Process of producing fireproof sofa artificial leather

A manufacturing method and technology of sofa leather, which are applied in textiles and paper making, etc., to achieve the effects of good aging resistance, reduced solvent composition, and good fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

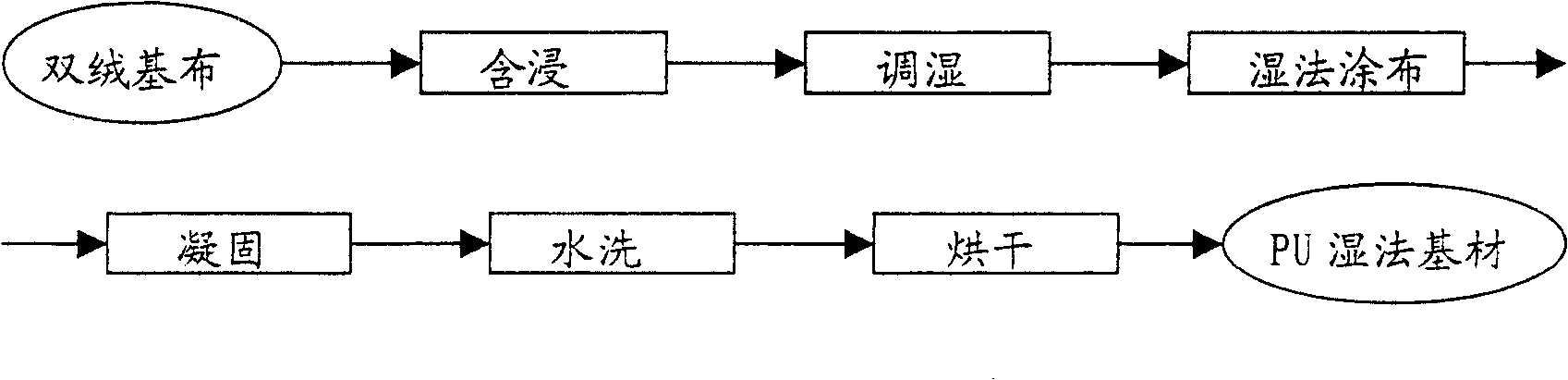

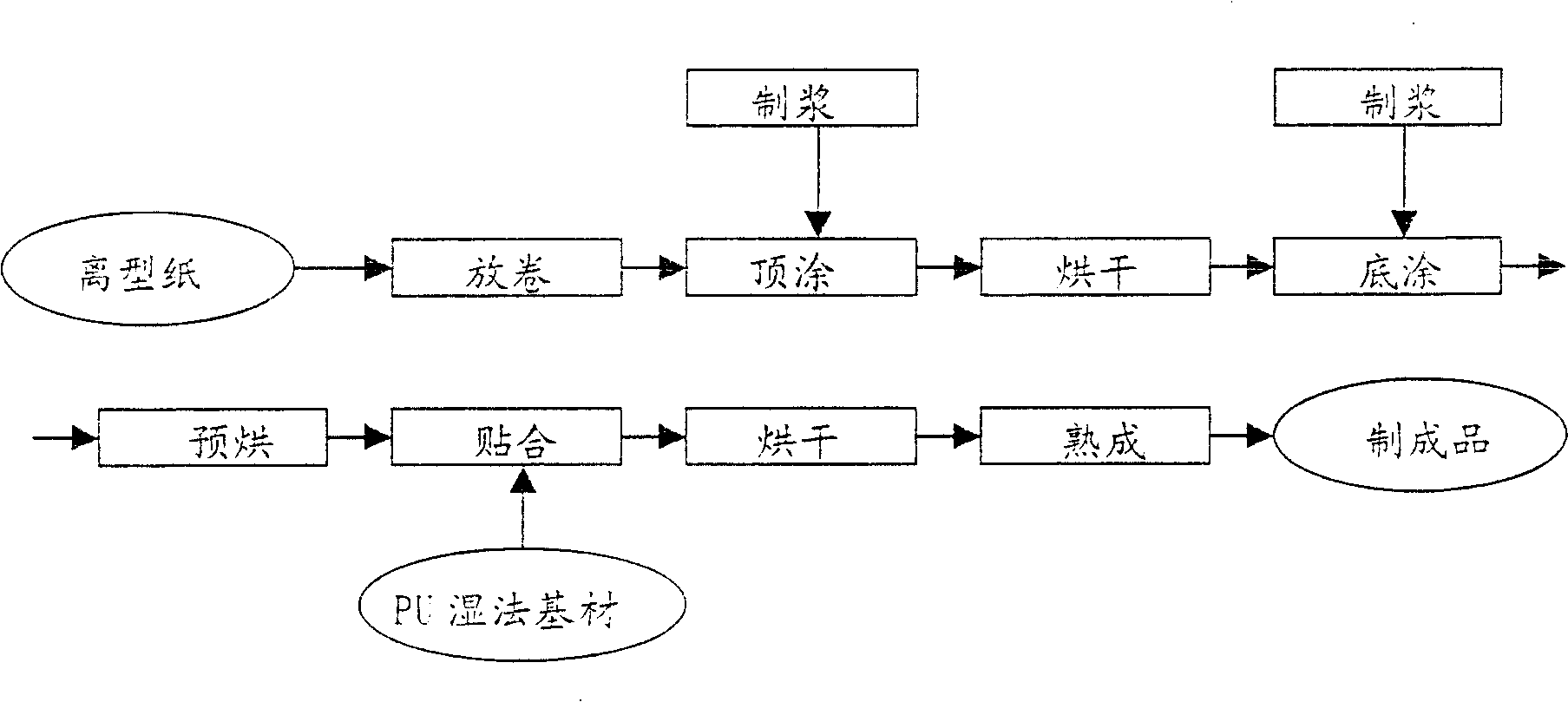

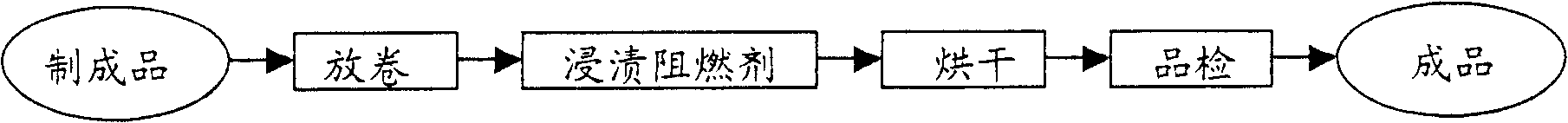

Method used

Image

Examples

Embodiment 1

[0045] A. Wet slurry formula:

[0046] Polyether and polycarbon polyurethane resin (model HX-3025A) 100 parts,

[0047] DMF 50 parts,

[0048] 1 part of solvent-based color paste,

[0049] Wood flour (model FD600 / 30) 5 parts,

[0050] Anti-mildew and antibacterial agent (model KF-100) 0.2 parts,

[0051] Phosphorous flame retardant (model VB-02) 2 parts.

[0052] B. Dry slurry process formula:

[0053] Top coat:

[0054] Aliphatic polycarbonate polyurethane resin (model HX-6075) 100 parts,

[0055] 10 parts of solvent,

[0056] 15 parts of coloring material,

[0057] Leveling agent 1 part,

[0058] 1 part peeling agent,

[0059] Phosphorus flame retardant (model VB-01) 3 parts;

[0060] Primer:

[0061] Aromatic polycarbonate polyurethane resin (model HX-6040) 100 parts,

[0062]10 parts of solvent,

[0063] 10 parts of coloring material,

[0064] Leveling agent 1 part

[0065] Phosphorous flame retardant (model VB-01) 2 parts.

[0066] C. The formula of water...

Embodiment 2

[0070] A. Wet slurry formula:

[0071] Polyether and polycarbon type polyurethane resin (HX-3025A) 100 parts,

[0072] DMF 60 parts,

[0073] 3 parts of solvent-based color paste,

[0074] Wood flour (FD600 / 30) 10 parts,

[0075] Phosphorous flame retardant (VB-02) 2.5 parts.

