Patents

Literature

836results about How to "Simple structure and process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

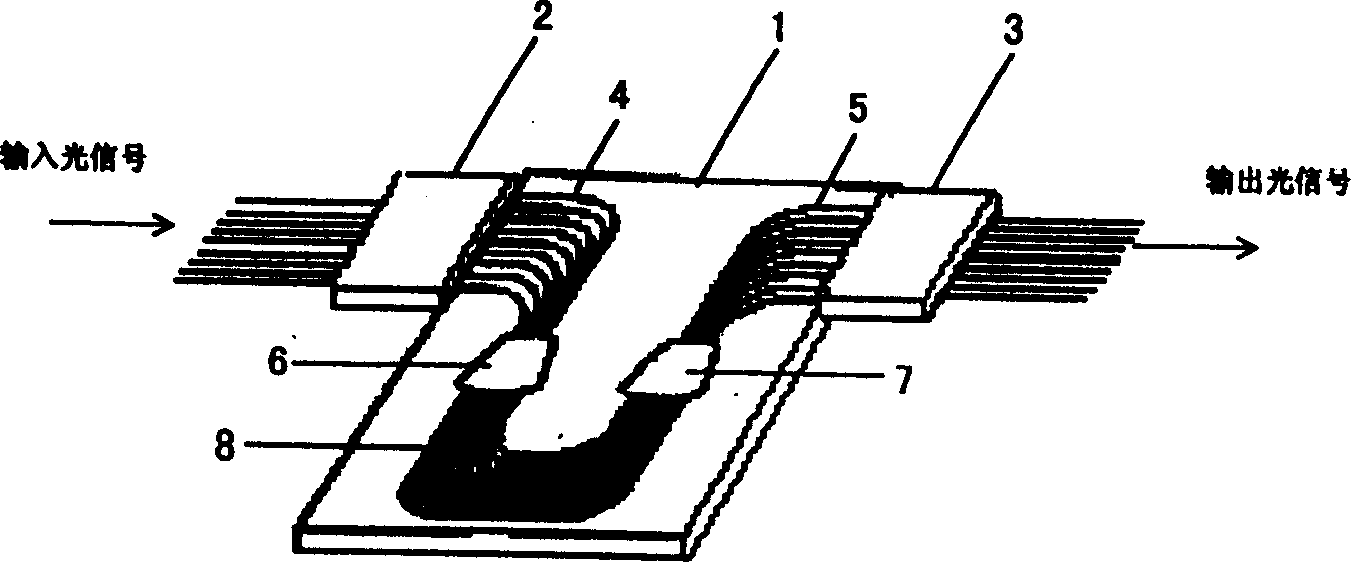

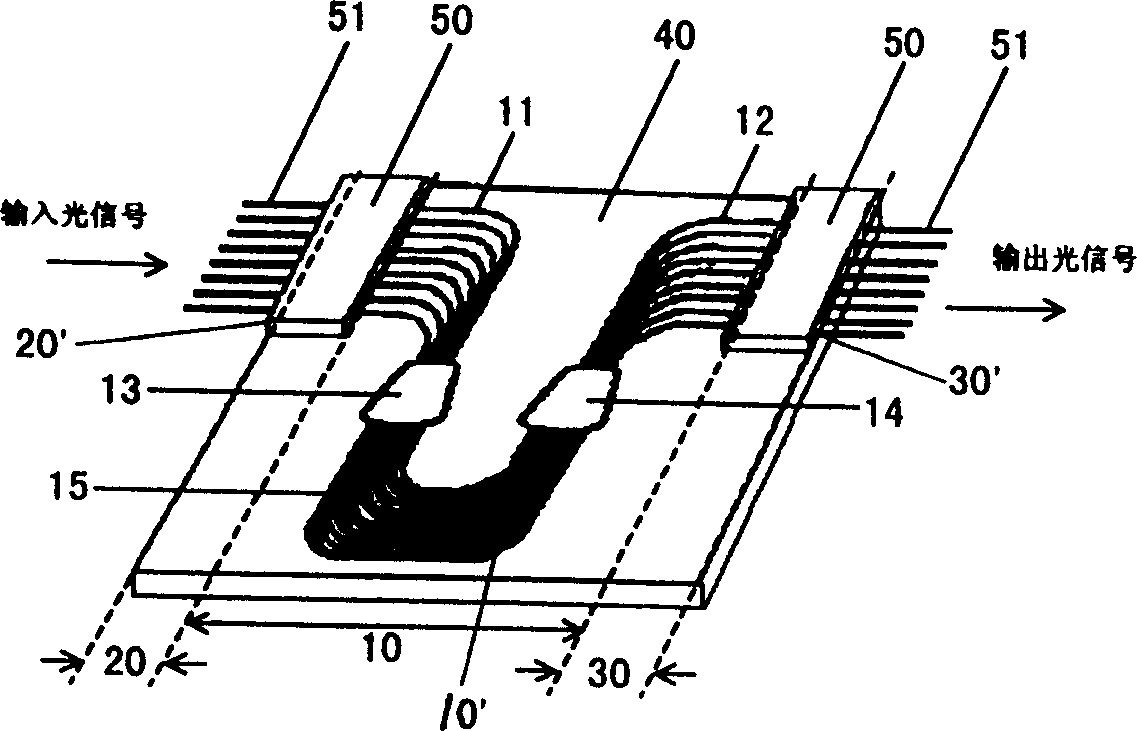

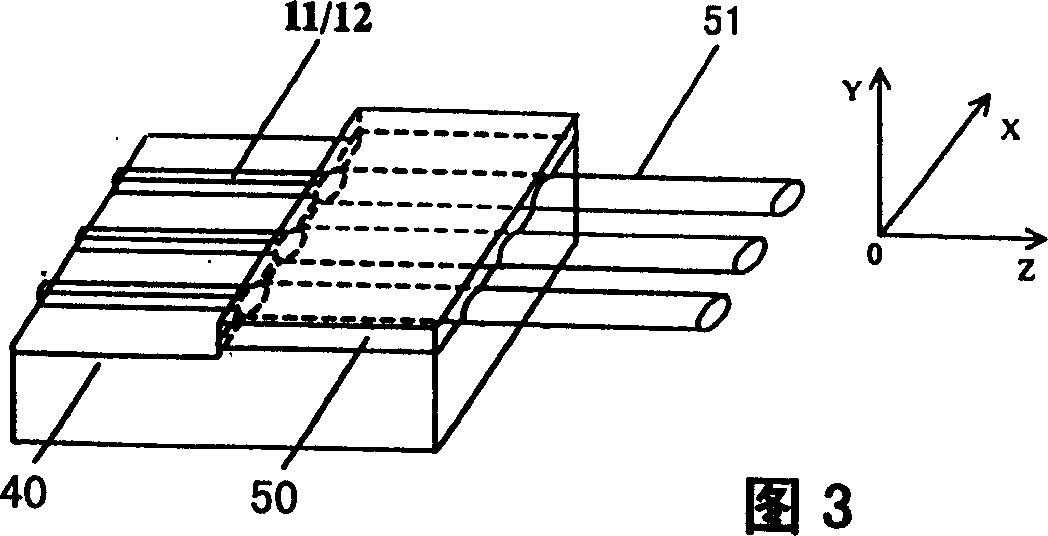

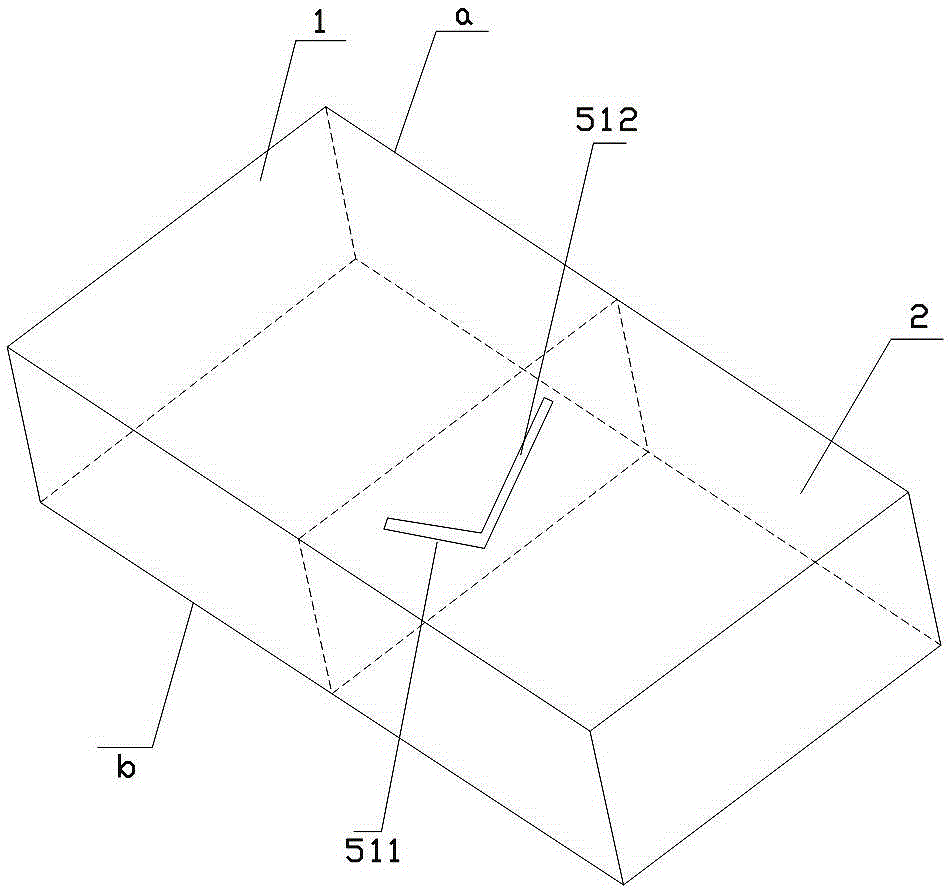

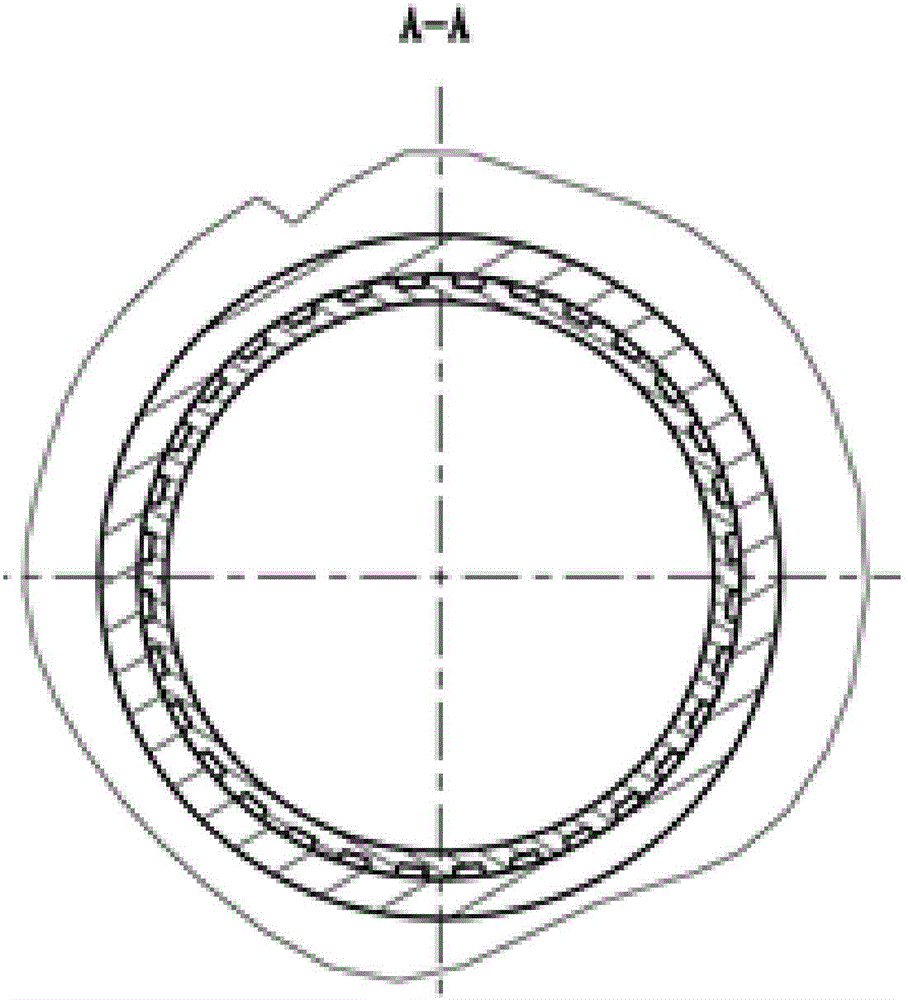

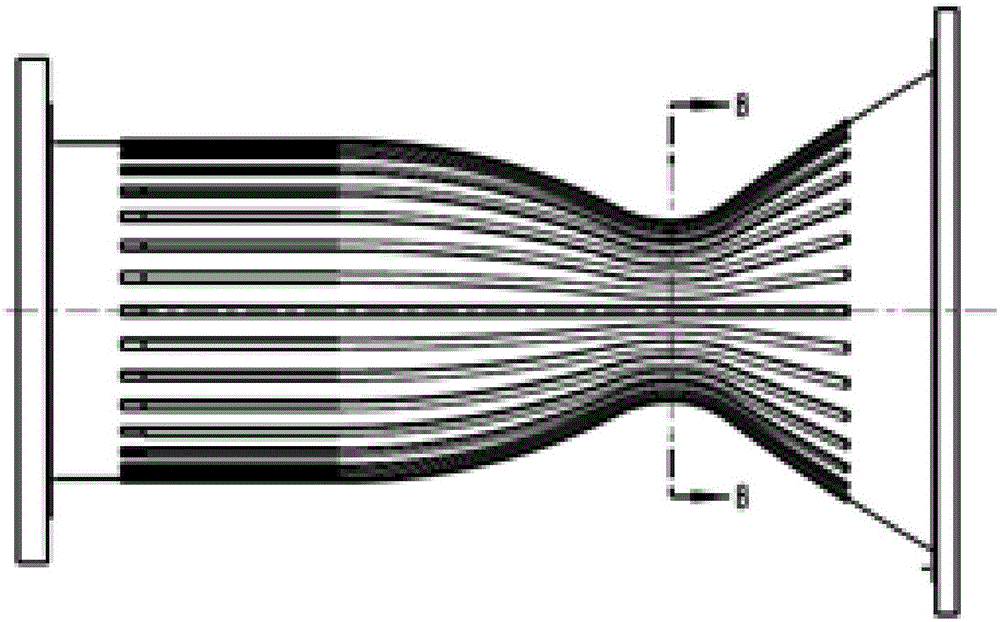

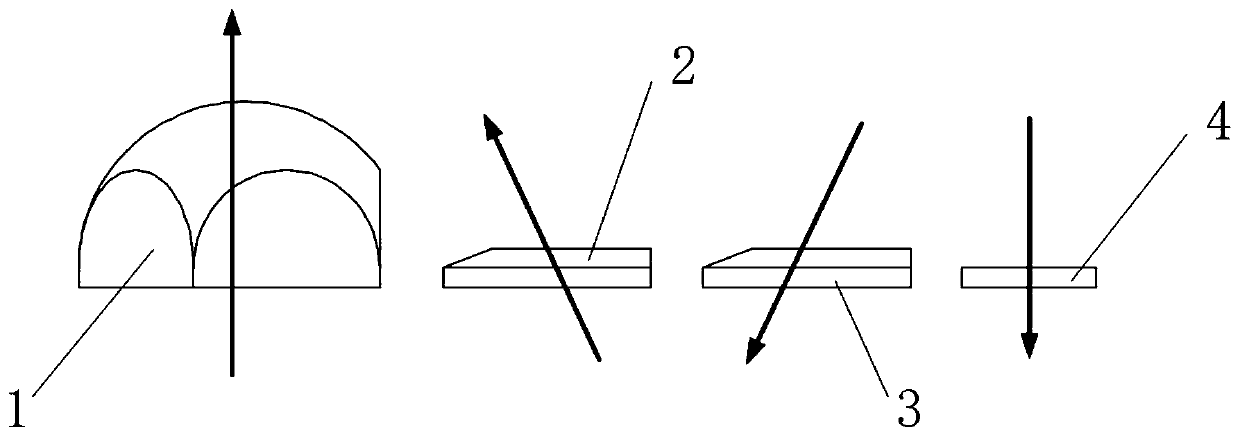

Integrated structure of array waveguide grating and optical fiber array and manufacture method thereof

InactiveCN1423140AAlignment coupling is easyLow costCoupling light guidesOptical waveguide light guideFiberGrating

The structure comprises the array of the wave-guide grating as well as the input and output optical fiber array, which is aimed at and coupled to the array of the input and output wave-guide in the array of the wave-guide grating. The array of the wave-guide grating and the input and output optical fiber array are integrated on the same silicon substrate. The self-alignment method is adopted in the invention to carry out the end surface coupling between the input and output wave-guide in the array of the wave-guide grating and the optical fiber array. The optical fiber array is prepared by using the adhesive agent to bond the array of the V or U shaped groove on the substrate, the upper cover piece and the monomode fiber with multiple cores.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

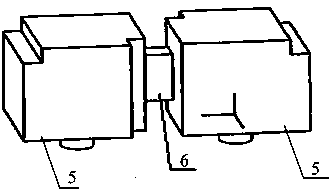

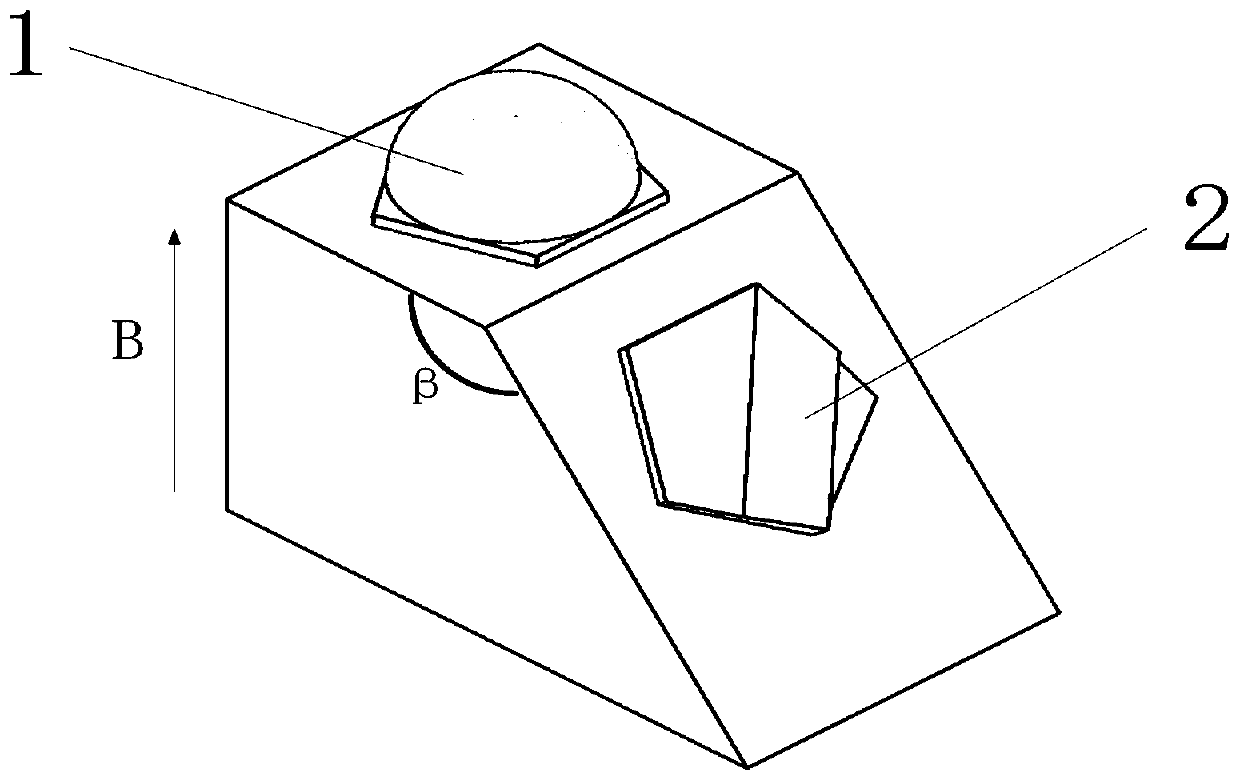

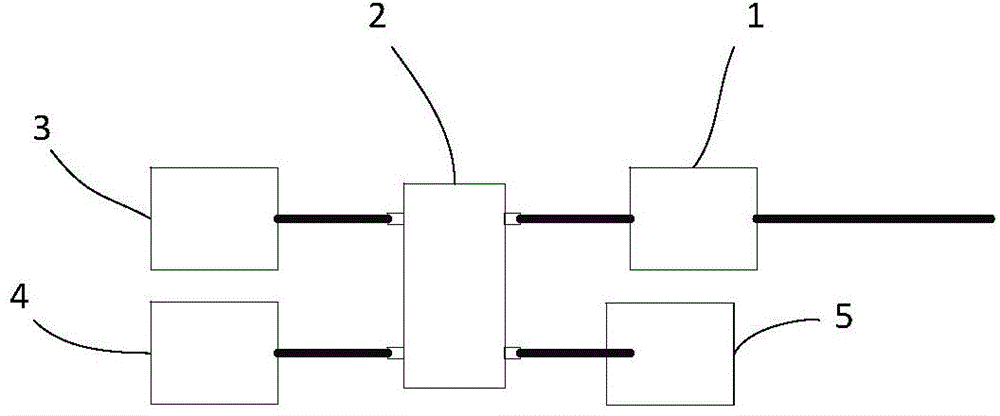

Mixed dielectric waveguide filter

ActiveCN103972621AIncrease flexibilityEasy to connect and fixResonatorsDielectricCondensed matter physics

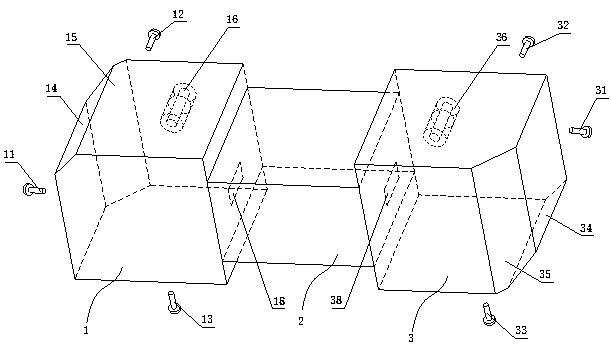

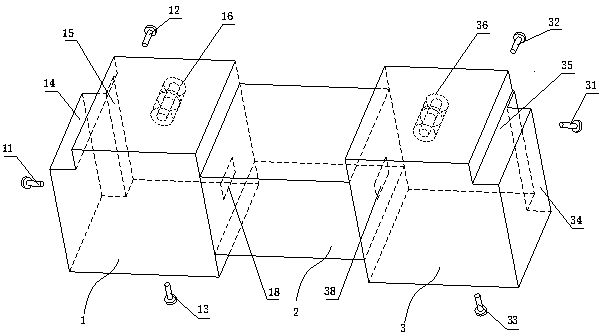

The embodiment of the invention provides a mixed dielectric waveguide filter. The mixed dielectric waveguide filter comprises a first three-mode resonator (1), a second three-mode resonator (3) and a single-mode resonator (2), wherein the face, making contact with the single-mode resonator (2), of the first three-mode resonator (1), and he face, making contact with the single-mode resonator (2), of the second three-mode resonator (3) are respectively provided with coupling windows (18 and 38), and dielectric of all the resonators is exposed, and used for coupling between the first three-mode resonator (1) and the single-mode resonator (2) as well as between the second three-mode resonator (3) and the single-mode resonator (2). According to the mixed dielectric waveguide filter, interference between the three-mode resonators can be reduced, and the topological structure is flexible, simple and easy to assemble.

Owner:SHENZHEN SAMSUNG COMM TECH RES +1

Dielectric waveguide filter

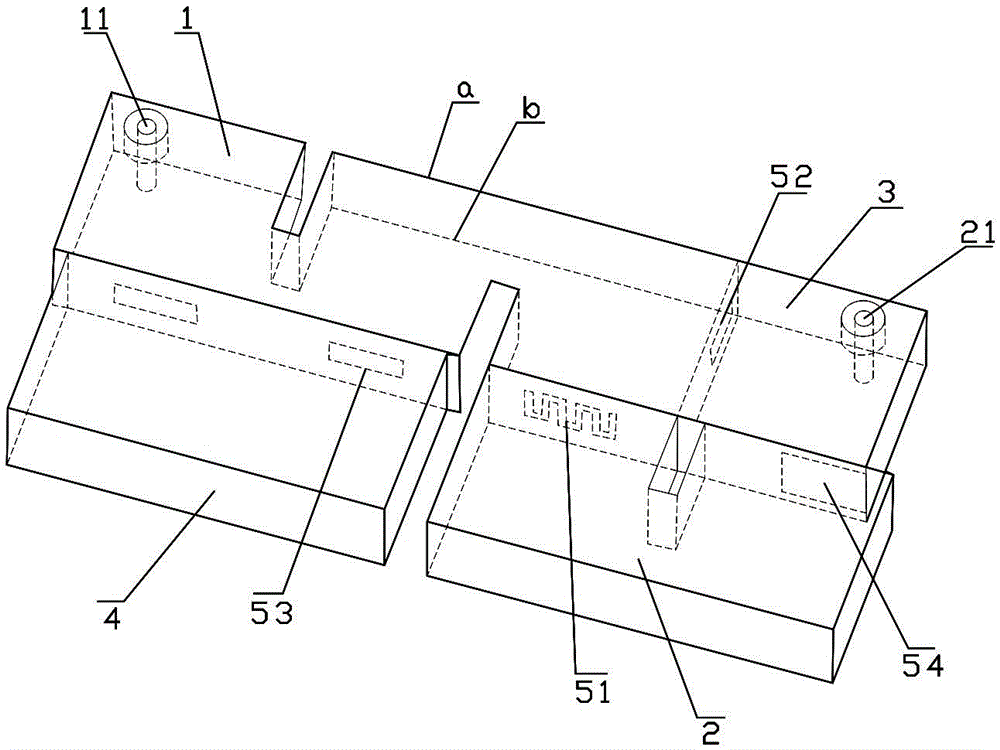

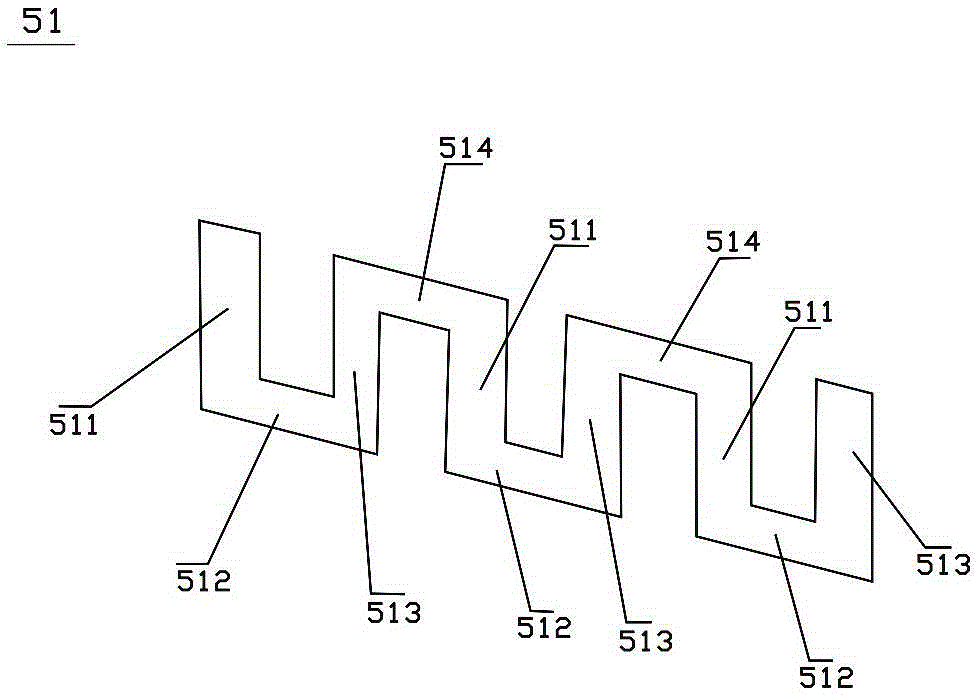

The embodiment of the invention provides a dielectric waveguide filter, and the filter at least comprises a first resonator which is provided with a dielectric block, wherein the surface of the dielectric block is covered with a conductive layer; and a second resonator which is provided with a dielectric block, wherein the surface of the dielectric block is covered with a conductive layer. The contact surfaces of the first and second resonators are provided with coupling windows, thereby exposing the mediums of the first and second resonators. The mediums are used for the coupling between the first and second resonators. The sizes of the length of the coupling windows are set to be greater than the half-wavelength of the working frequency of the filter, so as to enable the coupling polarities between the first and second resonators to be opposite. According to the embodiment of the invention, the filter can enable the coupling polarities between the first and second resonators to be opposite, and generates negative coupling. The filter is flexible in topological structure, is simple in structure, and is easy to assemble.

