Zirconia ceramic cylinder liner material and preparation method thereof

A technology of zirconia ceramics and ceramic cylinders, which is applied in the field of preparation of zirconia ceramic cylinder liner materials and zirconia ceramic cylinder liner materials, can solve the problems of uneven distribution of material components, different shrinkage rates of materials, and influence of ceramic performance, etc. Achieve the effects of reducing energy consumption for preparation, uniform particle size, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

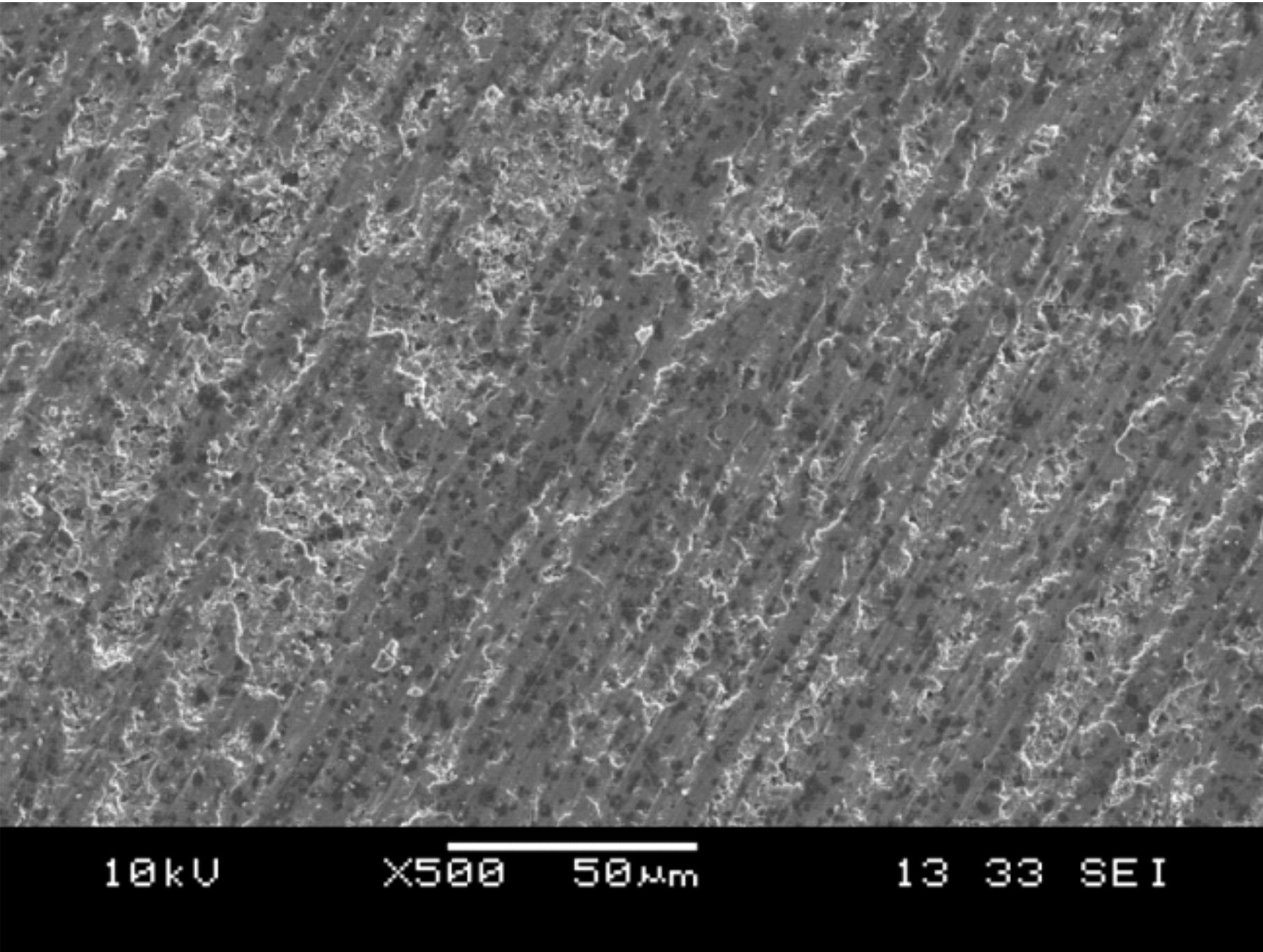

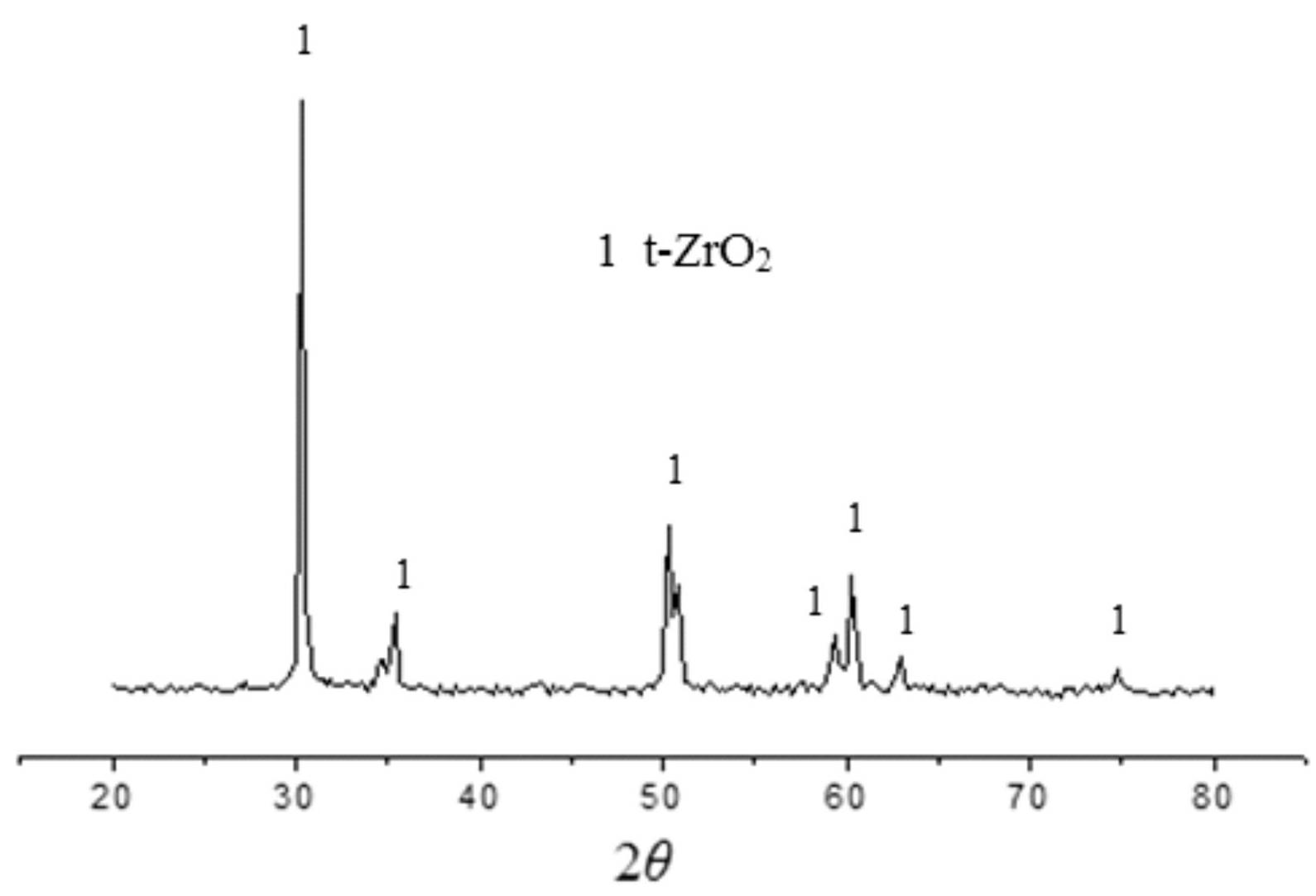

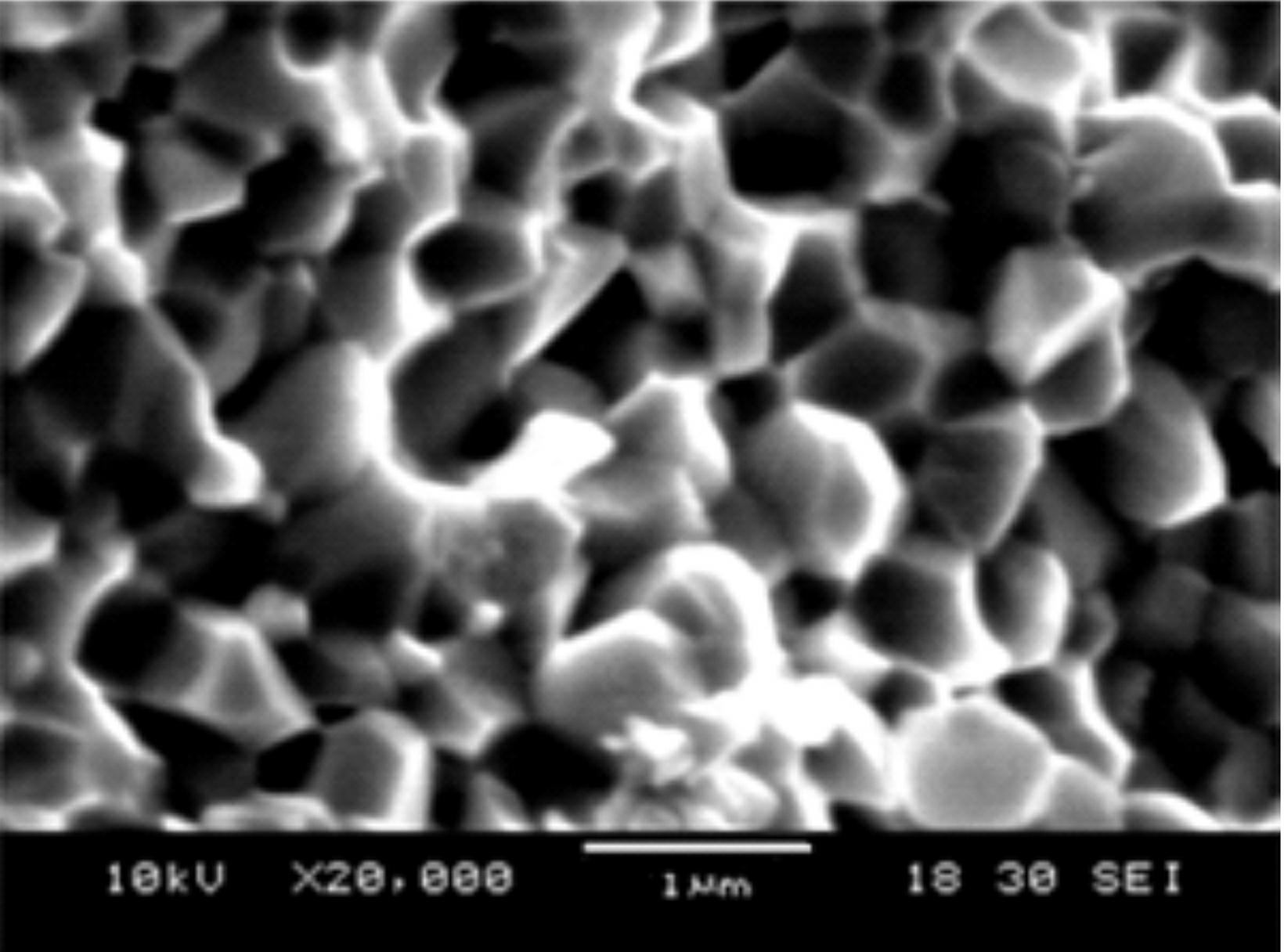

[0021] Example 1: refer to Figure 1 to Figure 3 .

[0022] (1) Preparation of reaction solution: 550 g ZrOCl 2 ?8H 2 O and 534 gAl(NO 3 ) 3 ?9H 2 O was dissolved in the reaction kettle, and 300 mL of dissolved 30.6 