Patents

Literature

62results about How to "Size standard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

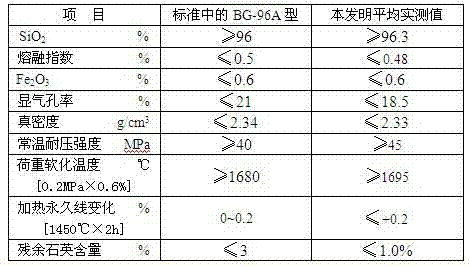

Silica brick for glass furnace

ActiveCN102515801ASmall volume expansionReduce crackingGlass furnace apparatusGlass productionPorosityBrick

The invention discloses a silica brick for a glass furnace, and belongs to the technical field of refractory materials. The silica brick for a glass furnace comprises: by weight, 30 to 45% of silica having particle sizes of 3 to 1.0mm, 5 to 25% of silica having particle sizes of 1.0 to 0.5mm, 30 to 50% of silica having particle sizes less than 0.5mm, an additive and a composite additive, wherein the weight of the additive is 5 to 15% of the total weight of the silica and the weight of the composite additive is 2 to 10% of the total weight of the silica. SiO2 content of the silica is great than or equal to 99%. Al2O3 content of the silica is less than or equal to 0.25%. Fe2O3 content of the silica is less than or equal to 0.45%. The additive is a waste silica material having SiO2 content great than or equal to 96%. The composite additive is a mixture of lime milk, mill scales and calcium lignosulphonate. The silica brick for a glass furnace has high SiO2 content, a high yield, low impurity content, low apparent porosity, good high-temperature performances and a long service life. A preparation technology of the silica brick for a glass furnace is simple and is suitable for large-scale production.

Owner:ZHEJIANG ZHAOSHAN SILICEOUS REFRACTORY MATERIAL

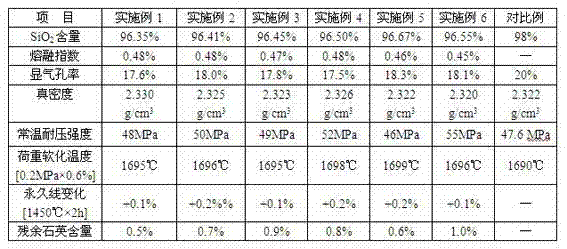

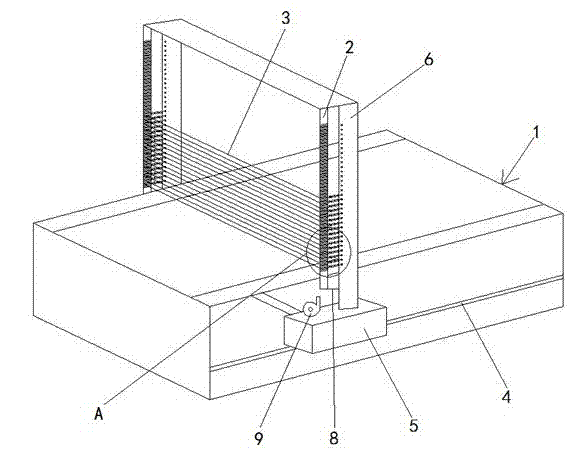

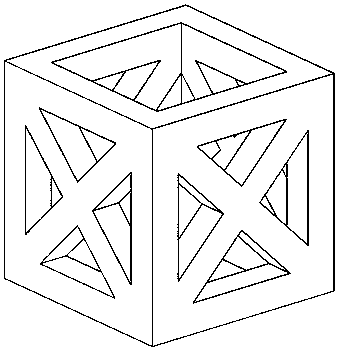

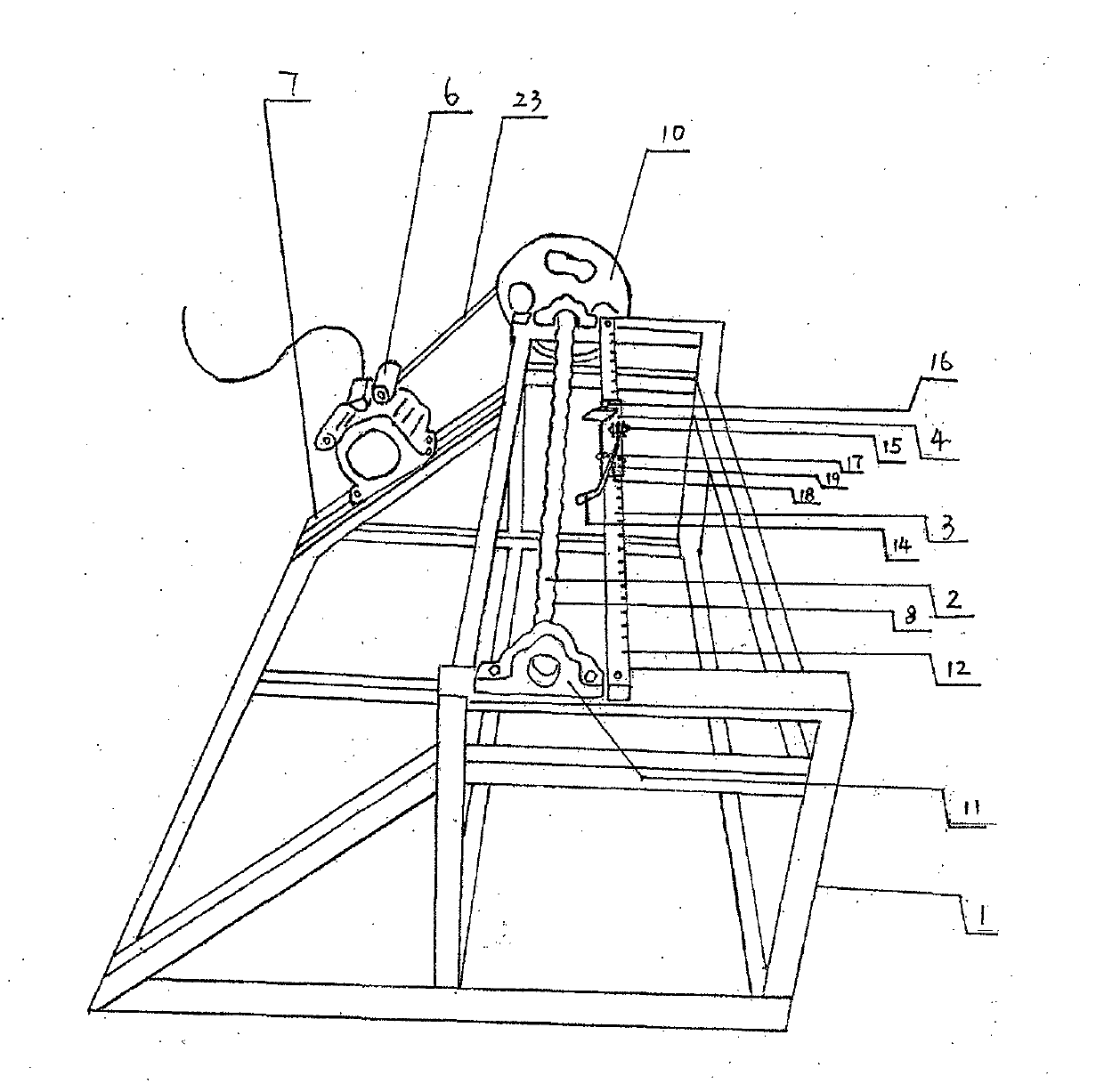

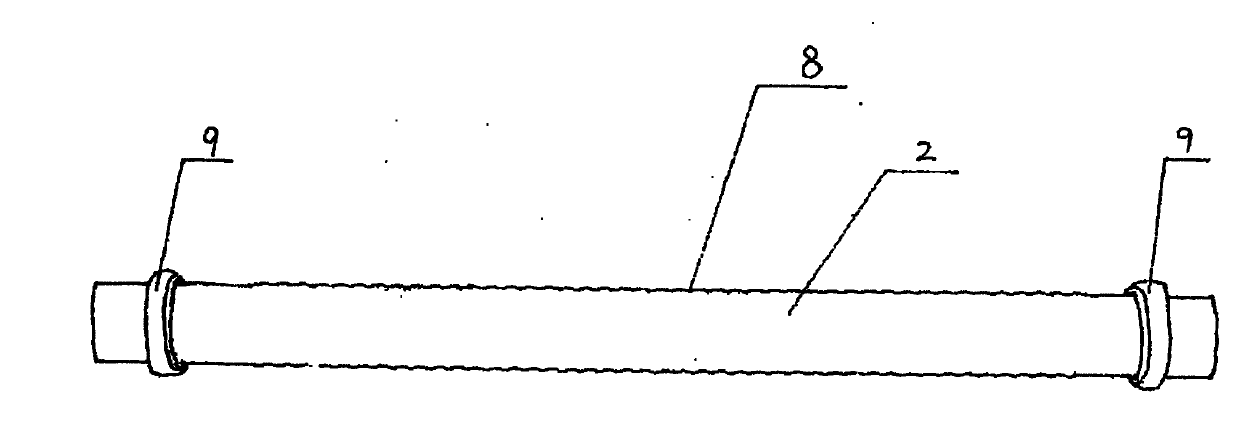

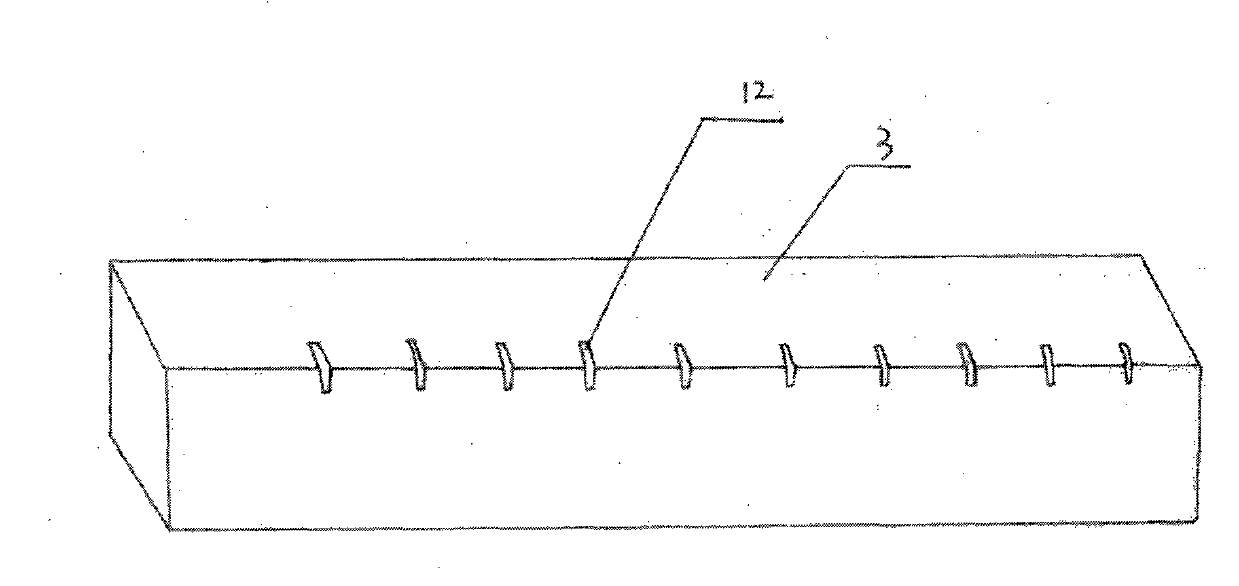

Technical cubic foam block cutting machine

The invention discloses a technical cubic foam block cutting machine, which comprises a rack, electric heating poles and electric heating wires, wherein the electric heating poles are vertically arranged on two sides of the rack; the electric heating wires are fastened between the electric heating poles; two sides of the rack are provided with guide rails; the guide rails are provided with sliding seats which move along the guide rail direction; the electric heating poles are vertically fixed on the sliding seats; wire tightening poles are arranged near the electric heating poles in parallel; and the bottom of the electric heating poles is provided with a blower. The technical cubic foam block cutting machine can be operated only by one person, thereby being convenient and quick; the produced cubic foam block has the advantages of standard size and tidy notch; the cubic foam blocks with various sizes can be produced on batch so as to greatly improve the production efficiency; meanwhile, in the production process, the chance for workers to contact with the machine is small; and therefore the accident that an operator is scaled by the electric heating wires is greatly reduced.

Owner:JIANGSU ANYANG CULTURE CREATIVE IND PARK

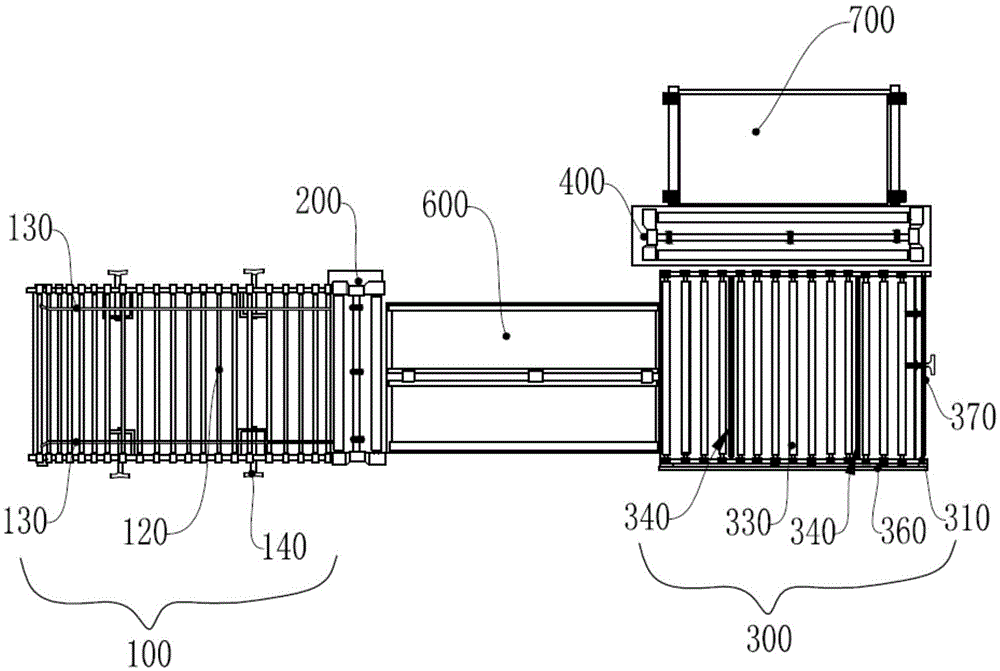

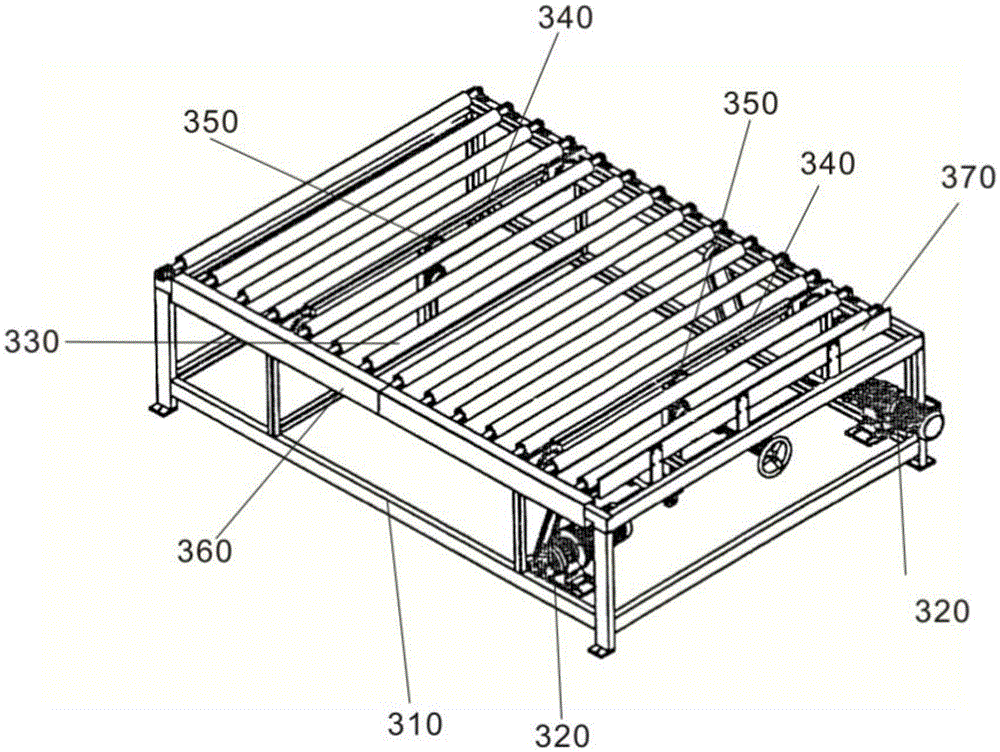

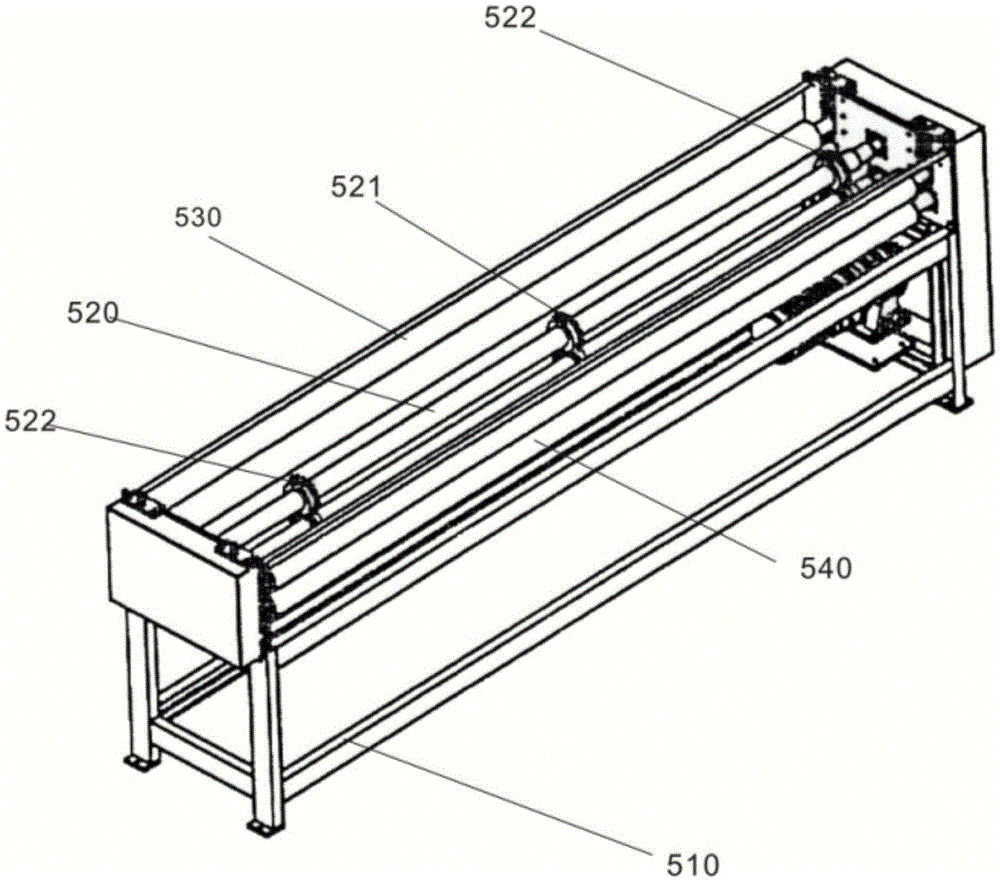

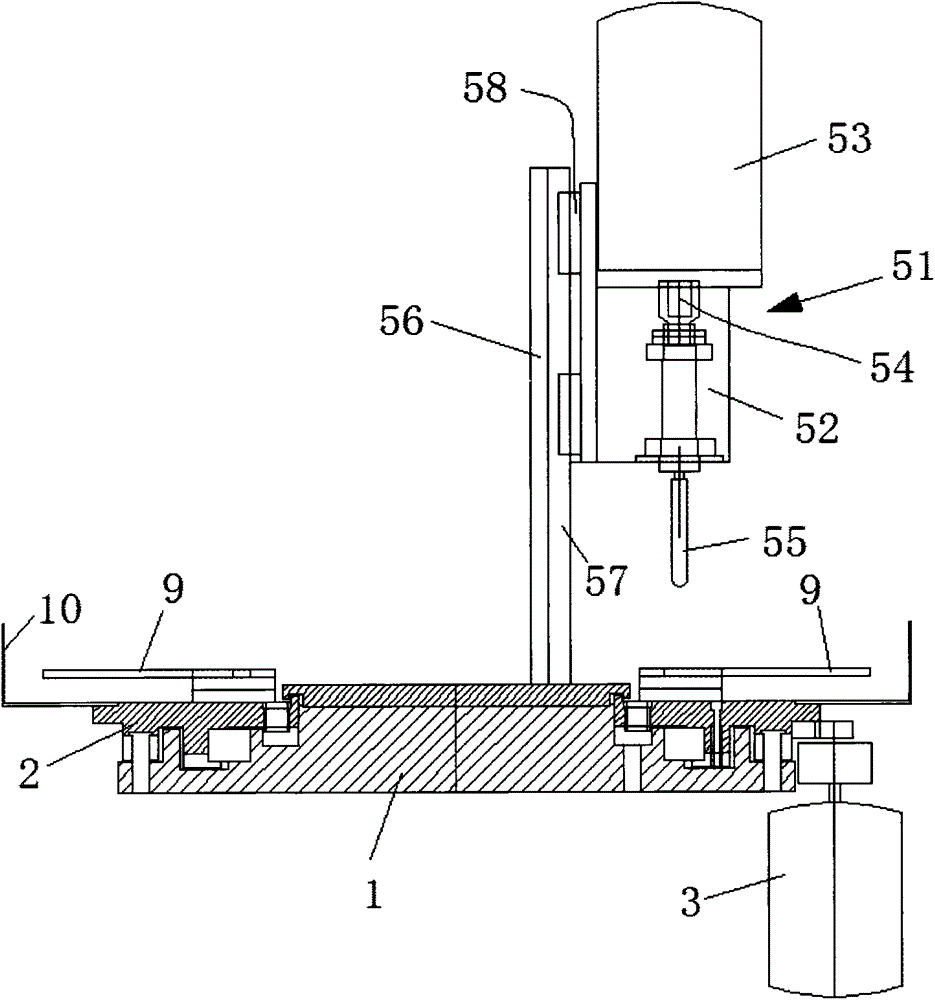

Splitting machine with transverse and longitudinal two-way cutting function

The invention relates to the field of board cutting mechanical equipment, in particular to a splitting machine with the transverse and longitudinal two-way cutting function. The splitting machine comprises a transverse transporting device, a transverse cutting machine, a steering transporting device and a longitudinal cutting machine. A transverse conveying mechanism and a longitudinal board pushing mechanism are arranged on a conveying platform of the steering transporting device. The conveying direction of the transverse conveying mechanism is perpendicular to the board pushing direction of the longitudinal board pushing mechanism. A feeding port of the transverse cutting machine is in butt joint with the discharging end of the transverse transporting device. A discharging port of the transverse cutting machine is in butt joint with the feeding end of the steering transporting device. The discharging end of the steering transporting device is in butt joint with a feeding port of the longitudinal cutting machine. The transporting devices and the cutting machines in the splitting machine all automatically and orderly work under the control of a programmable controller, the high-intelligent two-way cutting work can be achieved through the splitting machine, personnel operation is reduced, splitting efficiency is improved, and cutting errors are reduced.