Owner:SHENZHEN SAMSUNG COMM TECH RES +1

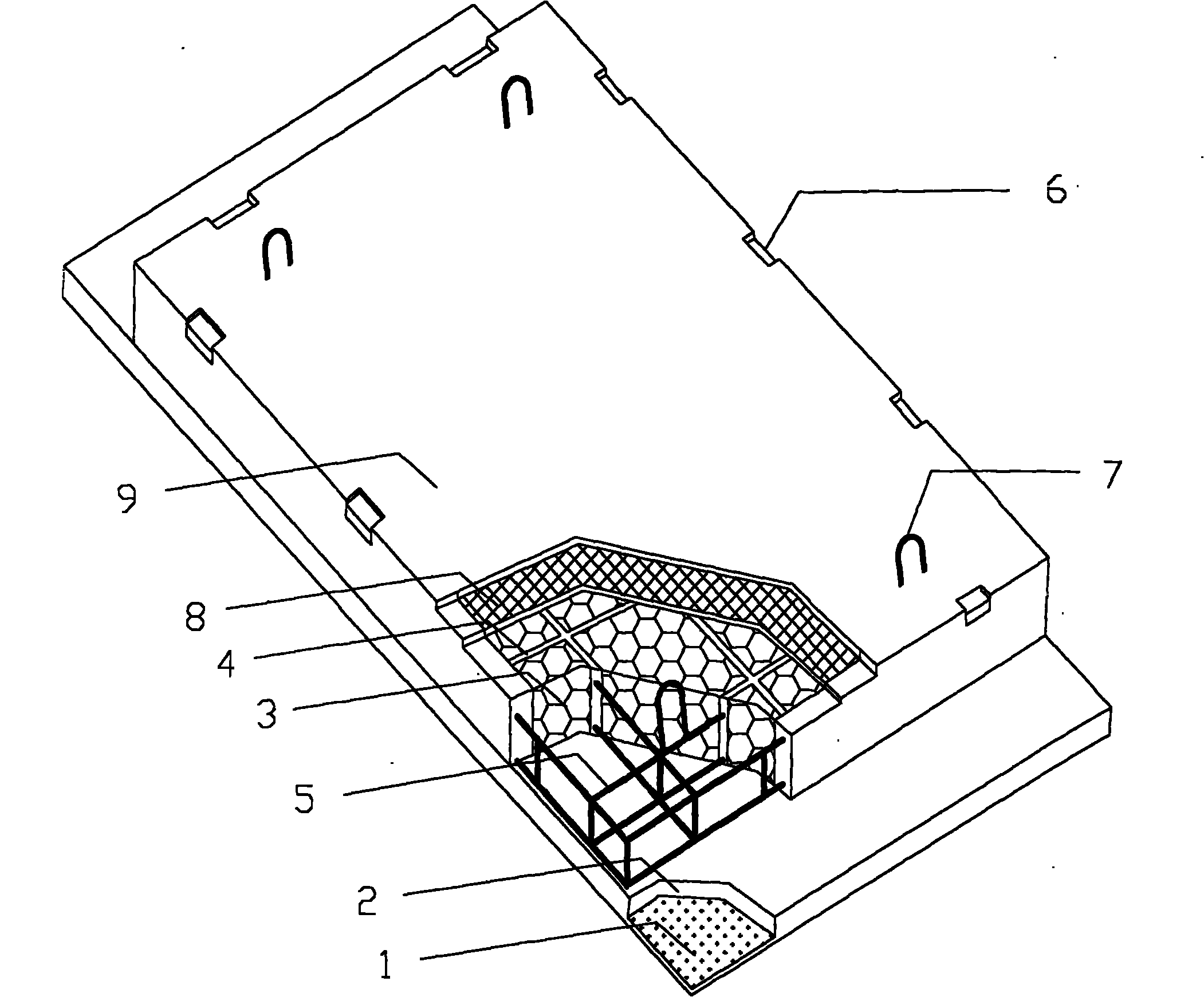

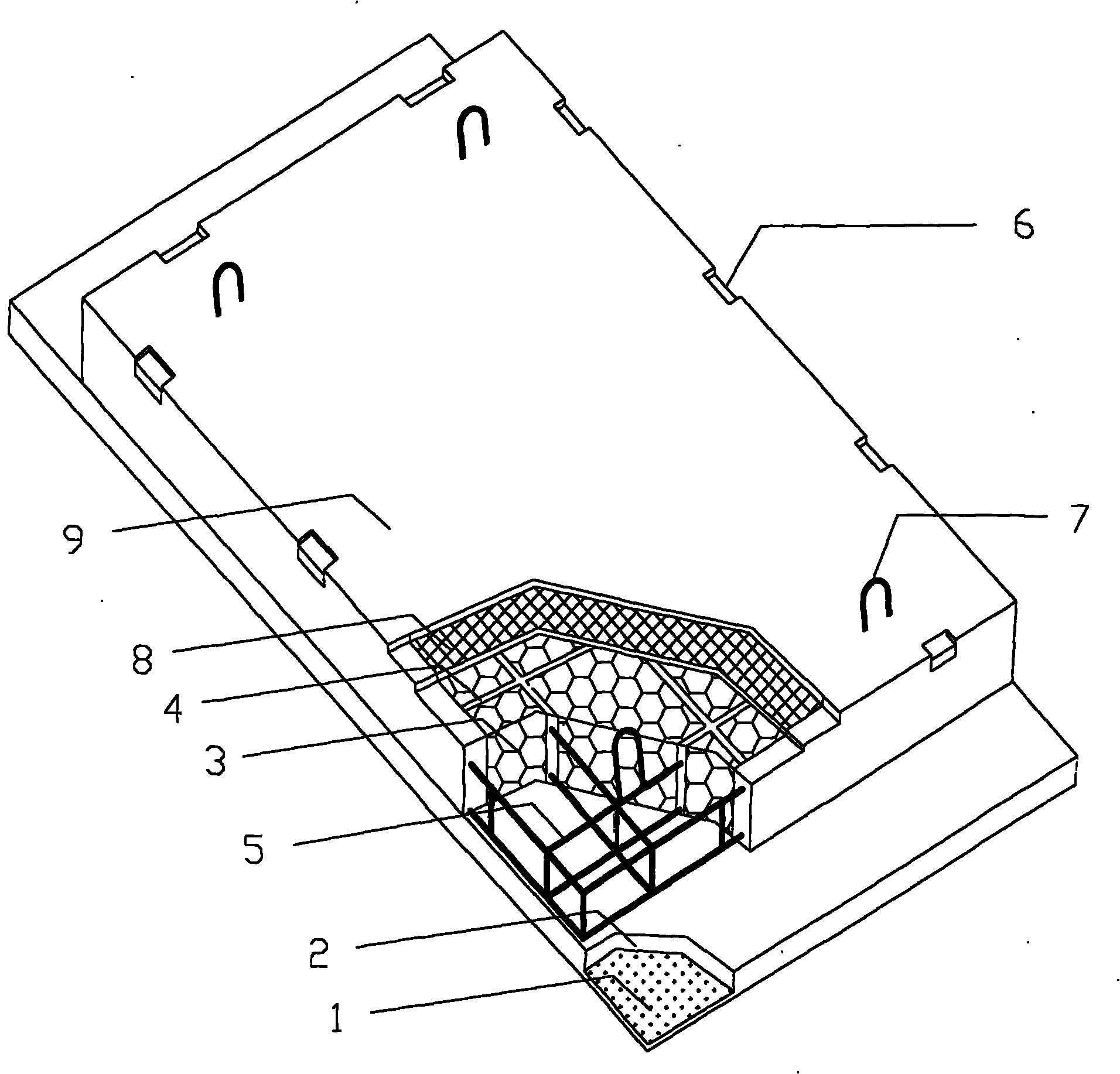

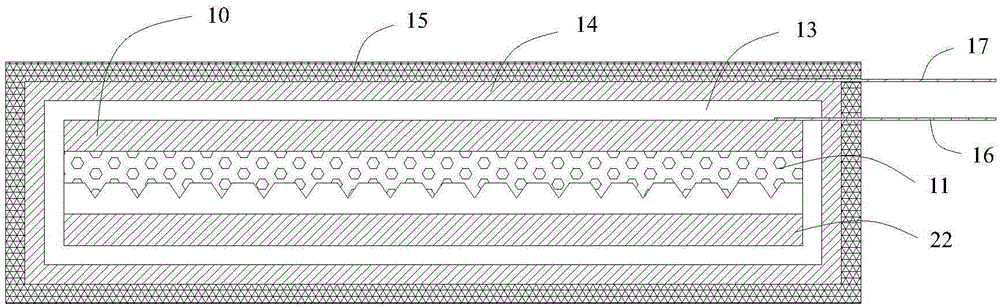

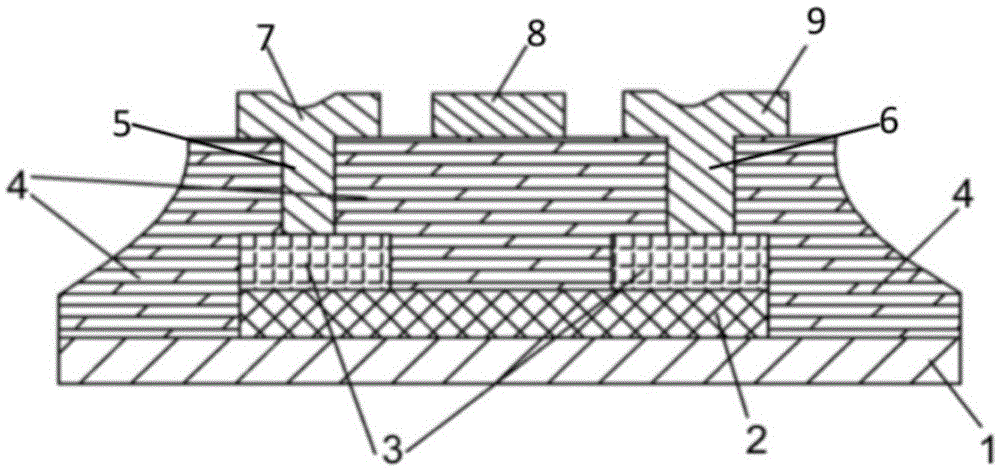

Glass fiber reinforced cement (GRC) insulation decorative wallboard and production method thereof

InactiveCN102094501AReduce pollutionReduce on-site workCovering/liningsCeramic shaping apparatusGlass fiberSteel frame

The invention relates to a glass fiber reinforced cement (GRC) insulation decorative wallboard and a production method thereof, which are applicable to structural envelope, heat insulation and decoration of an external wall for a building of a frame structure. The GRC insulation decorative wallboard comprises a decorative layer, a GRC structural layer I, a GRC structural layer II, an insulating layer, a GRC reinforcing rib, steel frames, an installation connection piece, a lifting ring and an anti-cracking material, wherein, the GRC structural layer I is compounded on the decorative layer andis equipped with the insulating layer; the GRC structural layer II is arranged on the insulating layer, and the GRC reinforcing rib is arranged in the insulating layer; the GRC structural layer I is connected with the GRC structural layer II through the GRC reinforcing rib; the steel frames are arranged in the GRC structural layer I, the GRC structural layer II and the reinforcing rib; and the anti-cracking material is laid in the GRC structural layer II.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

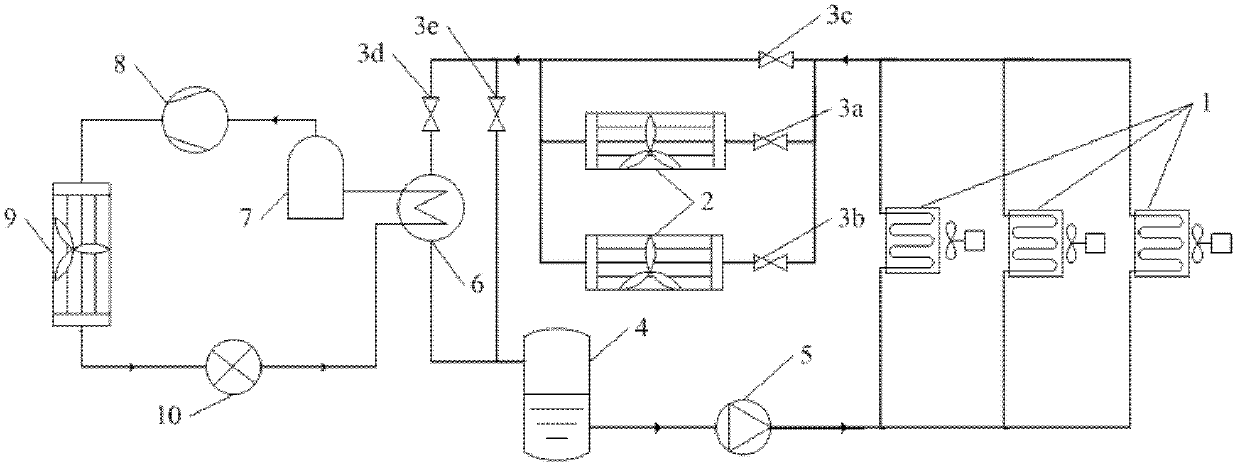

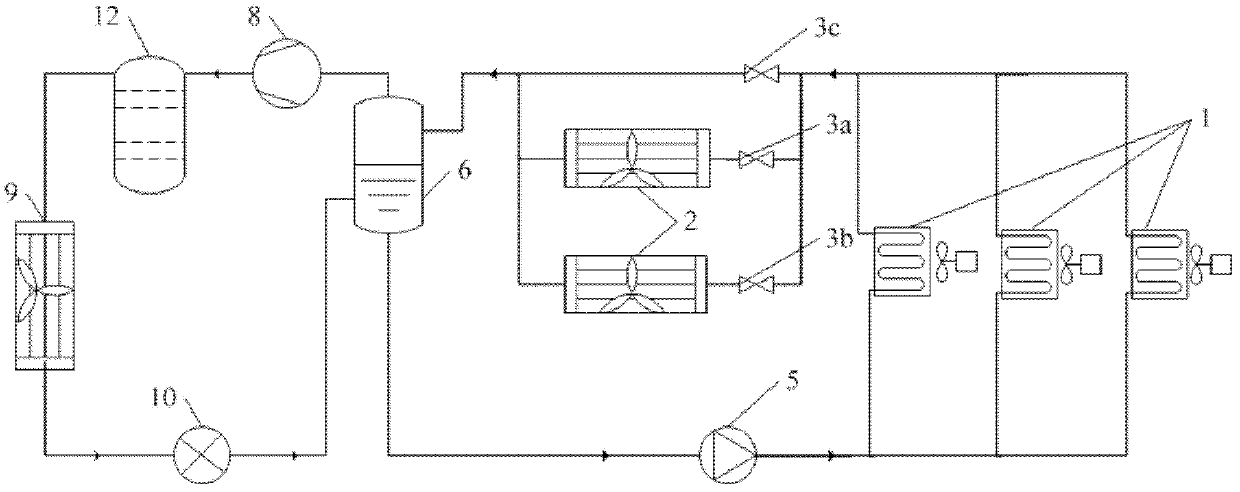

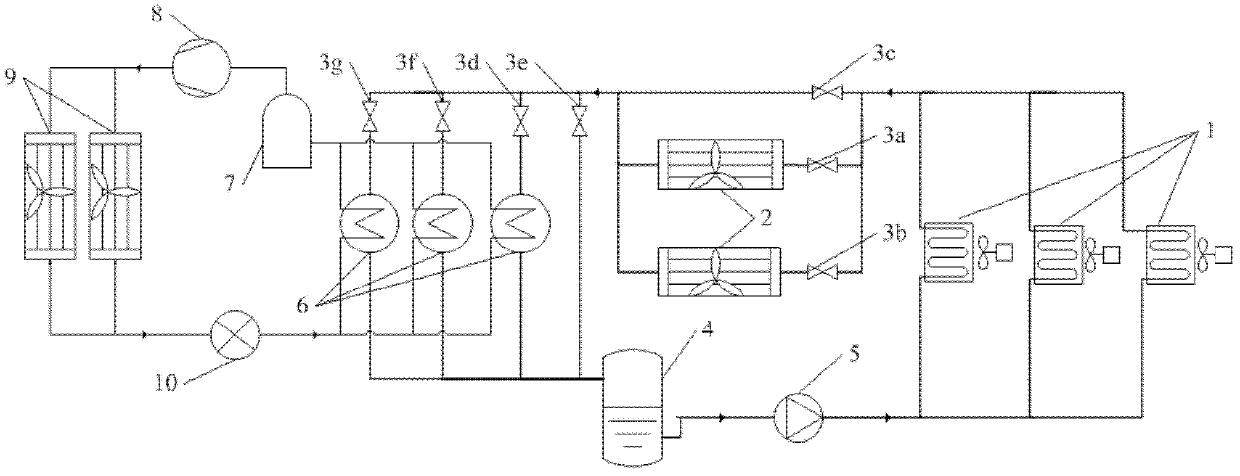

Liquid pump driving heat pipe device for cascade mechanical refrigerating and operation method

ActiveCN102607120AIncrease profitAvoid Oil Back DiscomfortLighting and heating apparatusSpace heating and ventilation detailsElectricityVapor–liquid separator

A liquid pump driving heat pipe device for cascade mechanical refrigerating and an operation method belong to the technical field of heat exchange of heat exchange devices. The liquid pump driving heat pipe device comprises a mechanical refrigerating loop and a heat pipe cooling loop, wherein the mechanical refrigerating loop is formed by a liquid-liquid heat exchanger group, a gas-liquid separator, a compressor, a condenser group and a throttling component sequentially from end to end or is formed by a liquid-liquid heat exchanger group, a compressor, an oil separator, a condenser and a throttling component sequentially from end to end. The other path of the liquid-liquid heat exchanger group is sequentially connected with a liquid reservoir, a liquid pump, an indoor heat exchanger group and an outdoor heat exchanger group from end to end. Refrigerating is conducted by respectively or simultaneously opening the mechanical refrigerating loop and the heat pipe cooling loop. Through the device and the method, a yearly operation method mainly relying on liquid pump driving heat pipe radiating and supplemented by mechanical refrigerating is achieved fast and conveniently, mechanical refrigerating and heat pipe cooling of a system are ensured to operate simultaneously, required electricity consumption is greatly reduced, and use rate of natural cold sources is greatly improved.

