Device for filling bottle-shaped packaging in sterile conditions

A technology of packaging and equipment, applied in the field of equipment for sterilizing and filling bottle-shaped packaging, which can solve the problems of consuming large amounts of sterilizing media for sterilizing air, health crises, etc., and achieve the effect of reducing the risk of re-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

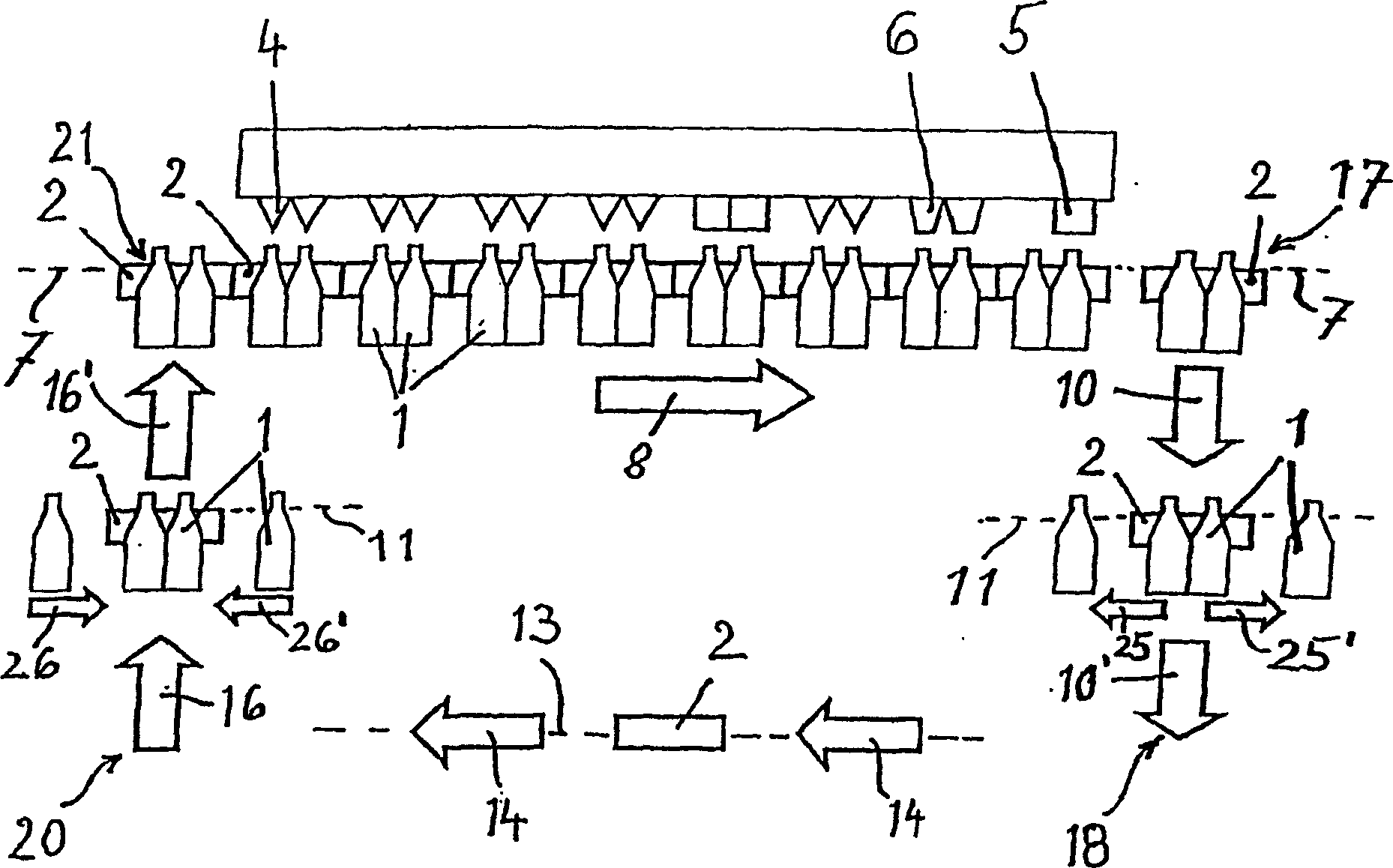

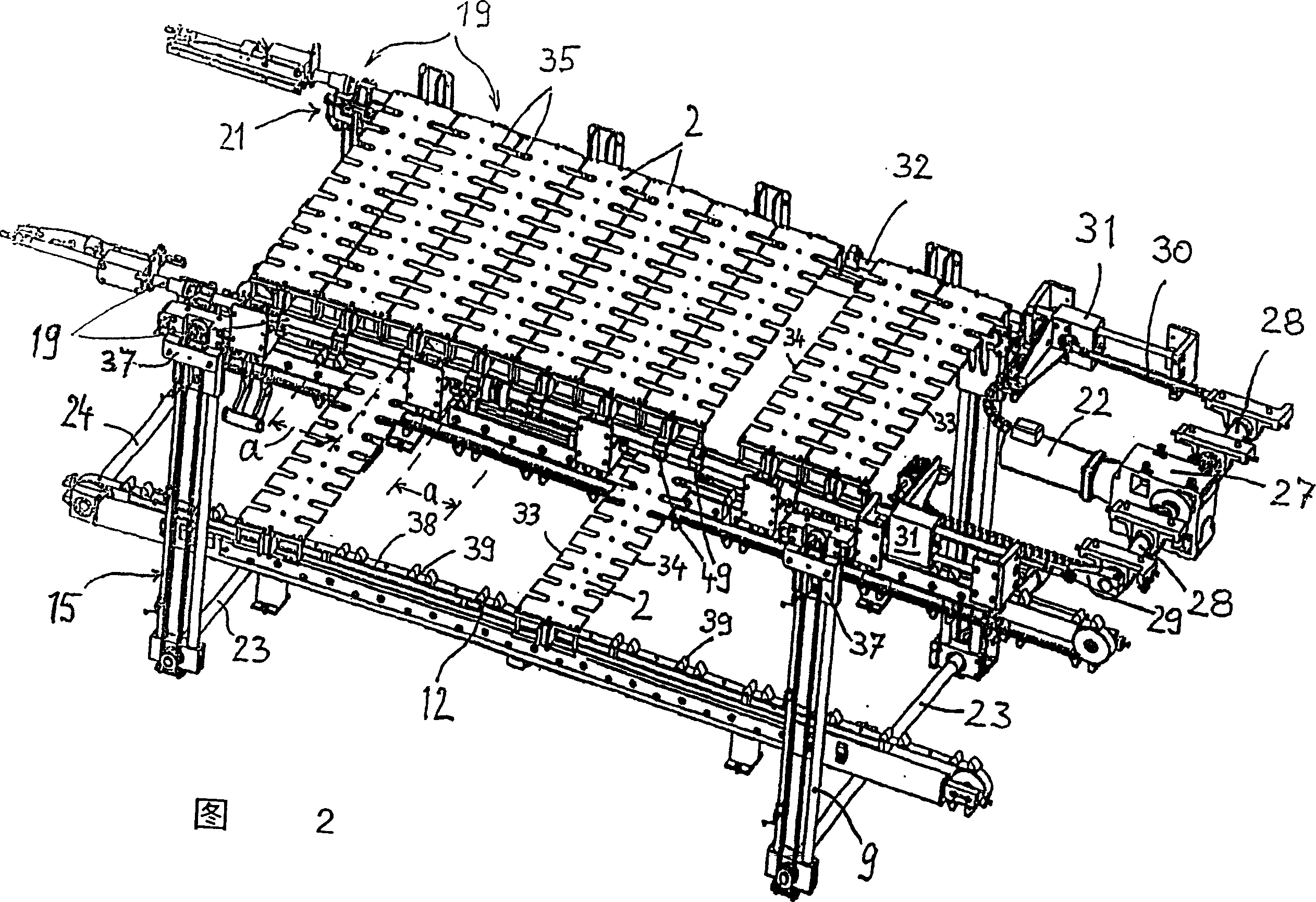

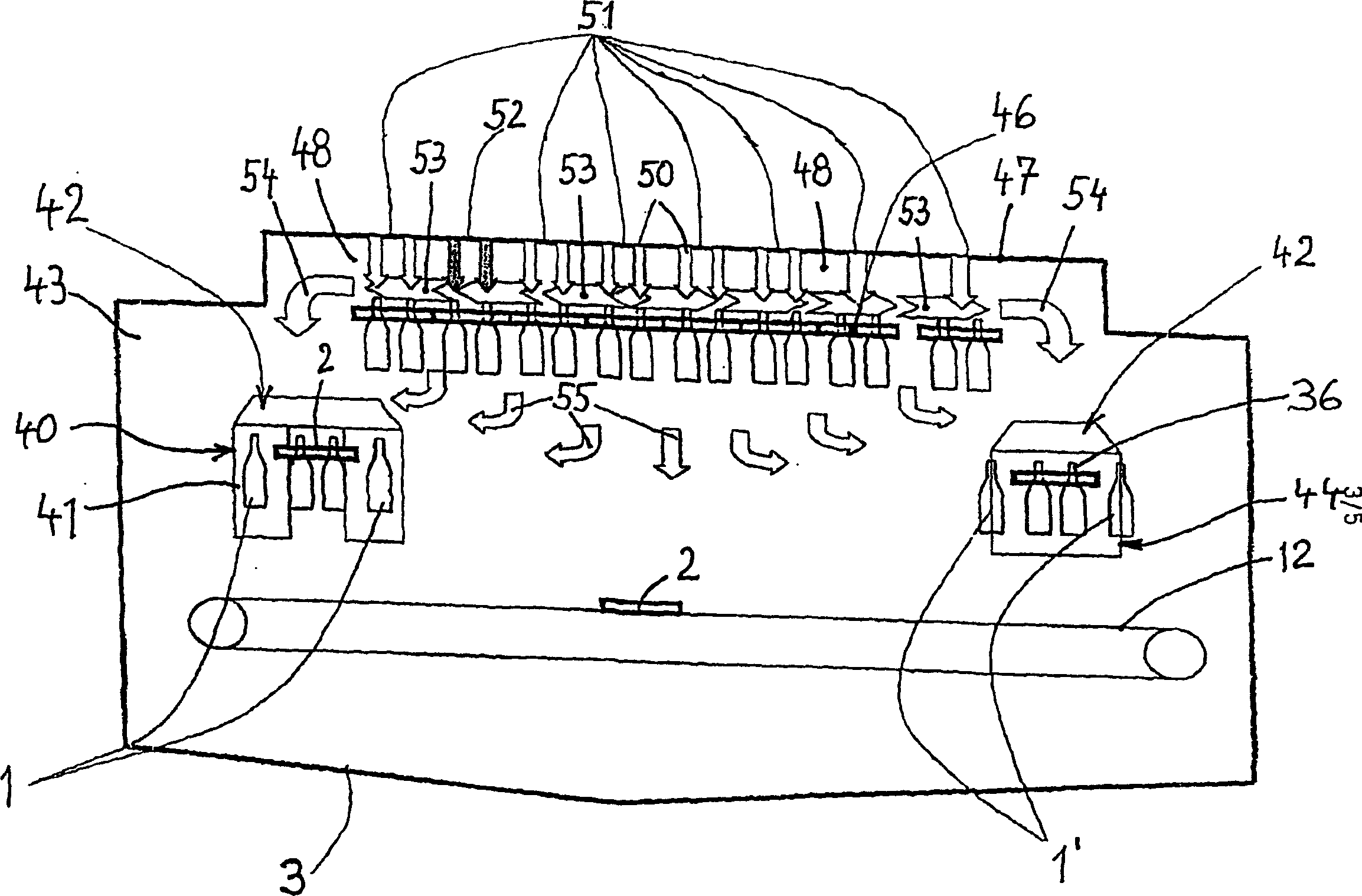

[0039] In the embodiment shown in this specification, the packages labeled "1" are some plastic bottles. In the description of the preferred embodiments below, the bottle-shaped packages 1 are called bottles, and these bottles are placed in the package in object bay 2. Below a frame that also forms the upper limit of a sanitary room 3, various workstations 4, 5, 6 are installed from left to right, such as air flow nozzles for preheating, and then the disinfecting mixture that will be used as a disinfecting medium. Spray nozzles in case of injection, followed by various drying stations, a cutting station, a filling station 6 and a sealing station 5 by which the filled bottle 1 is sealed. In a preferred embodiment for packaging liquid food, such sealing may be accomplished, for example, with a plastic-coated aluminum foil seal. Workstations 4 and 6 are formed in pairs, i.e. two rows of bottles are always processed at the same time, for example at filling station 6, while sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com