Patents

Literature

179results about How to "Improve fire protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prefabricated sandwich heat-preservation heat insulation concrete external wall panel and fabrication method

InactiveCN102650152AImprove manufacturing precisionReduce mistakesCeramic shaping apparatusBuilding componentsFire protectionEnergy conservation

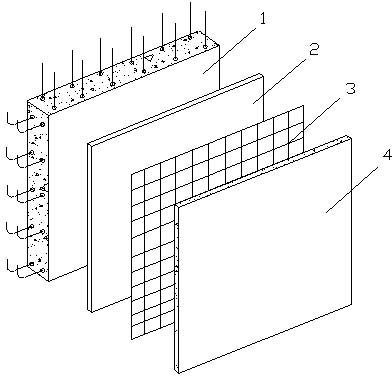

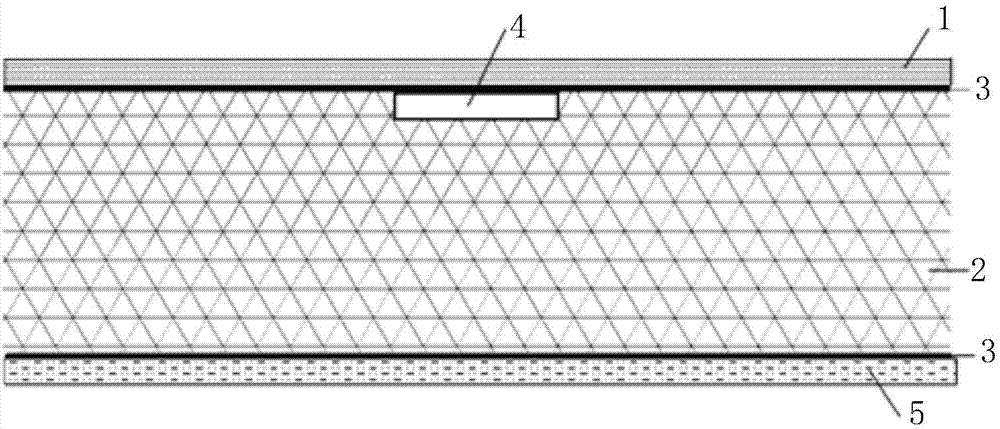

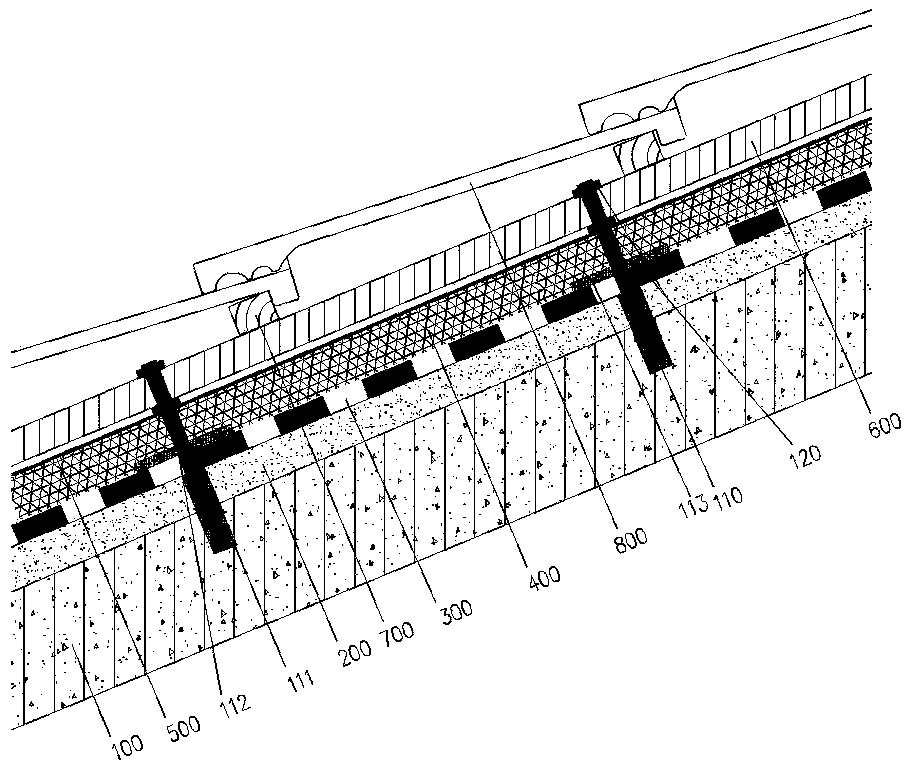

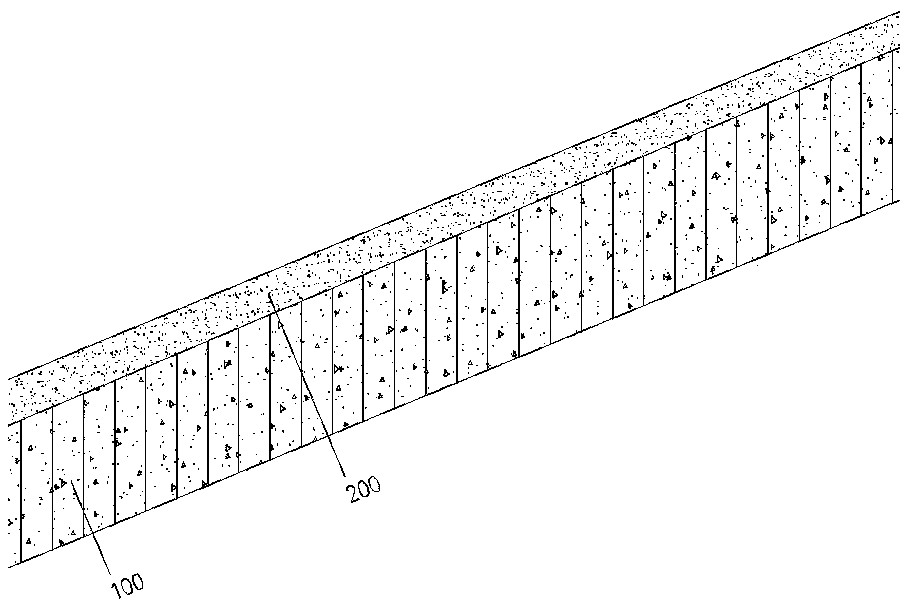

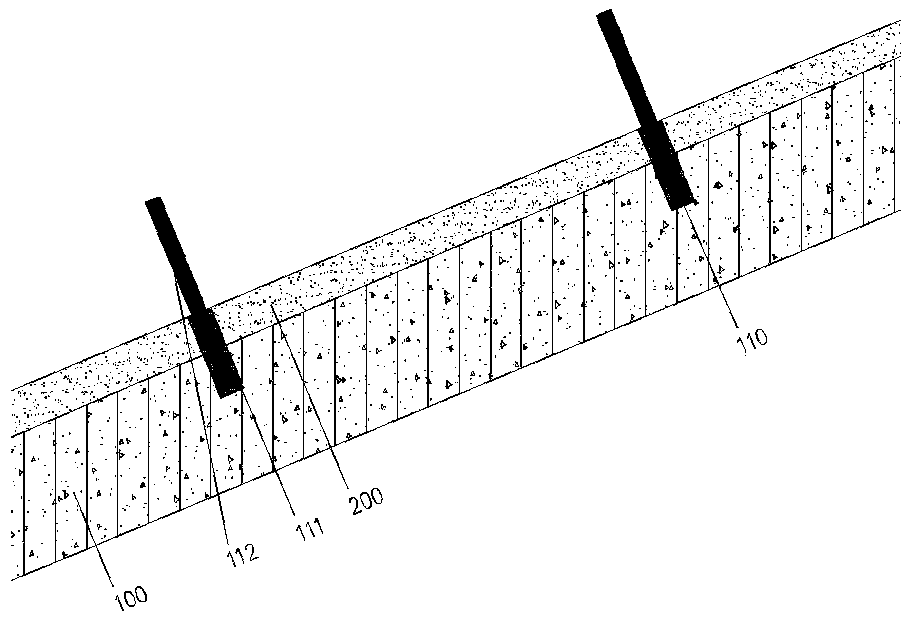

The invention discloses a prefabricated sandwich heat-preservation heat insulation concrete external wall panel and a fabrication method. An integral composite wall panel which is structured in a way of wall body- heat insulation-architectural decoration from interior to exterior is adopted, the wall body is a load-bearing concrete structural layer, the middle of the wall panel adopts a heat insulation board, and the outermost side of the wall panel is an architectural decoration cladding panel, the three layers of the wall panel are connected into a whole by heat insulation connectors, so that the composite external wall panel is applicable to assembling an integral shear wall structure or an integral frame-shear wall structure, and also meets the requirements of buildings on energy conservation and fire protection. The prefabricated sandwich heat-preservation heat insulation concrete external wall panel is prefabricated in a factory and is mounted on site, so that the production and construction efficiencies are high, and the quality is also ensured; besides, the external wall panel realizes energy conservation, environmental protection, fire protection and heat insulation, and also has remarkable comprehensive benefits.

Owner:CHINA MCC17 GRP

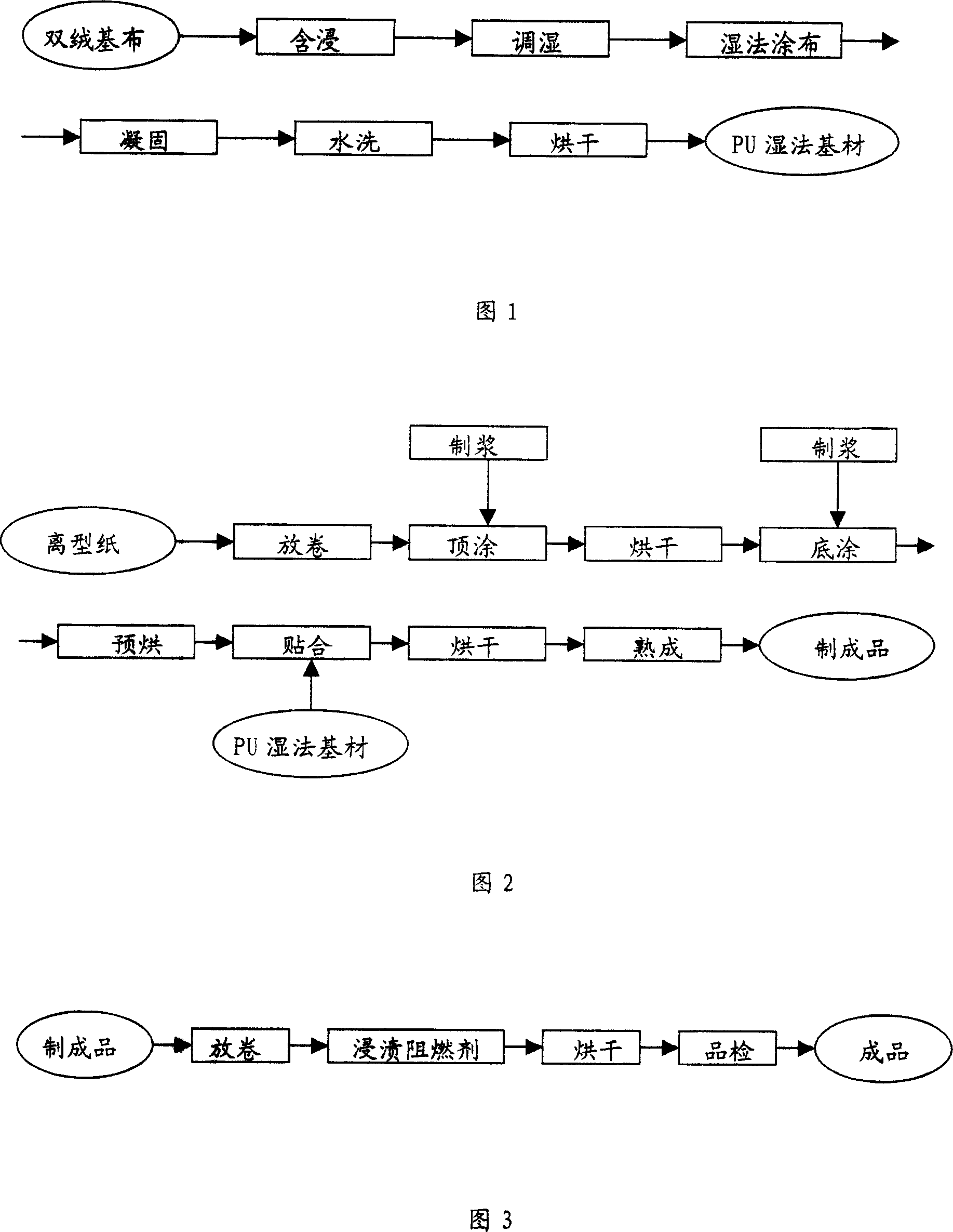

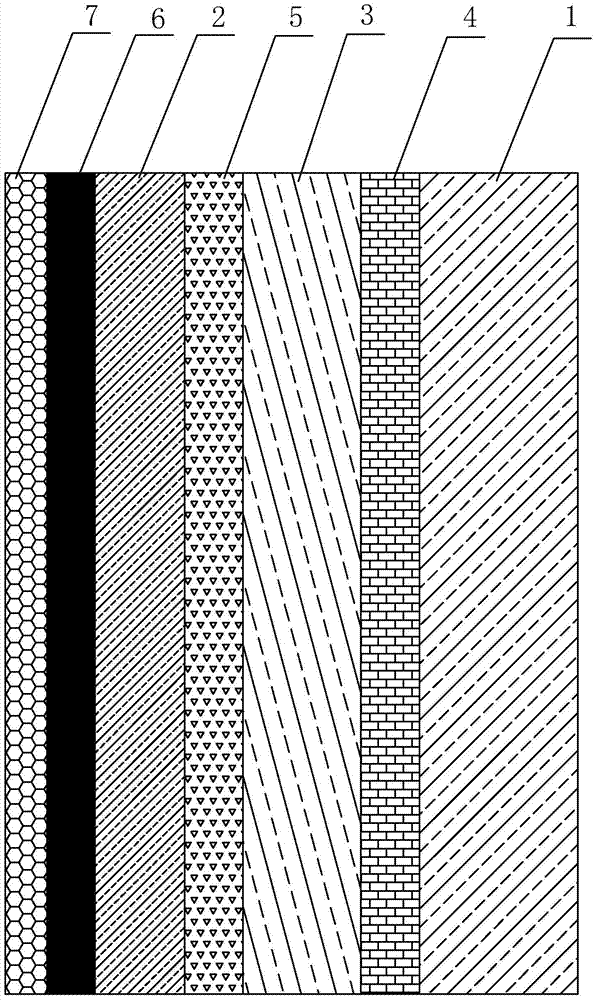

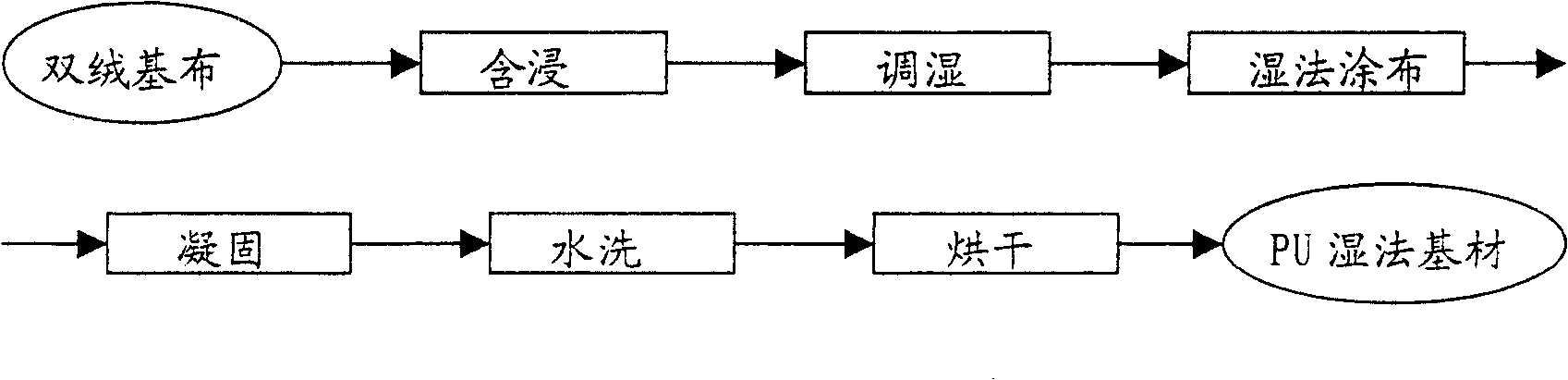

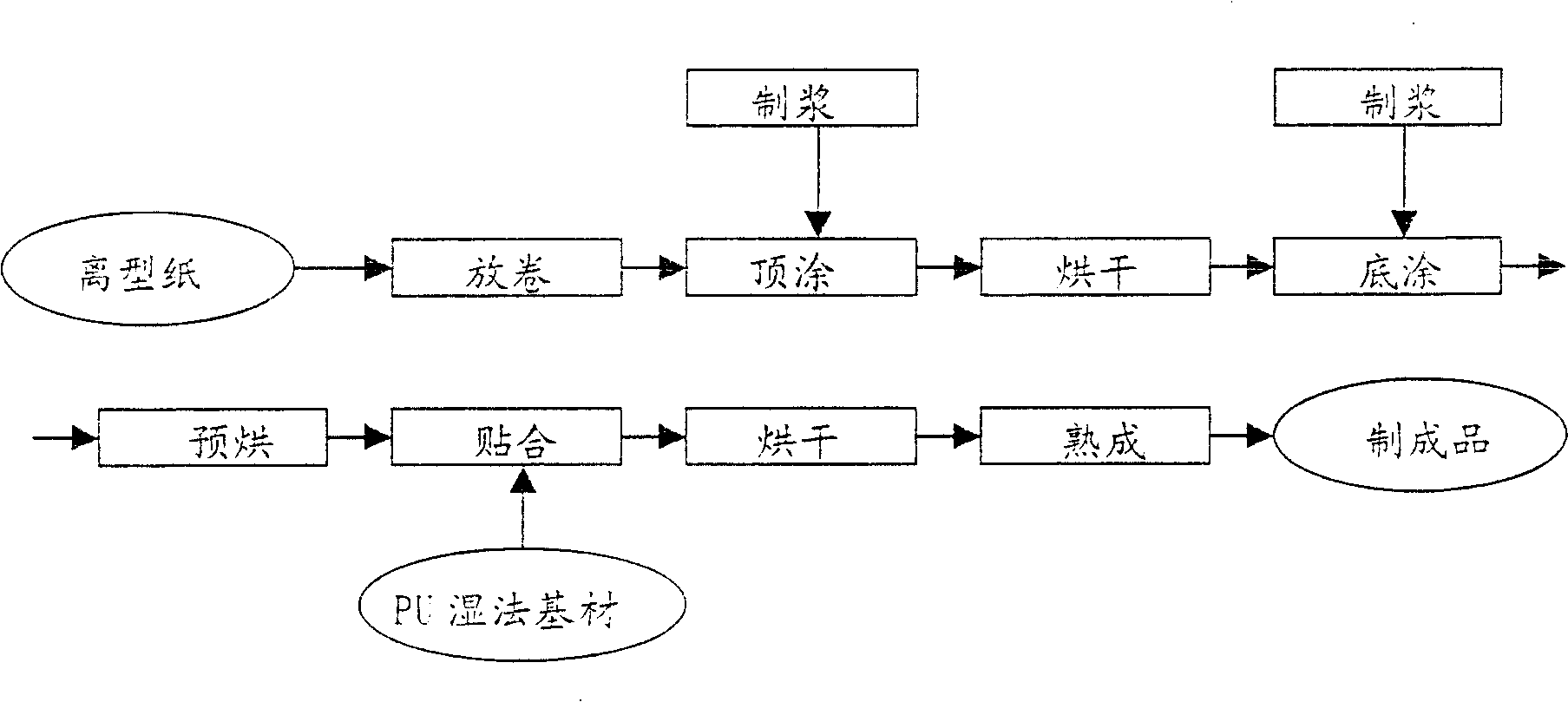

Process of producing fireproof sofa artificial leather

ActiveCN101021045AImprove flame retardant performanceImprove fire protectionTextiles and paperWater basedSlurry

The process of producing fireproof sofa artificial leather includes the following steps: 1. wet coating polyurethane layer on the base fabric; 2. dry adhering surface polyurethane layer on the semi-finished product; and 3. soaking the fabric in water-base environment friendly fire retardant solution and stoving to obtain the product. In the step 1, the polyurethane resin is polyether or polycarbon type polyurethane resin and has phosphate fire retardant added into the wet slurry; and in the step 2, the polyurethane resin is polycarbon type polyurethane resin with fatty resin, the adhering layer is of aromatic resin and the dry slurry has phosphate fire retardant added. The sofa artificial leather has excellent fireproof function, antiageing performance and antiwear performance.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

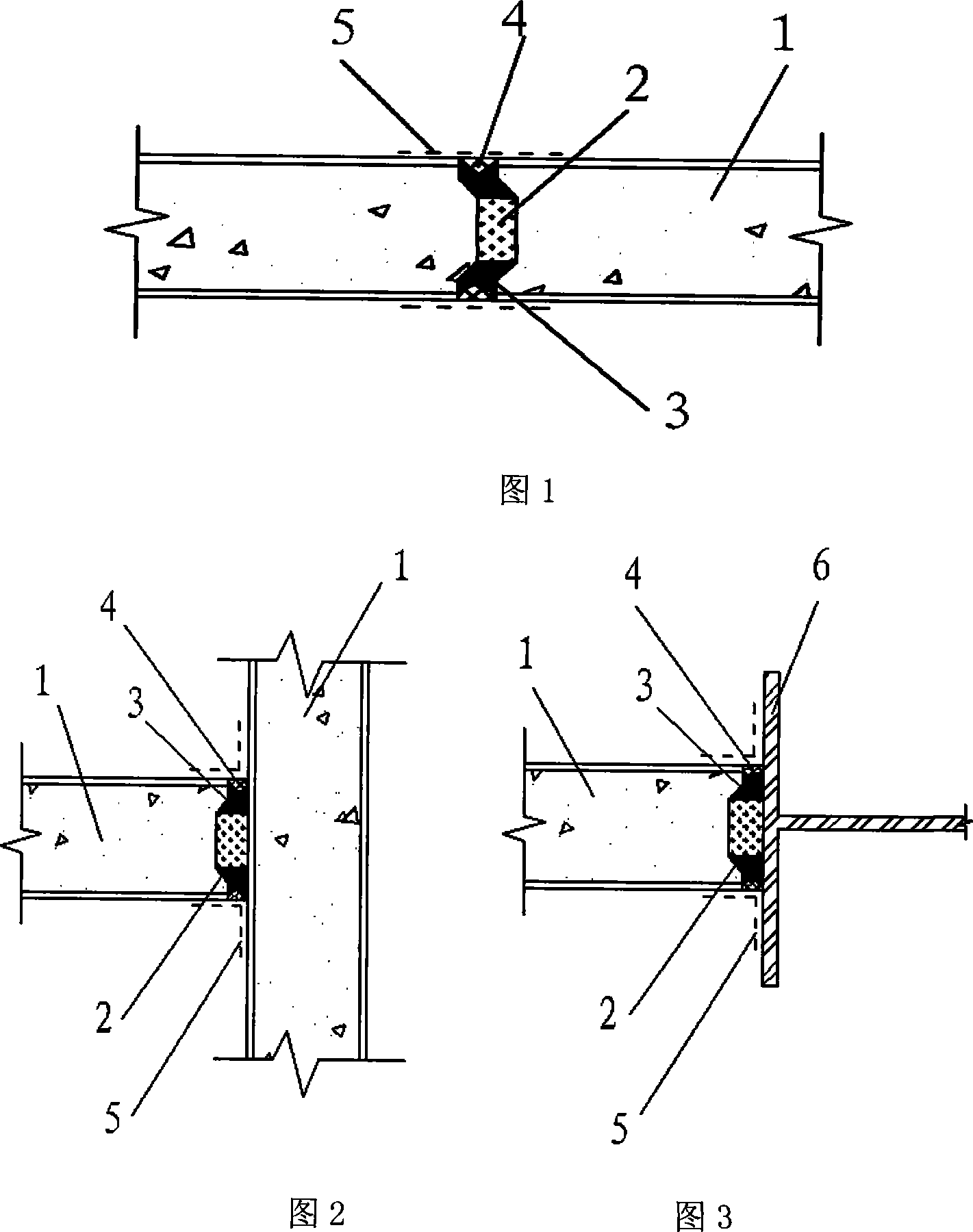

Inner wall board joint treatment technology

InactiveCN101230593ASolve common problems in the applicationPrevent board seam through seamWallsBuilding insulationsFireproofingEngineering

A wallboard seam processing technic belongs to the technical field of inner wallboard processing of building. The processing method is realized by that: a flute arranged at one side of a wallboard is internally affixed with rubber sponge with a certain thickness, the two sides of the rubber sponge are smeared with polymer sand pulp, and then the rubber sponge is abutting-jointed with a tenon of the wallboard or the side or the pillar of the wallboard as well as is tightly squeezed by force, so as to lead the rubber sponge to have a certain decrement; after that, the two sides of the seam are filled with elastic sealing compounds with a certain thickness, finally, the two sides of the seam are affixed with an anticracking gridding adhesive tape. The material in the seam of wall in the wallboard seam processing technic adopts elastic material, so as to solve the problem that generally appears and is hard to be settled of straight joint of slab joint caused by structural distortion or walling material drying shrinkage; furthermore, the rubber sponge adopted in the middle of the slab joint is made of fire resistant heat insulating material and can prevent a heat channel from generating among the slab joints, thereby having certain fireproofing performance. The invention is applicable to the slab joint processing of most of the inner wallboards such as a GRC board, a plasterboard, a hollow slat, etc. at the present time.