Owner:BEIJING UNIV OF TECH

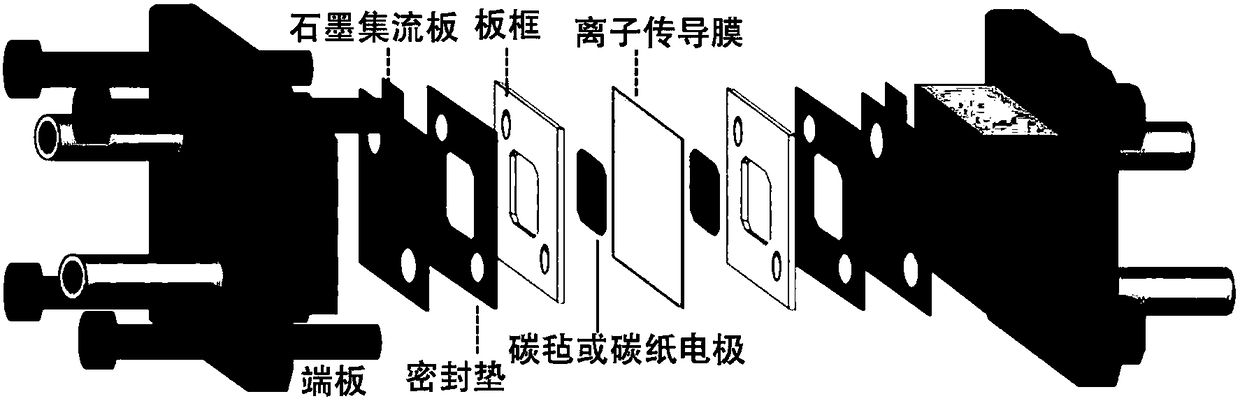

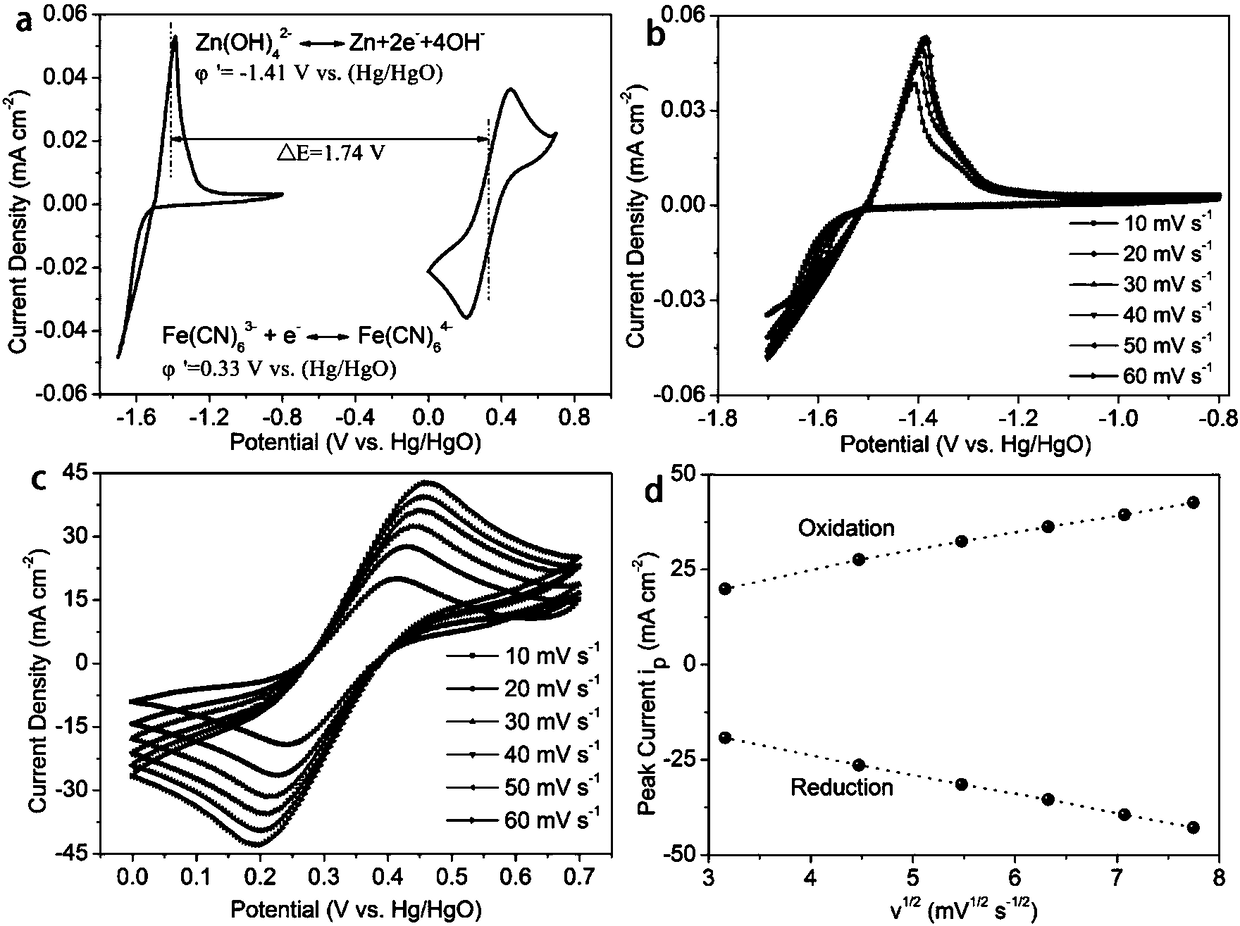

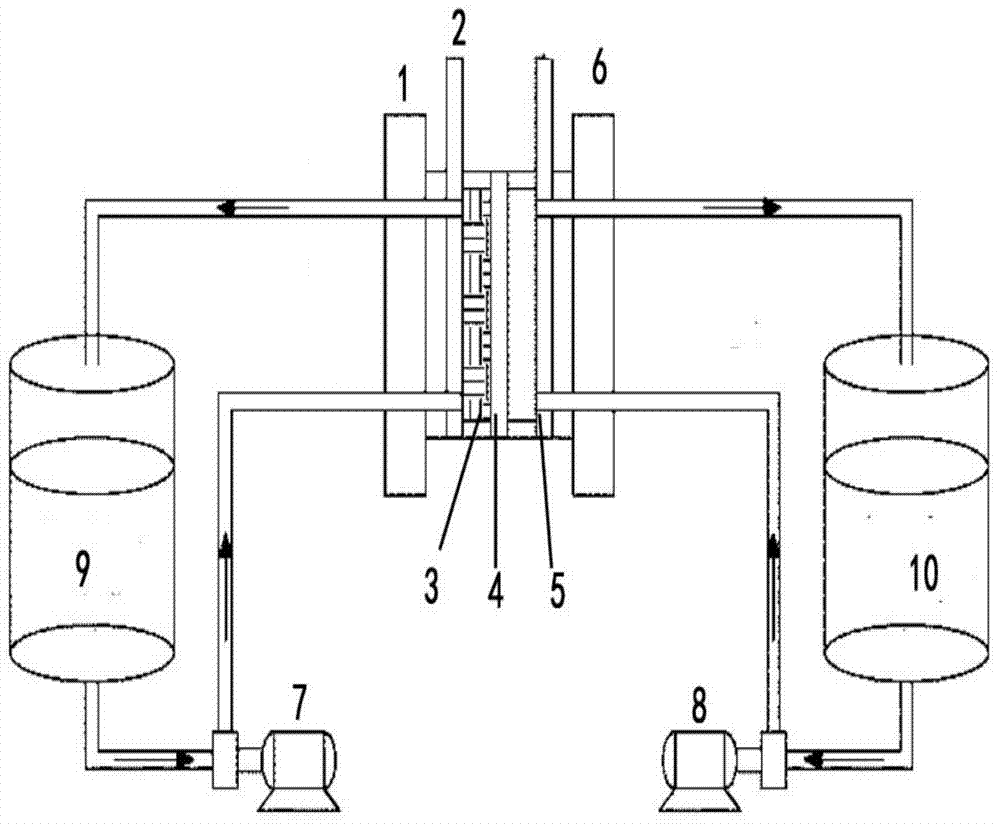

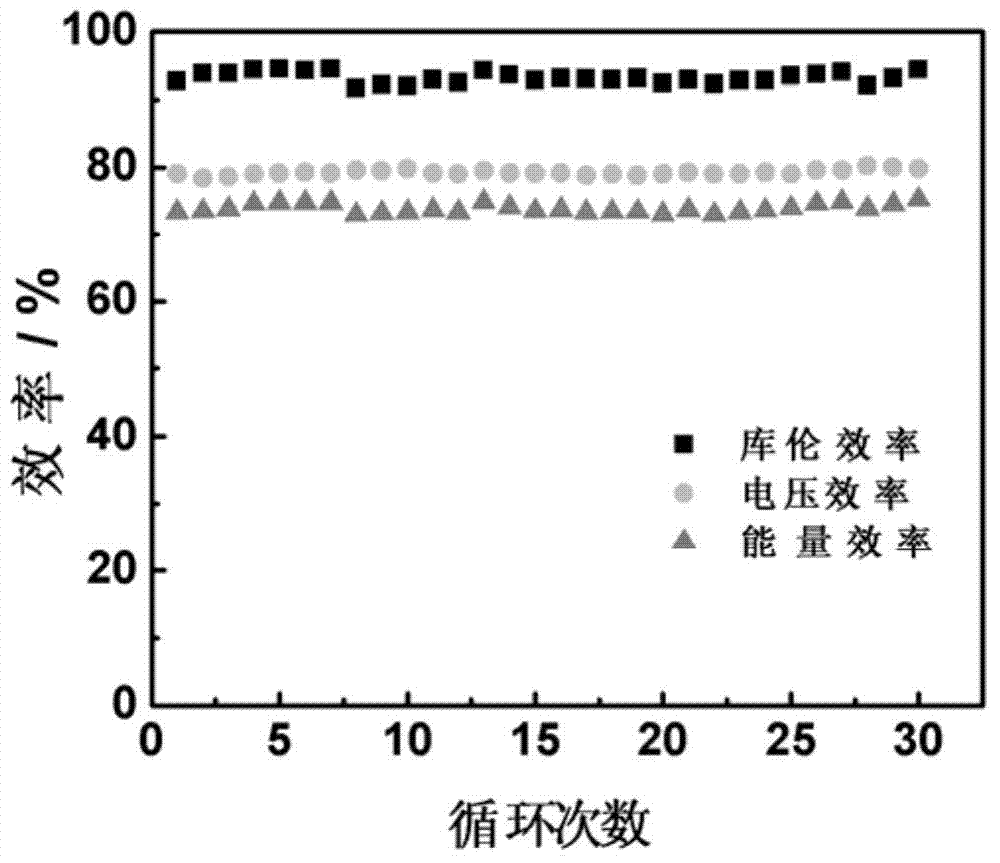

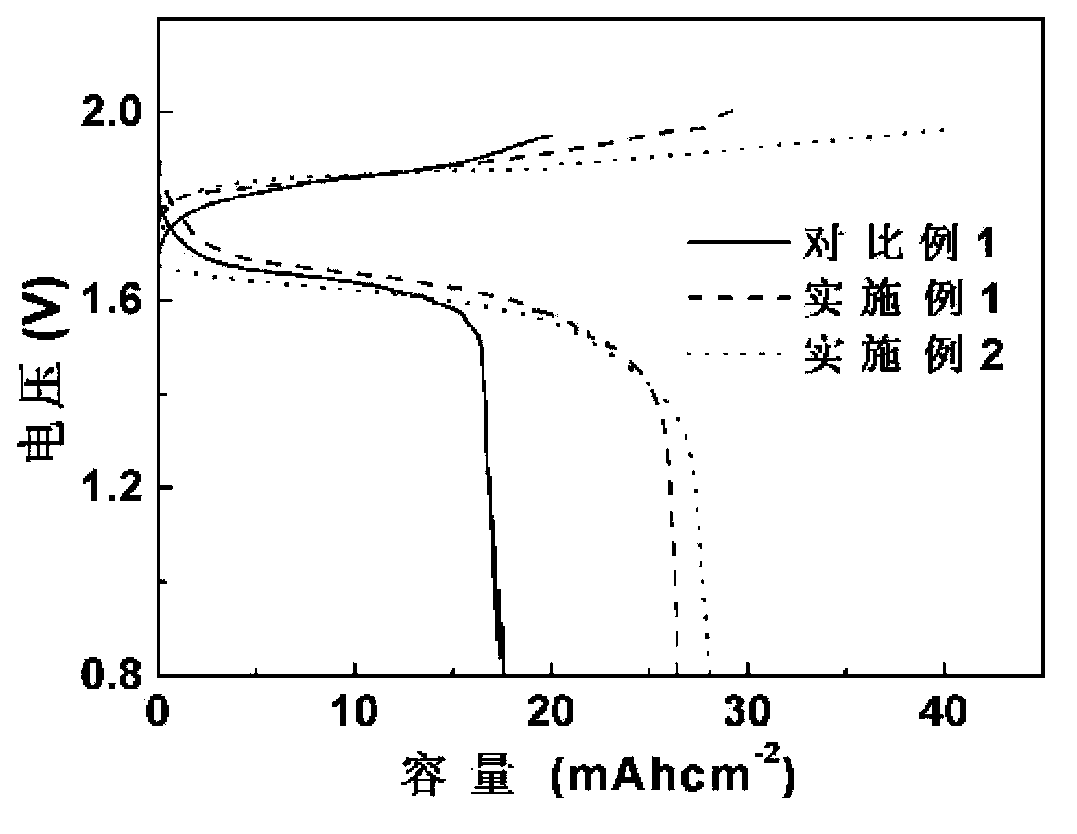

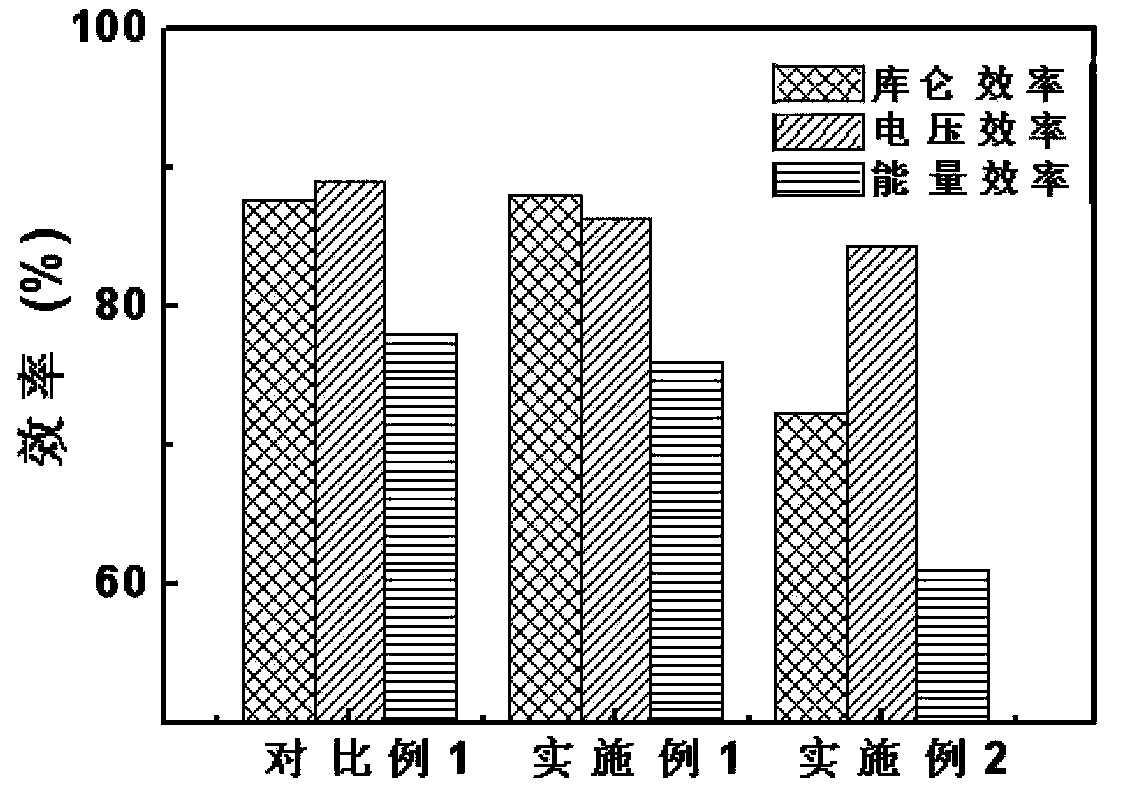

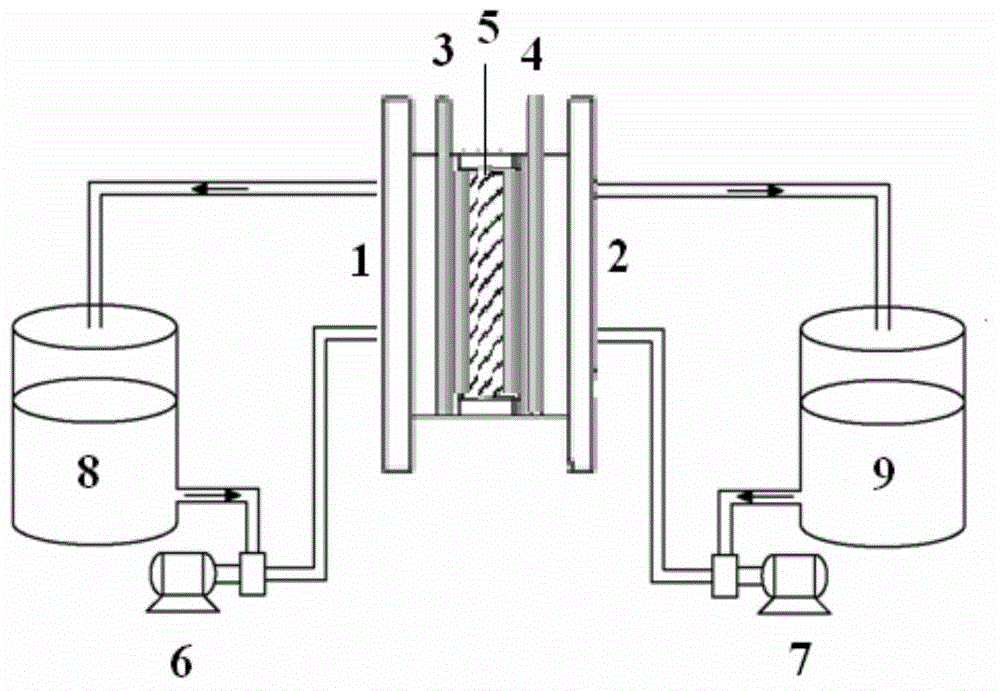

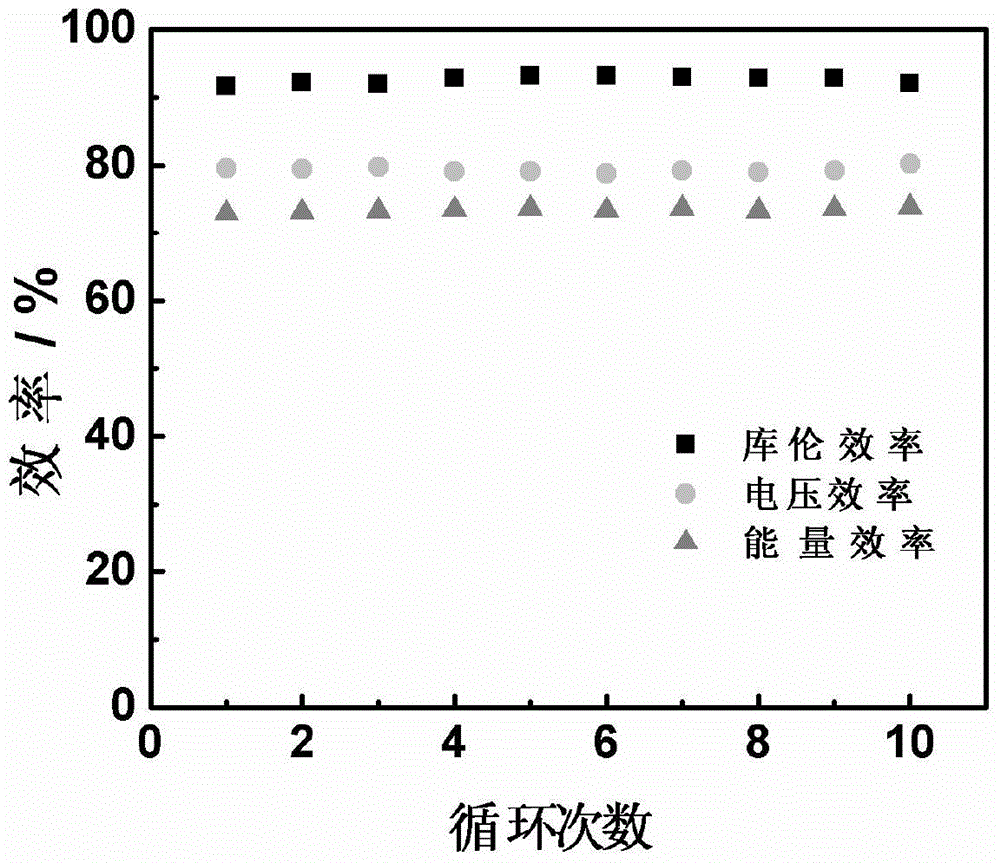

Alkaline zinc-iron flow battery

InactiveCN108461784ARich reservesLow costCell electrodesRegenerative fuel cellsHigh energyCarbon felt

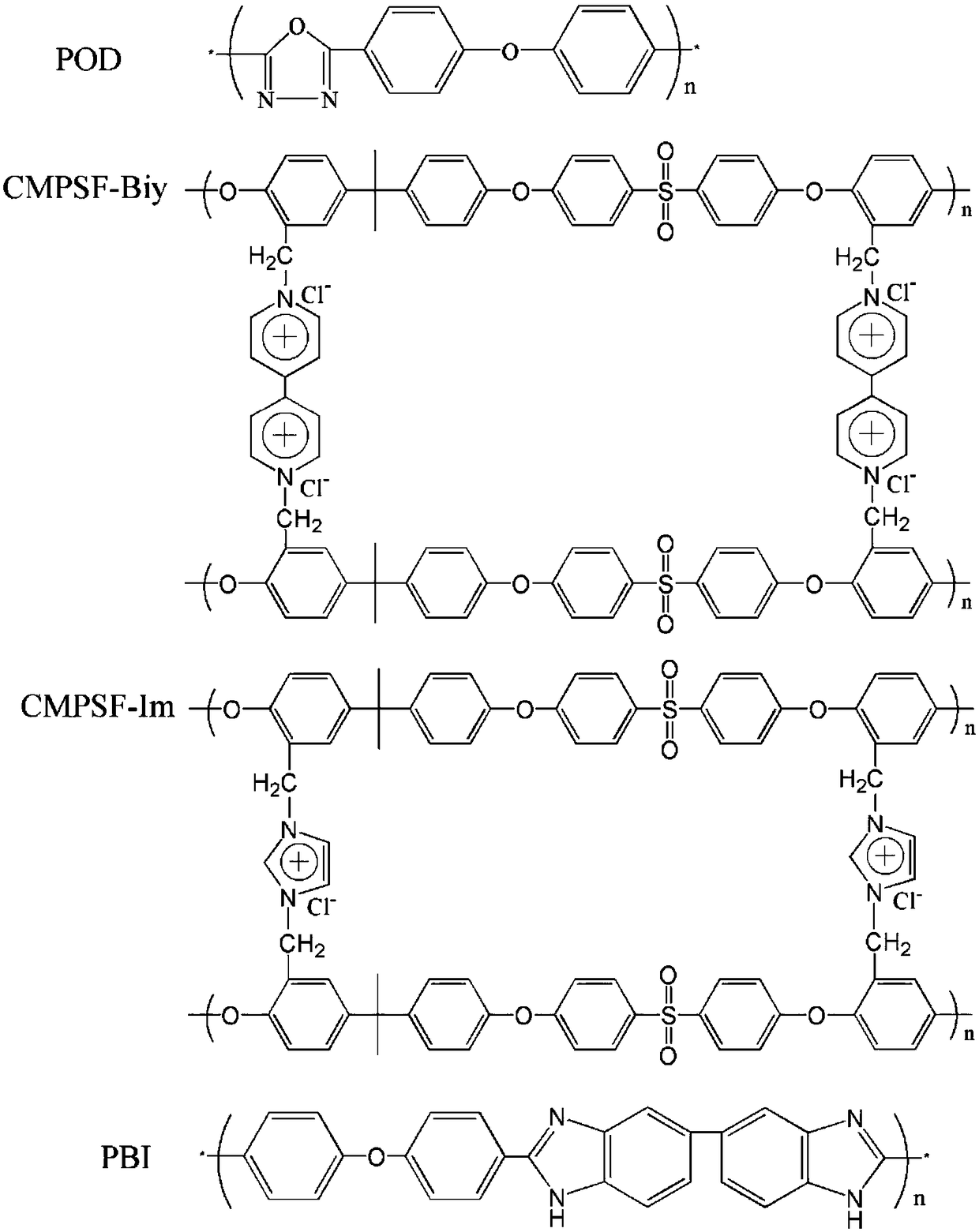

The invention relates to an alkaline zinc-iron flow battery, wherein an ion conduction membrane is prepared from an aromatic polymer containing nitrogen heterocycle, electrodes are carbon felt or carbon paper, a positive electrode electrolytic solution is the mixed aqueous solution of ferrocyanide and strong alkali, a negative electrode electrolytic solution is the mixed aqueous solution of a zincsalt or / and a zinc oxide and strong alkali, the concentrations of the strong alkalis in the positive electrode electrolytic solution and the negative electrode electrolytic solution are 0.001-10 mol / L, and the concentrations of the active substances in the positive electrode electrolytic solution and the negative electrode electrolytic solution are 0.001-3 mol / L. According to the present invention, a class of the alkaline zinc-iron flow batteries with characteristics of high energy density, high power density and long service life are provided, wherein the performance of the batteries is comparable to or superior to the current mature all-vanadium flow batteries, and the batteries have good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

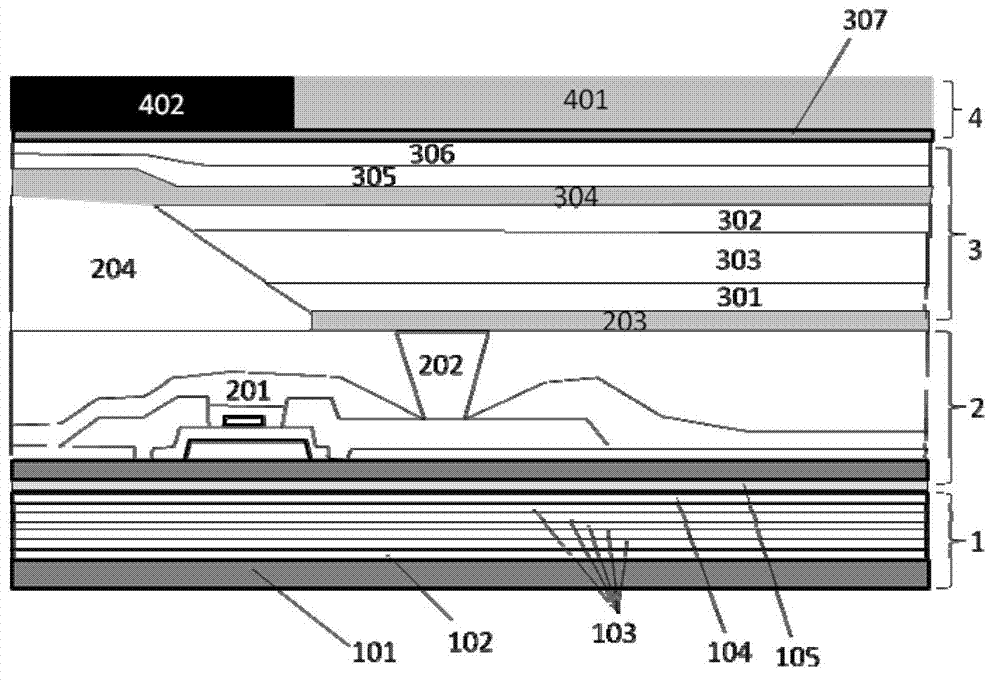

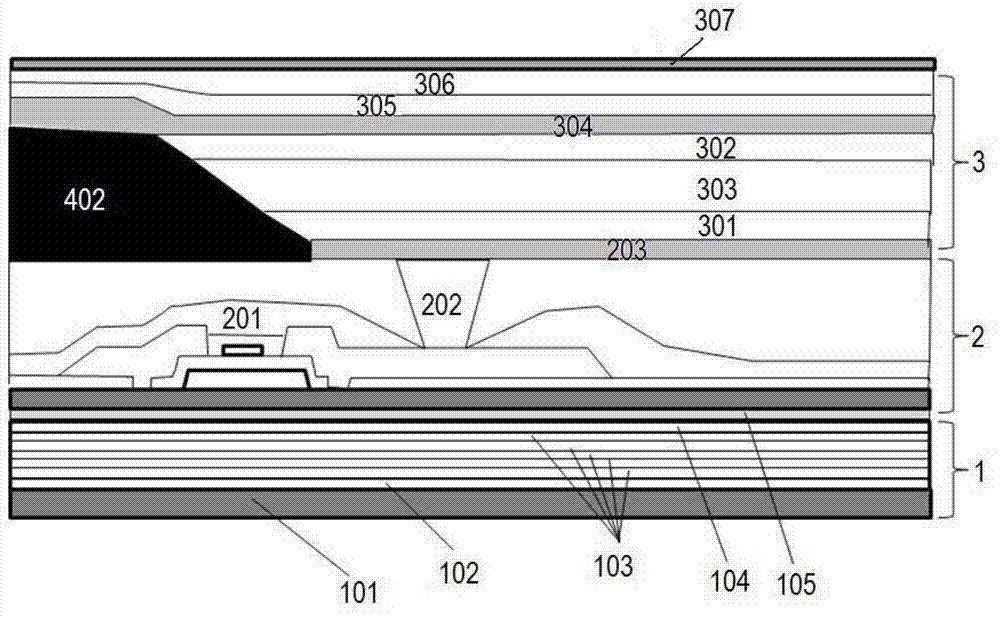

Active matrix display device

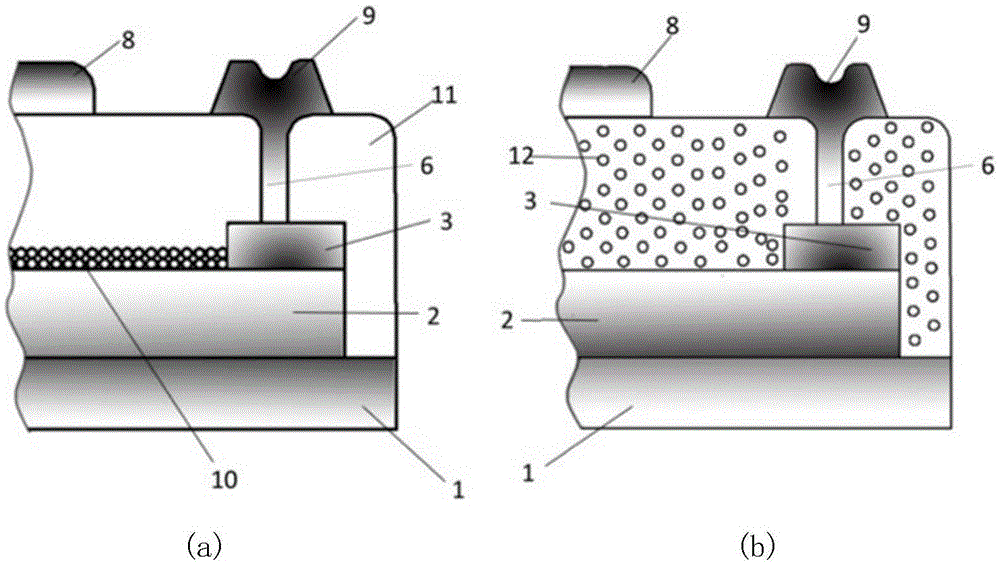

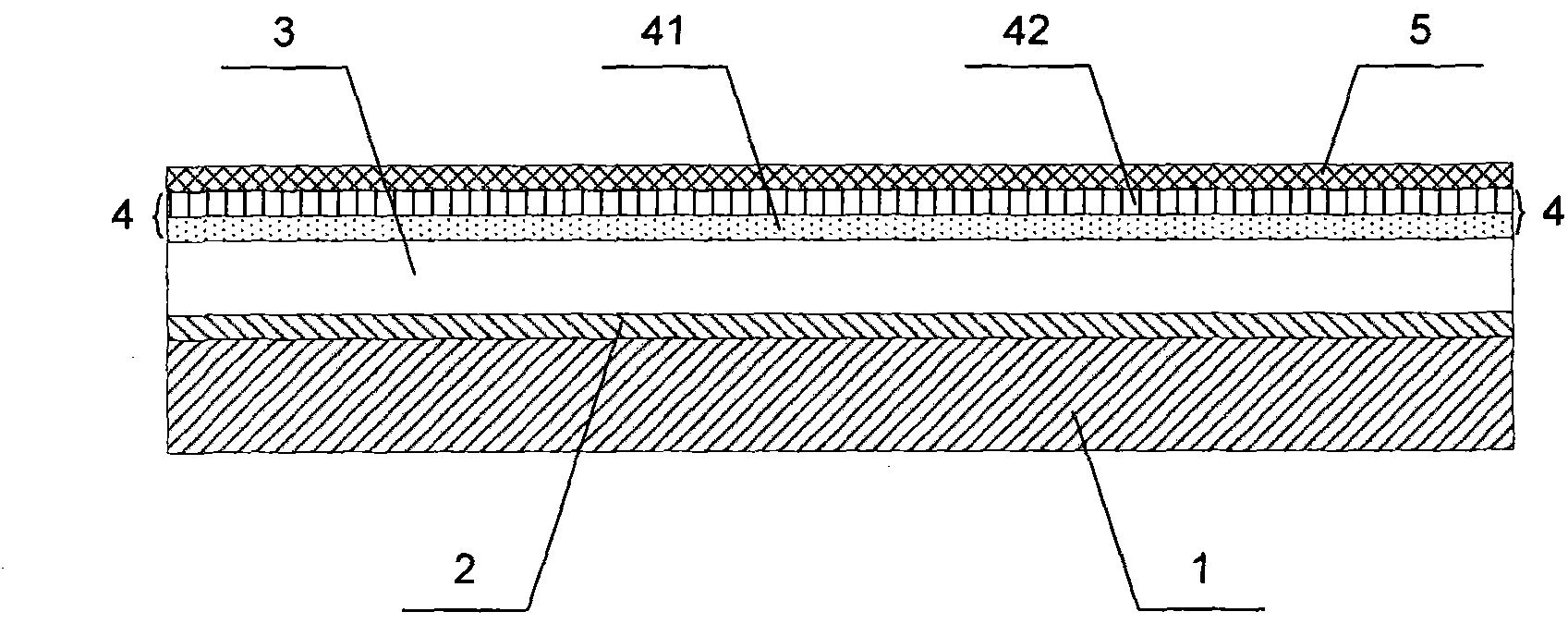

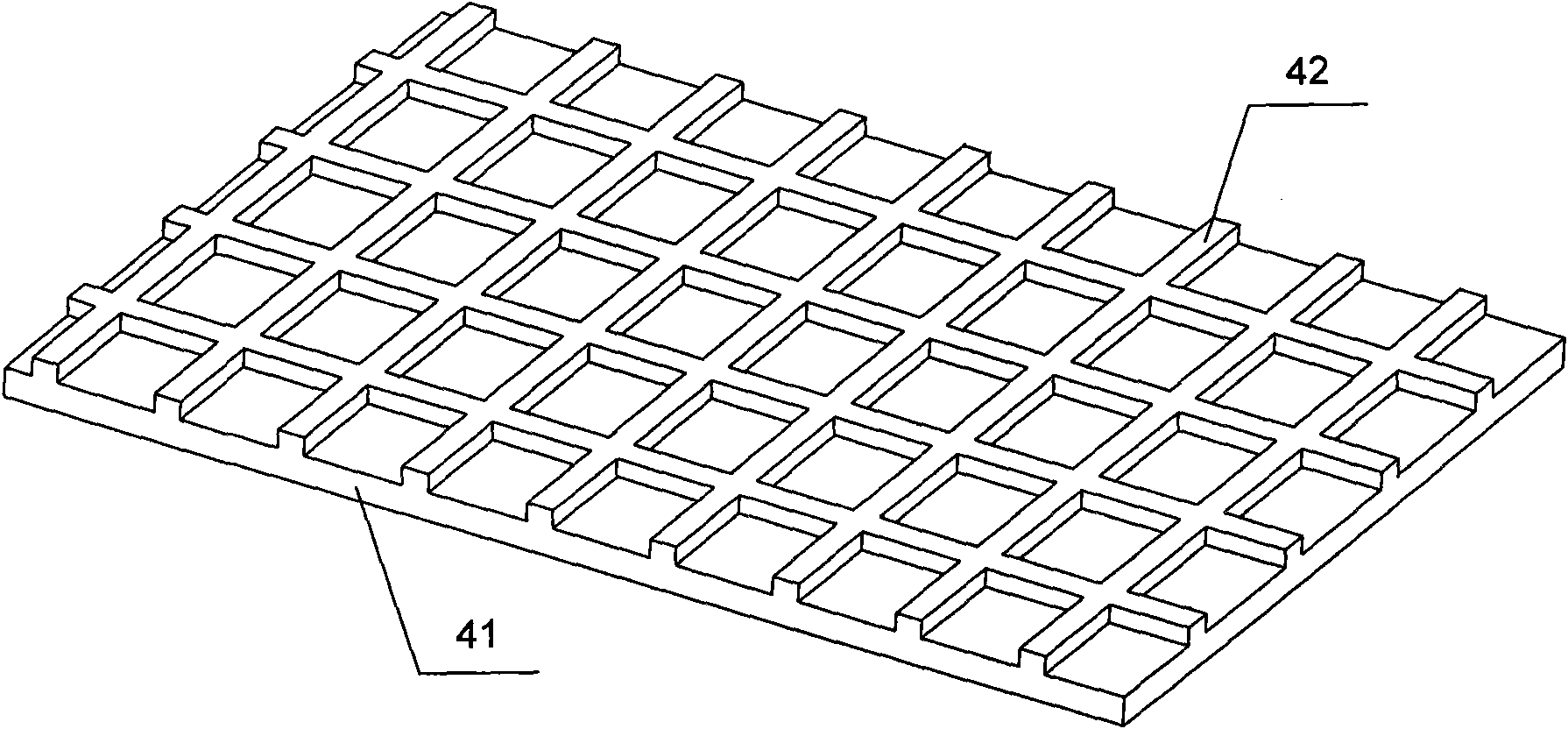

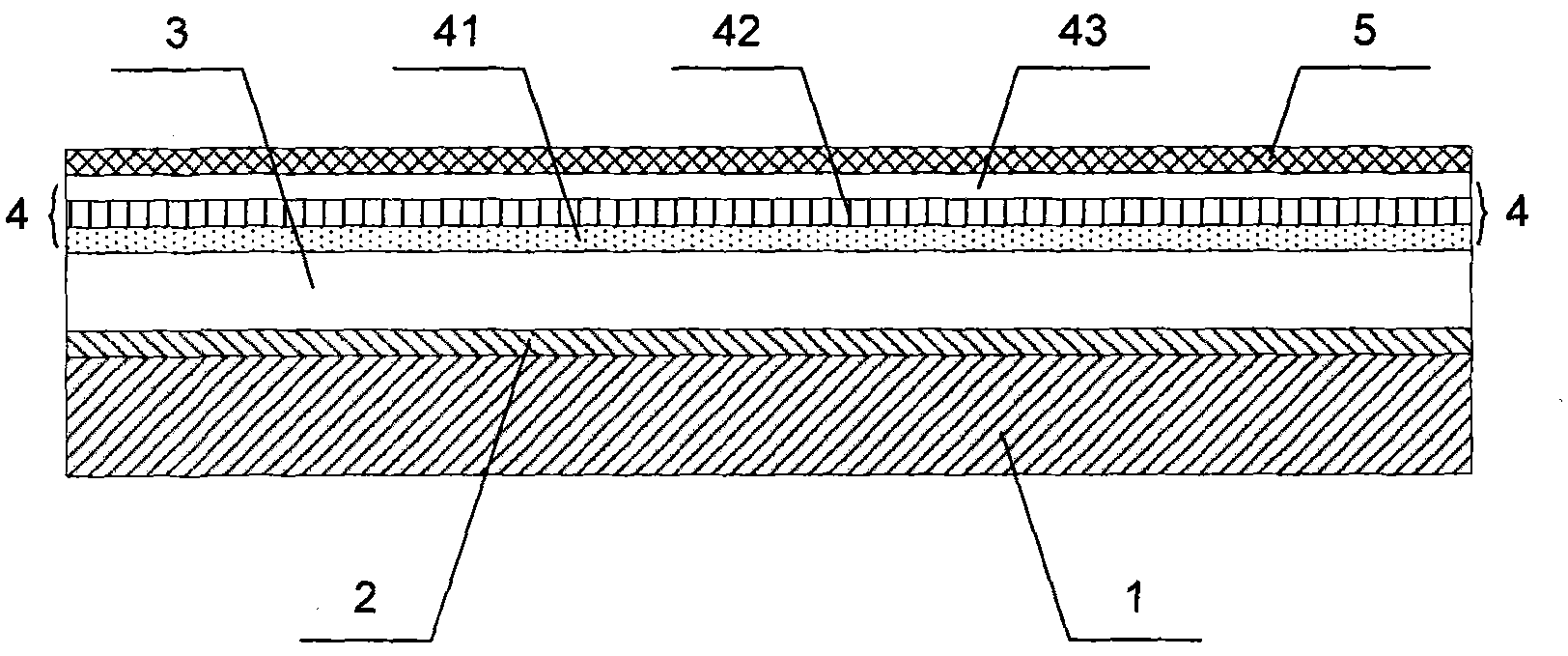

ActiveCN102967979ASimple structure and processSimple preparation processStatic indicating devicesNon-linear opticsSolid state electrolyteActive matrix

