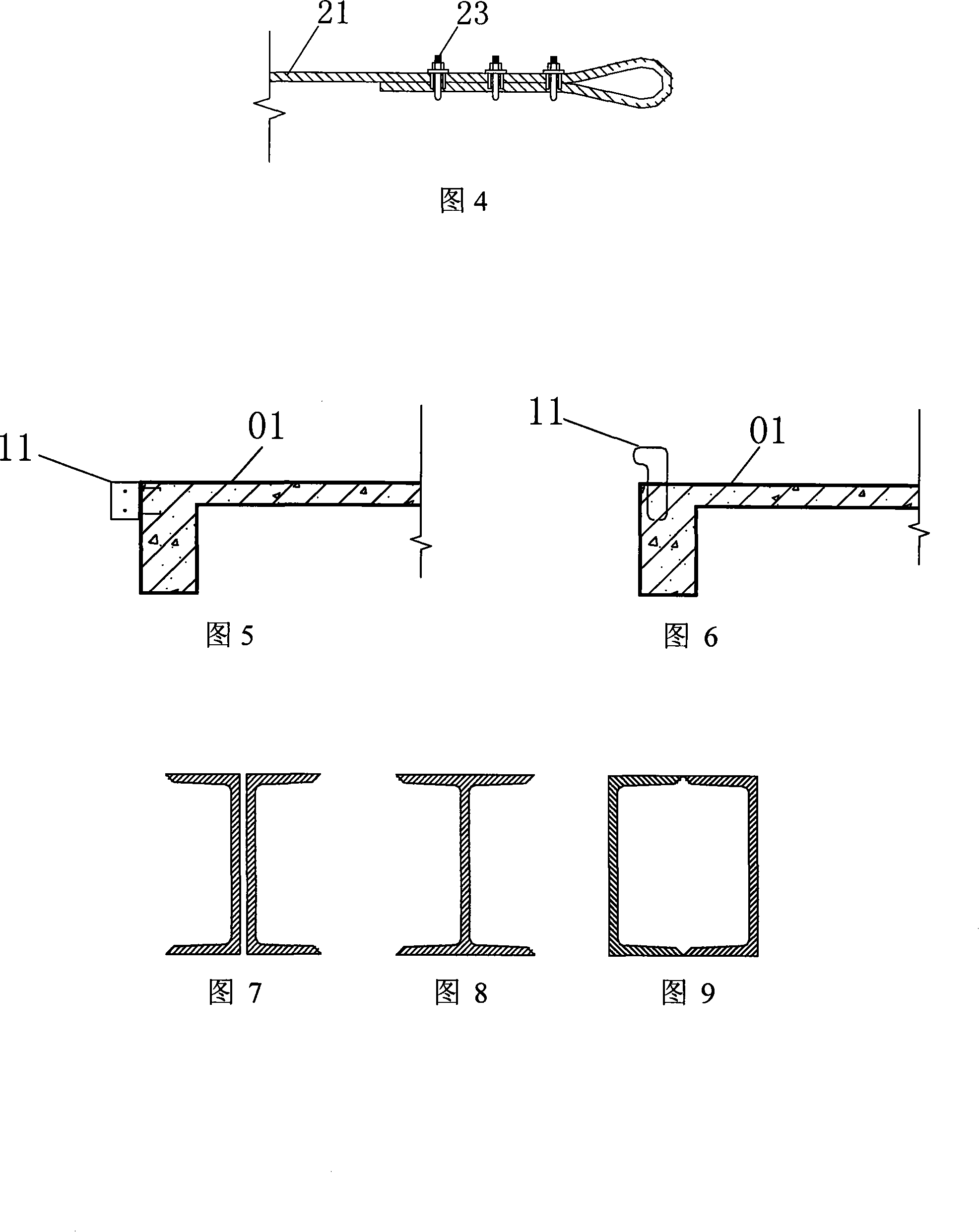

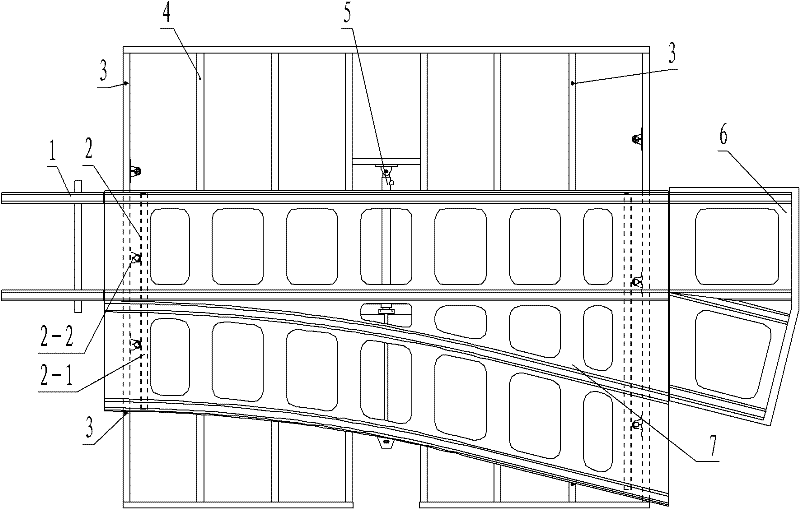

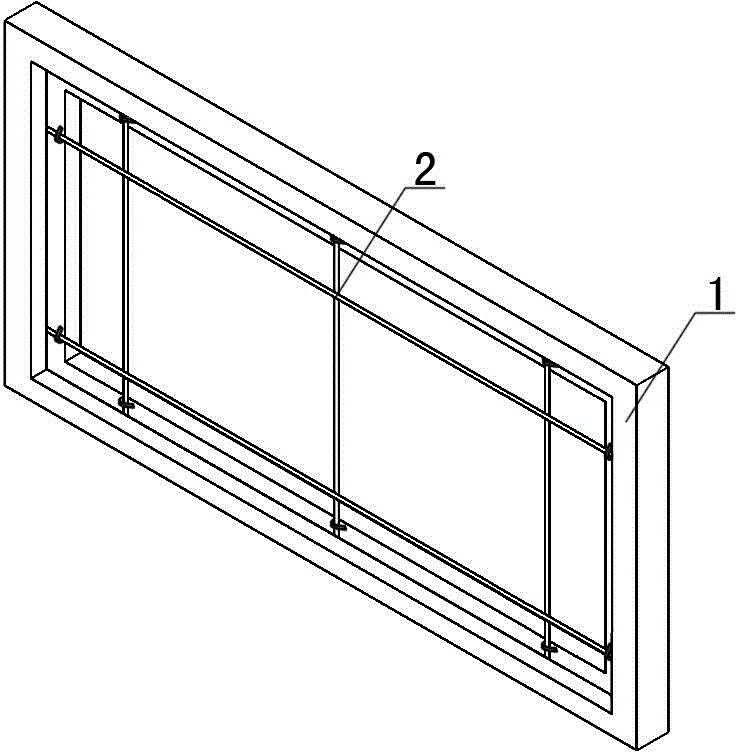

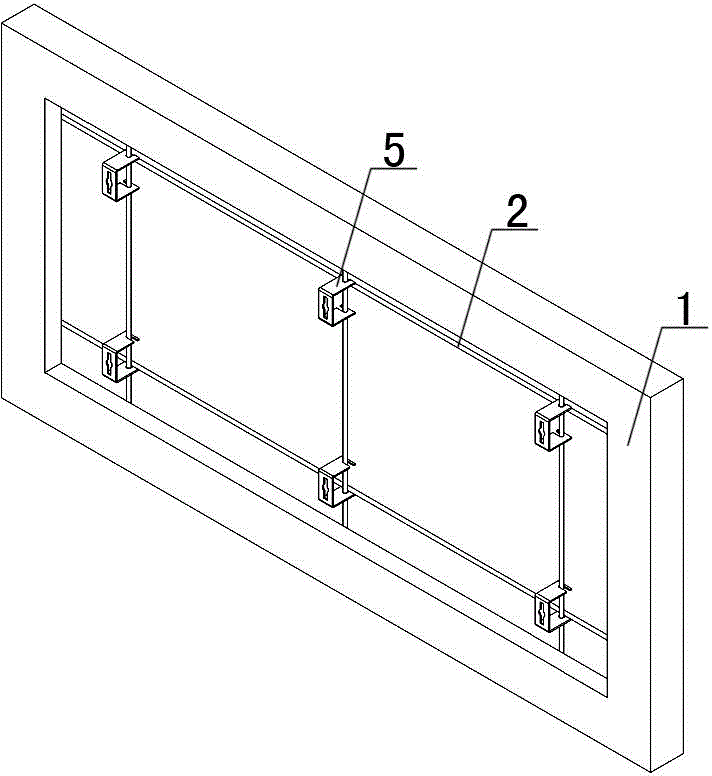

Overhead monorail for unit type glass curtain wall mounting construction and its mounting method

ActiveCN101239693AEasy installation and constructionAccelerate construction progressWallsCranesUpper floorUnit type

The present invention provides a monorail hoist for mounting unit type glass curtain wall and its mounting method, the monorail hoist includes a mounting floor fixed block fixed on the floor structure and an upper floor fixed block, a suspension gear for connecting the upper floor fixed block and the supporting beam, a supporting beam fixed on floor and hung by suspension gear, a rail fixed on the supporting beam, and a hoisting machine travelling on the track; when the monorail hoist is mounted, firstly mounting the supporting beam and the suspension gear, then hoisting the track to the supporting beam, the hoisting machine is mounted on the track and proceeded testing receiving inspection after correcting track; the invention processes inserting construction of the unit type glass curtain wall from below without accomplishment of the building main structure aimed at the problem of the longer construction period of the super high-rise building main structure, paralleling to the main structure, and synchronous construction, accelerating construction progress; and also has a convenient construction, high efficiency, high handling quality and safe construction; and repeatedly detachbale use and a lower equipment cost.

Owner:GUANGZHOU CONSTR ENG +1

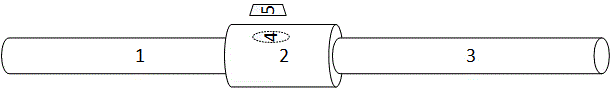

movable rail switch

InactiveCN102261023AEasy to passSolid foundationRail switchesFluid-pressure devices for scotch-blocksEngineeringMechanical engineering

The invention discloses a movable railway switch. This movable railway switch comprises a basic rail (1) and a switch rail (6), and the switch rail (6) comprises more than two groups of rails leading to different directions, and in the basic rail (1) and switch rail ( 6) Movable rails (7) are arranged between them, and the movable rails (7) are arranged side by side with more than two groups of rails corresponding to the frog rails (6), and are arranged below the movable guide rails (7) There are sliding devices. The movable railway switch of this technical scheme can ensure the passage of transport vehicles with transmission components in the middle of the railway track, has convenient operation, simple structure, and meets the requirements of actual use after trial use.

Owner:YANGZHOU KAISITE MACHINERY

Polyethylene cable duct

ActiveCN102617914AHigh tensile strengthNo brittle crackingCable installations in underground tubesPolymer scienceCrack resistance

The invention discloses a polyethylene cable duct. The polyethylene cable duct is characterized by being prepared from a modified polyethylene material; and the modified polyethylene material consists of the following components by weight: 100 parts of base material, 1 to 5 parts of ethylene propylene diene monomer resin, 0.1 to 1 part of polytetrafluoroethylene, 0.1 to 1 part of calcium stearate, 0.1 to 1 part of polyethylene wax and 0.01 to 0.1 part of pigment, wherein the base material consists of 85 to 95 weight percent of high-density polyethylene and 5 to 15 weight percent of ultra-high molecular weight polyethylene. The polyethylene cable duct has the following excellent performance: (1) high tensile strength; (2) high impact strength: the polyethylene cable duct has excellent low-temperature impact resistance and extremely low brittleness temperature and can be safely used at the temperature of between 20 DEG C below zero and 60 DEG C; (3) high abrasion resistance; (4) high toughness, flexibility and shock resistance; (5) high stress cracking resistance and low notch sensitivity; (6) corrosion resistance and long service life; and (7) simplicity in cable threading.

