Preparation method of wear-resistant and easy-to-repair superhydrophobic coating

A super-hydrophobic coating and wear-resistant technology, applied in the coating field, can solve the problems of high cost, complex process and high temperature, and achieve the effect of increasing the force-bearing area, simple process and good anti-wear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

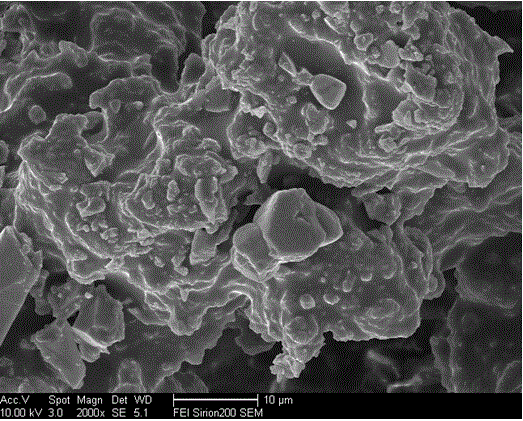

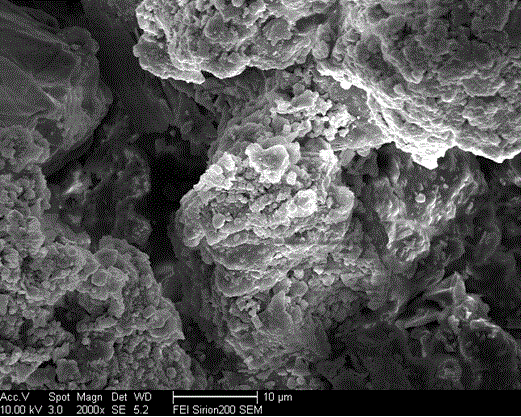

[0038] Step 1): Weigh 4.0 grams of 300-mesh styrene-butadiene rubber powder, mix them evenly with 4.0 grams of epoxy resin E-44 and 32 grams of ethyl acetate, add 0.4 grams of diethylenetriamine dropwise, spray on a glass sheet, and store at 20 °C Curing for 12 hours;

[0039] Process 2) Weigh 2.5 grams of epoxy resin E-44, 0.25 grams of diethylenetriamine, 0.25 grams of amino silicone oil dissolved in 31.02 grams of ethyl acetate and 15.98 grams of ethanol to form a uniform solution, and spray the solution on the product obtained in process 1) The surface of the coating was cured at 20°C for 12 hours to obtain a superhydrophobic coating.

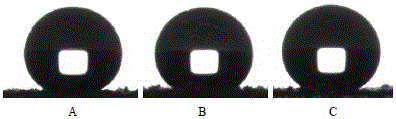

[0040]The contact angle of the above coating is 165°, and the coating is tested for wear resistance according to the American Society for Testing and Materials standard ASTM D 968-05 (the test for the determination of the wear resistance of organic coatings by falling sand abrasion method). The results show that the coating After 2 kg of q...

Embodiment 2

[0042] Step 1): Weigh 4.0 grams of 400-mesh styrene-butadiene rubber powder, mix them evenly with 5.34 grams of epoxy resin E-44 and 17.33 grams of ethyl acetate, add 0.53 grams of diethylenetriamine dropwise, spray on a glass sheet, and store at 20°C Curing for 12 hours;

[0043] Process 2) Weigh 2.5 grams of epoxy resin E-44, 0.25 grams of diethylenetriamine, 0.25 grams of amino silicone oil dissolved in 15.51 grams of ethyl acetate and 6.49 grams of ethanol to form a uniform solution, spray the solution on the obtained The surface of the coating was cured at 20°C for 12 hours to obtain a superhydrophobic coating.

[0044] The contact angle of the above coating is 163°, and the coating is tested for wear resistance according to the American Society for Testing and Materials standard ASTM D 968-05 (the test for the determination of the wear resistance of organic coatings by falling sand abrasion method). The results show that the coating After 2 kg of quartz sand was dropped...

Embodiment 3

[0046] Step 1): Weigh 4.0 grams of 500-mesh styrene-butadiene rubber powder, mix them evenly with 8.0 grams of epoxy resin E-44 and 28 grams of ethyl acetate, add 0.8 grams of diethylenetriamine dropwise, spray on a glass sheet, and store at 20°C Curing for 12 hours;

[0047] Process 2) Weigh 2.5 grams of epoxy resin E-44, 0.25 grams of diethylenetriamine, 0.25 grams of amino silicone oil dissolved in 15.51 grams of ethyl acetate and 6.49 grams of ethanol to form a uniform solution, spray the solution on the obtained The surface of the coating was cured at 20°C for 12 hours to obtain a superhydrophobic coating.

[0048] The contact angle of the above coating is 164°. The coating is tested for wear resistance according to ASTM D 968-05 (the test for the determination of the wear resistance of organic coatings by falling sand abrasion method) of the American Society for Testing and Materials. The results show that the coating After 2 kg of quartz sand was dropped from a tube wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com