An active matrix display device comprises a backlight module and a pixel unit layer which is arranged on the backlight module, wherein the pixel unit layer comprises a TFT (Thin Film Transistor) module and an electrochromic module; each pixel unit comprises a TFT (Thin Film Transistor) and an electrochromic device; the electrochromic device comprises an anode, a cathode as well as an electrochromic material layer and a solid electrolyte layer, wherein the electrochromic material layer and the solid electrolyte layer are arranged between the anode and the cathode; a drain of the TFT is connected with the anode of the electrochromic device through a connecting hole; and the TFT is used for controlling the electrochromic device to change color and / or transmission rate through voltage; simple structure and simple making process are achieved; the electrochromic material is an organic electrochromic material with high response speed as well as vibrant and rich colors; moreover, a light source selecting range of the backlight module is large and flexible display of the device can be achieved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

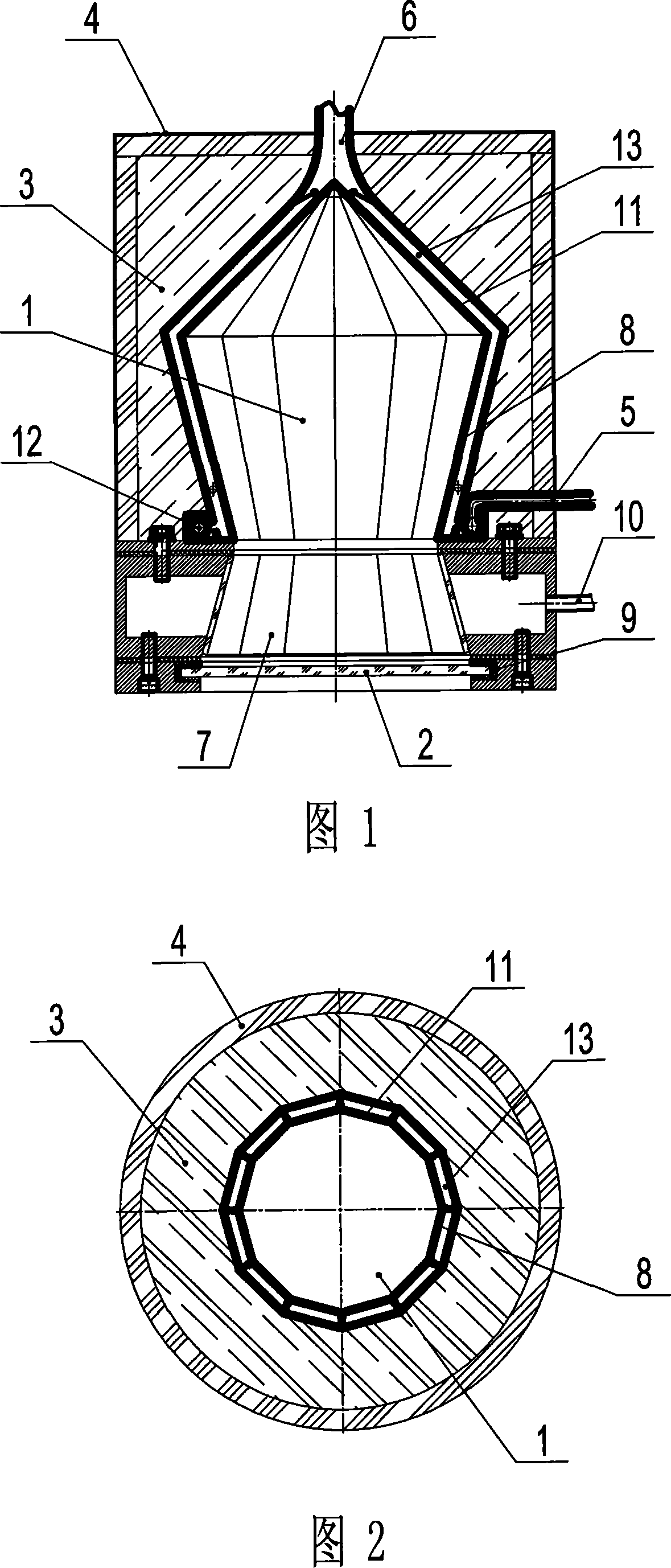

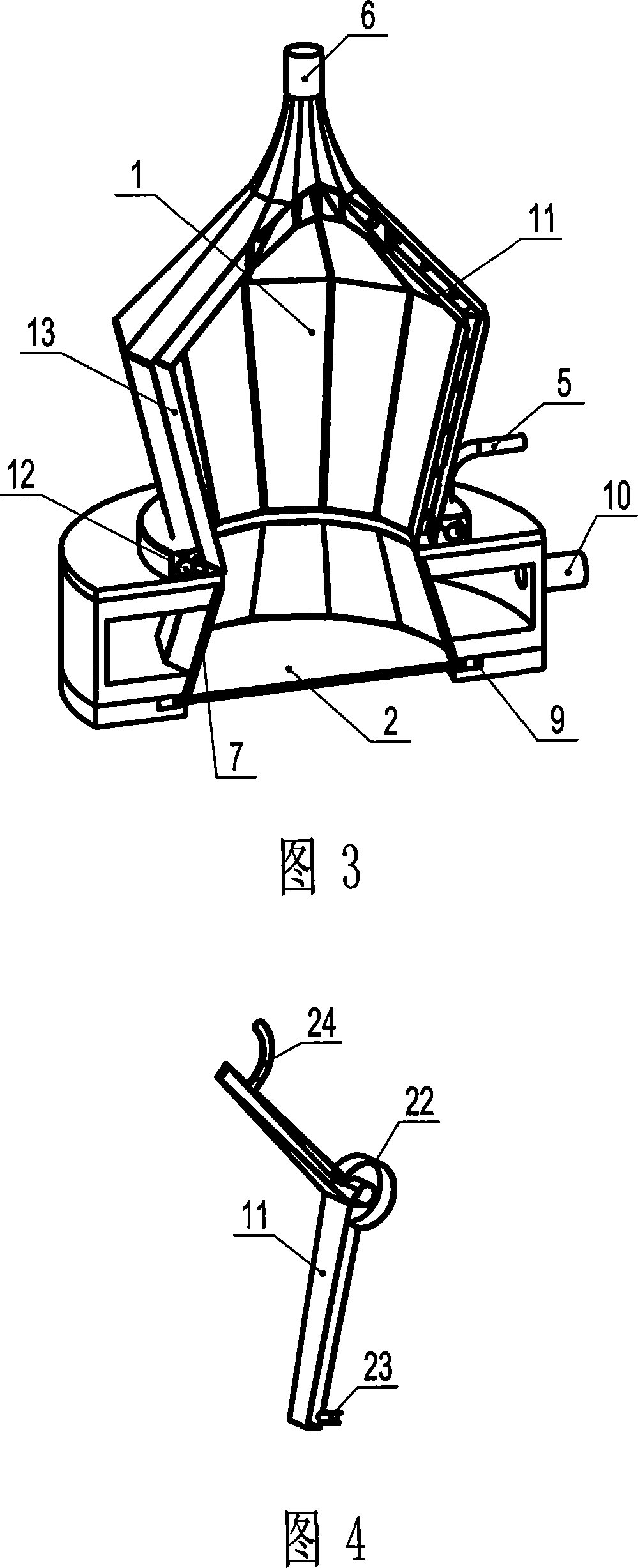

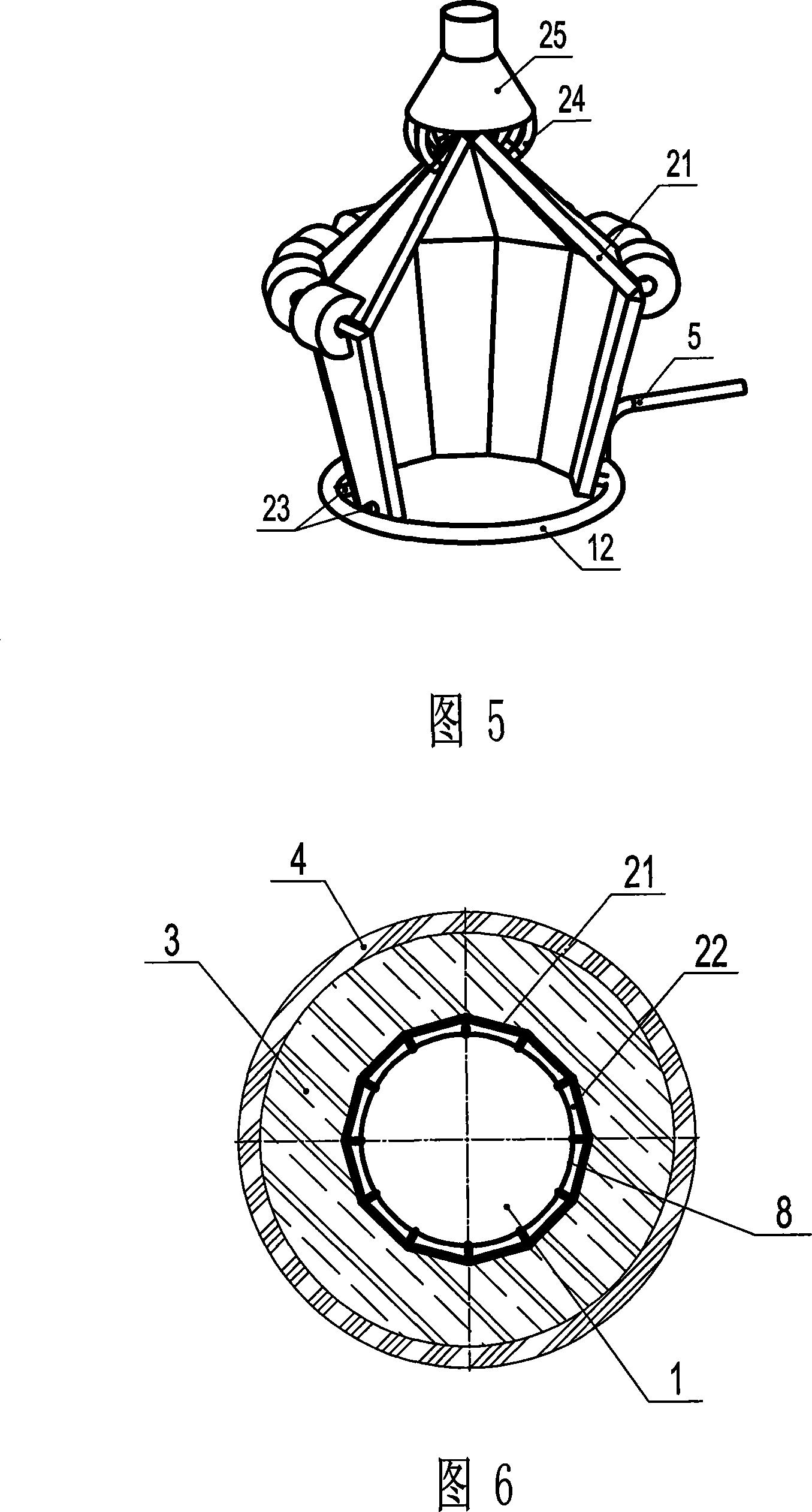

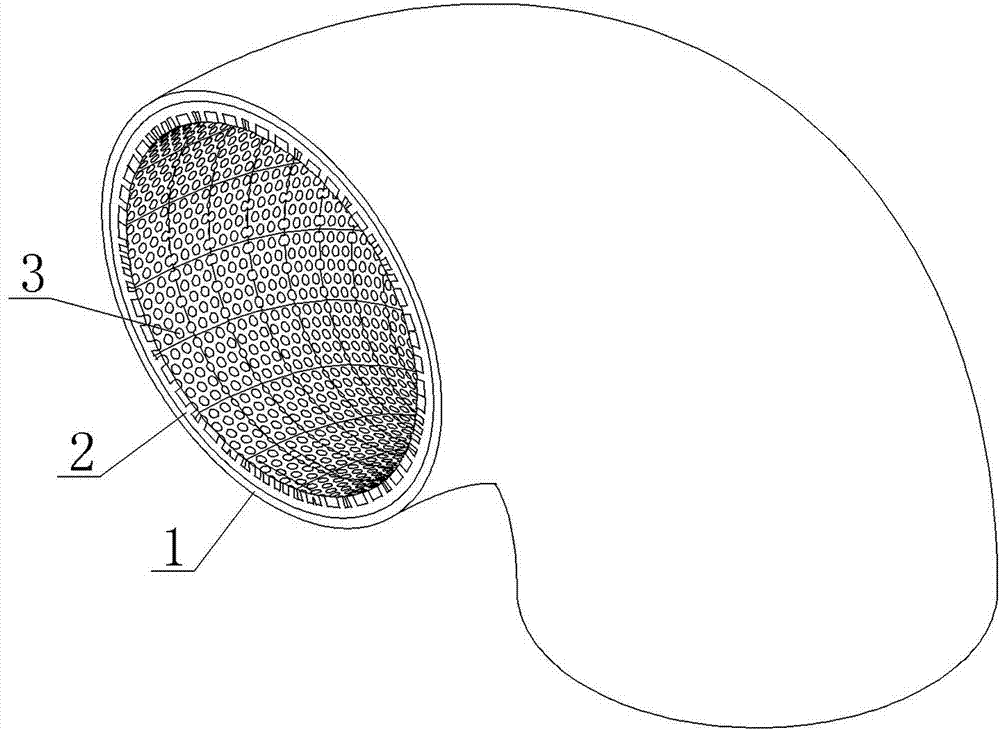

Special-shaped modular type hollow space solar energy high-temperature receiver

InactiveCN101216220AIncrease heat absorptionIdeal light-to-heat conversion rateSolar heating energySolar heat devicesGlass windowWall plate

The invention discloses a profiled module-type hollow solar high-temperature receiver, which belongs to the technical field of solar energy utilization. The product comprises a cup-like heat-absorbing chamber, a light-receiving transparent glass window, a heat-insulating layer, a shell, a working fluid inlet and a working fluid outlet. The heat-absorbing chamber is formed by the assembly of a group of sandwich wall plates which extend from the cup mouth thereof and gather in the center of the cup bottom thereof. The working fluid outlet is positioned in the center of the cup bottom and communicated with each sandwich wall plate gathered herein, forming working fluid passages that extend from the working fluid inlet, pass through the interlayer of each wall plate and finally gather in the working fluid outlet. The solar receiver has high efficiency of light- heat conversion, modular design and low cost; and helps to promote the development of solar energy industry.

Owner:SOUTHEAST UNIV +2

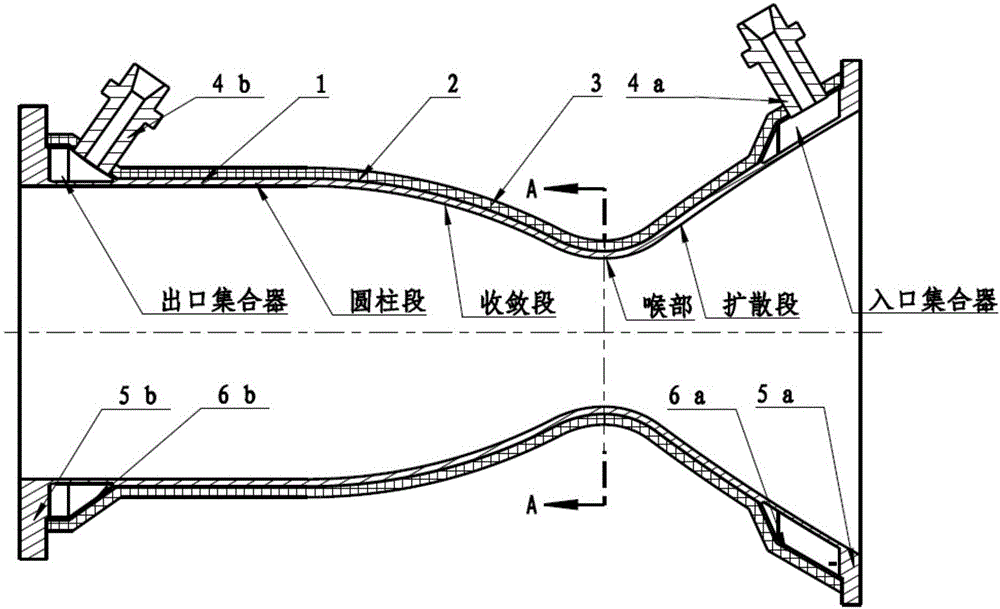

Combustion chamber of liquid rocket engine

InactiveCN106640424ASimple structure and molding processEasy to operateRocket engine plantsCombustion chamberClosed cavity

The invention discloses a combustion chamber of a liquid rocket engine. The combustion chamber comprises a metal inner wall, an adhesion layer, a non-metal outer wall, a propellant inlet connector, a propellant outlet connector, a rear-end flange, a front-end flange, a tail-end bearing plate and a front-end bearing plate, wherein the non-metal outer wall and the metal inner wall form one piece through the adhesion layer; a plurality of cooling grooves which are arranged in the peripheral direction are formed in the outer surface of the metal inner wall; the front-end bearing plate and the tail-end bearing plate form an outlet collector and an inlet collector which are in the shape of an annular cavity respectively with the front-end outer wall surface and the tail-end outer wall surface of the metal outer wall respectively; the front-end flange and the rear-end flange are fixed to the front-end bearing plate and the tail-end bearing plate respectively; the outlet collector and the inlet collector are made to form a closed cavity; and the propellant inlet connector and the propellant outlet connector are connected with the inlet collector and the outlet collector respectively. The combustion chamber disclosed by the invention has the advantages of being simple in structure and forming process, convenient to operate, low in manufacturing cost and short in manufacturing period.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

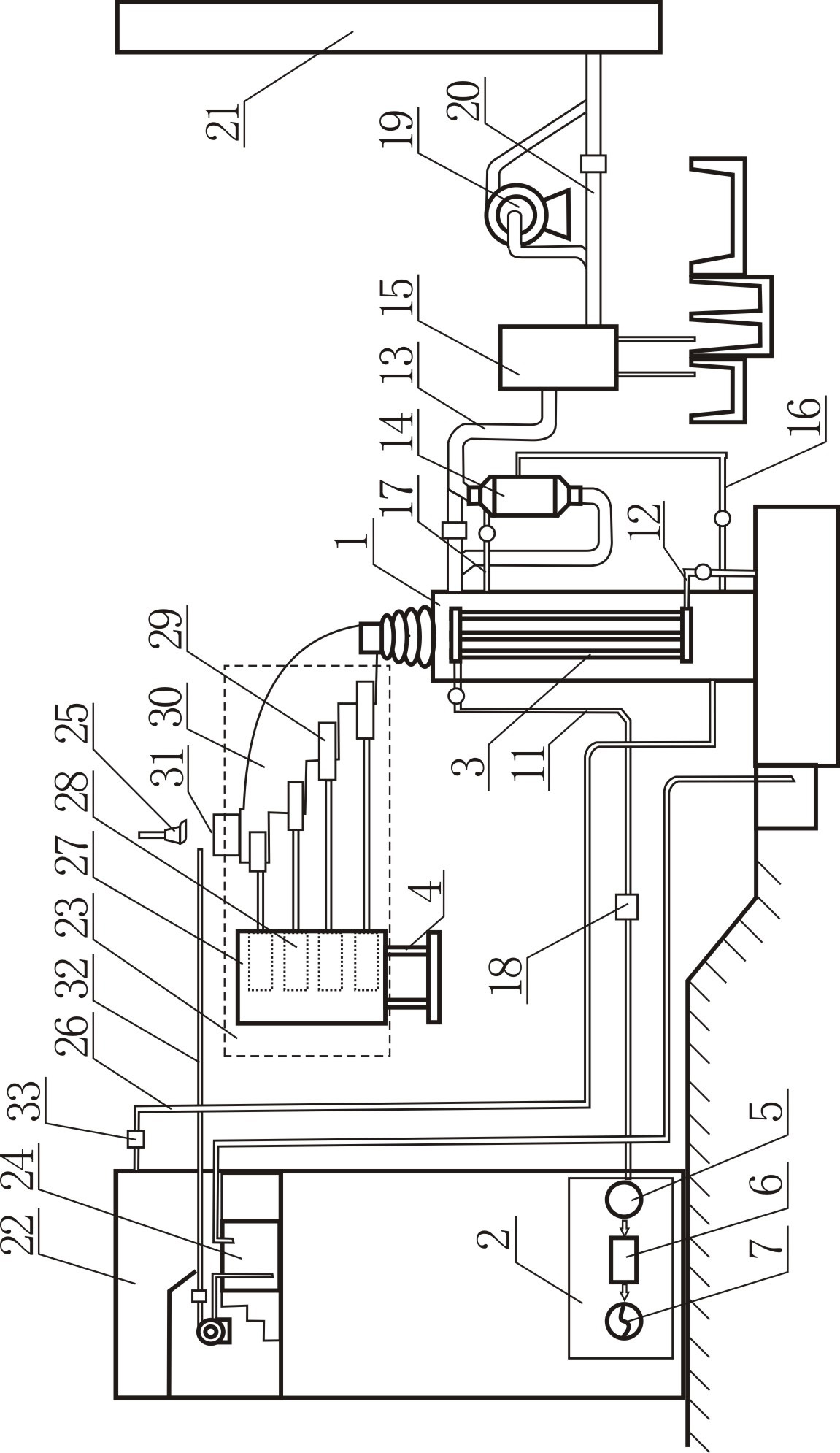

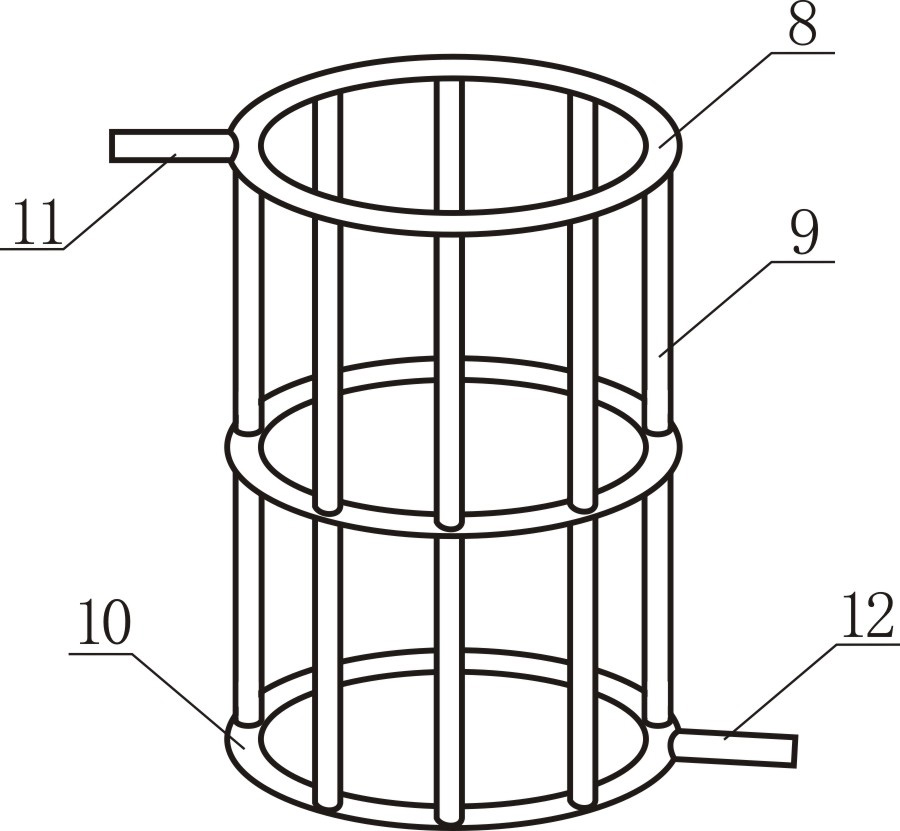

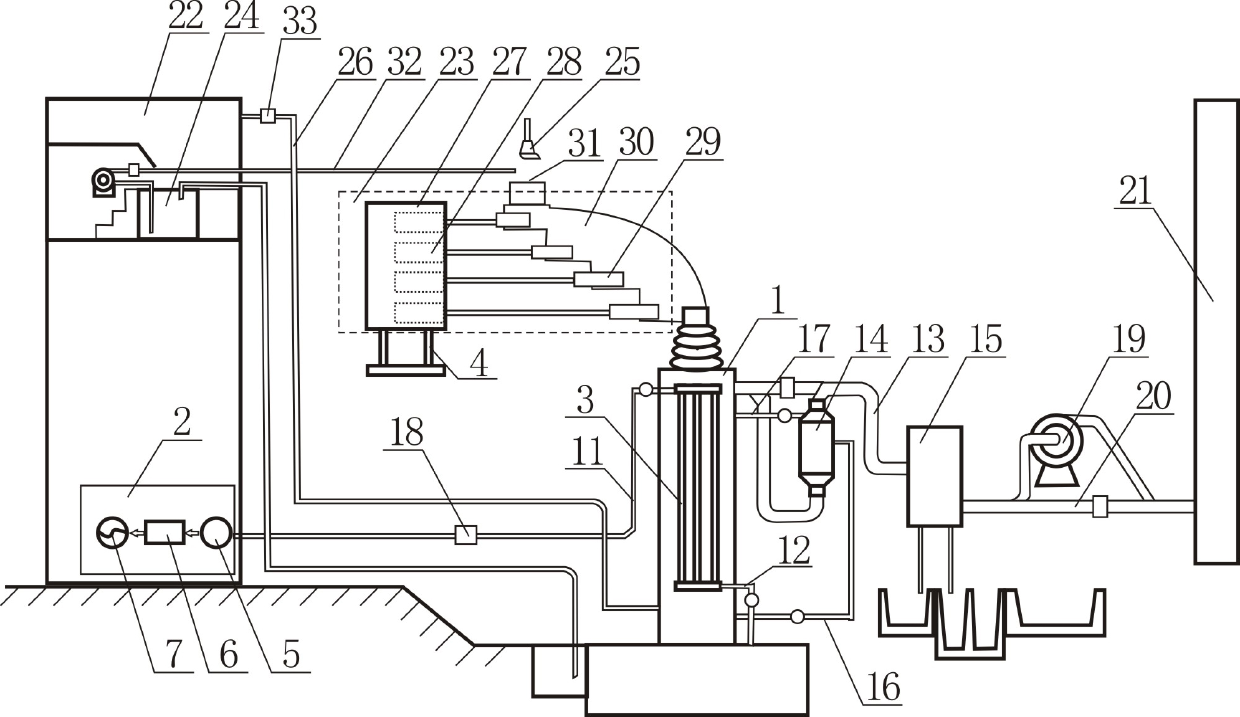

Garbage disposal waste heat power generation system with internal steam pipe

InactiveCN102606236AMaximize recoverySimple structure and processEnergy inputSteam engine plantsFlue gasSteam power

The invention discloses a garbage disposal waste heat power generation system with an internal steam pipe, which comprises a garbage gasifier and a turbine steam power generation device. The turbine steam power generation device comprises a steam generator, a steam discharge pipe, a steam drum, a steam turbine and a power generator, wherein the steam drum, the steam turbine and the power generator are sequentially connected, and the steam generator is arranged in the garbage gasifier and is of a cylindrical cage type structure comprising an upper annular pipe, a plurality of straight pipes and a lower annular pipe. As the steam generator is arranged in the garbage gasifier to realize primary heat exchange and a heat exchanger is additionally arranged in a flue gas channel to realize secondary utilization, heat generated in garbage disposal is used to the maximum extent, the technique with low heat utilization rate of a waste heat boiler for traditional garbage disposal steam power generation in the past is thoroughly changed, and garbage disposal heat recovery is maximized. Owing to a four-step hydraulic pusher, garbage is increasingly looser in the process of entering the garbage gasifier, and is not blocked.