Owner:GUANGDONG SANLING PLASTIC PIPE MATERIAL

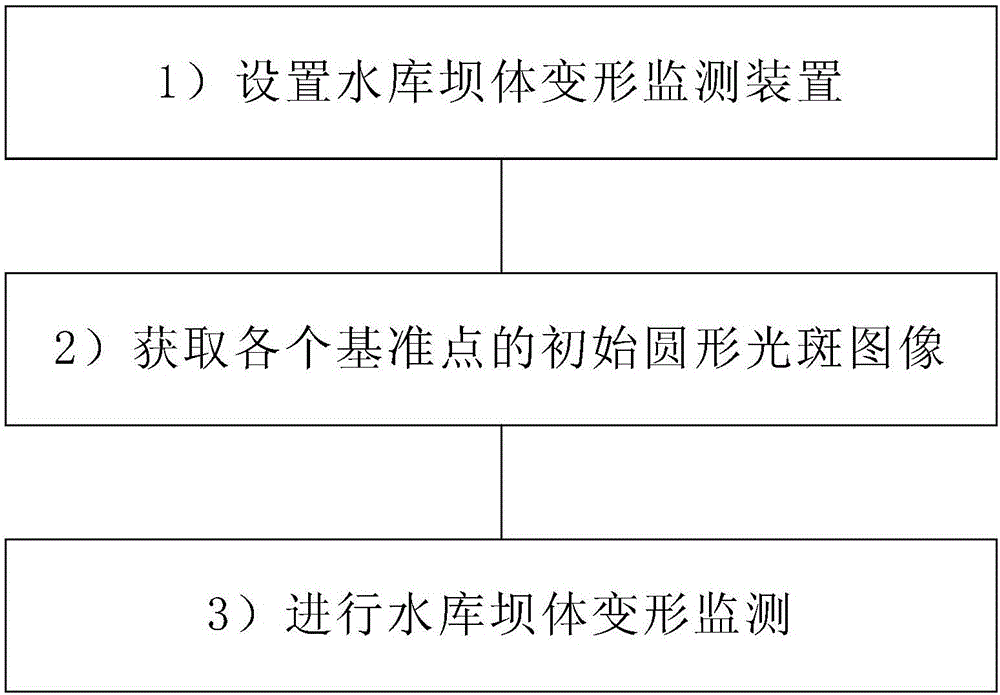

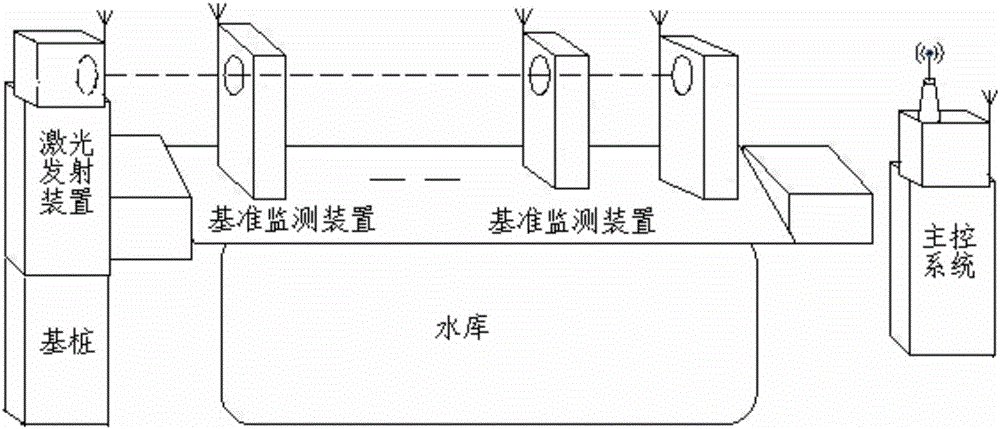

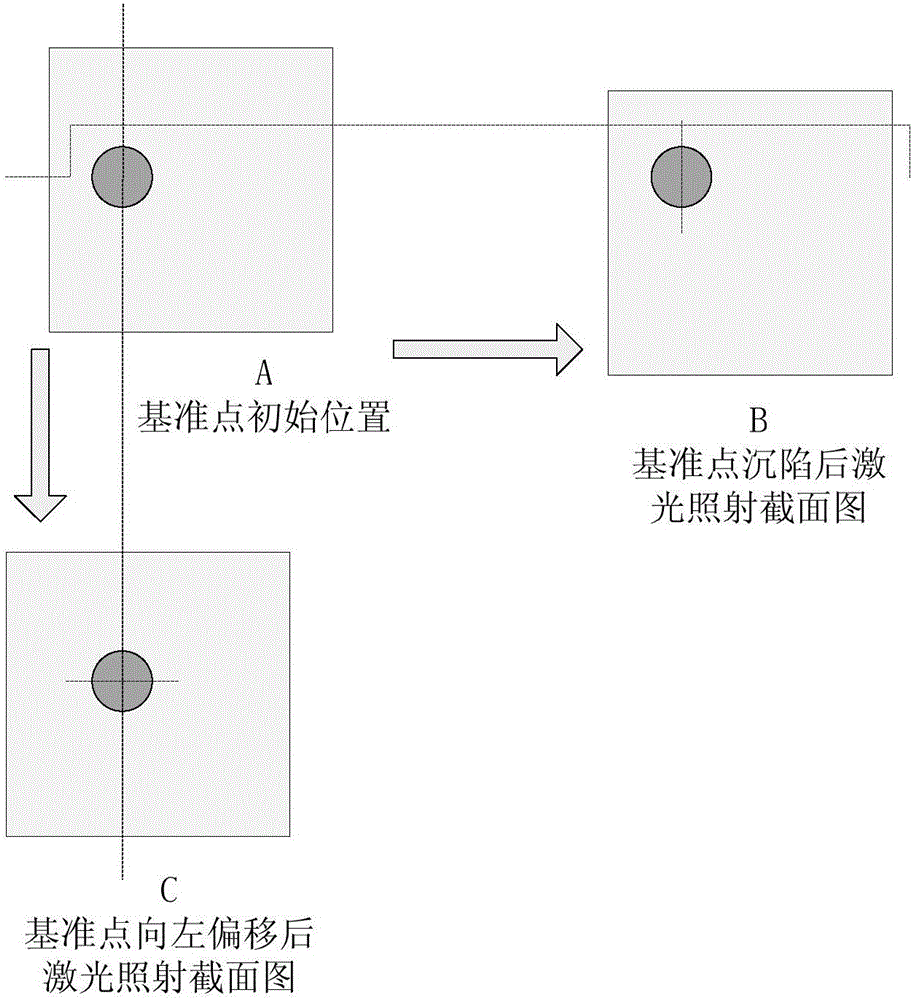

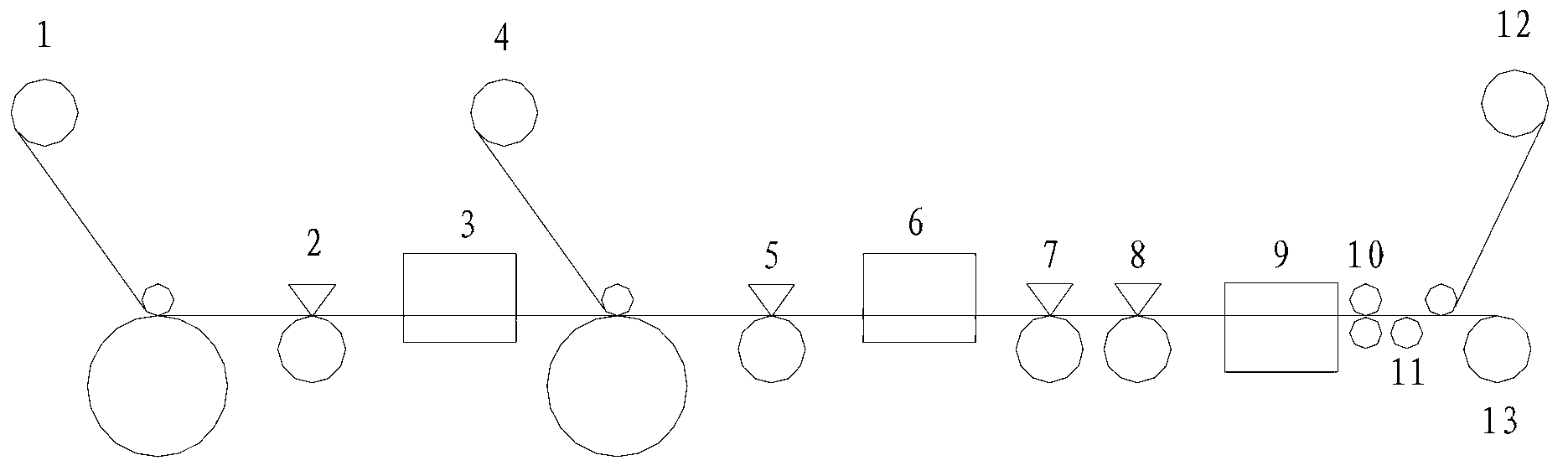

Reservoir dam deformation monitoring method and system

InactiveCN106595506AHigh measurement accuracyRealize automatic monitoring functionUsing optical meansLight spotControl system

The invention relates to a reservoir dam deformation monitoring method and system. The monitoring method includes the following steps that: 1) a reservoir dam deformation monitoring device is set; 2) the initial circular light spot images of each reference point are obtained; and 3) reservoir dam deformation monitoring is carried out. The reservoir dam deformation monitoring system includes a laser emitting device, reference point detecting devices and a main control system; the laser emitting device is arranged at one end of a dam and is used for emitting collimating laser light adopted as a reference line; a plurality of reference points with equal intervals are arranged one a ray with the laser emitting device adopted as an end point; one reference point detecting device is arranged at each reference point; the reference point detecting devices are used for detecting the subsidence and horizontal displacement of the dam; and the main control system is connected with the laser emitting device and the reference point detecting devices through a wireless communication mode and is used for transmitting detection commands, receiving detected data and performing analysis processing on the detected data. With the reservoir dam deformation monitoring method and system of the invention adopted, the automatic detection of the subsidence and horizontal displacement of the dam can be realized, the measurement accuracy of the reservoir dam is improved, and monitoring costs can be reduced.

