Patents

Literature

510 results about "Plastic fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition and method for forming a sprayable materials cover

InactiveUS20050084334A1Improve performanceImprove adhesionSolid waste disposalLandfill technologiesWater dispersibleSlurry

An alternative cover for landfill may be formed from a slurry mixture of water, cementitious binder, adhesion enhancing admixture and fiber. These constituents may be mixed and applied to cover landfilled wastes, granular material piles or for soil erosion control. The cover will harden to minimize water infiltration, wind blown dust, odor and affinity to birds, flies and other insects. The water may include tap water, landfill leachate and wastewater. The binder may include Portland cement, blended cement, cement kiln dust, class C fly ash, and / or calcium sulphate hemihydrate. The adhesion enhancing admixture includes water-dispersible polymers. The fibers may comprise shredded paper or wood or plastic fibers.

Owner:CJS TECH

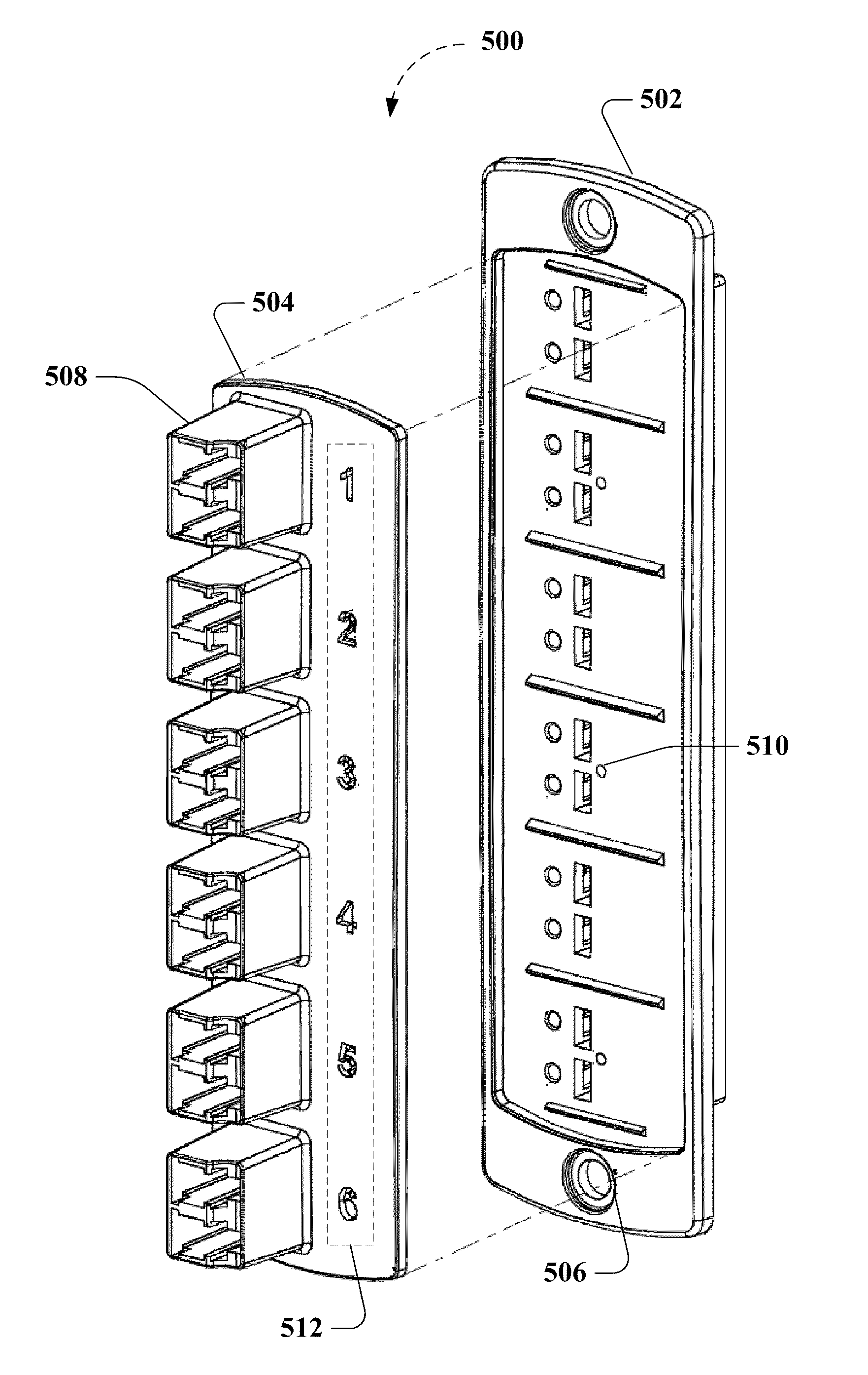

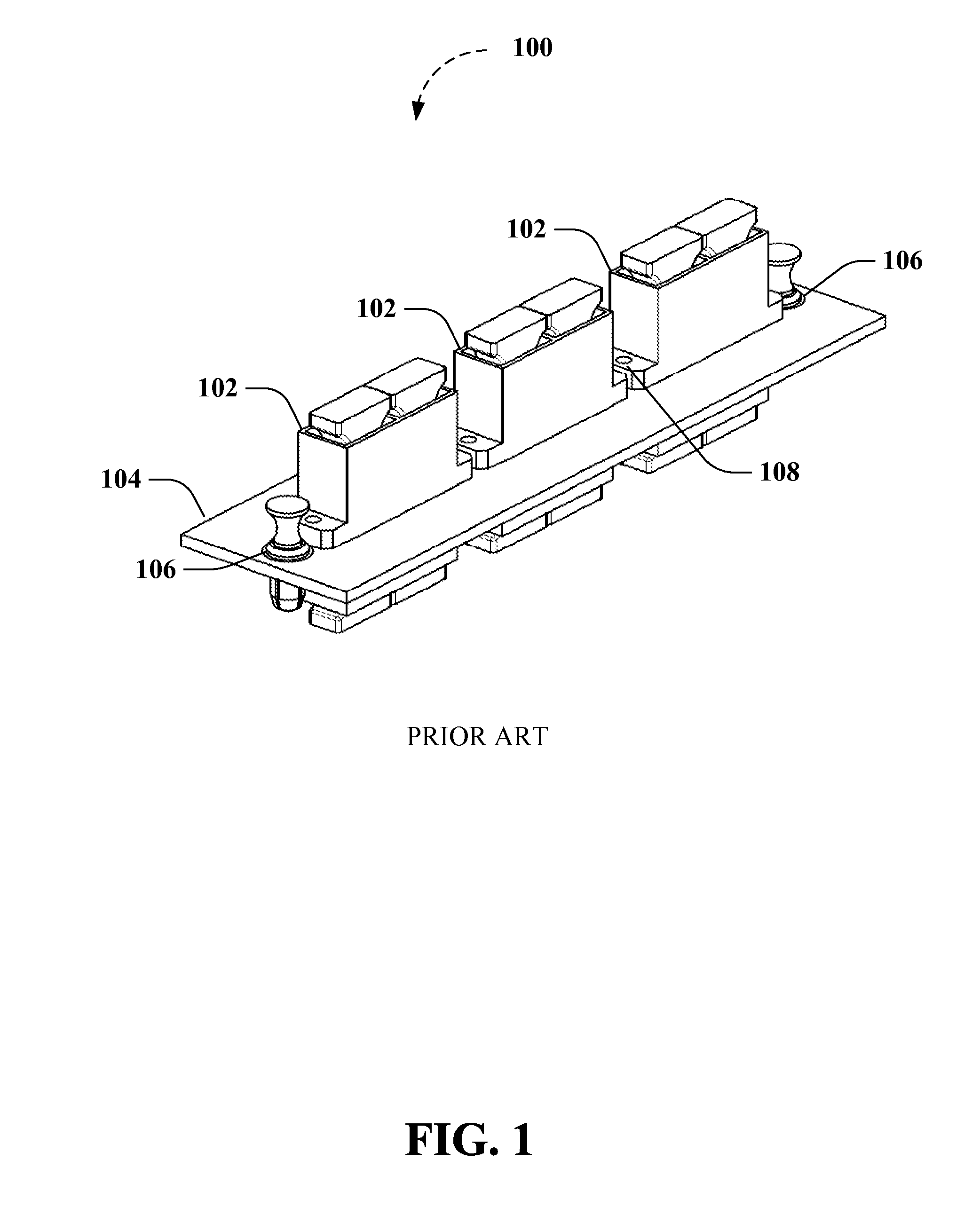

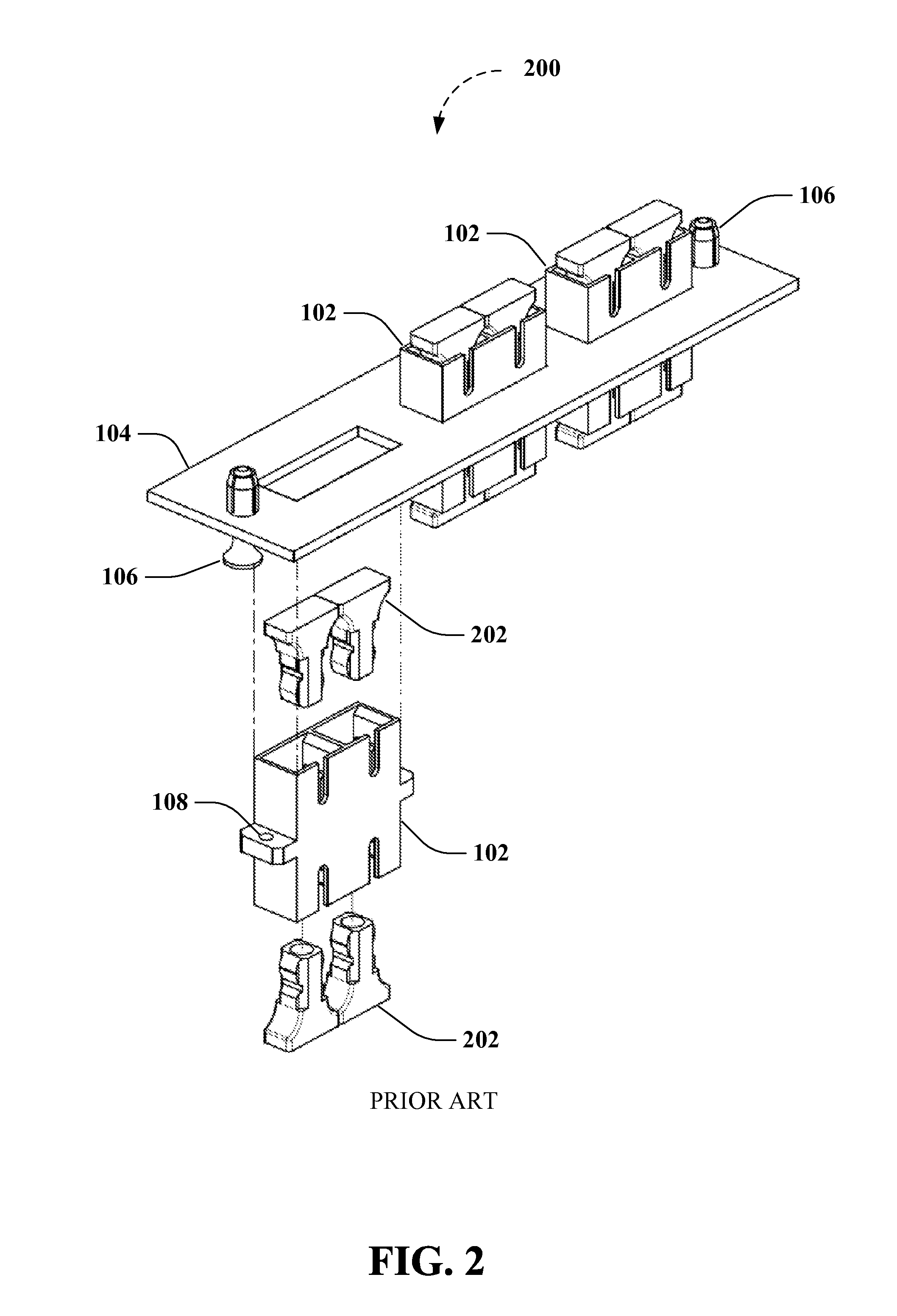

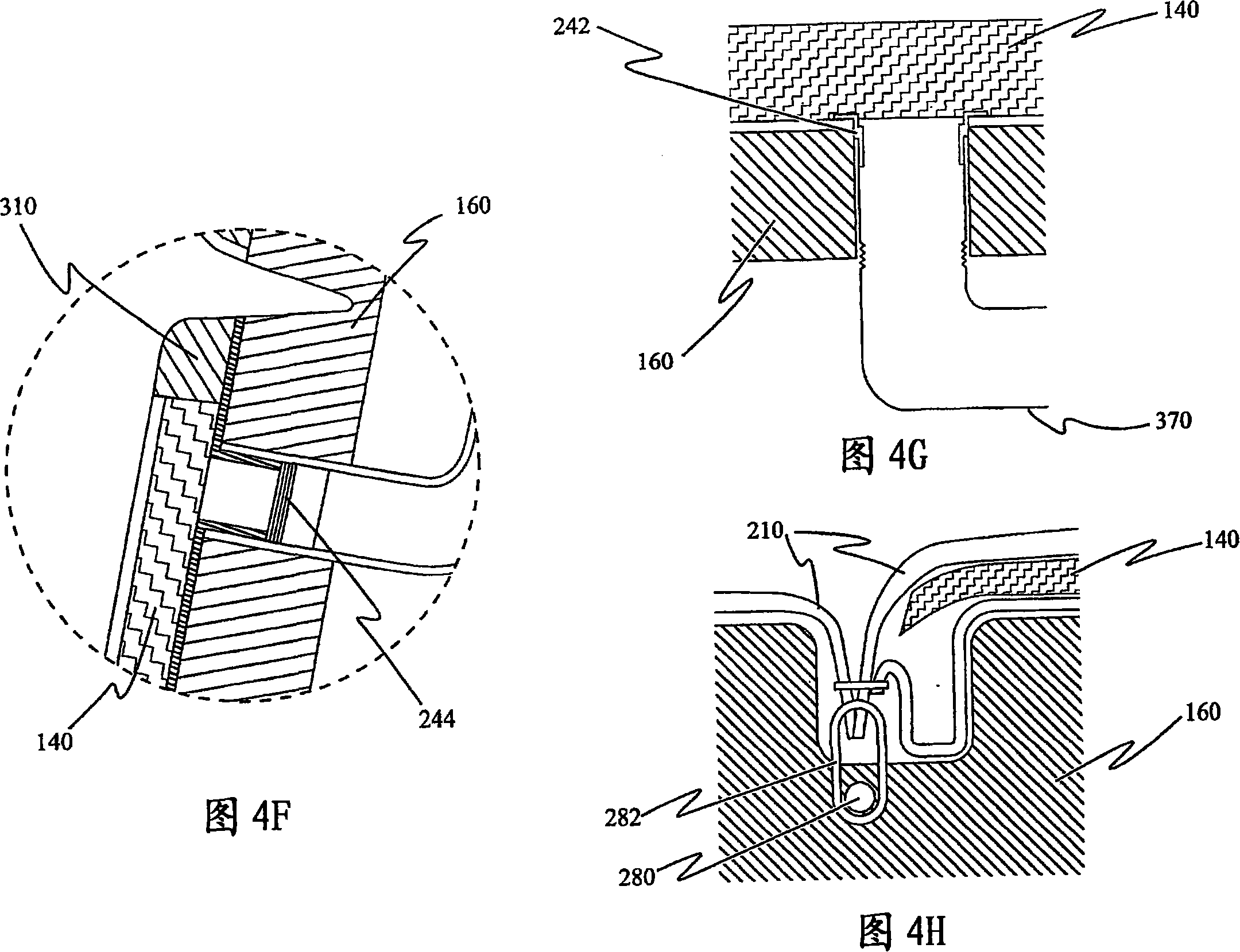

Fiber optic adapter plates with integrated fiber optic adapters

Structures, devices and methods are provided for creating fiber optic adapter plates with integrated fiber optic adapters. In one aspect, fiber optic adapter plates having integrated fiber optic adapter subassemblies are formed from a moldable plastic. For example, a molded plastic fiber optic adapter plate can include a molded plastic adapter back plate having a plurality of integrated fiber optic adapter subassemblies and one or more attachment mechanisms that facilitate locating and attaching an adapter front plate having a corresponding plurality of integrated fiber optic adapter subassemblies on the adapter front plate. Advantages provided by integrating fiber optic adapters into the molded plastic assemblies include superior mechanical strength, manufacturing cost reductions and adapter placement flexibility among other advantages.

Owner:LEVITON MFG

Device and method for charge removal from dielectric surfaces

InactiveUS6934142B2Optimized charge removalEasy to operateElectric discharge tubesEmergency protective arrangements for automatic disconnectionElectricityDielectric surface

A device and a method for at least partial removal of electric charges from dielectric surfaces, in particular surfaces of plastic films, paper webs or plastic fibers are described. First, a plasma is generated through microstructure discharges with a plasma device in at least one plasma region. In addition, the dielectric surface is introduced into the plasma region with a feed mechanism and is temporarily exposed to electrically charged particles generated by the plasma there.

Owner:ROBERT BOSCH GMBH

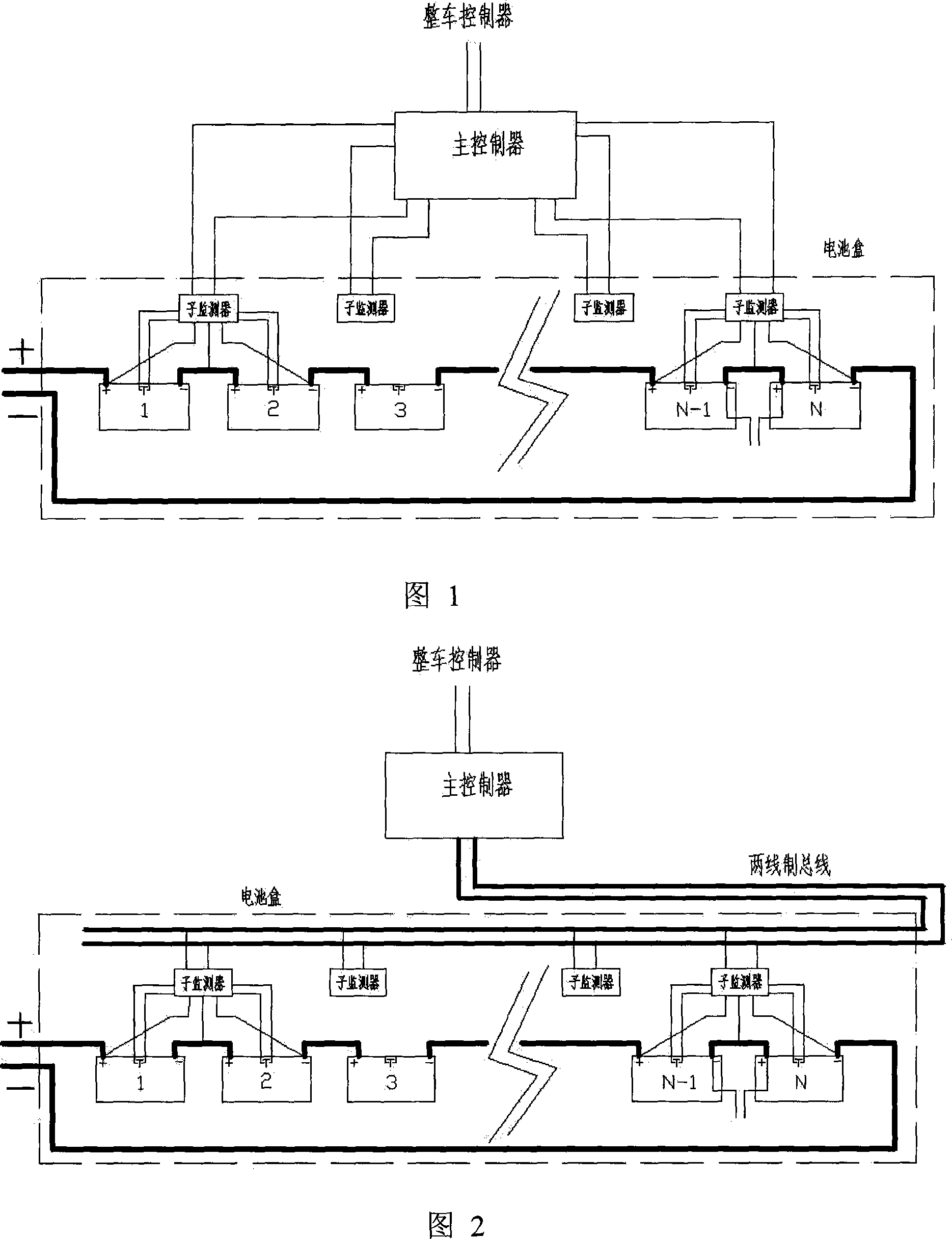

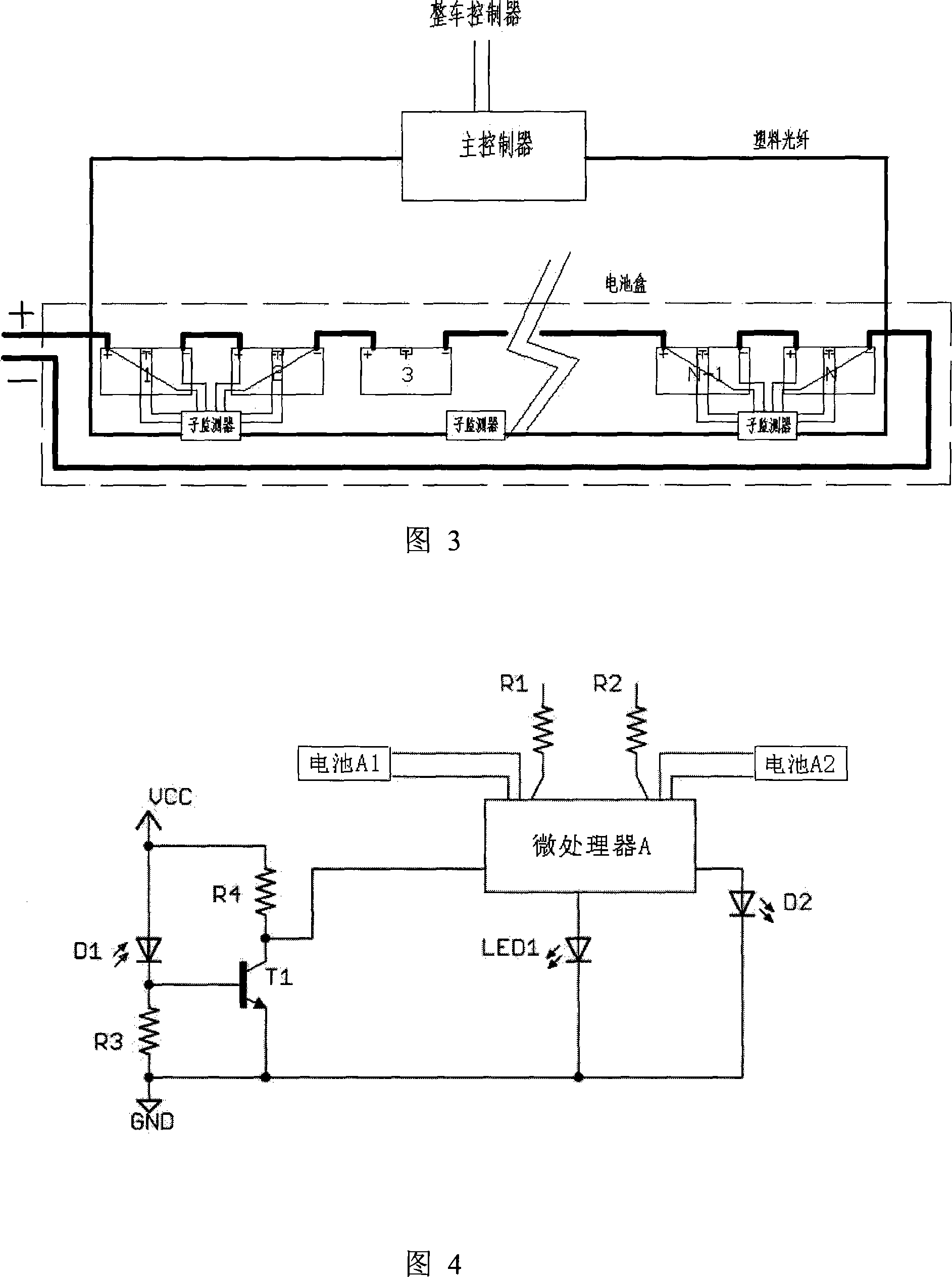

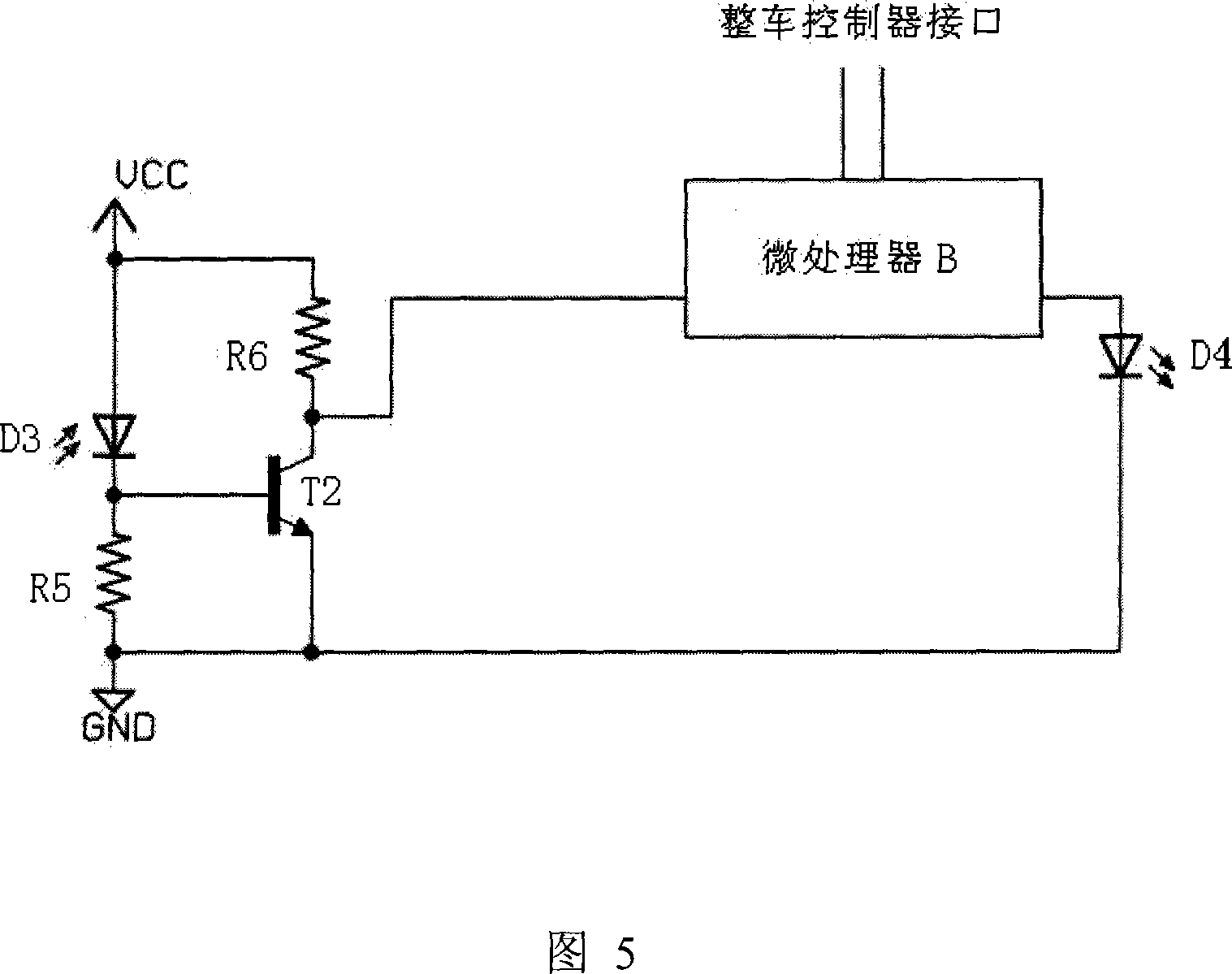

Battery management system for electric automobile

InactiveCN101119036AIncrease communication power consumptionCircuit monitoring/indicationCharge equalisation circuitElectrical batteryElectromagnetic interference

The present invention discloses a battery managing system for electromotive vehicle, which includes: a plurality of the monitors. Each monitor takes the sample for the voltage and temperature of a single battery or a plurality of the single batteries; a main controller which is used for receiving the voltage and temperature data emitted by the sub-monitor, and analyzing the data to realize the balance controlling for the battery, and simultaneously finish the communication with the whole vehicle controller. The main controller and a plurality of the sub-monitors are connected with each other in parallel by the plastic fiber, to form a loop circuit structure. Using the battery managing system with the structure, the main controller and the sub-monitor are connected with each other in parallel by the plastic fiber, to completely eliminate the potential safety hazard and the electromagnetic interference caused by the communication wires are distributed in the high voltage net of the pile with a large area.