Owner:SHANDONG LAIGANG CONSTR CO LTD

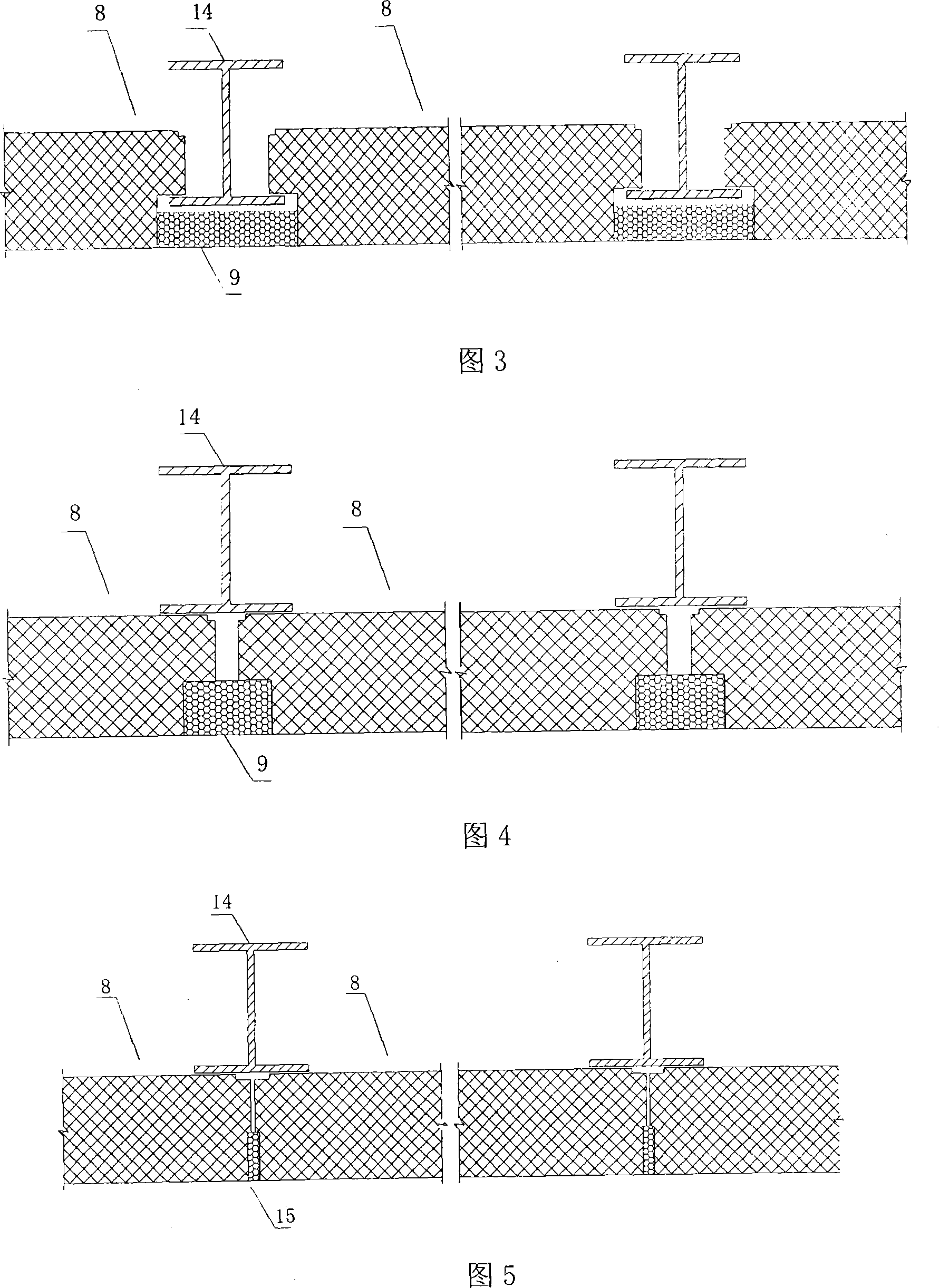

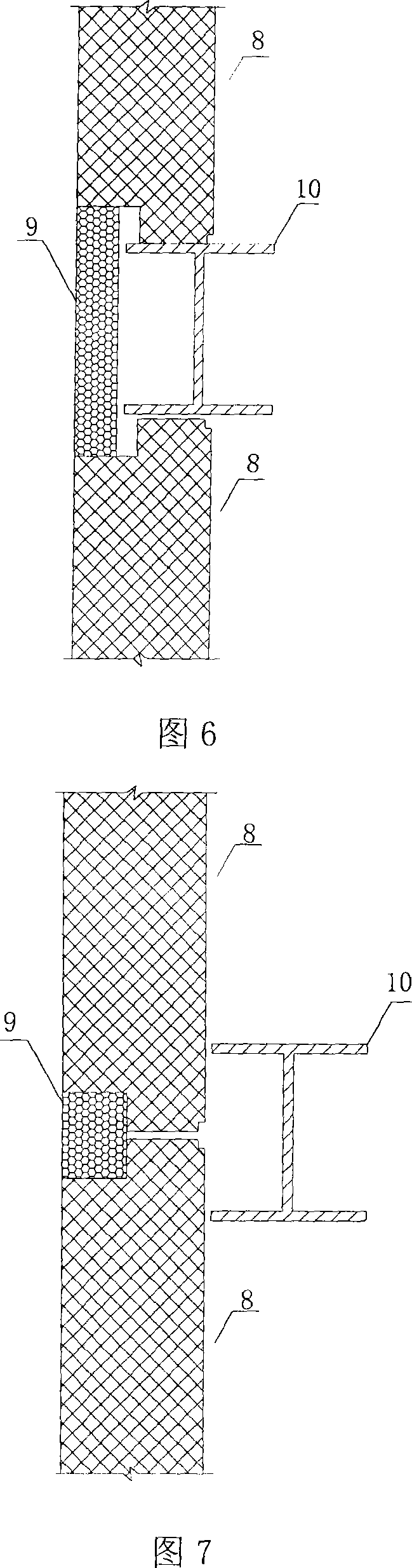

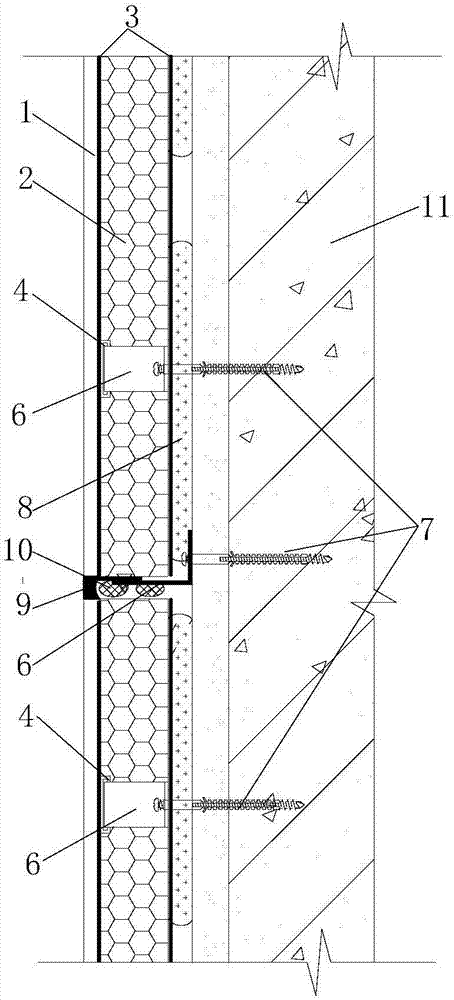

Composite thermal insulation wall body and method for producing and mounting the same

ActiveCN101144294AEnergy savingWith insulationWallsCeramic shaping apparatusThermal insulationFire prevention

The present invention relates to a composite insulation wall body, and the production and the installation method thereof. The composite wall body of the present invention is composed of a plurality of single block wall plates and insulation decorative plates. The present invention is characterized in that two adjacent single block wall plates are clamped and arranged among beams or columns; and the insulation decorative plates are embedded and arranged in the space formed between the two adjacent single block wall plates, and are firmly connected with the beams or columns. The present invention has the advantages that the composite wall body of the present invention not only has the performances of energy-saving, insulation, durability, lightweight and strong seismic capability, but also has the excellent fire prevention performance, and plays the good fire prevention protective function to the steel structure, and can be used as a firewall; and the decorative effect with various styles can be realized on the outer surface of the wall plate. The production and the installation method of the present invention realize the industrialized production, the on-site assembling is quick, and generally no on-site wet operation exists; the present invention can effectively increase the using area of the room, and lower the project construction cost of the building; and the construction is safe and reliable.

Owner:CUBIC DIGITAL TECH CO LTD

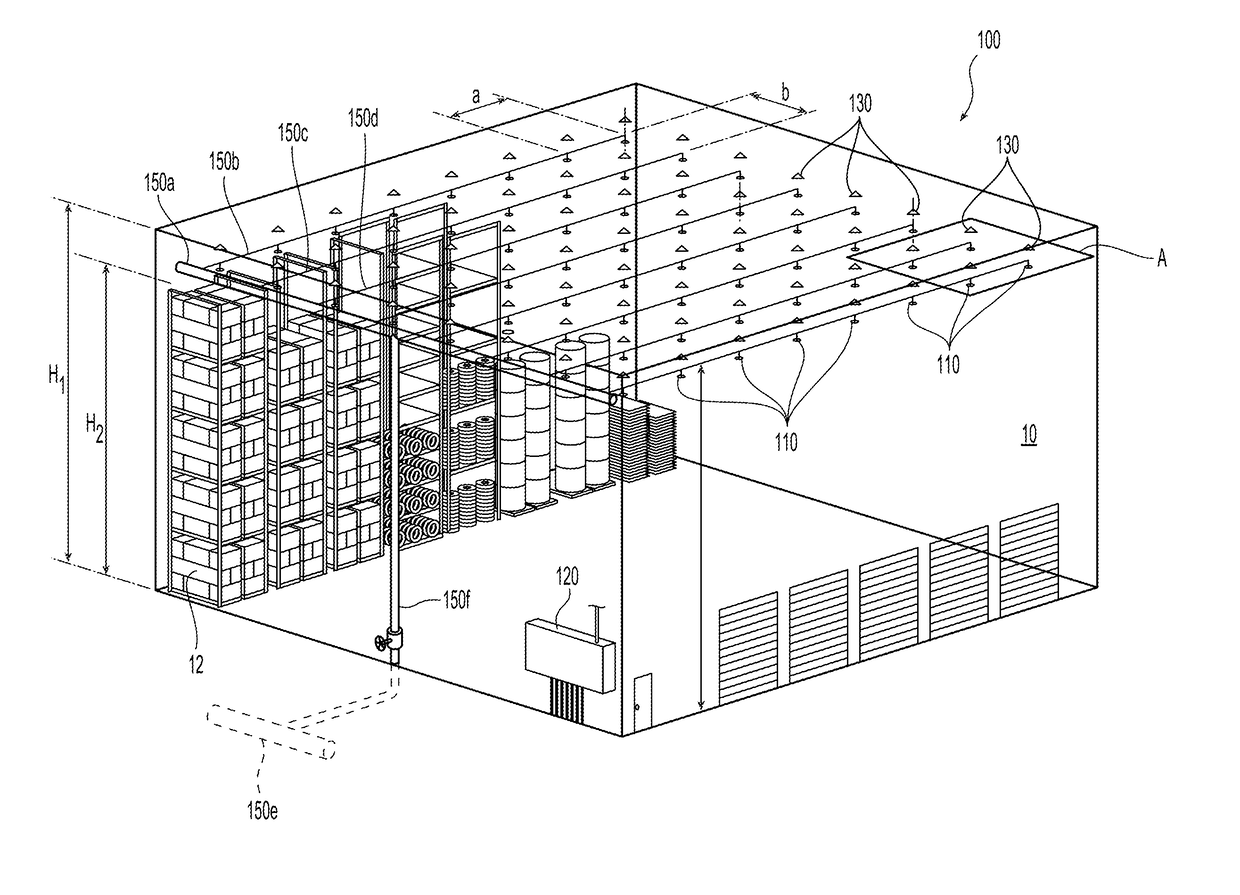

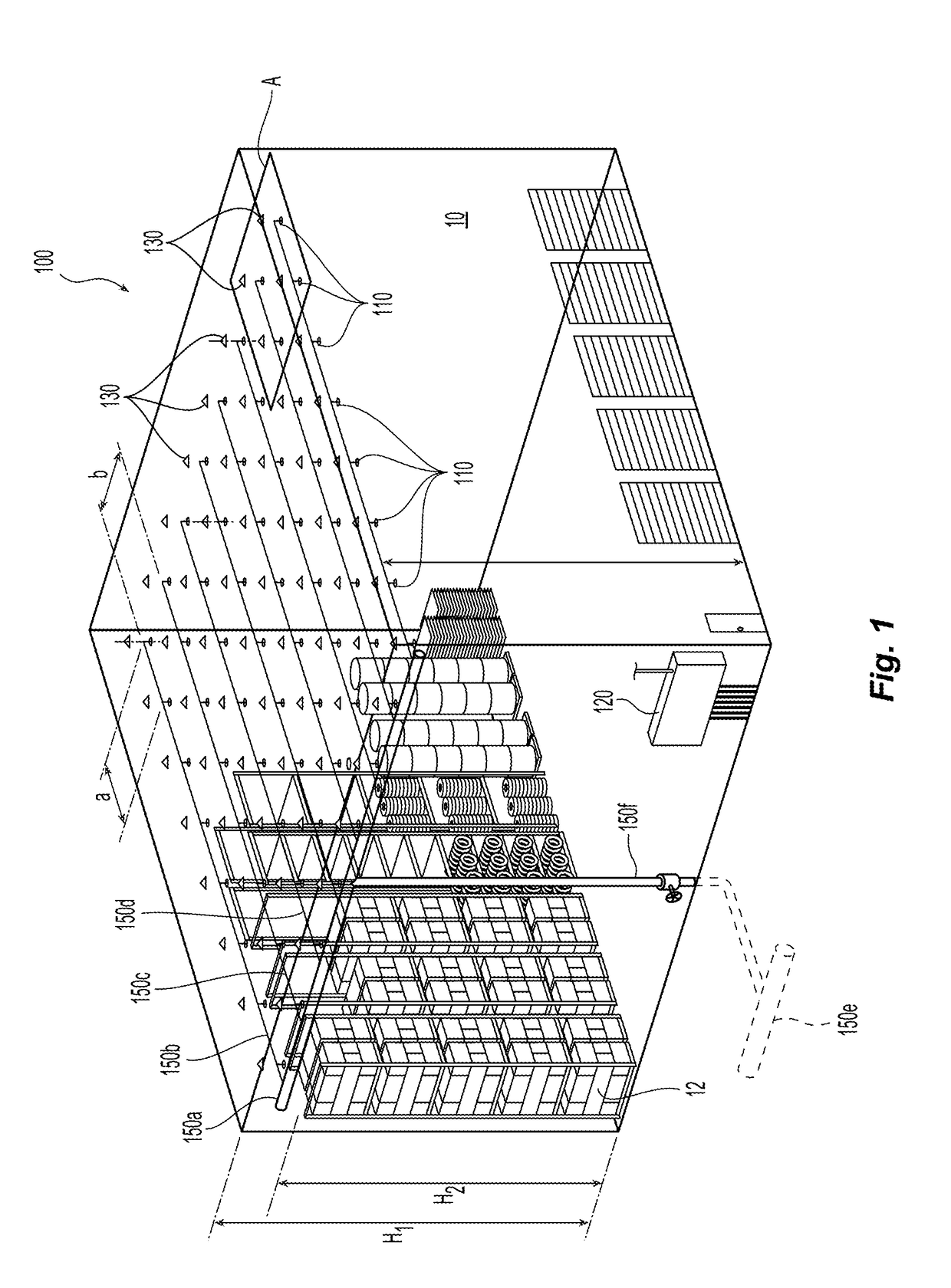

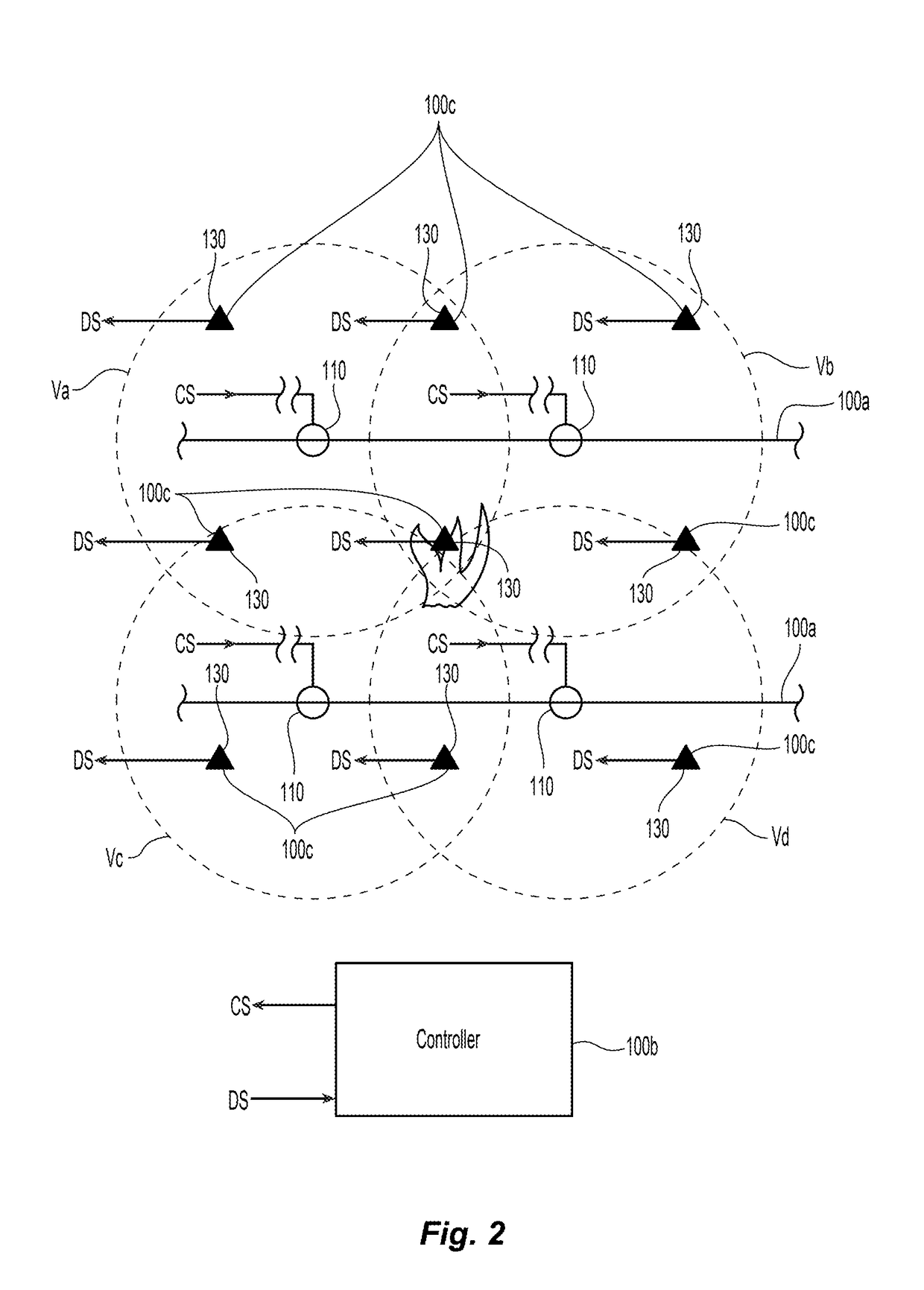

Controlled system and methods for storage fire protection

ActiveUS20170120090A1Improve fire protectionLimit impactInsulated cablesFire rescueEngineeringControl system

Fire protection systems and methods for ceiling-only high-piled storage protection. The systems include a plurality of fluid distribution devices disposed beneath a ceiling and above a high-piled storage commodity having a nominal storage height ranging from a nominal 20 ft. to a maximum nominal storage height of 55 ft. and means for quenching a fire in the storage commodity. The stored commodity to be protected may include exposed expanded plastics. The fluid distribution devices include a frame body having an inlet, an outlet, a sealing assembly, and an electronically operated releasing mechanism supporting the sealing assembly in the outlet.

