Especial-big span suspension bridge of uniparted hyperboloid space rope net main cable and construction method thereof

A hyperboloid, suspension bridge technology, used in suspension bridges, bridge construction, bridges, etc., can solve the problems of poor lateral stiffness, unable to meet the wind resistance stability requirements of 3,000-5,000-meter long-span strait suspension bridges, and poor torsional stiffness. , to achieve the effect of large structural space stiffness, solving the problem of anti-wind flutter stability, and large anti-lateral static wind load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

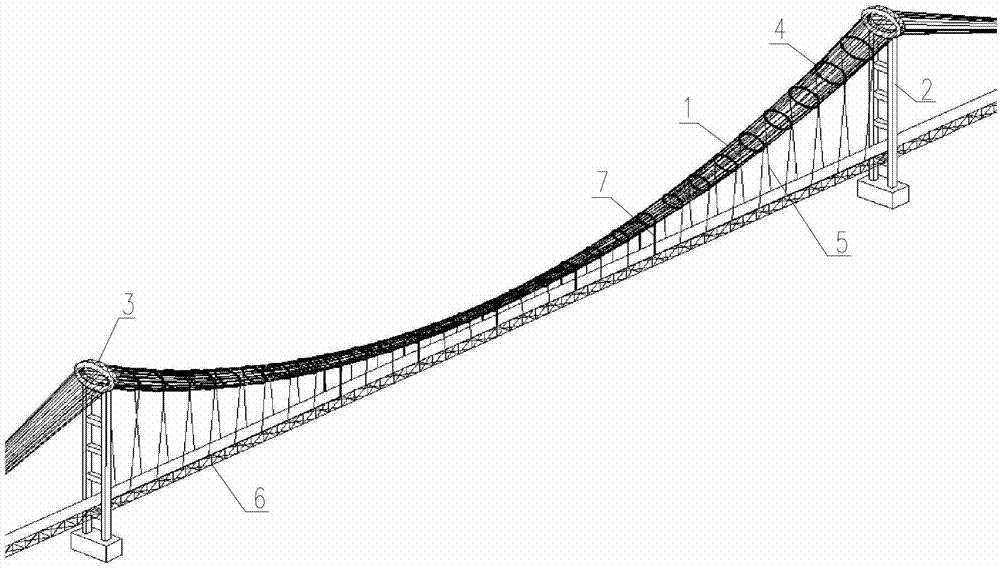

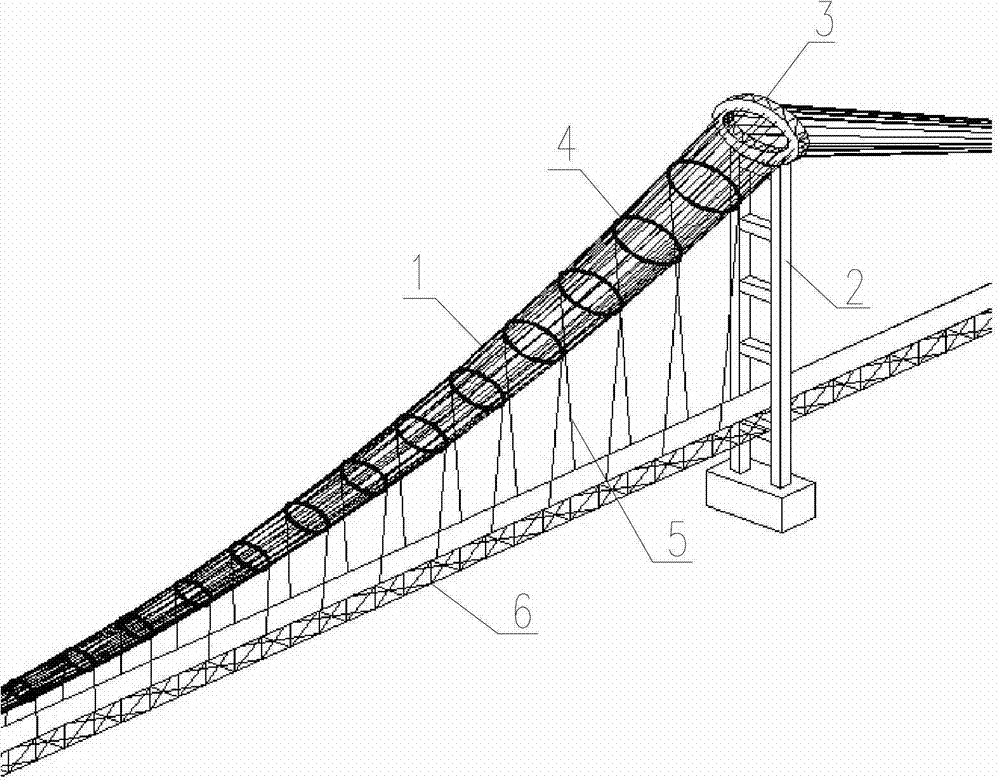

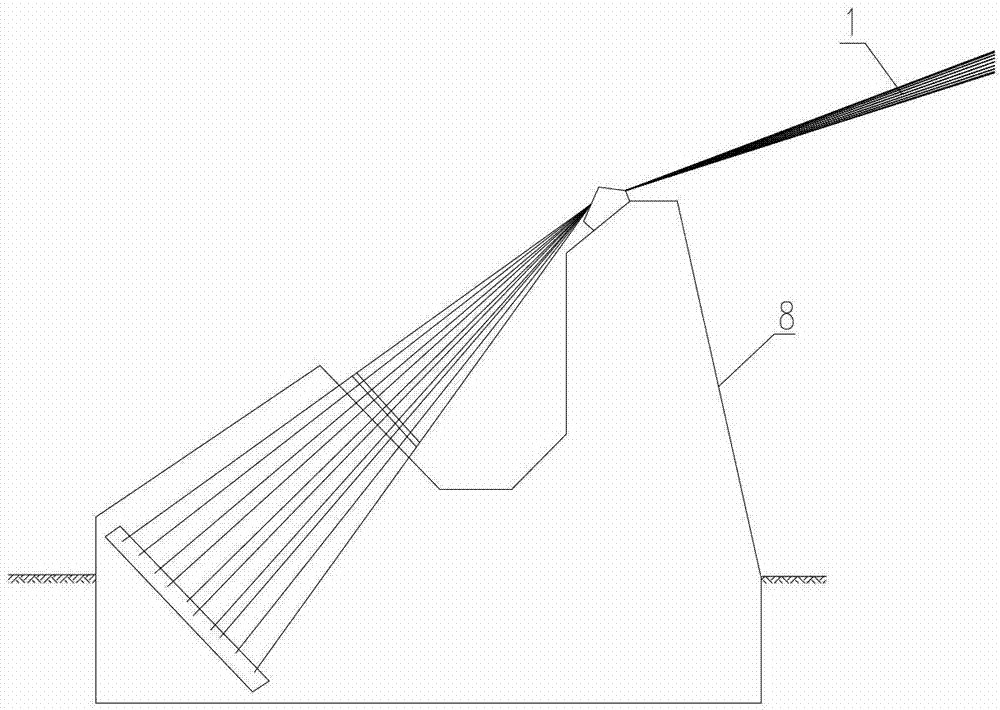

[0040] The super-large-span suspension bridge of the single-leaf hyperboloid space cable net main cable of the present invention comprises a cylindrical net space main cable 1, a bridge tower 2, a steel ring tower head 3, an elliptical steel ring beam 4, a suspender 5, and a stiffening steel The beam 6, the portal rigid central buckle 7 and the anchorage 8, the main cable 1 in the cylindrical mesh space is composed of several steel wire cables intersecting in space, and its spatial configuration is a closed cylindrical tubular cable formed by the drooping of the single-leaf hyperboloid space cable net. The main cable 1 of the tube mesh space is used as the main cable of the super-long-span suspension bridge, the steel ring tower head 3 fixes the top of the bridge tower 2, and the steel wire cable of the tube mesh space main cable 1 passes through the pre-wired steel ring tower head 3. Holes are left and anchored in the anchorage 8, and the main cable 1 in the tubular network sp...

Embodiment 2

[0042] The construction method of the extra-large-span suspension bridge of the single leaf hyperboloid space cable net main cable of the present invention comprises the following steps:

[0043] Step 1: According to the geological topography, landform conditions and navigation requirements, select the bridge site for the super-long-span Strait Suspension Bridge, excavate the foundation pit, construct the bridge foundation, and build the bridge tower 2 and steel ring tower head 3 of the super-long-span Strait Suspension Bridge and anchor 8;

[0044] Step 2: After erecting the traction cables and constructing temporary construction catwalks, carry out accurate measurement and lofting according to the equation of the single-leaf hyperboloid, arrange the multi-strand cables crosswise in space, and pass the traction wire cables through the steel ring tower head 3 reserved holes , anchored in the foundation of the anchorage 8, erect the main cable 1 in the cylindrical reticulated s...

Embodiment 3

[0049] A certain Strait Bridge is a super long-span suspension bridge for highway and railway, with a main span of 3600m and a bridge deck width of 60m. The sub-span of the suspension bridge is 1200m+3600m+1200m. The middle part of the bridge deck is a double-track railway. In order to meet the requirements of wind resistance and stability, a super-long-span suspension bridge with a single-leaf hyperboloid space cable network main cable is adopted. The bridge tower is a gate-post type bridge tower with a height of 420 meters. The bridge tower is a steel-concrete composite structure. Shaped underground continuous wall structure. The anchorage adopts a large-volume reinforced concrete structure, and the prismatic anchorage can make the anchorage embedded in the soil. An elliptical steel ring tower head is set on the top of the bridge tower structure. The major axis size of the steel ring tower head is 120 meters, and the short axis size is 60 meters. The main cable of the susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com