Owner:北京亿马先锋汽车科技有限公司

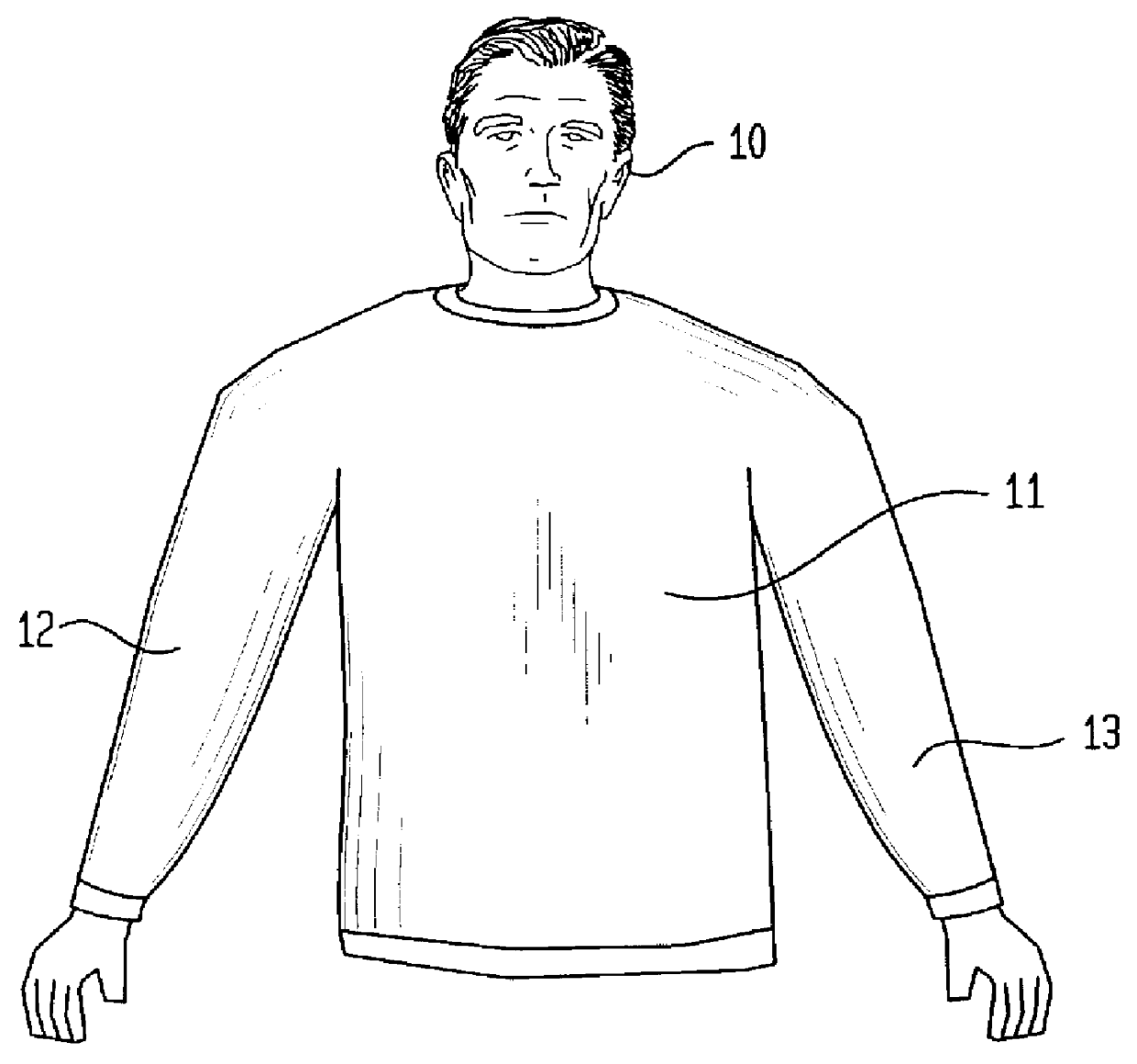

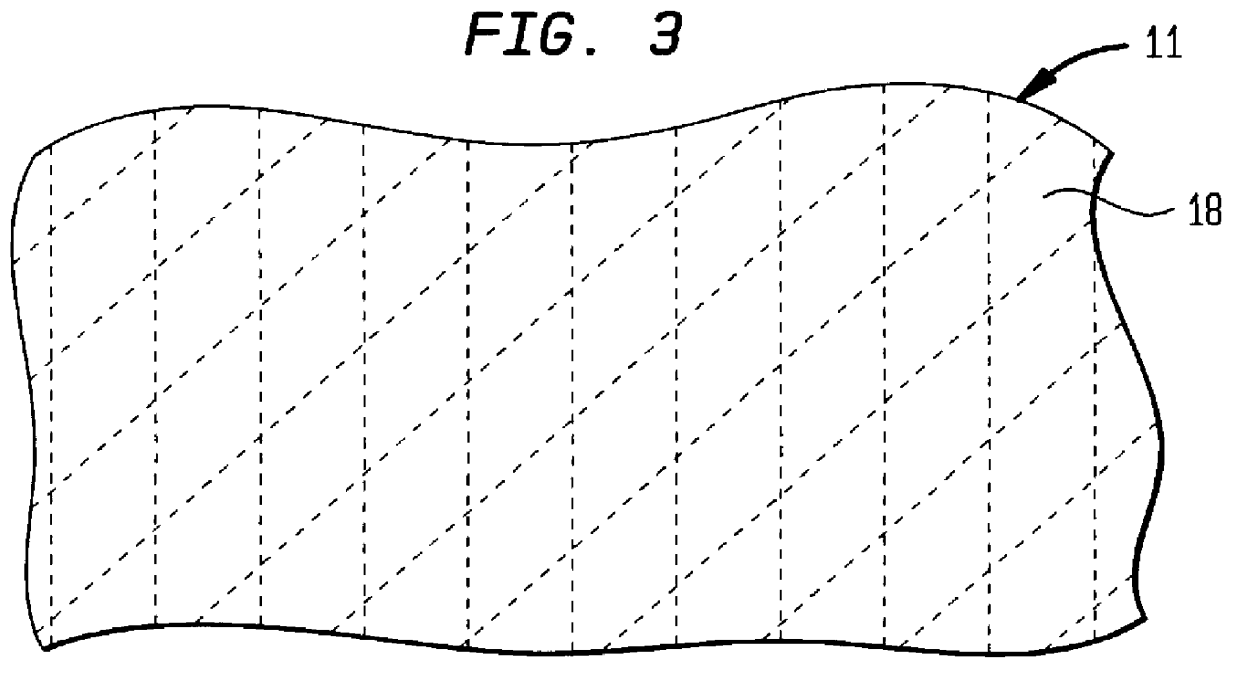

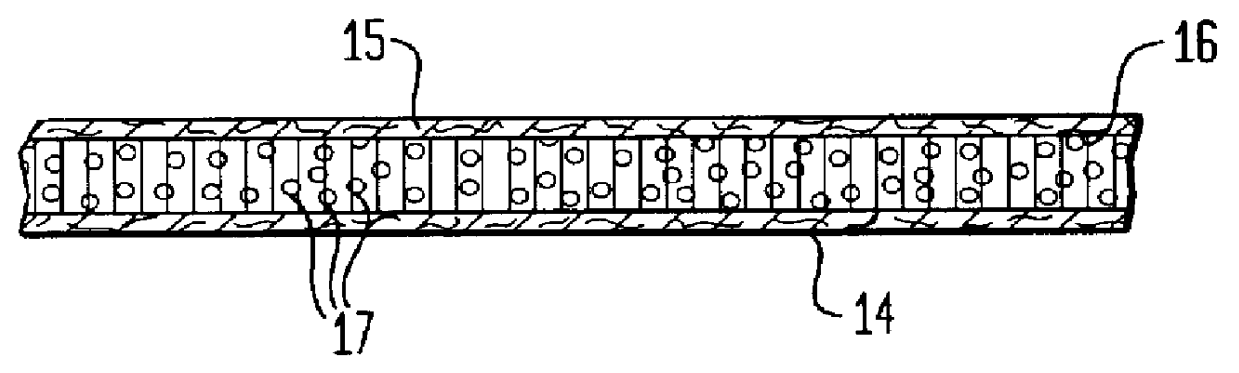

Water-resistant outerwear

A light-weight fabric for producing outerwear garments suitable for wear on boats, beaches and in other environments in which the wearer may be exposed to rain or water, as well as to cold temperature. The fabric is composed of inner and outer skins formed of woven synthetic plastic fibers, such as nylon, which render the skins water-resistant, yet permeable to vapor whereby the fabric is breathable. Sandwiched between the skins is a layer of polyester fiberfill which imparts thermal insulation-characteristics to the fabric. Dispersed throughout the fiberfill and imprisoned therein are fine, closed-cell foam plastic beads which impart buoyancy and quick-dry properties to the fabric.

Owner:SPECTOR DONALD

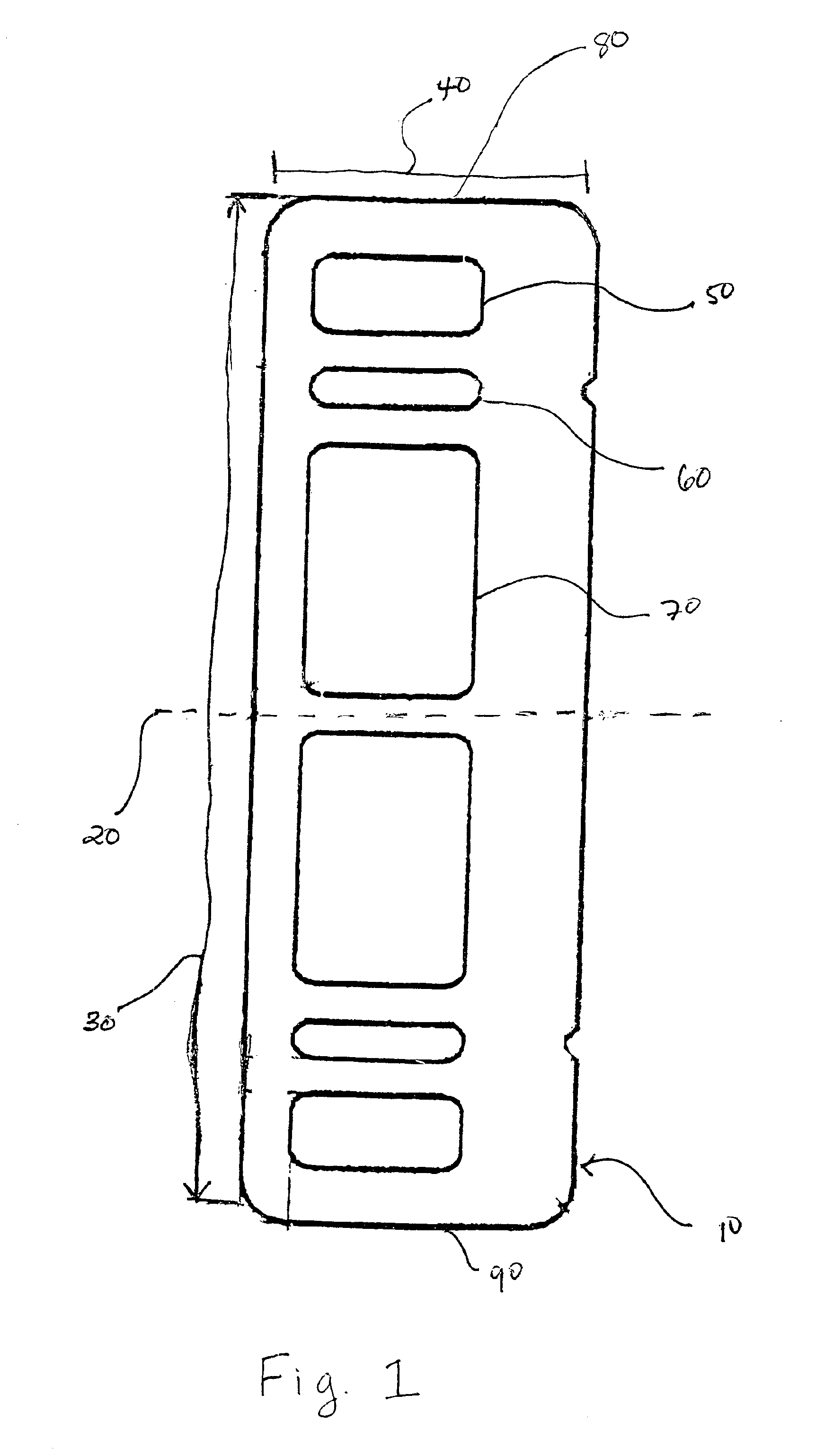

Composite materials, articles of manufacture produced therefrom, and methods for their manufacture

InactiveUS6881367B1Short lifeEasy to replaceSolid waste managementLaminationPolymer scienceUltraviolet lights

The invention is directed to a plastic fiber article of manufacture having composite-like high strength characteristics. The article of manufacture can be in the form of a panel or board. The panel or board is constructed from low cost fiber materials, industrial grade or high thermal plastic, and other additives to protect the board or panel from ultraviolet light, fugii growth, excessive heat, fire, insect infestation, and / or weathering. The plastic fiber panel or board may be textured and colored to resemble natural wood such as cedar, walnut, or oak. The plastic fiber panel or board is stronger more durable and may be cheaper than natural wood alternative panels or boards.

Owner:ELK COMPOSITE BUILDING PRODS

Composition and method for forming a sprayable materials cover

InactiveUS7284930B2Improve performanceImprove adhesionLandfill technologiesSolid waste disposalWater dispersibleSlurry

An alternative cover for landfill may be formed from a slurry mixture of water, cementitious binder, adhesion enhancing admixture and fiber. These constituents may be mixed and applied to cover landfilled wastes, granular material piles or for soil erosion control. The cover will harden to minimize water infiltration, wind blown dust, odor and affinity to birds, flies and other insects. The water may include tap water, landfill leachate and wastewater. The binder may include Portland cement, blended cement, cement kiln dust, class C fly ash, and / or calcium sulphate hemihydrate. The adhesion enhancing admixture includes water-dispersible polymers. The fibers may comprise shredded paper or wood or plastic fibers.

Owner:CJS TECH

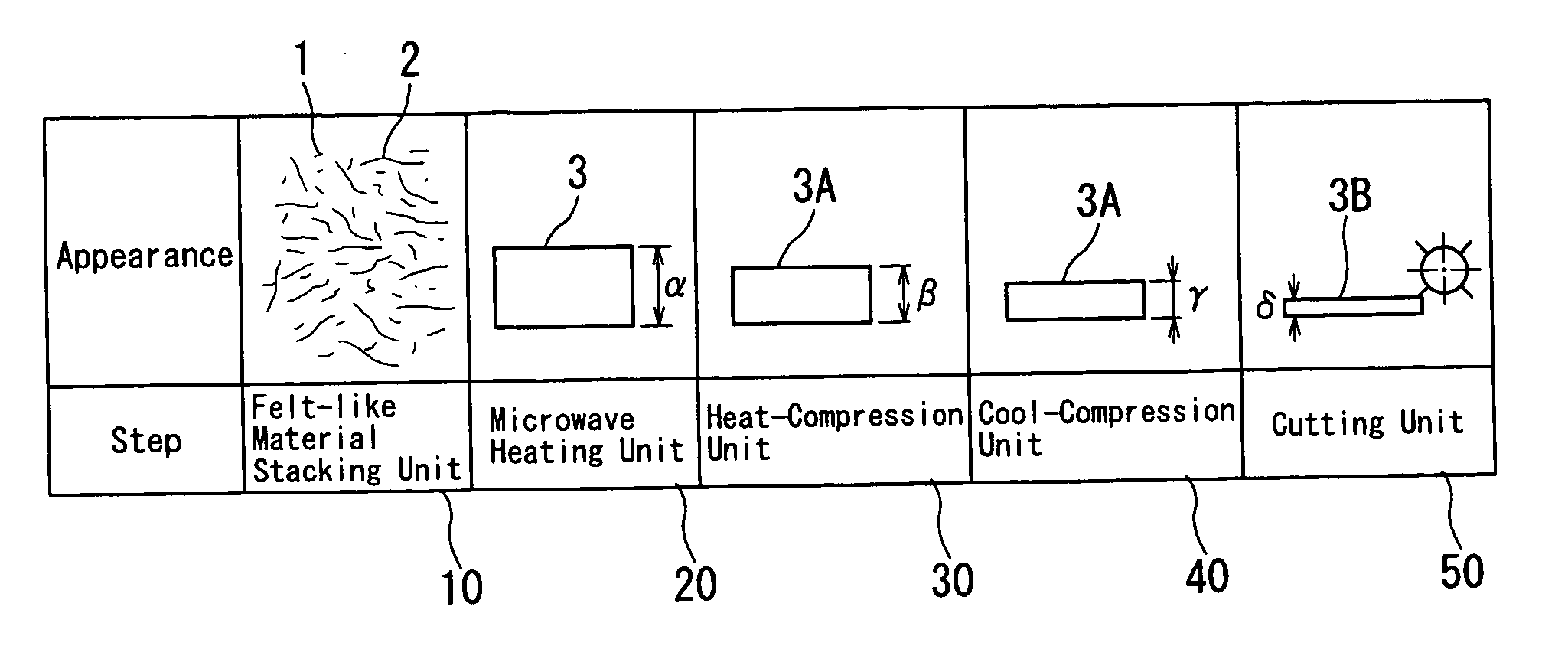

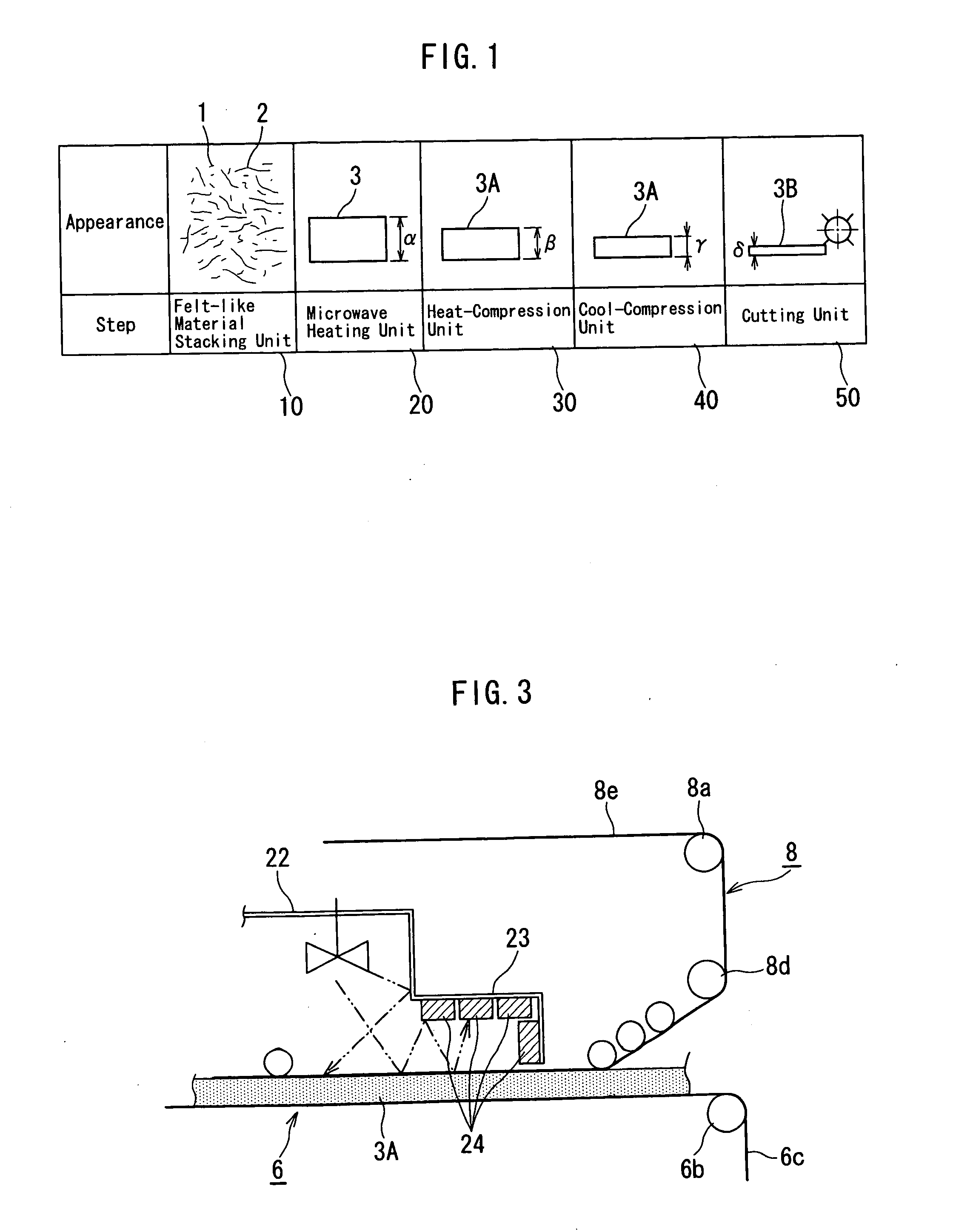

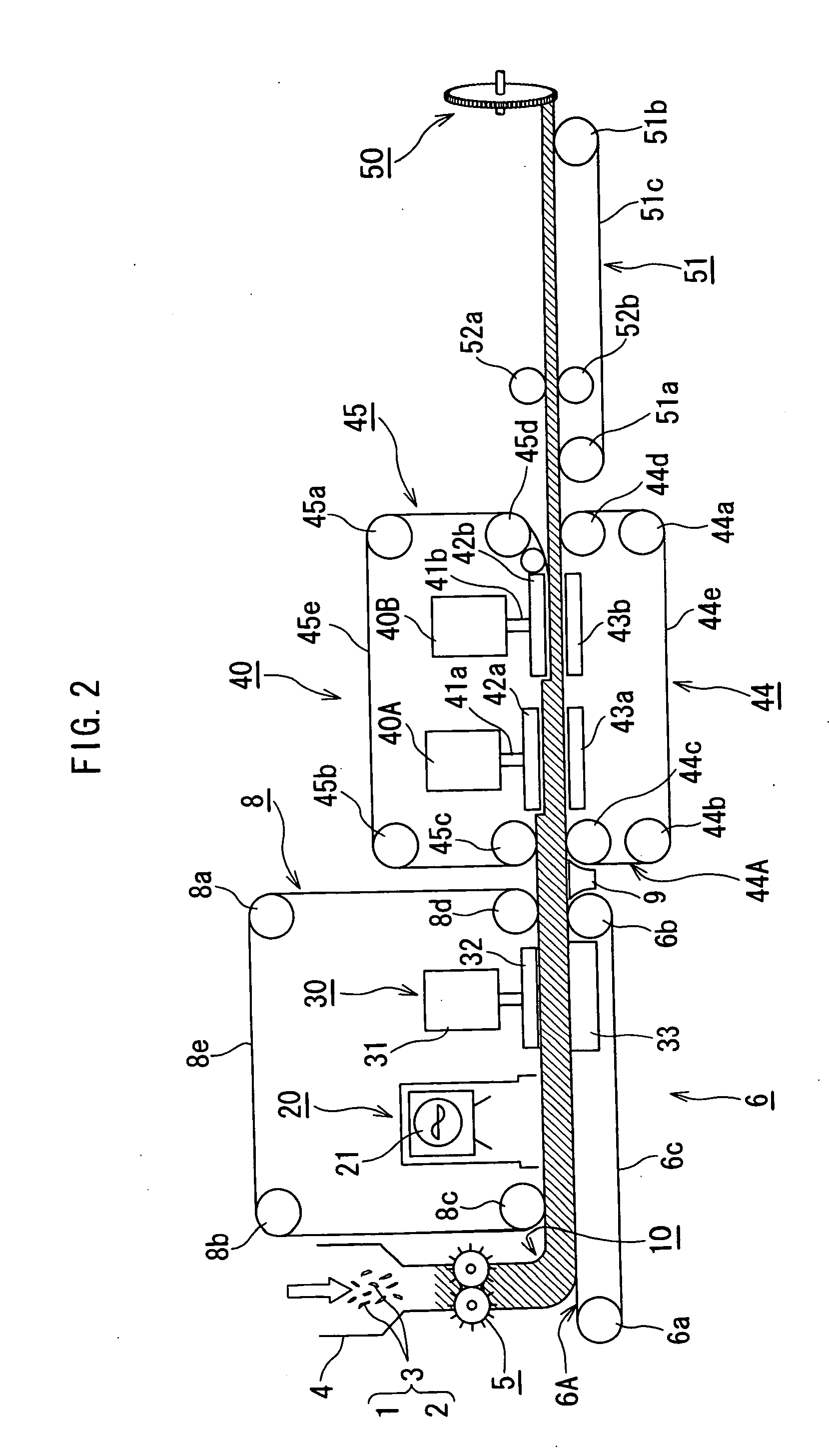

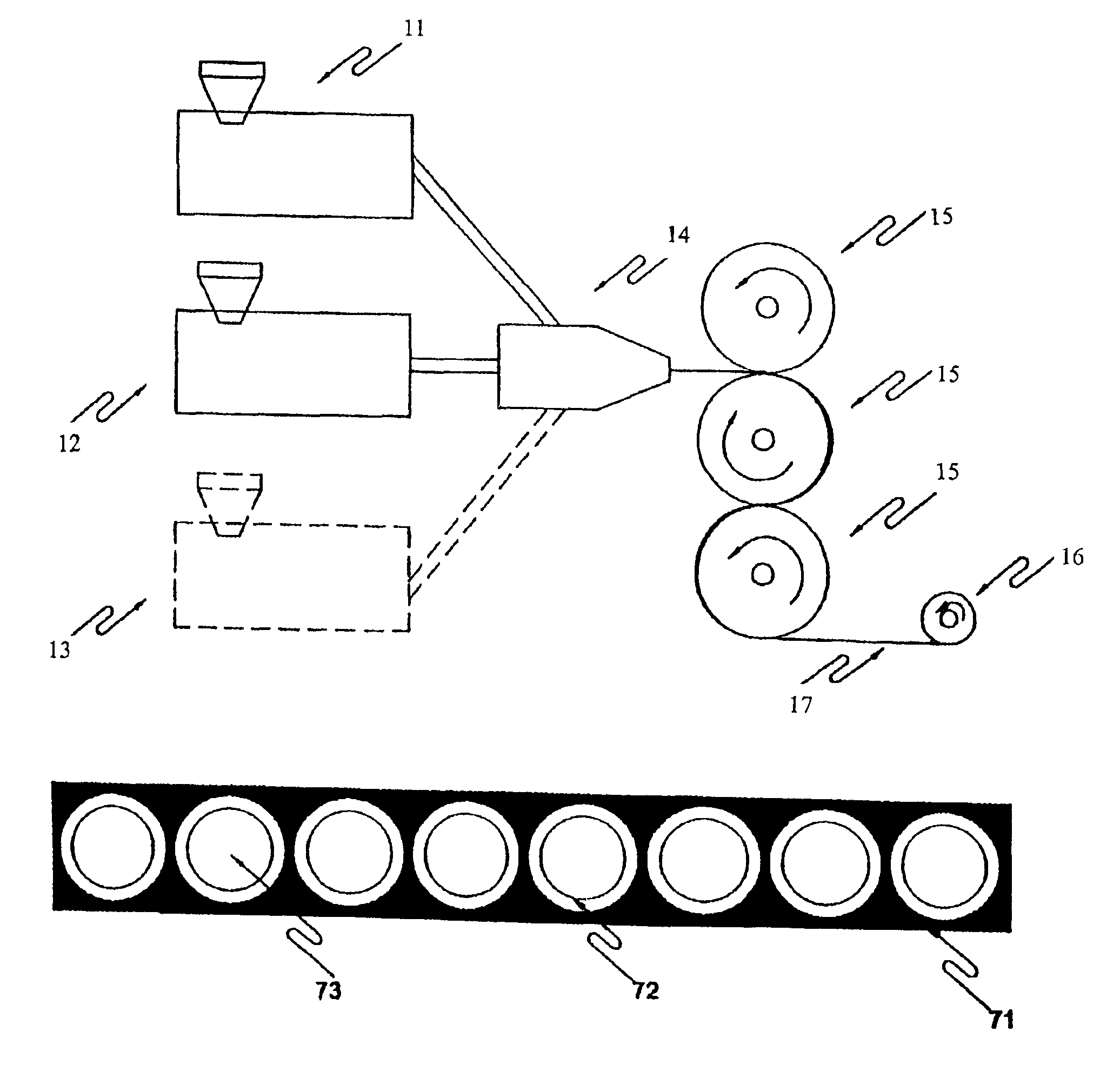

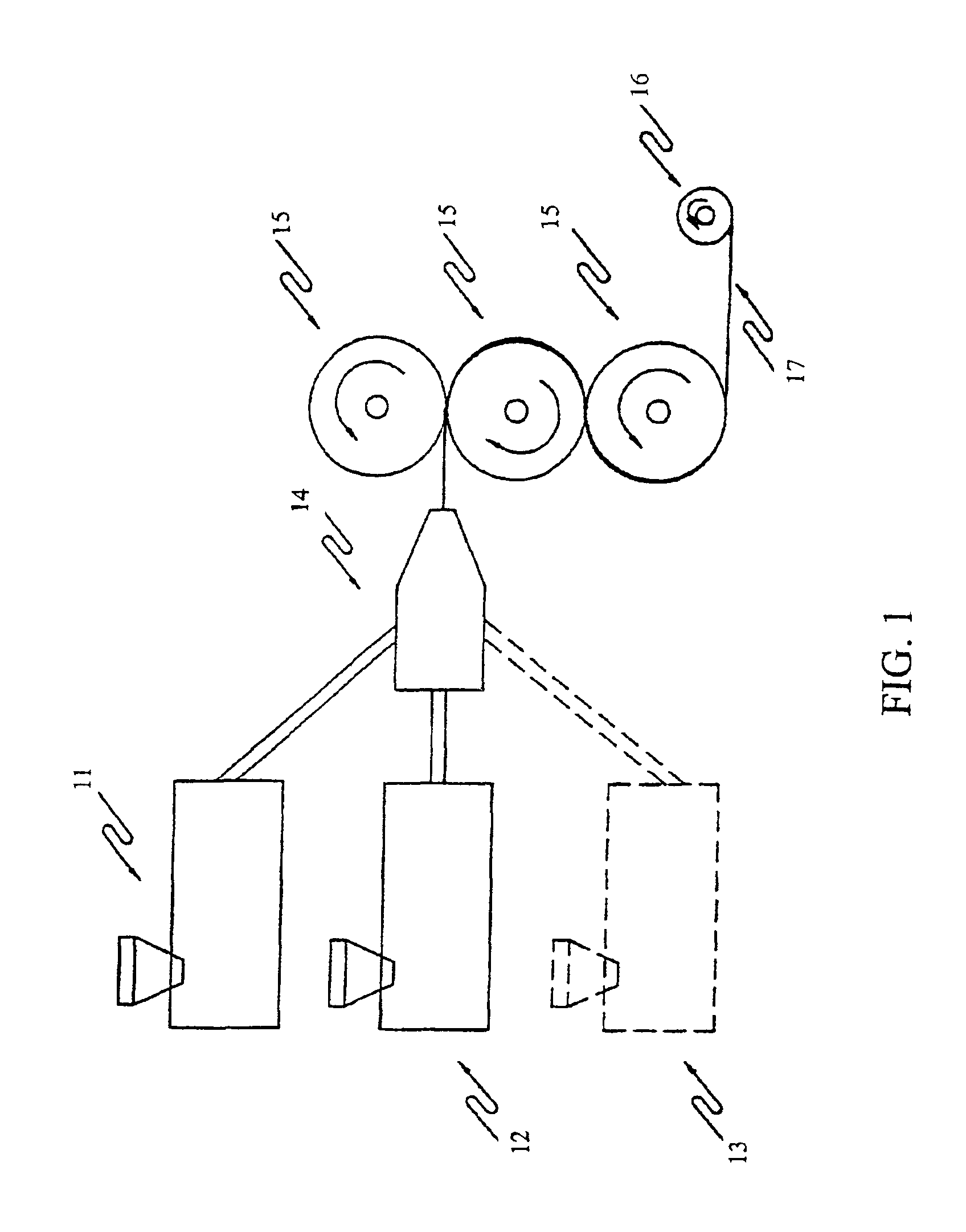

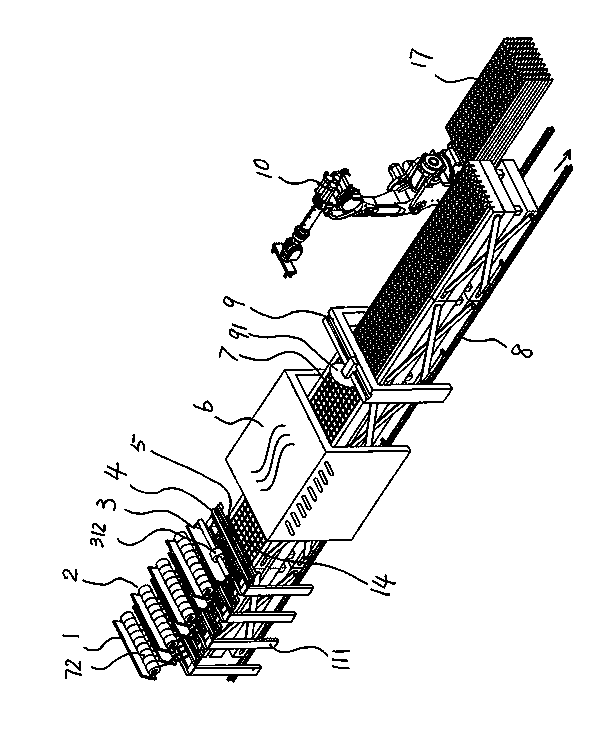

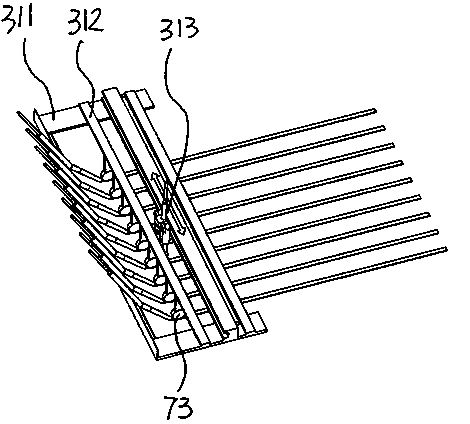

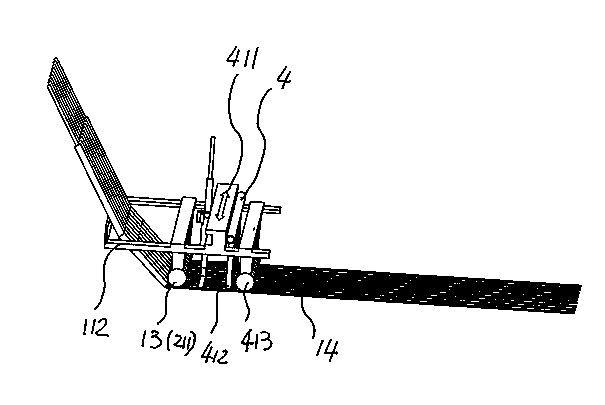

Plastic fiber molding, manufacturing method of plastic fiber molding and manufacturing apparatus for plastic fiber board

InactiveUS20050238865A1Increase physical strengthStrengthDielectric heatingConfectioneryPlant fibrePlastic fiber

Plastic fibers and plant fiber such as thinned woods, scrap woods of buildings, stumps, branches or barks are stirred and mixed with each other into a felt-like material. Microwaves are radiated on the felt-like fiber mixture material. After a sufficient temperature is ensured for the felt-like fiber mixture material of low density by the microwave radiation, the fiber mixture material is fed to a pair of upper and lower pressure plates and compressed thereat. The fiber mixture material is rapidly compressed by the pressure plates so as to be melted and integrated. Then, the fiber mixture material is cooled so as to be further packed by such cooling, thereby becoming a stronger plastic fiber board.