Owner:UNIV OF JINAN

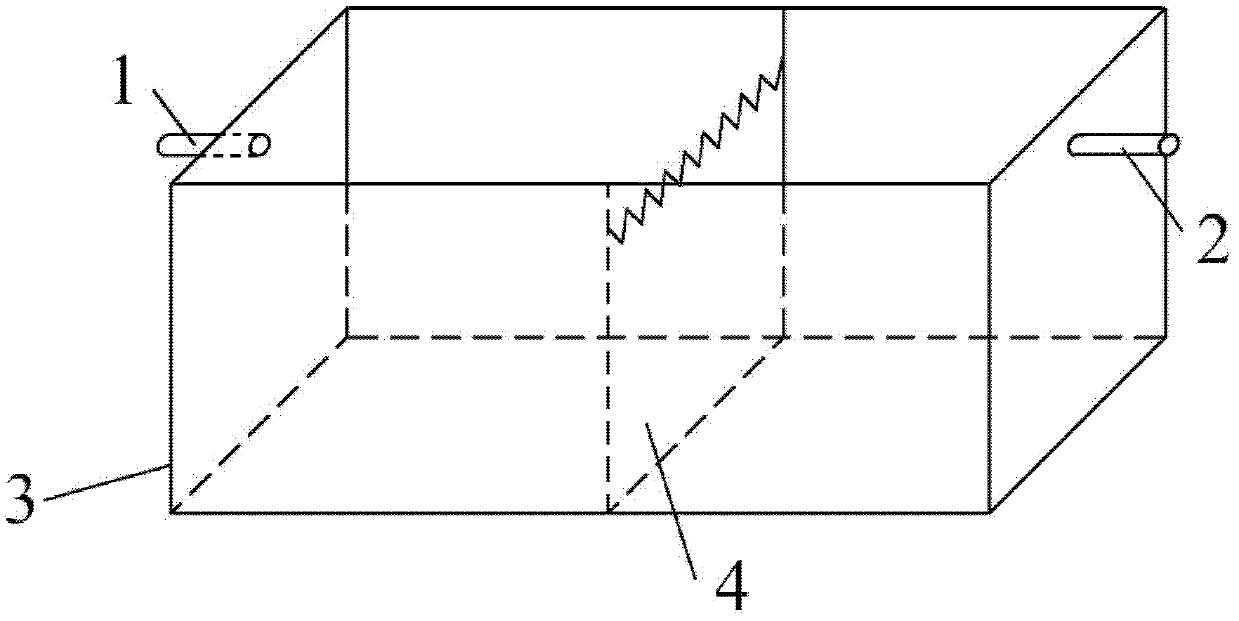

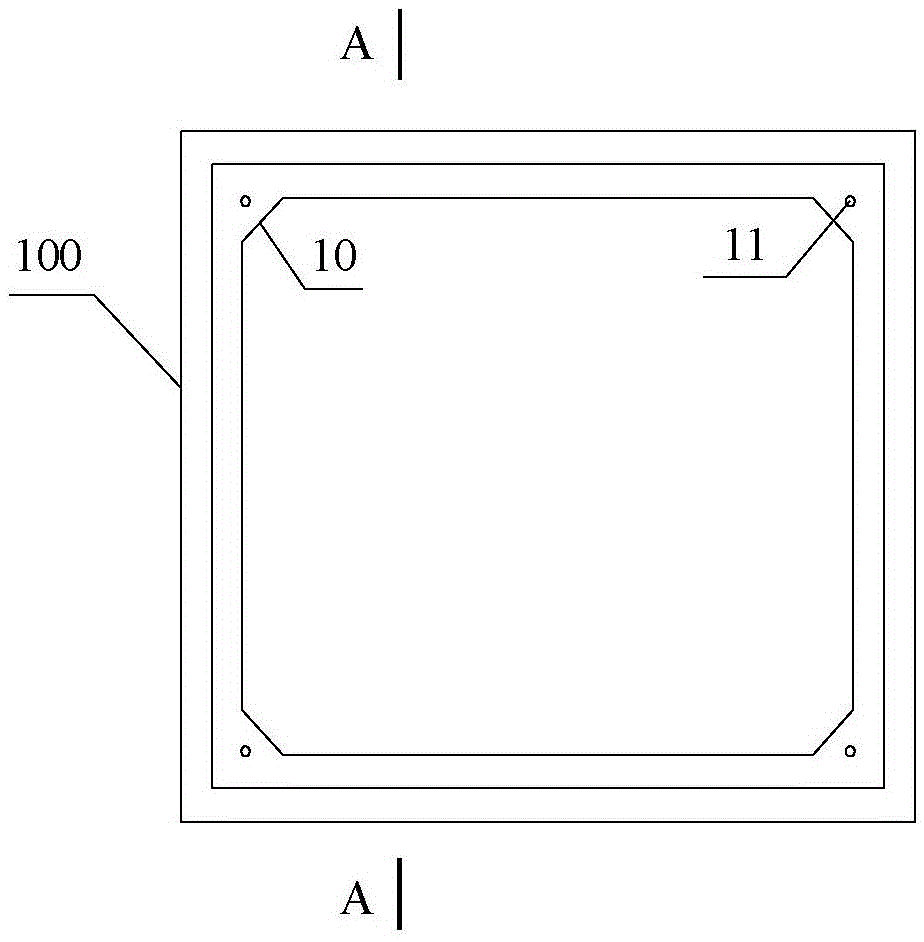

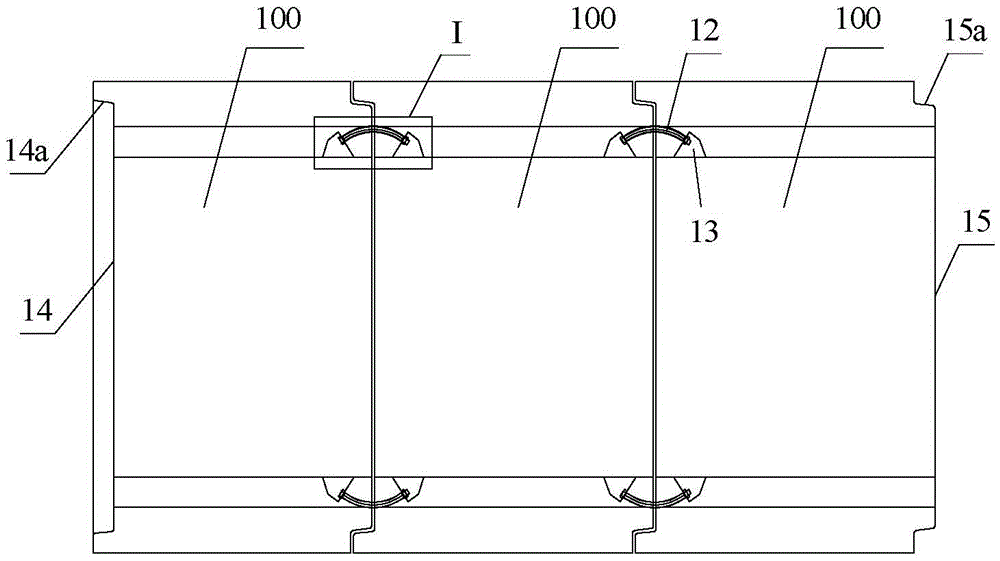

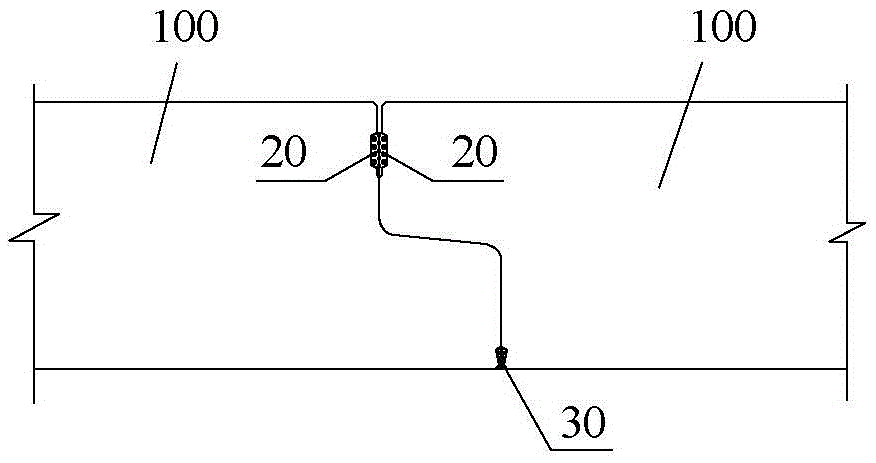

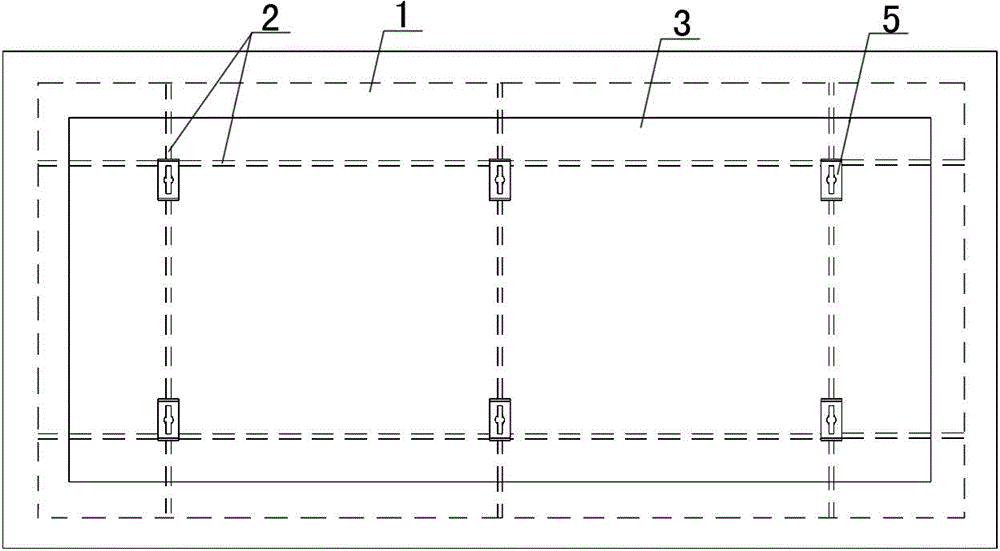

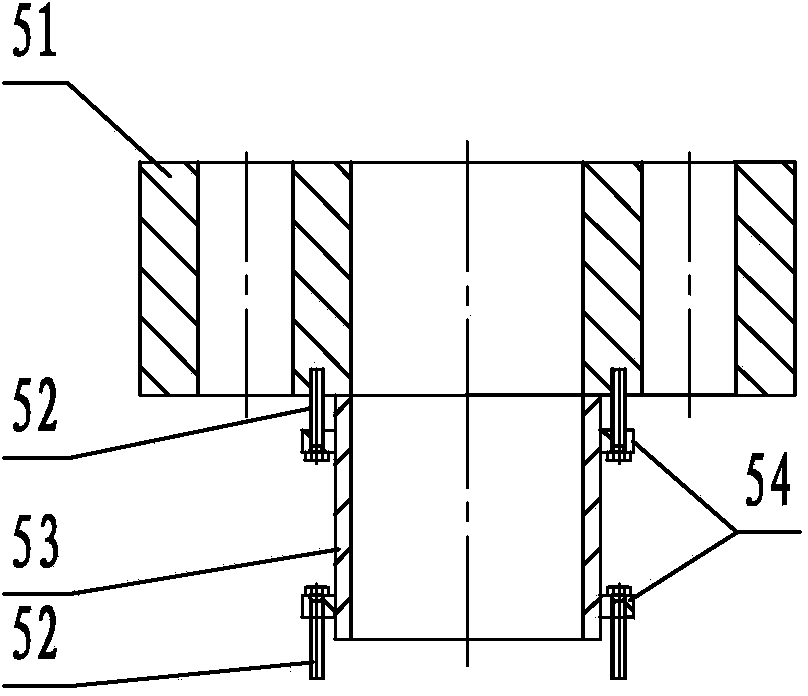

Pipe gallery prefabricated parts and assembly type rectangular comprehensive pipe gallery

ActiveCN105569076ASimple structureEasy installation and constructionArtificial islandsUnderwater structuresEngineeringButt joint

The invention provides pipe gallery prefabricated parts and an assembly type rectangular comprehensive pipe gallery. Each pipe gallery prefabricated part comprises a rectangular pipe section body. Each pipe section body comprises an insertion end and a socket end. The protruding portion of each insertion end is annularly arranged along an end opening and matched with an annular notch formed corresponding to the corresponding socket end. Circular-arc-shaped bolt connecting holes are correspondingly formed in all corners of each insertion end and the corresponding socket end. Nut operation hand holes are formed in the ends, located on the inner surface of each pipe section body, of all the bolt connecting holes. When two pipe gallery prefabricated parts are inserted, all corresponding bolt connecting holes in the inserting position are subjected to butt joint to form pipe gallery bolt connecting holes. The comprehensive pipe gallery comprises the pipe gallery prefabricated parts, circular-arc bolt mechanisms and sealing structures. Each circular-arc bolt mechanism comprises nuts and circular-arc-shaped bolts, and the bolts are matched with the bolt connecting holes. The pipe gallery prefabricated parts are sequentially inserted and matched end to end. The inserted pipe gallery prefabricated parts are connected to be a whole through the bolt connecting holes by the circular-arc bolt mechanisms. The sealing structures are circumferentially and annularly sealed on the inserting fitting surface along the pipe section bodies. According to the pipe gallery prefabricated parts and the assembly type rectangular comprehensive pipe gallery, the structure is simple, the spot construction site is small, the project amount is small, and efficient and rapid construction can be achieved.

Owner:SHENZHEN HUAHAN URBAN COMPREHENSIVE PIPE GALLERY TECH RES DEV CO LTD

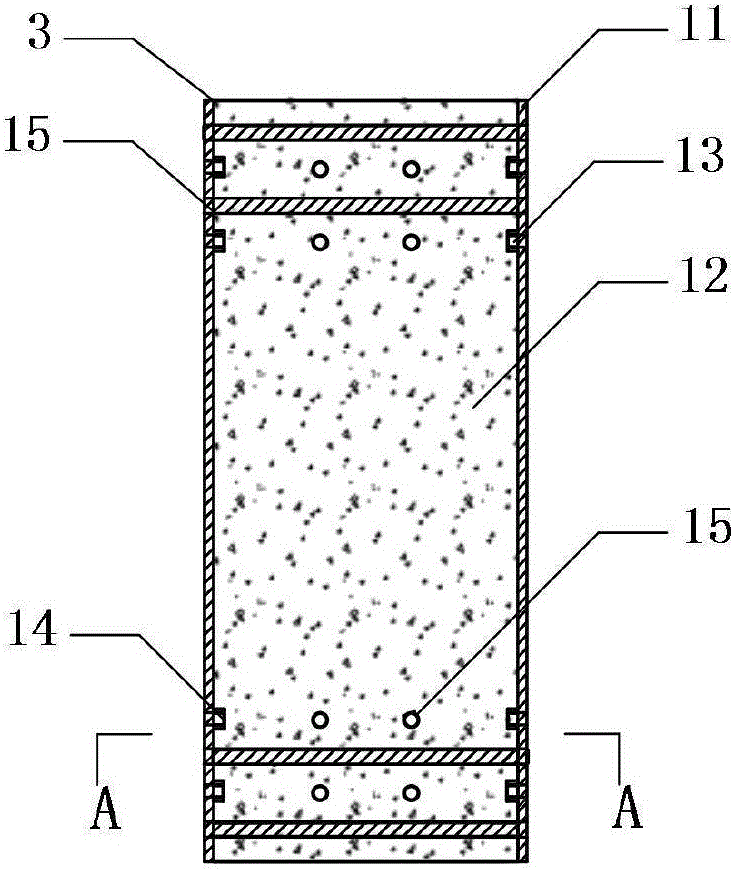

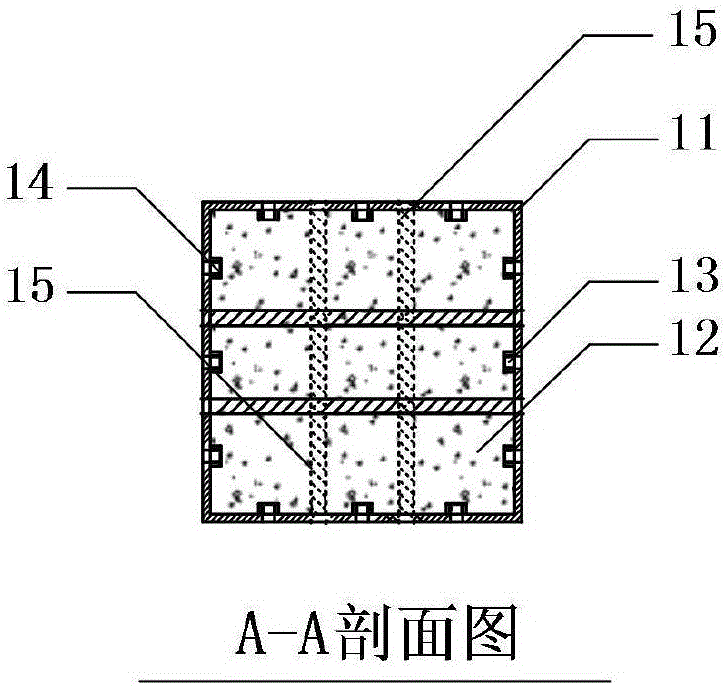

Non-dismantling die cast-in-place lightweight thermal insulation wall formboard, thermal insulation wall and construction method thereof

ActiveCN104674985AReduce the amount of constructionFast constructionWallsThermal insulationDie casting

Disclosed are a non-dismantling die cast-in-place lightweight thermal insulation wall formboard, a thermal insulation wall and a construction method thereof. The formboard comprises an inner formboard unit, an outer formboard unit and opposite-drawing connectors connecting the formboard units; the inner formboard unit comprises a formboard frame, steel bar grid frames connected between inner circles of the formboard frame, steel bar clamps connected to the cross points of the steel bars of the steel bar grid frames and a formboard core filling the inner side of the formboard frame; the inner formboard unit and the outer formboard unit are the same in structure and are connected at two ends of the opposite-drawing connector symmetrically; the steel bar clamps of the inner formboard unit and outer formboard unit are corresponded horizontally and are connected through the opposite-drawing connectors. The thermal insulation wall is simple in structure, by means of the double-layer wall formboard, the wall thickness consistence is guaranteed, the strength performance requirements are met, the thermal insulation wall is convenient to construct, the matching bar, core column and tie beam arrangement procedures are omitted, construction cost is lowered, constructing efficiency is improved, and the formboard can widely applied to wall construction.

Owner:北京振利节能环保科技股份有限公司

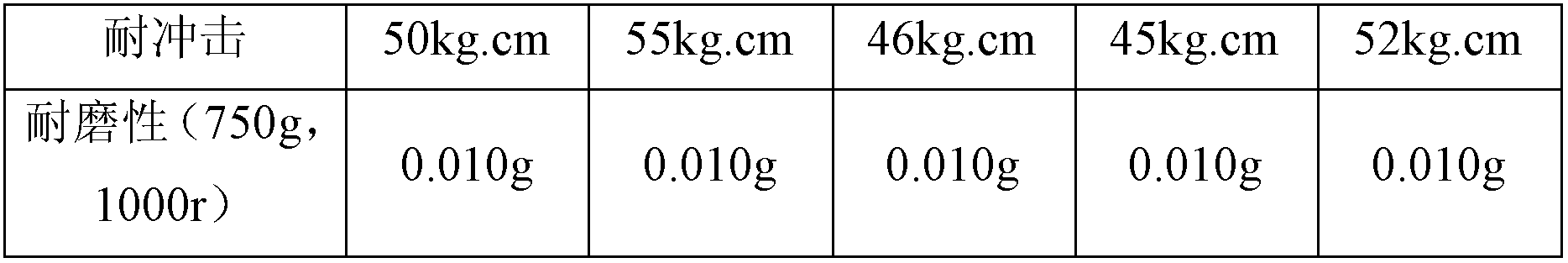

Anti-corrosion type fiber enhanced epoxy resin composite floor material and preparation method thereof

ActiveCN103057224AGood cured cross-linking regularityOvercoming the shortcomings of room temperature curingFireproof paintsSynthetic resin layered productsEpoxySurface layer

The invention discloses a preparation method for an anti-corrosion type fiber enhanced epoxy resin composite floor material. The method comprises the following steps: (1) first epoxy resin paint is coated on a support material layer, and is cured for the first time to obtain a first surface layer; (2) second epoxy resin paint is coated on the first surface layer, is compounded with a fiber fabric, and is cured for the second time to obtain an intermediate layer; and (3) after the surface is polished, the intermediate layer is coated with third epoxy resin paint; and a second surface layer is obtained through the curing for the third time, and is secondarily treated to obtain the anti-corrosion type fiber enhanced epoxy resin composite floor material. According to the anti-corrosion type fiber enhanced epoxy resin composite floor material and the preparation method thereof, the epoxy resin floor material with excellent corrosion resistance and good mechanical performance is prepared, and is laid on the floor when being needed to use, so that the problems of long construction period, weak construction environment and instable curing performance due to room-temperature curing in traditional anti-corrosive terrace paint systems, such as epoxy resin terrace, ethylene terrace and the like are avoided.

Owner:衢州壹沃科技有限公司

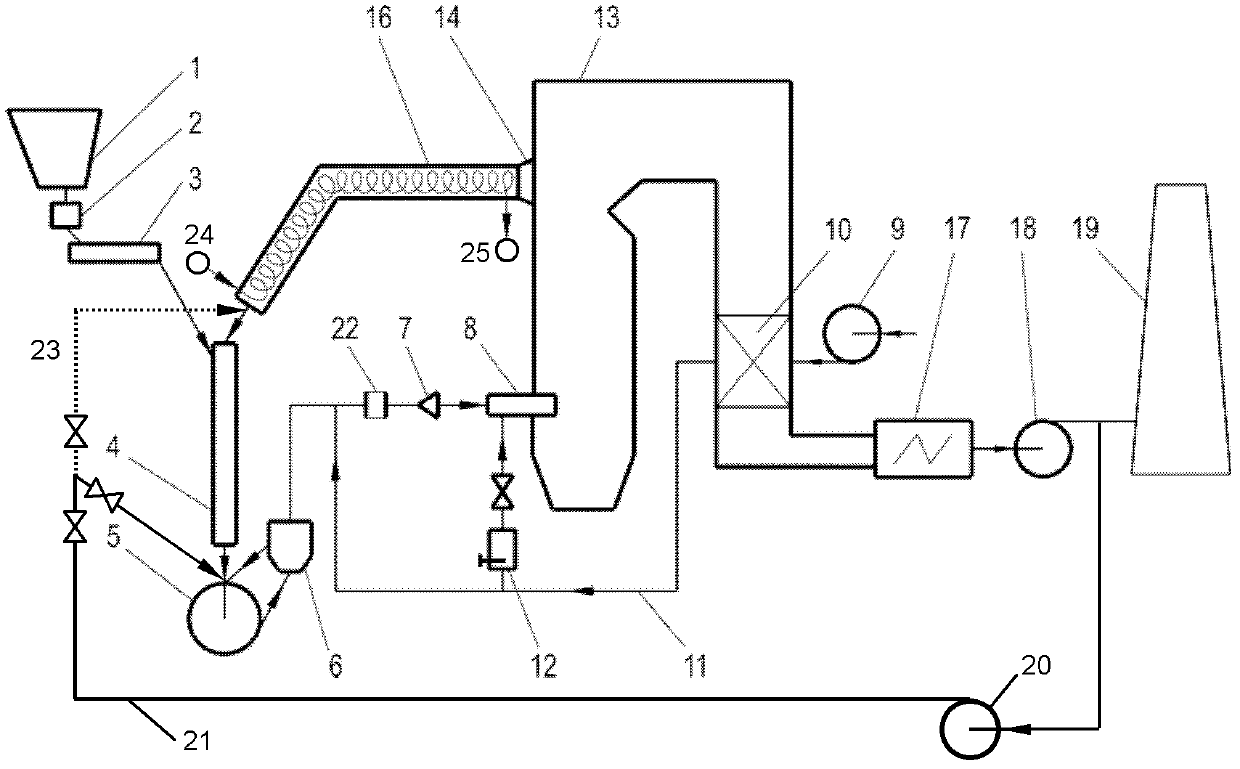

Direct fired pulverizing system of smoke drying lignite coal fan mill

ActiveCN102889607AGuaranteed temperatureReduce ventilationDrying gas arrangementsLump/pulverulent fuel preparationBoiler furnaceProcess engineering

The invention discloses a direct fired pulverizing system of a smoke drying lignite coal fan mill, which comprises a high temperature furnace smoke pipe and a hot wind mixer, wherein the high temperature furnace smoke pipe is formed by arranging a cluster of circular pipes in parallel to form a flue; the circular pipes are located in a vapor-water circulating system of a power plant; an outlet of the high temperature furnace smoke pipe is communicated with a down drying tube; an inlet is communicated with a hot smoke pumping port of a boiler furnace; the hot wind mixer is connected between a classifier and a pulverized coal distributer; the other route of the hot wind device is connected to the hot wind mixer; and a coal inlet of the fan coal mill is further connected with a cool smoke pumping port of the boiler flue. The direct fired pulverizing system of the smoke drying lignite coal fan mill has the advantages of safety in operation, simple structure, low investment and being capable of effectively utilizing heat energy of high-quality smoke.