[0076] B. Dry slurry process formula:

[0077] Top coat:

[0078] Aliphatic polycarbonate polyurethane resin (HX-6075) 100 parts,

[0079] 30 parts of solvent,

[0080] 15 parts of coloring material,

[0081] Leveling agent 0.5 parts,

[0082] 0.5 part of peeling aid,

[0083] Phosphorus flame retardant (VB-01) 2 parts;

[0084] Primer:

[0085] Aromatic polycarbonate polyurethane resin (HX-6040) 100 parts,

[0086] 20 parts of solvent,

[0087] 10 parts of coloring material,

[0088] Leveling agent 0.5 parts,

[0089] Phosphorus flame retardant (VB-01) 1.5 parts.

[0090] C. The formula of water-based environment-friendly flame retardant solution is by weight:

[0091] 30 parts of wate...

Embodiment 3

[0094] A. Wet slurry formula:

[0095] Polyether and polycarbon type polyurethane resin (HX-3025A) 100 parts,

[0096] DMF 80 parts,

[0097] 5 parts of solvent-based color paste,

[0098] Wood flour (FD600 / 30) 15 parts,

[0099] Phosphorus flame retardant (VB-02) 3 parts.

[0100] B dry slurry process formula:

[0101] Top coat:

[0102] Aliphatic polycarbonate polyurethane resin (HX-6075) 100 parts,

[0103] 40 parts of solvent,

[0104] 25 parts of coloring material,

[0105] Leveling agent 1 part,

[0106] 1 part peeling agent,

[0107] Phosphorus flame retardant (VB-01) 2 parts;

[0108] Primer:

[0109] Aromatic polycarbonate polyurethane resin (HX-6040) 100 parts,

[0110] 30 parts of solvent,

[0111] 15 parts of coloring material,

[0112] Leveling agent 1 part,

[0113] Phosphorus flame retardant (VB-01) 1.5 parts.

[0114] C. The formula of water-based environment-friendly flame retardant solution is by weight:

[0115] 70 parts of water,

[0116] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com