Owner:TOPIA

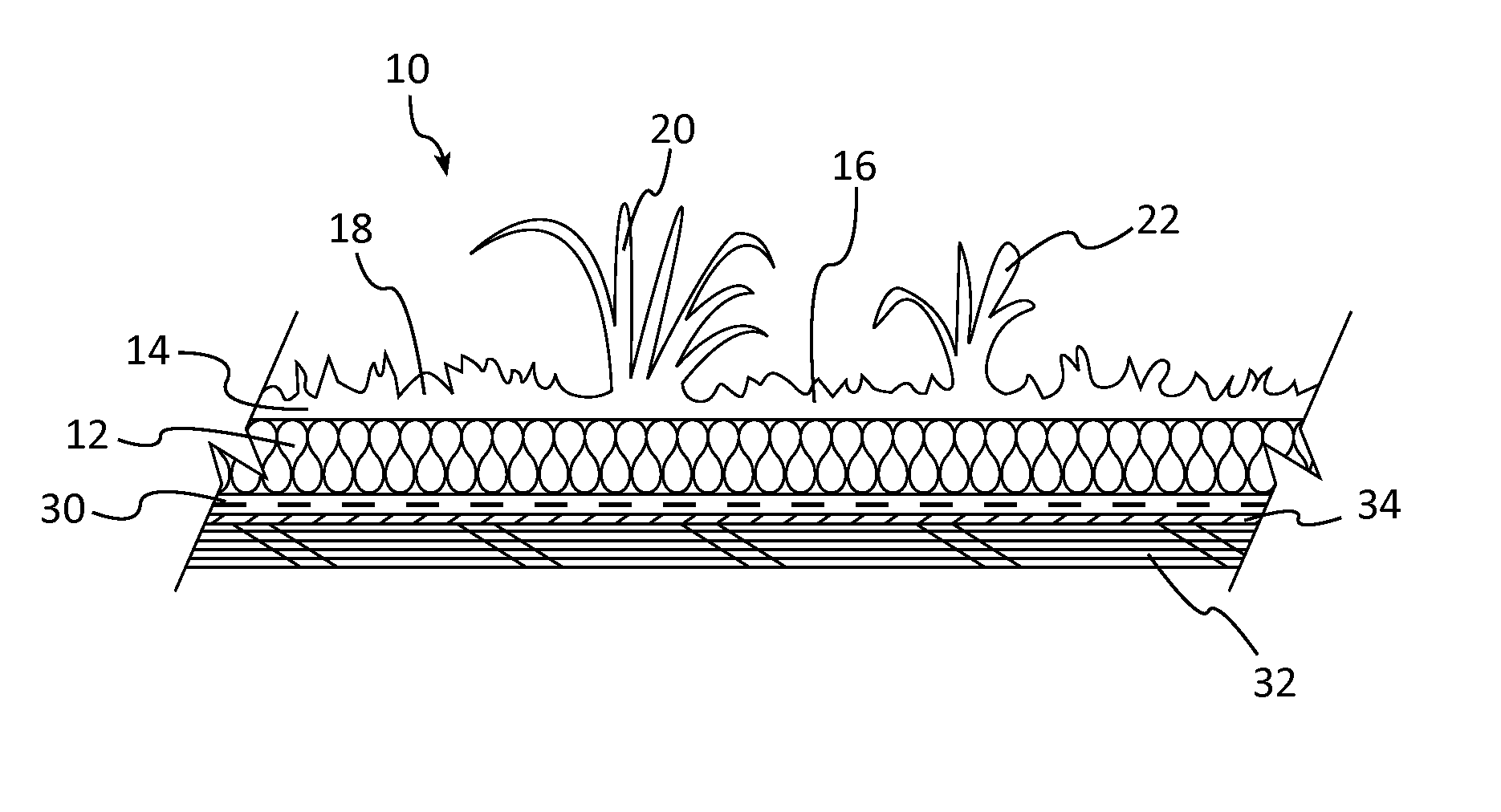

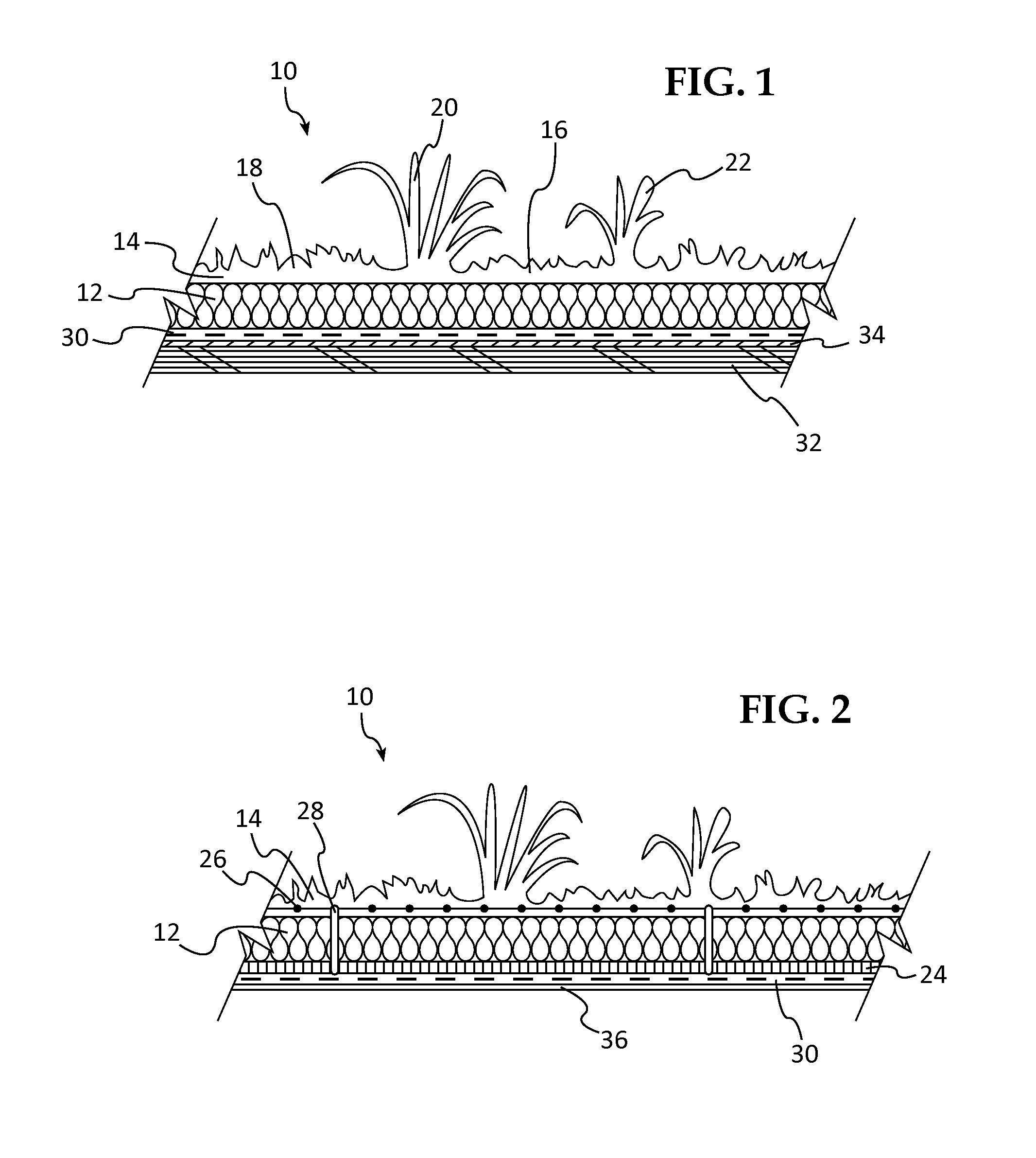

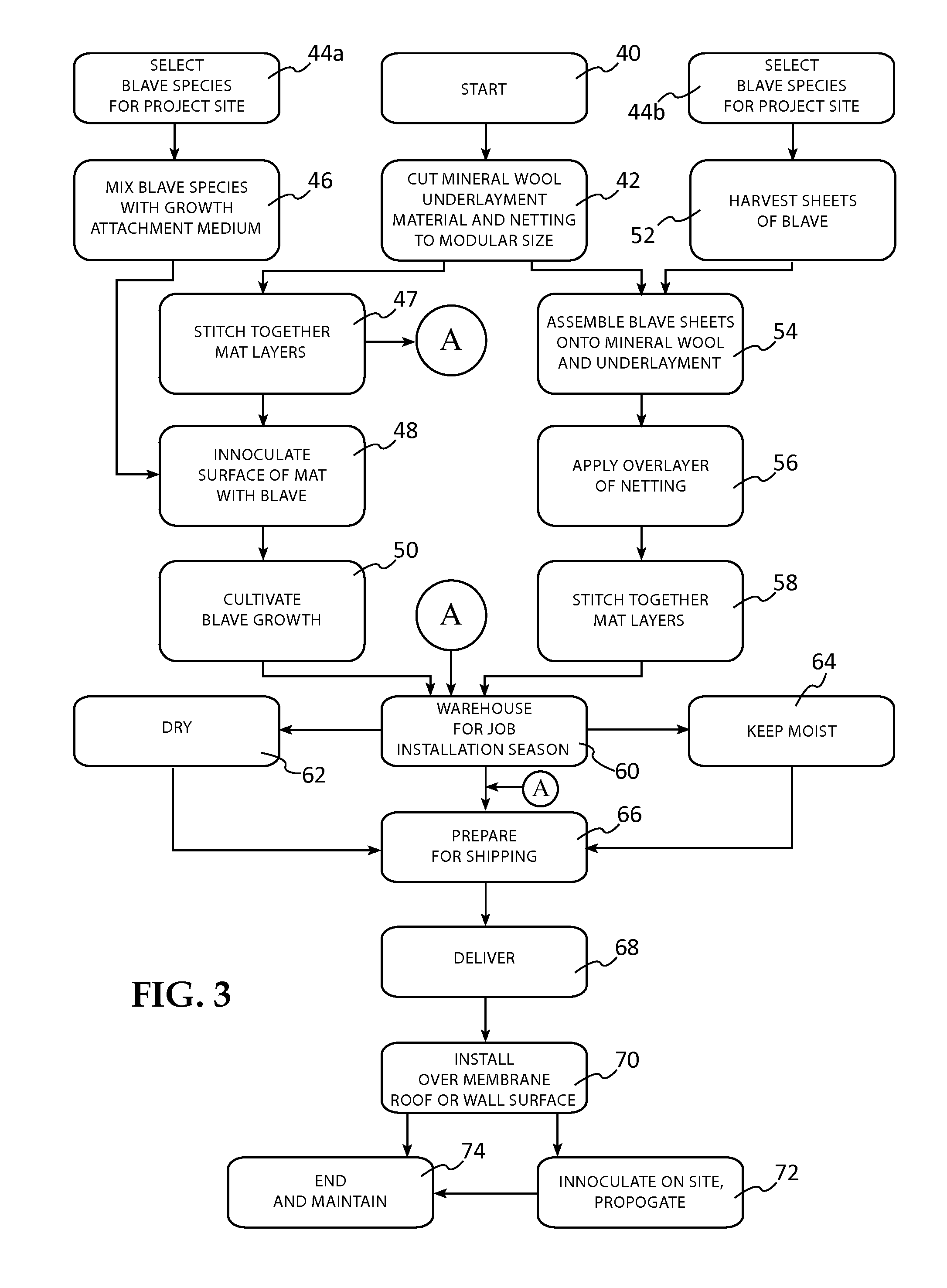

Living Roof and Wall Systems Using Cultivated Mineral Wool Mats to Support BLAVEs, Methods of Cultivation and InnoculantsTherefor

ActiveUS20110197504A1Improve integrityImproves Structural IntegrityRoof improvementHops/wine cultivationAdhesiveCell culture media

Soil-free living roof and wall systems comprising a living layer of Bryophytes, Lichen, And Vascular Epiphytes (BLAVE) on the surface of a thin, light-weight, flexible, fire-resistant mat of mineral wool having a density in the range of about 6-12 lbs / cu ft and thickness in the range of about ⅜″ to about ¾″. Mats are provided in modular units on the order of 2′×4′; no irrigation or growth medium is used. The mats are adhered to a roof or wall with adhesive or mastic, or may be secured with fasteners. In the preferred embodiment, modular units include flexible mineral wool mats over a base sheet of non-woven plastic fibers, on the order of from 2-4 mm thick, and a wide-mesh plastic netting over the BLAVE layer, sewn through to the base layer. Methods of mat module manufacture, innoculant mix production, installation and cultivation / propagation of BLAVE are disclosed.

Owner:ARCHIPHYTE

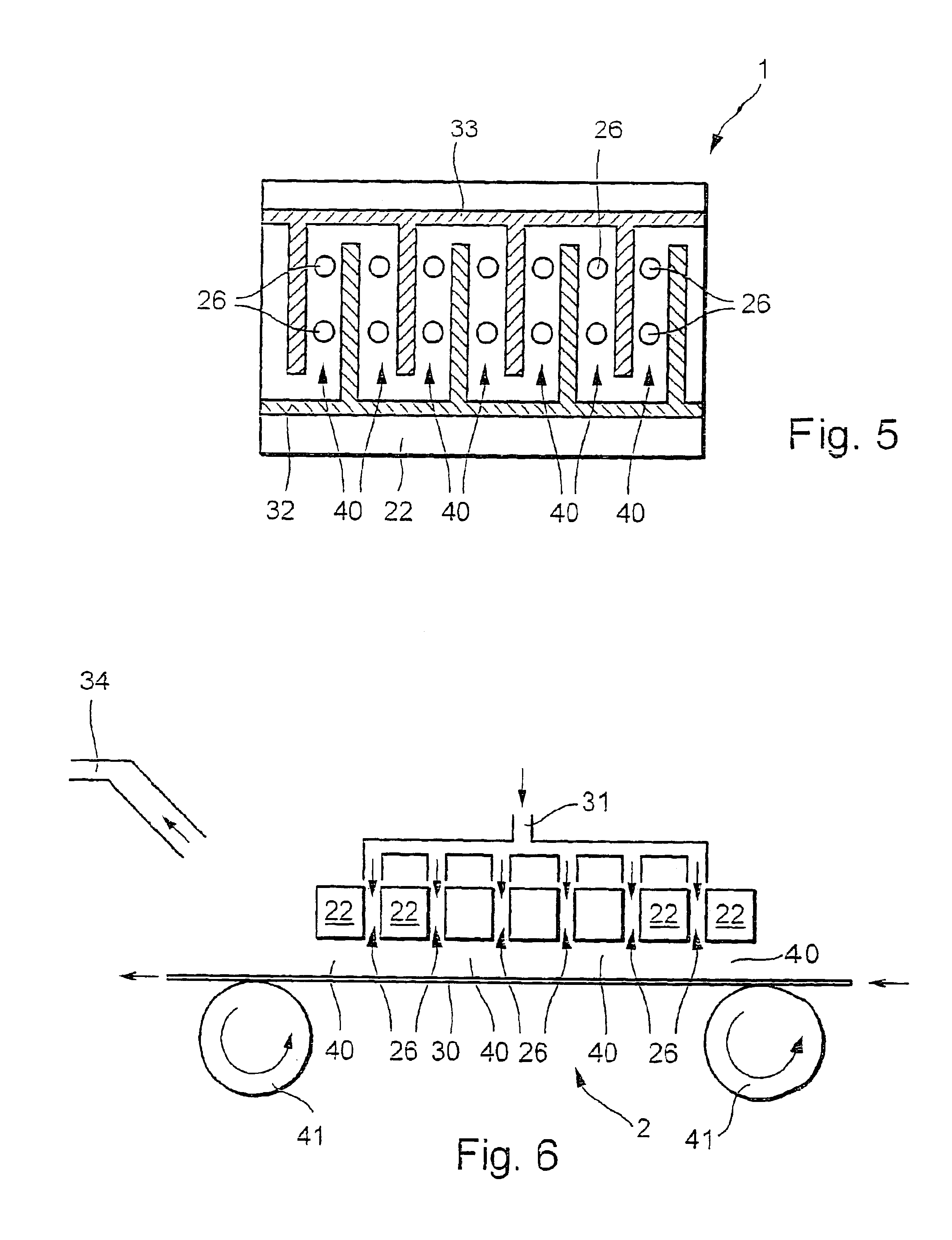

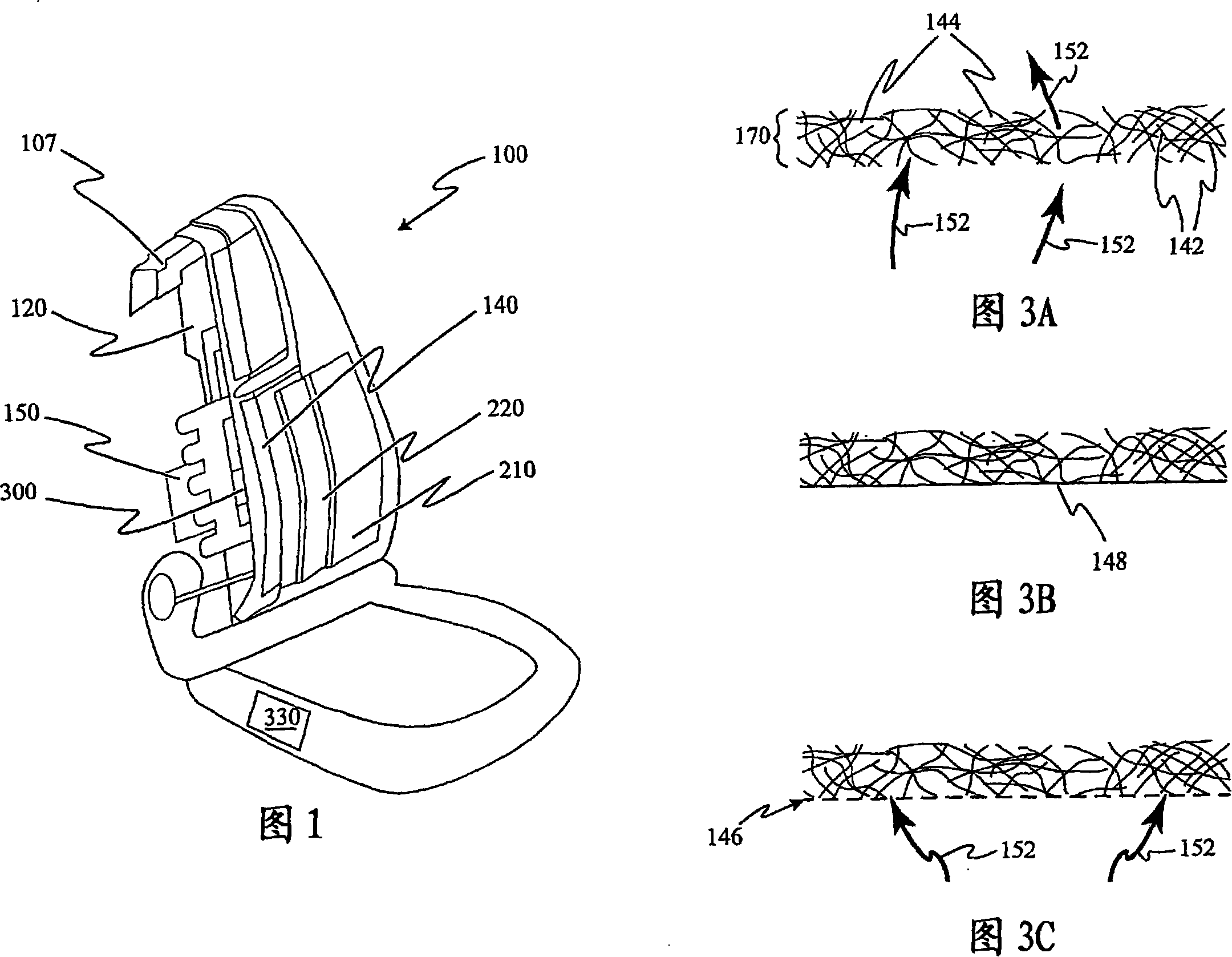

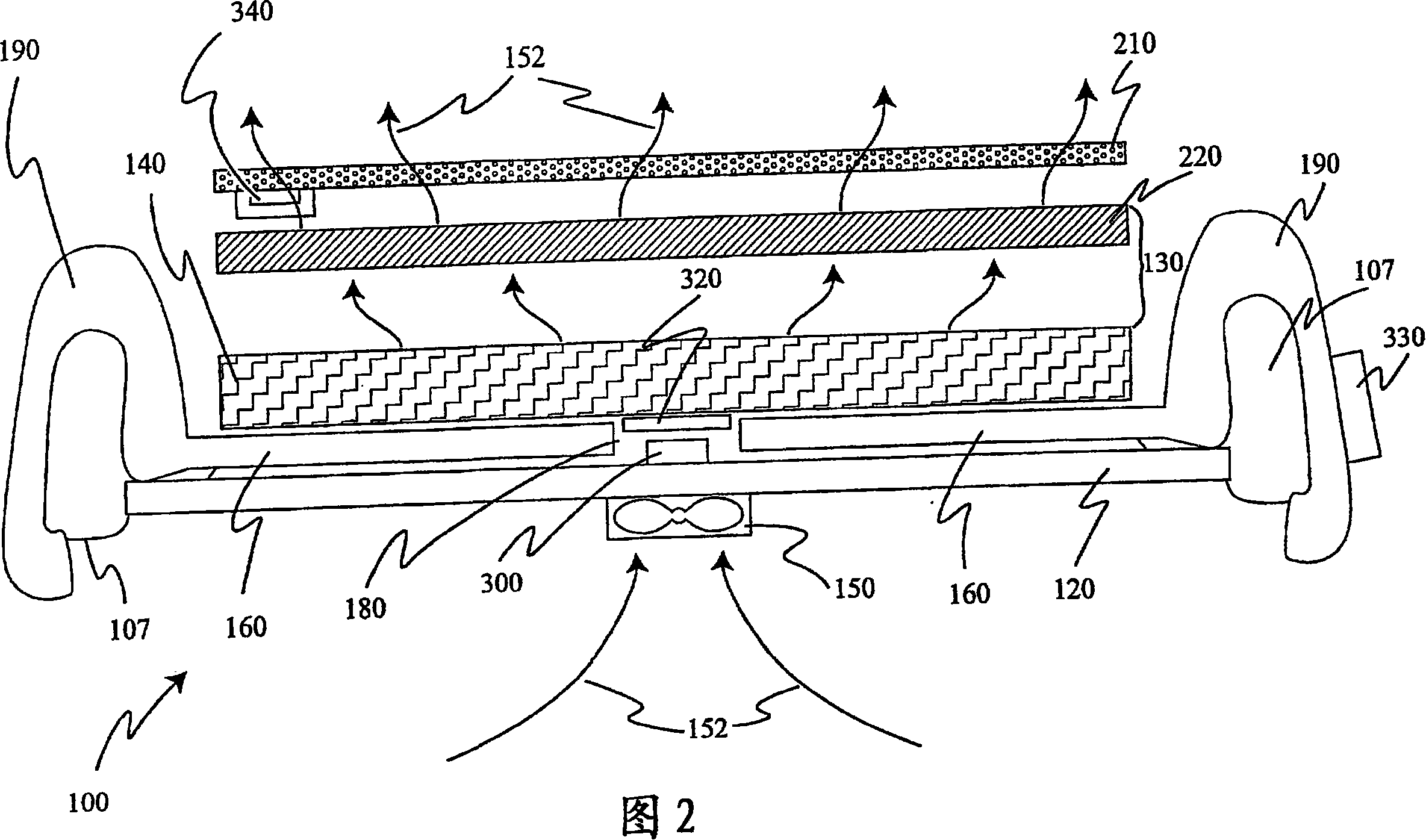

Heat, cool, and ventilate system for automotive applications

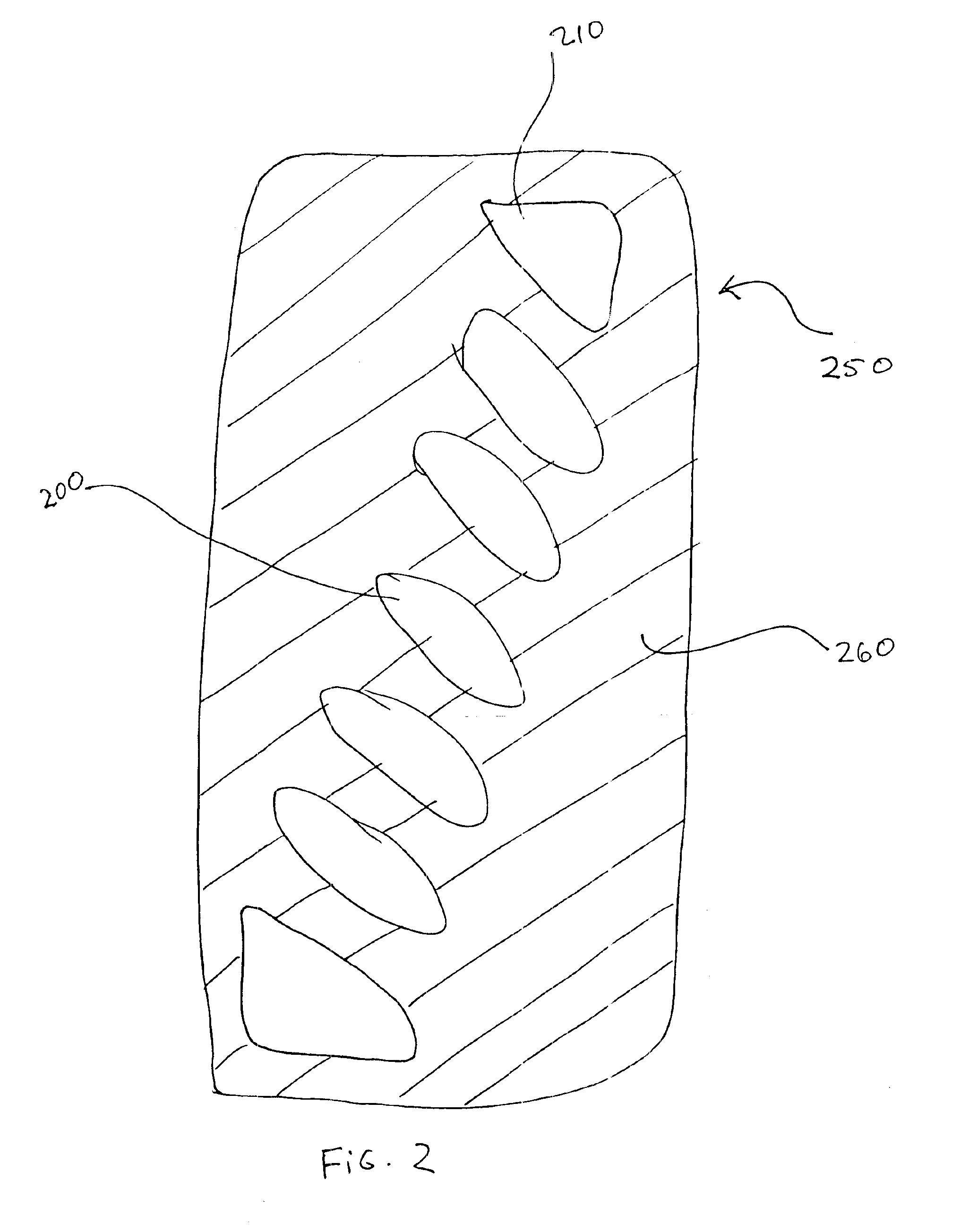

A ventilation, temperature regulation, and ergonomic comfort system for a vehicle seat, comprising: a pad including a ventilation layer comprising nonwoven plastic fibers fused together in a manner to allow airflow therethrough, the The ventilation layer has a seat surface side and an opposite side, wherein the ventilation layer is arranged in a substantially airtight compartment having an inlet hole for inputting air on the opposite side of the ventilation layer, and having a plurality of output holes on the seat surface side; an adjustable ergonomic support device, wherein the ergonomic support device is disposed on the opposite side of the ventilation layer and moves with the pad; a temperature conditioning system comprising an air moving device operatively connected to the inlet aperture on the opposite side of the ventilation layer, whereby the air moving device moves conditioned air into the a ventilation layer and vented through the plurality of output holes; and a control module including control means for controlling the operation of the thermoregulation system and ergonomic support means, wherein the seating surface is maintained at a under temperature.