Owner:SHANGHAI YUANMENG ELECTRIC POWER ENERGY TECH CONSULTING CENT

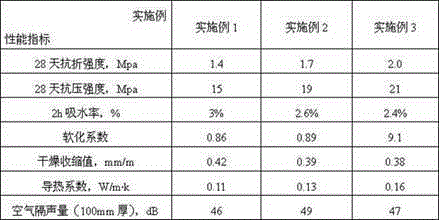

Waterproof phase-change heat storing plaster wallboard formed by reinforcing straw fibers

ActiveCN105060830AHigh strengthImprove waterproof performanceSolid waste managementCement boardPhase change

The invention discloses a waterproof type phase-change heat storing plaster wallboard formed by reinforcing straw fibers. The plaster wallboard is compounded from the following raw materials in percentage by weight: 20-60% of plaster gelate materials, 10-25% of phase-change heat storing microcapsules, 1-7% of a composite water repellent, 25-55% of mineral micro powder, 0.1-0.6% of straw fibers, 0.8-1.5% of a binder, 1-5% of an exciting agent and 0.2-1.5% of a water reducing agent. The preparation method comprises the following steps of: 1) firstly, adding the plaster gelate materials, the mineral micro powder, the straw fibers and the exciting agent into a reaction kettle, adding water, and uniformly stirring the plaster gelate materials, the mineral micro powder, the straw fibers, the exciting agent and the water so as to obtain a material A; 2) sequentially adding the phase-change heat storing microcapsules, the composite water repellent, the binder and the water reducing agent into the reaction kettle, and stirring the material A, the phase-change heat storing microcapsules, the composite water repellent, the binder and the water reducing agent once again so as to obtain a material B; and 3) directly pouring the material B in the reaction kettle into a mold through a grouting pump so as to obtain the phase-change heat storing plaster wallboard, wherein a fiber cement board is arranged on the inner surface of the mold. The waterproof type phase-change heat storing plaster wallboard disclosed by the invention has the advantages of being suitable for operation under humid environment, simple in production technology and environment-friendly.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

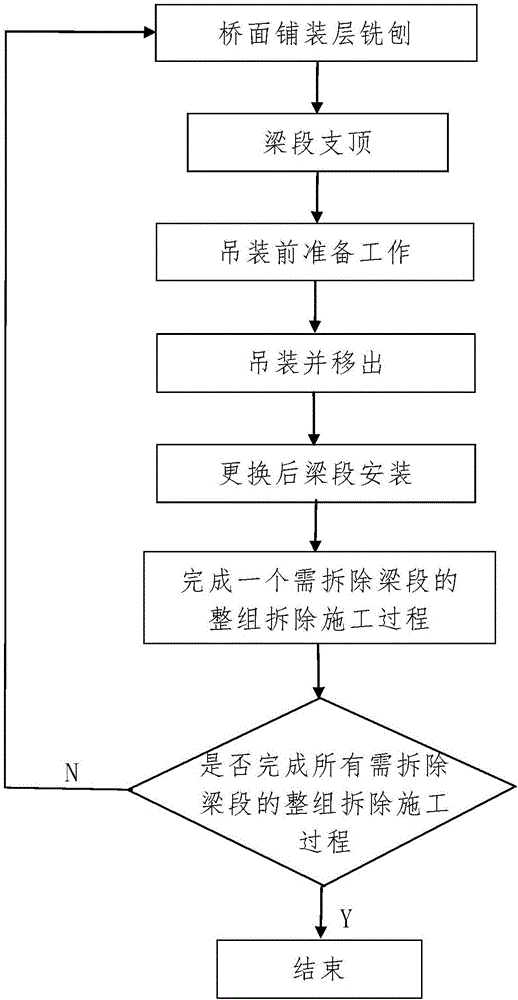

Full-set dismantling and installing construction method of bridge overpassing existing line

ActiveCN106149576ASimple stepsReasonable designBuilding repairsBridge erection/assemblyBuilding constructionEngineering

Owner:中铁二十局集团第三工程有限公司

Aluminum alloy for subway station ceiling and preparing method of aluminum alloy

The invention relates to an aluminum alloy for a subway station ceiling and a preparing method of the aluminum alloy. The aluminum alloy is characterized by comprising chemical components, including by mass percent, 0.45% to 0.6% of Mg, 0.3% to 0.5% of Si, 0.1% to 0.3% of Mn, 0.1% to 0.2% of Cr, 0.1% to 0.3% of Zr, 0.1% to 0.3% of Hf, 0.05% to 0.2% of Ta, 0.05% to 0.15% of Cu, not larger than 0.05% of Zn, not larger than 0.20% of Fe, not larger than 0.05% of Ti, and the balance Al, wherein the single content of other impurity elements is not larger than 0.05%, and the total content of other impurity elements is not larger than 0.15%. The aluminum alloy is obtained through the preparing method of smelting, refining, casting and homogenizing. Through optimizing of alloy components, adjustment is carried out, the trace of Zr, Hf and Ta is added, and the strength, the heat dissipation, corrosion resistance, humidity resistance, fatigue resistance, static electricity resistance, recrystallization resistance capacity and breaking resistance performance of the aluminum alloy can be obviously improved.

Owner:ALNAN ALUMINIUM CO LTD

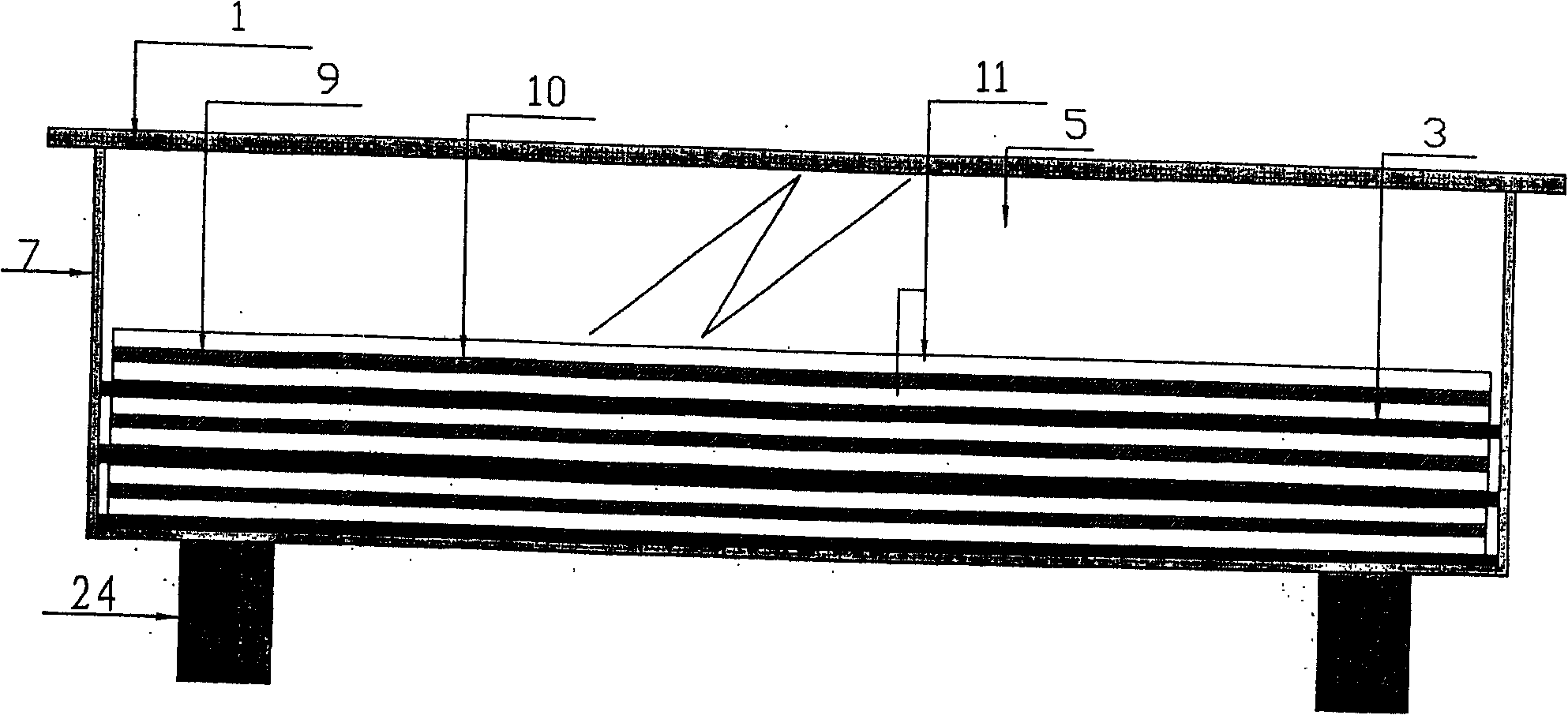

Method for making low-temperature adhesive plate vacuum glass and apparatus thereof

InactiveCN101298370AThe appearance of the product is beautifulProduct quality and long lifeSmooth surfaceGlass production

The invention relates to a method for producing vacuum slab glass that has a smooth surface and has no vertebrate tail and sealing plug and an equipment thereof. One piece of glass is cut into two pieces, then a support is arranged between the two pieces of glass, a bonding agent is coated on the four sides of the glass and one notch is left without coating the bonding agent and is used as vacuum passage of later step, the two pieces of glass are placed into a vacuum box after the bonding process is finished; the inside of the vacuum box is provided with a heating device and a glue-filling machine; also a vacuum pipe is arranged on the vacuum box, then the heating device is started to heat the glass, and a vacuum valve is started to vacuumize, then the glue-filling machine is started to seal the passage, finally the vacuum box is cooled and the pressure is relived to obttain the finished vacuum glass. Compared with the other vacuum glass which has vertebrate tail protuberance on the surface and is sealed by rubber plugs, the vacuum glass production process reduces the production procedure; also the product is more beautiful as the product has no projection or sealing rubber plug; the production line is short, which needs less investment, consumes less energy and reduces the manufacturing cost.

Owner:胡屹博 +2

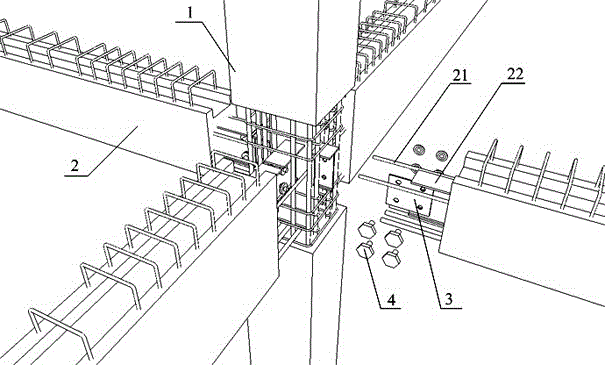

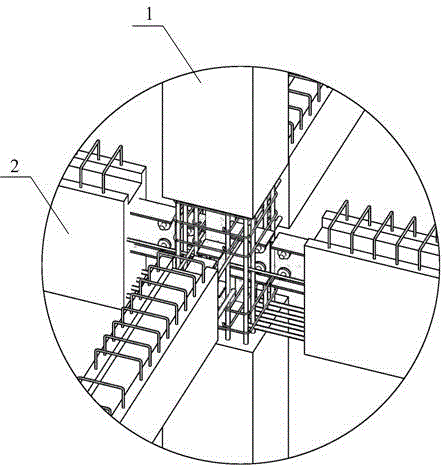

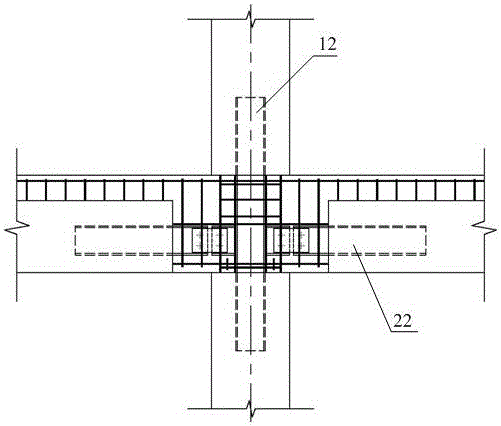

Prefabricated concrete frame structure and manufacturing method thereof

ActiveCN106149873AEnsure continuityEnsure integrityBuilding constructionsShear capacityAgricultural engineering

The invention discloses a prefabricated concrete frame structure which comprises prefabricated columns and prefabricated beams. Each prefabricated column is connected with one end of the corresponding prefabricated beam, a node area is formed at a joint of each prefabricated column and the corresponding prefabricated beam, each prefabricated beam is divided into an upper-layer column body and a lower-layer column body by the corresponding node area, each upper-layer column body and the corresponding lower-layer column body are connected through longitudinal reinforcing steel embedded in the prefabricated column in the corresponding node area, and column body longitudinal rebars are embedded in each prefabricated column and are continuous in the corresponding node area; beam end reinforcing steel is embedded at one end, connected with the corresponding prefabricated column, of each prefabricated beam, and the longitudinal reinforcing steel and the beam end reinforcing steel are connected through bolts. The invention further discloses a manufacturing method of the prefabricated concrete frame structure. Nodes of the prefabricated concrete frame structure are equivalent to cast-in-place concrete frame nodes in anti-seismic performance and energy dissipating capacity, anti-seismic concept design of 'strong nodes and weak components', 'strong shear capacity and weak bending capacity' and 'strong columns and weak beams' is realized, and construction process and difficulty can be reduced.