Owner:SHENZHEN JUNENG BIOMASS GASIFICATION TECH

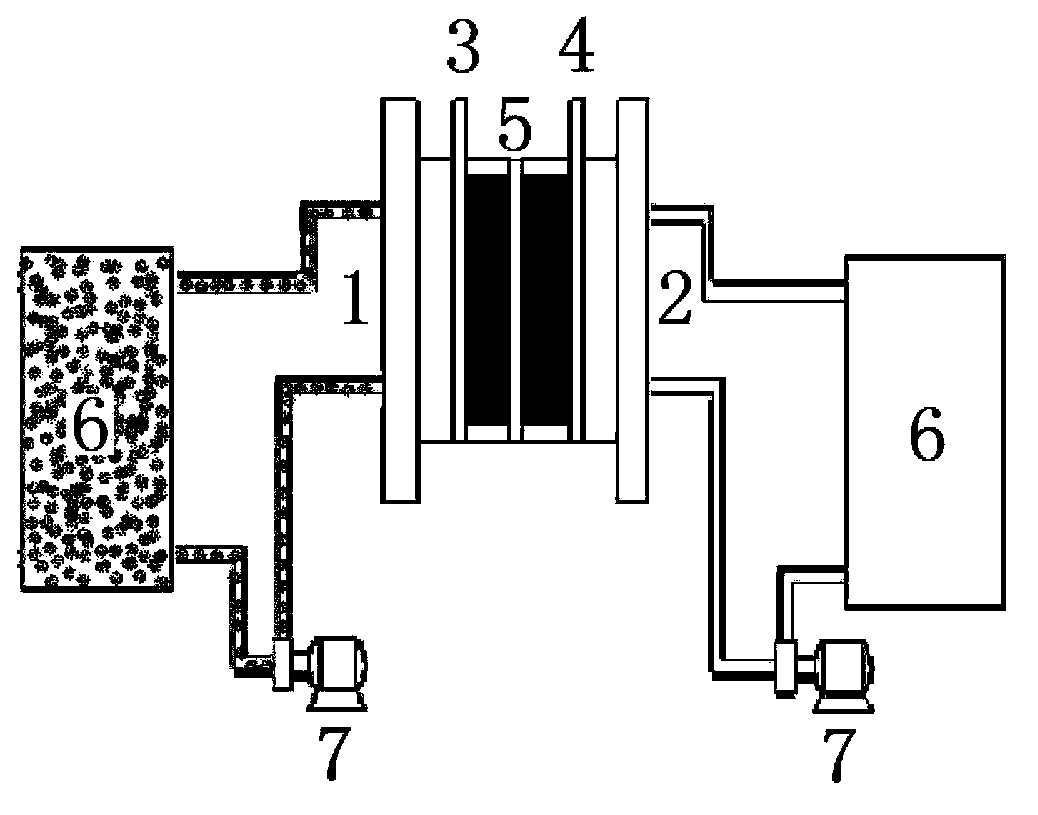

Neutral zinc iron double fluid flow battery

The invention discloses a neutral zinc iron double fluid flow battery, a single cell comprises positive and negative electrode end plates, a collector, a positive electrode, a film, a negative electrode, positive and negative electrode liquid storage tanks, a pipeline and a pump, wherein the positive electrode is a porous electrode, the negative electrode is a deposition type electrode, a positive electrode electrolyte solution is a neutral K4Fe (CN) 6 solution, and a negative electrolyte solution is a neutral zinc-ion-containing; when in charging, the electrolyte solutions respectively pass through the positive and negative electrode liquid storage tanks to be respectively sent to the positive electrode and the negative electrode, K3Fe (CN) 6 is produced by oxidation reaction of active material K4Fe (CN) 6 in the positive electrode storage tank, and zinc ions are directly deposited in the form of elemental zinc in the negative electrode; when in discharge, K4Fe (CN) 6 is produced by reduction reaction of active material K3Fe (CN) 6 in the positive electrode electrolyte solution, and the elemental zinc is oxidized into zinc ions to return through the pump back to the negative electrode liquid storage tank. The positive and negative electrode electrolyte solutions are neutral solutions, overcome the corrosion problems caused by a strong acid and a strong alkali as support electrolytes in the traditional liquid flow battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

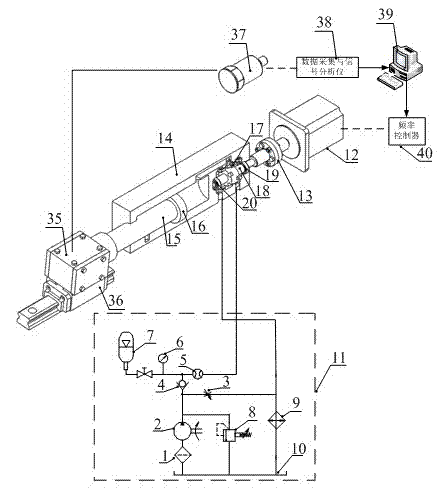

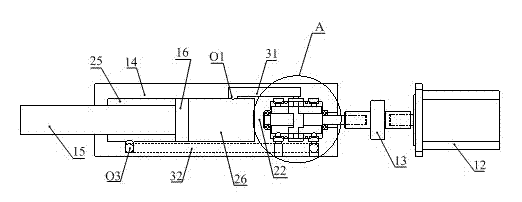

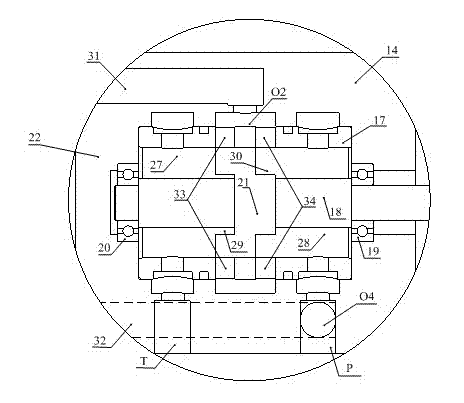

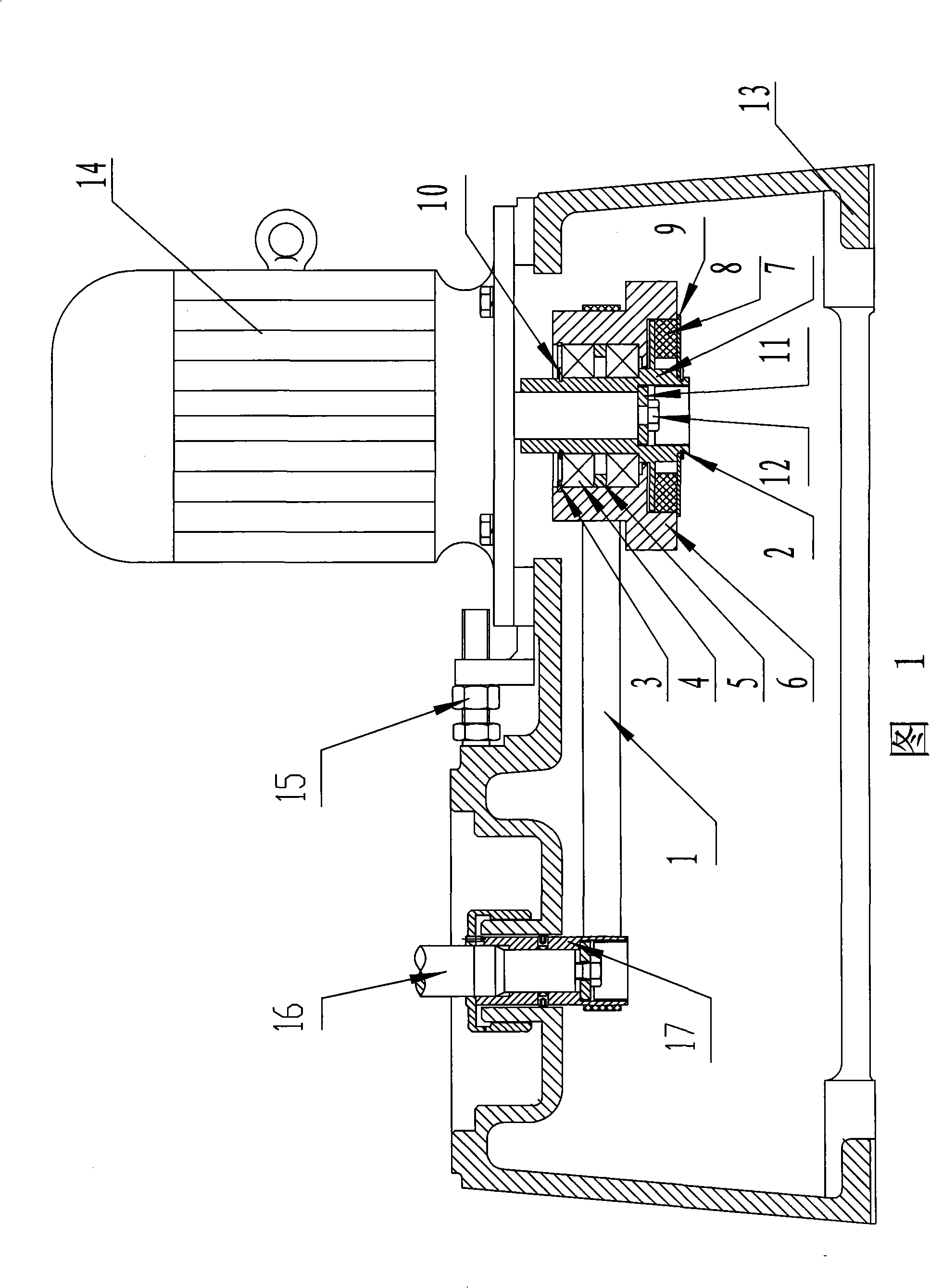

Electrohydraulic vibration exciter

InactiveCN102734279ARealize high frequency commutationHigh control precisionFluid-pressure actuator componentsCouplingEngineering

The invention discloses an electrohydraulic vibration exciter which comprises a step motor and a vibration excitation device. An accommodation cavity inside a case of the vibration excitation device is divided into a first chamber and a second chamber by a clapboard. The first chamber is divided into a rod cavity and a rodless cavity by a piston with a single-acting piston rod. A single-shoulder valve plug provided with a valve sleeve is arranged inside the second chamber and is connected with a main shaft of the step motor through a coupling. The second chamber is divided into a third cavity and a fourth cavity by the shoulder of the single-shoulder valve plug, an oil return port is arranged on the wall of the third cavity, and an oil inlet port is arranged on the wall of the fourth cavity. A first flow channel and a second flow channel are arranged on the wall of the accommodation cavity; the rodless cavity is communicated with the second chamber through the first flow channel, and the rod cavity is communicated with the oil inlet port through the second flow channel. First and second grooves which can be communicated with the first flow channel are arranged on the two sides of the shoulder of the single-shoulder valve plug along the circumferential direction at intervals. Along with the rotation of the single-shoulder valve plug, an opening at the other end of the first flow channel is communicated with either of the first and second grooves all the time.

Owner:ZHEJIANG UNIV

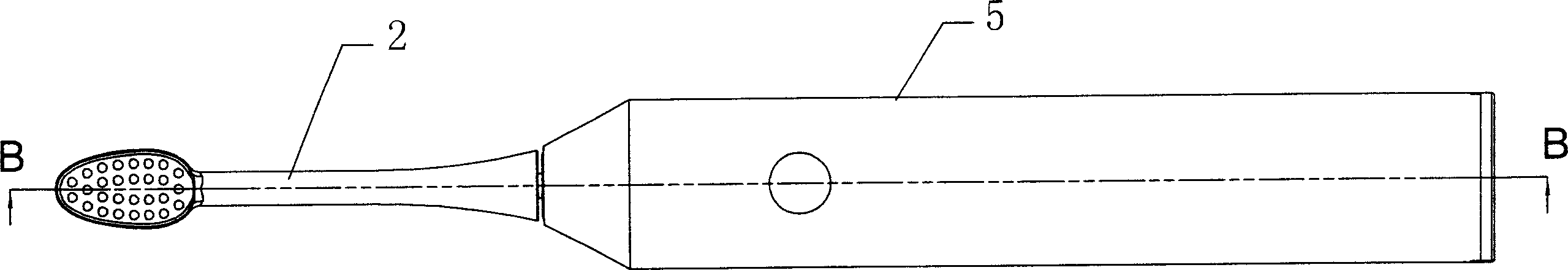

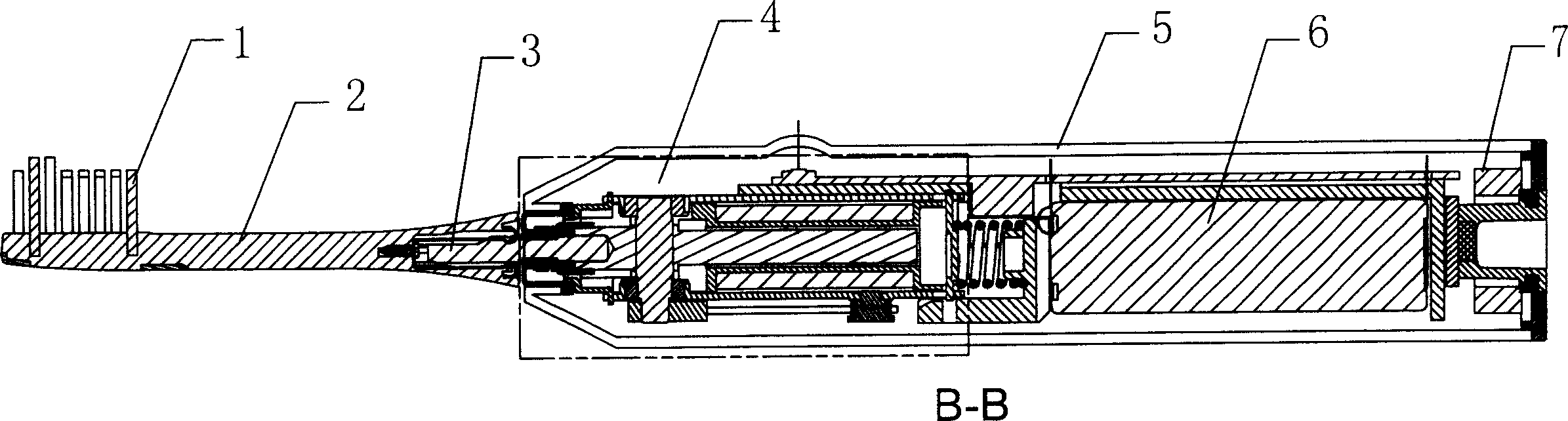

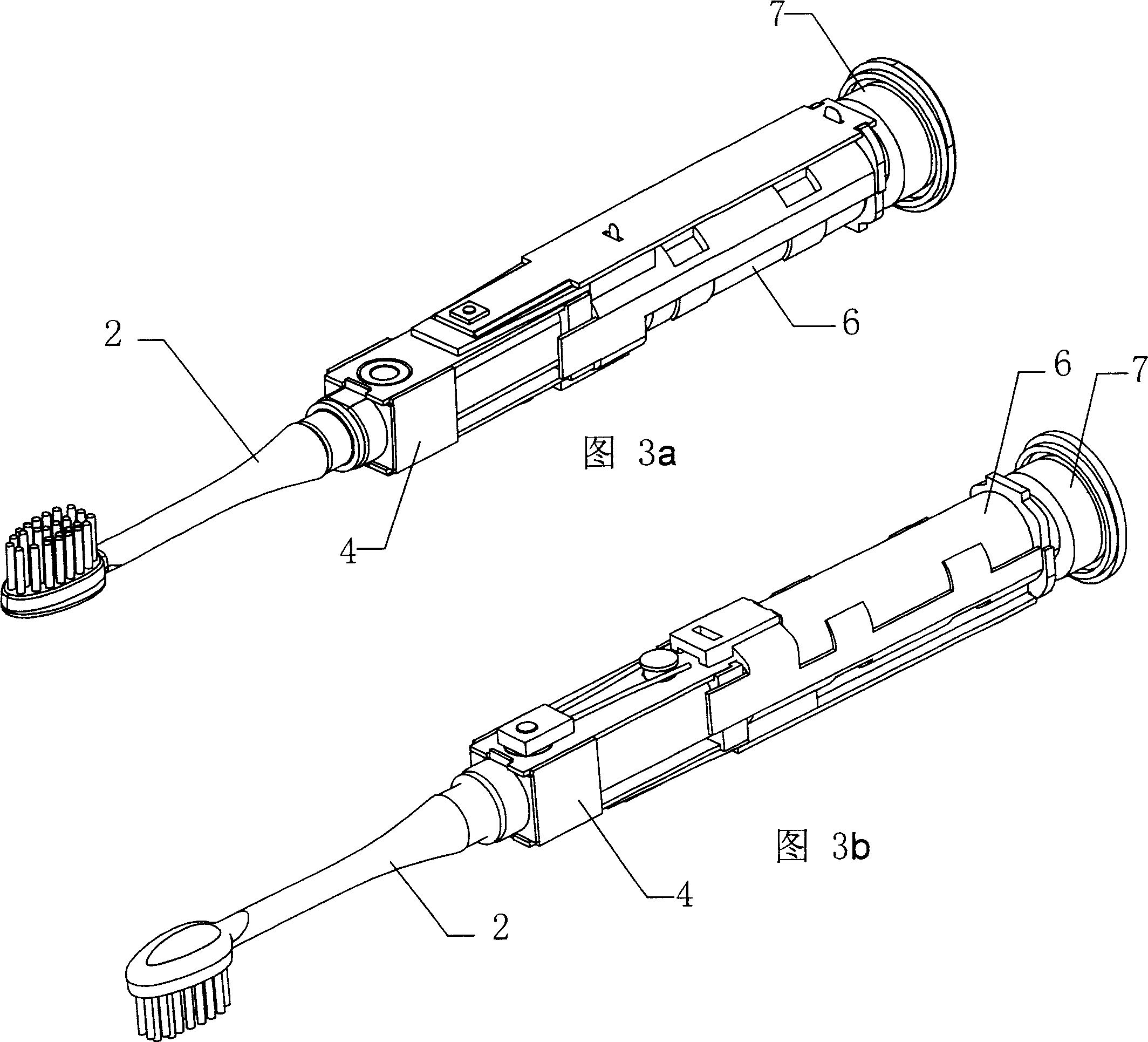

Acoustic toothbrush and its rotation axle electric machine

A sound-wave tooth-brush with high cleaning effect and low noise is composed of a brush head, a handle used as its main body, and the axle-swinging motor and its driver, which are arranged in said handle. Said axle-swinging motor consists of supporting frame, electromagnetic coil, swinging axle connected to brush head, two magnets close to another end of swinging axle and a frequency (350-550 H2) regulator.

