Insole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]The objects, the technical contents and the expected effectiveness of the present invention will become more apparent from the detailed description of the preferred embodiment in conjunction with the accompanying drawings.

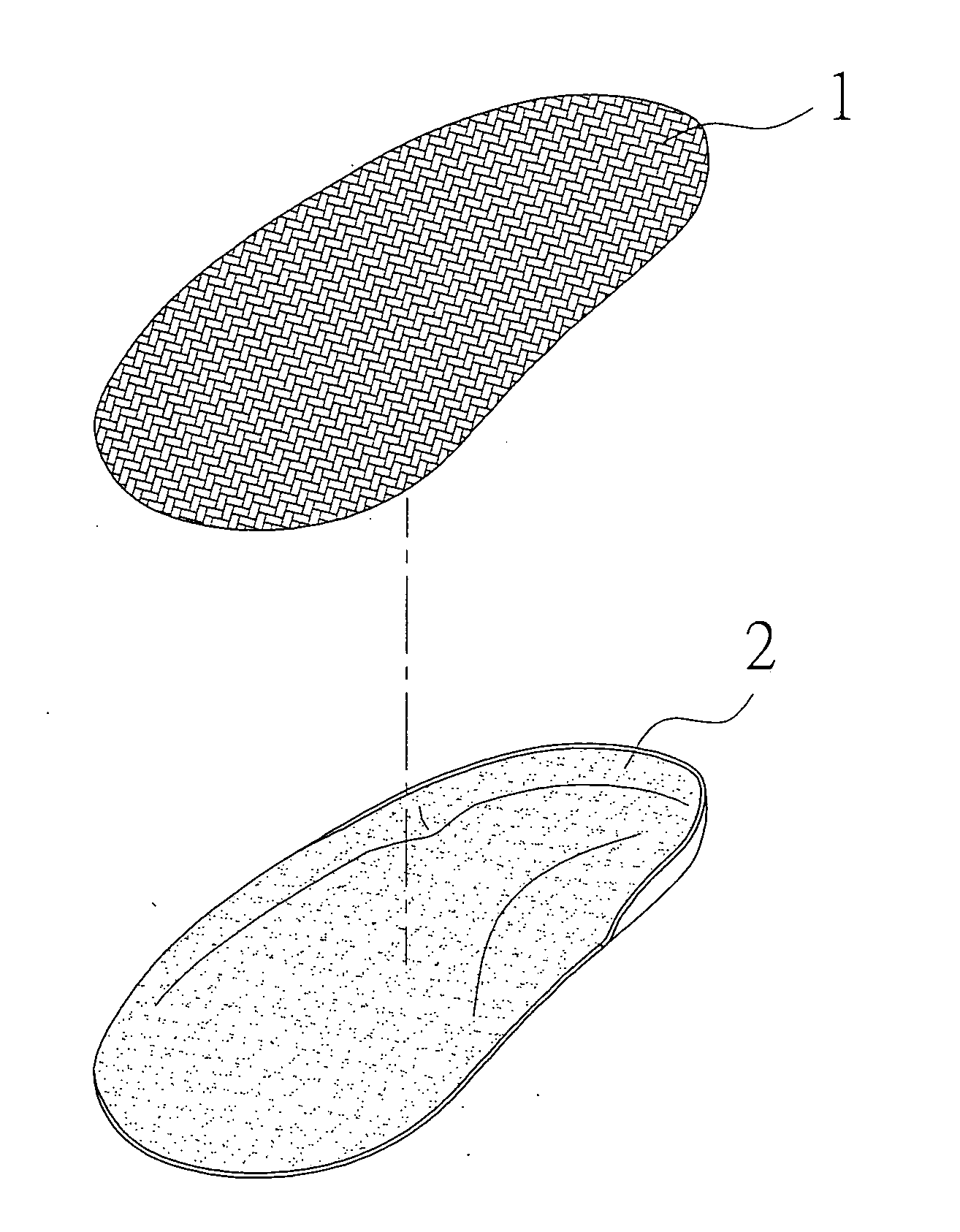

