A kind of preparation method of antiwear polysulfide superhydrophobic coating

A super-hydrophobic coating and anti-wear technology, applied in the field of coatings, can solve the problems of rough surface structure damage, super-hydrophobic surface failure, super-hydrophobic function failure, etc., to achieve increased stress area, good low temperature resistance, and good wear resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

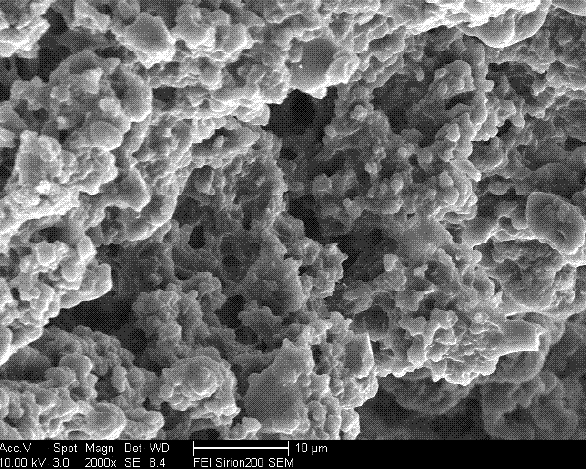

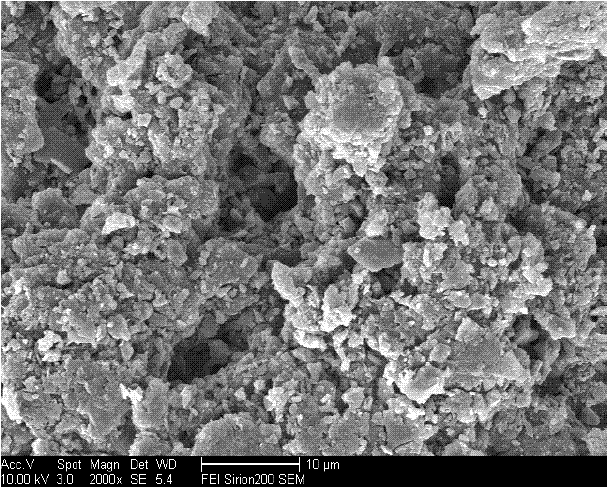

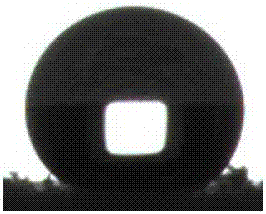

Embodiment 1

[0033] Step 1): Weigh 1.45 grams of liquid polysulfide rubber, 1 gram of toluene diisocyanate and 20 grams of ethyl acetate in a round bottom flask, and react at 60°C for 1 hour to obtain a polysulfide polyurethane prepolymer solution. Polyurethane prepolymer solution is slowly added dropwise to 28.06 grams of mass concentration in the ethanol solution of 1.0% diethylenetriamine, and the stirring speed of 300 revolutions per minute is maintained during the dropping process to obtain polysulfide powder rubber dispersion;

[0034] Step 2): uniformly mix the above polysulfide powder rubber dispersion with 12.63 grams of ethyl acetate solution of epoxy resin F-51 with a mass concentration of 10%, add 0.189 grams of triethylenetetramine and 0.253 grams of amino silicone oil dropwise, and mix Obtain the spray coating uniformly, spray it on the glass sheet with a spray gun, and cure it at 20 degrees Celsius for 12 hours, and the obtained coating is a super-hydrophobic coating.

[003...

Embodiment 2

[0037] Step 1): Weigh 1.9 grams of liquid polysulfide rubber, 1 gram of toluene diisocyanate and 20 grams of ethyl acetate in a round bottom flask, and react at 60°C for 1 hour to obtain a polysulfide polyurethane prepolymer solution. The polyurethane prepolymer solution is slowly added dropwise to 25.42 grams of mass concentration in the ethanol solution of 1.0% diethylenetriamine, and the stirring speed of 500 revolutions per minute is maintained during the dropping process to obtain the polysulfide powder rubber dispersion;

[0038] Step 2): uniformly mix the above-mentioned polysulfide powder rubber dispersion with 15.09 grams of ethyl acetate solution of epoxy resin F-51 with a mass concentration of 10%, add 0.19 grams of triethylenetetramine and 0.267 grams of amino silicone oil dropwise, and mix Obtain the spray coating uniformly, spray it on the glass sheet with a spray gun, and cure it at 20 degrees Celsius for 12 hours, and the obtained coating is a super-hydrophobic ...

Embodiment 3

[0041] Step 1): Weigh 1.9 grams of liquid polysulfide rubber, 1 gram of toluene diisocyanate and 20 grams of ethyl acetate in a round bottom flask, and react at 60°C for 1 hour to obtain a polysulfide polyurethane prepolymer solution. The polyurethane prepolymer solution is slowly added dropwise to 28.625 grams of ethanol solution with a mass concentration of 1.0% diethylenetriamine, and a stirring speed of 400 revolutions per minute is maintained during the dropping process to obtain a polysulfide powder rubber dispersion;

[0042] Step 2): uniformly mix the above polysulfide powder rubber dispersion with 16.1 grams of ethyl acetate solution of epoxy resin F-51 with a mass concentration of 10%, add dropwise 0.20 grams of triethylenetetramine and 0.284 grams of amino silicone oil, and mix Obtain the spray coating uniformly, spray it on the glass sheet with a spray gun, and cure it at 20 degrees Celsius for 12 hours, and the obtained coating is a super-hydrophobic coating.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com