Owner:GUANGDONG WALKKIND SPECIAL FIBERBOARD TECH

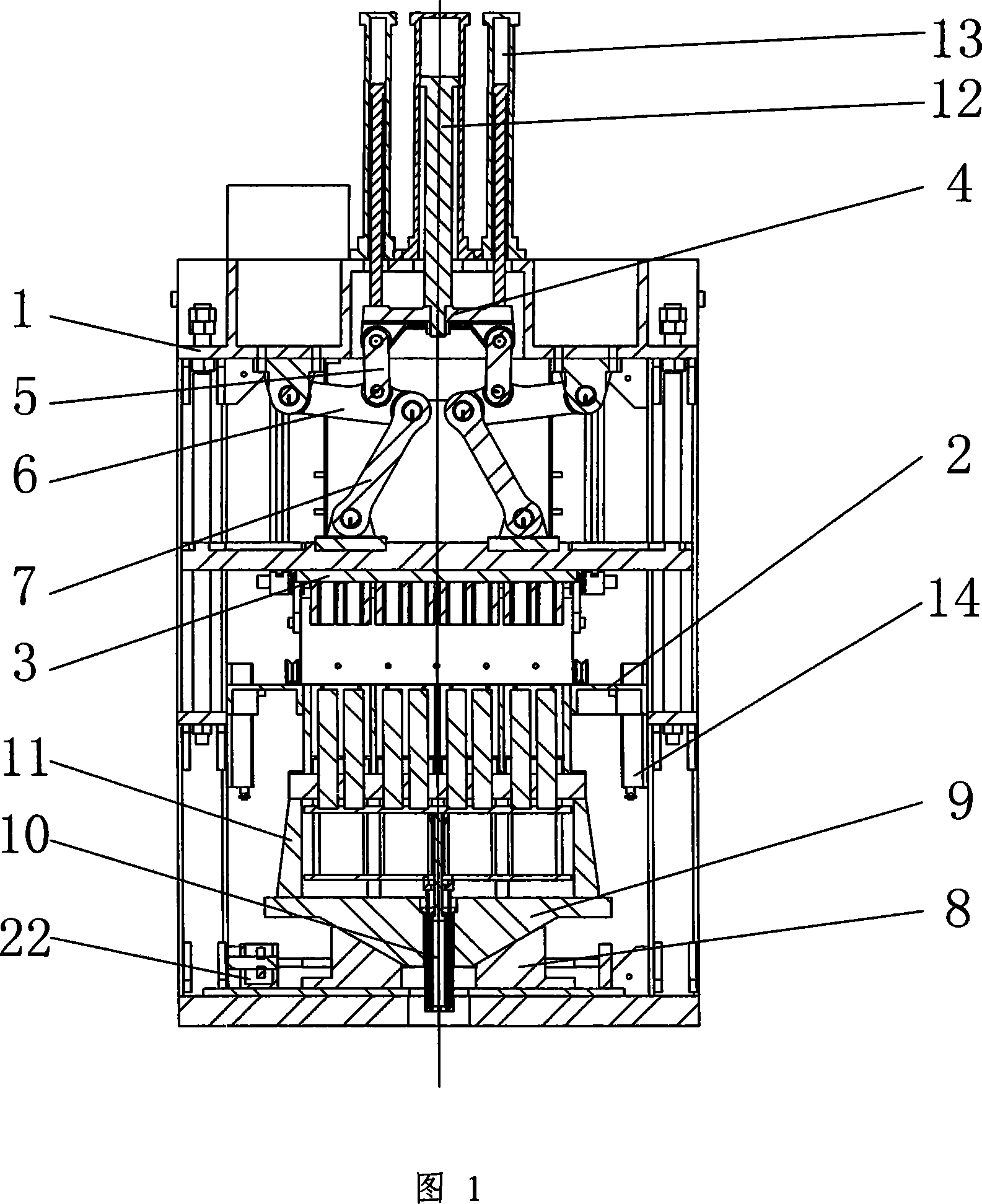

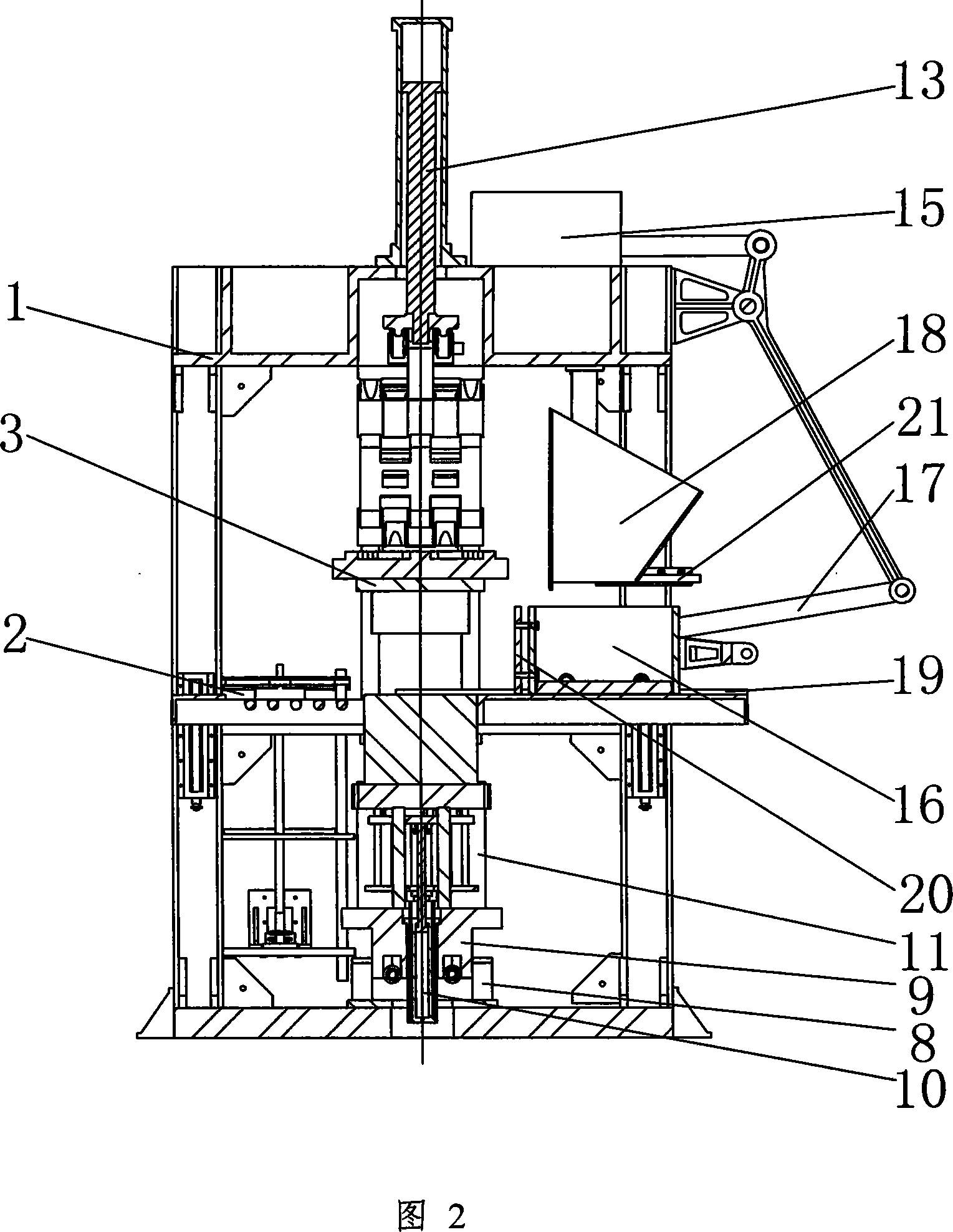

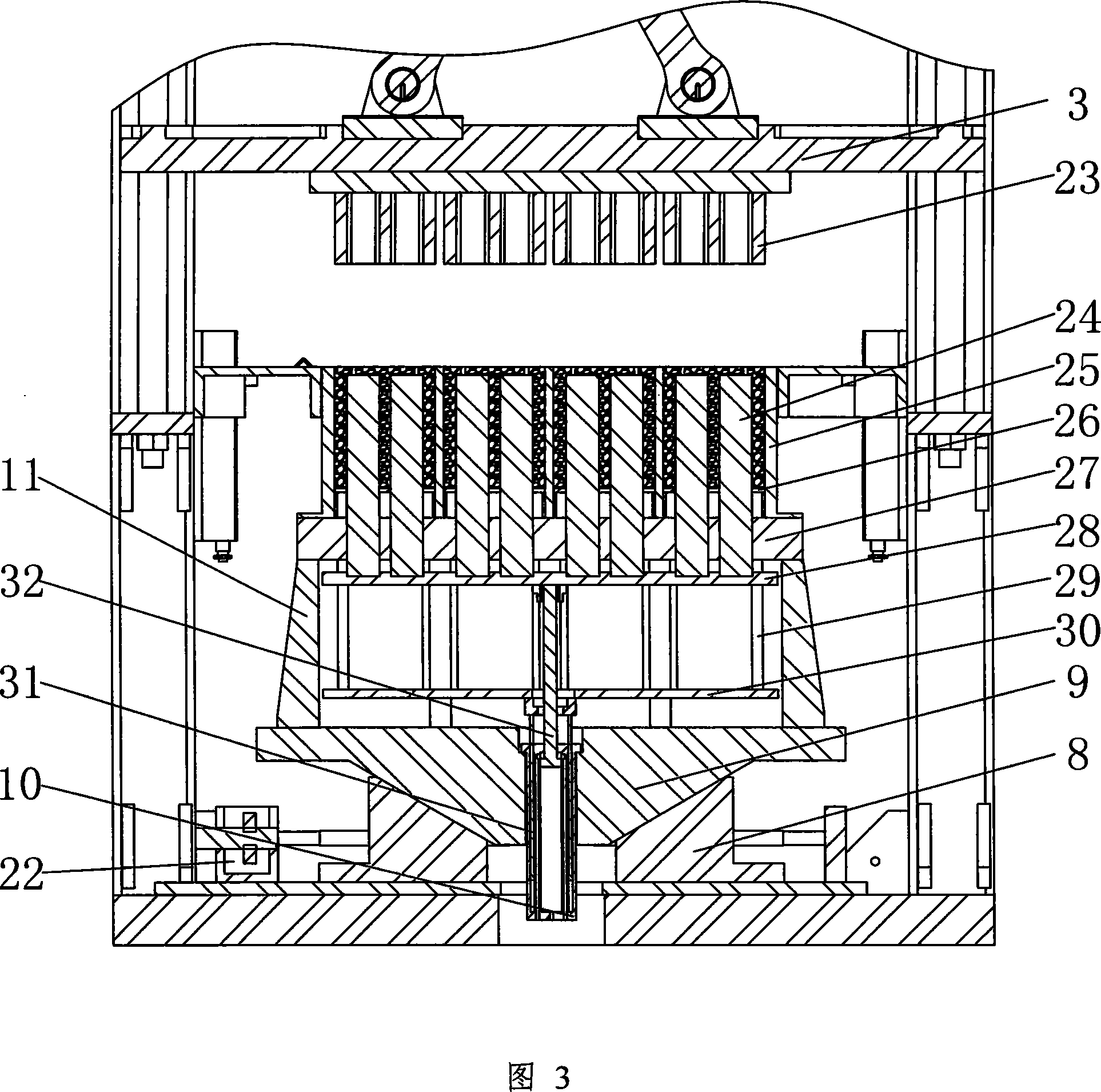

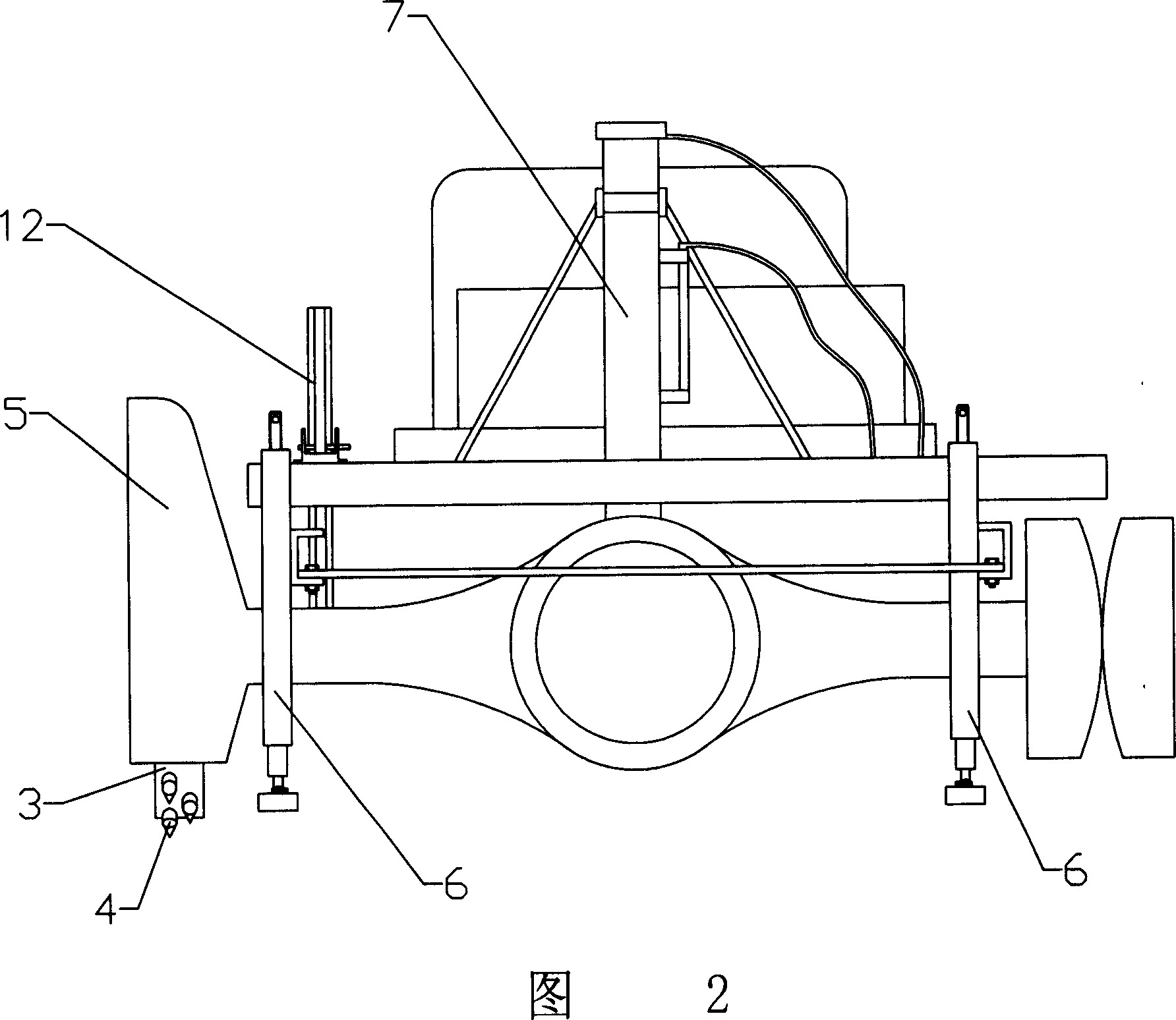

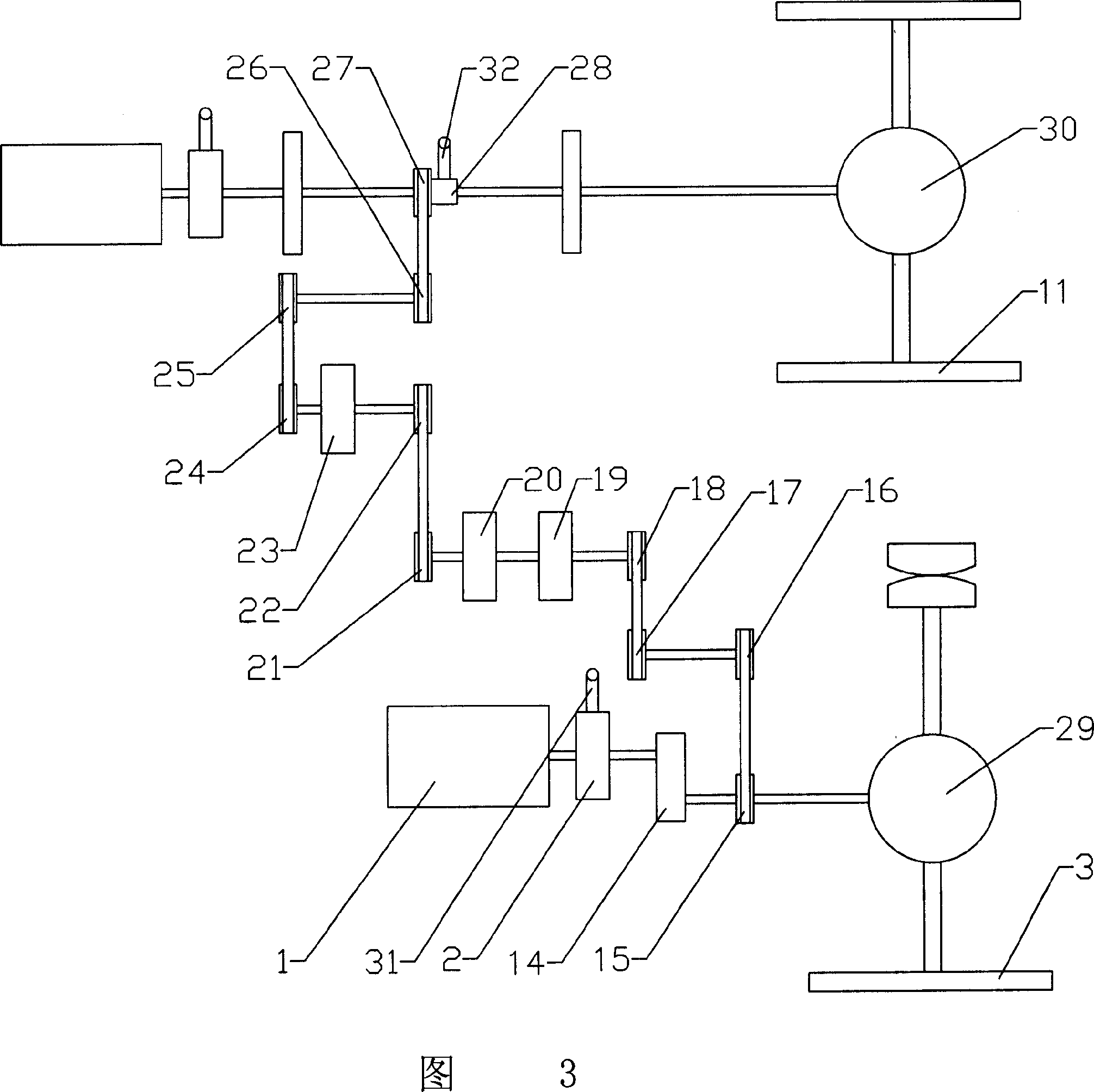

Full-automatic hydraulic without excitation building block shaping machine

InactiveCN101214734AHigh compressive strengthStandard sizePress ramShaping pressHydraulic cylinderEngineering

The invention provides a full automatic hydraulic building block forming machine without shock excitation, which comprises a frame, a workbench, an upper die, a lower die, a mould emptier, a feeding mechanism and a compaction mechanism. The compaction mechanism comprises a hydraulic cylinder, a hydraulic cylinder push frame, a bar chain force increasing and pressurizing mechanism. The hydraulic cylinder arranged on the frame passes through the frame; the lower end of the hydraulic cylinder is provided with the hydraulic cylinder push frame which is fixed. The lower end of the hydraulic cylinder push frame is provided with the bar chain force increasing and pressurizing mechanism. The lower end of the bar chain force increasing pressurizing mechanism is fixed with an upper templet. The invention provides a full automatic hydraulic forming machine of low power and large pressure without shock excitation, noise or a carrier for high strength bearing building blocks and interlocking building blocks.

Owner:陈大庆 +1

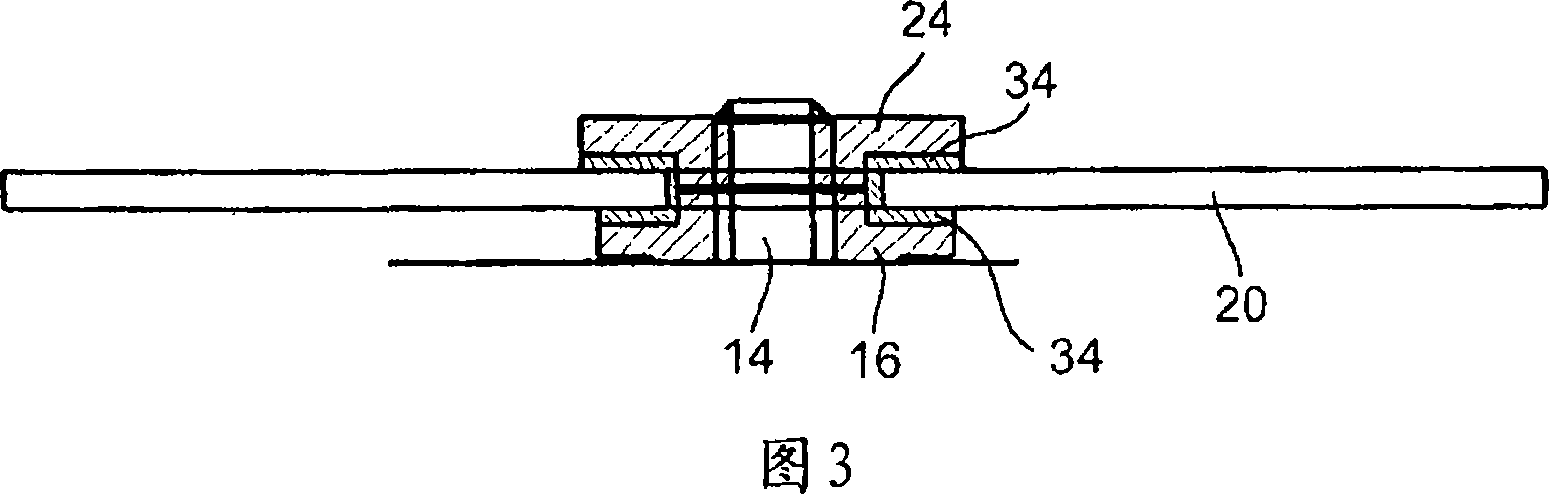

Device with vibration-damped component used for cutting and grinding, clamp device and rotary tool

InactiveCN101076431AUnchanged standard sizeSize standardMetal sawing devicesGrinding wheel securing apparatusMultivariate statisticalEngineering

Thousands of process and equipment measurements are gathered by the modern digital process control systems that are deployed in refineries and chemical plants. Several years of these data are historized in databases for analysis and reporting. These databases can be mined for the data patterns that occur during normal operation and those patterns used to determine when the process is behaving abnormally. These normal operating patterns are represented by sets of models. These models include simple engineering equations, which express known relationships that should be true during normal operations and multivariate statistical models based on a variation of principle component analysis. Equipment and process problems can be detected by comparing the data gathered on a minute by minute basis to predictions from these models of normal operation. The deviation between the expected pattern in the process operating data and the actual data pattern are interpreted by fuzzy Petri nets to determine the normality of the process operations. This is then used to help the operator localize and diagnose the root cause of the problem.

Owner:RHODIUS SCHLEIFWERKZEUGE

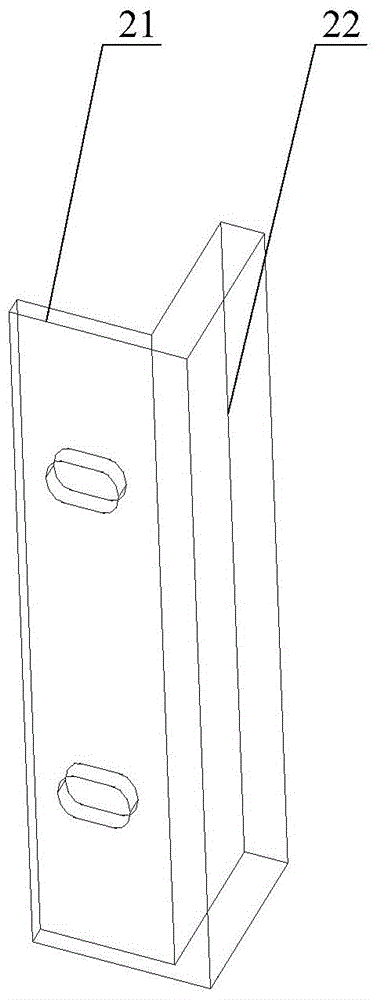

Plastic supports with shear walls and steel bar positioning

InactiveCN1424474AReasonable structural designHigh strengthWallsBuilding reinforcementsEngineeringSteel bar

A plastic frame for locating the reinforcing bar and arranging protecting layer of shear wall is made of engineering plastics. The left and right locating members are connected by spiral thread and have wheel-type unit with elastic opening and elastic fastening piece. Its straight rod has slots on its external surface. Its advnatages are high strength, elastic and reliability and precise size.