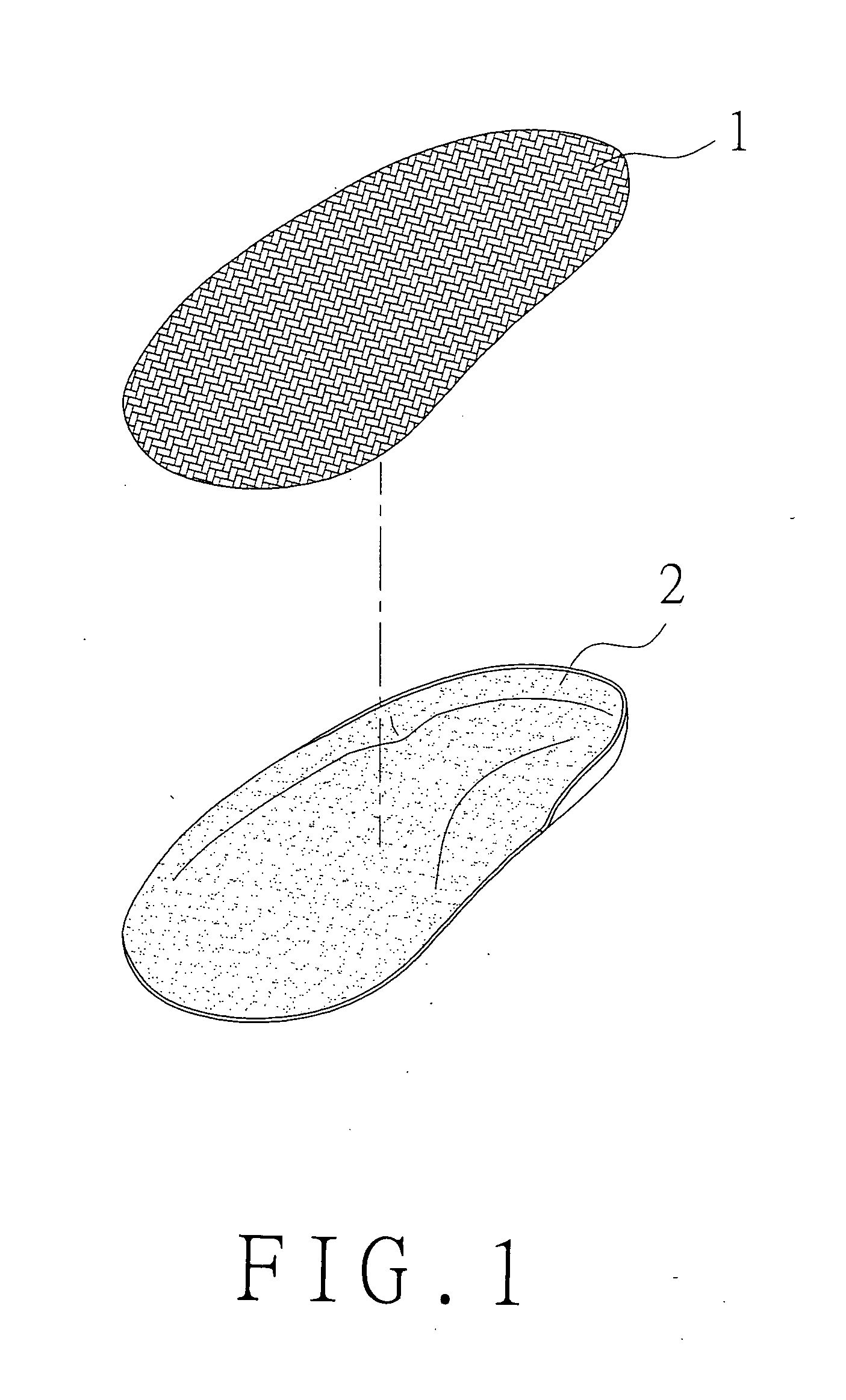

[0013]Firstly referring to FIG. 1 showing a perspective exploded view of the insole of the present invention, the insole is formed by a cover layer (1) adhered onto an air-permeable thick layer of nonwoven fabric (2).

[0014]The cover layer (1) can be formed by nonwoven fabric or general fabric.