Owner:TYCO FIRE PRODS LP

Foam metal and preparation method thereof

The present invention discloses a foamed metal and is characterized in that air holes are distributed in the metallic material. The diameter of the air hole is 3-25 millimeters and the porosity is 80-98 percent. The invention also discloses a method of preparing foamed metal. The foamed metal in the present invention has a good sound-absorbing effect and can be used for making sound absorption boards.

Owner:TONGJI UNIV

Fire-proof wheel and production technology thereof

InactiveCN102705356AImprove fire protectionImprove connection stabilityShaft and bearingsElevatorsElevator systemWork performance

The invention discloses a fire-proof wheel and a production technology of the fire-proof wheel. The fire-proof wheel comprises a wheel main body and a bearing which are made of metal materials. The wheel main body comprises a retaining ring and a wheel core which is provided with a through hole. One end of the wheel core is provided with a folded side, and the other end of the wheel core is provided with a first limiting step. The retaining ring is fixedly sleeved on the first limiting step. One end of the inner wall of the through hole of the wheel core is provided with a second limiting step, and the other end of the inner wall of the through hole of the wheel core is provided with a certain quantity of riveting points which are distributed in an annular shape. The bearing is fixed between the riveting points and the second limiting step. A Teflon ring is sleeved on the outer surface of the wheel core, and the Teflon ring is located between the retaining ring and the folded side. The fire-proof wheel provided by the invention comprises the wheel core and a baffle which are made of metal materials, so that the fire-proof function of the surface of the wheel is good; compared with the design of the polyurethane ring in the prior art, the Teflon ring is not influenced by high temperature, the use stability is high, and the work performance is good, so that the fire-proof wheel is quite suitable for fire elevator systems.

Owner:NINGBO HUALING ELEVATOR PARTS

Sintered decorative brick of dry wall and manufacturing method thereof

InactiveCN101666148ASave resourcesPromote environmental protectionCovering/liningsMixing operation control apparatusBrickFireproofing

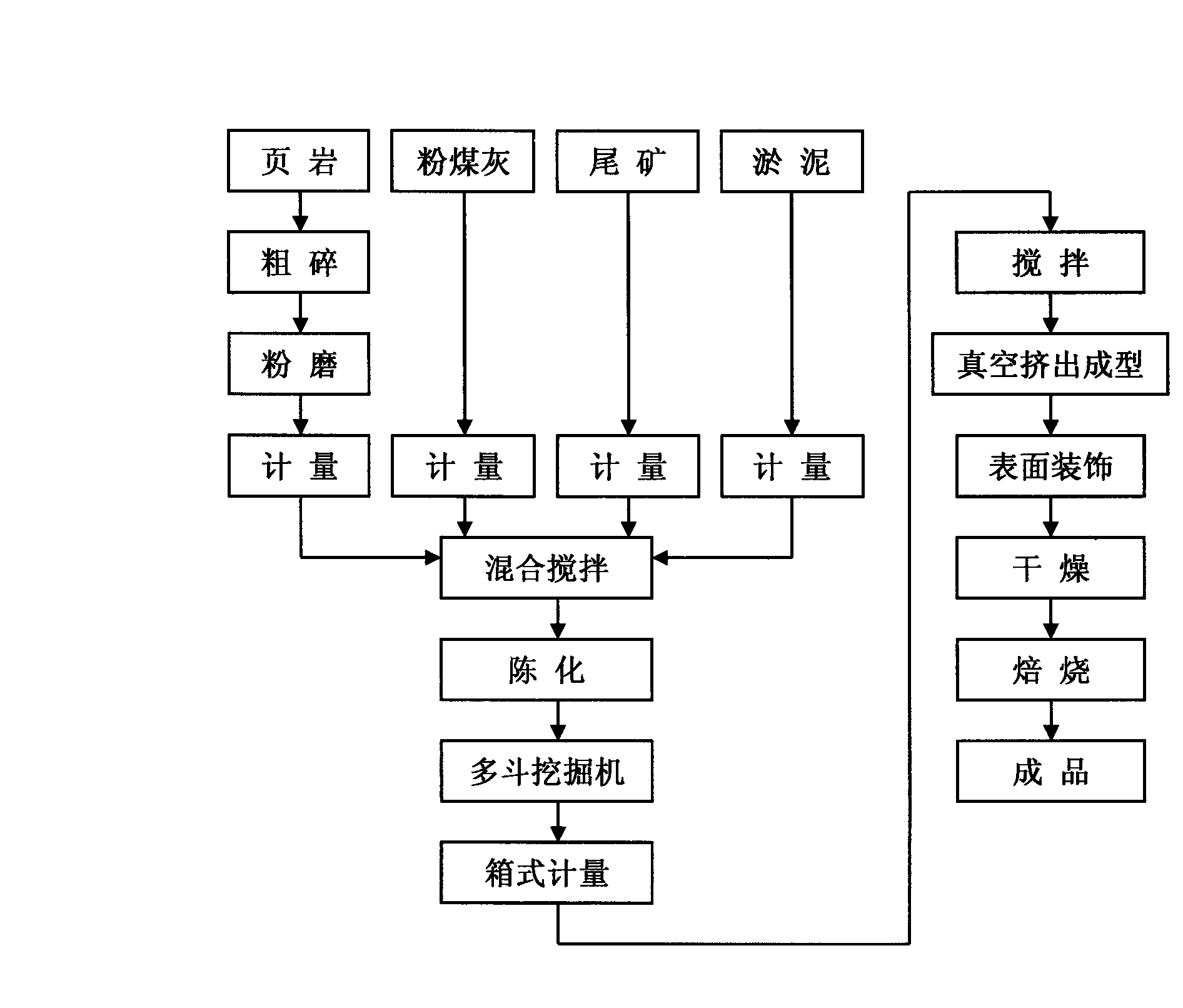

The invention provides a sintered decorative brick of a dry wall and a manufacturing method thereof. The decorative brick is made from the following raw materials in percentage by weight: 25-80 percent of shale, 10-30 percent of fly ash, 10-60 percent of metallurgy ore tailing or reservoir silt and 0-4 percent of admixture; the metallurgy ore tailing is one of a mineral gold ore tailing, a lead-zinc ore tailing, an iron ore tailing and an alumina ore tailing; and the admixture is one of chromium powder, manganese powder, cobalt powder and ferrous powder. The manufacturing method is achieved asfollows: coarsely rushing and milling the shale with the milling fineness less than or equal to 1mm, adding the fly ash, the metallurgy ore tailing or the reservoir silt and the admixture for mixing,adding water for stirring, then feeding the mixture to an ageing bunker to age for 72 hours, extruding the aged product by a high vacuum extruder for forming, treating the surface of the formed product, cutting and drying the formed product, and finally feeding the dried product to a calcining kiln to form a finished product. The invention uses the fly ash and the reservoir silt so as to save theenergy source and be beneficial to environmental protection; and the decorative brick has high compactness, high strength, favorable durability, good fireproofing function and elegant and beautiful appearance.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Processing technology for single-sheet cesium potassium fireproof glass

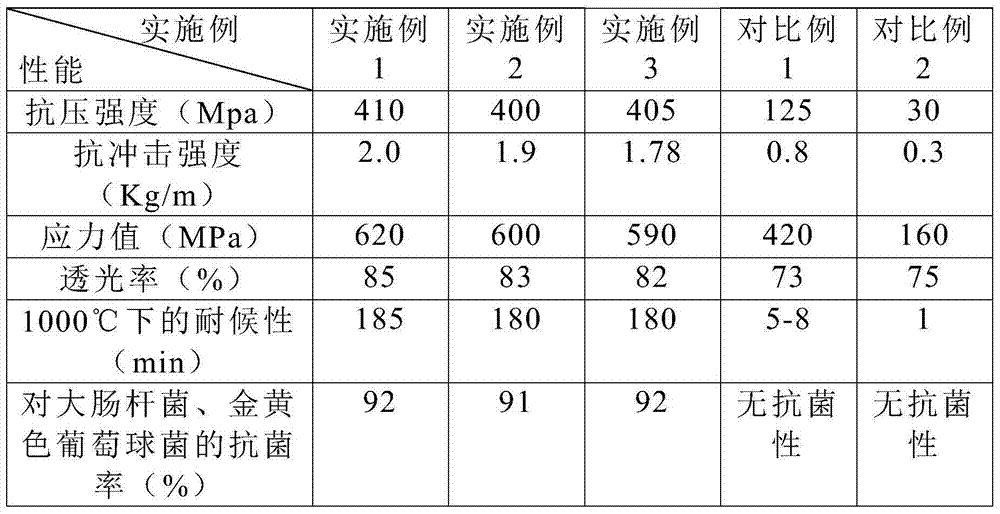

InactiveCN104291688AImprove fire protectionImprove antibacterial propertiesGlass tempering apparatusThermal insulationPotassium

Belonging to the technical field of building materials, the invention relates to a processing technology for a single-sheet cesium potassium fireproof glass. The processing technology comprises the following steps of: pretreatment of glass: conducting surface acid treatment on glass, then carrying out cleaning, drying and preheating to 380-400DEG C, and performing thermal insulation for 25-30min; ion exchange treatment: subjecting the glass to ion exchange treatment in a cesium potassium salt solution at 550-650DEG C for 18-22h; heat treatment: performing heat treatment on the glass subjected to the ion exchange treatment at 690-710DEG C, with the heating time being 40-50s per millimeter thickness; air cooling molding: taking out the glass and sending the glass into an air grid at a speed of 300-500mm / s to undergo air cooling molding, and finally conducting cooling to obtain the single-sheet cesium potassium fireproof glass. The processing technology provided by the invention is simple and practicable, and the prepared glass not only has very good fireproof function, but also has high strength, weathering resistance and machinability.

Owner:NINGBO HEXIN GLASS TECH

Fireproof cladding panel

ActiveCN102808488AImprove fire protectionImprove flame retardant performanceCovering/liningsSurface layerThermal insulation

The invention provides a fireproof cladding panel which comprises a surface layer and a bottom layer, wherein the bottom layer is formed by curing a mixture comprising aggregate and a first binder which is a fireproof binder, and the thickness of the bottom layer ranges from 5 millimeters to 100 millimeters. The fireproof cladding panel is capable of effectively achieving fire resistance, water resistance, weather fastness and thermal insulation.

Owner:BEIJING RECHSAND SCI & TECH GRP

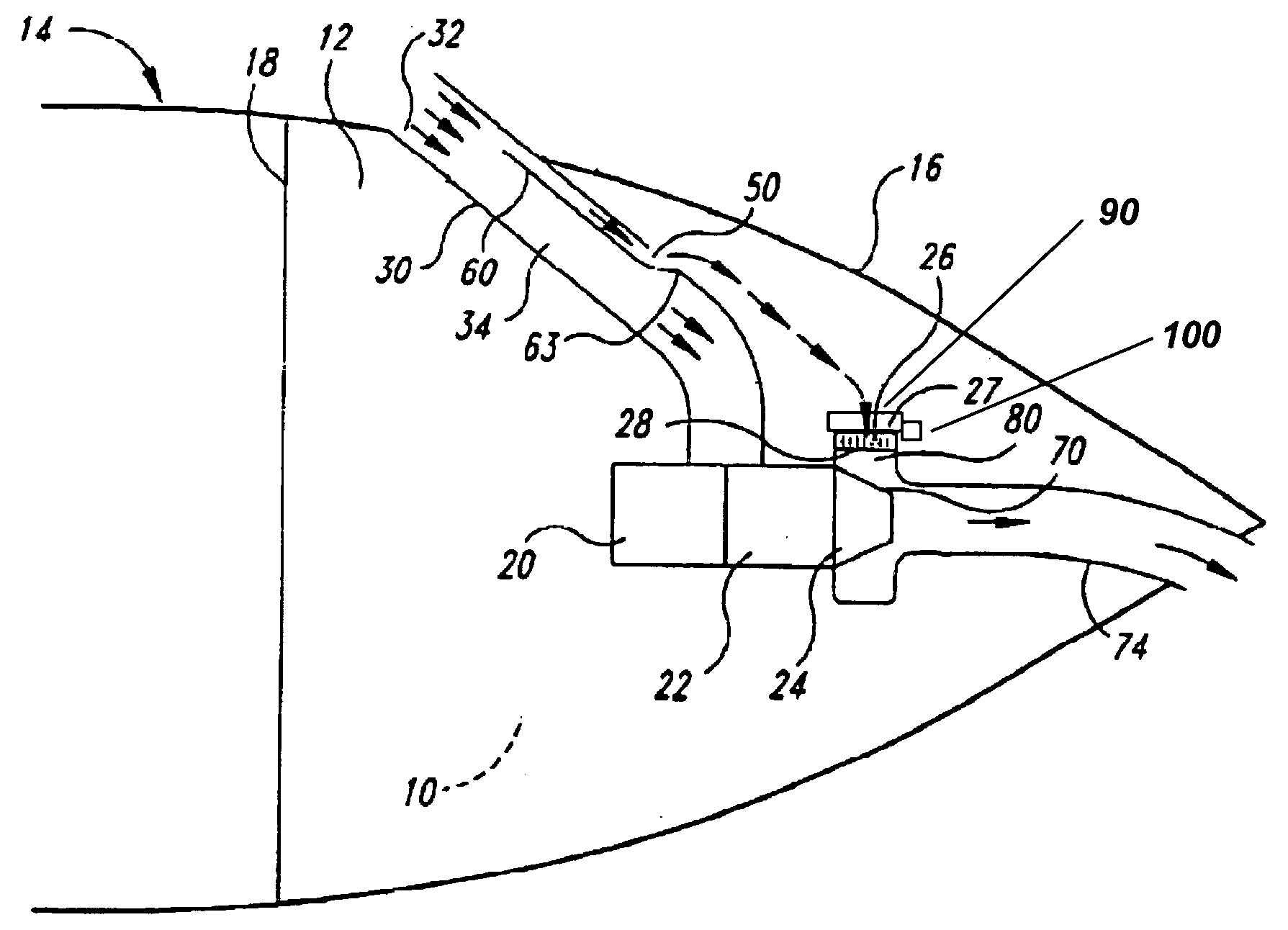

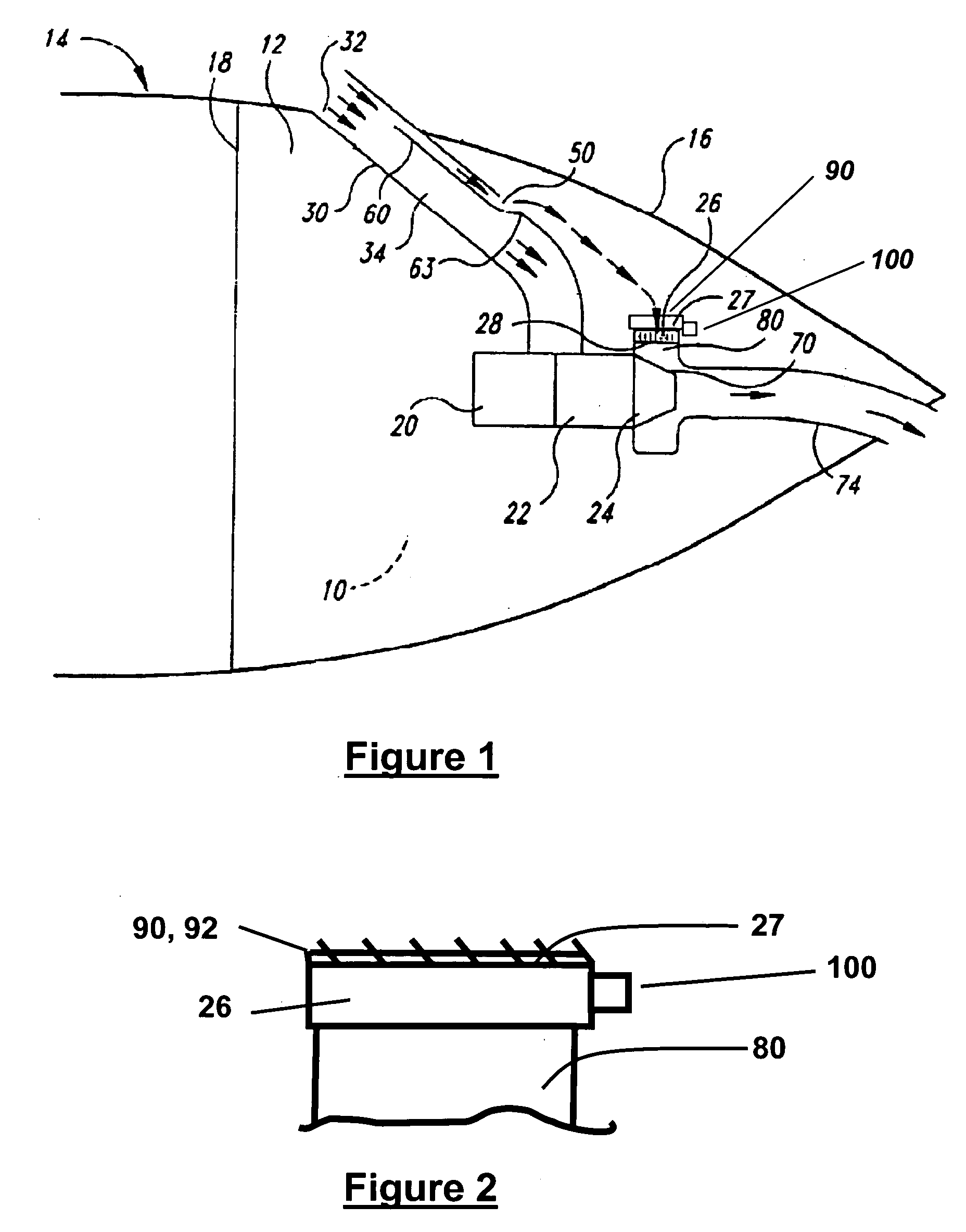

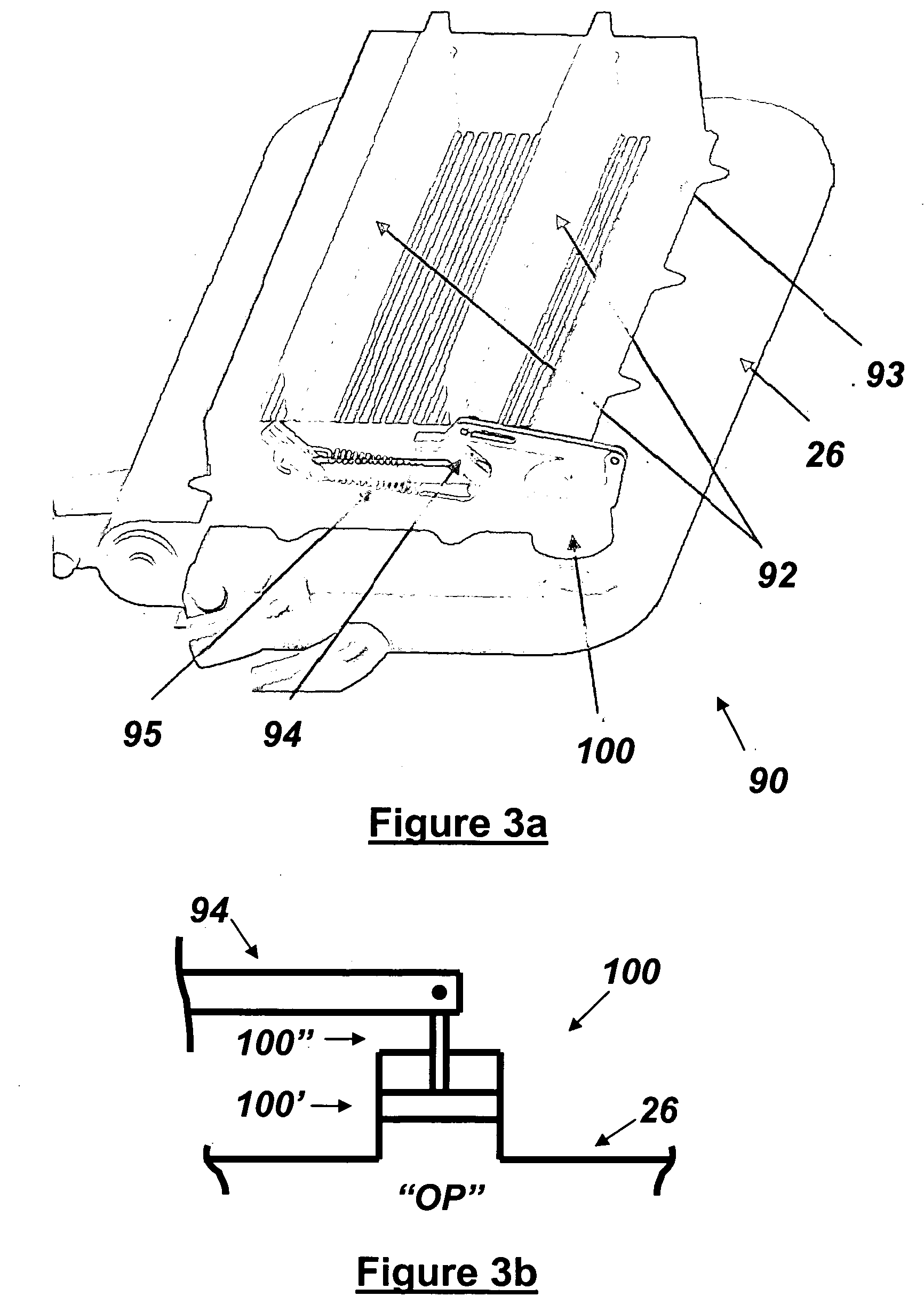

Fire shield apparatus and method

ActiveUS20050151017A1Improve fire protectionImprove fire performancePower plant cooling arrangmentsGas turbine plantsAutomotive engineeringAirplane

Provided is a method and system for providing fire shield protection to an aircraft auxiliary power unit, or portion thereof, or to other aircraft systems.