Owner:L & P PROPERTY MANAGEMENT CO

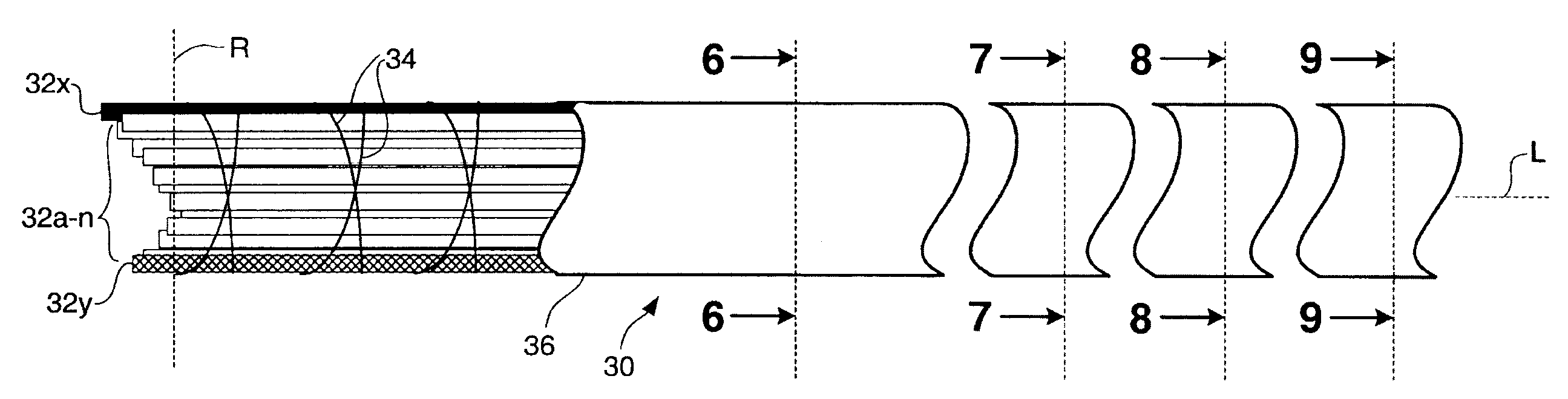

Method and device for handling elongate strength members

A method and device for handling an elongate strength member. In the method, an elongate strength member with a plurality of elongate composite rods, or metal wires or plastic fibers are bundled together with the composite rods, or metal wires, or plastic fibers in a generally parallel and untwisted and un-spiraled arrangement when the elongate strength member is extended along a generally straight path, wherein the composite rods are longitudinally and rotatably moveable relative to each other. It is then twisted relative to a longitudinal dimension of the elongate strength member and the path of the elongate strength member is curved, such as by coiling.

Owner:AIRLOG ACQUISITION CORP

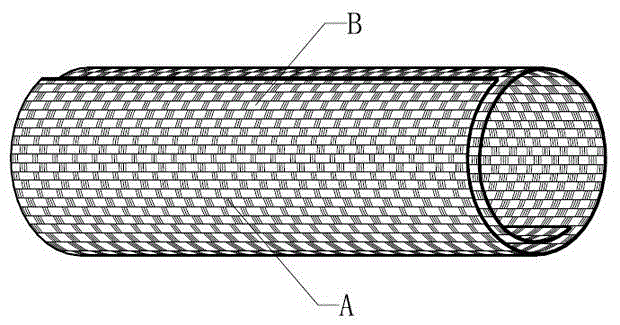

Plastic fiber cultivating soil and preparation method thereof

ActiveCN105367216AReduce weightGood construction curingOrganic fertilisersFertilizer mixturesPlastic fiberPlant soil

Plastic fiber cultivating soil is prepared from 15-35% of foundation soil, 5-35% of plant fiber powder, 10-50% of perlite, 5-15% of peat soil and 5-15% of dual-component hot-melt adhesion composite fibers. The composite fibers are formed by compositing two thermoplastic polymers through composite spinning according to a sheath-core type structural mode. The difference of melting points of the adopted two thermoplastic polymers is not lower than 30 DEG C. The composite fibers are composed of dual-component hot-melt adhesion composite fibers A with the particle size being 15-25 mm and dual-component hot-melt adhesion composite fibers B with the particle size being 3-8 mm. The composite fibers A and the composite fibers B can be made of same materials or different materials. The particle size of the plant fiber powder is 0.2-0.9 mm. The plastic fiber cultivating soil has the advantages that the cultivating soil can be cured and formed and is long in service life, not prone to weathering, low in weight, high in moisture-preserving performance and breathability, capable of being recycled after being discarded and the like. The plastic fiber cultivating soil has the main effects that the problems that in the vertical greening construction process, plants cannot be easily attached to walls, planting soil is large in gravity, and the soil is not easily shaped and is prone to dispersion are solved, and the problem that large-scale mechanical seedling inserting is difficult in upland soil planting. Due to the fact that most raw materials come from agricultural and forestry waste, a contribution can be made to agriculture and environmental protection, and the fiber soil can be recycled or directly used as combustion improver after being used.

Owner:湖南尚佳绿色环境有限公司

A compression packer rubber cartridge and its preparation method and application

InactiveCN102287161AImprove adhesionImprove ductilitySealing/packingHollow articlesRubber materialEngineering

The invention relates to a compression packer rubber cylinder, a preparation method and application thereof. The compression packer rubber cartridge has a composite shoulder of fiber or fabric and rubber material. Compared with the existing compression packer rubber sleeve, the compression packer rubber sleeve of the present invention has better adhesion, ductility, elasticity, pressure bearing capacity and sealing effect, thereby prolonging the use of the rubber sleeve life.

Owner:上海道氟实业有限公司

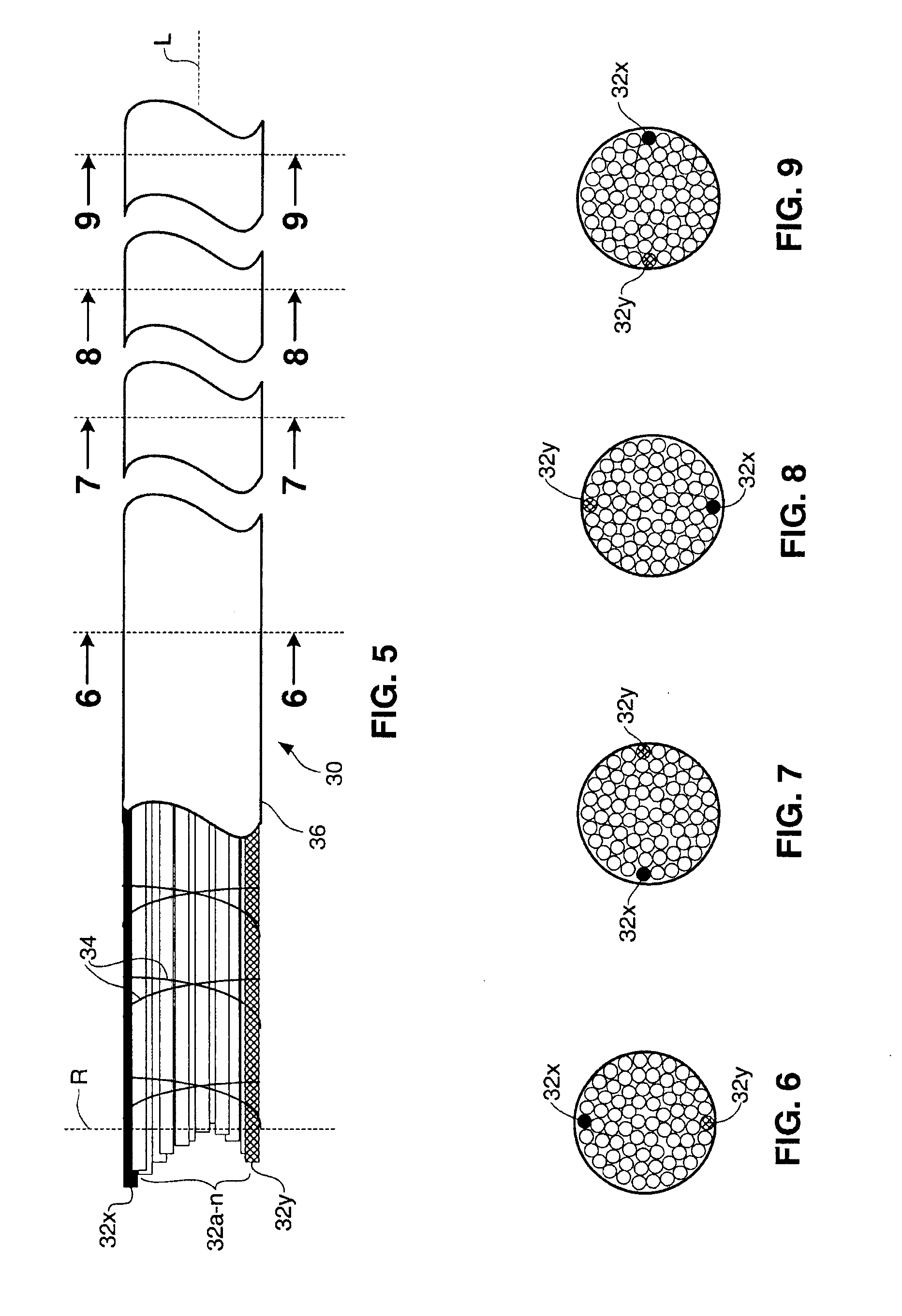

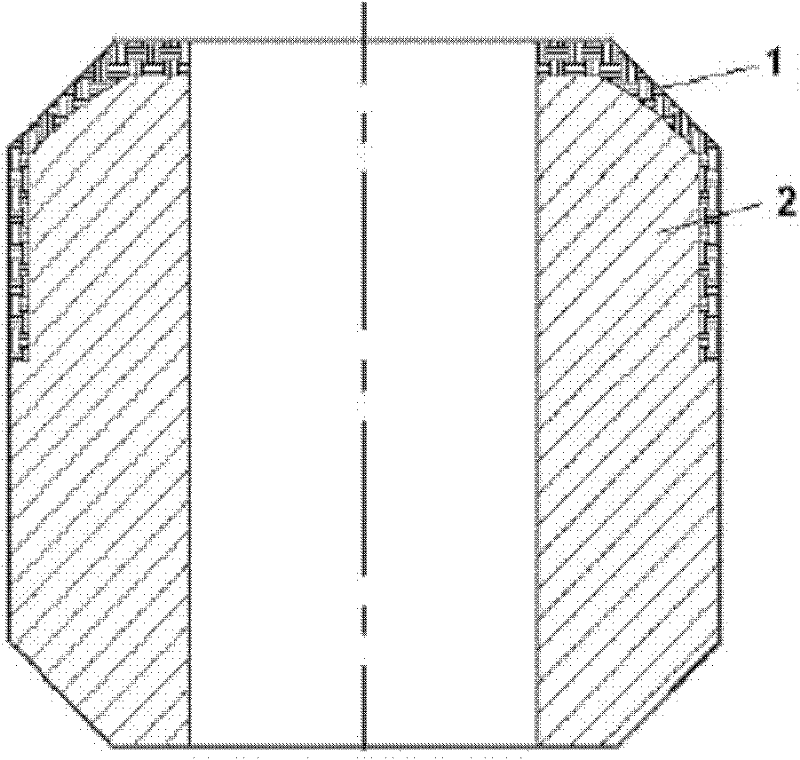

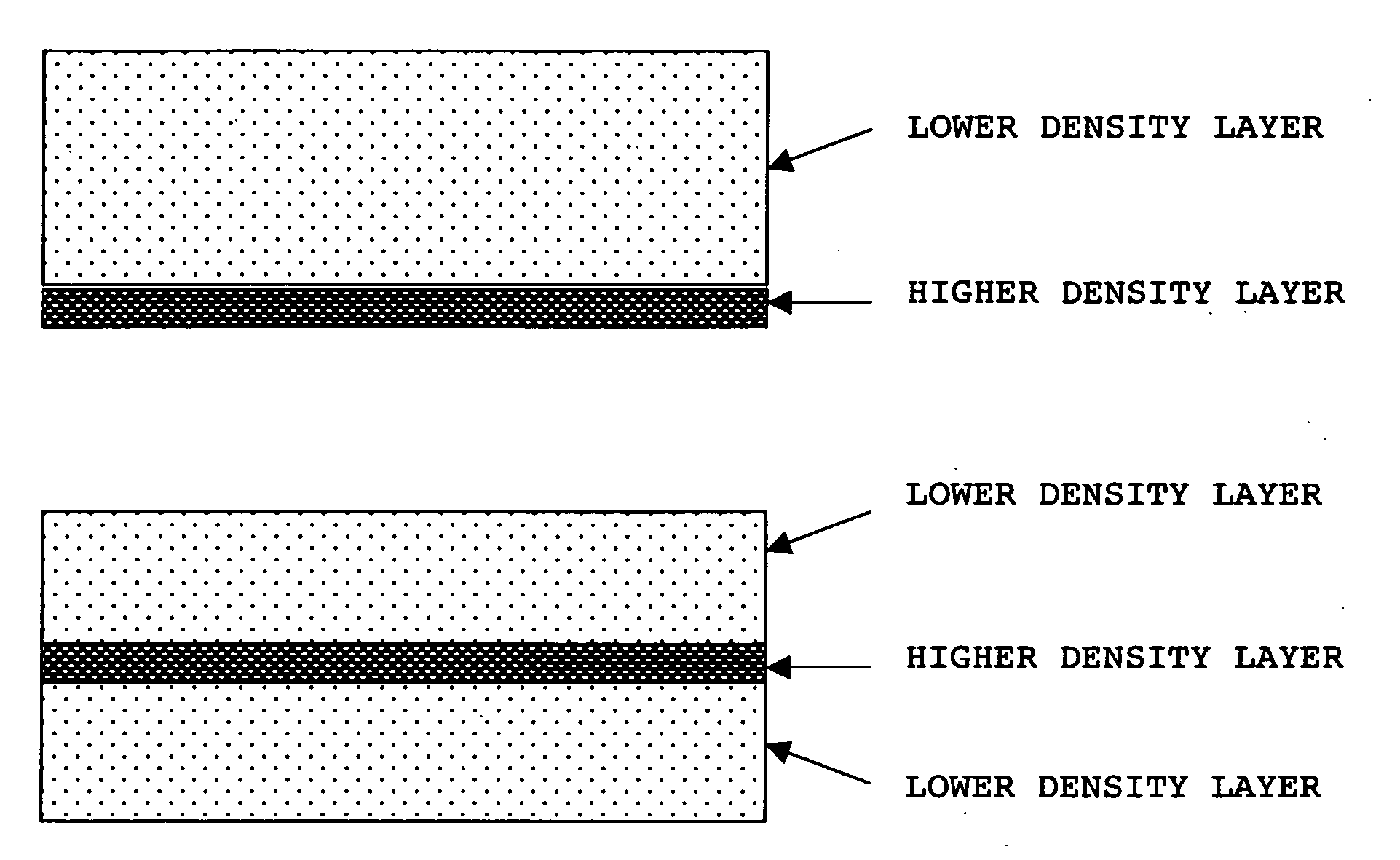

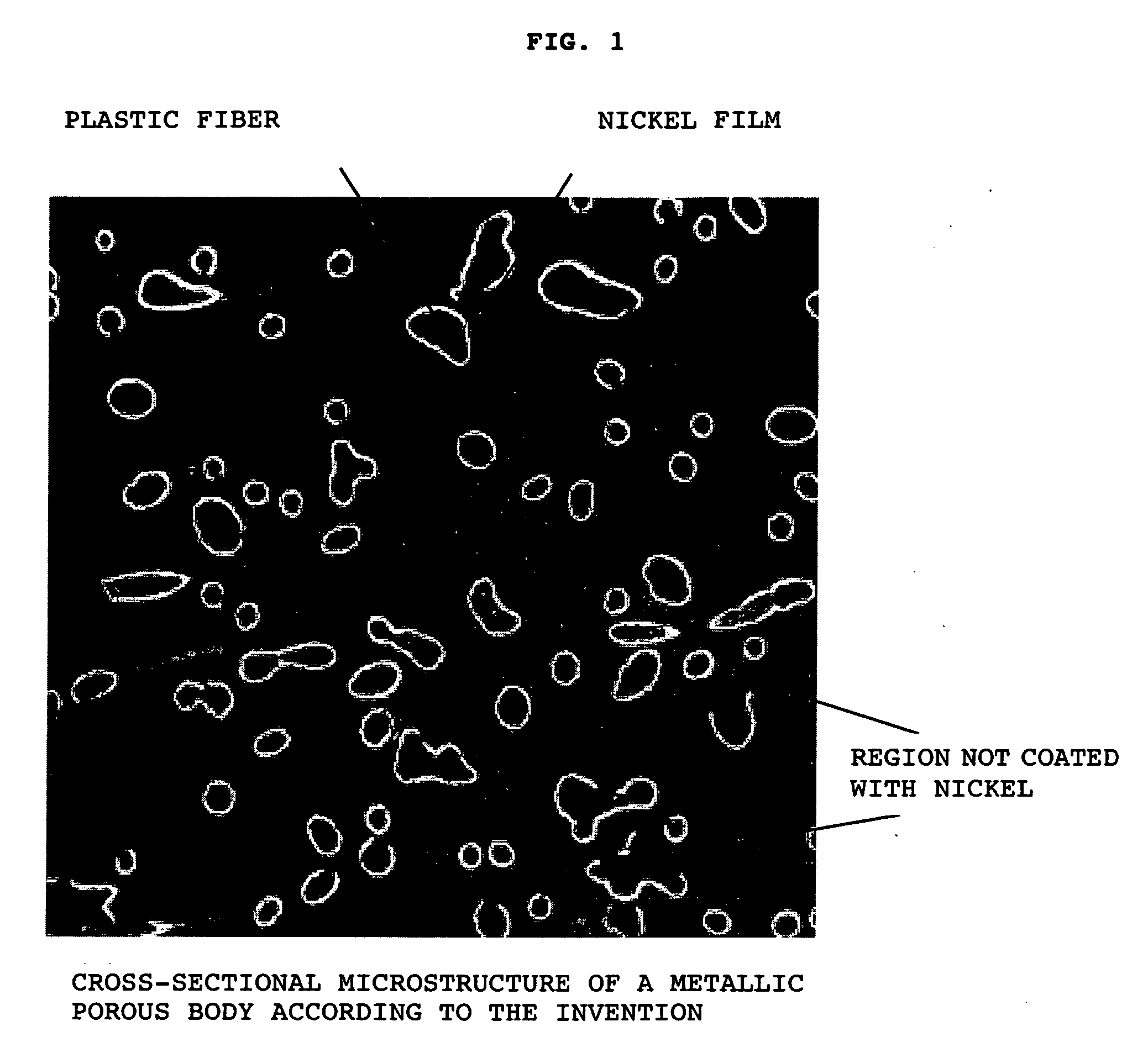

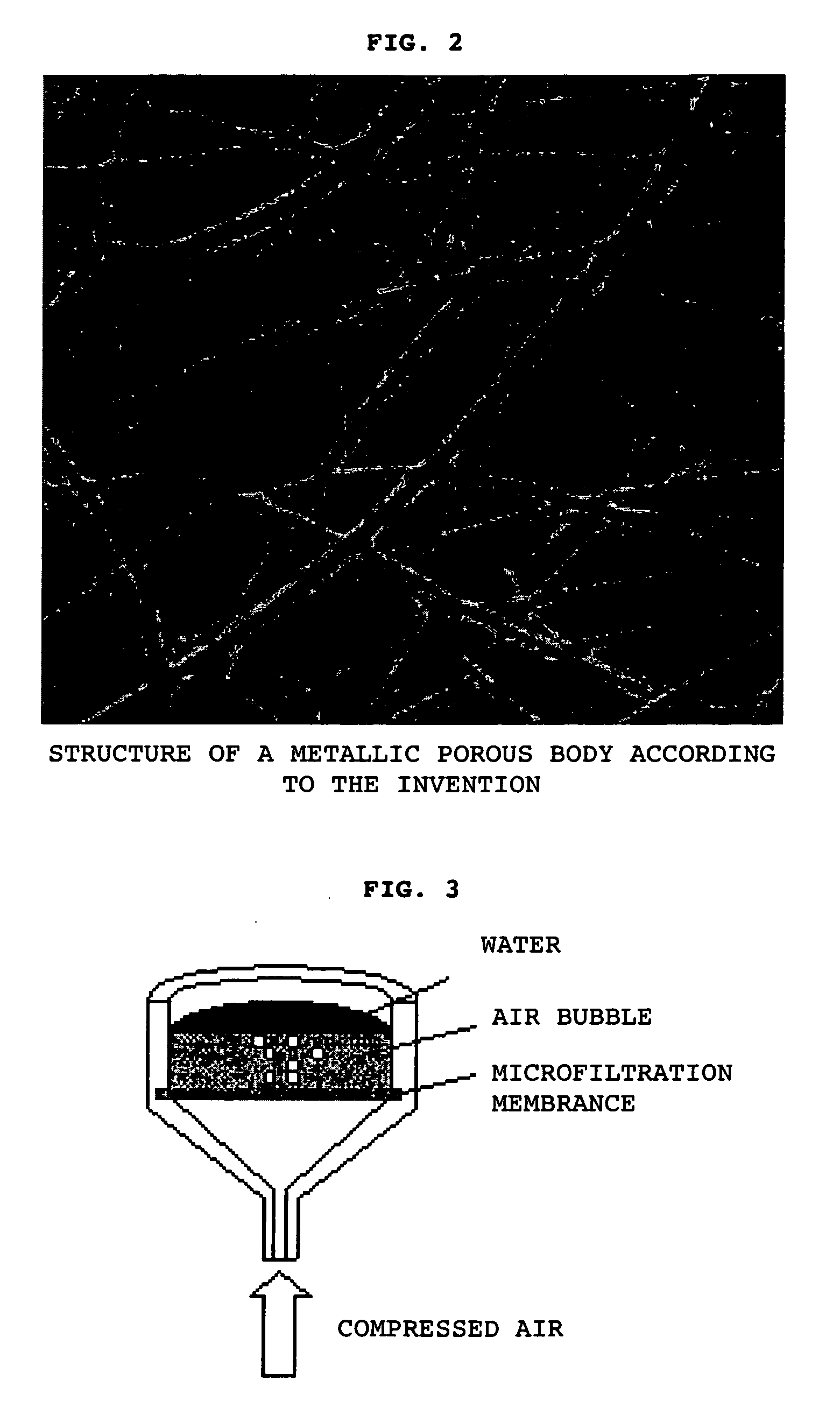

Collector, battery electrode substrate, and methods for producing the same

ActiveUS20060159998A1Satisfactory strengthSatisfactory flexibilityElectrode manufacturing processesFibre treatmentCoverage ratioHigh rate

A collector that has enough hardness and flexibility and a battery electrode substrate that uses this collector are provided. Also provided is a low-cost battery electrode substrate that exhibits excellent high-rate charge / discharge characteristics and low electrical resistance and that is able to avoid the decline in cycle characteristics caused by repetitive charging / discharging. The invention is a battery electrode substrate having a structure in which a nickel film is coated on the surface of plastic fiber of a woven or unwoven fabric, wherein a metallic porous body in which the average coverage ratio by the nickel film is not less than 85% is used. The invention is also a collector comprising a metallic porous body having a structure in which a surface of plastic fiber of a woven or unwoven fabric is coated with a nickel film so as to be an average coverage ratio of not less than 85%, wherein the metallic porous body comprises at least two layers of a lower density region and a higher density region in the thickness direction between which there is a difference in density of included nickel, and a thickness of the lower density region is not less than 1.5-times a thickness of the higher density region. The invention is also a battery electrode substrate that has a structure in which a surface of a plastic fiber in a unwoven fabric is coated with a nickel film, wherein the battery electrode substrate uses a metallic porous body in which a transverse-to-longitudinal ratio of the electrical resistance is not less than two times. The plastic fiber is preferably a fiber that has a core / sheath composite fiber structure in which the core is polypropylene and the sheath is polyethylene.