Owner:吴仁友

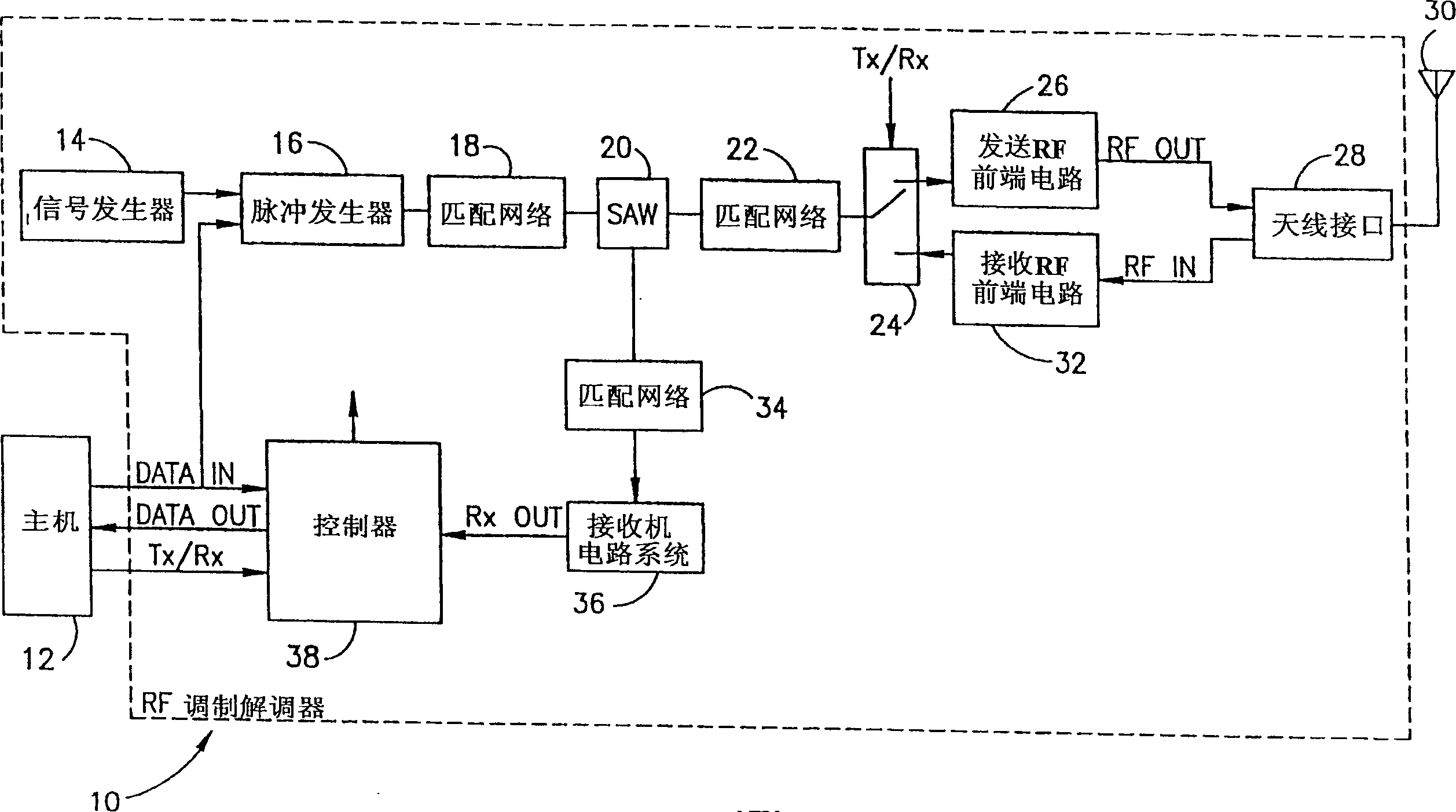

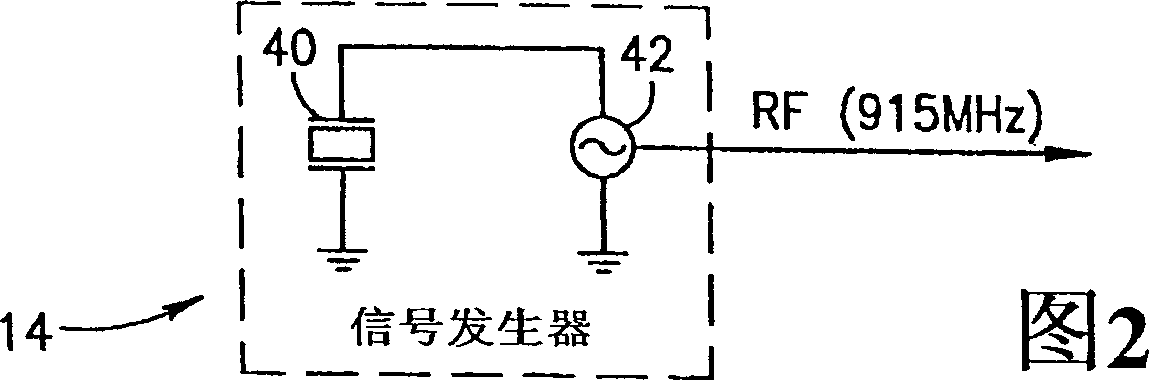

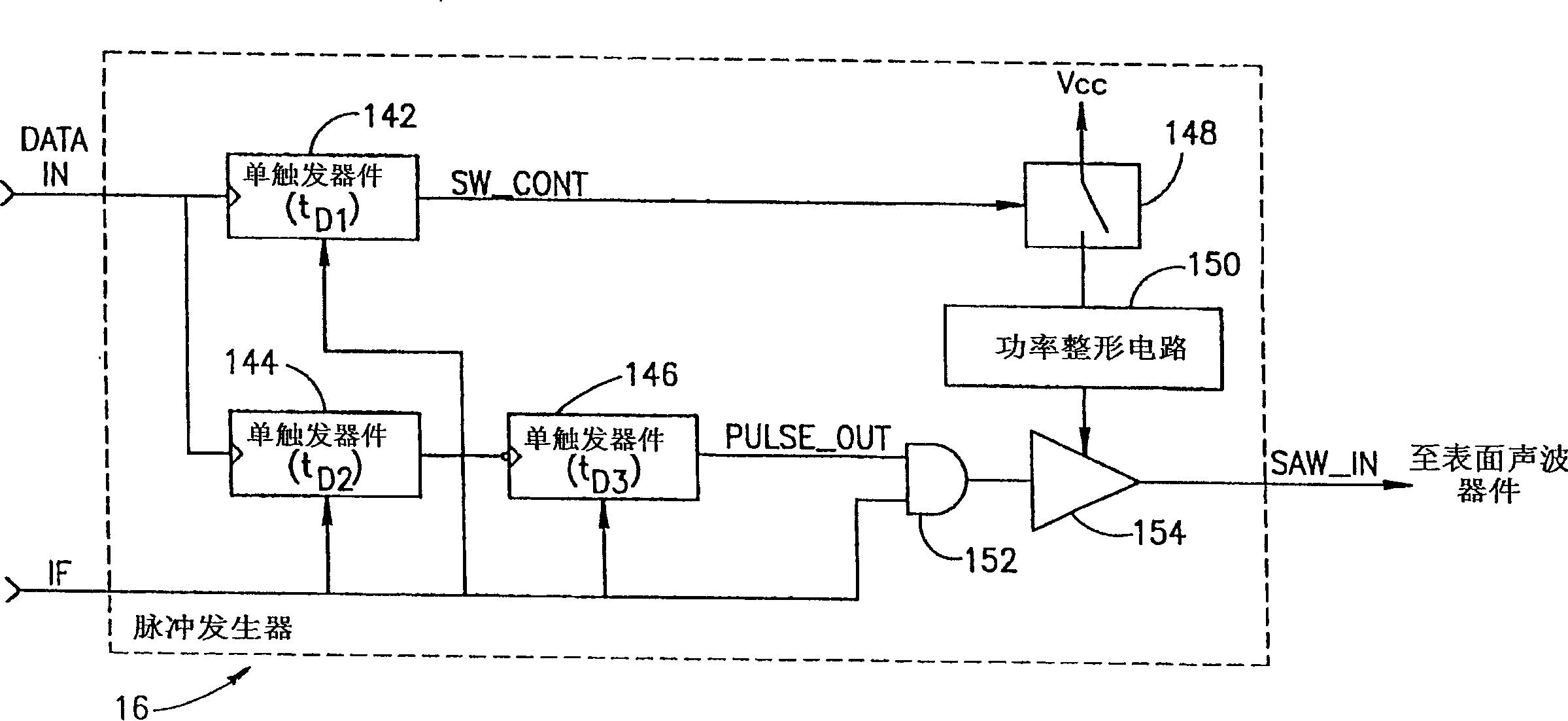

RF modem utilizing SAW device and pulse shaping

InactiveCN1578180ALow costLow production costDc level restoring means or bias distort correctionAmplitude-modulated carrier systemsFrequency changerModem device

A bidirectional direct sequence spread spectrum half-duplex RF modem which can be applied to transmit and receive numerous types of analog and digital pulse modulation. The modem incorporates two different SAW devices fabricated on a single monolithic substrate. A first SAW device is used as a resonator in the oscillator circuit while a second SAW device is used as the correlator for transmit and receive operations. The RF modem operates as an analog or digital pulse transmitter and receiver and is adapted to be generic and versatile enough to be used in many different types of data communication systems, such as OOK, PWM and PPM. The RF modem can be used as the physical (PHY) layer in a layered communication system such as the ISO OSI communication stack. In an alternative embodiment, the transmission bit rate is increased using a plurality of correlators wherein each is configured with a unique function (i.e., code) that is orthogonal with all other functions.

Owner:射频波有限责任公司

Detachable fast-assembly wild camping house

The invention provides a detachable fast-assembly wild camping house. The detachable fast-assembly wild camping house comprises corner columns, wall body unit modules, roof unit modules, roof fasteners, foundation connecting pieces, foundation beams, joist beams and floor plates. According to the detachable fast-assembly wild camping house, components such as wall bodies, floors, a roof, beams and columns are modularized and assembled together in connection modes such as through special nails, fasteners, and plug-in pieces, so that one wild camping house capable of being insulated from sound and heat and keeping warm is formed. Accordingly, a traditional wild camping mode will be changed according to the detachable fast-assembly wild camping house; meanwhile, the detachable fast-assembly wild camping house mode is different from a fixed construction camping mode, and the utilization range and the utilization rate of wood products are improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

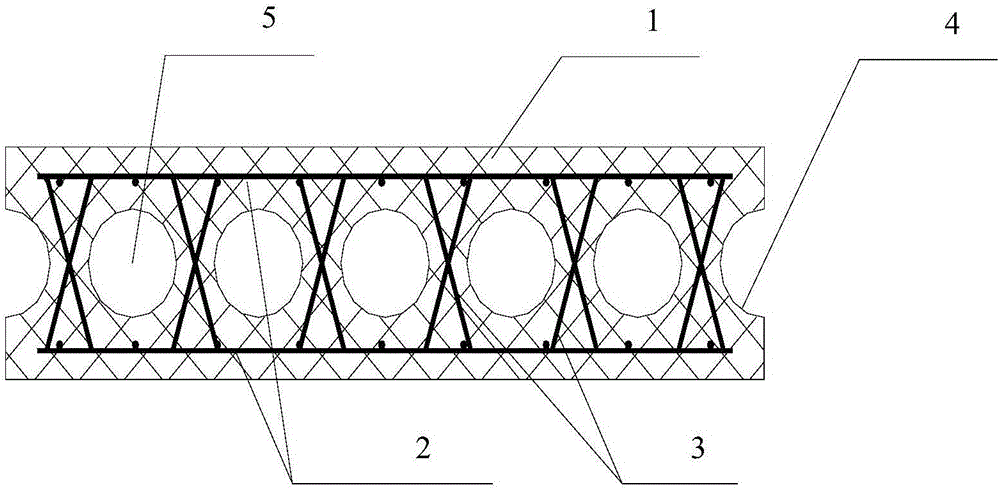

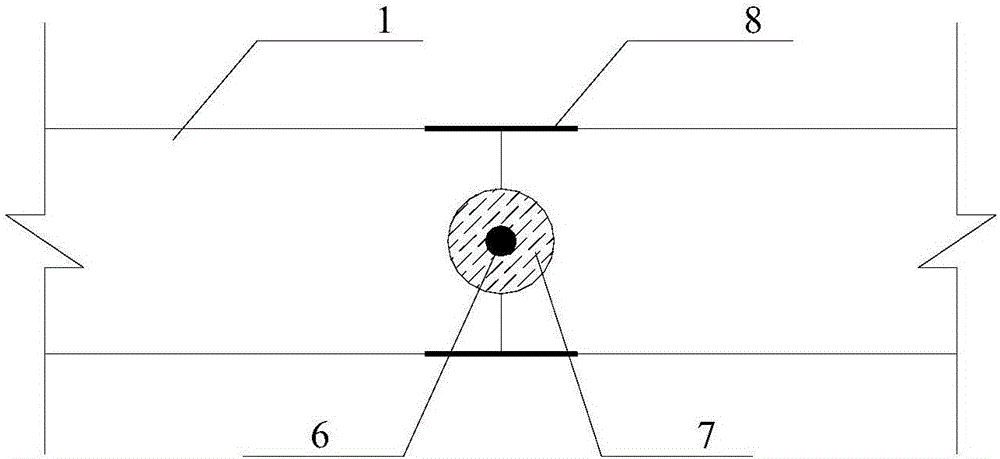

Lightweight partition board with net rack and fiber-reinforced hollows and splicing method thereof

InactiveCN105019597ASolve the adverse effects of earthquake resistanceEasy and flexible connectionBuilding componentsBuilding material handlingExpanded clay aggregateEngineering

The invention provides a lightweight partition board with a net rack and fiber-reinforced hollows and a splicing method thereof, and relates to the prefabricated partition boards of assembly type concrete structures in the field of architectural industrialization. The lightweight partition board comprises a board body, steel wire meshes, obliquely inserted bars, positioning grooves and cavities, wherein the obliquely inserted bars are fixedly connected with the upper steel wire mesh and the lower steel wire mesh to form the space net rack, the board body is formed by casting through ceramsite fiber concrete, and the upper surface and the lower surface of the board body are formed into natural rough surfaces through special formworks with foveolate protrusion structures. According to the lightweight partition board with the net rack and the fiber-reinforced hollows and the splicing method thereof, the problems that an existing partition board is prone to cracking, low in strength and high in water absorption are solved, the factory prefabrication can be achieved, the self weight is low, the flexible connection with a main body can be achieved, shock resistance can be better achieved, the construction is quick, the manufacturing cost is low, energy conservation and environment protection are achieved, safety and reliability are achieved, and sound insulation and heat preservation effects are good.

Owner:ANHUI XINHUA UNIV

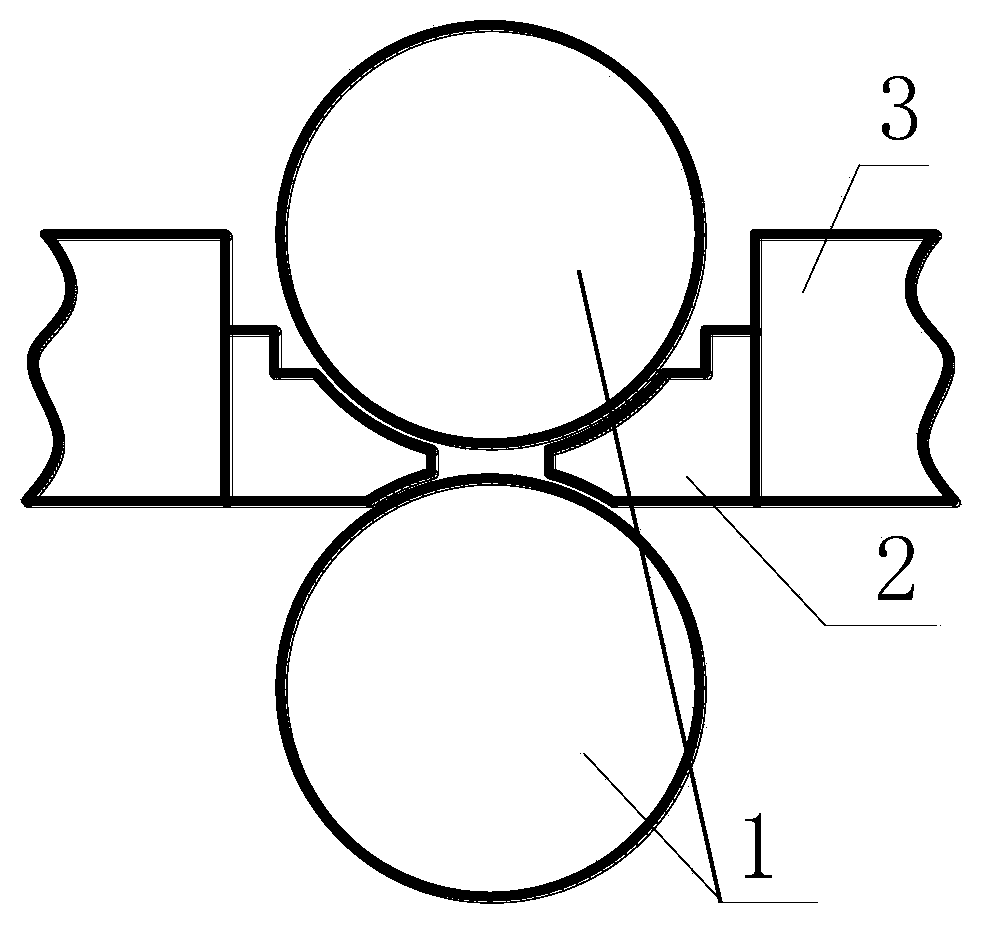

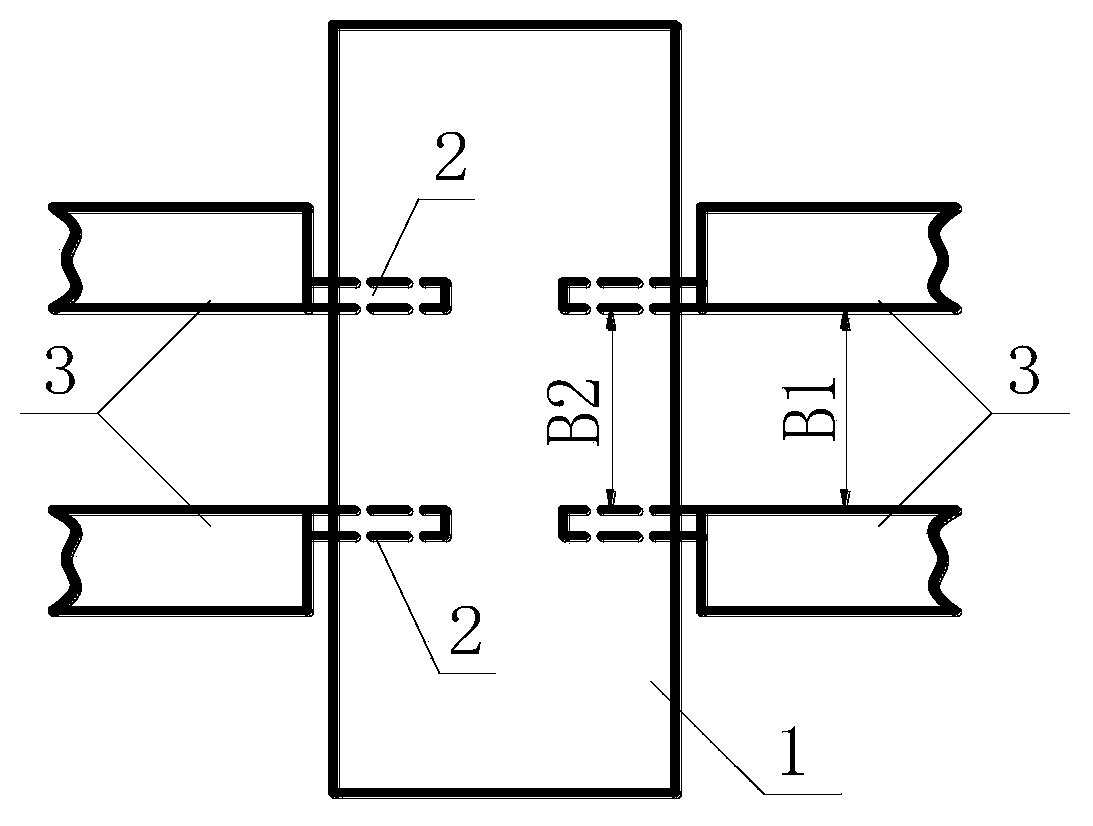

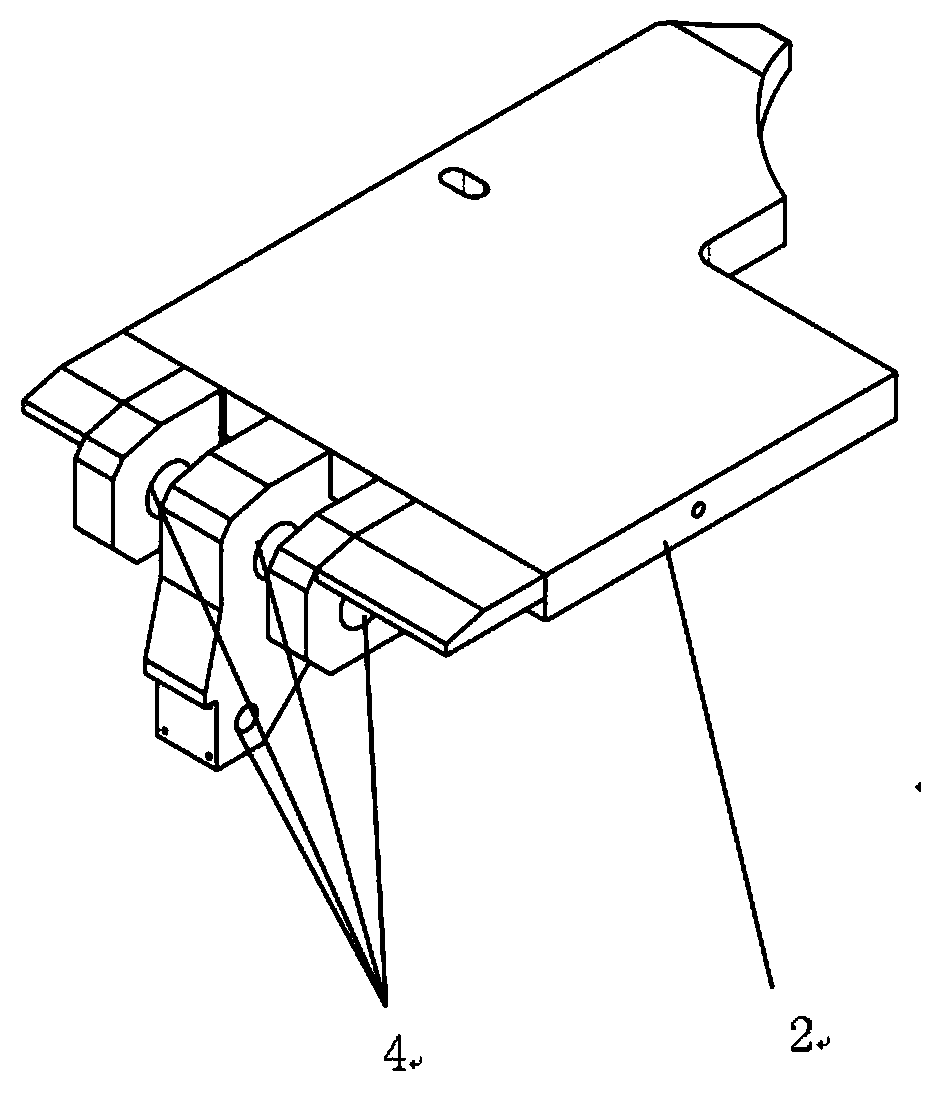

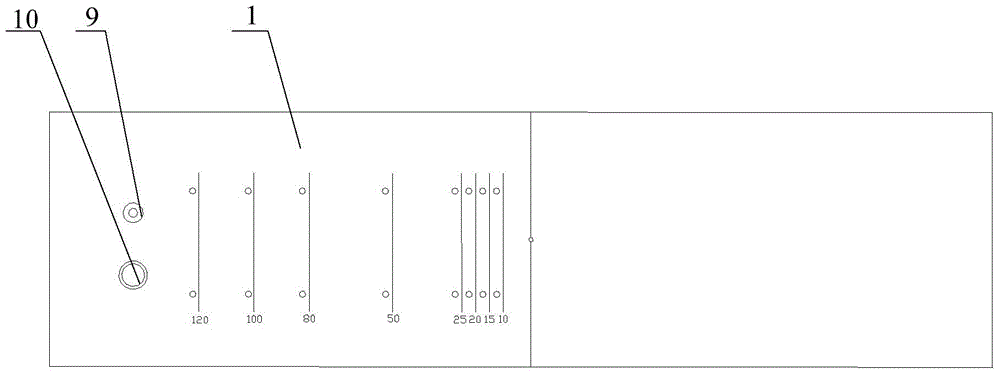

Method for employing large cross-section continuous casting round billet to roll round steel bar

InactiveCN104190706AOvercoming the defects of easy-to-fall steelHigh strengthMetal rolling arrangementsReduction ratioContinuous casting

The invention belongs to the field of iron steel processing and particularly relates to a method for employing large cross-section continuous casting round billet to roll a round steel bar. The method for employing the large cross-section continuous casting round billet to roll the round steel bar comprises the following steps: 1) clamping plates arranged on pushing beds are adopted to align the large cross-section continuous casting round billet with a rolling trough; the large cross-section continuous casting round billet is sent to a rough mill for rolling, so as to produce intermediate billet; from the third rolling pass of the rough mill, steel turning is carried out once in each odd-numbered pass ; 2) the intermediate billet is sent to finishing mills for rolling with 4-6 pressing passes, so as to produce finished round steel bar; the diameter Phi of the finished round steel bar is in a scope that is larger than or equal to 120 mm and is less than or equal to 150 mm; the rolling pass of the rough mill is the eleventh pass; the rolling passes of the finishing mills are 4-6 passes; or the diameter Phi of the finished round steel bar is in a scope that is larger than or equal to 160 mm and is less than or equal to 280 mm; the rolling pass of the rough mill is the thirteenth pass; the rolling passes of the finishing mills are 4-6 passes. The method for employing the large cross-section continuous casting round billet to roll round steel bar has the advantages of shallow-slot large rolling reduction cogging, high rolling efficiency, low rolling cost and energy conservation. The method for employing the large cross-section continuous casting round billet to roll round steel bar has an outstanding advantage that under equal specification, the reduction ratio of the finished round steel bar is large and the quality is good.