[0015]The air-permeable thick layer of nonwoven fabric (2) is formed by firstly reeling off single thread filament from recycled materials such as PET bottle, PET plastic material, waste fabric, or recycled yarn into fiber, then by intermingling plastic fiber with the above fiber of recycled material, and then conducting needle punching. The air-permeable thick layer of nonwoven fabric (2) has a thickness of approximately 3-10 mm.

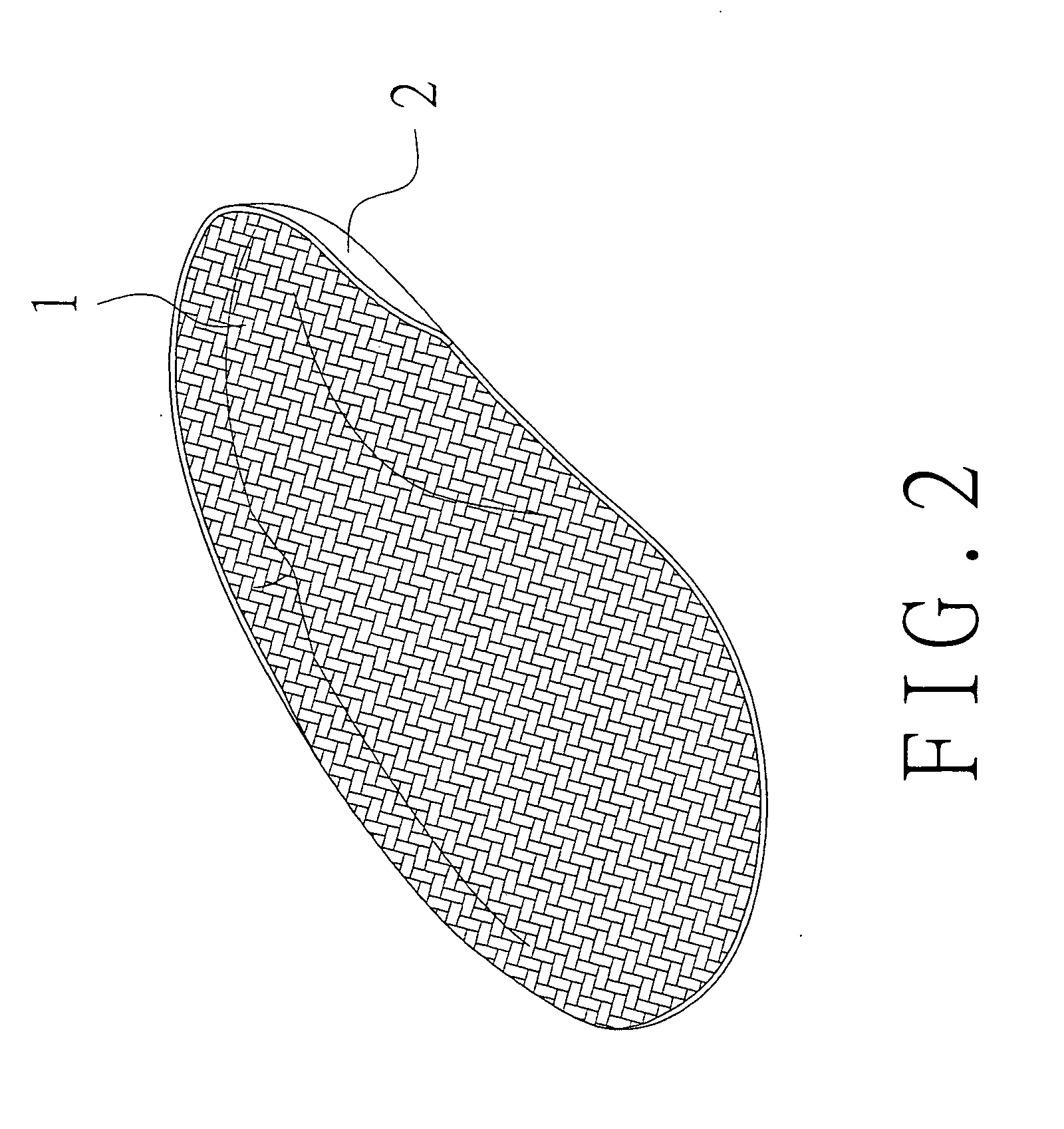

[0016]In this manner, please refer to FIG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com