Owner:PRATT & WHITNEY CANADA CORP

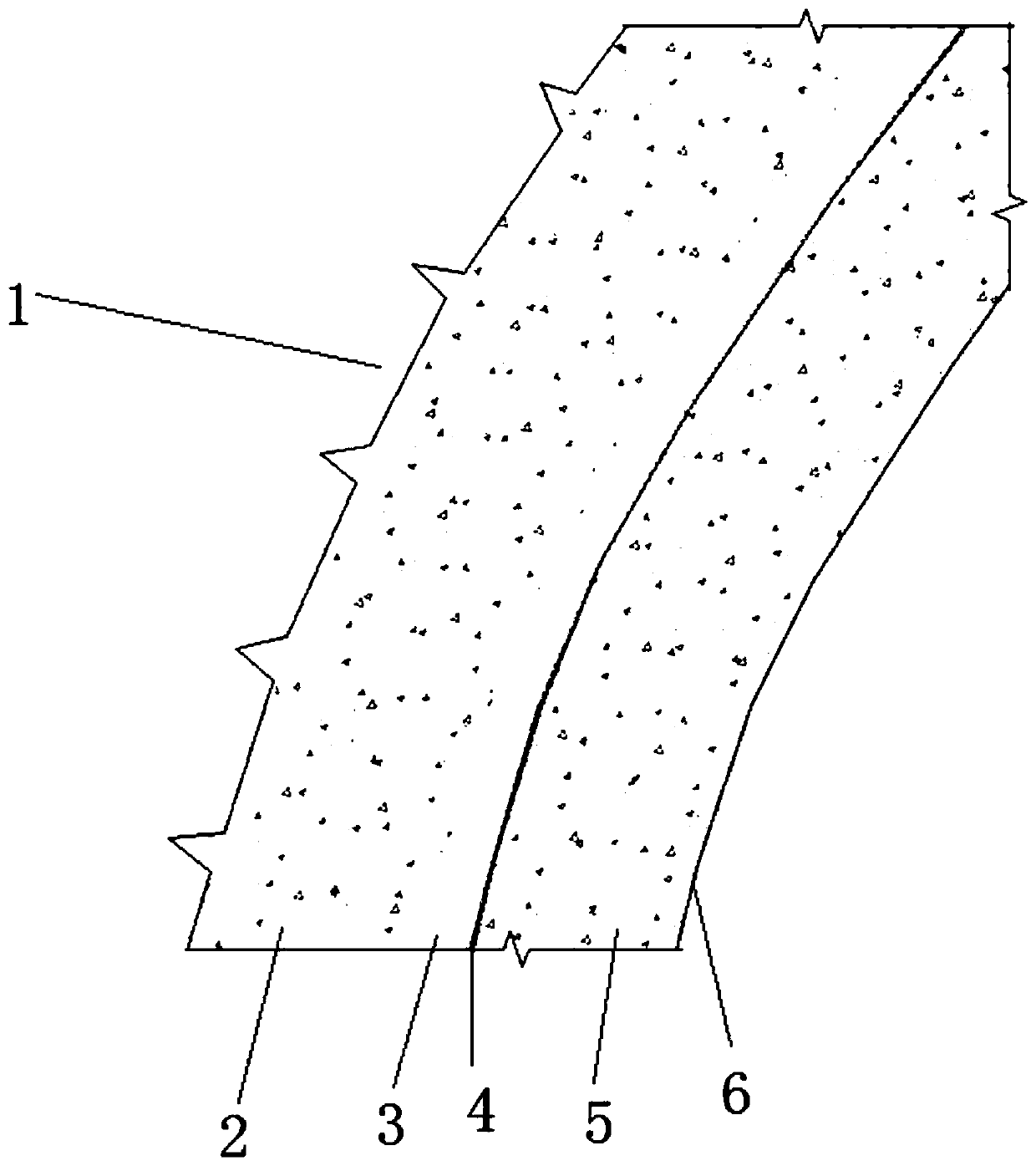

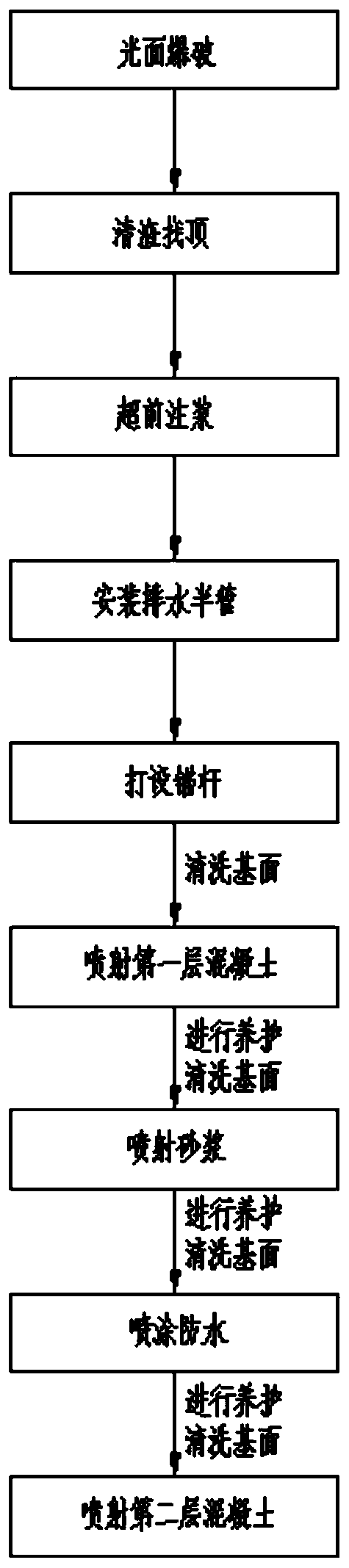

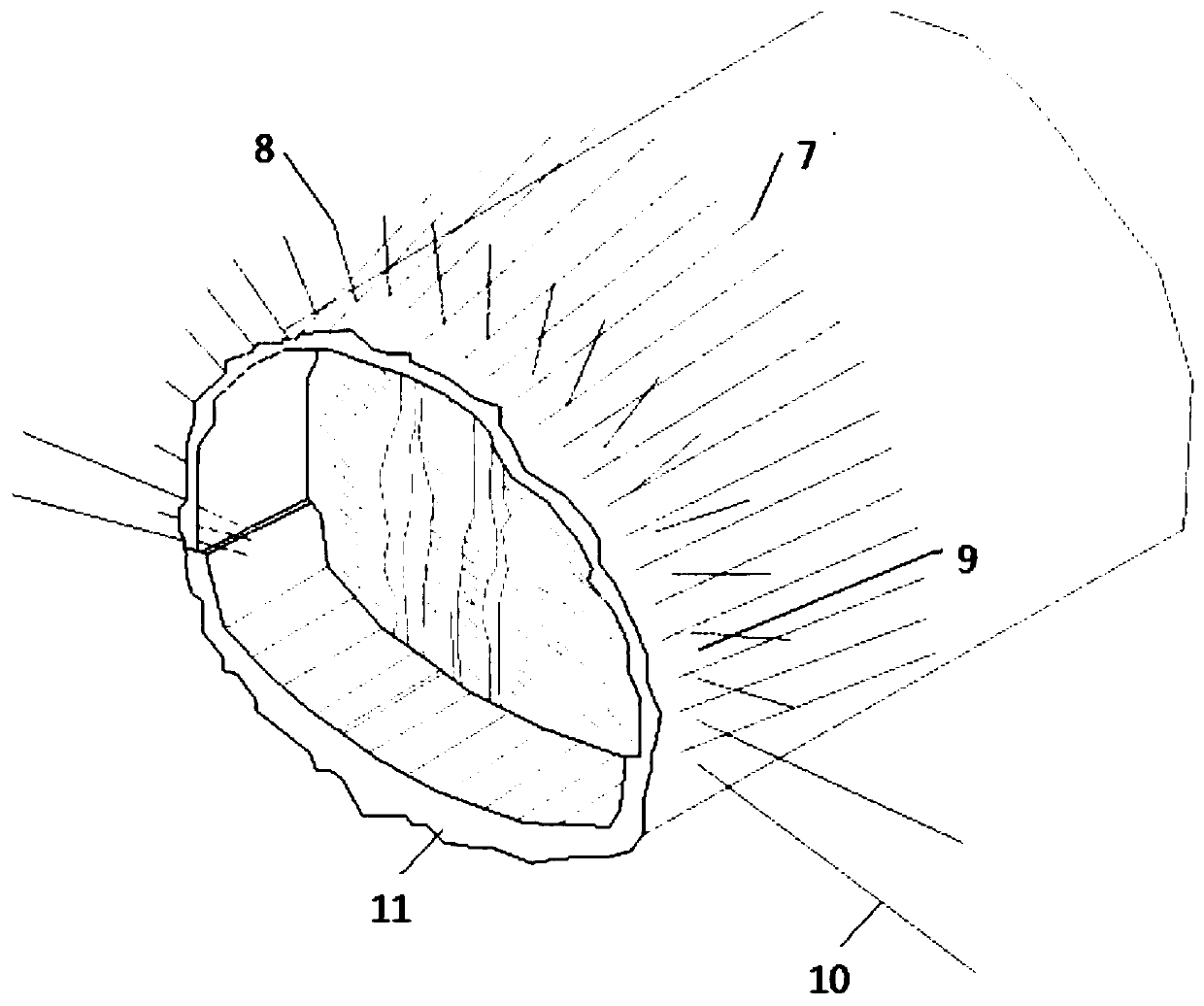

Waterproof type single-layer lining structure applicable to fourth level surrounding rock double-line track and manufacturing method thereof

ActiveCN110359915AEven by forceSimple construction processUnderground chambersTunnel liningFiberRock bolt

The invention discloses a waterproof type single-layer lining structure applicable to a fourth level surrounding rock double-line track. The waterproof type single-layer lining structure applicable tothe fourth level surrounding rock double-line track comprises fourth-level surrounding rocks subjected to smooth blasting treatment and further comprises omega-shaped spring drainage half pipes and anchored rods arranged in the fourth-level surrounding rocks in a struck manner. The anchored rods are perpendicular to the rock surfaces of the fourth-level surrounding rocks. The rock surfaces of thefourth-level surrounding rocks are further subjected to washing, injection of a first layer crude fiber concrete and curing, injection of mortar and curing, spraying of a waterproof material and curing, ejection of a second layer fine fiber concrete and curing in sequence. According to the waterproof type single-layer lining structure applicable to the fourth level surrounding rock double-track tunnel involved, force bearing of the single-layer lining structure formed by the technology is uniform; the structure has certain deformation resistant capacity; the construction technology is simple;the construction period is short; construction pollution is reduced; the structure is low-carbon and environment-friendly and widely applied to projects of fourth-level surrounding rock double-tracktunnel lining structures.

Owner:中铁科学研究院有限公司

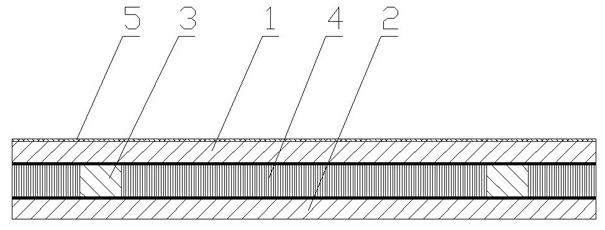

Method of manufacturing heat-preservation and fireproof decorative panel

ActiveCN102146720AClass A non-combustibleThermal insulationCovering/liningsFiberUltimate tensile strength

The invention discloses a method of manufacturing a heat-preservation and fireproof decorative panel, which comprises the following steps of: A, manufacturing an upper panel, a lower panel, a rock wool layer and reinforcing ribs; B, alternately bonding the rock wool layer and the reinforcing ribs on the lower panel, wherein fibers in the reinforcing ribs and the rock wool layer are respectively vertical to the lower panel; C, bonding the upper panel on the rock wool layer and the reinforcing ribs, wherein the upper panel and the lower panel are parallel; and D, compacting through a press. The invention also discloses a method of manufacturing the heat-preservation and fireproof decorative panel. The rock wool layer is bonded between the upper panel and the lower panel in a way that the fibers in the rock wool layer are respectively vertical to the upper panel and the lower panel. When the rock wool layer is stressed, the stress of the upper panel is directly transferred to the lower panel by the fibers in the rock wool layer, so that the tensile strength is increased, and the rock wool layer is not layered when being stressed; meanwhile, the rock wool layer has the advantages of A-level noninflammability and heat insulation and preservation, so that the heat-preservation and fireproof decorative panel has good energy-saving and fireproof functions. The reinforcing ribs increase the strength of the whole decorative panel, so that the whole decorative panel is not easily deformed.

Owner:重庆固安捷实业有限公司

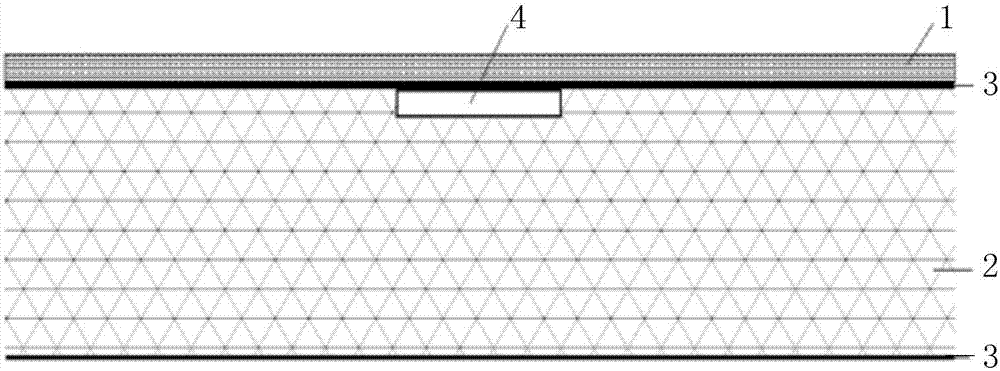

Light fireproof heat-insulation decorative composite plate and method for preparing same

InactiveCN107386561AReduced quality per unit areaReduce loadCovering/liningsWater-setting substance layered productComposite materialManufacturing engineering

The invention provides a light fireproof heat-insulation decorative composite plate and a method for preparing the same. The light fireproof heat-insulation decorative composite plate comprises a surface layer and a heat-insulation layer. The surface layer is a light flexible sheet with decorative finish, the heat-insulation layer is a heat-insulation plate which meets at least A-level fireproof requirements, leveling layers are arranged on two surfaces of the heat-insulation plate, the light flexible sheet with the decorative finish is arranged on the leveling layer on one of the surfaces of the heat-insulation plate by means of composition, anchoring component mounting straight slots are further formed in the heat-insulation plate, one end of each anchoring component can be inserted in the corresponding anchoring component mounting straight slot, and the light fireproof heat-insulation decorative composite plate can be fixed onto a mounting body. The light fireproof heat-insulation decorative composite plate and the method have the advantages that the surface layer is the light flexible sheet, accordingly, the weight of the light fireproof heat-insulation decorative composite plate can be reduced to a great extent, and the safety can be greatly improved; the light fireproof heat-insulation decorative composite plate is provided with the anchoring component mounting straight slots, and accordingly high and reliable anchoring force can be exerted; the heat-insulation layer is the heat-insulation plate which meets the at least A-level fireproof requirements, accordingly, the light fireproof heat-insulation decorative composite plate has an excellent fireproof function, has the light weight per unit area and can be firmly mounted, and the shortcomings in the prior art can be overcome.

