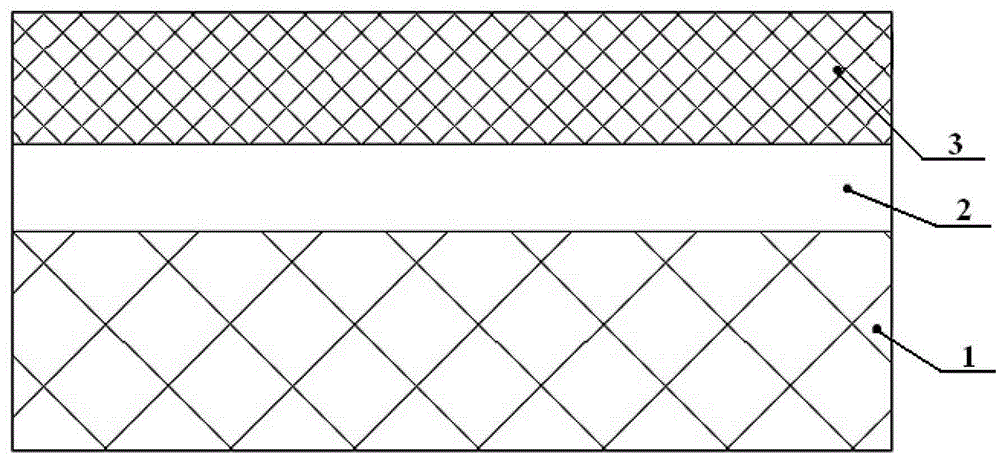

Structure of flat-plate type metal-support solid oxide fuel cell for immersing electrodes

A solid oxide and metal support technology, which is applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve the problems of long-term stability decline, oxidation resistance reduction, anode metal particle Ni coarsening, etc. Achieve the effects of simplifying the structure and preparation process, improving fuel applicability, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

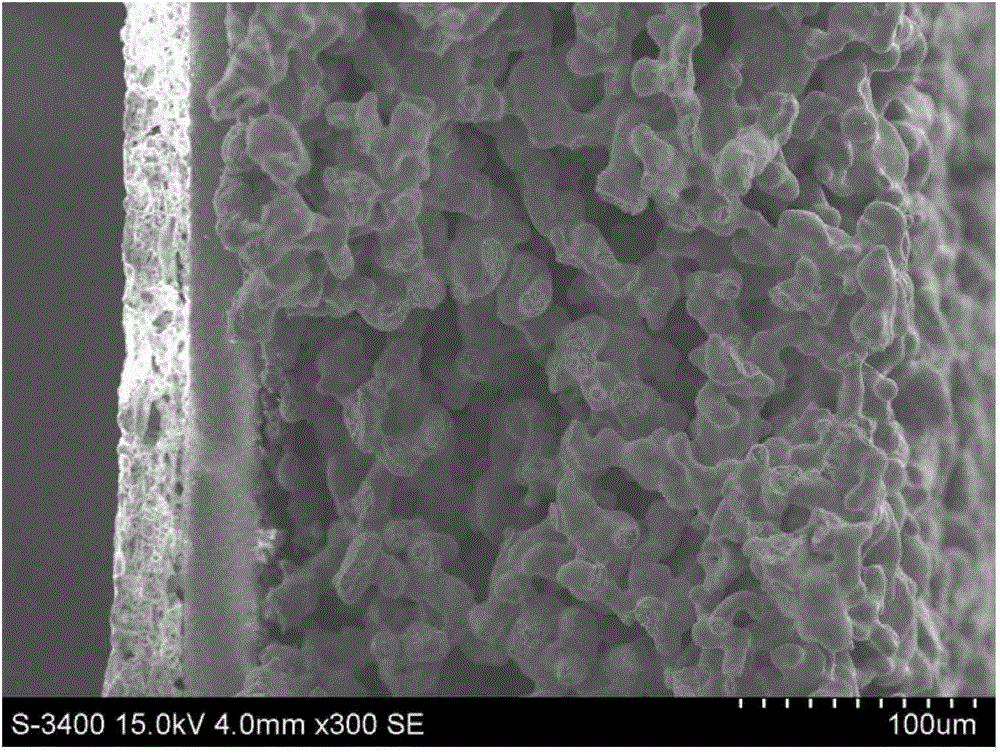

Embodiment 1

[0036] Take by weighing 430 stainless steel powder 50g, add solvent dehydrated alcohol 10g and butanone 5g successively, dispersant triethanolamine 6g, plasticizer dibutyl phthalate 2g, binding agent polyvinyl butyral 6g, make Pore agent ammonium oxalate 20g; Weigh 30g of electrolyte YSZ powder, add solvent xylene and butyl acetate 5g each, dispersant acrylic resin DM-55 1g, plasticizer benzoate B-50 2g and binder Polypropylene resin B-72 4g; Weigh 15g of cathode precursor layer YSZ powder, add solvent xylene and butyl acetate 4g each, dispersant acrylic resin DM-55 1g and dispersant acrylic copolymer BYK 1g, plasticizer benzene Formate B-50 0.5g, binder polypropylene resin B-72 1g, pore-forming agent ammonium oxalate 10g;

[0037] Ball mill the above three kinds of slurries respectively, and sieve the mixed slurries through sieves and vacuum treatment to remove the air in the slurries;

[0038] Tape-casting and drying the above three kinds of slurries respectively to prepa...