Owner:FOSHAN ELECTRIC POWER DESIGN INST +1

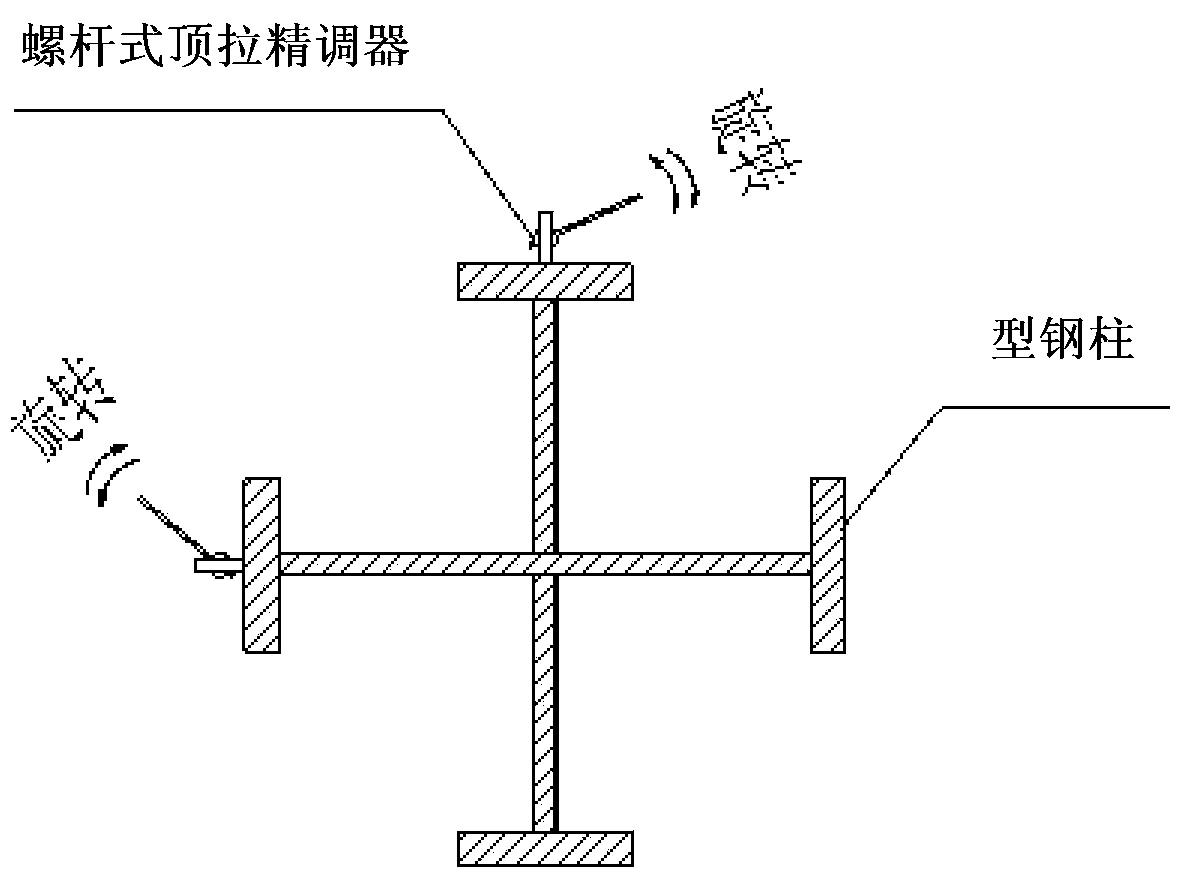

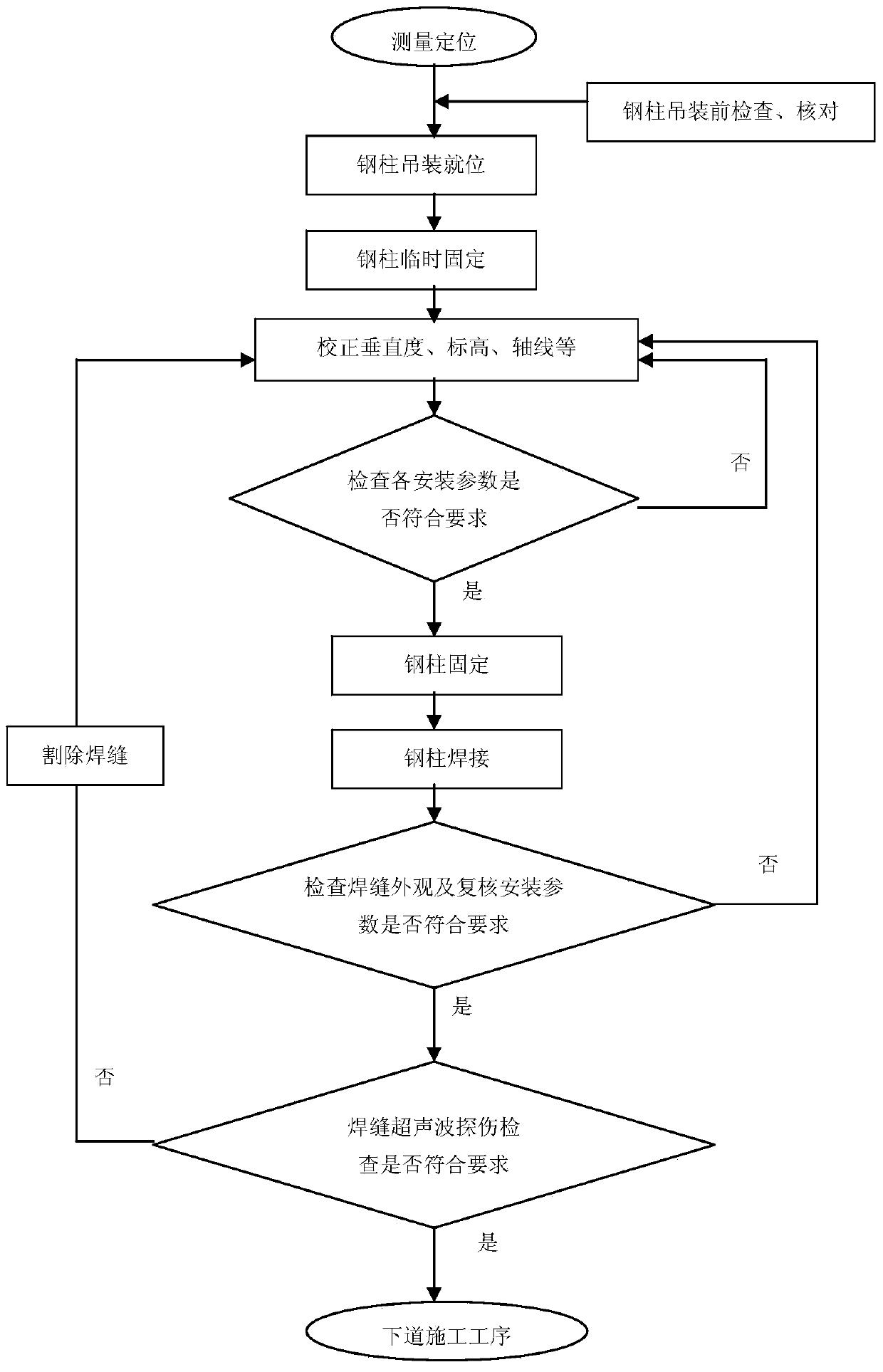

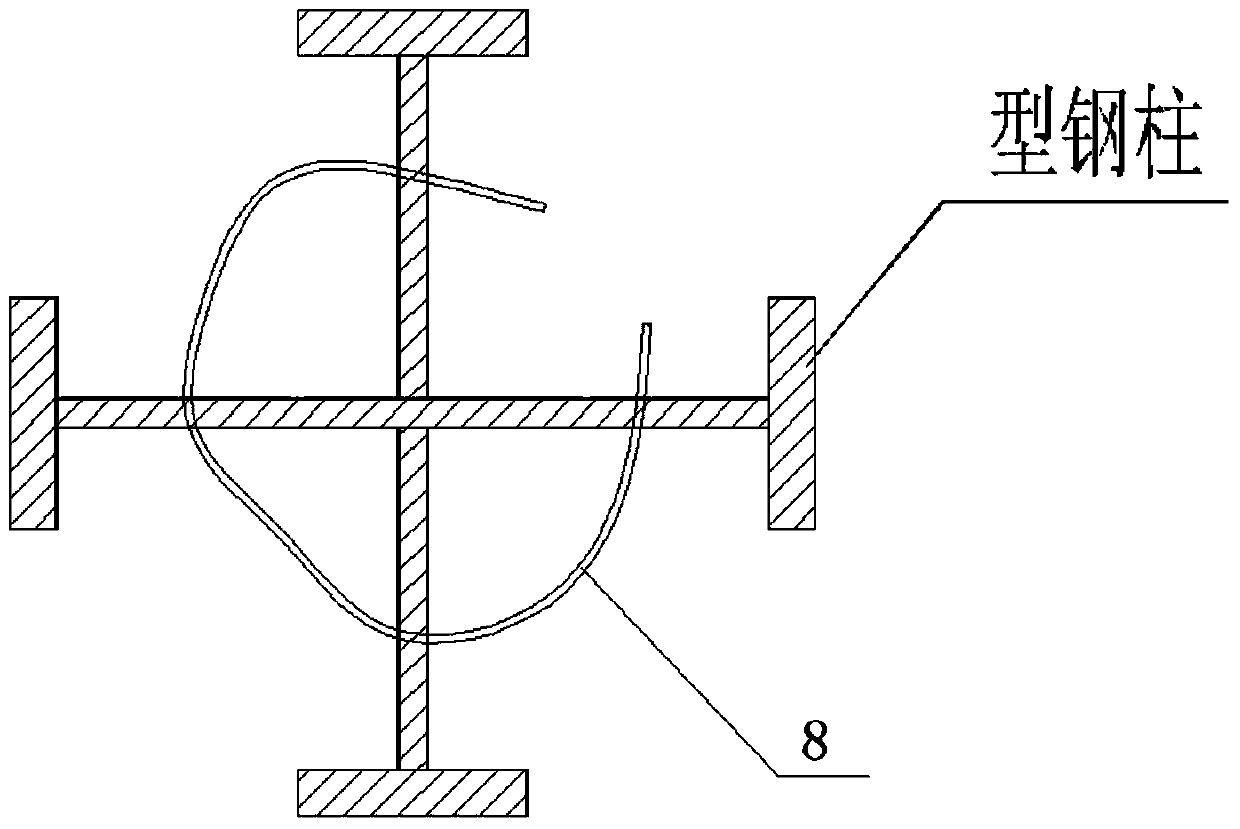

Construction method for H-type steel stiff column with cross fracture surface

InactiveCN103806669AAccurate axis controlAccurate control of verticalityBuilding material handlingSteel columnsHigh rise

The invention discloses a construction method for an H-type steel stiff column with a cross fracture surface. The construction method includes the steps of measuring and positioning, inspecting and checking before hoisting the H-type steel stiff column, hoisting the H-type steel stiff column in place, fixing the H-type steel stiff column temporarily, correcting the H-type steel stiff column, fixing the H-type steel stiff column, welding H-type steel stiff column and the like. The axis and perpendicularity of section steel column installation can be controlled accurately, structural construction is high in precision, construction quality is reliable, and the construction method is suitable for installation and construction of the H-type steel stiff columns with the cross fracture surfaces in a high-rise building, a super high-rise building, a long-span structure and a common structure.