Owner:OASIS GLOBAL

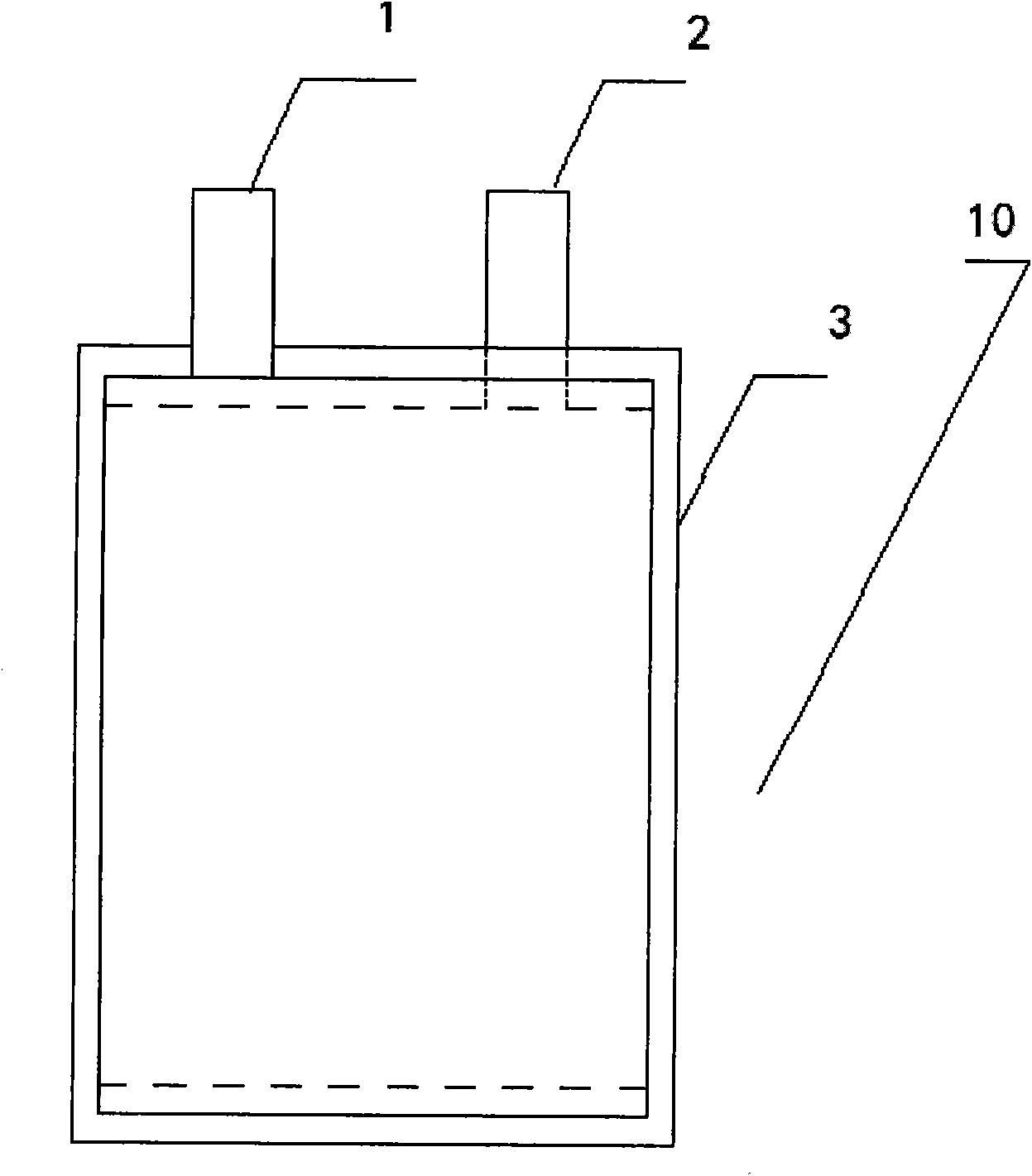

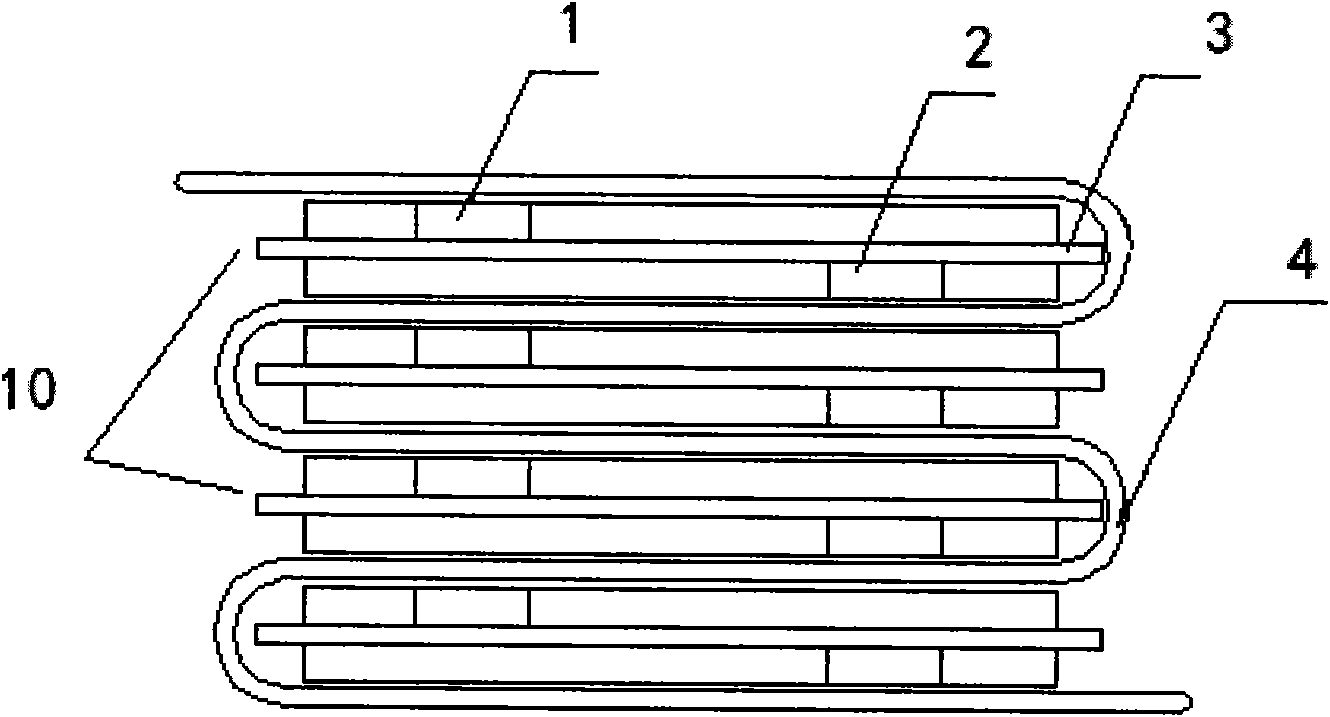

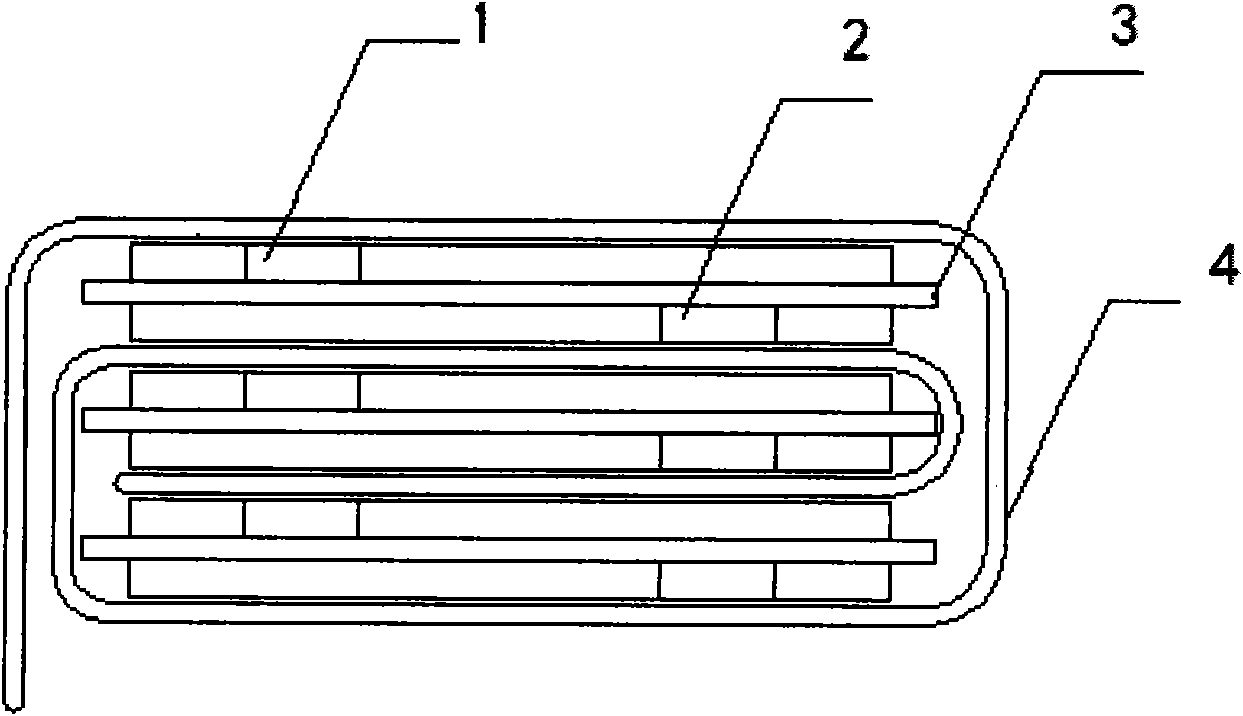

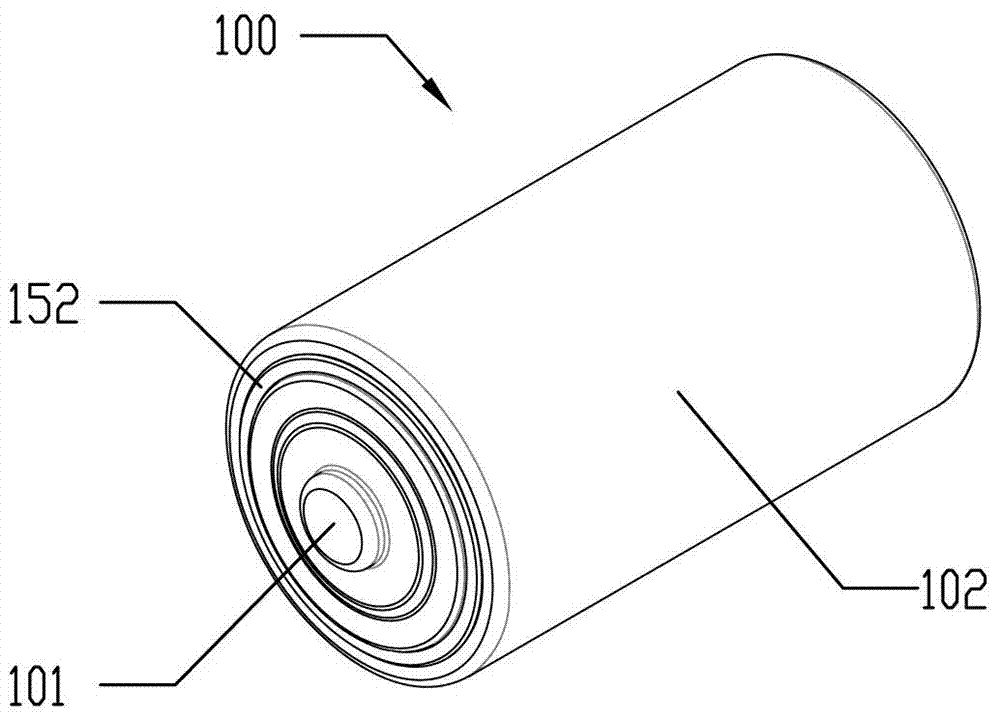

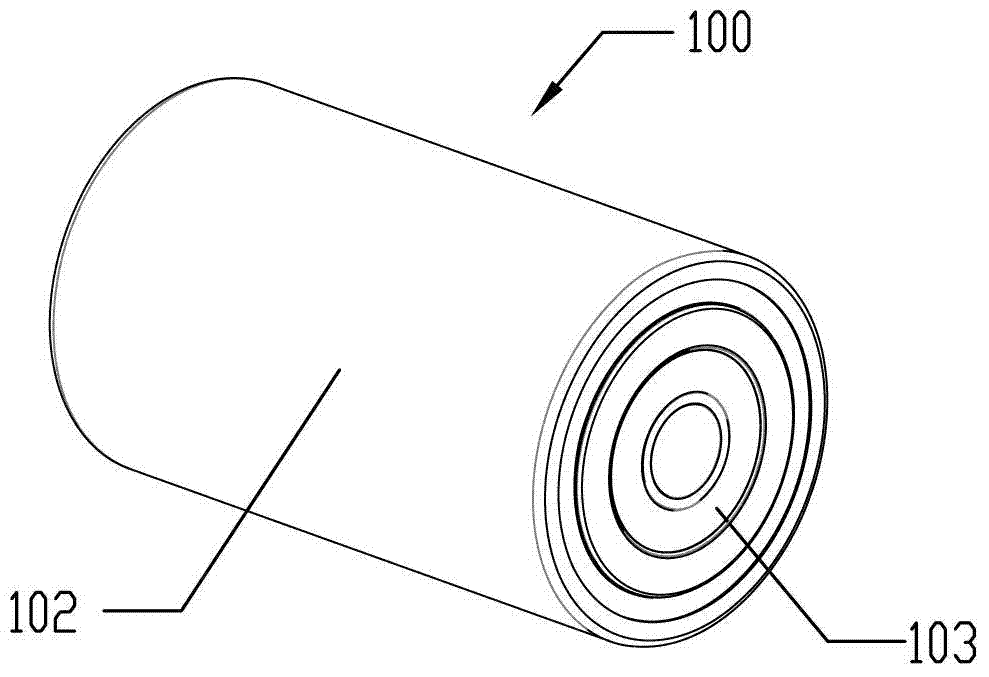

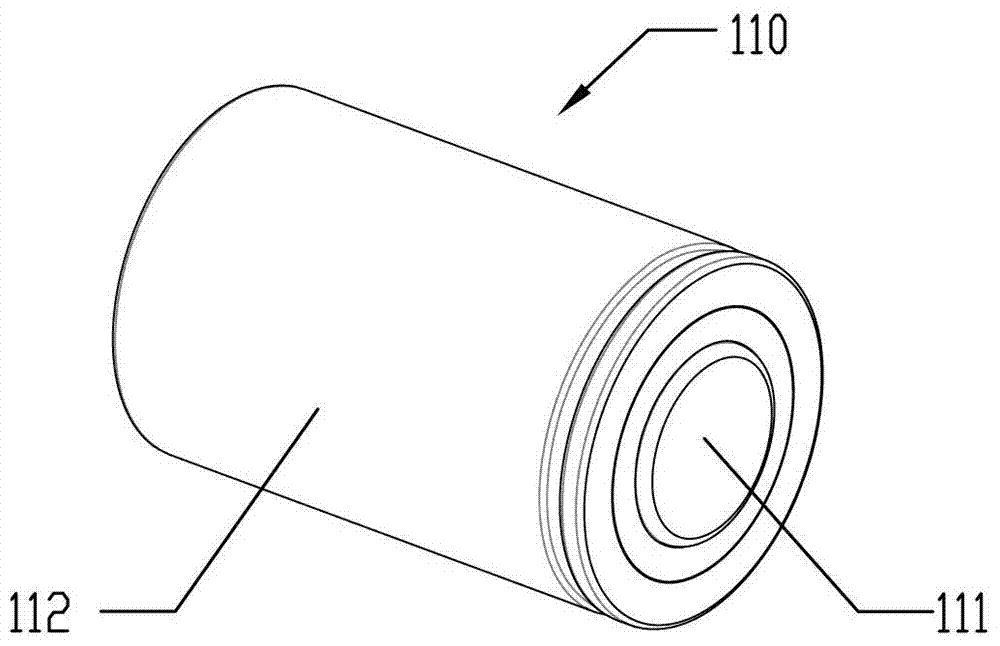

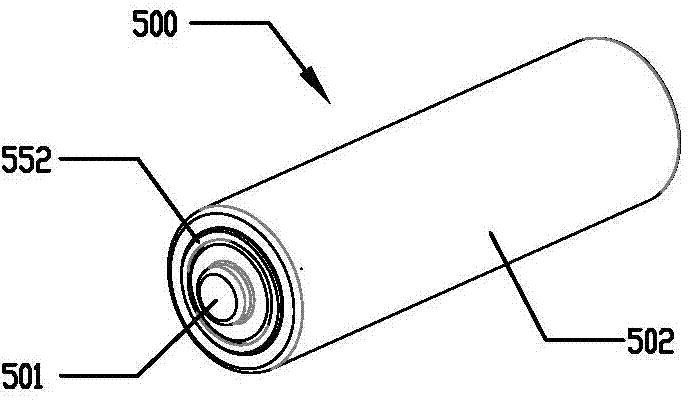

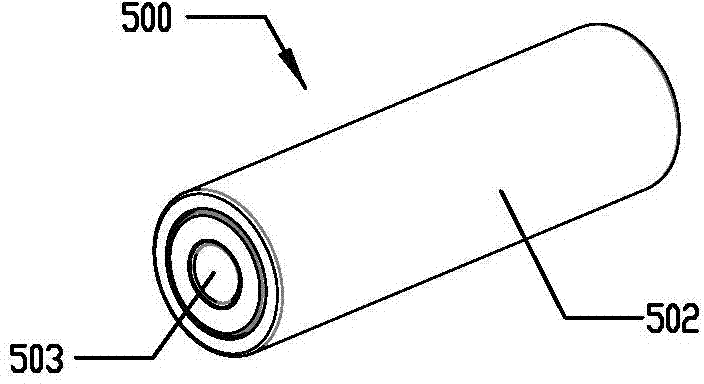

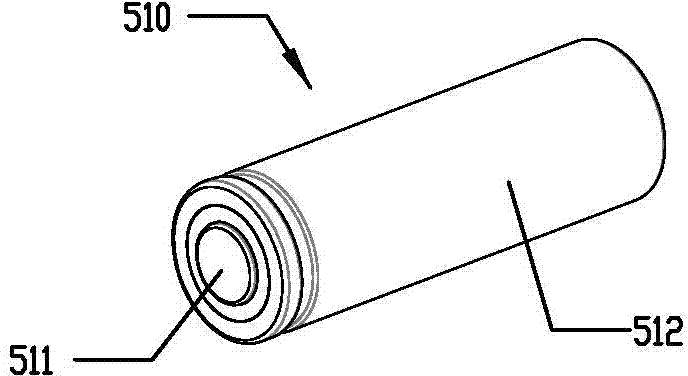

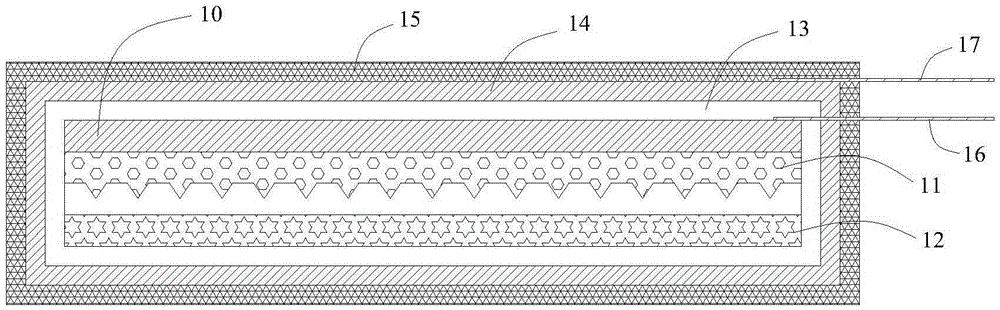

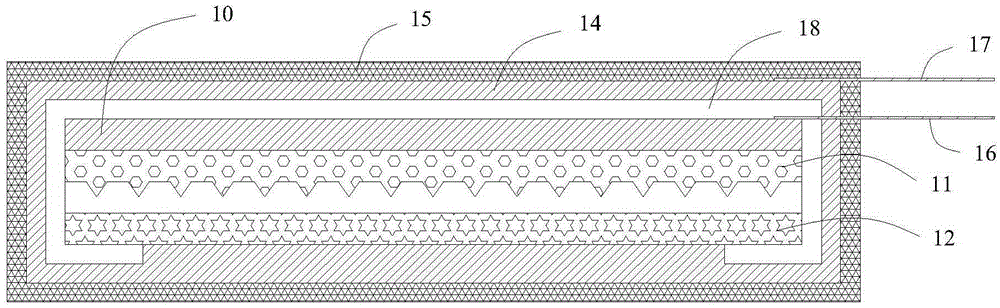

Core structure of lithium ion battery

InactiveCN101630757ALower internal resistanceImprove interface structureFinal product manufactureSecondary cellsInternal resistanceLithium-ion battery

The invention relates to a core structure of a lithium ion battery. In the core structure of the lithium ion battery, a core is formed by laminating and winding core monomers by means of a core septum; the core monomer is pressed by correspondingly laminating an anode sheet and a cathode sheet on two sides of the septum; and an anode ear of the anode sheet and a cathode ear of the cathode sheet are separated and positioned on two sides of the same side of the core monomer. The core septum wound with a plurality of the laminated core monomers can wind along the same direction and can also have a Z-shaped winding structure. The core is formed by laminating and winding the core monomers with the anode ears and the cathode ears by means of the core septum; the lithium battery with the core structure can effectively improve an interface structure between the core inner sheet formed by the laminated sheets and the septum, reduce the internal resistance of the core, improve the circulation performance and the rate discharge performance and can also prevent potential safety hazard triggered by misplacement of the anode sheet and the cathode sheet in the assembling process.

Owner:TCL CORPORATION

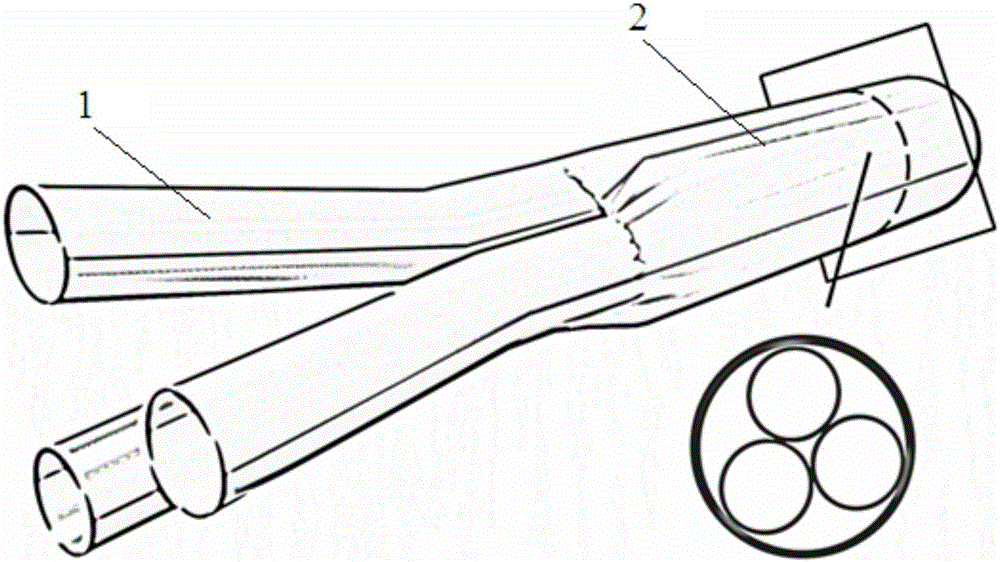

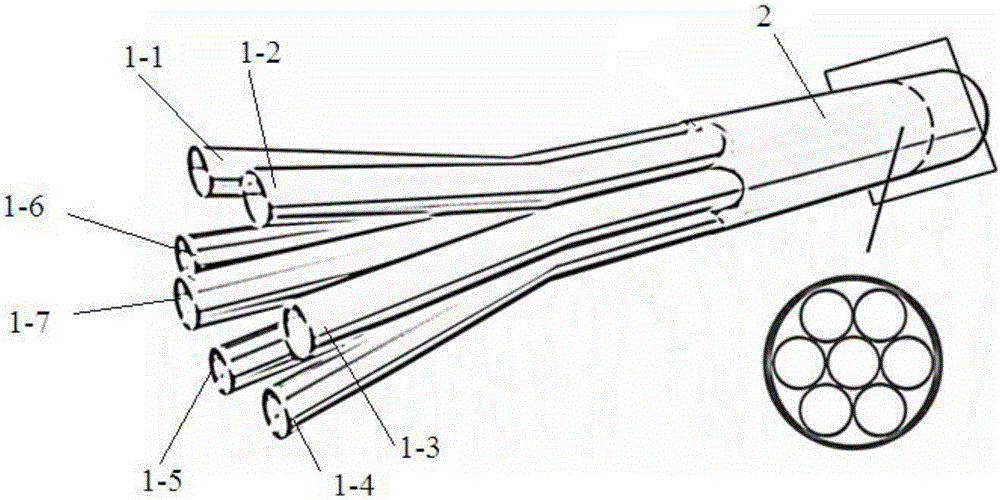

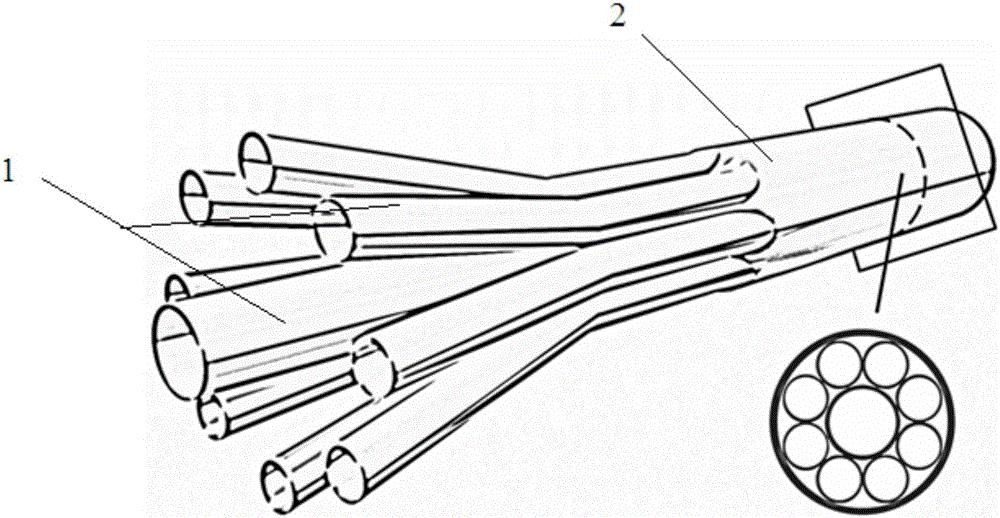

Multi-channel cocurrent flow microfluidic chip and controllable spinning method for linear multi-phase heterostructure fiber based on same

ActiveCN106215987ASimple structure and processSimple preparation processSpinnerette packsFilament/thread formingFiberMicro nano

The invention provides a multi-channel cocurrent flow microfluidic chip. The chip is composed of a plurality of bypass capillary tubes and a confluence capillary tube, different spinning solutions flow through the bypass capillary tubes independently in a hydrogel wet spinning process or static spinning process, and the spinning solutions flowing out of the bypass capillary tubes are converged through the confluence capillary tube. One end of each bypass capillary tube is embedded into the confluence capillary tube to be fixed from one port of the confluence capillary tube by the same depth, and the inserting port of the confluence capillary tube is sealed. The other end of each bypass capillary tube is the inlet of the whole multi-channel cocurrent flow microfluidic chip, and the other end of the confluence capillary tube is the outlet of the whole multi-channel cocurrent flow microfluidic chip. The invention further provides a controllable spinning method for linear multi-phase heterostructure fiber based on the multi-channel cocurrent flow microfluidic chip. The technological difficulty and cost of the microfluidic chip can be lowered, the practicability and durability are improved, and various linear multi-phase heterostructure micro-nano fibers can be continuously, rapidly and conveniently manufactured.

Owner:SICHUAN UNIV

Universal rechargeable battery formed by adopting lithium-ion battery and control method thereof

ActiveCN103490112ASimple structure and assembly processConducive to automated mass production assemblyCells structural combinationElectric powerElectrical batteryCommon battery

The invention provides a universal rechargeable battery formed by adopting a lithium-ion battery and a control method thereof. The universal rechargeable battery comprises an external packing casing, as well as a charging / discharging controller, a positive electrode welding piece, the lithium-ion battery and a negative electrode end cover which are sequentially assembled in the external packing casing in a press fit manner, wherein the charging / discharging controller comprises a charging / discharging controller casing as well as a charging / discharging control circuit welding body and a charging / discharging controller support, which are arranged in the charging / discharging controller casing; a lithium-ion battery charging / discharging control circuit is welded on a charging / discharging control circuit welding body; the lithium-ion battery charging / discharging control circuit comprises a lithium-ion battery charging control circuit welded on a circuit board, electrically connected with the lithium-ion battery and the positive electrode end cover respectively and further electrically connected with the negative electrode end cover via the charging / discharging controller casing and the external packing casing, a lithium-ion battery detection and control circuit, and a DC-DC step-down voltage stabilizing discharging circuit.

Owner:SHENZHEN MAIGESONG ELECTRICAL TECH CO LTD

Semi-solid-state zinc nickel flow cell

InactiveCN103840187AIncrease capacityImprove securityFuel cells groupingFinal product manufactureZincateHigh energy

The invention provides a semi-solid-state zinc nickel flow cell. A single cell is composed of positive and negative electrode end plates, a positive electrode, a negative electrode, a diaphragm, fluid storage tanks, a pipeline and a pump, wherein the positive electrode is a porous electrode, the negative electrode is a deposition type electrode, an active material-nickelous hydroxide in the positive electrode is suspended and dispersed in a positive electrode electrolyte, and a negative electrode electrolyte is a high-consistency alkaline zincate solution. In the charging process, the electrolytes are respectively conveyed to the positive electrode and the negative electrode from the fluid storage tanks by the pump, and the active material-nickelous hydroxide in the positive electrode electrolyte is oxidized into nickel oxide hydroxide; zinc ions in the negative electrode electrolyte is directly deposited in the negative electrode in a zinc elementary substance form. In the discharging process, the nickel oxide hydroxide in the positive electrode fluid storage tank is reduced to nickel hydroxide; a zinc elementary substance is oxidized to zinc ions which return to the negative electrode fluid storage tank by the pump. According to the semi-solid-state zinc nickel flow cell disclosed by the invention, a solid active material-nickel hydroxide involving in the reaction with the positive electrode is stored in the corresponding electrolyte, so that the power and energy can be singly designed, and the cell has the characteristics of high energy storage capacity, high safety, long circulation service life, low cost and simple structure and manufacturing process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Universal rechargeable battery formed by adopting lithium-ion battery and control method thereof

ActiveCN103490099AImplement charging modeRealize the charging rateFinal product manufactureElectrical testingElectrical batteryCharge control

The invention provides a universal rechargeable battery formed by adopting a lithium-ion battery and a control method thereof. The universal rechargeable battery formed by adopting the lithium-ion battery comprises an external packing casing as well as a charging / discharging controller, a positive electrode crimping sheet, a lithium-ion battery and a negative electrode end cover, which are sequentially assembled in the external packing casing in a press fit manner; the charging / discharging controller comprises a charging / discharging controller casing as well as a charging / discharging control circuit welding body, an insulating spacer, a charging / discharging controller support which are arranged in the charging / discharging controller casing; a lithium-ion battery charging / discharging control circuit is welded on the charging / discharging control circuit welding body; the lithium-ion battery charging / discharging control circuit comprises a lithium-ion battery charging control circuit welded on a circuit board, electrically connected with the lithium-ion battery and the positive electrode end cover respectively, and further electrically connected with the negative electrode end cover via the charging / discharging controller casing and the external packing casing, a lithium-ion battery detection and control circuit and a DC-DC buck voltage stabilizing discharging circuit.