Owner:ASIA CUANON TECH SHANGHAI

Outdoor safety power distribution cabinet

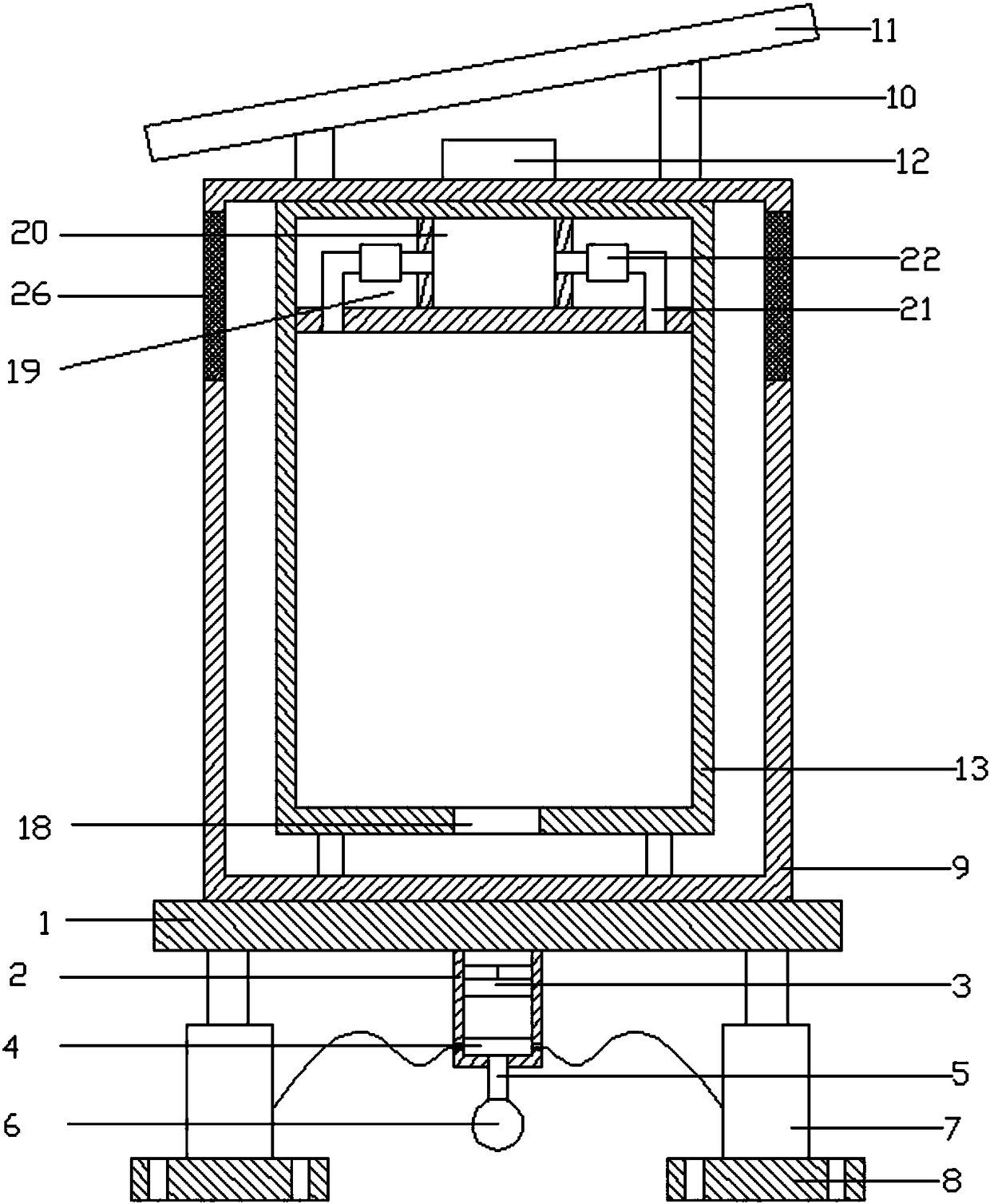

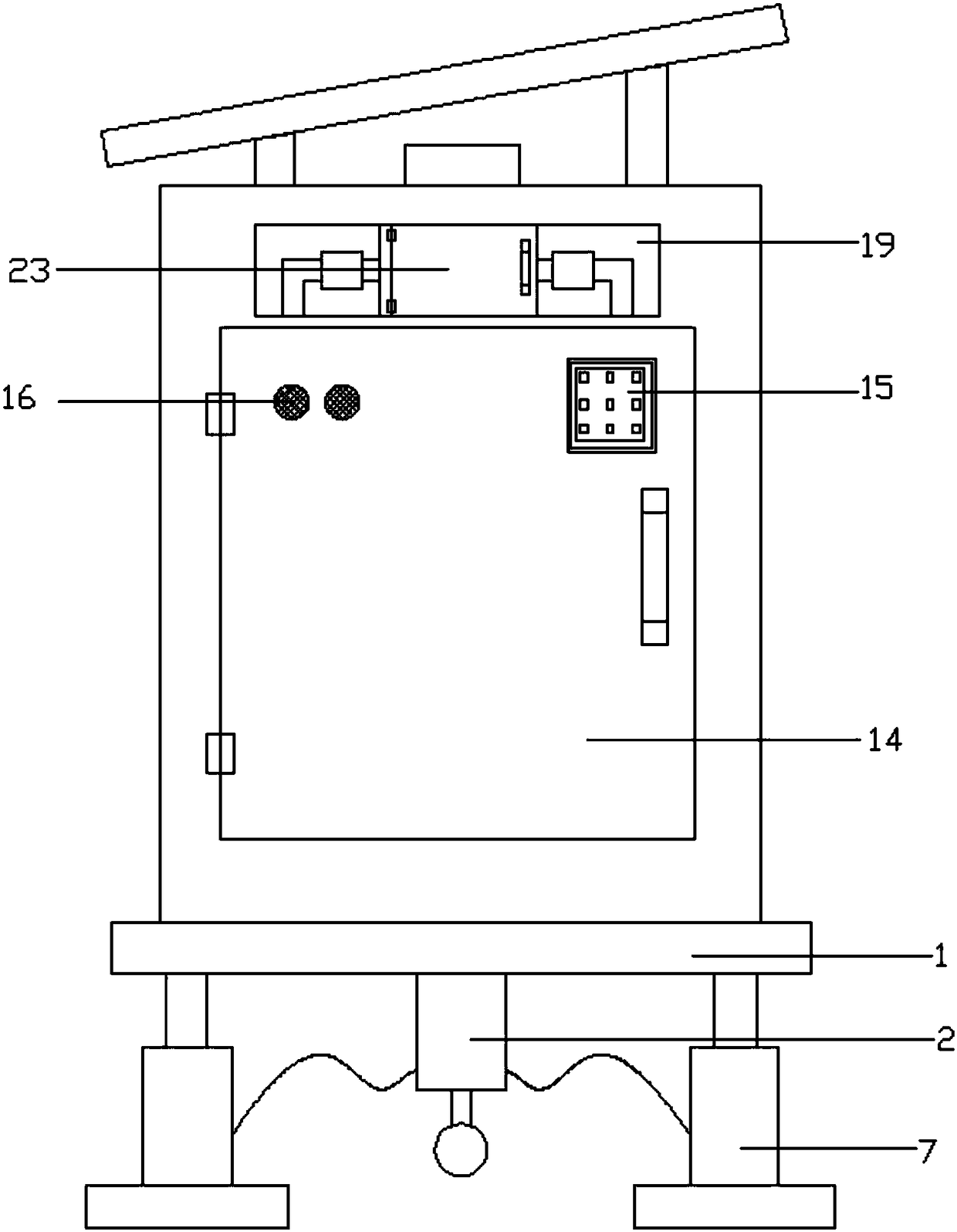

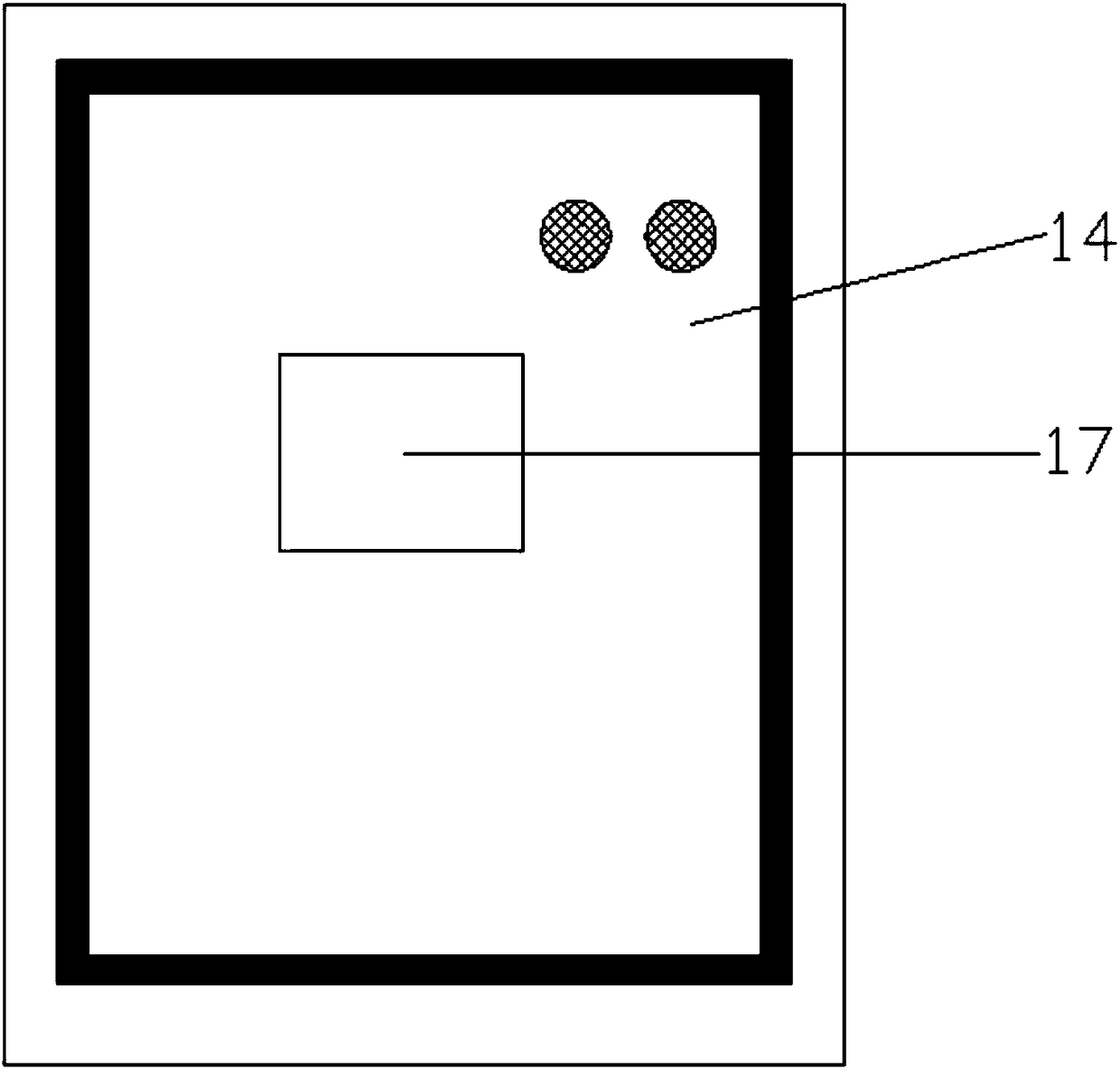

InactiveCN108281899AAutomatic height adjustmentEasy to useSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsPasswordEngineering

The invention discloses an outdoor safety power distribution cabinet which comprises a supporting plate. A connecting cover is arranged at the middle end of the lower side of the supporting plate, a first electric shock sheet is arranged at the inner upper end of the connecting cover, a second electric shock sheet is arranged at the inner lower end of the connecting cover, a connecting rod is arranged on the lower side of the second electric shock sheet, a floating ball is arranged on the lower side of the connecting rod, an electric telescopic rod is arranged on the lower side of the supporting plate, an outer shell is arranged on the upper side of the supporting plate, a solar panel is arranged on the upper side of the outer shell, an inner shell is arranged in the outer shell, a cabinetdoor is arranged in the front sides of the inner shell and the outer shell, a digital password lock is arranged at the right end of the front side of the cabinet door, an alarm is arrange don the upper side of the upper side of the left end of the cabinet door, a notch is formed in the upper side of the inner shell, a drying cavity is formed in the notch, the left side and the right side of the drying cavity are connected with the inner shell through connecting pipes, and a breathable mesh is arranged at the inner rear end of the drying cavity. The power distribution cabinet can be effectively ventilated, cooled and dried and can effectively prevent devices in the cabinet from being stolen and rainwater from entering the cabinet, and safety use of the devices is ensured.

Owner:合肥龙智机电科技有限公司

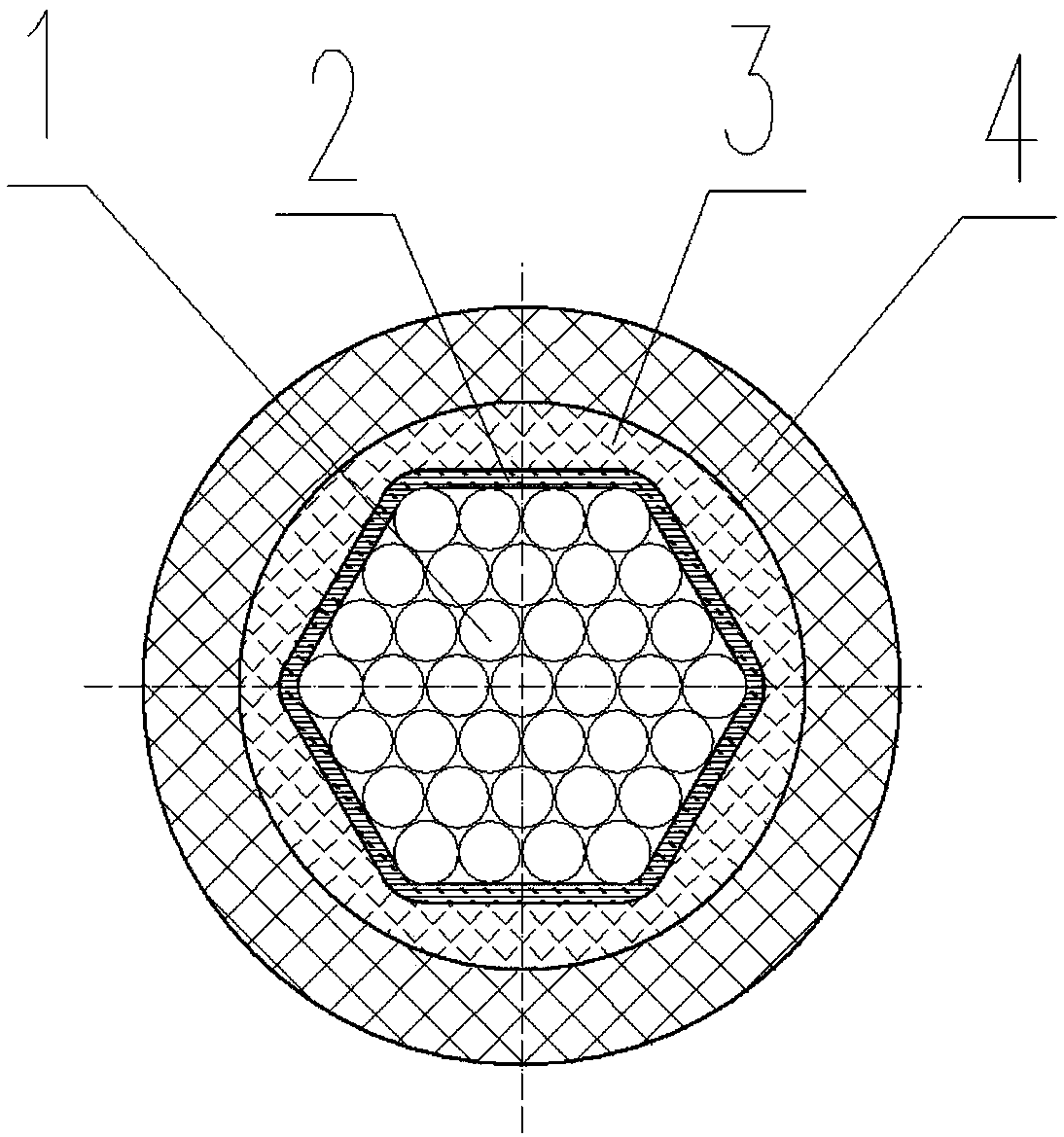

Anti-flaming inhaul cable

PendingCN109457612ALow costImprove heat resistanceBridge structural detailsWater basedThermal insulation

The invention relates to the technical field of bridge inhaul cables, in particular to an anti-flaming inhaul cable. The inhaul cable comprises a cable body, a polyurethane packaging belt, a thermal insulation layer and a fireproof rubber layer. The polyurethane packaging belt wraps the outer surface of the cable body, the thermal insulation layer wraps the outer surface of the polyurethane packaging belt, the fireproof rubber layer wraps the outer surface of the thermal insulation layer, and the fireproof rubber layer is formed by raw material compositions including water-based resin, ammonium polyphosphate, vermiculite, expanded graphite, perlite and water through a polymerization reaction. The fireproof rubber layer has the good heat resistance, cold resistance, anti-corrosion propertyand small environment factor influences, the full-fireproof cable body can be manufactured in a factory easily, the installing difficulty is lowered, the fireproof function of the inhaul cable is added, and the problem of traditional inhaul cable outer layer high-density polyethylene stress cracking is solved.

Owner:LIUZHOU OVM MASCH CO LTD

Method for producing preblended light aggregate concrete heat-preservation material

The invention discloses a method for producing a preblended light aggregate concrete heat-preservation material. The heat-preservation material is prepared by uniformly mixing and blending spherical light aggregate, fine aggregate, cement, admixture and additives, wherein the fine aggregate is one or more of sand, pottery sand, tailing sand, steel slag and water-quenched slag; the admixture is coal ash and / or mineral powder; the additives comprise a water reducing agent and a water retaining agent; the production raw materials of the spherical light aggregate comprise sludge and mud; the production process comprises steps of blending, pelleting, screening, drying, combusting to puff, cooling in air and cooling naturally. The raw materials used in the heat-preservation material produced by using the method disclosed by the invention are all anti-combustion materials, so that a heat-preservation structure manufactured by using the heat-preservation material is good in fireproof function; as the spherical light aggregate is of a porous structure, good heat preservation and sound insulation effects are achieved. When being applied to heat-preservation construction of roofs or building surfaces, the heat-preservation material is only provided with a proper amount of water, is uniformly mixed and blended, and is subsequently paved on the ground or the roof, and then an integrated heat-preservation structure is formed after the heat-preservation material is cured. The strength of the heat-preservation structure is greatly improved, and the heat-preservation construction is also convenient.