Owner:SUMITOMO ELECTRIC IND LTD +1

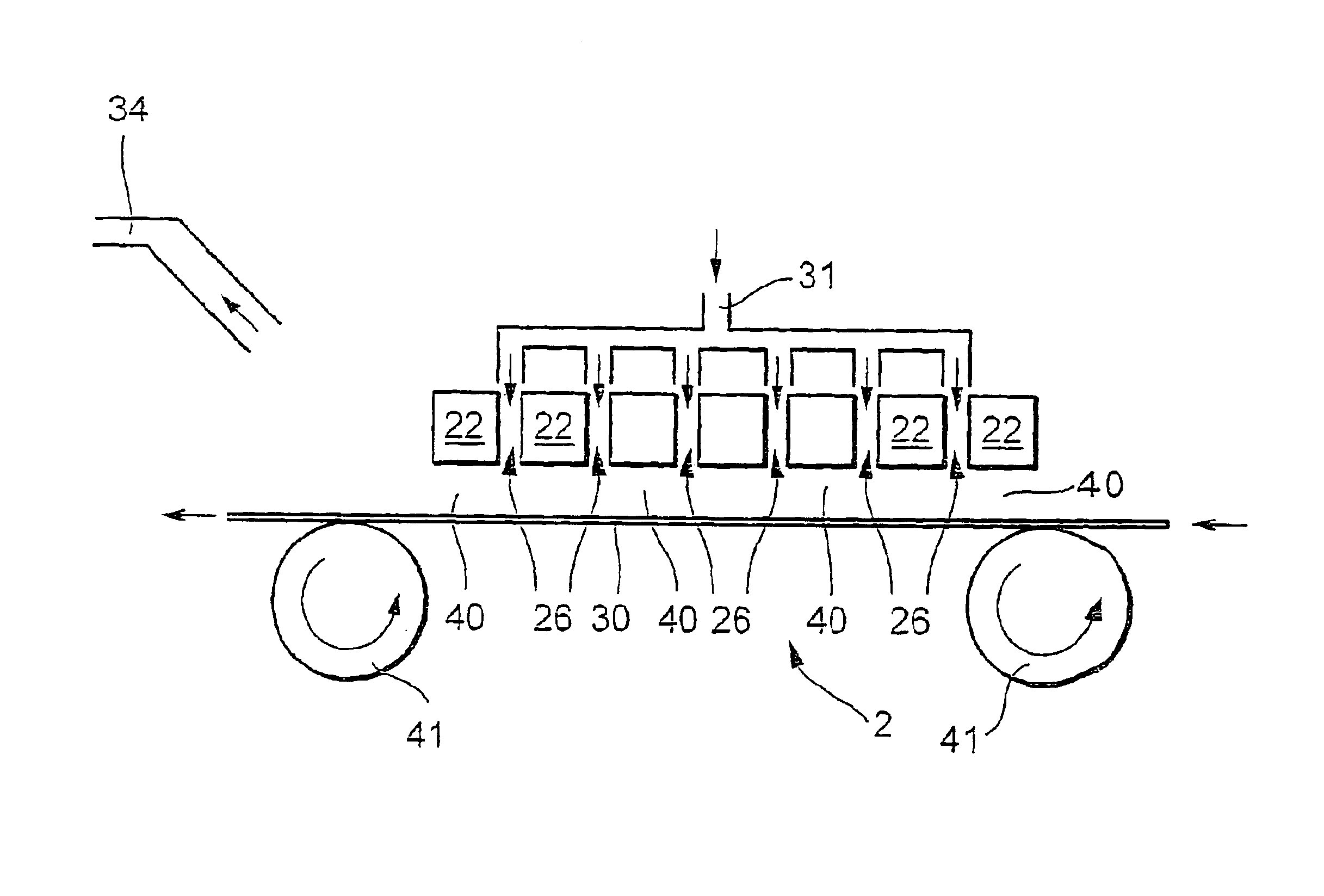

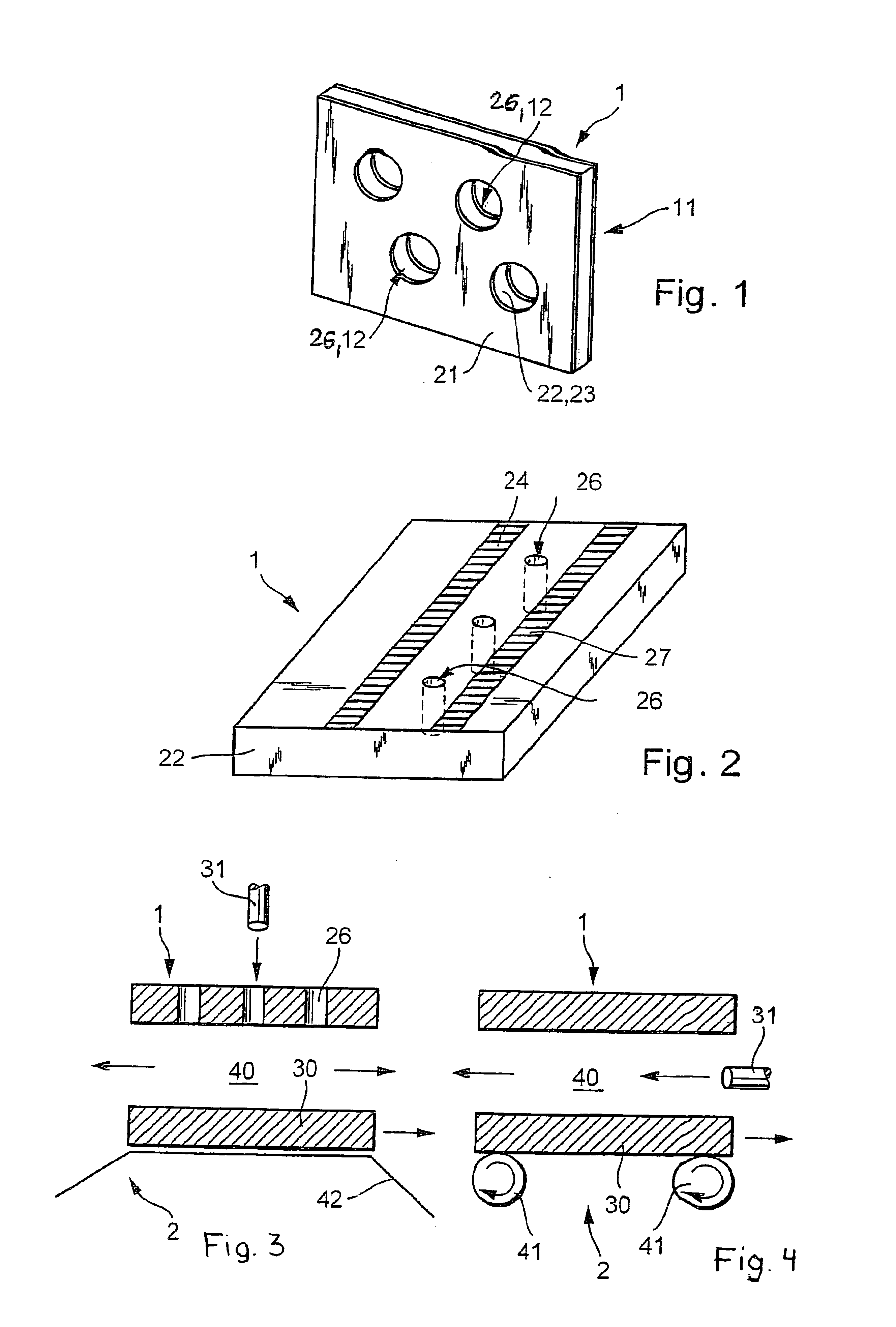

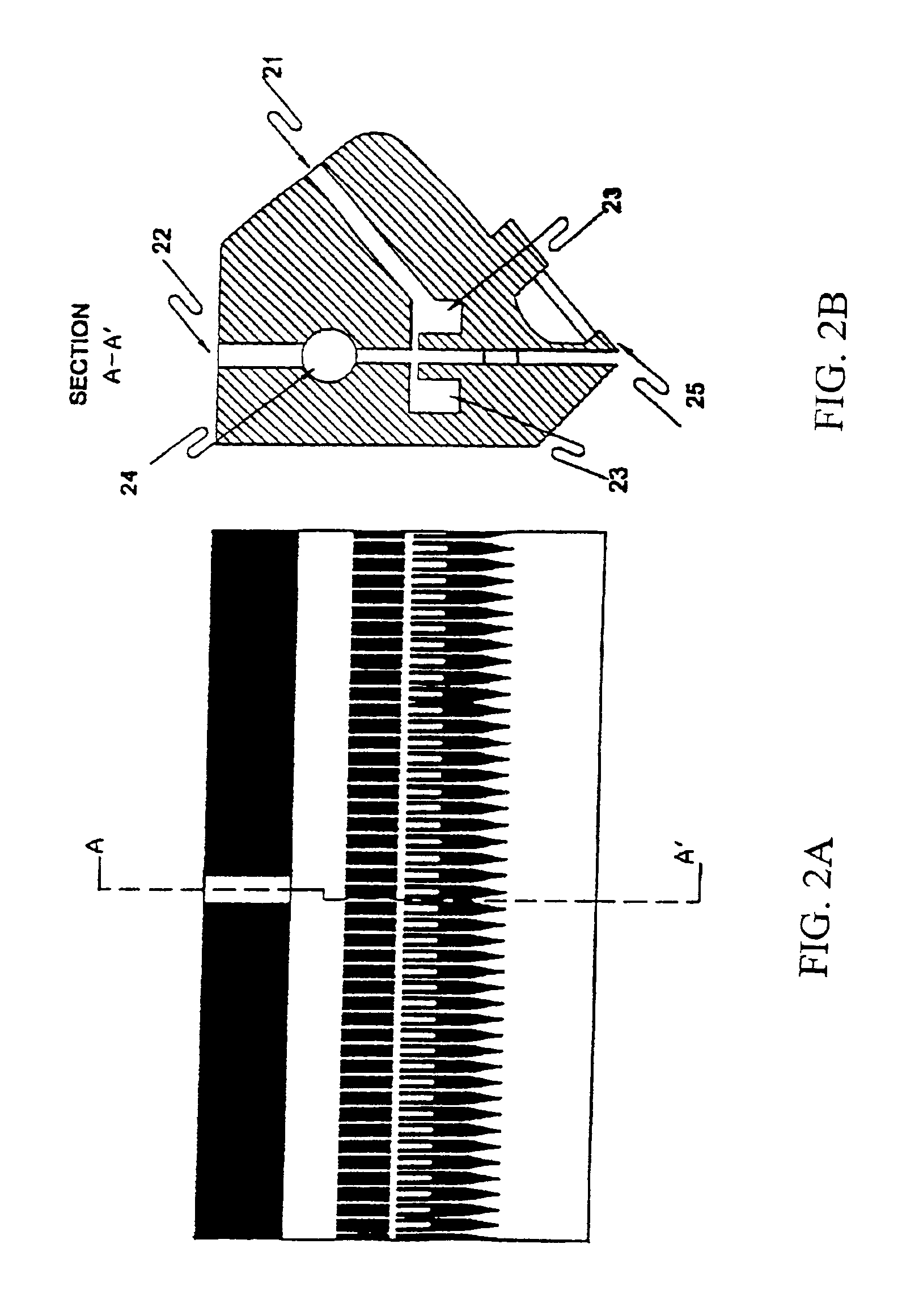

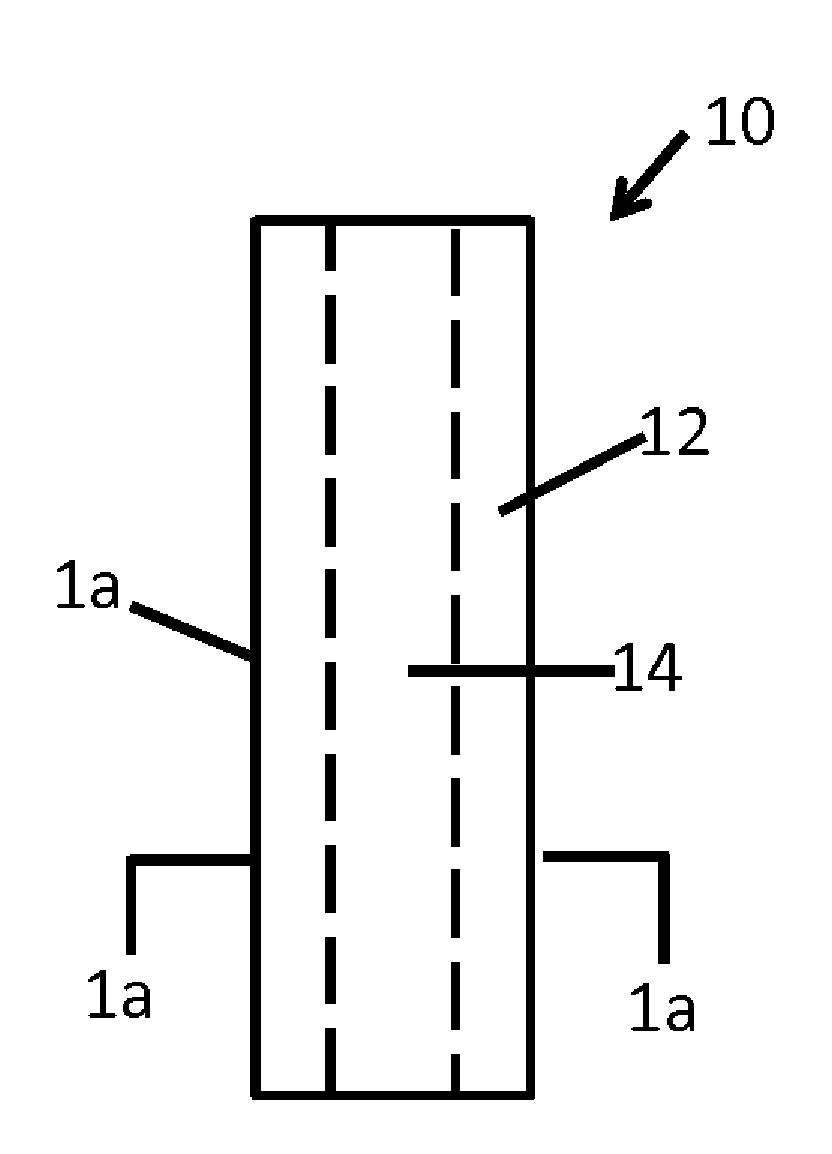

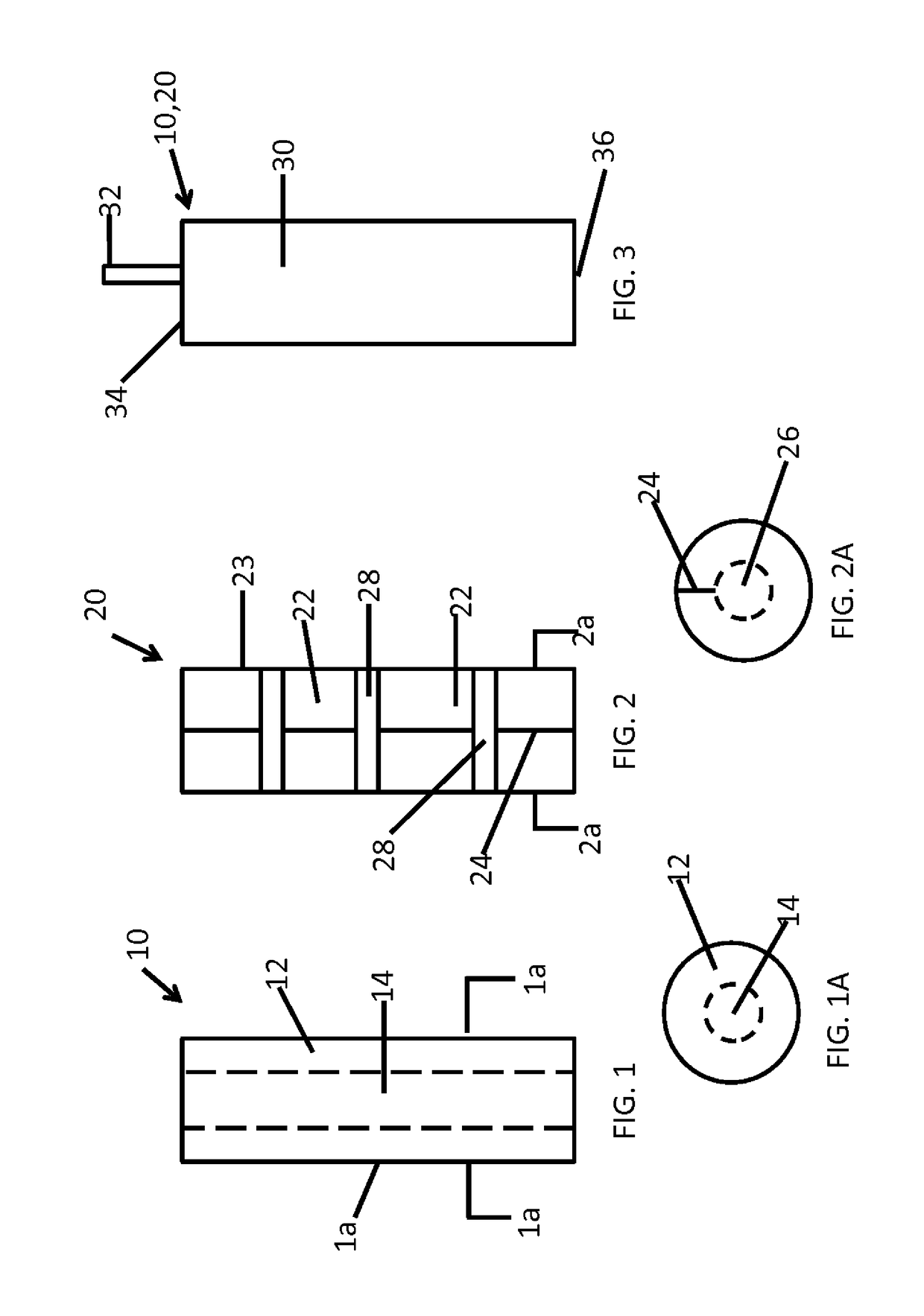

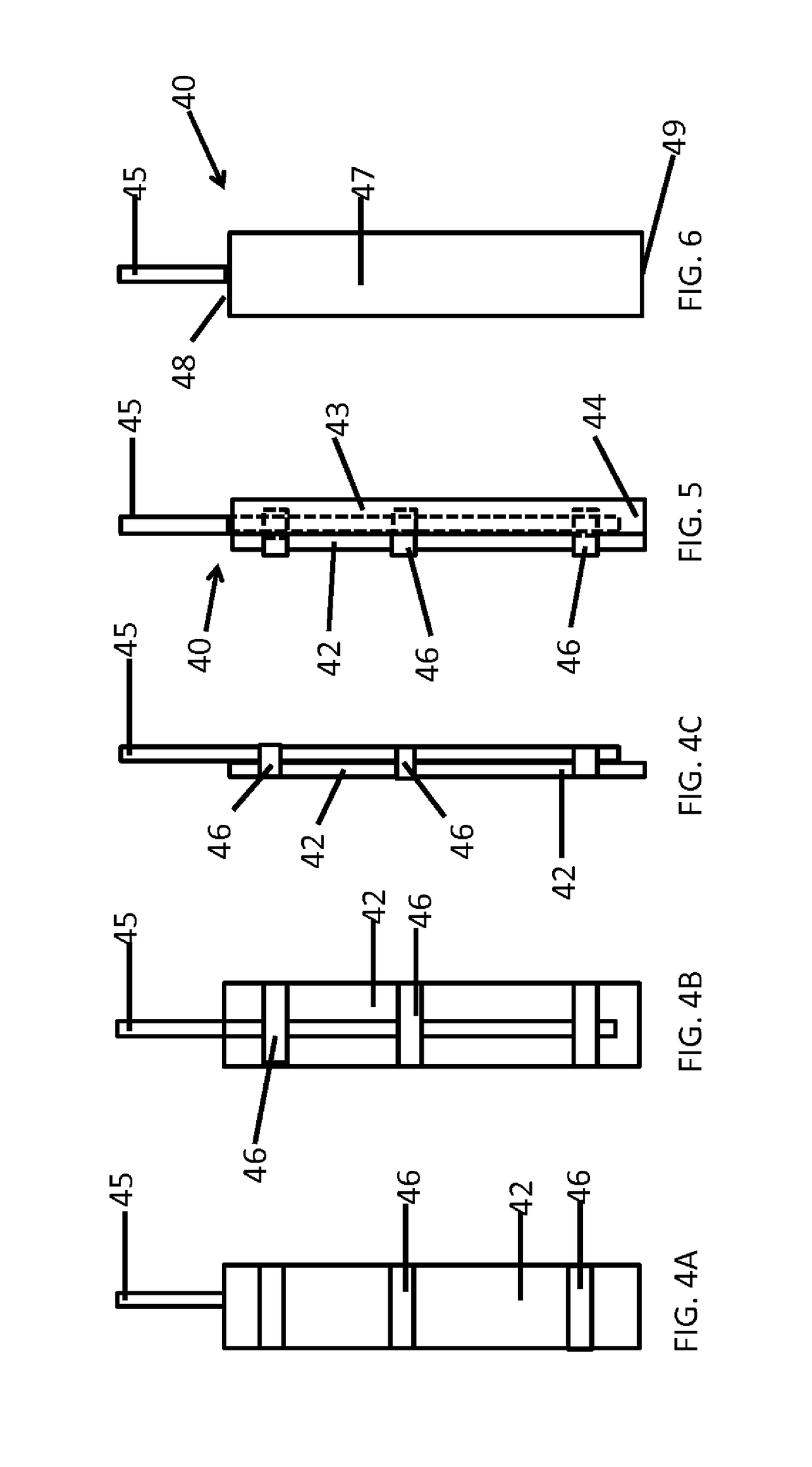

Method and apparatus for fabrication of plastic fiber optic block materials and large flat panel displays

InactiveUS6892011B2Firmly connectedGood light transmissionLamination ancillary operationsLaminationImage transferDisplay device

This invention concerns a method and apparatus for manufacturing a sheet and a two-dimensional matrix of plastic optical fibers. The fibers may be of the step-index or graded-index type. Co-extrusion through a specially designed die is used to produce a sheet composed of a fiber array. The fiber sheet (ribbon) can be used for transmitting optical signals. These arrays may also be stacked and fused at high temperatures to form the two-dimensional matrix required for many applications such as large area image transfer. In addition, a high-speed, continuous manufacturing method is disclosed to produce a massive two-dimensional matrix of fibers. The method of manufacture permits high quality image transfer at low manufacturing cost in a wide array of geometries.

Owner:FLORIDA UNIV OF A FLORIDA

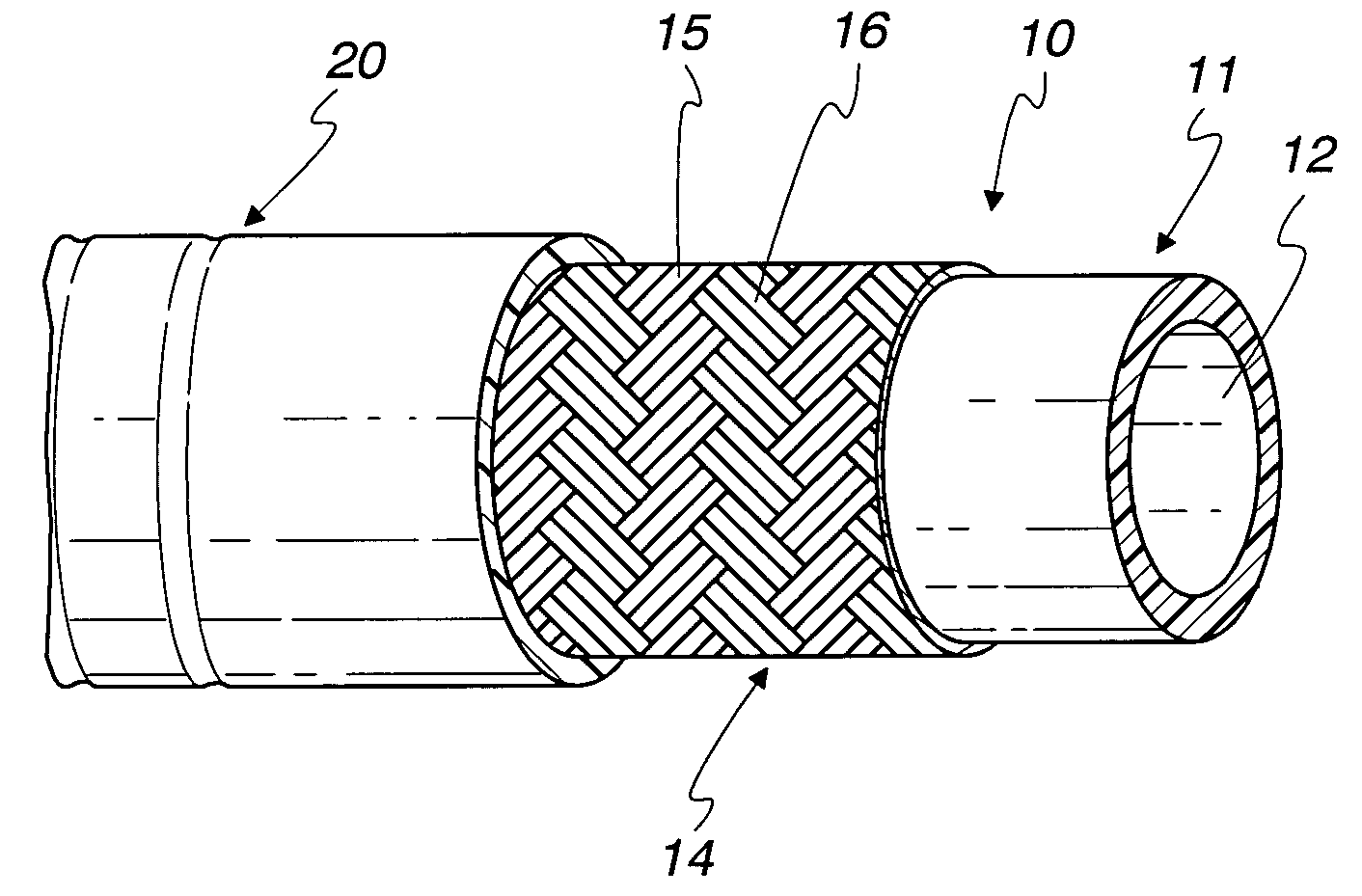

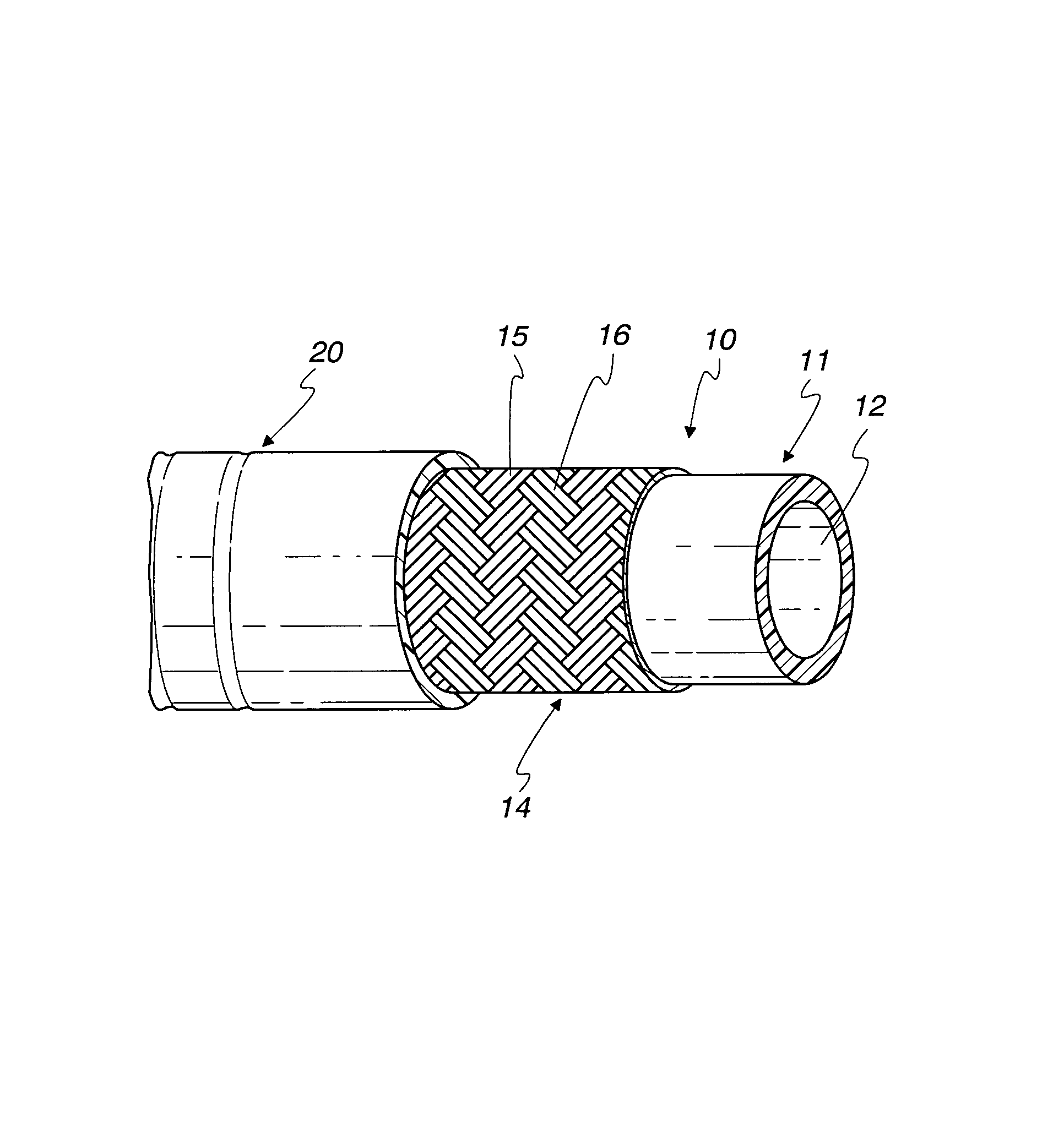

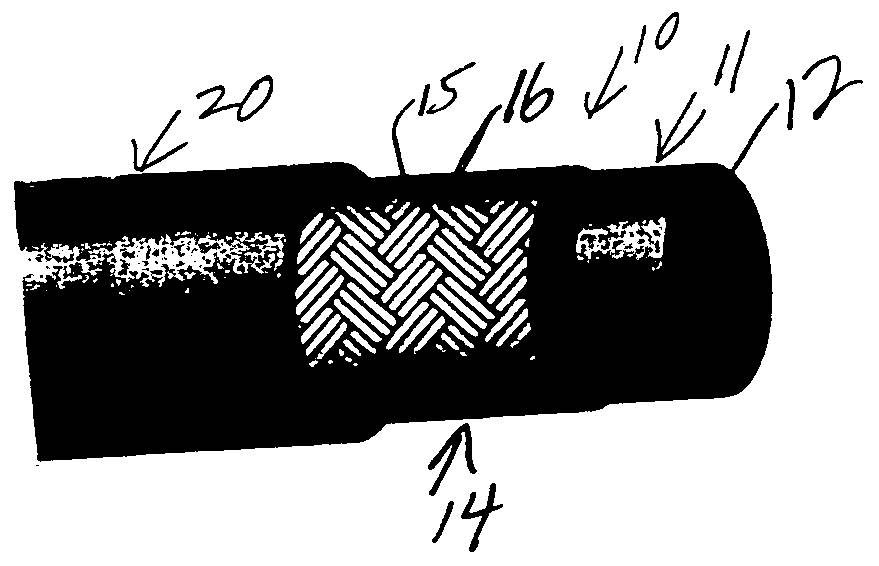

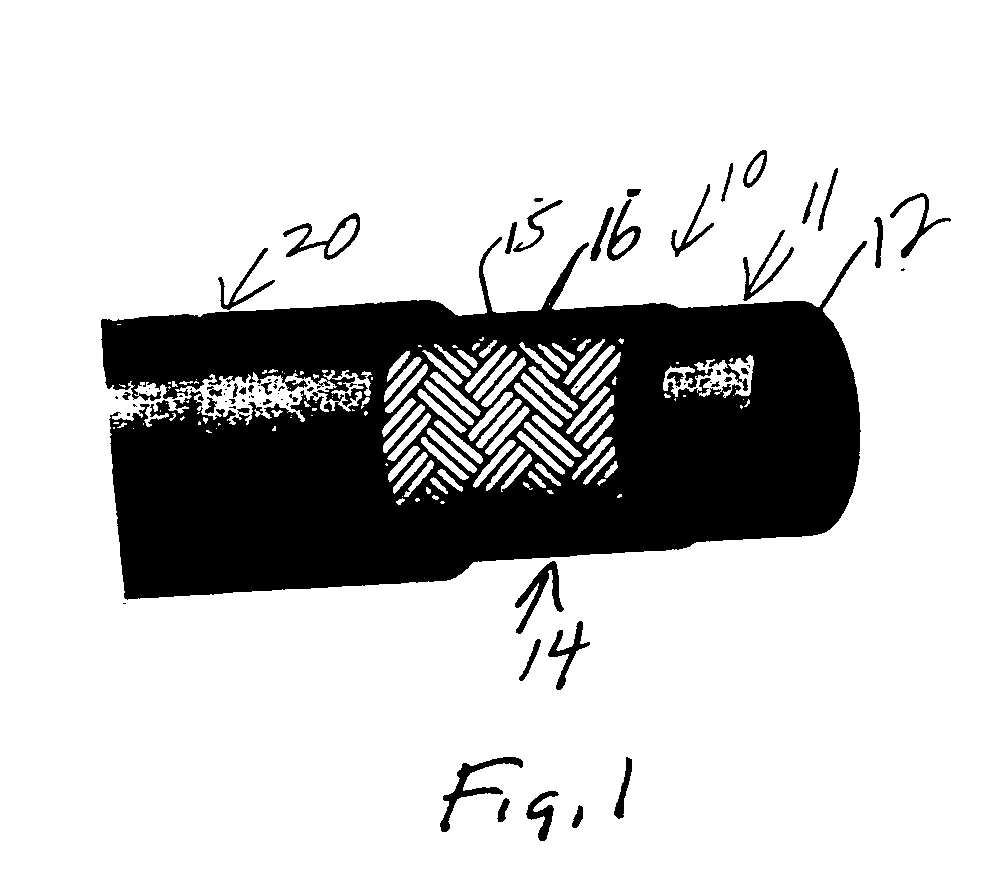

High pressure flexible hose

InactiveUS6978805B2High tensile strengthUniform diameterFlexible pipesRigid pipesTextile fiberMetal fiber

A flexible, thermoplastic hose for high pressure and high velocity flow is provided with a flexible braided reinforcement layer with a static drain therein for conducting static electricity towards a ground. This is achieved by having at least one textile fiber yarn with conductive fibers therein braided with non-conducting textile yarns to form the braided reinforcement layer. The preferred conducting fiber yarn is formed with metal fibers as well as plastic fibers. A method of manufacture of the hose comprises providing electrical conducting yarns and non-conducting yarns in a braiding machine and braiding them about a tube having a hollow bore through which fluid flows. An abrasion resistant outer cover layer of polyurethane is extruded over the braided layer having the drain therein. For higher pressure applications, a second braided reinforcement layer may also be provided over the inner braided layer having the electrically conductive yarns. Several conductive yarns may be used to have spaced electrically conductive yarns, e.g., at 3:00, 6:00, 9:00 and 12:00 in a circular cross-section through the hose.

