Preparation method of antiwear super-hydrophobic carbon black enhanced polyurethane coating

A technology of super-hydrophobic coating and polyurethane, applied in the field of coatings, can solve problems such as rough surface structure damage, super-hydrophobic surface failure, super-hydrophobic function failure, etc., to achieve increased stress area, improved tear resistance, and good adhesion performance effect

Inactive Publication Date: 2015-02-25

SHANDONG UNIV OF TECH

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Super-hydrophobic coatings refer to coatings with a contact angle greater than 150° with water droplets. Super-hydrophobic coatings have the functions of self-cleaning, waterproof, and anti-ice and snow adhesion. They have application prospects in daily life and industrial fields. Super-hydrophobic coatings have a highly rough structure , when the superhydrophobic surface is subjected to friction, in fact, the micron or nanometer protrusions on the surface bear the pressure and shear action, and the pressure and shear stress carried by the surface micro-protrusions are far greater than the apparent pressure and shear stress, thus causing the surface The rough structure is damaged due to stress concentration, which eventually leads to the failure of the superhydrophobic function

Therefore, the superhydrophobic surface is prone to wear and failure during use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0017] Example 2:

Embodiment 2

[0019] Example 3:

Embodiment 3

[0021] Example 4:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Login to View More

Abstract

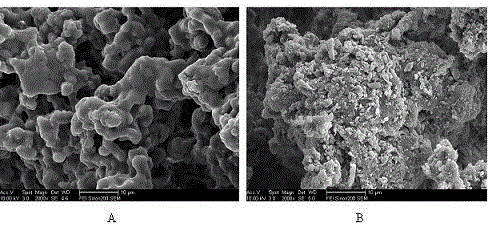

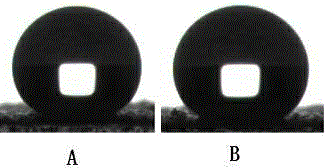

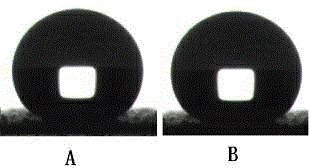

The invention relates to a preparation method of an antiwear super-hydrophobic carbon black enhanced polyurethane coating. The preparation method is characterized in that the coating is composed of carbon black enhanced polyurethane elastomers, the coating surface is of order micro-bump structure, the static contact angle of the coating surface and the water is not larger than 160 degrees, and the coating is subjected to antiwear performance test according to the standard ASTMD (American Society Testing and Materials) 968-05 (Test for measuring wear resistance of an organic coating by a falling sand wear method), and the result indicated that the coating is subjected to wear test by five kilograms of quartz sand falling from a guide pipe 960mm in height and 20mm in internal diameter. The static contact angle of the coating and the water is still kept larger than 150 degrees. The preparation method includes two steps of 1) synthesizing carbon black enhanced polyurethane powder rubber; 2) preparing and spraying coating liquid, after coating, and forming the order micro-bump structure on the surface of a base body, namely the super-hydrophobic coating. The antiwear super-hydrophobic carbon black enhanced polyurethane coating is applicable to glass, metal, wood and ceramic base bodies.

Description

technical field [0001] The invention relates to a preparation method of an anti-wear carbon black reinforced polyurethane superhydrophobic coating, which belongs to the technical field of coatings. Background technique [0002] Super-hydrophobic coatings refer to coatings with a contact angle greater than 150° with water droplets. Super-hydrophobic coatings have the functions of self-cleaning, waterproof, and anti-ice and snow adhesion. They have application prospects in daily life and industrial fields. Super-hydrophobic coatings have a highly rough structure , when the superhydrophobic surface is subjected to friction, in fact, the micron or nanometer protrusions on the surface bear the pressure and shear action, and the pressure and shear stress carried by the surface micro-protrusions are far greater than the apparent pressure and shear stress, thus causing the surface The rough structure is damaged due to stress concentration, which eventually leads to the failure of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D175/14C09D181/04C09D163/00C09D183/08C09D7/12C08G18/69C08G18/10C08G18/32B05D1/02B05D3/02

CPCC09D175/14B05D1/02C08G18/10C08G18/6594C08G18/69C08L2205/035C09D7/61C09D7/65

Inventor 粟常红宋李军吴锦利赵玉杰关丽霞丁琳王婷

Owner SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com