Owner:DALI CONSTR GRP +2

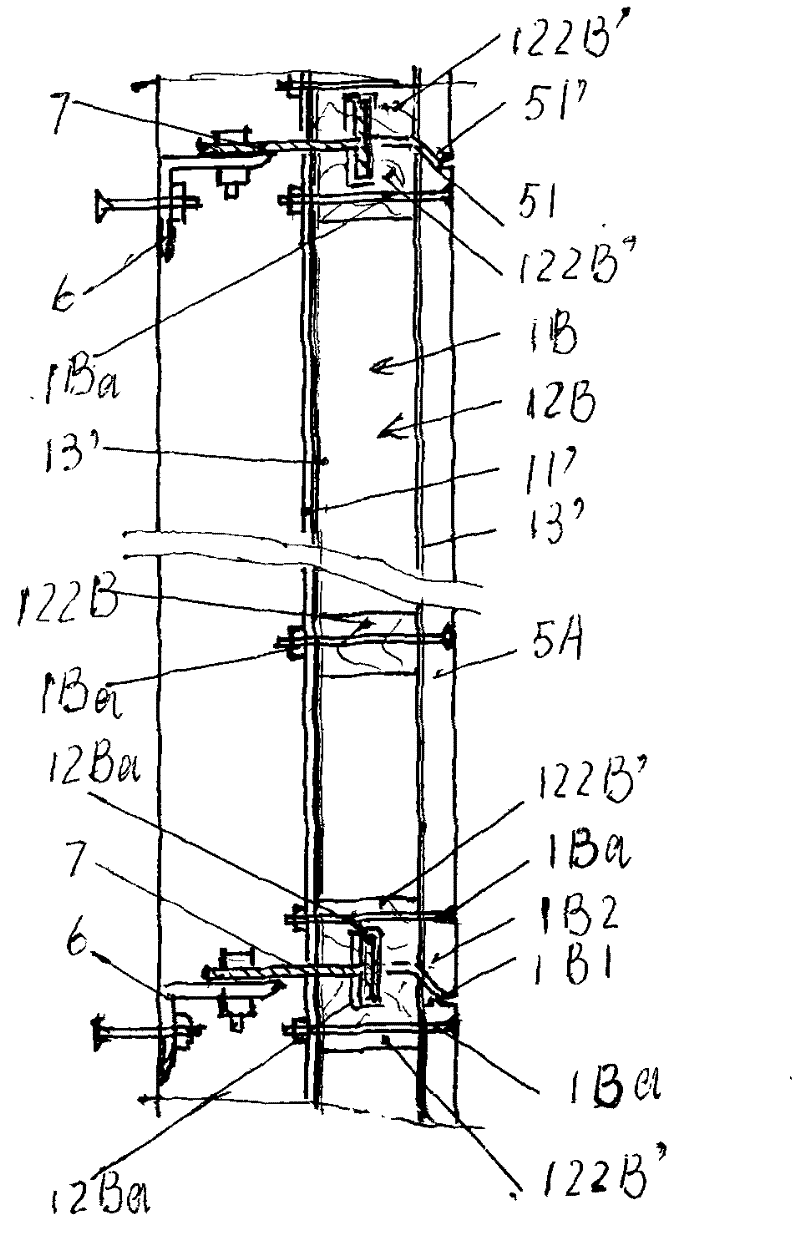

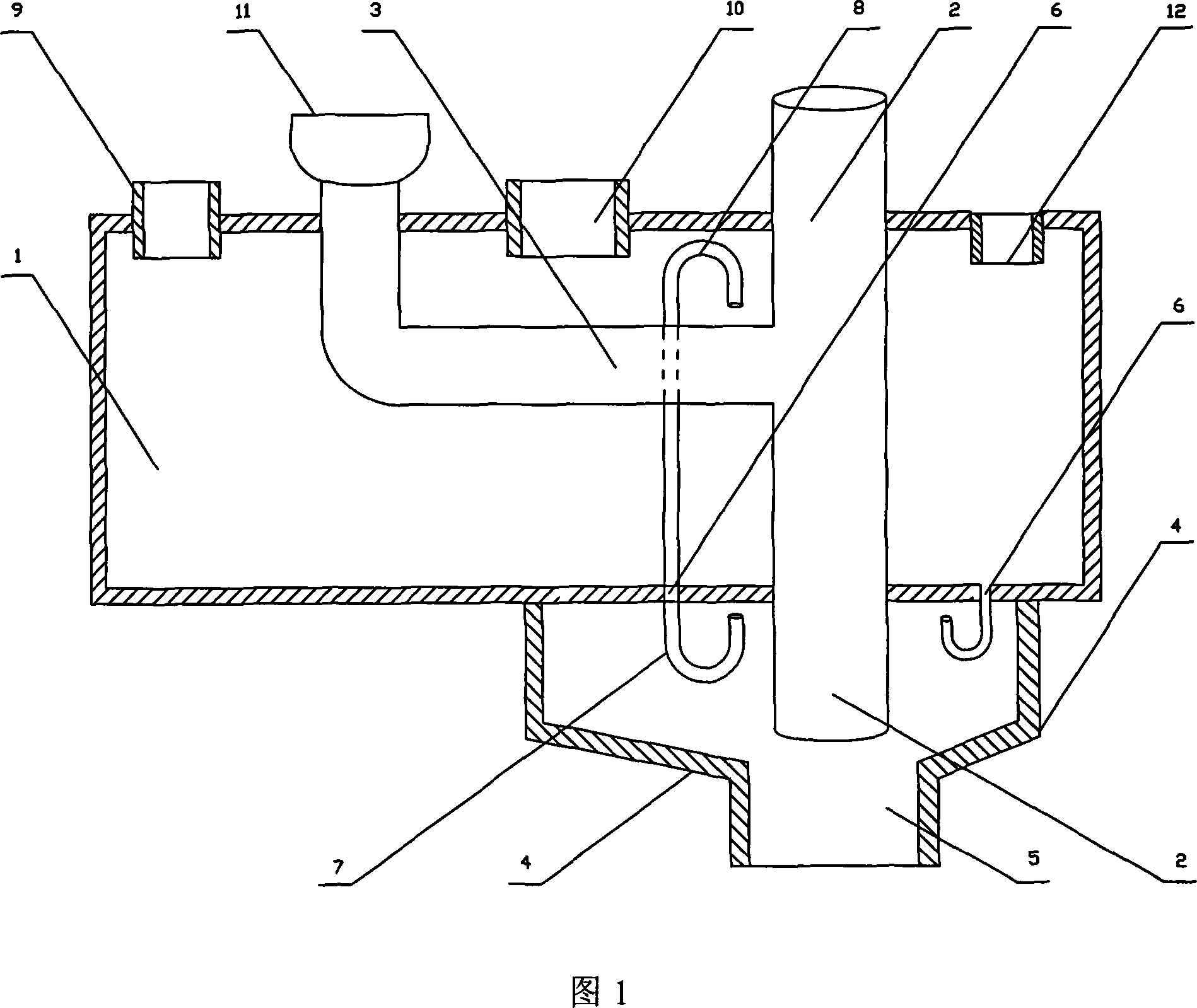

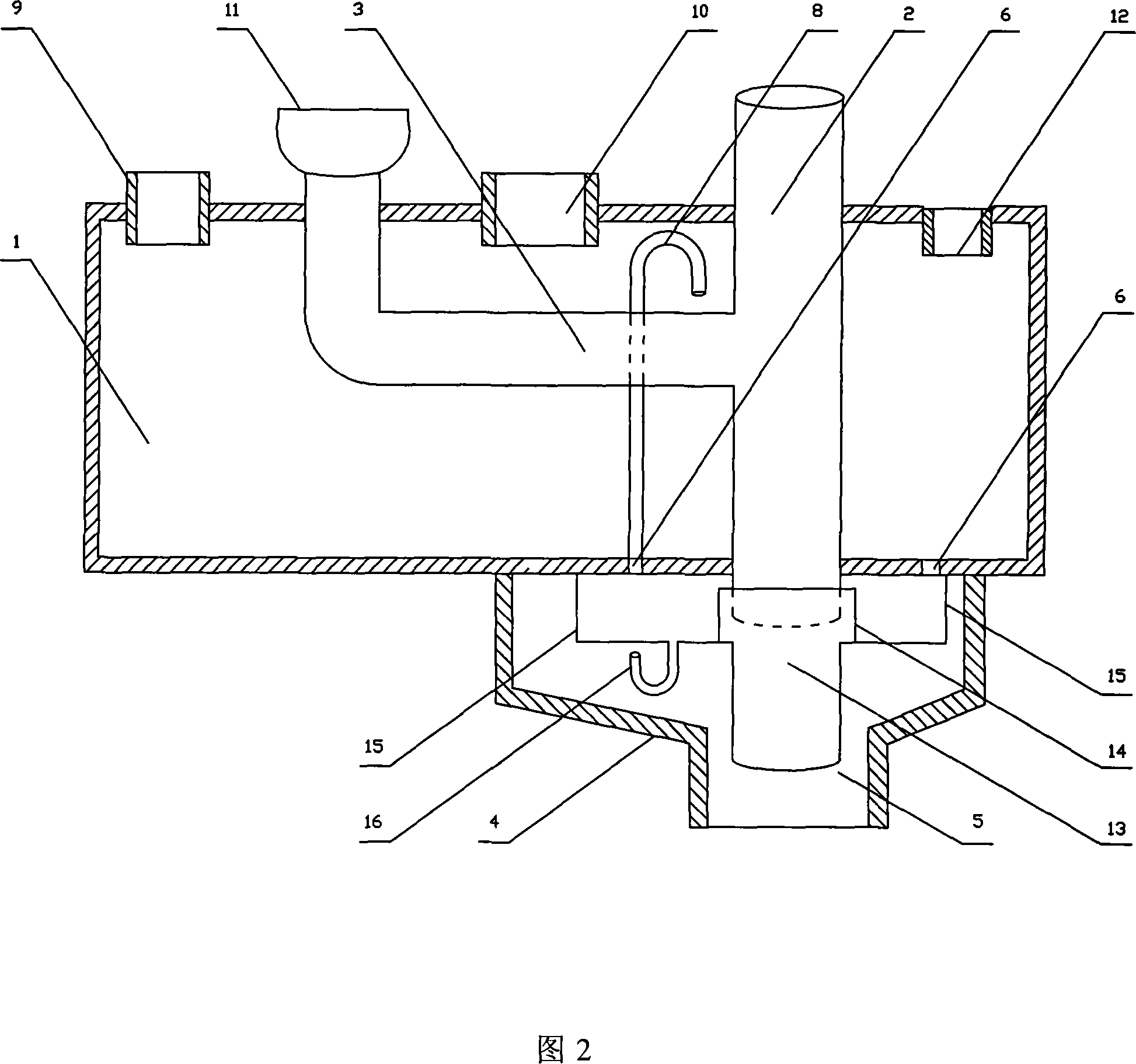

Kitchen-toilet modularization same floor water feeding and draining device

ActiveCN101058989AHighlight substantiveSignificantly progressiveDomestic plumbingInterior spaceDraining tube

The present invention provides a kitchen modular water supply and sewerage device in one layer. It includes gathering water tank, stand pipe short pitch, water supply and sewerage piece connecting mouth installed on gathering water tank, sealing horizontal branch pipe connecting with stand pipe short pitch and closet outlet connecting sealing horizontal branch pipe, said water supply and sewerage device also includes gathering bucket, said gathering water tank is installed on the top of said gathering bucket, the lower of said stand pipe short pitch is installed in said gathering bucket, the lower of said gathering bucket is equipped with escape-pipe; the bottom of said gathering water tank is equipped with water discharging hole, said water discharging hole is connected with gathering bucket; said water discharging hole lower is equipped with water sealing device; said water discharging hole upper is equipped with overflow pipes. The water supply and sewerage device changes the installation mode of prior water supply and sewerage system, sets out leakage, odor, blocking and other technical problems in prior toilet water discharging, and the installation is convenient, users can choose toilet equipment placement themselves and the interior space is beautified.

Owner:王凤蕊

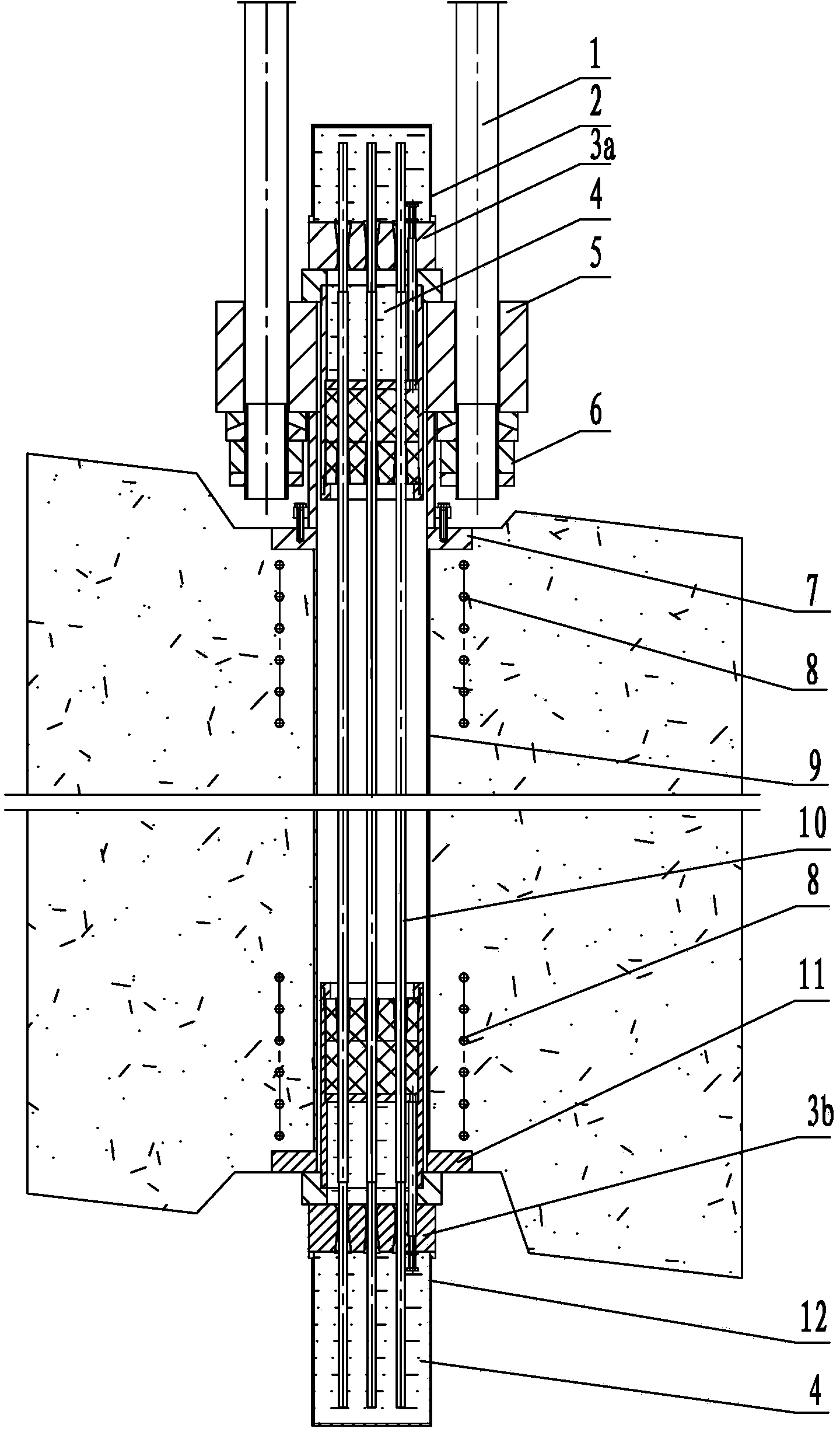

Single-cable-replaceable type anchorage pre-stressed anchor device and installation and cable replacement methods thereof

ActiveCN104372738AGood sealing effectPrevent leakageSuspension bridgeBridge structural detailsPre stressMechanical engineering

A single-cable-replaceable type anchorage pre-stressed anchor device comprises a pull rod, a front protection cover, a rear protection cover, anchor gear assemblies, a connector, a pull rod nut assembly, a front anchor backing plate, a rear anchor backing plate, spiral ribs, an embedded pipe and unbonded PF steel strands. The connector is installed on the front anchor backing plate. The front anchor gear assembly is installed on the end face of the connector, and the rear anchor gear assembly is placed under the rear anchor backing plate. The two ends of each unbonded PF steel strand are removed, the remaining part of each unbonded PF steel strand is wrapped by PE, the exposed parts of the upper ends of the unbonded PF steel strands are located in a sealed cavity formed by an anchor plate of the front anchor gear assembly and the front protection cover and anchored to the anchor plate through working clamping pieces, and the exposed parts of the lower ends of the unbonded PF steel strands are located in a sealed cavity formed by an anchor plate of the rear anchor gear assembly and the rear protection cover and anchored to the anchor plate through working clamping pieces. By pressing and ejecting inner sealing plates and outer sealing plates through screw rods and ejector rods, the diameter of through holes in the inner sealing plate and through holes in the outer sealing plate can be adjusted. A sealed cavity of the front anchor gear assembly, a sealed cavity of the rear anchor gear assembly, the sealed formed by the front protection plate and the anchor plate of the front anchor gear assembly and the sealed cavity formed by the rear protection plate and the anchor plate of the rear anchor gear assembly are filled with non-drying anticorrosive materials. The anchor device is reliable in use and low in cost, and installation construction and cable replacement construction are convenient.

Owner:LIUZHOU OVM MACHINERY

Permeable reaction medium for remediation of nitrobenzene-polluted underground water

InactiveCN102417213ALow costEasy installation and constructionWater contaminantsWater/sewage treatment by sorptionChemical reactionNitrobenzene

The invention relates to a permeable reaction medium for the remediation of nitrobenzene-polluted underground water. The permeable reaction medium is granular and is formed through the cementation of zero-valent iron and straw powder by using a cementing agent; the content of the zero-valent iron and the content of the straw powder are respectively 25-35 mass% and 55-65 mass%; and the content of the cementing agent is 6-11 mass%. According to the permeable reaction medium for the remediation of the nitrobenzene-polluted underground water, the zero-valent iron and the straw powder are selectedas raw materials of a filling medium of a permeable reactive barrier, the zero-valent iron and the straw powder are cemented into a granular shape, and chemical reaction and physical adsorption can be reasonably combined, so that the permeable reaction medium has an excellent treatment effect for nitrobenzene, a short remediation cycle and no secondary pollution; the zero-valent iron and the straw powder are low in price and easy to get; on the premise of reasonable cost, the excellent treatment effect for the nitrobenzene is achieved, and thus, the permeable reaction medium has broad prospects.

