A handheld plastic optical fiber end face processing device and processing method

A plastic optical fiber and end-face processing technology, applied in the field of optical fiber production, can solve the problems of large insertion loss and return loss, unfavorable communication quality, single function, etc., to reduce insertion loss and return loss, widen the scope of use, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

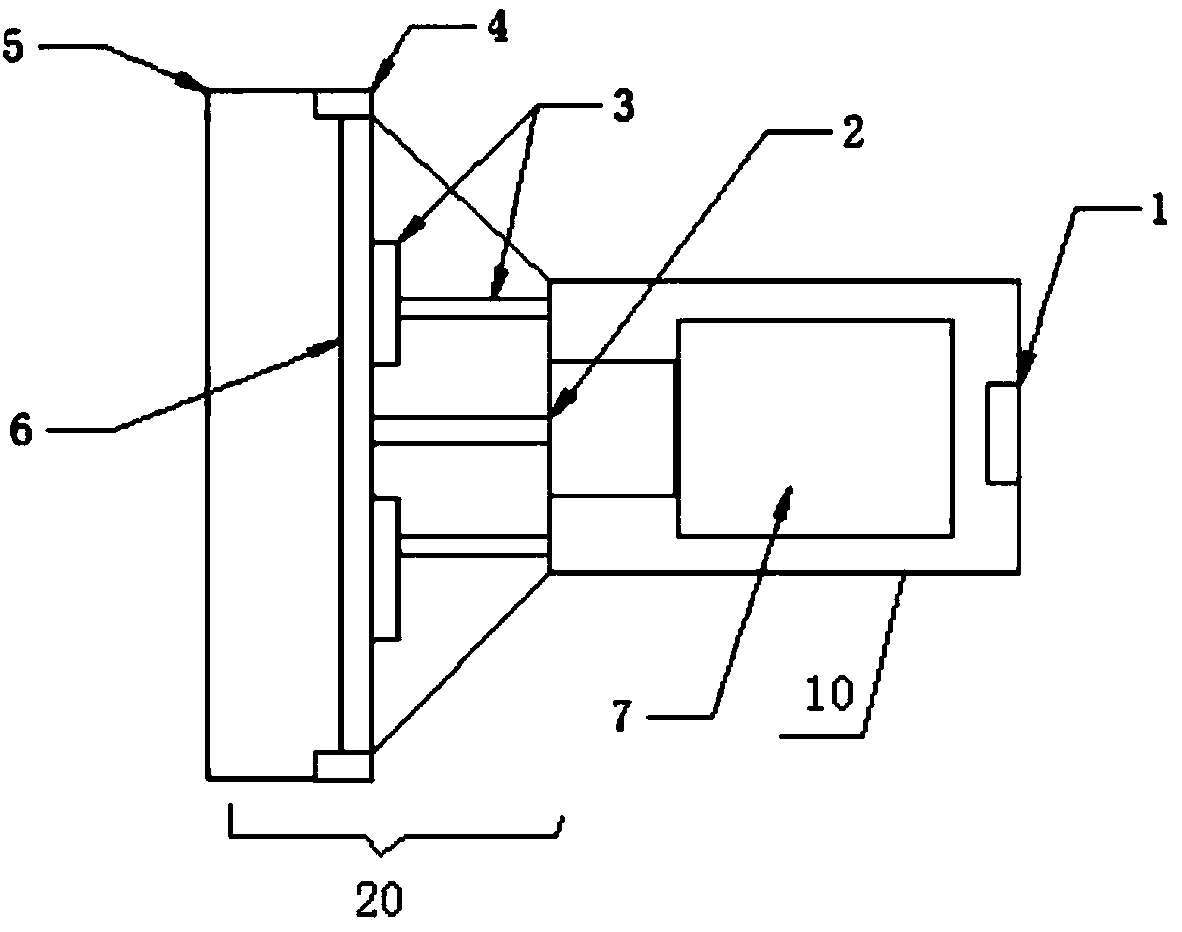

[0030] Such as figure 1 As shown, this embodiment discloses a hand-held plastic optical fiber end-face processing device, which includes a hand-held end housing 10 and an end-face processing assembly housing 20 connected to one end of the hand-held end housing 10. In order to facilitate the hand-held use of the device , the shape of the device can be set to look like a flashlight. In other embodiments, there can be other shape structures, which are not limited here.