Owner:DYNAFLEX

Auto-rolling shielding sleeve

ActiveCN103607875ASimple structure and processSimple preparation processMagnetic/electric field screeningPipe protection against damage/wearEngineeringPlastic fiber

The invention discloses an auto-rolling shielding sleeve. An axial line of the sleeve is taken as a longitude direction, and a circumference direction of the sleeve is taken as a latitude direction. The sleeve comprises a sheet material prepared through weft knitting of a first strand along the longitude direction and a second strand along the latitude direction, the first strand is a strand composited by single metal wire and / or plastic fiber, the second strand is a strand composited by single metal wire and / or single plastic wire, the sheet material is molded into a hollow scroll-like structure which automatically rolls along the axial direction and is at least partially overlapped, so the scroll-like sheet material can be opened and sleeved on a tubular object such as a wire harness under the action of external force and automatically recovers to the scroll-like structure without the external force. The auto-rolling shielding sleeve has advantages of simple structure and making and convenient and flexible operation.

Owner:SHENZHEN JDD TECH NEW MATERIAL CO LTD

Automatic continuous production device for fiber reinforced plastic gratings

The invention belongs to the technical field of fiber reinforced plastic grating production equipment, and particularly discloses an automatic continuous production device for fiber reinforced plastic gratings. The device structurally comprises a laying mechanism, a solidification mechanism, a grating cutting mechanism, a carrying mechanism and a mold plate which are arranged sequentially, wherein the grating cutting mechanism is used after demolding of a mold; and the mold plate is arranged in a supporting bracket and driven to move by a power mechanism and comprises longitudinal slots and horizontal slots. By means of the device, continuous production of the fiber reinforced plastic gratings can be realized, and the production efficiency is improved; and longitudinal fiber reinforced plastic fiber in the prepared grating is long fiber with integral uniform specification, and mechanical laying, glue filling and compaction are adopted, so that the product quality of the gratings is remarkably improved.

Owner:JIZHOU ZHONGYI FRP TECH CO LTD +1

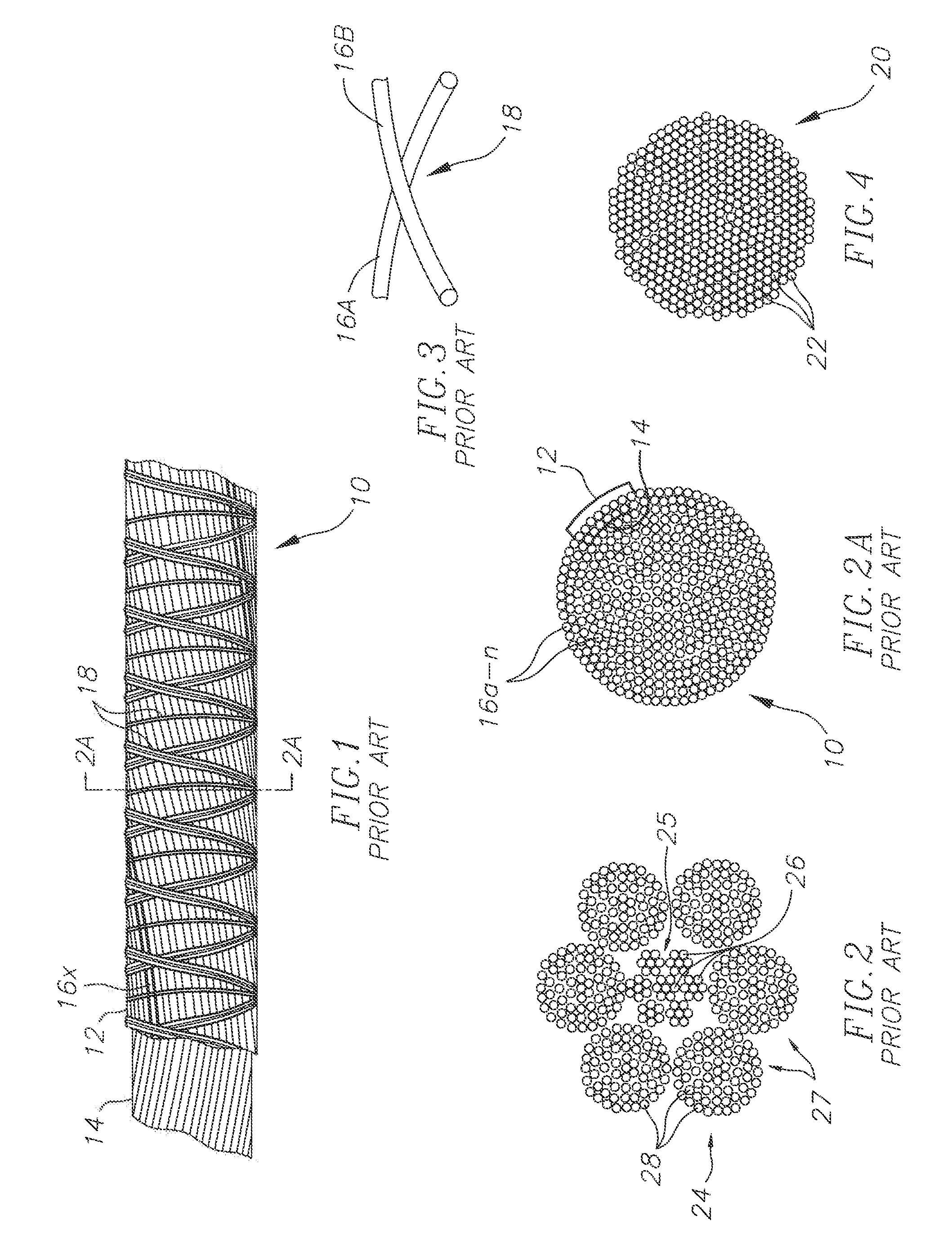

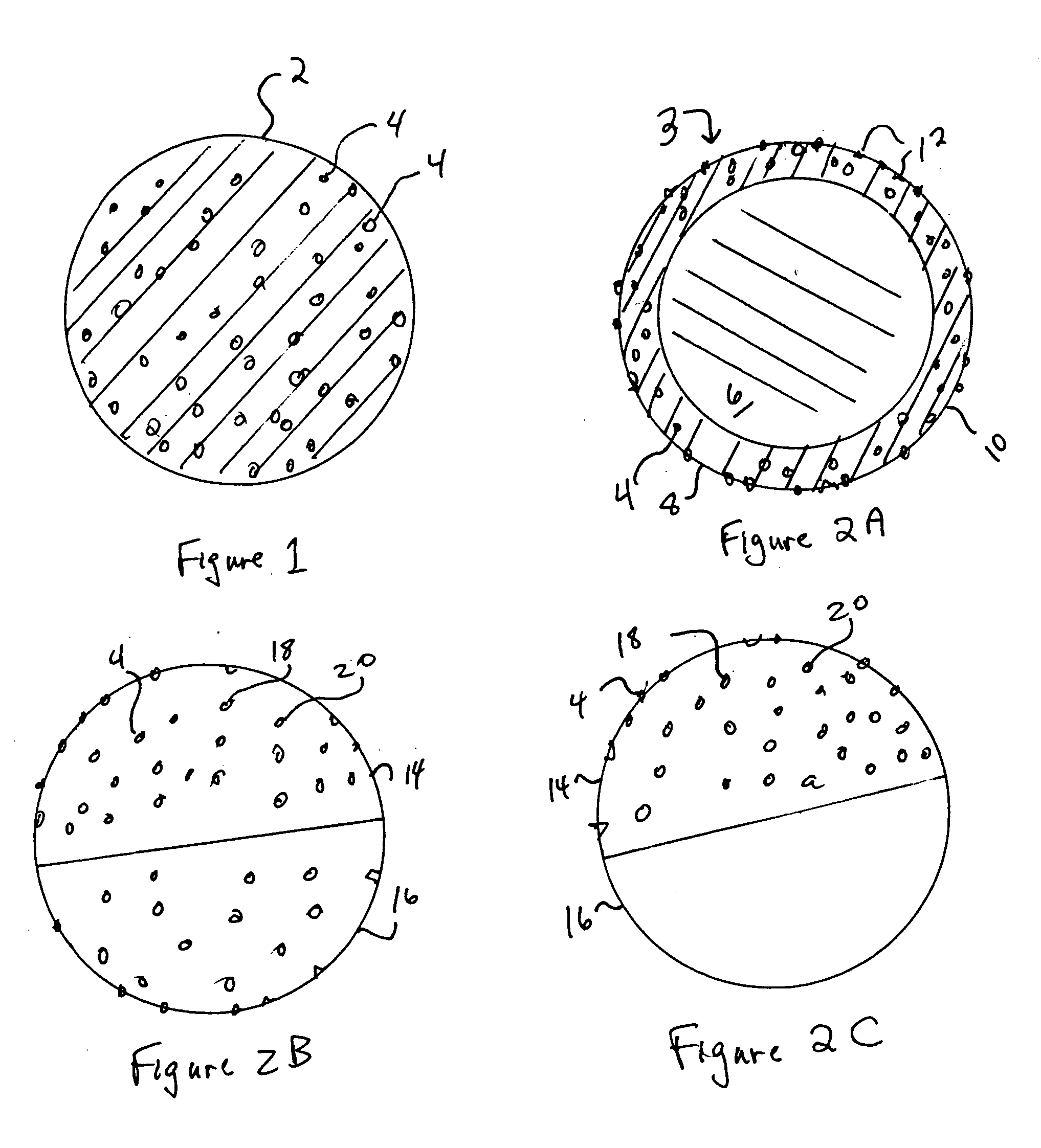

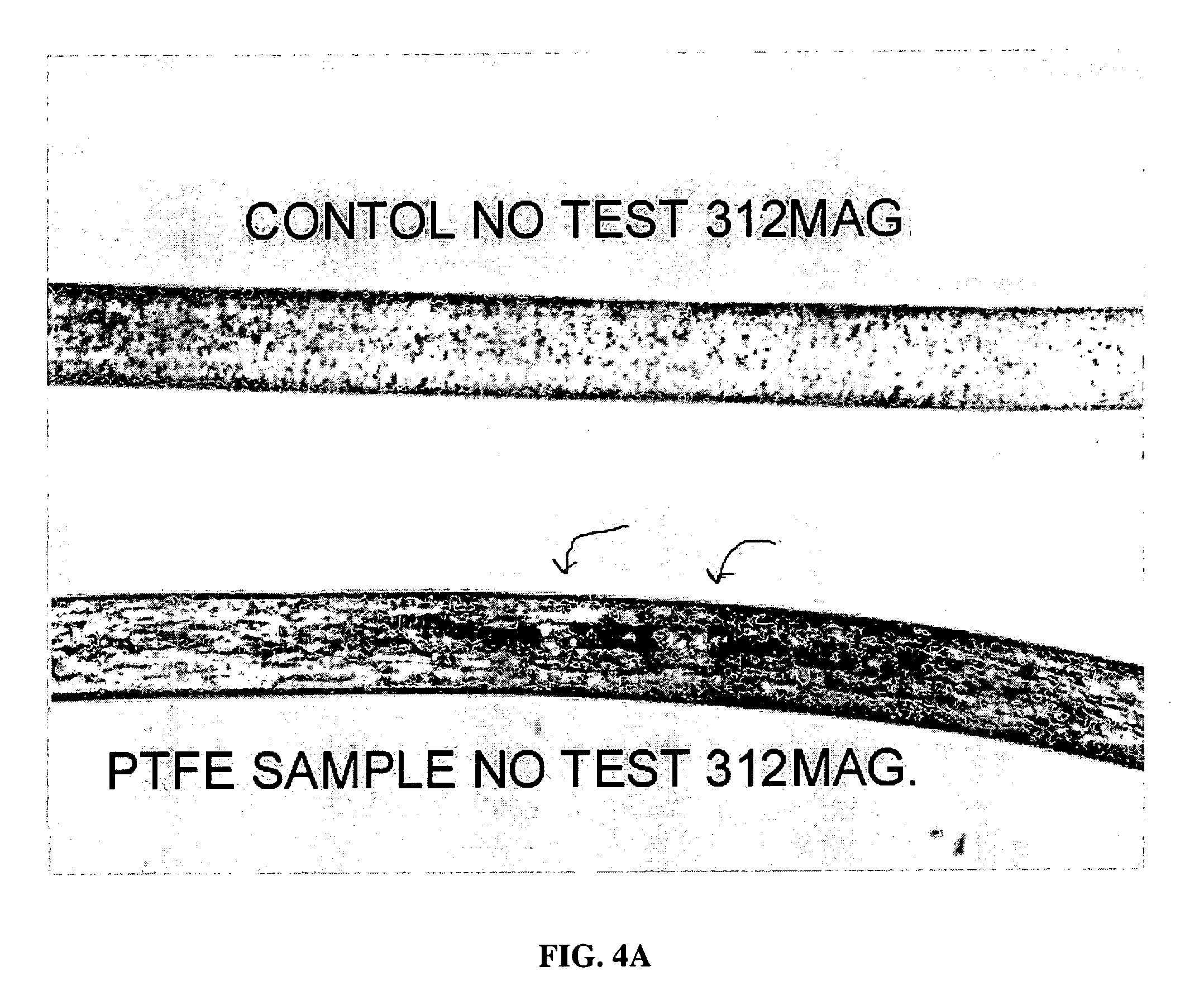

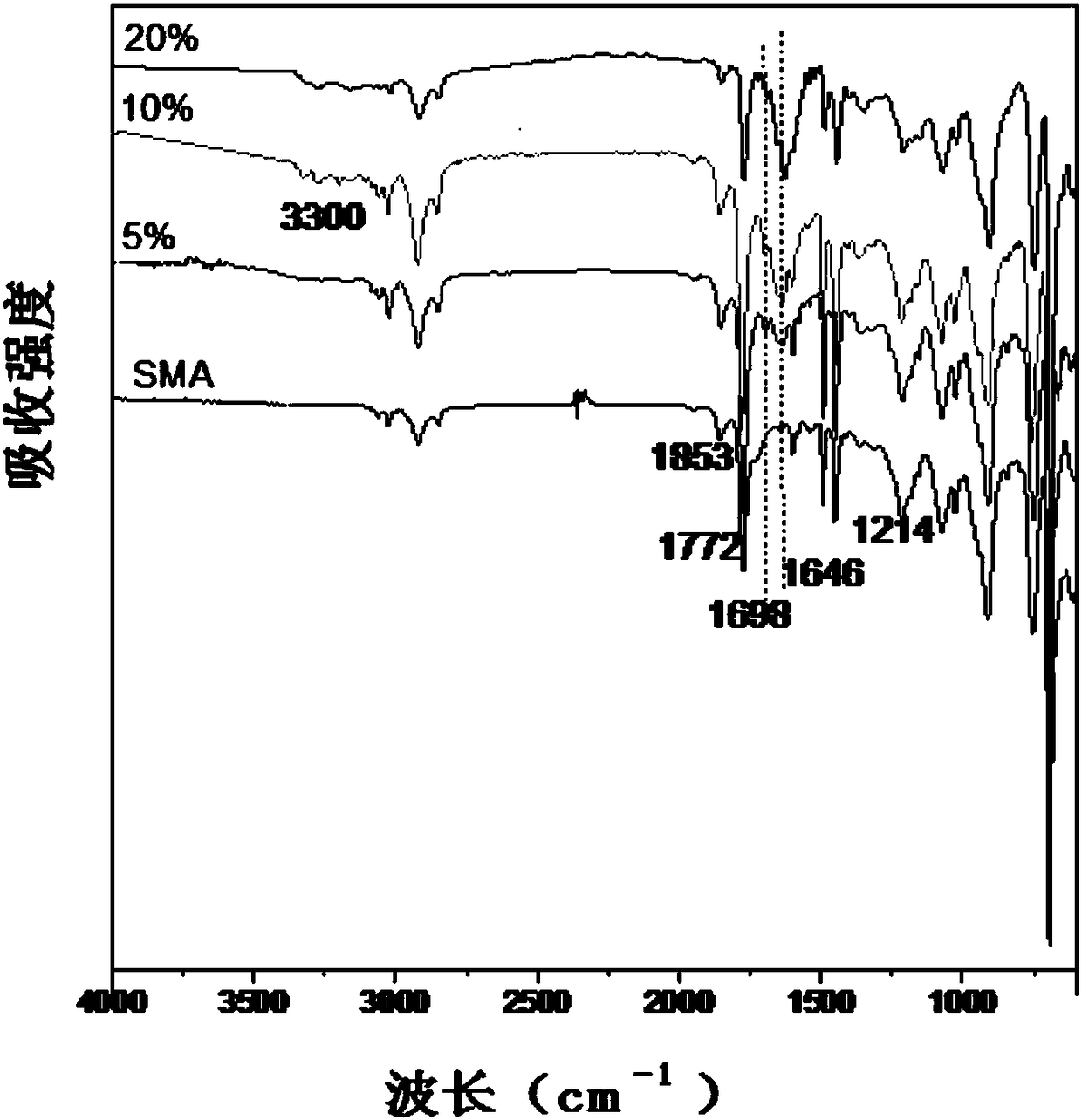

Synthetic fibers modified with PTFE to improve performance

InactiveUS20050100733A1Improve hydrophilicityImprove stain resistanceConjugated synthetic polymer artificial filamentsYarnPolyesterUV degradation

Synthetic plastic fibers are enhanced by inclusions therein of micro-polyester particles (4), preferably sized or otherwise optimized to enhance surface (10) characteristics (abrasion resistance, hydrophilicity, coating receptiveness, increase dullness), reduce UV degradation. The synthetic plastic matrix is preferably polyester but can be any synthetic plastic. The invention is preferentially implemented in multi-component fibers (e.g. core (6)-sheath (8) bi-component fibers (3)) with the inclusions entirely or primarily in one or some, but not all such components. The PTFE inclusions, sizing, concentration, morphology can be adjusted to optimize their enhancing effects, reduce costs and enhance throughput of fiber production. Co-inclusions can be made with the PTFE including anti-microbial and / or coloring agents and with synergistic effects.

Owner:FOSS MFG CO LLC

High pressure flexible hose

InactiveUS20050051226A1Uniform diameterHigh tensile strengthFlexible pipesRigid pipesTextile fiberMetal fiber

A flexible, thermoplastic hose for high pressure and high velocity flow is provided with a flexible braided reinforcement layer with a static drain therein for conducting static electricity towards a ground. This is achieved by having at least one textile fiber yarn with conductive fibers therein braided with non-conducting textile yarns to form the braided reinforcement layer. The preferred conducting fiber yarn is formed with metal fibers as well as plastic fibers. A method of manufacture of the hose comprises providing electrical conducting yarns and non-conducting yarns in a braiding machine and braiding them about a tube having a hollow bore through which fluid flows. An abrasion resistant outer cover layer of polyurethane is extruded over the braided layer having the drain therein. For higher pressure applications, a second braided reinforcement layer may also be provided over the inner braided layer having the electrically conductive yarns. Several conductive yarns may be used to have spaced electrically conductive yarns, e.g., at 3:00, 6:00, 9:00 and 12:00 in a circular cross-section through the hose.

