Vine-binding strap film cutting machine

A cutting machine and strapping technology, which is applied in the field of machinery manufacturing, can solve the problems of high production cost of PVC strapping, high production equipment cost, increased cost, etc., and achieves a novel structure and composition, low production cost and low maintenance cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

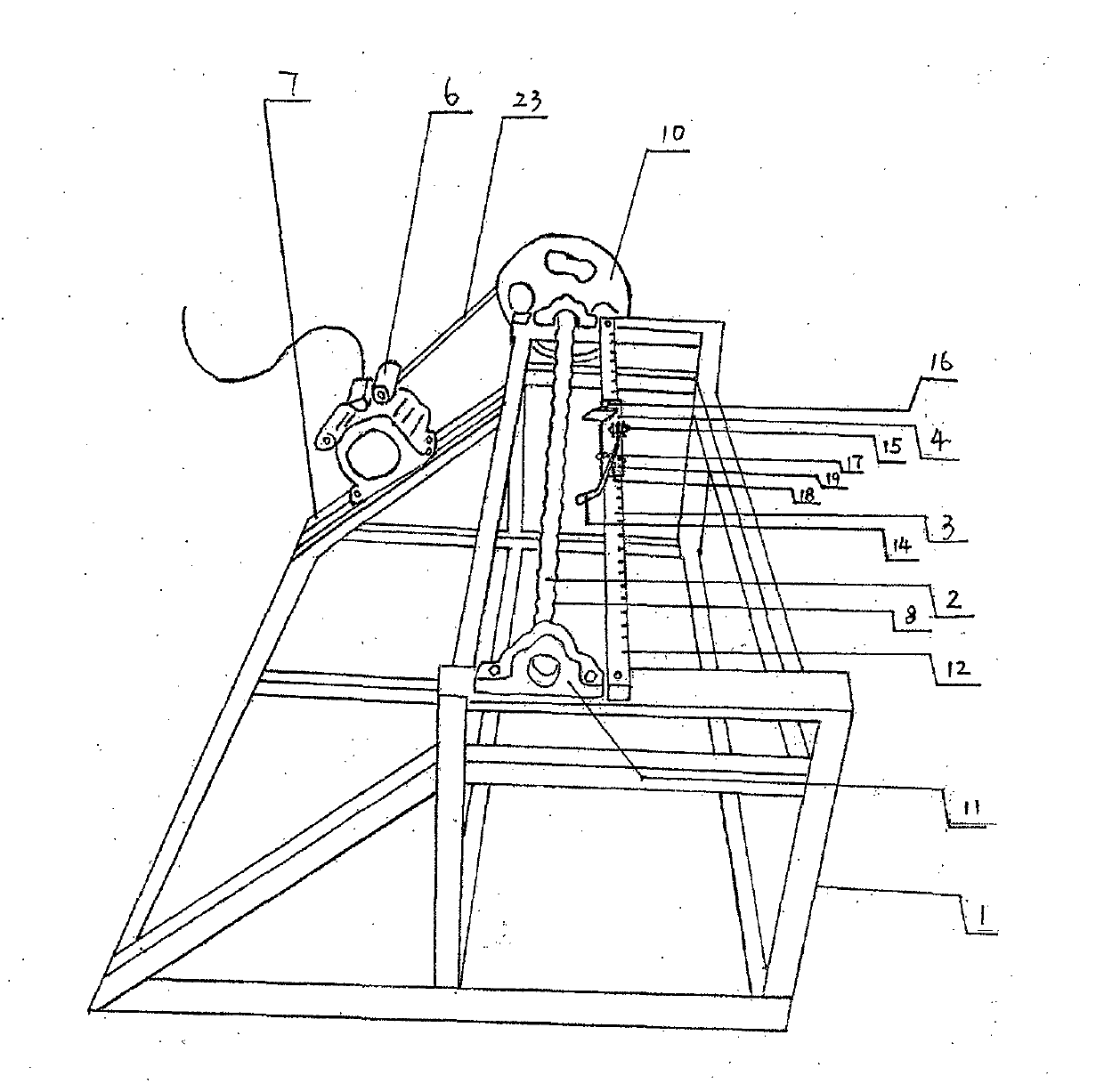

[0031] Now in conjunction with accompanying drawing, the present invention is described in detail:

[0032] The invention is composed of a body frame (1), a rotating shaft (2), a calibration rod (3), a blade holder (4), a blade (5) and a motor (6). Wherein, the rotating shaft (2) and the fixed rod (3) are fixed on the top of the body frame (1) in parallel, the blade holder (4) is sleeved on the fixed rod (3), and the blade (5) is placed on the blade holder (4) In the blade placement mouth, motor (6) is installed on the motor frame of body frame (1), and motor (6) is connected with rotating shaft (2) with belt.

