Outer wall plate structure with fireproof function and production method of outer wall plate structure

A technology of exterior wall panels and functions, applied in fire prevention, chemical instruments and methods, walls, etc., can solve the problem that the fire resistance performance cannot meet the requirements, and achieve rich styles, good fire resistance performance, and high structural rigidity and lateral rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] This embodiment is an exterior wall panel structure with fireproof function.

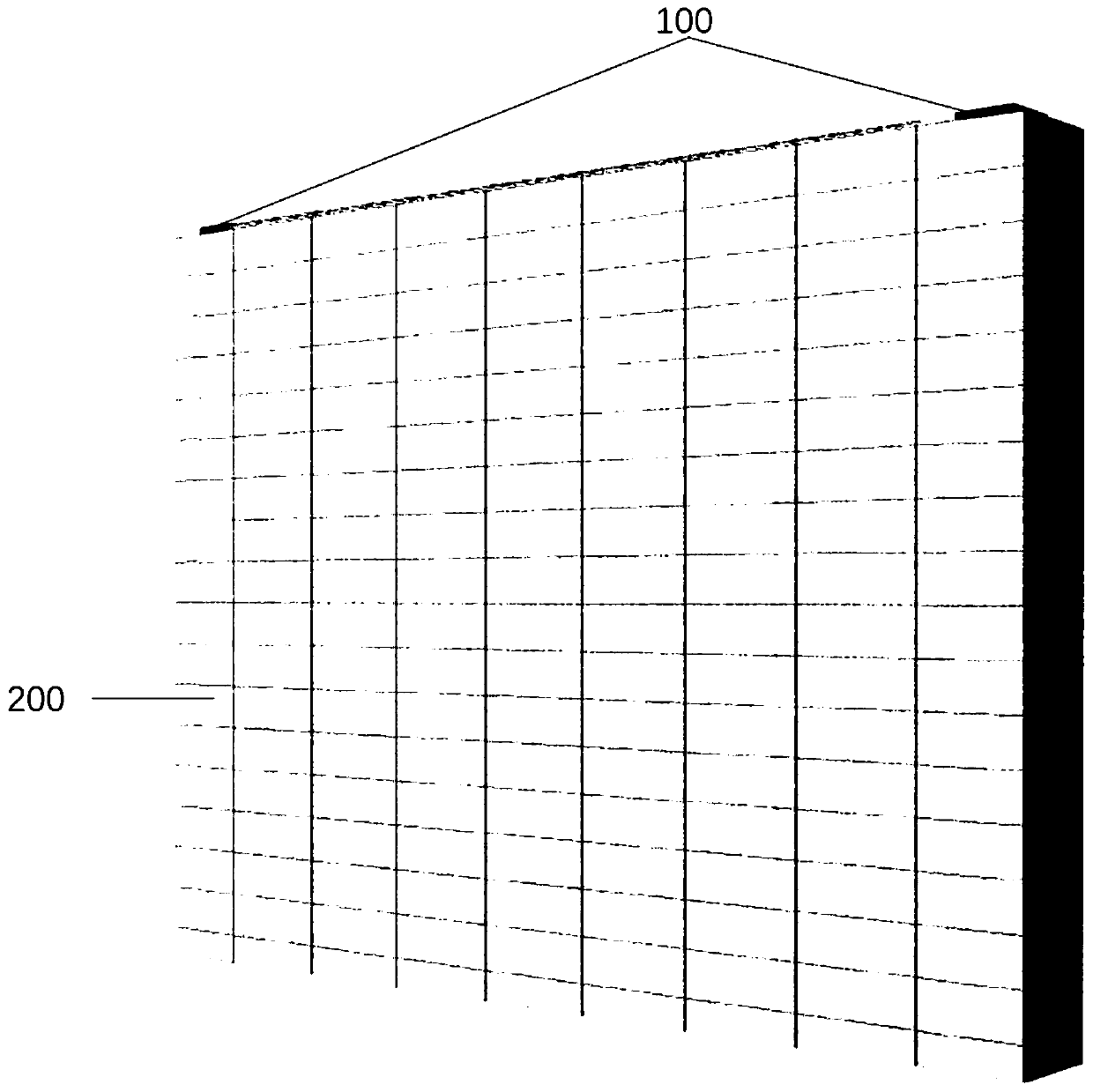

[0093] figure 1 This is a three-dimensional view of the external wall panel with fire protection function of this embodiment. Such as figure 1 As shown, the exterior wall panel structure with fire protection function of this embodiment includes a load-bearing metal frame 100 and a plate 200.