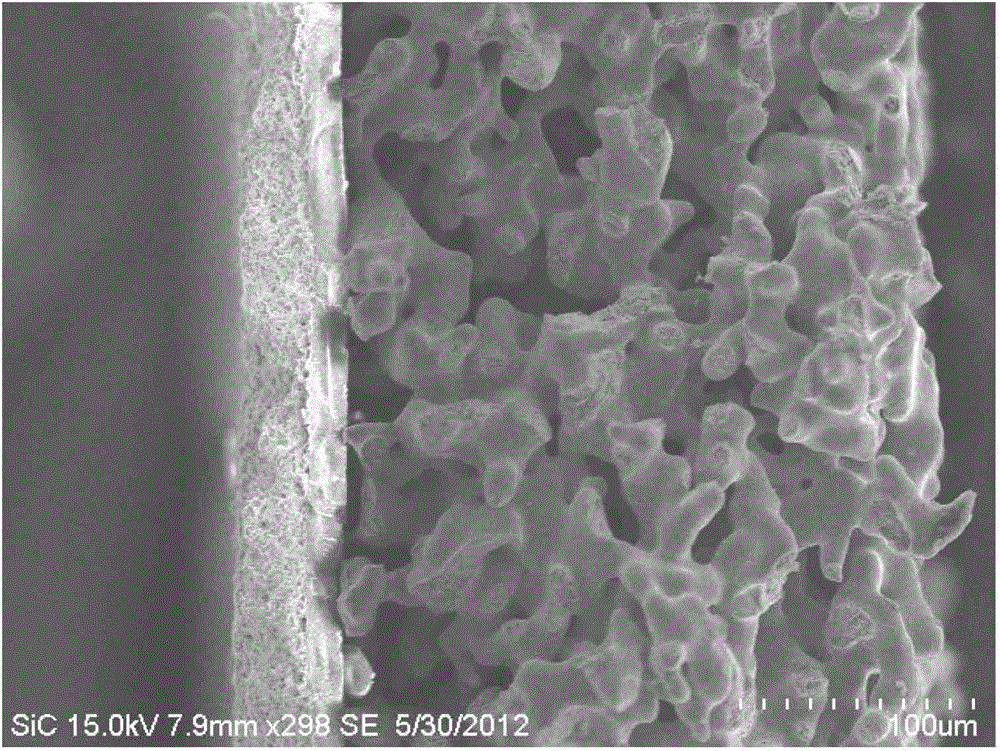

Embodiment 2

[0043] Weigh 50g of 430 stainless steel powder, add solvent absolute ethanol 12g and butanone 6g, dispersant triethanolamine 5g, plasticizer dibutyl phthalate 2g and polyethylene glycol 2g, binder polyvinyl alcohol Butyral 3g, pore-forming agent ammonium carbonate 20g; weigh 30g of electrolyte YSZ powder, add solvent xylene and butyl acetate 5g each, dispersant acrylic resin DM-551g, plasticizer benzoate B-50 2g and binder polypropylene resin B-72 4g; Weigh 15g of cathode precursor layer YSZ powder, add solvent xylene and butyl acetate 4g each, dispersant acrylic resin DM-55 1.5g and acrylic acid copolymer BYK1g, Plasticizer benzoate B-50 1g, binder polypropylene resin B-72 2g, pore-forming agent ammonium oxalate 15g;

[0044] Ball mill the above three kinds of slurries respectively, and sieve the mixed slurries through sieves and vacuum treatment to remove the air in the slurries;

[0045] Tape-casting and drying the above three kinds of slurries respectively to prepare gree...

Embodiment 3

[0050] Weigh 50g of 430 stainless steel powder, add solvent absolute ethanol 15g and butanone 7.5g, dispersant triethanolamine 5g, plasticizer dibutyl phthalate 2g and polyethylene glycol 2g, binder polyethylene glycol Alcohol butyral 3.5g, pore-forming agent wheat flour 20g; Weigh 30g of electrolyte YSZ powder, add solvent xylene and butyl acetate 5g each, dispersant acrylic resin DM-551g, plasticizer benzoate B- 50 2g and binder polypropylene resin B-72 4g; weigh 15g of cathode precursor layer YSZ powder, add solvent xylene and butyl acetate each 4g, dispersant acrylic resin DM-55 1g and acrylic copolymer BYK 1g , plasticizer benzoate B-50 0.5g, binder polypropylene resin B-72 1g, pore-forming agent wheat flour 10g;

[0051] Ball mill the above three kinds of slurries respectively, and sieve the mixed slurries through sieves and vacuum treatment to remove the air in the slurries;

[0052] Tape-casting and drying the above three kinds of slurries respectively to prepare gree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com