Owner:麦格松(湖北)电源系统有限责任公司

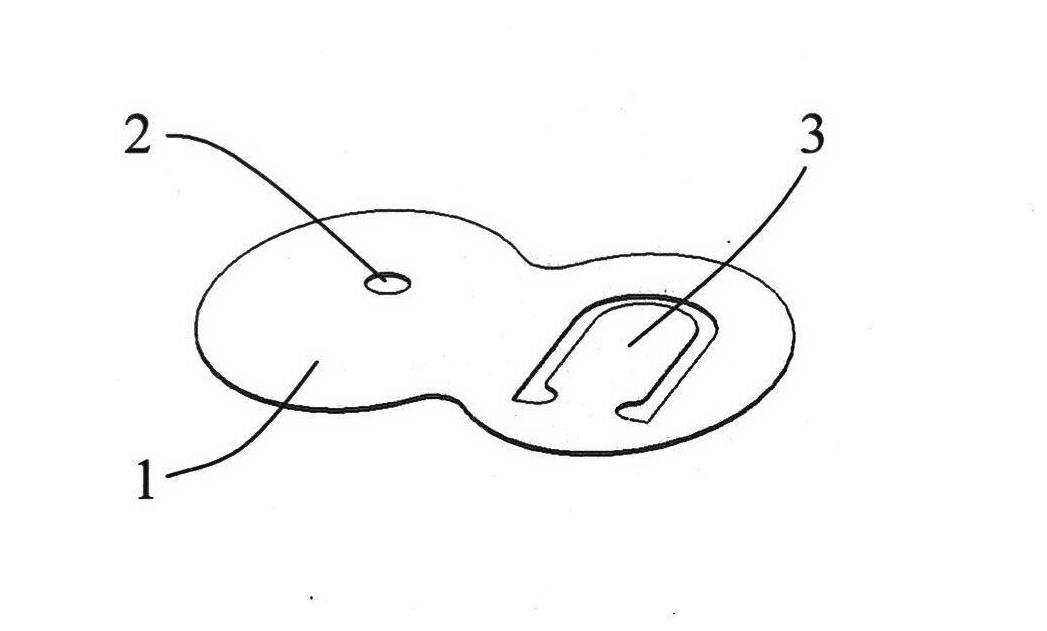

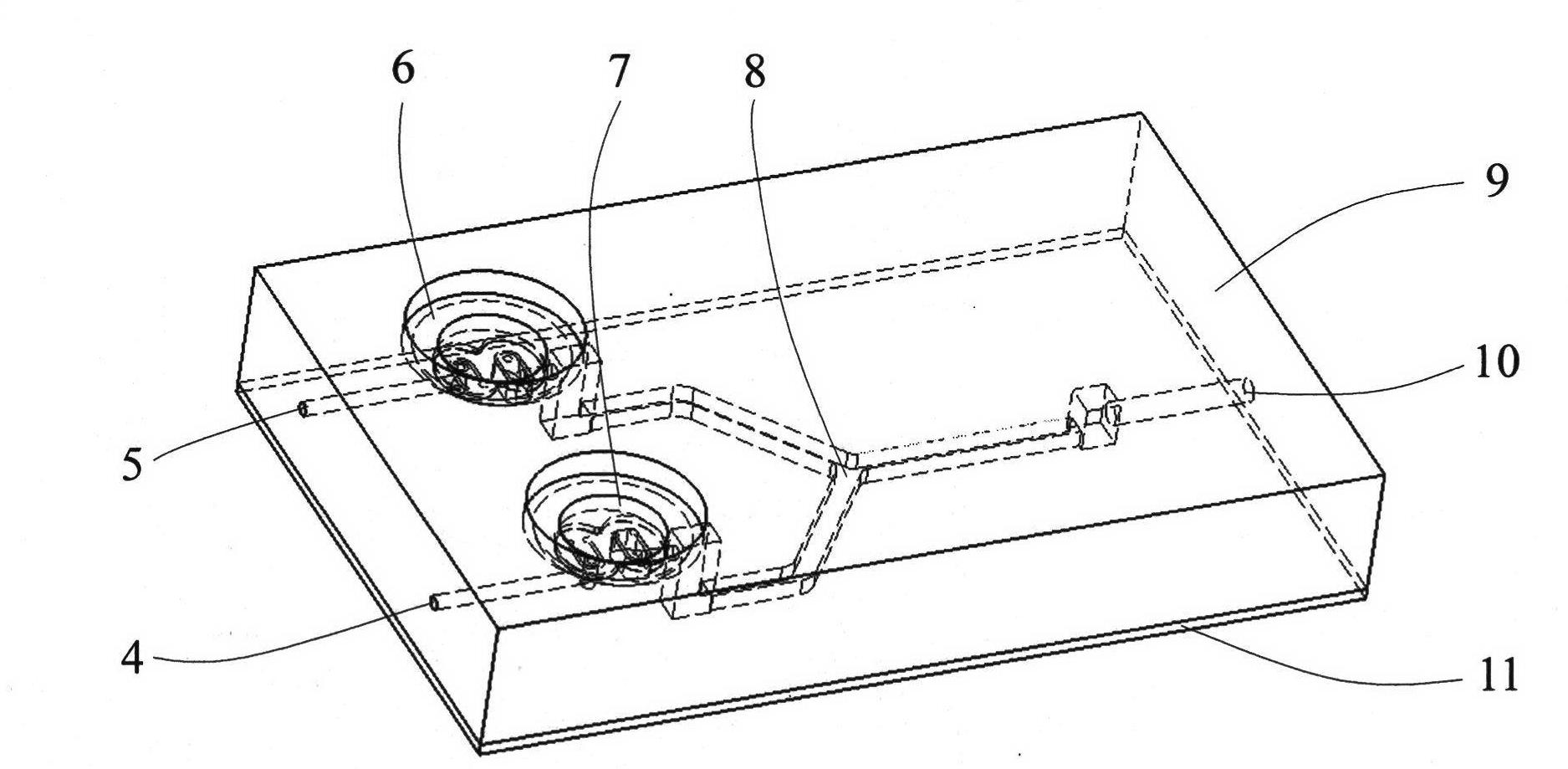

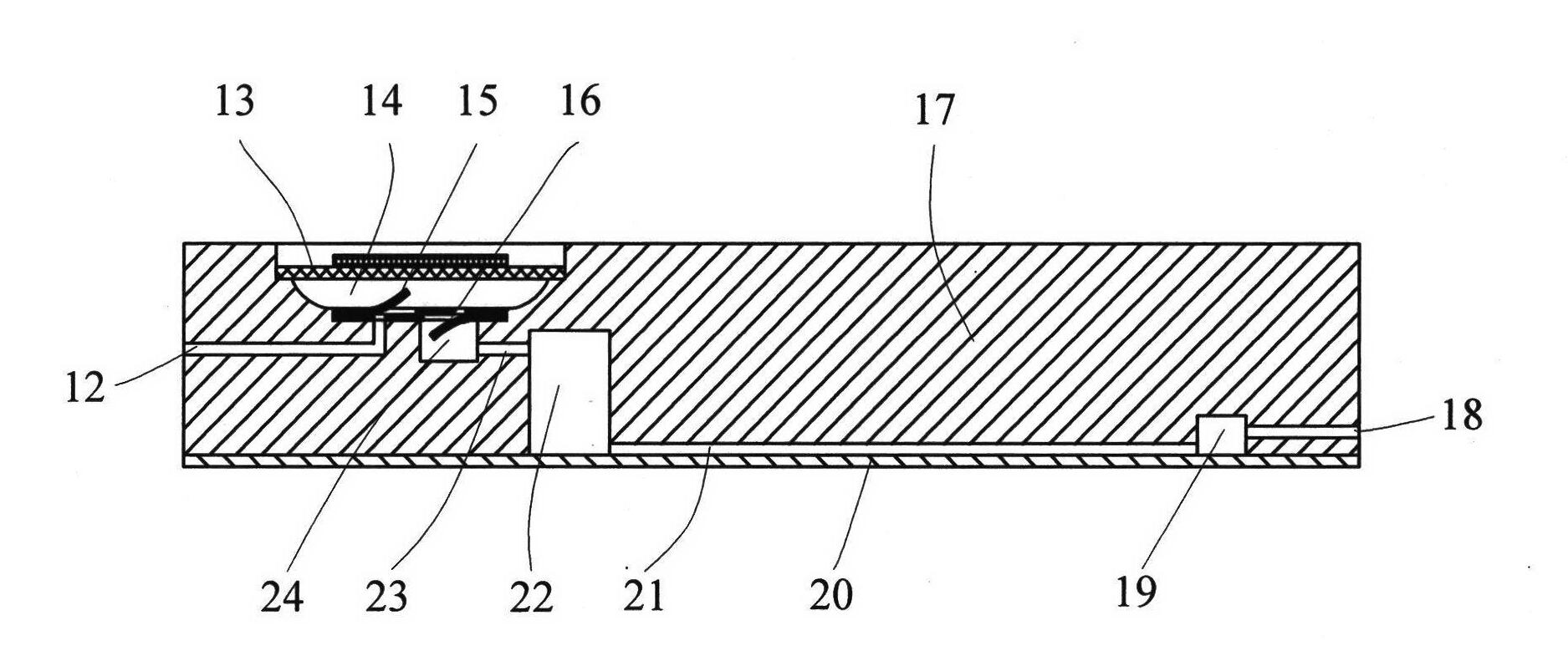

Piezoelectrically actuated micro-mixer, manufacturing method and control method of piezoelectrically actuated micro-mixer

InactiveCN102671572ALarge controllable rangeImprove mixing efficiencyMixer accessoriesPump controlElectricityEngineering

The invention discloses a piezoelectrically actuated micro-mixer, a manufacturing method and a control method of the piezoelectrically actuated micro-mixer, belonging to the technical field of a micro-mixer. With the adoption of the micro-mixer, a micro-fluid drive unit (namely a piezoelectric pump) and a micro-mixing unit (namely a mixing runner) are integrated into a whole via an overall PDMS (polydimethylsiloxan) substrate; a single chip piezoelectric vibrator and a one-way valve block are encapsulated together with the PDMS substrate to form the piezoelectric pump; a glass base plate is encapsulated together with the PDMS substrate to form the mixing runner; and the piezoelectric vibrator is stimulated by adopting different voltages, frequencies, different waveforms and phase staggered drive electric signals so as to achieve high-frequency pulsating displacement mixing of the micro-fluid in a micro-mixing runner. With the adoption of the piezoelectrically actuated micro-mixer, the defects of low mixing efficiency, long time and the like caused by that the micro-fluid is mixed by laminar diffusion under a micro-scale are effectively overcome, so that efficient turbulent mixing is realized. The piezoelectrically actuated micro-mixer disclosed by the invention has the advantages of being simple in manufacturing method, low in cost, high in mixing efficiency, short in time, small in volume and easy in integration, and capability of widely applying to the fields such as analytical chemistry, micro-chemical system, environment monitoring, life science and the like.

Owner:JILIN UNIV

Zinc-iodine flow battery

ActiveCN105742656AIncrease energy densityImprove cycle lifeCell electrodesRegenerative fuel cellsManufacturing technologyEngineering

The invention provides a zinc-iodine flow battery, which comprises a battery module, a positive electrolyte storage tank, a negative electrolyte storage tank, a circulating pump and a circulating pipeline, wherein the battery module is formed by connecting more than one or two of single batteries in series; each single battery comprises a positive end plate, a negative end plate, a positive electrode, a negative electrode and a membrane; the negative oxidation-reduction couple is Zn<2+> / Zn; and the positive oxidation-reduction couple is I3<-> / I<->. The energy density of the battery is high; and meanwhile, the zinc-iodine flow battery has the characteristics of being long in cycle lifetime, low in cost, simple in structure and simple in manufacturing technology.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

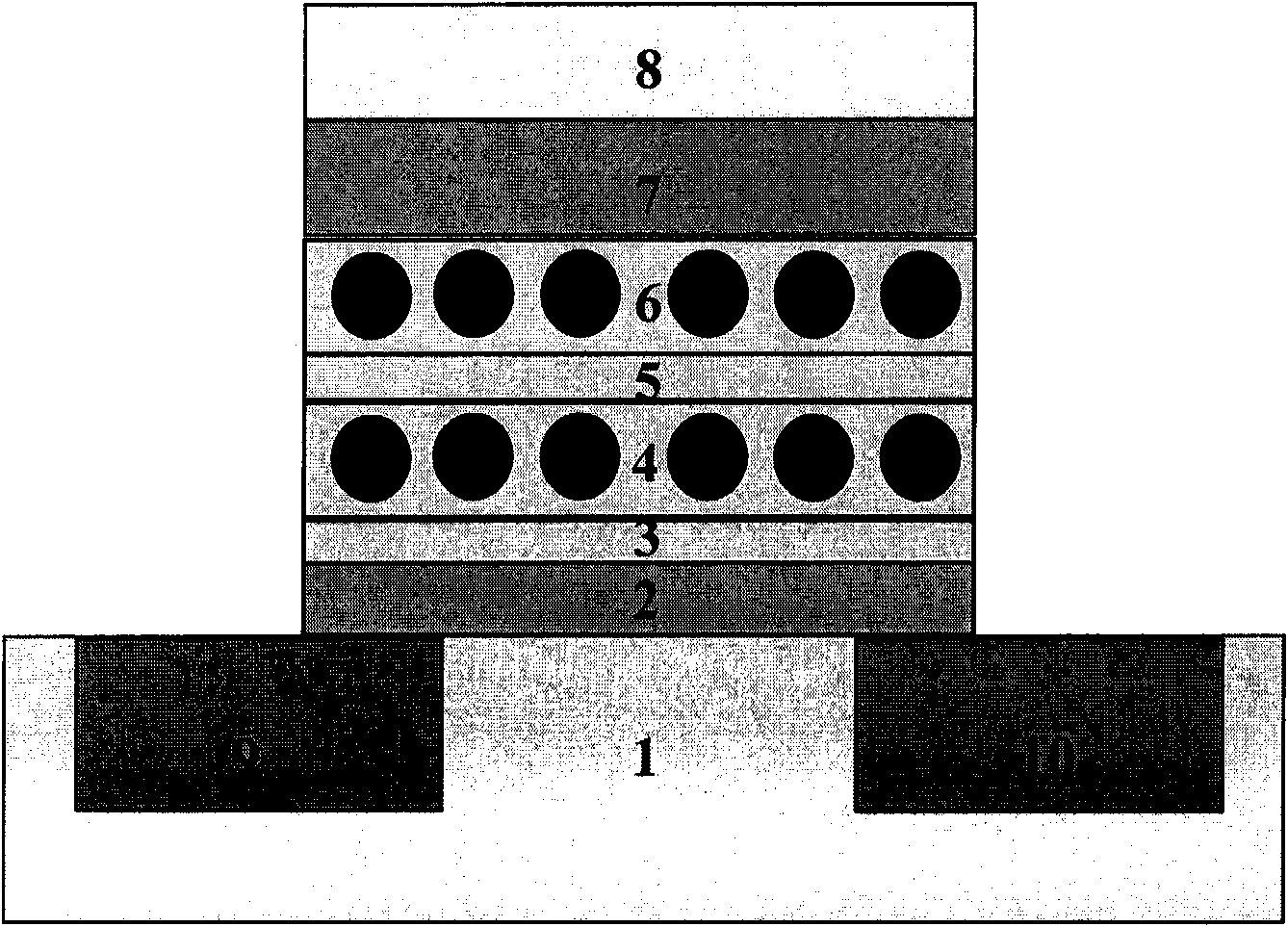

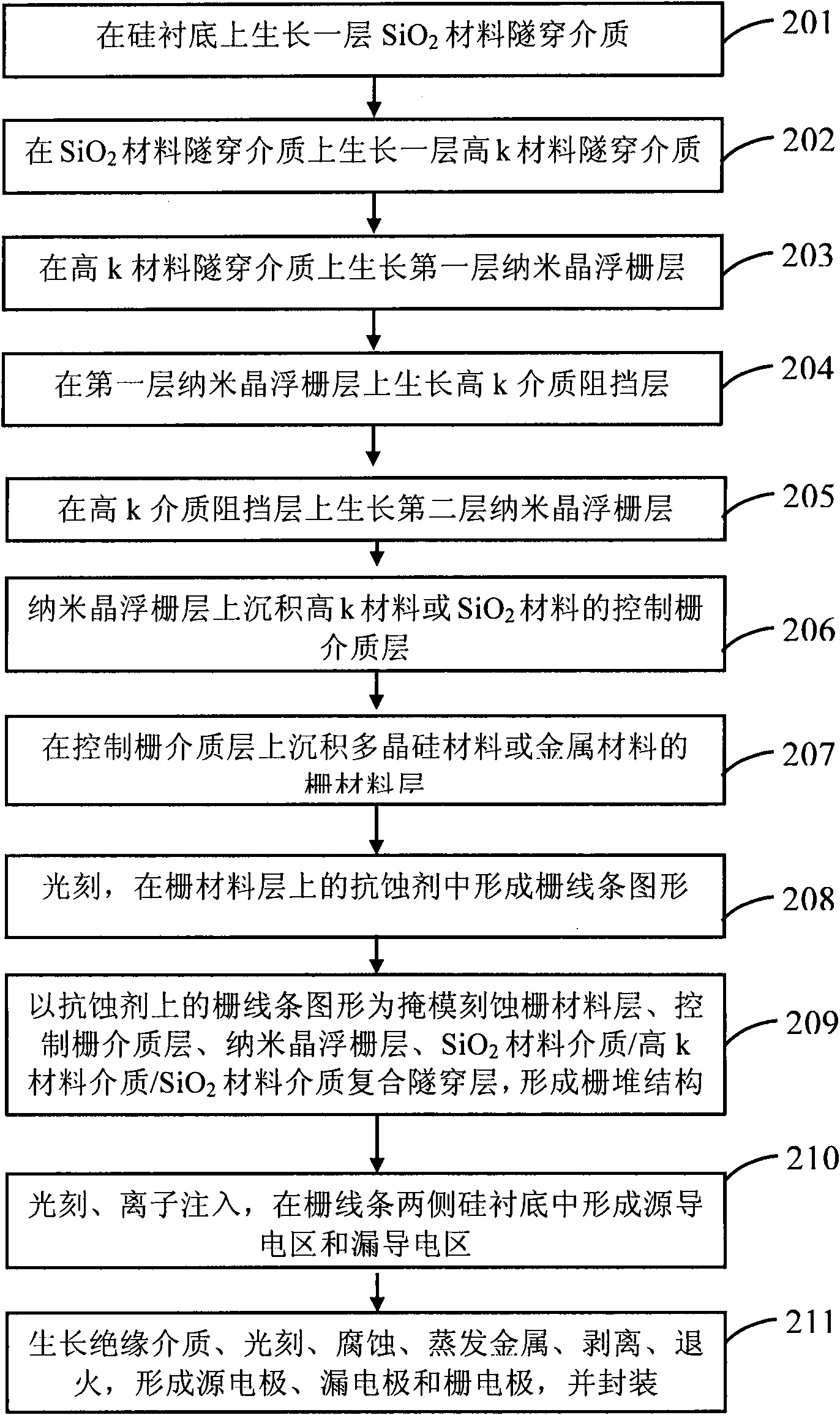

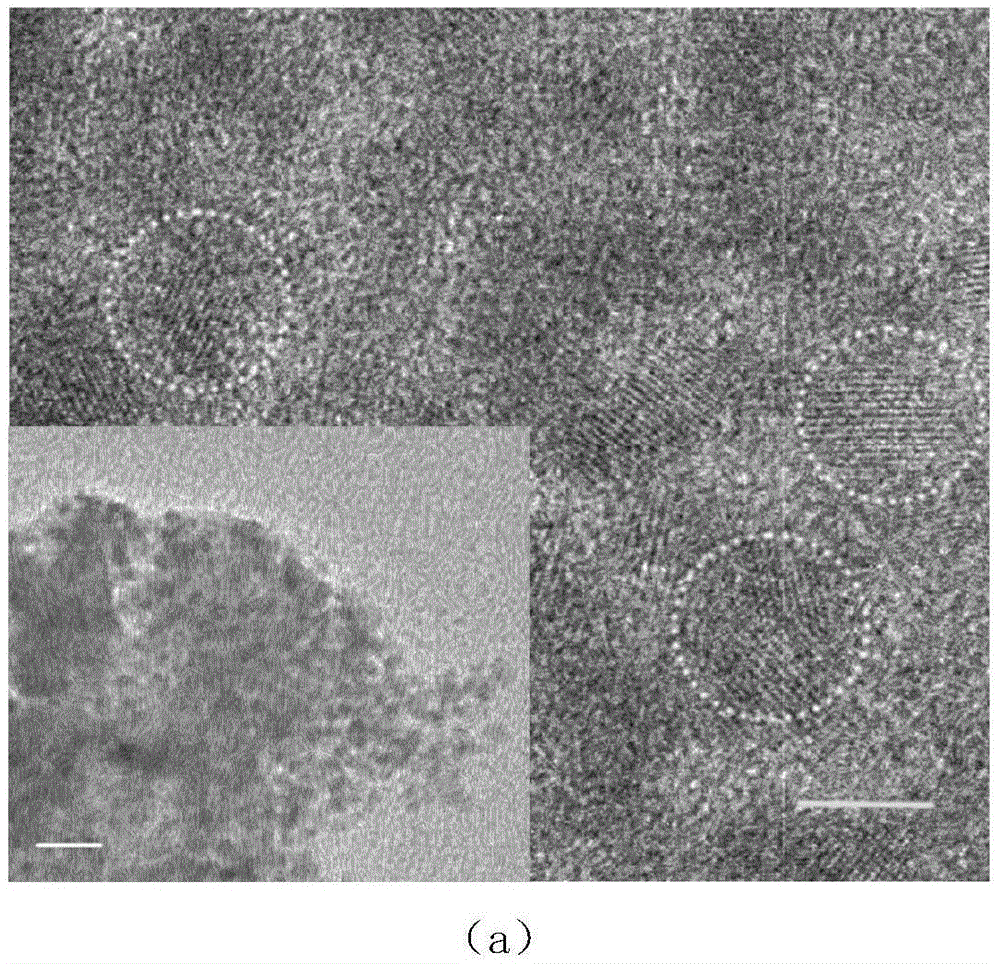

Nano-crystal floating gate nonvolatile memory and manufacturing method thereof

InactiveCN101807576ALow costImprove cooling effectTransistorIndividual molecule manipulationNanocrystalMedia layer

The invention discloses a nano-crystal floating gate nonvolatile memory with a multi-value storage function and a manufacturing method thereof. The memory comprises a silicon substrate, a source conduction region, a drain conduction region, a composite tunneling layer, a first nano-crystal floating gate layer, a barrier layer medium, a second nano-crystal floating gate layer, a control gate medium layer and a gate material layer, wherein the source conduction region and the drain conduction region are heavily doped on the silicon substrate; the composite tunneling layer is covered on a current carrier channel between the source and drain conduction regions, and consists of an SiO2 material medium and a high-k material medium from the bottom to the top; the first nano-crystal floating gate layer is covered on the composite tunneling layer; the barrier layer medium is covered on the first nano-crystal floating gate layer and used as a barrier layer between double layers of nano-crystals; the second nano-crystal floating gate layer is covered on the barrier layer medium; the control gate medium layer is covered on the second nano-crystal floating gate layer, and consists of a high-k material or an SiO2 material; and the gate material layer is covered on the control gate medium layer. The integration density of the floating gate nonvolatile memory is improved, the storage performance of the memory is comprehensively improved, namely the programming / erasing speed and tolerance and data holding property are improved, and the programming / erasing voltage and the operating power consumption are reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

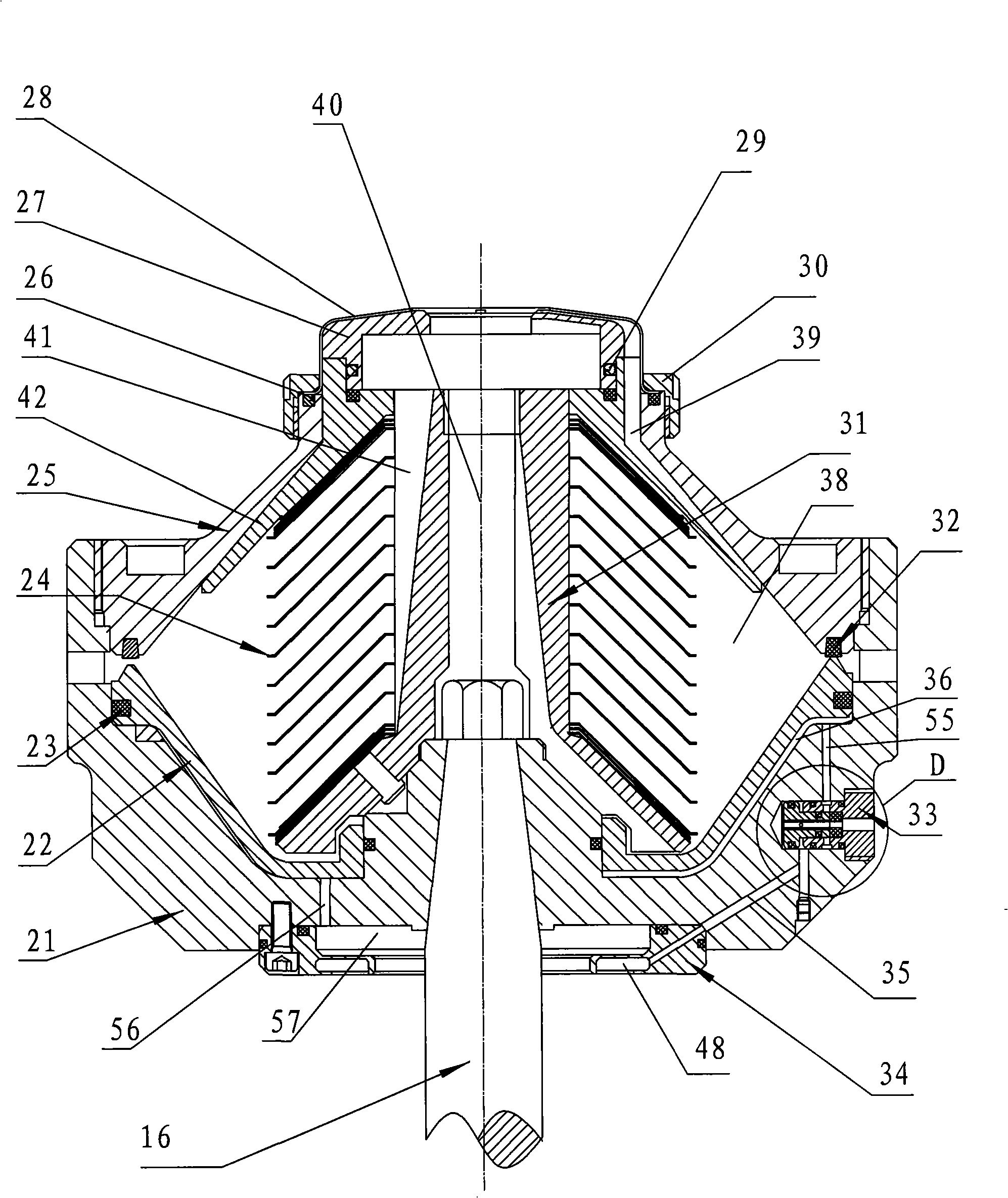

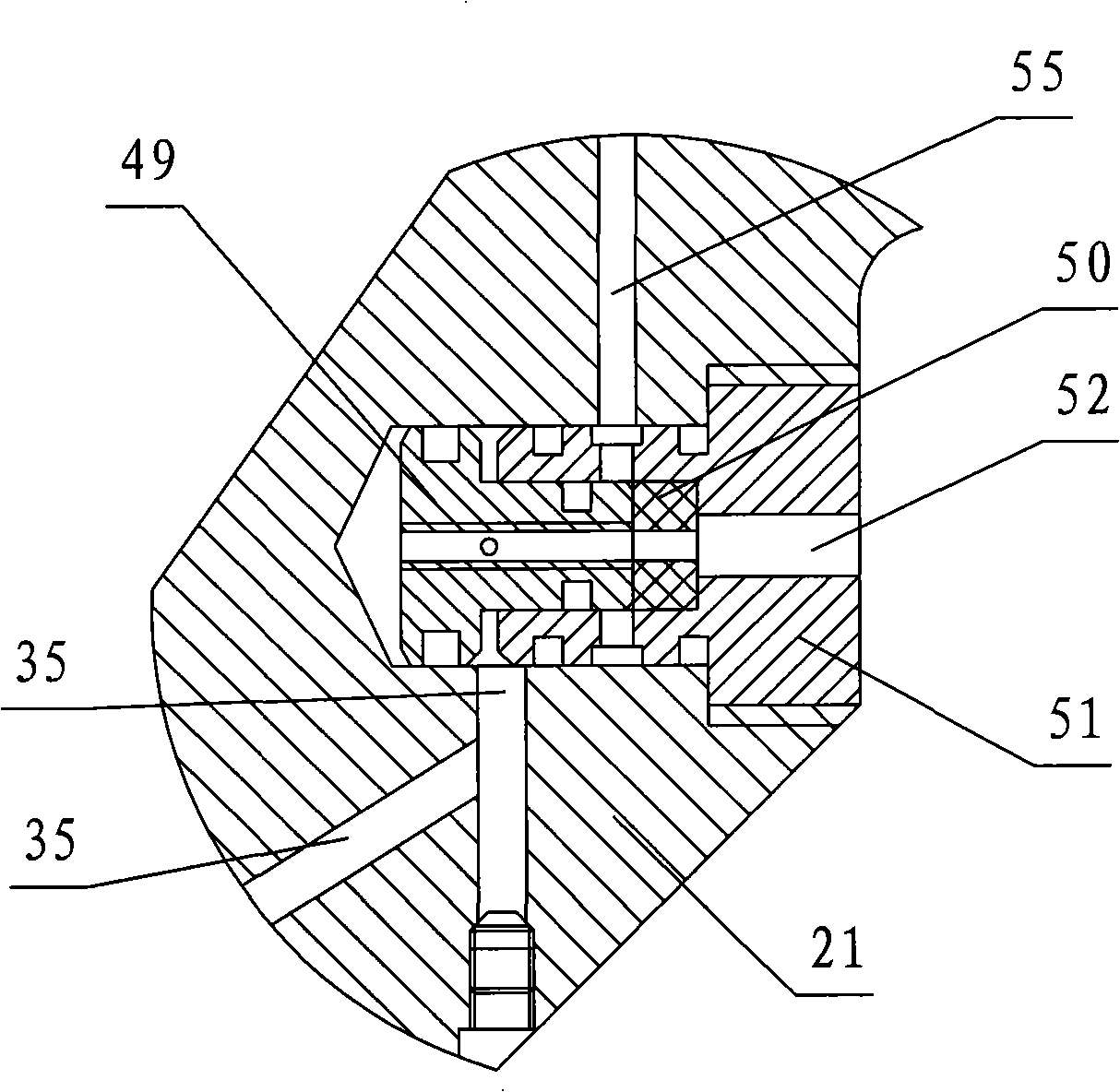

High speed dish type circular valve highly effective slag draining and separating machine

The invention relates to a separation machine, in particular to a high-speed disc type ring valve high-efficient slag-discharge separator. The technical proposal provided by the invention is that, a separation mechanism and a transmission mechanism thereof are arranged on a base; a separation cylinder in the separation mechanism is arranged on a vertical shaft, a cylinder cover is arranged on the separation cylinder, a separation cavity is formed between the separation cylinder and the cylinder cover, a disc rack with a sewage inlet channel at the interior is arranged at the center of the separation cavity, a plurality of discs covered reversely are arranged on the outer wall of the disc rack, a piston which can slide up and down relative to the separation cylinder is arranged at the upper surface of the separation cylinder, and a slag discharge port is formed on the separation cylinder; the separator is characterized in that: a control channel is arranged in the separation cylinder, the control channel communicates with a gap formed between the piston and the separation cylinder, a control valve for closing or opening the control channel is arranged on the control channel, when the control valve is opened, high-pressure fluid positioned at the bottom part of the piston enters the control valve to be discharged for pressure relief by a pressure relief channel, thus descending the piston and opening the slag discharge port. The separator can simplify structure, reduce energy consumption and facilitate maintenance.

