Novel high-performance light modulation thin film transistor based on quantum dot doped gate insulating layer

A technology of thin-film transistors and gate insulating layers, which is applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of slow detection speed and loss of IGZO thin-film transistors, achieve simplified structure and preparation process, simple preparation process, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

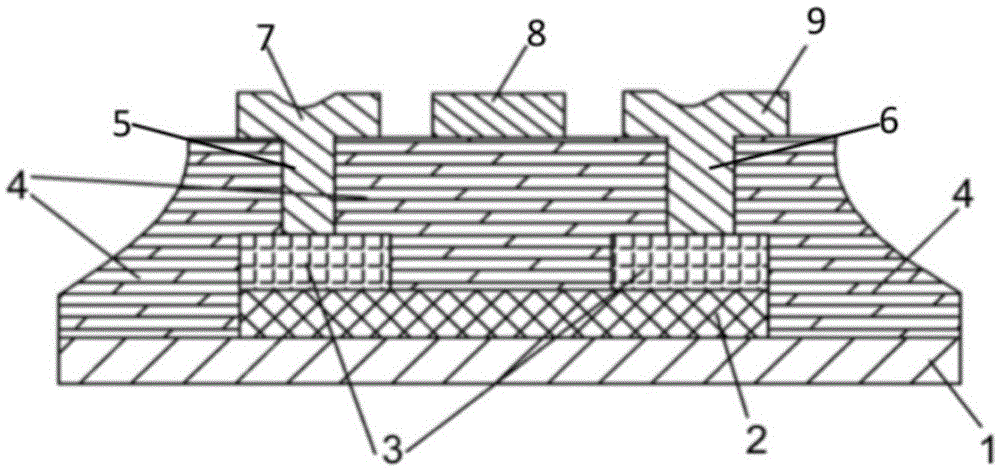

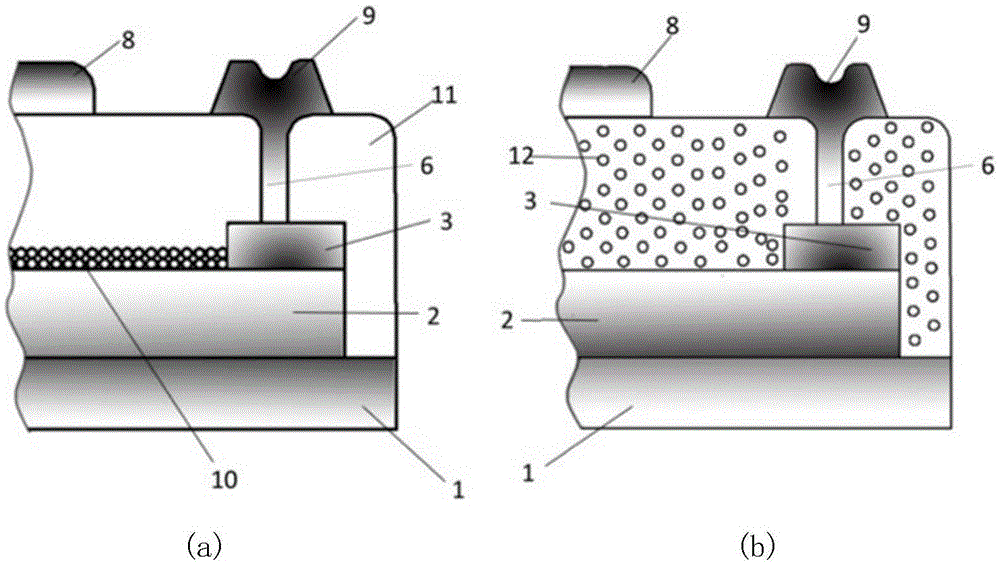

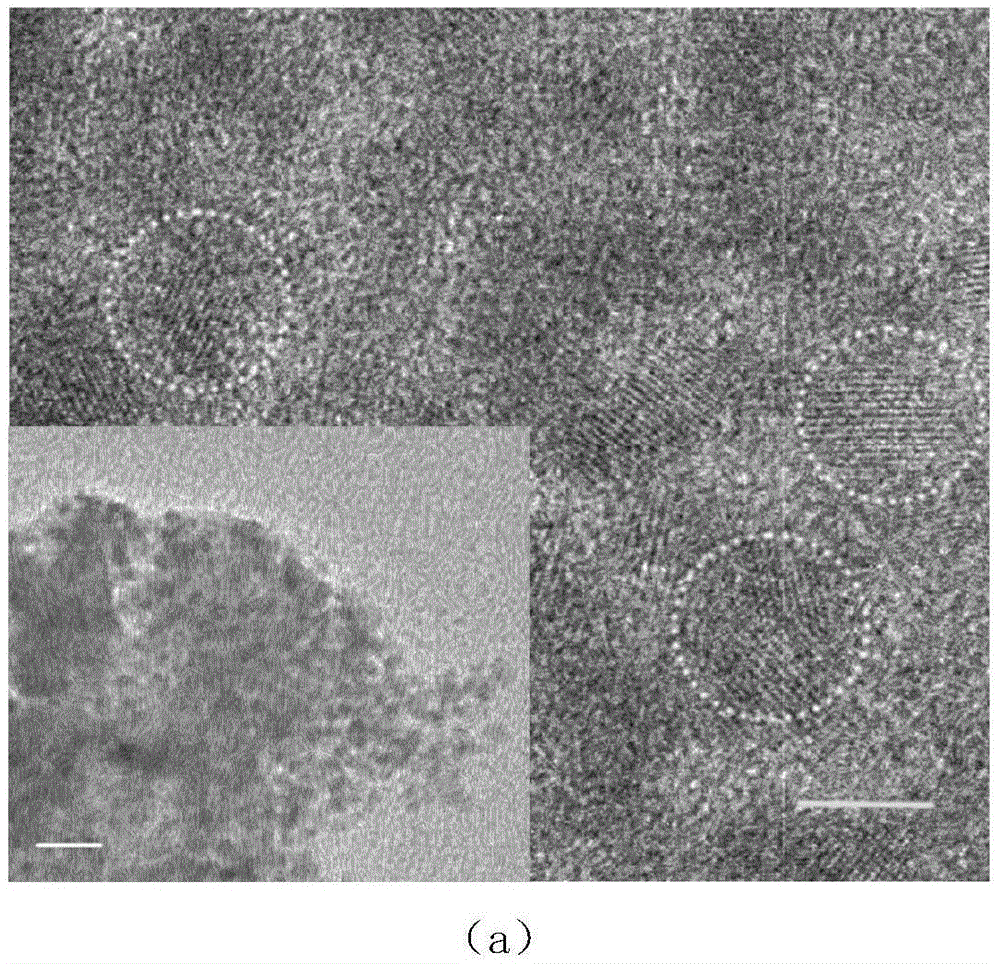

[0035] Example 1, the device structure is as figure 2 As shown in (a), the quantum dot layer 10 needs to be prepared first, so the process is as follows: a. Dissolve the solid quantum dot material in an ethanol solvent, and ultrasonicate for 15 minutes until the quantum dot nanoparticles are uniformly dispersed in ethanol. b. Spin-coat quantum dots on the glass substrate that has completed the process of step 1, select a spin-coating speed that accelerates from 1500 rpm to 1000 rpm, and set the spin-coating time to 30 seconds. c. Heating in air to 160° C. and annealing for 10 minutes to evaporate all remaining ethanol solution and form a quantum dot layer 10 of about 40 nm by thermal crosslinking at the same time. The particle size of the PbS quantum dots and the surface morphology of the film are as follows figure 2 (a) TEM picture shows. d. Continue to use the spin coating process to deposit Su8 photoresist on the substrate to wrap the formed quantum dot layer (process para...

example 2

[0036] Example 2, the structure is as figure 2 As shown in (b), it is necessary to mix and disperse Su8 organic photoresist and quantum dots in advance. Therefore, the process is as follows: a. Use an ultrasonic oscillator to ultrasonically stir at room temperature for 15 minutes so that the quantum dot material is evenly dispersed in the organic photoresist. In the mixed photoresist, too high concentration of quantum dots will lead to deterioration of the uniformity and insulation of the gate insulating layer. If the concentration is too low, the photoresponse characteristics of the photosensitive layer will be insufficient, so that the efficiency of the device will be low and it will not be able to generate sufficient photocurrent. Through our research, it is found that the quantum dot Su8 solution with a concentration of 1-3mg / ml can balance the performance of these two aspects. b. Spin-coat the Su8 photoresist mixed with PbS quantum dots onto the substrate. The specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com