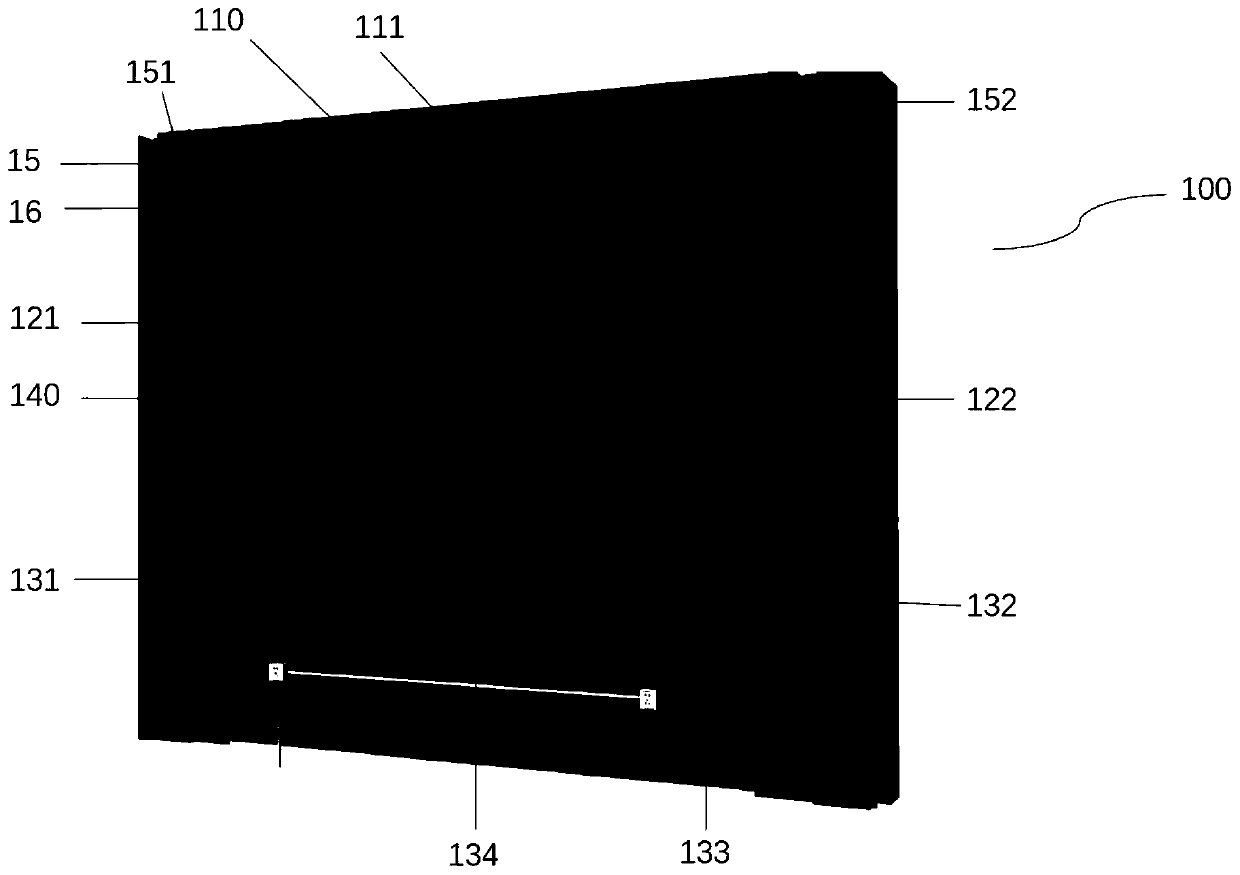

[0094] figure 2 This is a structural diagram of the load-bearing metal frame 100 of this embodiment. Such as figure 2 As shown, the load-bearing metal frame 100 includes horizontal beams 110, columns, supports, and steel mesh 140. The horizontal beam 110 is located on one side of the load-bearing metal frame and is parallel to the horizontal direction of the external wall structure. The load-bearing metal frame 100 is used to support the entire external wall panel structure in a horizontal direction. The uprights are used to support the exterior wall panel structure in the vertical direction. The colum...

Embodiment 2

[0100] Except for the difference in the composition of the fireproof layer, the structure of the exterior wallboard of this embodiment is the same as that of Embodiment 1. The fireproof layer in this embodiment is a self-extinguishing extruded polystyrene board, and its composition is as follows:

[0101] 90 parts of polystyrene resin monomer particles, 1.5 parts of tert-butyl peroxybenzoate, 5 parts of a mixture of aluminum hydroxide and calcium carbonate, 5 parts of ethanol and 3 parts of phosphorus-containing polyisocyanate: Wherein X and R are each ethylene.

[0102] The above-mentioned raw materials are mixed, stirred and mixed uniformly at a temperature of 95-115°C, and then added into an extruder for extrusion molding, and the self-extinguishing extruded polystyrene board is obtained after the discharge. The ignition temperature of the obtained extruded polystyrene board was determined to be 377°C. When the heating efficiency is 20%, it does not ignite within 2800 seconds,...