Owner:HOHAI UNIV

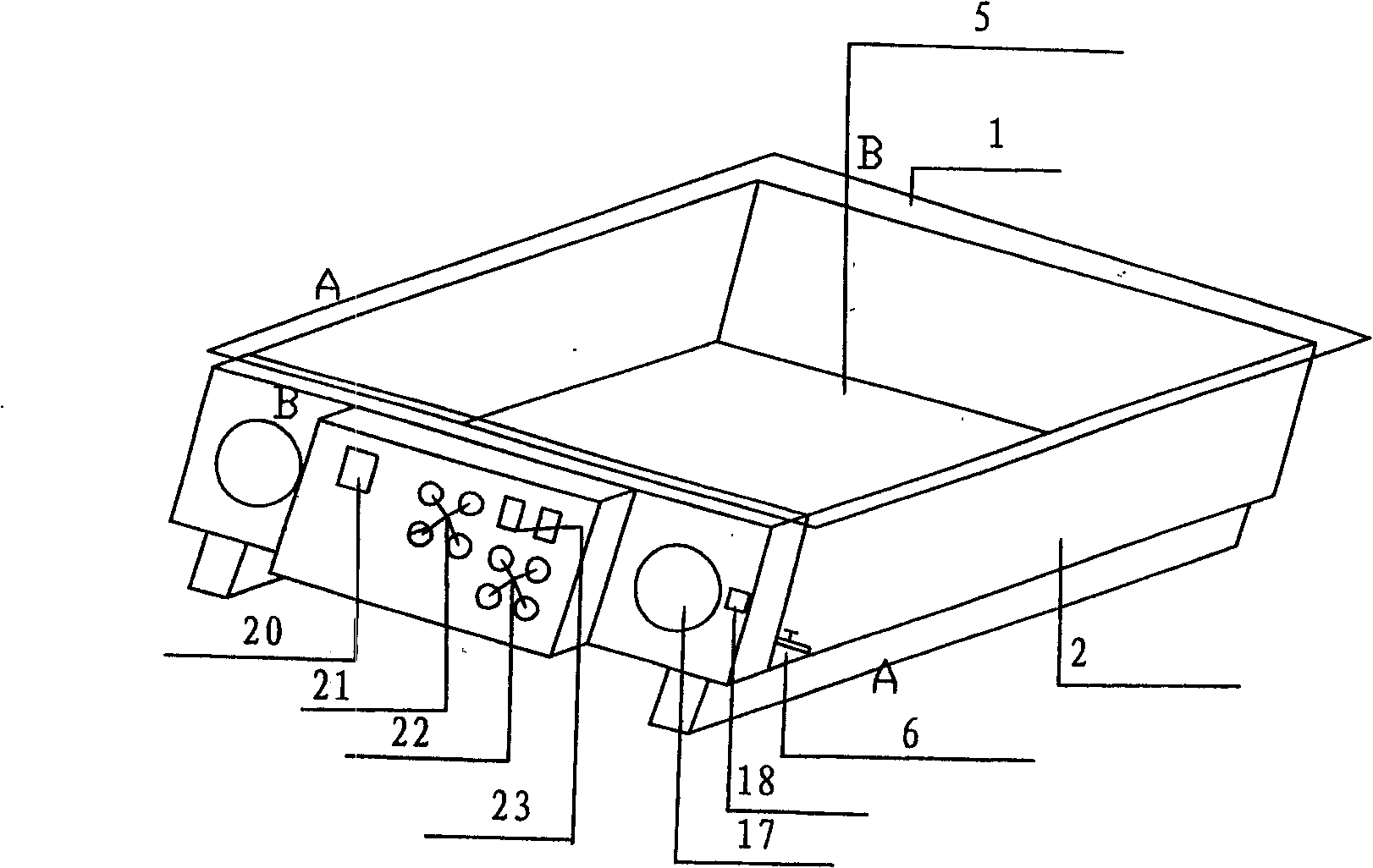

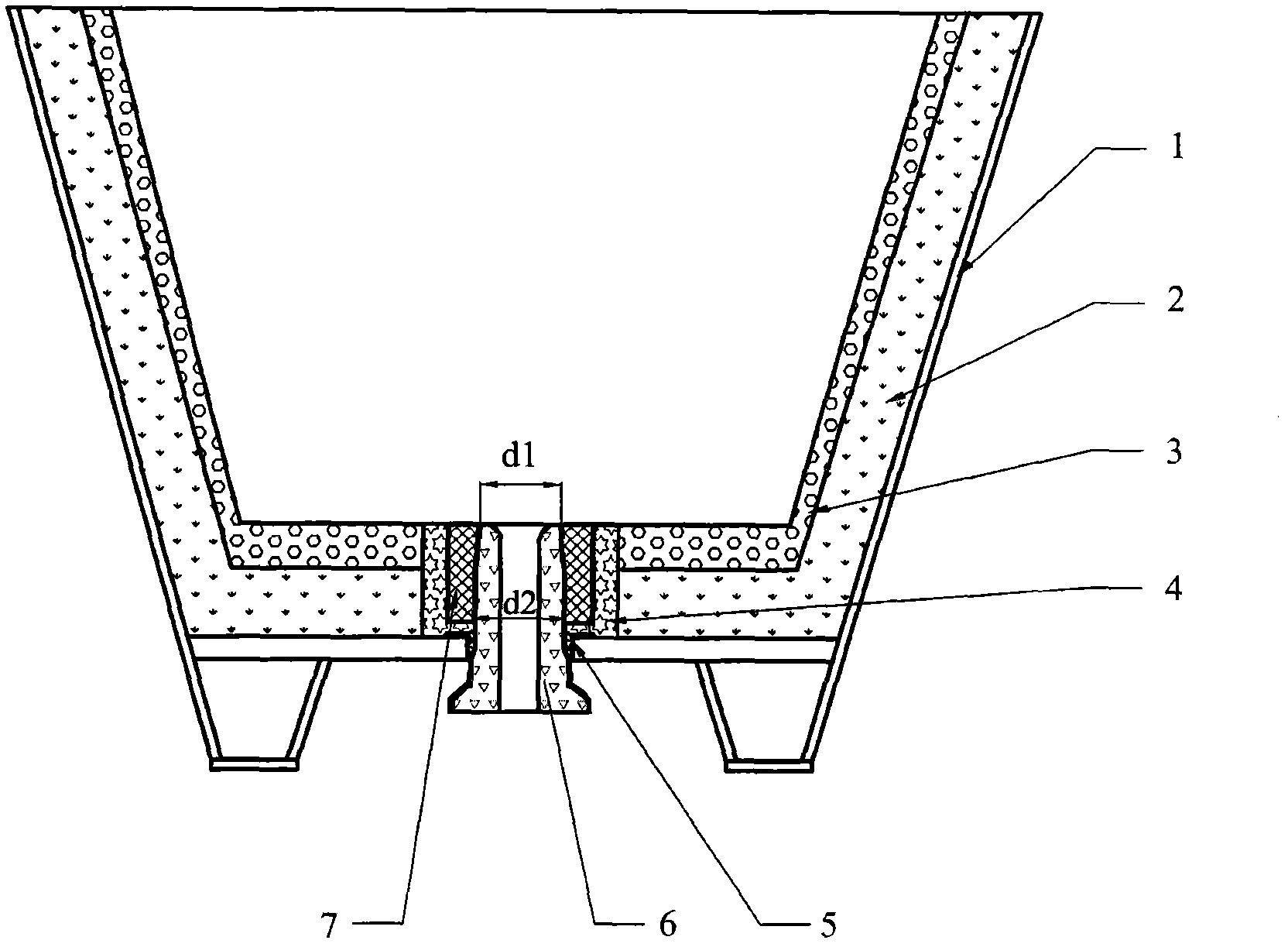

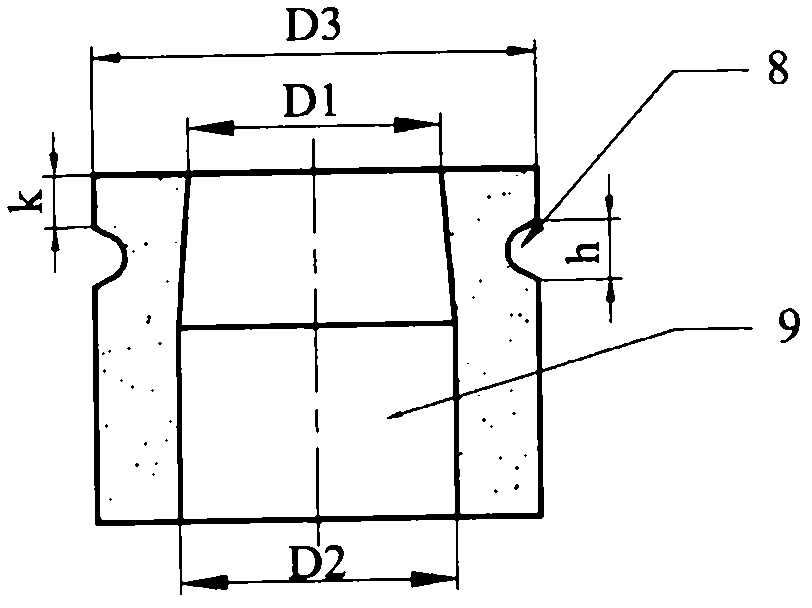

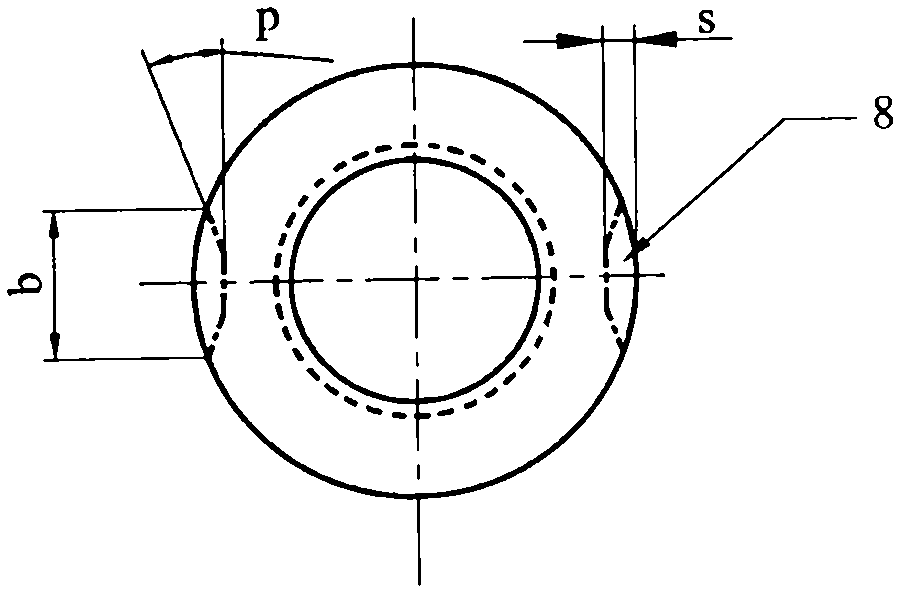

Continuous casting tundish and manufacturing method thereof

InactiveCN102151822APrevent penetration of steelPrevent the problem of piercing steelMelt-holding vesselsBrickRefractory

The invention provides a continuous casting tundish and a manufacturing method thereof. The continuous casting tundish comprises a cup-shaped tundish body and a molten metal outlet, wherein, the tundish body comprises a tundish shell, a permanent lining and a working lining from outside to inside; and the molten metal outlet comprises a nozzle pocket brick, an upper nozzle, a refractory seal ring and a refractory ramming material, wherein, the middle part of the nozzle pocket brick is equipped with an upper nozzle mounting hole with a big end down inner diameter, the upper nozzle is matched with the nozzle pocket brick so as to ensure that the upper surface of the upper nozzle is leveled with that of the nozzle pocket brick or the upper surface of the nozzle pocket brick is slightly higher than that of the upper nozzle when the upper nozzle is installed in the nozzle pocket brick, the refractory seal ring is filled between the upper nozzle and the tundish shell, and the refractory ramming material is arranged above the refractory seal ring and / or the tundish shell and is filled in clearance between the nozzle pocket brick and the tundish body. The continuous casting tundish and the manufacturing method thereof have the beneficial effects that problems such as steel penetration in the upper nozzle pocket brick and the like are solved, the service life of the upper nozzle is prolonged, and the continuous casting heats per tundish of the continuous casting tundish are increased from 8-14 to 20-26, thus improving the qualification rate of a continuous casting billet, and lowering the continuous casting production cost.

Owner:LAIWU IRON & STEEL GRP

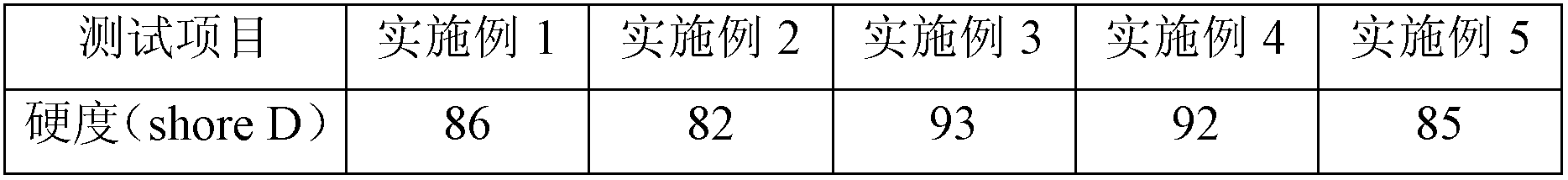

Formula of modified polypropylene corrugated pipe for electric power

InactiveCN102964680AHigh strengthMolding stabilityCable installations in underground tubesAntioxidantUltraviolet lights

The invention relates to a formula of modified polypropylene corrugated pipe for electric power. The formula comprises the following ingredients: polypropylene, talc powder, a compatilizer, organic rectorite, an impact modifier, a fire retardant, a lubricant, an antioxidant, an ultraviolet light absorber and toner. The formula provided by the invention can meet the performance demands of the modified polypropylene corrugated pipe for electric power, and the product prepared by the formula has the advantages of high ring stiffness, good heat resistance, excellent fire resistance, good low-temperature impact performance, good forming stability and strong cost performance, etc.

Owner:广东威立瑞科技有限公司

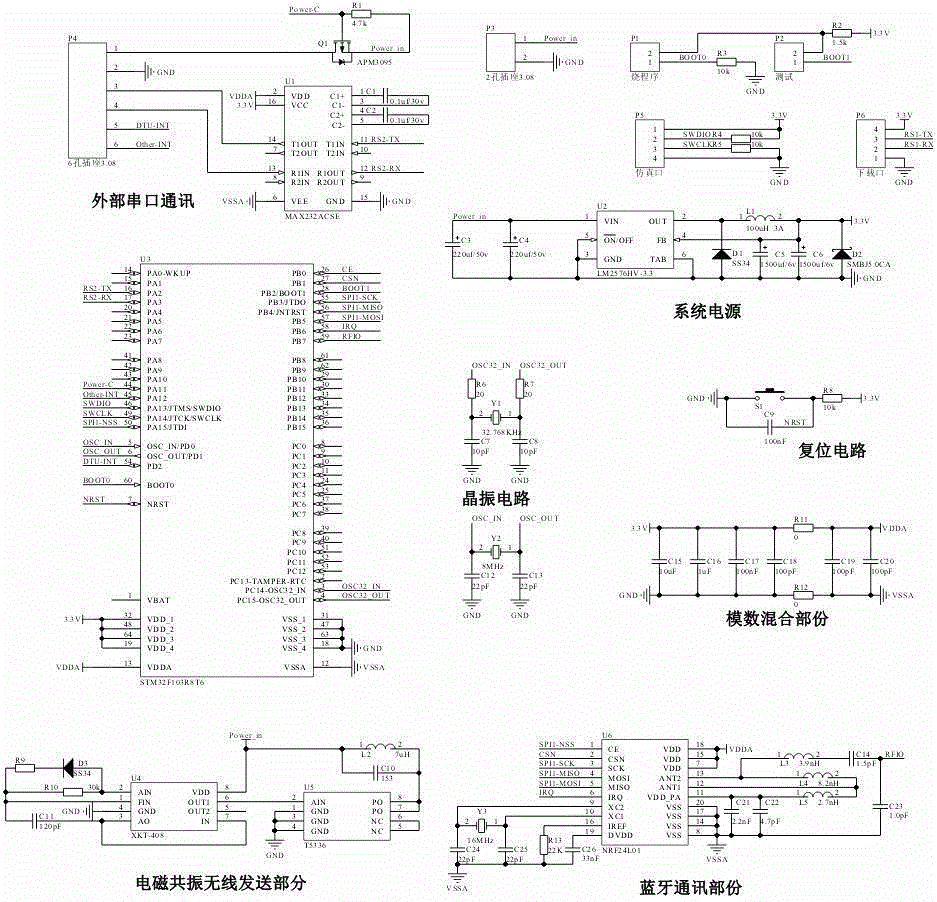

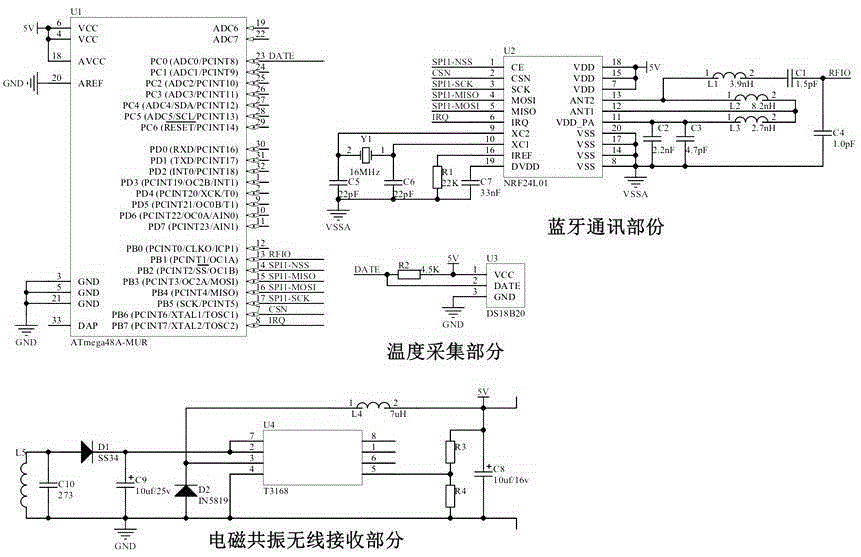

Cable intermediate joint wireless temperature sensing device based on electromagnetic resonance

InactiveCN105318976AEasy installation and constructionNo wiring harness costsThermometer detailsTransmission systemsInternet networkResonance

The invention relates to a cable intermediate joint wireless temperature sensing device based on electromagnetic resonance. A host possesses wireless power supply and Bluetooth communication capabilities, launches electromagnetic waves to the passive wireless communication temperature sensor in a cable intermediate joint, and organizes temperature data to be standard rules when receiving Bluetooth signals from the passive wireless communication temperature sensor, the standard rules being sent to an Internet network and finally arriving at a server, thereby realizing the management of intelligent on-line monitoring equipment. The cable intermediate joint wireless temperature sensing device employs an electromagnetic resonance principle and a Bluetooth data communication form to realize sensor passive power supply and wireless data acquisition, and makes installation more convenient and faster; the cable intermediate joint is safer in an on-line monitoring process, and collects data more efficiently.