Owner:TIANJIN TONGJUN BUILDING MATERIALS CO LTD

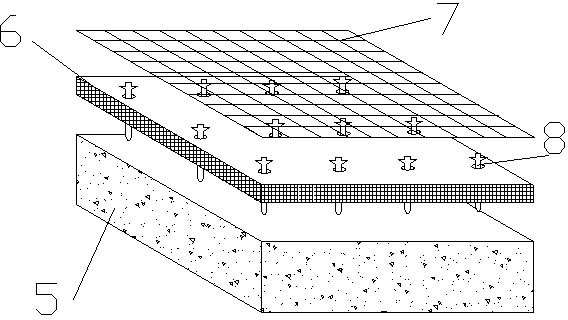

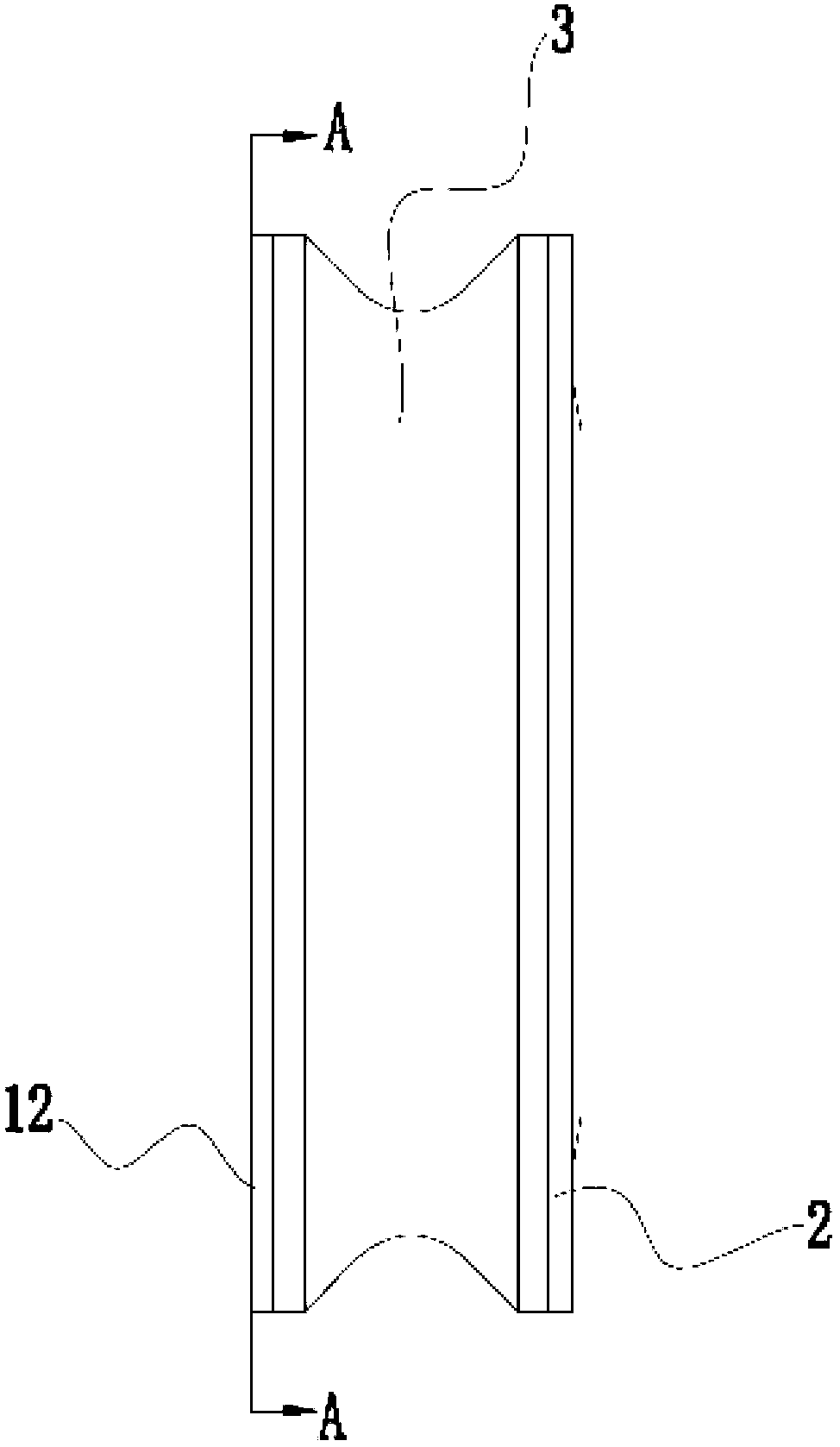

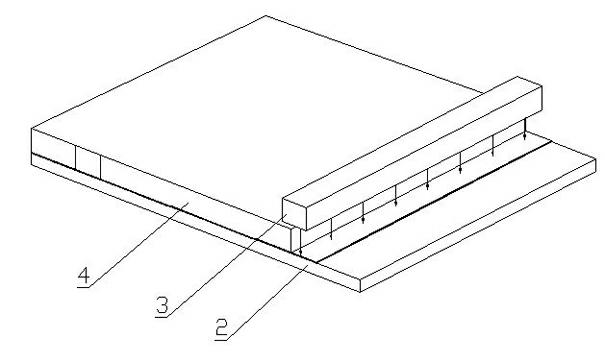

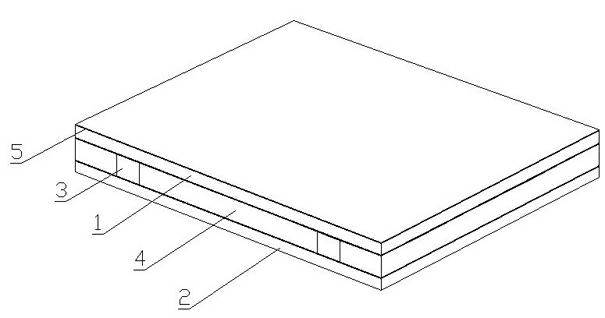

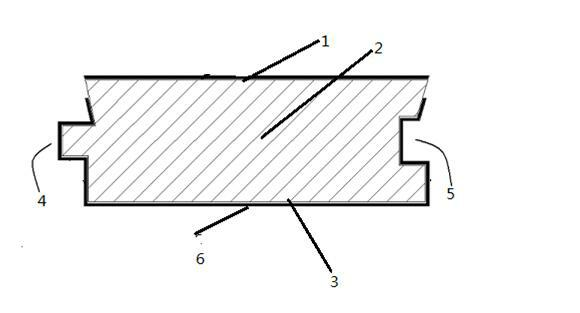

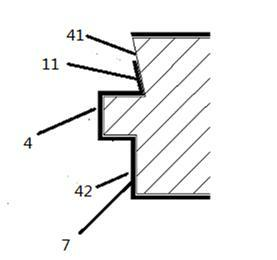

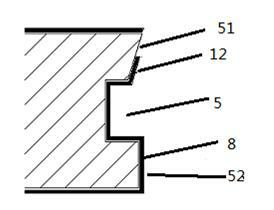

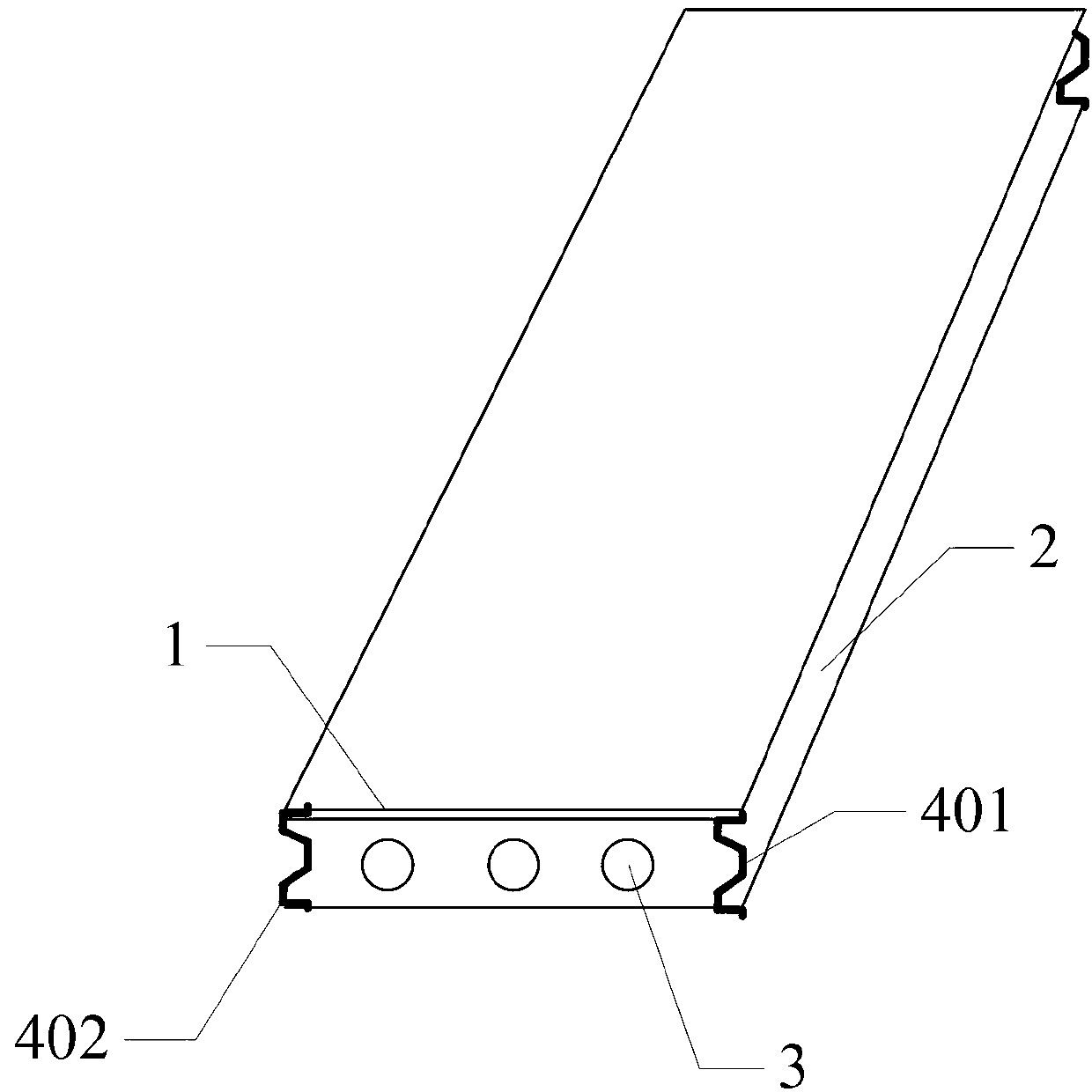

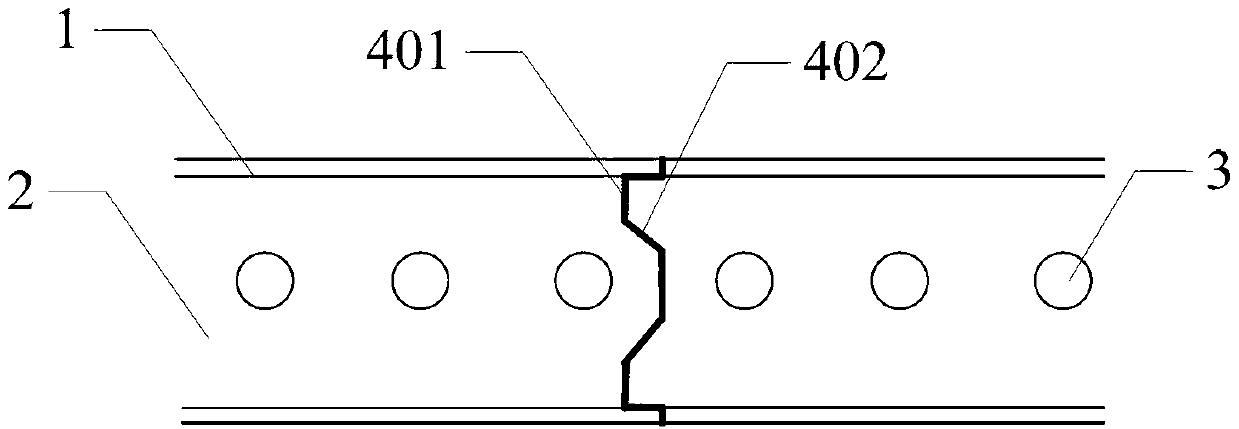

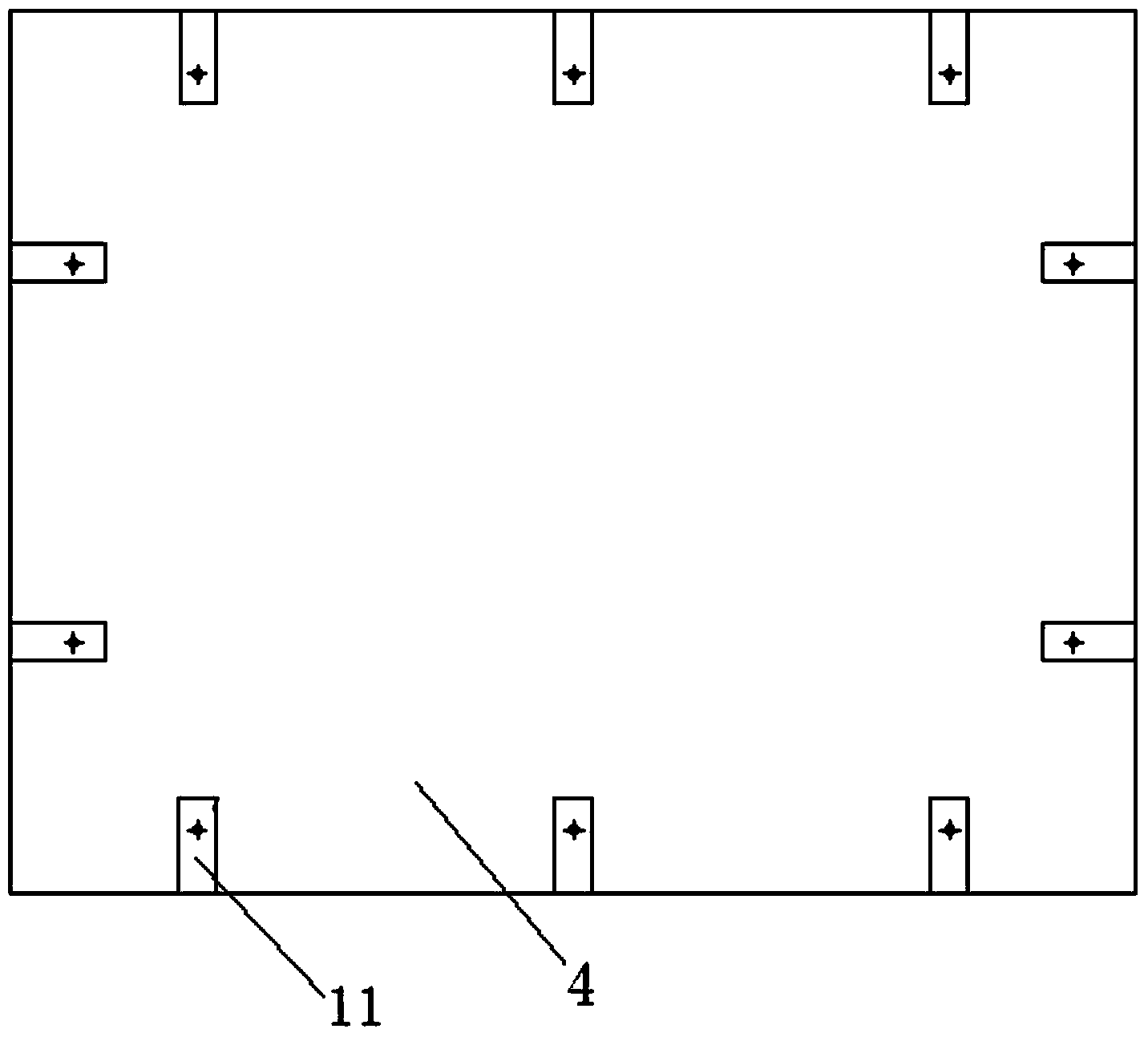

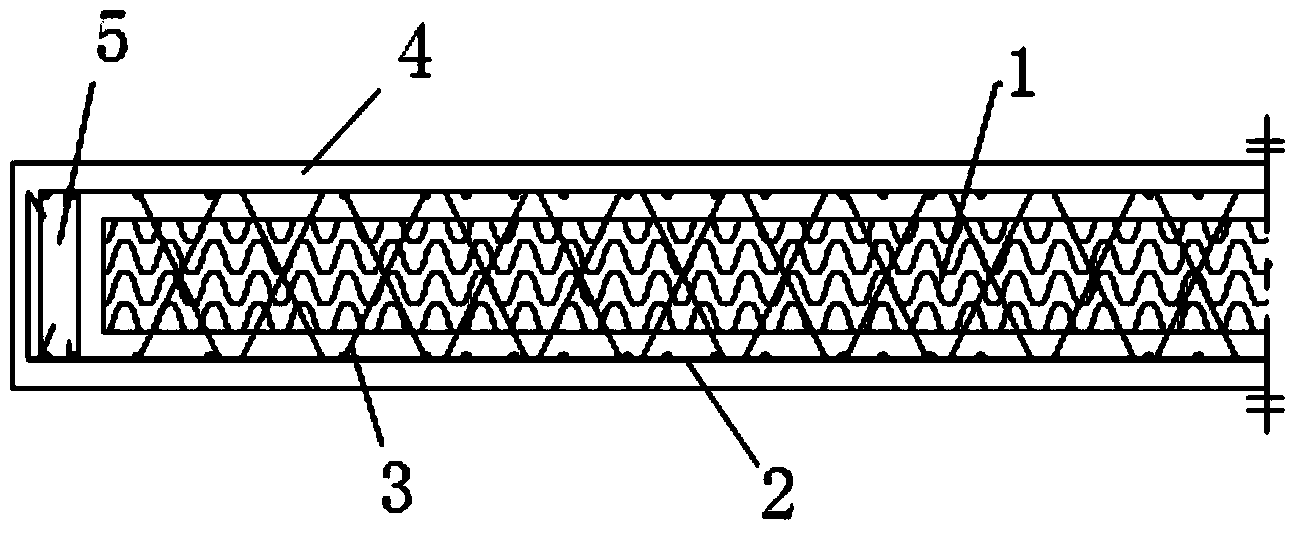

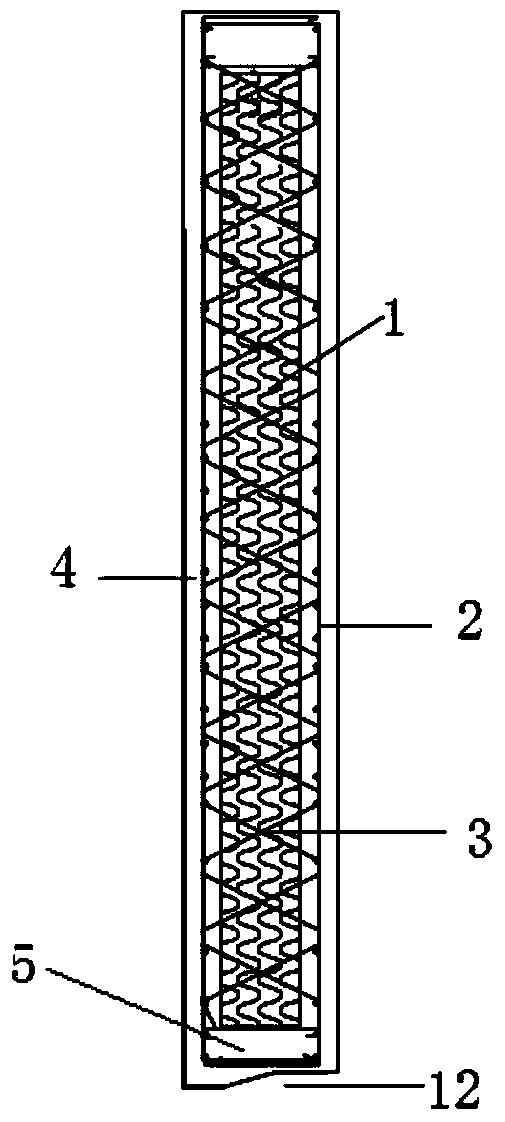

Domestic composite-structure floor and processing method thereof

InactiveCN102383576AHigh strengthImprove fire protectionFlooringMetal layered productsComposite structureEngineering

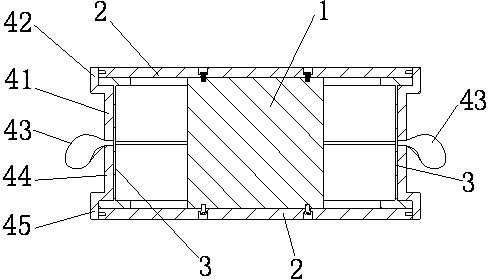

The embodiment of the invention discloses a domestic composite-structure floor and a processing method thereof. The floor comprises a matrix (2) made of a refractory material, a floor upper surface (1) and a floor lower surface (3); at least one side face of the floor is provided with a tenon (4) and at least the other side face of the floor is provided with a groove (5); the floor lower surface (3) is compounded with a metal plate (6), and is coated by the metal plate (6); a first plane (42) between the floor lower surface (3) and the tenon (4) is compounded with a metal plate (7) and coated by the metal plate (7); and a second plane (52) between the floor lower surface (3) and the groove (5) is compounded with a metal plate (8) and coated by the metal plate (8). The strength of the floor can be improved, the floor has a fireproof function, and the domestic composite-structure floor cannot be deformed during floor heating.

Owner:常州华通新立地板有限公司

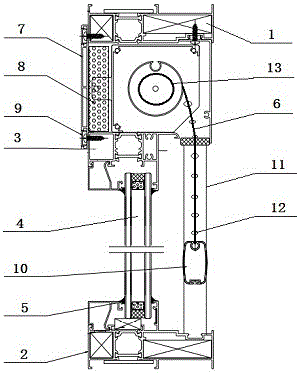

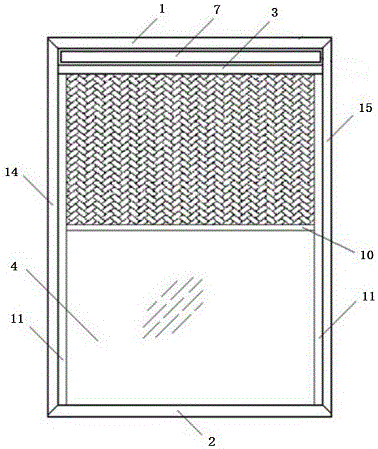

Fireproof and external sunshade integrated window

InactiveCN106223823AWith external sunshade curtain functionImprove fire protectionFireproof doorsLight protection screensPhysicsStructural integrity

The invention relates to a fireproof and external sunshade integrated window which comprises a rectangular window frame composed of an upper cross beam, a lower cross beam, a left column and a right column. The fireproof and external sunshade integrated window is characterized in that an upper-middle cross beam connected with the left column and the right column and parallel to the upper cross beam and the lower cross beam is arranged between the upper cross beam and the lower cross beam of the window frame, a window curtain device is arranged in the space formed by the upper-middle cross beam and the upper cross beam, an inner baffle is arranged between the upper-middle cross beam and the upper cross beam, and a bearing section bar is made from a glass fiber reinforced polyurethane material. According to the innovation point, the fireproof and external sunshade integrated window has the special advantages that the glass fiber reinforced polyurethane material is applied to the window section bar, innovation point is 0.22W / (mk), and an energy-saving effect is good; the structural integrity is ensured in flames of 900 DEG C for one hour, and a fireproof effect is good. Building external window parts having a fireproof function and outdoor window curtain parts are perfectly integrated together, various functions of existing building external windows are kept, the fireproof and external sunshade integrated window also has an external sunshadewindow curtain function, and the fireproof function is added.

Owner:NANJING 26 DEGREE BUILDING ENERGY SAVING ENG CO LTD

Composite decorative sheet

InactiveCN103572930ASave wood resourcesStable structureCovering/liningsSynthetic resin layered productsSurface layerProtection layer

The invention discloses a composite decorative sheet which comprises a base plate, a surface decoration layer, and a surface layer arranged between the base plate and the surface decoration layer, wherein a waterproof coating is coated between the surface layer and the base plate, a protection layer is coated between the surface layer and the surface decoration layer, the base plate is a polyurethane foaming plate, and the outer surface of the surface decoration layer is further coated with an flame retarding fireproof layer. Compared with the prior art, the composite decorative sheet has the characteristics of corrosion resistance, strong wear resistance, solid durability, non-deformation, dampproofness and waterproofness.

Owner:GUILIN JINSHUIMU DECORATION DESIGN ENG

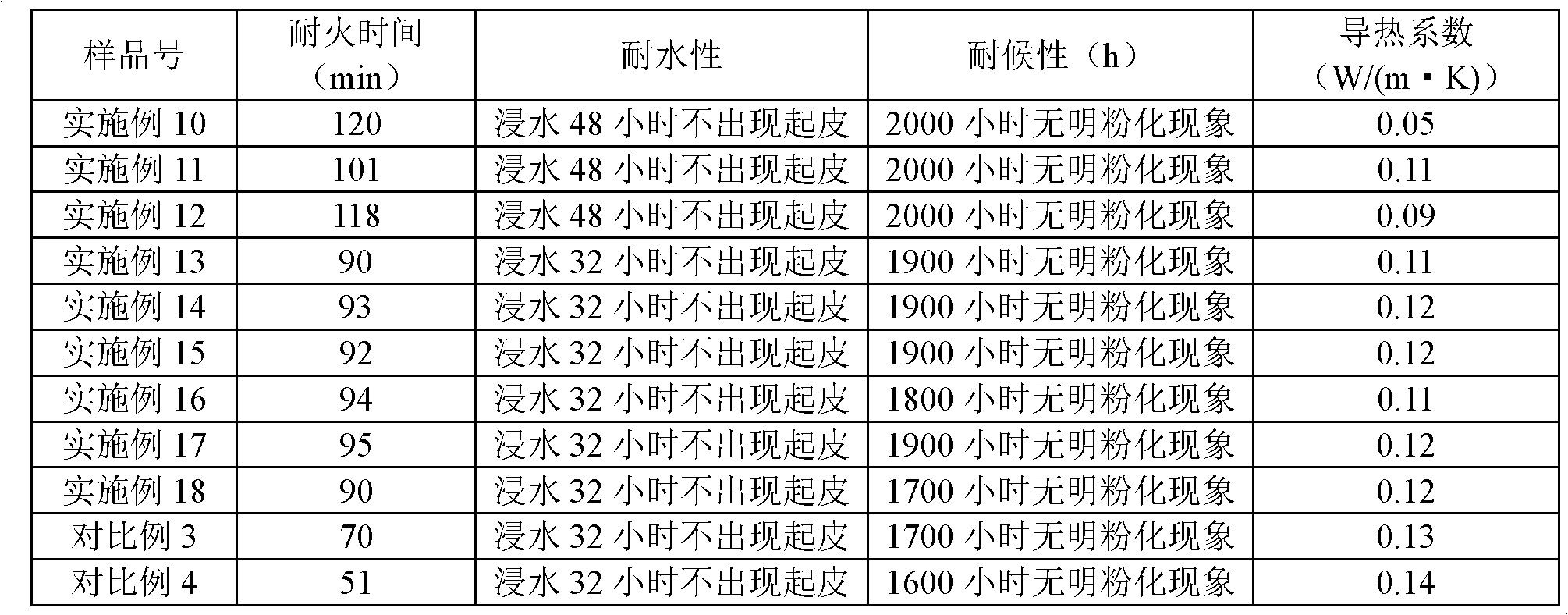

Waterproof and fireproof water soluble inorganic paint

This invention provides an inorganic coating with dual functions of water-proofness and fire-proofness. Its main components includes main material and functional assistant, the main material A includes alkali metal silicate (40-60 kg, preferably 45-55kg) and flyash (30-50 kg, preferably 40-45 kg) and the functional assistant B include meta-acid metal salt (0.8-1.2 kg, preferably 0.9-1.1 kg). The compenents and proportion mix of B are: water 15-20 kg, copper sulphate 0.13-0.18 kg, aluminium potasium sulphate 0.50-0.60 kg, ferrous sulphate 0.20-0.35 kg and potassium alaite 0.02-0.03 kg.

Owner:李群楫

Process of producing fireproof sofa artificial leather

ActiveCN100458010CImprove flame retardant performanceImprove fire protectionTextiles and paperWater basedSlurry

The process of producing fireproof sofa artificial leather includes the following steps: 1. wet coating polyurethane layer on the base fabric; 2. dry adhering surface polyurethane layer on the semi-finished product; and 3. soaking the fabric in water-base environment friendly fire retardant solution and stoving to obtain the product. In the step 1, the polyurethane resin is polyether or polycarbon type polyurethane resin and has phosphate fire retardant added into the wet slurry; and in the step 2, the polyurethane resin is polycarbon type polyurethane resin with fatty resin, the adhering layer is of aromatic resin and the dry slurry has phosphate fire retardant added. The sofa artificial leather has excellent fireproof function, antiageing performance and antiwear performance.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