Owner:DYNAFLEX

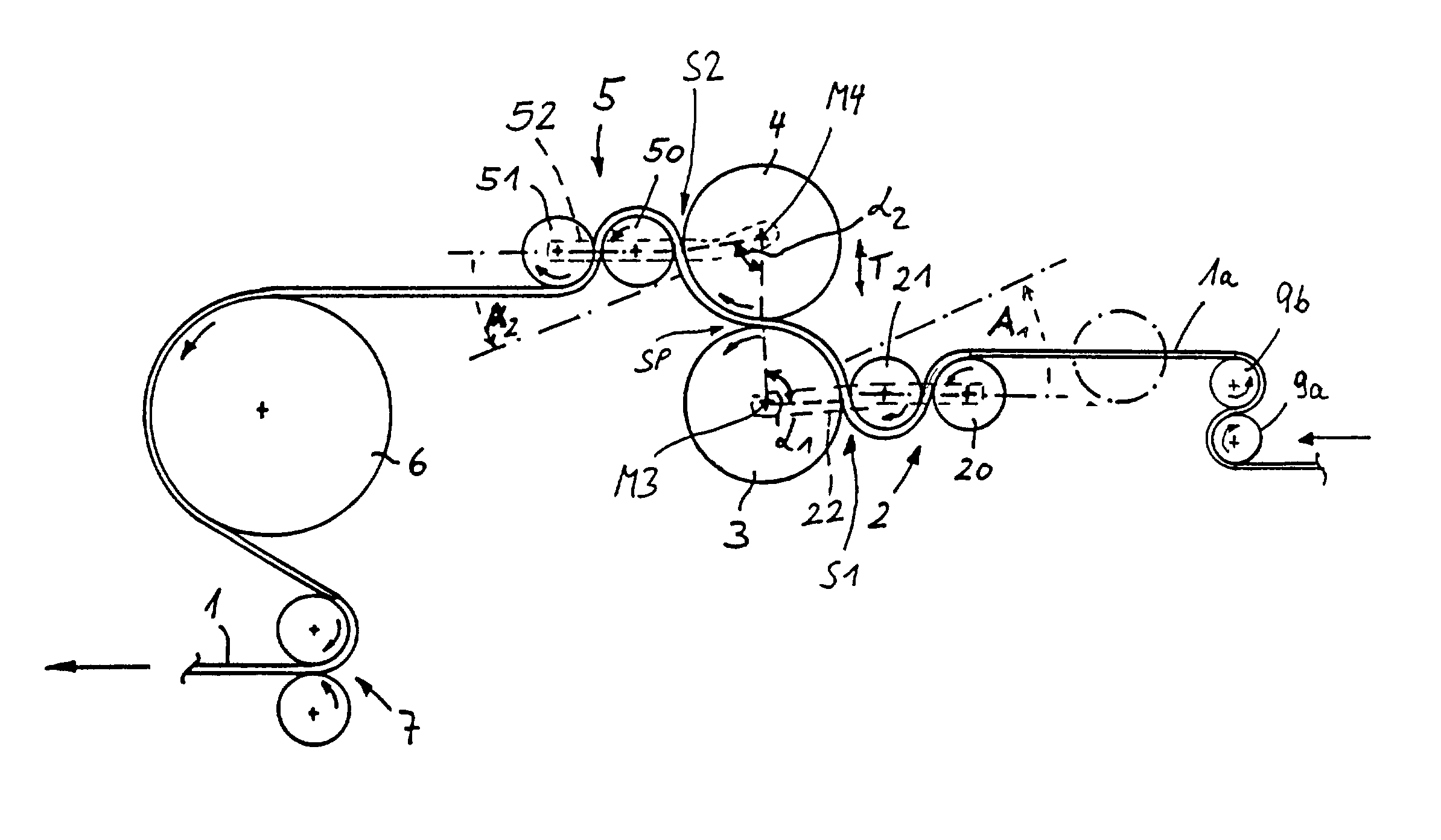

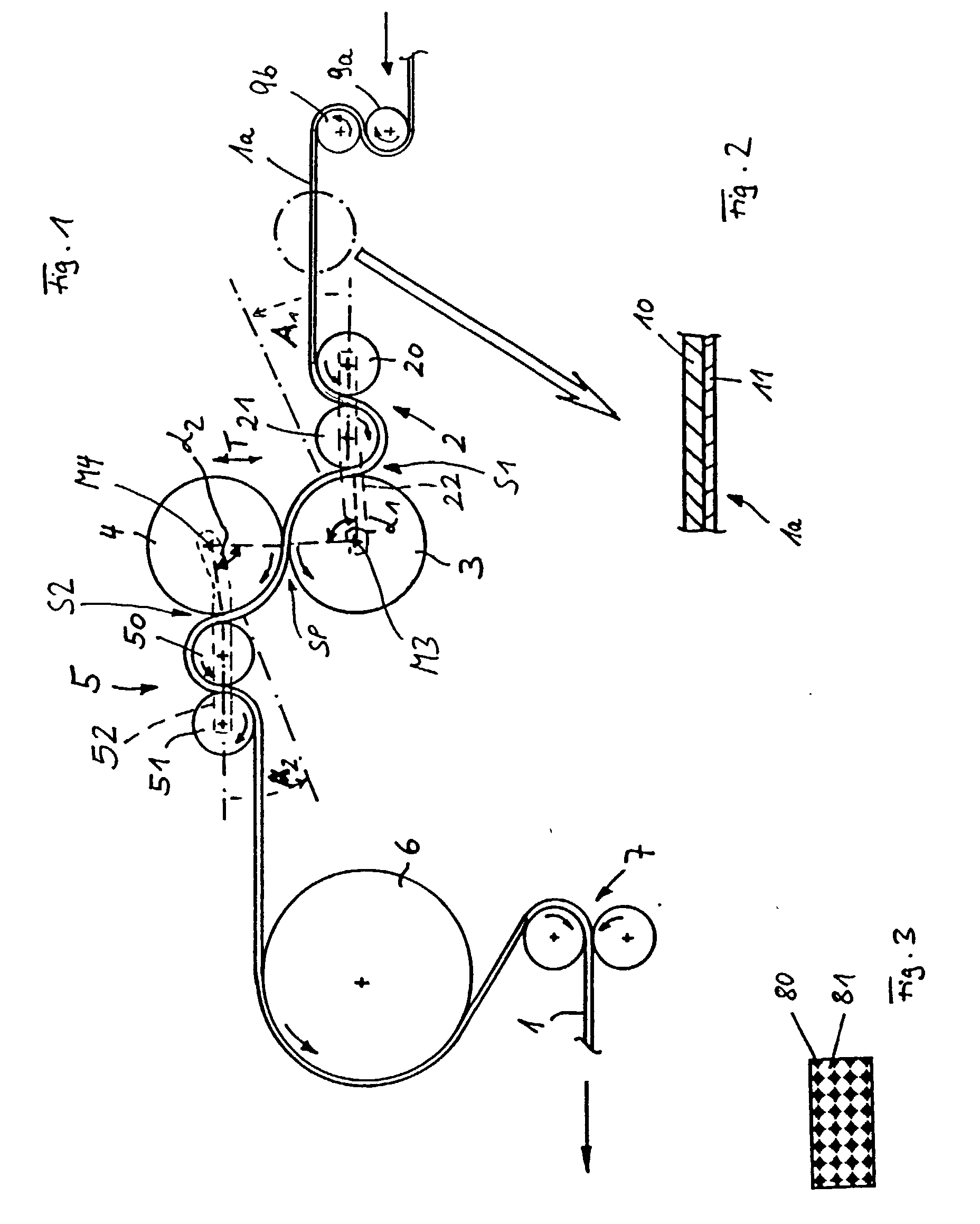

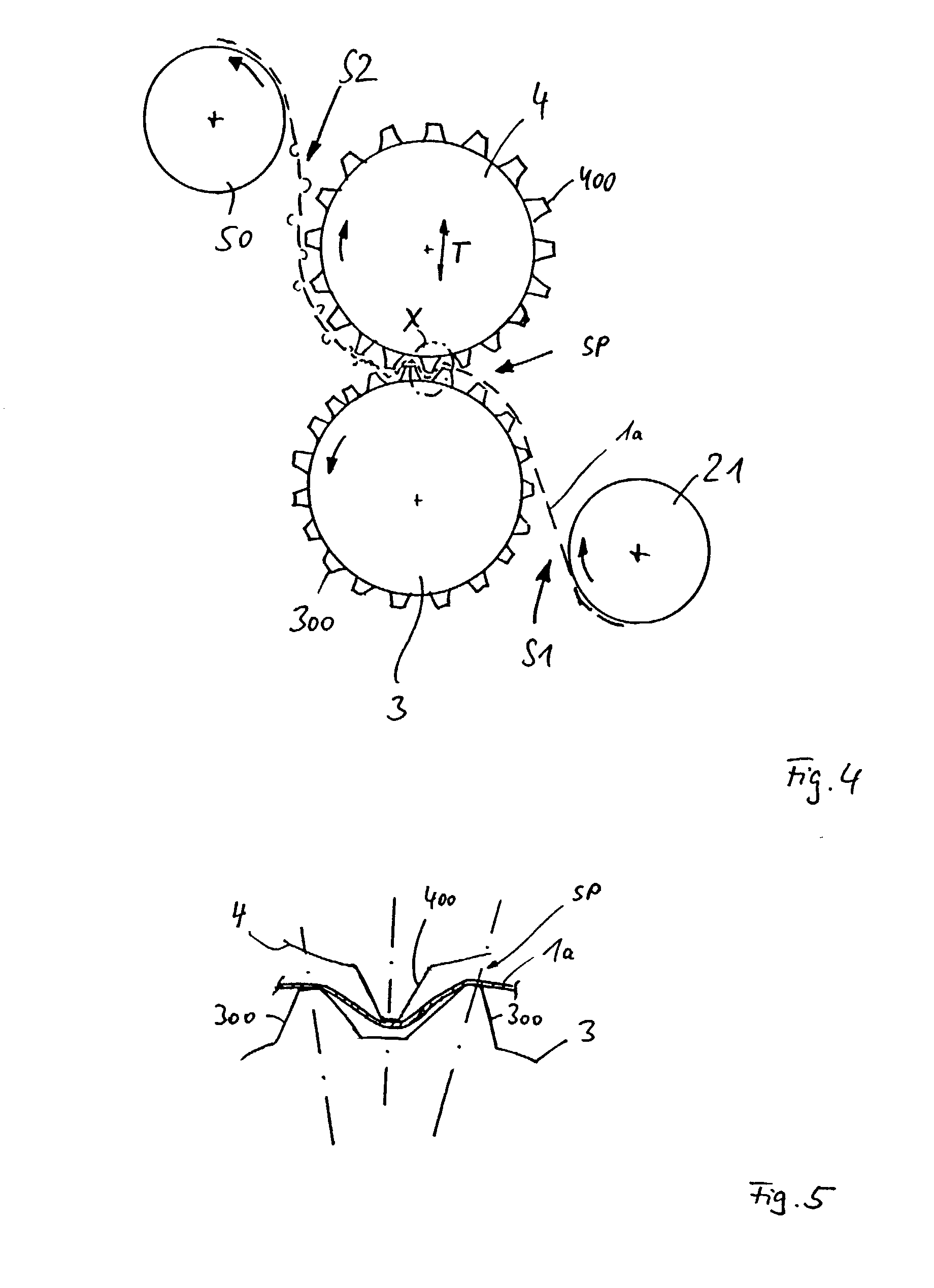

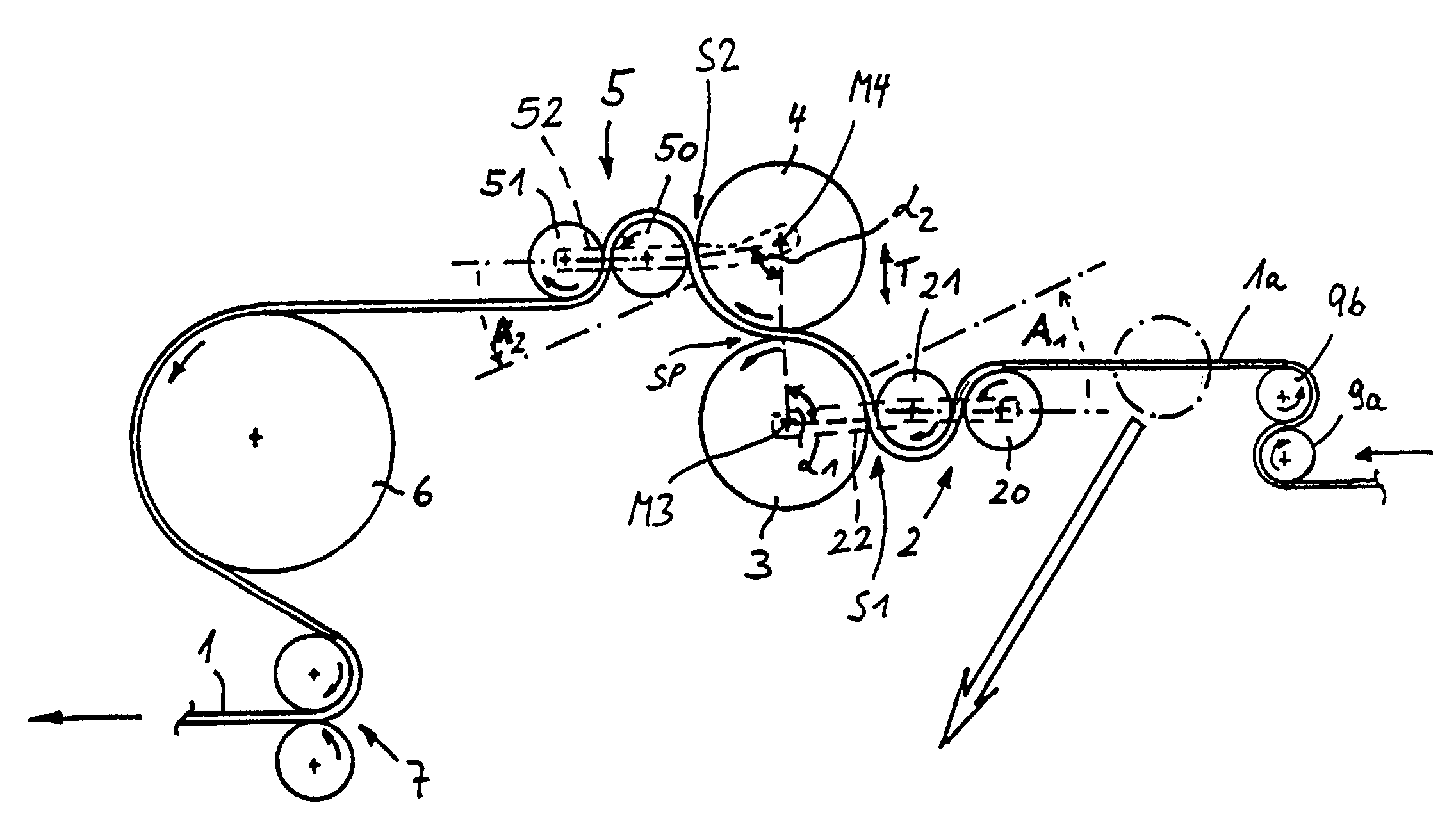

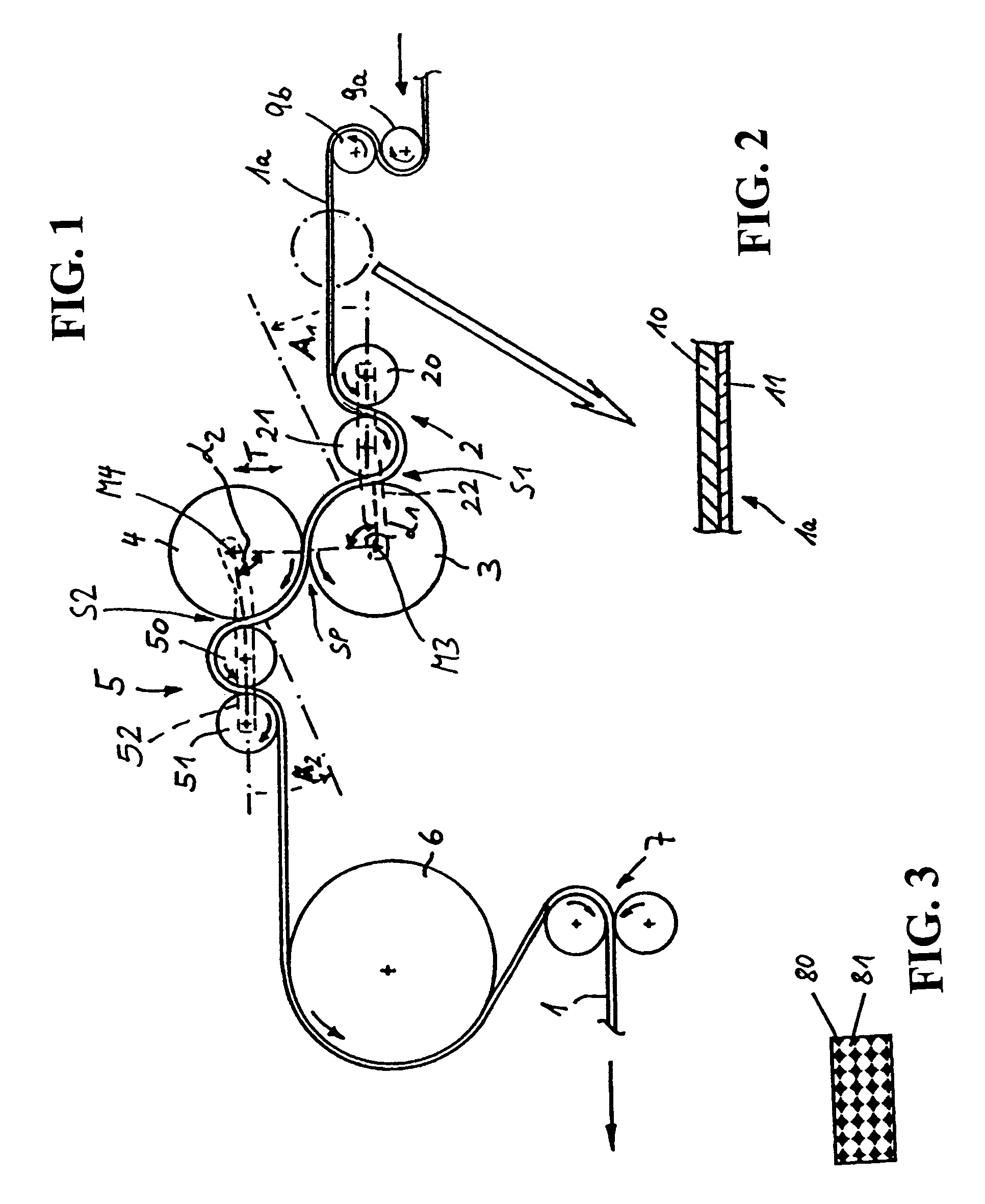

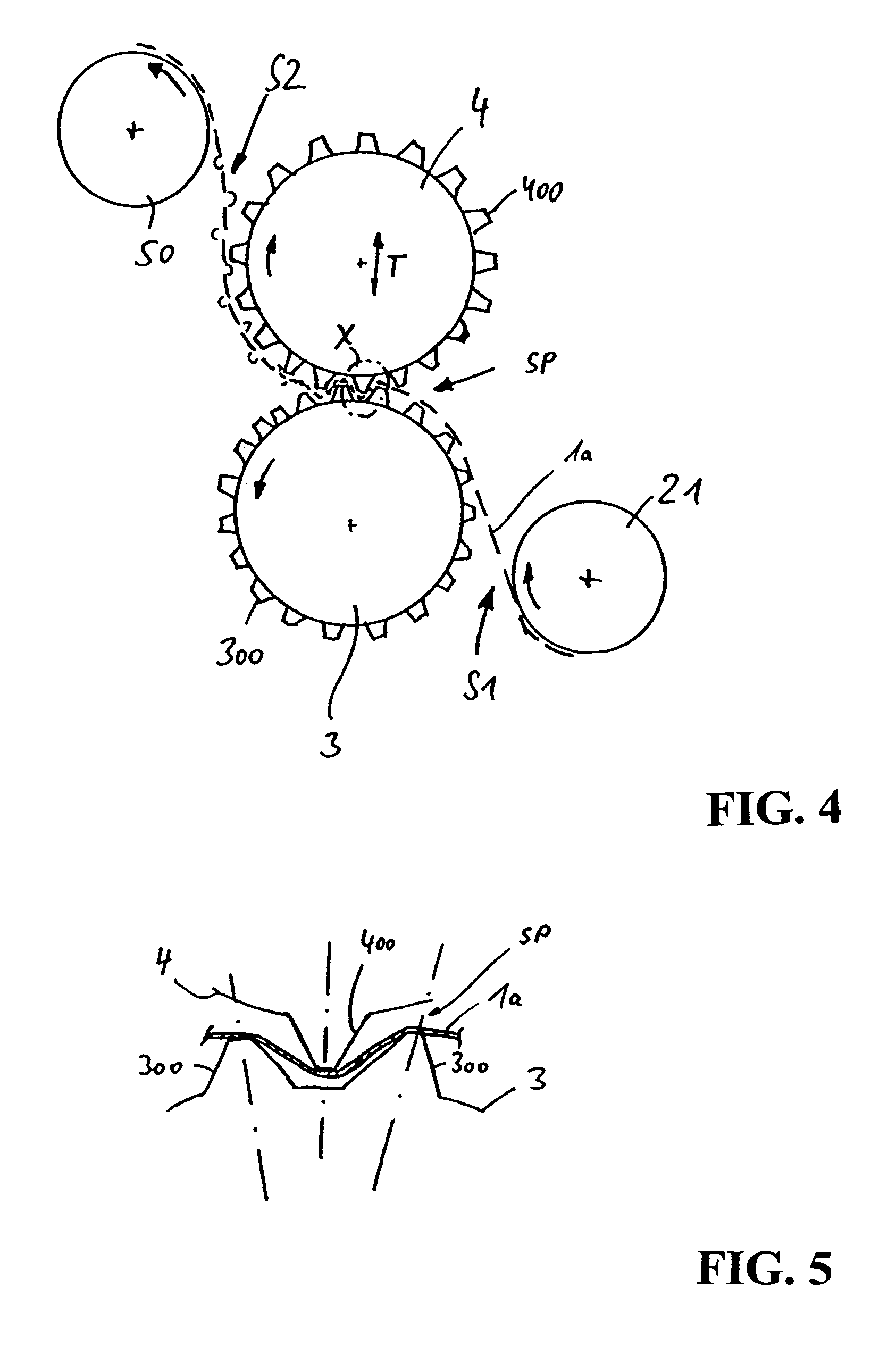

Method and apparatus for the preparation of a web with good breathing properties

InactiveUS20030067091A1Maintain good propertiesLow usageLayered productsConfectioneryPolymer sciencePlastic fiber

A method and a device for production of a web with good breathing properties, for example having a nonwoven web based on plastic filaments and / or plastic fibers and a plastic film, applied on one side of the nonwoven web and containing at least one mineral filler. For the production of the good breathing properties, the web is stretched in the longitudinal direction of the same, in two successive steps, and an embossing is carried out, at least in certain sectors of the surface, between the two steps which effect the stretching in the longitudinal direction.

Owner:REIFENHAUSER GMBH & CO MASCHFAB

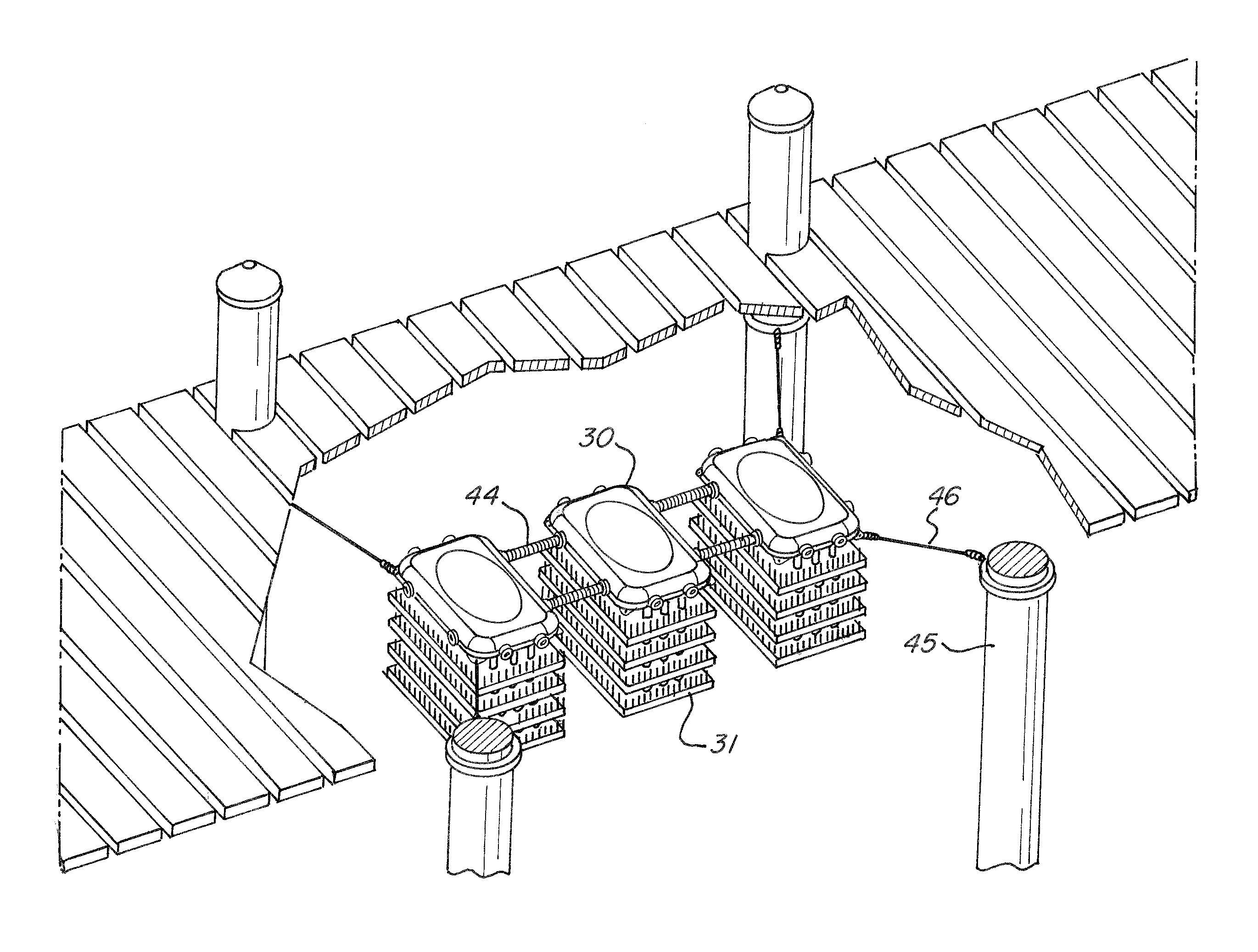

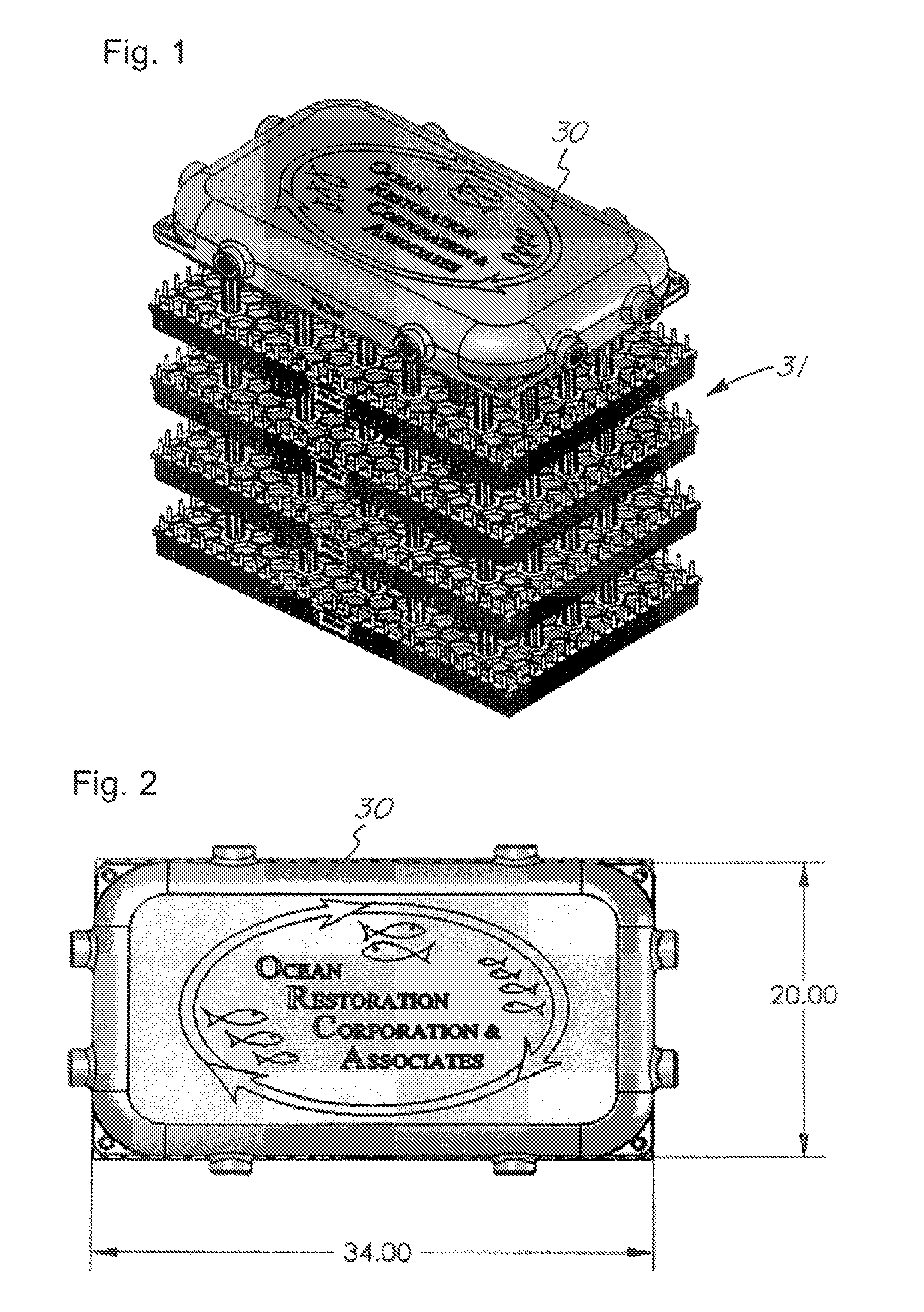

Marine Habitat Systems

InactiveUS20090320766A1Easy to replaceIncrease diversityClimate change adaptationPisciculture and aquariaOysterMarine habitats

A marine habitat system comprising one or more assembled units, each formed of a flotation element and a plurality of habitat tiers fixed to and spaced below the flotation element. The habitat tiers are comprised of frame assemblies formed of upper and lower open frame elements and side walls, forming a space. The space is filled with a mesh matrix of plastic fibers which forms an ideal environment in which various desirable juvenile marine creatures (crabs, lobsters, oysters, etc.) can thrive. Upwardly projecting, simulated prop roots can be provided on the habitat tiers to provide additional anchorage area for marine life to attach.

Owner:OCEAN RESTORATION CORP & ASSOCS

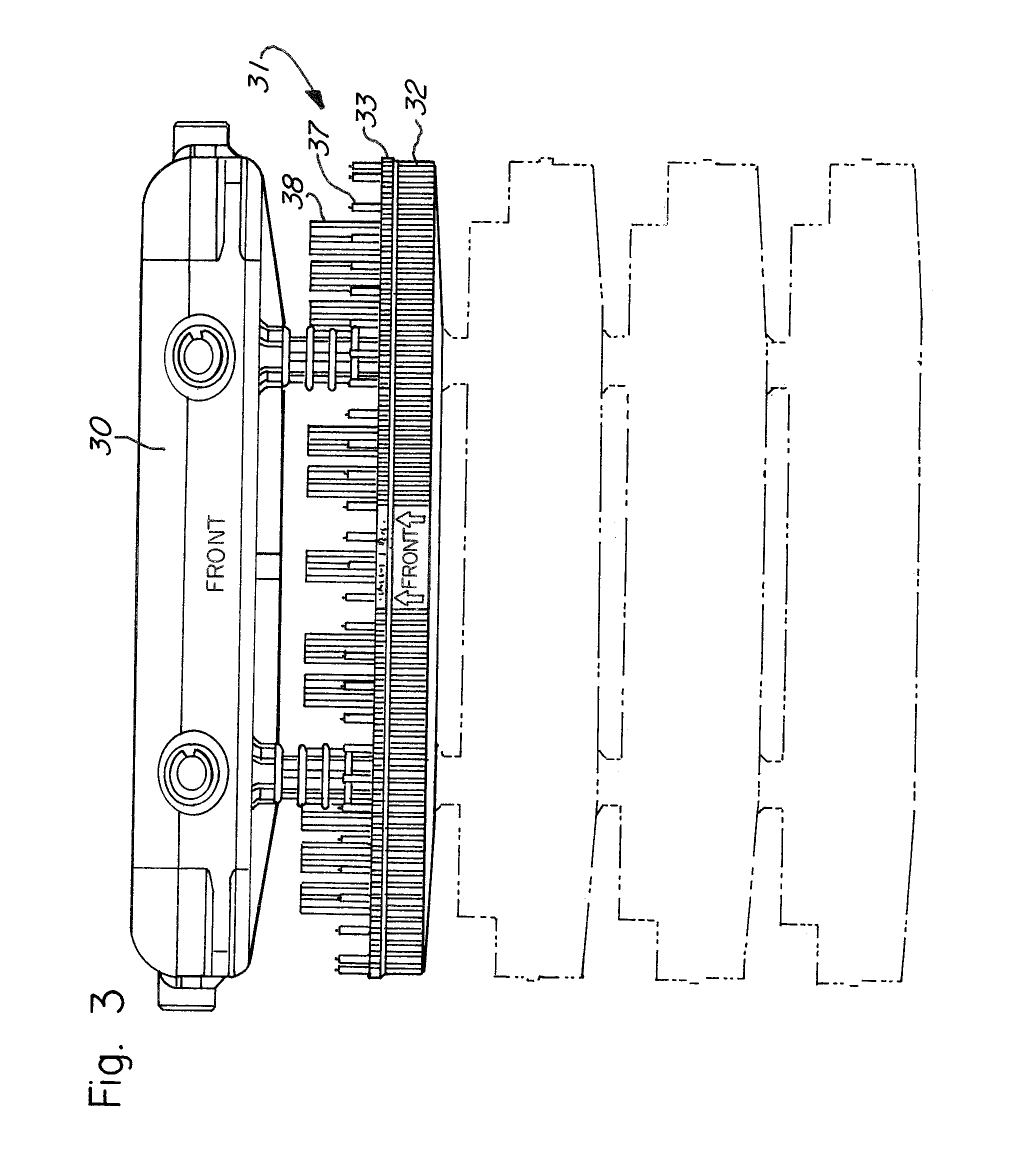

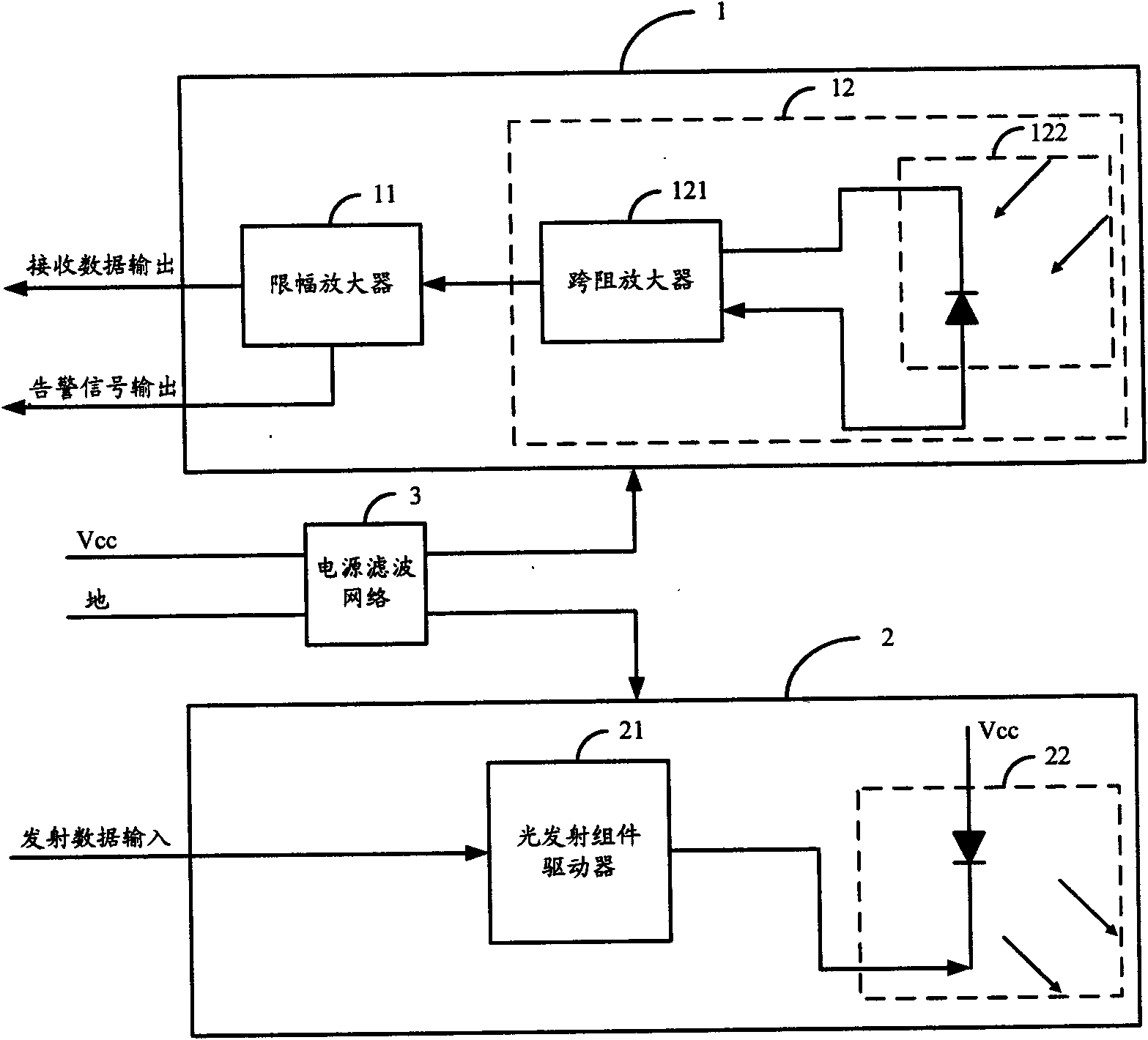

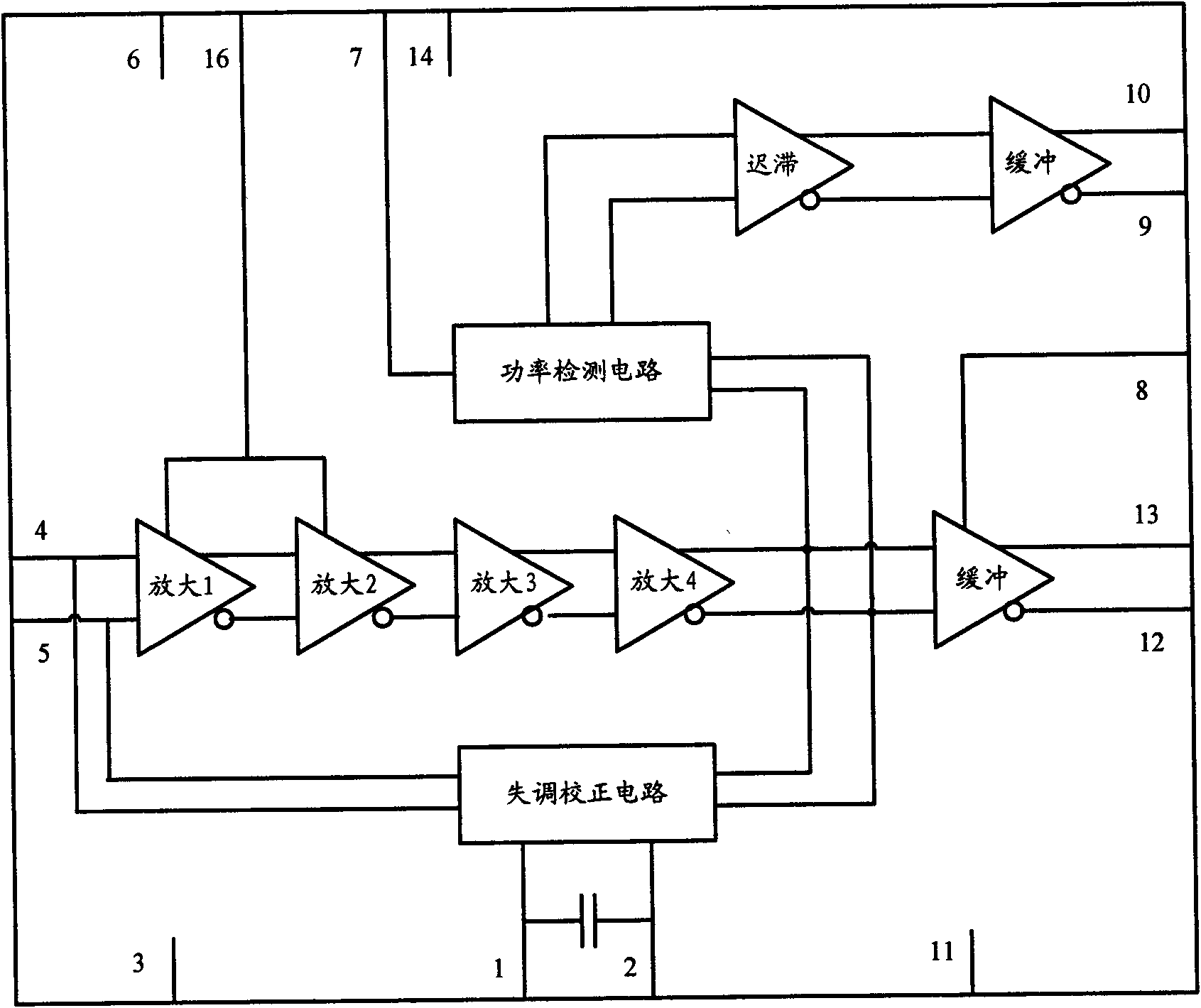

Optical fiber transceiver module and plastic optical fiber communication system

The invention relates to the technical field of optical fiber communication, in particular to an optical fiber transceiver module based on plastic fiber and a plastic optical fiber communication system. The optical fiber transceiver module comprises an optical receiver and an optical sender, wherein the optical sender comprises an optical sending module for sending optical signals with the wavelengths being in a visible optical band and an optical sending module driver for driving the optical sending module to light; the optical receiver comprises an optical receiving module for converting input optical signals with the wavelengths being in the visible optical band into electric signals and a limiting amplifier for limiting and amplifying the electric signals output by the optical receiving module. The invention adopts the optical sending module with the working wavelength being in the visible optical band and a photoelectric detector with large detection area so that the optical fiber transceiver module can be applied to the plastic optical fiber communication.