Owner:SHANDONG IRON & STEEL CO LTD

Dry forming process for purple clay porcelain

Owner:GUANGXI QINZHOU QIANQIU CERAMIC

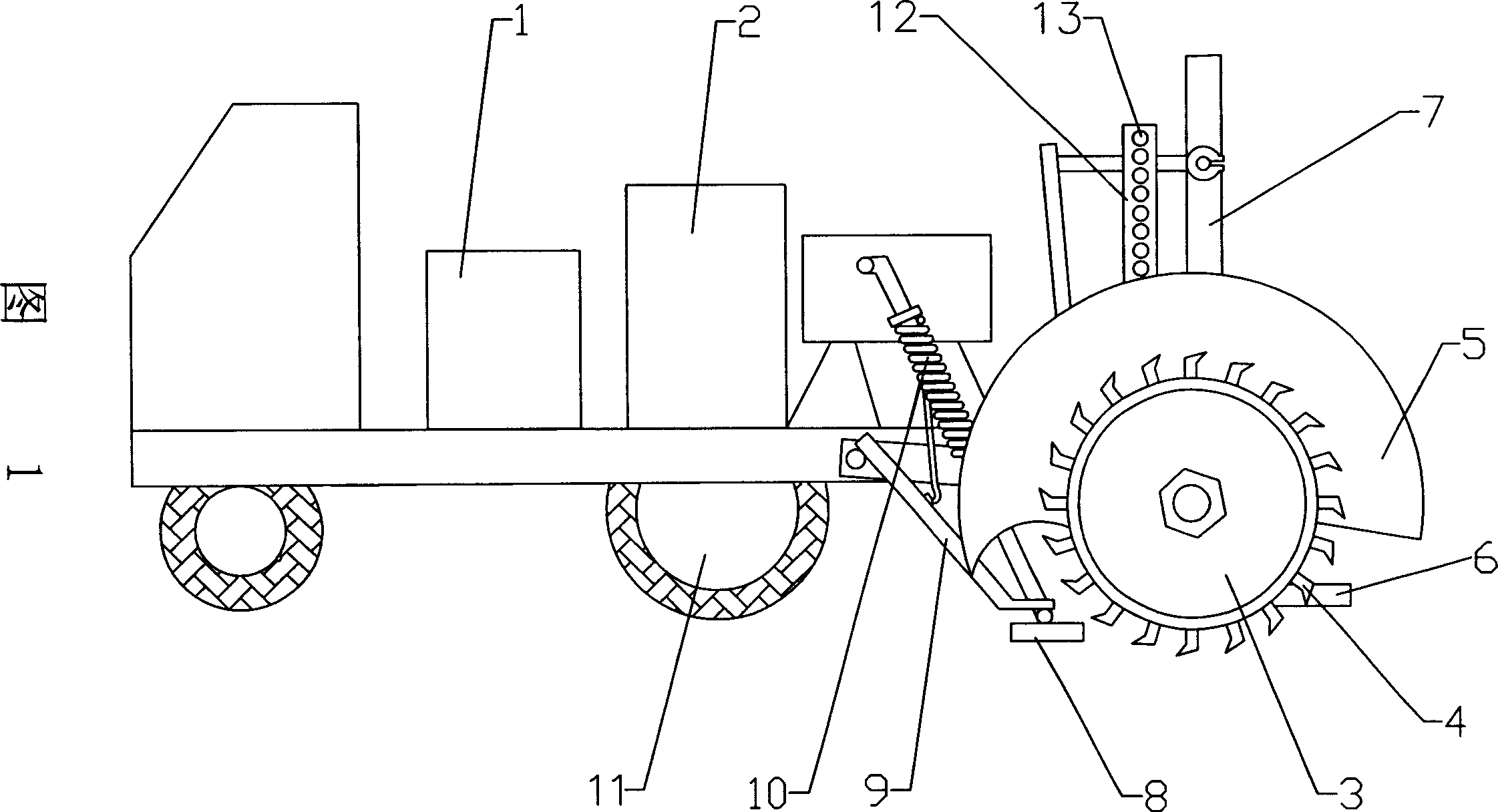

Groover

The invention discloses a groover, comprising vehicle body, power device and grooving device. Said power device, set on vehicle body, comprises engine and gearbox. Said grooving device comprises grooving rotary wheel and controlling mechanism. Driving device is set between power device and said grooving device on which tools are set. Controlling mechanism comprises depth controller for constraining groove depth, which can exactly limit depth of groove or pipe trench in need so that the dimension of grooved groove or pipe trench is more standard, and road surface protector, which can be used to protect un-grooving road surface, especially the road surface lay by granite or floor brick so as to protect road surface around the groove not damaging. Two columns or more than two columns of said tools are set on the surface of grooving rotary wheel so that the grooving efficiency is higher.

Owner:郝安阶

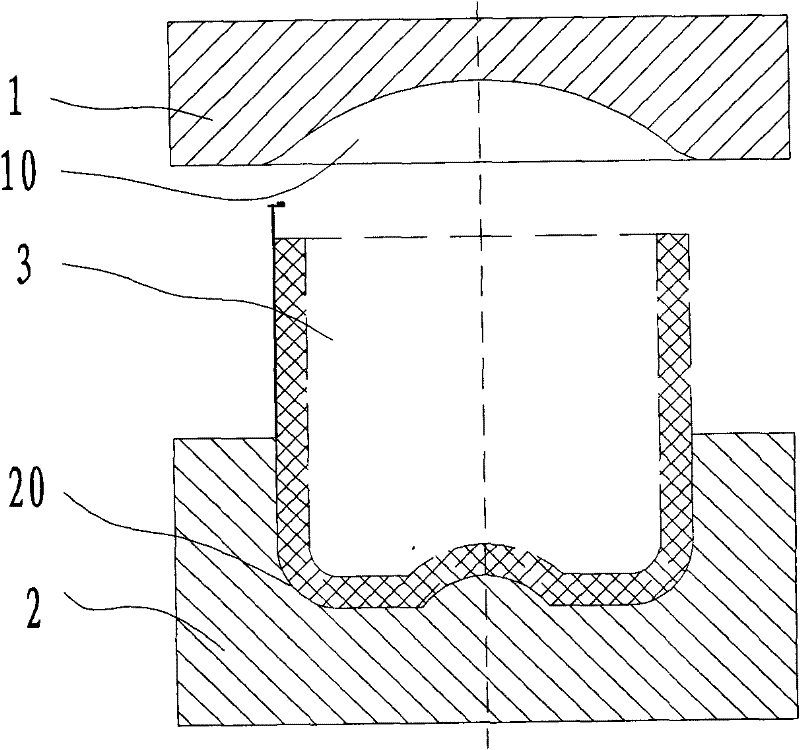

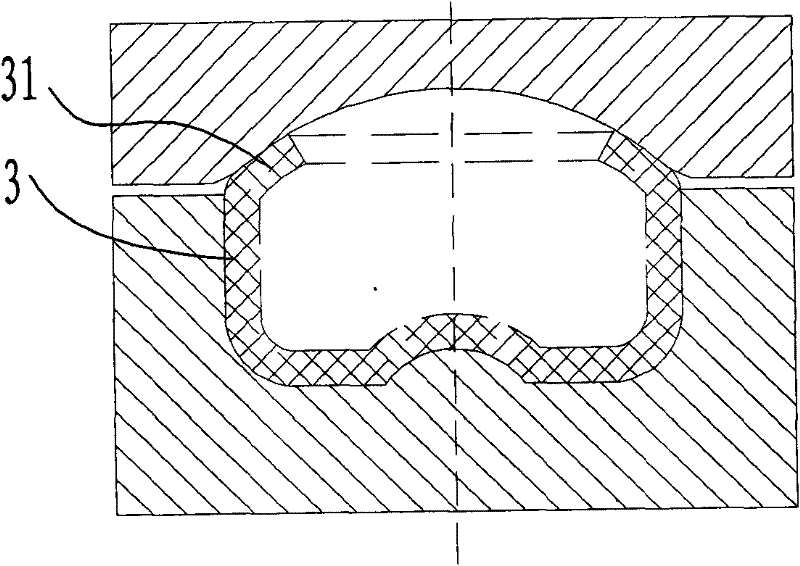

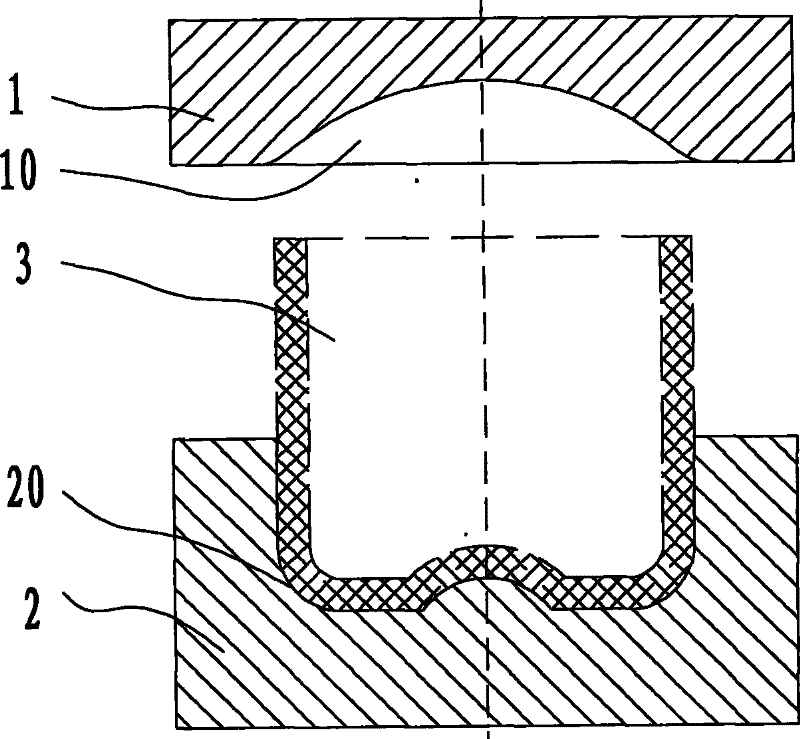

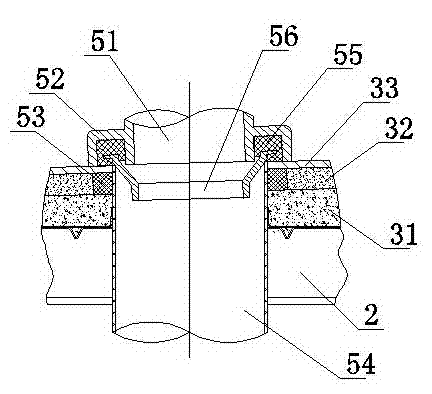

Opening closing mould of pressure equalizing barrel

InactiveCN102672044AImprove plastic deformation abilityImprove efficiencyShaping toolsFlangingAluminium alloy

The invention relates to an opening closing mould of a pressure equalizing barrel, and relates to an opening closing mould of an inward flanging of a barrel opening of a pressure equalizing barrel made of aluminum alloy material. The opening closing mould is characterized by simple structure and low cost, and comprises an upper mould and a lower mould, wherein the lower mould comprises a mould cavity which is identical to the surface outline of a barrel body on the lower part of the pressure equalizing barrel; the bottom surface of the upper mould is provided with a spherical-crown groove; and the maximal diameter of the notch of the spherical-crown groove is larger than the diameter of the barrel opening of the pressure equalizing barrel. According to the opening closing mould provided by the invention, material characteristics is combined; a mould pressing proposal using a stamping one-time forming method is disclosed; because the aluminum material has preferable plastic deforming capacity correspondingly to a cold board and a hot board, a smooth opening closing structure can be stamped for one time on a condition that the shape of the upper mould is suitable; situations such as draping, cracking and the like cannot be happened; and the opening closing mould is characterized by high mould efficiency, precise size, low cost and smooth appearance of a finished product.

Owner:JIANGSU YONGLONG ELECTRIC

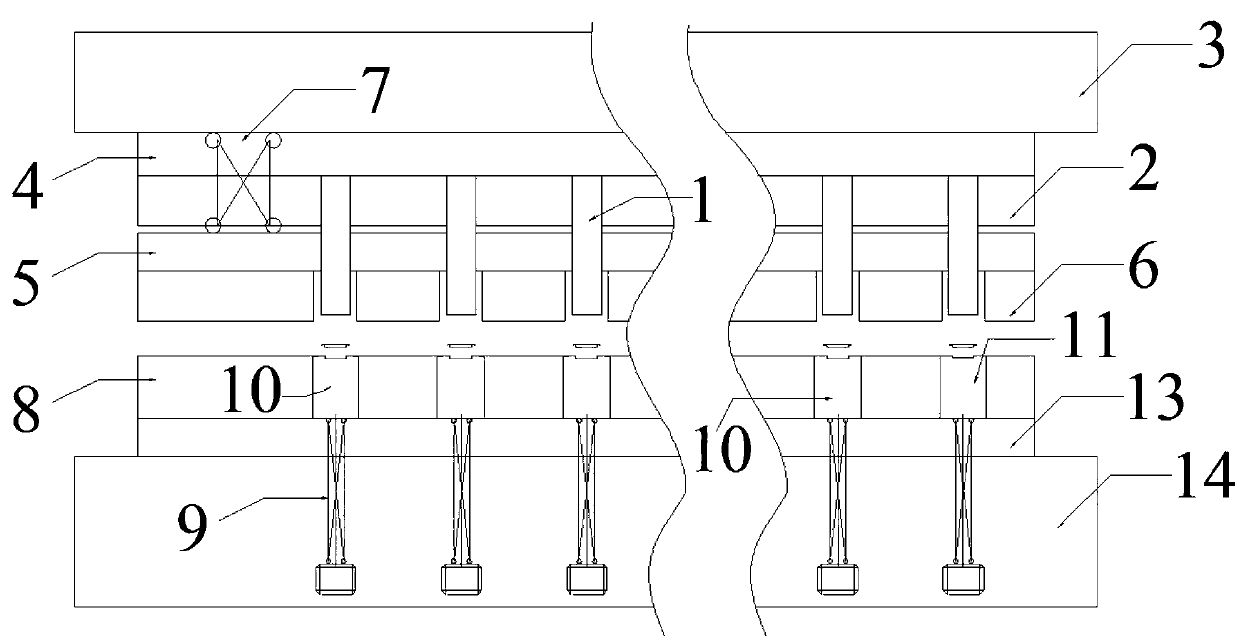

Continuous stamping die and stamping method for mobile phone camera component

The invention discloses a continuous stamping die and a stamping method for a mobile phone camera component. The continuous stamping die comprises an upper die set and a lower die set, the upper die set consists of a plurality of extrusion punches for completing a thinning process, the lower die set comprises a lower die plate and a plurality of lower die inserts corresponding to the extrusion punches, an upper plate surface of the lower die plate is horizontal, the lower die inserts include a plurality of thinning inserts and a restrike insert, and each of the thinning inserts and the restrike insert consists of a sunken pre-machining groove with vertical side walls. The stamping method mainly includes a, pre-machining a material by multiple times by cooperation of the thinning inserts and the corresponding extrusion punches; and b, finally machining the material by the restrike insert and the corresponding extrusion punch, and directly machining the material to form a final product with the target side. The continuous die is adopted, the product is finally formed after a plurality of pre-machining steps, and is low in deformation, standard in size and high in quality, a nitrogen spring is small in size, high in elasticity and constant in spring force, sufficient pressing force is guaranteed during shape punching, and accordingly the product is excellent in flatness.

Owner:KUNSHAN SANJING SCI & TECH

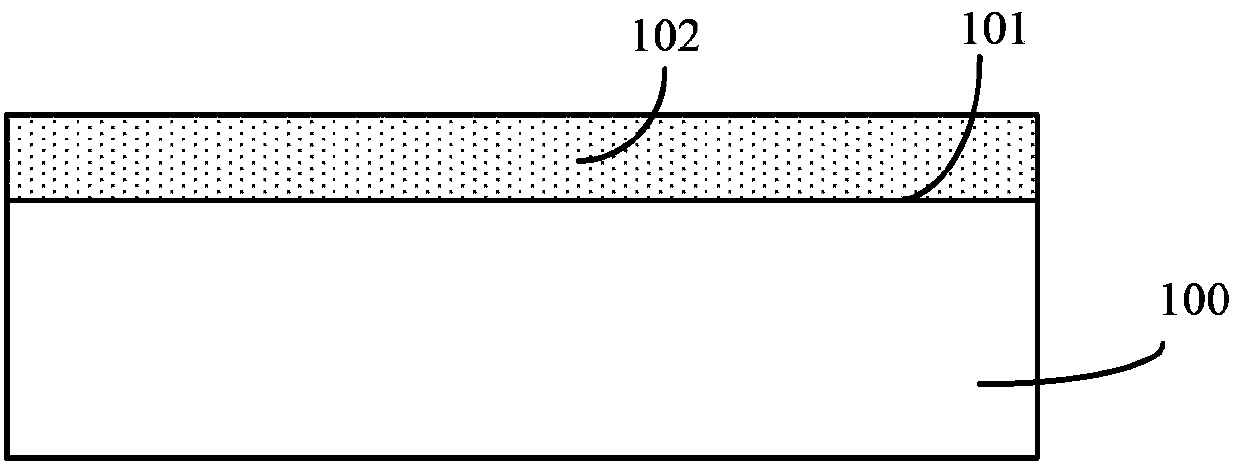

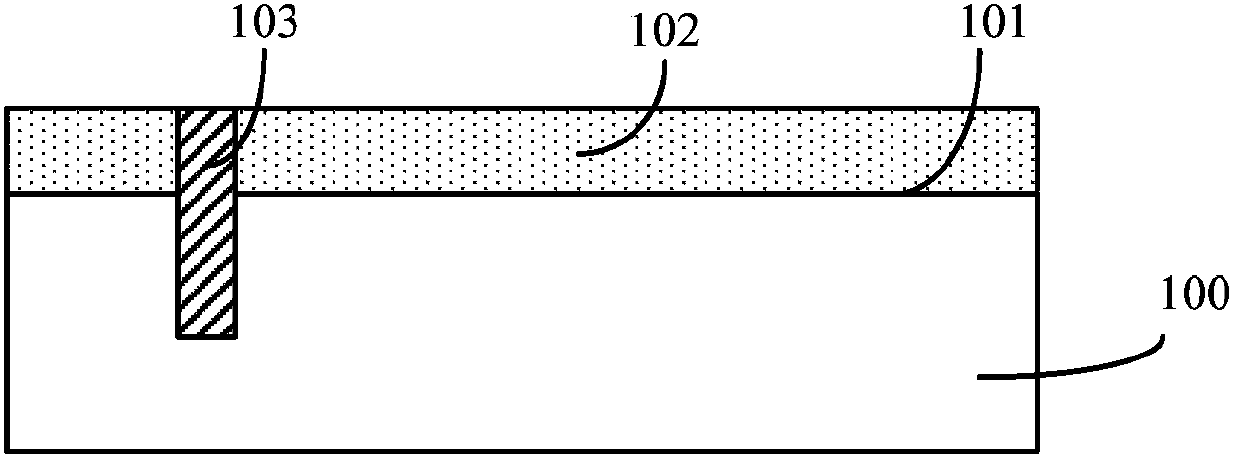

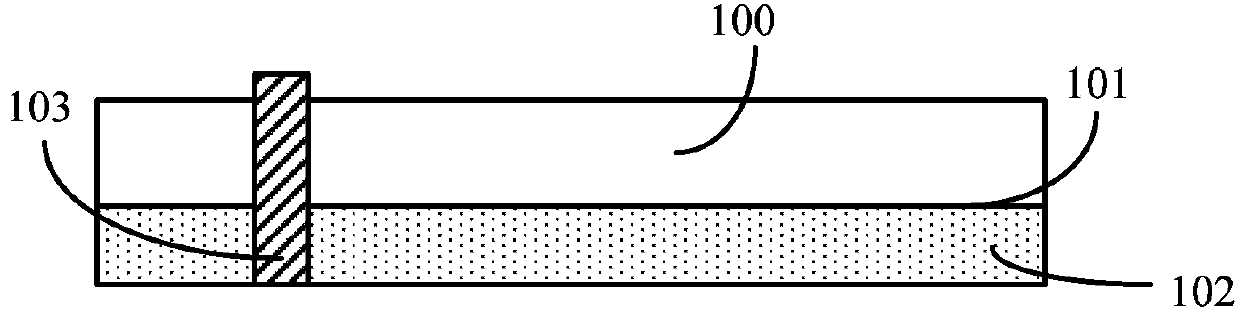

Formation method for semiconductor structure

ActiveCN103633017AImprove performanceSize standardSemiconductor/solid-state device manufacturingPower semiconductor deviceSemiconductor structure

Provided is a formation method for a semiconductor structure. The formation method comprises that: a semiconductor substrate is provided; ion injection is performed on the semiconductor substrate, and a stop layer is formed inside the semiconductor substrate; after the stop layer is formed, a device layer is formed on a first surface of the semiconductor substrate; a conductive plug is formed in the device layer and the semiconductor substrate, wherein the conductive plug is contacted with the stop layer; after the conductive plug is formed, a second surface of the semiconductor substrate is chemically-mechanically polished until the stop layer is exposed, where in the second surface is opposite to the first surface; the stop layer and partial semiconductor substrate are removed so that the conductive plug is protruded out of the second surface of the semiconductor substrate; and after the stop layer and the partial semiconductor substrate are removed, a passivation layer is formed on the second surface of the semiconductor substrate, wherein the surface of the passivation layer is leveled with the top part of the conductive plug. Size of the formed semiconductor device is controllable, and the semiconductor device is stable in performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

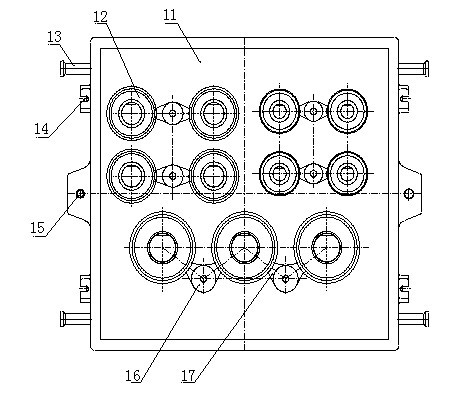

One-box multi-cast plate and casting method

InactiveCN102652986ASmall shape errorClamping error is smallMoulding flasksUtilization rateMaterials science

The invention discloses a one-box multi-cast plate and a casting method, belongs to the technical field of casting molds and casting methods, and is used for a one-box multi-cast process. According to the technical scheme, the one-box multi-cast plate comprises an upper template and a lower template, wherein a plurality of upper part models and an upper pouring opening model are processed on the upper template; a plurality of lower part models and a lower pouring opening model are processed on the lower template; the upper part models and the lower part models are matched with each other; the upper pouring opening model and the lower pouring opening model are matched with each other; and sand box positioning devices are respectively arranged on two sides of the upper template and the lower template. The casting method comprises the steps of: preparing the designed templates for shaping; after shaping is finished, correcting a cavity; smearing fireproof materials in the cavity; and pouring. The process is simple; the shaping efficiency is greatly improved, and the utilization rate of casting sand is greatly improved; a standard sand box is beneficial to automatic casting; due to the high-precision templates, the blank precision of a casting is improved; and the one-box multi-cast plate can meet various requirements of castings with different shapes.

Owner:河北木源泵业有限责任公司

Five-station automatic rotary machine tool and part machining method applying same

InactiveCN104647036AReduce labor costsUniform sizeOther manufacturing equipments/toolsLarge fixed membersEngineeringMachining process

The invention relates to the technical field of machining equipment and discloses a five-station automatic rotary machine tool. The machine tool comprises a rotary work table and five stations. Five tools are arranged on the work table on a machine head, the five stations are arranged on the outside of the rotary work table respectively, and the location positions of the rotary work table are corresponding to the five stations respectively. The invention further discloses a part machining method applying the five-station automatic rotary machine tool. By means of the machine tool and the method, four machining processes of parts can be completed by only one operator, so that labor costs are saved, full-automatic machining is performed, the product sizes are uniform and standard, the machine tool is compact in structure and convenient to operate, and product machining efficiency is high.

Owner:YUYAO GOLDEN SUN TOOLS

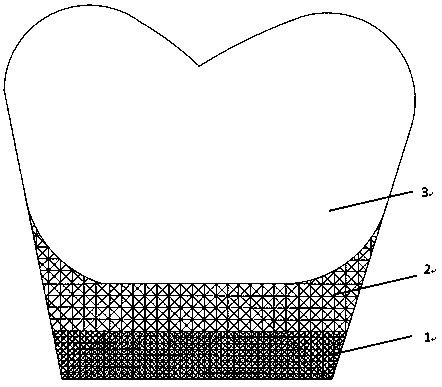

Method for 3D printing of rapidly renewable cobalt-chromium alloy coated tooth

PendingCN109464205AFast preparationHigh precisionImpression capsArtificial teethCarbon nanotubeBiocompatibility Testing

The invention discloses a method for 3D printing of a rapidly renewable cobalt-chromium alloy coated tooth. Laser scanning is adopted to assist manufacturing of an individual false tooth model, by using a 3D printing technique, zirconium dioxide powder is mixed with a small amount of graphene and carbon nanotube powder to make a false tooth main body, cobalt-chromium alloy powder is mixed with a small amount of the graphene and the carbon nanotube powder to make a false tooth base which is small and large gradually, and coating treatment is carried out on the false tooth base. The problems that a pure metal material is not attractive in appearance, a pure ceramic material is too crispy and long in recovery period after implanting can be overcome, people can feel that a false tooth and gingiva grow together, and an individual false tooth which is high in precision, good in wearing resistance, good in acid-alkali resistance, high in mechanical strength and good in biocompatibility can befinally manufactured.

