Groover

A slotting machine and control mechanism technology, applied in the field of excavating machinery, can solve problems such as unusable, low work efficiency, non-standard grooves, etc., and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

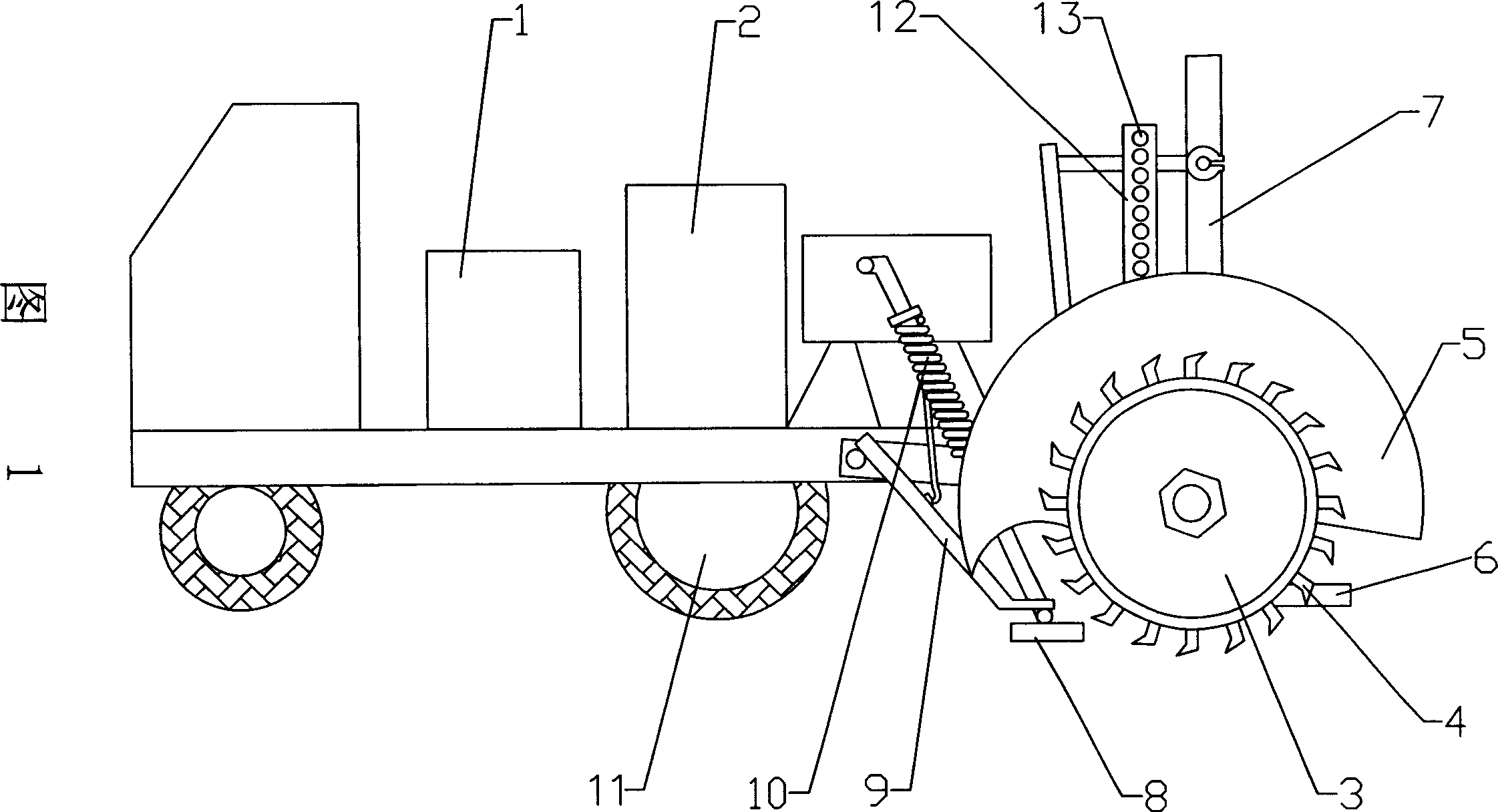

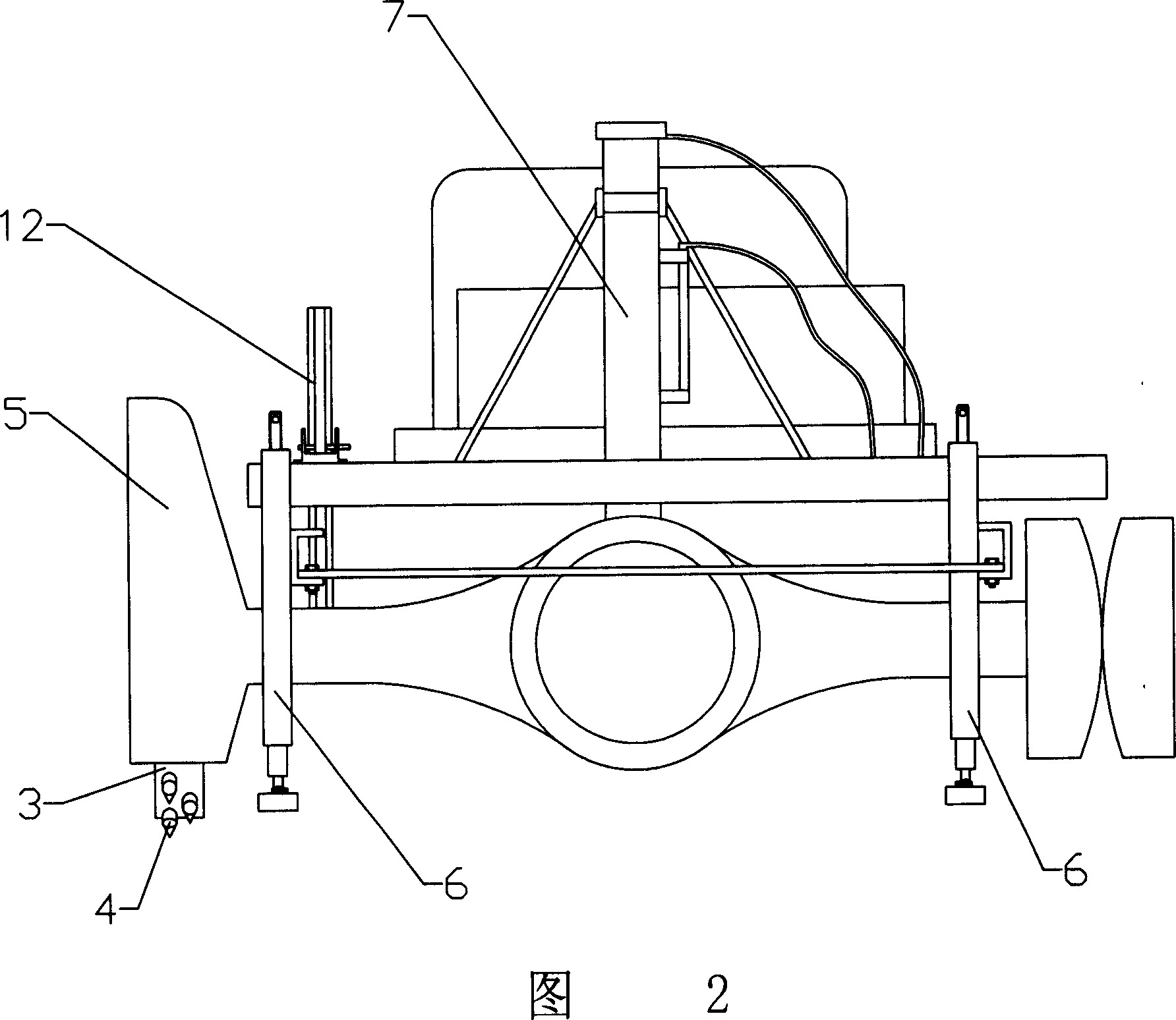

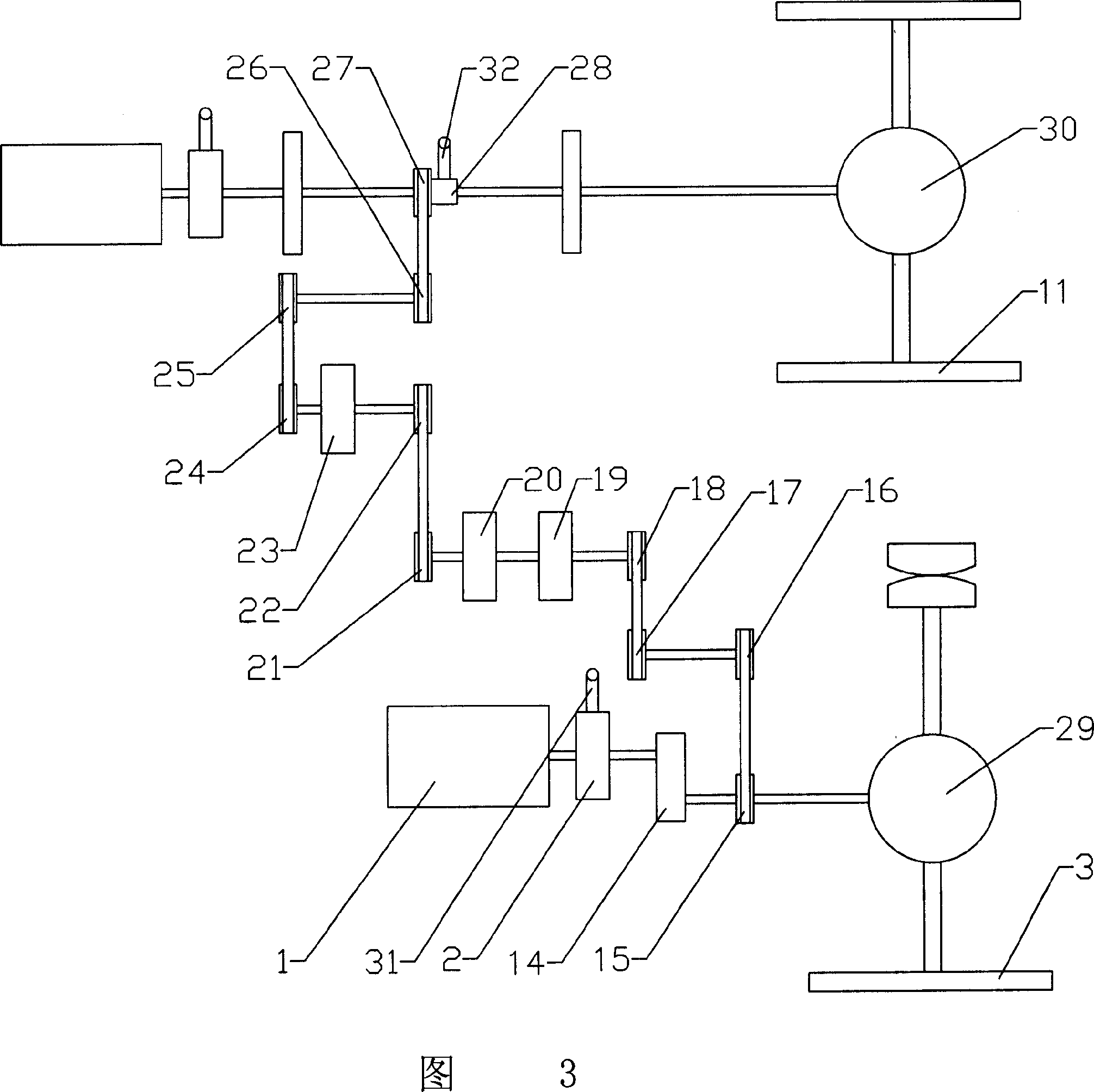

[0017] As shown in Figure 1, a slotting machine includes a vehicle body, a power unit, and a slotting device. The power unit is arranged on the vehicle body. The power unit includes a working engine 1 and a gearbox 2. 3 and the control mechanism, the grooving runner 3 is provided with a cutter 4, and the cutter 4 is provided with two rows on the surface of the grooving runner 3, and the grooving runner 3 is provided with a protective cover 5 used to prevent fragments from splashing, and the grooving rotor A transmission device is provided between the wheel 3 and the power unit. As shown in Figure 2, the control mechanism includes a depth controller 6 that limits the depth of the groove. The depth controller 6 includes a shell fixed on the vehicle body, and the shell is provided with The screw rod that performs spiral motion relative to the shell, the hydraulic cylinder 7 used to control the grooving runner 3 and the depth controller 6 lifting, the road protector 8 used to prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com