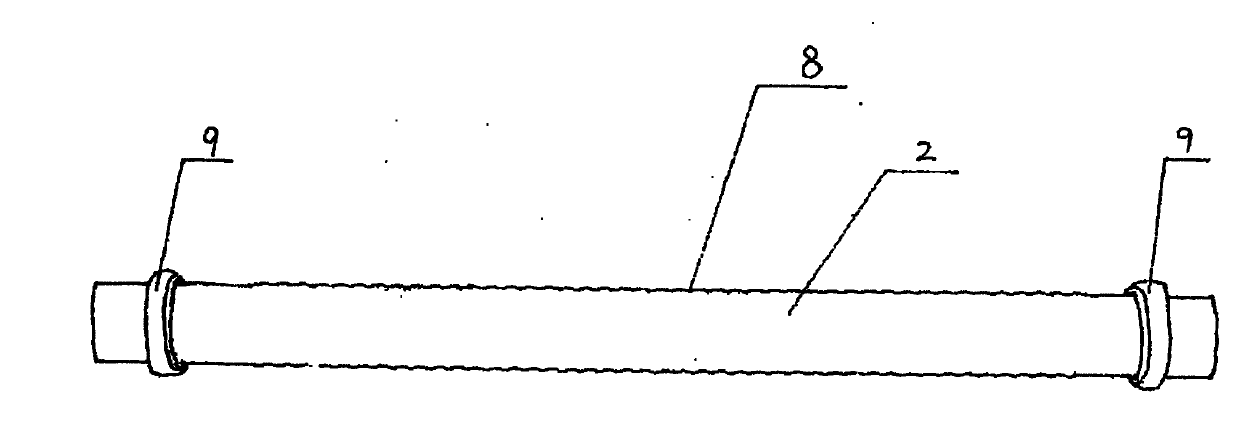

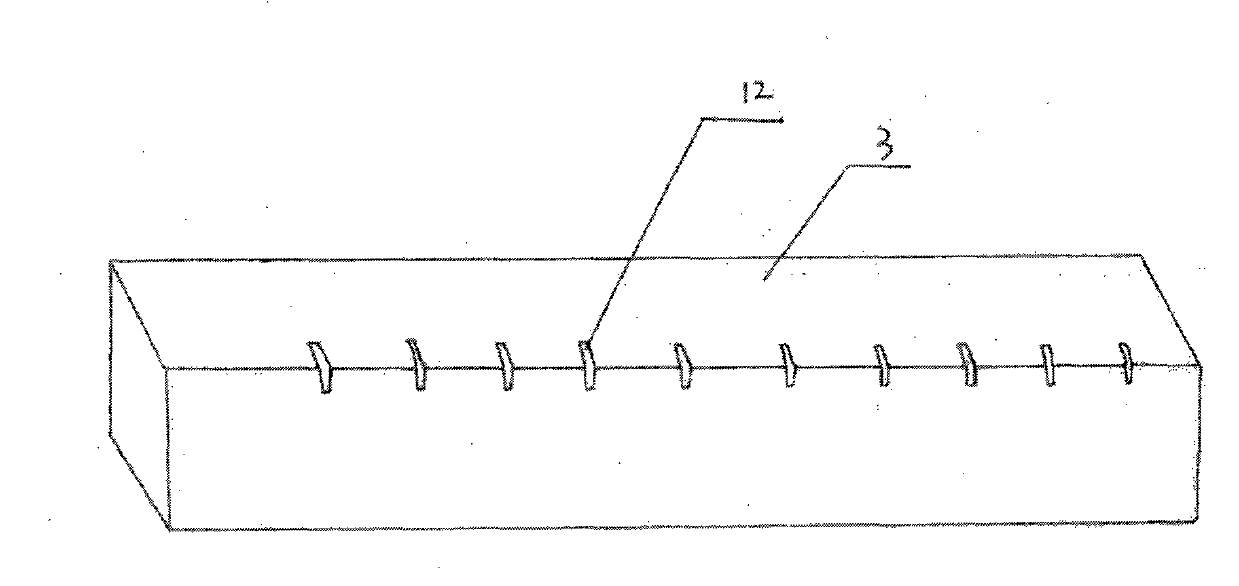

[0033] figure 1 Shown, 1 is body frame (1), and 2 is rotating shaft (2), and 3 is timing bar (3), and 4 is blade frame (4), and 6 is motor (6), and 7 is motor frame (7), 8 is a groove (8) provided on the rotating shaft, 10 is a belt pulley (10) installed on one side of the rotating shaft, 11 is a bearing sleeve (11), 12 is a scale fixing groove (12) provided by a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com