Owner:SHANDONG JIANZHU UNIV

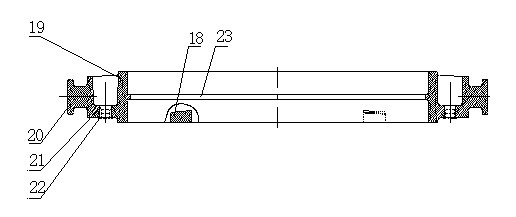

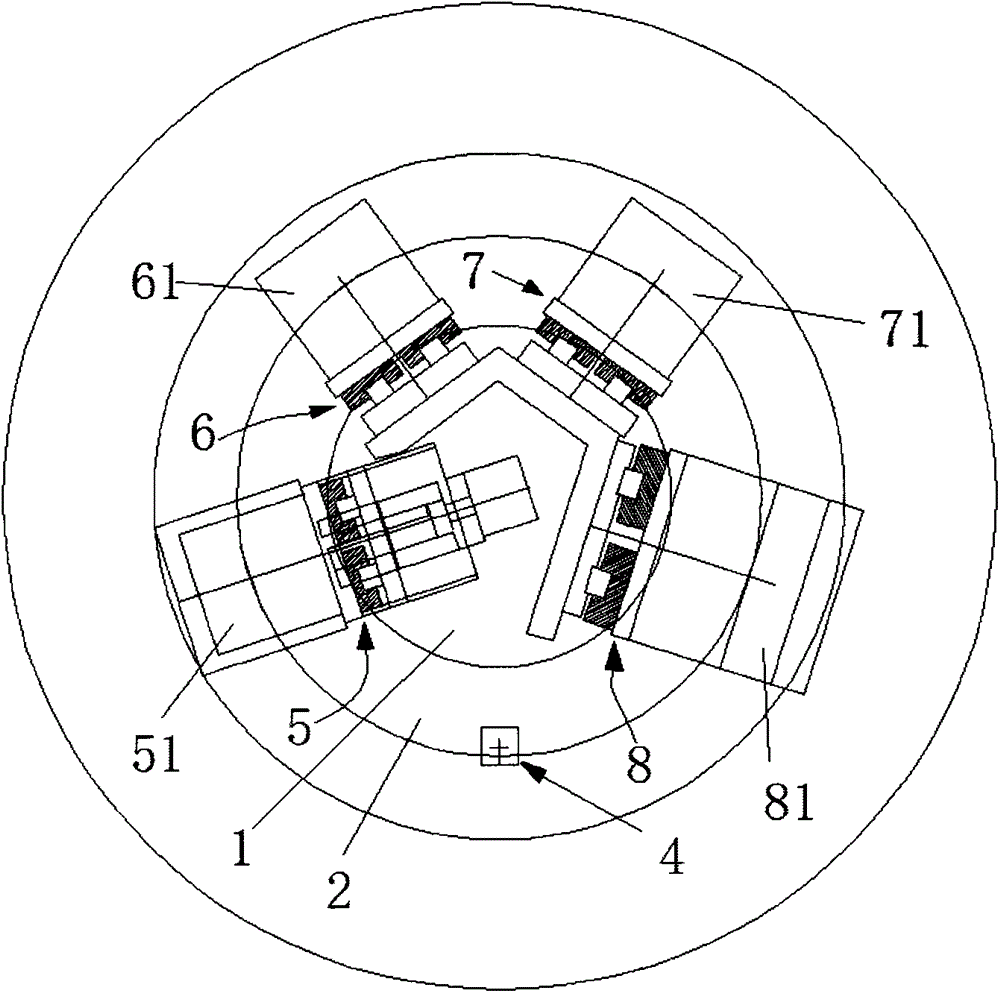

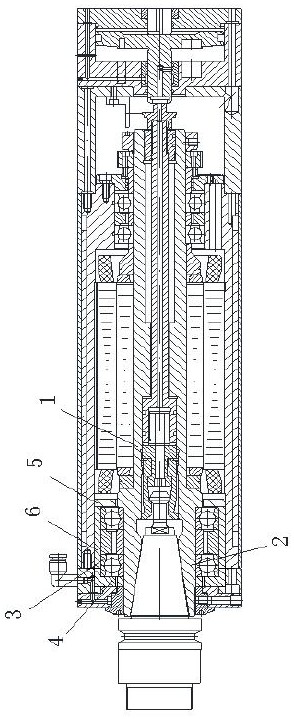

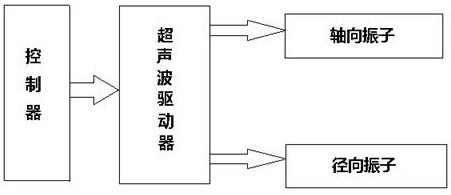

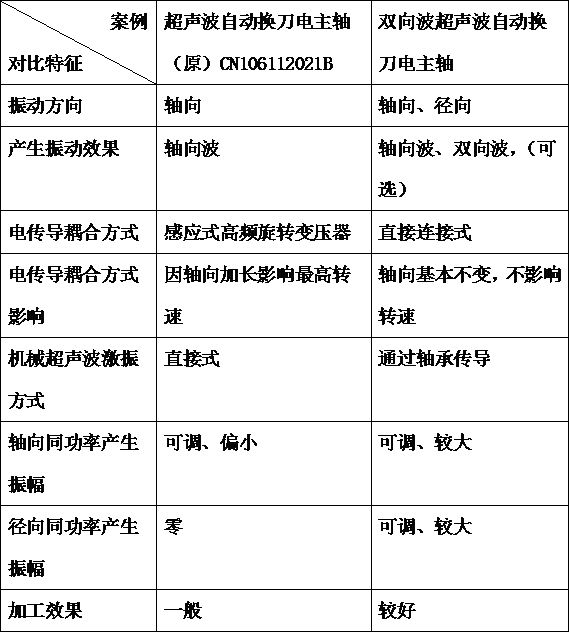

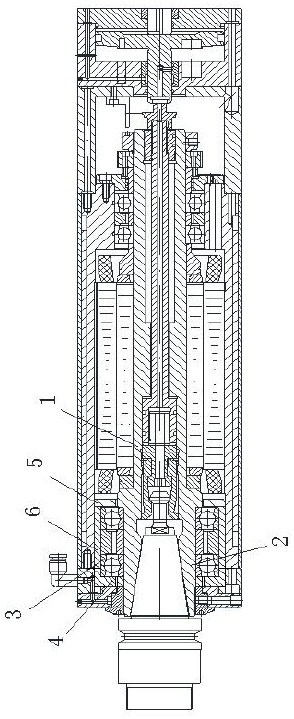

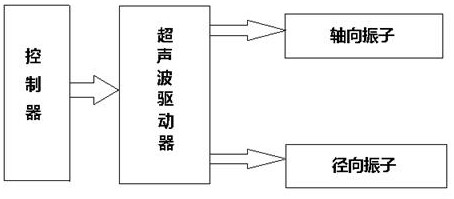

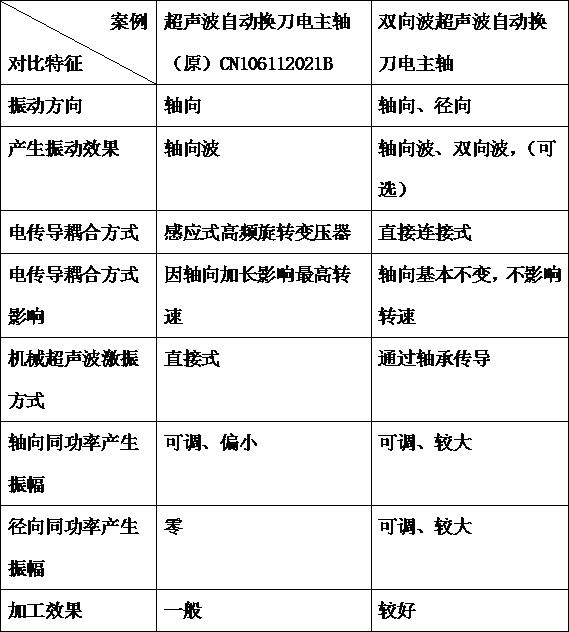

Two-way wave ultrasonic automatic tool change electric spindle

ActiveCN113560611BSimple structureSize standardMechanical vibrations separationLarge fixed membersRotor (electric)Acoustics

Owner:常州捷乾机电科技有限公司

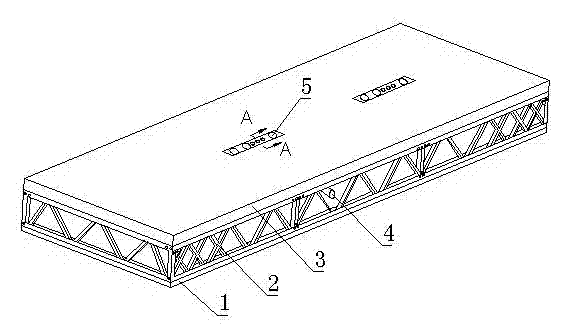

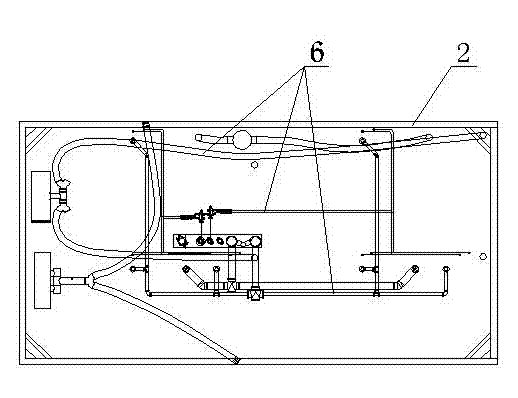

Floor slab with preinstalled pipelines

The invention relates to a floor slab with preinstalled pipelines. The floor slab comprises a steel structure frame plate, a floor and a ceiling. The floor is arranged on the steel structure frame plate and composed of a concrete layer, a waterproof mortar layer and a floor tile layer. The floor slab is prefabricated and massively produced in a factory and is high in productivity, reliable in quality, uniform in size, good in waterproof effect of pipeline connectors, firm in sealing, and long in service life.

Owner:张跃

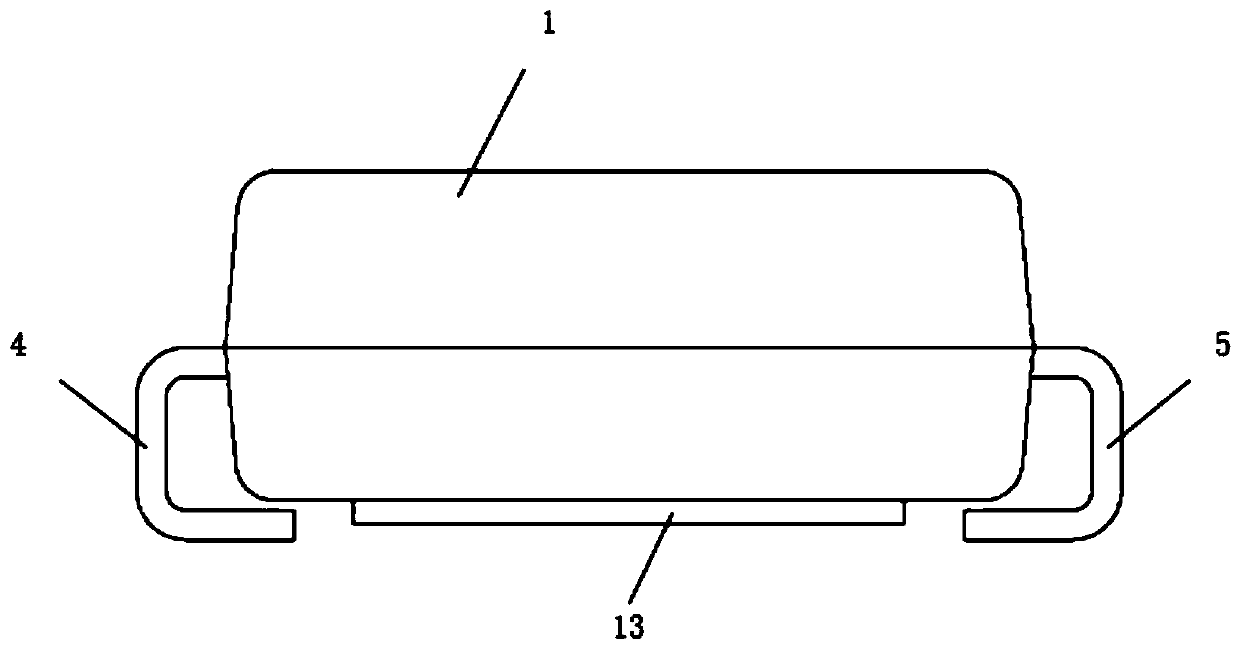

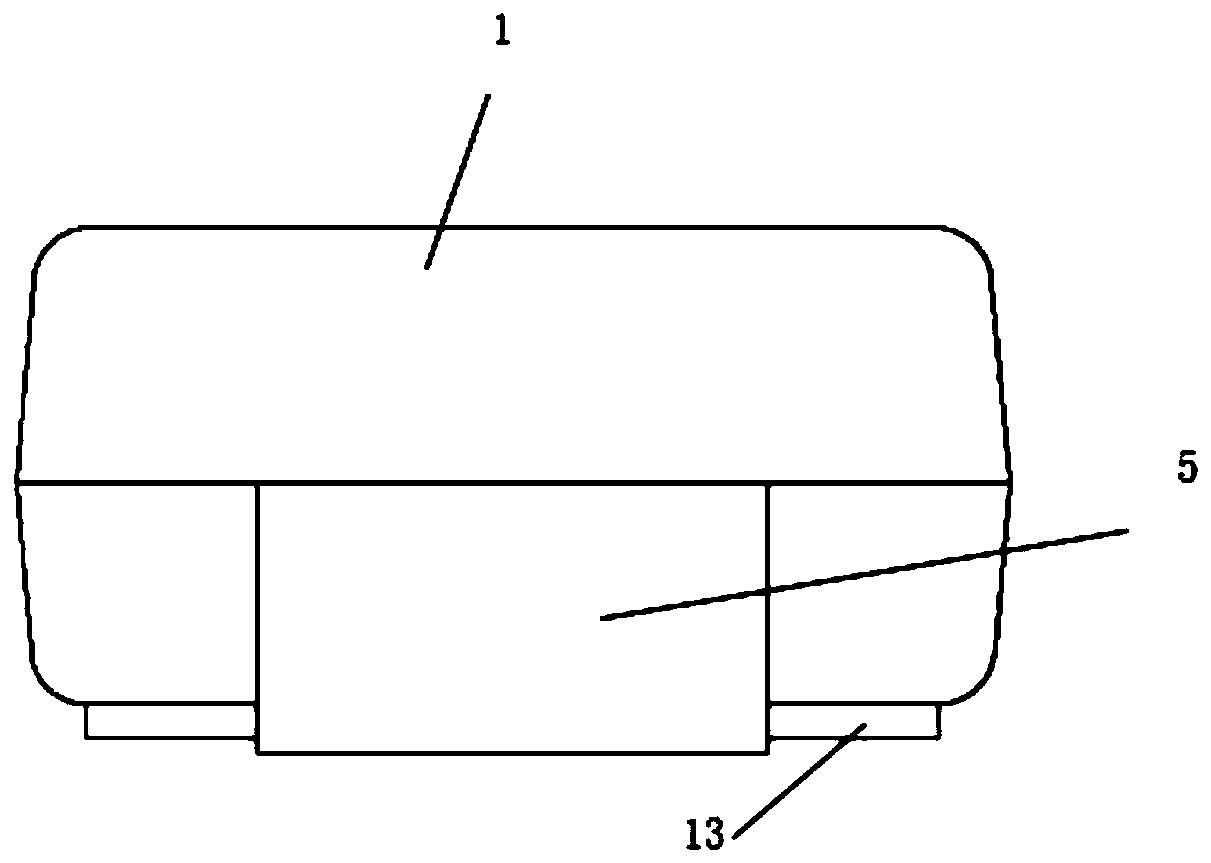

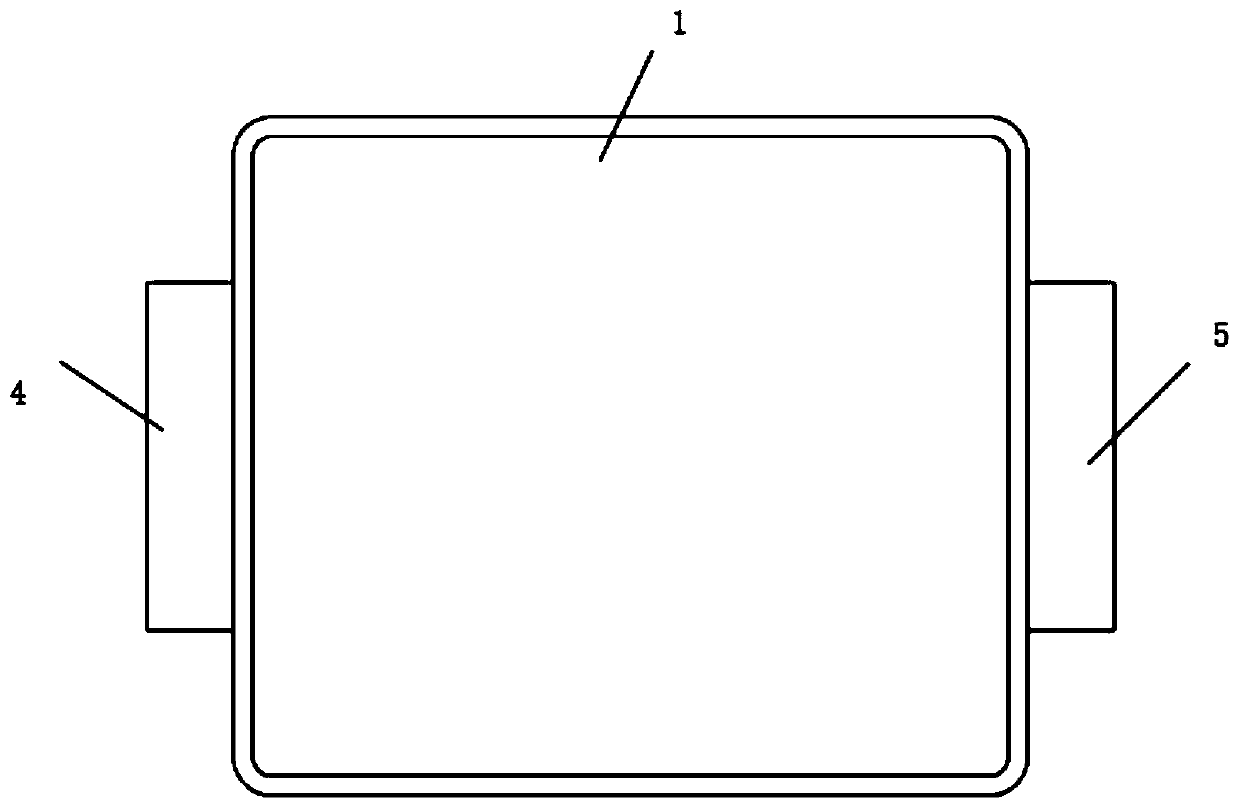

Ceramic capacitor

InactiveCN110676050AReduce volumeImprove assembly efficiencyFixed capacitor dielectricFixed capacitor housing/encapsulationCapacitive effectMetallic electrode

The invention relates to a ceramic capacitor which comprises a plastic package body 1, a first metal electrode layer 2, a second metal electrode layer 3, a first metal pin 4, a second metal pin 5 anda single-layer ceramic medium 6. The first metal electrode layer 2 and the second metal electrode layer 3 are respectively attached to the two opposite surfaces of the single-layer ceramic medium 6. The first metal pin 4 and the second metal pin 5 are respectively welded and electrically communicated with the first metal electrode layer 2 and the second metal electrode layer 3. The ceramic capacitor is an SMD package. The electrode layers are arranged on the two sides of the single-layer ceramic medium, and the electrode layers are connected through the pins to generate electric fields on thetwo electrode layers so that the capacitive effect is generated between the two pins. The single-layer ceramic medium and the SMD packaging are selected so that the ceramic capacitor has the advantages of small volume, more standardized product size, high assembling efficiency, high yield and good high frequency performance.