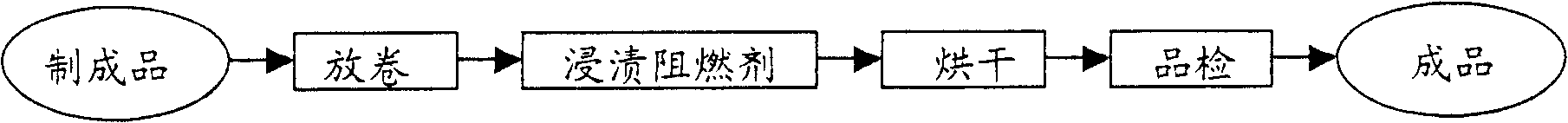

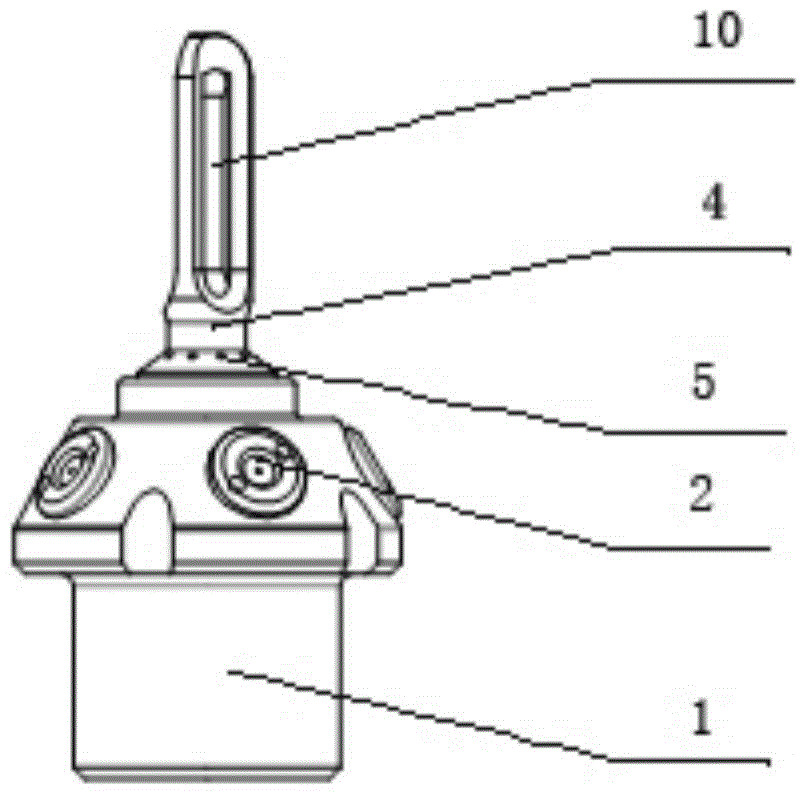

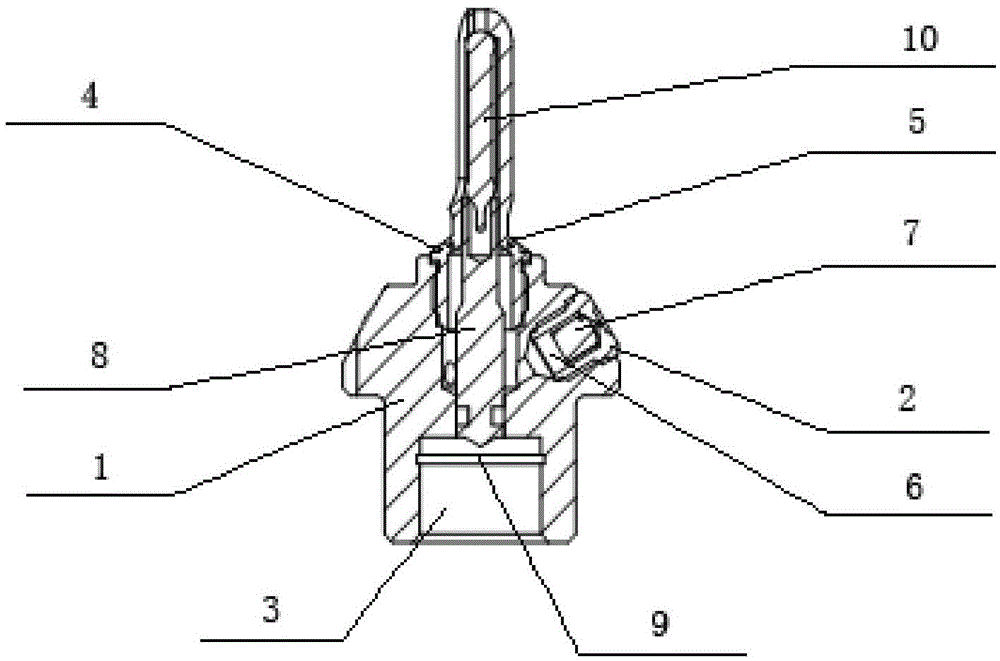

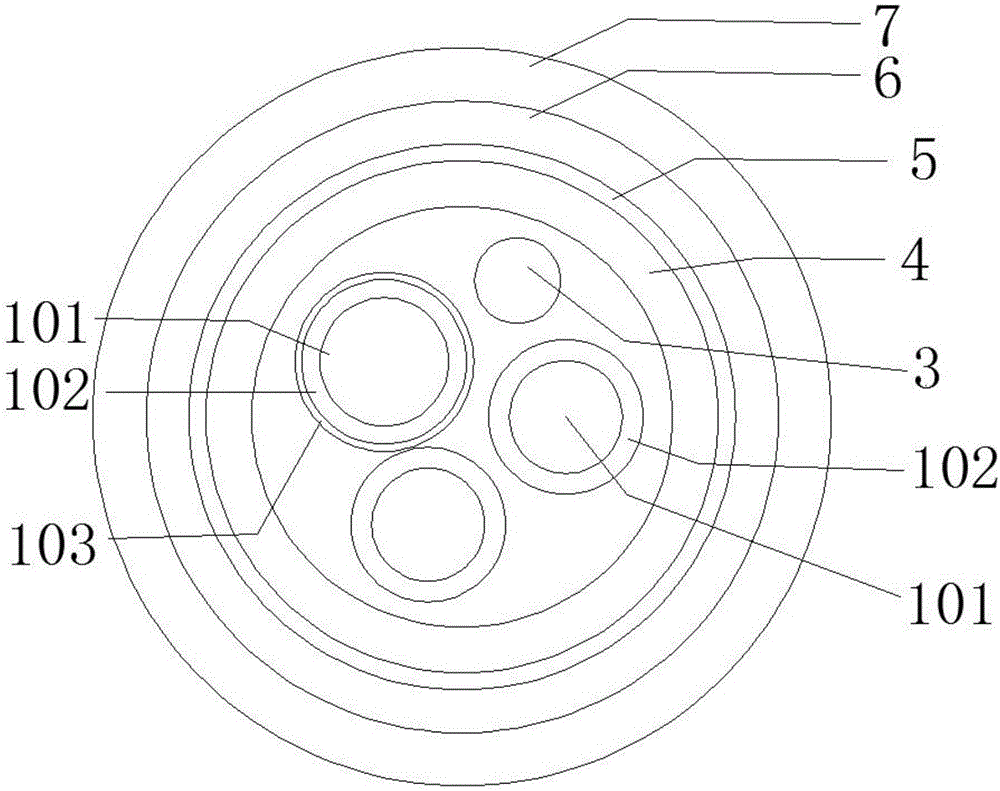

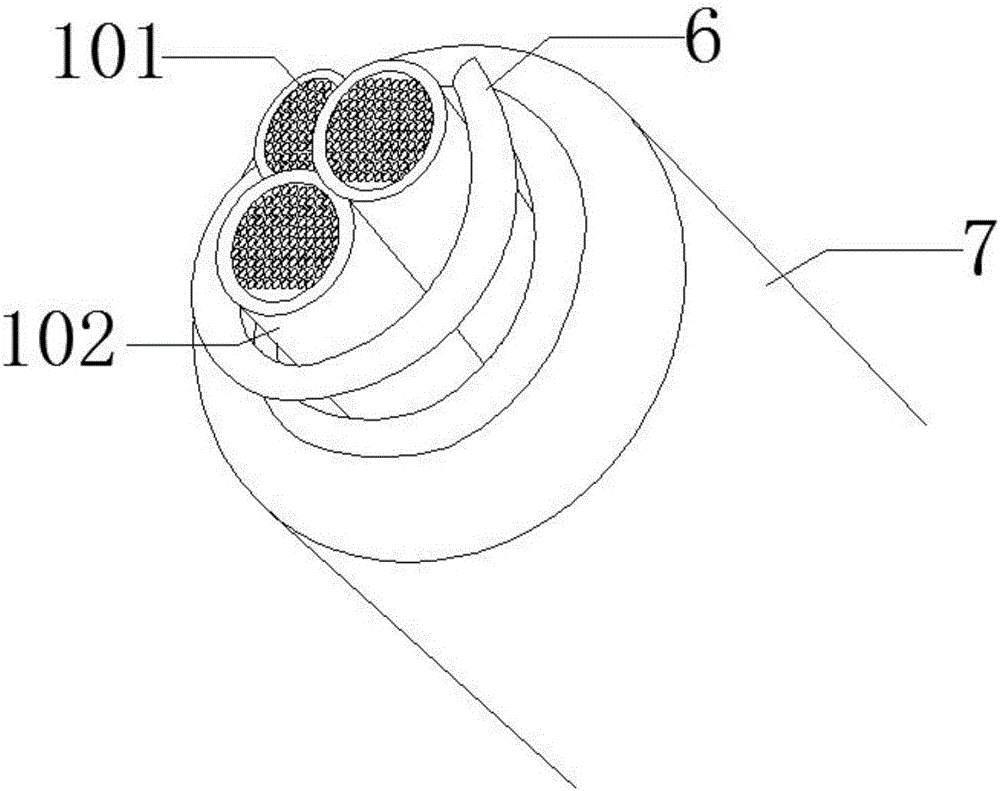

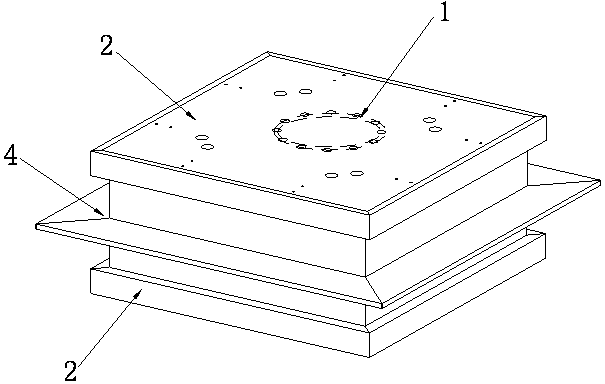

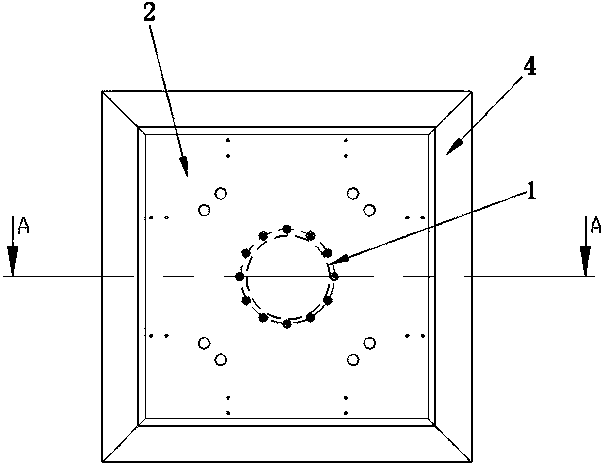

Water mist nozzle with combination of direct-spray atomizing nozzle and cyclone atomizing nozzles

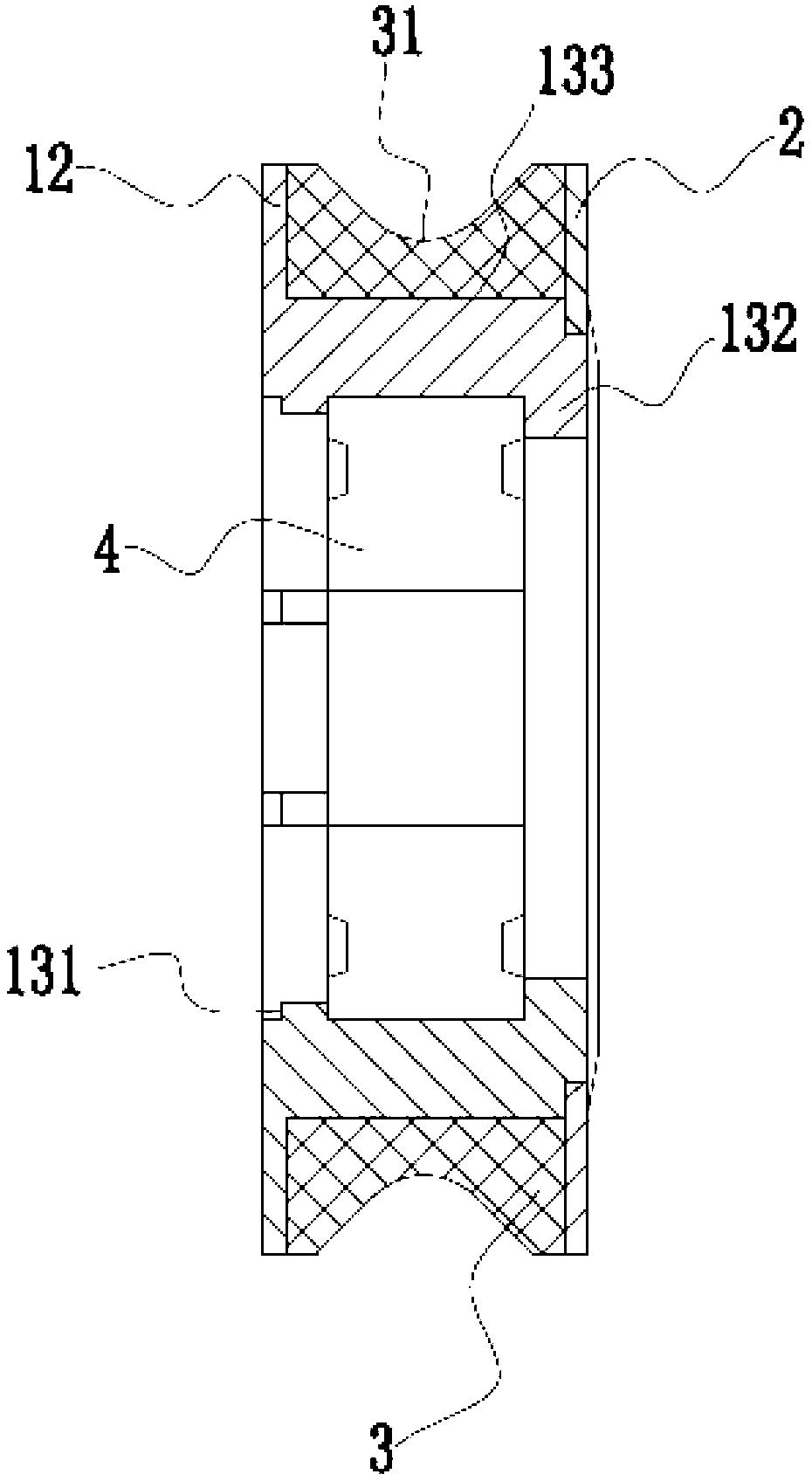

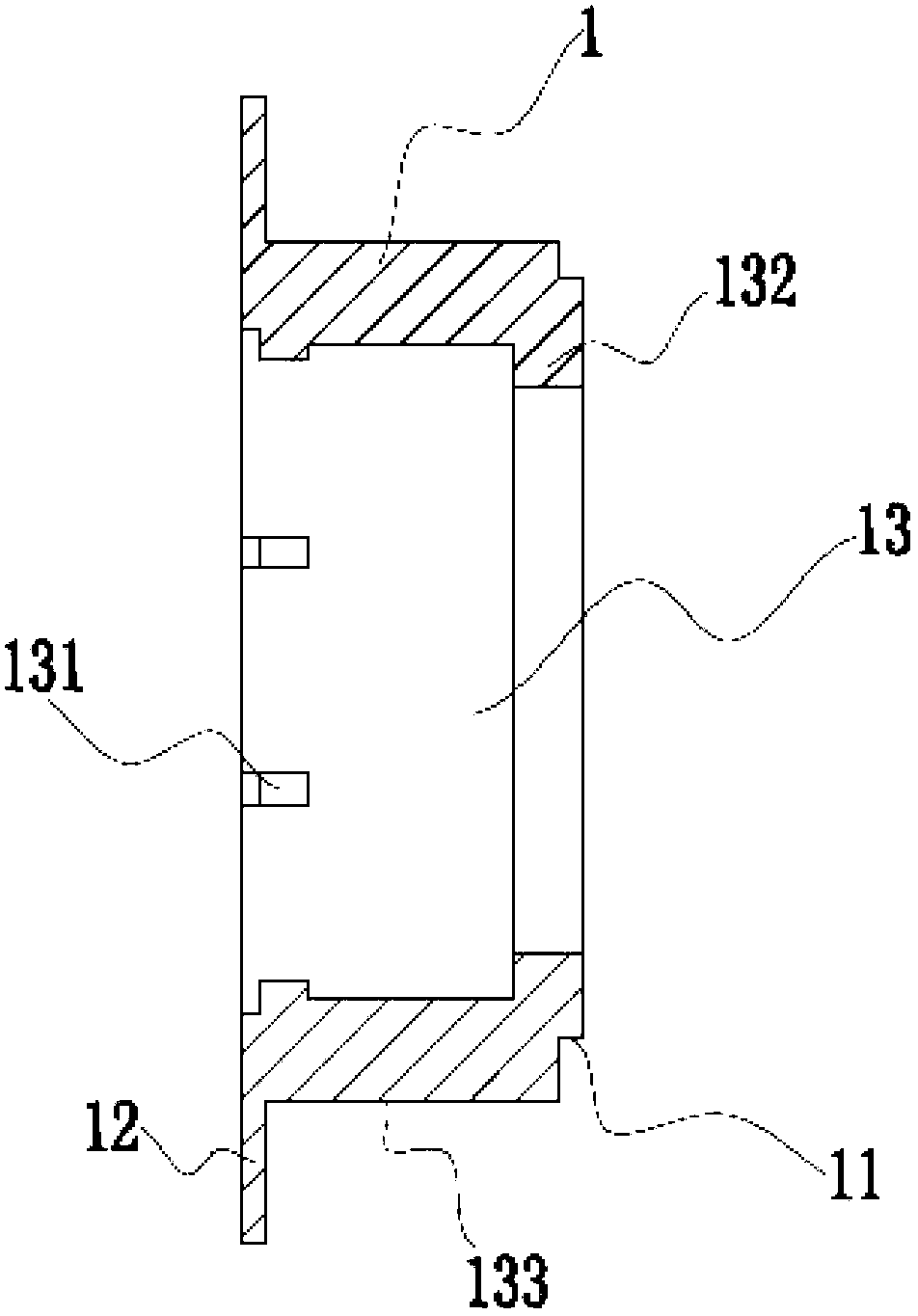

The invention discloses a water mist nozzle with combination of direct-spray atomizing nozzle and cyclone atomizing nozzles. The water mist nozzle comprises a nozzle body (1) and a plurality of cyclone atomizing nozzles (2) arranged on the nozzle body (1), wherein a water channel (3) is formed in the nozzle body (1), and a direct-spray atomizing nozzle (4) is also arranged on the nozzle body (1); the direct-spray atomizing nozzle (4) is a cavity with one water inlet and more than one water outlet (5), and the water inlet of the direct-spray atomizing nozzle (4) is communicated with the water channel (3). The water mist nozzle with combination of direct-spray atomizing nozzle and cyclone atomizing nozzles not only has better atomizing effect, but also has stronger penetrating power and smaller atomizing distance, and can extinguish the fire far away from or close to the nozzle.

