Domestic composite-structure floor and processing method thereof

A technology of composite structure and processing method, which is applied in the field of flooring, can solve the problems of insufficient floor strength, poor heat conduction effect, and inability to realize fire prevention function, etc., and achieve the effect of good fire prevention function, fast speed and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the drawings and embodiments.

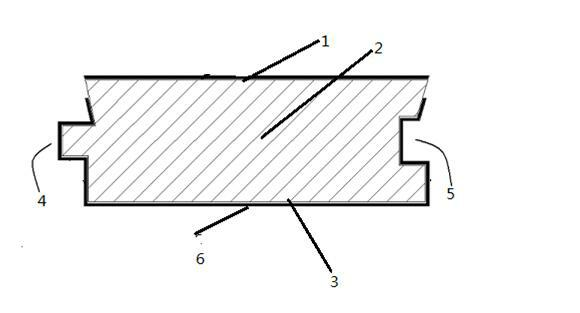

[0030] figure 1 It is a cross-sectional view of the structure of a household composite structure floor according to an embodiment of the present invention, such as figure 1 As shown, it includes the substrate (2), the upper surface of the floor (1), and the lower surface of the floor (3). The floor has a side that contains a tenon (4), which can also be called the first side, and correspondingly, the floor has another side that contains a groove (5), which can also be called the second side, wherein the Tenon (4) and groove (5) can fit well.

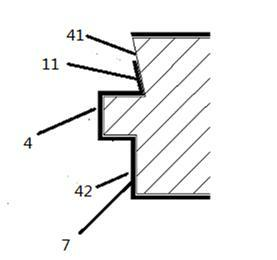

[0031] figure 2 A schematic diagram of the first side of the household composite structure floor provided for the embodiment of the present invention including the tenon (4), wherein (4) is a tenon, which may be a cube or a cuboid. The tenon (4) is connected to the upper surface of the floor (1) through a third plane (41)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com