Owner:四川特锐祥科技股份有限公司

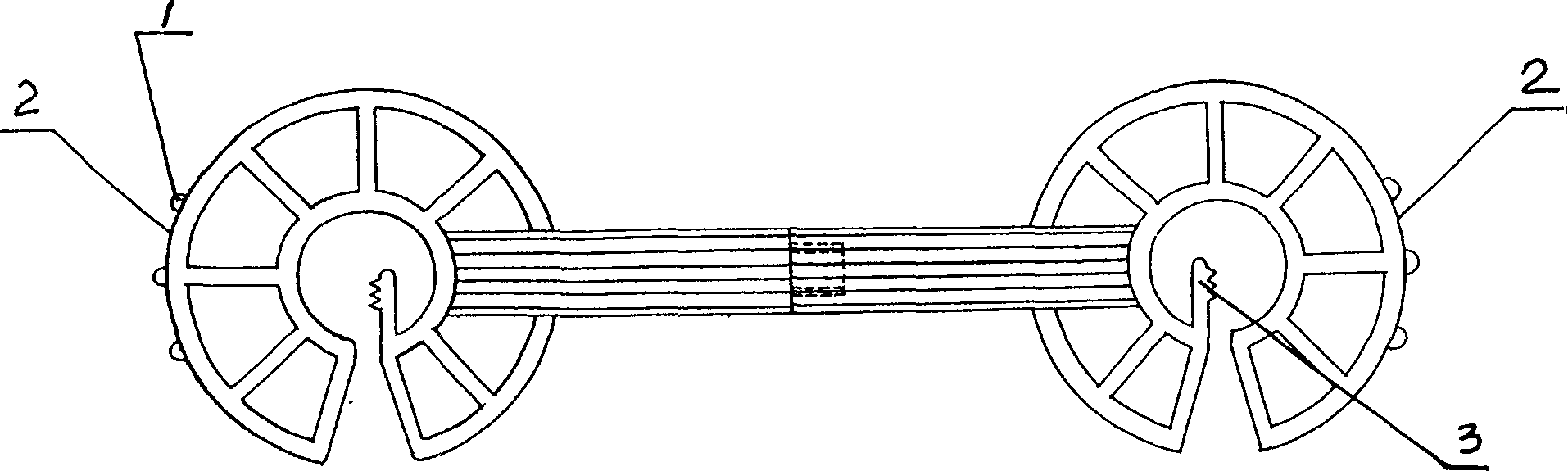

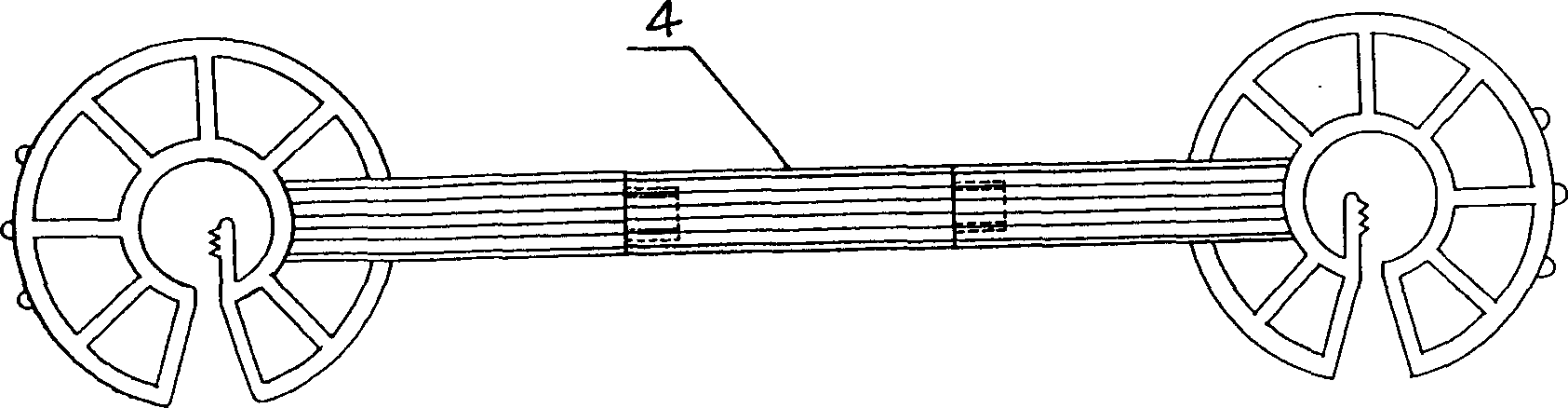

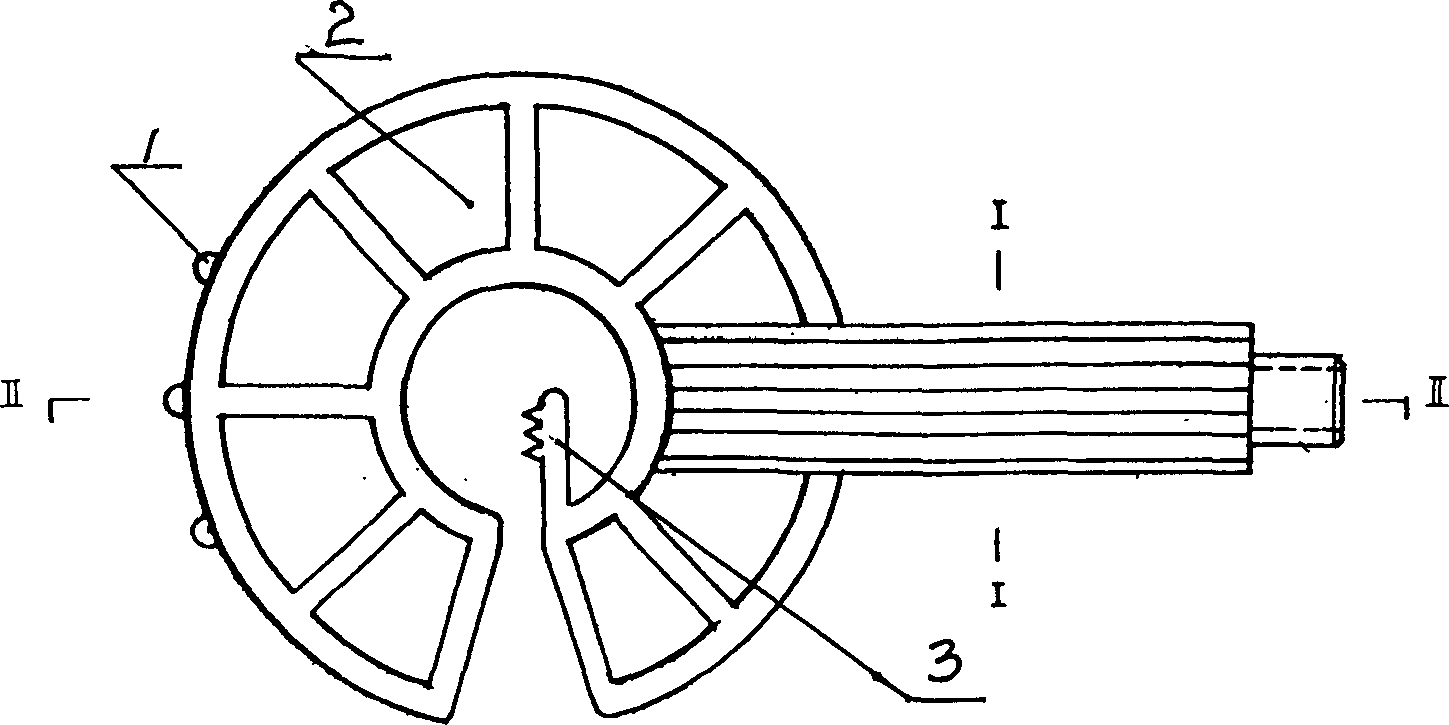

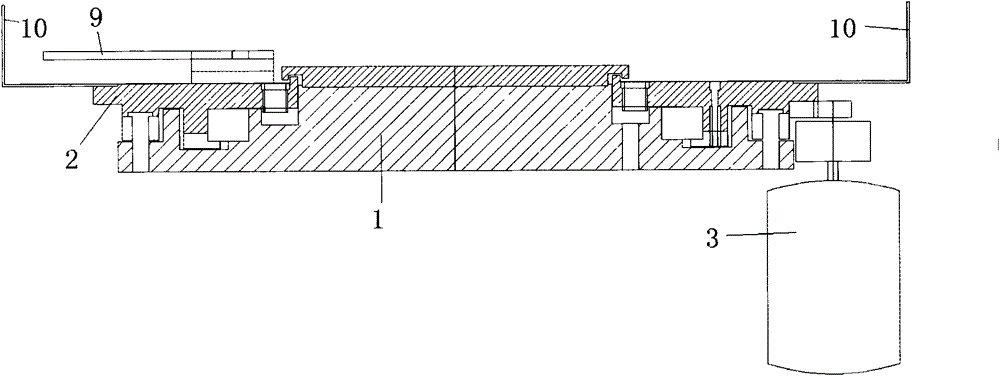

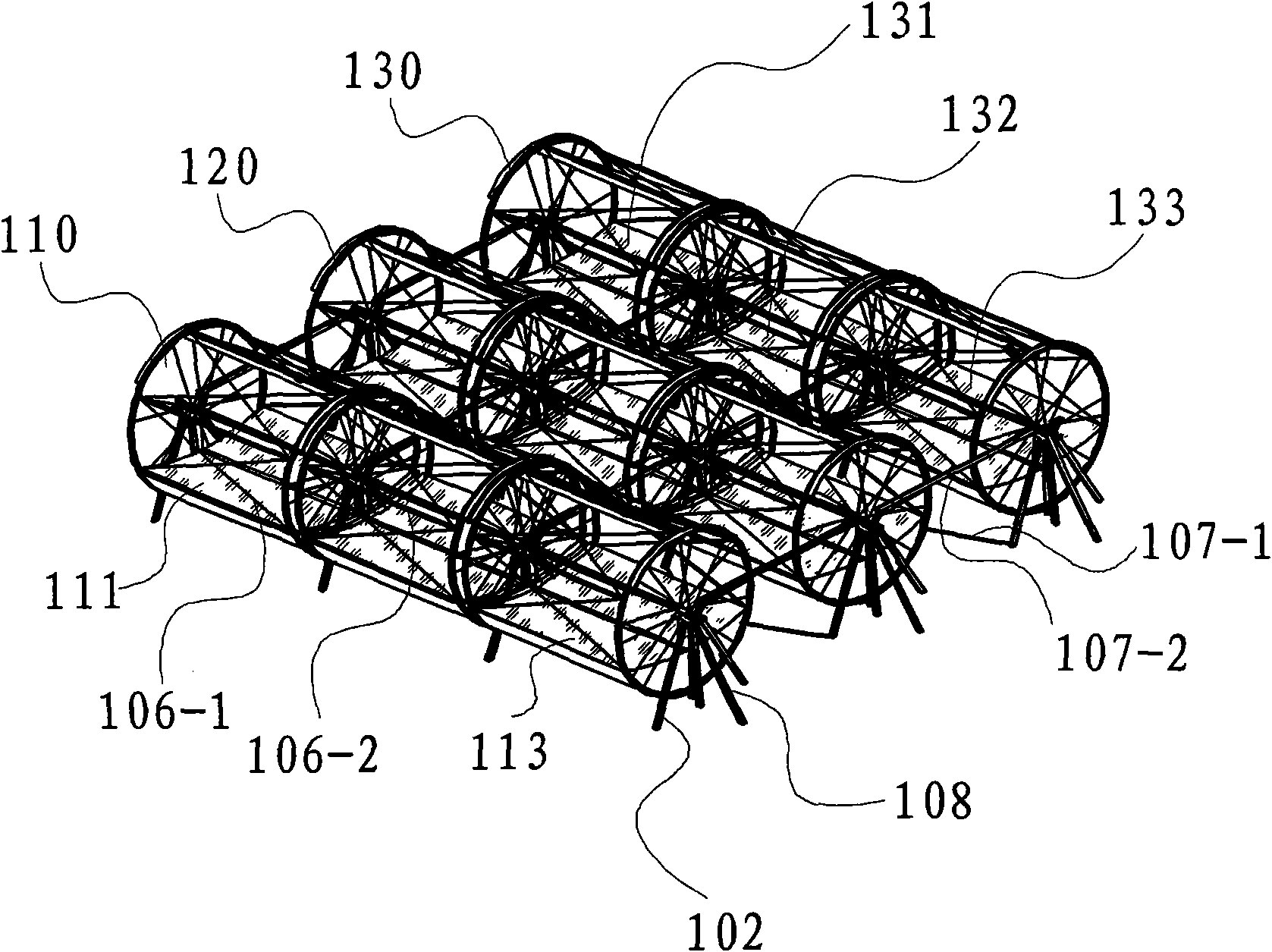

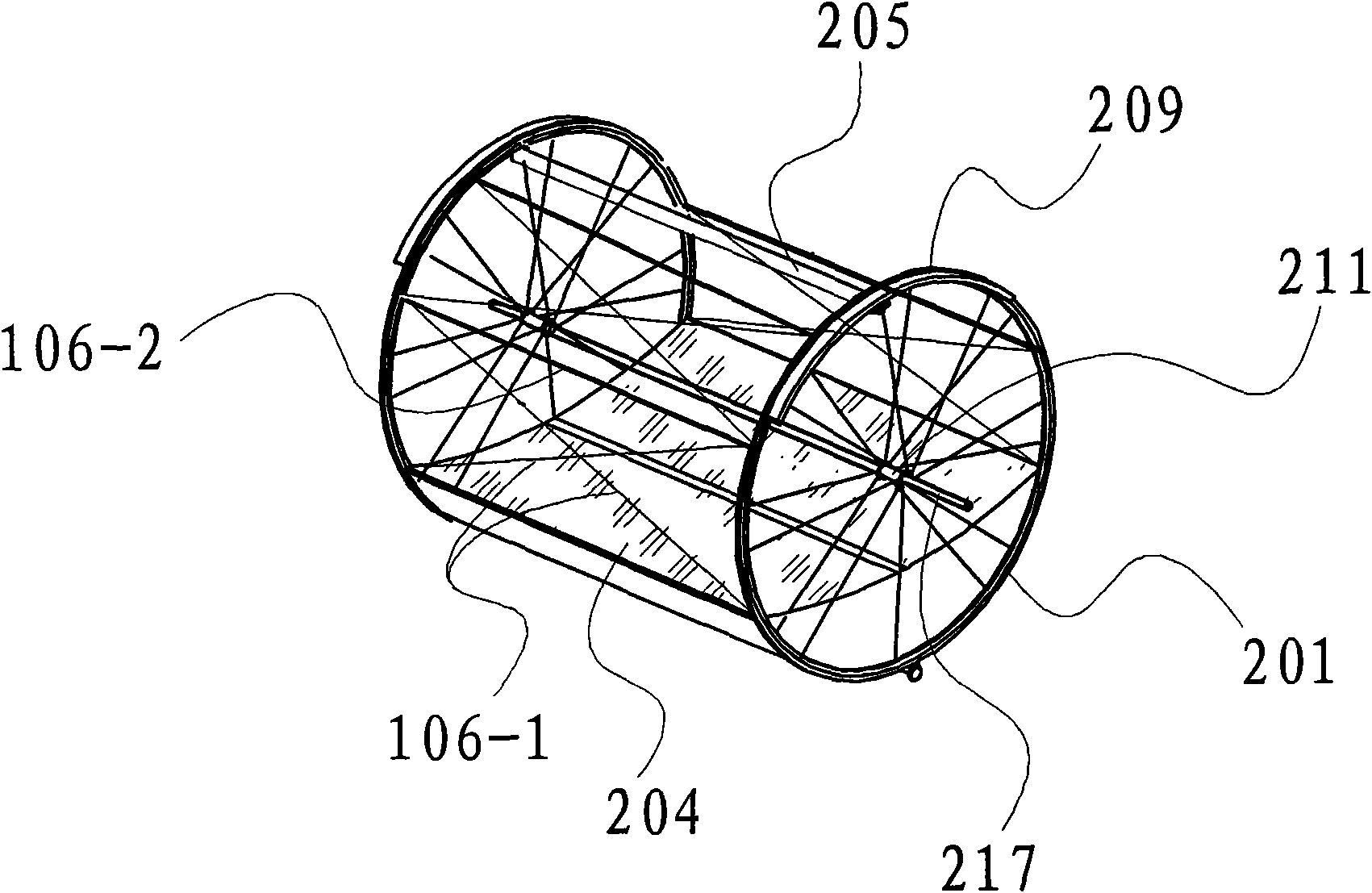

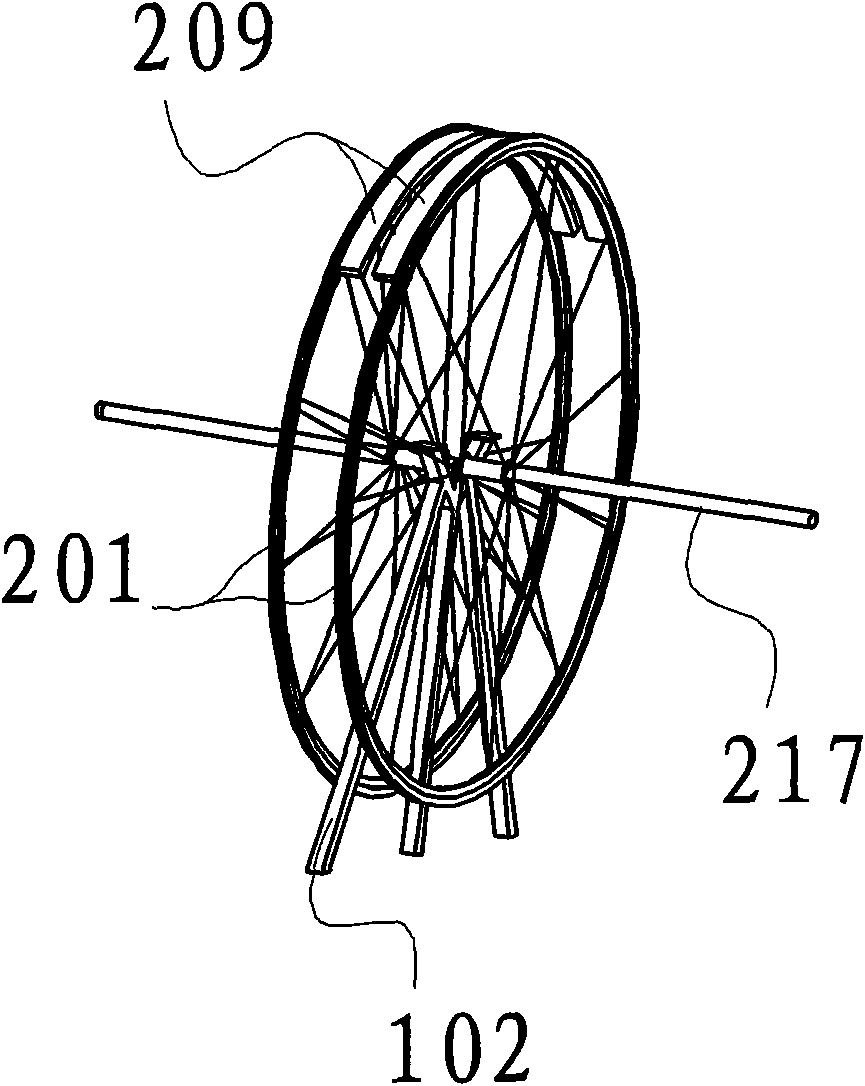

Solar energy collecting equipment and application thereof

InactiveCN102374680AHigh mechanical strengthImprove stabilitySolar heat devicesPhotovoltaicsWorkloadAdverse weather

The invention disclosed solar energy collecting equipment. The solar energy collecting equipment comprises at least two spoke wheels, a central supporting shaft, a solar energy condenser, a receiver and a basic supporting structure, wherein the two spoke wheels comprise a first spoke wheel and a second spoke wheel which are arranged in opposite directions, are spaced in parallel, and are relatively fixed by a connecting piece; the central supporting shaft passes through the first spoke wheel and the second spoke wheel; the solar energy condenser is arranged between the first spoke wheel and the second spoke wheel and is fixed on rims of the first spoke wheel and the second spoke wheel; the receiver is fixed between the first spoke wheel and the second spoke wheel, is positioned on a focal line of the solar energy condenser, and is used for absorbing sunlight reflected by the condenser; the basic supporting structure is used for supporting the at least two spoke wheels; and the first spoke wheel, the second spoke wheel, the solar energy condenser and the receiver can be rotated together so as to track and concentrate sunrays. The solar energy collecting equipment is easy to manufacture, has standardized size and low field assembly workload, is suitable for modular production, is extremely convenient to assemble and maintain, can be operated in multiple kinds of adverse weather and is suitable for large-scale popularization and application.

Owner:BEIJING TERASOLAR PHOTOTHERMAL TECH CO LTD

Foamed plastic cutting device

InactiveCN104669361AQuality improvementAvoid bumpingMetal working apparatusEngineeringElectrical and Electronics engineering

The invention provides a foamed plastic cutting device. The foamed plastic cutting device comprises a working table, a positioning unit arranged on the working table for positioning a group of opposite sides of foamed plastic, an electrically heated wire for cutting the foamed plastic, and an electrical heating unit for heating the electrically heated wire. When the foamed plastic cutting device works, the foamed plastic is positioned on the working table through the positioning unit, the heating unit is started for heating the electrically heated wire, and the foamed plastic is pushed to be cut by the electrically heated wire when the temperature of the electrically heated wire reaches the required temperature. The foamed plastic cutting device uses the electrically heated wire is used for cutting and the heat and the linear structure of the electrically heated wire are used for effectively avoiding the uneven cutting surface of the foamed plastic, thereby improving the quality of the foamed plastic. In addition, the size of an obtained sample can be standard by ensuring the smooth cutting surface of the foamed plastic.

Owner:GREE ELECTRIC APPLIANCES INC

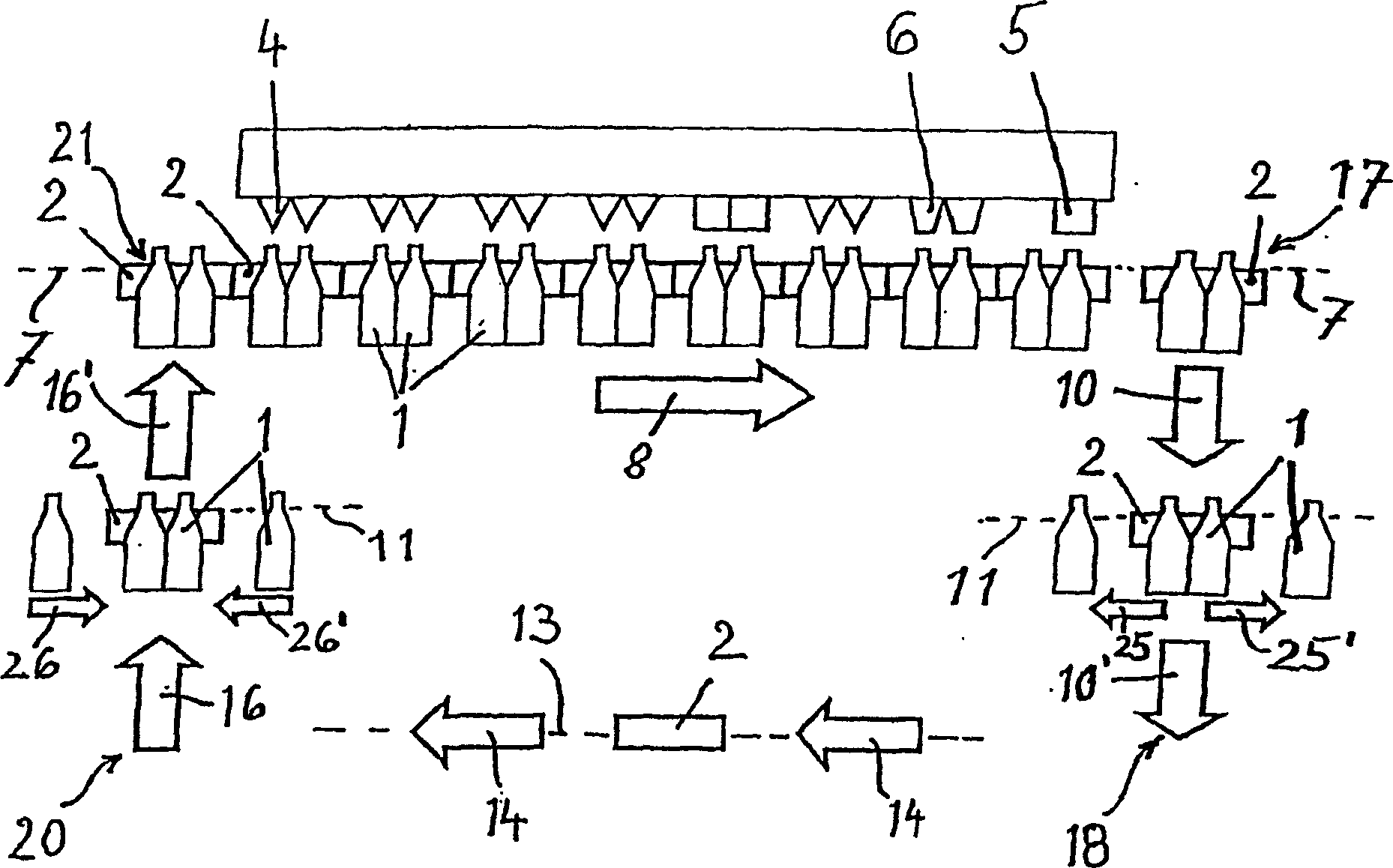

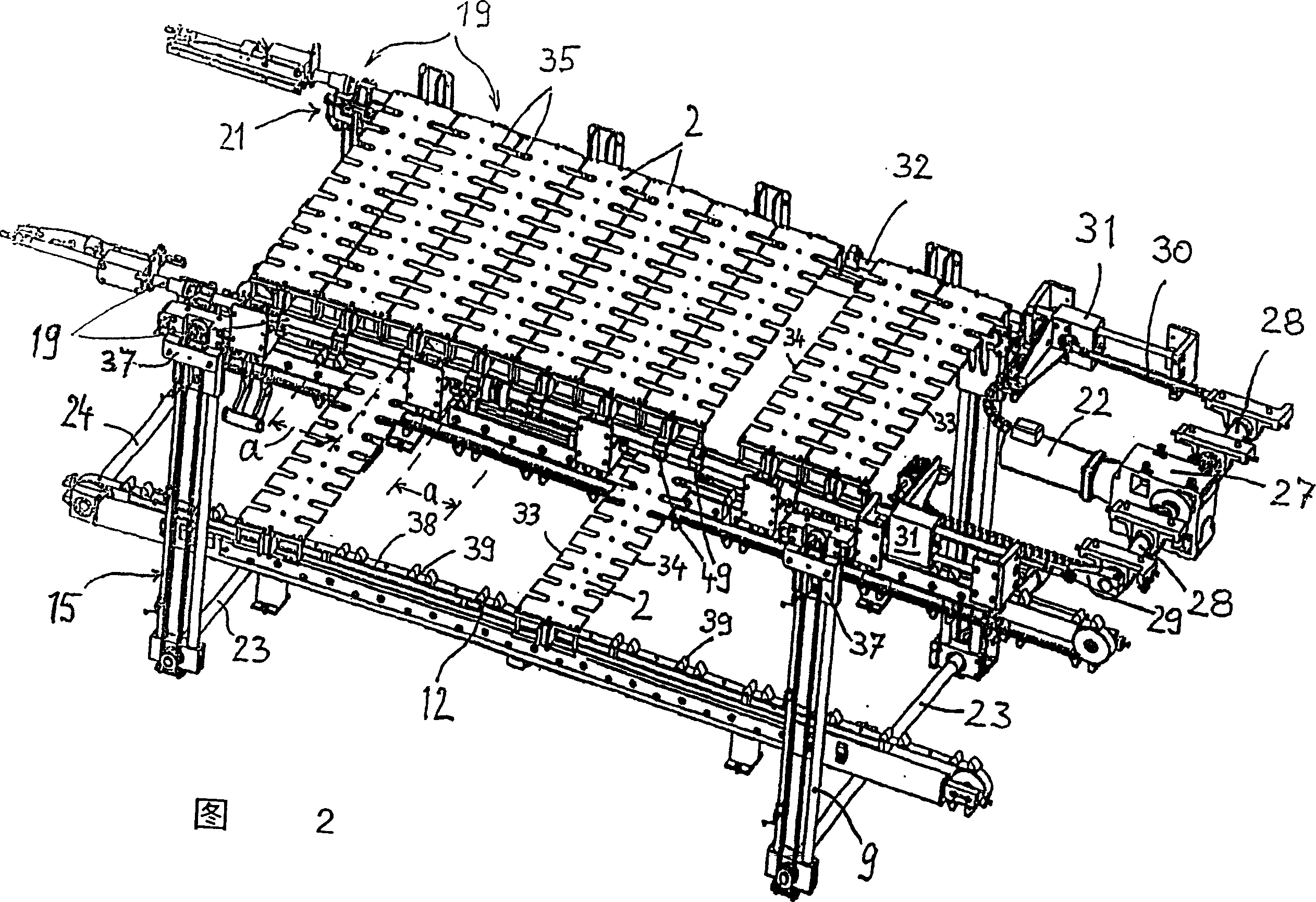

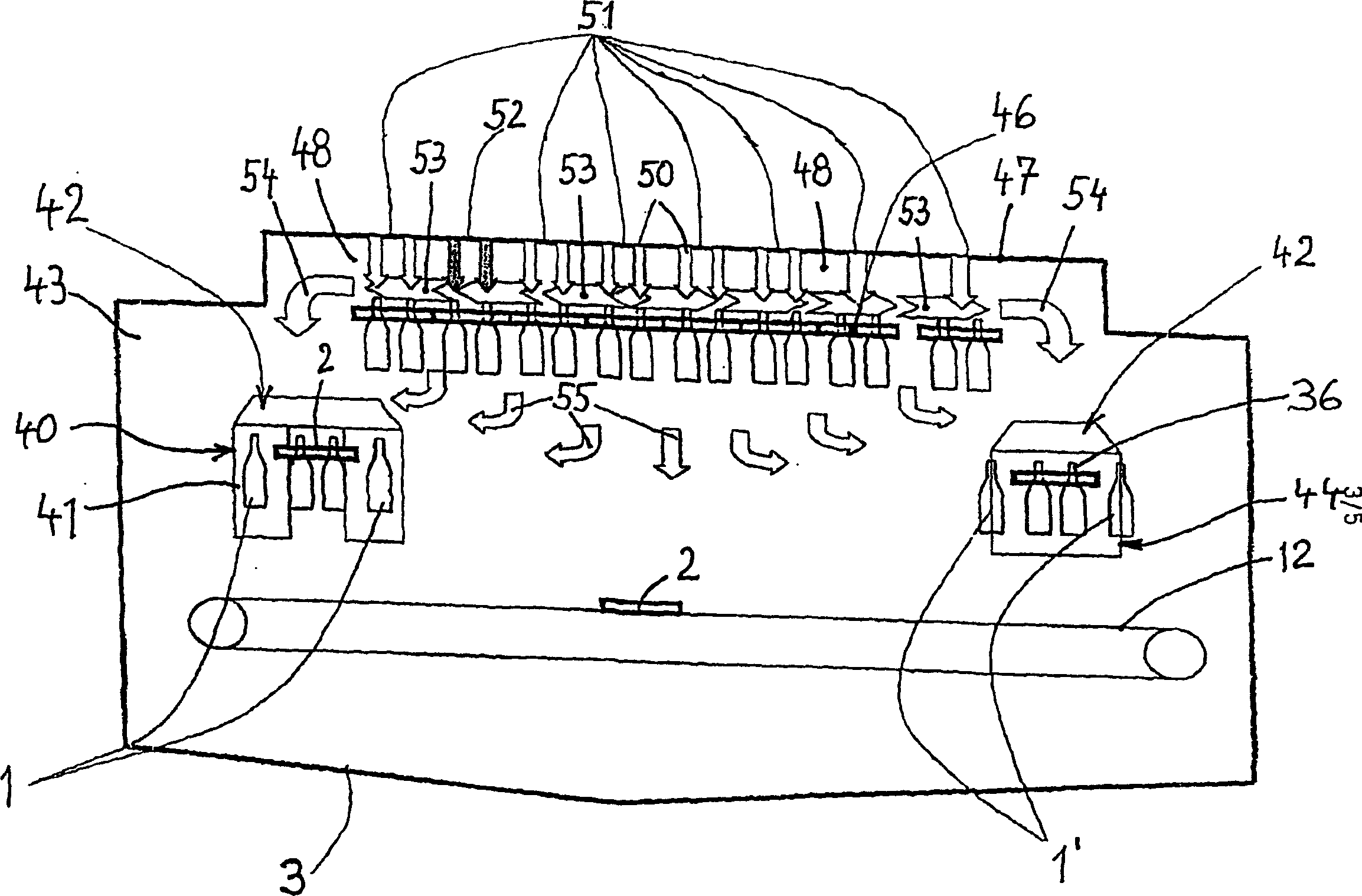

Device for filling bottle-shaped packaging in sterile conditions

InactiveCN1205110CIncrease capacityLarge capacityPackage sterilisationBottle-handling machinesMicroorganismProcess engineering

A device for filling bottles with liquid foodstuff in sterile conditions wherein an intermittently driven device is provided with bottle supports arranged successively in a line in the direction of conveyance and which passes through processing stations. The device is arranged in a hygienic chamber having through openings for the containers of the inlet and outlet thereof, including at least one inlet for introducing sterilizing medium in the upper wall of the hygienic chamber. Contiguous bottle supports form a closed area within the upper wall of the hygienic chamber and gas extraction systems are disposed in the vicinity of the bottle openings and on the outside of the hygienic chamber perform as dynamic sluice elements. The growth conditions for microorganisms in the hygienic chamber are hindered even in the event the amount of sterilizing agent is reduced.