Owner:HANGZHOU DIANZI UNIV

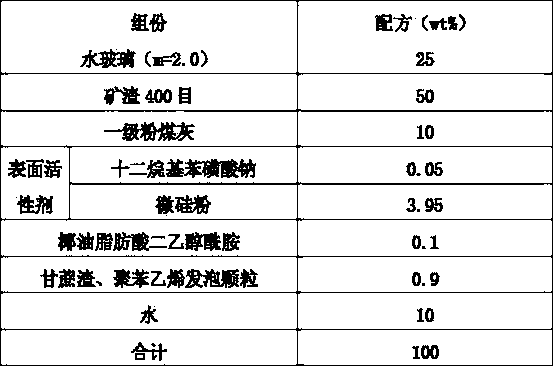

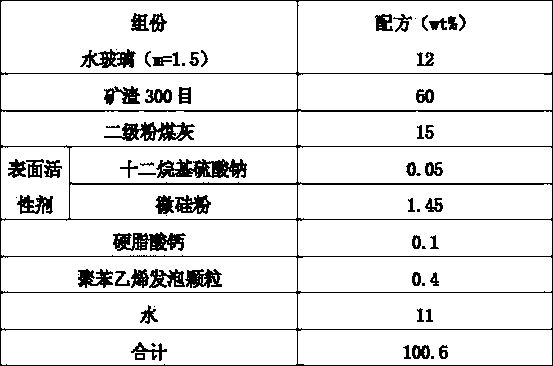

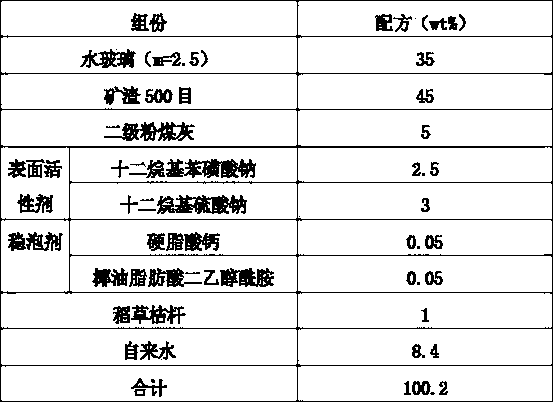

Sandwich layer used for making light partition wall batten

InactiveCN103482950ALow thermal conductivityReduce weightSolid waste managementSlagAdditional values

The invention discloses a sandwich layer used for making a light partition wall batten. The sandwich layer mainly comprises 12-35 parts of water glass, 45-60 parts of superfine slag powder, 1-15 parts of coal ash, 1.5-5.5 parts of surfactants, 0.02-0.1 part of foam stabilizer, 0.03-1 part of light packing and 10-20 parts of water. The invention further discloses a method for making the light partition wall batten through the sandwich layer. The method mainly includes the steps of evenly mixing raw materials, stirring, placing a model, grouting the model, carrying out maintenance and the like. The main raw materials of the sandwich layer are ground polymer, the ground polymer raw materials are rich in source and environmentally friendly, the light partition wall batten made through the sandwich layer made of the ground polymer is low in heat conductivity coefficient, light in weight, good in sound insulation and high in production efficiency, and the product is low in cost and high in additional value, can be planed, nailed and drilled, is convenient to install and construct and meets the national energy-saving and emission-reduction policy. After fiber reinforcement is carried out, the sandwich layer can be further used for making various GRC components.

Owner:刘海锋 +1

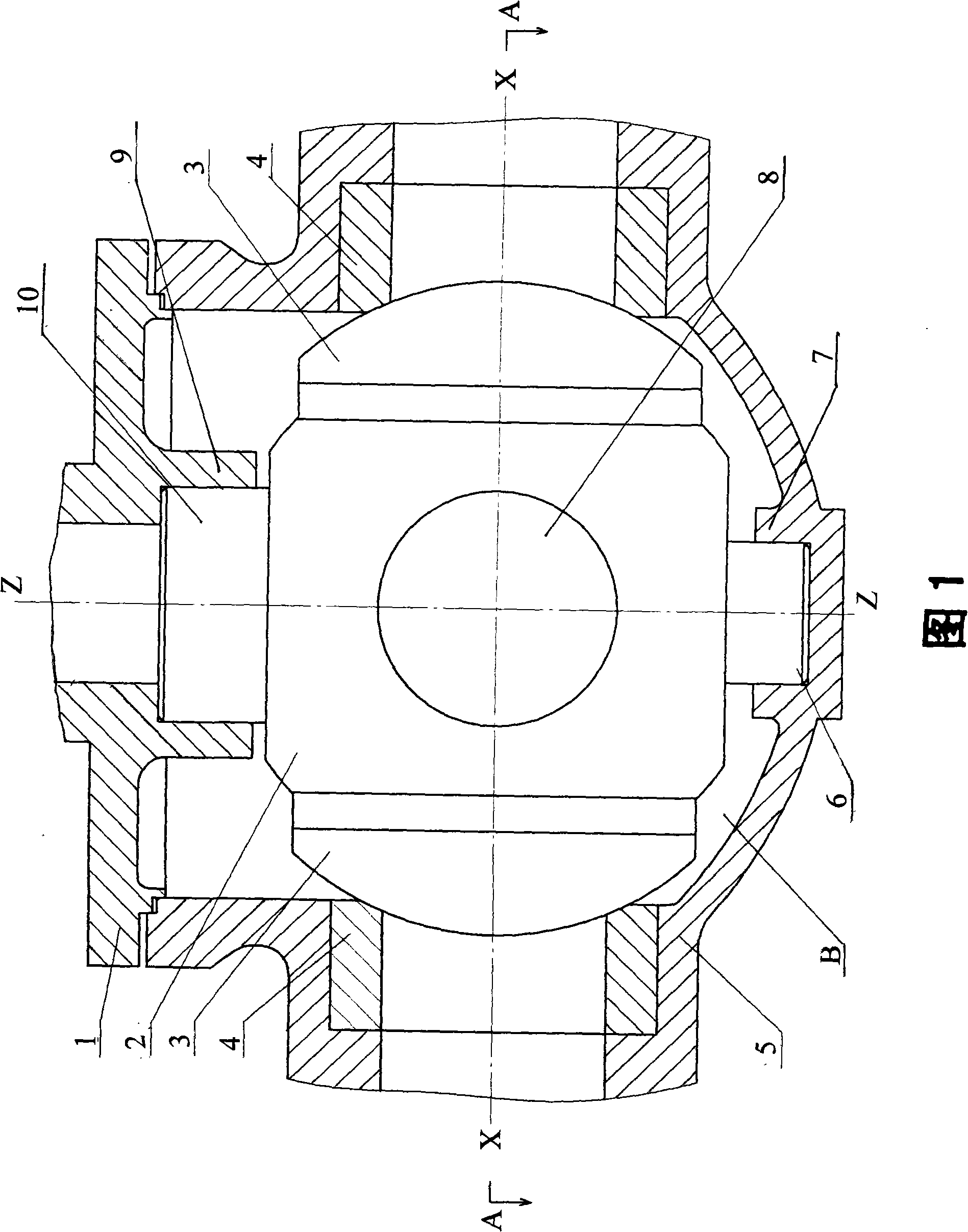

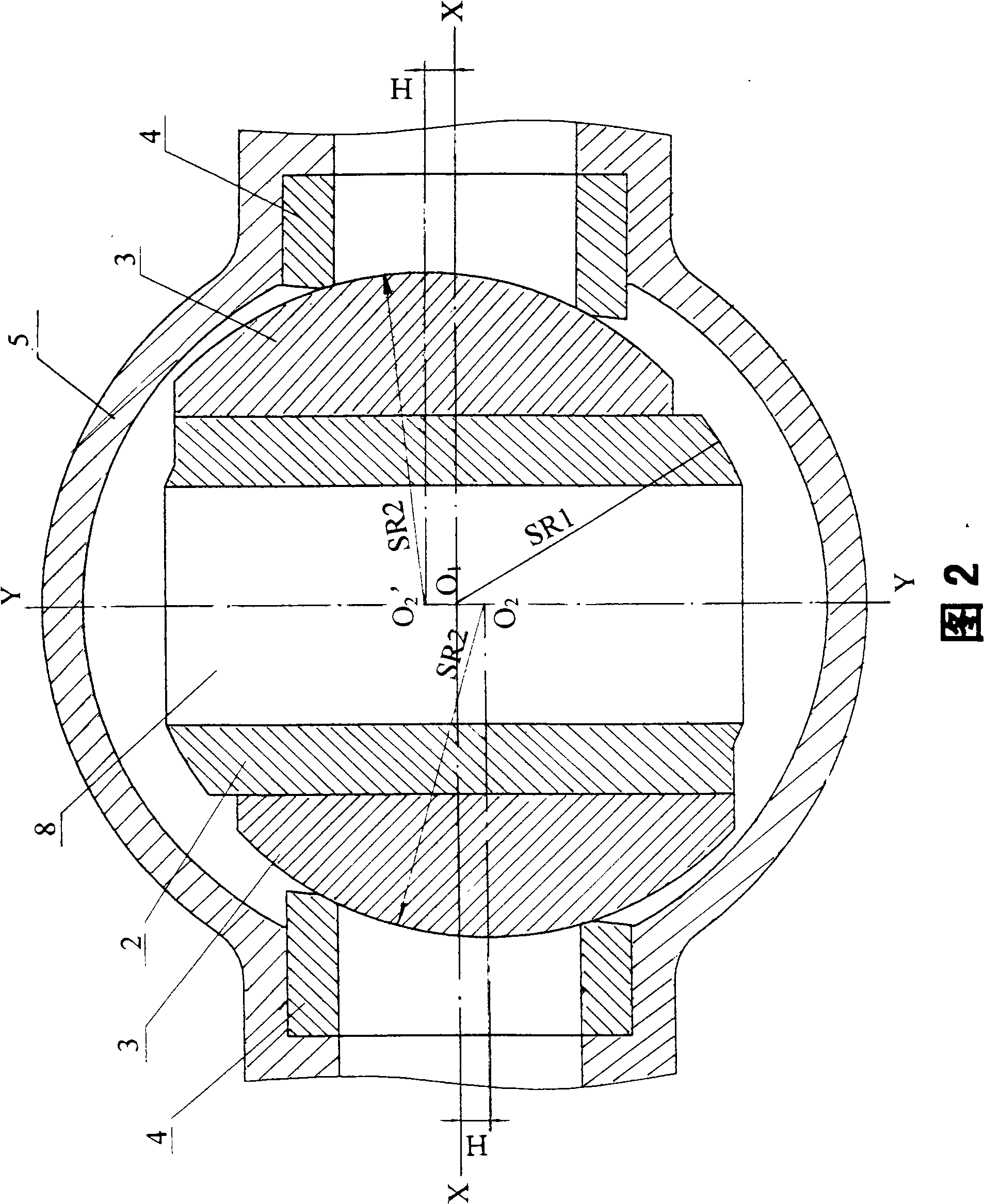

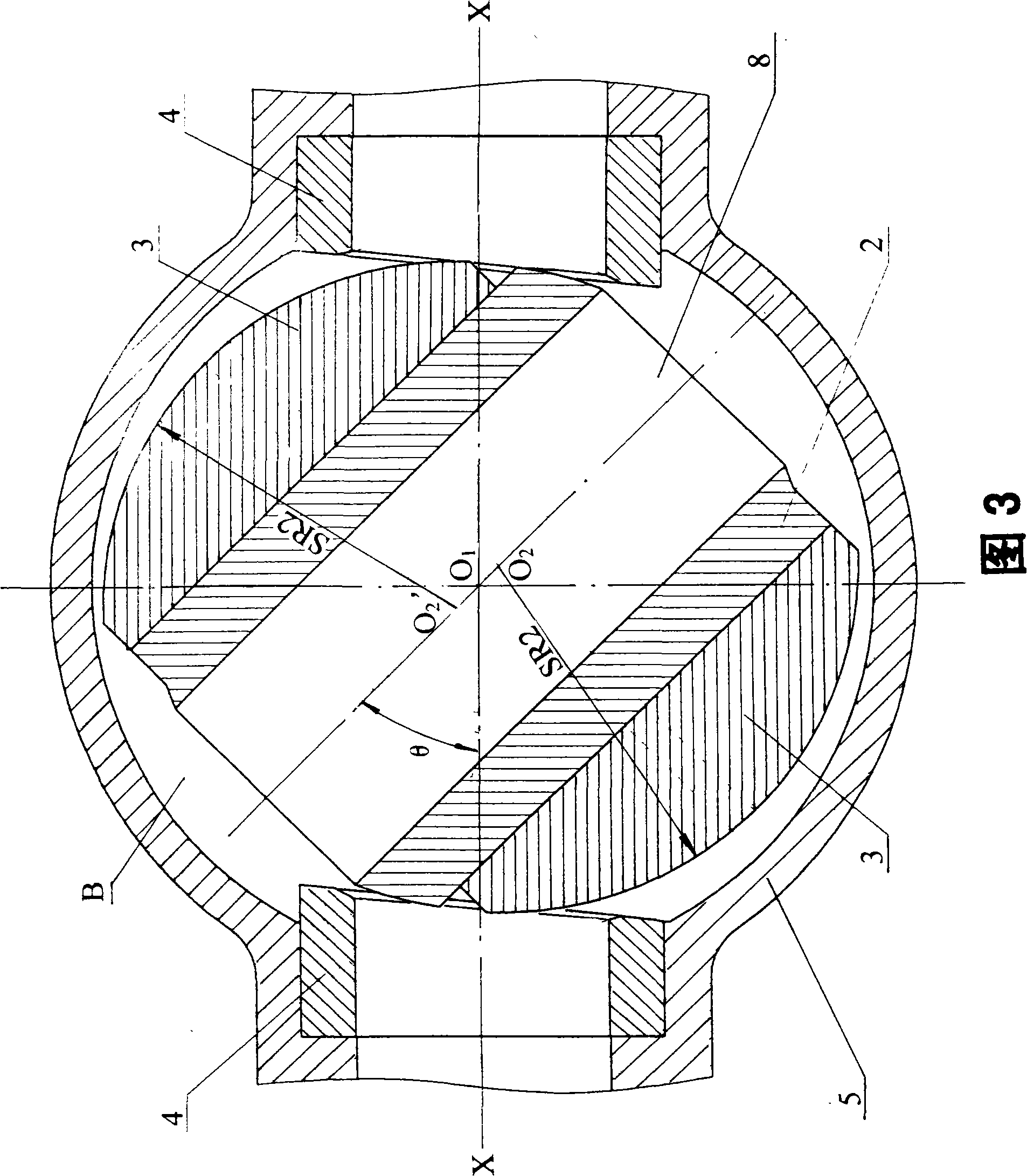

Screwing type hard seal ball valve

InactiveCN101270820AUniform loadImprove sealingPlug valvesValve member-seat contactsAngle alphaValve seat

The invention relates to a ball valve. A tightly screwed ball valve with a hard seal includes valve seat and a valve core, which is characterized in that the valve core is a spheroid composed of a main ball body and two metal spherical caps which serve as the sealing face. The radius of the main ball body is less than the radius of the metal spherical caps. The sphere centers of the two metal spherical caps are respectively biased at the two sides of the longitudinal axial line X-X of the valve body symmetrically and are located on the horizontal axial line Y-Y of the valve body. The valve seat is metal and the end plane thereof provided with the sealing face and the longitudinal axial line X-X of the valve body form an inclination angle alpha. The invention solves the technical problem that the metal valve seat and the valve core realize zerofriction seal between the sealing faces.

Owner:SHANGHAI VALVE FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com