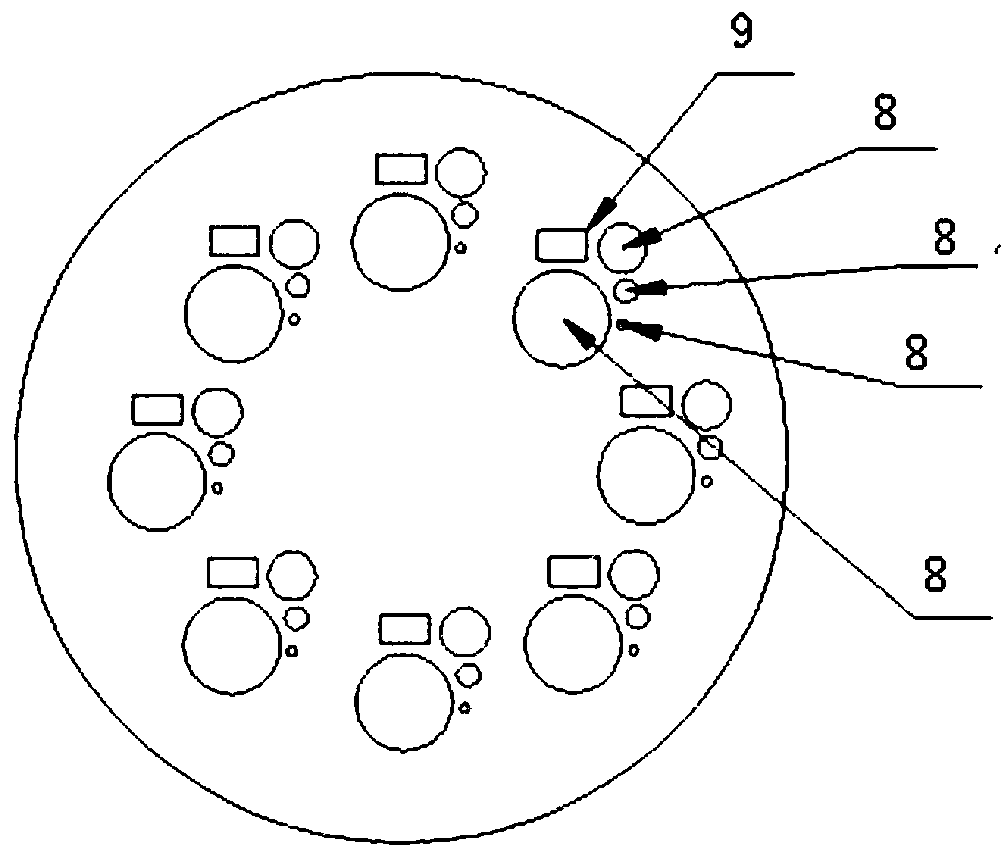

[0031] In this embodiment, a micromotor 2 and a 12V rechargeable battery pack 7 are arranged inside the above-mentioned hand-held terminal housing 10, and the above-mentioned 12V rechargeable battery pack 7 supplies power for the above-mentioned micromotor 2, and the charging port 1 of the above-mentioned 12V rechargeable battery pack 7 is arranged on The end of the above-mentioned handheld terminal housing 10 . The output end of the micro motor 2 is connected with a polishing assembly, and the micro motor 2 dri...

Embodiment 2

[0040] The structure of the hand-held plastic optical fiber end face treatment device disclosed in Example 2 is the same as that disclosed in Example 1. The difference is that the heating element 3 in Example 2 is selected as a heating resistor, and the heat conducting element 6 is selected as smooth iron plate.

[0041] The above-mentioned device can realize the functions of polishing and thermoforming the plastic optical fiber at the end of the single-core and double-core plastic optical fiber cable, and effectively reduces the insertion loss and return loss of the ready-to-use communication plastic optical fiber or optical cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com