Owner:TETRA LAVAL HLDG & FINANCE SA

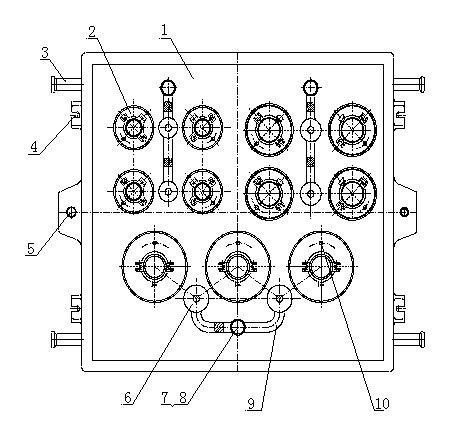

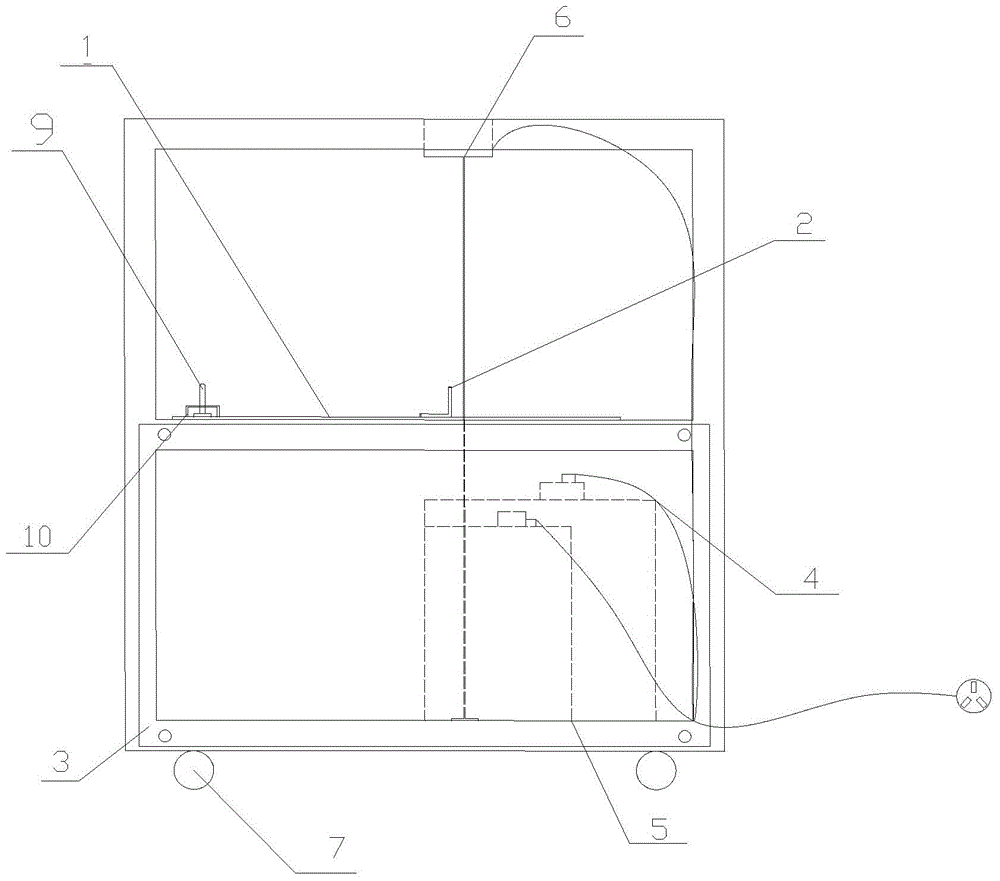

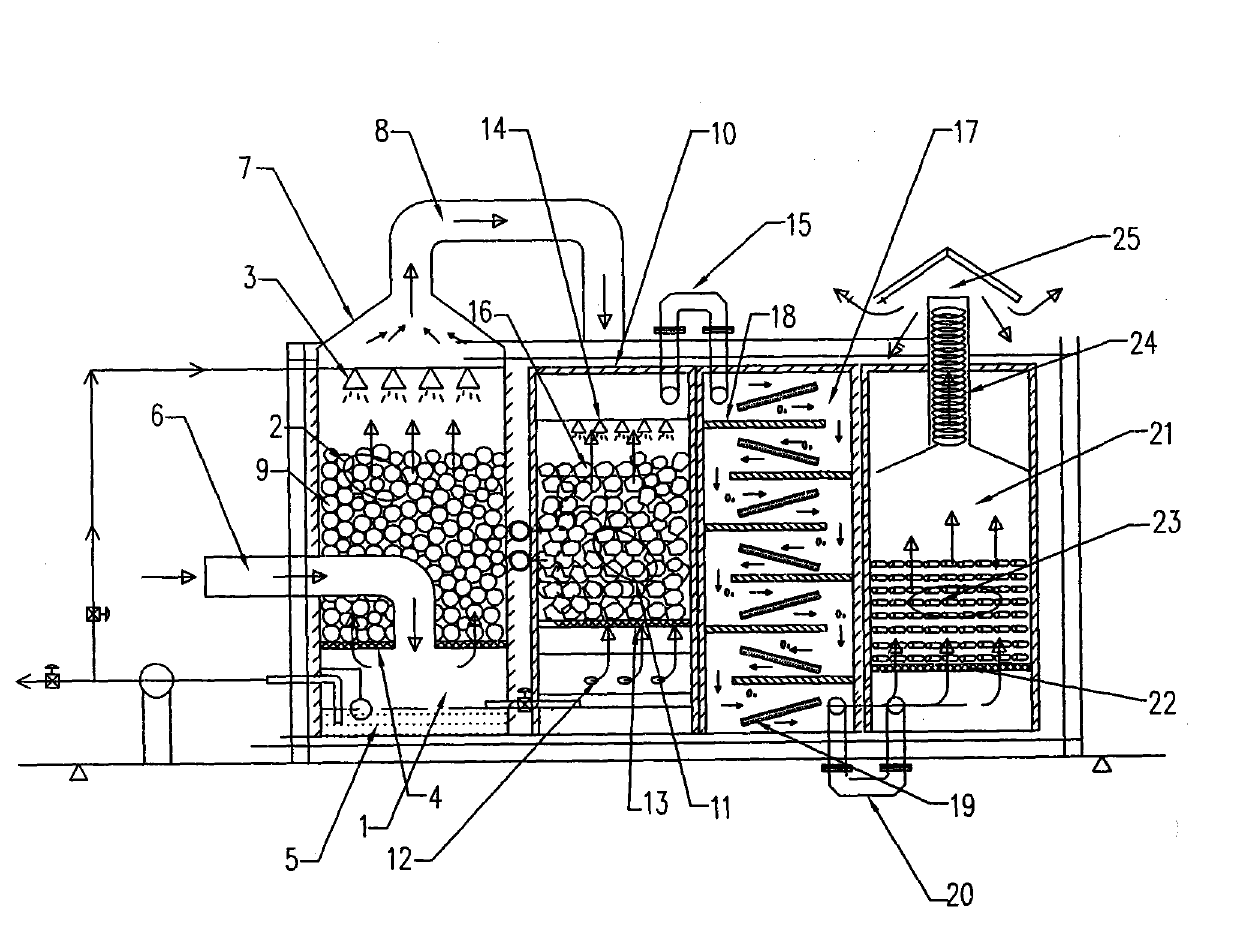

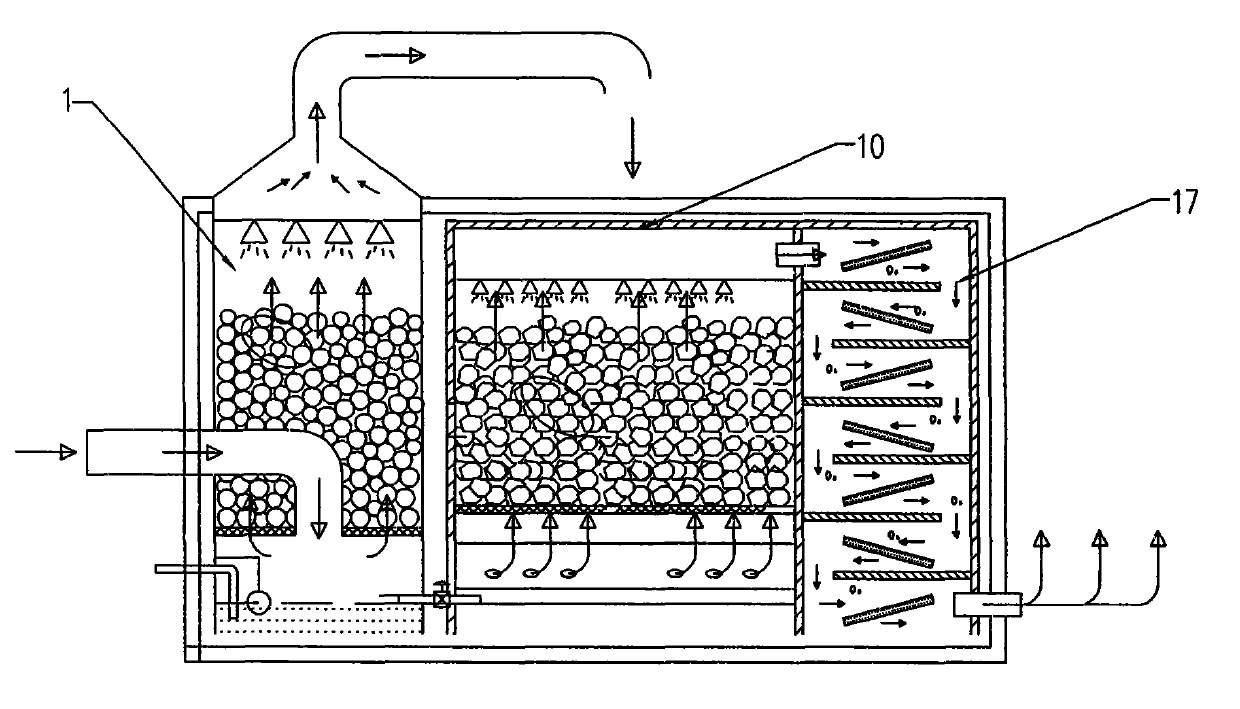

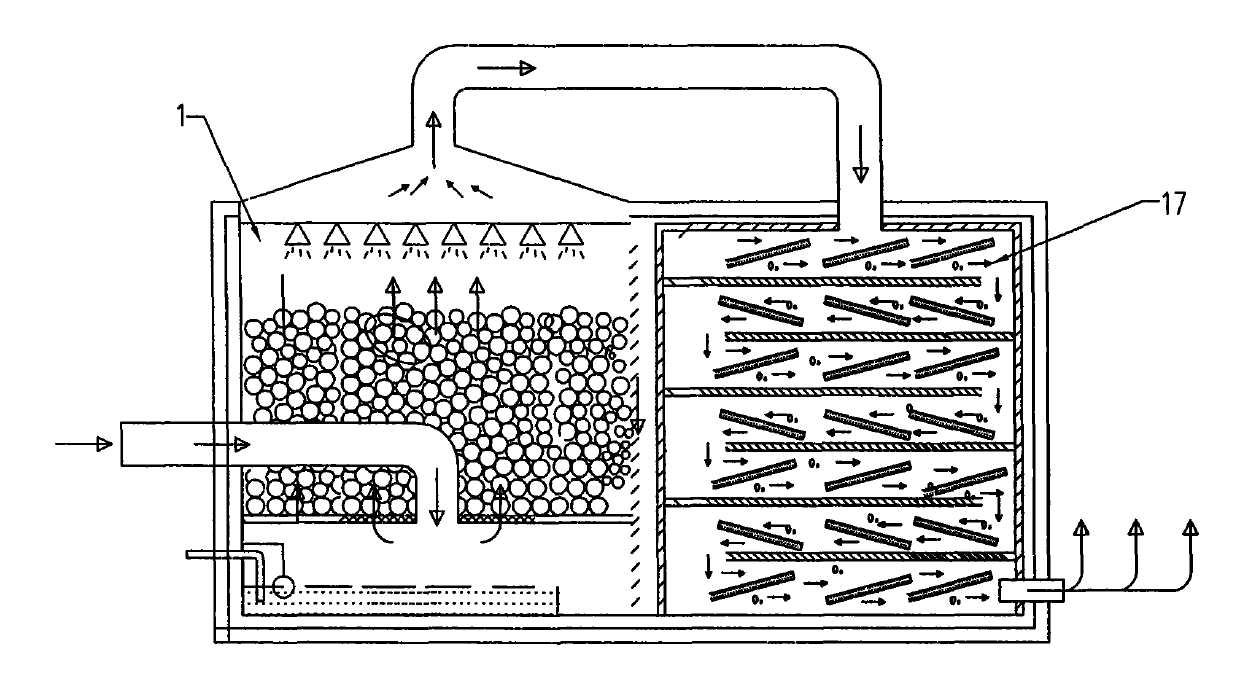

Integrated type modularization comprehensive deodorization device

InactiveCN101607166BImprove deodorization efficiencyImprove efficiencyDispersed particle separationGaseous substancesFiltrationBiomedical engineering

The invention relates to a mixed odor exhaust treatment device which is an integrated type modularization comprehensive deodorization device. The integrated type modularization comprehensive deodorization device is formed by combining different exhaust treatment bin modules, each treatment bin is an independent unit, and the units are connected by interfaces and are arranged in one or a pluralityof frames. The integrated type modularization comprehensive deodorization device has a standardized size, all main body devices are arranged in a frame with a standard shape size and are assembled ina module mode, and only one (or a plurality of) units need to be inserted for regulating the changing and treating capability of a technology. The treatment (devices) units comprising the steps of water film filtration and absorption, biomembrane degradation, ozone oxidation, natural material absorption and filtration, and the like can be assembled into an integrated type device according to the complicated degree of treated odor exhaust and different technical principles, and complicated mixed odor exhaust which enters the treatment bins can be sequentially and respectively treated until clean and fresh air is exhausted.

Owner:王晓军

Vine-binding strap film cutting machine

InactiveCN102990691ASimple preparation processNovel ideaMetal working apparatusAgricultural engineeringVine

The invention relates to the technical field of mechanical manufacturing, in particular to a vine-binding strap film cutting machine. Specifically, the vine-binding strap film cutting machine consists of a body frame, a rotating shaft, a fixed scale rod, a blade holder, a blade and a motor, wherein the rotating shaft and the fixed scale rod are fixedly arranged on the top part of the body frame in parallel, the blade holder is sleeved on the fixed scale rod, the blade is arranged in a blade mounting port, and the motor is arranged on a motor rack and is connected with the rotating shaft through a belt. During operation of the machine, the purpose of fixing the blade holder in a specified position is realized through a scale fixing card on the blade holder sleeved on the fixed scale rod and a scale fixing slot in the fixed scale rod, and a cylindrical film sleeved on the rotating shaft is cut by the blade through the blade mounting port and is finally cut into a uniform vine-binding strap film product of standard size.

Owner:黄青转

A handheld plastic optical fiber end face processing device and processing method

ActiveCN105278038BSuitable for outdoor constructionSimple structureCoupling light guidesHand heldReady to use

The invention relates to a hand-held plastic fiber end face processing apparatus. The hand-held plastic fiber end face processing apparatus comprises a hand-held end housing and an end face processing assembly housing, wherein a micromotor, heating members and a heat conduction member are arranged in the hand-held end housing; the other end of the end face processing assembly housing is detachably provided with a plastic fiber fixing piece; the output end of the micromotor is connected with the heat conduction member; a piece of sand paper is arranged on the heat conduction member; the plastic fiber fixing piece can fix a plastic fiber to be processed; when the micromotor drives the heat conduction member to rotate, the sand paper is driven to polish the plastic fiber end face; when the plastic fiber end face is polished and becomes smooth, the heating members are energized to heat the heat conduction member; the heat conduction member transfers the heat to the plastic fiber; and the plastic fiber is pasted on the heat conduction member for completing thermoplastic moulding. The hand-held plastic fiber end face processing apparatus can realize polishing and thermoplastic moulding functions for the plastic fiber at single-core and double core plastic optical cable end, and can effectively reduce the insertion loss and return loss of a communication plastic optical fiber or cable which is ready to use after cutting.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH

Method for producing porous shale sintering brick from crystal solid waste shale coal gangue

InactiveCN106145994AImprove emission standardsImprove mixing uniformityCeramic materials productionCeramicwareWastewaterEngineering

The invention relates to a method for producing a building material from solid wastes, in particular to a method for producing a porous shale sintering brick from crystal solid waste shale coal gangue. According to the method, crystal solid waste shale is used, coal gangue tailings are added in proportion, the mixture is crushed and strongly stirred, crystal wastewater is added during stirring and uniformly mixed, raw materials are sent into a storage chamber for plasticity treatment and can be sent into a strong stirrer by a grab machine and a conveyor and then sent into a hard-plastic extruder after being stirred to form various porous building blocks, the building blocks are sent into a special drying kiln by a ferry vehicle to be preheated, the mixture forms a porous brick, and the porous brick enters a calcining kiln to be calcined after being dried. The porous shale sintering brick has high strength, good durability, standard size, complete outline, uniform color and luster and as well as primitive, plain and natural appearance, can be used for a dry wall, and can also be used for any external decoration. Thus, the porous shale sintering brick replacing a clay brick is an upgraded new building material product with great development prospect.