Owner:上海金盾消防安全设备有限公司

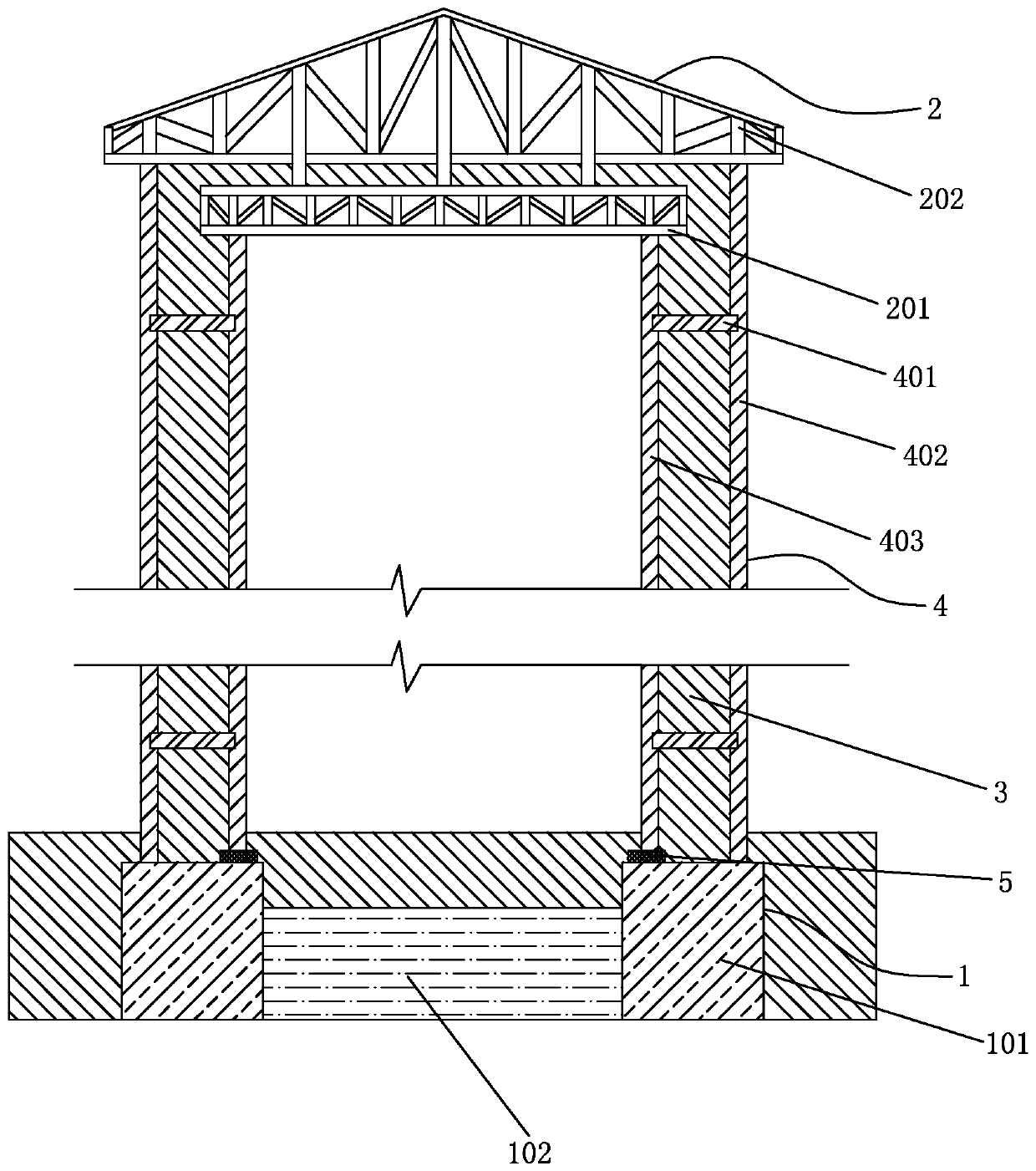

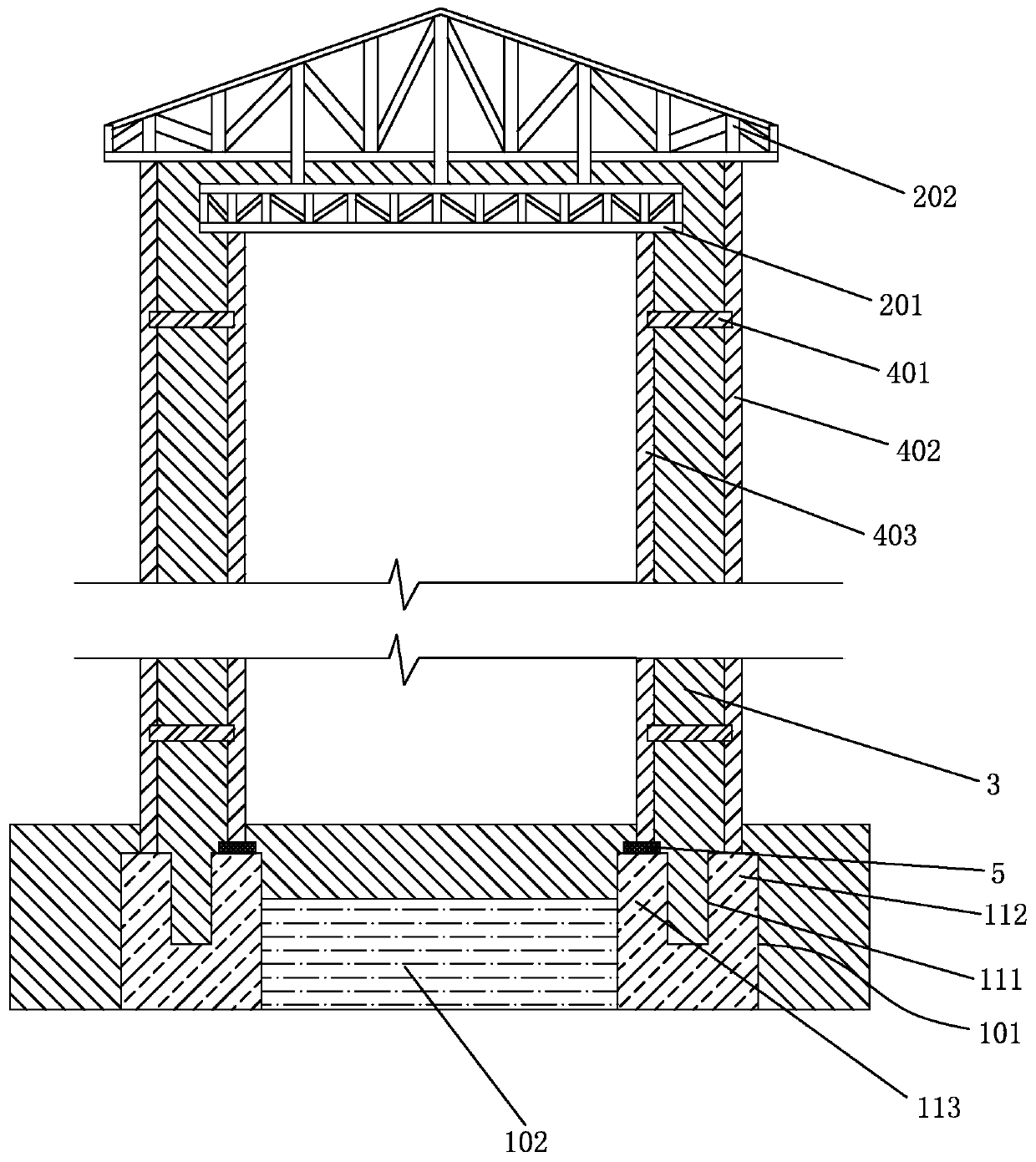

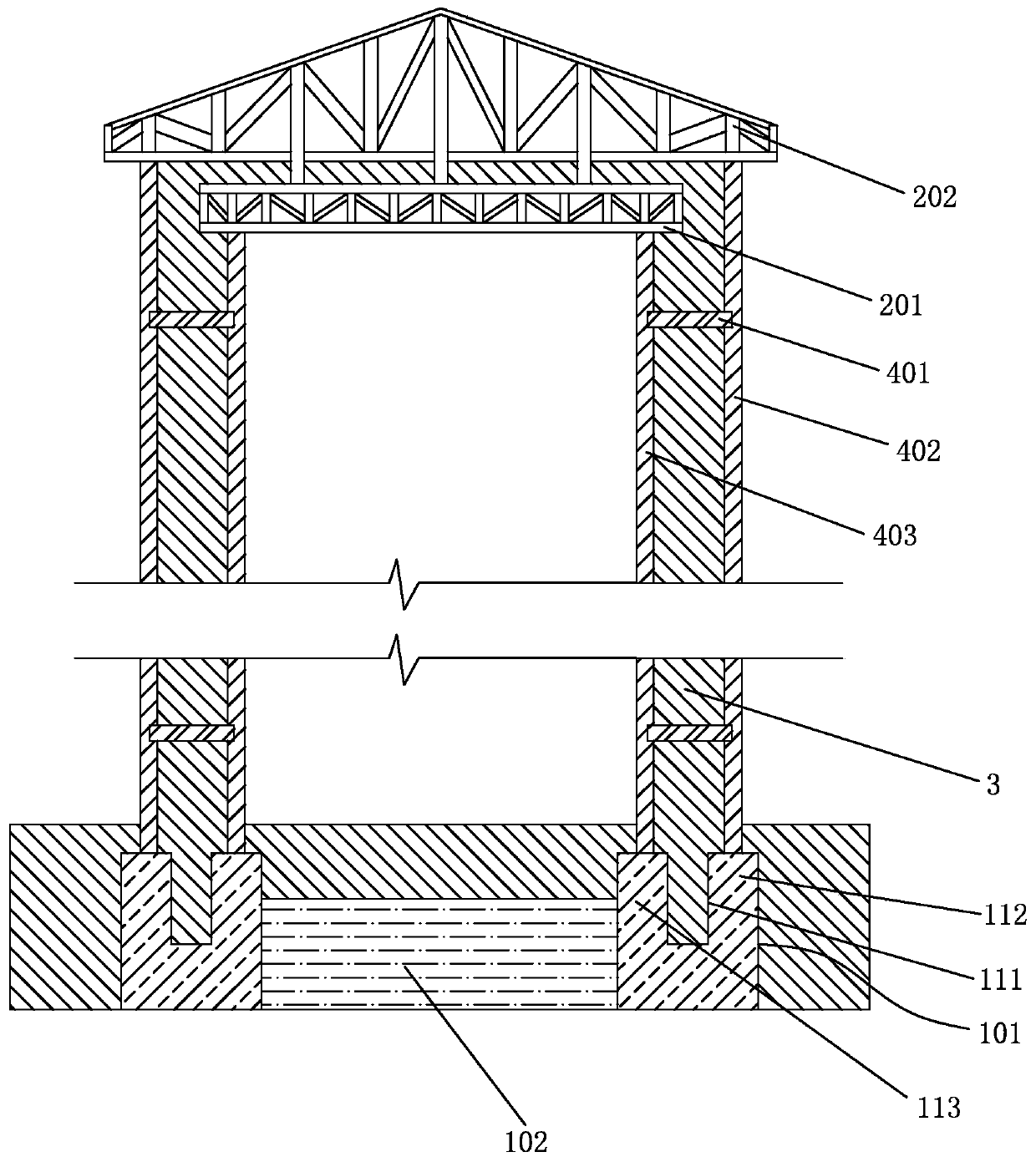

Low-energy-consumption energy-saving building system

PendingCN109797875AImprove thermal insulation performanceImprove thermal insulationBuilding roofsWallsThermal bridgeEngineering

The invention belongs to the field of energy-saving buildings and particularly relates to a low-energy-consumption energy-saving building system. The low-energy-consumption energy-saving building system is characterized in that both an outer support and an inner support are arranged on a ground ring beam; a backfill layer is arranged on one side of the ground ring beam; a heat-insulating pad is arranged between the inner support and the ground ring beam; a porous silicate insulation material is cast between the outer support and the inner support, onto the backfill layer and outside the groundring beam, so that basic thermal bridge is greatly relieved, and heat insulation of a building is improved; both the connection of a foundation and an exterior wall and the connection of the exteriorwall and a roof system are provided with the porous silicate insulation material, the strength is high, weatherability and freezing and thawing cycle resistance are good, the fireproof function is excellent, the potential fire hazard during construction and lifetime service is thoroughly eliminated, powdering upon damp taking is avoided, foundation settlement cracks are avoided, the system hereinhas good environmental friendliness and safety, zero peculiar odor and good thermal insulation, and thermal bridge is effectively eliminated.

Owner:南京依科国特新材料科技有限公司

Cable for conduction charge system of electric vehicle

InactiveCN106448843AImprove tensile propertiesImprove anti-sway performanceFlexible cablesMetal/alloy conductorsElectrical conductorInterference resistance

The invention discloses a cable for a conduction charge system of an electric vehicle. The cable for the conduction charge system of the electric vehicle is characterized by comprising at least two conductor cores, a signal core, an inner sheath layer, a shielding layer, a spring and an outer sheath layer. The cable has the functions of improvement of tension resistance and swinging resistance and the beneficial effects of improvement of the roundness of the cable, control on mechanism movement and component positions, buffering and shock absorption, the deformation of the cable can be alleviated under the action of external force, the cable can be rebounded to an original state after the external force is eliminated, and thus the interference resistance and the reciprocation bending property of the wire cable can be improved; and the mechanical property of the cable is improved, and thus the cable is relatively good in vehicle crushing resistance.

Owner:张大明

Light partition wall board, and manufacture method and installation method thereof

InactiveCN103132644ALow water absorptionGood flexural resistanceCeramic shaping apparatusBuilding componentsCelluloseMixed materials

The invention relates to the field of buildings, and in particular relates to a light partition wall board, and a manufacture method and an installation method thereof. The light partition wall board comprises a pair of autoclaved non-asbestos building cellulose building fibre cement CCA boards; an interlayer is arranged between the pair of autoclaved non-asbestos building cellulose building fibre cement CCA boards; a mixed material is filled in the interlayer; and the mixed material comprises the following components in part by weight: 50-60 parts of silicate cement, 50-60 parts of ceramsite, 1-3 parts of building fibre, 40-50 parts of water, 10-15 parts of rice straw fibre, and 0.5-1.2 parts of cement coagulant. The light partition wall board, and the manufacture method and the installation method thereof disclosed by the invention have the advantages of being preferable in heat insulation performance, sound insulation performance and fireproof performance, high in production efficiency and convenient to install.

Owner:刘兆明

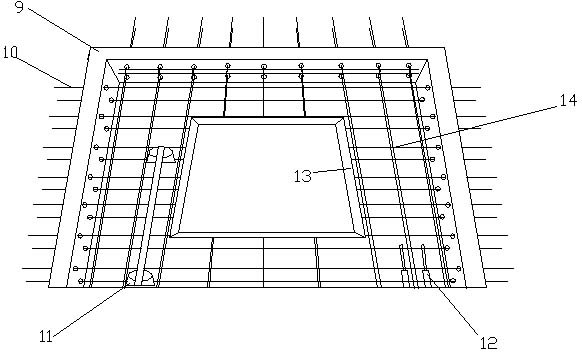

Roof heat preservation system structure

PendingCN108915163AEliminate reworkReduce material waste and labor lossBuild-up roofsRoof covering insulationsRebarSystem structure

The invention aims to disclose a roof heat preservation system structure, which comprises a reinforced concrete base layer and a mortar leveling layer laid on the reinforced concrete base layer, wherein pay-off embedded steel bars, a waterproof layer, a heat preservation layer, a protective layer and counter battens are sequentially arranged on the mortar leveling layer, roof battens are laid on the counter battens, hanging roof tiles are arranged on the roof battens, the counter battens are fixed on the protective layer through a metal bar structure and are levelled, and the protective layeris a mortar protective layer or an easy-to-coil material covering protective layer. Compared with the prior art, the roof heat preservation system structure has good waterproof effect, is suitable forconstruction of various modeling slope roofs, has good heat preservation performance, less wet operation and strong air convection, has effects of energy conservation and environment protection, greatly reduces the use of non-renewable or less-renewable resources, is an advocacy of green building engineering and achieves the objective of the present invention.

Owner:北京利泰装饰工程有限公司

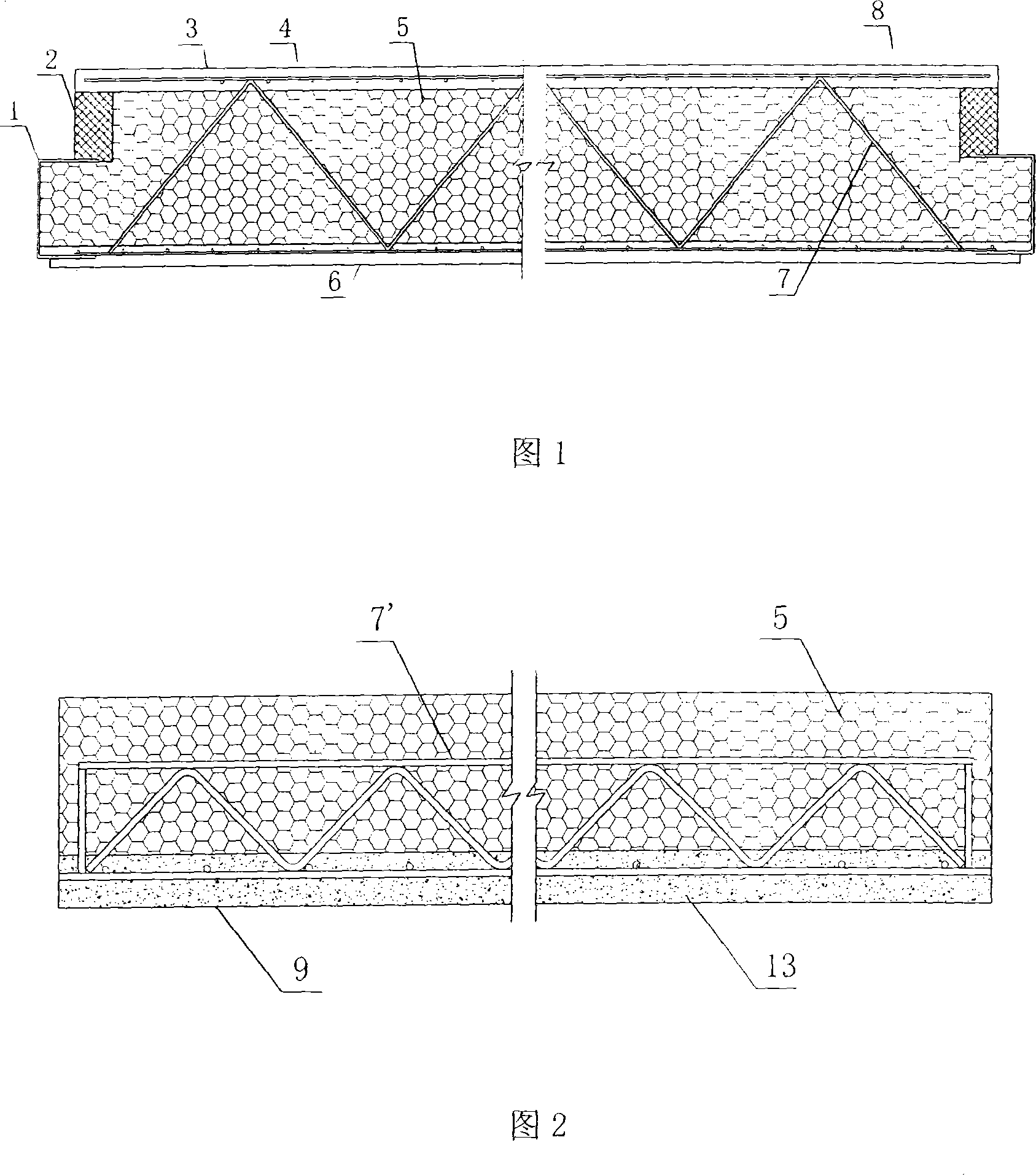

Self-heat-preservation prefabricated outer wall board with frame net rack

InactiveCN104234302AReduce the workload of insulationFast constructionBuilding componentsEngineeringSelf weight

The invention discloses a self-heat-preservation prefabricated outer wall board with a frame net rack. The prefabricated outer wall board comprises a heat-preservation sandwich board, steel wire net sheets and inclined inserting bars, wherein a space steel wire net rack is formed by the upper and lower steel wire net sheets and the heat-preservation sandwich board is arranged in the space steel wire net rack; the upper and lower steel wire net sheets are arranged at the peripheral edges along with the heat-preservation sandwich board, are bent inwards by two rows and are additionally provided with tie bars to form a frame steel bar cage; and lightweight concrete wall bodies are arranged on the upper and lower surfaces, and the peripheries of the space steel wire net rack. According to the self-heat-preservation prefabricated outer wall board, industrial prefabrication can be realized and the self weight is light; the periphery can be in flexible connection with a main body so that the anti-seismic effect is better; and meanwhile, the self-heat-preservation prefabricated outer wall board has the characteristics of rapid construction speed, low construction cost, energy conservation and environmental friendliness, safety and reliability and good heat preservation effect.

Owner:ANHUI YUTAI BUILDING TECH GRP

Novel fire-proof and wind-resistant combined device of isolation rubber support

ActiveCN104314193AMake up for the problem of insufficient wind resistanceImprove fire protectionBridge structural detailsShock proofingTongue and grooveStructural engineering

The invention discloses a novel fire-proof and wind-resistant combined device of an isolation rubber support. The combined device comprises the isolation rubber support and connecting plates which are arranged at the upper and lower ends of the isolation rubber support respectively, wherein the periphery of the isolation rubber support is wrapped by a tongued and grooved steel plate; a fire-proof component is arranged at the periphery of the tongued and grooved steel plate. The device has a wind resistance function and a fire proofing function during use at ordinary time; a tongue and groove part of the tongued and grooved steel plate can be sheared by using earthquake force during earthquake, but a fire-proof component can still work normally, and the free horizontal deformation of the isolation rubber support is not obstructed; the purposes of damping and upper structure protection are achieved; after the earthquake ends, the newly machined tongued and grooved steel plate is connected to the upper and lower connecting plates of the isolation rubber support by using bolts, and the corresponding fire-proof component is arranged to newly achieve the wind resistance, fire proofing and isolation functions.

Owner:GUANGZHOU UNIVERSITY

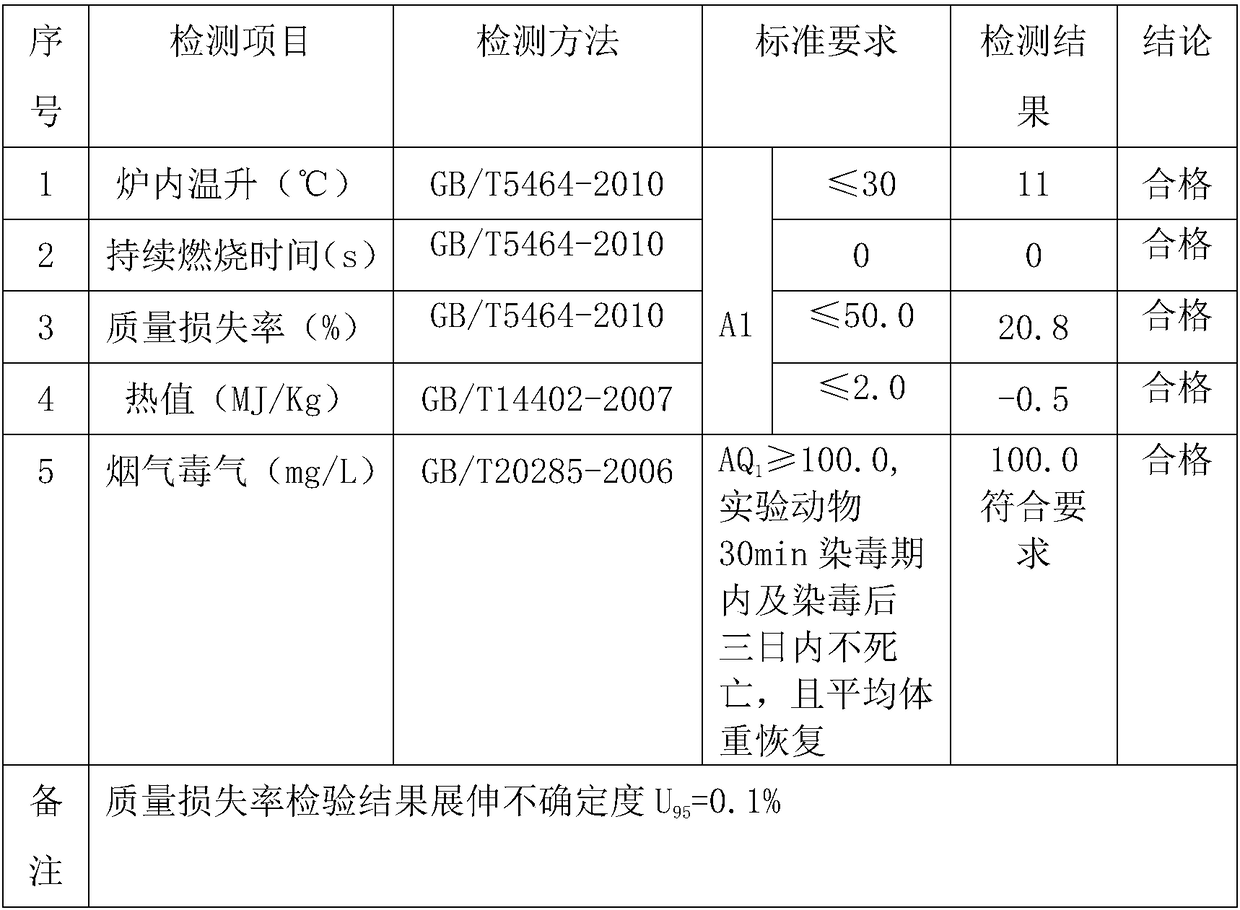

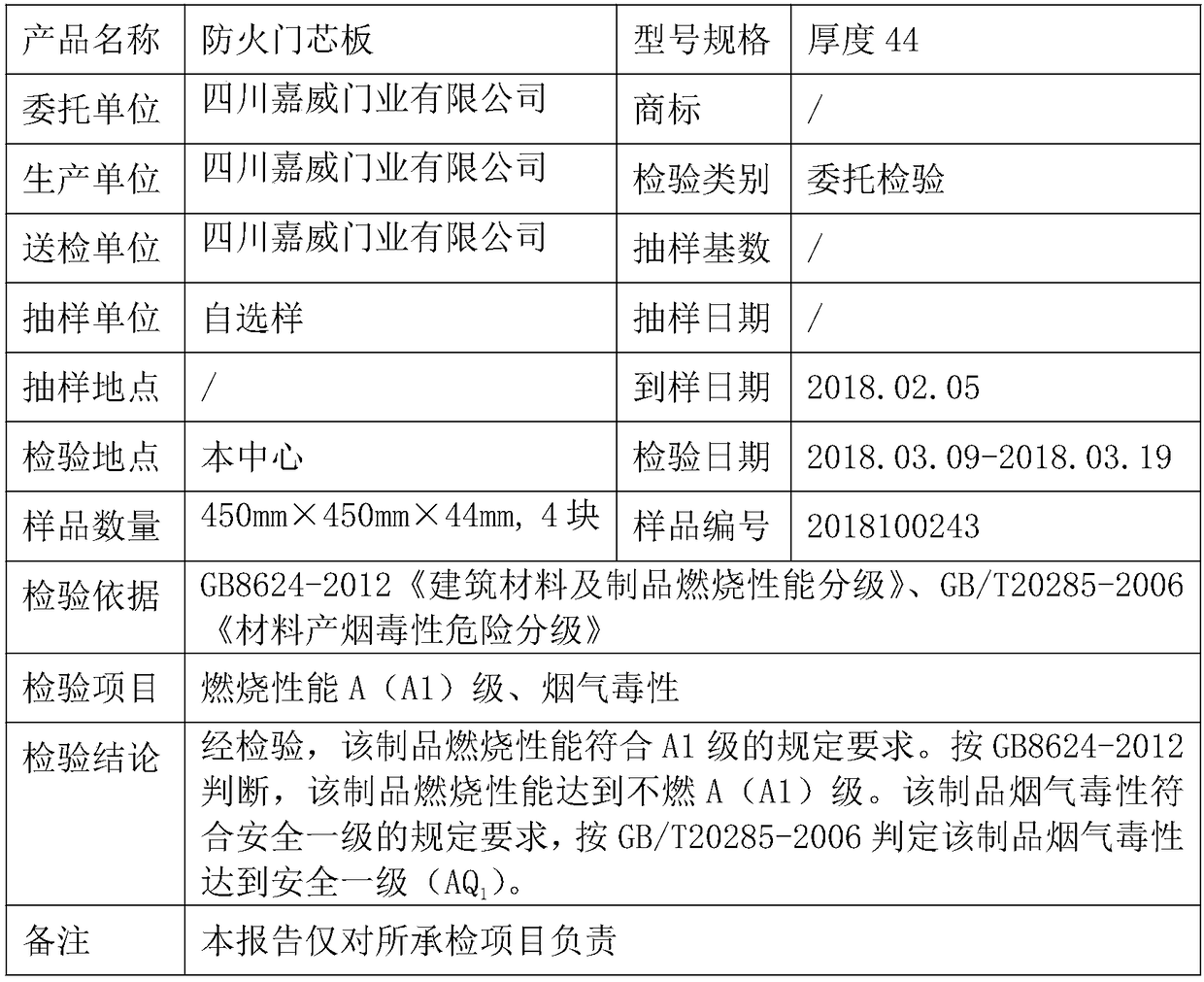

Fireproof door core plate material and preparation process thereof

The invention belongs to an inner filling material of a fireproof door, and particularly relates to a fireproof door core plate material for fireproofing and heat insulation and a preparation processthereof. The fireproof door core plate material is prepared from the following raw materials in parts by weight: 300 to 400 parts of Alpha type High-strength gypsum, 3 to 6 parts of tert-acetic emulsion, 0.2 to 1 part of polyvinyl alcohol, 0.05 to 0.1 part of gypsum retarders, 20 to 40 parts of foaming agent water solution, 0.5 to 2 parts of fiber and 100 to 140 parts of water, wherein the weightratio of the foaming agent in the foaming agent water solution to the water in the foaming agent water solution is 1:(70 to 90). The fireproof door core plate material has the advantage that the adverse influence caused by a fireproof door core plate on the quality of a fireproof door can be avoided.

Owner:四川嘉威门业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com