Non-releasing polymer antibacterial masterbatch containing guanidyl side chain, preparation method and applications

A technology of antibacterial masterbatch and polymer, which is applied in the field of non-releasing polymer antibacterial masterbatch and its preparation, can solve the problems of poor plastic compatibility and processing performance, and achieve good compatibility, good antibacterial effect, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

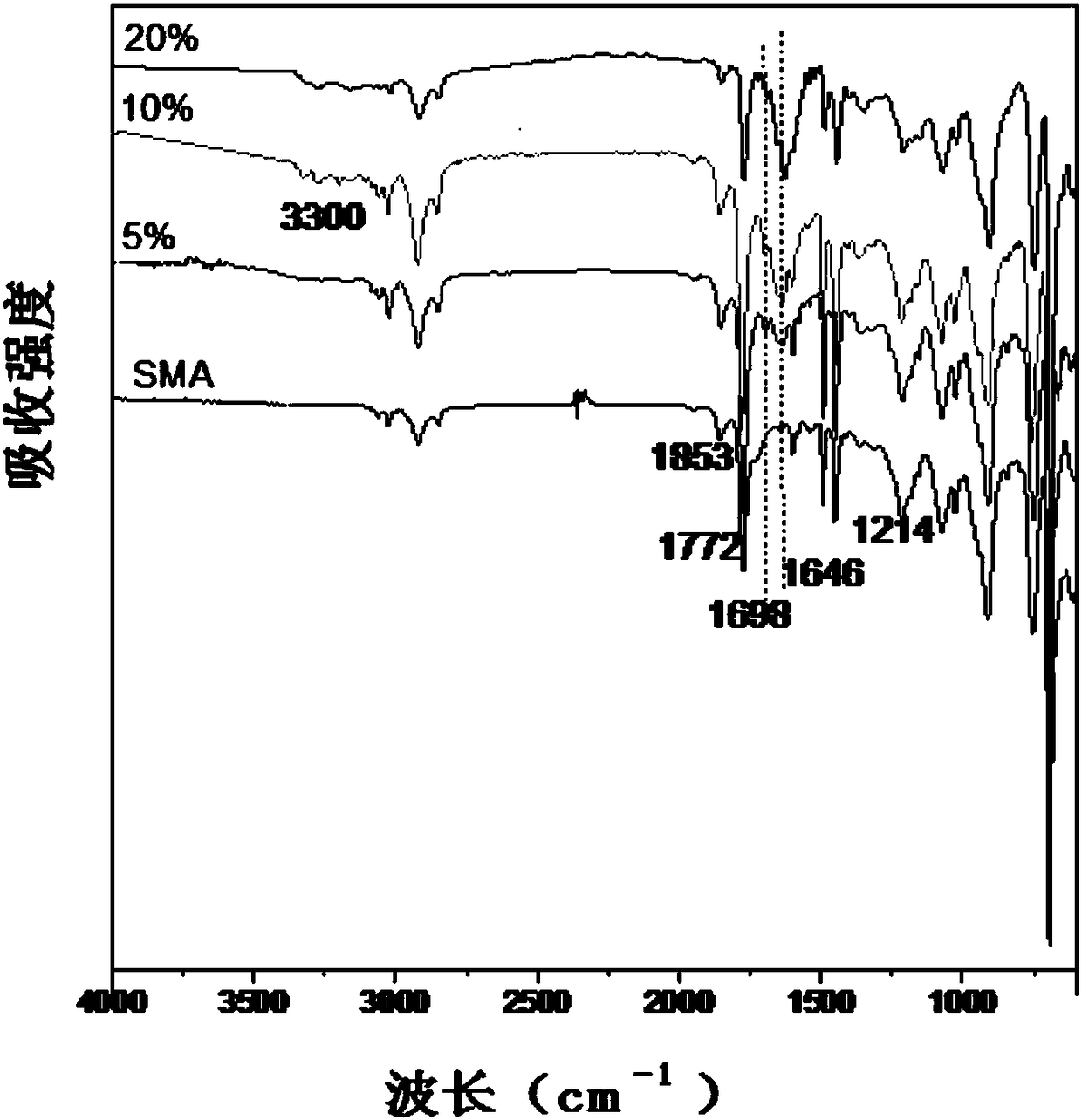

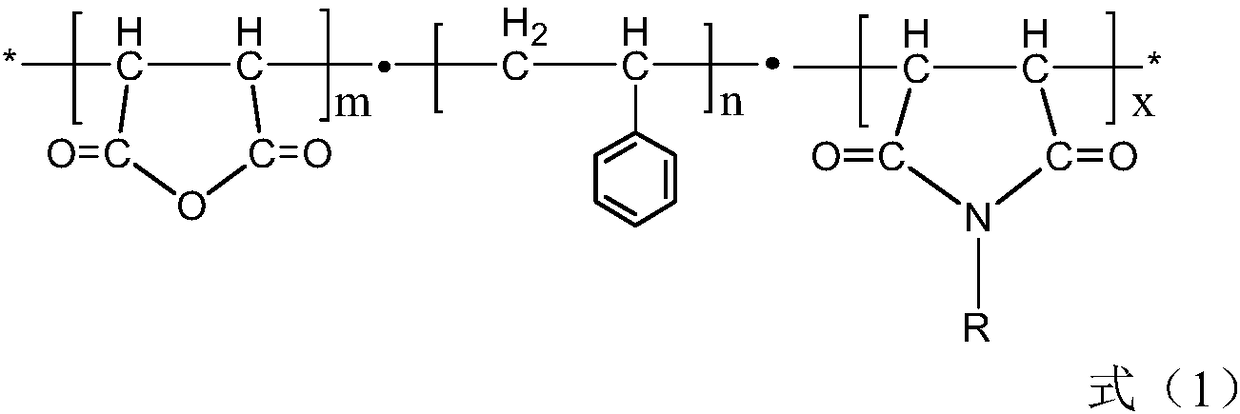

Embodiment 1

[0047] 50g maleic anhydride molar content is that the SMA of 35% and the PHGC of 2.5g carry out mechanical blending, obtain the first mixture; The first mixture is dried 24h in the oven of 60 ℃; Both are at 210°C, and the rotation speed is 50r / min; the dried first mixture is added into the cavity of the internal mixer, the time from feeding to discharging is 4min, and it is pulverized after discharging to obtain SMA with a ratio of PHGC to SMA of 5%. (35%)-PHGC antibacterial masterbatch.

Embodiment 2

[0049] 50g maleic anhydride molar content is that the SMA of 35% and the PHGC of 5.0g carry out mechanical blending, obtain the first mixture; The first mixture is dried 24h in the oven of 60 ℃; Both are at 210°C, and the rotation speed is 50r / min; the dried first mixture is added to the cavity of the internal mixer, and the time from feeding to discharging is 10 minutes, and it is pulverized after discharging to obtain SMA with a ratio of PHGC to SMA of 10%. (35%)-PHGC antibacterial masterbatch.

Embodiment 3

[0051] 50g maleic anhydride content is that the SMA of 35% and the PHGC of 10.0g carry out mechanical blending, obtain the first mixture; The first mixture is dried 24h in the baking oven of 60 ℃; It is 210 ℃, and the rotating speed is 50r / min; The first mixture that will dry is joined in the banbury mixer chamber, is 12min from charging to discharging time, pulverizes after discharging, obtains the SMA that PHGC and SMA ratio are 20% 35%)-PHGC antibacterial masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com