Owner:ZHEJIANG PUJIANG JIANGHE NEW BUILDING MATERIALS CO LTD

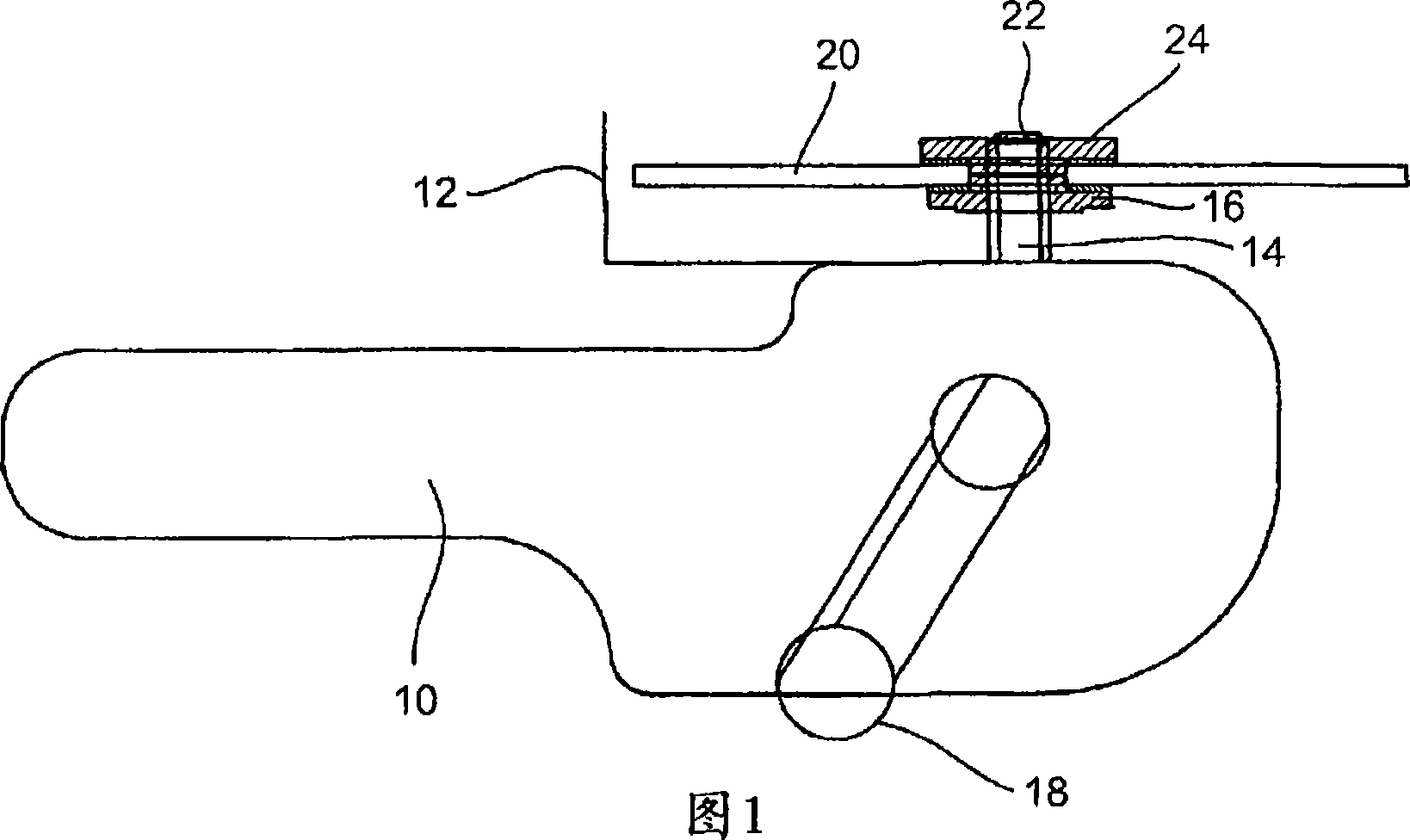

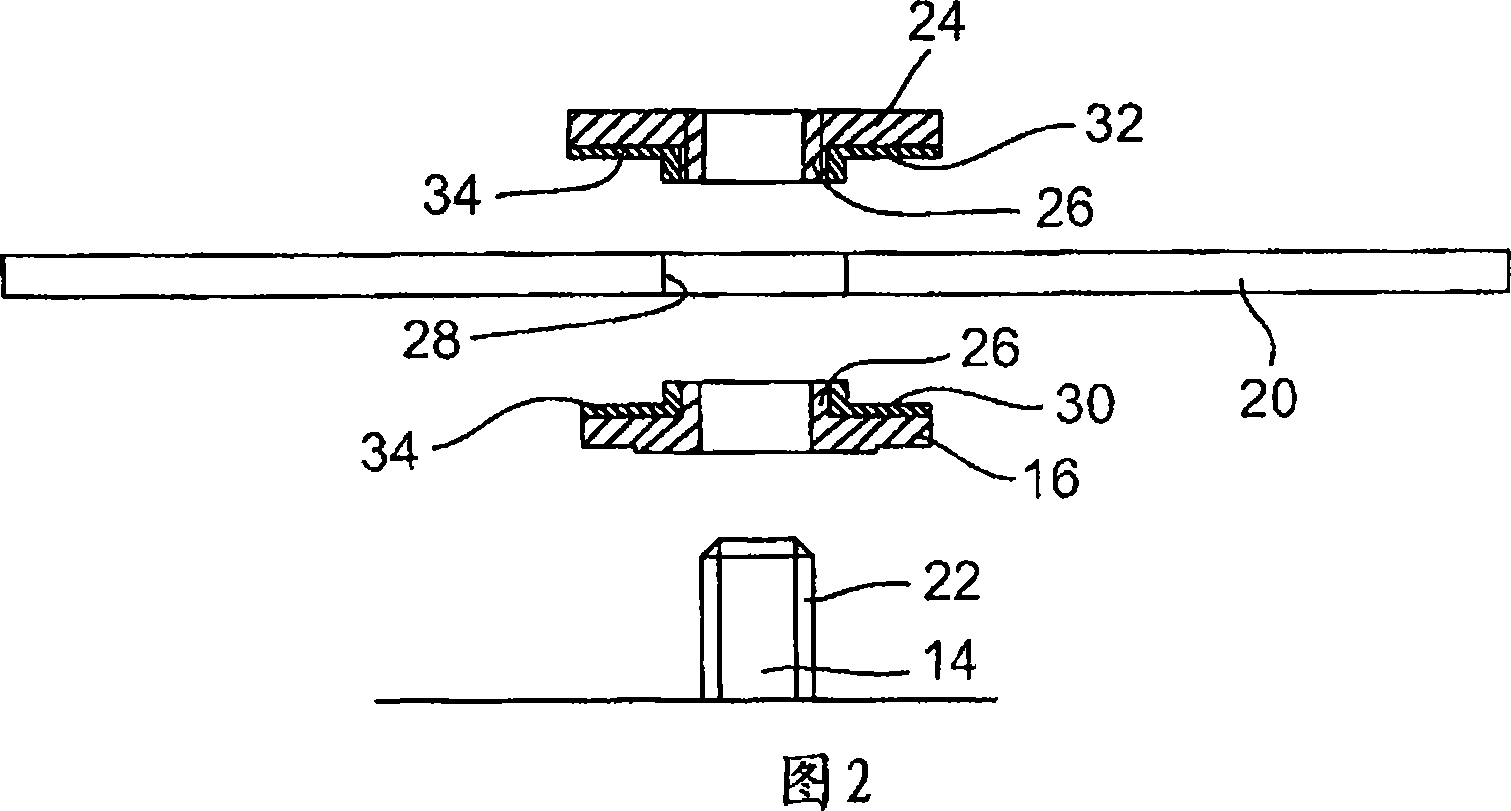

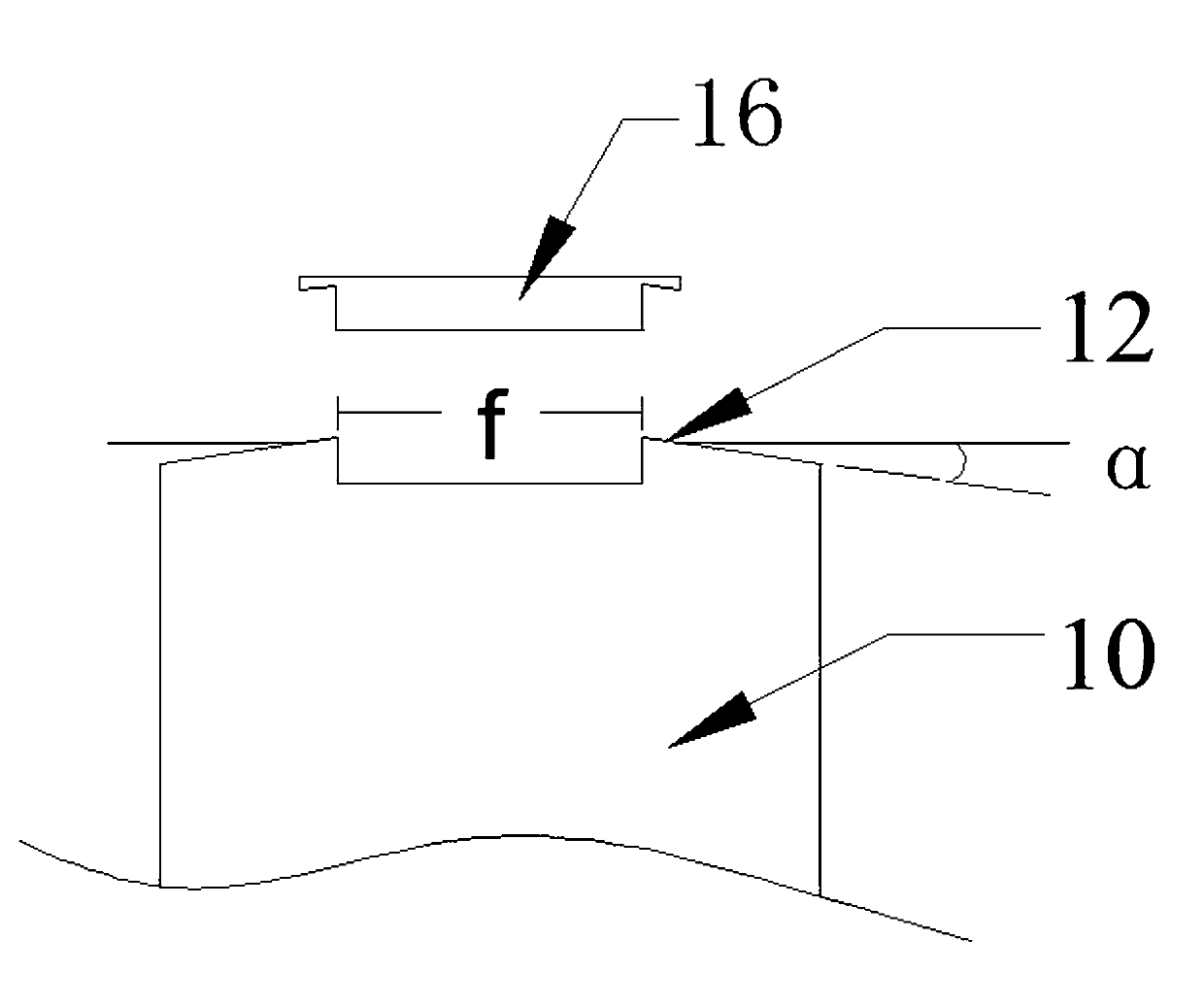

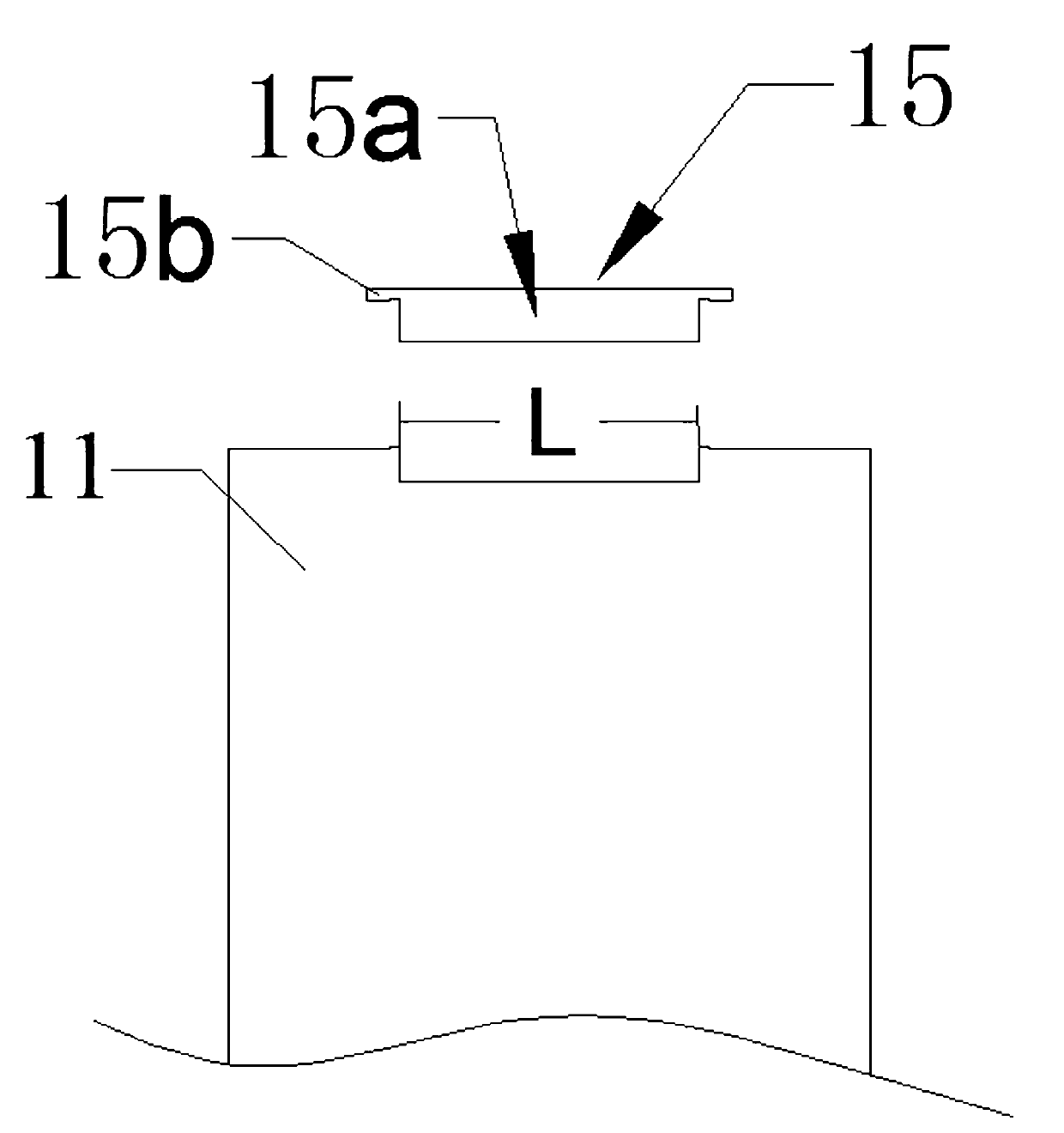

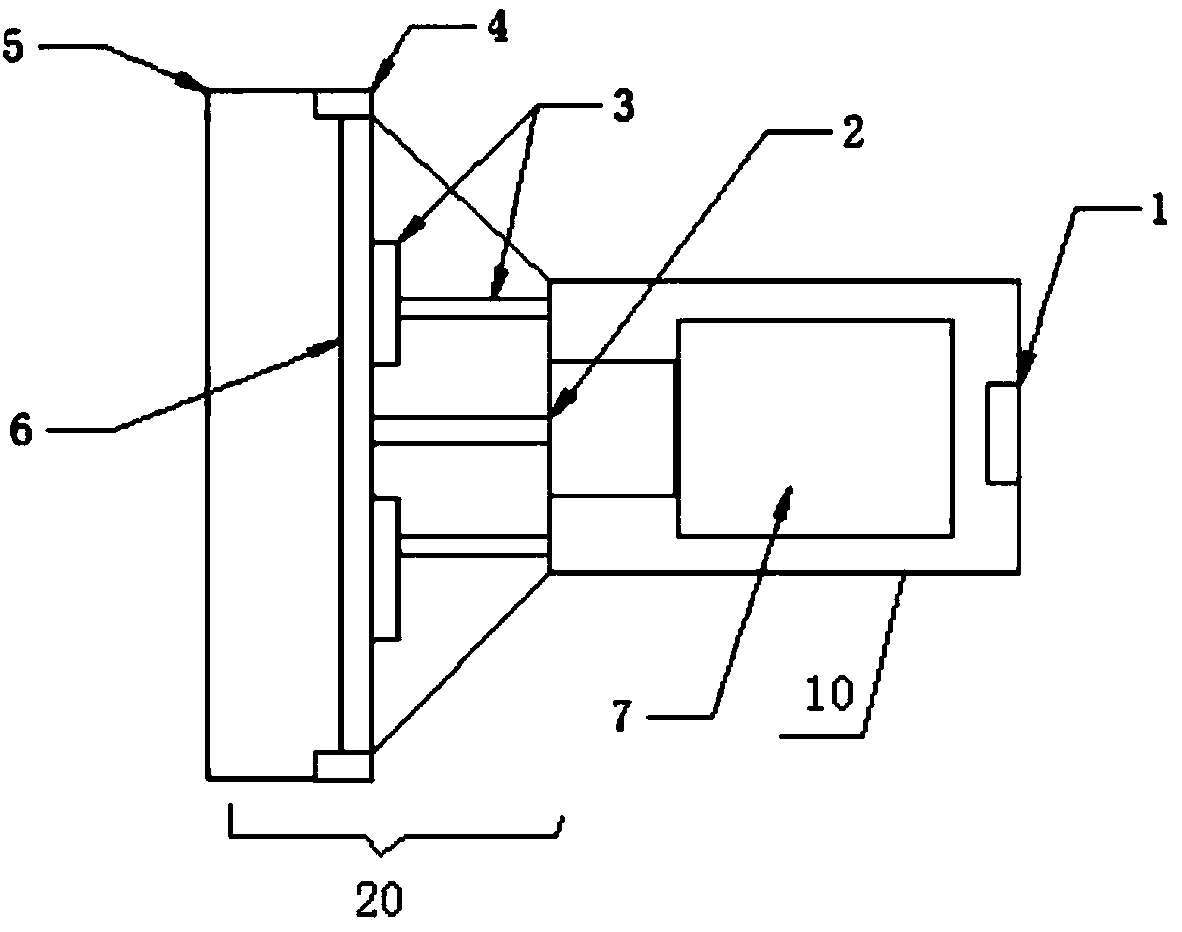

Device with vibration-damped component used for cutting and grinding, clamp device and rotary tool

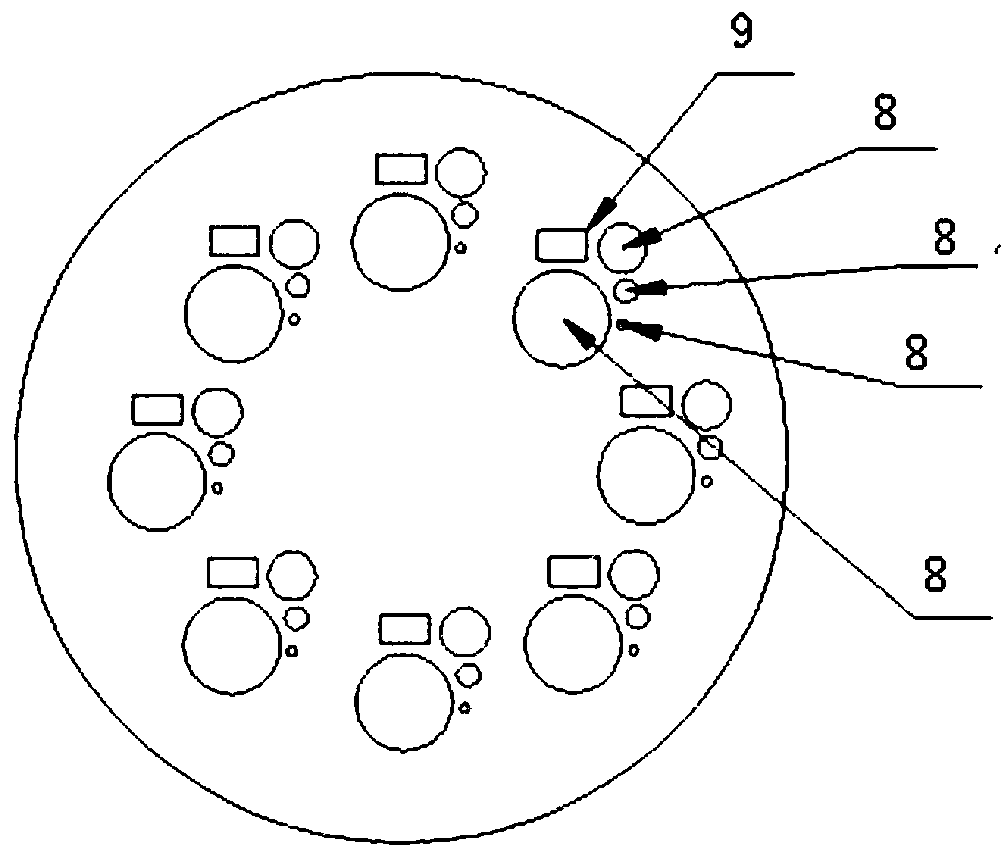

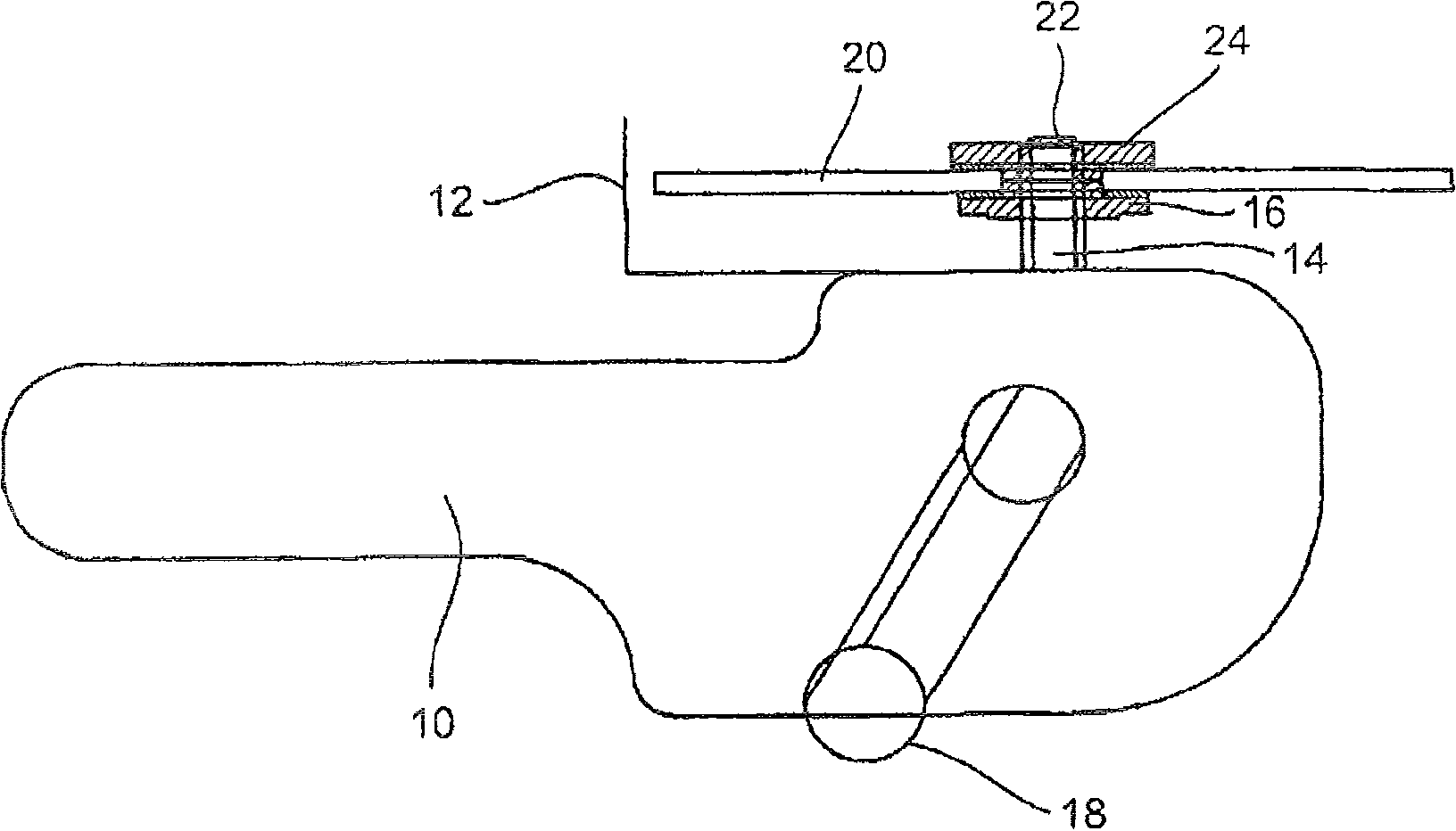

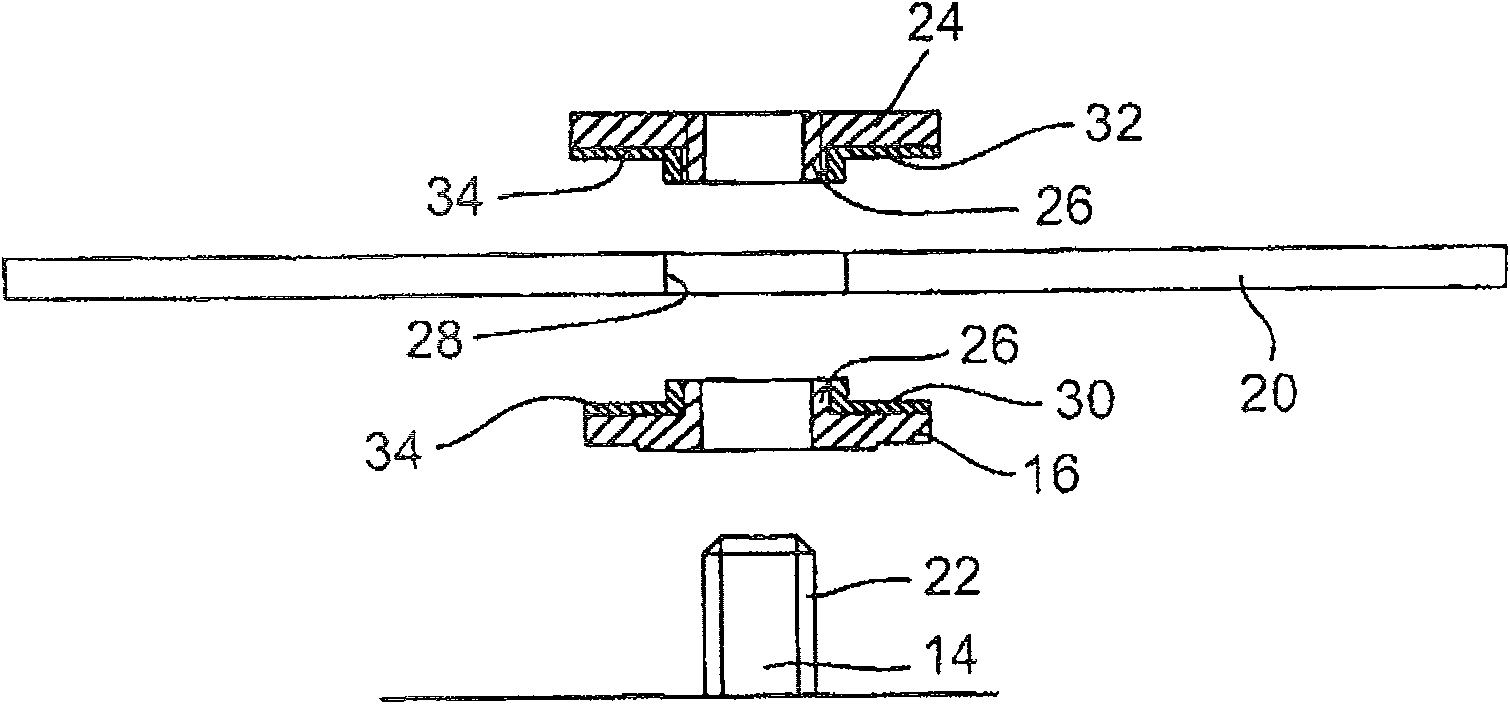

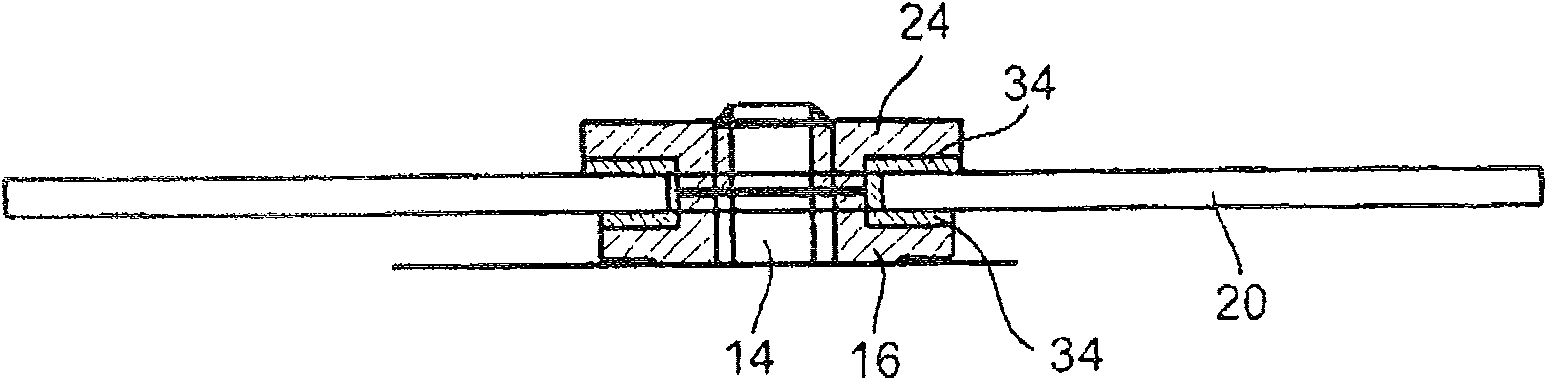

InactiveCN100560292CUnchanged standard sizeSize standardMetal sawing devicesGrinding wheel securing apparatusDrive shaftEngineering

The invention relates to a device for cutting and grinding comprising a drive unit (10), a drive spindle (14) and a clamping element (16) for clamping a rotary tool (20) on the drive spindle (14) ,twenty four). There is a vibration damper between the tool (20) and the clamping part (16, 24). The damping element is in the form of an elastic material coating on the clamping part (16, 24) or the tool (20) or in the form of one or more springs inserted between the tool (20) and the clamping part (16, 24). The mode of material disc (36) constitutes.

Owner:RHODIUS SCHLEIFWERKZEUGE GMBH & CO KG

Bidirectional ultrasonic automatic tool changing motorized spindle

ActiveCN113560611AGreat installation redundancySimple structureMechanical vibrations separationLarge fixed membersPhysicsEngineering

The invention relates to a bidirectional ultrasonic automatic tool changing motorized spindle which comprises a motorized spindle body and a rotor shaft. The rotor shaft penetrates through an inner ring of a bearing to achieve rotation, an axial vibrator and a radial vibrator are installed at the position of a tool bit of the rotor shaft, and the axial vibrator and the radial vibrator are arranged on the outer end face of the bearing in a sleeving manner; and the axial vibrator and the radial vibrator are connected with an ultrasonic driver, the axial vibrator can axially excite the bearing, the radial vibrator can radially excite the bearing, the bearing is sleeved with an elastic deformation pad, and the two ends of the elastic deformation pad abut against the axial vibrator and the radial vibrator correspondingly. By means of the bidirectional ultrasonic automatic tool changing motorized spindle, an axial and radial vibration superposition method is adopted, a rotary tool bit is subjected to excitation, excitation can be conducted in the same frequency and in the same phase or in the same frequency and in different phases or alternately according to the cutting effect, finally, the rotor shaft vibrates in the axial direction and also vibrates in the radial direction, and bidirectional vibration is formed. The bidirectional ultrasonic automatic tool changing motorized spindle is easy to install, firm in structure, stable in work and capable of achieving axial and radial cutting.

Owner:常州捷乾机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com