Owner:广东一普实业有限公司

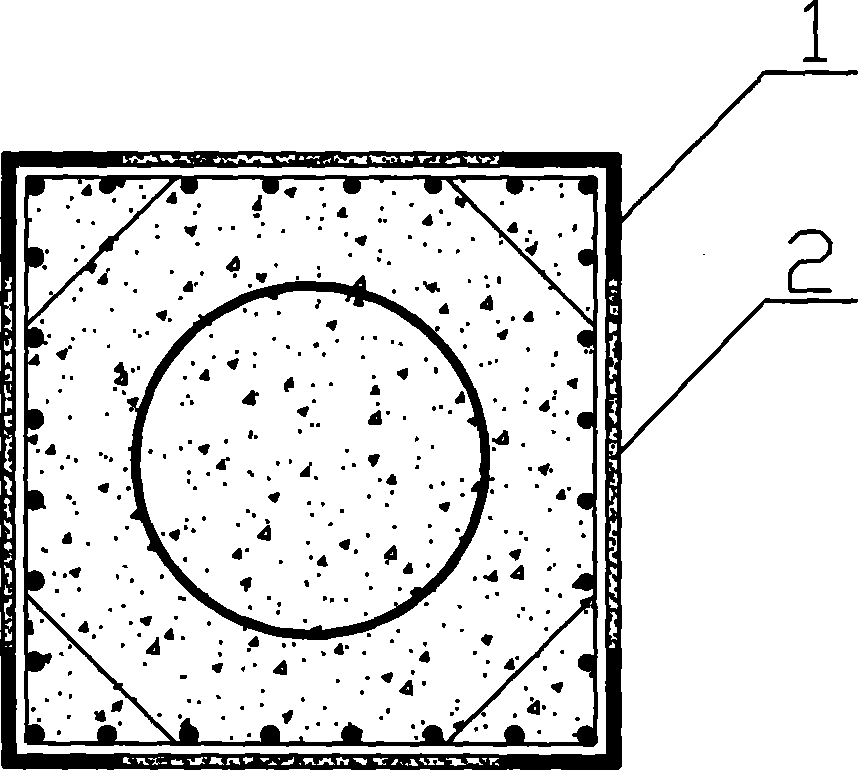

Carbon fiber-reinforced plastic steel reinforced-steel tube concrete combination column

InactiveCN101235661AImprove carrying capacityImprove ductilityStrutsPillarsCarbon fibersPlastic fiber

A carbon fiber reinforced plastic steel skeleton-steel tube concrete combination column relates to a building component form, which comprises carbon fiber reinforced plastic fabric, steel skeleton and steel tube concrete core columns, wherein the steel skeleton is located on the four corners of the steel tube concrete core columns, carbon fiber reinforced plastic fabric is adhered on the outer side of the steel skeleton, and carbon fiber reinforced plastic fabric, steel skeleton and steel tube concrete core column are integrated. A reinforcing method which is adopted by the invention after the steel tube concrete core column is damaged can well increase the loading and the ductility of the steel tube concrete core column compared with the reinforcing method of simply adopting angle steel.

Owner:SHENYANG JIANZHU UNIVERSITY

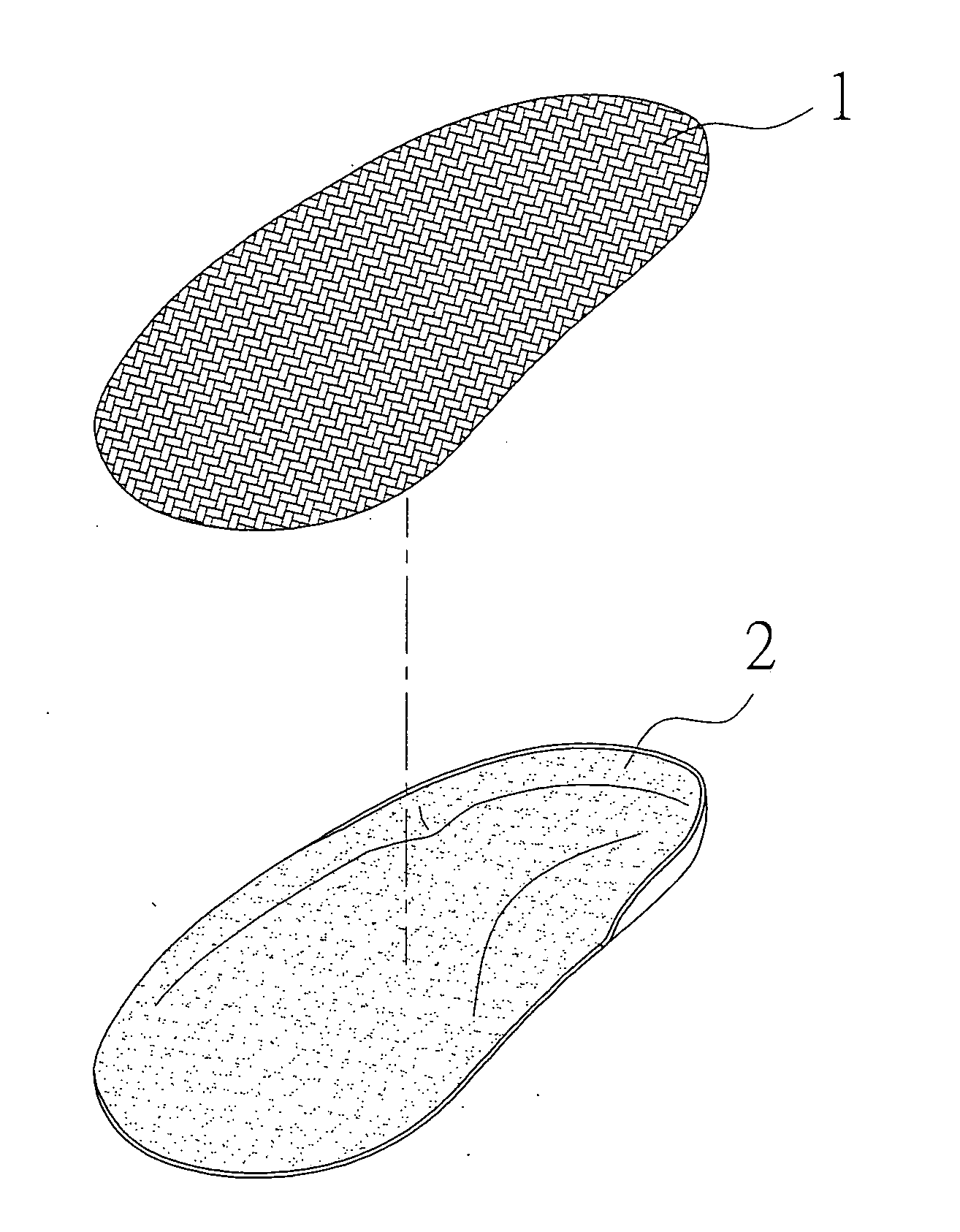

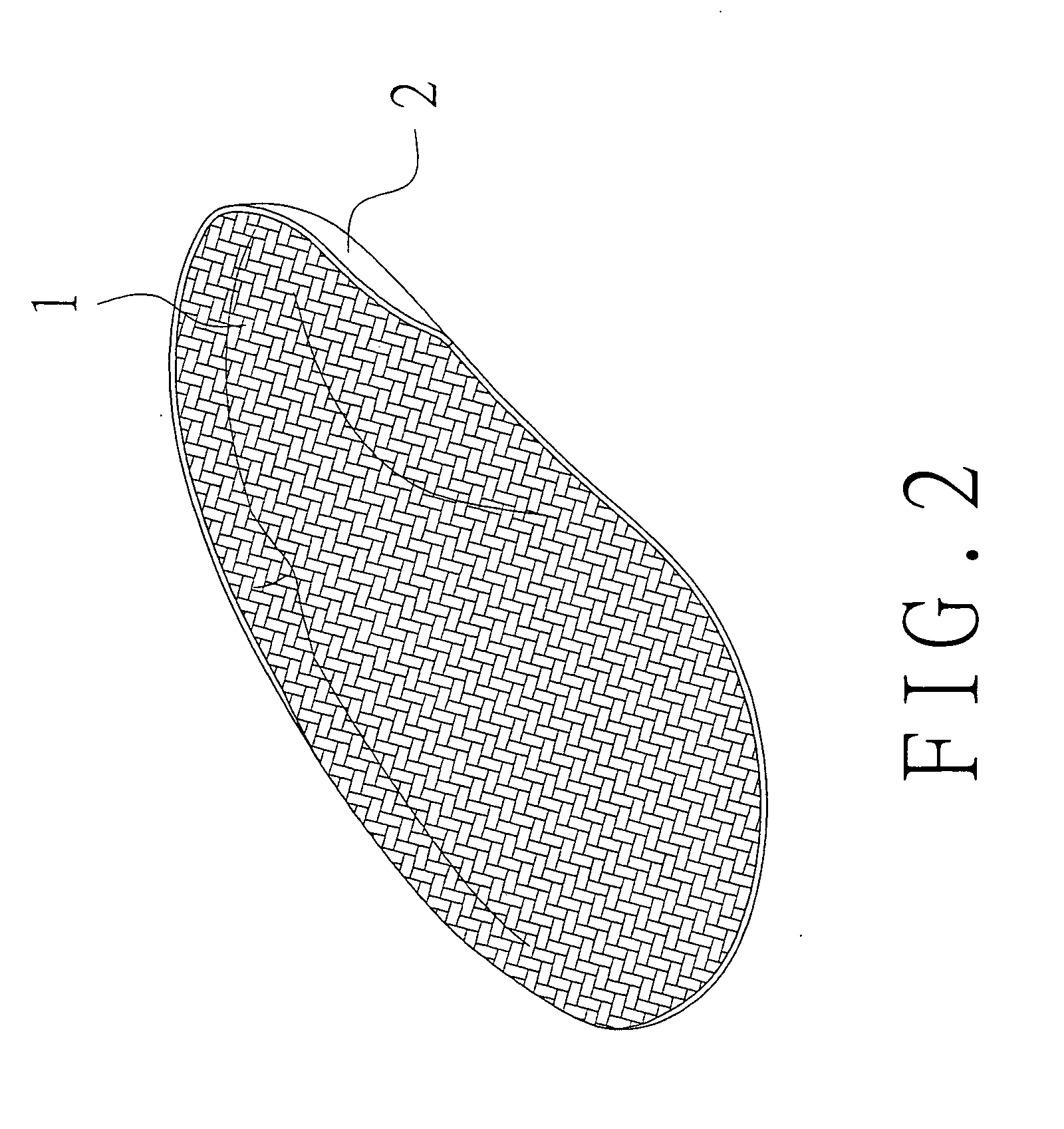

Insole

The present invention relates to a insole which is mainly made by the following process: reeling off single thread filament from recycled materials such as PET bottle, PET plastic material, waste fabric, recycled yarn into fiber; intermingling plastic fiber with the above fiber of recycled material and then conducting needle punching to form air-permeable thick layer of nonwoven fabric having 3-10 mm thickness; adhering nonwoven fabric or cover layer made by general fabric onto the air-permeable thick layer of non-woven fabric; conducting heat forming and cutting into suitable size. In this manner, not only the insole made by recycled material possesses environment protection feature but also the air-permeable thick layer of nonwoven fabric, which is needle punched from fiber, has excellent air permeability and appropriate elastic effect. Therefore, users have snug feeling achieved by good air permeability and shock absorption so that it has better performance in its total application.

Owner:ALWAYS CHAMPION ENTERPRISE

Method of making a web having good breathing properties

InactiveUS6991758B2Promote respirationGood moisture permeabilityButtonsLamination ancillary operationsMedicineEngineering

Owner:REIFENHAUSER GMBH & CO MASCHFAB

Container for collecting liquid for transport

ActiveUS20170143534A1Limit and impairs mobilityMedical devicesIntravenous devicesPolyesterEngineering

A container for collecting liquid for transport, comprising: a web of flexible porous material defining at least a portion of a chamber in which liquid can be collected for transport. The chamber is configured to receive a tube in a position within the chamber that enables the tube to transport liquid from the chamber while the liquid collects within the chamber upon being drawn through the web when a partial vacuum is applied within the chamber via the tube. The porous material comprises a web of spun plastic fibers, such as spun polyester fibers. In one embodiment, the web of spun plastic fibers is configured to define an elongated portion of the chamber. In another embodiment, a backing of non-permeable material covers a portion of the web and is so combined with the web as to further define the chamber.

Owner:PUREWICK

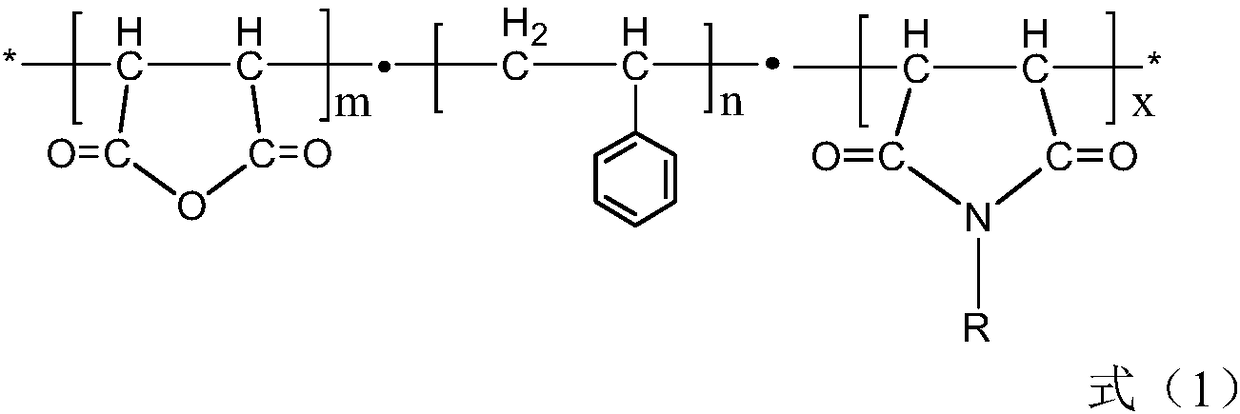

Non-releasing polymer antibacterial masterbatch containing guanidyl side chain, preparation method and applications

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

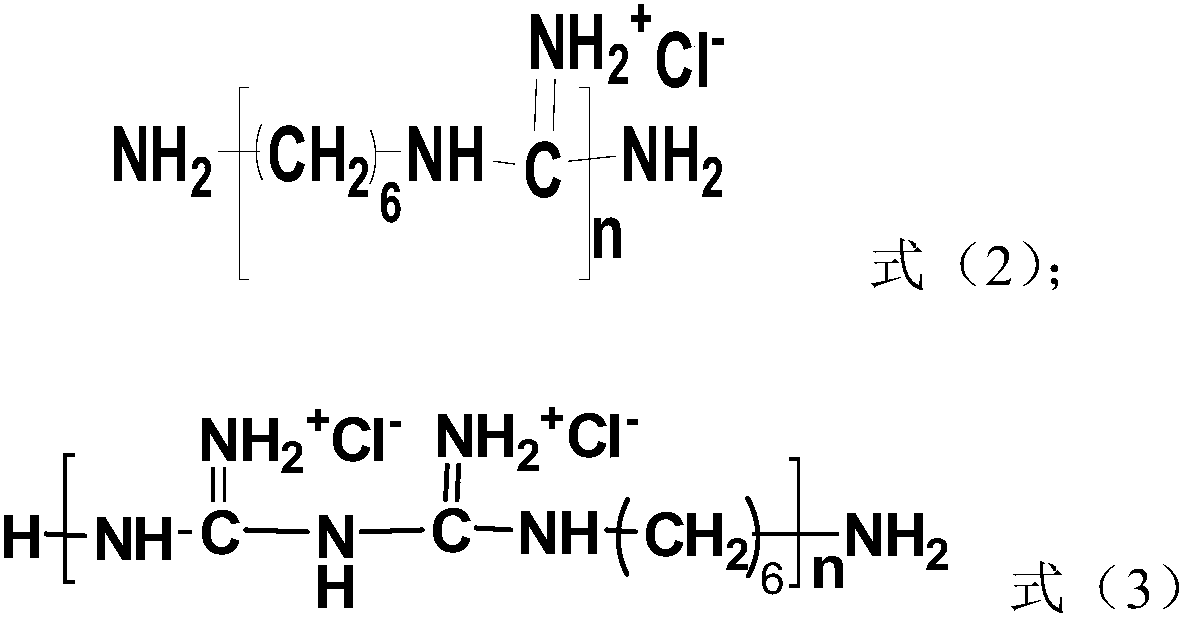

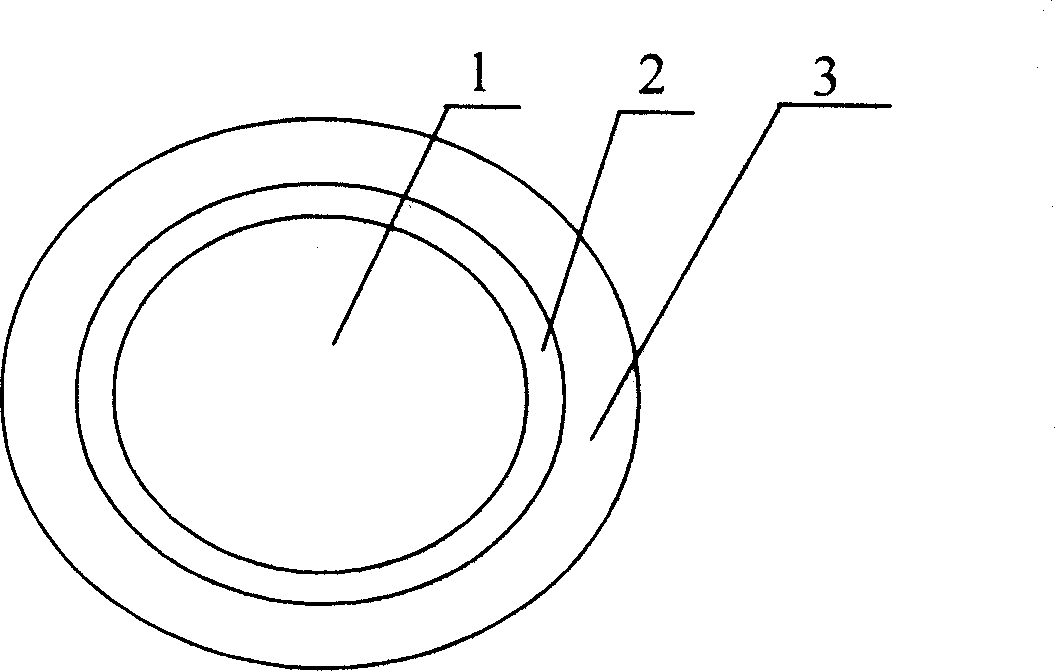

Method for continuously preparing phase step type plastics optical fibre by multi-layer co-extruded method

The invention belongs to the field of broadband access network in a high speed light communication network and the field of multimedia material technology in information communications, which more particularly relates to the preparation method of a step typed plastic fiber with a mutagenic refractive index. The continuous multilayer composite extrusion method provided by the invention adds a flexible layer to strengthen the flexibility of the plastic fiber on the basis of ordinary two layers through an annular circular tube die with the same core and with each layer compressing together; the flexible layer is coated at the outmost layer of the fiber, so the transparency performance of the fiber is not affected and at the same time, the flexibility of the plastic fiber is greatly increased. Furthermore, if needed, an external protective layer can also be added at the same time of drawing the fiber to form a four-layer structure so as to lead the productions of the plastic fiber and optical cable to be completed at the same time and on the same machine unit.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

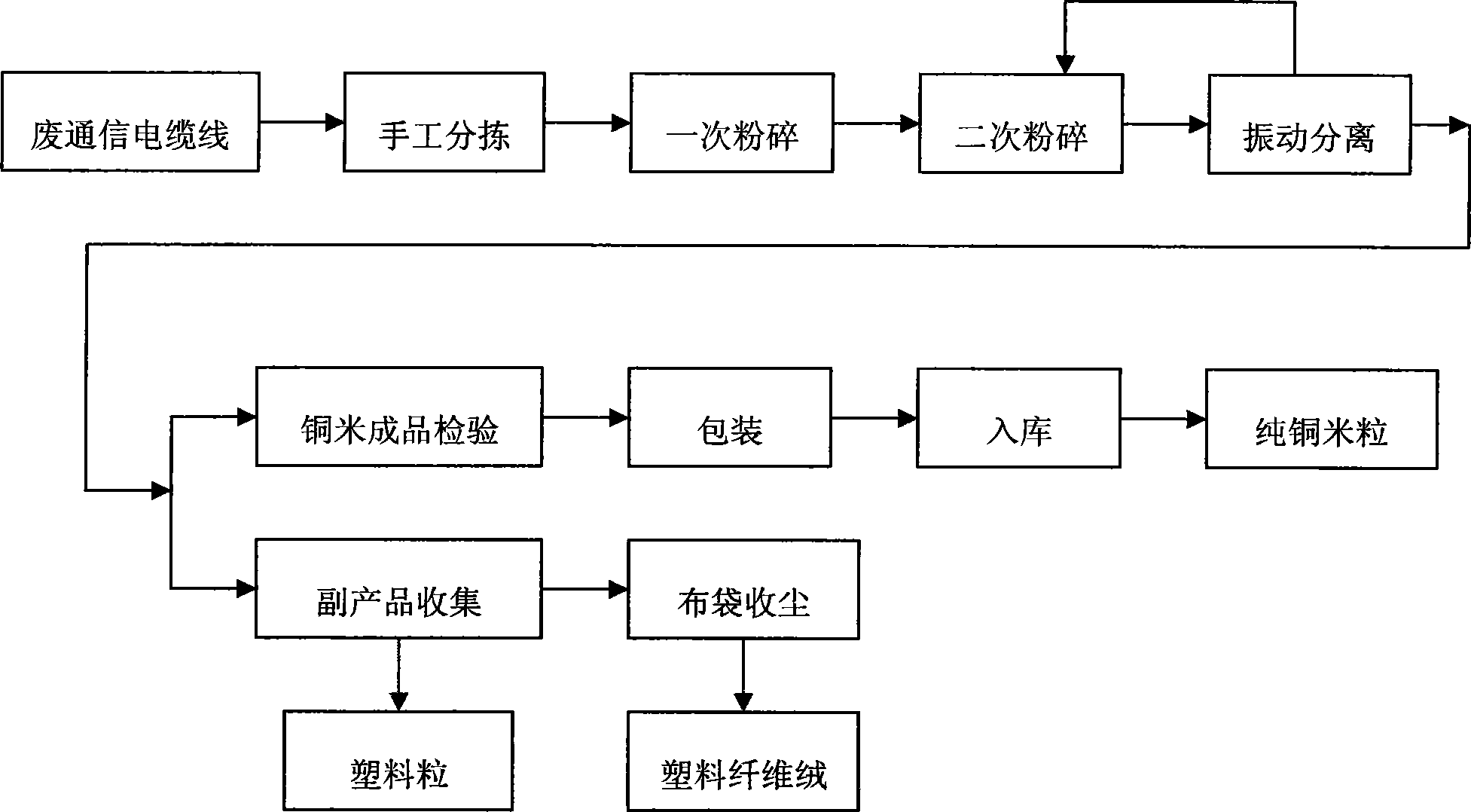

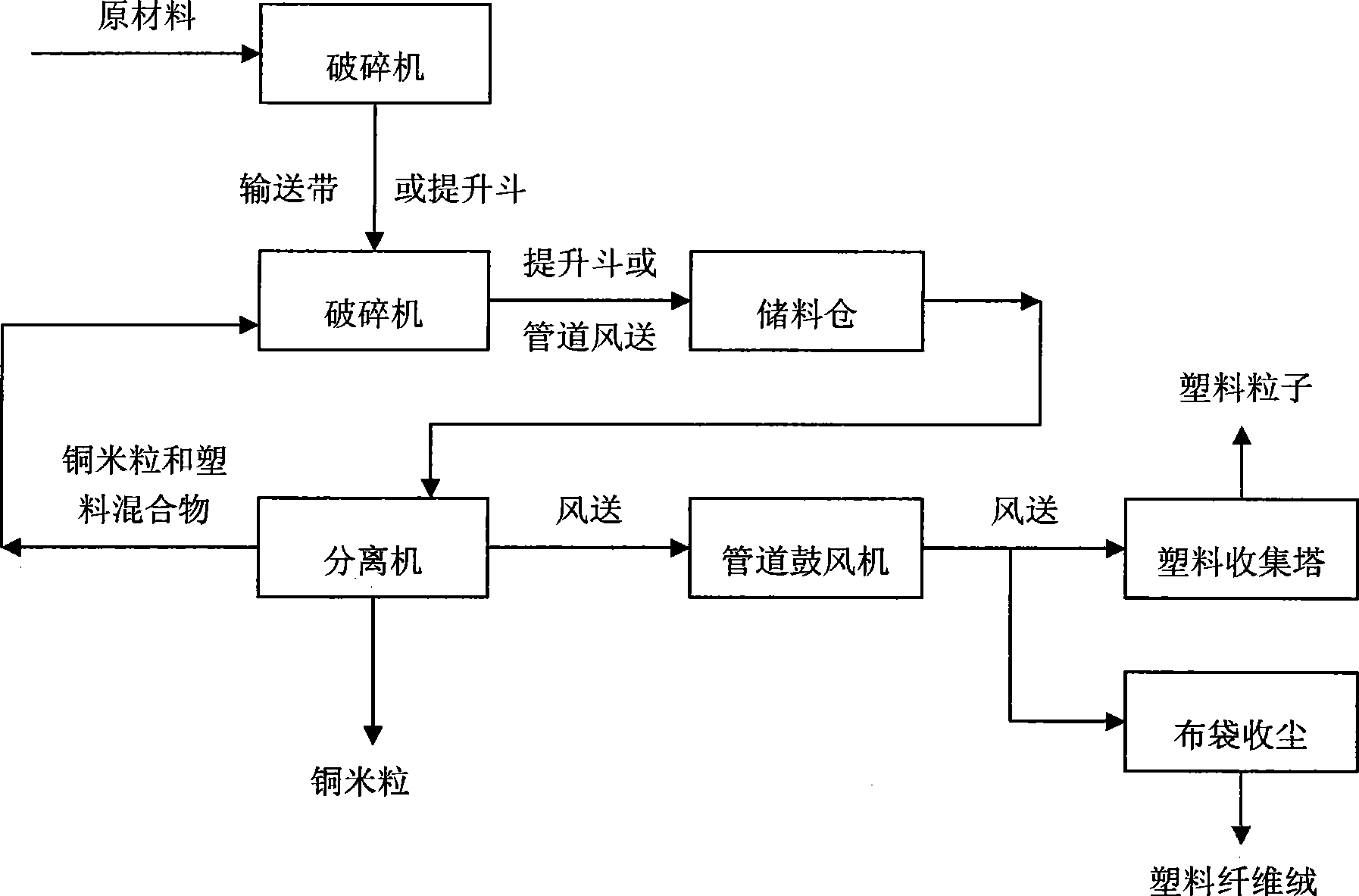

Process for recycling and manufacturing copper granule from waste and old electric wire and cable

InactiveCN101367084ALow costReduce energy consumptionSievingSolid waste disposalEngineeringMixed materials

The invention discloses a technological method for producing copper rice grains by recovering waste wires and cables based on an improvement of the prior production mode that the waste wires and cables recover copper raw materials. The technological method has low cost, small energy consumption, less discharge and no waste pollution, meets the requirement of circular economy development, and can obtain a copper rice grain product the purity of which reaches 99.9 percent. The technological process comprises the steps of classification inspection, loading, primary crushing, secondary crushing, and vibration separation; the angle of a vibration sieve is adjusted according to the content of copper and the wire diameter, and the copper rice grains and plastic are subjected to optional separation through vibration sieving; a material from a mixed material port flows into an air suction pipe, and is sent for secondary crushing through a circulating air pipe; the air suction pipe above the vibration sieve sucks plastic fibers and other dust in the space of the vibration sieve to a dust collector for treatment; the qualified copper rice grains obtained at a copper outlet flow into a packing bag; and the finished product inspection is performed, namely the obtained copper rice grains enter a warehouse through the inspection.

Owner:南京东南铜业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com