Embodiment 3

[0104] This embodiment is a production method of an exterior wall panel structure with fireproof function. The method of this embodiment includes:

[0105] (1) Place the line on the mold table of the processing production line, and set up the side mold according to the size of the wallboard;

[0106] (2) Pave the exterior wall tiles on the bottom mold with the reverse punching process (the decorative materials need to be equipped with mechanical tie measures), and apply 3-5mm polymer mortar on the bottom of the decorative tiles, and then apply cement mortar and The alkali-resistant glass fiber mesh forms a 5mm thick first protective layer;

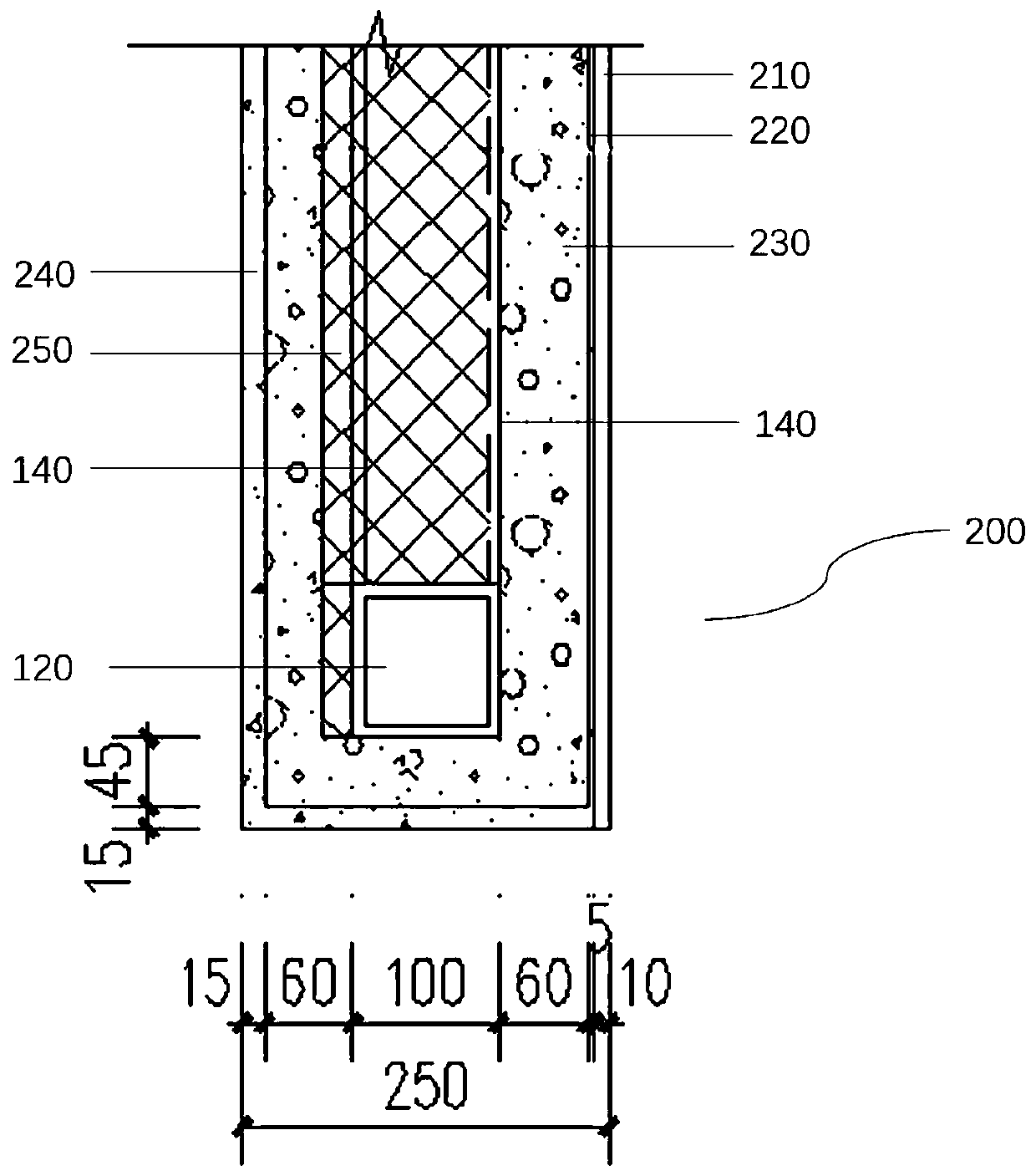

[0107] (3) The welded body of the load-bearing metal frame and the steel wire mesh (the load-bearing metal frame is welded by columns, beams, supports, etc.), and the periphery is welded Steel wire mesh) is hoisted into the template, so that the thickness of the steel wire mesh to the first protective layer is 20mm, and the pouring volume in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com