Owner:无锡市减速机械有限公司

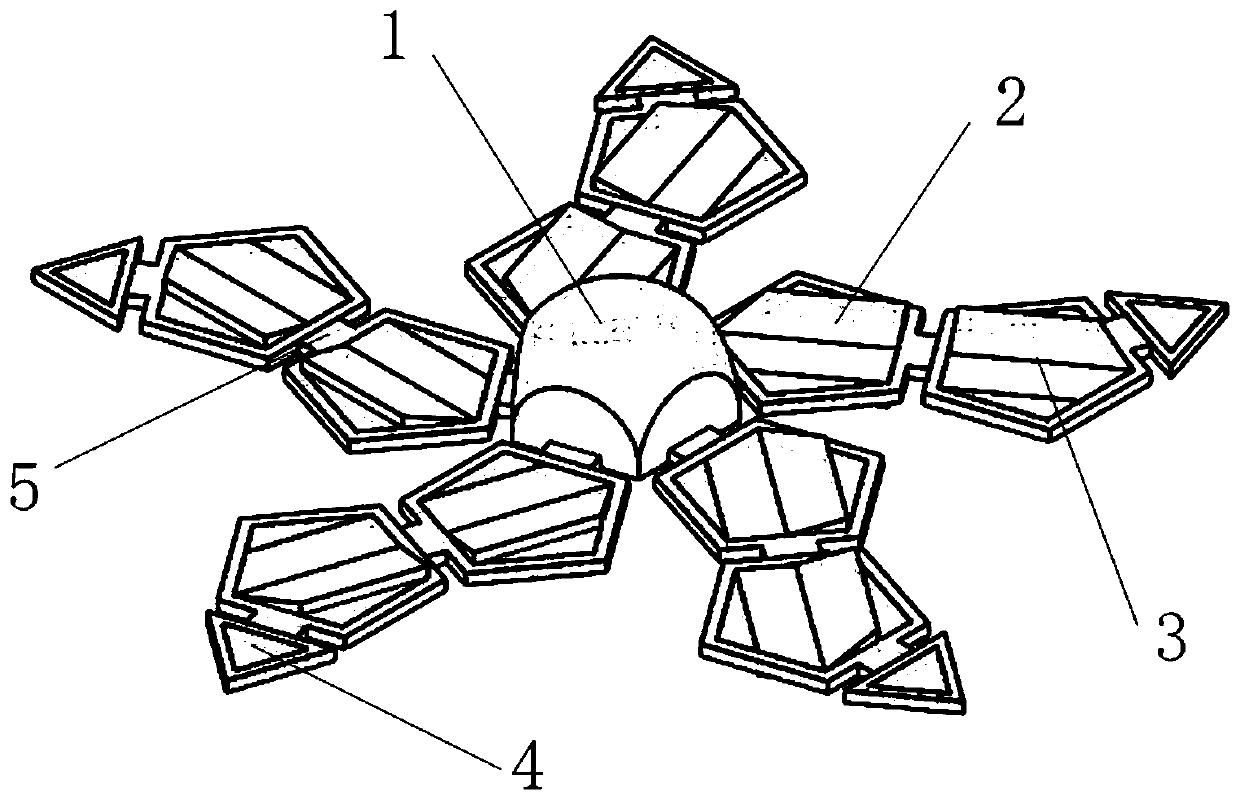

Jellyfish magnetic control miniature soft robot and preparation method and driving method thereof

ActiveCN110076749ASimple structure and processSimple preparation processMicromanipulatorPropulsive elements of non-rotary typeDodecahedronEngineering

The invention discloses a jellyfish magnetic control miniature soft robot. The jellyfish magnetic control miniature soft robot comprises a head and five movable arms which are arranged on the same plane, and the five movable arms are uniformly distributed in the circumferential direction of the head and are arranged in a radial manner; the movable arm comprises an upper arm, a front arm and a hand; the head, the upper arm, the front arm and the hand are sequentially connected through elastic ribs; the head part, the upper arm, the front arm and the hand are rigid parts with different magneticfield directions, so that the five movable arms can move in multiple degrees of freedom under the action of an external magnetic field, and the five movable arms can be bent and locked into a class dodecahedron under the action of the external magnetic field. The jellyfish magnetic control miniature soft robot is simple in structure and manufacturing process, easy to control, cable of achieving six movement modes including clamping objects, crawling movement, rolling movement and horizontal dragging movement, spiral swimming motion and tensioning type swimming motion mode under the driving ofa conversion magnetic field, and has extremely high biological form simulation characteristics and repeated use characteristics.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

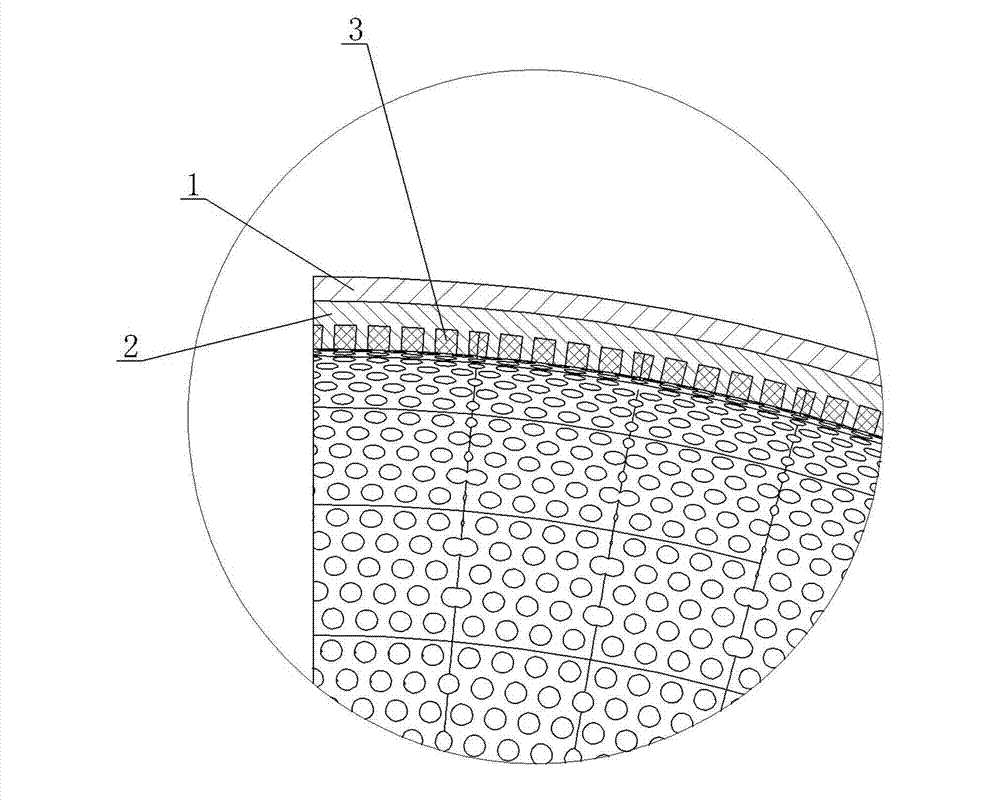

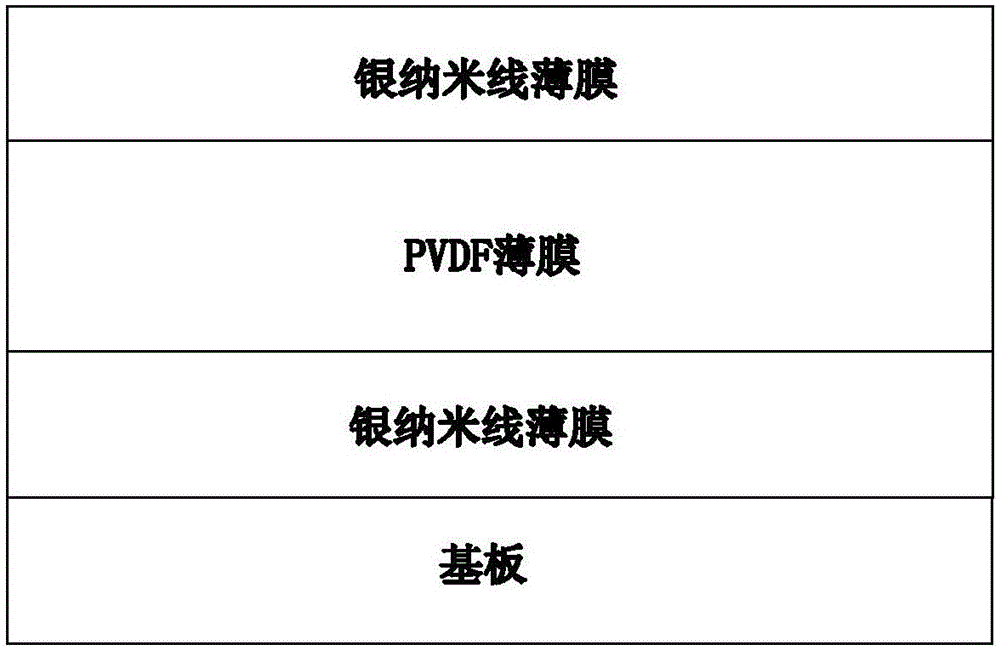

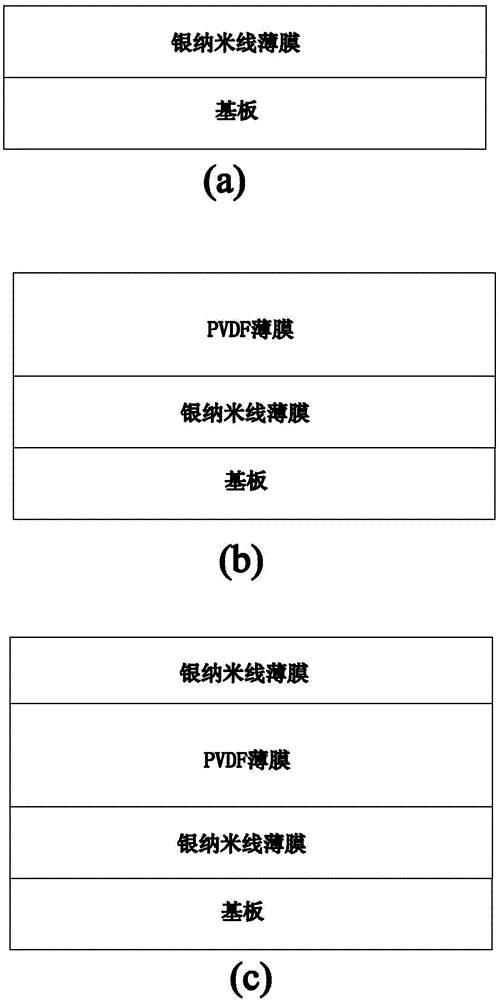

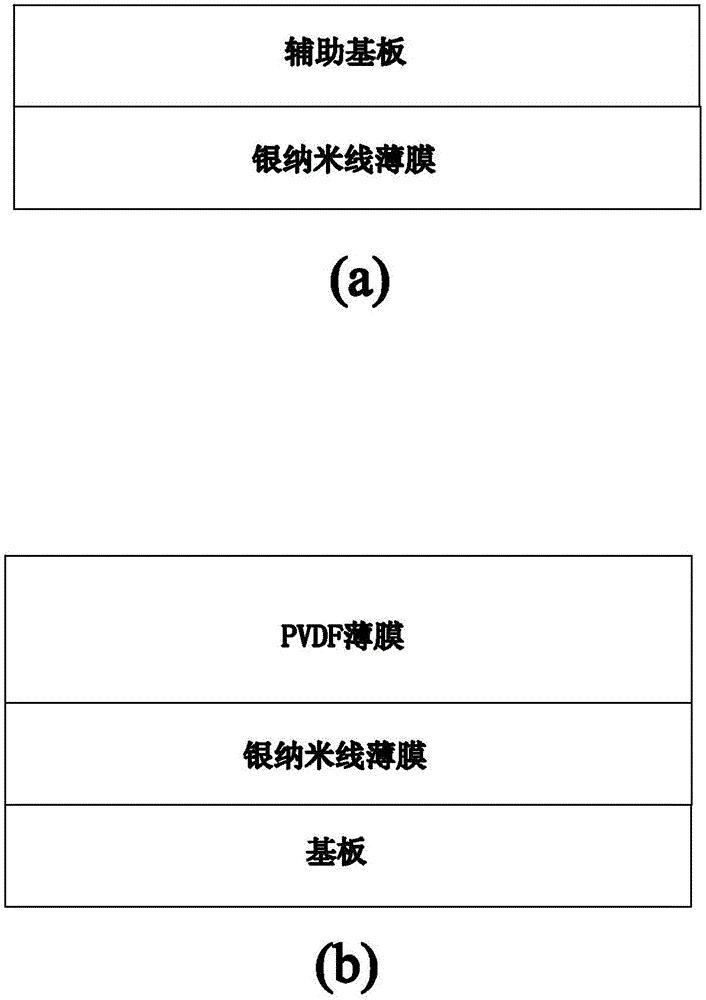

Physiological monitoring sensing belt and manufacturing method thereof, physiological monitoring mattress and monitoring system

ActiveCN105553323AHigh sensitivityStable output electrical signalSensorsMeasuring/recording heart/pulse rateSelf shieldingMoisture

The invention discloses a physiological monitoring sensing belt and a manufacturing method thereof, a physiological monitoring mattress and a monitoring system. The physiological monitoring sensing belt comprises a first friction power generation layer and a second friction power generation layer which are laminated, wherein a friction interface is formed between the first friction power generation layer and the second friction power generation layer; an insulating layer which wraps the first friction power generation layer and the second friction power generation layer; a conductive shielding layer which wraps the first friction power generation layer, the second friction power generation layer and the insulating layer; and a first lead-out electrode and a second lead-out electrode which act as the output electrodes of the physiological monitoring sensing belt. The physiological monitoring sensing belt has the characteristics of being self-powered, high in sensitivity, stable in output electric signals, easy to use and operate, randomly adjustable in size, low in mass, comfortable and convenient to use for a user, simple in structure and manufacturing technology, low in cost and suitable for large-scale industrial production. Meanwhile, the physiological monitoring sensing belt also has self-moisture-proof and self-shielding functions so that stability of the output electric signals can be increased and the service life can be prolonged.

Owner:NAZHIYUAN TECH TANGSHAN LLC

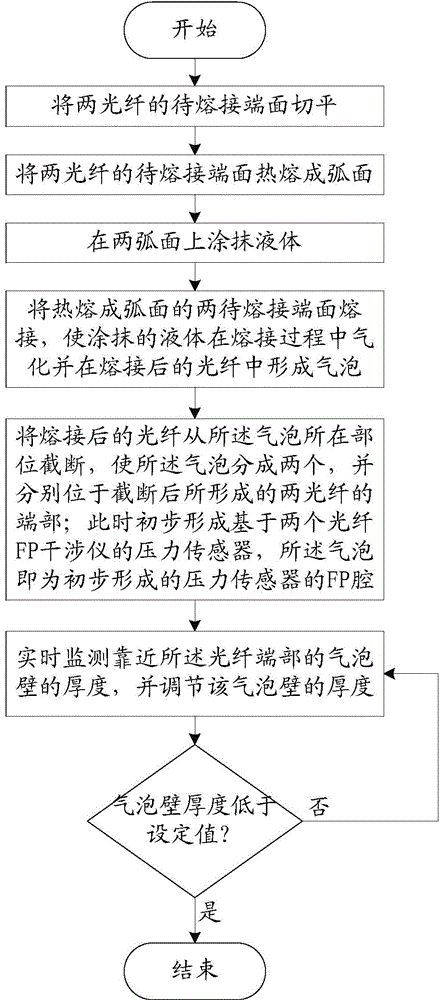

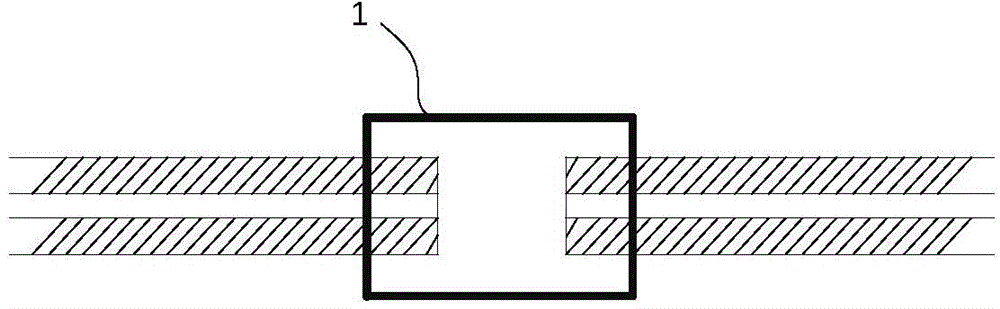

Pressure sensor based on optical fiber FP interferometer and manufacturing method of pressure sensor

ActiveCN103954387ASimple structure and processSimple preparation processForce measurement by measuring optical property variationFluid pressure measurement by optical meansManufacturing technologyElectromagnetic interference

The invention relates to the technical field of optical fiber application, in particular to a pressure sensor based on an optical fiber FP interferometer and a manufacturing method of the pressure sensor. The method comprises the following steps that the end faces to be fused of two optical fibers are coated with liquid and fused, the coating liquid is vaporized in the fusion process, and a bubble is formed in the fused optical fiber; the fused optical fiber is cut off from the portion of the bubble, so that the bubble is divided into two bubbles which are located at the ends of the two cut-off optical fibers respectively; the two pressure sensors based on the optical fiber FP interferometer are formed preliminarily and the bubbles are FP cavities of the preliminarily-formed pressure sensors; the thickness of the bubble walls close to the ends of the optical fibers is monitored in real time and is adjusted, so that the thickness of the bubble walls is lower than a set value. According to the pressure sensor based on the optical fiber FP cavity and manufactured through the technical scheme, a full-optical-fiber structure is adopted and electromagnetic interference can be avoided. Meanwhile, the structure and the manufacturing technology of the pressure sensor are simple and reliability and sensitivity are high.

Owner:SHENZHEN UNIV

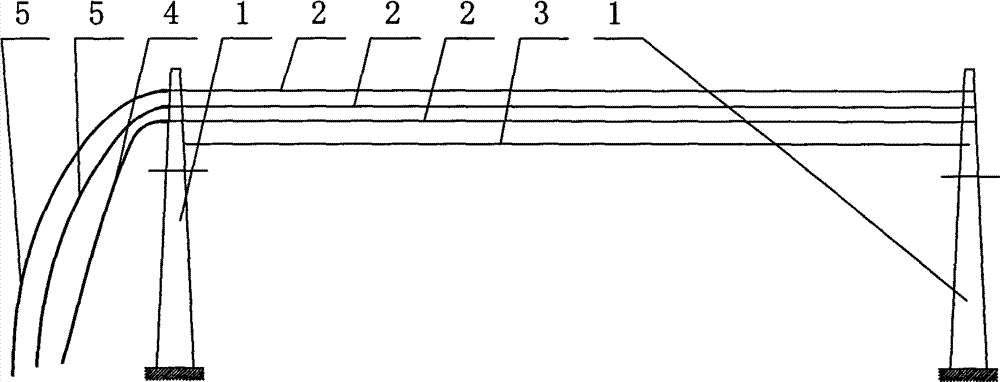

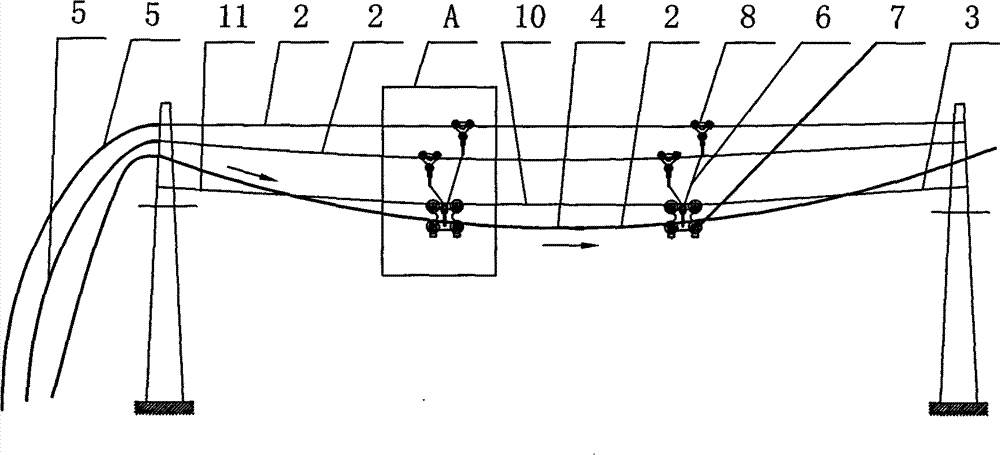

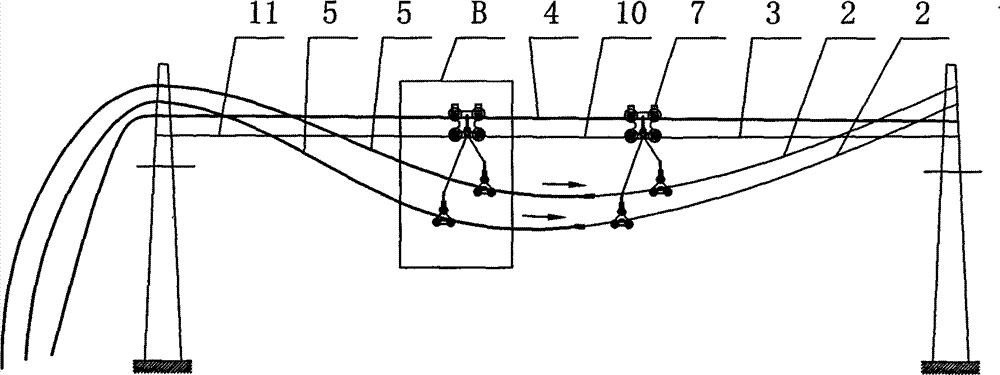

Obstacle bridging construction method for power line wiring and wiring pulleys

InactiveCN102780178AWill not harmNo harmApparatus for overhead lines/cablesEngineeringTraveling block

The invention discloses an obstacle bridging construction method for power line wiring and wiring pulleys. The method is convenient and quick to construct, small in labor number and high in universality. The method sequentially includes: laying three pulling ropes and a front dragline, enabling the tree pulling ropes to respectively penetrate through at least one pulley block at one ends of towers, pulling the pulling rope in a main pulley to enable a middle guide line to go through from one tower to another tower under the suspension of the other two pulling ropes and auxiliary pulleys, pulling the pulling rope in the two auxiliary pulleys to enable two side guide lines to go through from one tower to another tower under the suspension of the auxiliary pulleys, and recovering the pulley block to finish wiring works of enabling the guide lines to pass through the obstacles. The whole wiring process is performed on the two towers, each guide line is suspended through the pulling ropes without contacting with the ground and free of control by people standing below, so that damages to ground crops and blockage to traffic lines below the guide lines are avoided.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD

Novel high-performance light modulation thin film transistor based on quantum dot doped gate insulating layer

ActiveCN105552131ASimple structure and preparation processSimple preparation processTransistorSemiconductor/solid-state device manufacturingQuantum dotDetection performance

The invention discloses a novel high-performance light modulation thin film transistor based on a quantum dot doped gate insulating layer. A preparation method thereof comprises the following steps: depositing an active layer and a source and drain electrode contact layer on a base in sequence; spinning quantum dots and organic optical cement on the active layer to prepare the gate insulating layer; etching via holes for connecting the contact layer with active and drain electrodes on the gate insulating layer; and finally preparing a transparent electrode on the gate insulating layer, and etching the transparent electrode as the drain electrode, gate electrode and source electrode of a plane. Besides the three modulation electrodes of a traditional source and drain gate, the thin film transistor device disclosed by the invention can be taken as a fourth end modulation electrode through incident light. The light modulation thin film transistor with photoelectric detection and signal read functions is prepared by using the thin film transistor gate insulating layer doped with the quantum dots, so that the structure and preparation technology of the light modulation thin film transistor are greatly simplified, the dimensions of the device are shortened, and the photoelectric detection performance is improved.

Owner:SOUTHEAST UNIV

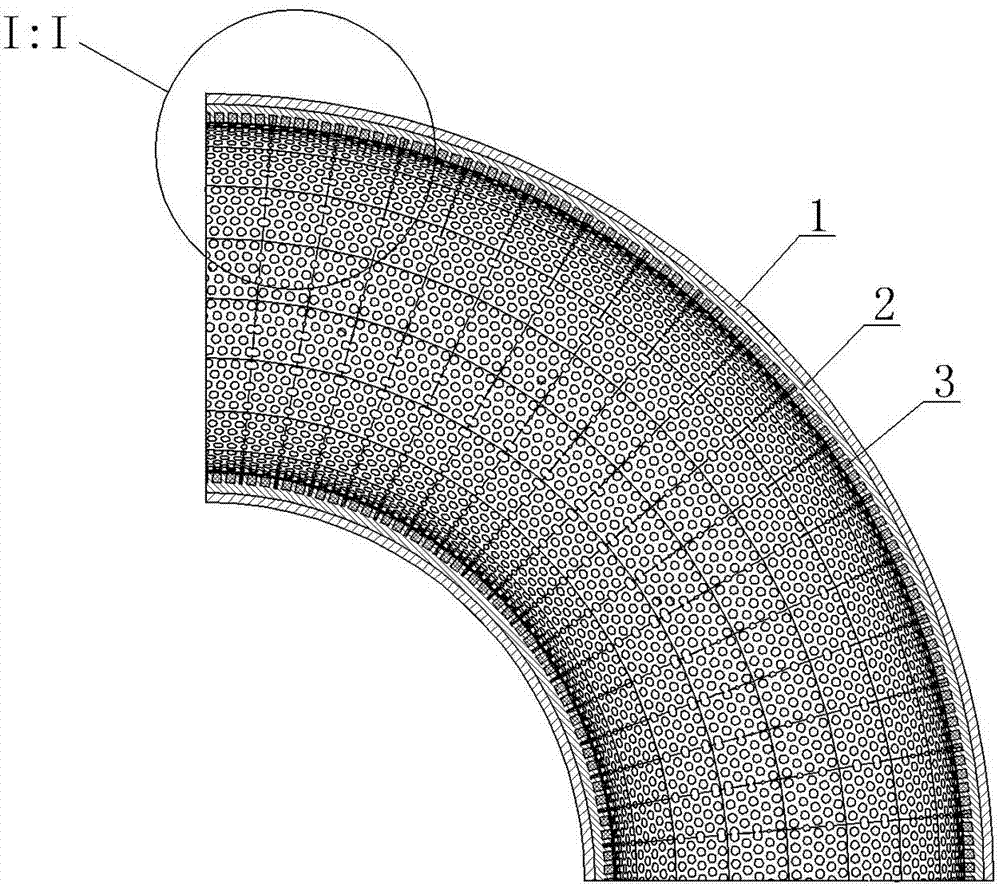

Composite profiled pipeline and manufacturing method thereof

ActiveCN103206589AStable supportExtended service lifeBranching pipesPipe protection against damage/wearBond propertiesMetal

Provided are a composite profiled pipeline and a manufacturing method thereof. The composite profiled pipeline is a nonstandard pipeline and composed of an outer layer and an inner layer of a pipeline, wherein ceramic particle prefab bodies combined with the inner layer of the pipeline in casting mode are distributed in the inner layer of the pipeline at intervals, and the outer layer and the inner layer of the pipeline are combined in metallurgical mode. According to the composite profiled pipeline, the inner wall of the composite profiled pipeline has excellent abrasion performance, the outer wall of the composite profiled pipeline has good weld-ability, bonding properties of an interface between the inner wall and the outer wall of the composite profiled pipeline are good, and simultaneously cast infiltration properties among base metal and the ceramic particle prefab bodies are good, and therefore the base metal and the ceramic particle prefab bodies are firmly combined and difficultly to fall off, and the composite profiled pipeline is long in service life. Furthermore, the base metal in the inner layer of the pipeline can support the ceramic particle prefab bodies well, ceramic particles in the ceramic particle prefab bodies gradually protrude to bear main attrition during the wearing process and thereby effectively prevent surrounding base metal from being further abraded, and the composite profiled pipeline further has the advantages of being simple in structure and manufacture process, adjustable in structure and the like.

Owner:GUANGDONG INST OF NEW MATERIALS

Touch sensor, preparation method thereof and display device provided with touch sensor

InactiveCN105094425ASimple structure and processLow costInput/output for user-computer interactionGraph readingDisplay deviceEngineering

Owner:NUOVO FILM SUZHOU CHINA INC

Organic electroluminescence component and manufacturing method thereof

InactiveCN101783395ASolve defects such as low aperture ratioIncrease opening ratioSolid-state devicesSemiconductor/solid-state device manufacturingHigh resistanceDisplay device

The invention relates to an organic electroluminescence component and a manufacturing method thereof. The organic electroluminescence component comprises a basal plate, wherein a first electrode, an organic material layer, a second electrode and a sealing layer are sequentially formed on the basal plate, the first electrode is used as an anode, and the second electrode is used as a cathode and is a composite transparent structure layer for realizing the light emitting at the top. By forming the composite transparent cathode emitting light at the top, the invention enables the organic electroluminescence component to emit the light from the top and enhances the light-emitting utilization rate and the light transmission rate effectively, which not only enhances the aperture opening ratio of a display screen but also can obtain better display effect. Meanwhile, by adding a netty confluence layer on a semitransparent metal layer with high resistance, the invention ensures high transmissivity, also enhances the conducting power of current, meets the requirement of a top transmission type organic electroluminescence component effectively and can be applied to a display device with double-face display. The invention has simple and reliable structure and preparation process and extensive application prospect.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com