gTiCl was added to it 4 Alcohol, then add dissolved 13.6 gY 2 o 3 and La 2 o 3 The hydrochloric acid solution is configured into C Zr 4+ =0.1~0.3 mol / L solution mixed solution, after cooling to room temperature, slowly add precipitant C according to the metering ratio under stirring 6 h 12 N 4 The solution (concentration C=0.2~0.6 mol / L) is mixed evenly. And then add an appropriate amount of dispersant.

[0023] (2) Preparation of xerogel: The above solution was gradually heated and reacted for 2 hours under stirring, and then the pH was adjusted with ammonia water to obtain a sol. The sol was suction-filtered, washed 6 to 7 times, alcoholized, dried in an oven at 100°C, and sieved to obtain a xerogel.

[0024] (3) ZrO 2 Preparation of ceramic cy...

Embodiment 2

[0029] Example 2: (1) Preparation of reaction solution: 650 g ZrOCl 2 ?8H 2 O and 434 gAl(NO 3 ) 3 ?9H 2 O was dissolved in the reaction kettle, and 300 mL of dissolved 30.6 gTiCl was added to it 4 Alcohol, then add dissolved 14.6 gY 2 o 3 and La 2 o 3 The hydrochloric acid solution is configured into C Zr 4+ =0.1~0.3 mol / L solution mixed solution, after cooling to room temperature, slowly add precipitant C according to the metering ratio under stirring 6 h 12 N 4 The solution (concentration C=0.2~0.6 mol / L) is mixed evenly. And then add an appropriate amount of dispersant.

[0030] (2) Preparation of xerogel: The above solution was gradually heated and reacted for 2 hours under stirring, and then the pH was adjusted with ammonia water to obtain a sol. The sol was suction-filtered, washed 6 to 7 times, alcoholized, dried in an oven at 100°C, and sieved to obtain a xerogel.

[0031] (3) ZrO 2 Preparation of ceramic cylinder liner powder: after calcining the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com